Patents

Literature

3107results about How to "The production process is simple" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

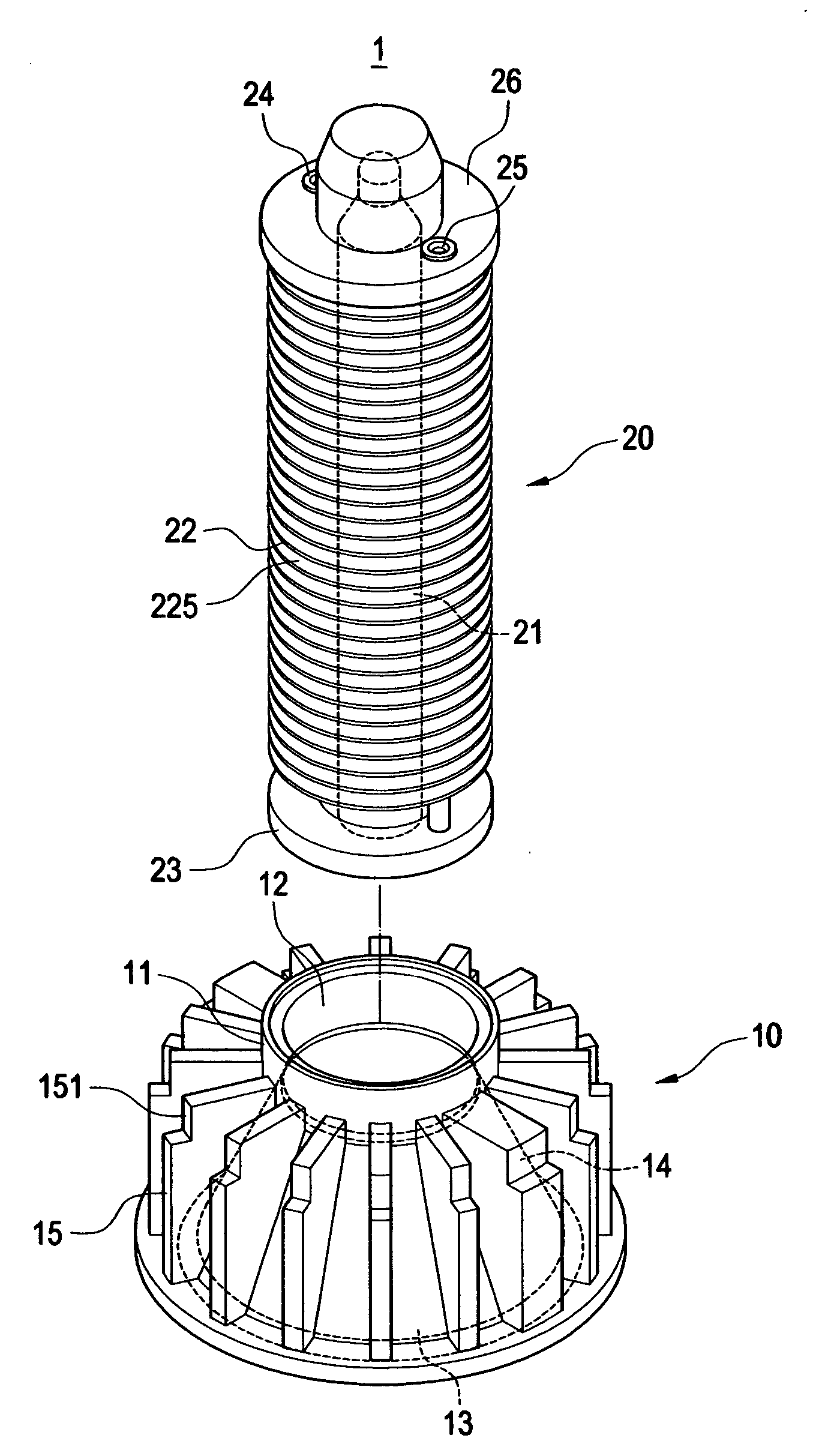

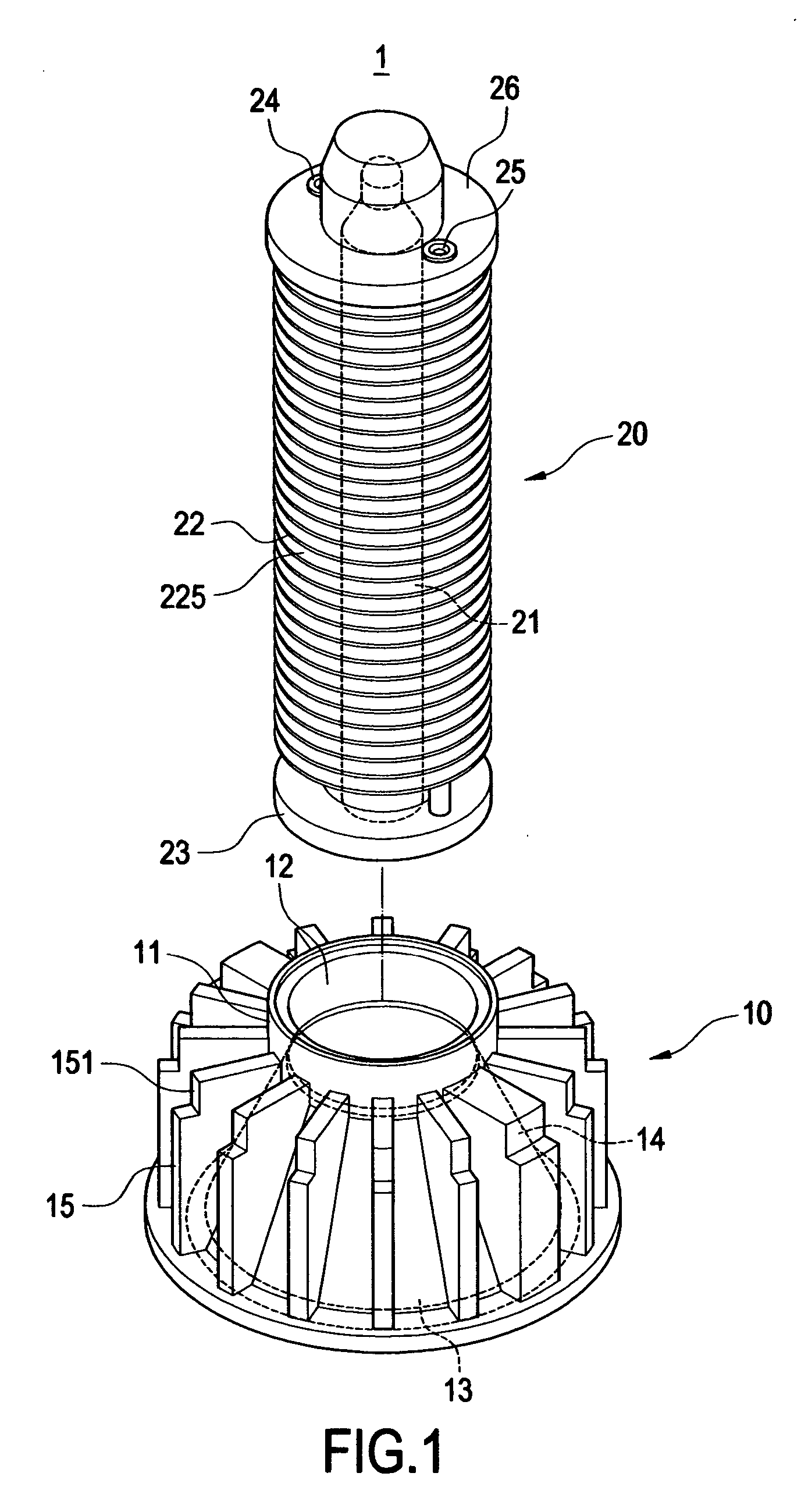

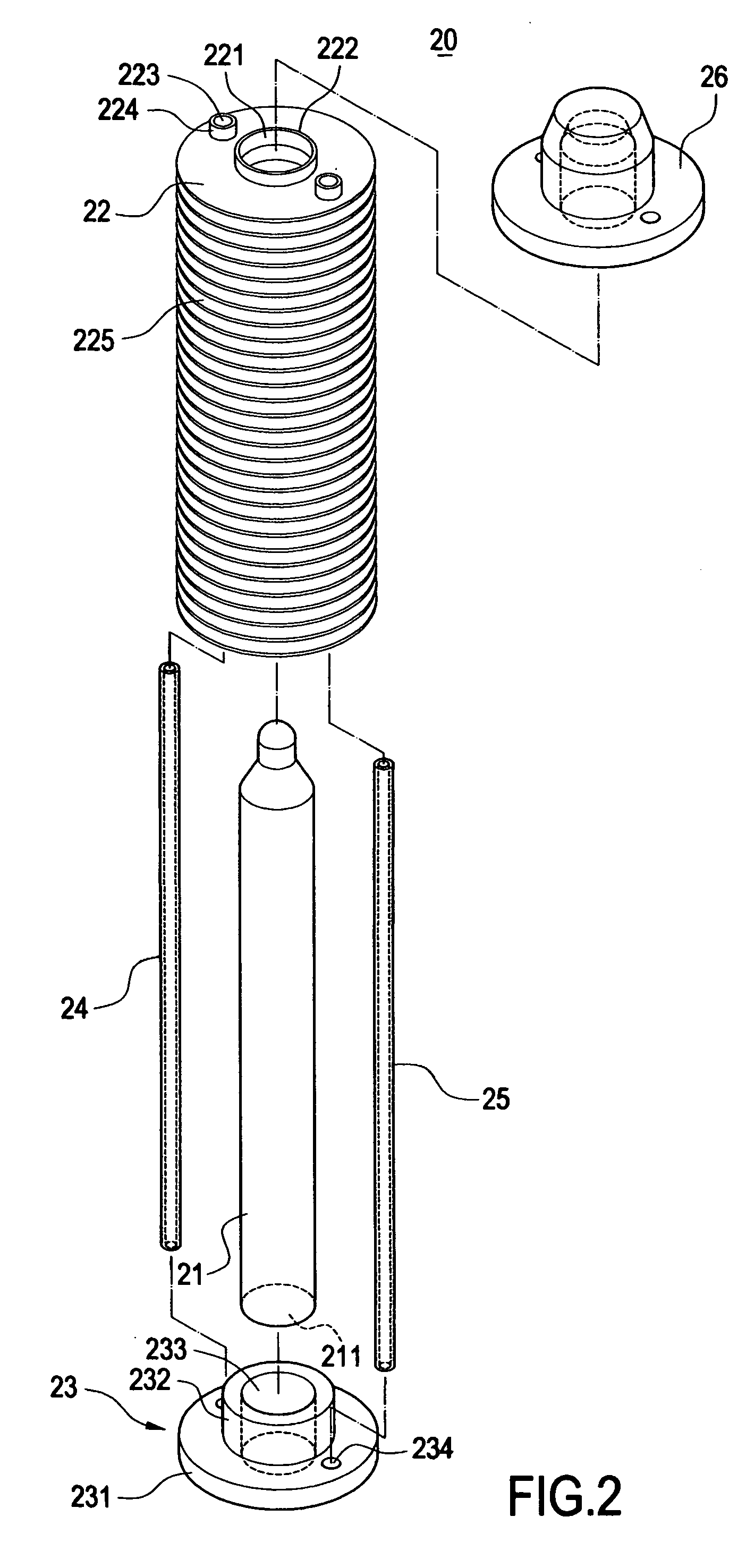

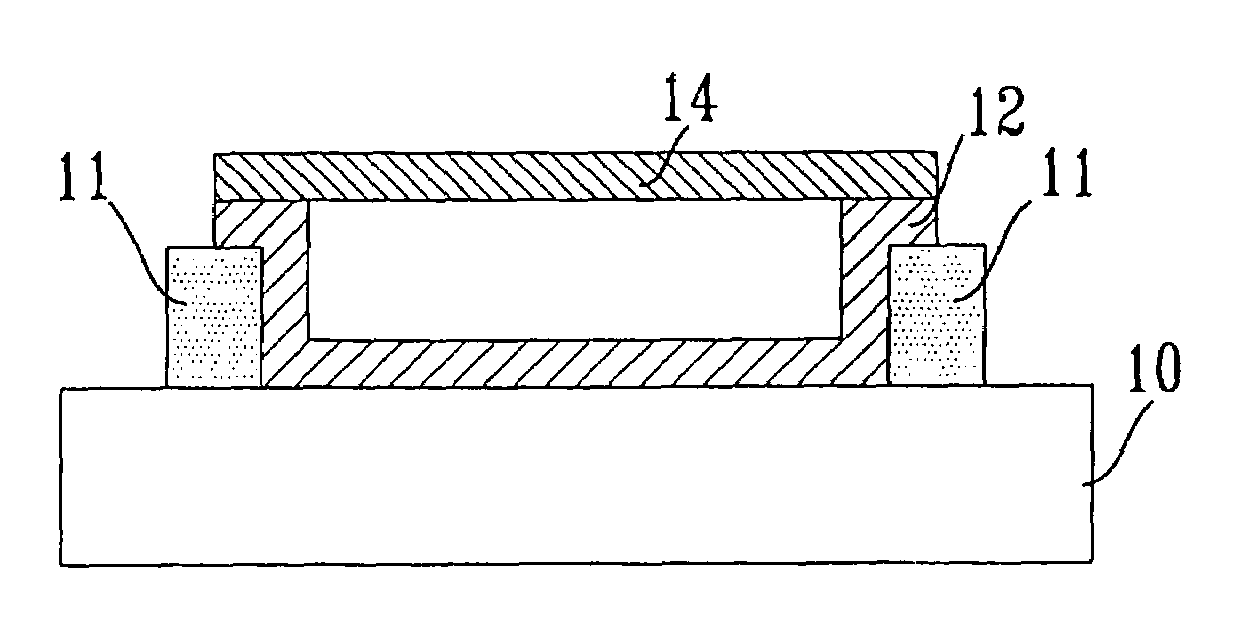

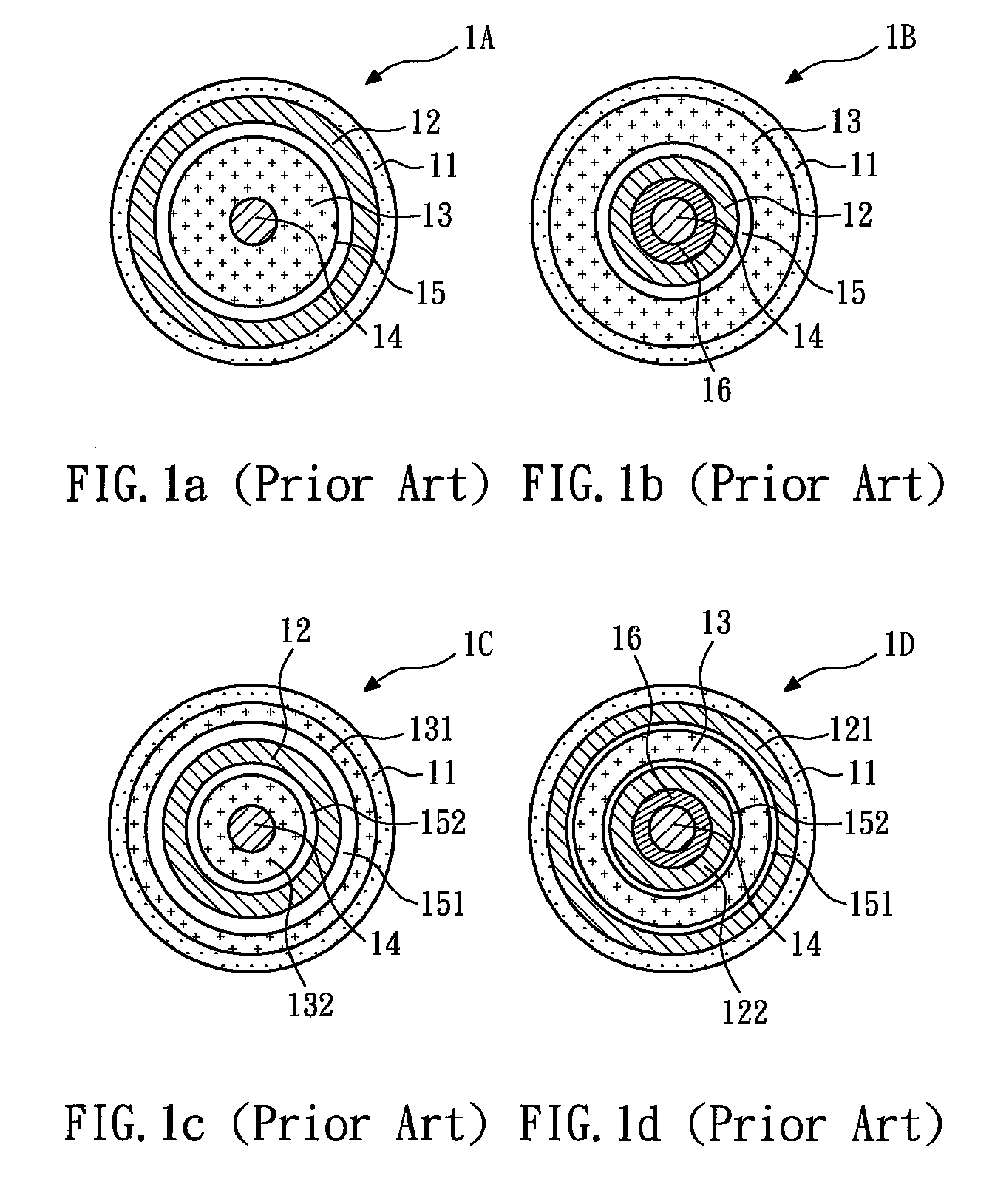

LED lamp and heat-dissipating structure thereof

InactiveUS20070253202A1Prolong lifeThe production process is simplePoint-like light sourceLighting heating/cooling arrangementsWorking temperatureEngineering

The present invention is directed to a LED lamp and the heat-dissipating structure thereof. The heat-dissipating structure is used to dissipate the heat generated by the LED and comprises a first heat-dissipating body and a second heat-dissipating body. The first heat-dissipating body has a casing with an opening formed thereon. The second heat-dissipating body is connected on the first heat-dissipating body and comprises at least one heat pipe and a plurality of heat-dissipating fins connected to the heat pipe. With this arrangement, the LED continuously operates under a suitable working temperature and the life of the LED can thus be prolonged.

Owner:CHAUN CHOUNG TECH

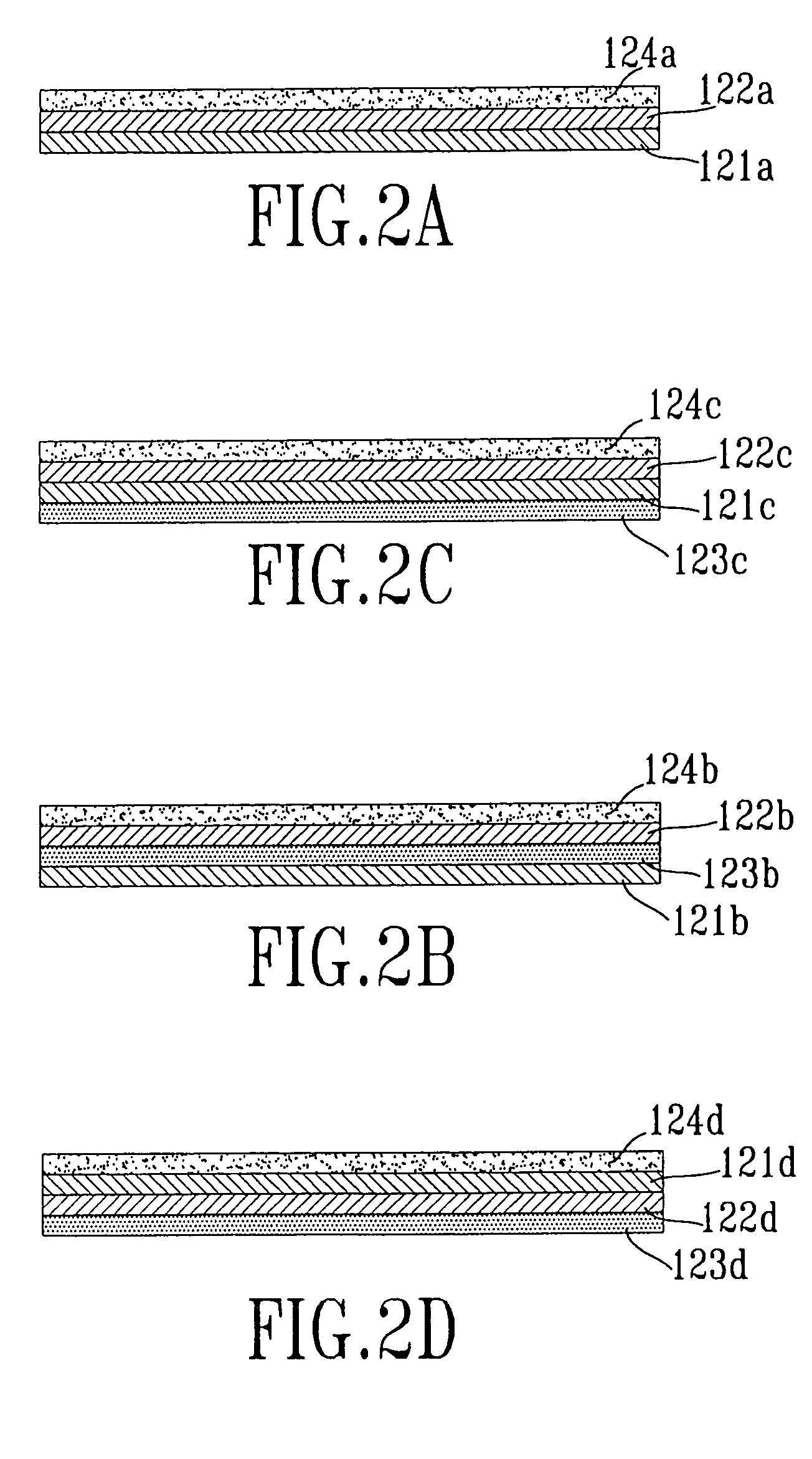

Optical-interference type reflective panel and method for making the same

ActiveUS6999236B2The production process is simpleEasy to manufactureLayered productsDecorative surface effectsEngineeringElectrically conductive

Owner:SNAPTRACK

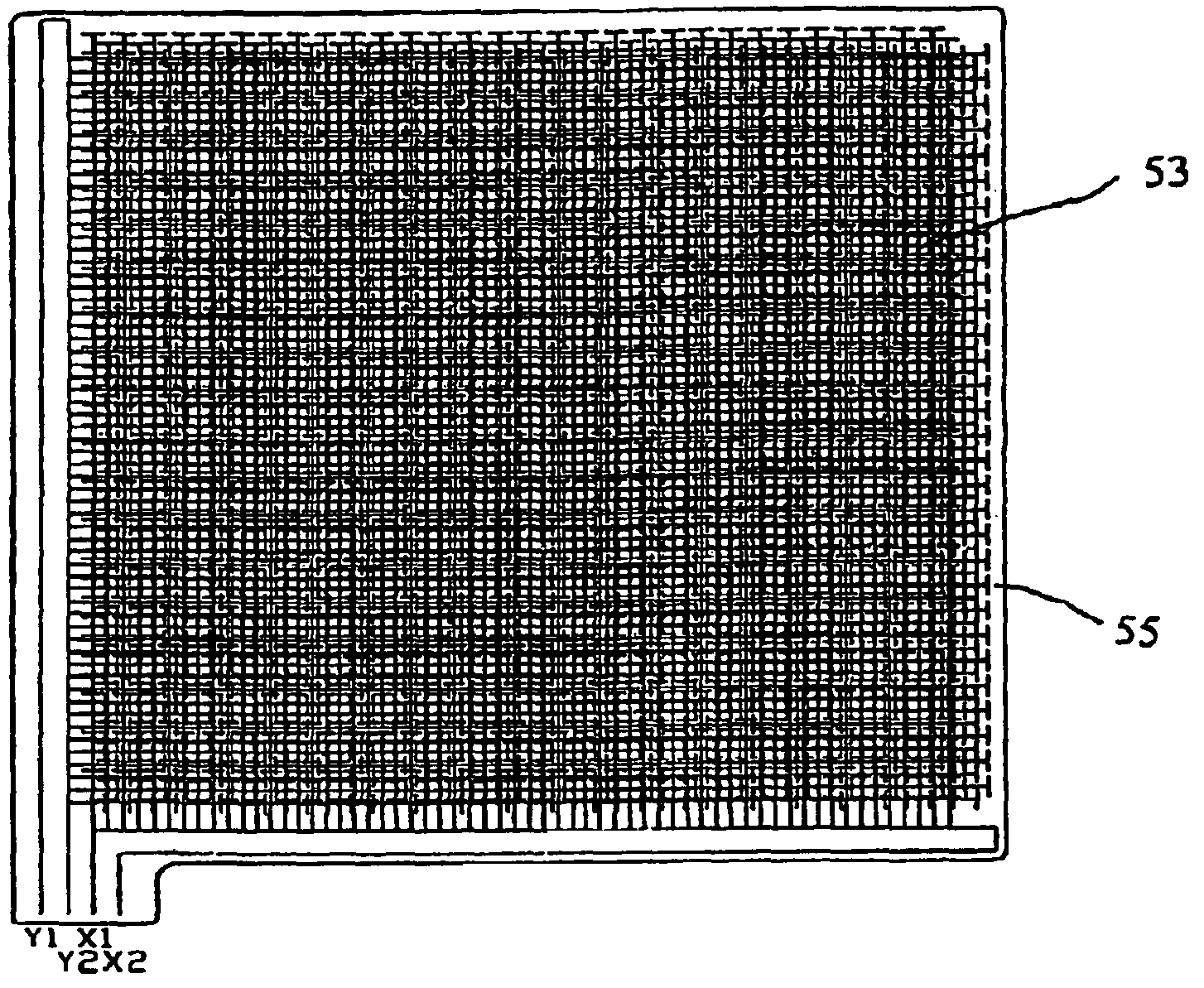

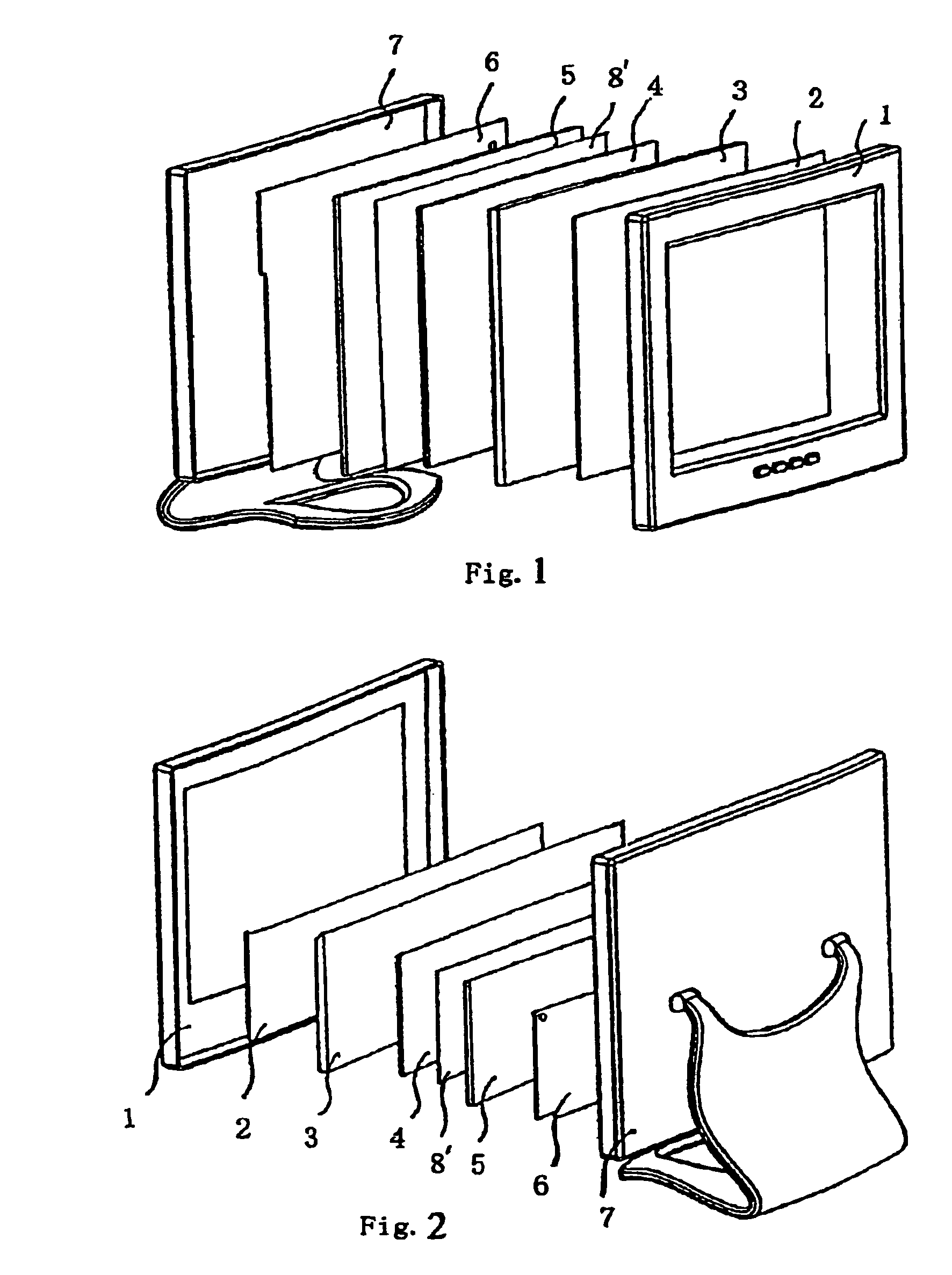

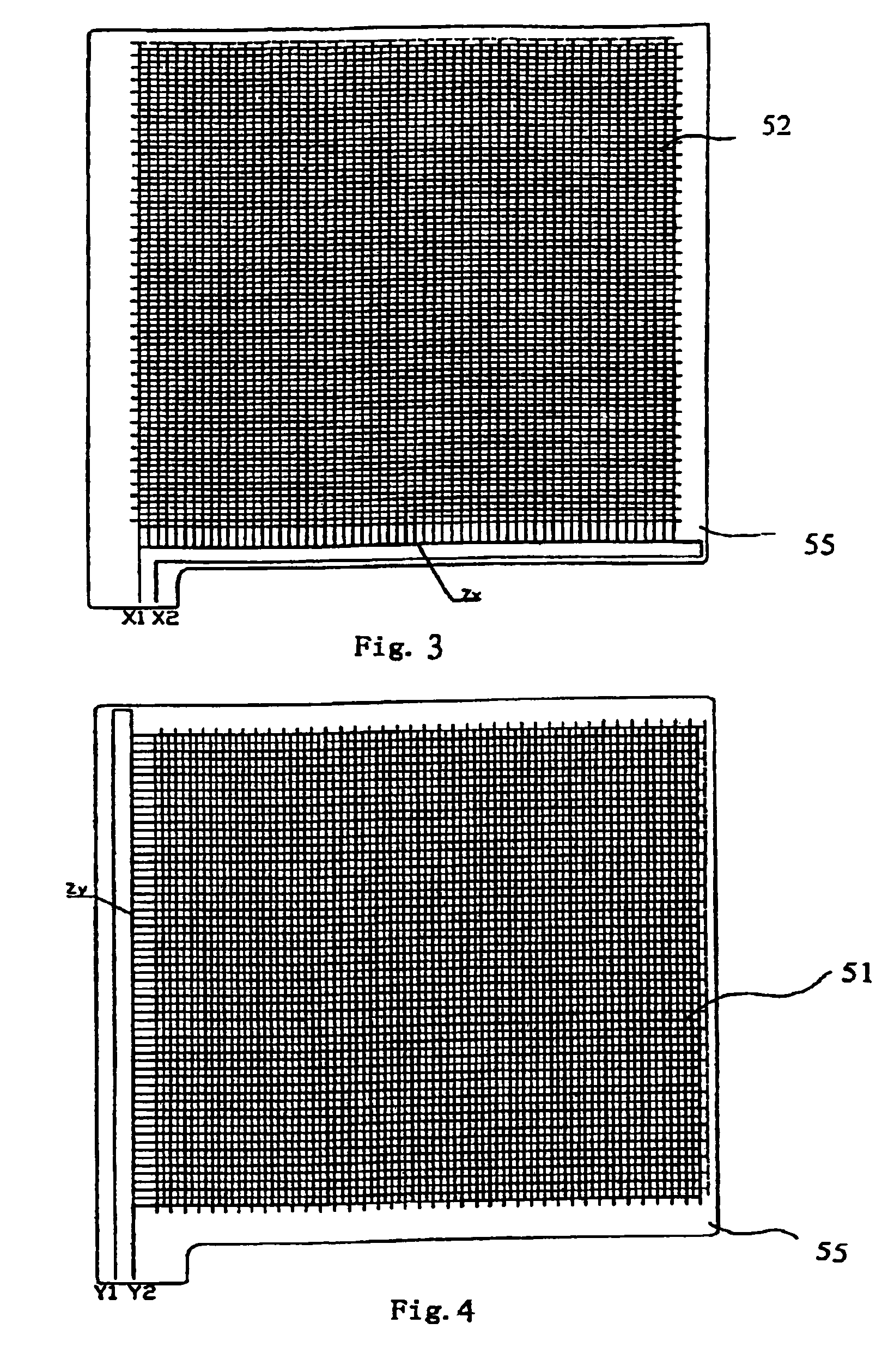

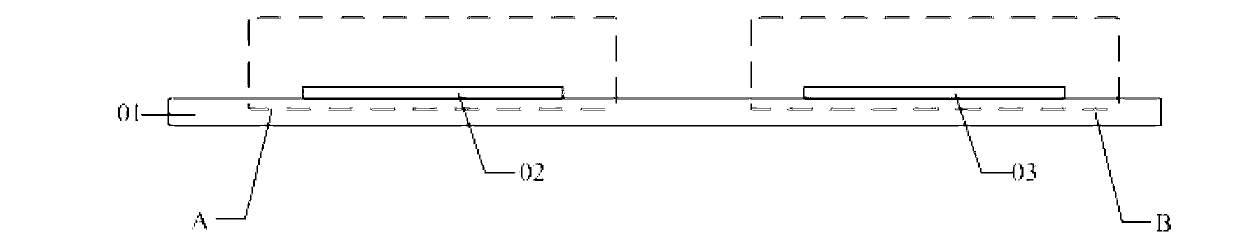

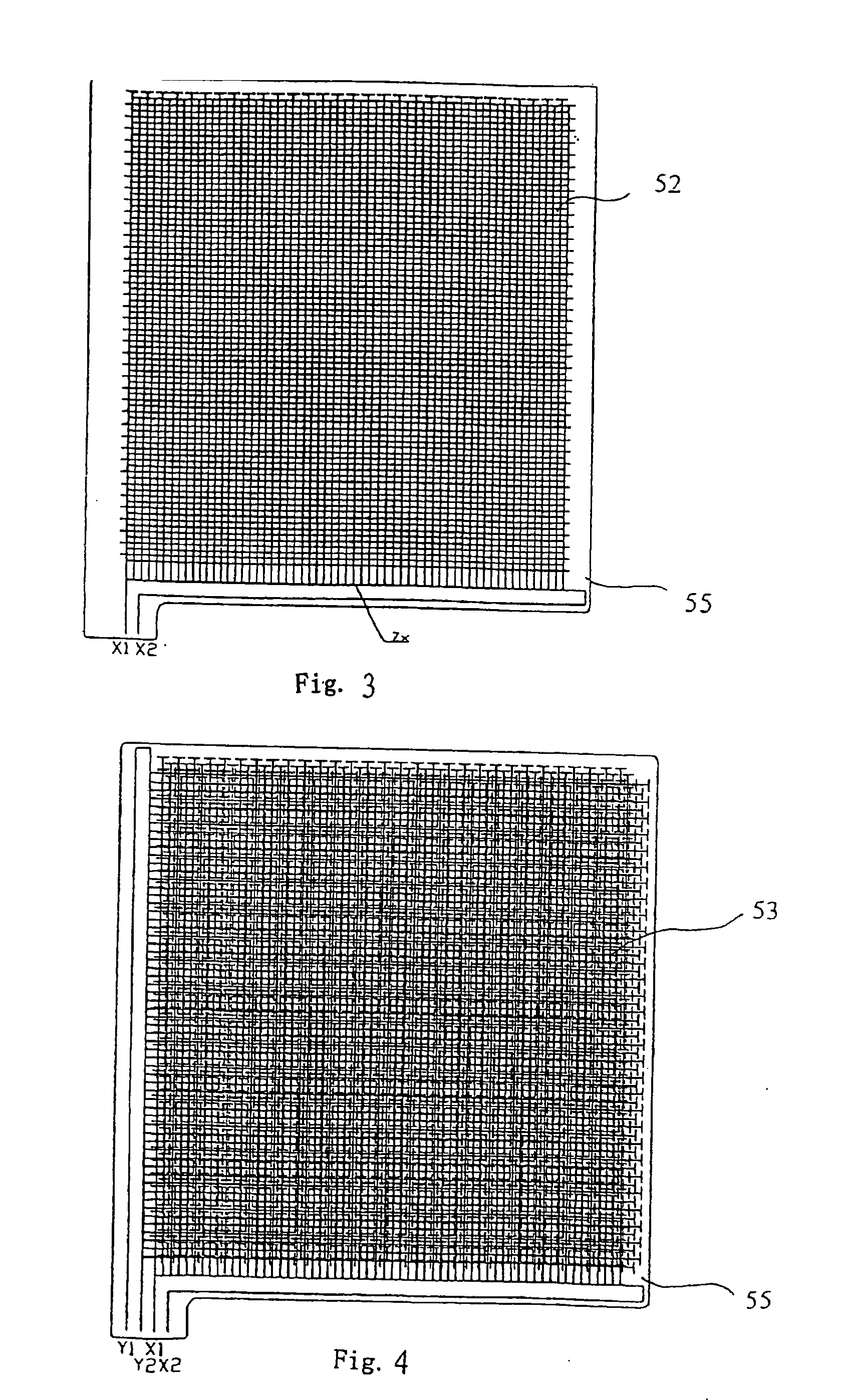

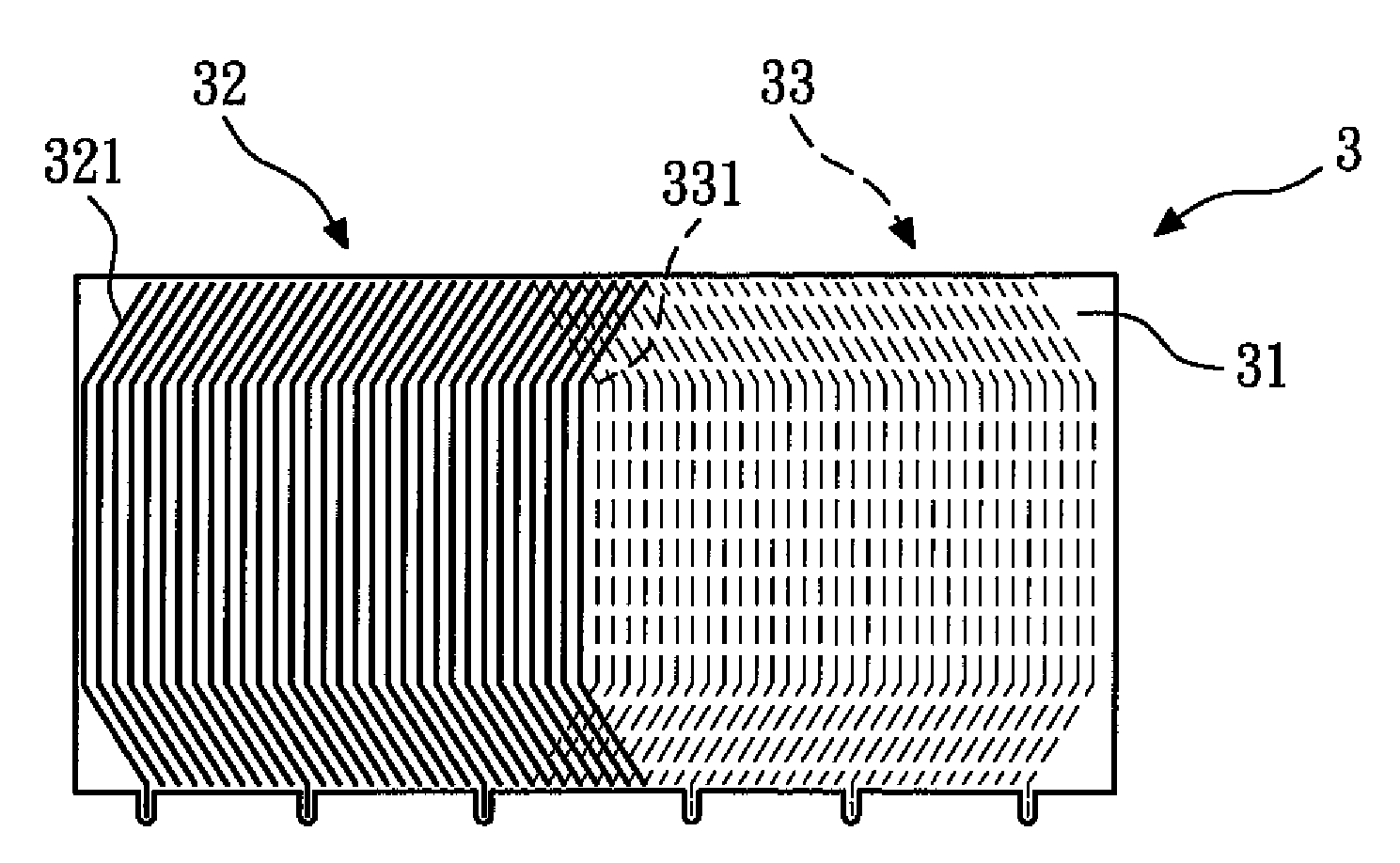

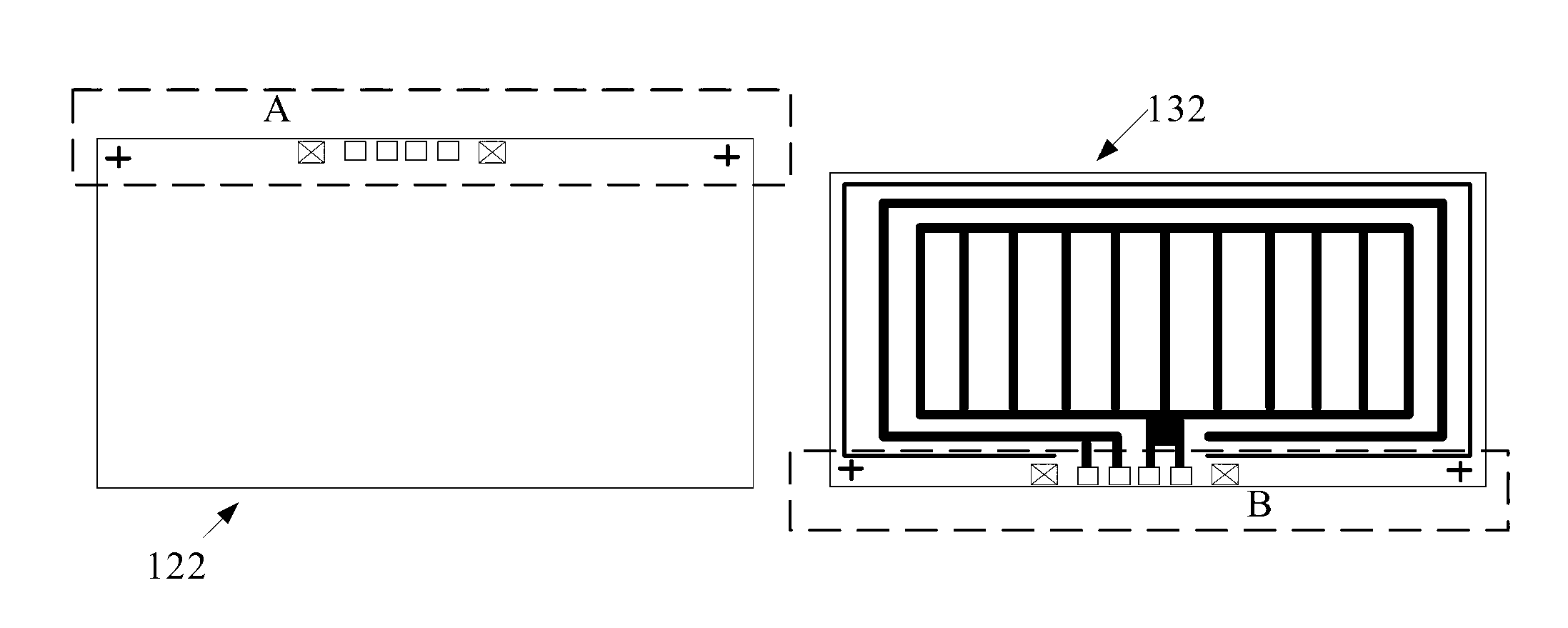

Touch control display screen with a built-in electromagnet induction layer of septum array grids

ActiveUS7796122B2The production process is simpleImprove accuracyTransmission systemsCathode-ray tube indicatorsHandwritingTectorial membrane

A touch control display screen with built-in membrane antenna array lattice electromagnetic induction layer, including at least a display screen and a shell; wherein an induction layer is provided in the rear of the display screen, the output of the induction layer is connected to an induction control circuit, a display screen control circuit is also provided in the shell; the induction layer is the antenna array printed on the insulation membrane and arranged along the X, Y axes, therein the area enclosed by each lattice unit constitutes one induction cell. Because the electromagnetic induction layer is provided in the rear of the display screen and flexible membrane-type, printed electromagnetic induction array antenna is used as the identifying induction component according to the present invention, the manufacture is easy, the cost is low, and the advantage in cost-cut is prominent in comparison with the prior art when the area of the display screen is larger. The accuracy of identification is high, and the mouse information or handwriting information can be input exactly by means of brush strokes of finger strokes; as a touch screen, the display screen is covered by a protecting film to avoid the physical damage, so it has long operating life.

Owner:MORGAN TOUCH TECH (HK) CO LTD +1

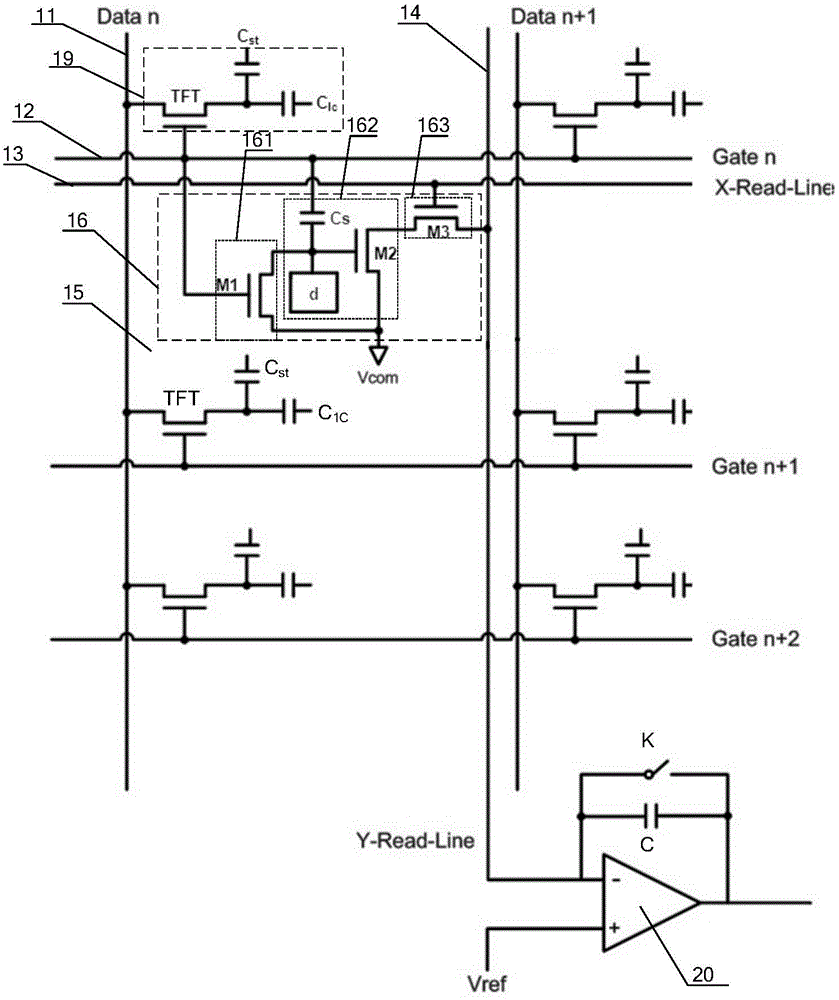

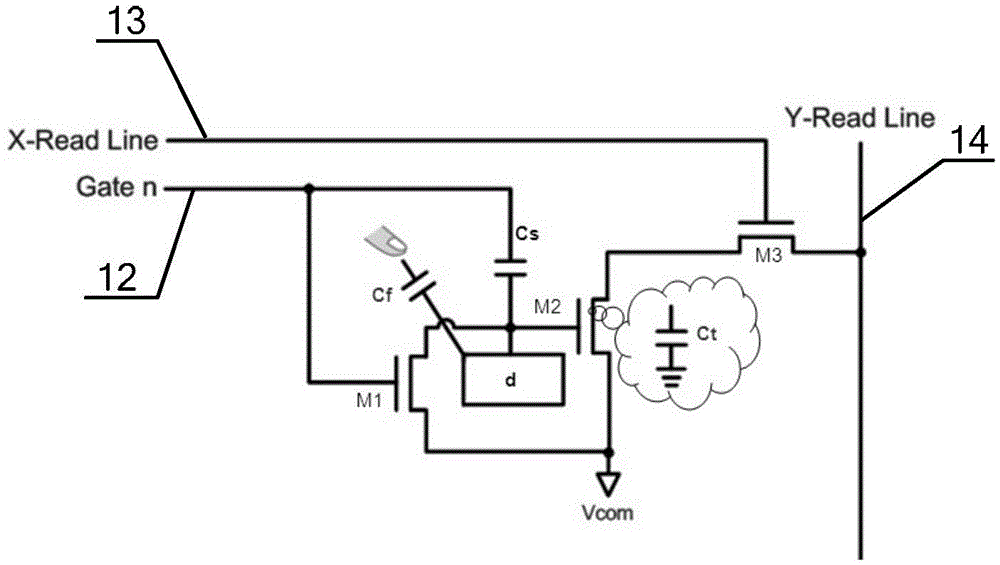

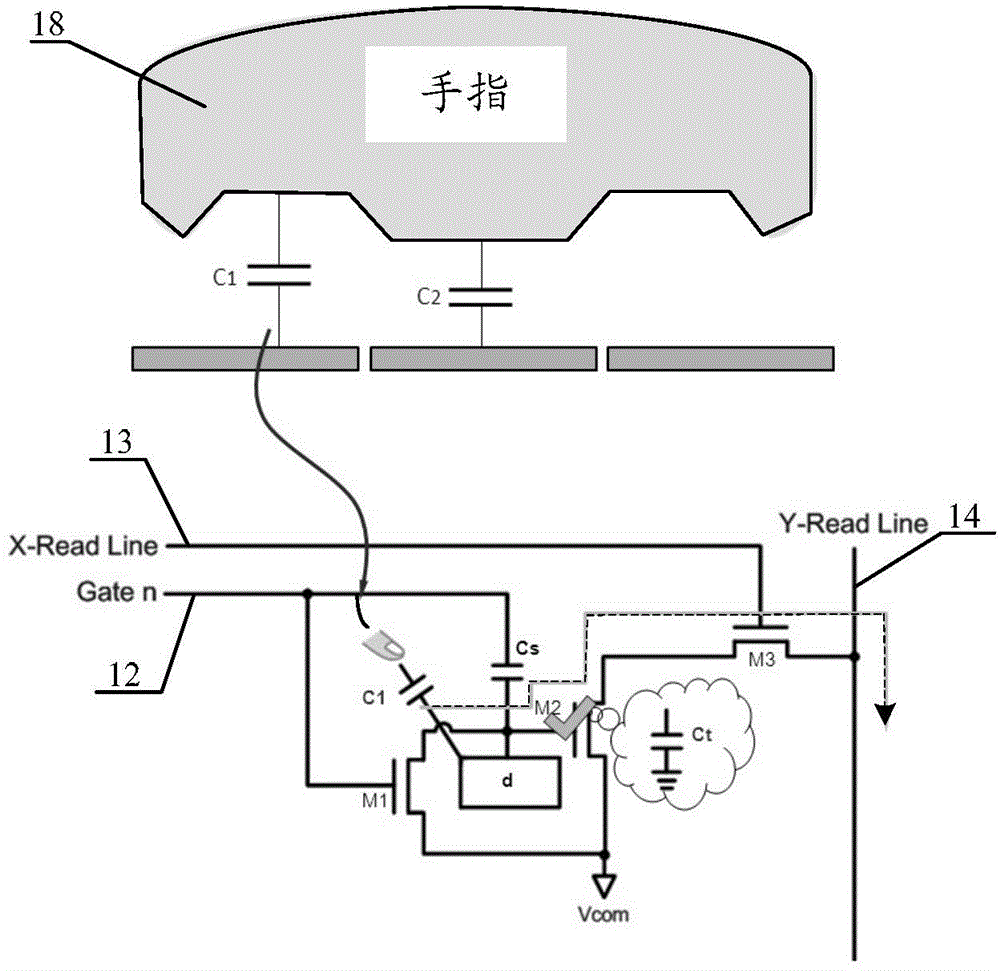

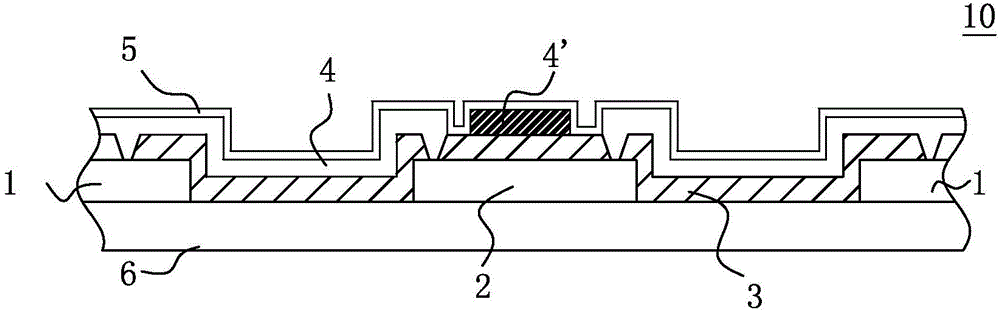

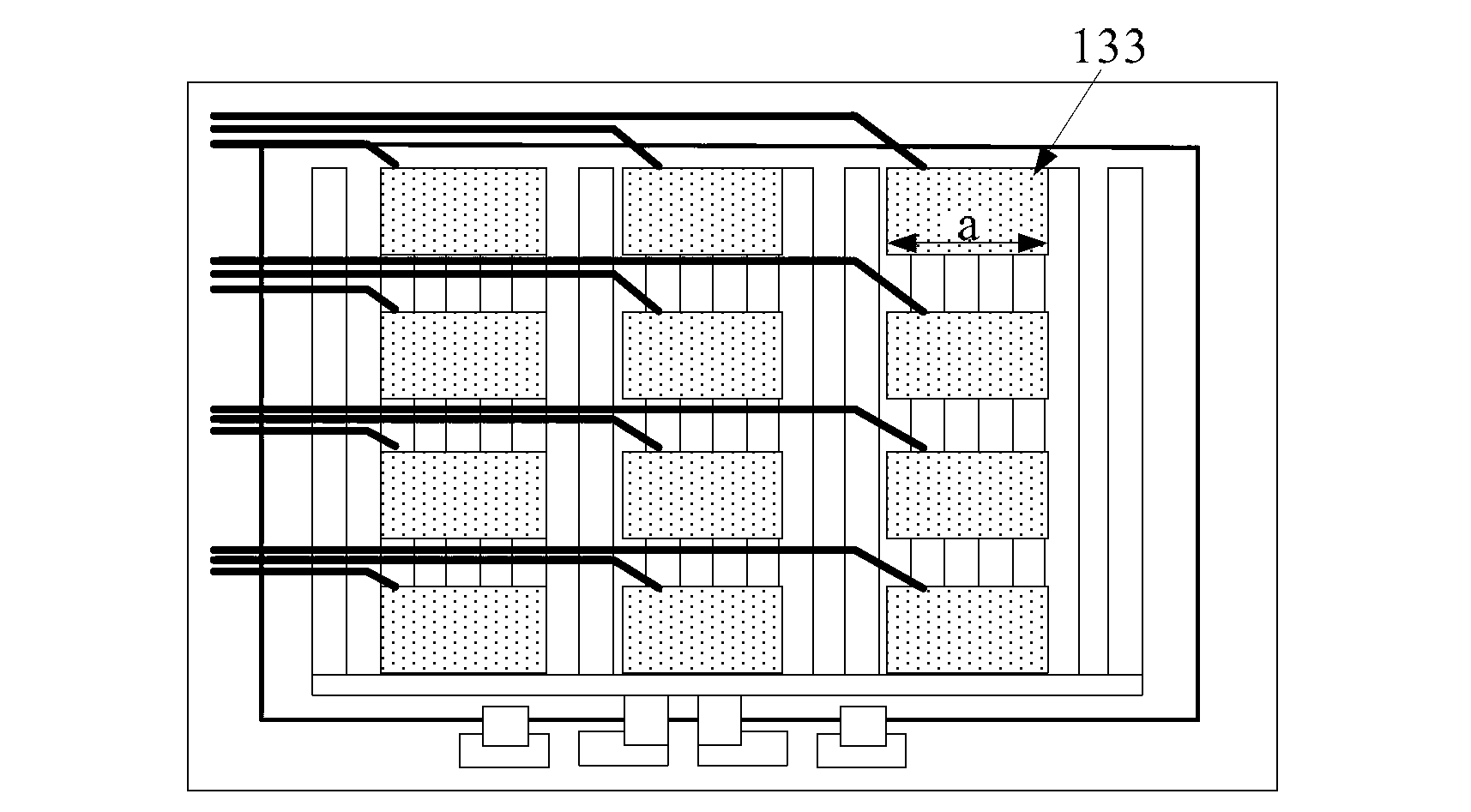

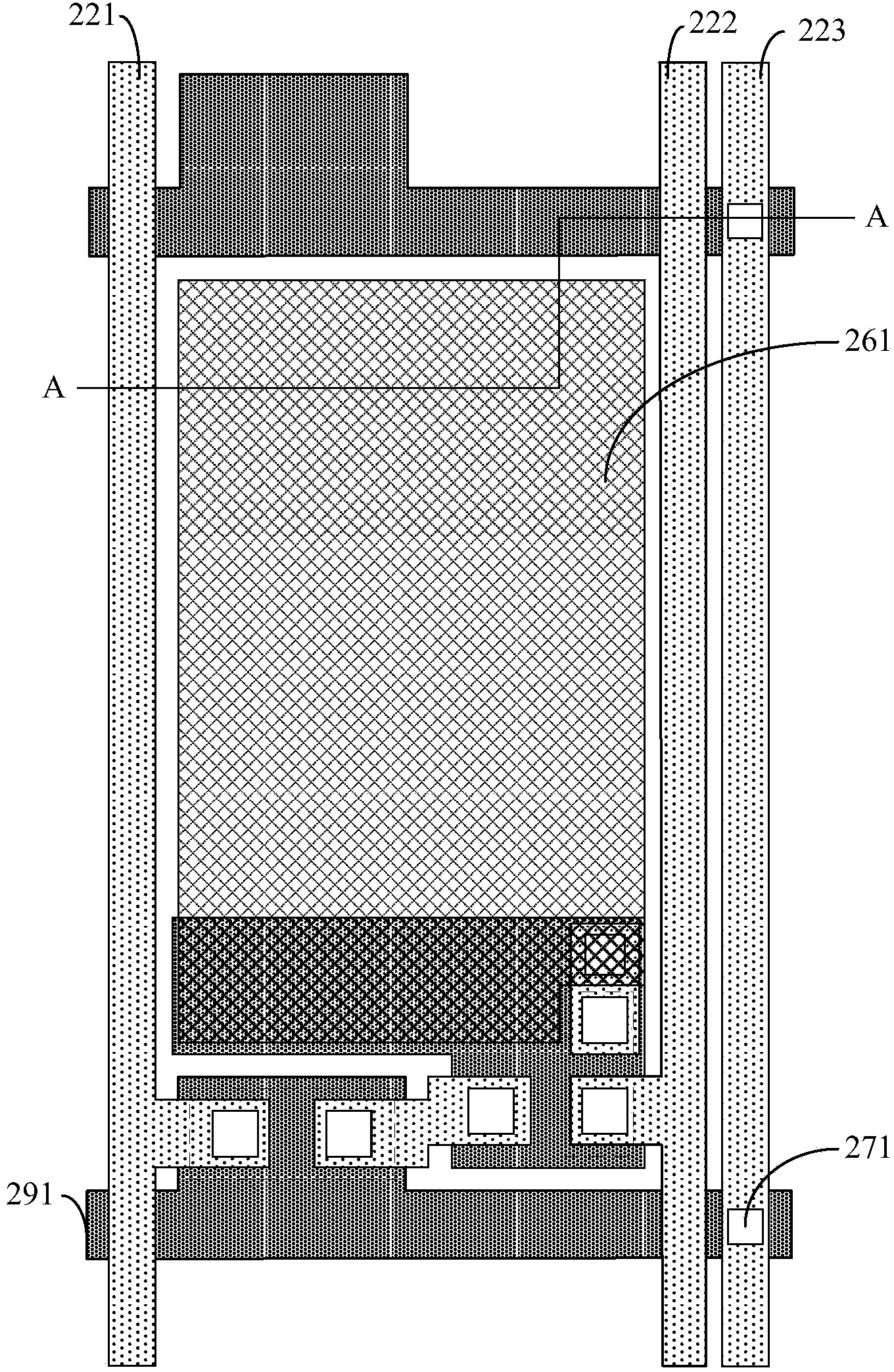

Array substrate, driving method of array substrate and display device

ActiveCN104155785AThe production process is simpleStatic indicating devicesPrint image acquisitionDisplay deviceEngineering

The embodiment of the invention discloses an array substrate, a driving method of the array substrate and a display device, and relates to the field of displaying. A fingerprint identification module can be arranged inside a display area, so that the purpose of simplifying operations and a manufacturing process is achieved. The array substrate comprises a substrate body, grid lines, data lines and pixel units defined by the grid lines and the data lines, the substrate body is also provided with a plurality of fingerprint identification circuits used for carrying out fingerprint identification, and the fingerprint identification circuits are arranged inside the pixel units.

Owner:BOE TECH GRP CO LTD +1

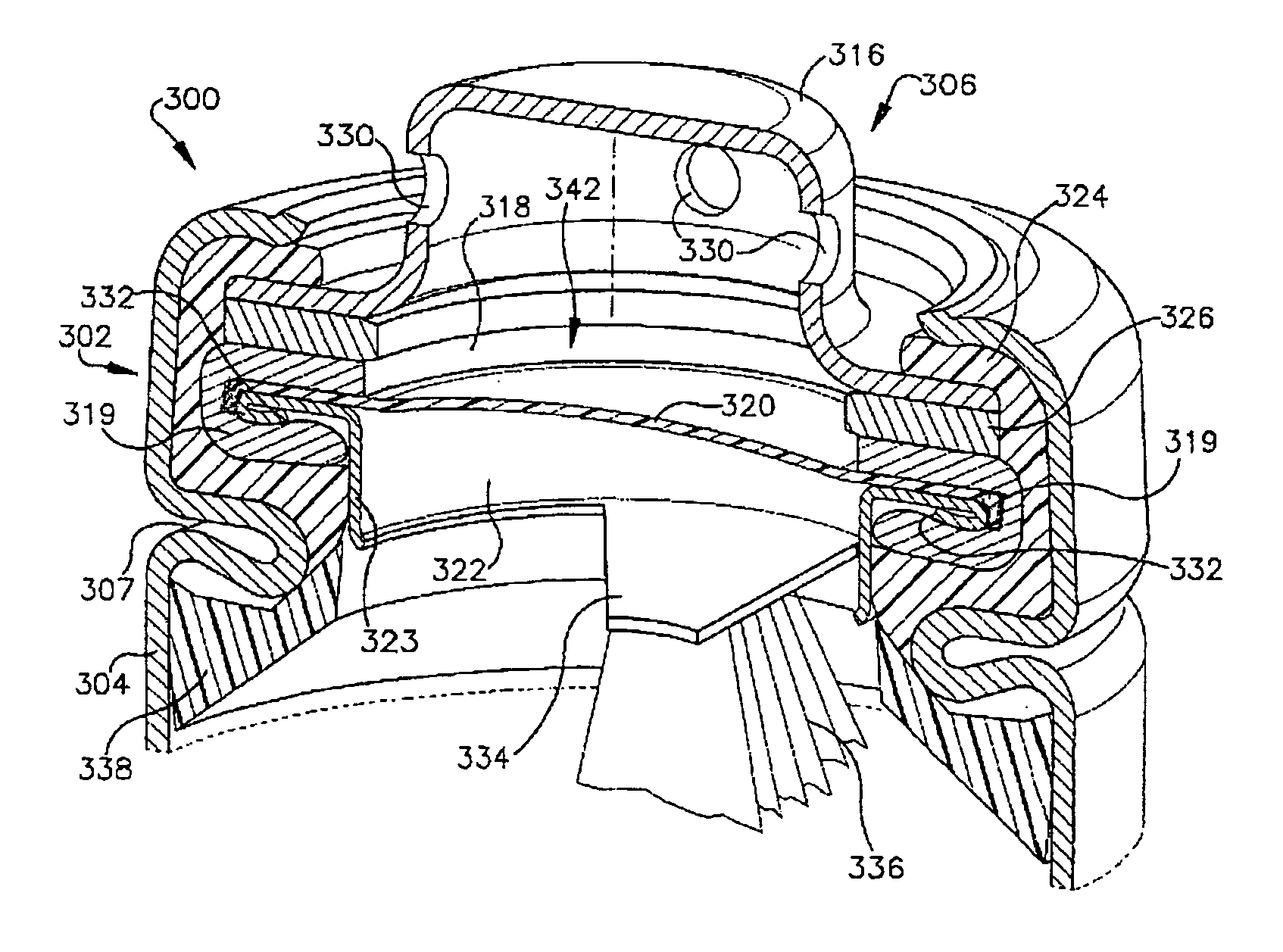

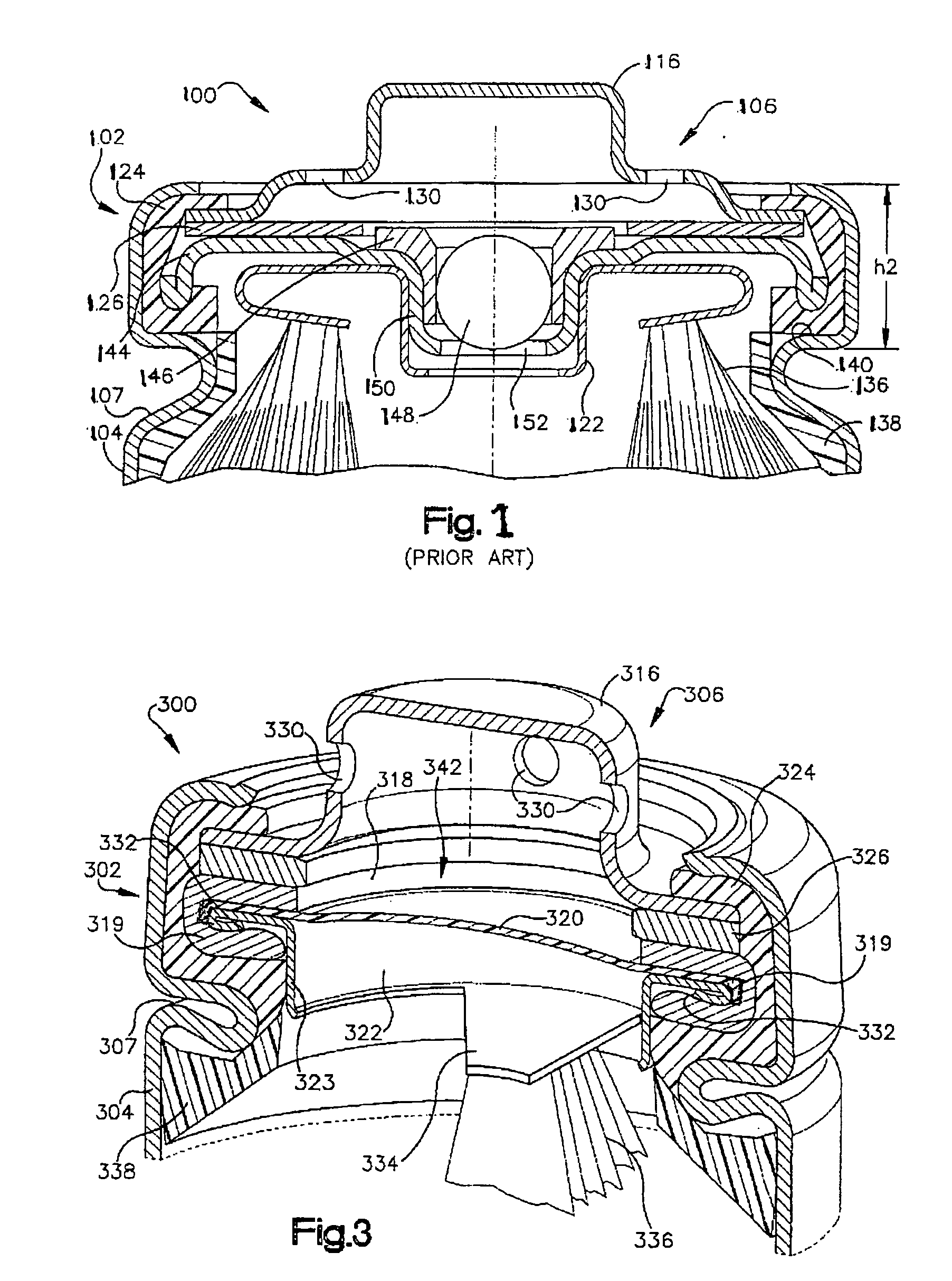

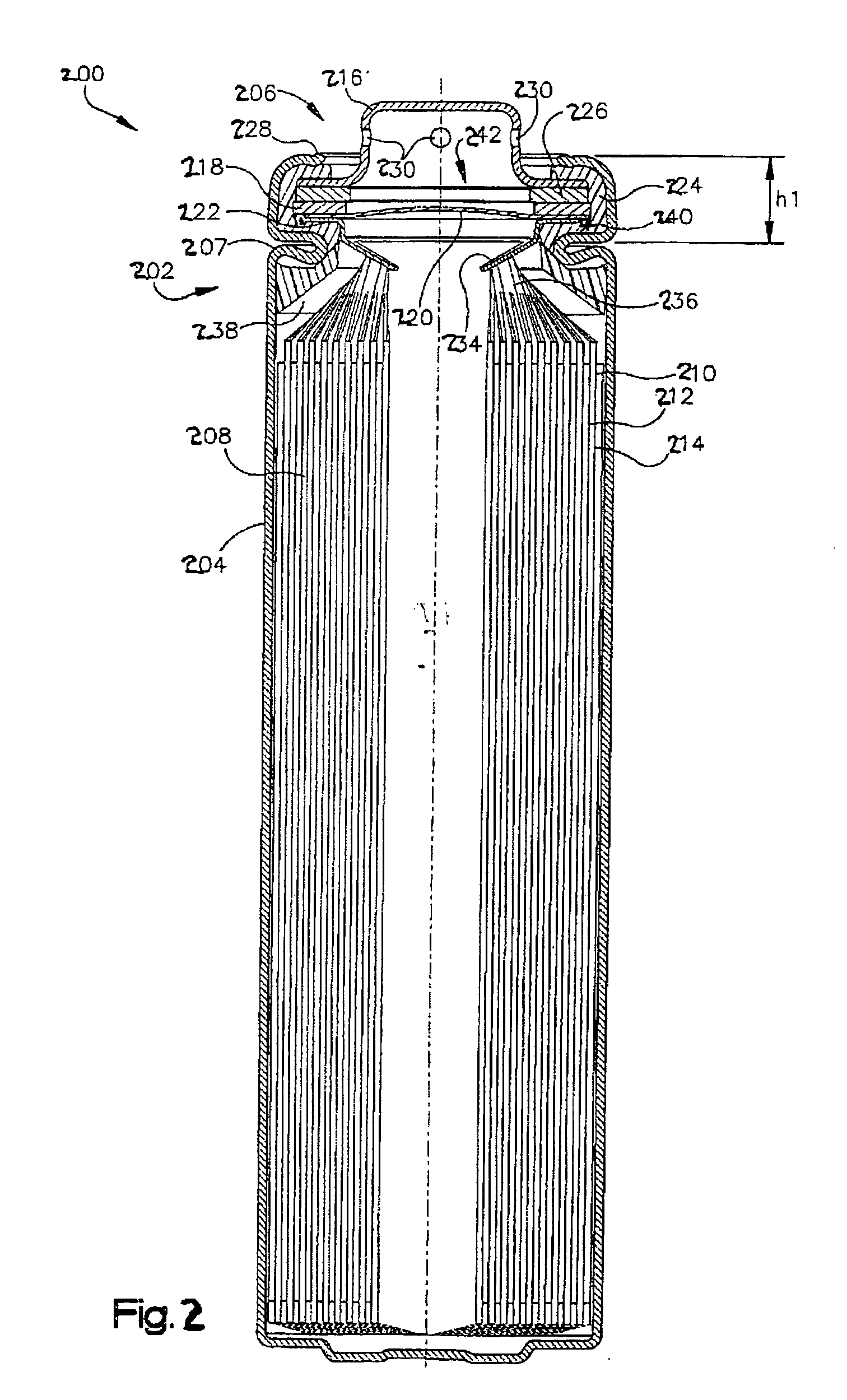

Closure vent seal and assembly

InactiveUS20060228620A1Increase battery capacityThe production process is simpleClosuresFinal product manufactureEngineeringMechanical engineering

A closure assembly and rupturable vent seal adapted for use in an electrochemical battery cell is disclosed. The vent seal includes a series of peripheral projections that can be folded to insure proper sealing of the vent without wrinkles or overlapping folded portions. Methods of accomplishing the invention are also contemplated.

Owner:EVEREADY BATTERY CO INC

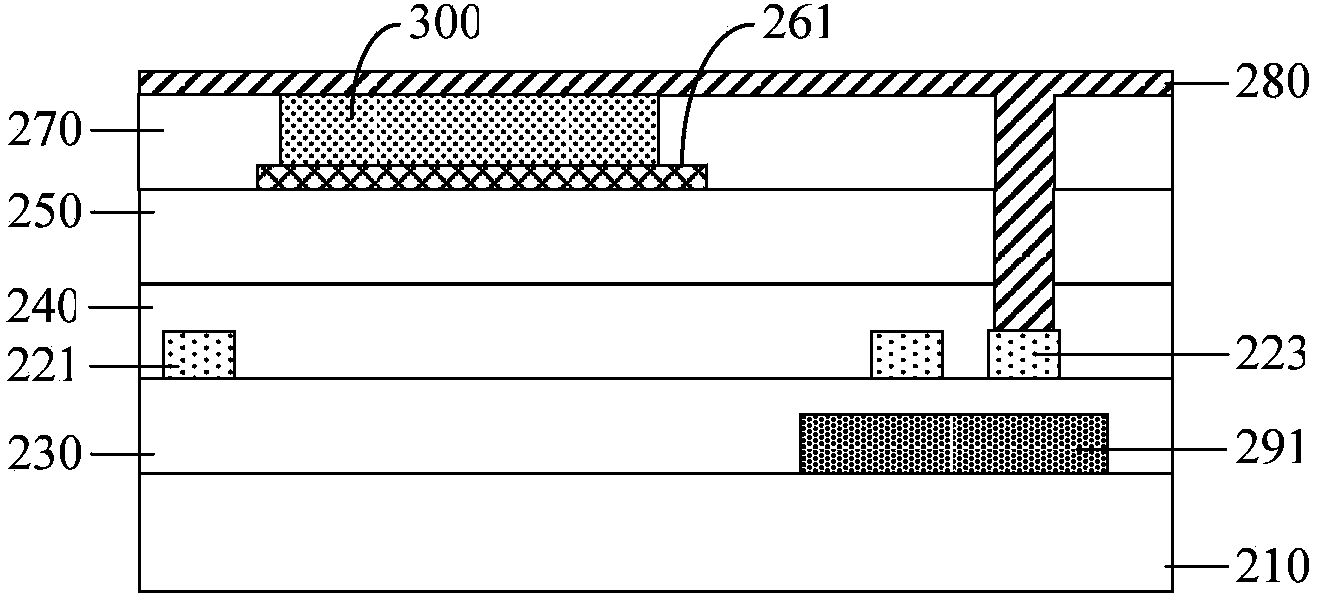

Complementary metal oxide semiconductor (CMOS) circuit structure and manufacture method and display device thereof

ActiveCN103000632AThe production process is simpleExtended service lifeTransistorSolid-state devicesCMOSDisplay device

The invention discloses a complementary metal oxide semiconductor (CMOS) circuit structure and a manufacture method and a display device thereof. A P-channel metal oxide semiconductor (PMOS) area in the CMOS circuit structure is of a low temperature poly silicon (LTPS) thin film transistor (TFT) structure, namely a P type mingled polycrystalline silicon material is utilized to prepare a PMOS layer. An N-channel metal oxide semiconductor (NMOS) area is of an Oxide TFT structure, namely an oxide material is utilized to prepare an NMOS layer. The oxide material is utilized at the NMOS area to replace the existing polycrystalline silicon material to prepare the NMOS layer, three mingled processes of the NMOS area in the LTPS process are saved, manufacture flow of the CMOS circuit structure is simplified, and production cost is reduced. Further, the oxide material is adopted to manufacture the NMOS layer of the NMOS area, crystallization is only needed to be conducted on the PMOS layer in the PMOS area, service life of a laser tube is prolonged, and production cost is reduced.

Owner:BOE TECH GRP CO LTD

Electromagnetic induction electronic board with antenna arrayed in gridding inside

ActiveUS20050052424A1Low costSimple manufacturing procedureWriting boardsCathode-ray tube indicatorsElectromagnetic inductionMembrane configuration

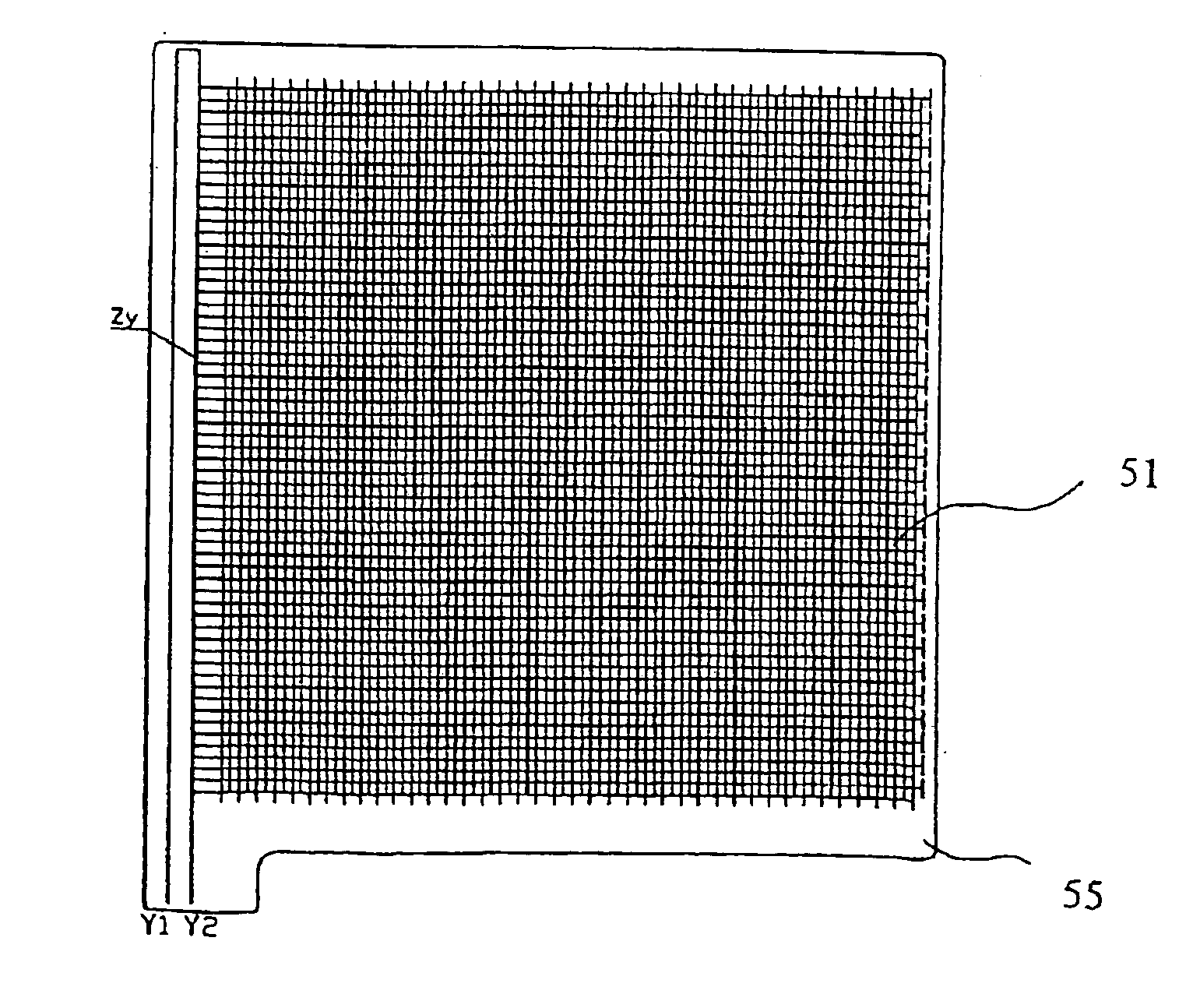

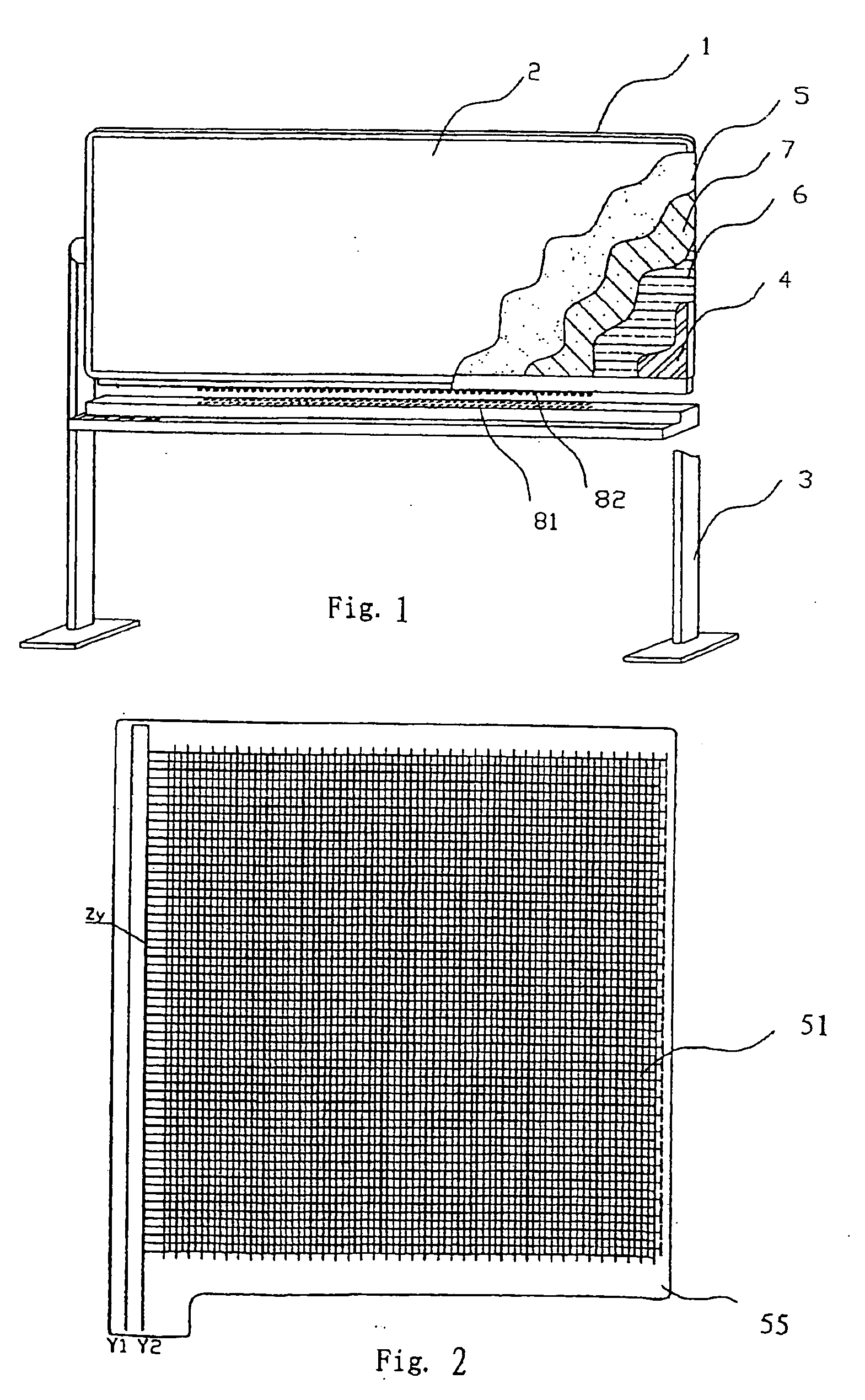

An electronic whiteboard with built-in membrane antenna array lattice electromagnetic induction layer includes: a writing input portion; a covering frame provided around the periphery of the electronic whiteboard; and a control circuit; wherein, the writing input portion has multilayer structure and is enclosed in the frame, the said writing input portion includes a surface writing layer, an underlayer, and an input induction layer which is connected to the control circuit by its output; the said induction layer may be the antenna array printed on the insulation membrane and arranged along the X, Y axes, therein the area enclosed by each lattice unit constitutes one induction cell.

Owner:MORGAN TOUCH TECH (HK) CO LTD +1

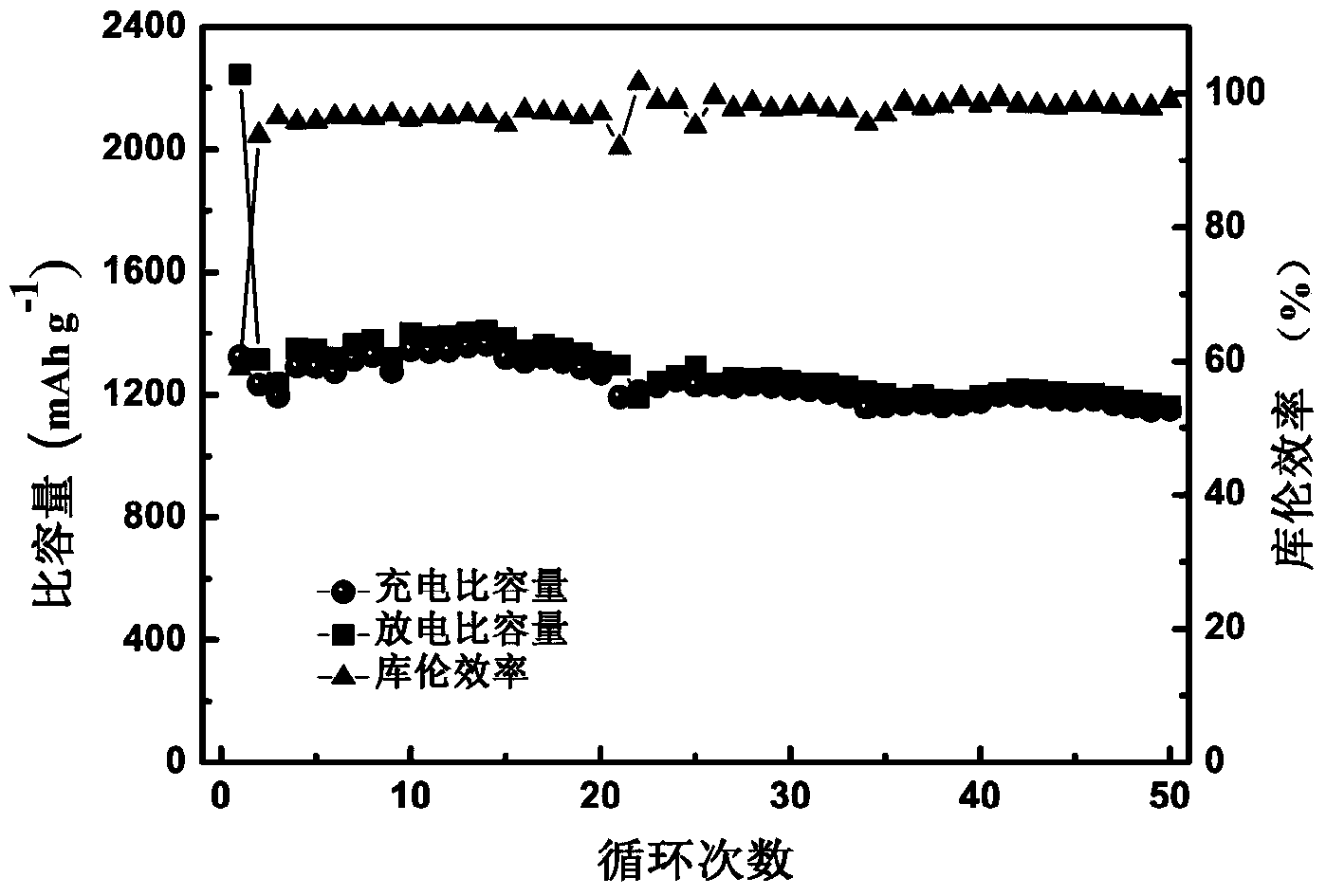

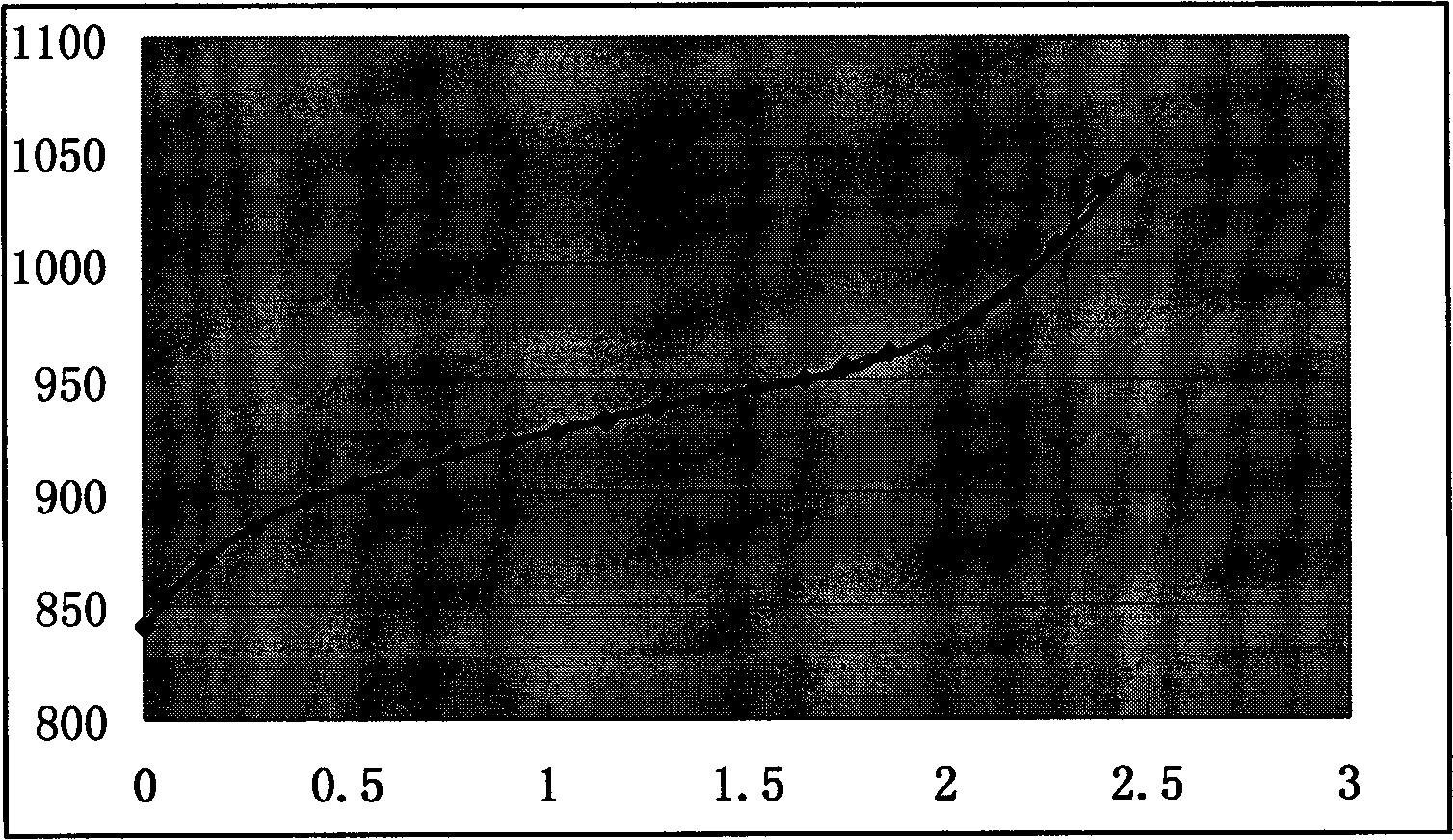

Method for preparing nitrogen-doped porous carbon nanofiber cloth

ActiveCN103855361ALow costGood spinnabilityMicroscopic fiber electrodesSecondary cellsLithium electrodeCarbon nanofiber

The invention relates to a method for preparing nitrogen-doped porous carbon nanofiber cloth. The nitrogen-doped porous carbon nanofiber cloth is prepared by adding a nitrogen-rich compound into an organic solution, electrospinning and subsequent carbonizing-activating, has a self-support structure, omits preparation steps of size mixing, coating and the like, needs no conductive agent or binder, and can be directly used as the negative electrode of a lithium ion battery. The electrochemical performance of the negative electrode material of the lithium ion battery is improved by doping nitrogen and activating and forming pores; compared with a commercial graphite lithium ion battery negative electrode material, the nitrogen doping porous carbon nanofiber cloth used as the negative electrode material of the lithium ion battery has simple steps for preparing the electrode, has higher specific capacity, good power performance and circulatory stability. The method also can be used as the electrode material of super capacitors and other novel batteries.

Owner:TSINGHUA UNIV

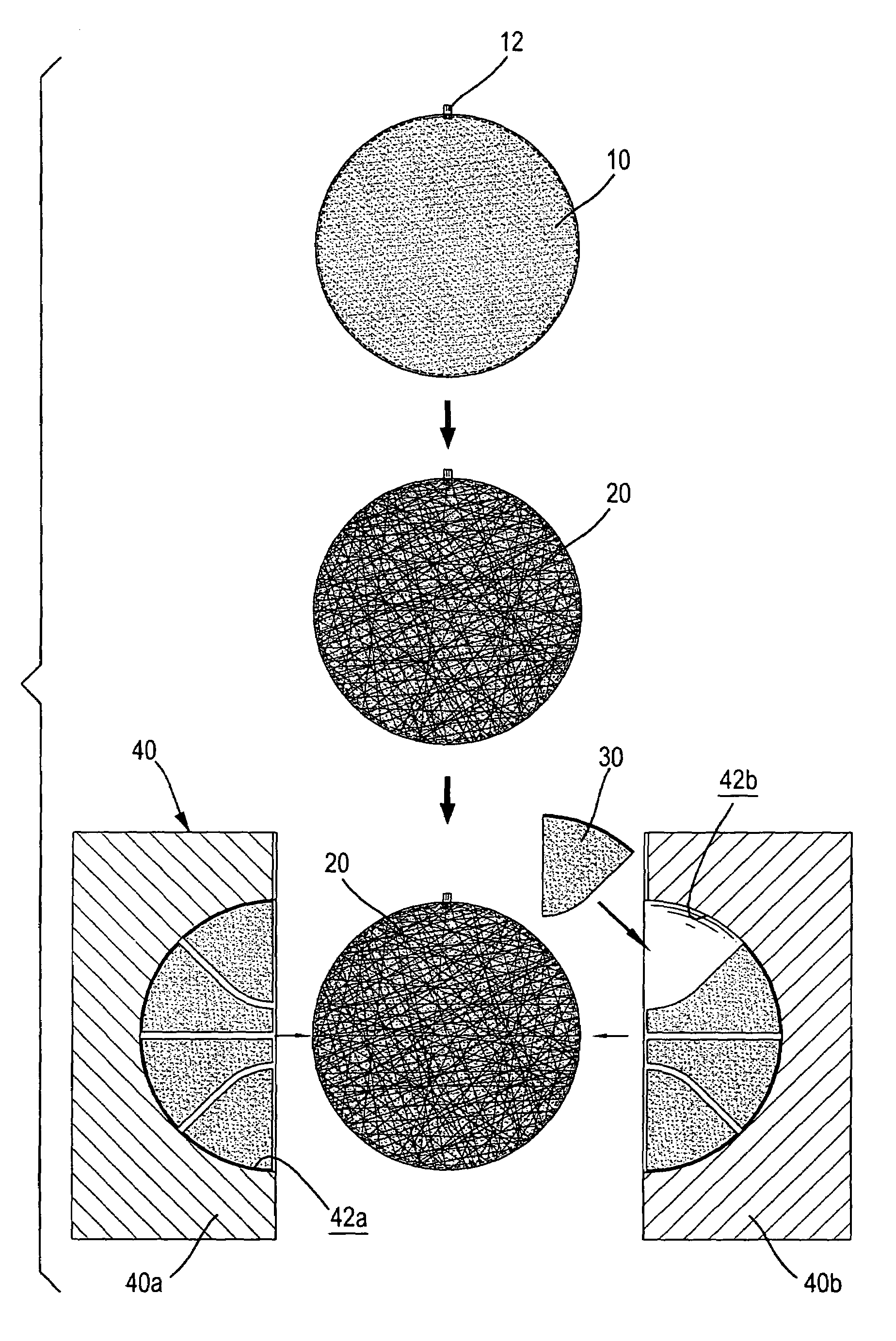

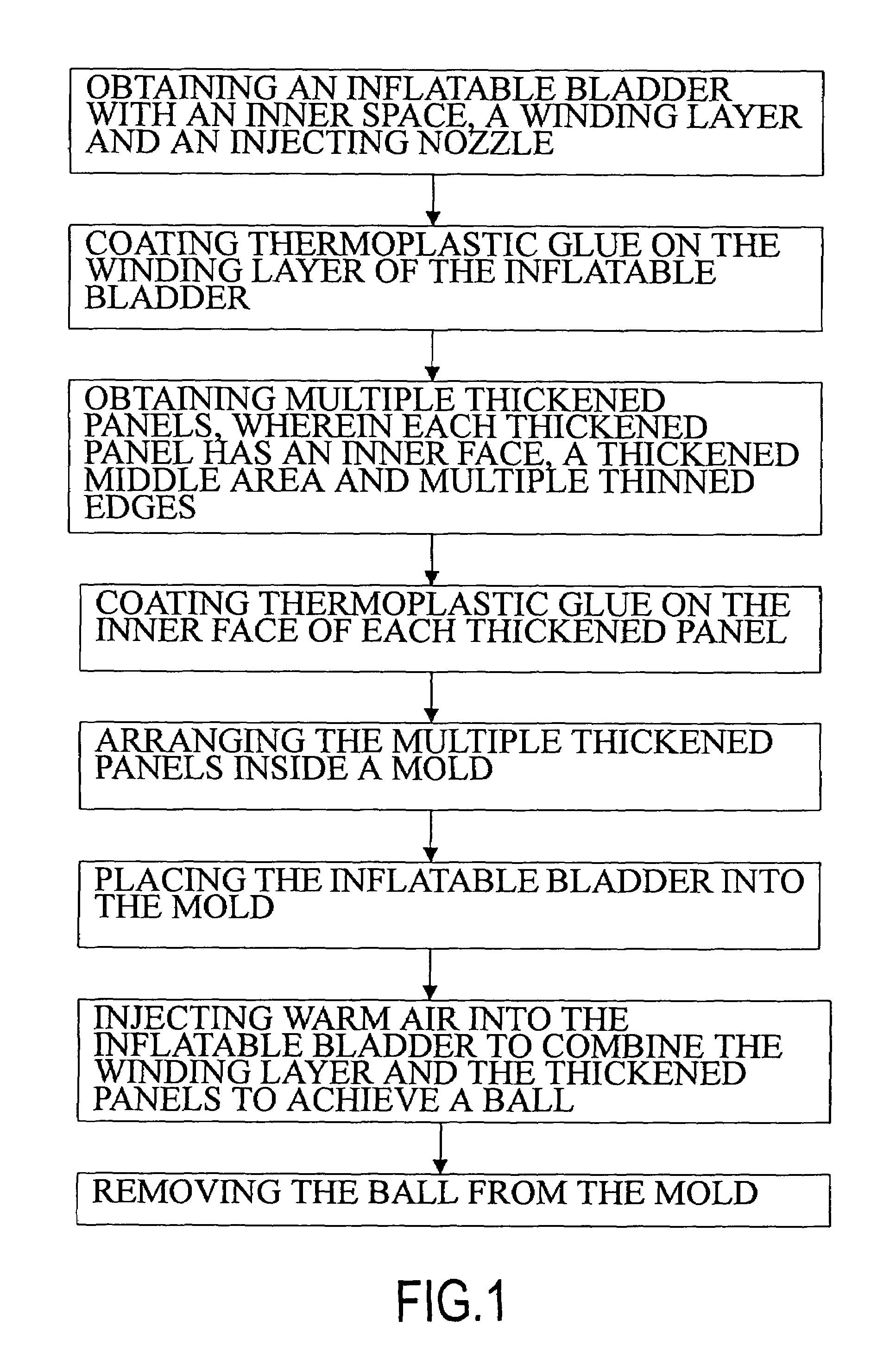

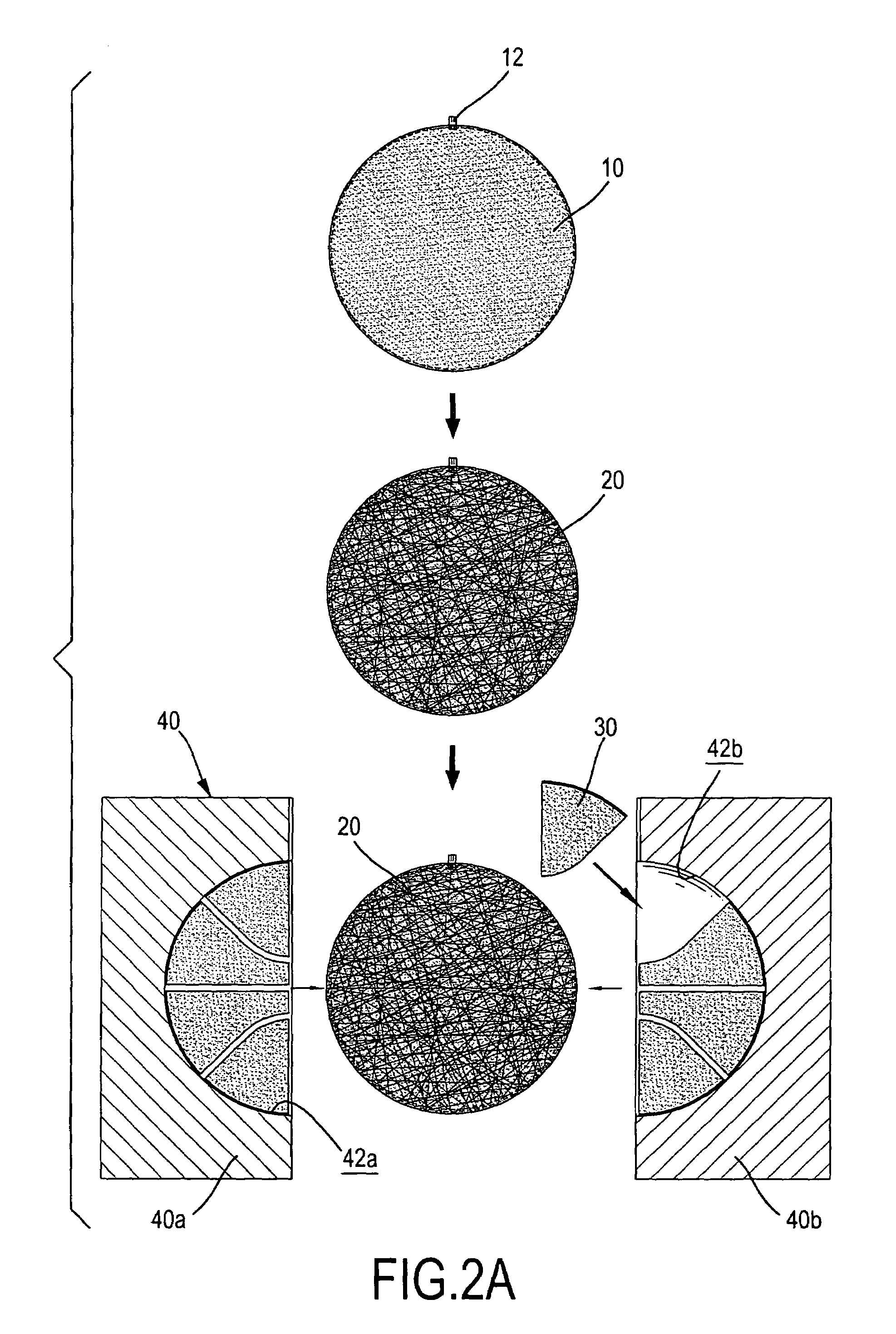

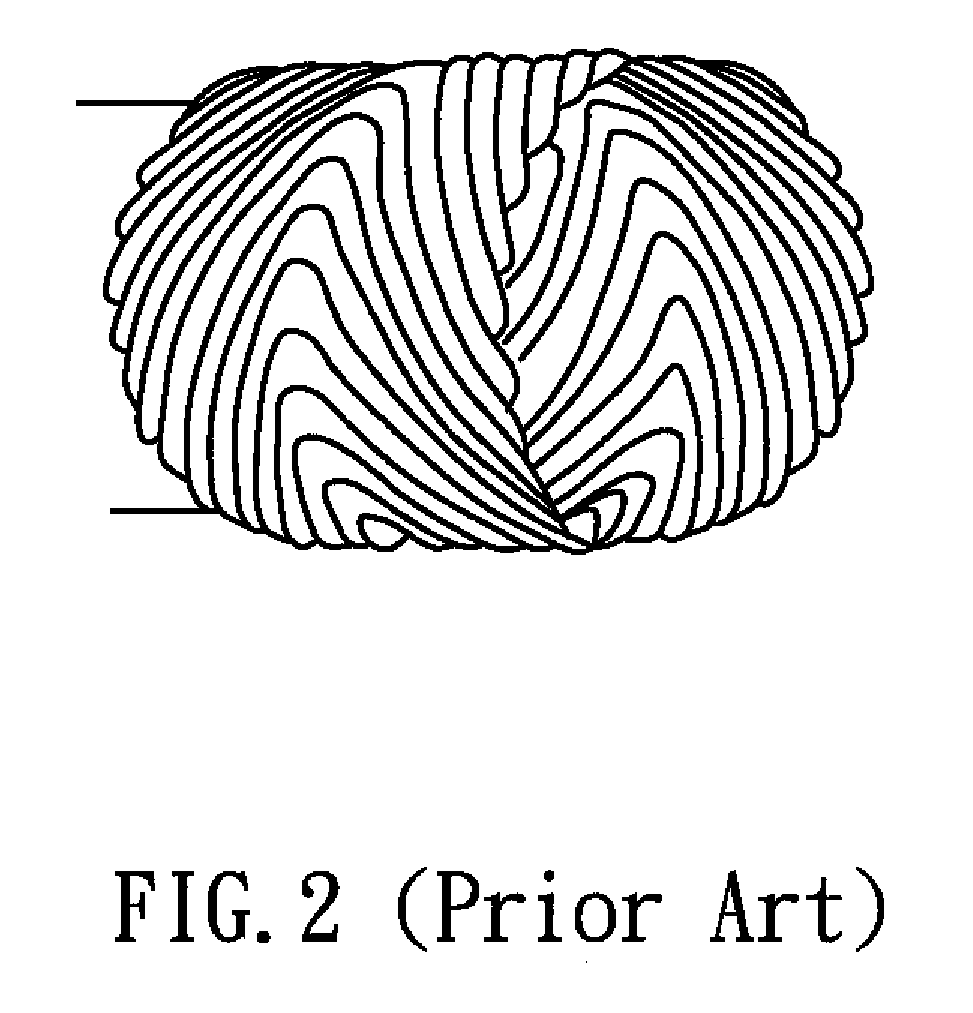

Method for manufacturing an inflatable ball and a ball made with the method

InactiveUS7066853B2Quick and simplified procedureGood appearanceHollow inflatable ballsHollow non-inflatable ballsVulcanizationThermal deformation

A method for manufacturing an inflatable ball has the following acts of: obtaining an inflatable bladder with a winding layer; coating thermoplastic glue on the winding layer; obtaining multiple thickened panels; coating thermoplastic glue on the thickened panels; arranging the thickened panels and the inflatable bladder inside a mold; and injecting thermal air into the inflatable bladder to make the winding layer combine with the multiple thickened panels. Wherein, each thickened panel is made of a leather layer and an optional filling layer and has a thickened middle area and multiple thinned edges around the thickened middle area. By eliminating the rubber layer in the prior arts, vulcanization is avoided. Moreover, heating the inflatable ball from inside of the mold avoids thermal deformation of outer pebbled patterns of the panels.

Owner:CHANG YEN LI

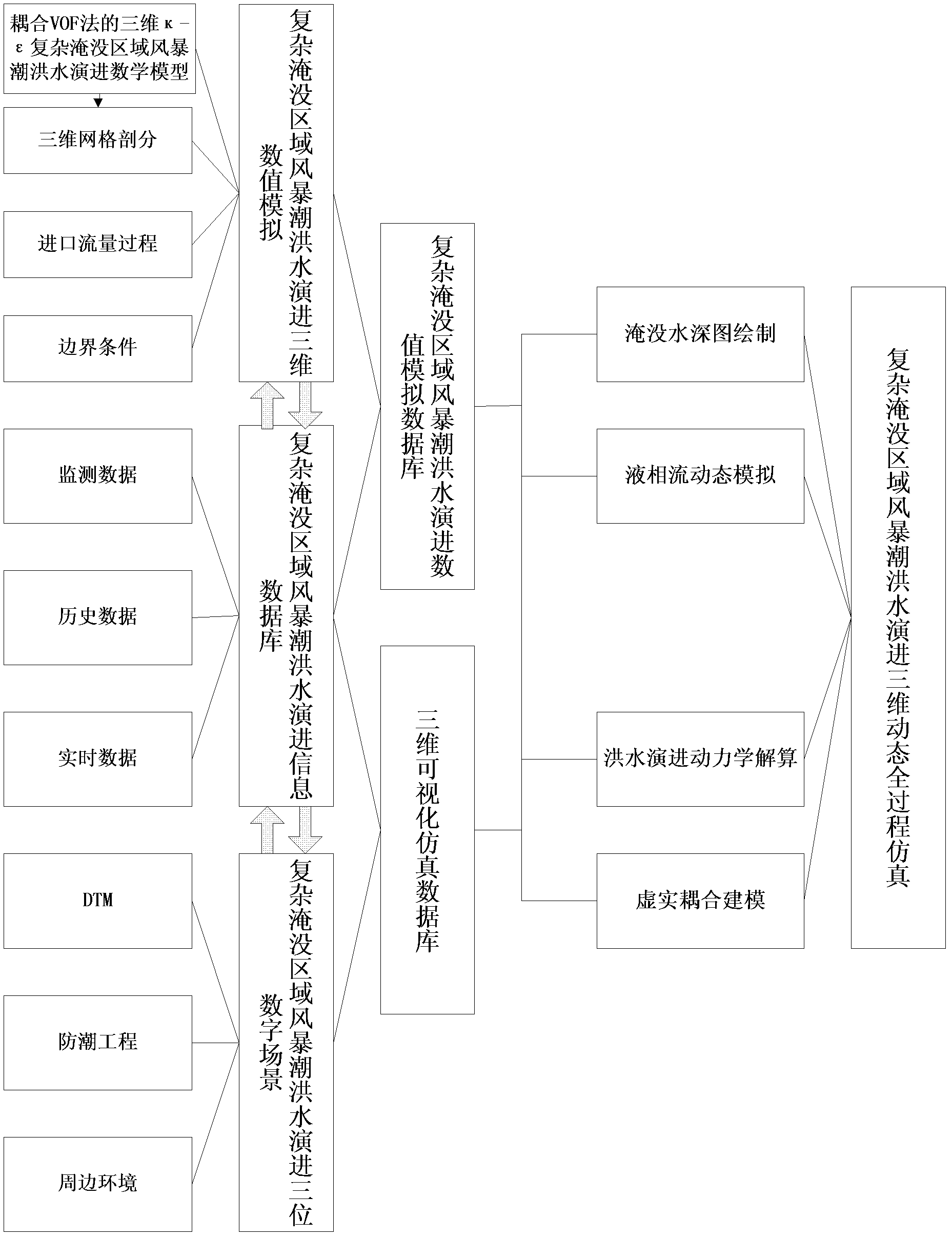

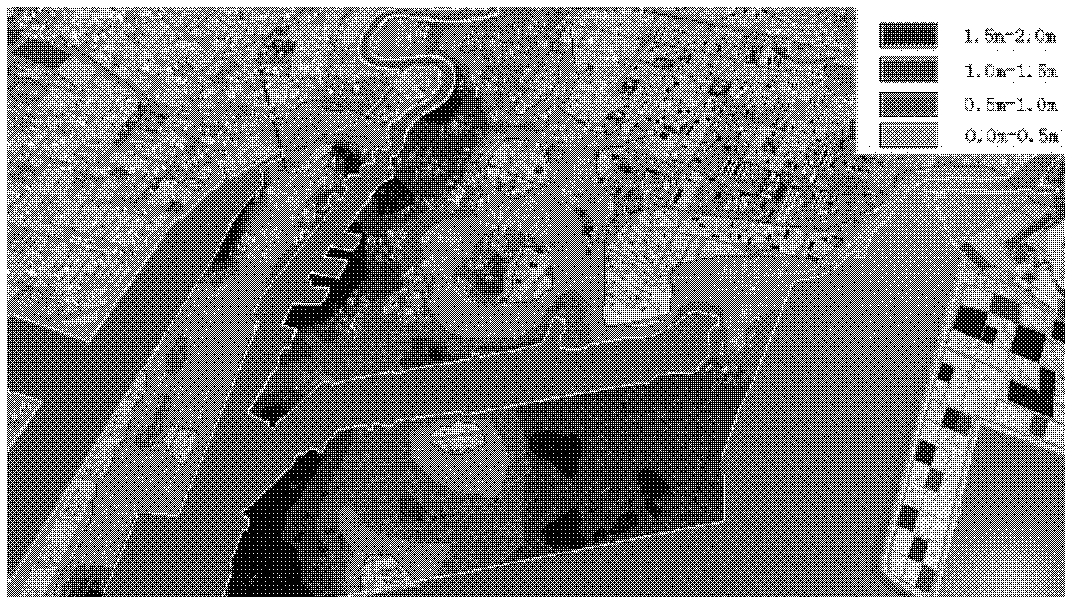

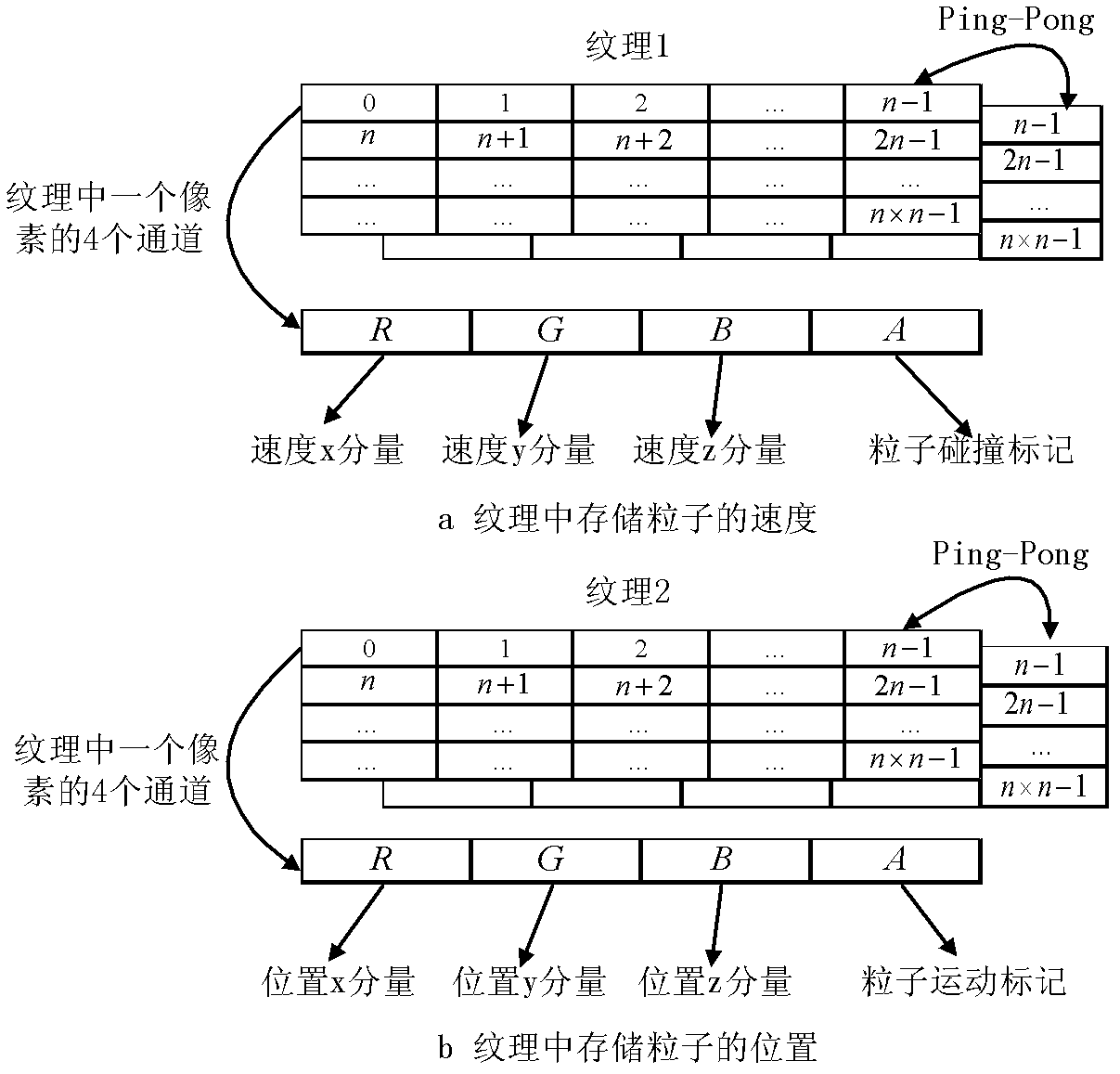

Three-dimensional dynamic whole-process simulation method for storm surge and flood routing in complex flooding areas

InactiveCN102663827AIn line with the law of flowAchieve drawing3D modellingMathematical modelProcess simulation

Owner:TIANJIN UNIV

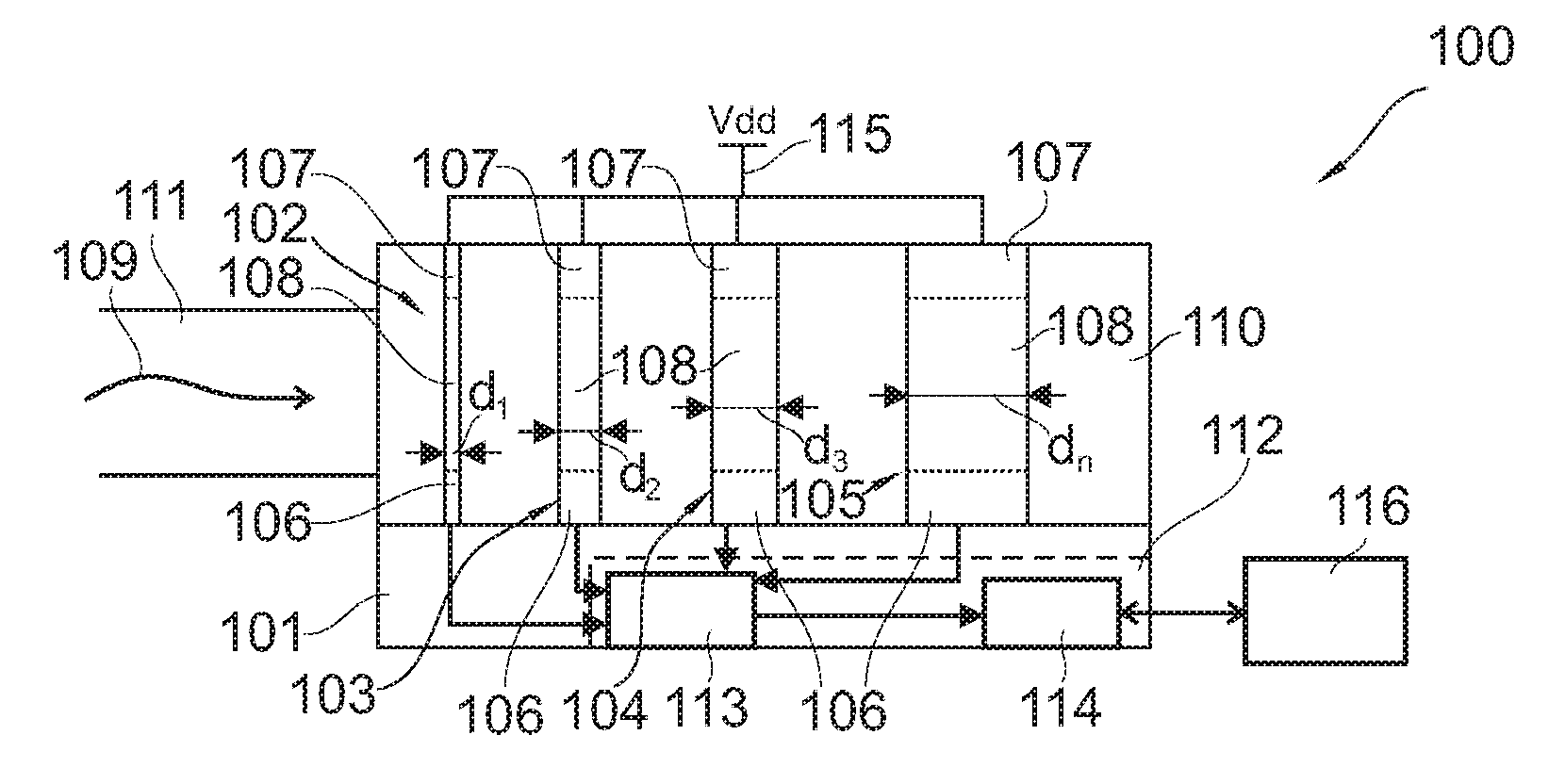

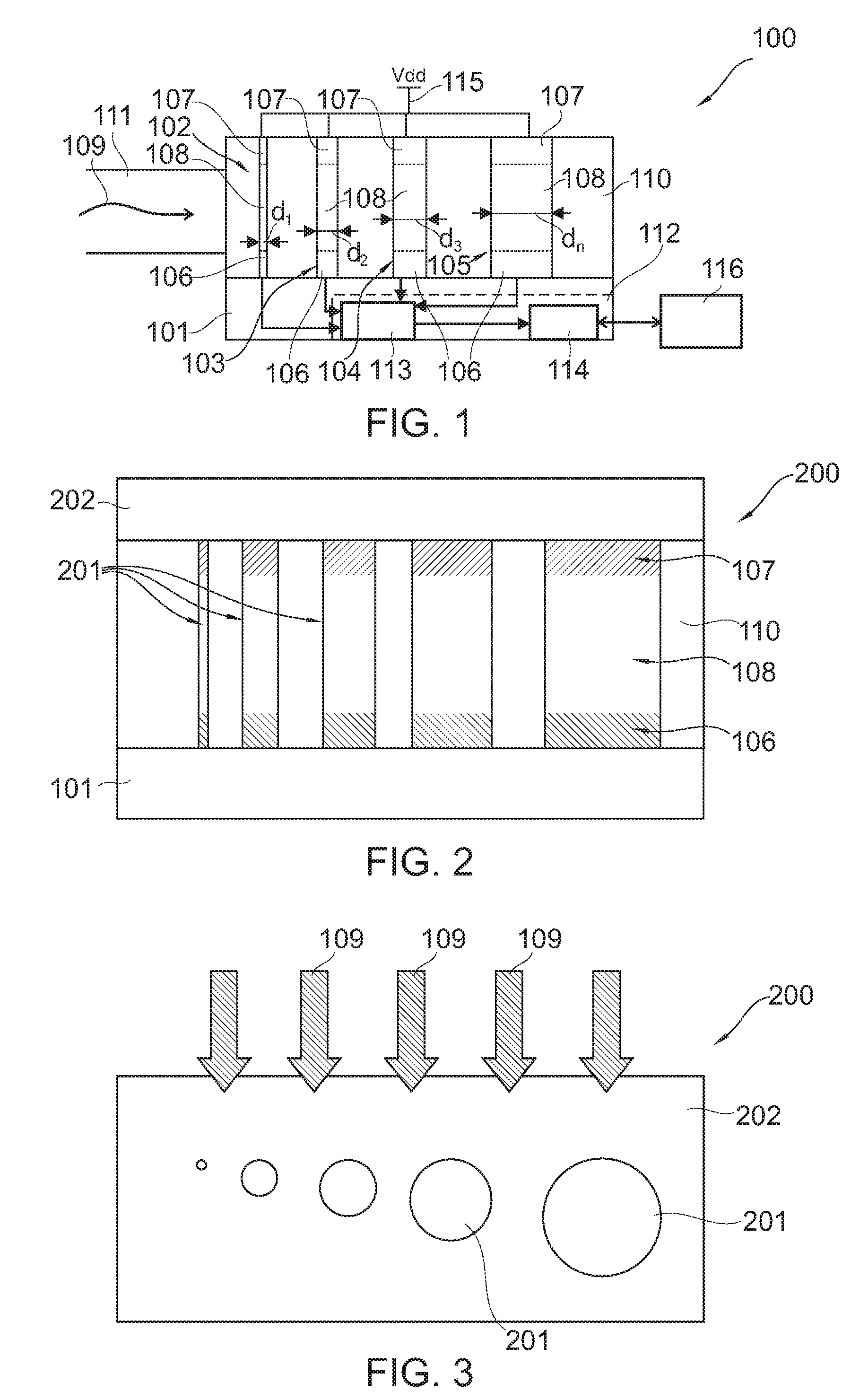

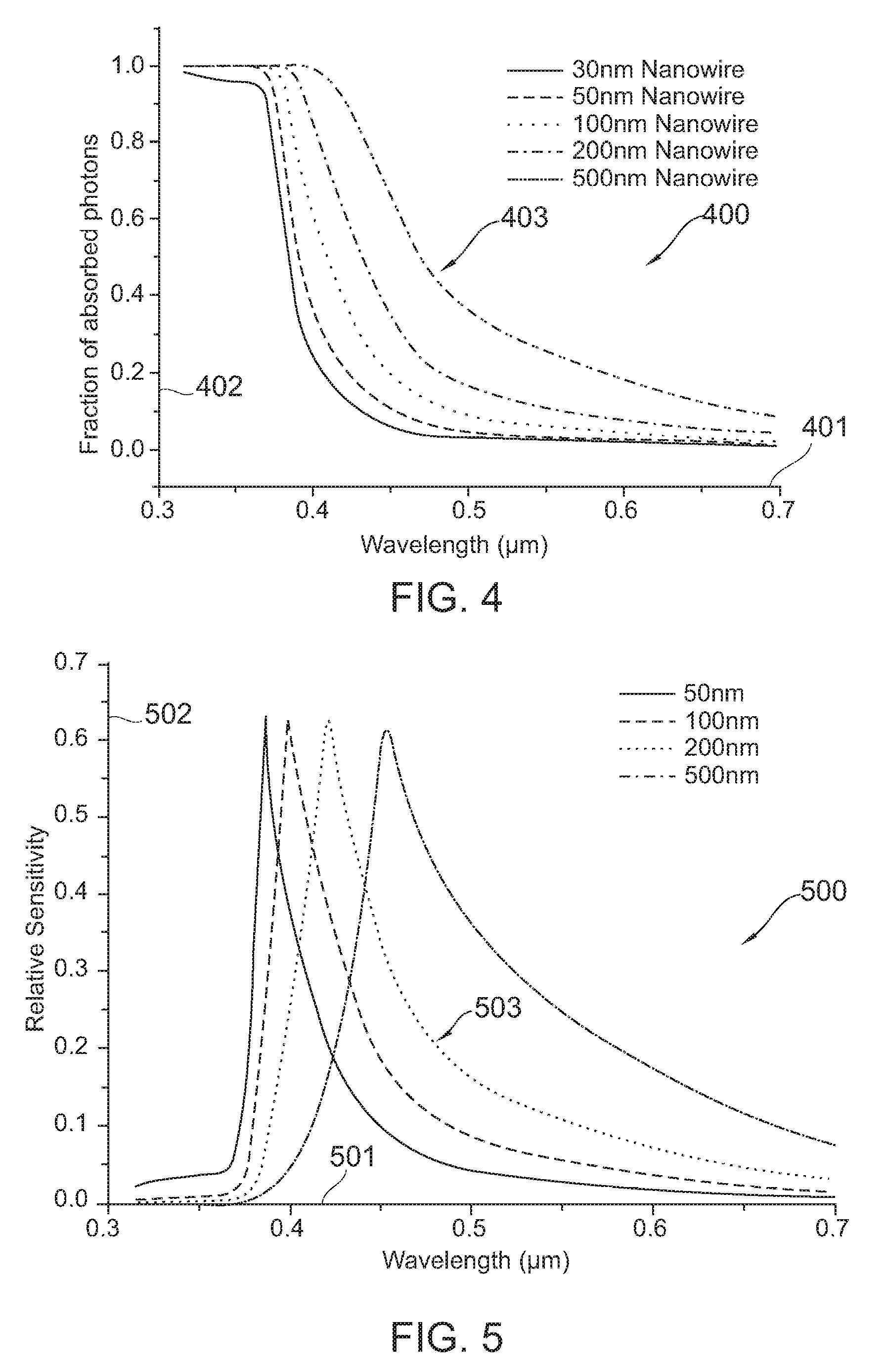

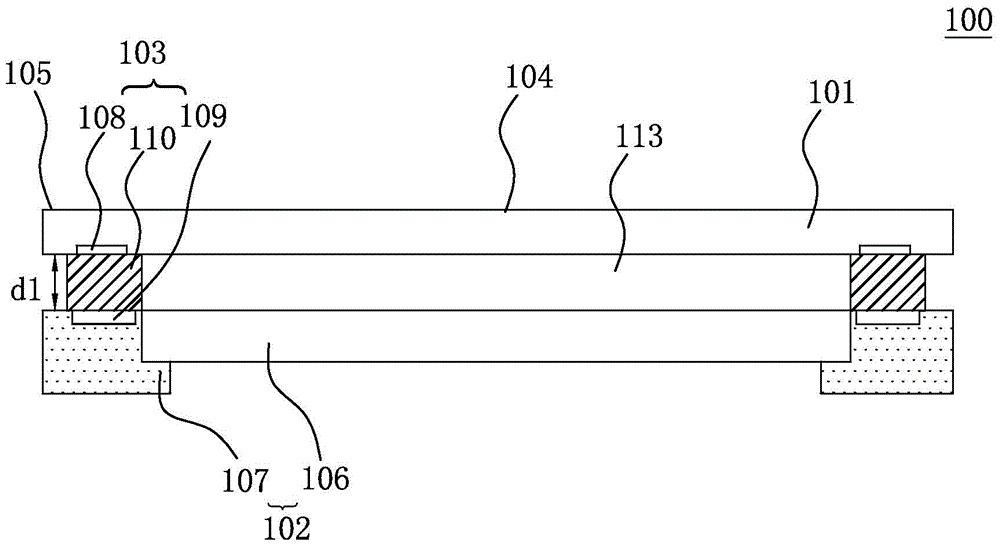

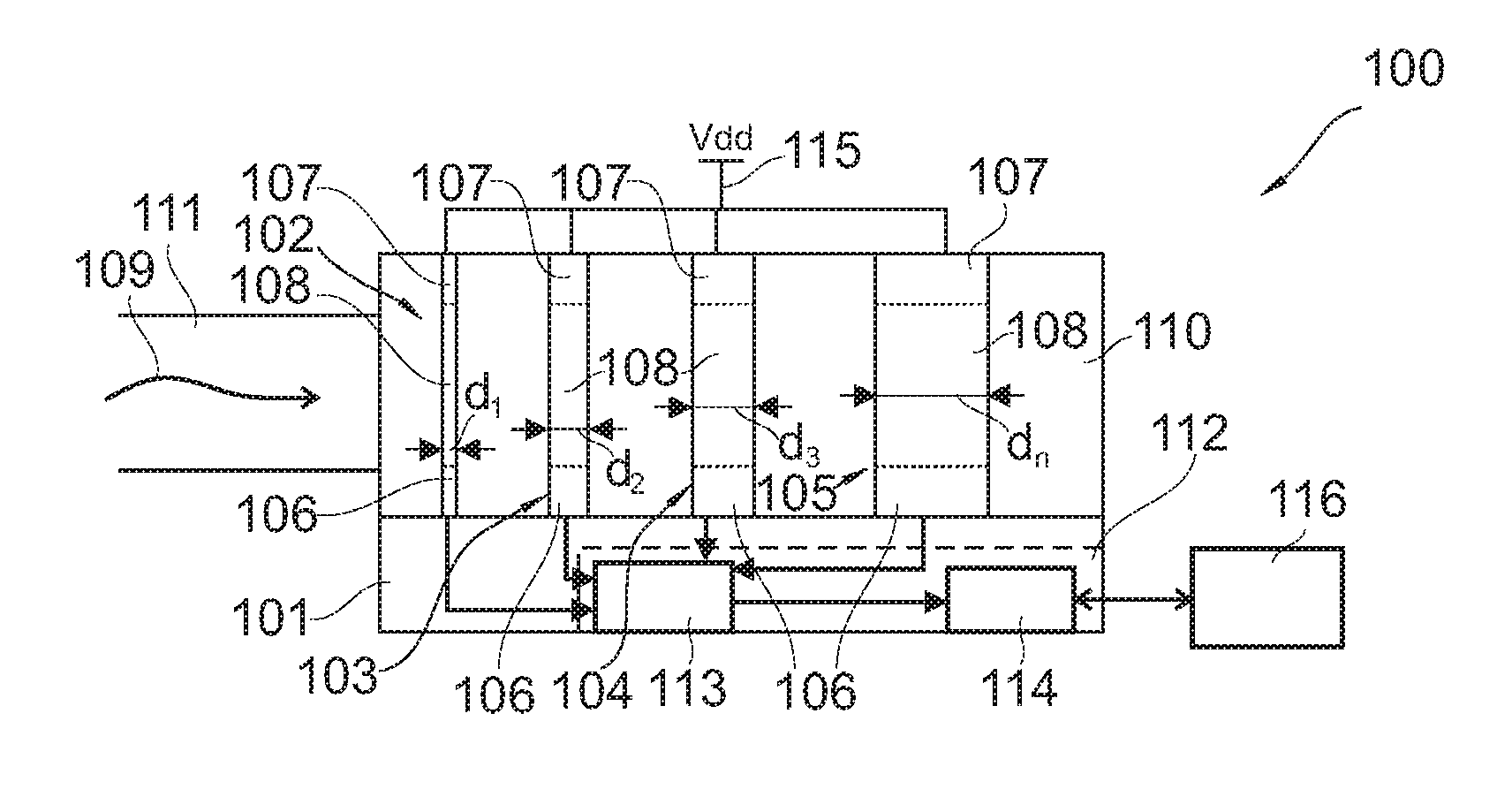

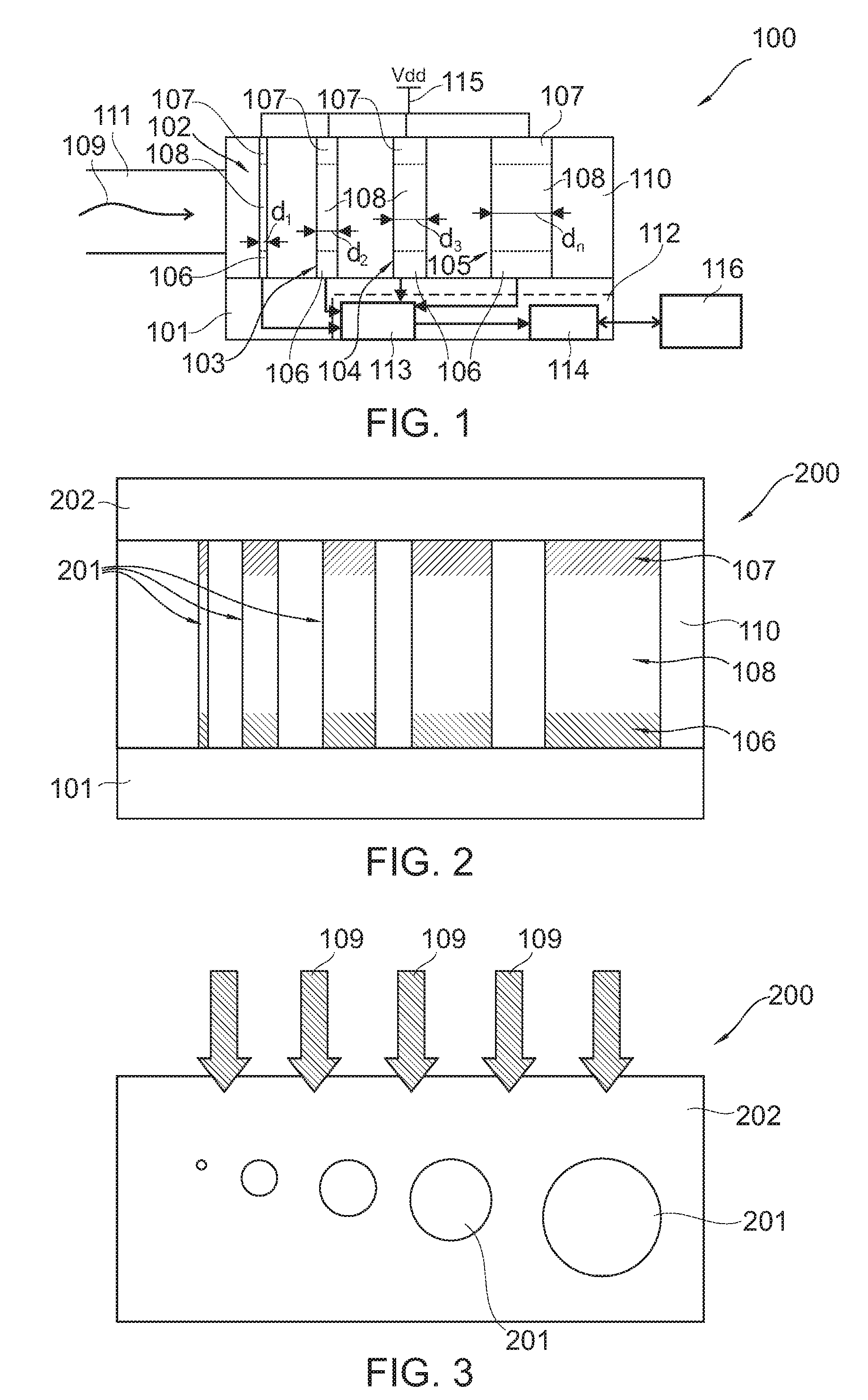

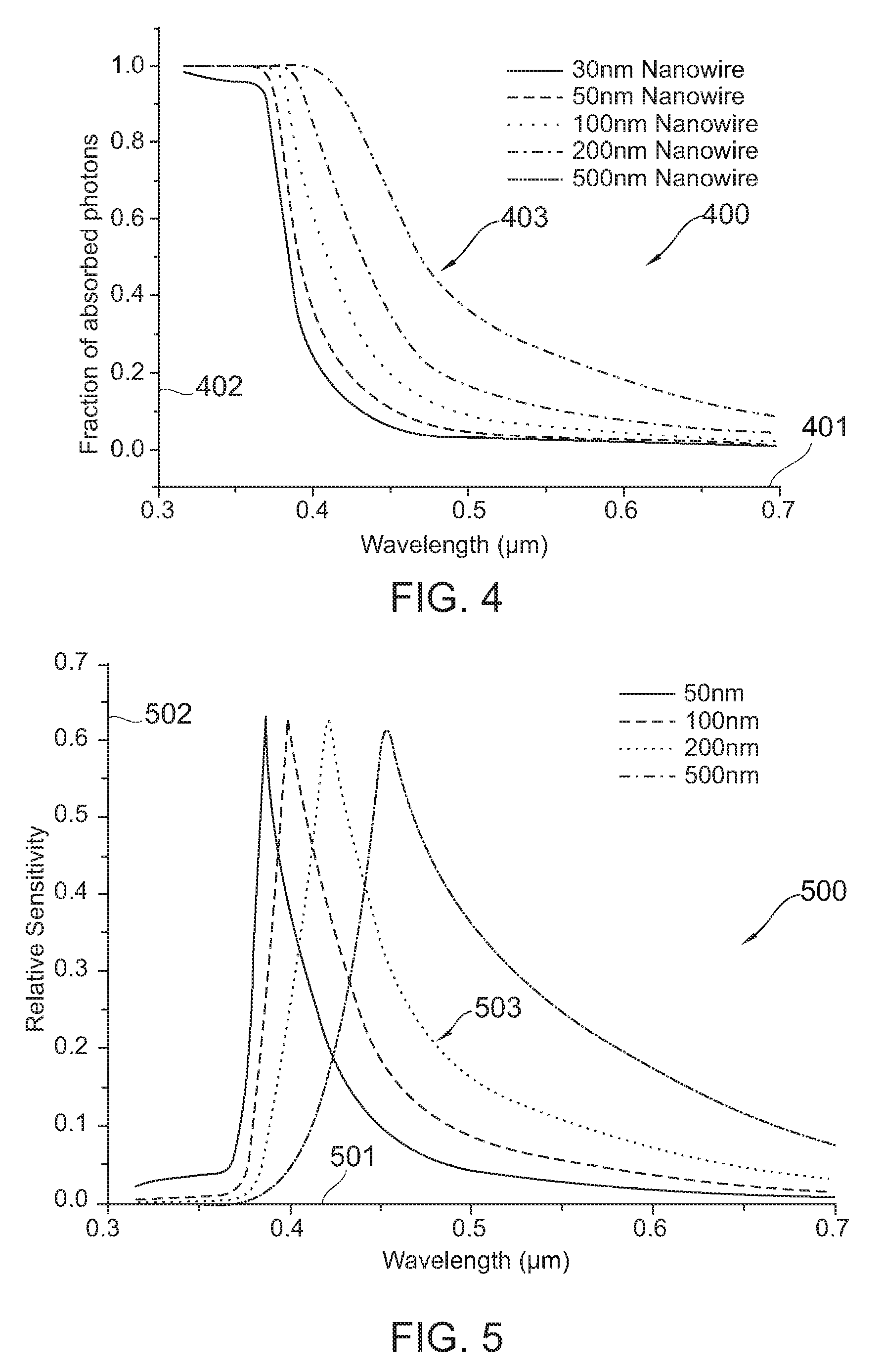

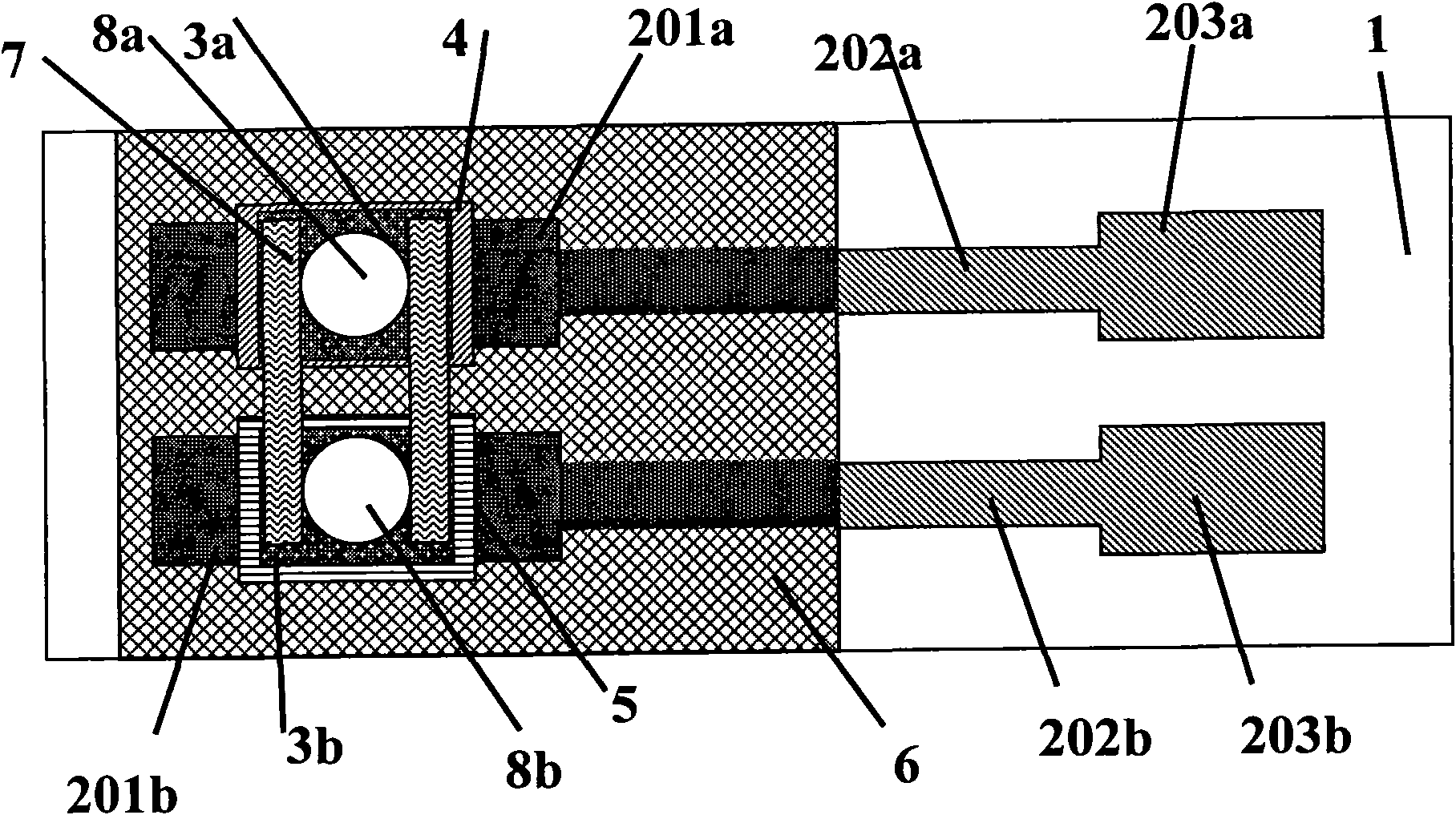

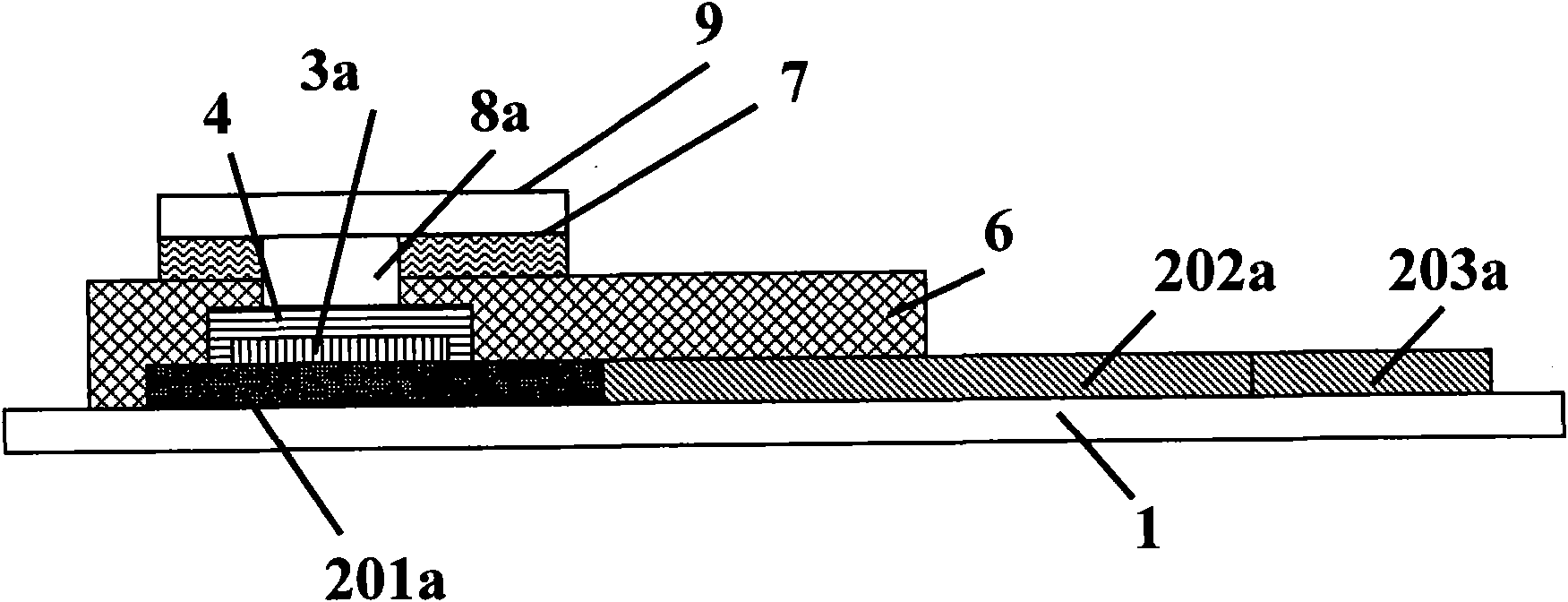

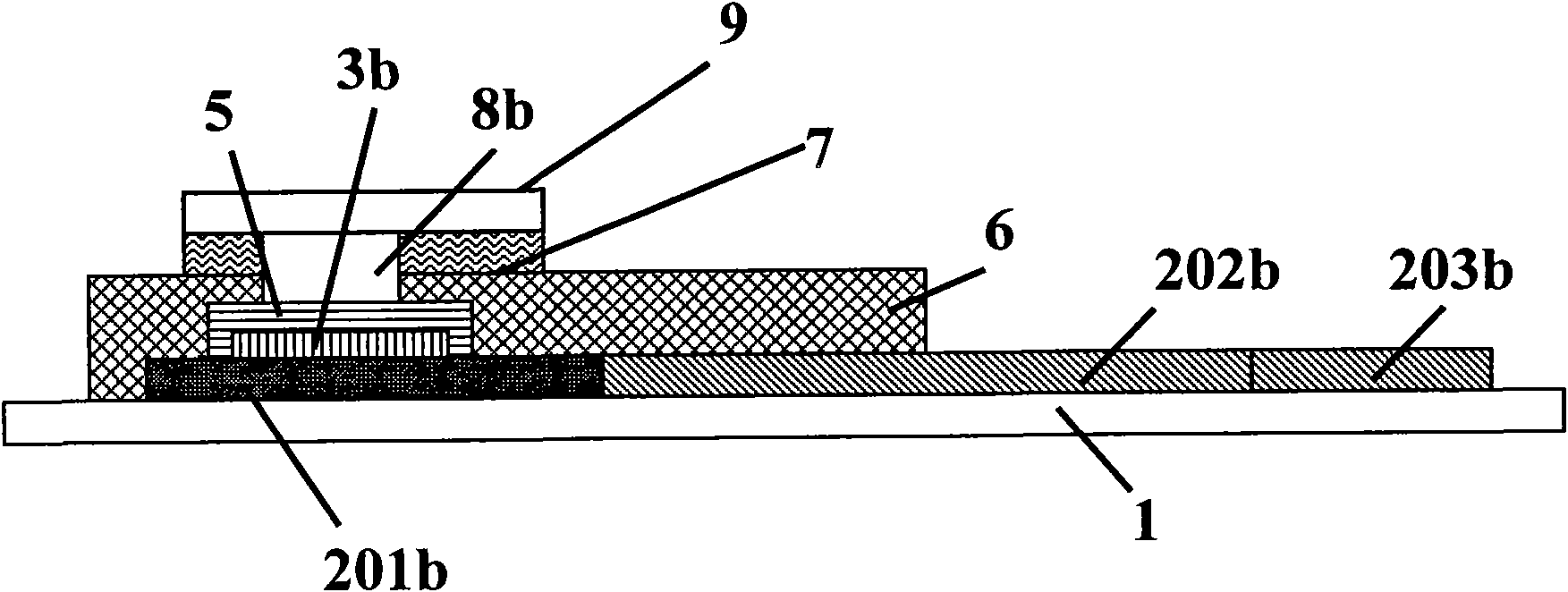

Photosensitive device and a method of manufacturing a photosensitive device

ActiveUS20100127153A1Low effortLow costMicrobiological testing/measurementSolid-state devicesEngineeringNanometre

A photosensitive device (100), the photosensitive device (100) comprising a substrate (101) and a plurality of vertically aligned nanowire diodes (102 to 105) provided on and / or in the substrate (101).

Owner:NXP BV

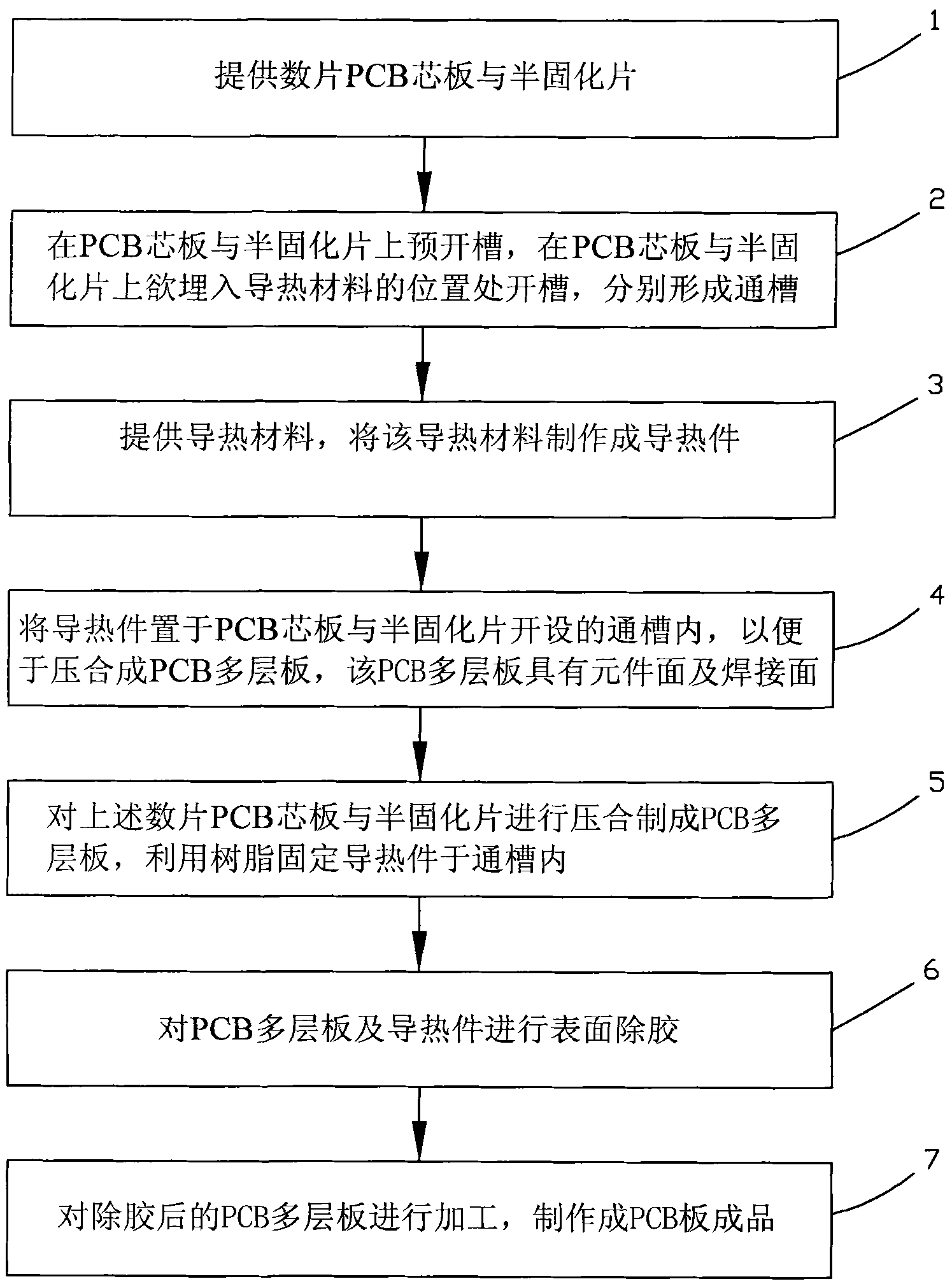

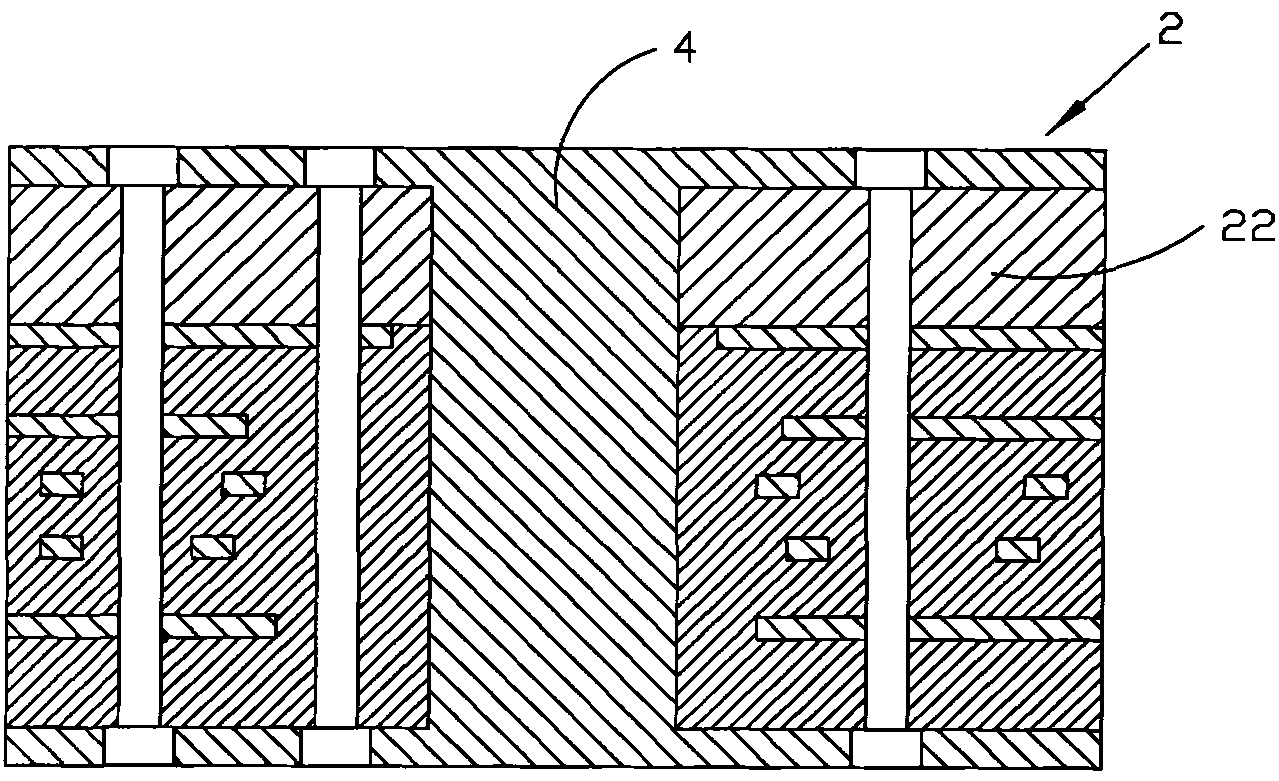

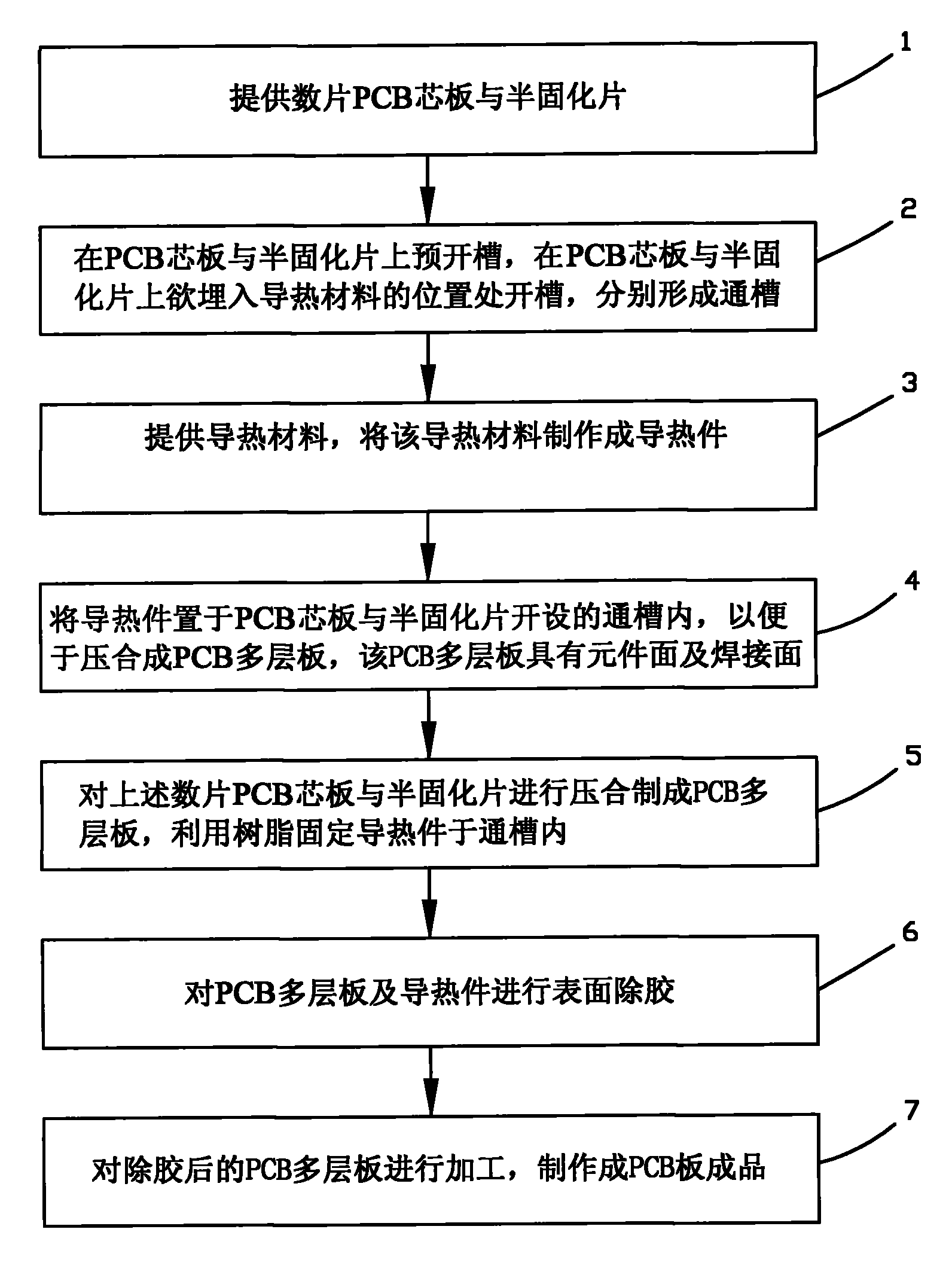

Method for manufacturing embedded high-conductivity printed circuit board (PCB)

ActiveCN101790290AImprove cooling effectIncrease powerPrinted circuit detailsMultilayer circuit manufactureConductive materialsPrinted circuit board

The invention discloses a method for manufacturing an embedded high-conductivity printed circuit board (PCB). The method comprises the following steps of 1, providing a plurality of PCB core boards and prepregs; 2, pre-slotting on the PCB core boards and the prepregs, slotting at positions where conductive materials are to be embedded on the PCB core boards and the prepregs, and respectively forming slots, wherein the core boards and the prepregs have matched positioning holes; 3, providing the conductive materials and manufacturing conductive elements by using the conductive materials; 4, placing the conductive elements in the slots of the PCB core boards and the prepregs for laminating the conductive elements into PCB multi-layer boards which have component faces and welding faces; 5, laminating the plurality of PCB core boards and prepregs to manufacture PCB multi-layer boards and fixing the conductive elements in the slots by using resins; 6, performing degumming on the surfaces of the PCB multi-layer boards and the conductive elements; and 7, processing the PCB multi-layer boards after degumming to obtain PCB finished products. The method has the advantages of simple manufacturing flows and realization of high radiation, high-speed signal transmission and the like by embedding the conductive materials into the PCB in a laminating manner and matching the conductive materials with the thickness of the PCB.

Owner:DONGGUAN SHENGYI ELECTRONICS

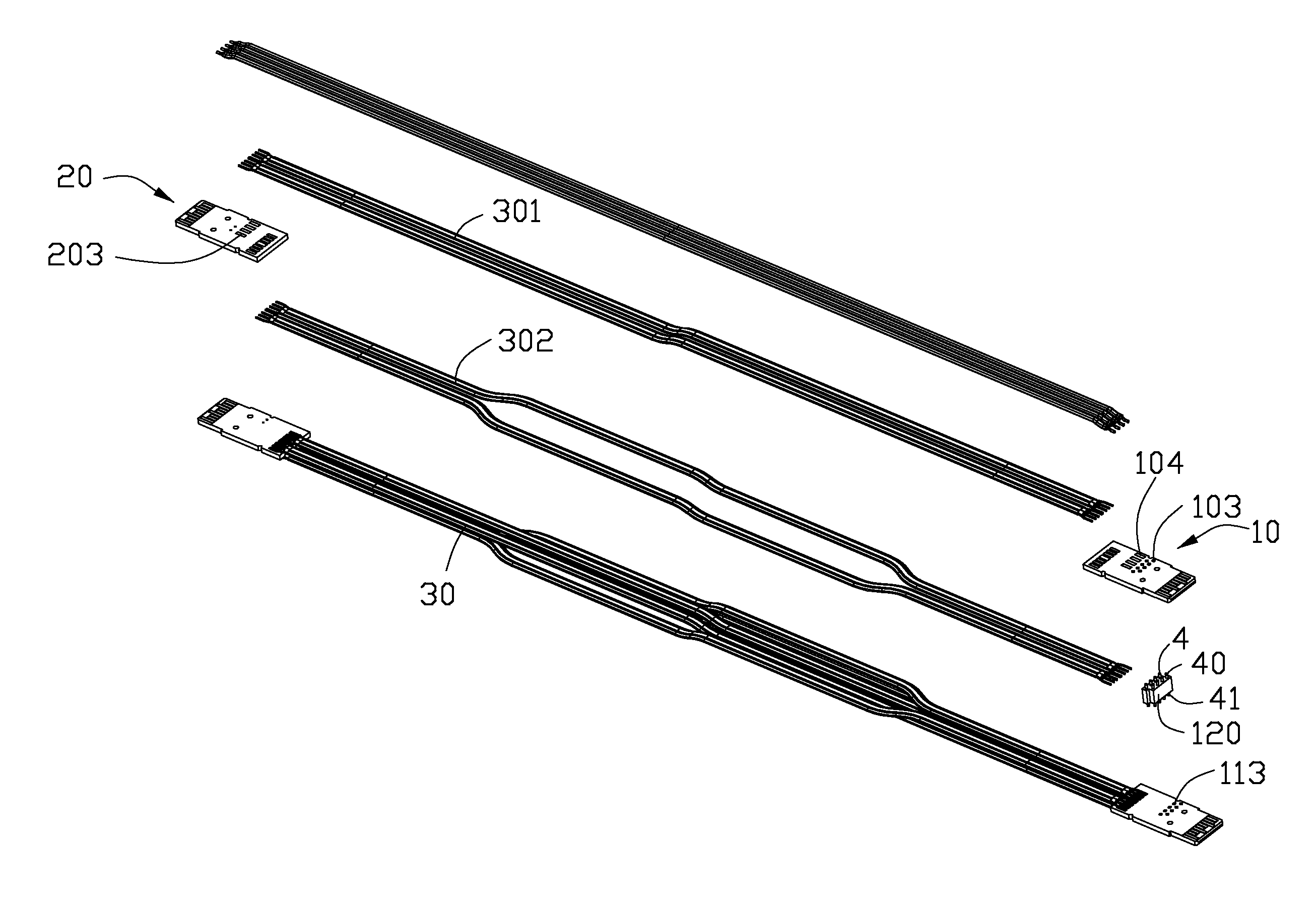

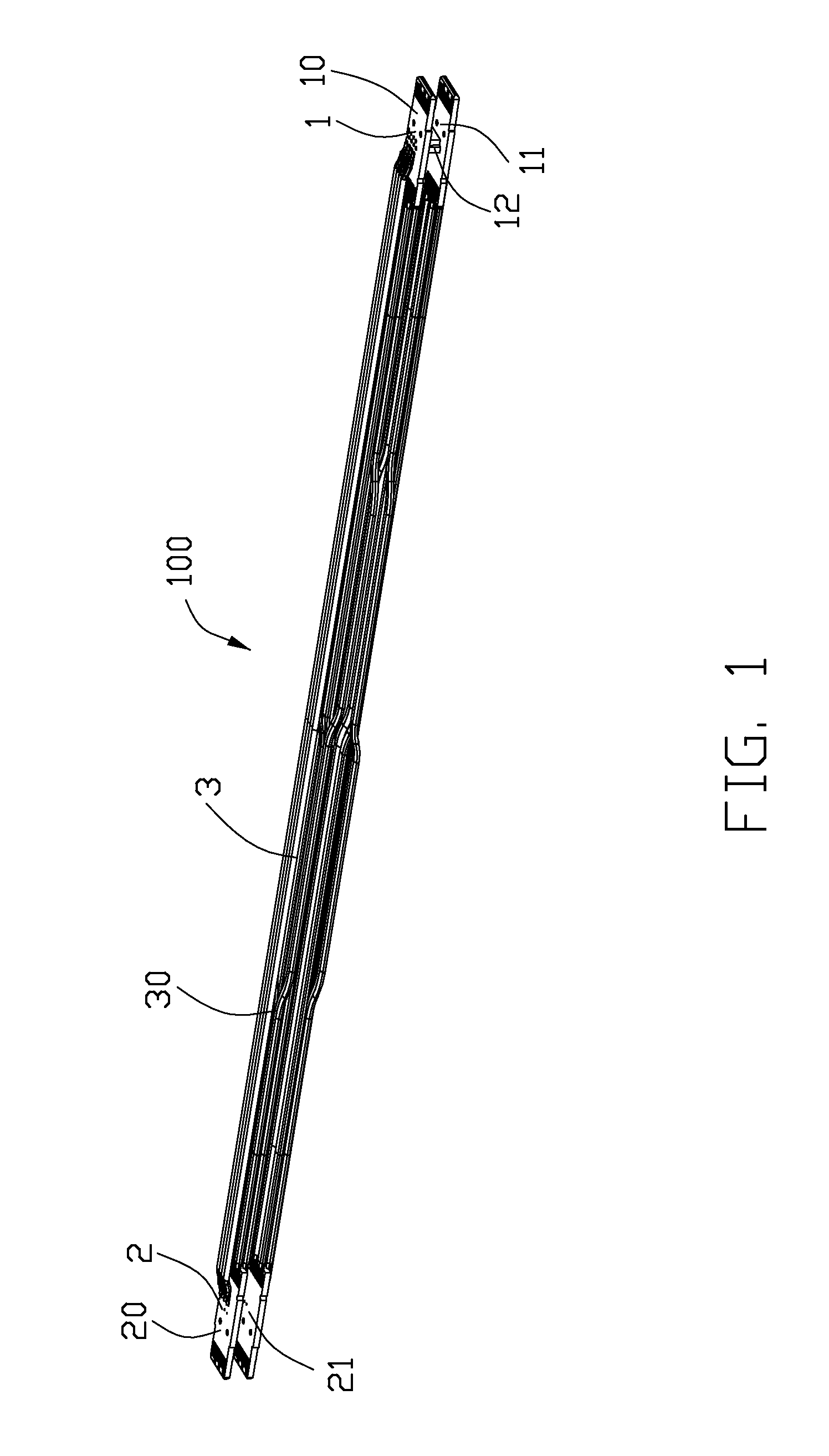

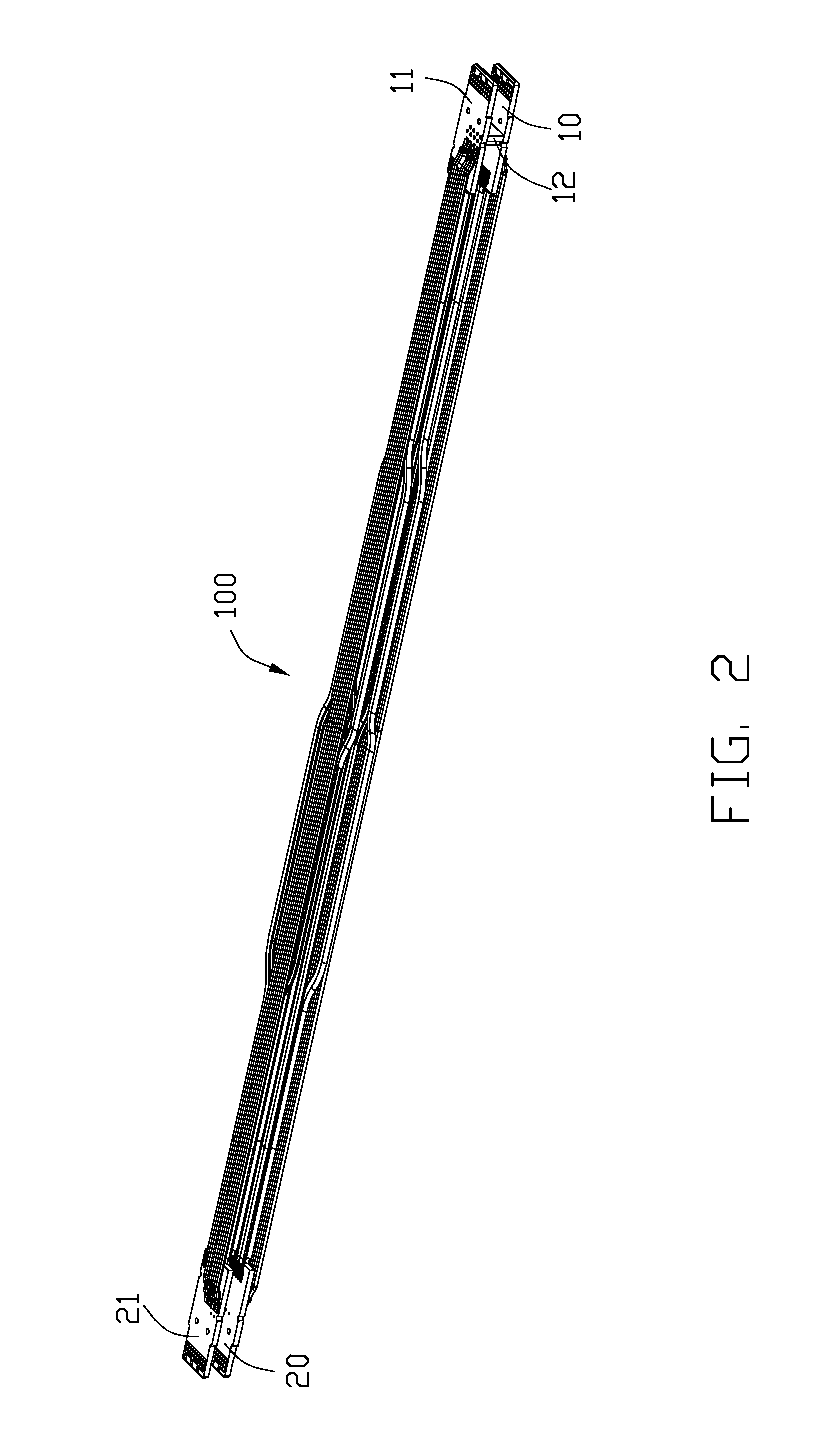

Cable connector assembly having simple wiring arrangement between two end connectors

ActiveUS9203171B2The production process is simpleTwo-part coupling devicesFixed connectionsControl signalPrinted circuit board

Owner:HON HAI PRECISION IND CO LTD

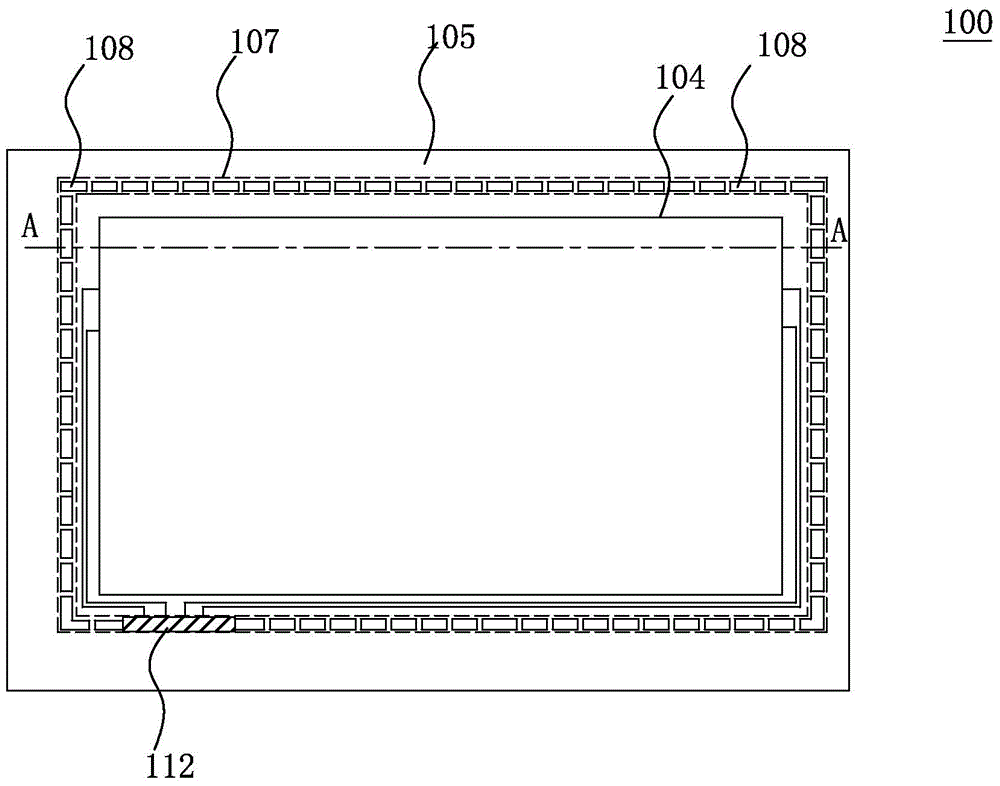

Touch display device

InactiveCN104423748AThe production process is simpleWill not be disturbedInput/output processes for data processingCapacitanceDisplay device

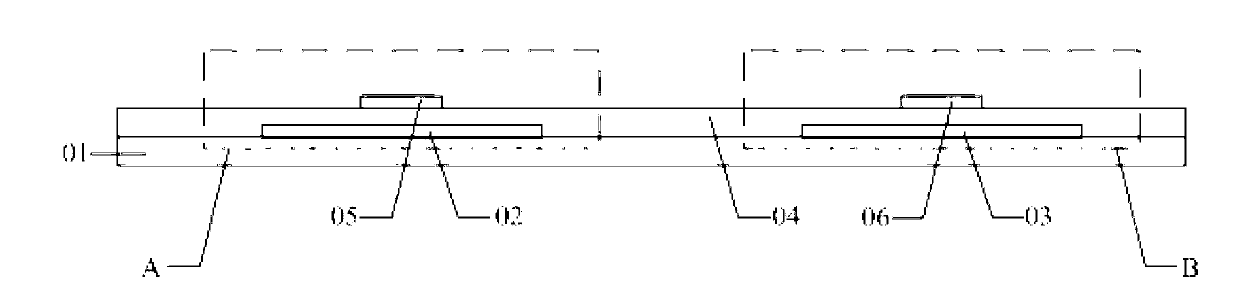

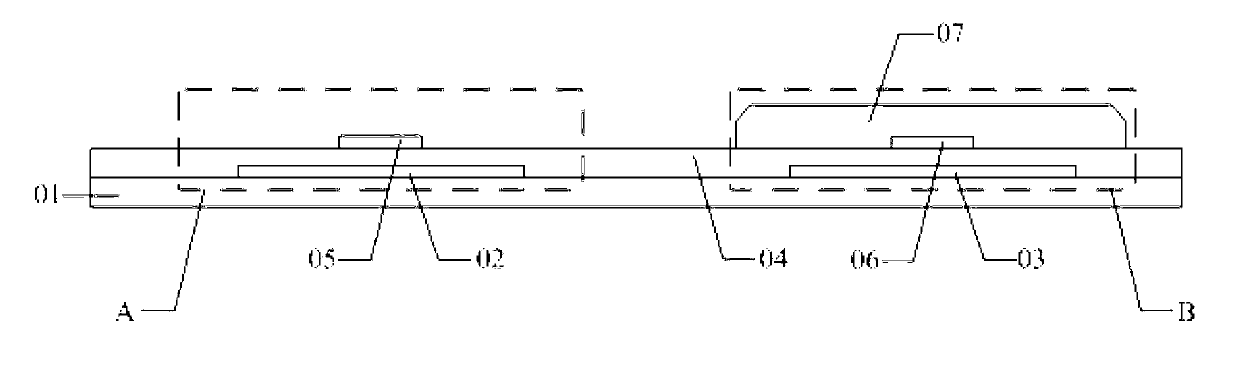

The invention discloses a touch display device. The touch display device comprises a touch panel, a display module and at least one pressure sensing unit, wherein the touch panel is provided with a sensing area and a peripheral area; the display module comprises a display panel and a frame body; the display panel can be accommodated in the frame body; each pressure sensing unit comprises a first electrode, a second electrode and an elastic insulator; the first electrodes are arranged on the peripheral area of the touch panel; the second electrodes are arranged on the frame body; the elastic insulators are arranged between the touch panel and the display module; each elastic insulator is positioned between the corresponding first electrode and the corresponding second electrode; and a pushing force, which is inputted to the touch panel, of a user is determined by the touch display device according to the variable quantity of a capacitance between each first electrode and the corresponding second electrode. Under the condition that an electromagnetic stylus or another pressure sensor is not used, touch pressure can be detected with the aid of the variable quantity of the capacitances of the pressure sensing units of the peripheral area and is quantified.

Owner:AU OPTRONICS CORP

Traditional Chinese medice healthy liquid and preparation method thereof

InactiveCN101716000AImprove immunityThe production process is simpleFood preparationSpecific gravityBlood circulation

The invention relates to a traditional Chinese medice healthy liquid. The preparation method comprises the following steps of: preparing 73 materials of ginseng, atractylodes macrocephaia, poria, and the like into a stock solution; then adding 8 materials of ginseng, cortex encomia, astragalus root, and the like to water for decoction, wherein the 8 materials and the water are in a weight ratio of 1:25; decocting until the weight ratio of the raw materials to the water is 1:20 to obtain an auxiliary solution; proportioning the stock solution and the auxiliary solution in a weight part ratio of 1:4 and adding a proper amount of auxiliary materials; and mixing and standing for 6 months to obtain the healthy liquid. The healthy liquid can improve the immunological competence of human bodies after being taken, release fatigue, smooth the kidneys and activate the blood circulation. Moreover, the healthy liquid has simple preparation process and is easy for industrialization production.

Owner:深圳市唤然生物科技开发有限公司

Preparation method of electrolyte used for all vanadium redox flow batteries

ActiveCN101562256AThe production process is simpleEasy to operateFinal product manufactureRegenerative fuel cellsIonChemistry

The invention discloses a preparation method of electrolyte used for all vanadium redox flow batteries, which is characterized in that one or more reducing agents are added to vanadium pentoxide and sulfuric acid, and the mixture fully reacts at the temperature of 50-100 DEG C for 0.5-10h to prepare the electrolyte with vanadium ion concentration between 1mol / L and 6mol / L. In the method, isobutyl alcohol, butyraldehyde, dicarboxyl, 1, 3-propanediol, 2-butylene or the mixture thereof is used as a reducing agent; the preparation process is simple, the operation is easy and the cost is low, in particular, the high-purity vanadium battery electrolyte with vanadium ion concentration between 1mol / L and 6mol / L is prepared; besides, the above process only produces carbon dioxide and water but no other wastes, thus being environment-friendly; the reducing agents used in the prior art are generally inorganic matters such as sulphur powder, thus easily producing huge amounts of pollutants, but in the method, organic matters are used as reducing agents and only produce carbon dioxide and water in the whole process, thus reducing the pollution in the process of preparing the high-purity vanadium battery electrolyte.

Owner:QINGDAO WUXIAO GRP

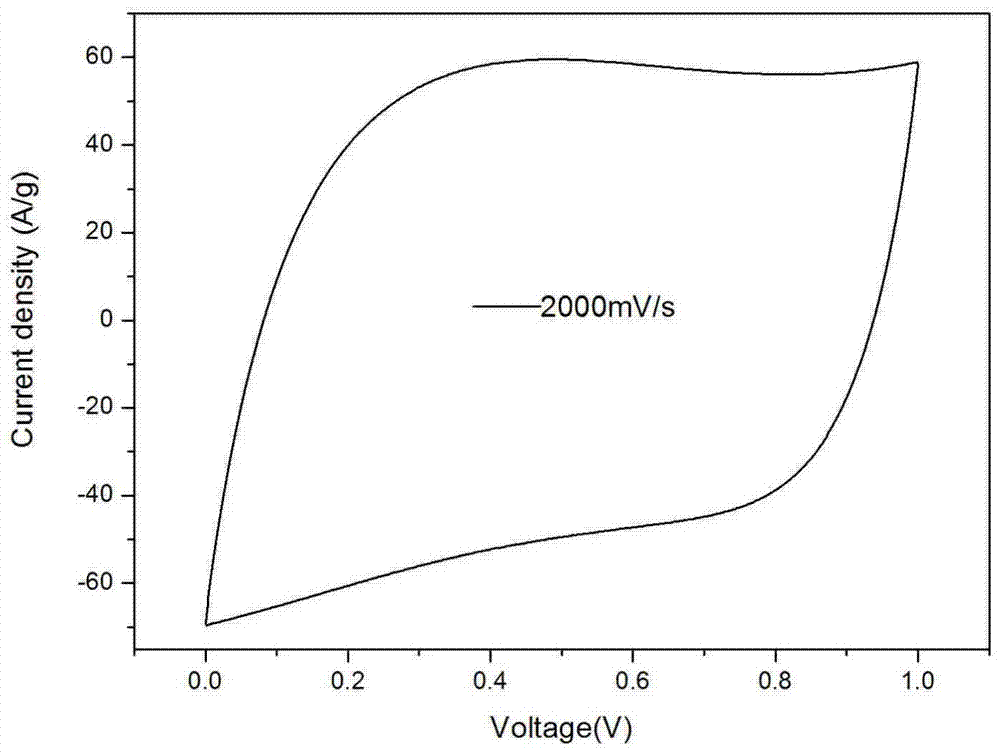

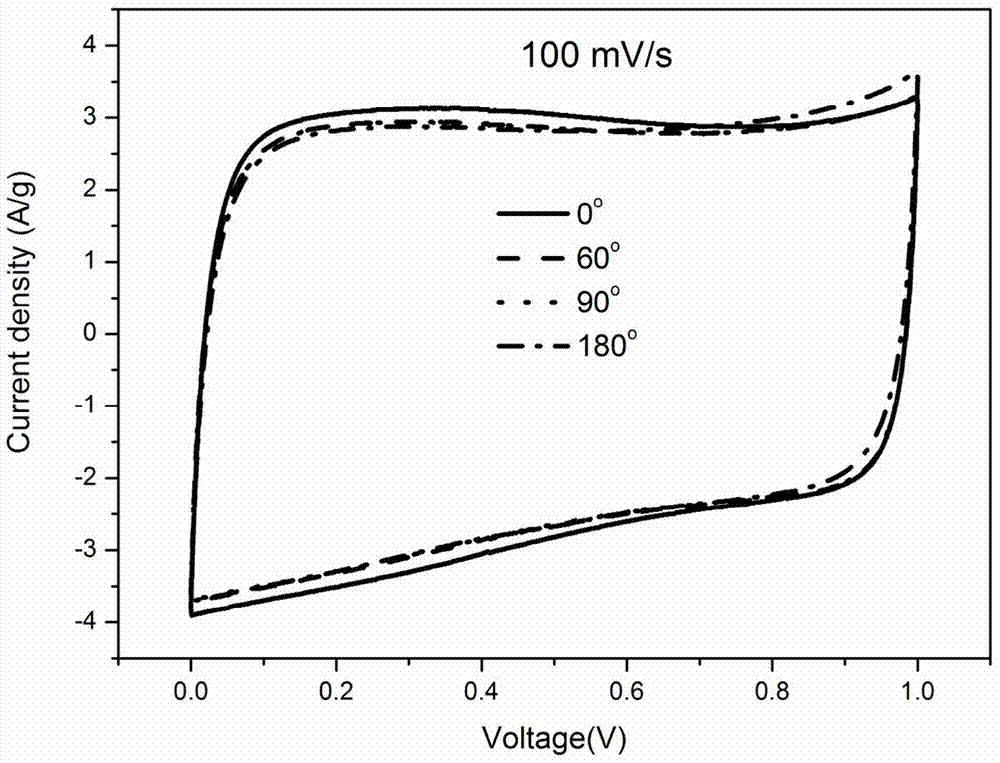

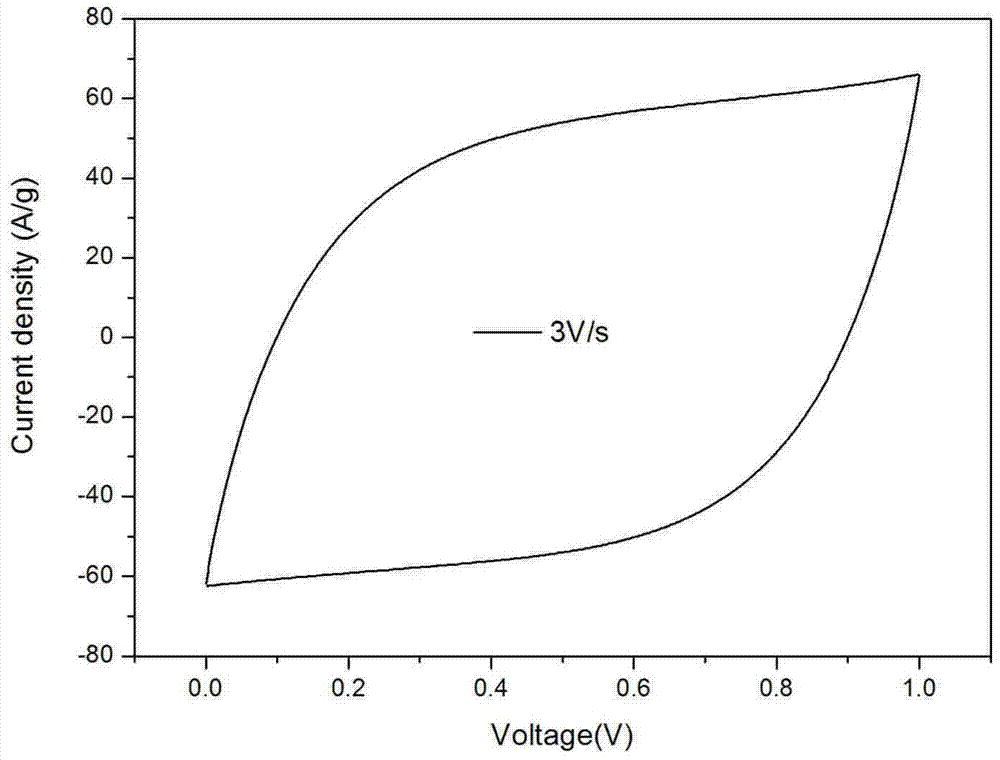

Supercapacitor electrode material preparation method based on three-dimensional graphene

InactiveCN103545121AImprove performanceReduce manufacturing costHybrid/EDL manufactureMoistureHydroiodic acid

A supercapacitor electrode material preparation method based on three-dimensional graphene comprises the steps that foamed nickel with surface oxide removed is steeped in oxidized graphene dispersion liquid, the oxidized graphene is made to be deposited on the foamed nickel, and then the foamed nickel is aired to remove moisture at room temperature after being taken out. The steeping method comprises the steps that the foamed nickel is steeped in the oxidized graphene dispersion liquid with the concentration of 0.5mg / ml-10mg / ml, and is aired after ultrasonic processing is carried out for 1-30 minutes; the quality of the oxidized graphene deposited on the foamed nickel is controlled through the concentration of the oxidized graphene and steeping times, and the steeping times is 1 to 30 times. The prepared oxidized graphene / foamed nickel composite electrodes are reduced through ascorbic acid, then a part of metal nickel is etched and removed by using a chemical etching method or a part of the metal nickel is simultaneously reduced, etched and removed through hydroiodic acid to obtain graphene / foamed nickel composite electrodes. The supercapacitor electrode material preparation method based on the three-dimensional graphene is simple, easy to operate, capable of improving the performance of supercapacitors and reducing manufacturing cost, and suitable for mass production.

Owner:NANJING UNIV

Slotless winding for rotating electric machine and manufacturing method thereof

InactiveUS20090072651A1Improve applicabilityImprove performanceMagnetic circuitTransformers/inductances coils/windings/connectionsElectric machineBarrel Shaped

The present invention relates to a slotless winding for a rotating electric machine and a manufacturing method thereof. The slotless winding includes at least one flexible printed circuit board having at least one circuit, and one piece of flexible printed circuit board(s) is curved or a plurality of pieces of flexible printed circuit board(s) is mutually combined to form a barrel shape, thereby simplifying the procedure of manufacturing the slotless winding, improving production speed and reliability, and enabling diversified designing schemes to meet the demands of the rotating electric machine. In addition, it is not necessary for the coil winding to be cured for assembling, and assembling yield is thus enhanced.

Owner:METAL INDS RES & DEV CENT

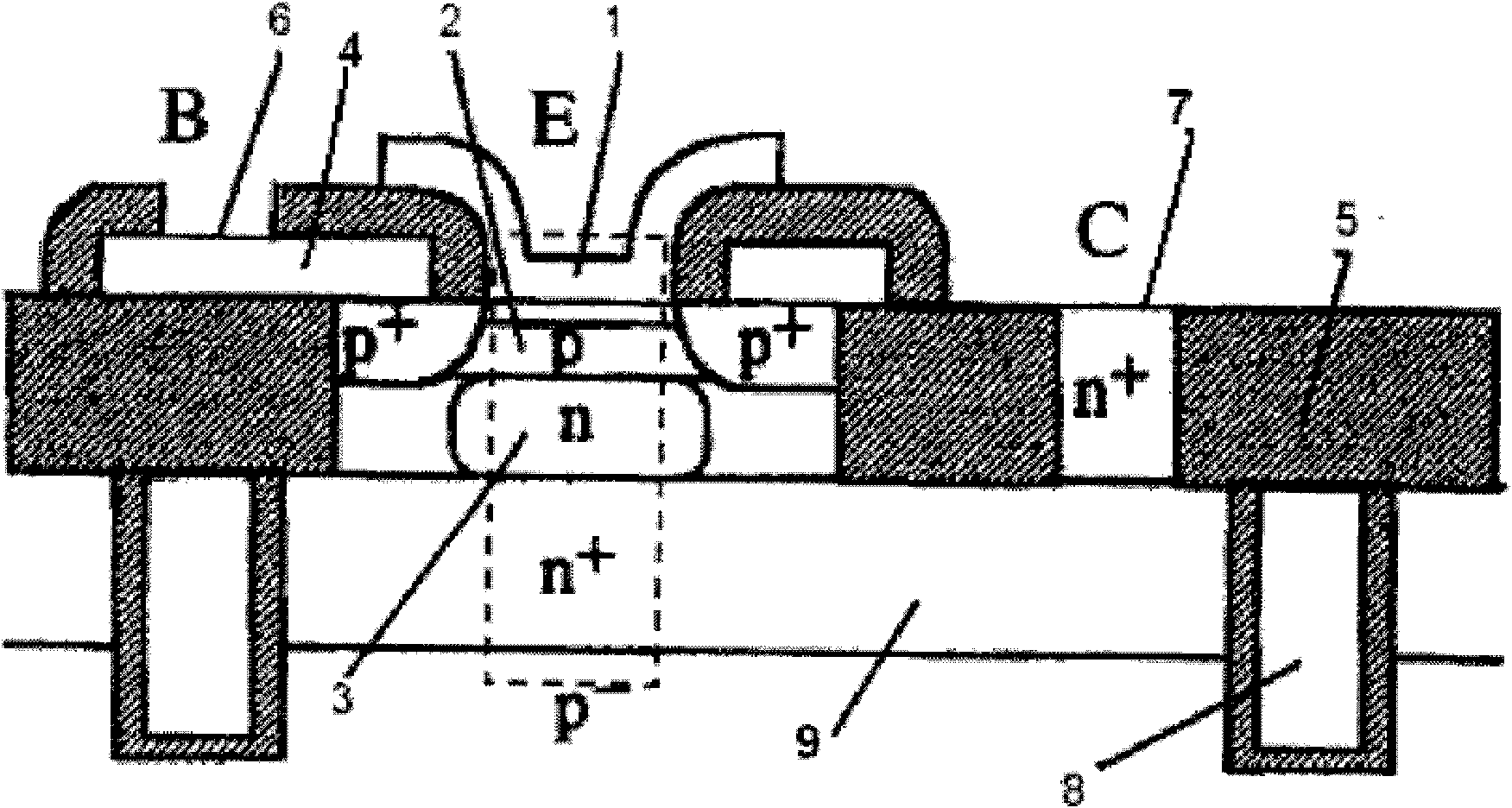

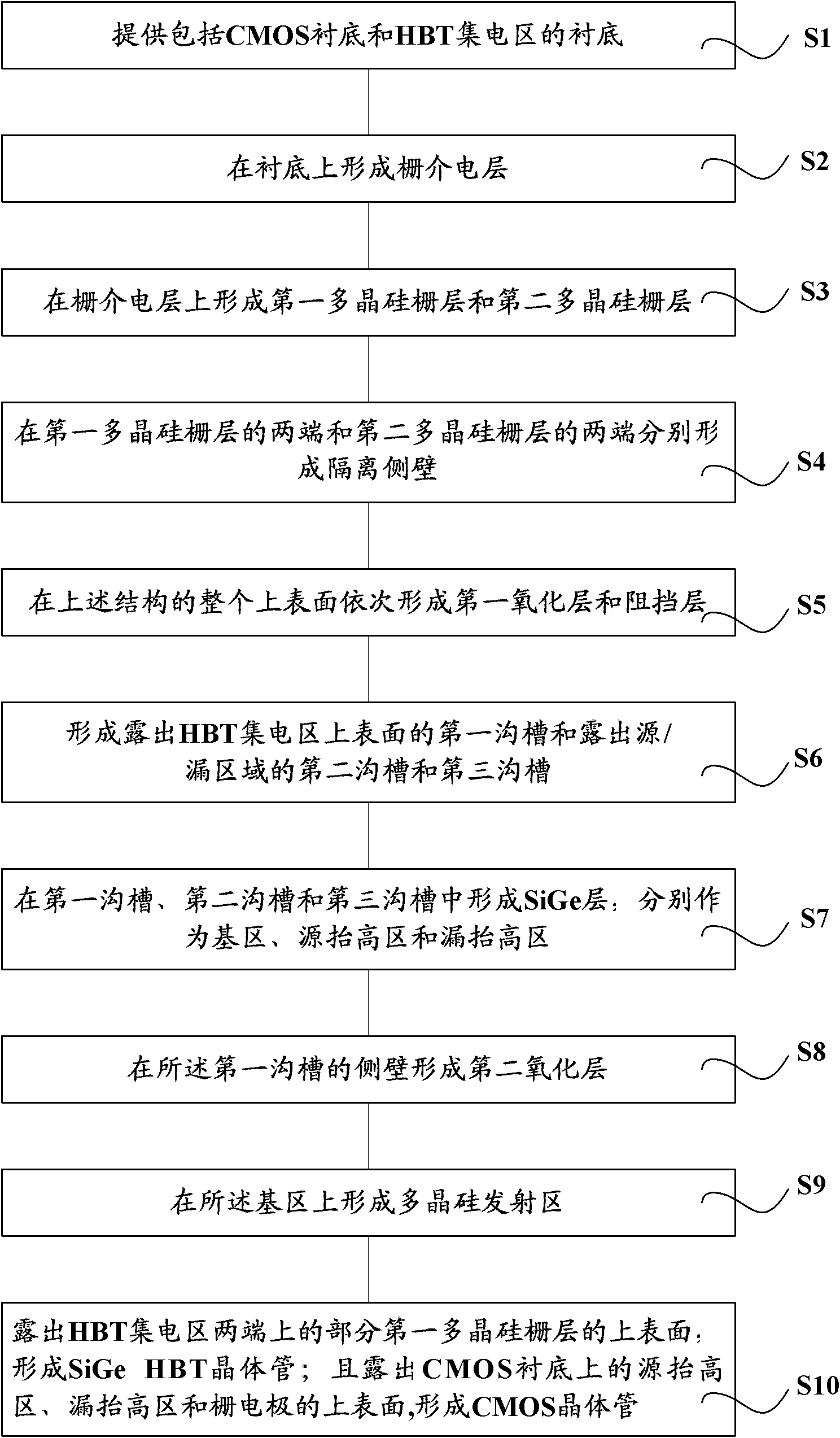

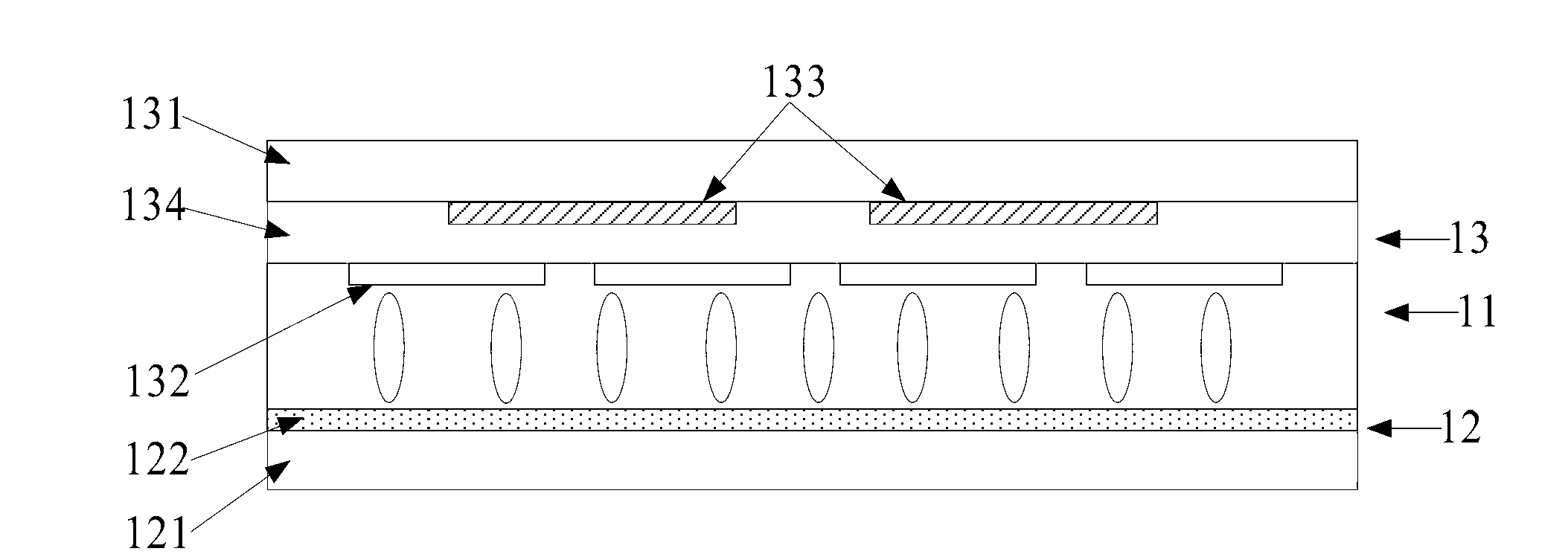

Method for manufacturing semiconductor device and method for manufacturing SiGe HBT (Heterojunction Bipolar Transistor)

ActiveCN102184898ASimplify the production processReduce manufacturing costSemiconductor/solid-state device manufacturingOxide semiconductorCMOS

The invention relates to a method for manufacturing a semiconductor device and a method for manufacturing an SiGe HBT (Heterojunction Bipolar Transistor), wherein the method for manufacturing the SiGe HBT comprises the steps of: offering a substrate comprising an HBT collector region; sequentially forming a gate dielectric layer, a polysilicon gate layer, an oxide layer and a barrier layer on the HBT collector region; removing partial barrier layer as well as the oxide layer, the polysilicon gate layer and the gate dielectric layer under the partial barrier layer on the HBT collector region so as to form a groove where the upper surface of the HBT collector region is exposed; forming an SiGe layer in the groove to serve as a base region; forming a polysilicon emitter region on the base region; and removing the partial barrier layer and the oxide layer under the partial barrier layer on two ends of the HBT collector region till the upper surface of partial polysilicon gate layer on the two ends of the HBT collector region is exposed and preserving the barrier layer surrounding the polysilicon emitter region and the oxide layer under the barrier layer. In the invention, the manufacturing processes of the two kinds of transistors are compatible and the cost is saved; the source / drain region of a CMOS (Complementary Metal Oxide Semiconductors) transistor is raised; and therefore, the self alignment of the base region and the emitter region of the SiGe HBT is realized.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

3D (3-dimensional) touch liquid crystal lens grating, display device and manufacturing methods of 3D touch liquid crystal lens grating and display device

ActiveCN102707514AReduce thicknessThe production process is simpleStatic indicating devicesSteroscopic systemsSurface electrodeLiquid crystal

The embodiment of the invention provides a 3D (3-dimensional) touch liquid crystal lens grating, display device and manufacturing methods of the 3D touch liquid crystal lens grating and the display device and relates to the technical field of display, and the thickness of the 3D touch display device can be reduced. The 3D touch liquid crystal lens grating comprises a lower substrate and an upper substrate, wherein the lower substrate and the upper substrate are formed by box-box molding; the lower substrate comprises a lower transparent substrate and a surface electrode; the upper substrate comprises an upper transparent substrate a strip-shaped electrode; liquid crystal is filled between the surface electrode and the strip-shaped electrode; at least one touch electrode arranged in an adjacent mode is arranged between the upper transparent substrate and the strip-shaped electrode; and a transparent isolated cushion layer is arranged between the touch electrode and the strip-shaped electrode. A double-layer electrode used for touch in the prior art can be reduced to a single-layer electrode by the embodiment of the invention, thus the thickness of the 3D touch display device is reduced, the manufacturing process is simplified, and the production cost of a product is reduced.

Owner:BEIJING BOE OPTOELECTRONCIS TECH CO LTD

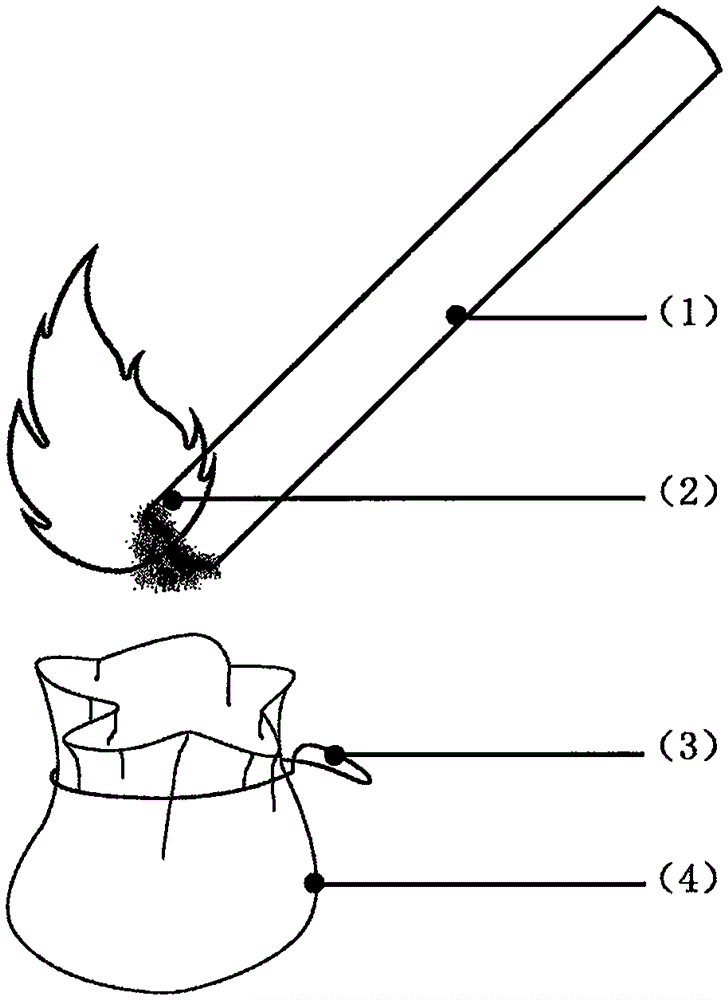

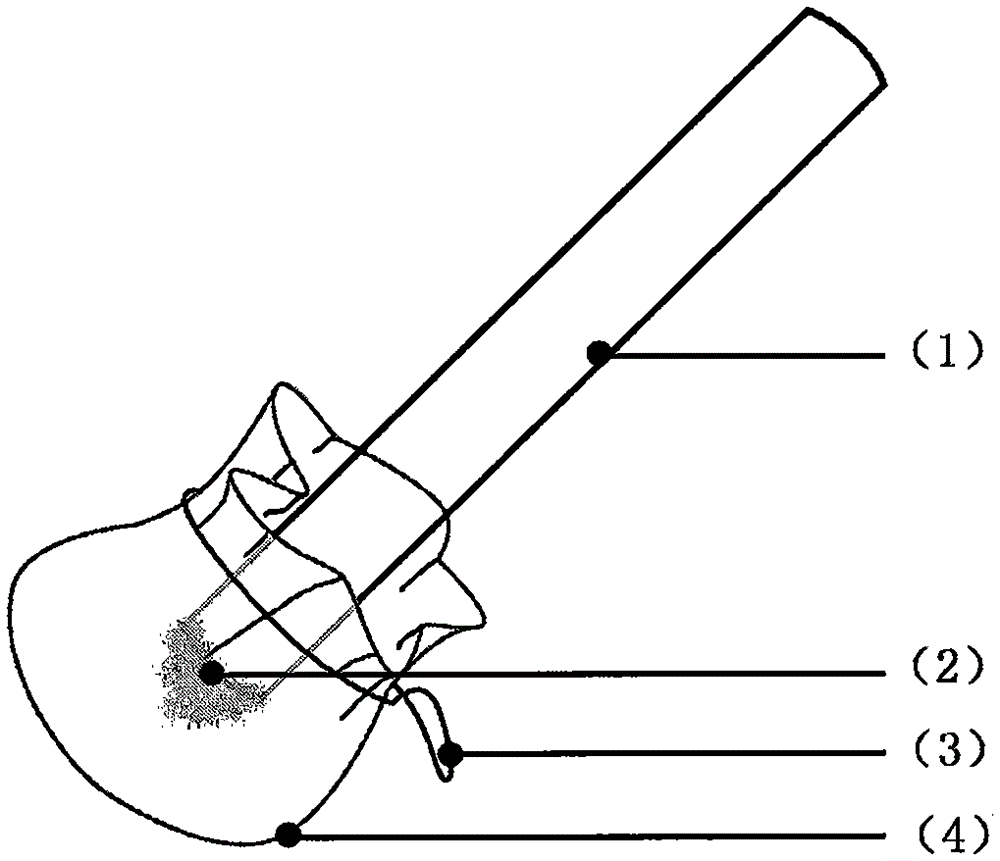

Moxa stick, moxa stick fabrication method and moxibustion device

ActiveCN105412938AEasy to useChange the way to add ingredients to medicinesDevices for heating/cooling reflex pointsDrug compositionsChemistryAnimal oil

The invention discloses a moxa stick. The moxa stick comprises wormwood processing objects, medicinal constituents and oil and fat; the wormwood processing objects absorb the oil and fat through contact; the oil and fat weight accounts for 10% and above the total weight of the moxa stick, and the oil and fat is vegetable oil and fat, animal oil and fat, vegetable oil and fat processing objects or animal oil and fat processing objects. A moxa stick fabrication method comprises the steps of getting the moxa stick to make contact with the oil, and getting the moxa stick to make contact with medicine. The medicinal constituents are added in the following one or more modes that: 1, the medicine is added to the moxa stick in the solid state; 2, the medicine is added to the moxa stick in the form of liquid medicine; 3, the medicine makes contact with the oil and fat, so that the medicine or the medicinal constituents are added to the moxa stick.

Owner:BEIJING XIAYANG INVESTMENT MANAGEMENT CO LTD

Photosensitive device and method of manufacturing a photosensitive device using nanowire diodes

ActiveUS8330090B2More sensitiveThe production process is simpleMicrobiological testing/measurementSolid-state devicesNanowireEngineering

Owner:NXP BV

Full-solid potassium ion sensor and preparation method thereof

InactiveCN101871912AAchieve integrationMiniaturizationMaterial electrochemical variablesHigh volume manufacturingExternal reference

The invention discloses a full-solid potassium ion sensor, which comprises a substrate, a potassium ion selective electrode and an external reference electrode, wherein the potassium ion selective electrode and the external reference electrode are positioned in parallel on the substrate; both the potassium ion selective electrode and the external reference electrode comprise a reaction electrode,a contact electrode and a conductive lead for connecting the two electrodes; the reaction electrode is provided with an electrolyte layer; the electrolyte layer of the potassium ion selective electrode is provided with a potassium ion sensitive film; the electrolyte layer of the external reference electrode is provided with a reference film; and an insulating layer encircles the potassium ion sensitive film and the reference film and is provided with an opening for exposing the potassium ion sensitive film and the reference film, wherein the opening is used as a reaction area contacting solution to be detected during practical detection. The traditional potassium ion selective electrode and the traditional external reference electrode are integrated on the substrate, so the potassium ion sensor realizes microminiaturization and has the advantages of convenience for carrying, simple operation and rapid response. The invention also provides a preparation method for the full-solid potassium ion sensor. The preparation method simplifies the manufacturing flow, reduces the manufacturing cost and is suitable for mass production.

Owner:ZHEJIANG UNIV

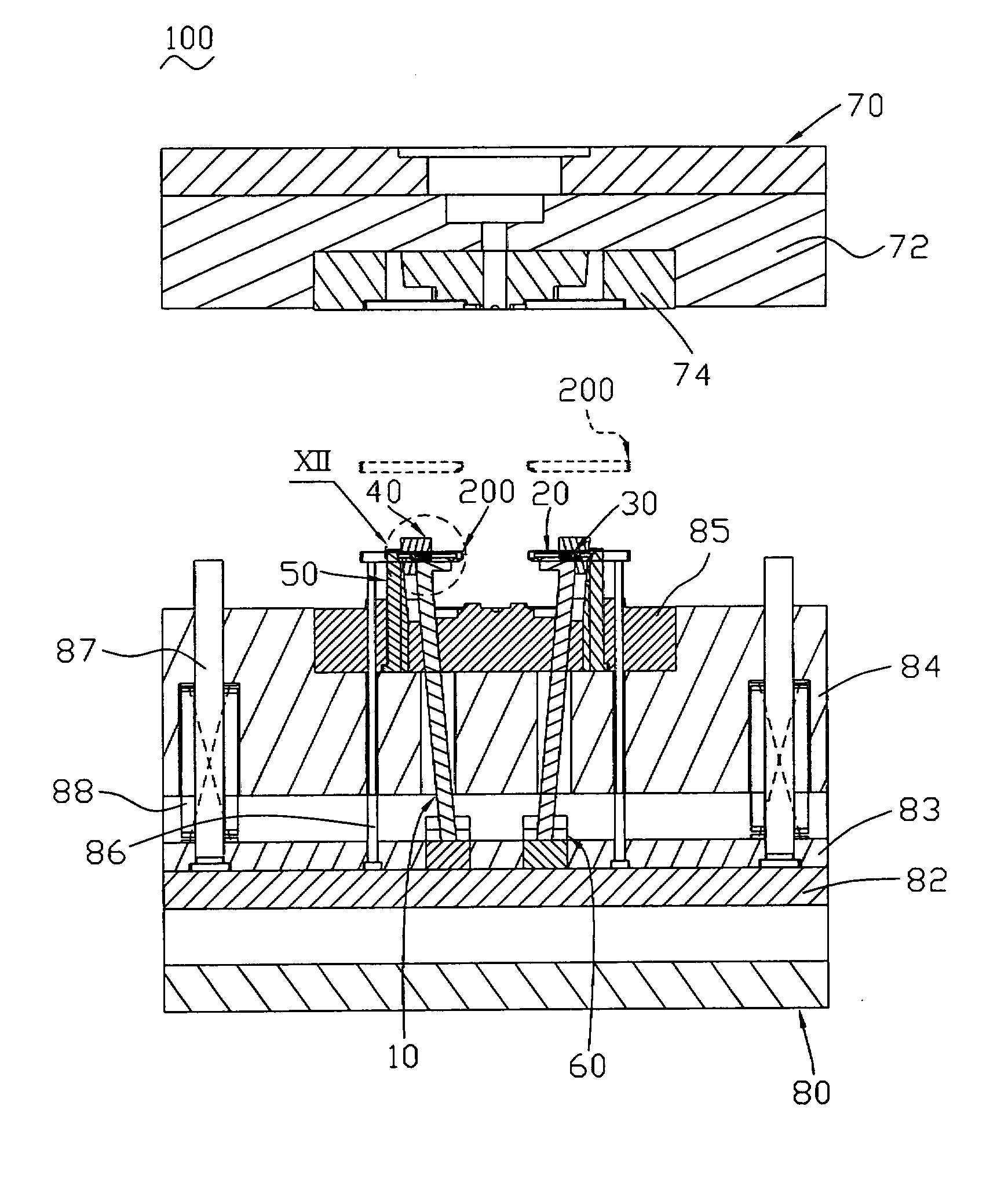

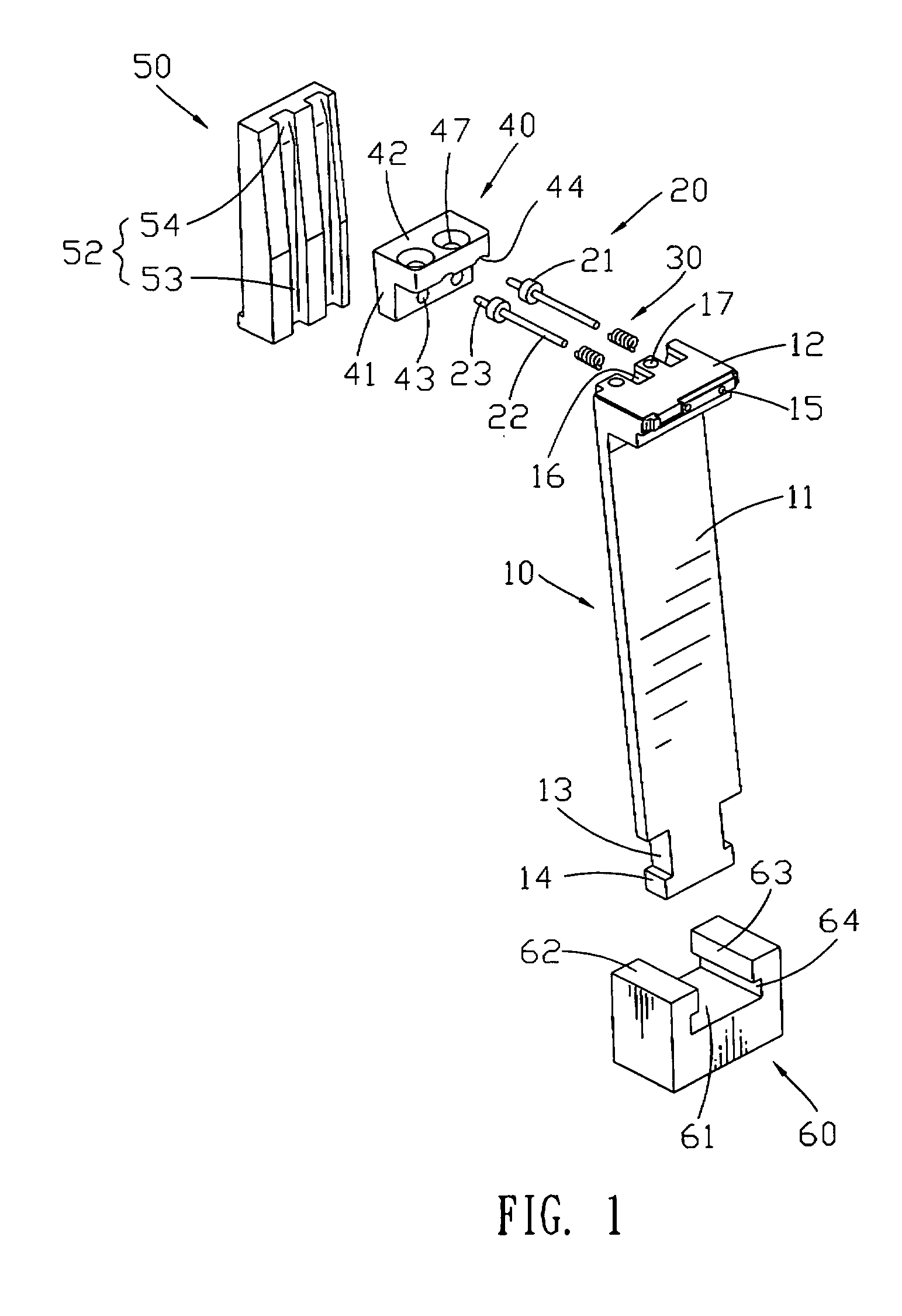

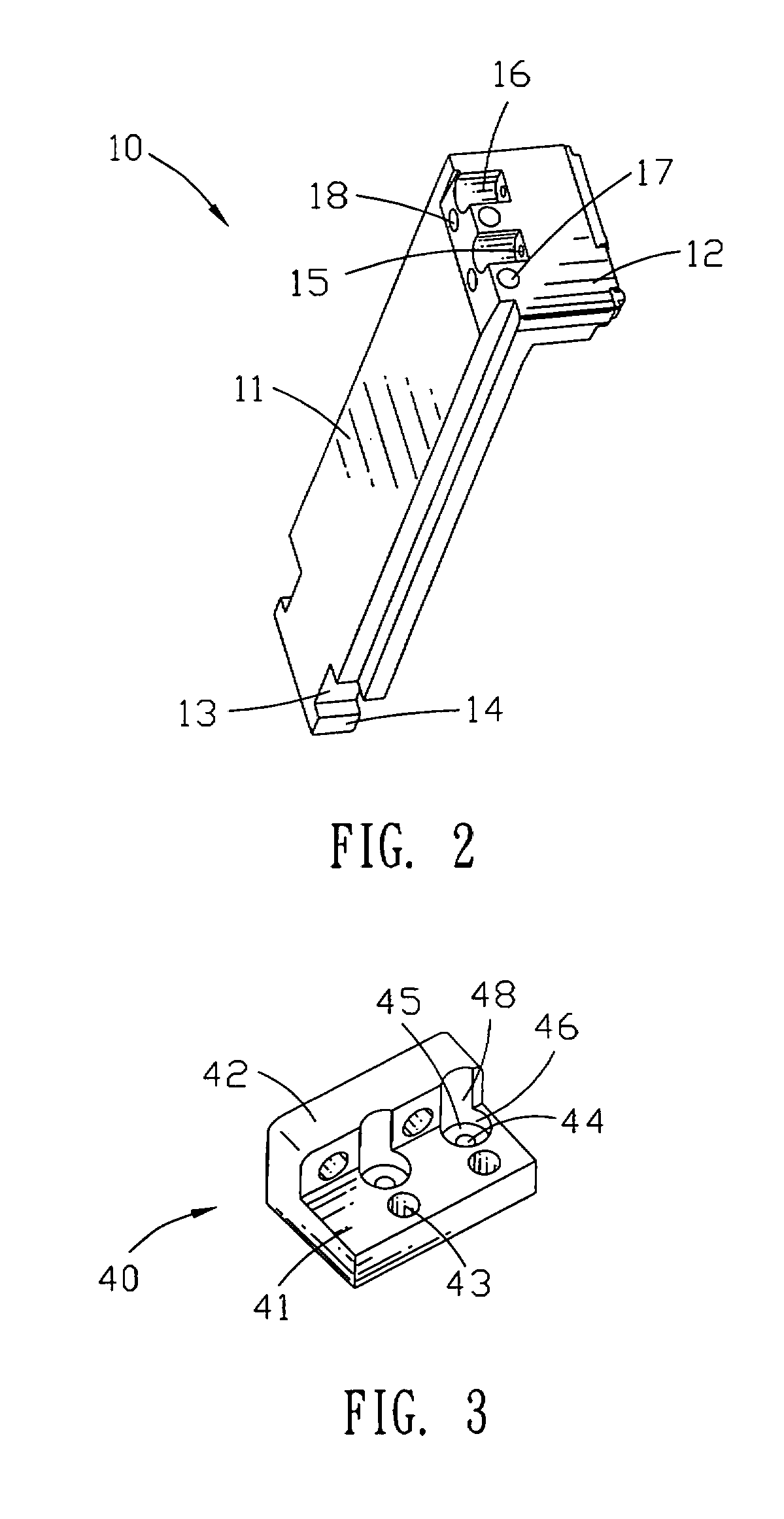

Angular ejector mechanism and injection mold with the same

InactiveUS20070243286A1Simplify manufacturing procedureReduce manufacturing costDischarging arrangementMouldsInjectorEngineering

An angular ejector mechanism for ejecting a plastic article with a recess in an inner side includes an angular ejector pin, a sliding pin, an elastic elements and a stopping block. The angular ejector pin includes a molding plate and a supporting plate. A moving hole and a sliding groove are respectively defined in a front face and an opposite rear face of the molding plate to communicate with each other. The sliding pin has a stopping protrusion dividing the sliding pin into a moving portion and a sliding portion. A sliding channel is defined on a front face of the stopping block. The sliding includes a vertical channel and a inclined channel. The moving portion is received in the moving hole of the molding plate, and the sliding portion slides from the sliding channel into the inclined channel until the angular ejector pin separates from the plastic article.

Owner:CHENG UEI PRECISION IND CO LTD

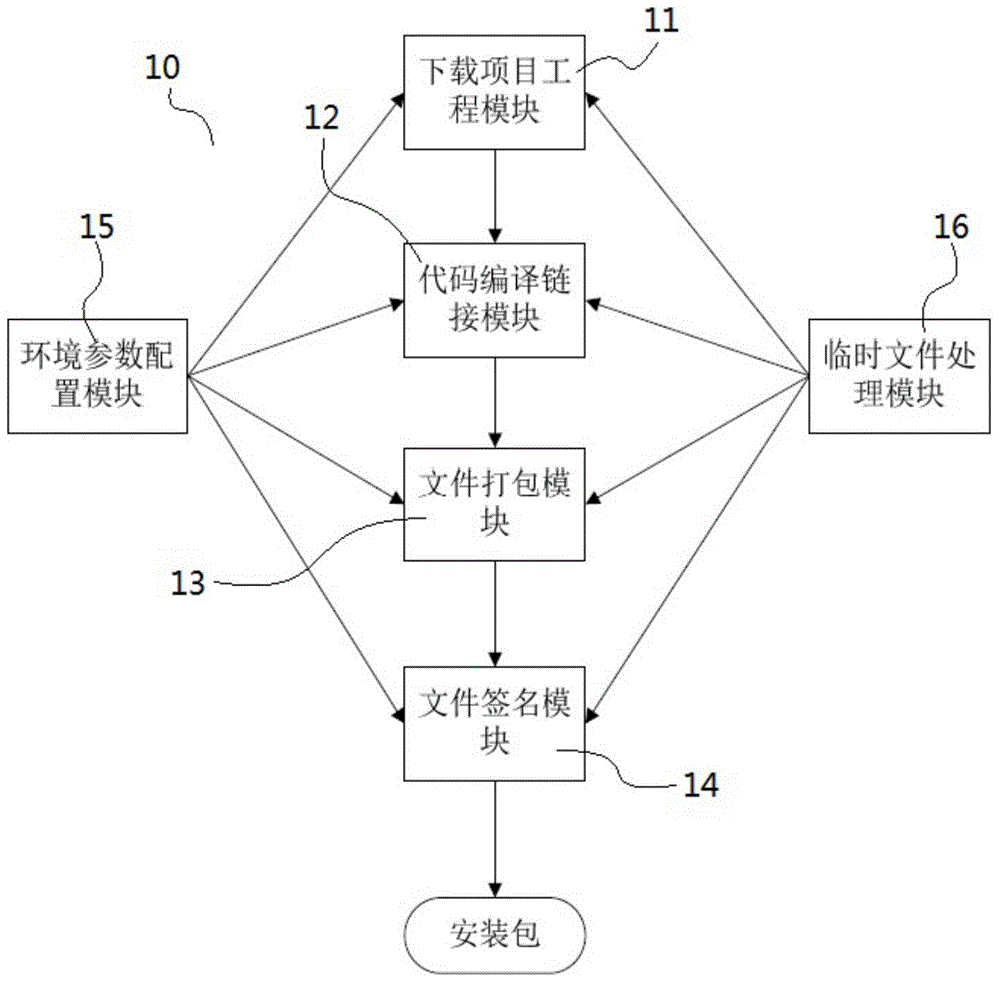

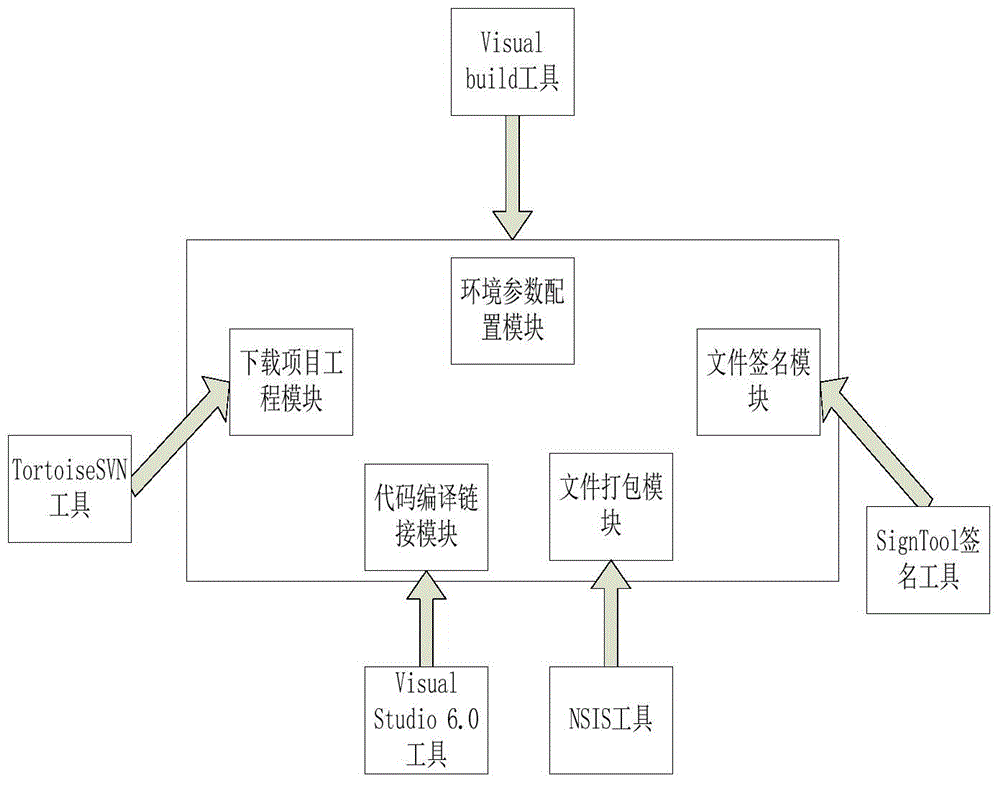

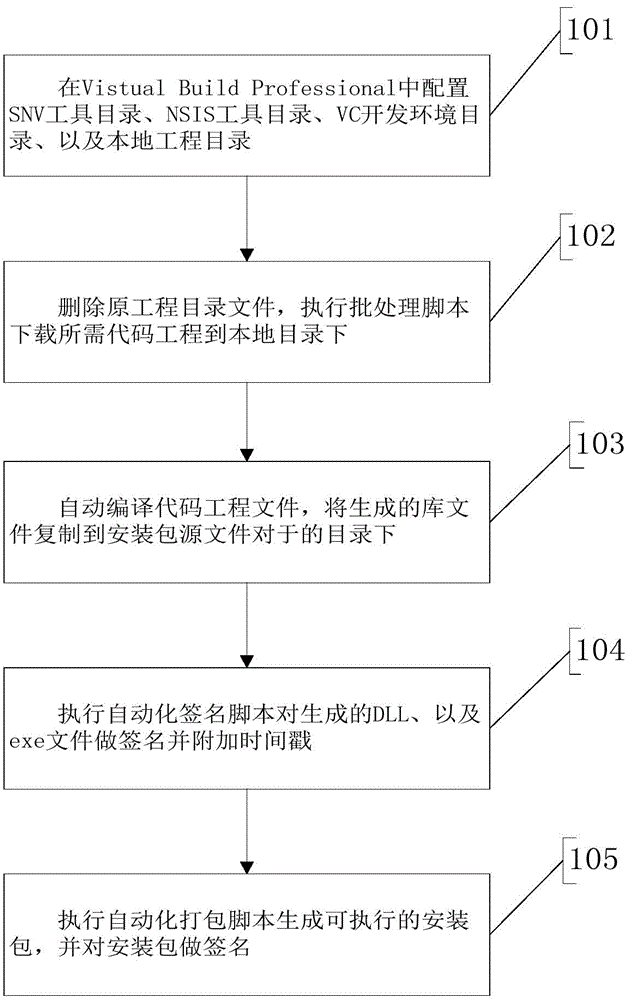

Automatic quick generation system and method for UKey installation package

ActiveCN104572237AAutomatic generatedQuick buildProgram controlMemory systemsSource code fileSoftware engineering

The invention discloses automatic quick generation system and method for a UKey installation package. The system comprises a download item project module, a code compiling and linking module, a file packaging module, a file signature module, an environmental parameter configuration module and a temporary file processing module which are matched with each other. The method comprises the installation package generation steps of (1) configuring and integrating a development environment directory, a SVN path, an NSIS path and a local directory; (2) creating a project folder in the local directory, and downloading a source code file of the project from a source code SVN sever; (3) automatically compiling a script, and compiling a program library as requirement; (4) preparing a signature time stamp for the generated library document; (5) packing the script through NSIS, and generating an installation package executable file. According to the scheme, the system and method have the advantages that the UKEY installation package can be automatically generated, thus the preparation process is greatly simplified, and the working efficiency of developers can be effectively increased.

Owner:DYNAMICODE

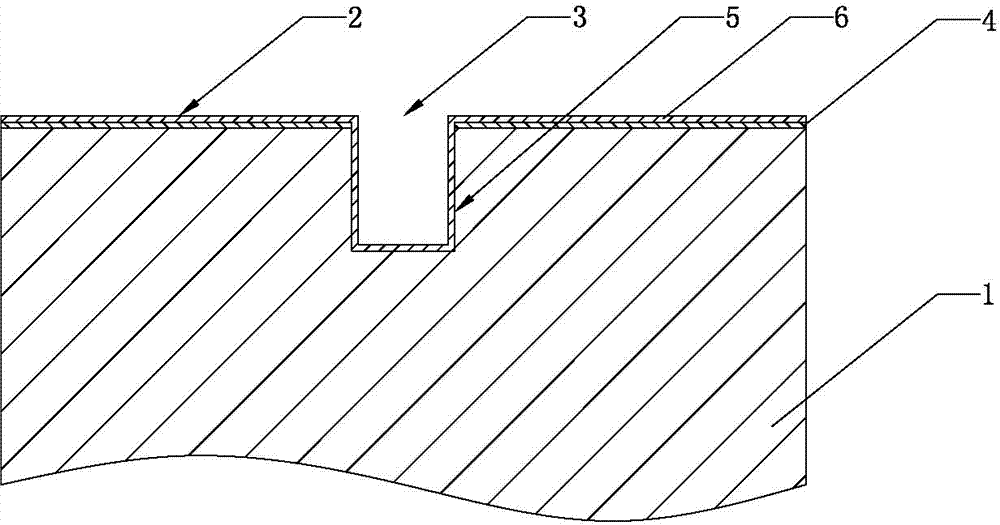

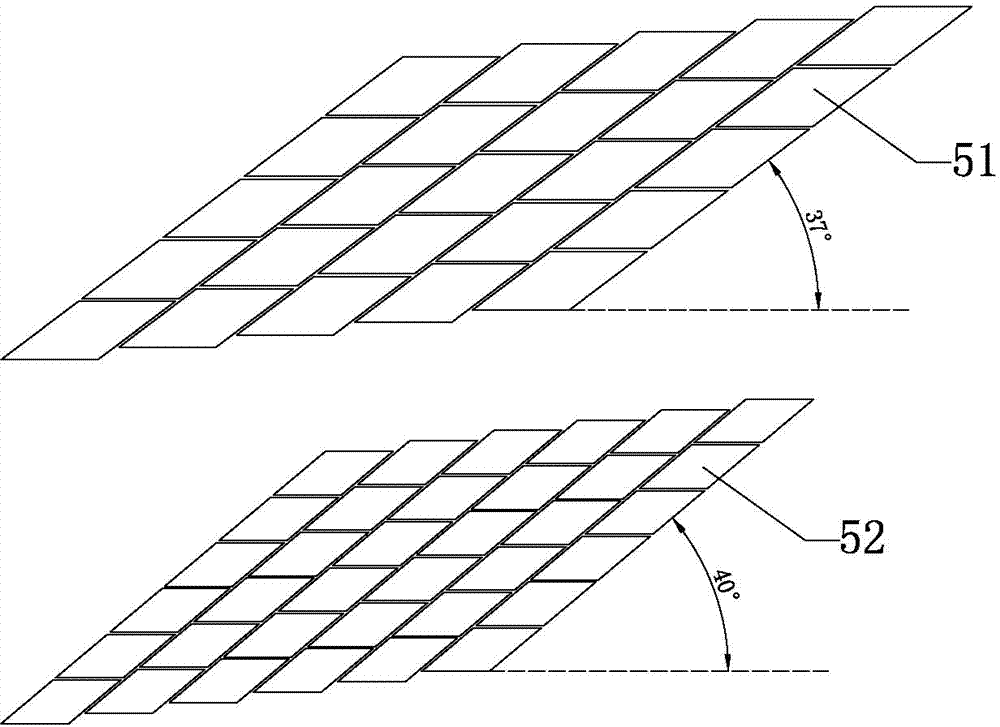

Printing roller for laser paper printing and manufacture process thereof

InactiveCN103481638AThe printing level is natural and gentleThe production process is simplePlate printingFoil printingPhysicsPaper sheet

The invention relates to the technical field of gravure printing rollers, in particular to a printing roller for laser paper printing and a manufacture process thereof. The manufacture process comprises the steps of copper plating, rubber coating, laser carving, etching, decoating and chrome plating. The printing roller comprises a roller body, wherein a non-printing area and a printing area are arranged on the outer surface of the roller body; a copper-coated layer is fixedly connected to the surface of the non-printing area; the laser-carved layer is formed in the surface of the printing area; a chrome-plated layer is fixedly connected to the surfaces of both the copper-coated layer and the laser-carved layer; the laser-carved layer comprises a first carved layer and a second carved layer; the carved screen line number and the carved screen angle of the first carved layer are different from those of the second carved layer. Through the twice-carving process, the gravure-printed faults are dislocated, so that the printing layers are natural and smooth. The manufacture process is simple, the control is convenient and the production efficiency is high.

Owner:DONGGUAN YUNCHENG PLATE MAKING

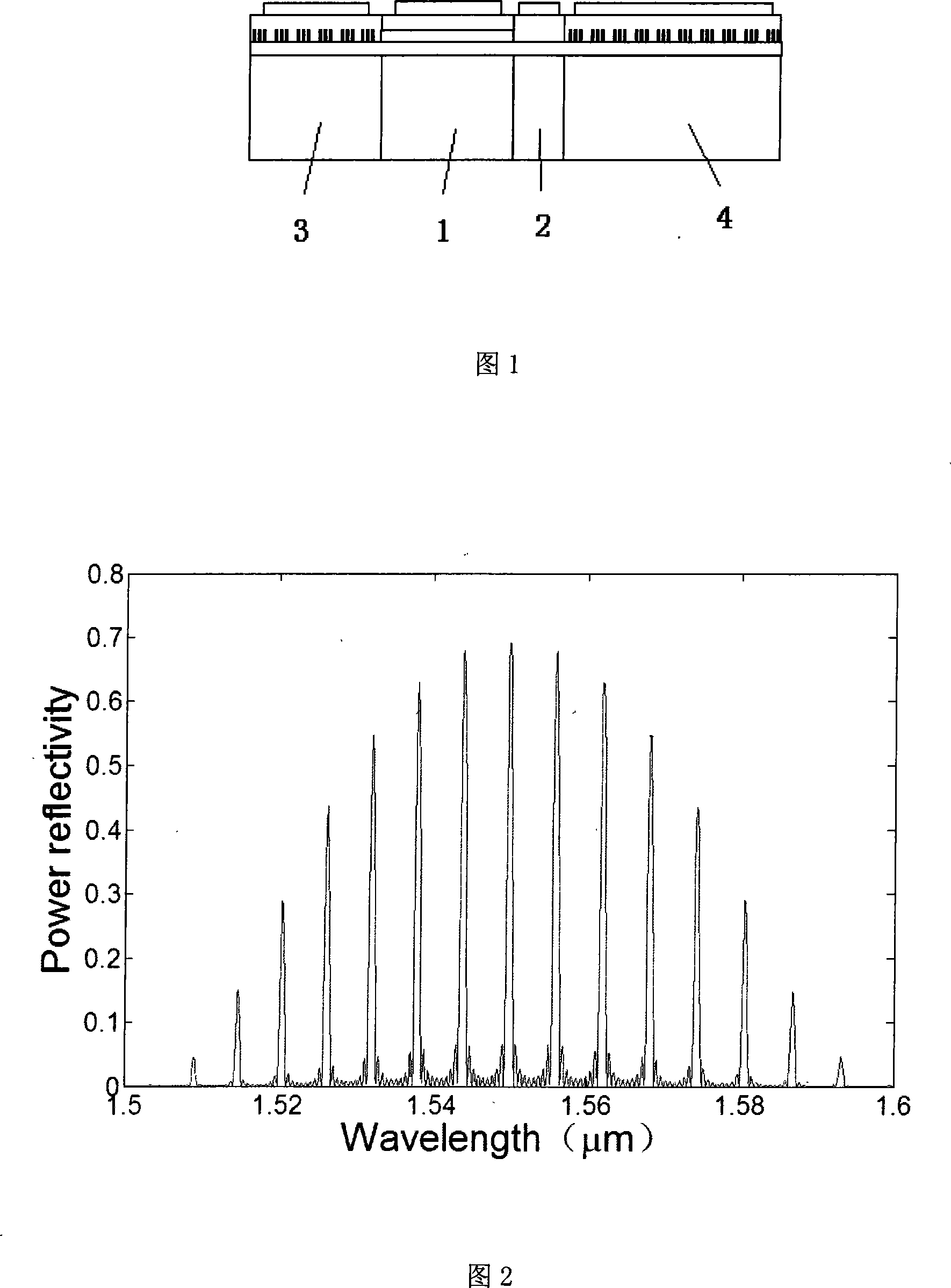

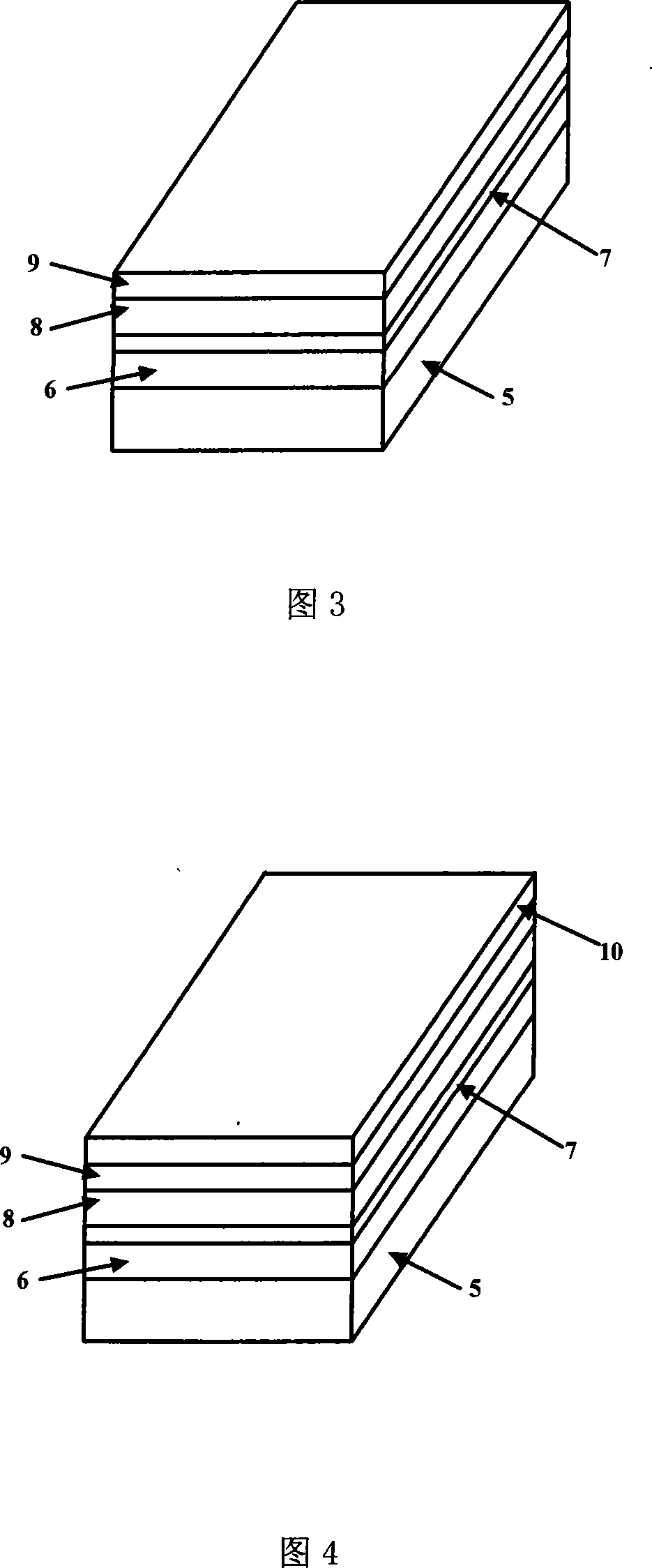

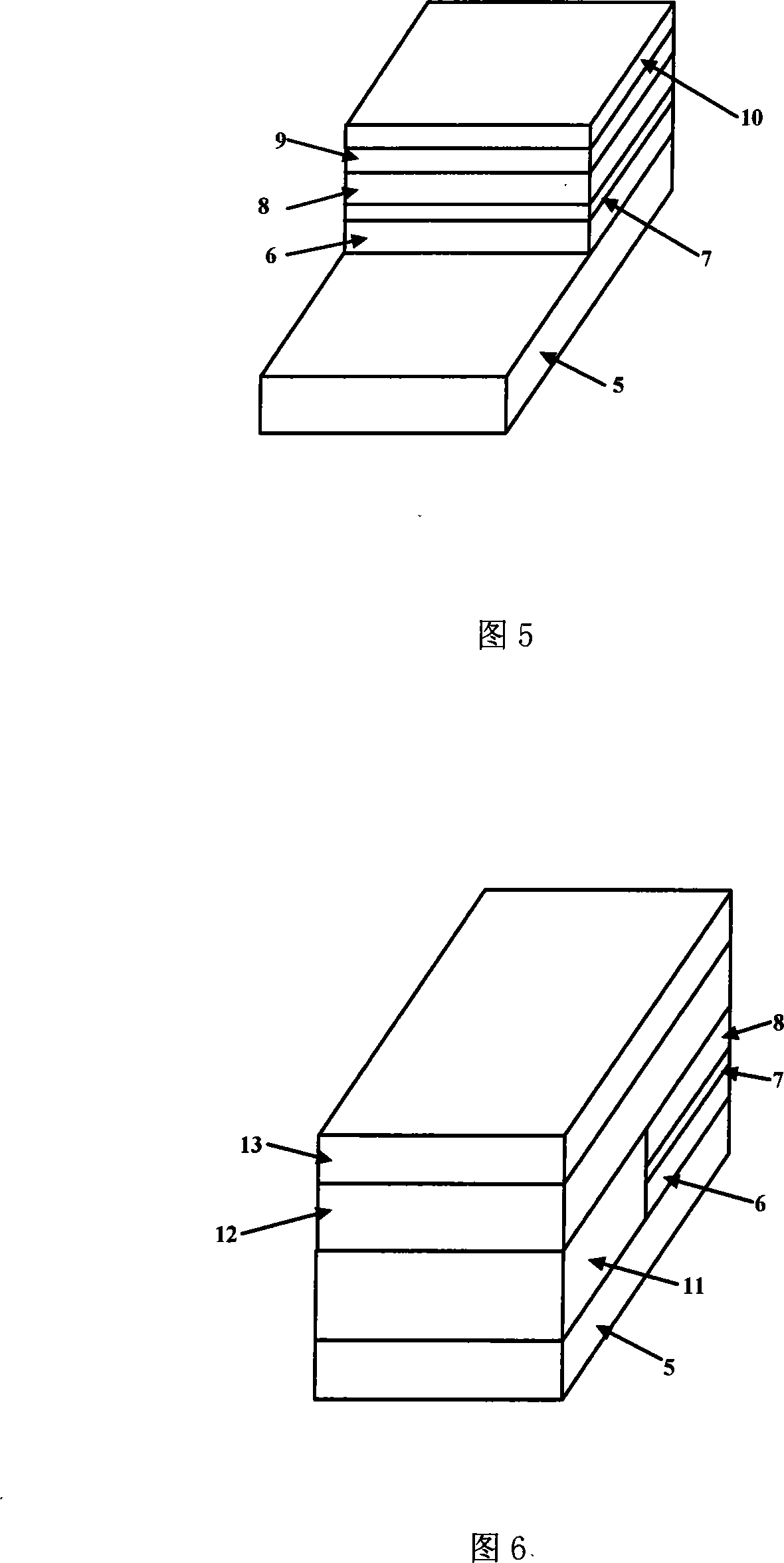

Manufacturing method of tunable semiconductor laser and tunable semiconductor laser

ActiveCN101227061AIncrease investmentShorten the development cycleOptical wave guidanceLaser detailsGratingWaveguide

Provided is a making method of a tunable semiconductor laser and a tunable semiconductor laser, wherein the making method comprises the following procedures: growing lower waveguide layer, multiple quantum trap structure, upper waveguide layer and indium phosphide layer epitaxially and sequentially on the n type substrate; growing earth silicon dielectric membrane on the epitaxial layer; dividing into active waveguide region and raster region; butting passive waveguide portion; removing earth silicon dielectric membrane and indium phosphide layer on the surface of the active waveguide region; growing ridge waveguide indium phosphide material and low resistivity InGaAs ternary layer sequentially; growing earth silicon dielectric membrane; making raster graphic of the ridge waveguide and the ridge waveguide on the raster region; etching raster of the ridge waveguide and the ridge waveguide on the raster region; growing earth silicon dielectric membrane continuously; opening the window separately on active waveguide region and raster region in order to make electrode isolation ditch; making P face and N face electrode of laser. The invention has good product property and high automation degree of the product making, which simplifies the technology process and has good product ratio.

Owner:GUANGXUN SCI & TECH WUHAN

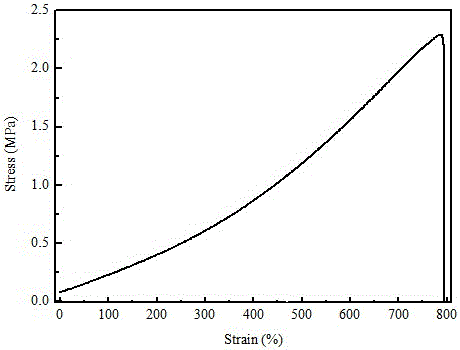

Method for preparing high-strength polyvinyl alcohol hydrogel

The invention discloses a method for preparing a high-strength polyvinyl alcohol hydrogel. The method comprises the following steps: taking polyvinyl alcohol as an initial raw material, and heating and dissolving in a water bath, thereby obtaining a polyvinyl alcohol aqueous solution; performing repeated low-temperature freezing-thawing on the polyvinyl alcohol aqueous solution, thereby obtaining polyvinyl alcohol hydrogel; adding the polyvinyl alcohol hydrogel into a saturated saline solution, thereby obtaining the high-strength polyvinyl alcohol hydrogel. According to the invention, a hydrogen bond cross-linking structure and a microcrystalline domain are sequentially constructed by a two-step method, and then the high-strength polyvinyl alcohol hydrogel is prepared. The preparation method disclosed by the invention is simple and environmental-friendly, and the prepared high-strength polyvinyl alcohol hydrogel has excellent mechanical property, non-toxicity and high biocompatibility.

Owner:FUZHOU UNIV

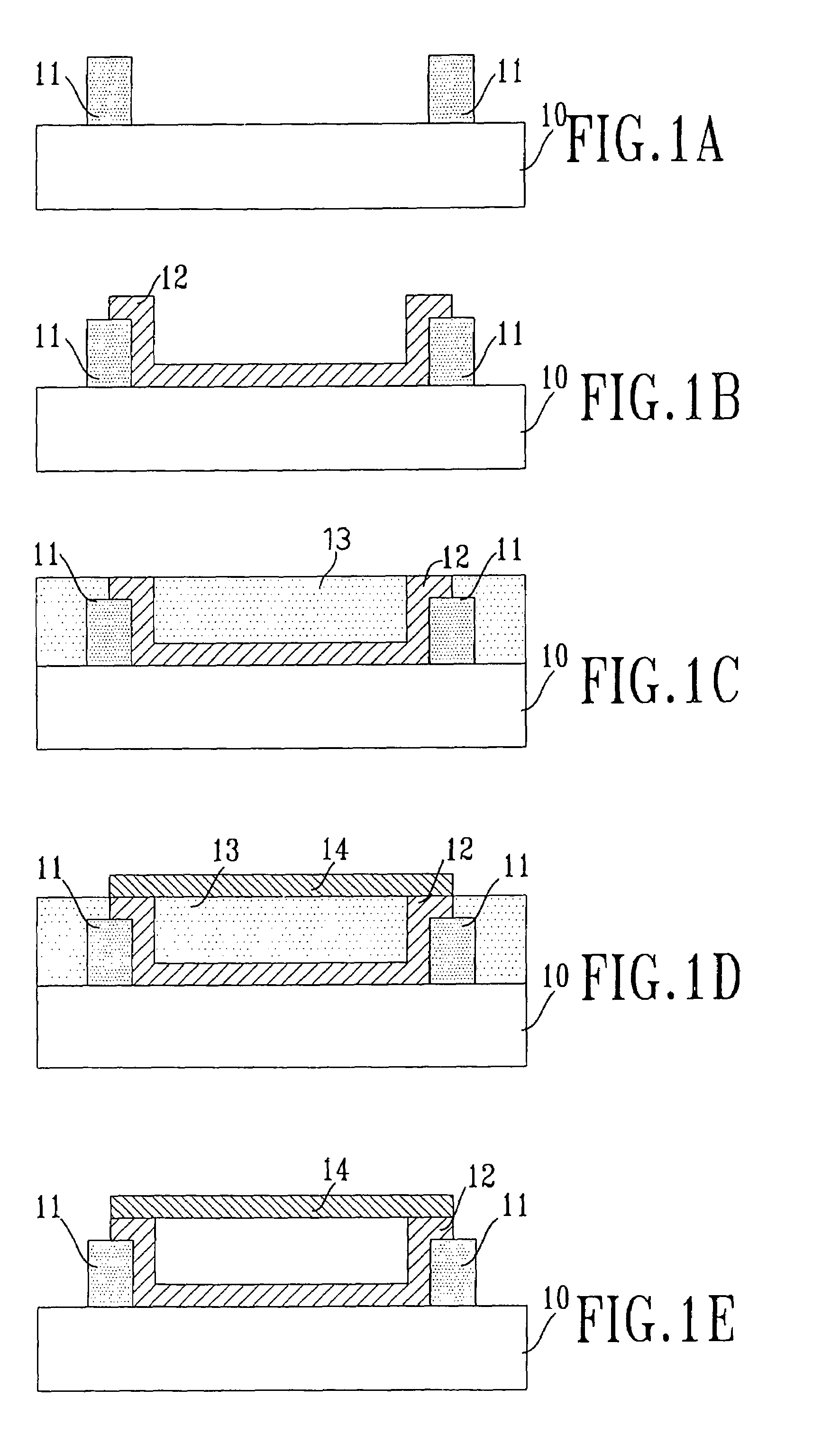

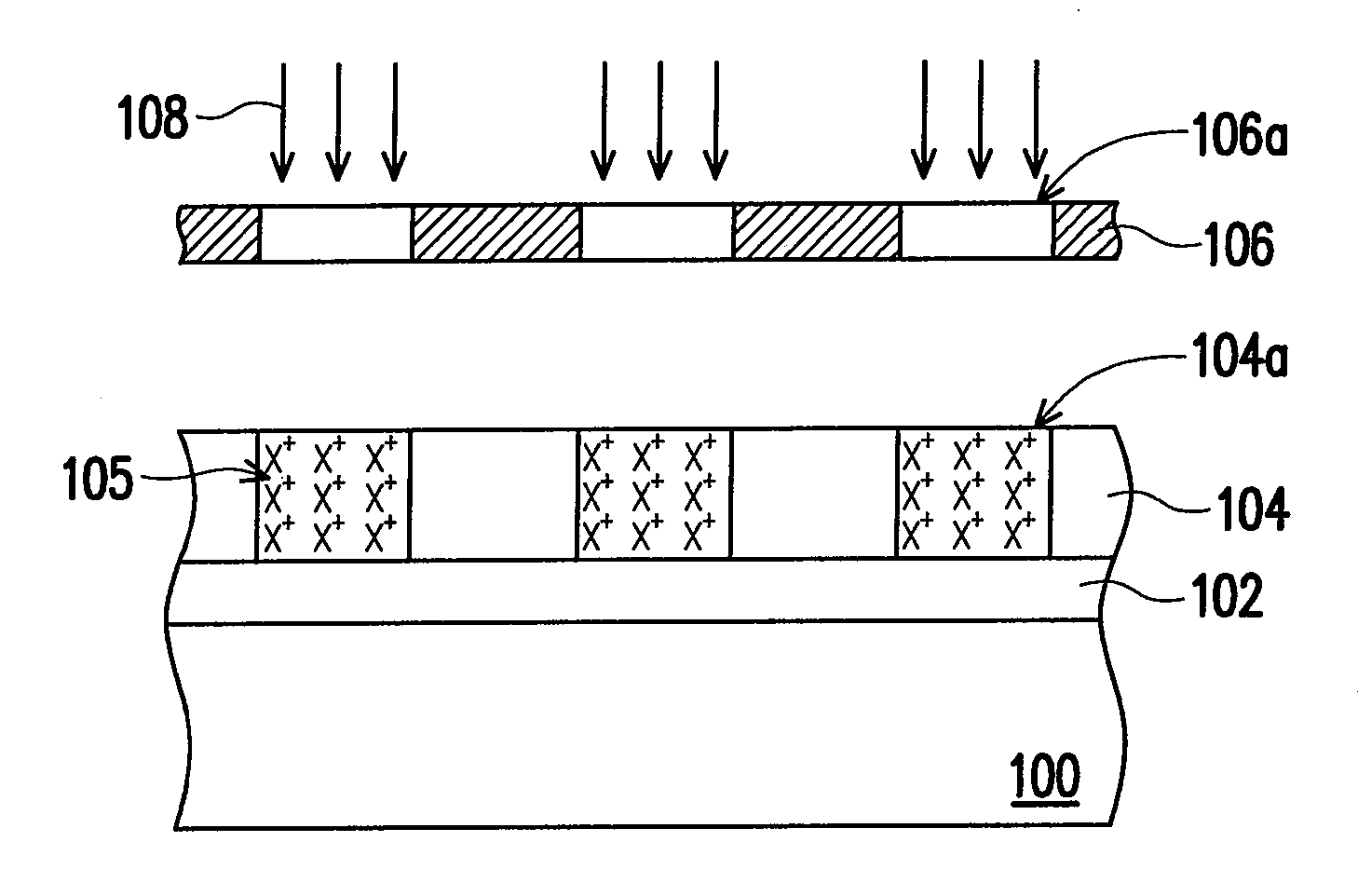

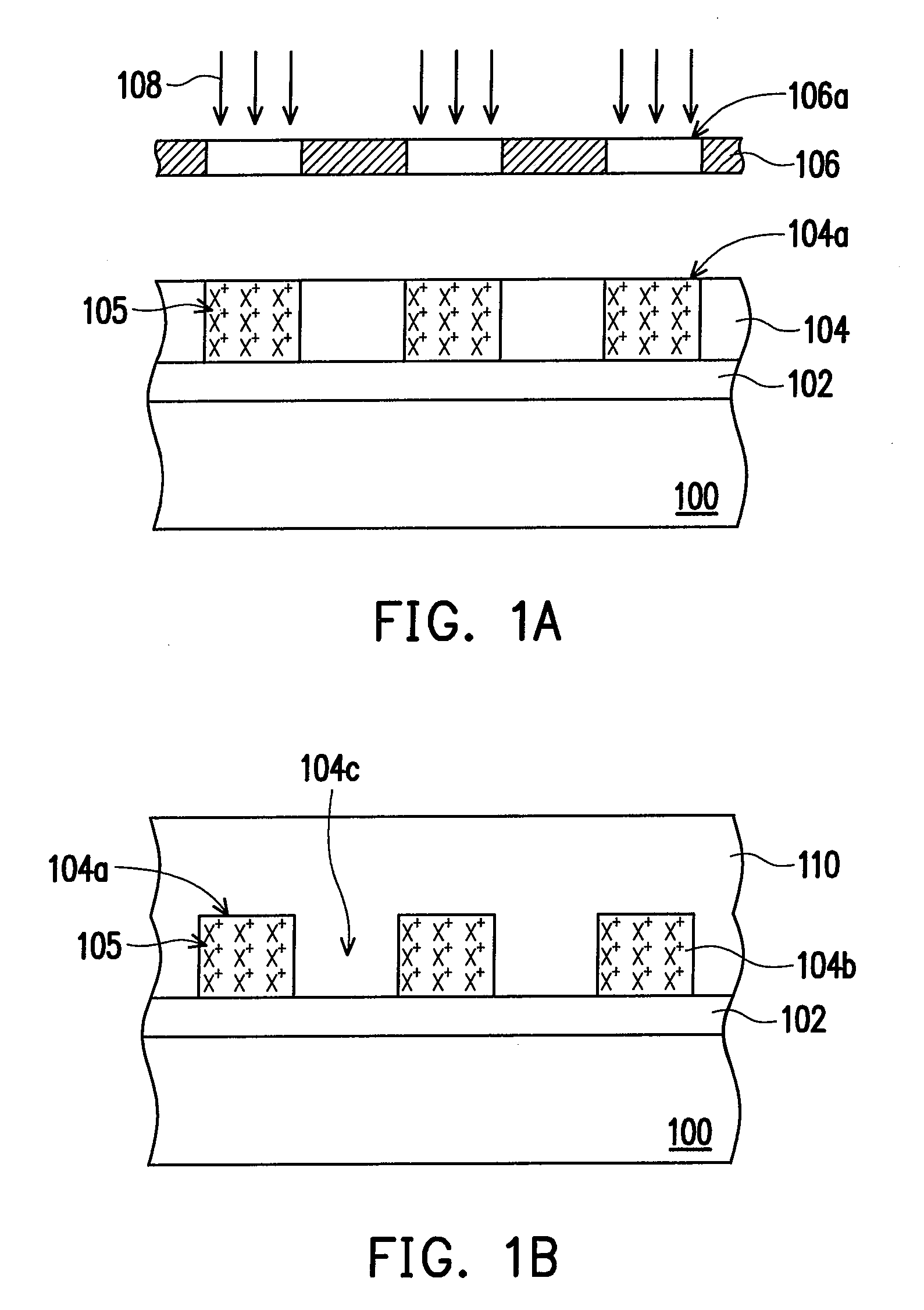

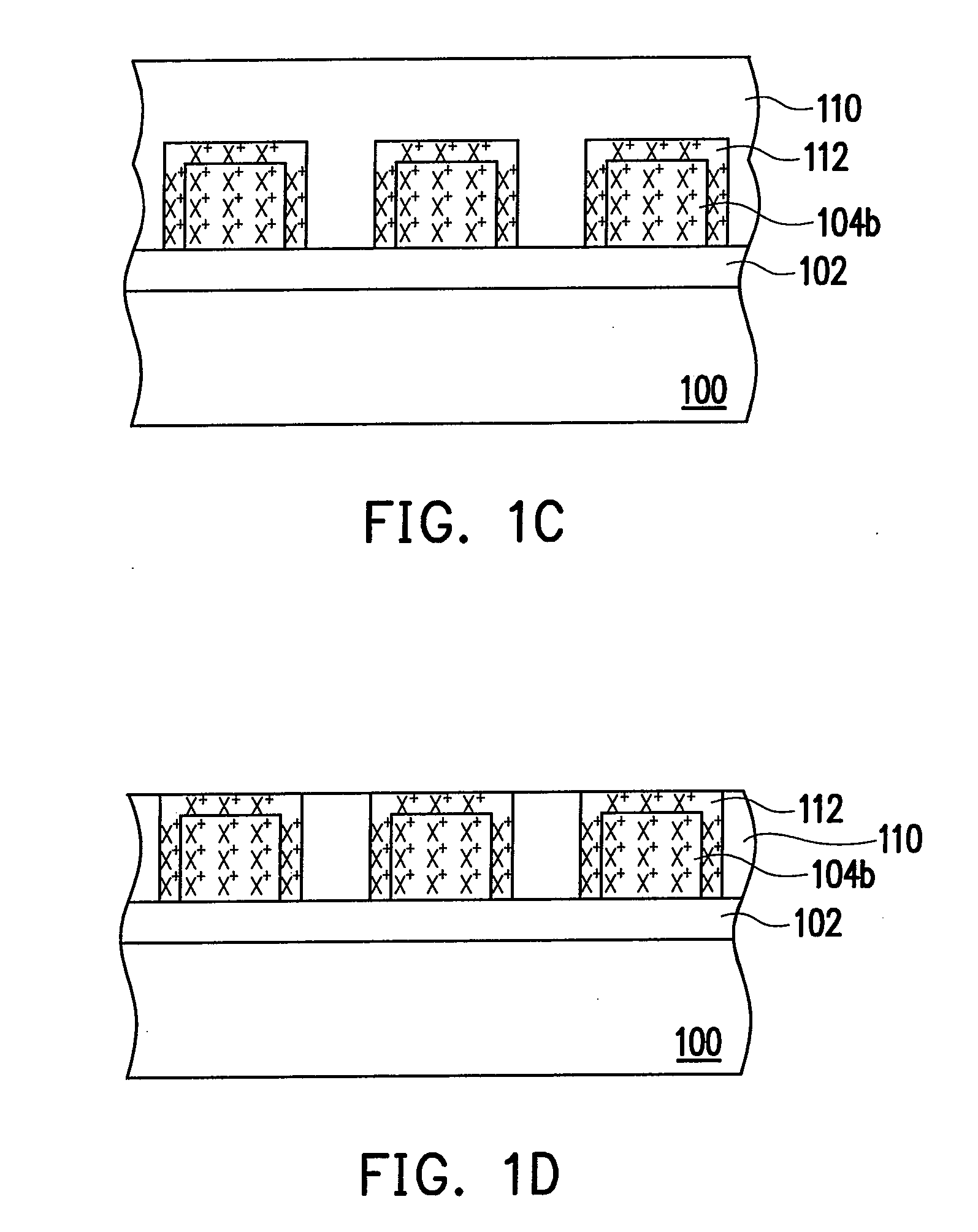

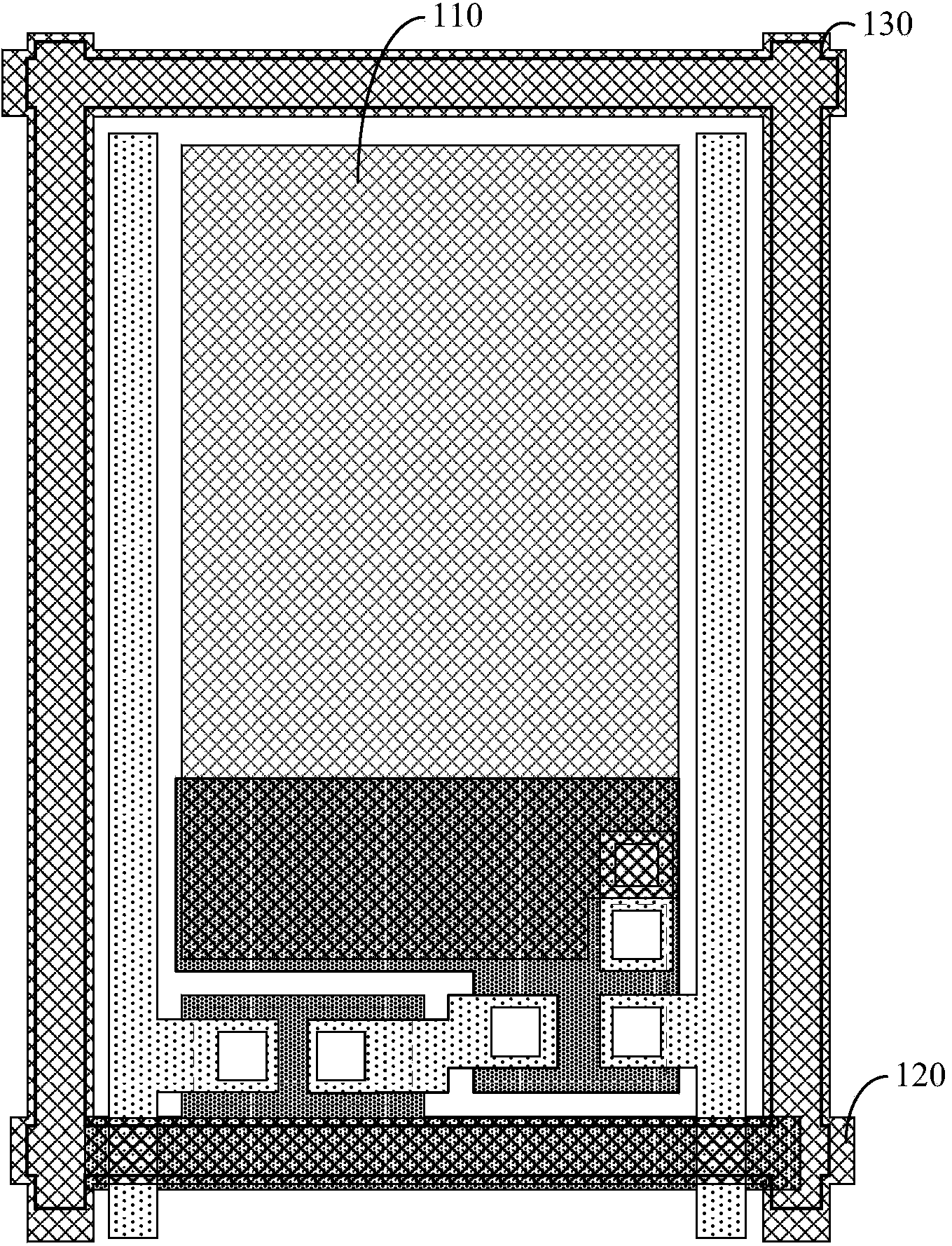

Patterning process

ActiveUS20090130612A1Easy to makeReduce manufacturing costPhotosensitive materialsPhotosensitive material processingInterface layerComputational physics

The invention is directed to a method for patterning a material layer. The method comprises steps of forming a first mask layer on the material layer and then patterning the first mask layer. The patterned first mask layer has a pattern therein and a plurality of gaps within the patterns and the gaps expose a portion of the material layer. Further, a second mask layer is formed over the material layer and the second mask layer fills the gaps. An interface layer is formed between the patterned first mask layer and the second mask layer. A portion of the second material layer is removed until the top surface of the interface layer is exposed. The interface layer is removed to expose a portion of the material layer and the material layer is patterned by using the patterned first mask layer and the second mask layer as a mask.

Owner:MACRONIX INT CO LTD

AMOLED array substrate and display device

ActiveCN103715205ALower cathode resistanceThe production process is simpleSolid-state devicesSemiconductor devicesSignal linesOptoelectronics

The invention discloses an AMOLED array substrate. The AMOLED array substrate comprises a plurality of pixel structures formed in an array mode on a substrate base plate, wherein each pixel structure is defined by a grid line, a signal line and a power line, and the signal line and the power line are perpendicular to the grid line. Each pixel structure comprises a thin film transistor structure, a positive electrode, a negative electrode and an organic luminous layer between the positive electrode and the negative electrode, wherein the positive electrode is located in a region corresponding to each pixel structure, and the negative electrode is a transparent electrode covering the whole substrate base plate. Each pixel structure further comprises a first negative electrode auxiliary line parallel to the signal line, wherein the first negative electrode auxiliary line is connected with the negative electrode through at least two dotted first through holes. In the AMOLED array substrate, each negative electrode is connected with the corresponding first negative electrode auxiliary line on the same layer with the corresponding signal line through the at least two dotted first through holes to enable each negative electrode and the corresponding first negative electrode auxiliary line to be connected in parallel, and the negative electrode resistance is reduced. In addition, the width of each first negative electrode auxiliary line can be decreased, the influence on the opening rate is reduced, and the opening rate is improved compared with the prior art.

Owner:BOE TECH GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com