Manufacturing method of tunable semiconductor laser and tunable semiconductor laser

A manufacturing method and laser technology, which are applied to semiconductor lasers, optical waveguide semiconductor structures, lasers, etc., can solve the problems of laser performance impact and laser manufacturing technology differences, so as to reduce the number of device growth, shorten the research and development cycle, product high performance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The manufacturing method of the semiconductor laser and the semiconductor laser thereof of the present invention will be described in detail below with reference to the drawings and embodiments.

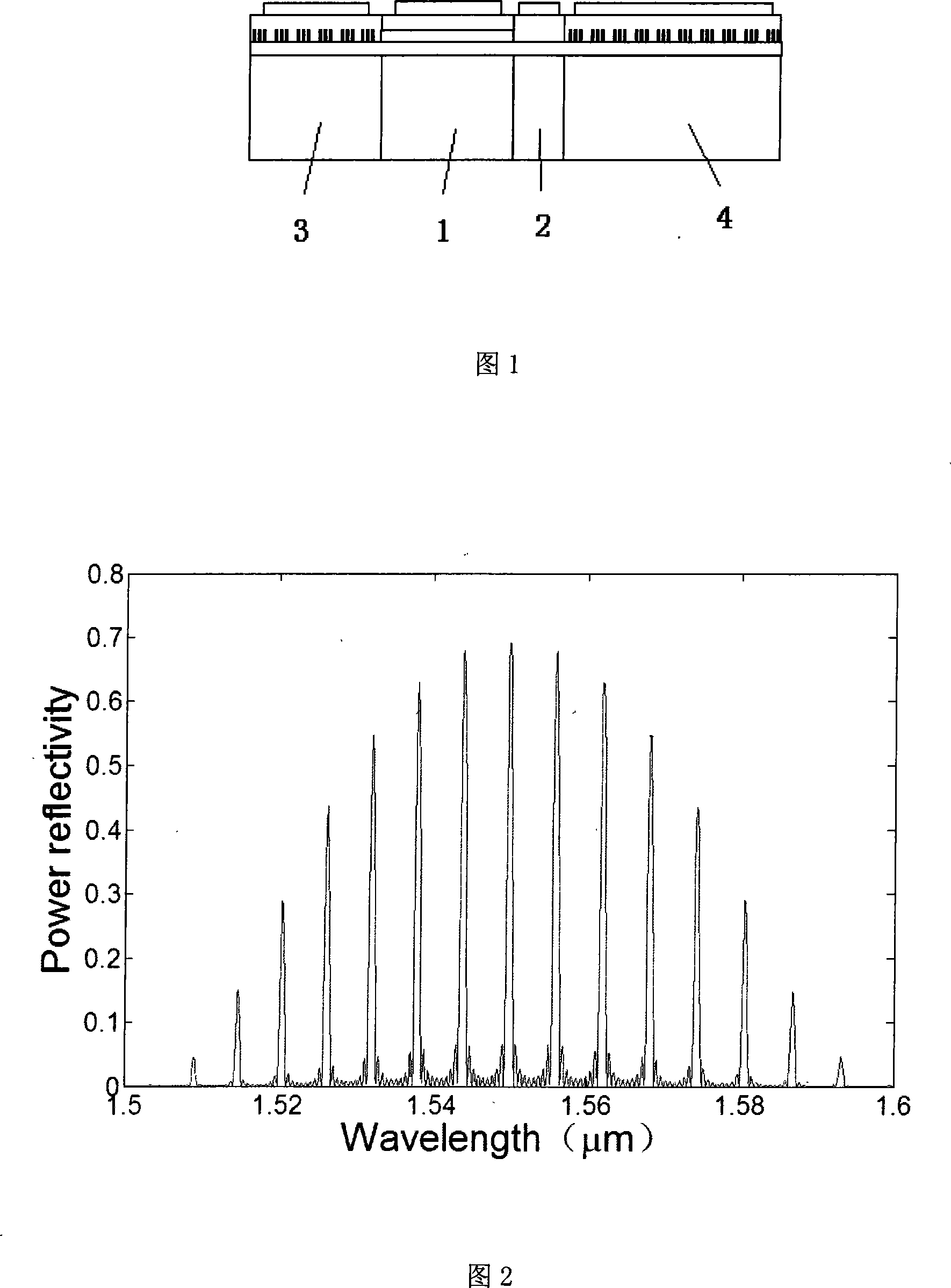

[0044]The fabrication method of the tunable semiconductor laser of the present invention comprises the following process steps (in conjunction with two-stage DBR):

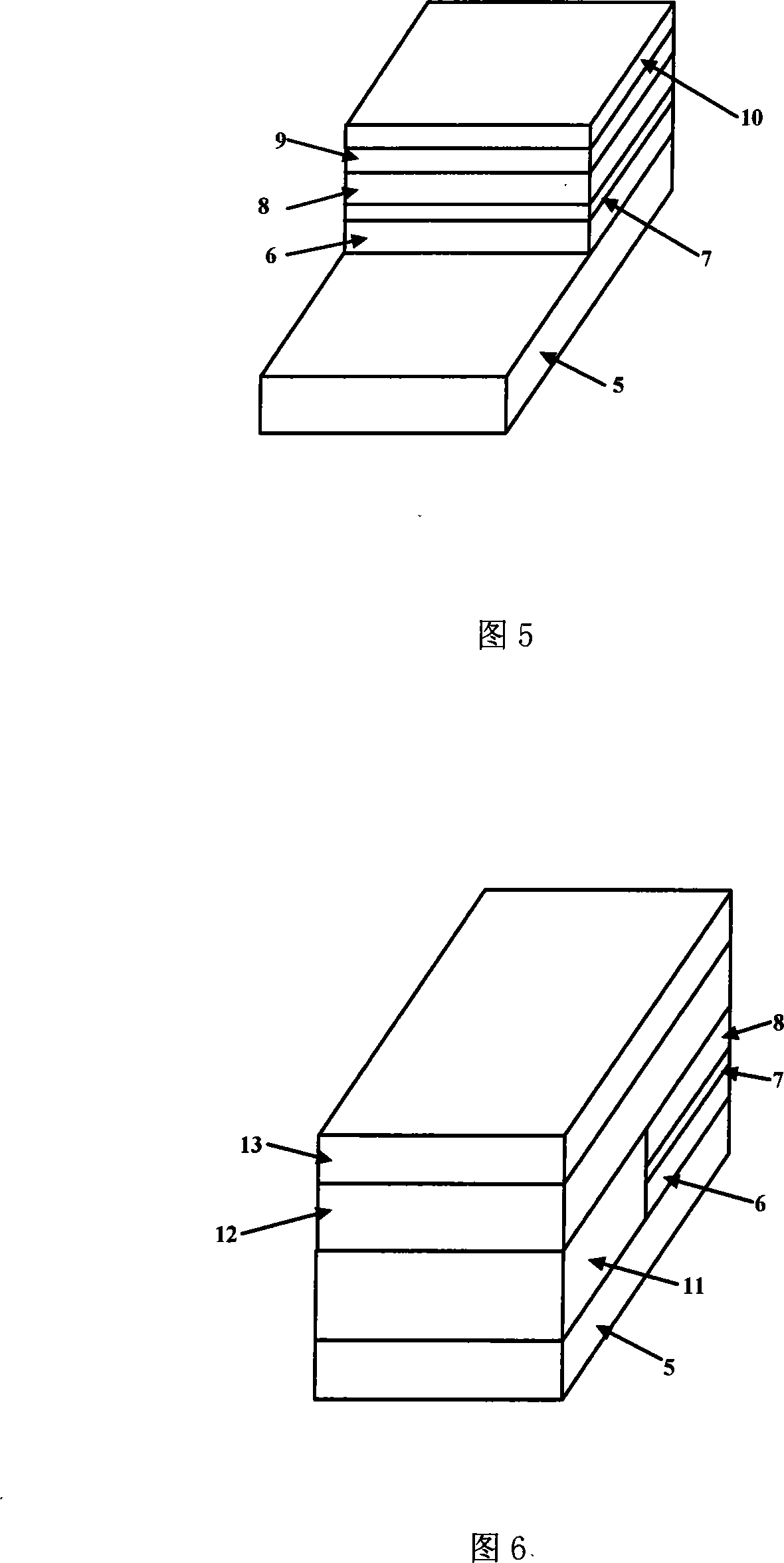

[0045] 1) As shown in Figure 3, epitaxial growth is performed on an n-type indium phosphide (InP) substrate 5, and the epitaxial layer structure from bottom to top is the lower waveguide layer 6, the multi-quantum well structure 7, the upper waveguide layer 8, and the phosphorus indium layer (InP) 9;

[0046] 2) As shown in FIG. 4, a silicon dioxide dielectric film 10 is grown on the epitaxial layer by using a plasma-enhanced chemical vapor deposition system (PECVD);

[0047] 3) As shown in Figure 5, the active waveguide area and the grating area (grating area) are divided into segmented graphics by photolithogra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com