Method for preparing high-strength polyvinyl alcohol hydrogel

A polyvinyl alcohol and hydrogel technology, applied in the field of polymer material preparation, can solve problems such as low mechanical strength, and achieve the effects of ultra-high strength and toughness, good biocompatibility and biodegradability, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] A preparation method of high-strength polyvinyl alcohol hydrogel, using polyvinyl alcohol as a starting material, dissolving in a high-temperature water bath to obtain a certain concentration of polyvinyl alcohol aqueous solution, introducing the polyvinyl alcohol aqueous solution into a mold, The polyvinyl alcohol hydrogel is obtained by subfreezing and thawing, and the polyvinyl alcohol hydrogel is soaked in a saturated saline solution to obtain a high-strength polyvinyl alcohol hydrogel.

[0021] Described preparation method specifically comprises the following steps:

[0022] 1) Add polyvinyl alcohol to deionized water and heat to dissolve to obtain a polyvinyl alcohol aqueous solution with a concentration of 5 wt% to 20 wt%;

[0023] 2) After introducing the polyvinyl alcohol aqueous solution obtained in step 1) into the mold, freeze at -40~-5 °C, and then thaw at a temperature of 20~60 °C, repeat the freezing and thawing process 2~5 times to obtain polyvinyl alcoh...

Embodiment 1

[0027] A preparation method for high-strength polyvinyl alcohol hydrogel, specifically comprising the steps of:

[0028] Take 5 parts of polyvinyl alcohol, add 95 parts of deionized water, heat and dissolve under stirring in a water bath to obtain a 5 wt% polyvinyl alcohol aqueous solution, introduce the polyvinyl alcohol aqueous solution into a molding mold, and freeze at -40 °C for 6 h, then thaw at room temperature 30 °C, and repeat the freezing and thawing process 5 times to obtain polyvinyl alcohol hydrogel, soak the polyvinyl alcohol hydrogel in saturated sodium chloride aqueous solution for 60 min, and obtain high-strength polyethylene alcohol hydrogel.

[0029] The water content of the gel was calculated using the following formula:

[0030] WC=(W s -W d ) / W s

[0031] W s — mass of swollen gel; W d —The weight of the gel after drying at 105 °C for 24 h.

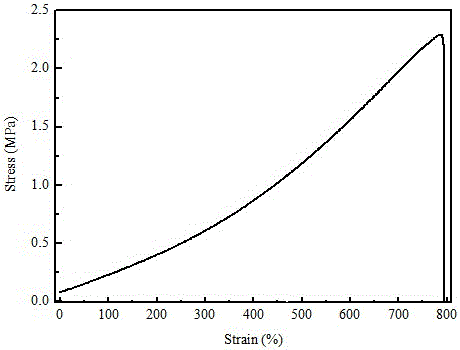

[0032] The test of the tensile properties of the gel is as follows: the tensile test is carried out on a u...

Embodiment 2

[0035] A preparation method for high-strength polyvinyl alcohol hydrogel, specifically comprising the steps of:

[0036] Take 10 parts of polyvinyl alcohol, add 90 parts of deionized water, heat and dissolve under stirring in a water bath to obtain a 10 wt% polyvinyl alcohol aqueous solution, introduce the polyvinyl alcohol aqueous solution into a molding mold, and freeze at -20 °C for 10 h, then thaw at room temperature 30 °C, and repeat the freezing and thawing process 4 times to obtain polyvinyl alcohol hydrogel, soak the polyvinyl alcohol hydrogel in saturated potassium chloride aqueous solution for 20 min, and obtain high-strength polyethylene alcohol hydrogel.

[0037] According to the test method in Example 1, the obtained results are: tensile strength 1.62 MPa, elongation at break 652%, gel water content 88%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com