Method for manufacturing embedded high-conductivity printed circuit board (PCB)

A technology of PCB board and manufacturing method, applied in multilayer circuit manufacturing, printed circuit manufacturing, electrical components and other directions, can solve the problems of PCB high frequency signal influence, complex welding process, large electrical signal transmission loss, etc. The effect of power miniaturization PCB design, simple production process and stable heat dissipation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

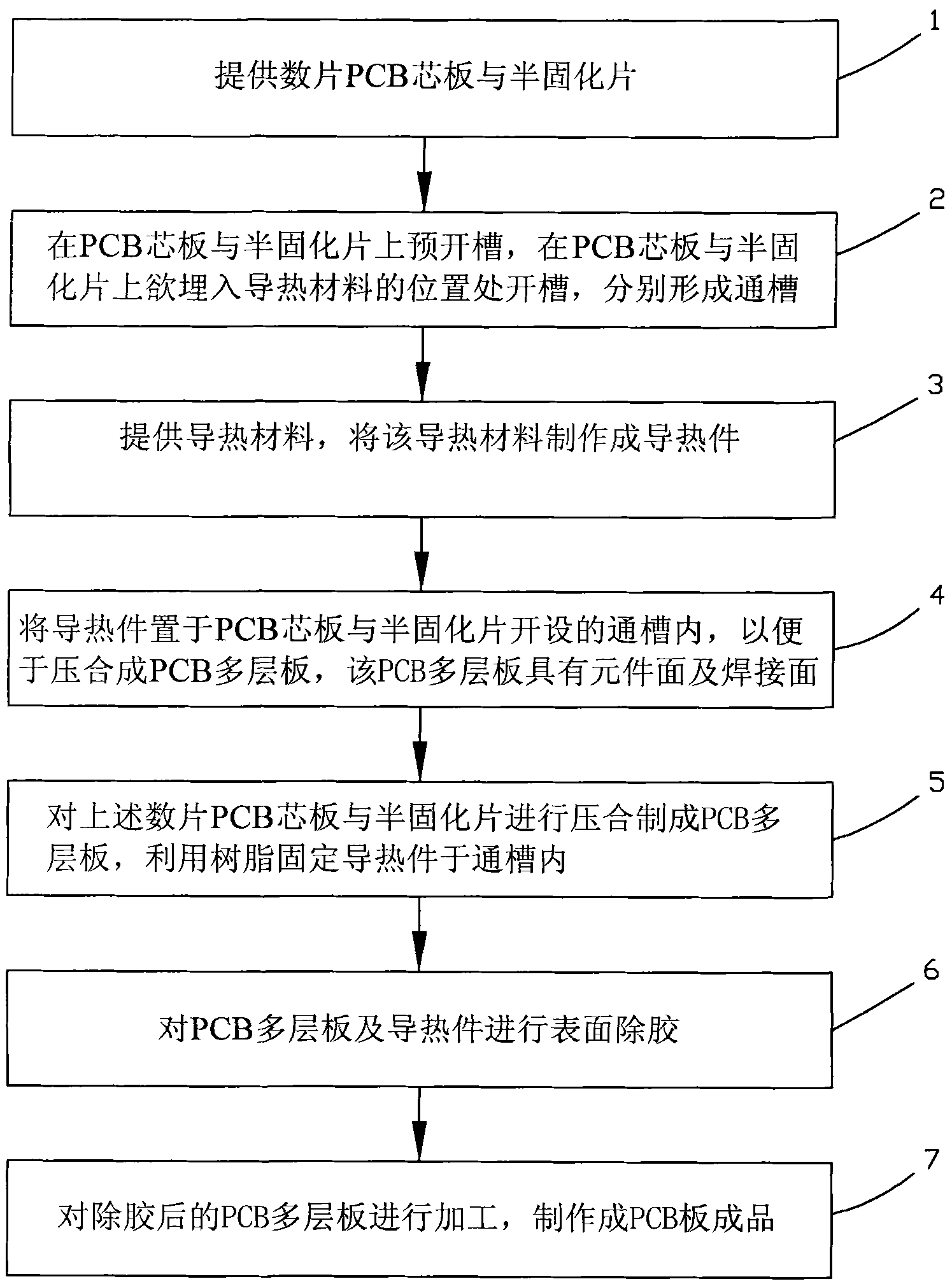

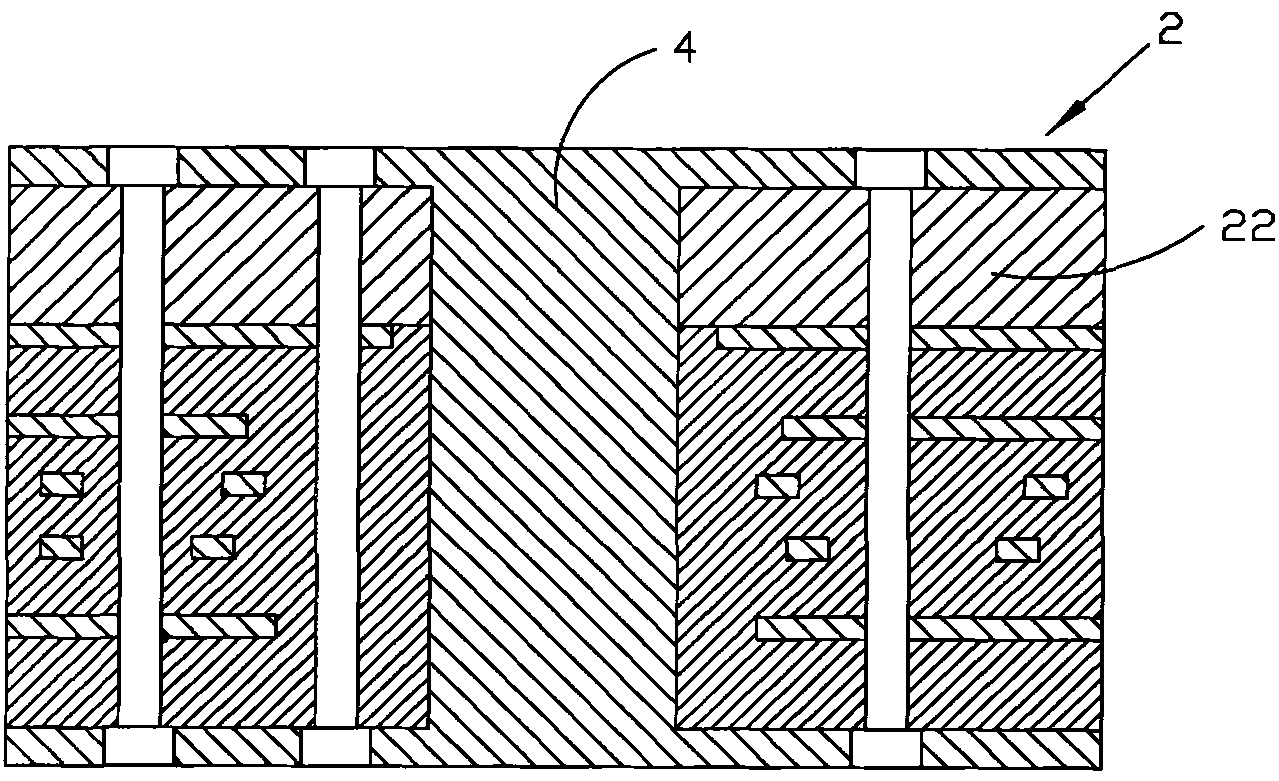

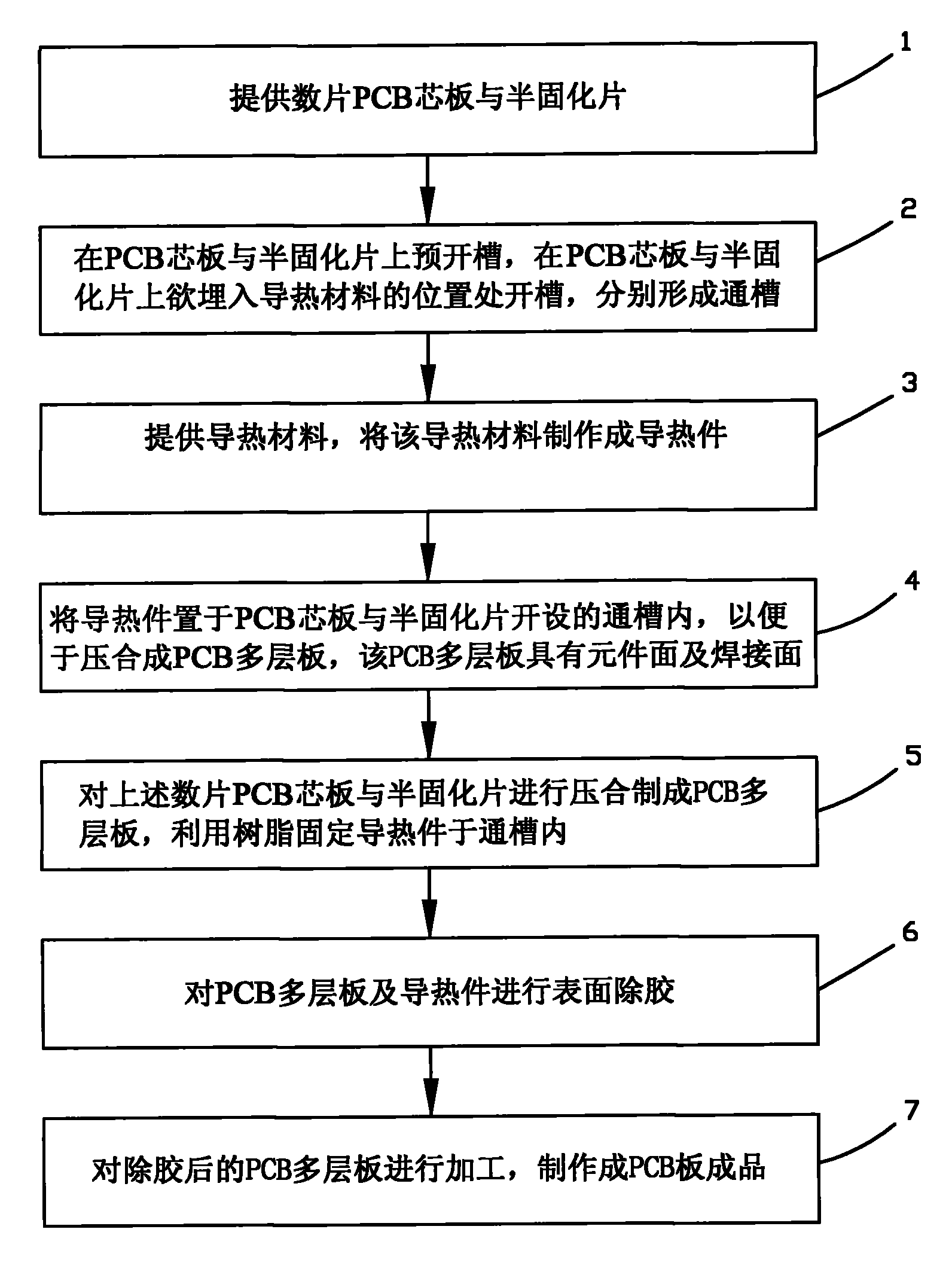

[0025] Such as Figure 1-2 Shown, the manufacture method of embedded type high thermal conductivity PCB board of the present invention, it comprises:

[0026] Step 1. Provide several PCB core boards and prepregs. The PCB core board and prepreg can be provided by existing technology, wherein one or more layers of materials are made of low dielectric constant (LOW Dk) materials, for example, the commercially available models are Ro4350, Ro3003, or RF35-A2, etc. Material.

[0027] Step 2. Pre-slot on the PCB core board and the prepreg. Slots are made on the PCB core board and the prepreg where the heat-conducting material is to be embedded to form through grooves respectively, and the core board and the prepreg have matching positioning holes.

[0028] Step 3, providing a thermally conductive material, and making the thermally conductive material into a thermally conductive member 4 . In the embodiment of the present invention, the heat conducting element is a rectangular par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com