Supercapacitor electrode material preparation method based on three-dimensional graphene

A technology for supercapacitors and electrode materials, applied in the field of energy storage materials, can solve problems such as expensive CVD equipment and maintenance costs, limit large-scale industrial production, and increase the cost of electrode material production. The method is simple and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] After the nickel foam with the surface oxide removed was cut into 1cm×2.5cm, it was pre-wetted with absolute ethanol and deionized water, and then soaked in the graphene oxide dispersion with a concentration of 2mg / ml or 4mg / ml, and ultrasonically Let dry after 15 minutes. After drying, soak it into the graphene oxide dispersion and let it stand for 15 minutes, then let it dry. The quality of the graphene oxide deposited on the nickel foam is controlled by controlling the times of immersion, and the times of immersion can be 1 time, 2 times, 3 times, 4 times, 5 times, 6 times. Soak the dried graphene oxide electrode into a beaker filled with 20ml of ascorbic acid aqueous solution (concentration: 10mg / ml), seal it with plastic wrap, and then put the beaker in a water bath at a temperature of 60 degrees. After maintaining this temperature for 5 hours, the samples were rinsed and dried to remove moisture.

[0033] The prepared three-dimensional graphene / nickel foam compo...

Embodiment 2

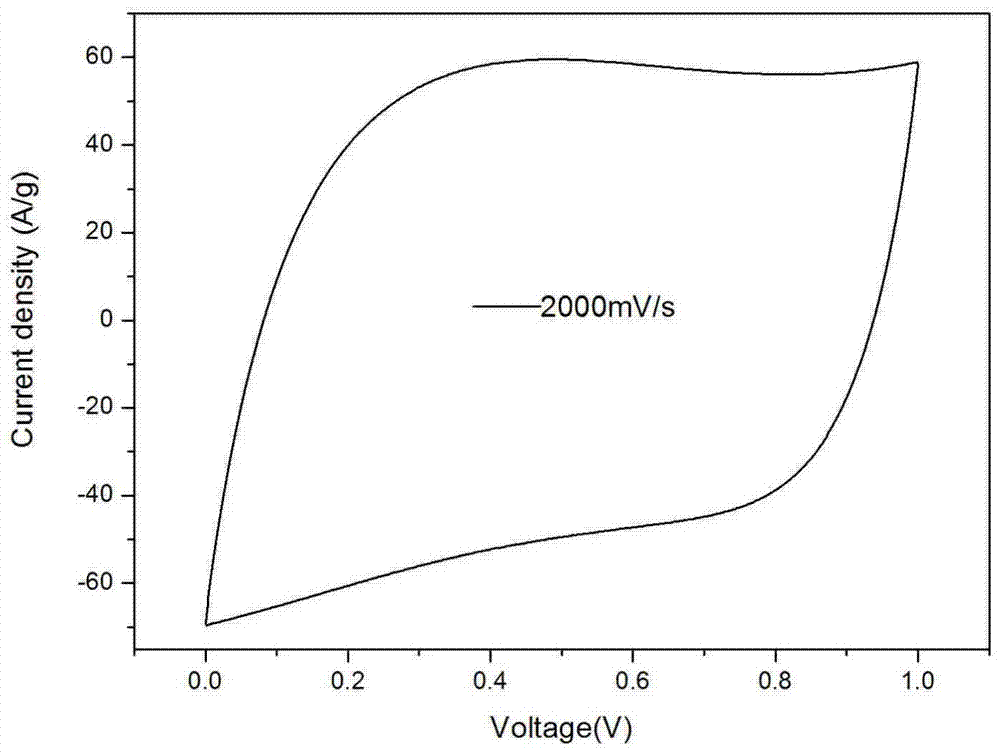

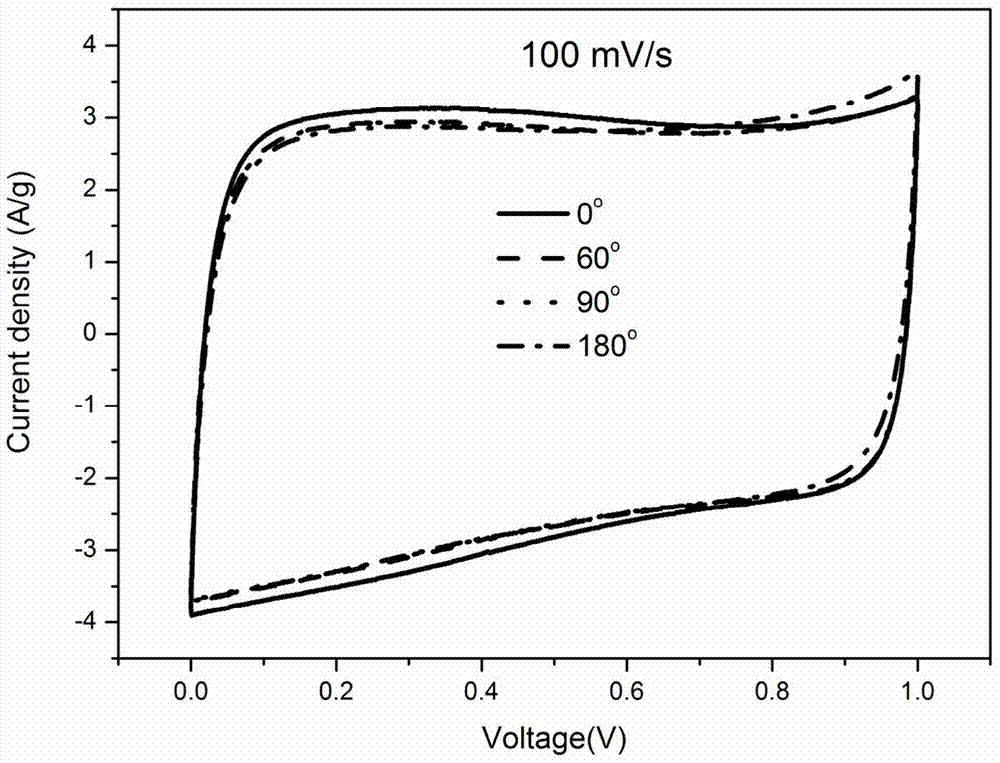

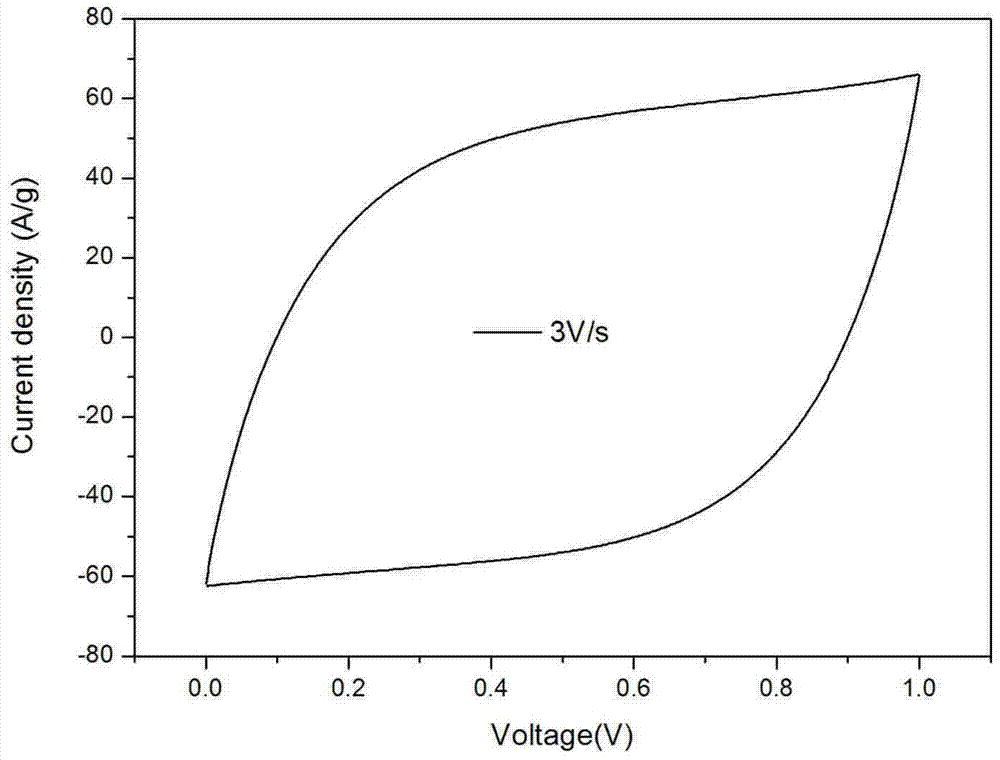

[0036] Put the three-dimensional graphene / nickel foam composite electrode prepared in Example 1 into a beaker of hydrochloric acid solution with a molar concentration of 3mol / L, then put the beaker into a water bath with a temperature of 80°C, and keep the temperature for 25 minutes , the surface density of the graphene / nickel foam composite electrode is changed from the original 30.6mg / cm 2 Reduced to 22.8mg / cm 2 . The prepared three-dimensional graphene / nickel foam composite electrode was composed of a symmetrical two-electrode system, and a cyclic voltammetry test and a constant current charge-discharge test were performed in a 5M KOH electrolyte. The cyclic voltammetry curve is close to a rectangle at a higher scan rate, showing an ideal electric double layer capacitance behavior; the mass specific capacitance is as high as 131F / g when the charge and discharge current density is 1mA / cm2.

Embodiment 3

[0038] Put the three-dimensional graphene / nickel foam composite electrode prepared in Example 1 into a beaker of hydrochloric acid solution with a molar concentration of 3mol / L, then put the beaker into a water bath with a temperature of 80°C, and keep the temperature for 50 minutes , the surface density of the graphene / nickel foam composite electrode is changed from the original 30.6mg / cm 2 Reduced to 13.1mg / cm 2 . The prepared three-dimensional graphene / nickel foam composite electrode is composed of a symmetrical capacitor device, and a cyclic voltammetry test and a constant current charge and discharge test are performed in a 5M KOH electrolyte. At a higher scan rate, the cyclic voltammetry curve is close to a rectangle, showing an ideal electric double layer capacitance behavior; when the charge and discharge current density is 1mA / cm 2 When the mass specific capacitance is as high as 124F / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com