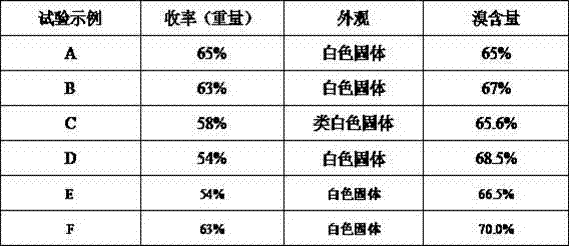

Patents

Literature

369 results about "Isobutyl alcohol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Isobutanol is an aliphatic alcohol. Isobutanol is a colorless, flammable, organic compound with a characteristic smell. Isobutanol is widely used in industry, as a solvent in chemical reactions, as well as being a useful starting material for organic synthesis.

Integrated Process to Selectively Convert Renewable Isobutanol to P-Xylene

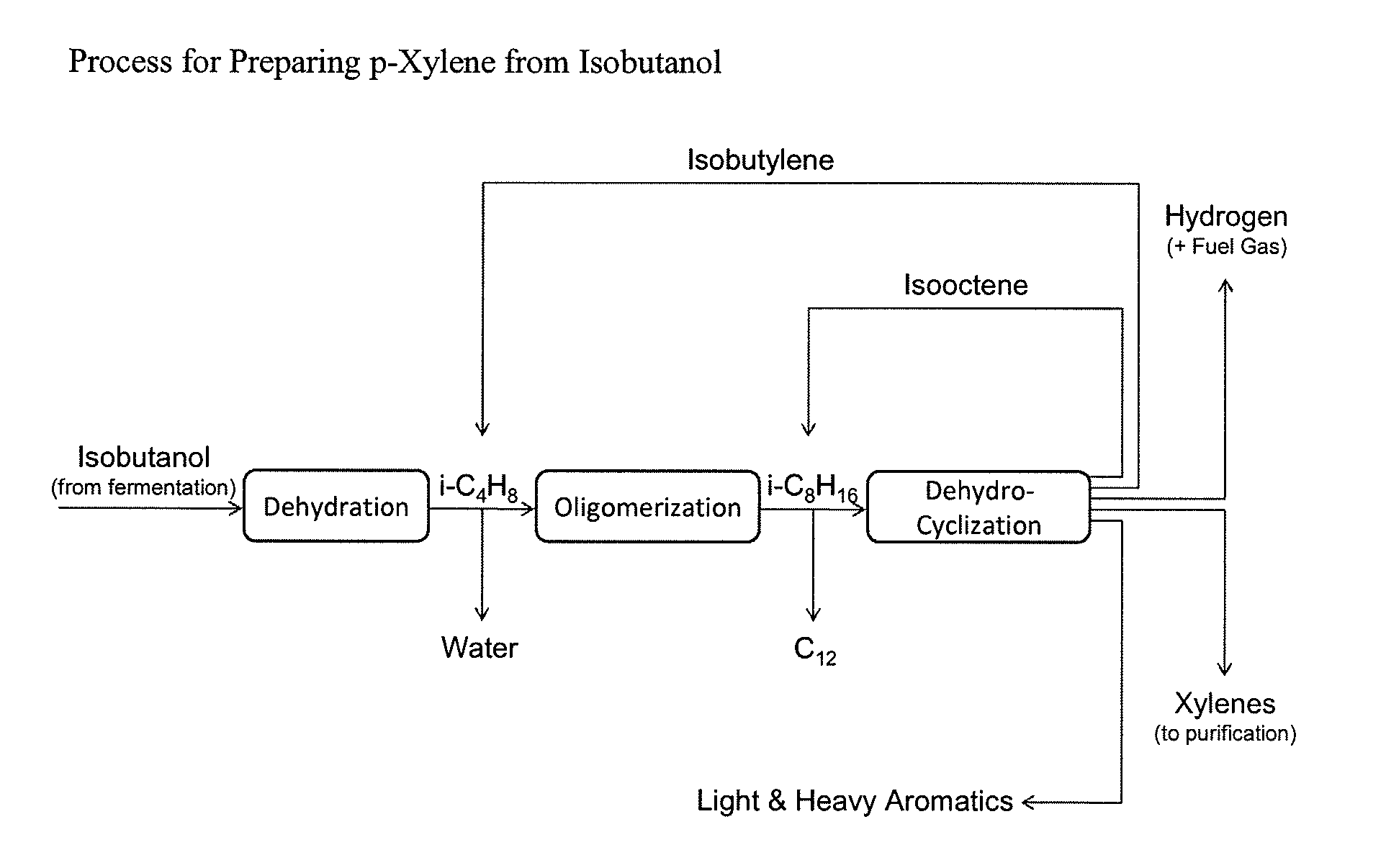

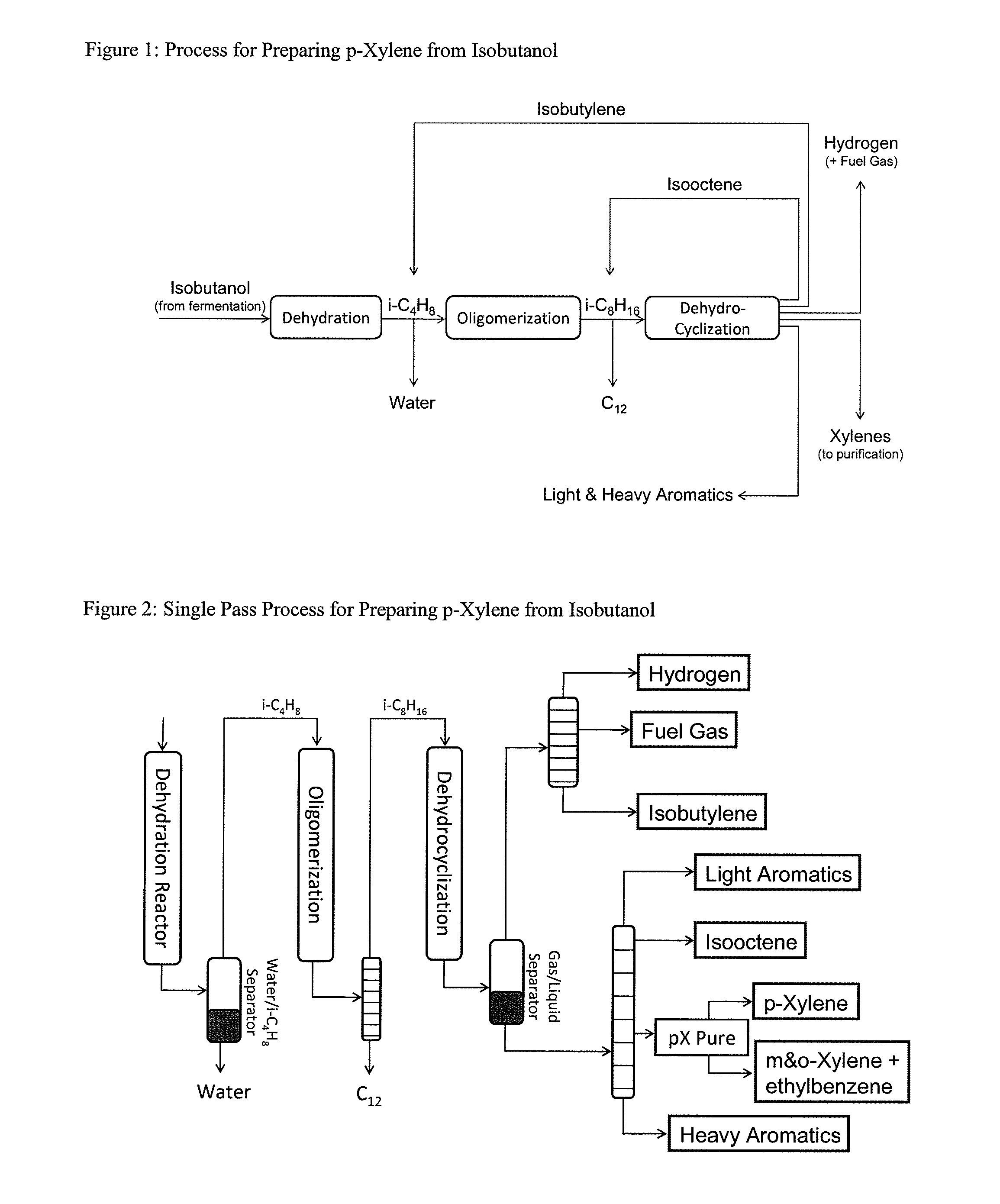

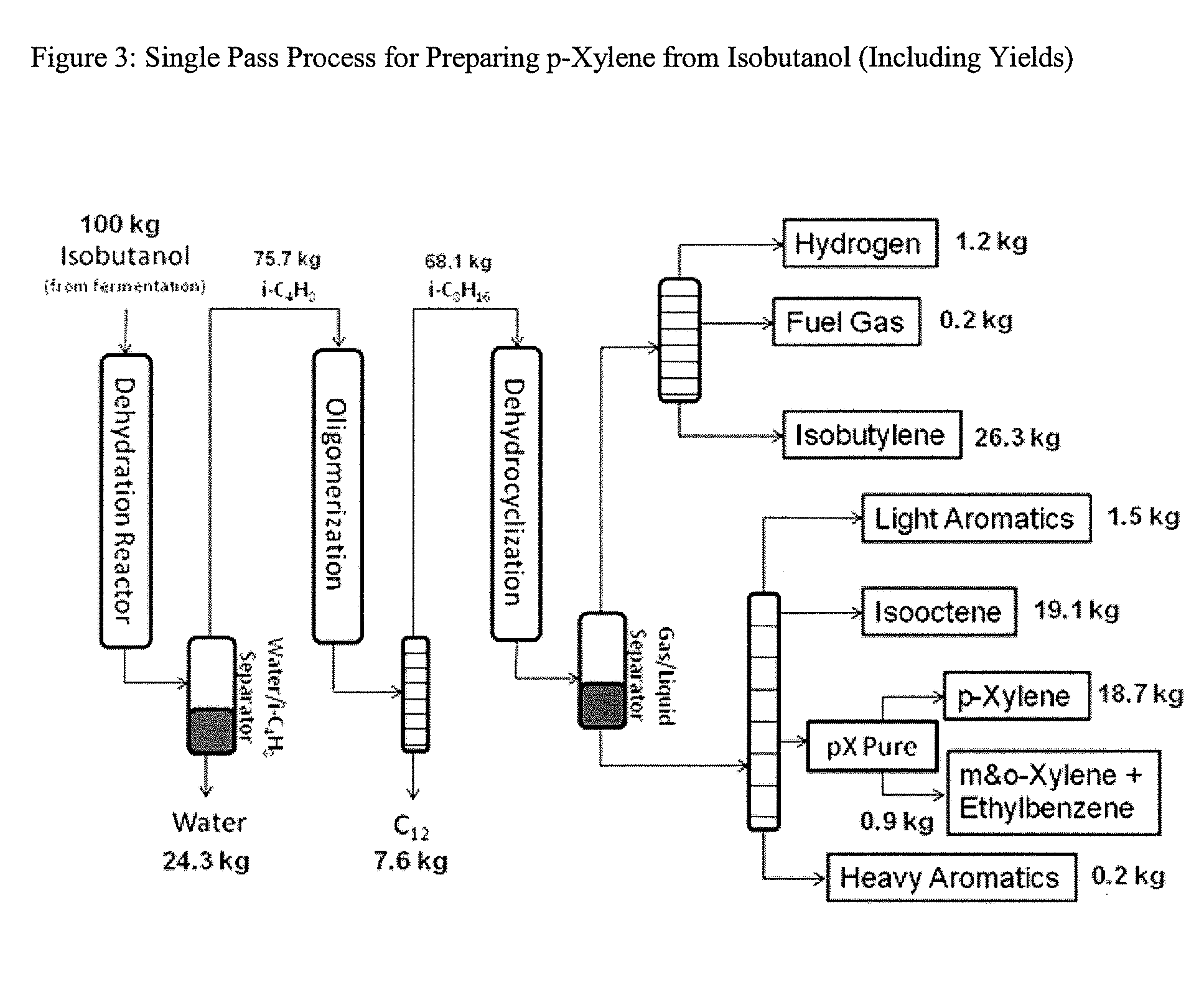

The present invention is directed to a method for preparing renewable and relatively high purity p-xylene from biomass. For example, biomass treated to provide a fermentation feedstock is fermented with a microorganism capable of producing a C4 alcohol such as isobutanol, then sequentially dehydrating the isobutanol in the presence of a dehydration catalyst to provide a C4 alkene such as isobutylene, dimerizing the C4 alkene to a form one or more C8 alkenes such as 2,4,4-trimethylpentenes or 2,5-dimethylhexene, then dehydrocyclizing the C8 alkenes in the presence of a dehydrocyclization catalyst to selectively form renewable p-xylene in high overall yield. The p-xylene can then be oxidized to form terephthalic acid or terephthalate esters.

Owner:GEVO INC

Fermentive production of four carbon alcohols

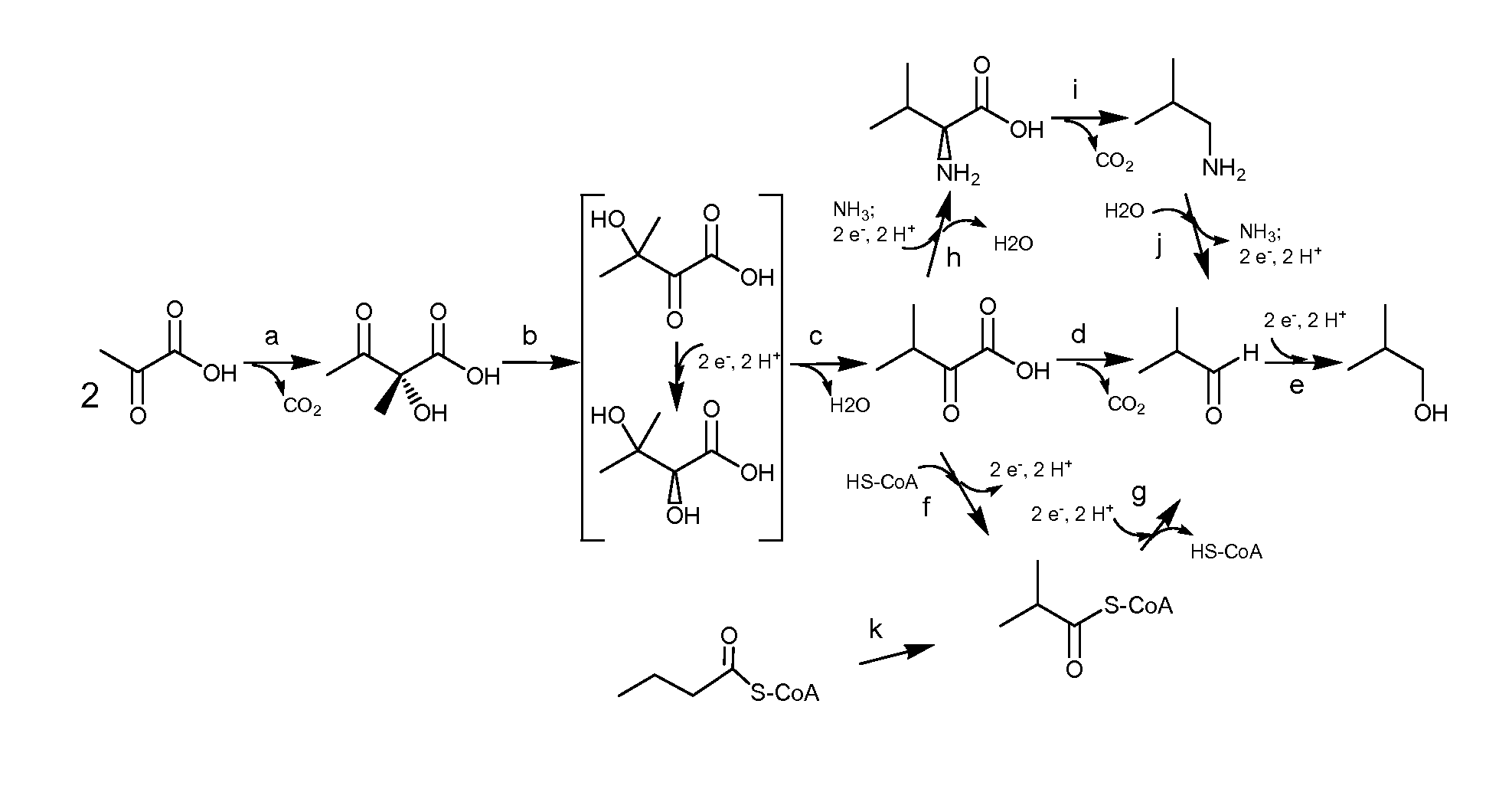

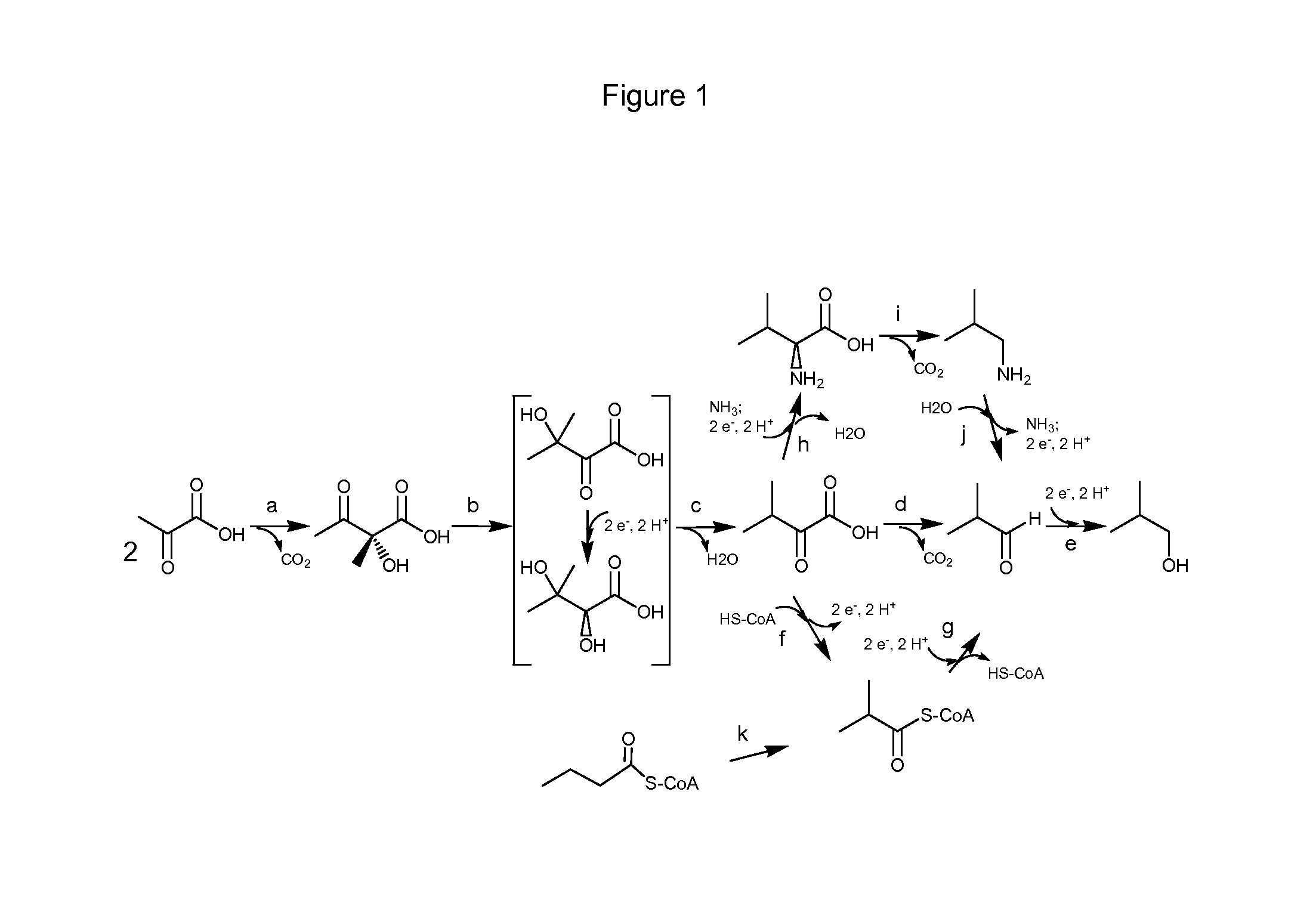

Methods for the fermentative production of four carbon alcohols is provided. Specifically, butanol, preferably isobutanol is produced by the fermentative growth of a recombinant bacterium expressing an isobutanol biosynthetic pathway.

Owner:GEVO INC

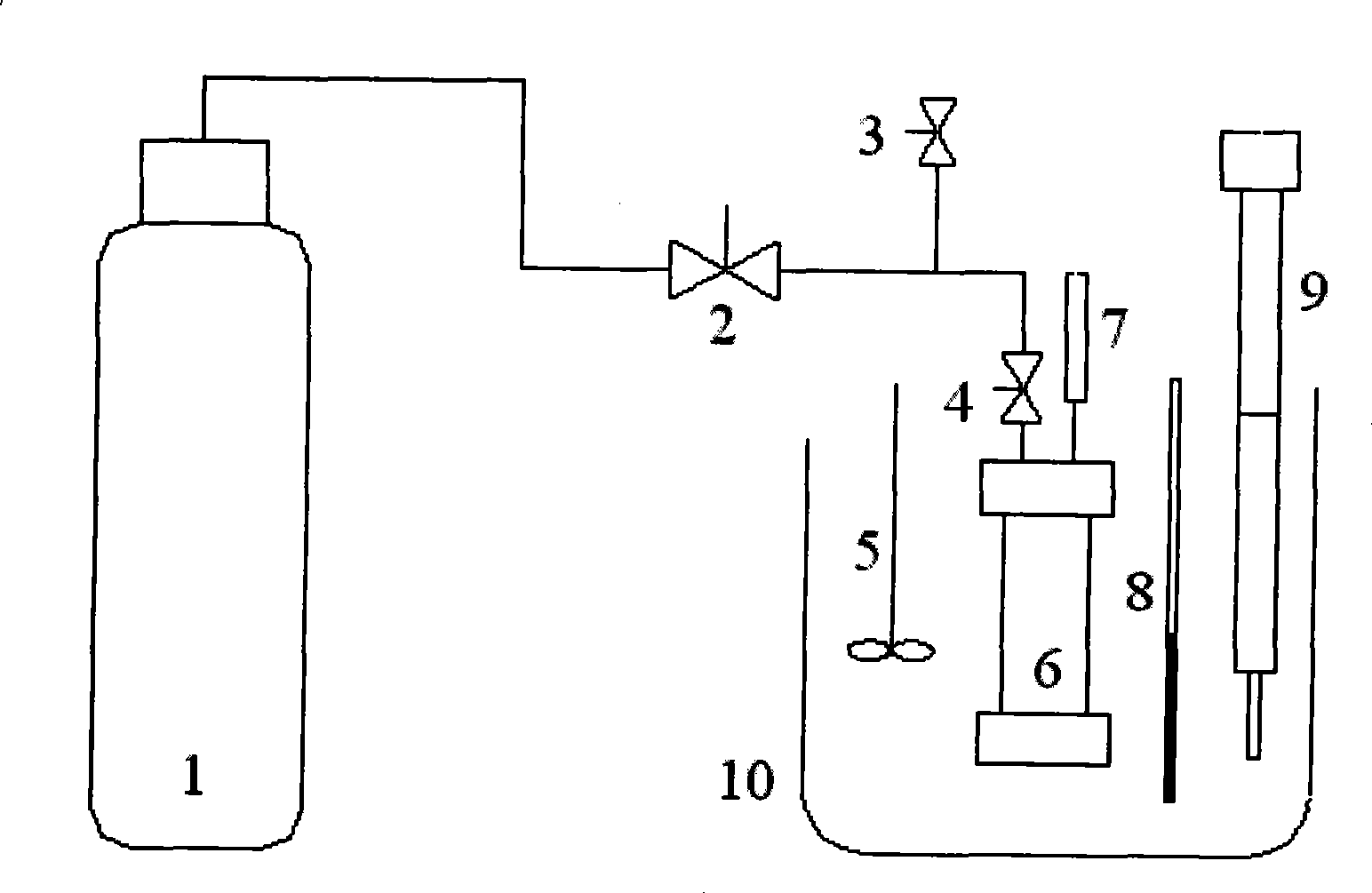

Method for processing cellulose by supercritical carbon dioxide, products and use thereof

The invention relates to a method for utilizing supercritical carbon dioxide to process cellulose; firstly, the cellulose and a cosolvent or an inorganic sol or a former body of the inorganic sol are arranged in a high pressure container; carbon dioxide is pumped by a pumping pressure; the reaction condition is 15 to 200 DEG C; the pressure is 4 to 40MPa; the reaction time is 0.5 to 24 hours; then the activated cellulose is manufactured; the cosolvent relates to carbinol, ethanol, normal butanol, isobutyl alcohol, acetone, tetrahydrofuran, formaldehyde, n-butyl aldehyde and isobutyraldehyde; the cellulose is a natural cellulose and a ramification thereof; the natural cellulose relates to chopped cotton fibers, cotton fabrics, bagasse, straws, paper products, bamboo, flax and wood. The method for utilizing the supercritical carbon dioxide to process the cellulose has the advantages that: the processing method is simply and easily operated; the supercritical carbon dioxide is adopted, thus having no burning, no pollution and no toxic action and being conveniently recycled and being repeatedly used; the content of the mixed inorganic oxide in a compound fiber material is high; the product is easily separated and purified; the characteristic is uniform and stable; the method for utilizing the supercritical carbon dioxide to process the cellulose has broad application prospects in the fields of catalyzing, chemical engineering, packaging, weaving, etc.

Owner:FUDAN UNIV

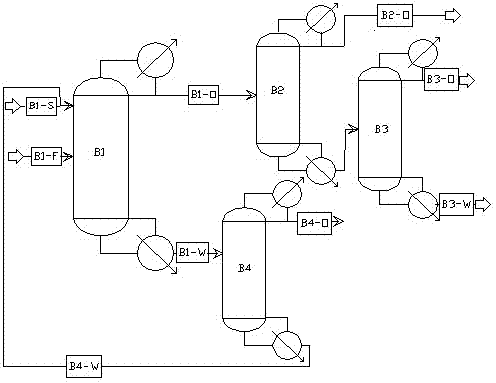

Method for continuously extracting, rectifying and separating mixed alcohols from water

InactiveCN103193590ABroaden your optionsEasy to industrializeOrganic compound preparationHydroxy compound preparationN-Propyl alcoholIsobutyl alcohol

The invention discloses a method for continuously extracting, rectifying and separating mixed alcohols from water, relates to a chemical separating method, and in particular to a method for continuously extracting, rectifying and separating mixed alcohols such as aqueous mixtures of ethanol, n-propyl alcohol, isobutyl alcohol and the like. According to the method, extractive distillation and common rectifying are combined together, and a multi-column combined step-by-step separating method is adopted to separate mixed alcohols from water step by step and recycle components with high purity. The method comprises steps of: with ethylene glycol as an extraction agent, separating the mixed alcohols from water in an extractive rectifying column B1, wherein the column B1 adopts normal pressure rectification, the reflux ratio is 1:1-10:1, the mixed alcohols can be get from the column top, and a mixture of a solvent and water can be get from the column bottom; recovering most of the solvent from a solvent recovering column B4 and recycling the solvent; and effectively separating the mixed alcohols through columns B2 and B3. According to the method, extractive distillation and common rectifying are combined together, the extraction agent is used to avoid the azeotrope of alcohols and water, and continuous separation of multiple columns are adopted to recover the components with high purity step by step, so that the method has high economic and environmental benefits.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

Novel method for extracting anthocyanin in bilberry by double water phases

InactiveCN101531652ASmall volumeIncrease concentrationOrganic chemistryDigestive systemDipotassium hydrogen phosphateMonopotassium phosphate

The invention relates to a novel method for extracting anthocyanin in bilberry by double water phases, and belongs to the technical field of biological engineering. The method is characterized by comprising the following steps: adding inorganic salt solution and hydrophilic low-molecular organic substance into bilberry fruit residue, stirring the mixture evenly, keeping the mixture standing, layering the mixture, extracting the anthocyanin to an upper phase, and distributing the residue at the lower phase or between the two phases so as to achieve the aim of extracting the anthocyanin from the bilberry fruit residue. The inorganic salt is one or a combination of sodium chloride, ammonium sulphate, sodium sulfate, sodium carbonate, potassium carbonate, potassium phosphate, monopotassium phosphate and dipotassium hydrogen phosphate, preferably ammonium sulphate; and the hydrophilic low-molecular organic substance is one or a combination of methanol, ethanol, normal propyl alcohol, isopropyl alcohol, normal butanol, isobutyl alcohol, glycol and acetone, preferably ethanol. The method has the advantages that a novel method for extracting the anthocyanin is developed, the method is easy to industrialize, the utilization ratio of the bilberry is improved, and the production cost of the anthocyanin is lowered.

Owner:DALIAN UNIV OF TECH

Alcohol-base liquid fuel

This invention discloses an alcoholic group liquid fuel, its goal is to provides an alcoholic group liquid fuel of high heat value, stable flame, low cost, convenient using, and propitious to environment protection. The fuel is consisted by following components of weight portions, methanol 50~100, ethanol 10~20, acetone 8~2, isobutyl alcohol 5~10, hydrogen peroxide 0.5~5, potassium permanganate 0.3~1.5, camphor 1~3, water 5~15, stabilizer 10. The stabilizer is consisted by bean oil 3~8, glycerol 0.5~3, tung oil 1.5~4 of weight protions. The fuel in this invention can replace other fuels for special cooking machine as cooking fuel. Its stability is high, burning is full, heat value is high, and no pollution to air. There is no residue, no fume and dust, no favor, no carbon deposition, and environment is not polluted, human body is not harmed. The fuel is almost no volatilization, and can dissolve in water, it can be damped down when it is firing, so it is safety and reliable.

Owner:谷宝龙 +1

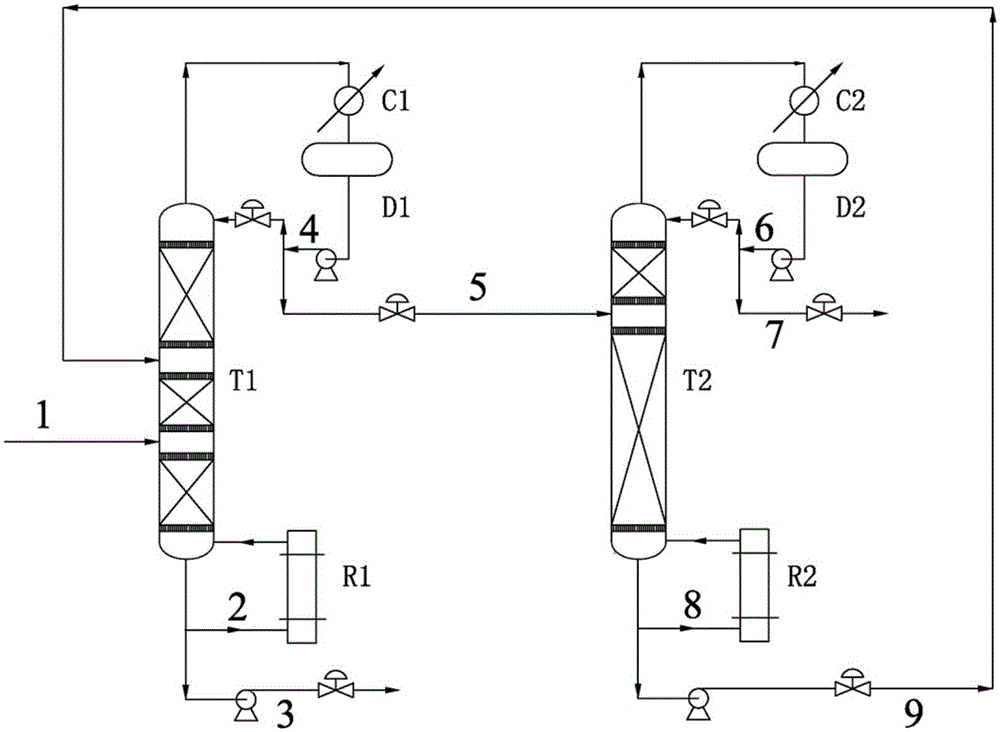

Method for separating isobutyl alcohol and normal heptanes azeotropic system by using pressure swing distillation

ActiveCN105001056AHigh purityLow investment costOrganic compound preparationChemical industryIsobutyl alcoholReboiler

The invention relates to a method for separating an isobutyl alcohol and normal heptanes azeotropic system by using pressure swing distillation and a device applicable to the method. The device mainly comprises an atmospheric tower T1, a pressurized tower T2, a condenser C1, a condenser C2, a reflux drum D1, a reflux drum D2, a reboiler R1 and a reboiler R2, wherein the reboiler R1 and the reboiler R2 are respectively connected at the bottoms of the atmospheric tower T1 and the pressurized tower T2, the condenser C1 and the reflux drum D1 are sequentially connected at the top of the atmospheric tower T1, the condenser C2 and the reflux drum D2 are sequentially connected at the top of the pressurized tower T2. The separation steps are as follows: a fresh material first enters into the atmospheric tower T1, an isobutyl alcohol product is extracted at the bottom of the tower, after being condensed through the condenser C1, and collected through the reflux drum D1, part of overhead vapor is back flowed, part of the extract enters into the pressurized tower T2 for a secondary rectification, a normal heptanes product is extracted at the top of the pressurized tower T2, and the material flow at the bottom of the tower cycles to the atmospheric tower T1. The method provided by the invention solves the difficult separation problem that the azeotropic behaviors of the system respectively show up a lowest feature and a highest feature along with the raising pressure, and has the advantages of low energy consumption and high product recovery rate.

Owner:QINGDAO UNIV OF SCI & TECH

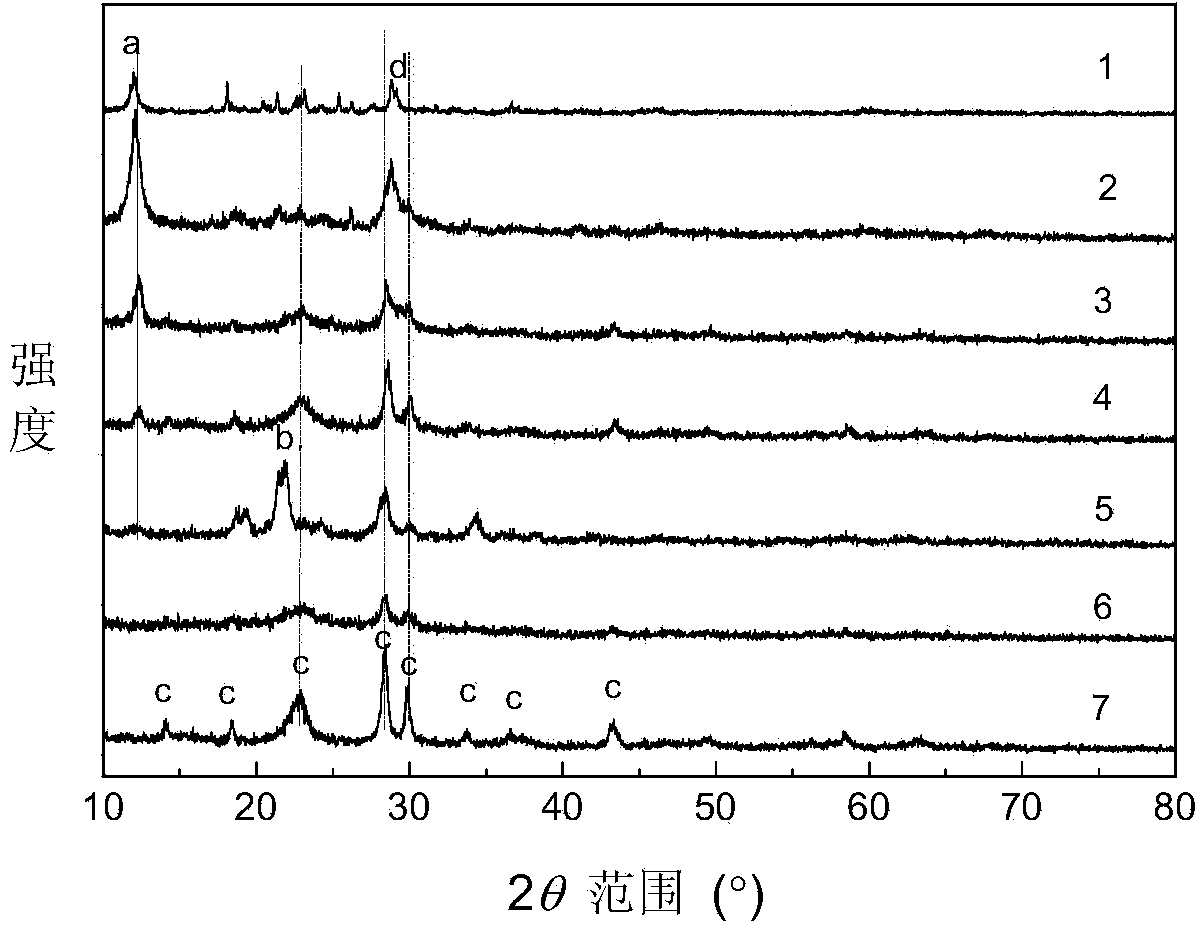

Vanadium-phosphorus-oxide (VPO) catalyst and application in preparation of crylic acid (ester) by reacting acetic acid (ester) with formaldehyde

InactiveCN103816930AHigh catalytic efficiencyHigh activityPhysical/chemical process catalystsOrganic compound preparationO-Phosphoric AcidGeneration rate

The invention discloses a vanadium-phosphorus-oxide (VPO) catalyst for preparing crylic acid or methyl acrylate by condensing acetic acid or methyl acetate with formaldehyde. A preparation method of the vanadium-phosphorus-oxide (VPO) catalyst comprises the following steps: reducing pentavalent vanadium (vanadium pentoxide) through monobenzyl alcohol or a mixed alcohol of benzyl alcohol / isobutyl alcohol, adding a polyethylene glycol (PEG6000) surfactant into an alcohol medium, then adding phosphoric acid, adjusting a ratio of P (phosphorus) / V (vanadium) to be 1.05 to prepare a catalyst precursor, and activating the catalyst precursor in pure nitrogen, pure air and 1.5%( volume fraction) butane-air mixture atmosphere. Since the PEG is added and / or the types of prepared medium alcohols and different precursor activation atmospheres are changed in the preparation process of the catalyst, a crystal phase shape and crystallinity, reaction reactivity of lattice oxygen, ratio of V<5+> / V<4+> on the surface of the catalyst can be significantly modulated, thus significantly modulating reaction behavior of the catalyst. The catalyst for preparing crylic acid (ester) by condensing acetic acid (methyl ester) with formaldehyde is high in catalytic efficiency, and by-products are few; a greatest generation rate of (crylic acid plus acrylic ester) can reach 32.1micromoles / gcat<-1> / min<-1>.

Owner:NANJING UNIV

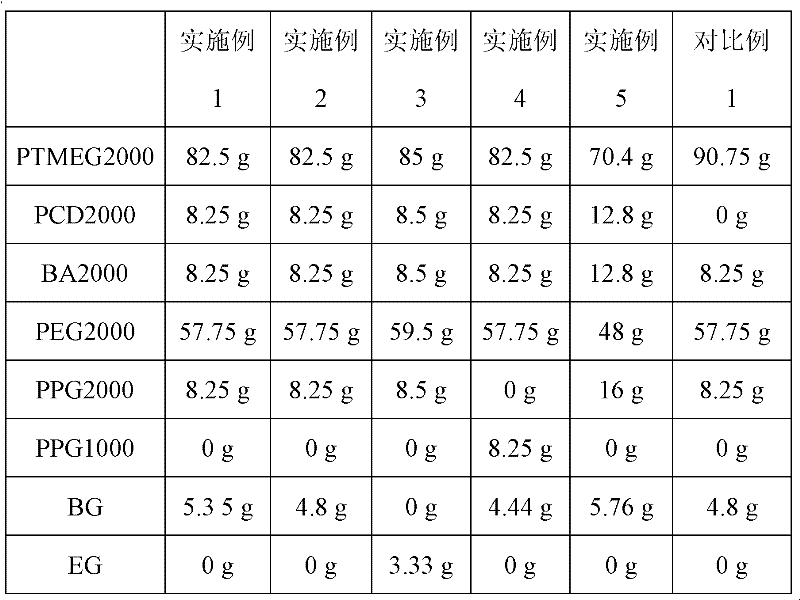

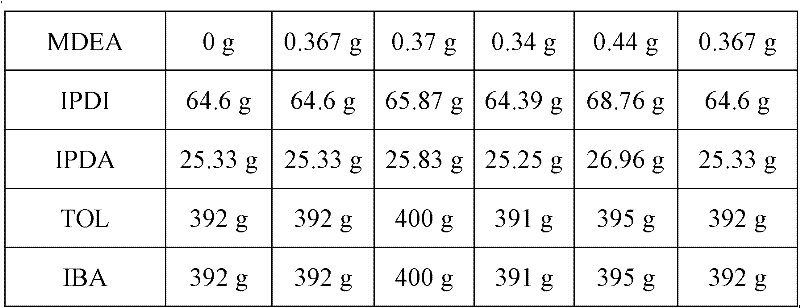

Easily-dyed aliphatic polyurethane resin and preparation method thereof

The invention relates to easily-dyed aliphatic polyurethane resin, comprising the following components in percent by weight: 0.5%-1.5% of polyester polyol, 0.5%-1.5% of polycarbonate diol, 5%-7% of mixed polyether polyol, 0.2%-0.6% of chain extender, 6%-7% of isophorone diisocyanate, 2%-3% of isophorone diamine and 75%-80% of solvent. A preparation method comprises the following steps of: firstlyleading the polyester polyol, the polycarbonate diol, the mixed polyether polyol, the chain extender, the isophorone diisocyanate, the isophorone diamine and methylbenzene to react for 3-5 hours at the temperature 90-120 DEG C; and then adding isobutyl alcohol solution of the isophorone diamine, adding the solvent after a reaction system becomes viscous, leading the final viscosity of a product to be 30-50Pa s under the temperature of 25 DEG C, and ending the reaction.

Owner:SHANGHAI HUIDE TECH CO LTD

Wood grain transfer printing water paint, aluminum alloy wood grain transfer printing section and manufacturing method thereof

ActiveCN103289551AStrong adhesionStrong weather resistanceSynthetic resin layered productsPretreated surfacesAcrylic resinUltraviolet lights

The invention discloses a wood grain transfer printing water paint, an aluminum alloy wood grain transfer printing section and a manufacturing method thereof. The aluminum alloy wood grain transfer printing section respectively comprises an aluminum base material, a silane polymer protection layer, a priming paint layer, a finish paint layer and a wood grain transfer printing film from underside to surface thereof; the priming paint layer and the finish paint layer both are formed by the wood grain transfer printing water paint by means of electrostatic spraying, wherein the wood grain transfer printing water paint is prepared with water-base organic silicon modified acrylic resin, isocyanate curing agent, propylene glycol monomethyl ether, n-butyl alcohol, isobutyl alcohol, adhesion promoter, ultraviolet light absorber, flatting agent, thickening agent, antioxidant, defoaming agent and the balance of deionized water. According to the invention, the water paint is uniformly sprayed on the aluminum alloy base material by the electrostatic spraying method, after hot setting, an even, flat and smooth paint film is formed, and the high-quality aluminum alloy wood grain transfer printing section with the advantages, such as strong adhesive force, excellent covering power, strong resistance to corrosion, excellent weather fastness, difficult pulverization and color fading, is provided.

Owner:FOSHAN KINNO METAL TECH

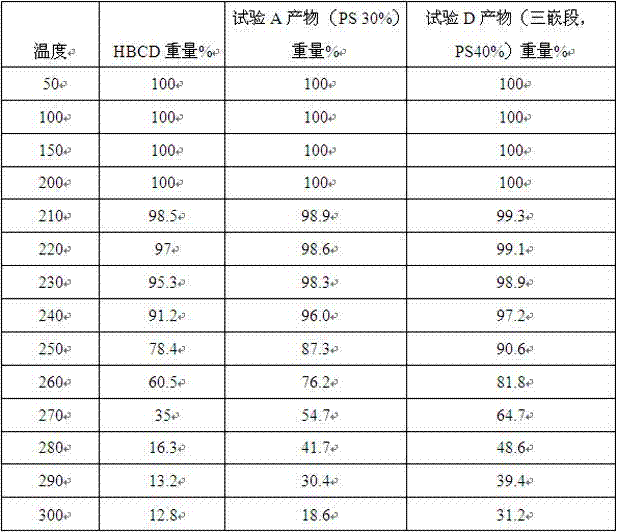

Brominated styrene/butadiene copolymer fire retardant and bromination method thereof

InactiveCN104327214AEffect on mechanical propertiesImprove flame retardant performancePtru catalystButadiene Dioxide

The invention provides a brominated styrene / butadiene copolymer fire retardant and a bromination method thereof. The copolymer of the fire retardant is formed by polymerizing a brominated styrene monomer and a butadiene monomer. In the brominated styrene / butadiene copolymer, the brominated aryl of styrene comprises 2-bromostyrene, 4-bromostyrene and 2,4-dibromostyrene. A preparation method comprises the following steps: (1) selecting the following raw materials: a styrene / butadiene copolymer (shortened as SBS), sodium bromide of which the content is 98%-99%, chlorine gas of which the content is higher than 99% and isobutyl alcohol of which the content is higher than 99%; (2) adding the SBS in an enamel reactor and dissolving the SBS in a heating manner by using isobutyl alcohol; (3) adding a sodium bromide solution, introducing an oxidant, stirring during a reaction process, and absorbing unreacted oxidant by using lime milk at the tail part of the reactor; (4) afterwards cooling to room temperature, adding a catalyst and continuing to stir and heat; (5) filtering after cooling to room temperature to obtain a target product brominated styrene / butadiene polymer.

Owner:青岛方泰克新材料有限公司 +2

Mineral-floating foaming agent and its prepn

The present invention proposes one kind of mineral-floating foaming agent and its preparation. The foaming agent contains alcohol with branch chain and epoxy ethane and / or epoxy propane in the weight ratio of 1 to 1-6, and the alcohol with branched chain may be isopropyl alcohol, isobutyl alcohol or isoamyl alcohol. It is prepared through mixing alcohol with branched chain and epoxy ethane and / or epoxy propane, adding oxide of K or Na in 0.3-1% of material weight as catalyst, reaction at 0.01-1.2 MPa pressure and 170-190 deg.c temperature for 2-3 hr, decreasing the pressure to nomral pressure, cooling to below 50 deg.c and filtering. The foaming agent is water soluble, good in dispersivity, great in formed foam, favorable to secondary enrichment and recovery of fine mineral and has no environmental pollution.

Owner:WUHAN UNIV OF TECH

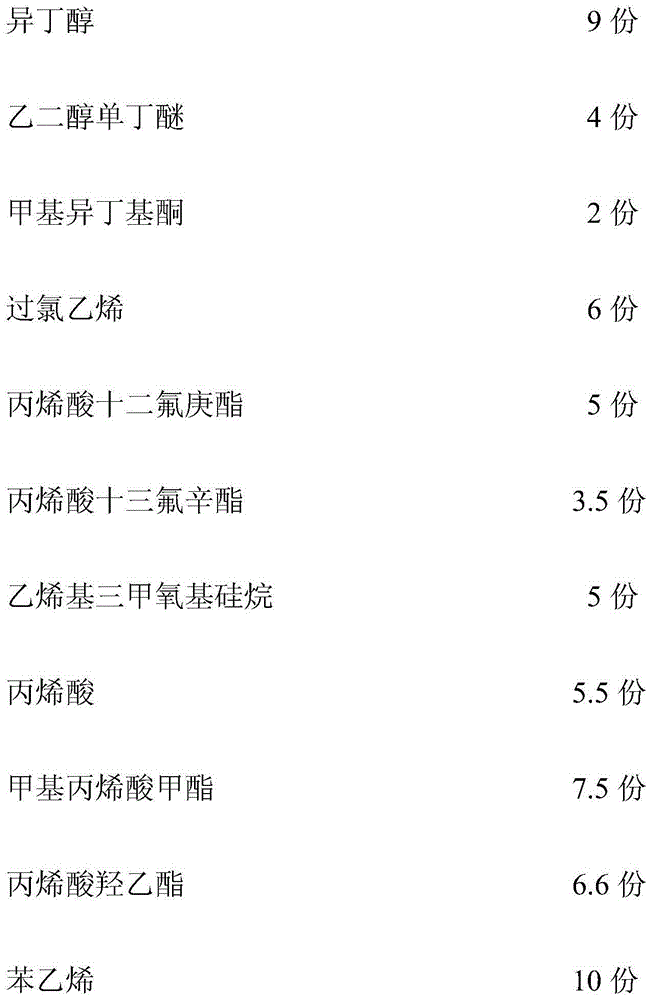

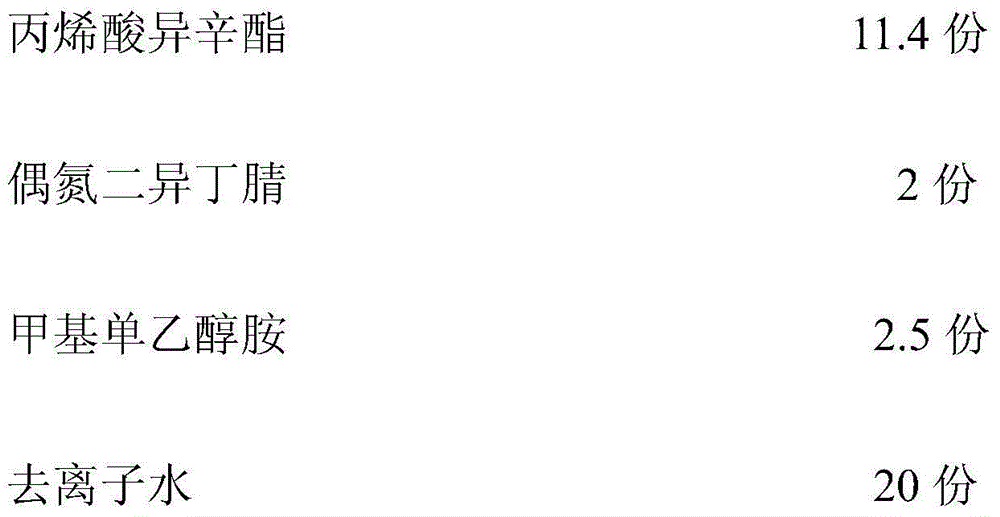

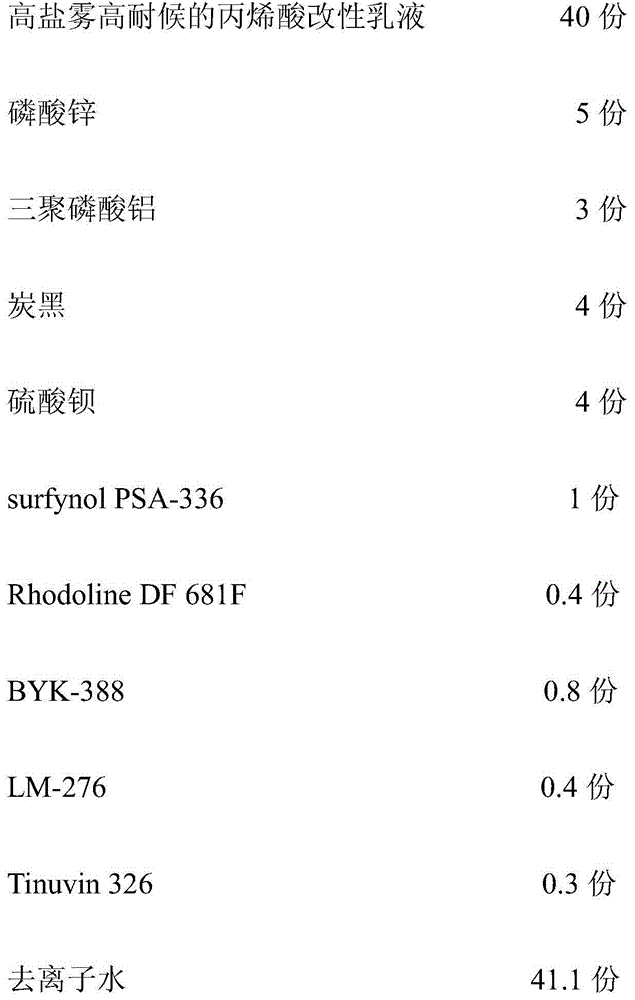

High-salt-mist high-weather-proof water paint and preparing method thereof

ActiveCN104140732AFlat and bright appearanceImprove the level ofAnti-corrosive paintsMethacrylateIsooctyl acrylate

The invention relates to high-salt-mist high-weather-proof water paint and a preparing method of the high-salt-mist high-weather-proof water paint. The high-salt-mist high-weather-proof water paint mainly comprises acrylic acid modified emulsion. The acrylic acid modified emulsion is composed of isobutyl alcohol, ethylene glycol monobutyl ether, methyl isobutyl ketone, vinylidene chloride, dodecafluoroheptyl methacrylate, perluorooctyl acrylate, vinyl trimethoxy silane, acrylic acid, methyl methacrylate, hydroxyethyl acrylate, phenylethylene, 2-ethylhexyl acrylate, azodiisobutyronitrile, N-methyl monoethanolamine and deionized water. The paint is quite excellent primer-topcoat coating and suitable for metal workpieces, the paint is dried at normal temperature after being sprayed, the appearance of a coating is smooth and bright, the leveling property is good, the mechanical property is good, the weather-proof property is excellent, after 2500 hours of QUV aging tests, the dulling rate is smaller than or equal to 15%, and delta E is smaller than or equal to 1.5, meanwhile, corrosion resistance is good, salt mist resistance reaches 1000 hours, and the one-way corrosion width is smaller than or equal to 2 mm.

Owner:HAOLISEN COATING SHANGHAI +1

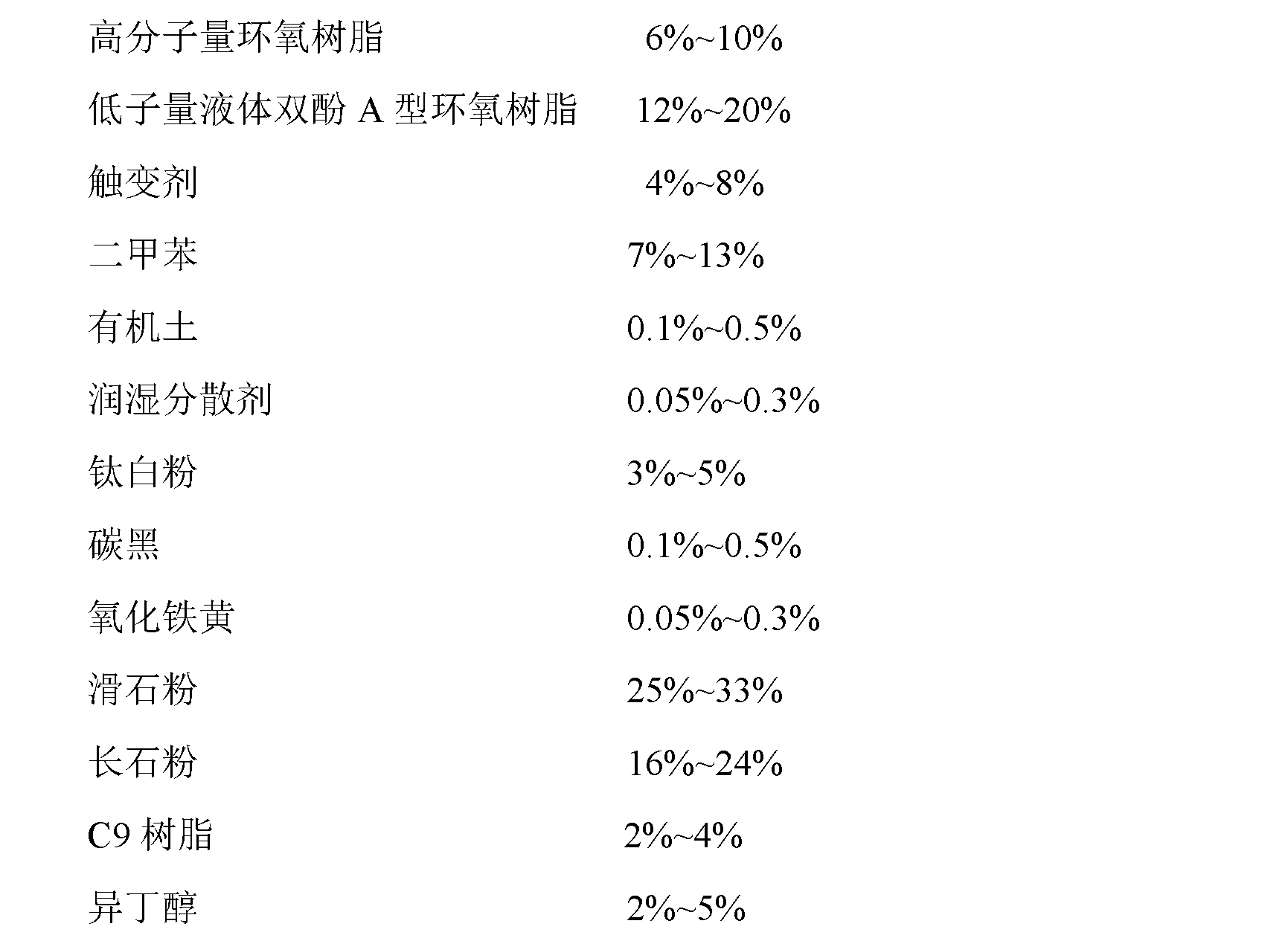

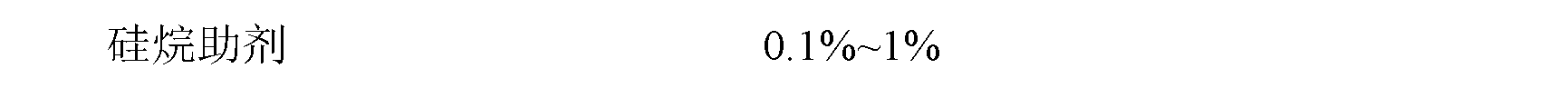

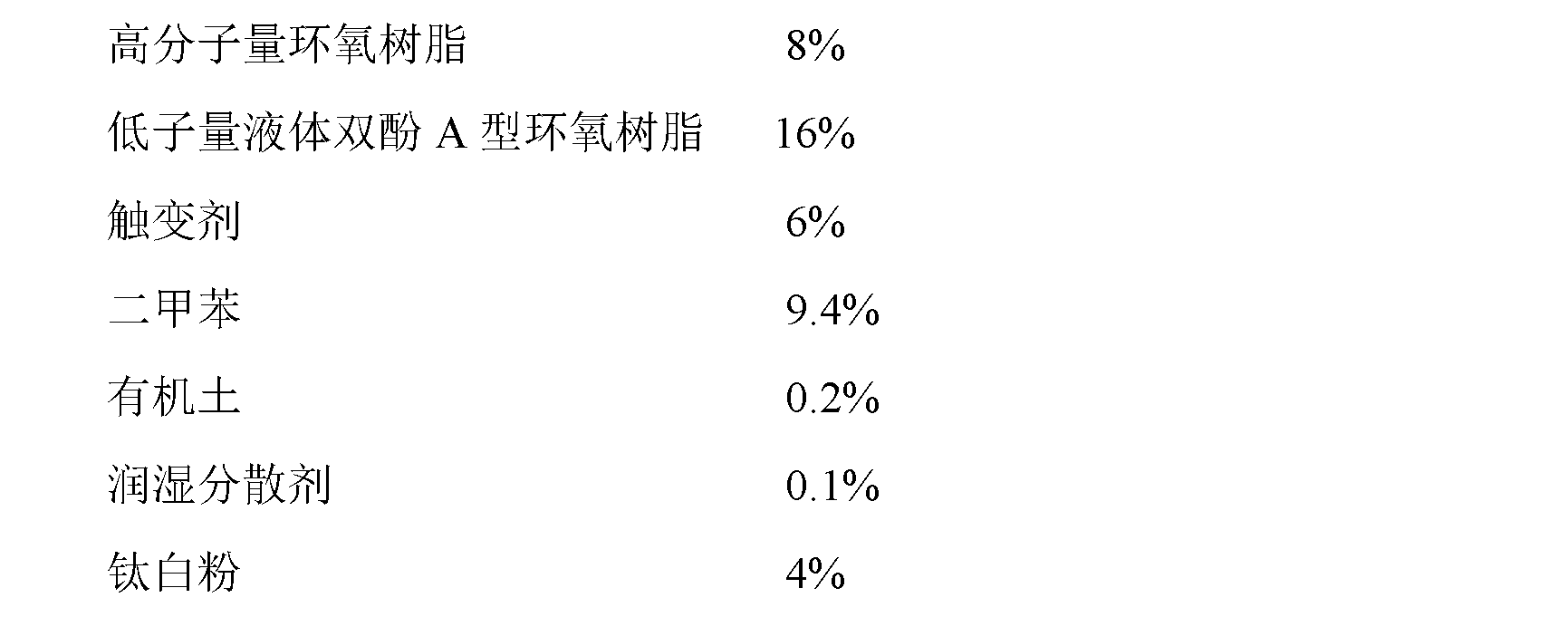

Epoxy universal primer for ships and preparation method thereof

ActiveCN103013276AShorten coating timeEasy constructionAnti-corrosive paintsEpoxy resin coatingsSilanesIsobutyl alcohol

The invention discloses an epoxy universal primer for ships and a preparation method thereof. The epoxy universal primer for the ships comprises components A and components B, wherein the components A comprise the following components in percentage by weight: high molecular weight epoxy resin, low molecular weight liquid bisphenol A epoxy resin, thixotropic agent, dimethylbenzene, organic soil, wetting dispersant, titanium dioxide, carbon black, iron oxide yellow, talcum powder, feldspar powder, C9 resin, isobutyl alcohol and silane auxiliaries; the components B comprise the following components in percentage by weight: polyamide curing agent and epoxy curing accelerator; in a using process, the mixing mass ratio of the components A to the components B is (6-7) to 1. The epoxy universal primer for the ships provided by the invention can be coated to 400 microns by one step without sagging, saves coating time, can be directly matched with the original coating without a transitional layer, is simple to construct, easy to grasp, and time-saving and labour-saving.

Owner:WUXI HUHUANG PAINT

Methanol gasoline modified alcohol additive

InactiveCN101024788ASolve the problem of easy water absorptionDoes not reduce the use effectLiquid carbonaceous fuelsBenzoic acidZinc peroxide

The invention relates to a methanol gas oil modification alcohol additive that uses acetone, toluol, isobutyl alcohol, benzoic acid, ferrocene and zinc peroxide as raw material, and whisking equal in the volume under room temperature and normal pressure to gain the product. It adds 1-3% additive into methanol to gain modified mellow after whisking, and adding the mellow into naphtha or 90# diesel oil to gain the 90#, 93#, 97# and 98# methanol gas oil. The gas oil condensation point would be decreased by adjusting the methanol gas oil and the pollution would be sharply decreased. It has great social benefits and economic benefits.

Owner:北京福众金源环保科技有限公司

Preparation method of laser modified titanium dioxide photocatalyst

InactiveCN101391210AEasy to manufactureSolve the load problemOrganic-compounds/hydrides/coordination-complexes catalystsPolyesterFiber

The invention discloses a preparation method of a laser modified titanium dioxide photocatalyst, which belongs to the technique field of environmental pollution treatment and the research field of new energy sources, and the method comprises the following steps: 1) surface treatment of a high-strength and high-elasticity porous polyester fiber net; 2) loading the titanium dioxide photocatalyst; and 3) modification of a titanium dioxide film by laser. The method is to sequentially carry out the protective sorting to the polyester fiber net according to the cleaned fiber net surface, then coat a film on the fiber net surface by using a sol-gel-coating method and taking tetra-iso-propyl titanate and isobutyl alcohol as raw materials under the weak base condition, and modify the film in a textile laser processor. The invention has advantages of extensive sources of raw materials, simple process, low cost, good stability of the prepared titanium dioxide film, and high photo-catalytic activity and efficiency, and has the antifouling, self-cleaning, antibacterial and air-cleaning effects, and the method can be used for the degradation of environmental harmful substance, and can serve as air purification material and dyeing wastewater treatment photocatalysis material.

Owner:DONGHUA UNIV

Preparation method of reactive MQ silicon resin

The invention discloses a preparation method of reactive MQ silicon resin. The method comprises the following steps of: (1) hydrolyzing and condensing siloxane, alkoxy silane and a homopolymer thereof; (2) leaching a product prepared in the step (1) with a weak-polar or non-polar solvent; (3) washing the product with an aqueous solution to a neutral state; and (4) distilling and concentrating at reduced pressure to obtain the reactive MQ silicon resin, wherein an M unit of the reactive MQ silicon resin in the step (1) contains hexamethyldisiloxane, divinyl tetramethyl disiloxane, tetramethyldisiloxane, 1,1,3,3-tetramethyl-1,3 diphenyldisiloxane, 1,3-diethyl-1,1,3,3-tetramethyldisiloxane or a mixture thereof; a Q unit of the reactive MQ silicon resin contains tetramethyl silicate, tetraethoxysilane, tetraisopropoxidesilane, tetrabutoxysilane, tetrakis(butoxyethoxy)silane and a mixture of homopolymers thereof; the solution in the step (3) consists of a methanol aqueous solution, an ethanol aqueous solution, an isopropanol aqueous solution, a normal butanol aqueous solution, an isobutyl alcohol aqueous solution or a mixed aqueous solution thereof; and the mass fraction of the solution is 30-80.

Owner:ZHONGKAI UNIV OF AGRI & ENG

Modification method of cellulose ether product

The invention discloses the modifying method for cellulose ether product, comprising: mixing the reaction raw material with solvent and getting the product, then washing, drying and breaking the product, the solvent used in the reacting and washing course is water, alcohol isopropylicum and butyl alcohol; or water, alcohol isopropylicum and isobutyl alcohol; or water, alcohol isopropylicum and tert-butanol. The invention is characterized by the little pollution to environment, high reaction efficiency, easy to remove solvent and high efficiency for product washing, which effectively improves the quality of cellulose ether product such as hydroxypropyl cellulose (HPC), hydroxypropylmethylcellulose (HPMC),glycol cellulose (HEC), cellulose ethyl ether (EC) and cationic cellulose.

Owner:SOUTH CHINA UNIV OF TECH

Production method of unleaded gasoline for vehicle

InactiveCN101787310AEmission reductionReduce fuel consumptionLiquid carbonaceous fuelsIsobutyl alcoholManganese

The invention discloses a production method of unleaded gasoline for a vehicle, wherein the unleaded gasoline is prepared from the following raw materials in parts by weight: 35-65 parts of methanol, 60-30 parts of gasoline, 2-4 parts of isobutyl alcohol, 1-3 parts of acetone, 2-4 parts of methyl tertiary butyl ether, 2-5.5 parts of toluene or dimethyl benzene, 0.01-0.03 part of methyl cyclopentadienyl manganese tricarbonyl, 0.03-0.1 part of butyl octyl zinc thiophosphate and 0.1-3 parts of dicyclopentadienyl iron; the unleaded gasoline is prepared by the method comprising the following steps of: sequentially adding the acetone, the toluene or the dimethyl benzene, the isobutyl alcohol, the methyl tertiary butyl ether, the butyl octyl zinc thiophosphate, the dicyclopentadienyl iron and the methyl cyclopentadienyl manganese tricarbonyl as the raw materials into a container at normal temperature and under normal pressure, fully stirring to obtain a yellow transparent liquid, then adding the yellow transparent liquid into the methanol and fully stirring to obtain modified methanol; adding the modified methanol liquid into the gasoline and uniformly stirring to obtain a finished product. The invention has the advantages of low cost, low pollution, low oil consumption, low corrosion and high power, and each item index of the invention exceeds that of the traditional gasoline.

Owner:刘超

Paint remover and method for removing paint from surface of plastic articles

InactiveCN1831052ACause damageHigh paint removal efficiencyChemical paints/ink removersCelluloseAccelerant

This invention relates to a paint remover composing and a method of using it to remove pain on plastic surface. It includes water, alcohols, solve accelerant agent and surface activator, the alcohols is at least one of methanol, ethanol, normal propyl alcohol, isopropyl alcohol, normal butyl alcohol, isobutyl alcohol, ethylene glycol. The alcohol can be replaced by cellulose solution, and the cellulose solution is at least one of methyl cellulose, ethyl cellulose or propyl cellulose. The solution accelerant is sodium hydroxide, and the surface activator is one of sodium dodecanesulphonate or sodium dodecyl sulfate. The method is that the paint remover is heated to 20-70 degrees centigrade, and the plastic is agitated in the paint remover for 5-20 minutes for fully contact to the agent. The remover in this invention has high paint removing efficiency, the cost is low, and less pollution to environment.

Owner:MITAC PRECISION TECH CO LTD SHUNDE DISTRICT FOSHAN CITY

Fuel oil blending additive and preparation method thereof

InactiveCN103509615APowerfulHigh calorific valueLiquid carbonaceous fuelsFuel additivesFuel oilCold filter plugging point

The invention provides an additive for blending fuel oil. The additive comprises an emulsifier formed by complexing a Span-series emulsifier and a Tween-series (or OP-10) emulsifier, a pH value buffering pair formed by combination of sodium petroleum sulfonate and barium petroleum sulfonate, tricresyl phosphate, isooctyl nitrate, a co-emulsifying dispersing agent, an antioxidant, isobutyl alcohol and an organic solvent. The additive is prepared according to certain content and a certain preparation method. The additive can be used for blending methanol, methanol-oleic acid mixture, and other methanol modified complex into a biological fuel oil, and can be used for further blending biodiesel. The blended biological fuel oil and the biodiesel have the advantages of high cetane number, high flash point, low pour point, low cold filter plugging point, low corrosivity, low emission, and low cost.

Owner:刘粤荣 +1

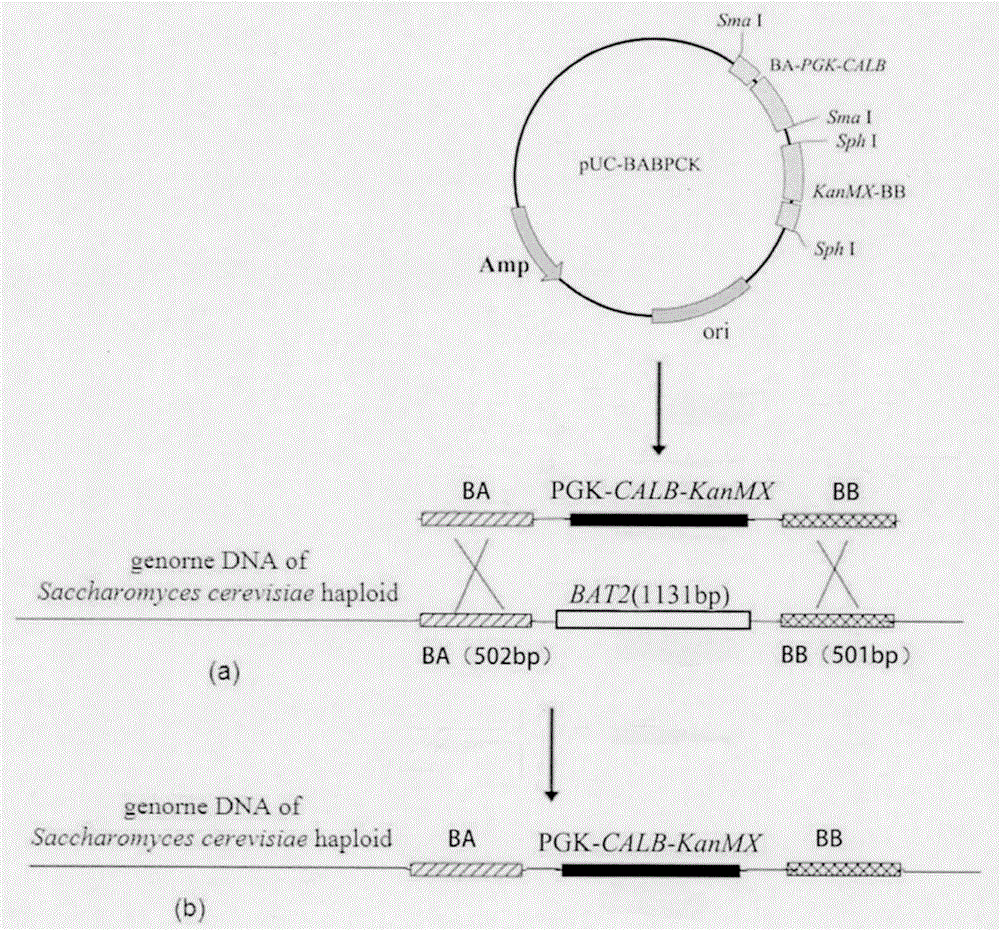

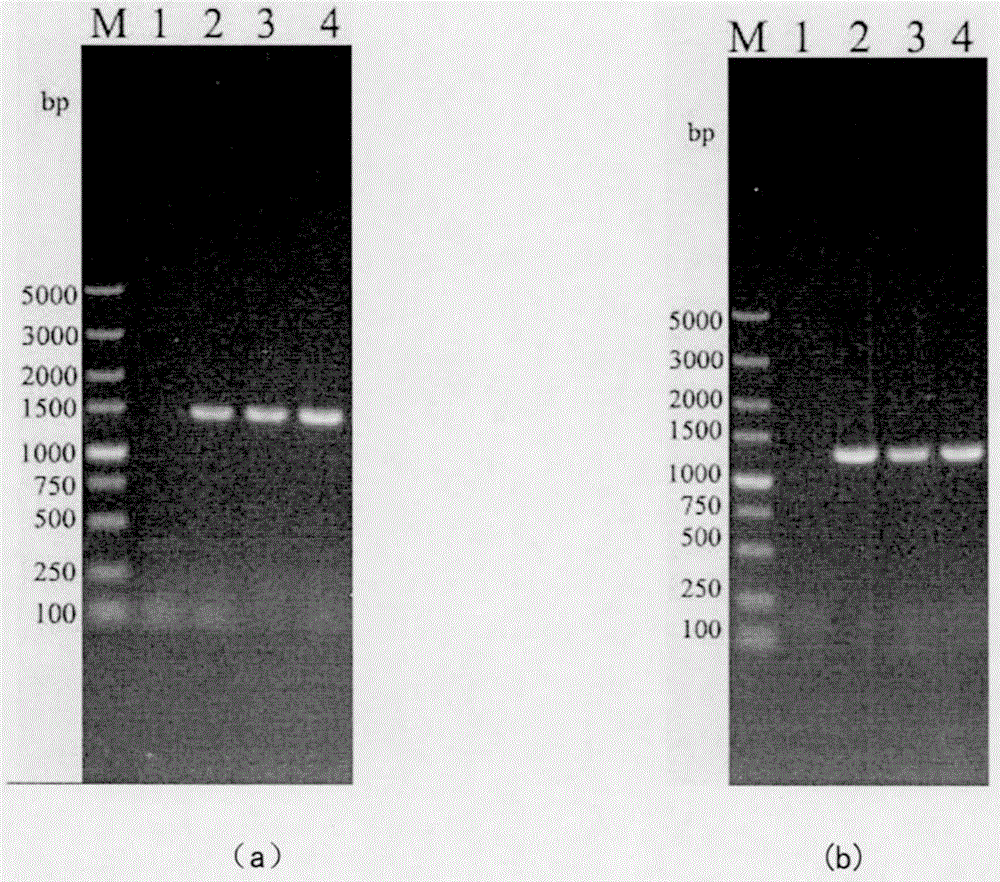

Low-yield high-grade alcohol high-yield ethyl lactate saccharomyces cerevisiae strain and construction method thereof

InactiveCN105969678AReduce productionOvercome flavor incongruityFungiHydrolasesHeterologousAlcohol production

The invention relates to a low-yield high-grade alcohol high-yield ethyl lactate saccharomyces cerevisiae strain and a construction method thereof. The method comprises acquisition of a target gene, construction of a chromosome integrated vector and fermented verification of the breeding bacterial strain. The selected bacterial strain performs heterogenous secrete expression on pseudonym antarctica lipase B, compared with parent strains, the fermentation performance of the constructed saccharomyces cerevisiae is not influenced, after fermentation by sorghum raw material semi-solid liquor for 6 days, ethyl lactate content of the breeding bacterial strain is increased by 57.4%-84.5%; the high-grade alcohol production amount is obviously reduced, isoamyl alcohol is reduced by 9.5%, isobutyl alcohol is reduced by about 50.0%, and active-amyl alcohol is reduced by about 44.0%. According to the breeding bacterial strain, the production amount of ethyl lactate is obviously increased, the high-grade alcohol production amount is obviously reduced, the problem of incompatibility of flavor of the wind can be solved at certain degree, and the method has wide application prospect in the wine-related filed.

Owner:TIANJIN UNIV OF SCI & TECH

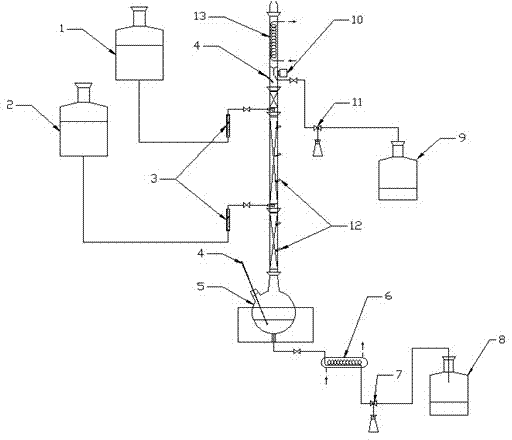

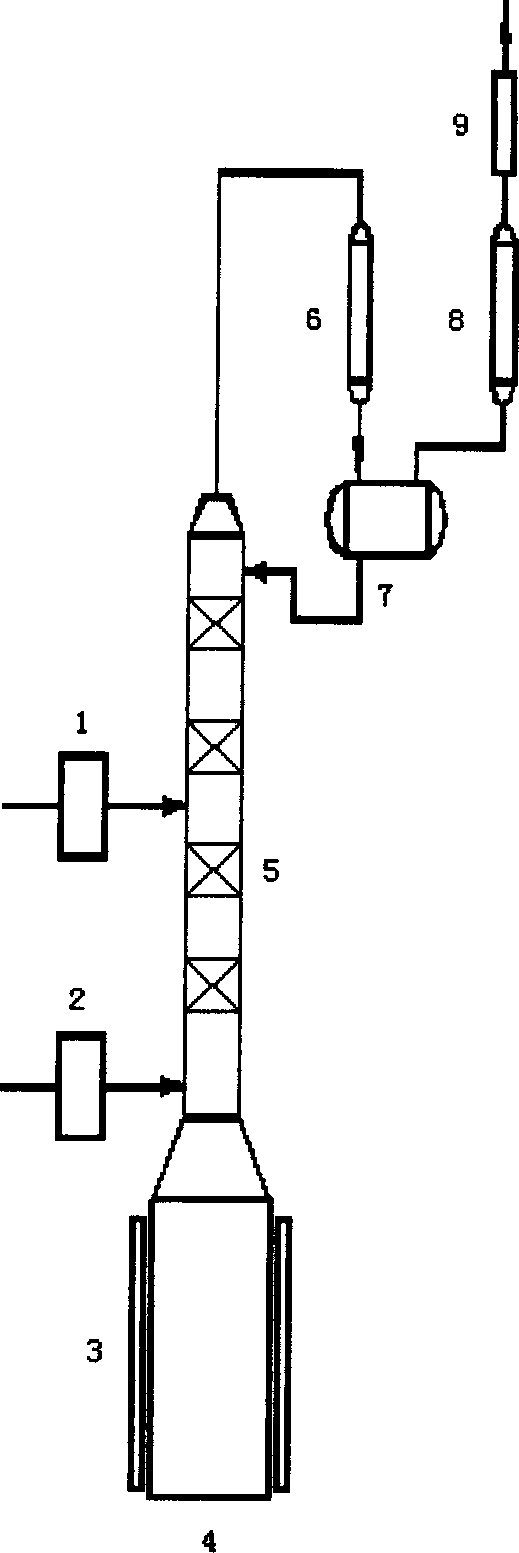

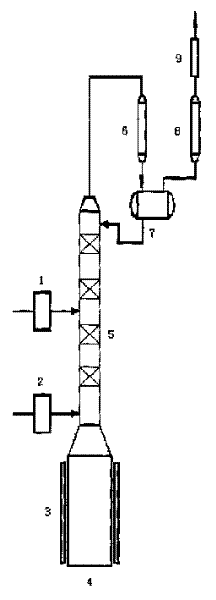

Method for synthesizing methyl isobutyl ketone/methyl isobutyl alcohol

InactiveCN1488617AReduce manufacturing costImprove efficiencyOrganic compound preparationHydroxy compound preparationHydrogenMethyl isobutyl ketone

The invention provides a method for synthesizing methyl isobutyl ketone / methyl isobutyl ethyl by catalyst and distillation. In the catalyst and distillation pole, the upper part is filled with catalyst which has condensation and hydrotreating functions, the lower part is the catalyst with single hydrotreating function, acetone and hydrogen are put into the distillation tower after preheated, the product accumulates in the tower, the unreacted acetone is distilled out from the top of the tower and traced back to the tower to react again.

Owner:CHINA PETROLEUM & CHEM CORP +1

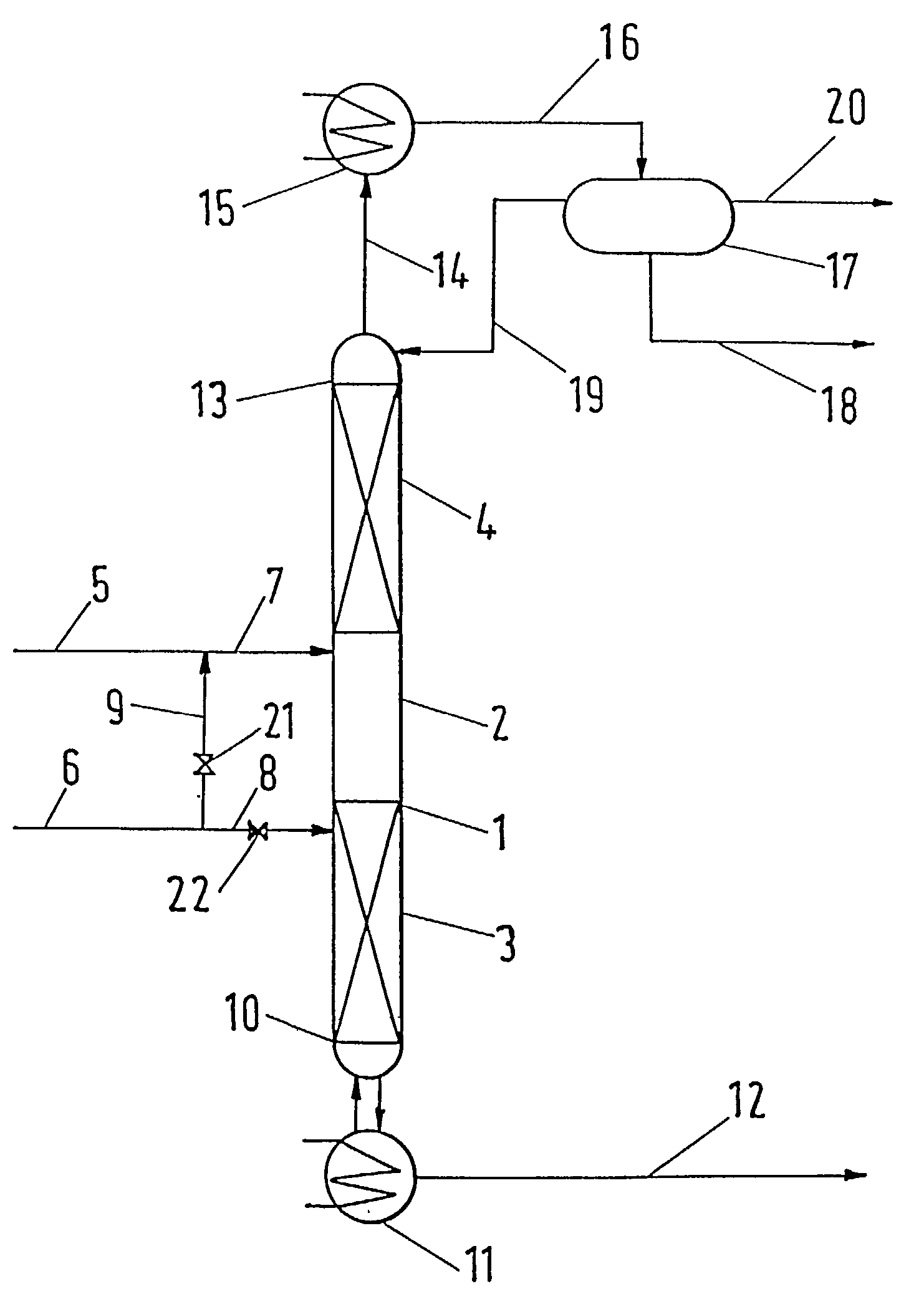

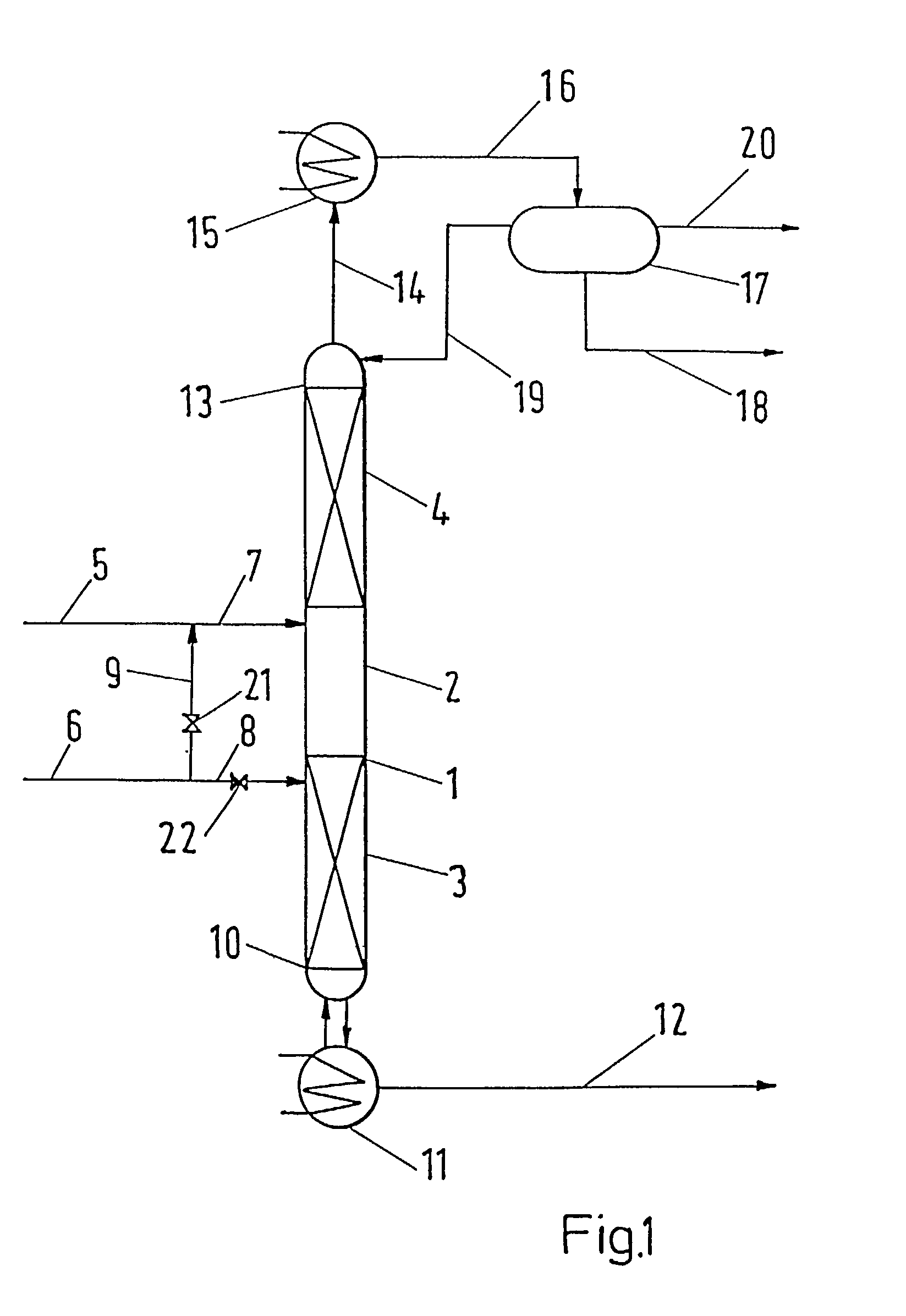

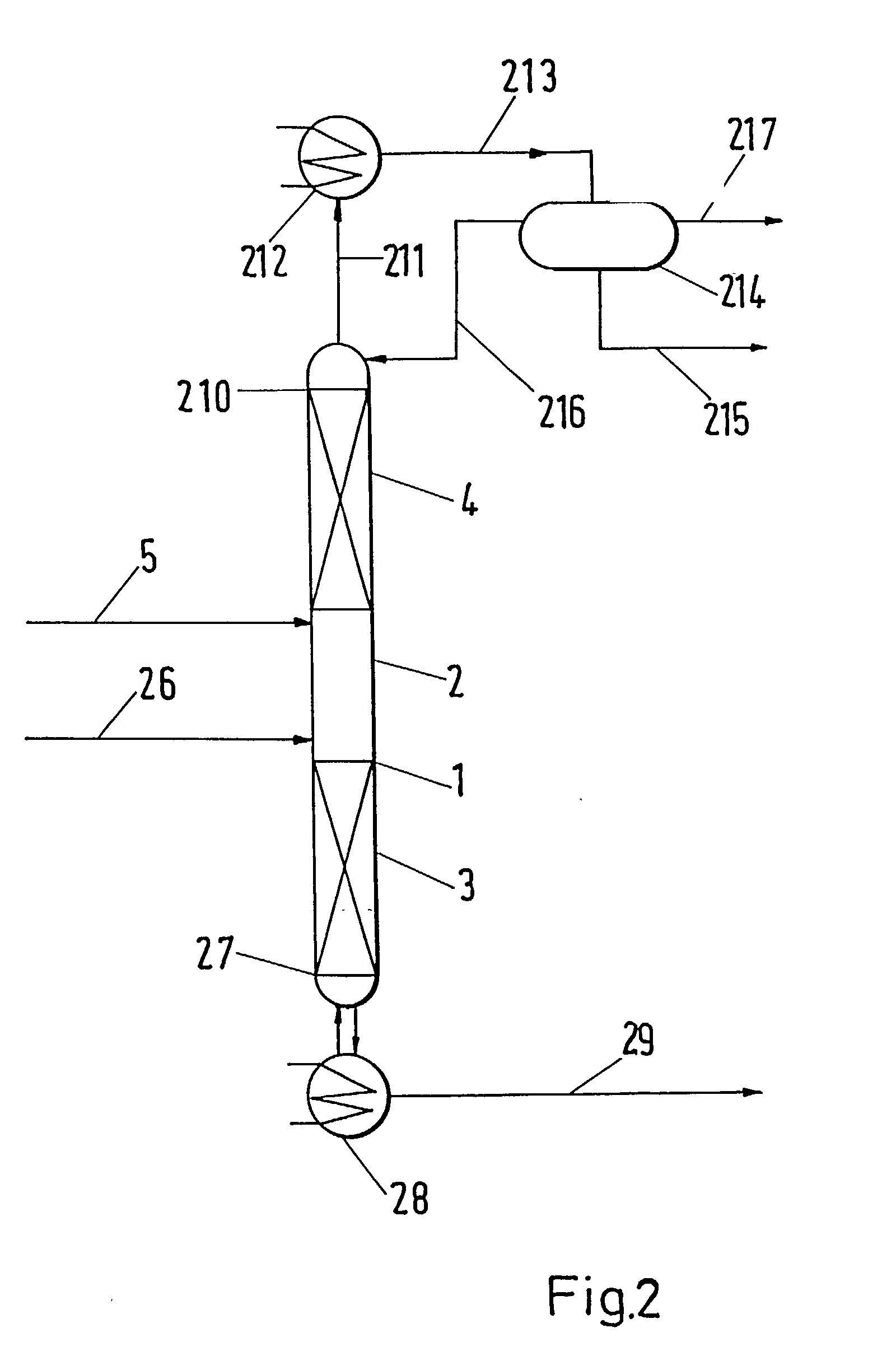

Process and apparatus for the production of butylacetate and isobutylacetate

InactiveUS7160524B2Improve productivityImprove overall utilizationPhysical/chemical process catalystsOrganic compound preparationIsobutyl alcoholButanol

The invention relates to an apparatus for the production of butylacetate by esterification of acetic acid with butanol in the presence of a solid acidic catalyst in which distillatory separation of components runs simultaneously with esterification. Thus, acetic acid and butanol are introduced in defined amounts and in the molar ratio 1:1 to 1:10 into a system, in which the reaction and the distillatory separation proceeds in three zones. The reaction together with distillatory separation of the components with different boiling points run in the reaction zone, while only distillation takes place in lower and upper separation zones. A volatile mixture is separated in the upper separation zone, from which, after being cooled at 5 to 80° C., water and organic phases are separated, the latest being refluxed into the system. The ratio of the feed amount to the organic phase reflux amount is 1:1 to 1:20, the reflux amount representing 60 to 100% of the whole amount of the organic phase. Butylacetate is separated as a high boiling bottoms product. The invention relates also to the production of isobutylacetate by esterification of acetic acid with isobutyl alcohol in the presence of a solid acidic catalyst in which separation of components by distillation runs simultaneously with esterification.

Owner:SULZER CHEMTECH AG +1

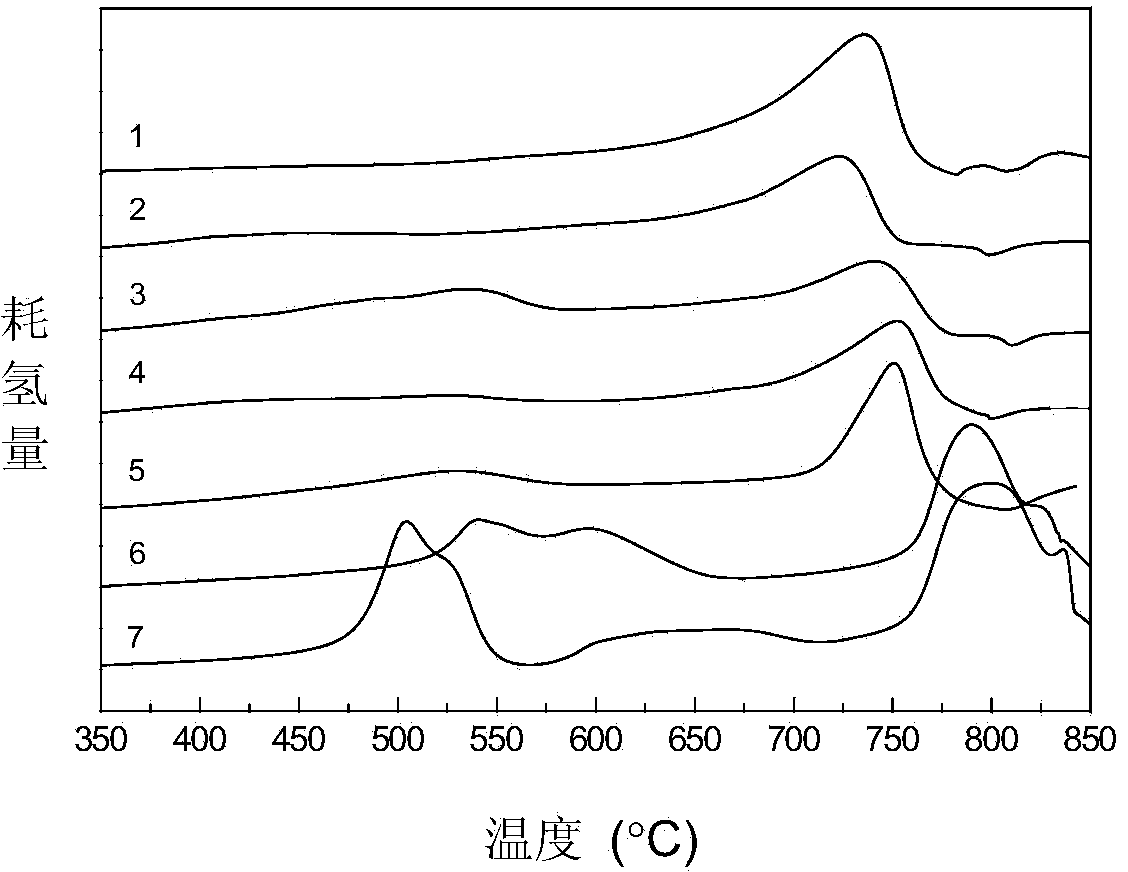

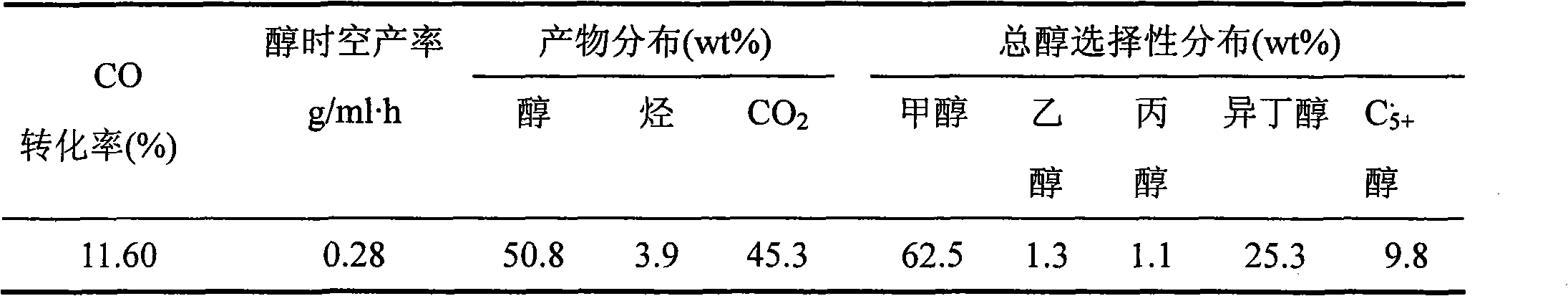

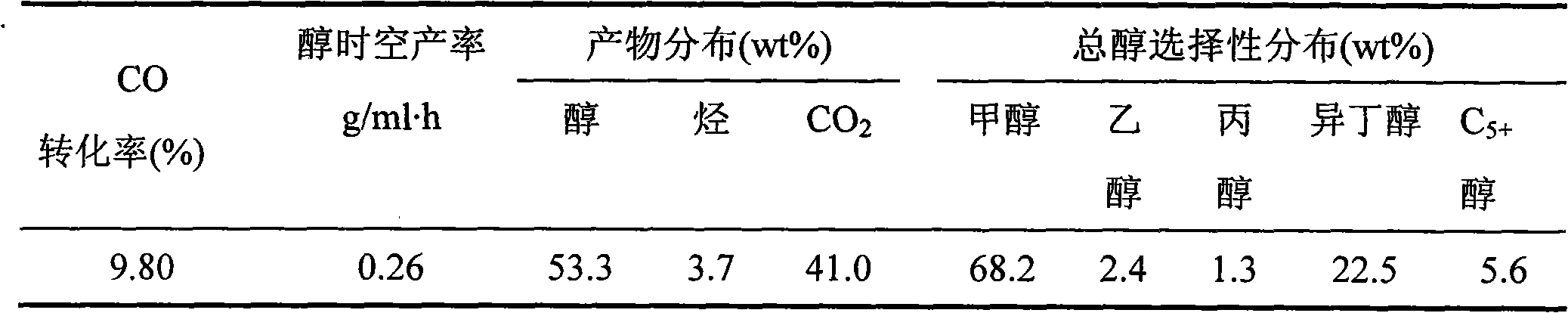

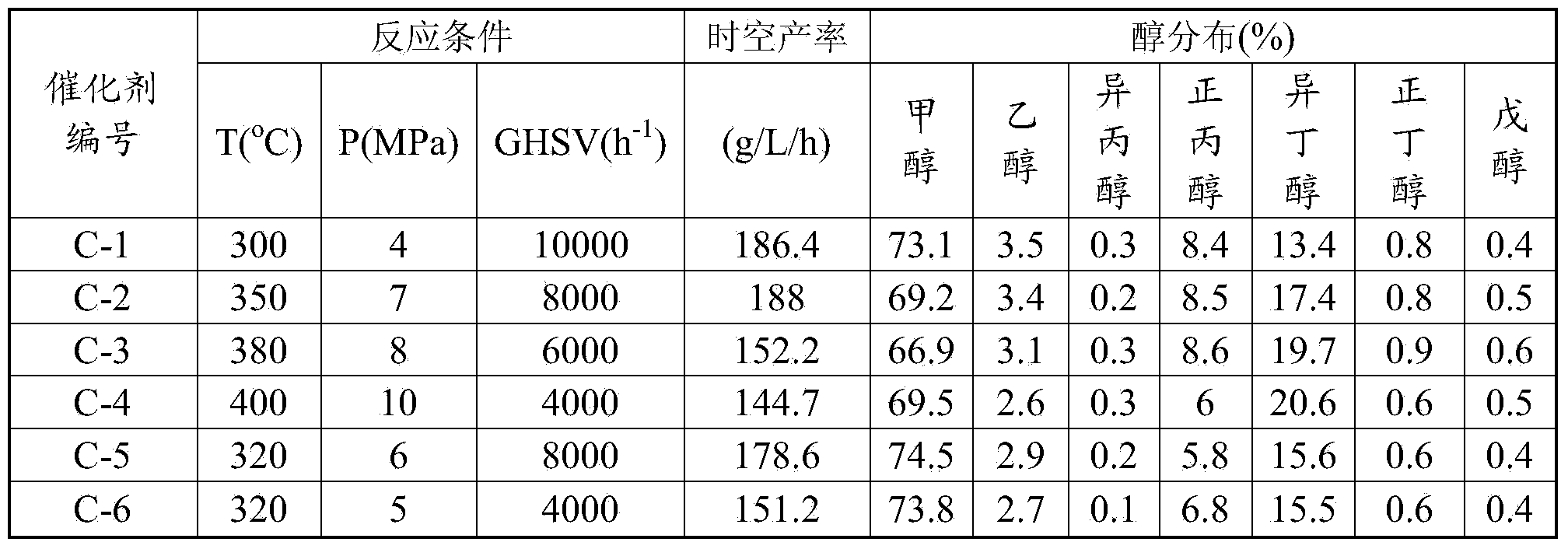

Catalyst for preparing low-carbon mixed alcohol by using synthesis gas and preparation method thereof

ActiveCN102029166AHigh selectivityMild reaction conditionsOrganic compound preparationHydroxy compound preparationSyngasNitrate

The invention discloses a catalyst for preparing low-carbon mixed alcohol by using synthesis gas, which comprises the following components in percentage by weight: 54 to 75 percent of ZrO, 10 to 20 percent of MnO2, 0.4 to 1.0 percent of RxO, 3 to 5 percent of CuO, 4 to 20 percent of C and 0.5 to 1.5 percent of noble metal. The catalyst is prepared by adopting a co-precipitation method, wherein the precursors of the Zr, Mn and Cu elements are nitrates, and the precursor of the C is starch. The catalyst has mild reaction conditions, the selectivity of C2+ alcohol can be more than 36 weight percent, the selectivity of isobutyl alcohol can be more than 25 weight percent, and the selectivity of hydrocarbon (mainly comprising methane) can be less than 4 weight percent. By adding the starch in the preparation of the catalyst and forming amorphous porous carbon in the drying and roasting processes, the specific surface area of the catalyst can be improved, the dispersion of metal oxides is effectively improved, sintering is prevented, and the stability of the catalyst is remarkably improved.

Owner:SHANGHAI HUAYI ENERGY CHEM

Methanol diesel oil fuel and preparation method thereof

InactiveCN101235325ASolve layeringImprove performanceLiquid carbonaceous fuelsAcetic acidIsobutyl alcohol

The invention relates to novel vehicular energy-saving environment-friendly methanol diesel oil and a manufacturing method, the proportion of each component of methanol diesel oil fuel according to weight by parts is that diesel oil 23-50, methanol 35-70 and combined addition agent 5-13, wherein the components and contents of the combined addition agent are that ethyl nitrate 0-3, cyclopean ferrocene 0-0.008, carbon dodecanol 0-2.5, isobutyl alcohol 0-3, diethyl carbonate 0-4, acetic ether 0-2.5, benzyl alcohol 0-0.5 and butanol 0-3. The process for preparation comprises getting dissel oil, methanol and combined addition agent according formula ratio under the condition of normal temperature and normal pressure, firstly, adding combined addition agent in methanol, preparing denatured methanol after completely dissolving, secondly, adding the above denatured methanol in diesel oil, finally completely evenly stirring for 10-20 minutes to get products. The products have excellent property and environmental protection.

Owner:浙江赛孚能源科技有限公司

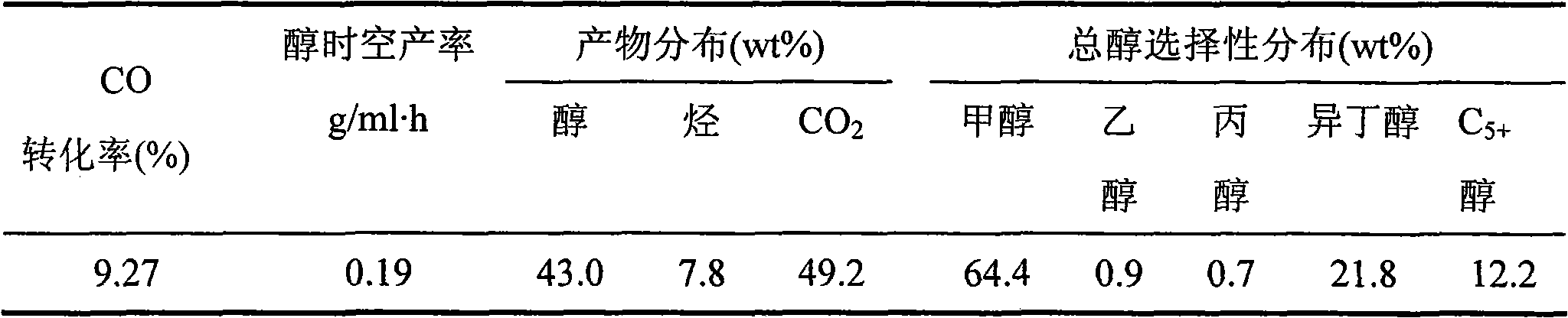

Catalyst for producing low-carbon mixed alcohol by using synthesis gas as well as preparation method and application of catalyst

InactiveCN104368356AHigh activityHigh selectivityOrganic compound preparationHydroxy compound preparationIsobutyl alcoholCopper oxide

The invention provides a catalyst for producing low-carbon mixed alcohol by using synthesis gas. The catalyst comprises copper oxide, zinc oxide, zirconium oxide and auxiliaries, and the general formula of the catalyst is CuaZnbZrcMdNeOx, wherein M refers to at least one of metal elements such as Mn, Ce, Mg, Fe, Co and Ni; N refers to an alkali metal; a is equal to 0.3-4.0; b is equal to 0.5-3.5; c is equal to 1.0-5.0; d is equal to 0.02-0.3; e is equal to 0.01-0.2; and x refers to the sum of number of oxygen atoms needed by all the metal elements in the general formula. The invention also discloses a preparation method and application of the catalyst. The catalyst has high C2<+> alcohol selectivity, high selectivity of isobutyl alcohol and low hydrocarbon selectivity, the water content in the liquid phase product is low, the preparation method is simple and feasible, and industrialization is easily realized.

Owner:NANJING TECH UNIV +2

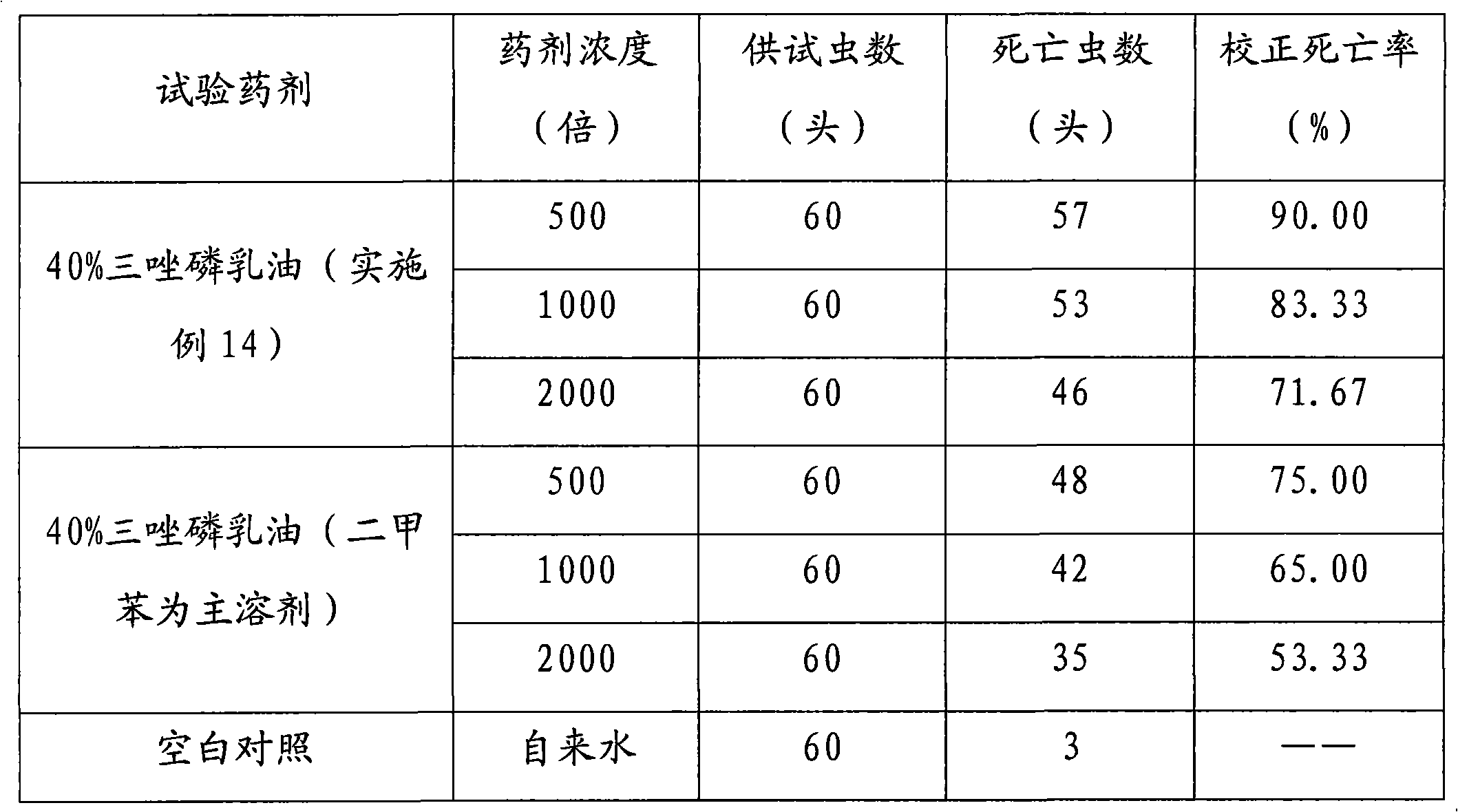

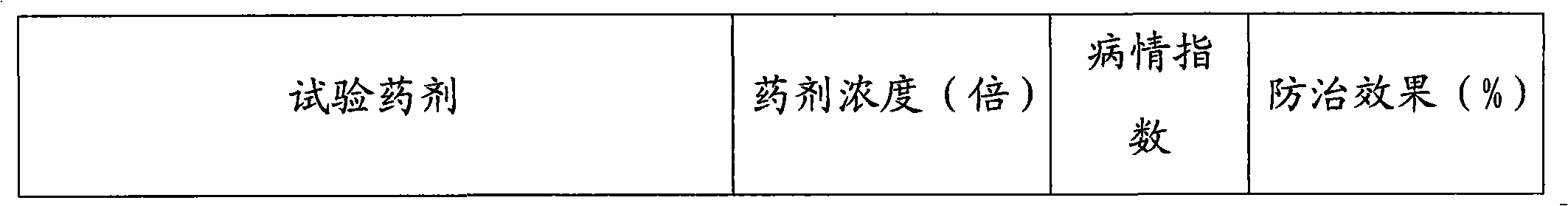

Pesticide adjuvant and applications thereof

InactiveCN101658163ASynergistic effect is obviousLow costBiocideAnimal repellantsAdditive ingredientMethyl salicylate

The invention relates to a pesticide adjuvant and applications thereof. The pesticide adjuvant is characterized by comprising the following ingredients by mass percentage: 90 to 100 percent of pine-stump light oil and 0 to 10 percent of cosolvent, wherein the cosolvent is at least one of n-butyl alcohol, isobutyl alcohol, N-methylpyrrolidone, N-hydroxyethylpyrrolidone and methyl salicylate. The pesticide adjuvant is applicable to various pesticides, and particularly applicable to missible oil, oiling agent, oil suspension solvent, suspension emulsion, micro-emulsion, aqueous emulsion and ultra-low volume concentrate, and also can be used as barrel pesticide mixing assistant agent; and the pesticide adjuvant is applicable to preparation of ingredients of pesticides such as insecticide, acaricide, bactericide, herbicide, plant growth regulator and the like. The pesticide adjuvant and the barrel-mixing agent have strong dissolving power, is environment-friendly, have synergy effect on agents, wide source and moderate use cost, and is the ideal choice substituting for triphenyl organic solvents.

Owner:SHENZHEN NOPOSION AGROCHEM

Magnesia partly stabilized zircite floamed ceramic filter

InactiveCN101486573AImprove high temperature strengthHigh strengthFiltration separationCeramicwareCyclohexanoneSuperalloy

The invention belongs to a ceramic foam filter used in the casting industry. The invention proposes a technique which employs an organic solvent as a dispersing medium, a polymer material being capable of being dissolved into the organic solvent as a caking agent, and magnesia and monoclinic phase zirconia as the main materials to prepare a magnesia partially-stable zirconia ceramic foam filter. Absolute ethyl alcohol is preferably selected as the organic solvent for the consideration of environment protection. But the organic solvent covered by the invention also comprises the organic solvents capable of dissolving macromolecular caking agent like methanol, acetone, cyclohexanone, isobutyl alcohol, benzene, toluene, and the like. PVB is mainly selected as the macromolecular caking agent. The invention has the advantages of quick drying speed of a foamed ceramics biscuit, and saving the production time; moreover, the ceramic grains are piled compactly in the biscuit; the sintered foamed ceramic has uniform clearance and high high-temperature intensity, thus being capable of completely meeting the filtering on molten steel and high temperature alloy fused masses.

Owner:WUXI ZHUOXIN CERAMIC TECH

Preparation method for micron order superfine sodium chloride

InactiveCN101565190AHigh yieldSmall particle sizeNanostructure manufactureAlkali metal halide formation shapePolyethylene glycolSolvent

The invention relates to a preparation method for micron order superfine sodium chloride, namely a method for preparing the micron order superfine sodium chloride by a desolvation method. The method comprises the following steps: at room temperature, dissolving sodium chloride into water to prepare a saturated sodium chloride solution; then adding alcohols as counter solvents; adding a modifying agent; stirring the mixture; quickly filtering and collecting crystals; and drying the crystals in a vacuum drying chamber at 80 DEG C to obtain micron order superfine sodium chloride powder, wherein the alcohols can be methanol, ethanol, isopropanol, normal butanol, isobutyl alcohol, 1,2-propanediol or 1,4- butanediol, preferably the ethanol, the isopropanol or the 1,4- butanediol; and the modifying agent can be tween 80, sorbierite, citric acid, polyethyleneglycol-200 (PEG) or polyvinylpyrrolidon (PVP), preferably the sorbierite or the polyvinylpyrrolidon (PVP). The method has simple process; the productivity of the superfine sodium chloride is higher, and the modifying agent is used, so that the granular diameter of the sodium chloride can be markedly reduced and the granular diameter distribution is narrow.

Owner:JIANGSU UNIV

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com