Solar thermoelectric power generation system

A technology of thermoelectric power generation and solar panels, which is applied in the directions of solar thermal power generation, wind power generation, and mechanical power generation with solar energy, and can solve the problems of wind power generation fluctuation and intermittency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

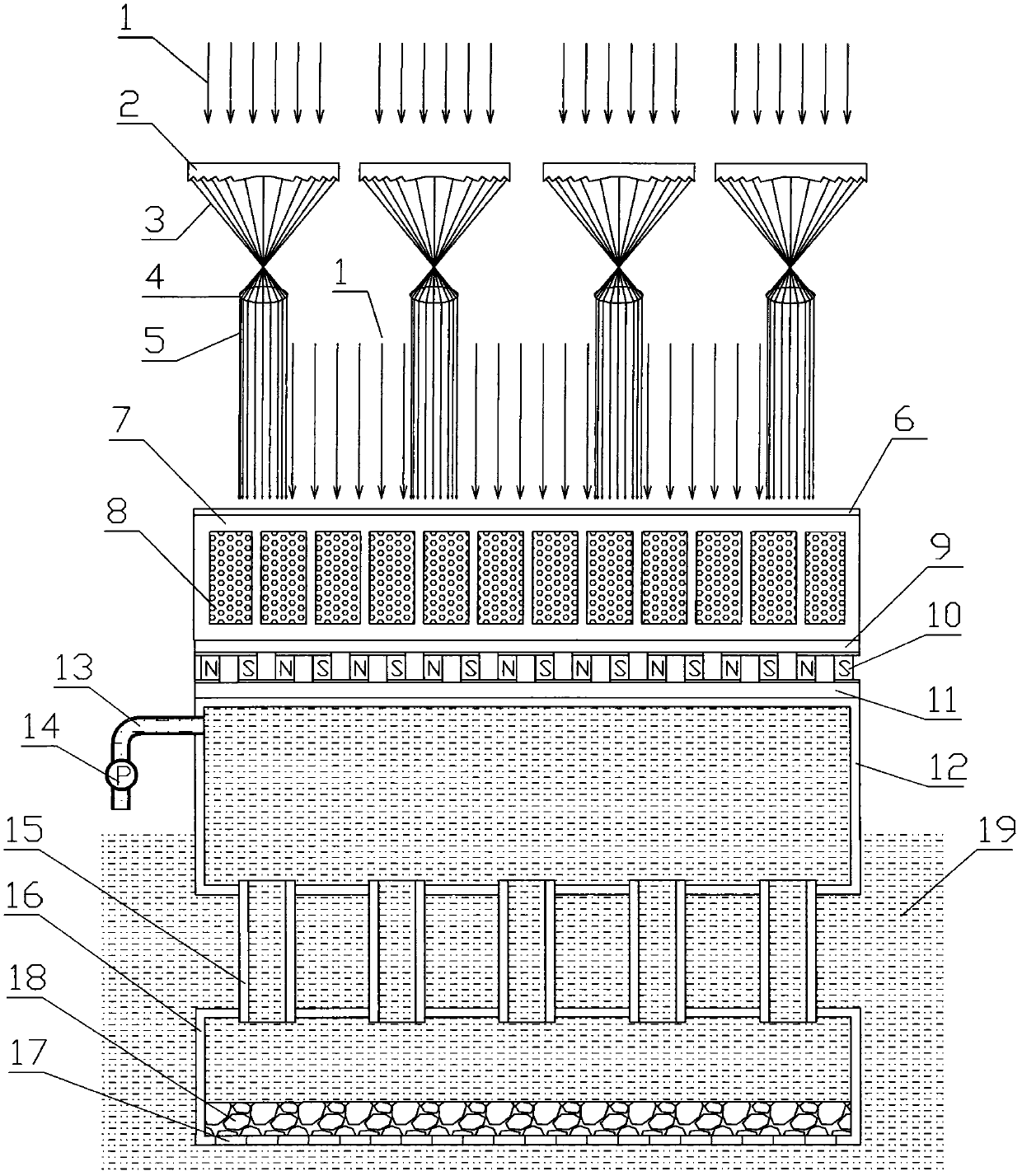

[0019] The cross-sectional structure diagram of the solar thermoelectric power generation system is as follows: figure 1 As shown, among them: 1 is the sunlight, 2 is the strip Fresnel condenser, 3 is the reflected light, 4 is the collimating lens, 5 is the concentrated light, 6 is the solar heat absorbing coating, 7 is the metal light-to-heat conversion device , 8 is the phase change energy storage material, 9 is the hot end of the thermoelectric power generation device, 10 is the semiconductor thermoelectric chip, 11 is the cold end of the thermoelectric power generation device, 12 is the upper water tank, 13 is the drain pipe, 14 is the guide pump, and 15 is the connecting pipe 16 is the lower water tank, 17 is the water inlet of the lower water tank, 18 is filter sand, and 19 is lake water or river water or sea water or pond water.

[0020] When in use, the sunlight 1 is irradiated on the strip Fresnel condenser 2, the reflected light 3 is irradiated on the collimator lens...

Embodiment 2

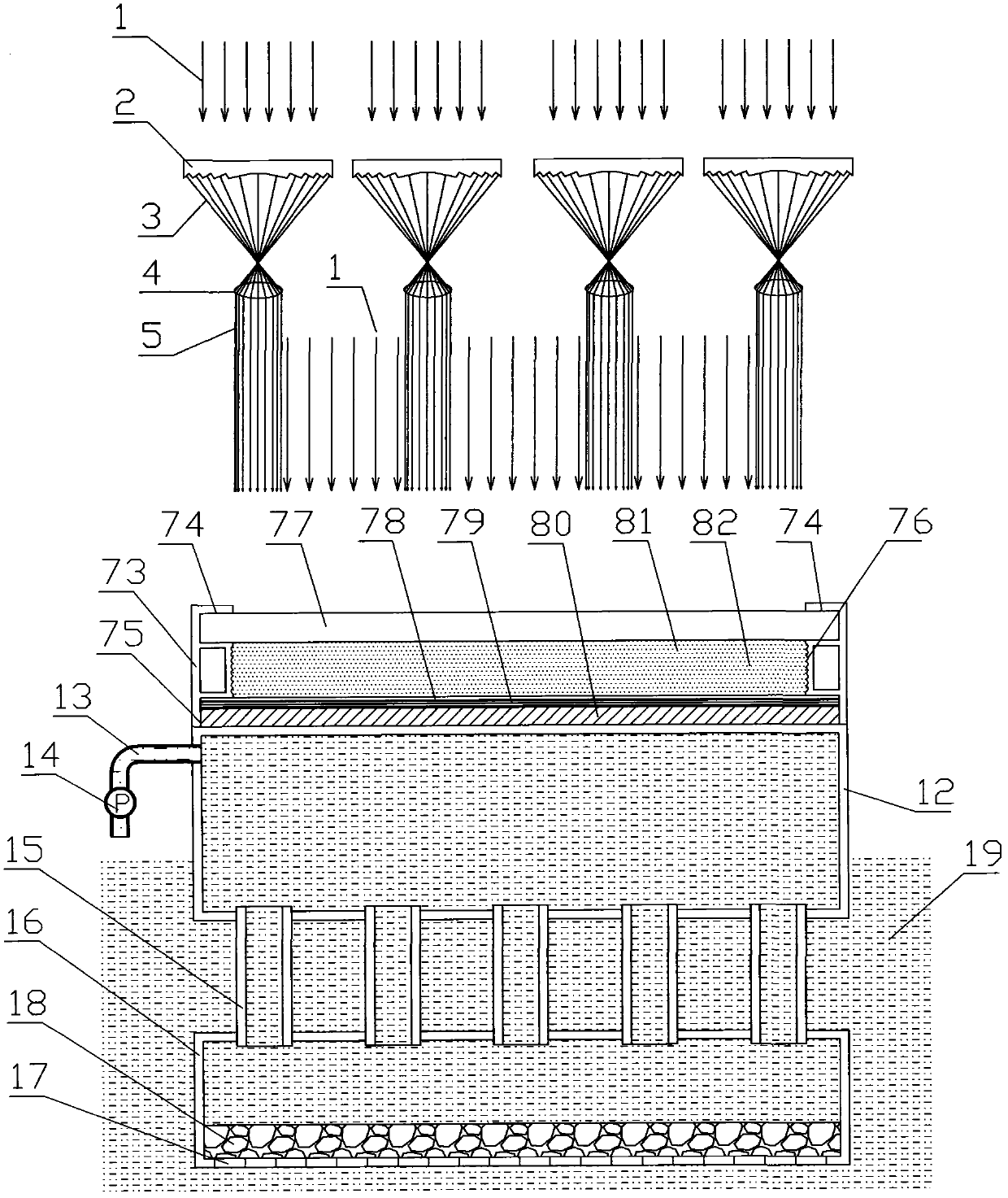

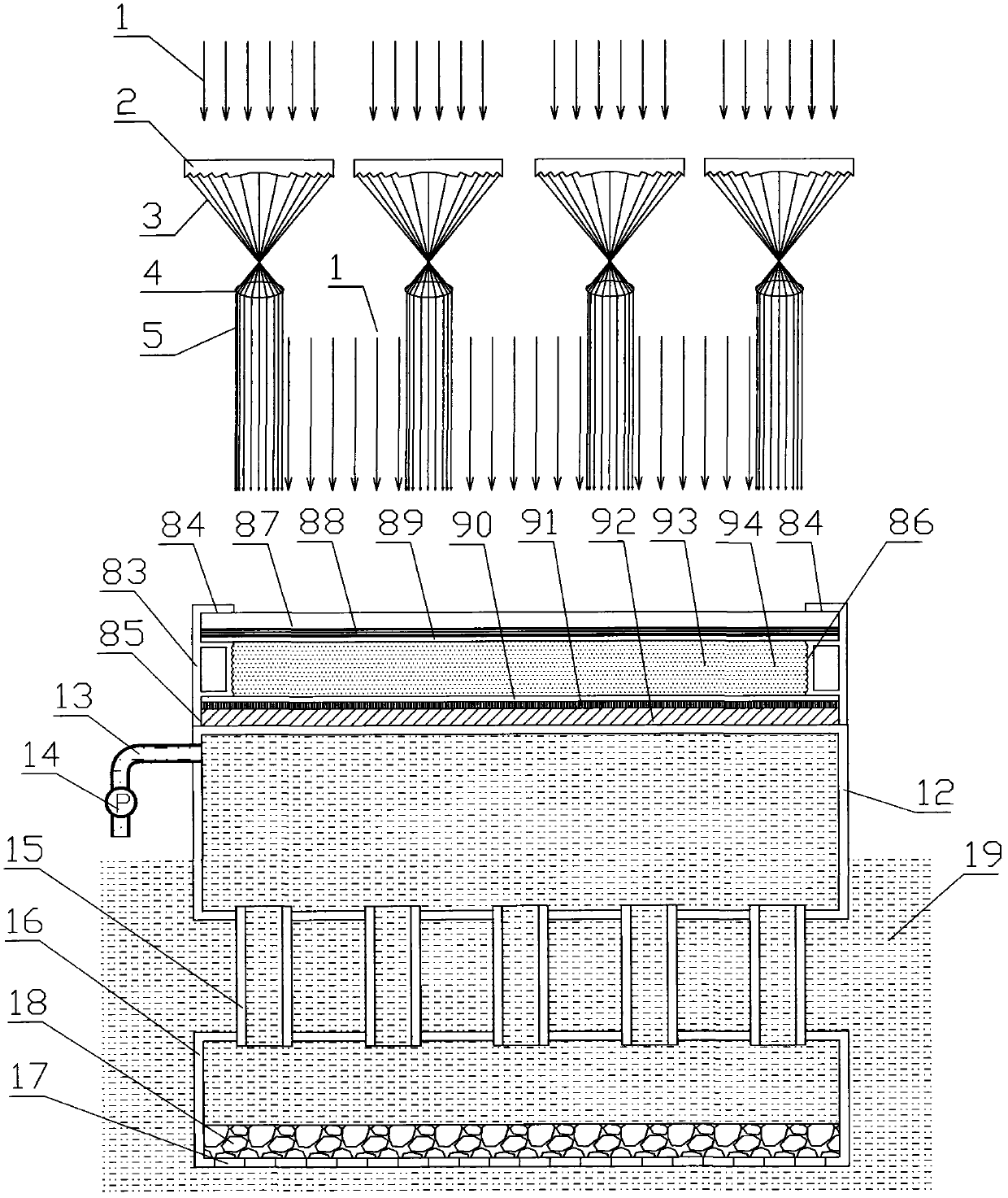

[0022] The combined cross-sectional structure diagram of the solar thermoelectric power generation system and the closed gas turbine power generation system is shown in figure 2As shown, wherein: 20 is sunlight, 21 is a strip Fresnel condenser, 22 is reflected light, 23 is a collimating lens, 24 is concentrated light, 25 is a solar heat absorbing coating, and 26 is a metal light-to-heat conversion device , 27 is the liquid circulation water of the metal photothermal conversion device, 28 is the liquid circulation water output pipe, 29 is the phase change energy storage material storage chamber, 30 is the phase change energy storage material, 31 is the hot end of the thermoelectric power generation device, 32 is the semiconductor temperature difference Chip, 33 is the cold end of the thermoelectric power generation device, 34 is the upper water tank, 35 is the drain pipe, 36 is the guide pump, 37 is the connecting pipe, 38 is the lower water tank, 39 is the water inlet hole of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com