Crankcase anti-explosion valve

An explosion-proof valve, crankcase technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of complex explosion-proof valve processing process, unfavorable replacement of external flame retardants, and reduced production efficiency, etc., to achieve convenient replacement, The effect of reducing maintenance difficulty and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

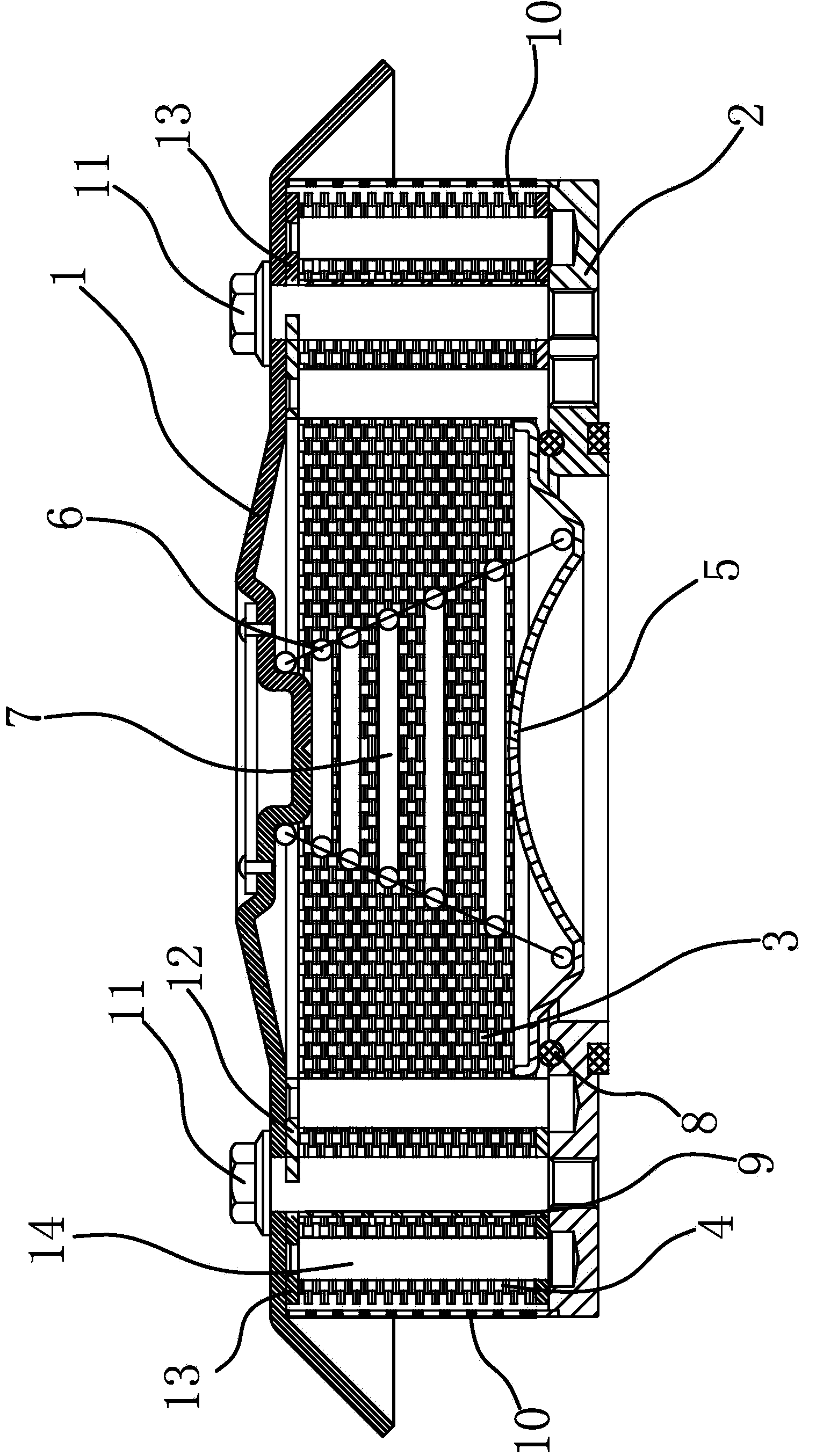

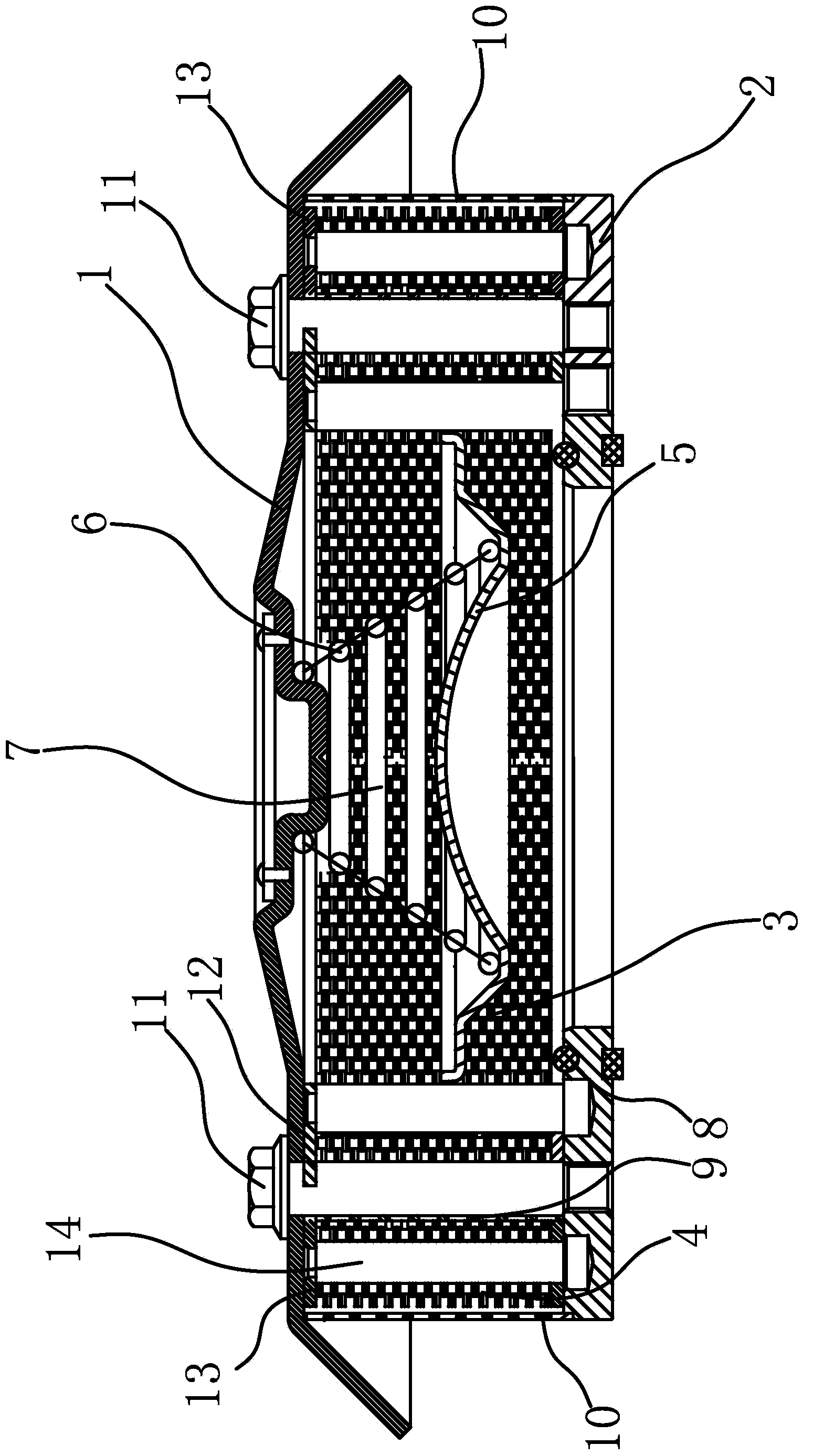

[0023] Such as figure 1 and figure 2 As shown, when the crankcase explosion-proof valve explodes inside the crankcase to generate high-pressure airflow and high-temperature flame and release them, the pressure is weakened and the flame is extinguished in the explosion-proof valve. The crankcase explosion-proof valve is composed of a panel 1, a seat plate 2, an inner flame retardant block 3, an outer flame retardant block 4, a valve plate 5, and a spring 6 and the like.

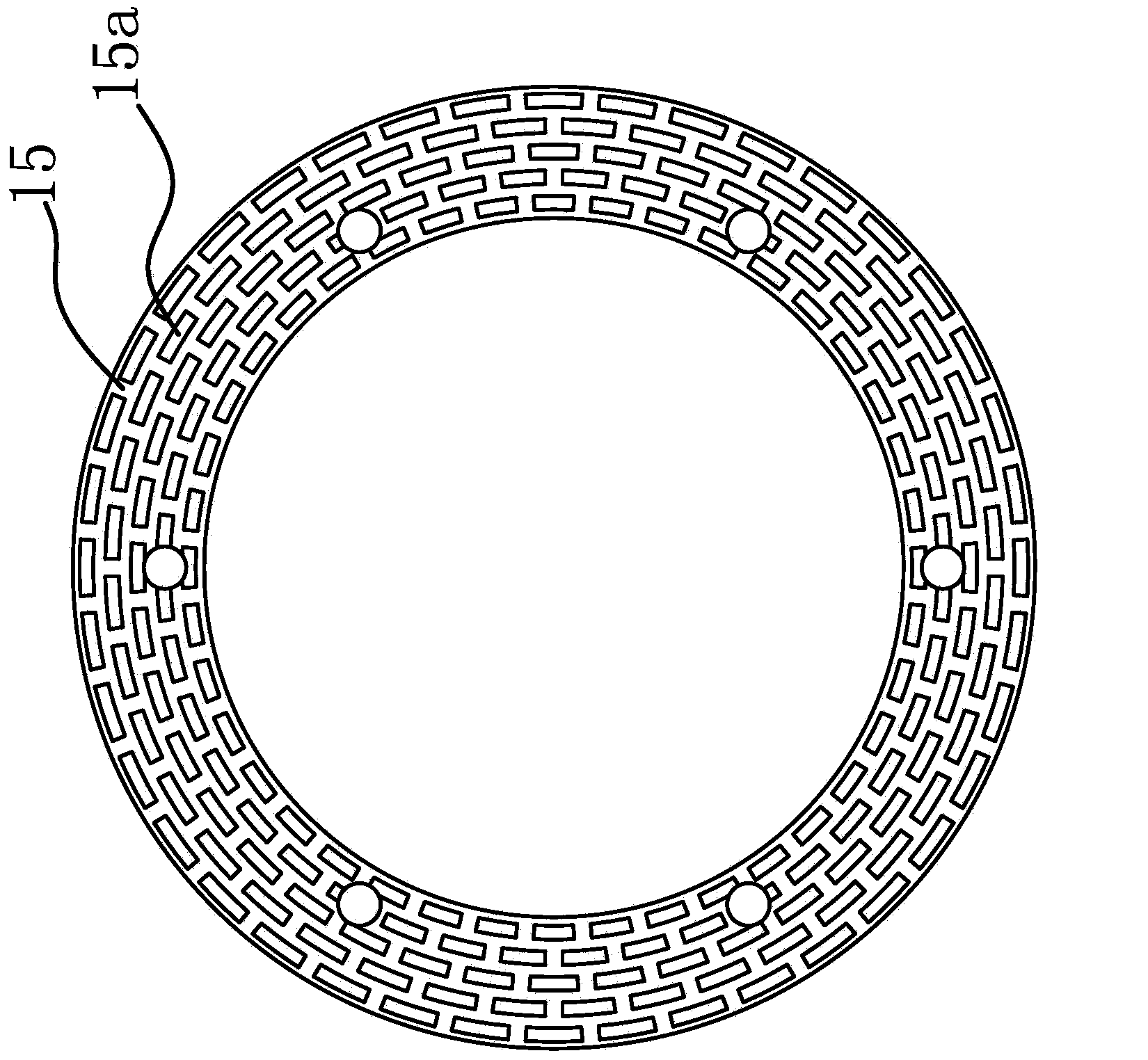

[0024] Wherein, the seat plate 2 is in the shape of a ring, and the explosion-proof valve is connected to the crankcase through the seat plate 2, and the seat plate 2 is fixedly connected with a panel 1 parallel to it, and the panel 1 is disc-shaped. The inner flame retardant block 3, the outer flame retardant block 4, the valve plate 5 and the spring 6 are all located between the seat plate 2 and the panel 1, wherein a valve cavity 7 is formed between the inner flame retardant block 3, the panel 1 and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com