Printing roller for laser paper printing and manufacture process thereof

A production process and plate roller technology, applied in printing process, printing surface preparation, printing and other directions, can solve the problems of high cost, ugly layered plates, low efficiency, etc., and achieve the effect of solving waste and controlling product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

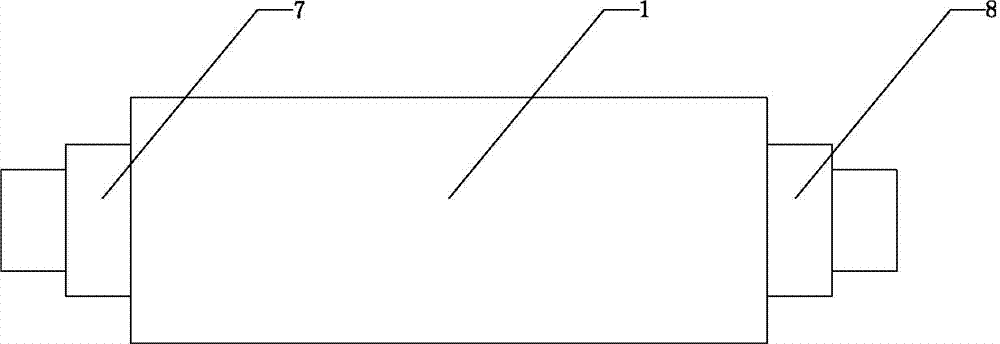

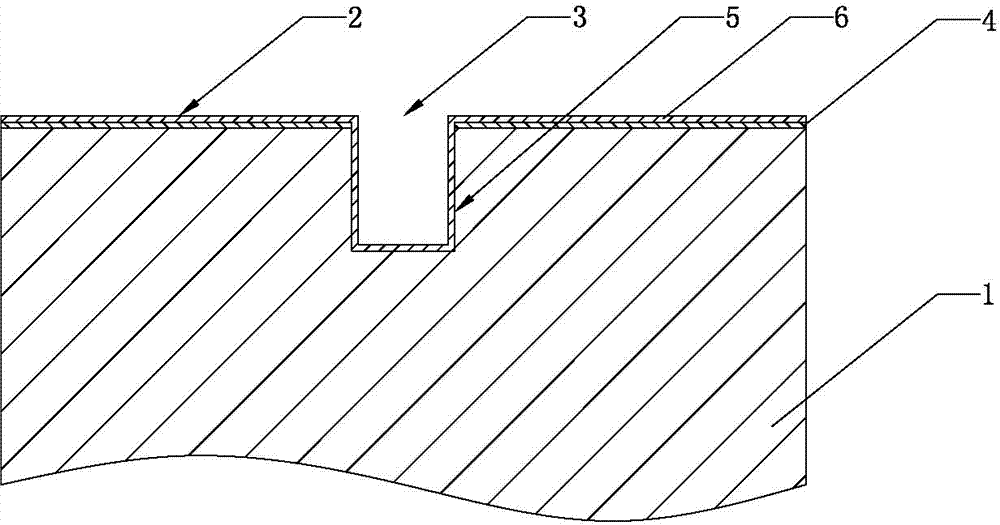

[0060] A manufacturing process for a plate roller for laser paper printing, comprising the following steps:

[0061] A. Copper plating: put the roller body 1 into an electroplating bath equipped with a copper plating solution for electroplating, the current density is 16ASF, the electroplating temperature is 30°C, the electroplating time is 30min, the Vickers hardness is 180, and the copper layer is plated The thickness is 10um; in the step A, the copper plating solution is composed of the following raw materials: copper sulfate 5g / L, disodium edetate 10g / L, potassium sodium tartrate 5g / L, formaldehyde 2g / L, sodium hydroxide 10g / L, methanol 0.001g / L and sodium silicate 0.1g / L; the pH value of the copper plating solution is 12; the anode material for electroplating is a copper plate with a phosphorus content of 2‰;

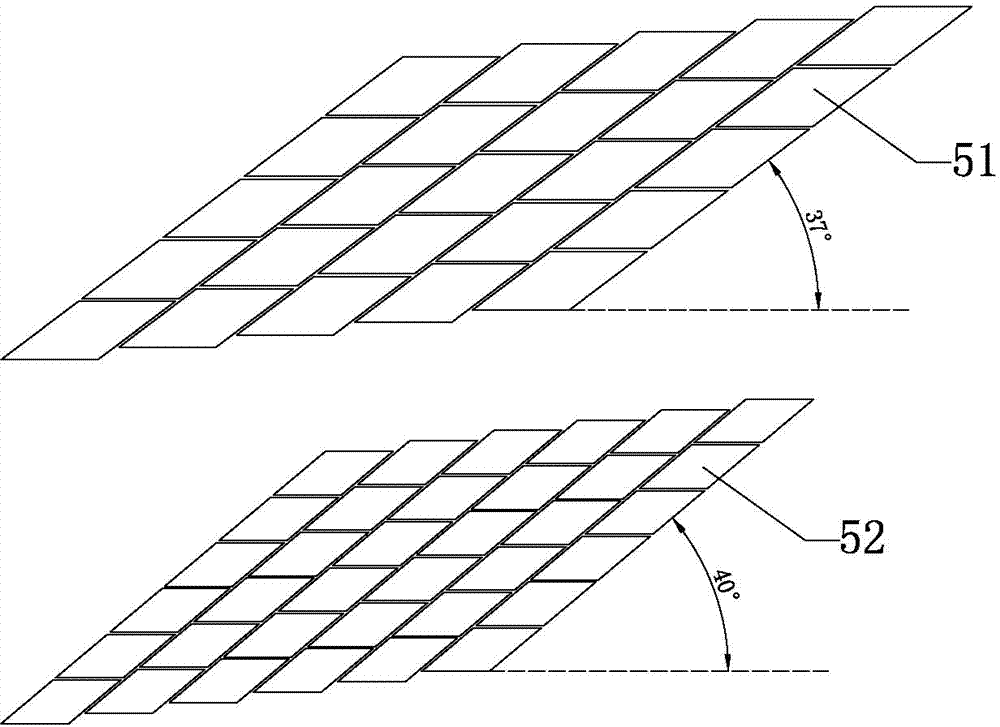

[0062] B. Glue wrapping: hang the copper-plated roller body 1, and set a circular film on the outside of the roller body 1. The circular film is connected with a b...

Embodiment 2

[0074] A manufacturing process for a plate roller for laser paper printing, comprising the following steps:

[0075] A. Copper plating: Put the roller body 1 into an electroplating tank equipped with a copper plating solution for electroplating. The current density is 17ASF, the electroplating temperature is 40°C, the electroplating time is 45min, and the Vickers hardness is 195. The copper layer is plated. The thickness is 12um; in the step A, the copper plating solution is composed of the following raw materials: copper sulfate 12g / L, disodium edetate 20g / L, potassium sodium tartrate 12g / L, formaldehyde 3.5g / L, hydroxide Sodium 12.5g / L, methanol 0.05g / L and sodium silicate 1g / L; the pH value of the copper plating solution is 12.5; the anode material for electroplating is a copper plate with a phosphorus content of 3‰;

[0076] B. Glue coating: hang the copper-plated roller body 1, and set a circular film on the outside of the roller body 1. The circular film is connected wit...

Embodiment 3

[0088] A manufacturing process for a plate roller for laser paper printing, comprising the following steps:

[0089] A. Copper plating: put the roller body 1 into an electroplating tank equipped with a copper plating solution for electroplating, the current density is 18ASF, the electroplating temperature is 50°C, the electroplating time is 60min, the Vickers hardness is 210, and the copper layer is plated The thickness is 14um; in the step A, the copper plating solution is composed of the following raw materials: copper sulfate 20g / L, disodium edetate 30g / L, potassium sodium tartrate 20g / L, formaldehyde 5g / L, sodium hydroxide 15g / L, methanol 0.1g / L and sodium silicate 2g / L; the pH value of the copper plating solution is 13; the anode material for electroplating is a copper plate with a phosphorus content of 5‰;

[0090] B. Gluing: hang the copper-plated roller body 1, and set a circular film on the outside of the roller body 1. The circular film is connected with a box contai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com