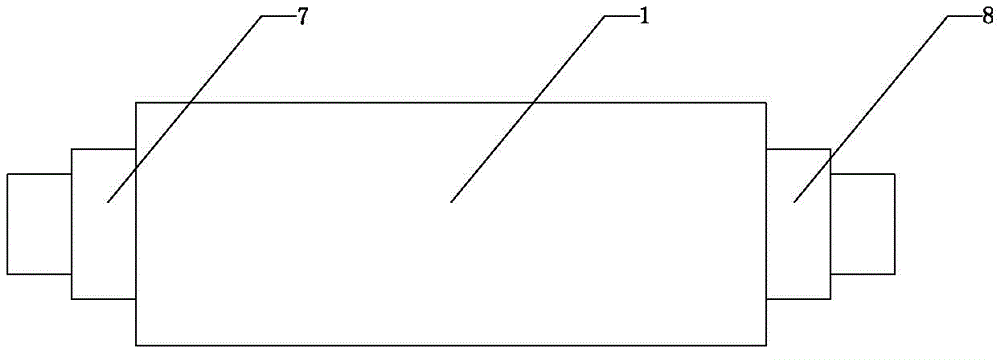

Printing roller for laser paper printing and manufacture process thereof

A production process and technology of plate rollers, applied in printing process, preparation of printing surface, printing, etc., can solve problems such as high cost, unsightly layered plate, and difficult ink on the surface, and achieve the effect of solving waste and controlling product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

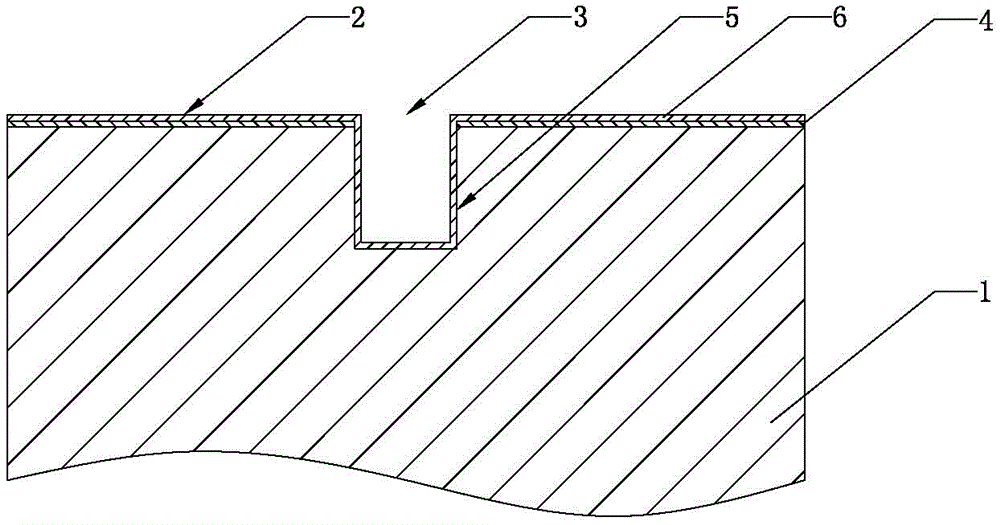

[0060] B. Glue wrapping: hang the copper-plated roller body 1, and set a circular film on the outside of the roller body 1. The circular film is connected with a box containing glue. Driven by the power of the motor at 10Hz, the circular film The film moves vertically downward along the roller body 1 at a constant speed, and evenly coats a layer of 0.05mm glue solution on the outside of the roller body 1, and dries naturally for 30 minutes after the coating is completed;

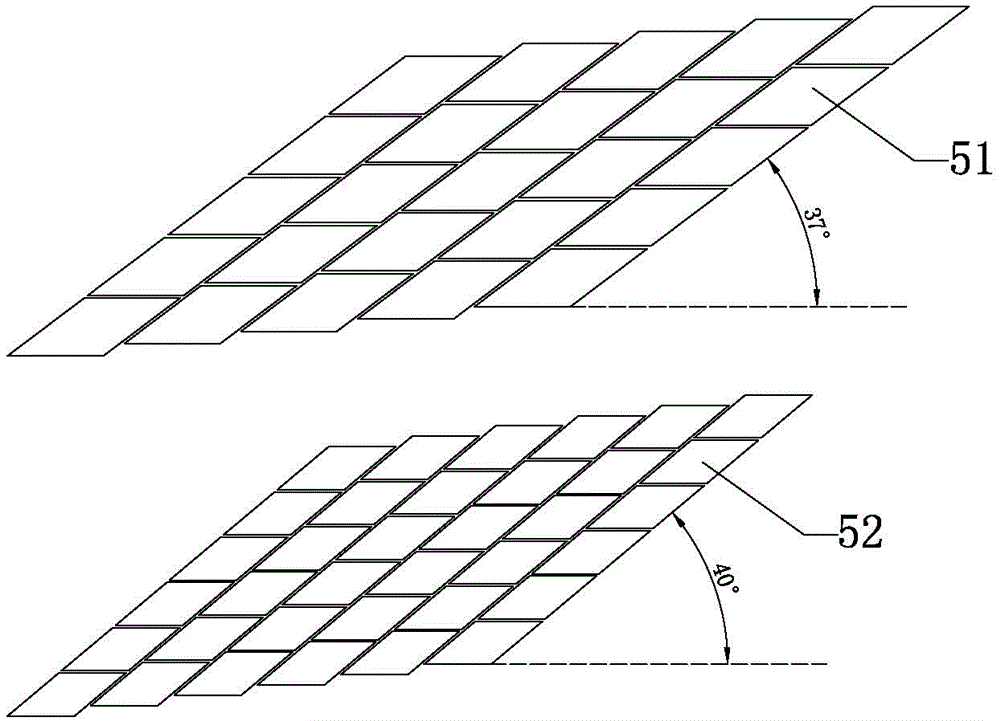

[0061] C. Laser engraving: put the roller body 1 after the rubber coating has dried into the laser engraving machine, set the number of engraving screen lines and engraving screen angle, and carry out laser engraving according to the designed pattern. The depth of laser engraving is 60mm; In step C, the design of pattern comprises the following steps:

[0062] (1) Scanning: Select the wood grain, use a high-definition lens with a focal length of 120mm, and an input resolution of 1800dpi to scan the wood grai...

Embodiment 2

[0074] B. Glue coating: hang the copper-plated roller body 1, and set a circular film on the outside of the roller body 1. The circular film is connected with a box containing glue. Driven by the power of the motor at 15Hz, the circular film The film moves vertically downward along the roller body 1 at a constant speed, and evenly coats a layer of 0.15mm glue solution on the outside of the roller body 1, and dries naturally for 35 minutes after the coating is completed;

[0075] C. Laser engraving: Put the dried roll body 1 into the laser engraving machine, set the number of engraving mesh lines and the engraving mesh angle, and carry out laser engraving according to the designed pattern. The depth of laser engraving is 120mm; In step C, the design of pattern comprises the following steps:

[0076] (1) Scanning: Select the wood grain, use a high-definition lens with a focal length of 120mm, and an input resolution of 1900dpi to scan the wood grain, and the distance between the...

Embodiment 3

[0088] B. Gluing: hang the copper-plated roller body 1, and set a circular film on the outside of the roller body 1. The circular film is connected with a box containing glue. Driven by the power of the motor at 20Hz, the circular film The film moves vertically downward along the roller body 1 at a constant speed, and evenly coats a layer of 0.25mm glue solution on the outside of the roller body 1, and dries naturally for 40 minutes after the coating is completed;

[0089] C. Laser engraving: Put the rubber-covered roller body 1 into the laser engraving machine, set the number of engraving mesh lines and engraving mesh angle, and carry out laser engraving according to the designed pattern. The depth of laser engraving is 150mm; In step C, the design of pattern comprises the following steps:

[0090] (1) Scanning: Select the wood grain, use a high-definition lens with a focal length of 120mm, and an input resolution of 2000dpi to scan the wood grain, and the distance between th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com