Patents

Literature

173results about "Alkali metal halide formation shape" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Methods for controlling crystal growth, crystallization, structures and phases in materials and systems

InactiveUS20060037177A1Growth inhibitionExisting techniquePolycrystalline material growthOxygen/ozone/oxide/hydroxidePhase formationEnergy regulation

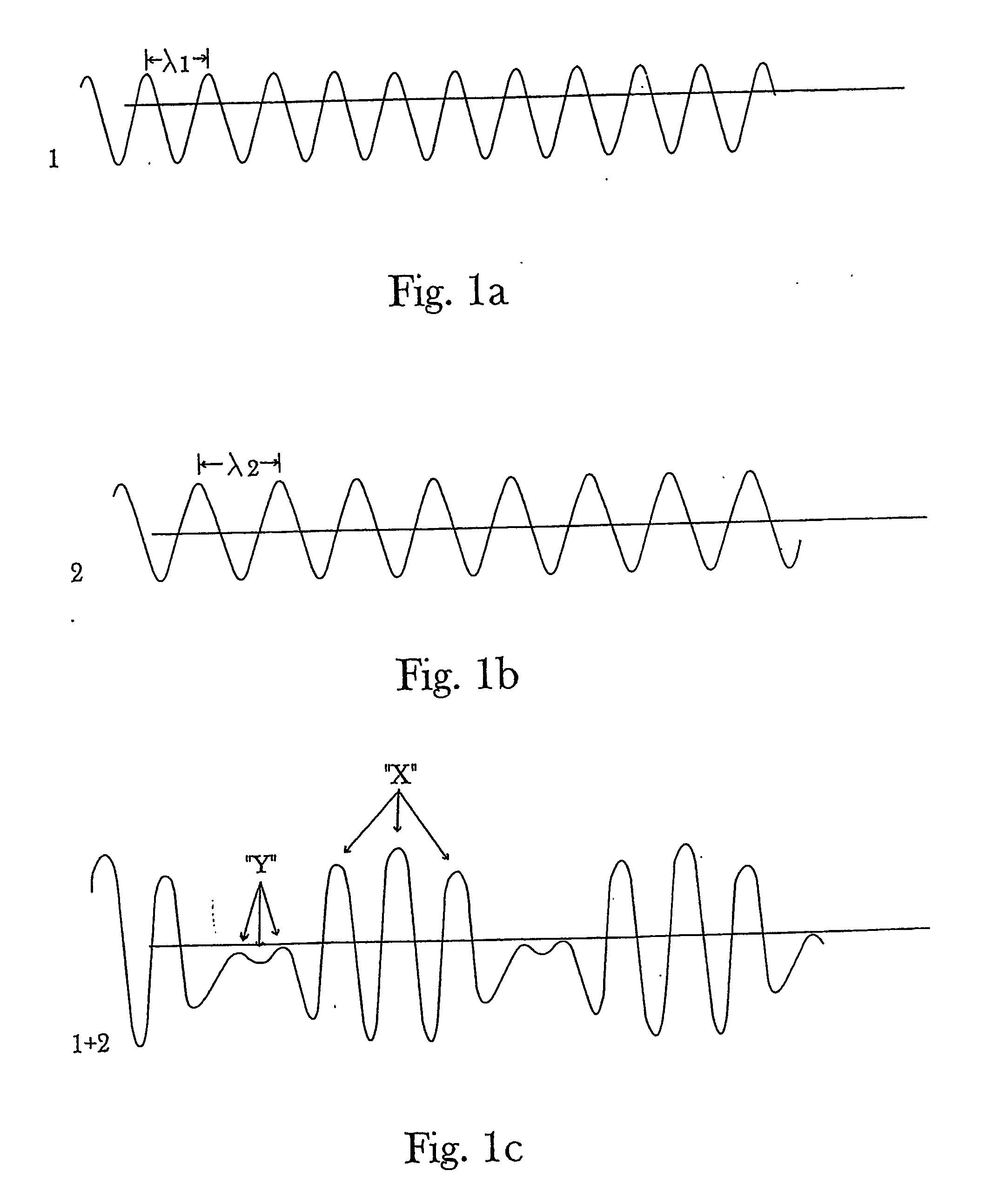

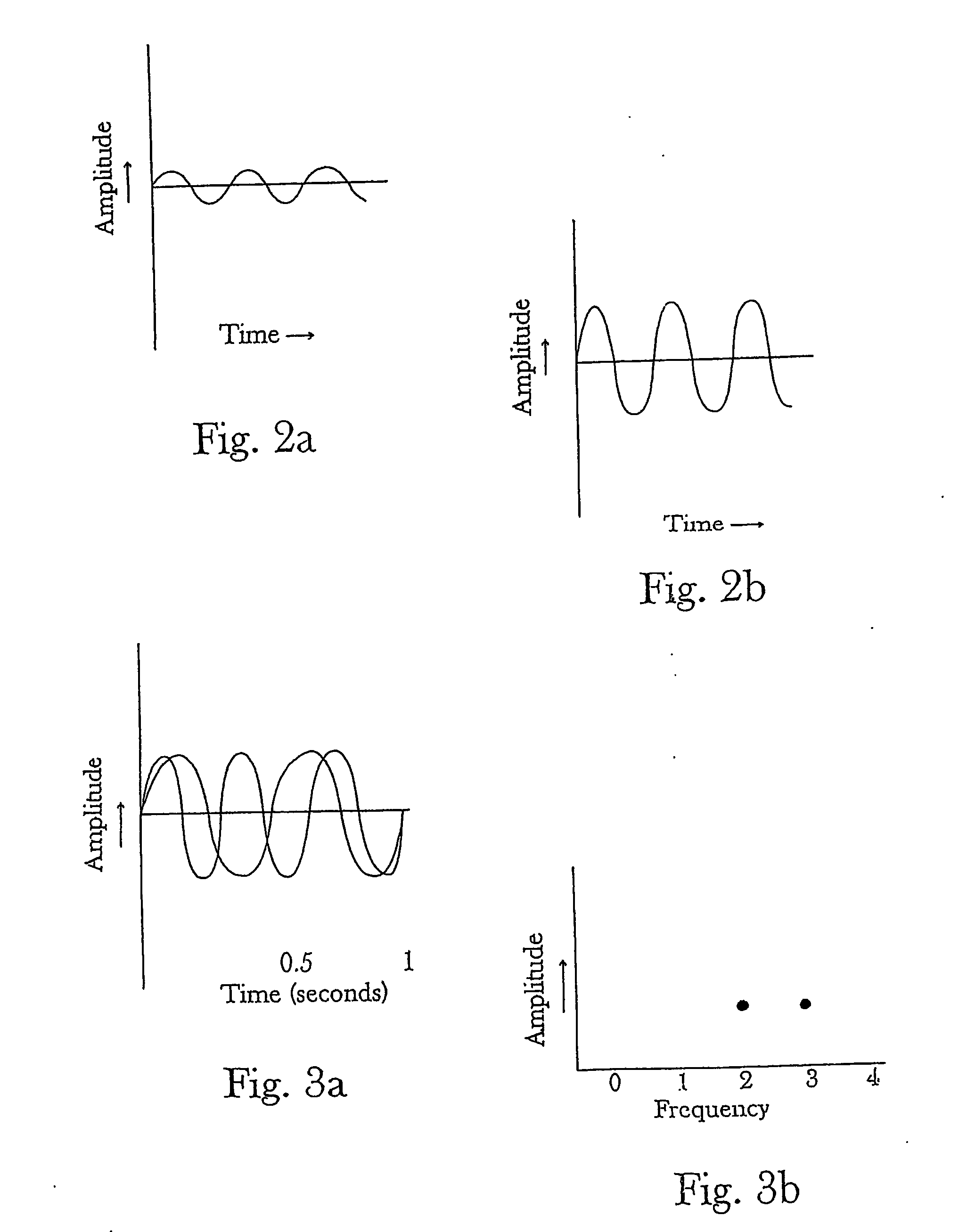

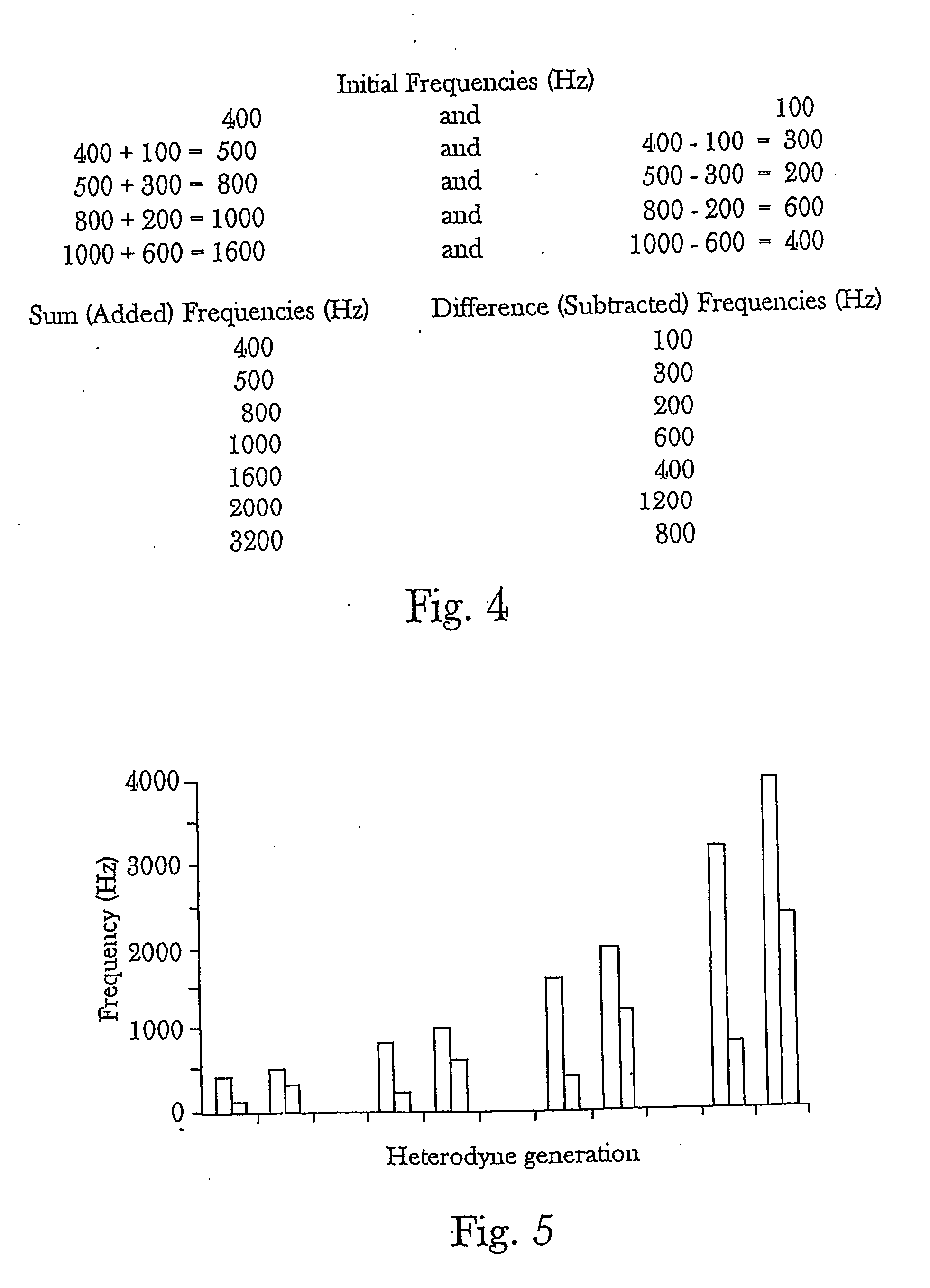

This invention relates to novel methods for affecting, controlling and / or directing various crystal formation, structure formation or phase formation / phase change reaction pathways or systems by exposing one or more components in a holoreaction system to at least one spectral energy pattern. In a first aspect of the invention, at least one spectral energy pattern can be applied to a crystallization reaction system. In a second aspect of the invention, at lest one spectral energy conditioning pattern can be applied to a conditioning reaction system. The spectral energy conditioning pattern can, for example, be applied at a separate location from the reaction vessel (e.g., in a conditioning reaction vessel) or can be applied in (or to) the reaction vessel, but prior to other (or all) crystallization reaction system participants being introduced into the reaction vessel.

Owner:GR INTELLECTUAL RESERVE LLC

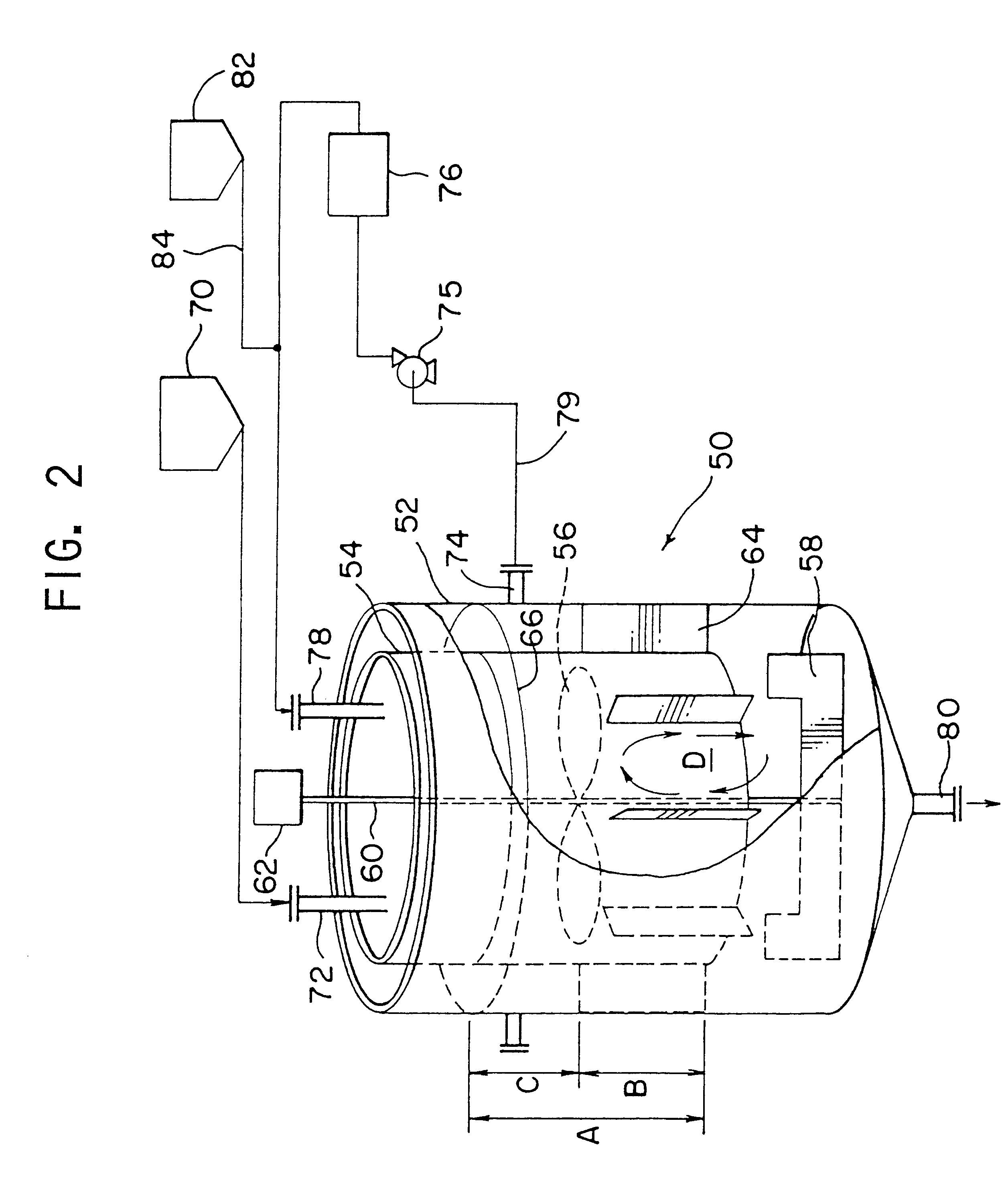

Hydrodynamic cavitation crystallization process

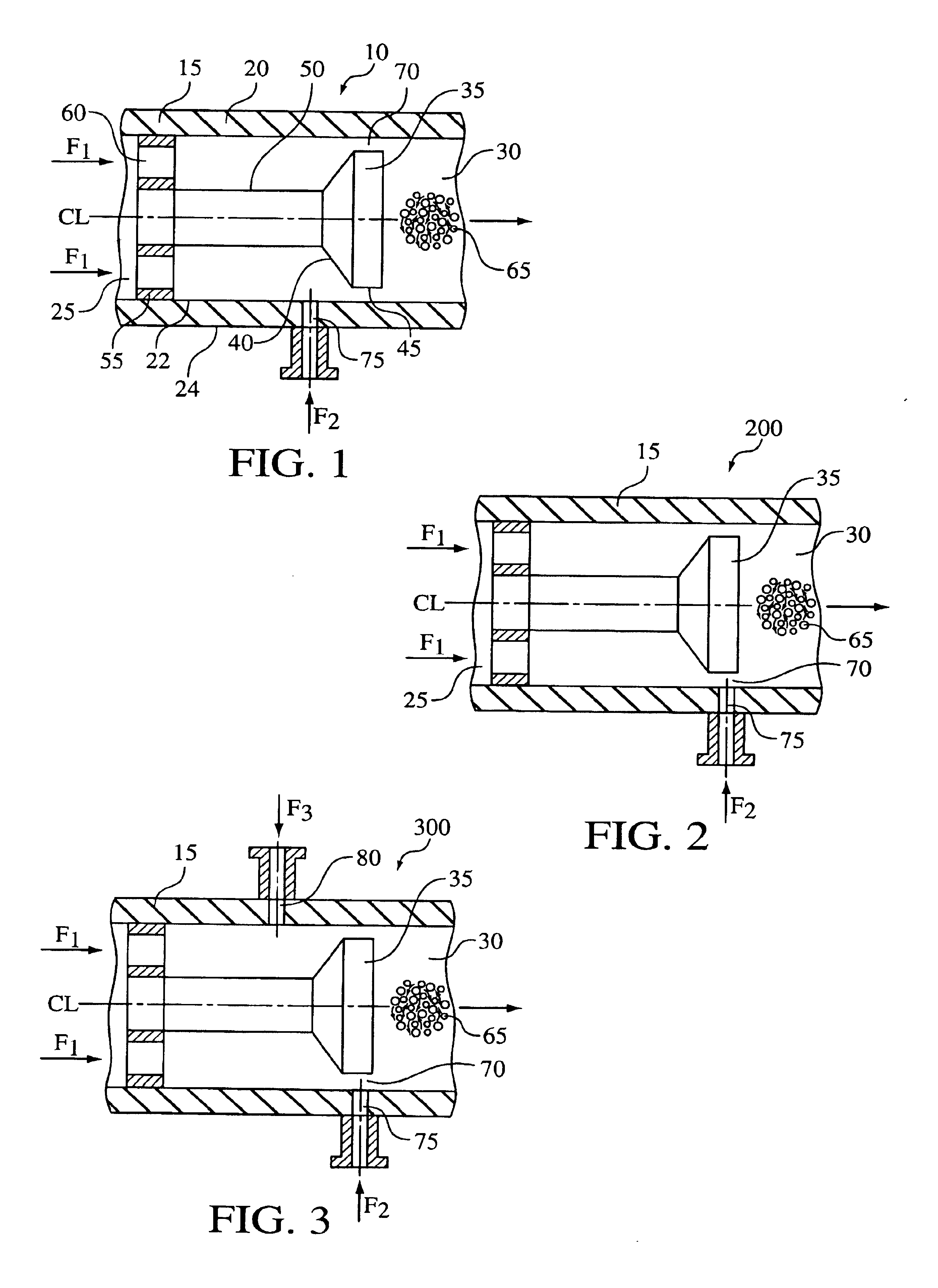

A device and process for crystallizing a compound using hydrodynamic cavitation comprising the steps of mixing at least one stream of a solution of such compound to be crystallized with at least one stream of an anti-solvent and passing the mixed streams at an elevated pressure through a local constriction of flow to create hydrodynamic cavitation thereby causing nucleation and the direct production of crystals.

Owner:ARISDYNE STSTEMS INC

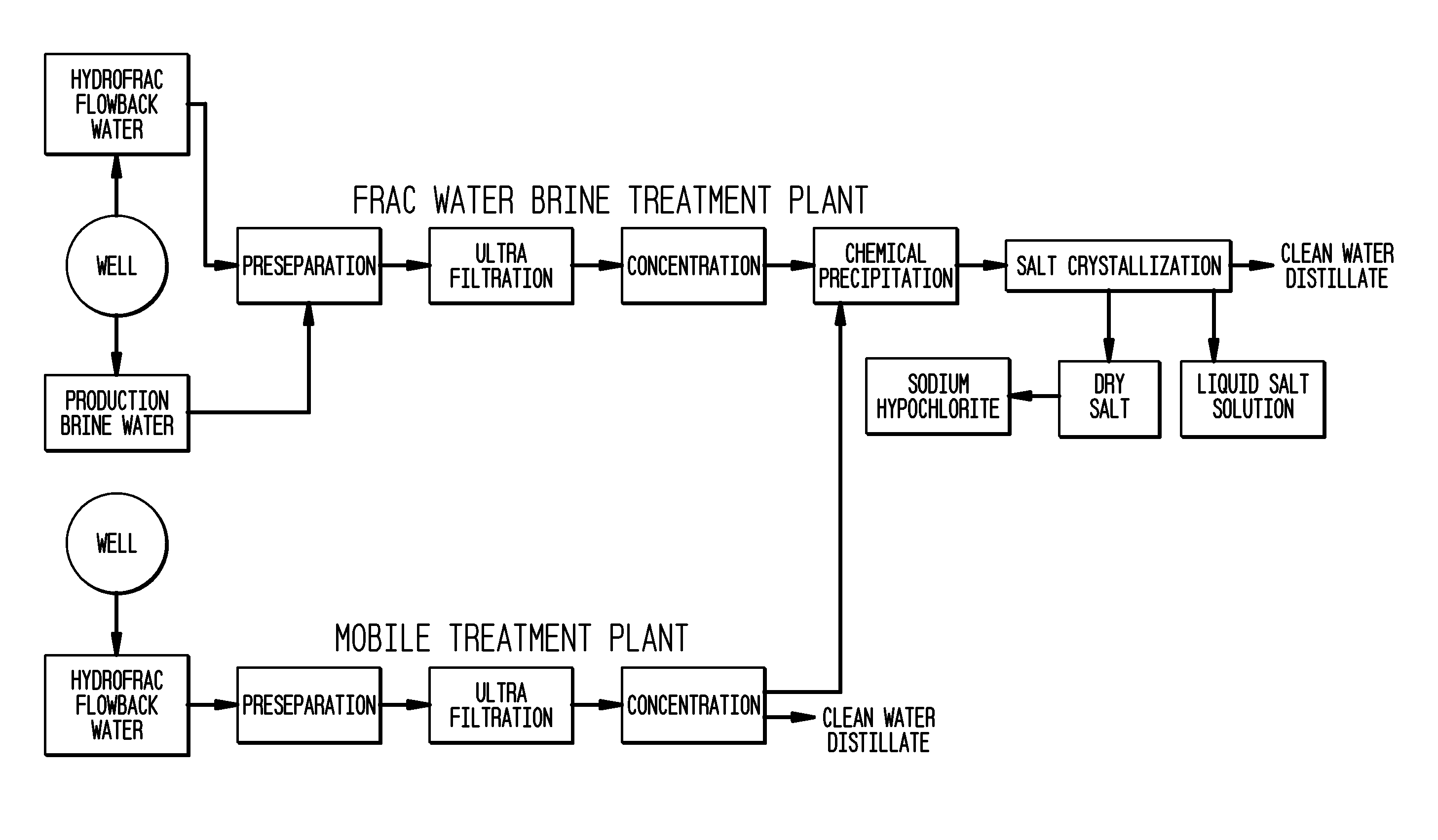

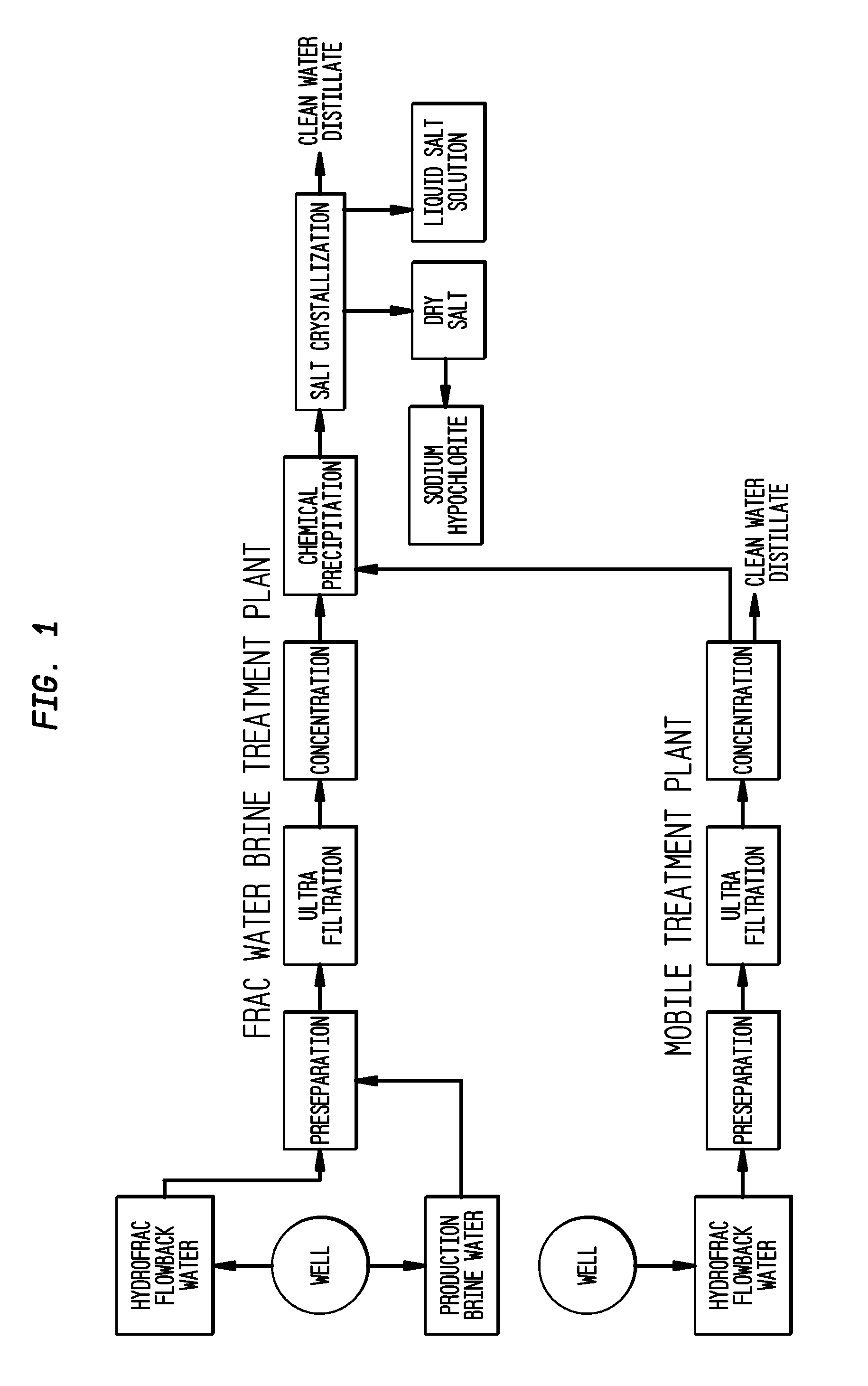

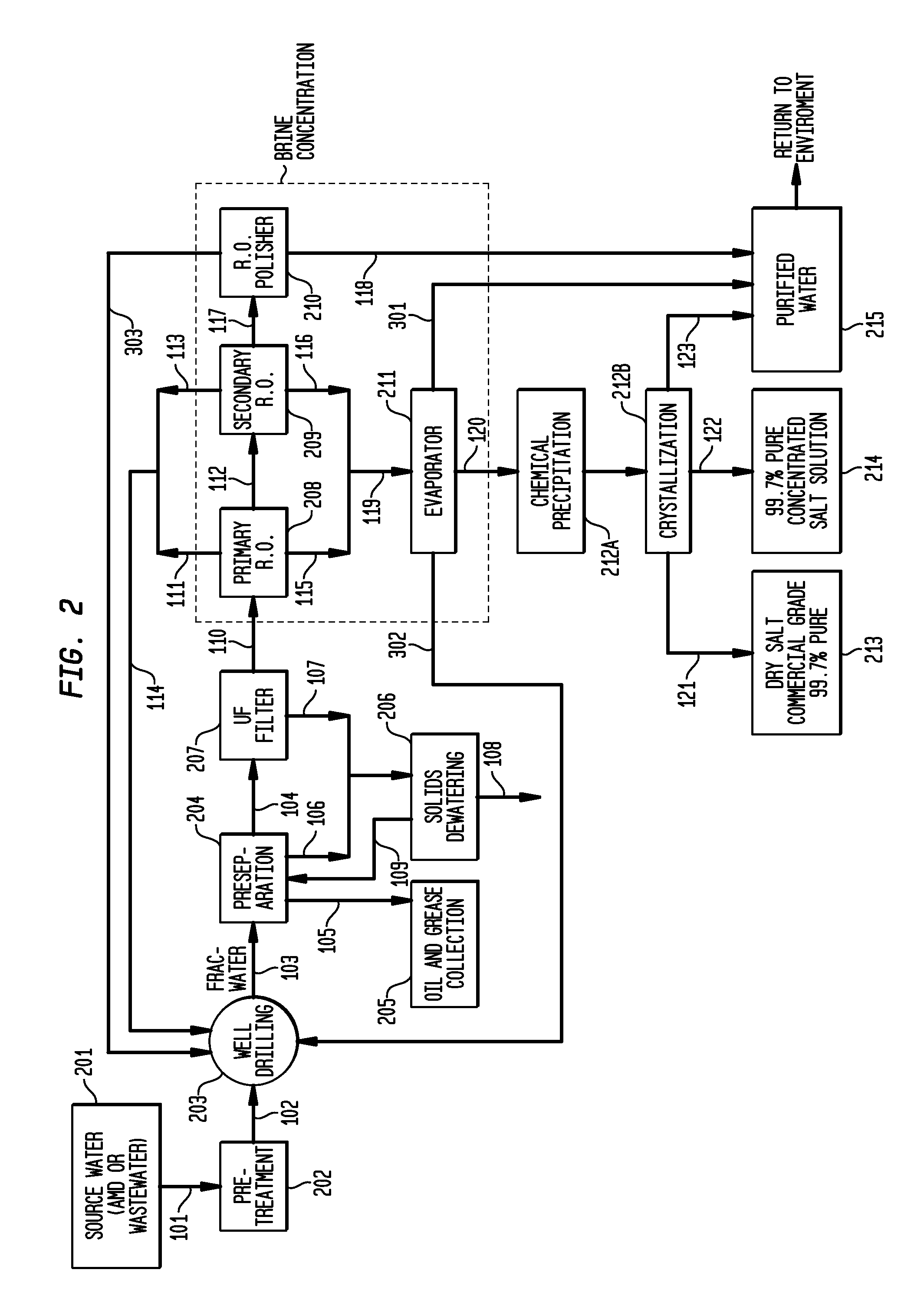

Method of making pure salt from FRAC-water/wastewater

ActiveUS8158097B2Yield maximizationQuality improvementCalcium/strontium/barium carbonatesCalcium/strontium/barium chloridesWater useParticulates

The present invention relates to a method for making pure salt comprises recapturing post-drilling flowback water from hydro-fracturing; removing oil from the flowback water; filtering the flowback water using an ultra filter with a pore size of about 0.1 microns or less to remove solid particulates and large organic molecules, such as benzene, ethylbenzene, toluene, and xylene, from the water; concentrating the flowback water to produce a brine that contains from about 15 wt % to about 40 wt % of salt relative to the total weight of the flowback brine; performing one or more chemical precipitation process using an effective amount of reagents to precipitate out the desired high quality commercial products, such as, barium sulfate, strontium carbonate, calcium carbonate; and crystallizing the chemically treated and concentrated flowback brine to produce greater than 99.5% pure salt products, such as sodium and calcium chloride.

Owner:FRACPURE HLDG

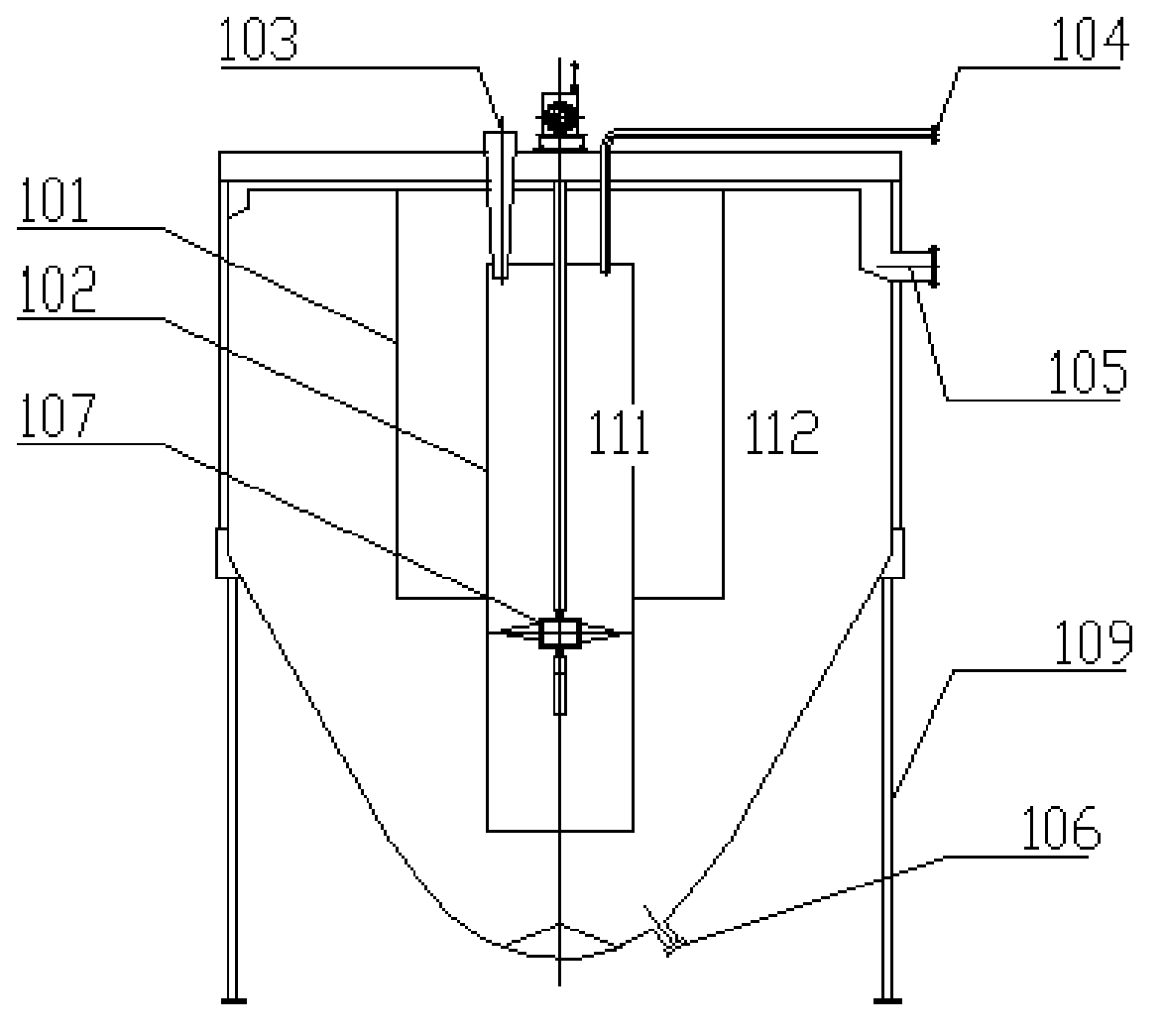

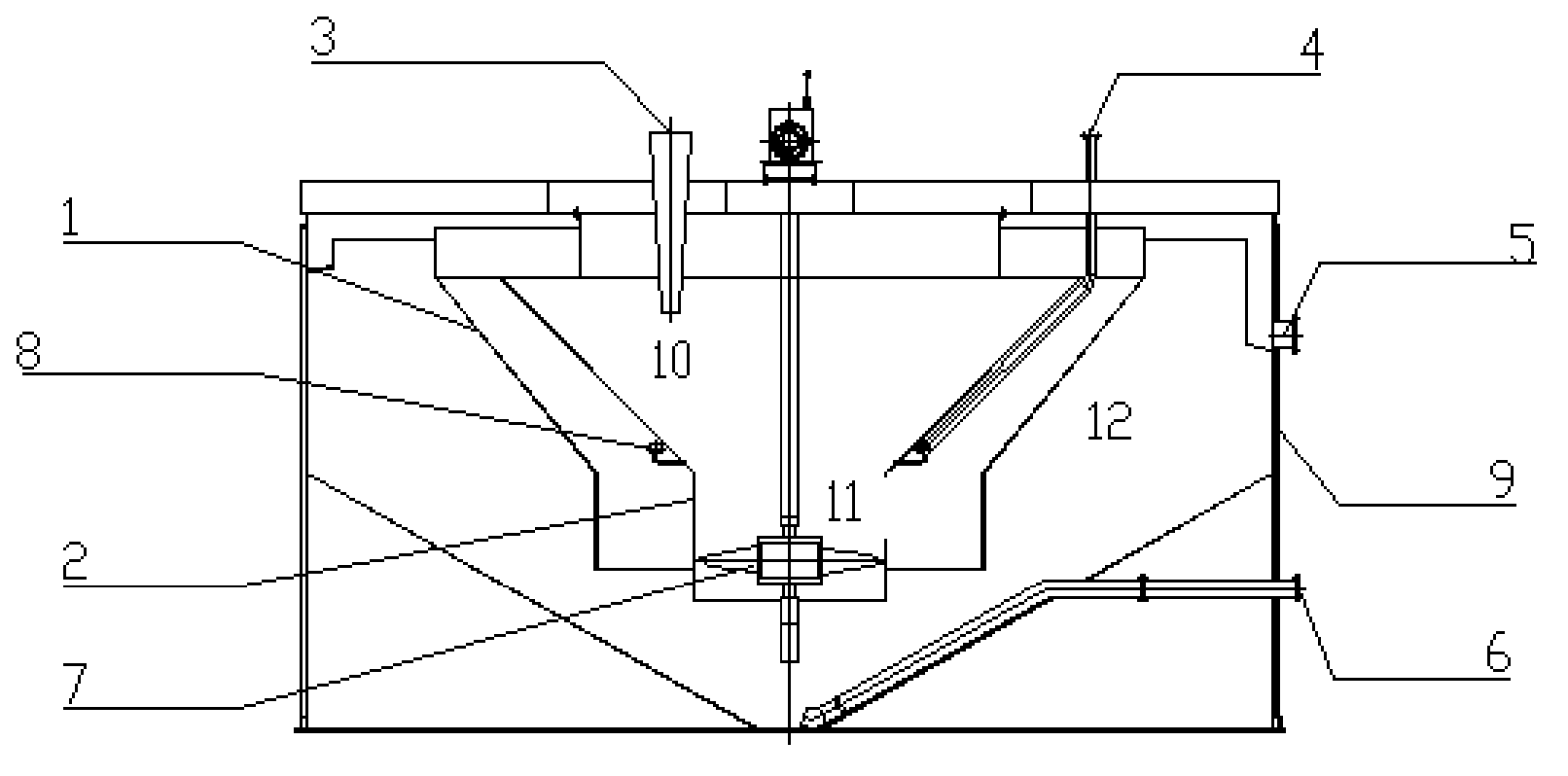

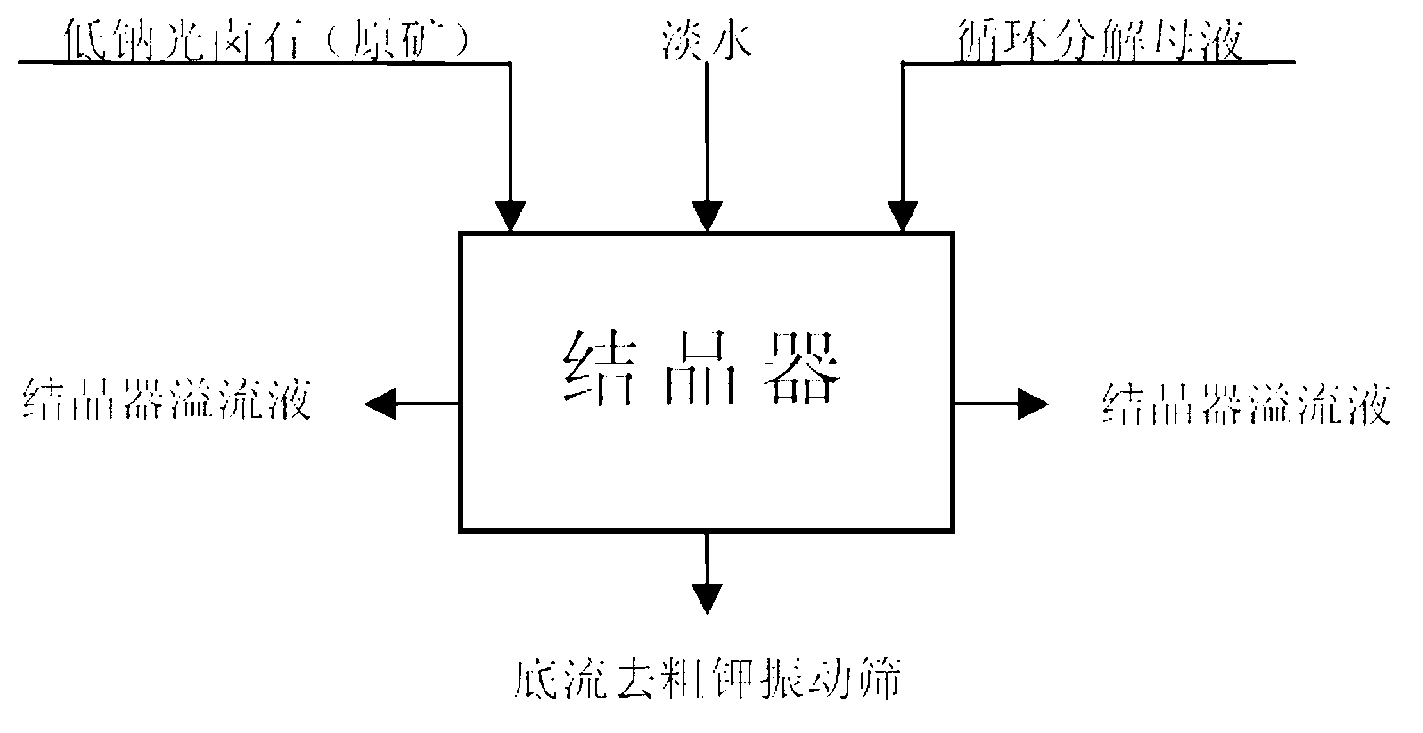

Crystallizer for hydrolyzing carnallite

ActiveCN103073030AIncrease contact areaSolve the problem of overflow from the upper part of the inner cylinder to the bottom of the crystallizer without sufficient mixing and decompositionAlkali metal halide formation shapeDecompositionChloride

The invention relates to a crystallizer for hydrolyzing carnallite. The crystallize comprises an inner cylinder, an outer cylinder, a mother solution distributor, a stirring paddle, a crystallizer cylinder body, a low-sodium carnallite inlet, a mother solution inlet, a decomposition liquid outlet and a product outlet. According to the crystallizer, the remaining time of low-sodium carnallite in a dissolving region can be prolonged, and the problem that low-sodium carnallite is not fully mixed and decomposed and then overflows to the bottom of the crystallizer from the upper part of the inner cylinder in the existing crystallizer is solved; and generated potassium chloride particles can grow above 0.2mm in particle size to ensure that solid potassium chloride is easily dewatered and dried, and washing water and heat energy required by drying are saved.

Owner:ЦИНХАЙ СОЛТ ЛЕЙК ИНДАСТРИ ГРУП КО ЛТД

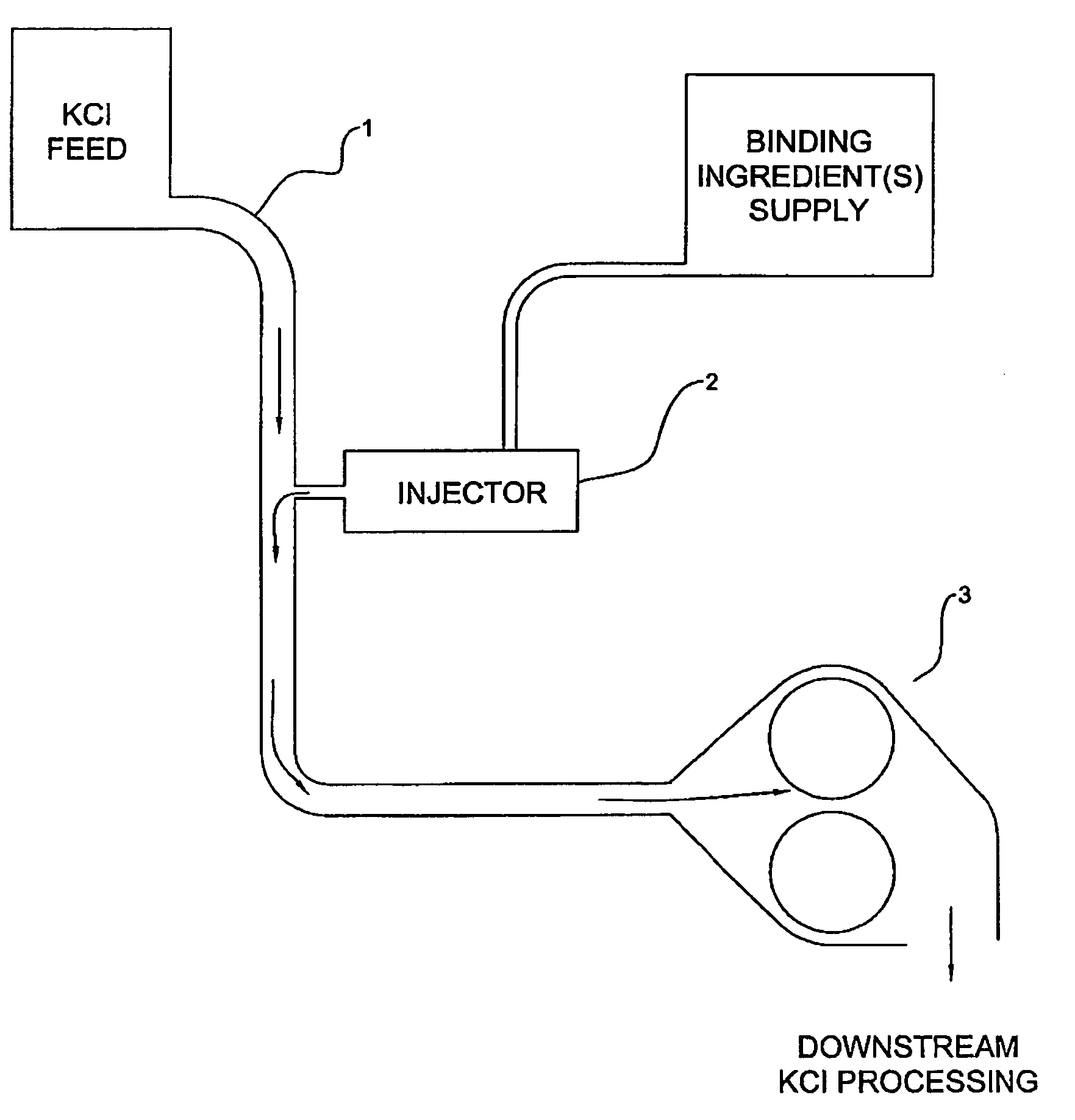

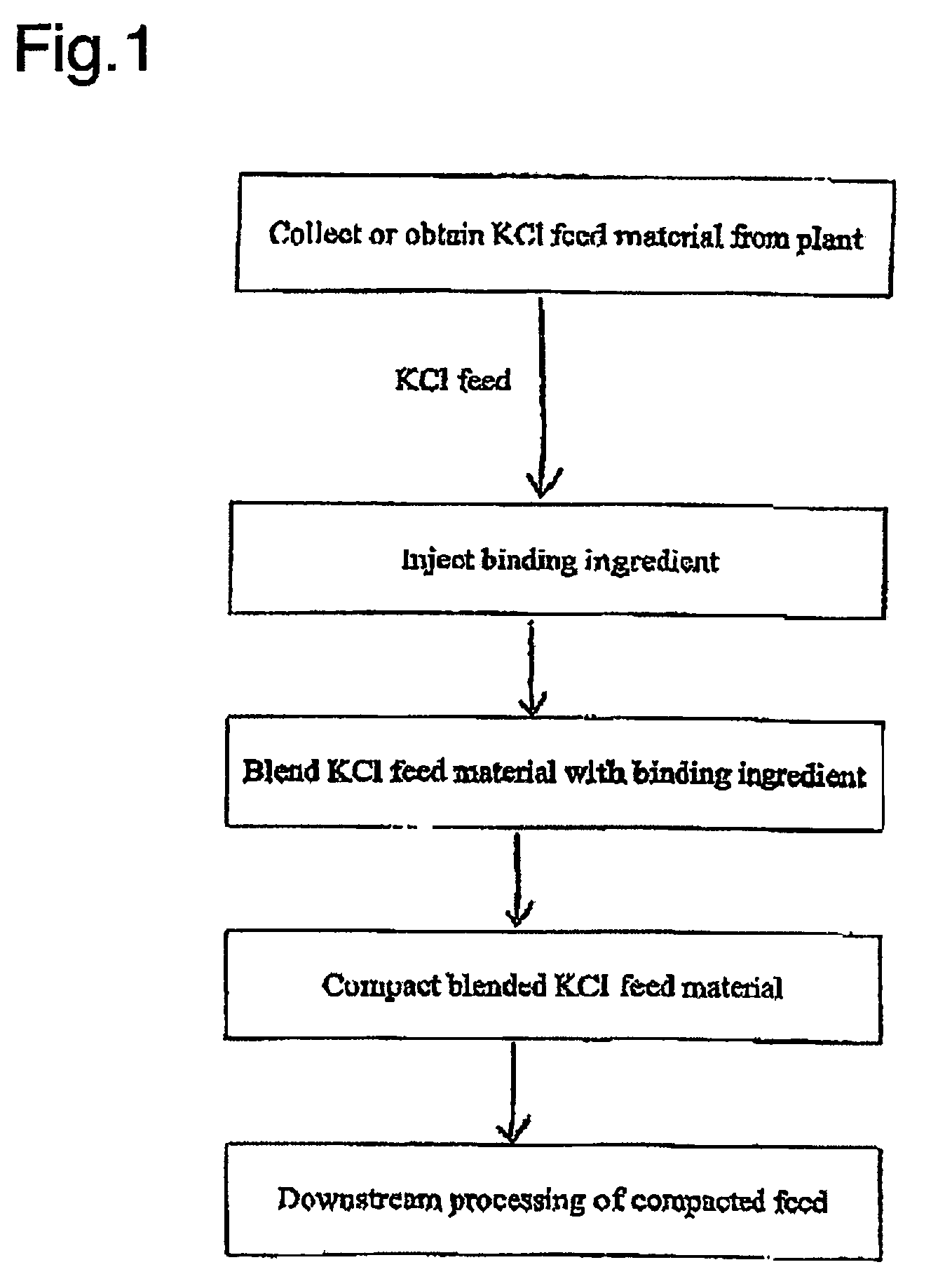

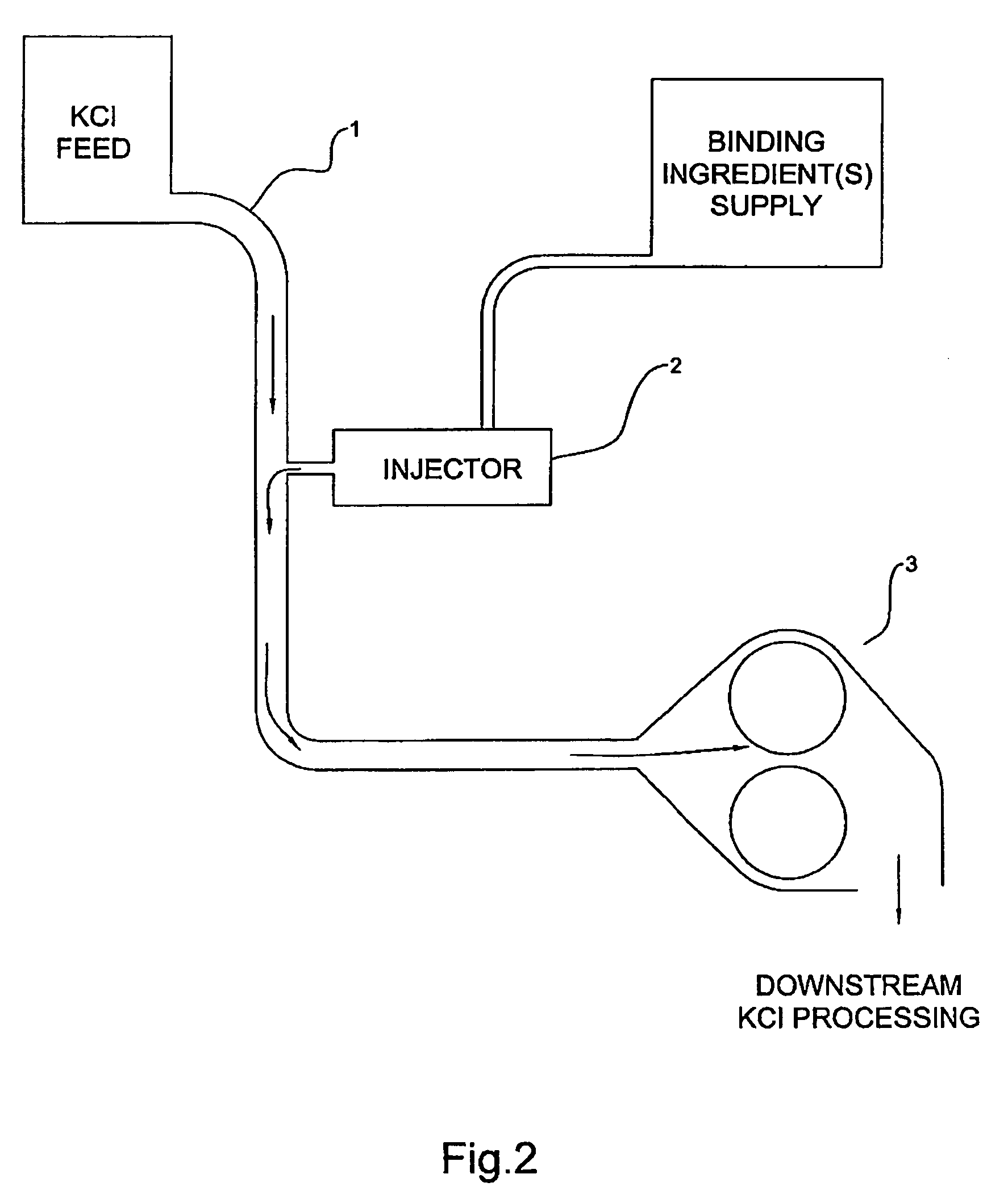

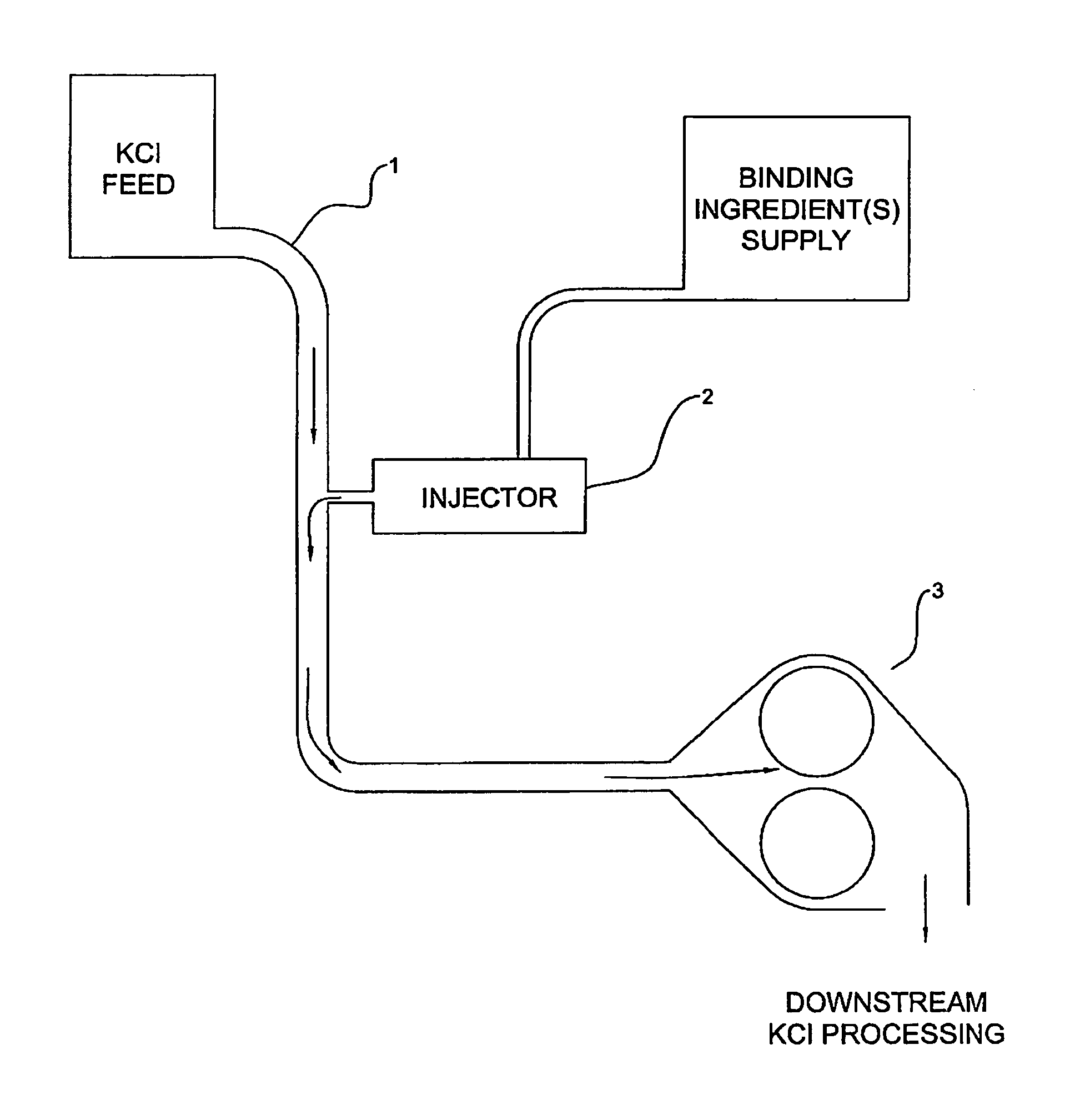

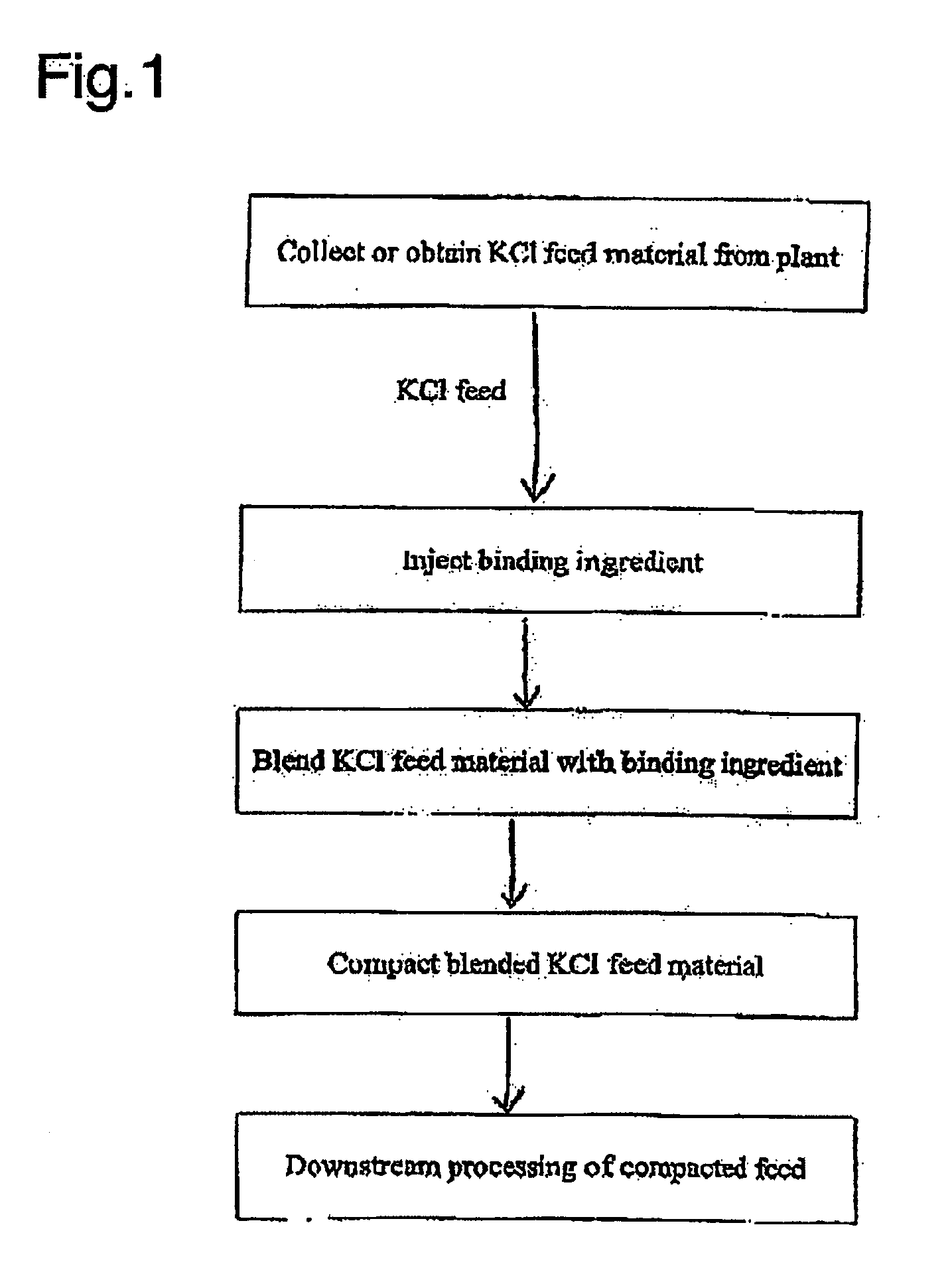

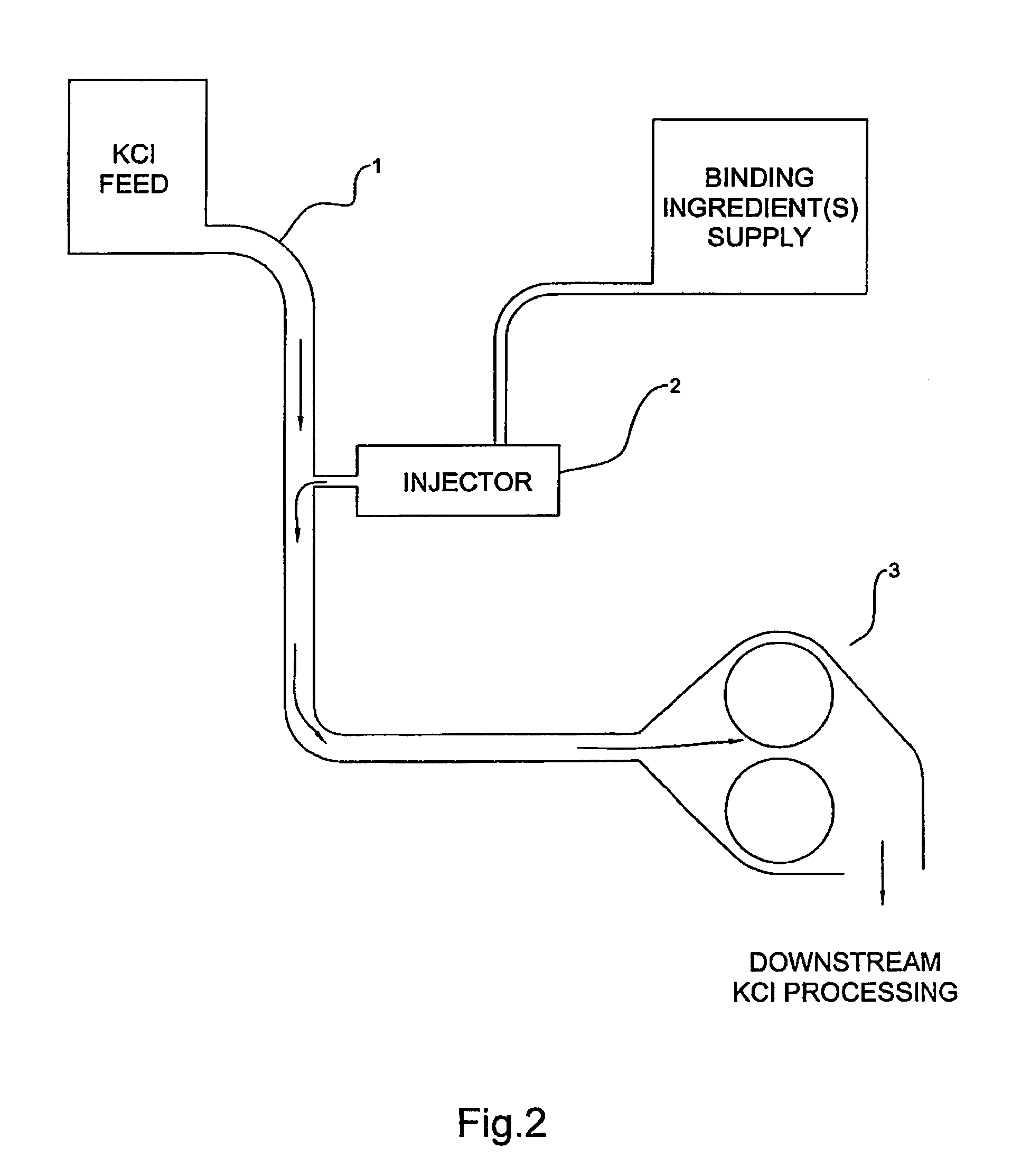

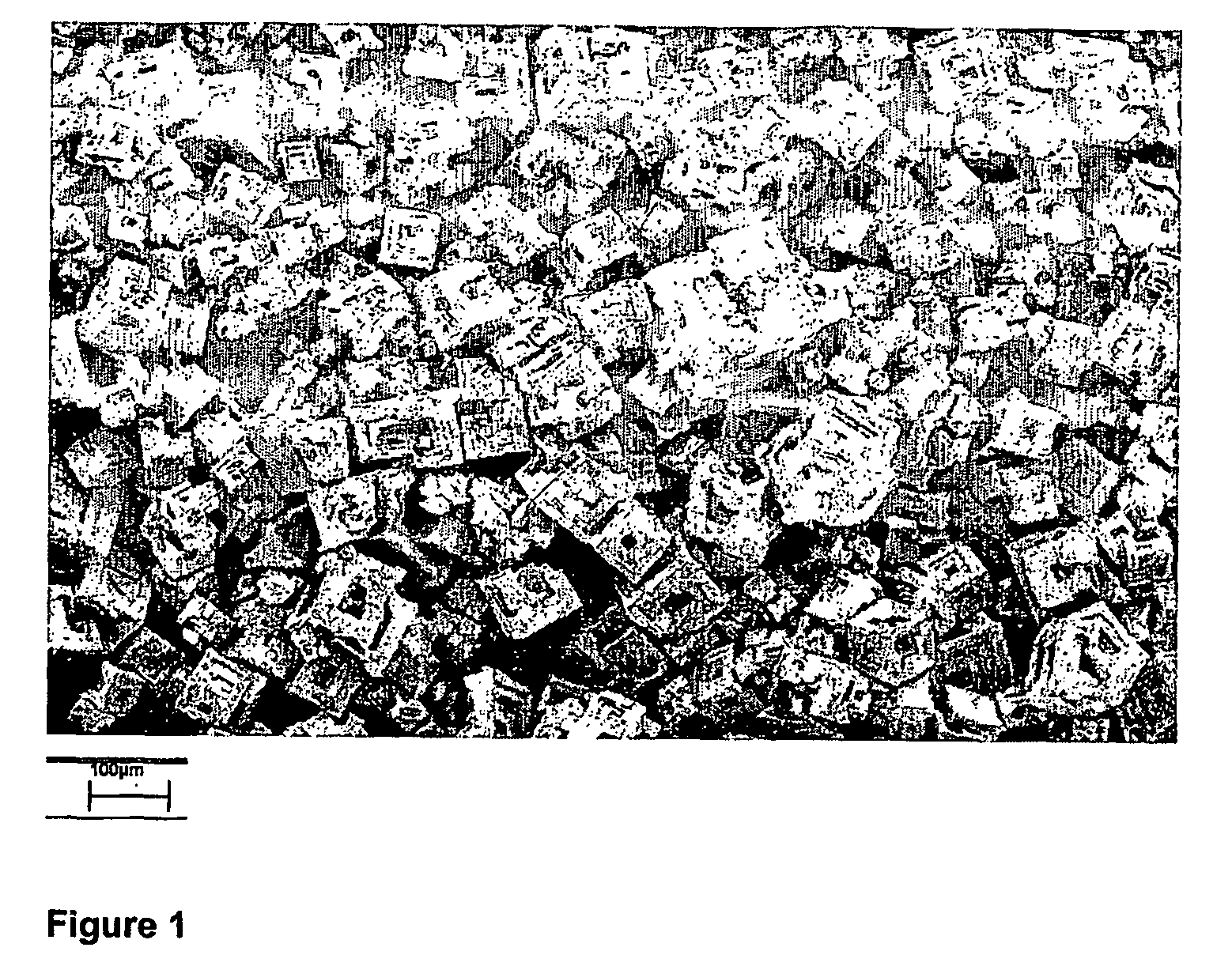

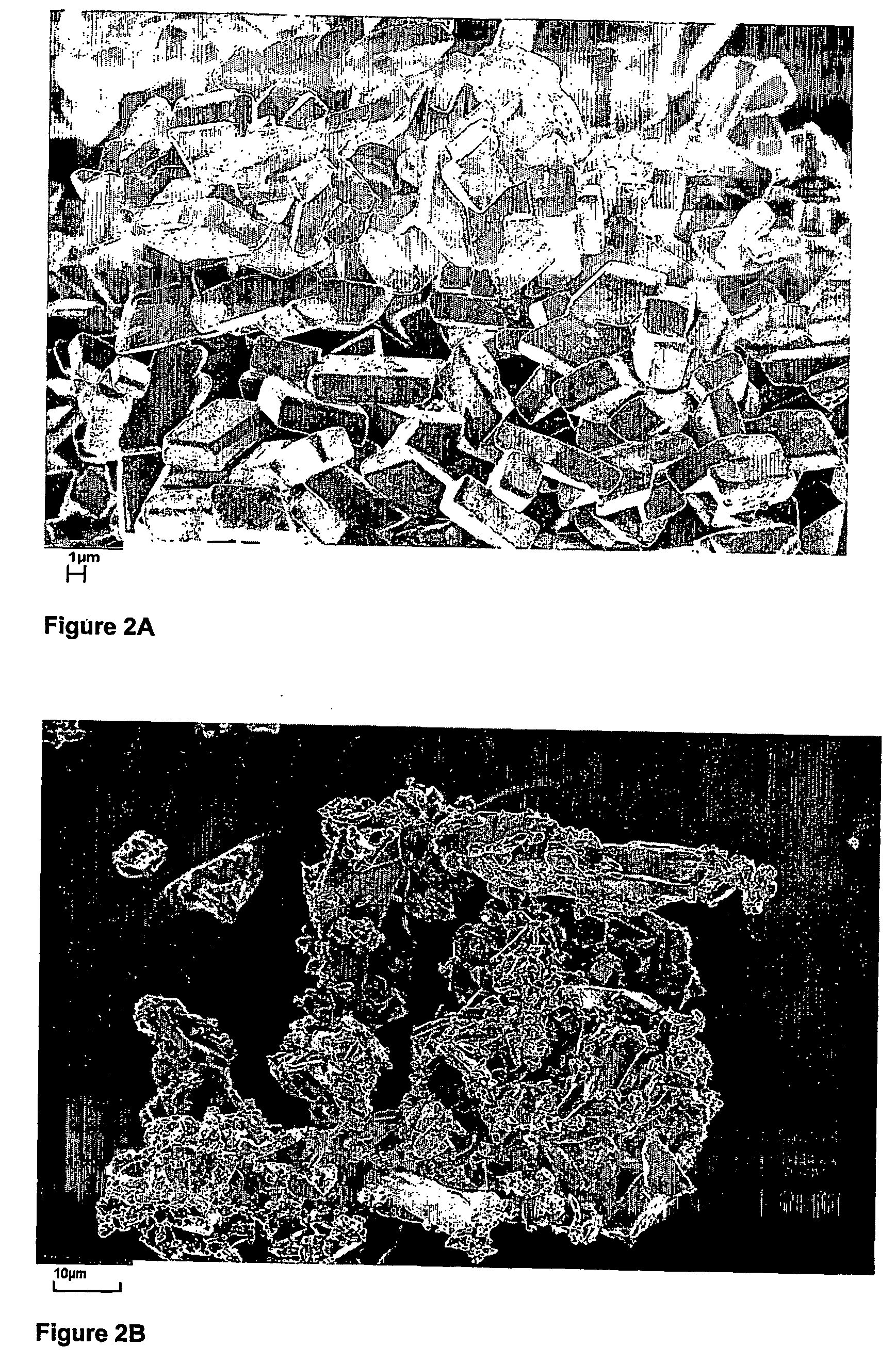

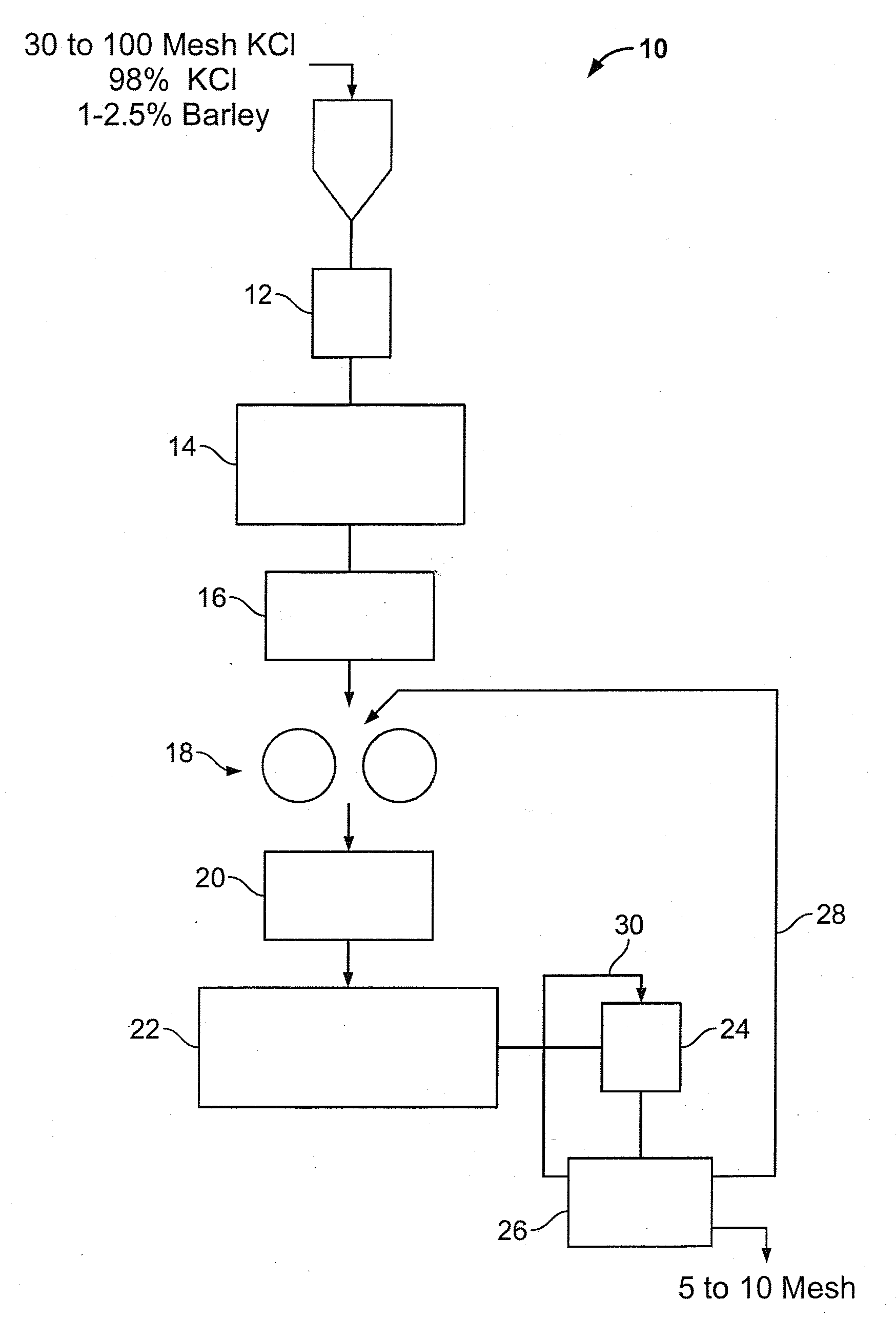

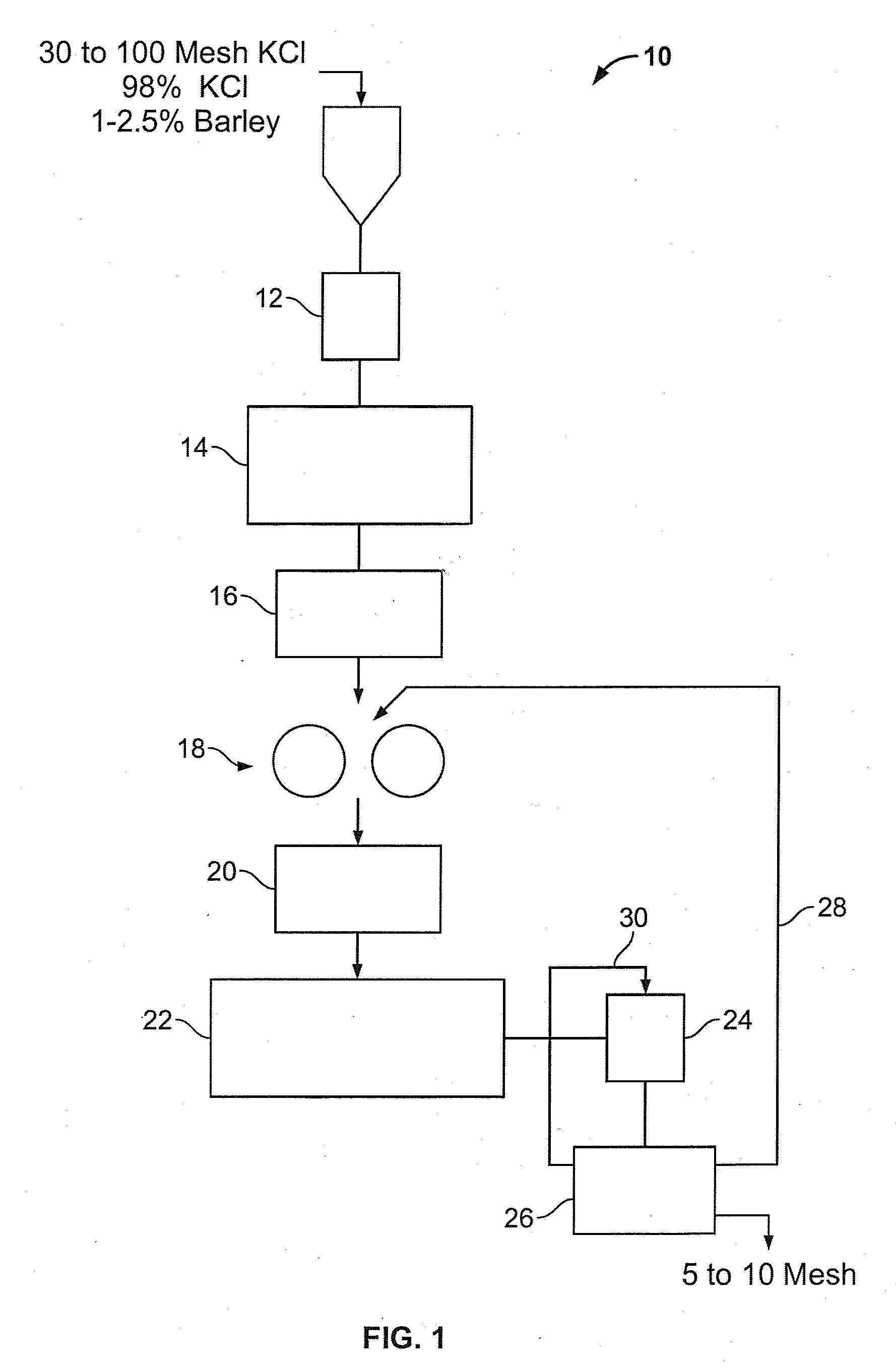

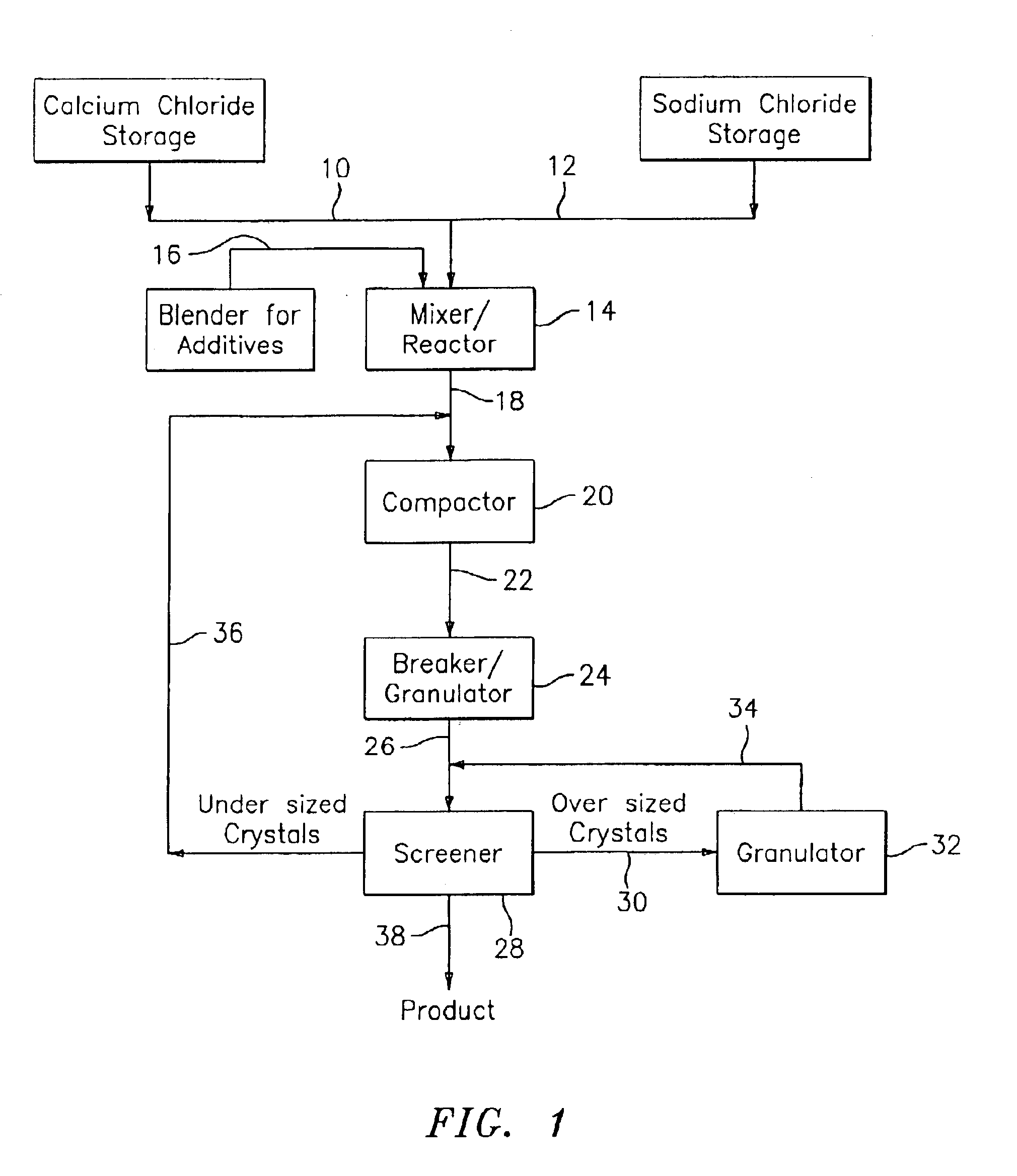

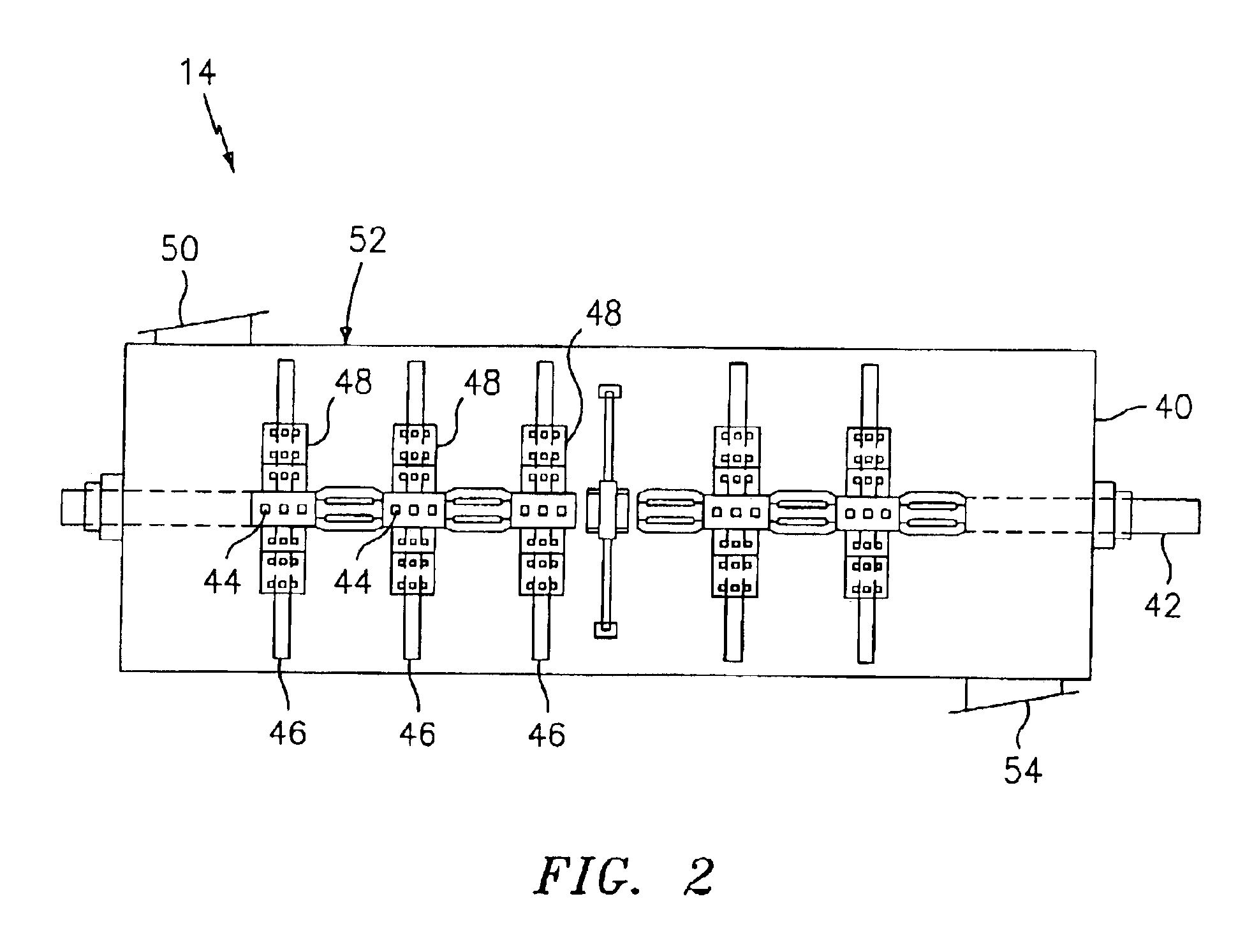

Compacted granular potassium chloride, and method and apparatus for production of same

ActiveUS7727501B2Improve handling qualityLess handlingAmmonium nitratesPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesPotassiumChloride

Apparatus and method are disclosed for the production of compacted granular potassium chloride with improved handling qualities. A binding ingredient such as sodium hexametaphosphate is blended with the potassium chloride feed material in advance of compaction. The product of this apparatus and method has improved handling, storage, strength and other qualities over compacted granular potassium produced using prior art methods.

Owner:THE MOSAIC COMPANY

Compacted granular potassium chloride, and method and apparatus for production of same

ActiveUS20050036929A1Improve handling qualityLess handlingAmmonium nitratesPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesPotassiumChloride

Apparatus and method are disclosed for the production of compacted granular potassium chloride with improved handling qualities. A binding ingredient such as sodium hexametaphosphate is blended with the potassium chloride feed material in advance of compaction. The product of this apparatus and method has improved handling, storage, strength and other qualities over compacted granular potassium produced using prior art methods.

Owner:THE MOSAIC COMPANY

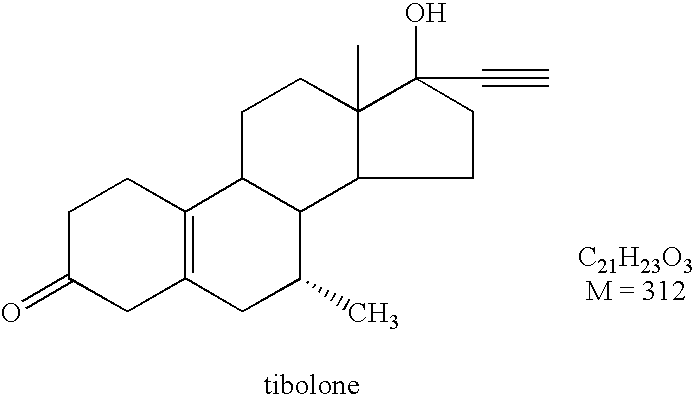

Antisolvent solidification process

The present invention relates to a antisolvent solidification process wherein a liquid medium comprising at least one organic or inorganic compound which is to be solidified is forced through a membrane into one or more antisolvents, or wherein one or more antisolvents are forced through a membrane into a liquid medium comprising at least one organic or inorganic compound which is to be solidified, yielding a composition comprising solid particles comprising said organic and / or inorganic compound(s).

Owner:NV ORGANON

Simultaneous recovery of potassium chloride and KCL enriched edible salt

The present invention relates to recovery of industrial grade potassium chloride and low sodium edible salt from bittern as part of an integrated process. The process comprises, mixing low sulphate concentrated feed bittern (a by-product of salt industry) of density 31.5 to 32.5° Be (sp.gr. 1.277–1.289) with high density end bittern of density 36.5 to 37.5° Be′ (sp.gr. 1.336–1.35), thereby producing low sodium carnallite, from which industrial grade potassium chloride is produced. The resultant bittern is evaporated in forced evaporation system, thereby producing crude carnallite, from which low sodium salt that would be beneficial to persons suffering from hypertension is produced. When sulphate-rich bittern is used, such bittern is desulphated with CaCl2 that is generated from carnallite decomposed liquor through reaction with lime, and wherein low B2O3-containing Mg(OH)2 is a by-product. The entire content of potassium in feed bittern is recovered in the process of the invention.

Owner:COUNCIL OF SCI & IND RES

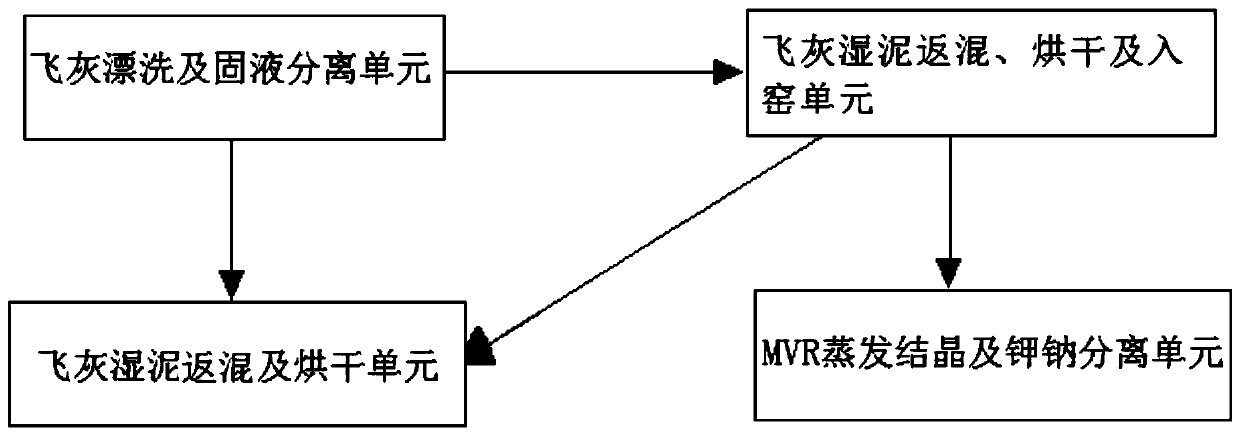

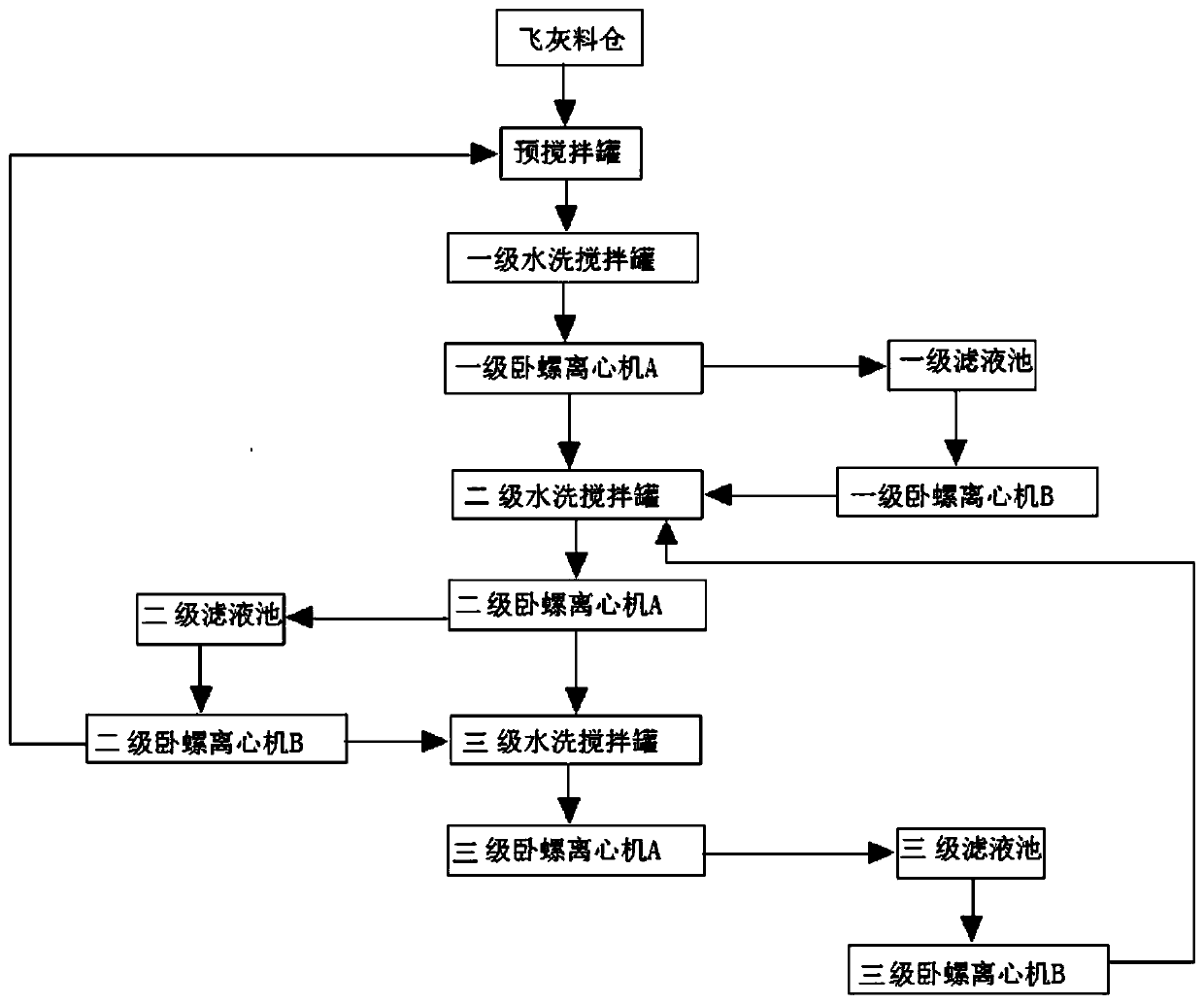

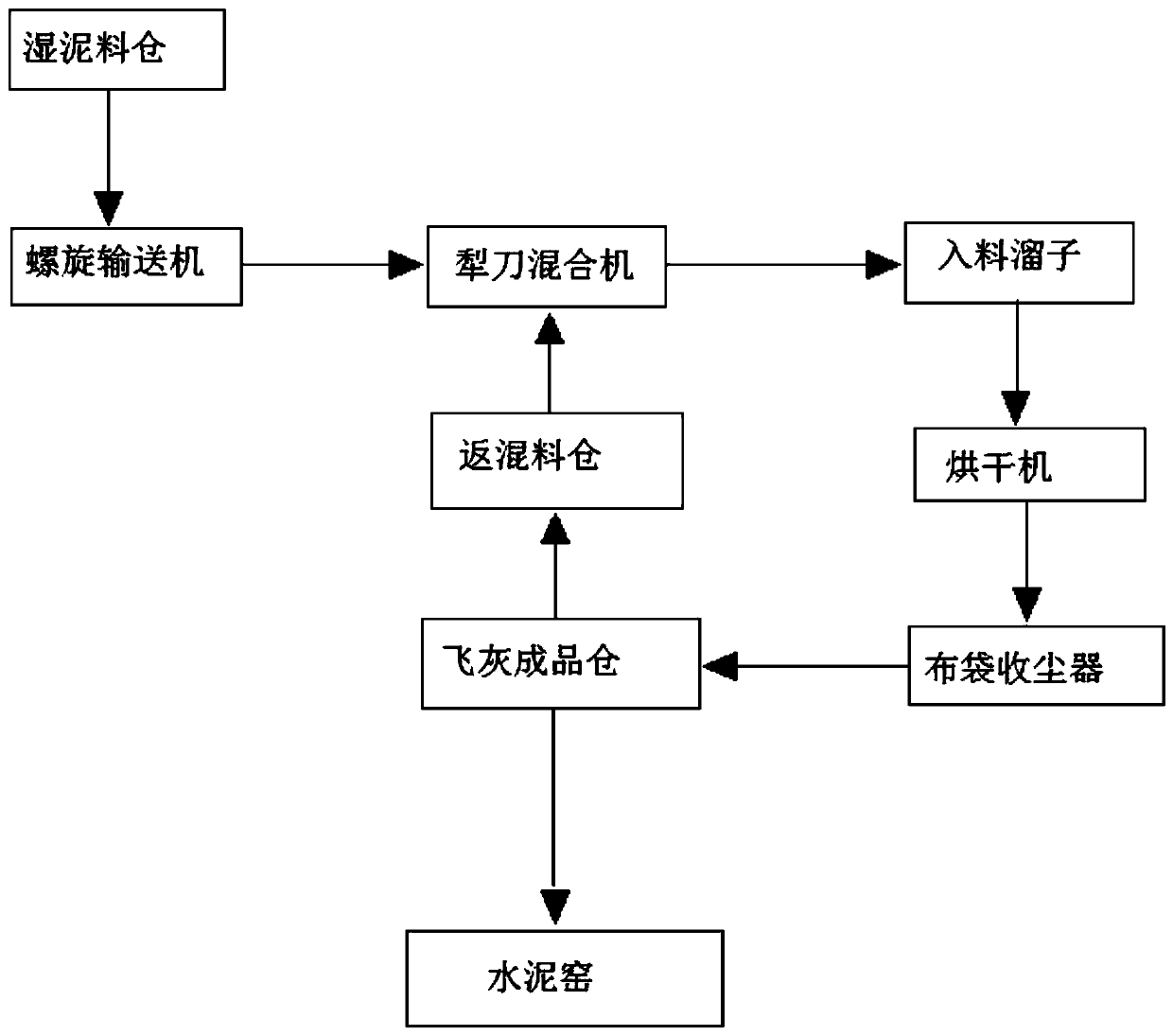

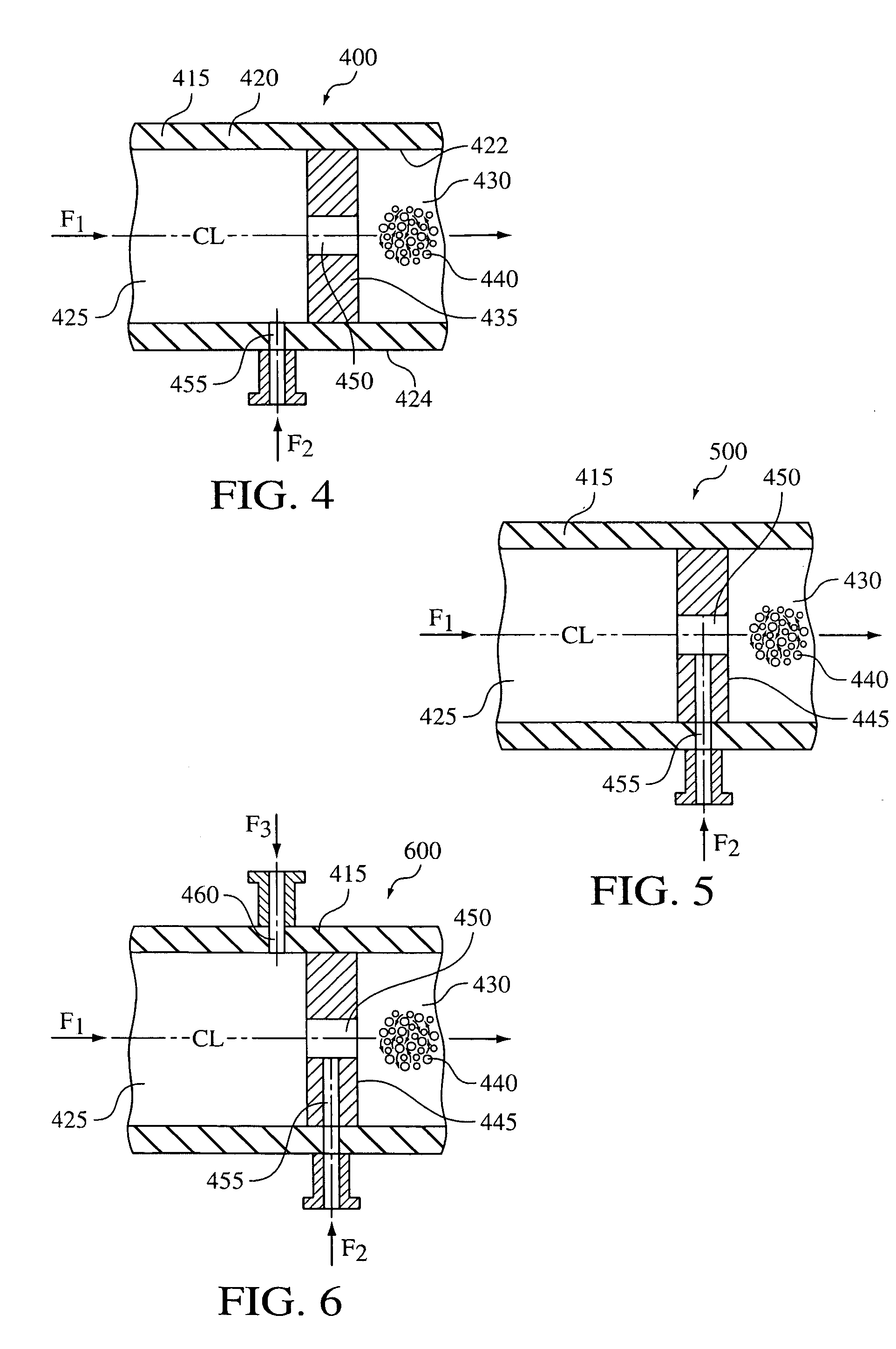

Fly ash washing cement kiln collaborative disposal and resource comprehensive utilization system and method

PendingCN110255933AReduce usageAchieve recyclingWater/sewage treatment by centrifugal separationTransportation and packagingWastewaterFly ash

The invention relates to a fly ash washing cement kiln collaborative disposal and resource comprehensive utilization system and method. The system includes: a fly ash rinsing and solid-liquid separation unit, a fly ash wet mud backmixing, drying and kiln entry unit, a fly ash washing liquid pretreatment unit and an MVR evaporative crystallization and potassium-sodium separation unit. The fly ash rinsing and solid-liquid separation unit is respectively connected to the fly ash wet mud backmixing, drying and kiln entry unit and the fly ash washing liquid pretreatment unit, and the fly ash washing liquid pretreatment unit is respectively connected to the MVR evaporative crystallization and potassium-sodium separation unit and the fly ash wet mud backmixing, drying and kiln entry unit. The system provided by the invention is a resource recycling and comprehensive utilization system, and completely has no discharge of wastewater and waste residue. The fly ash washing cement kiln collaborative disposal and resource comprehensive utilization method provided by the invention is simple, the system setting is reasonable, and by combining the technological characteristics of cement kiln, harmless, reduction and recycling disposal of waste incineration fly ash in large scale can be realized.

Owner:BEIJING LIULIHE CEMENT

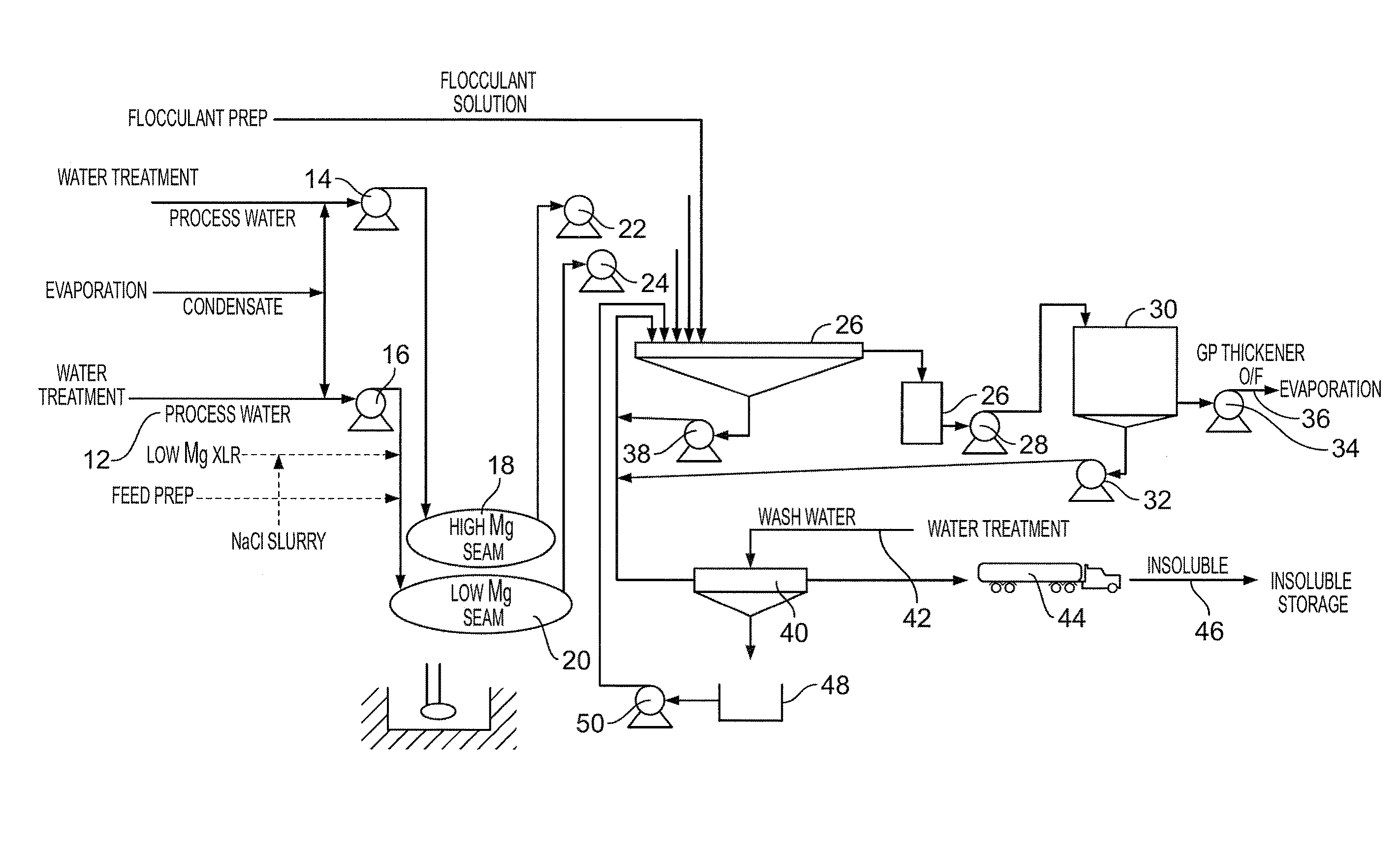

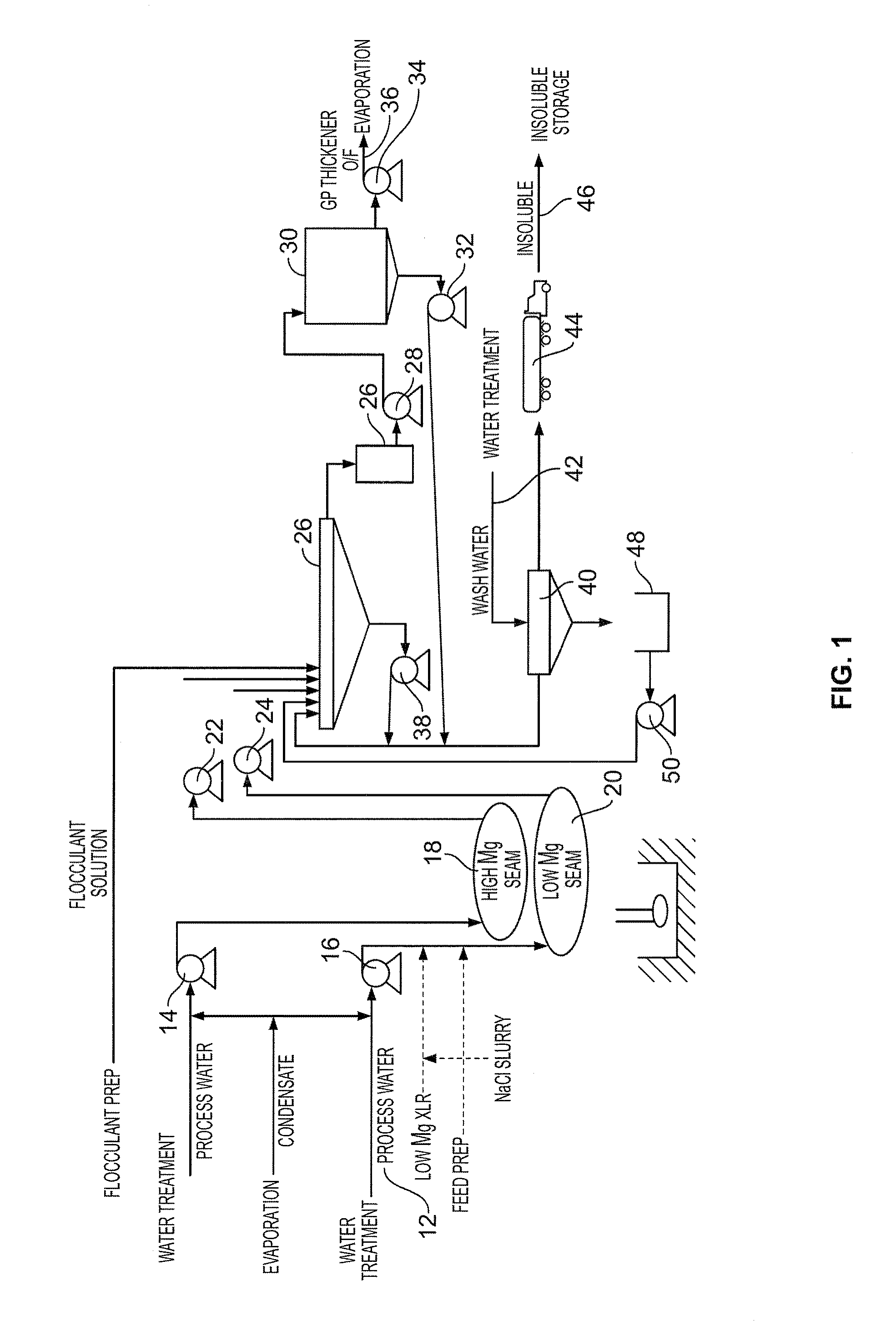

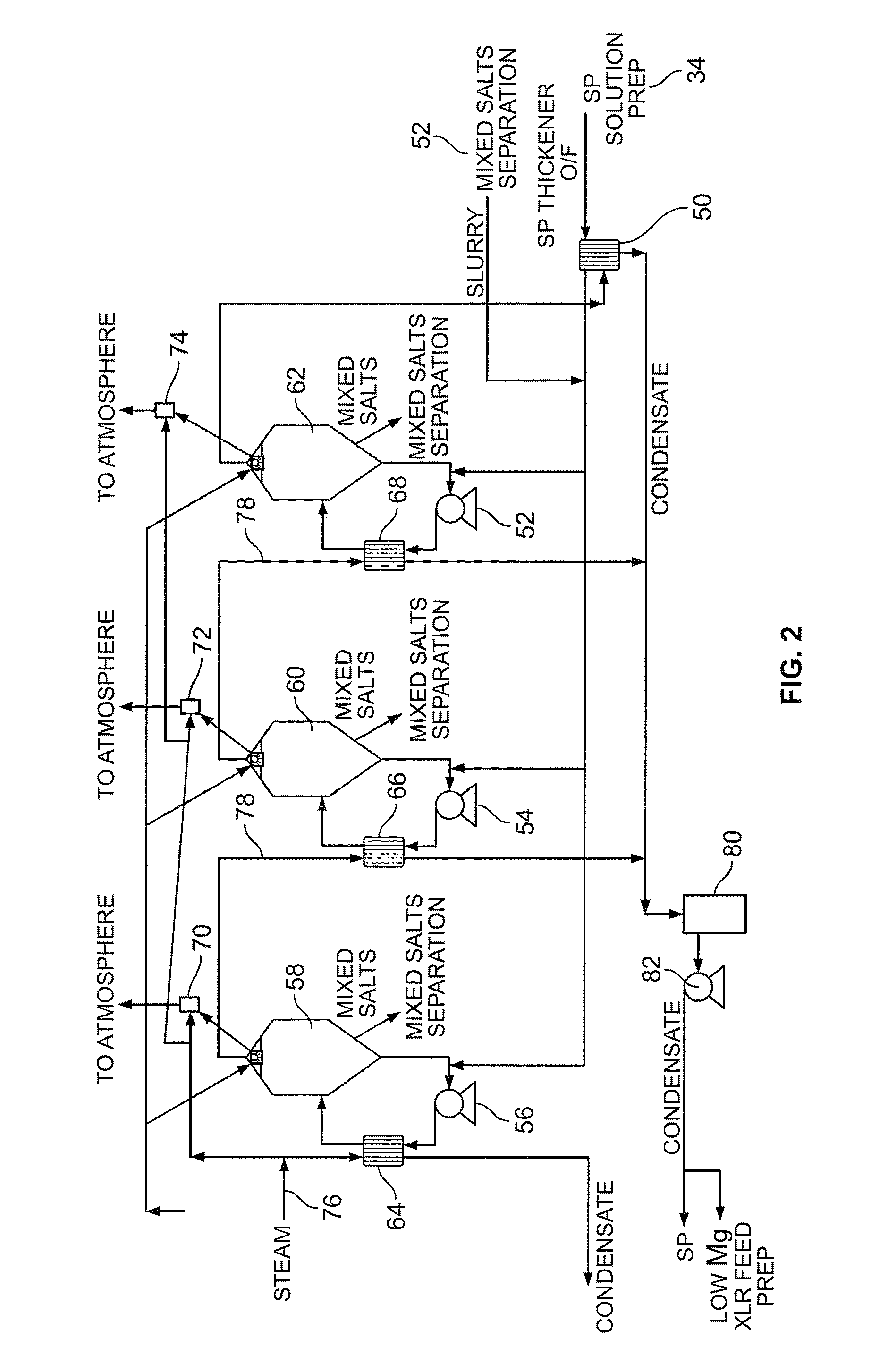

Process for the formulation of potassium chloride from a carnallite source

A process for formulating high purity potassium chloride from a carnallite source. The process takes advantage of solubility differences and saturation levels in a multiple salt system generated upon dissolution of carnallite. In the system, the sodium chloride is kept in solution and the magnesium chloride present in the system is controlled to be in a concentration range of between 12% and 25% by weight. This avoids co-precipitation of sodium chloride with the potassium chloride during crystallization and therefore prevents the sodium chloride from contaminating the potassium chloride. The result is high grade potassium chloride.

Owner:KARNALYTE RESOURCES

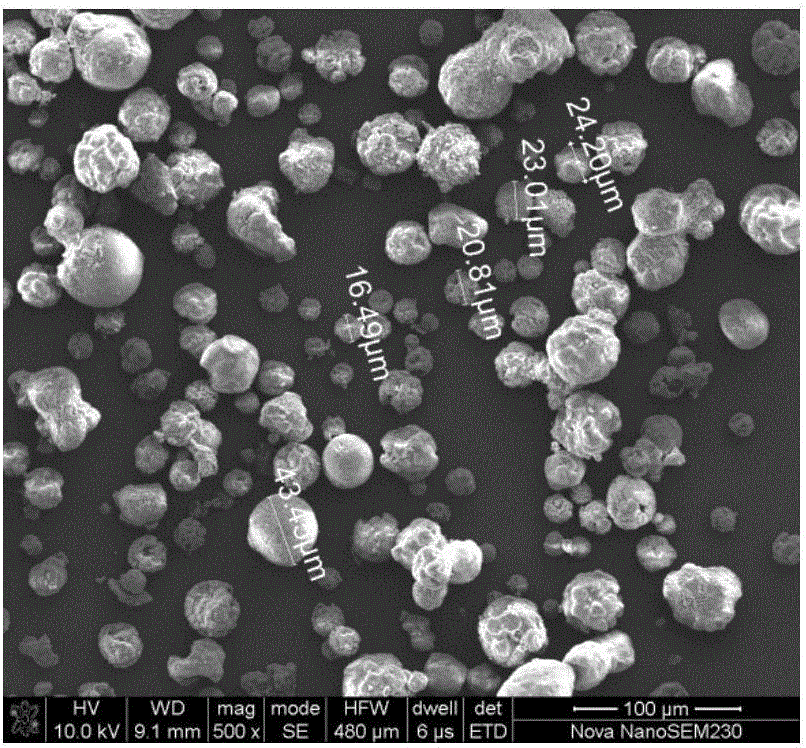

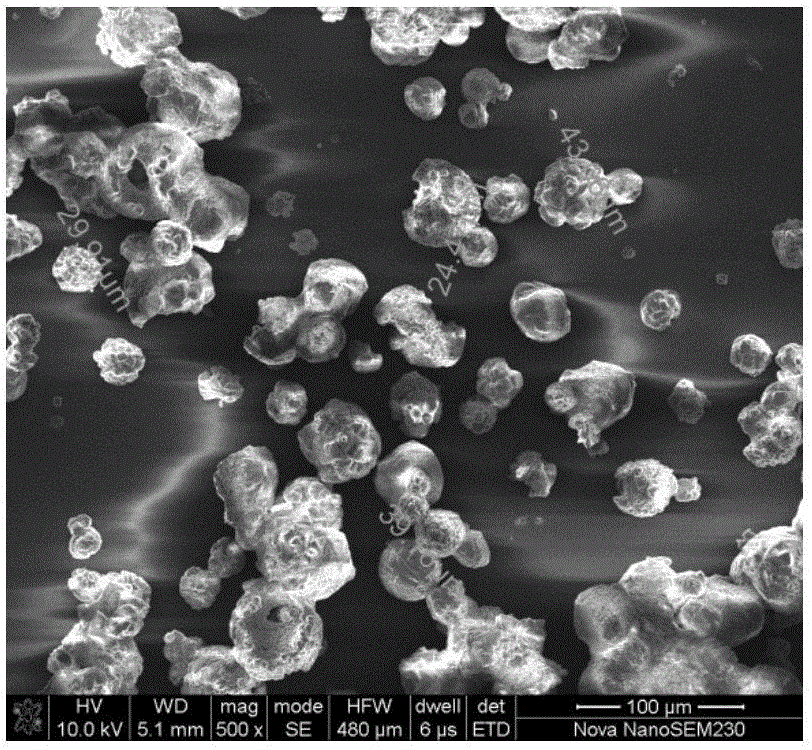

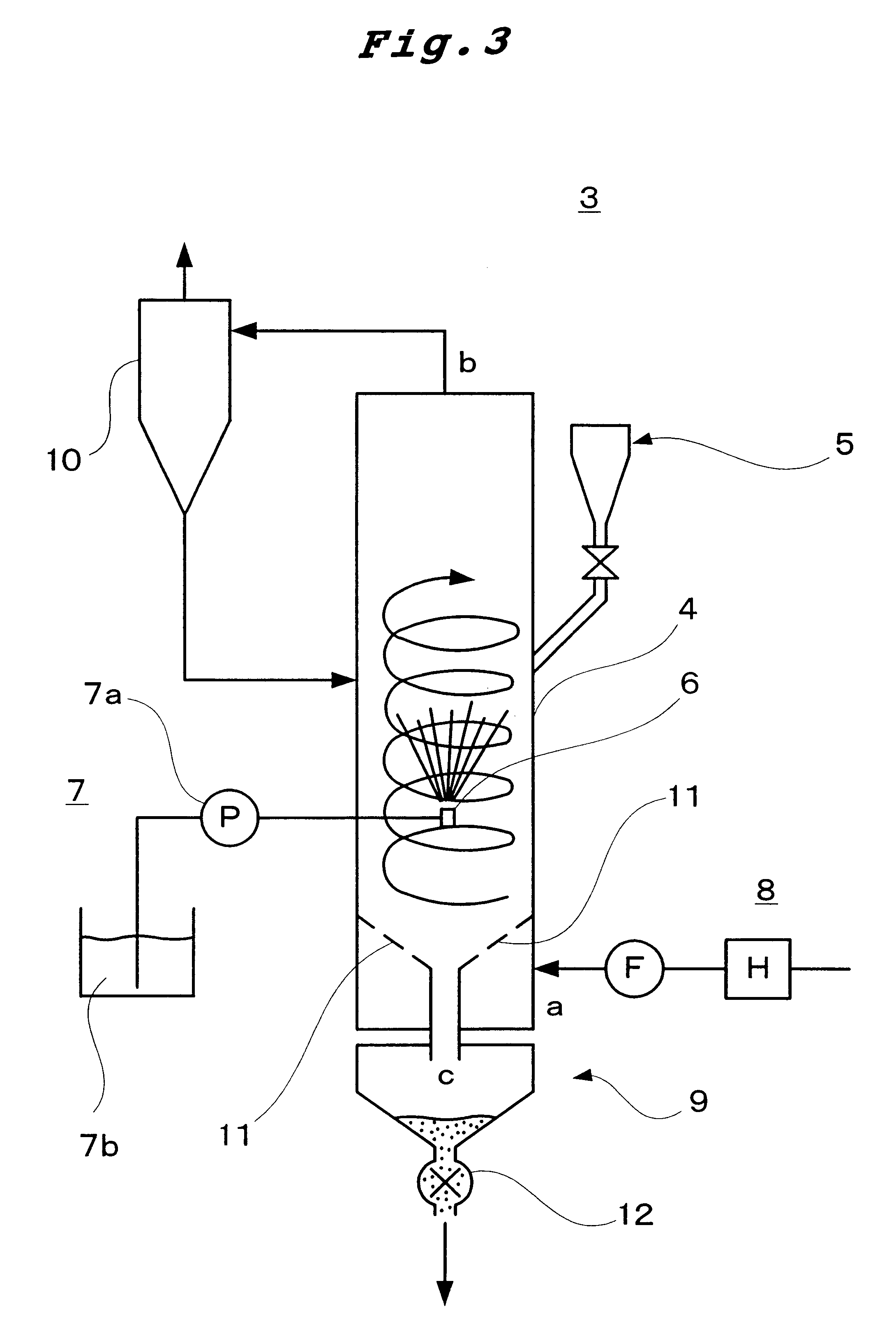

Preparation method of micron superfine spherical sodium chloride

ActiveCN106430251AParticle size controllableSmall particle sizeAlkali metal halide formation shapeAqueous solutionChloride sodium

The invention relates to a preparation method of micron superfine spherical sodium chloride, in particular to a method for preparing micron superfine spherical sodium chloride for pore drilling with glycine used as a control agent with a spray centrifugal drying method through atomization drying equipment. The preparation method comprises steps as follows: glycine is added to a saturated sodium chloride aqueous solution and evenly stirred, and micron superfine spherical sodium chloride is prepared with the spray centrifugal drying method; the adding mass of glycine is 2%-5% of the total mass of the saturated sodium chloride aqueous solution. The preparation process is simple, the particle size is smaller, the yield of superfine sodium chloride is higher, and the method is applicable to batch preparation of the micron superfine spherical sodium chloride powder for pore forming, the operation is simple and flexible, and mass industrial application is facilitated. The prepared micron superfine spherical sodium chloride is applicable for pore forming.

Owner:CENT SOUTH UNIV

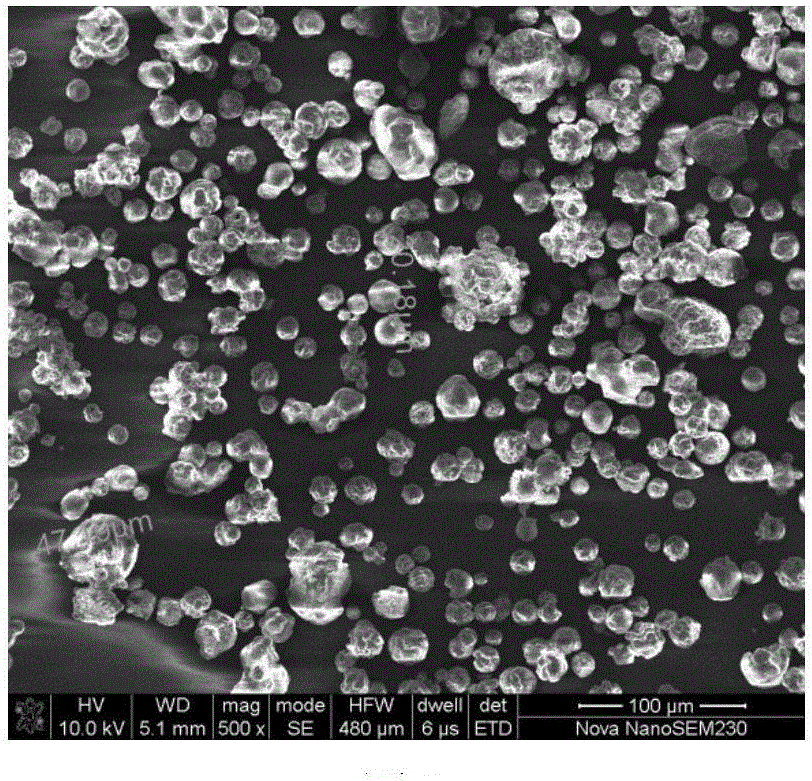

Preparation method for micron order superfine sodium chloride

InactiveCN101565190AHigh yieldSmall particle sizeNanostructure manufactureAlkali metal halide formation shapePolyethylene glycolSolvent

The invention relates to a preparation method for micron order superfine sodium chloride, namely a method for preparing the micron order superfine sodium chloride by a desolvation method. The method comprises the following steps: at room temperature, dissolving sodium chloride into water to prepare a saturated sodium chloride solution; then adding alcohols as counter solvents; adding a modifying agent; stirring the mixture; quickly filtering and collecting crystals; and drying the crystals in a vacuum drying chamber at 80 DEG C to obtain micron order superfine sodium chloride powder, wherein the alcohols can be methanol, ethanol, isopropanol, normal butanol, isobutyl alcohol, 1,2-propanediol or 1,4- butanediol, preferably the ethanol, the isopropanol or the 1,4- butanediol; and the modifying agent can be tween 80, sorbierite, citric acid, polyethyleneglycol-200 (PEG) or polyvinylpyrrolidon (PVP), preferably the sorbierite or the polyvinylpyrrolidon (PVP). The method has simple process; the productivity of the superfine sodium chloride is higher, and the modifying agent is used, so that the granular diameter of the sodium chloride can be markedly reduced and the granular diameter distribution is narrow.

Owner:JIANGSU UNIV

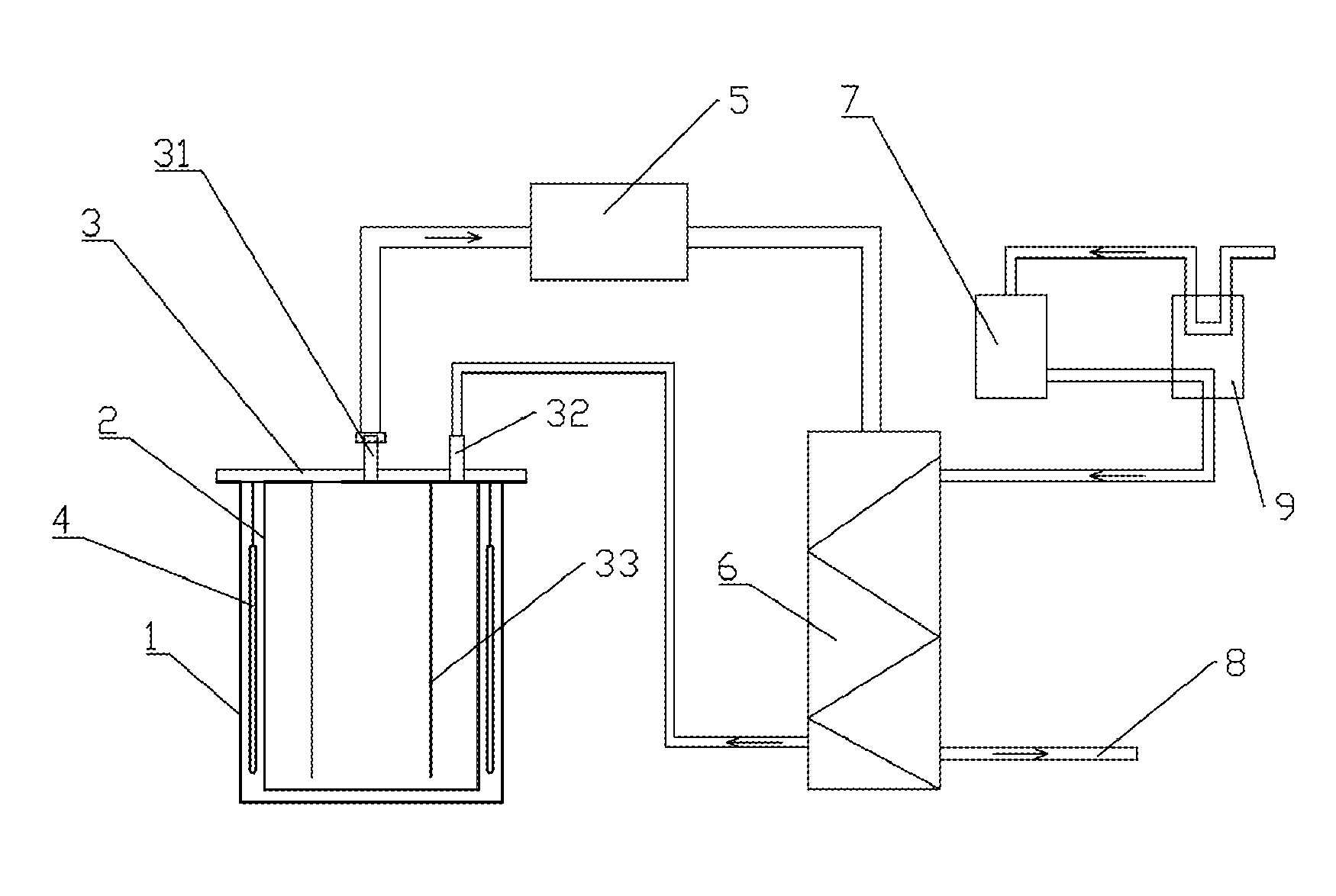

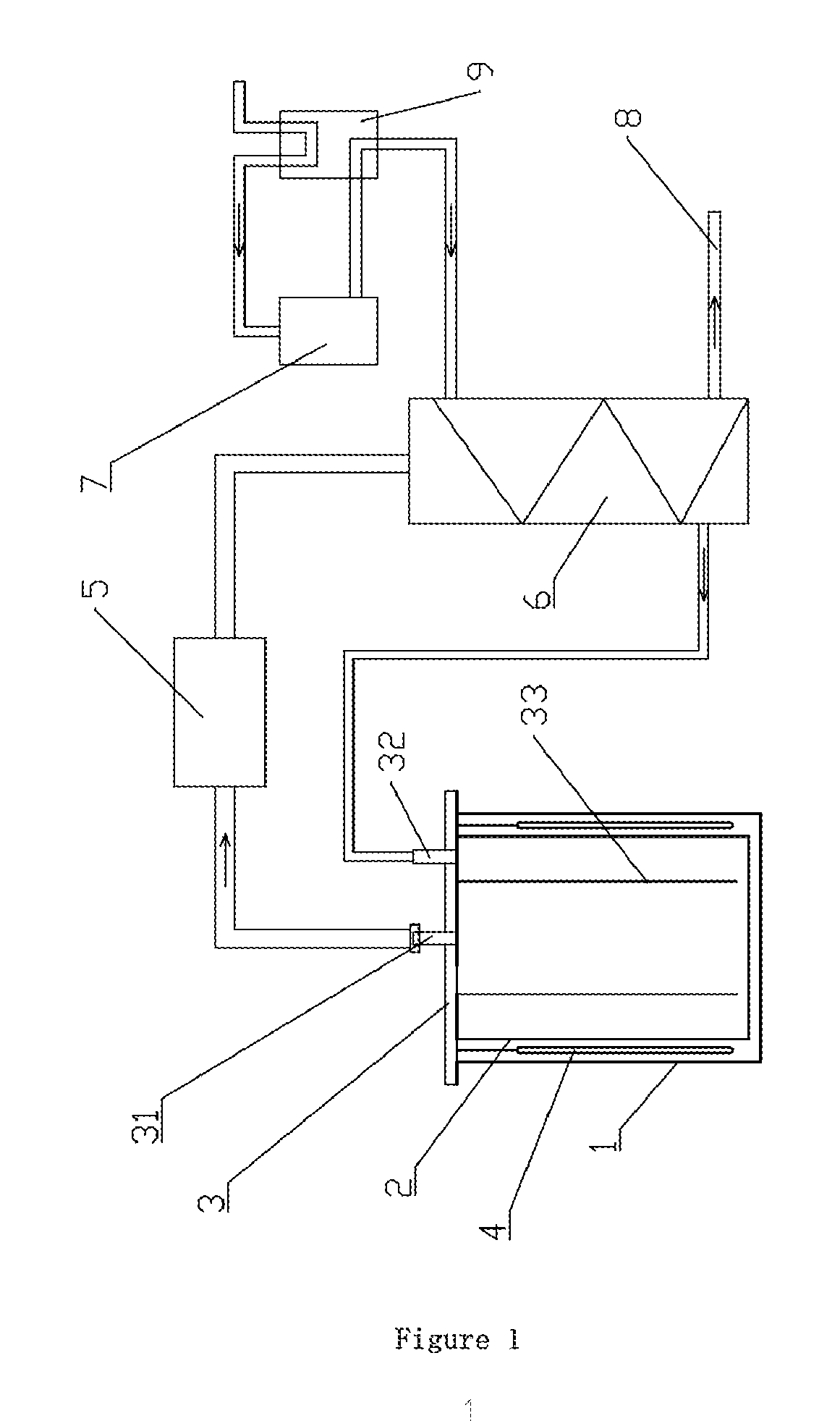

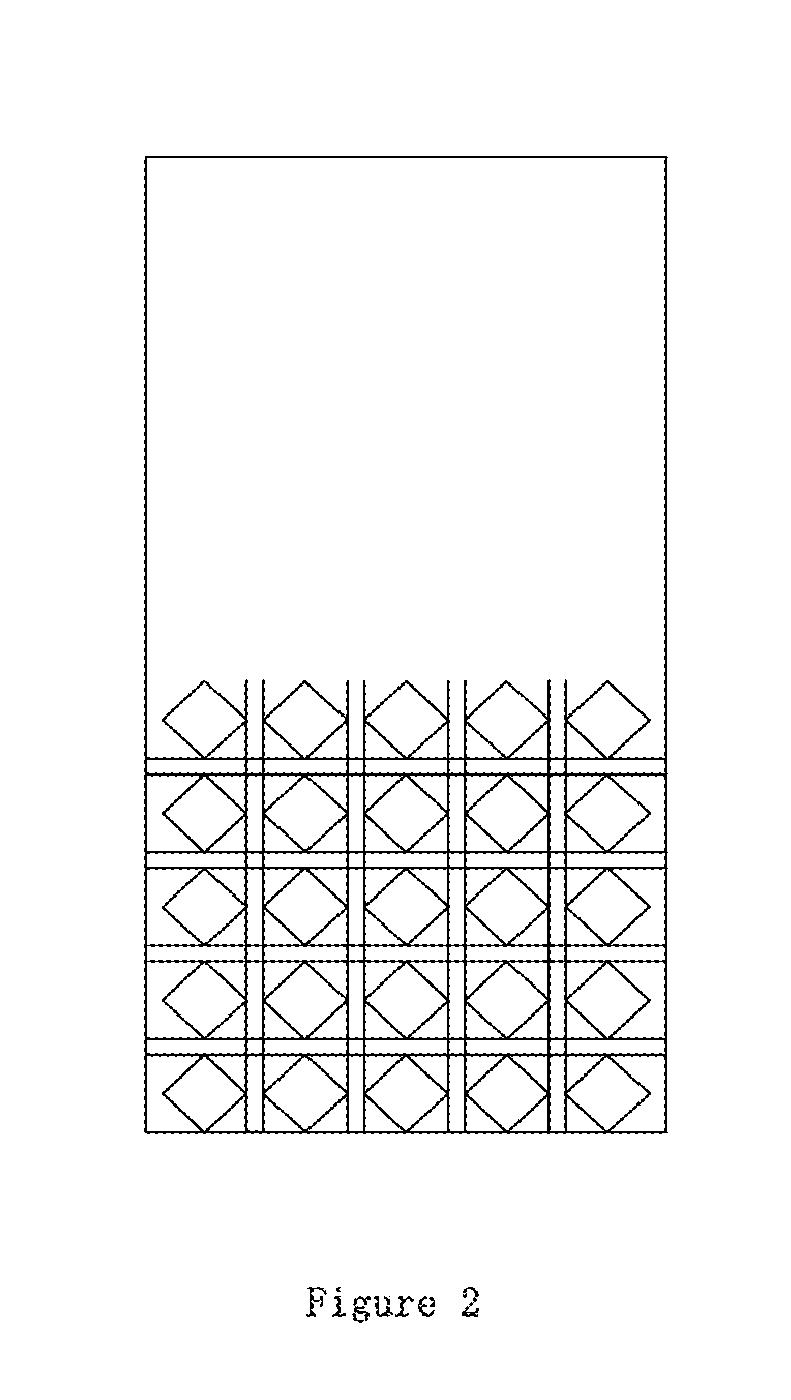

Method and System for Quickly Extracting Lithium Carbonate from Saline Lake Water

ActiveUS20160115040A1Excess saturationIncrease the areaAlkali metal carbonates shape formationCrystallization by component evaporationSaline waterVacuum pumping

The present invention discloses a method for quickly extracting lithium carbonate from saline lake water and a system for the same. The method comprises: first quick-freezing the saline lake water to obtain lithium-rich brine, then evaporating under reduced pressure to enable lithium carbonate to be rapidly precipitated out. The method has advantages of short process flow and less labor consumption, thereby enabling continuous automatic operation, high energy utilization and environment-friendly. Further, the crystallization rate is several times faster than that of the salt-pan process and the grade of lithium carbonate salt mine obtained can reach 95% or more, therefore the method of the present invention is particularly suitable for industrial production in the remote saline lake region. The system comprises a reduced-pressure evaporation crystallizer, a vacuum-pumping apparatus, a brine preheating apparatus and a brine cooling apparatus, which concentrates the brine by quick-evaporation of the water, promotes lithium carbonate to form non-uniform nucleus, and improves the crystallization efficiency.

Owner:ZHU BINYUAN +1

Melting and purifying method for acquiring high purity NaCl crystal grains

ActiveCN106629780AThe taste is refreshing and deliciousReduce production energy consumptionAlkali metal halide purificationAlkali metal halide formation shapeSocial benefitsWater discharge

The invention discloses a melting and purifying method for acquiring high purity NaCl crystal grains. A technical method does not have waste water discharge, the equipment is simple, production has low energy consumption and high efficiency, purity of the obtained NaCl product reaches 99.99% or above, and the product yield is higher than 80%. The method can be used for substantially improving production efficiency of large scale industrial preparation of the high purity NaCl material, and the economic benefits and social benefits are predicted to be considerable.

Owner:吉林光盐三百国际贸易有限公司

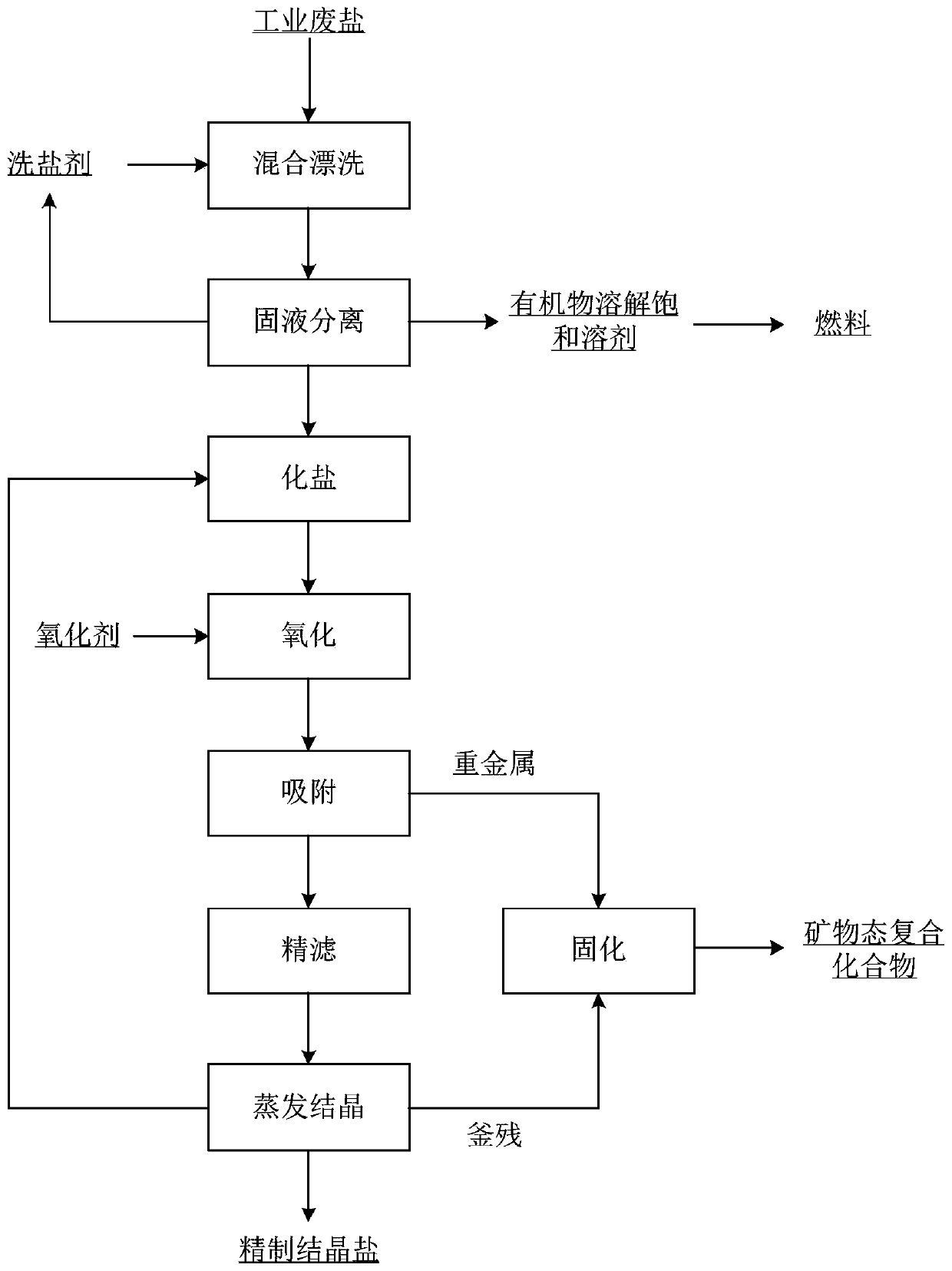

Method for refining industrial waste salt

InactiveCN110642270AAchieve refinementMaximize resource utilizationAlkali metal sulfite/sulfate purificationAlkali metal halide purificationFiltrationProcess engineering

The invention relates to a method for refining an industrial waste salt. The method comprises the following steps: the industrial waste salt is mixed and preprocessed with a salt leaching agent, and then solid-liquid separation is carried out to obtain a preprocessed salt and a filtrate; the preprocessed salt is subjected to salt dissolving, and then is oxidized to obtain a primary treatment liquid; and the primary treatment liquid is adsorbed and finely filtered, and then is crystallized to obtain a refined crystallized salt. The method realizes effective separation of organic matters and salt in the waste salt, ensures effective separation and removal of the organic matters in the industrial waste salt and adsorption and fine filtration removal of other impurities in the industrial wastesalt, and realizes the refining of the high-quality crystallized salt. The method has the advantages of simple process, low energy consumption, low cost and mild conditions, does not produce industrial three wastes in the treatment process, and is an environmentally-friendly salt refining technology.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Potassium-chloride product and preparation method thereof

The invention discloses a salt-compound product and a preparation method thereof and concretely relates to an edible potassium-chloride product and a preparation method thereof; the mass of potassium-chloride crystal particles with the granularity of more than 0.5mm in the potassium-chloride product accounts for more than 80 percent of that of the potassium-chloride product; and the average granularity of the crystal particles in the potassium-chloride product disclosed in the invention is larger, so that when potassium chloride is used for preparing edible salt, particularly low-sodium salt, the potassium-chloride crystal particles and sodium-chloride crystal particles in the edible salt are more uniformly distributed, and furthermore, the intaking amount of the potassium chloride is more uniform when people use the edible salt each time.

Owner:YIYANTANG YINGCHENG HEALTH SALT MFG

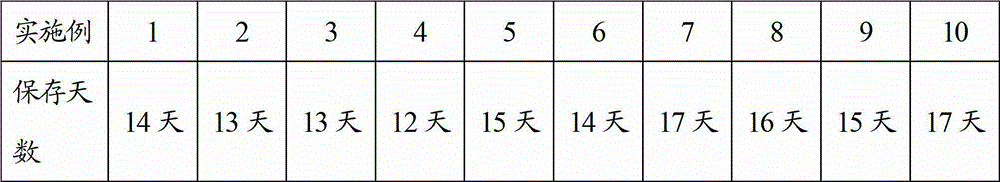

PTA incineration boiler ash residue solution salt separation crystallization process

ActiveCN112811444AFulfill quality requirementsRealize resourcesAlkali metal carbonates shape formationEnergy inputPhysical chemistryWastewater

The invention relates to a PTA incineration boiler ash residue solution salt separation crystallization process, and belongs to the technical field of evaporative crystallization. The process comprises the following steps of: dissolving ash of the PTA incineration boiler with waste heat into a nearly saturated solution of sodium carbonate and sodium bromide, and removing metals and other insoluble substances from the solution by adopting a metal sintering filter, separating the obtained filtrate by adopting an evaporative crystallization method to obtain sodium carbonate monohydrate crystals, removing sodium carbonate from the mother liquor by adopting a replacement method, and then separating by adopting an evaporative crystallization method to obtain sodium bromide crystals. Sodium carbonate and sodium bromide in the PTA boiler ash are separated and recovered by adopting an evaporative crystallization method, the process flow is simple, the operation conditions are simple, convenient and stable, and industrialization is facilitated; the high-purity sodium carbonate and sodium bromide recovered by the method can meet the quality requirements of industrial-grade products and can be directly recovered and reused or sold as by-products, so that the purpose of treating waste residues and wastewater is achieved, the requirements of the current environmental protection situation are met, waste can be turned into wealth, recycling of salt is realized, and the benefits of factories are improved.

Owner:河北工大晟珂工程科技有限公司

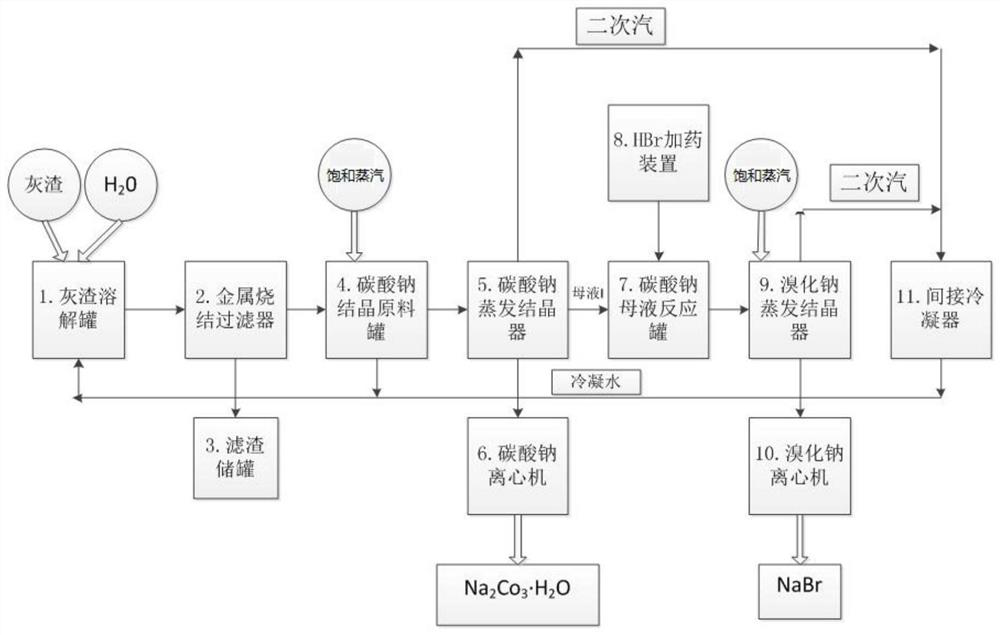

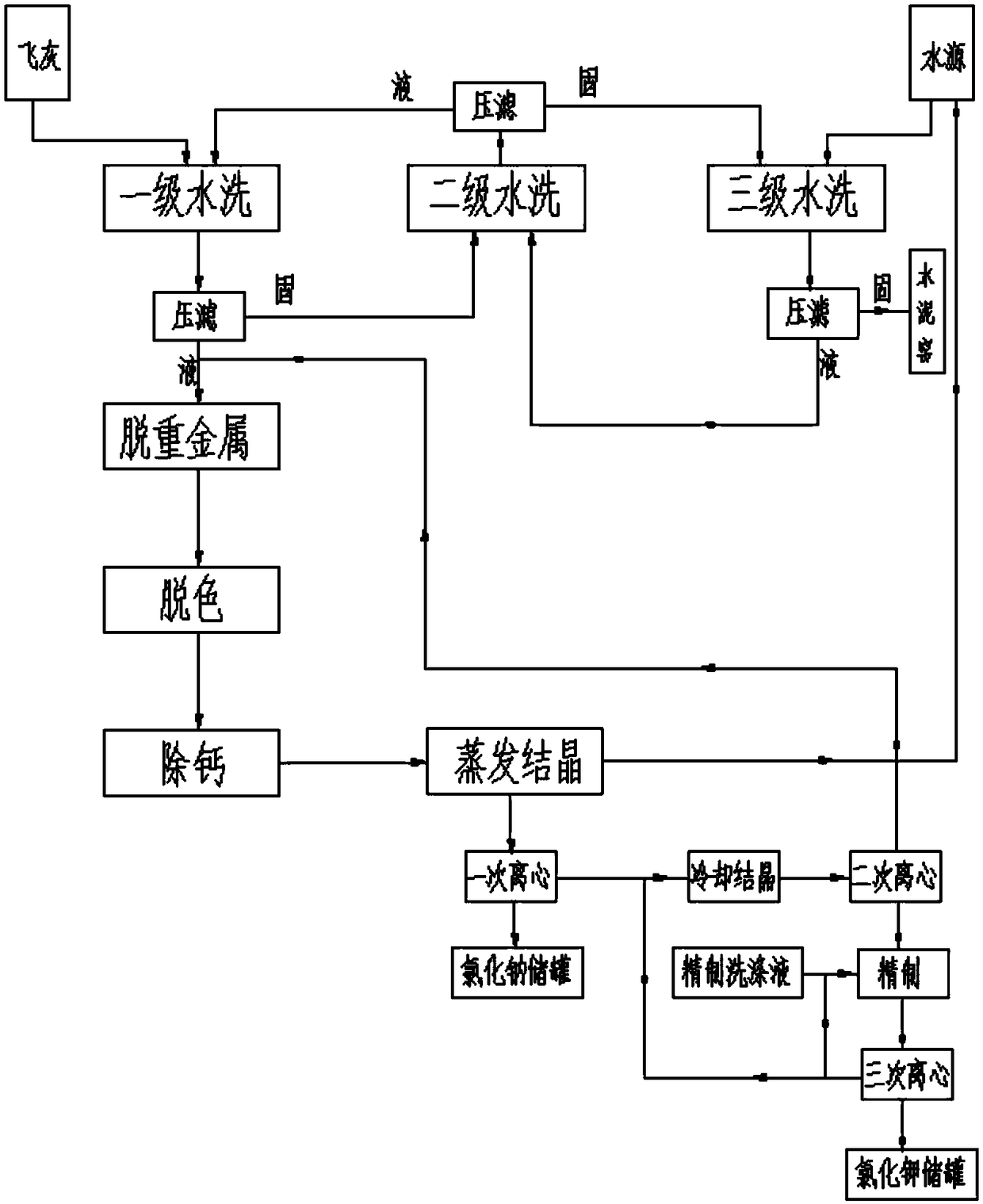

Process for preparing high-quality industrial salt by utilizing garbage fly ash

PendingCN109455738AReduce processReduce maintenance costsAlkali metal chloridesAlkali metal halide purificationNational standardFly ash

The invention discloses a process for preparing high-quality industrial salt by utilizing garbage fly ash. The process comprises the steps of washing the fly ash with water, removing heavy metals, decolorizing, removing calcium, carrying out evaporative crystallization and performing potassium-sodium separation; during the evaporative crystallization, when the mother liquor density reaches 1.15-1.25g / cm<3>, primary centrifugal separation is carried out, sodium chloride obtained by the primary centrifugal separation is collected, and liquid obtained by the primary centrifugal separation is cooled and crystallized; after cooling and crystallizing are finished, secondary centrifugal separation is carried out; the liquid obtained by the secondary centrifugal separation re-enters the step of removing the heavy metals, and the solid obtained by the secondary centrifugal separation is refined by using a saturated potassium chloride solution as a refining washing liquid; after refining is finished, third centrifugal separation is carried out; potassium chloride obtained by the third centrifugal separation is collected. The process provided by the invention can effectively separate potassium and sodium by using an industrial method, and can enable the content of heavy metals produced by the garbage fly ash from different sources to be in line with the requirements of the national standard; the quality of the produced industrial salt is stable.

Owner:杭州秀澈环保科技有限公司

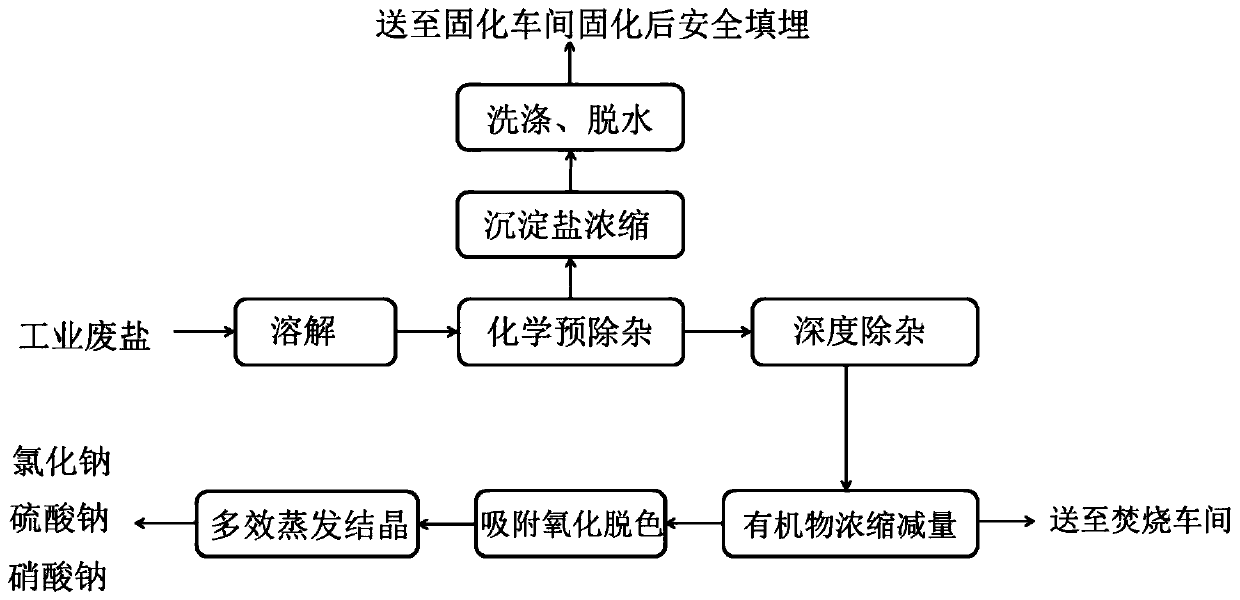

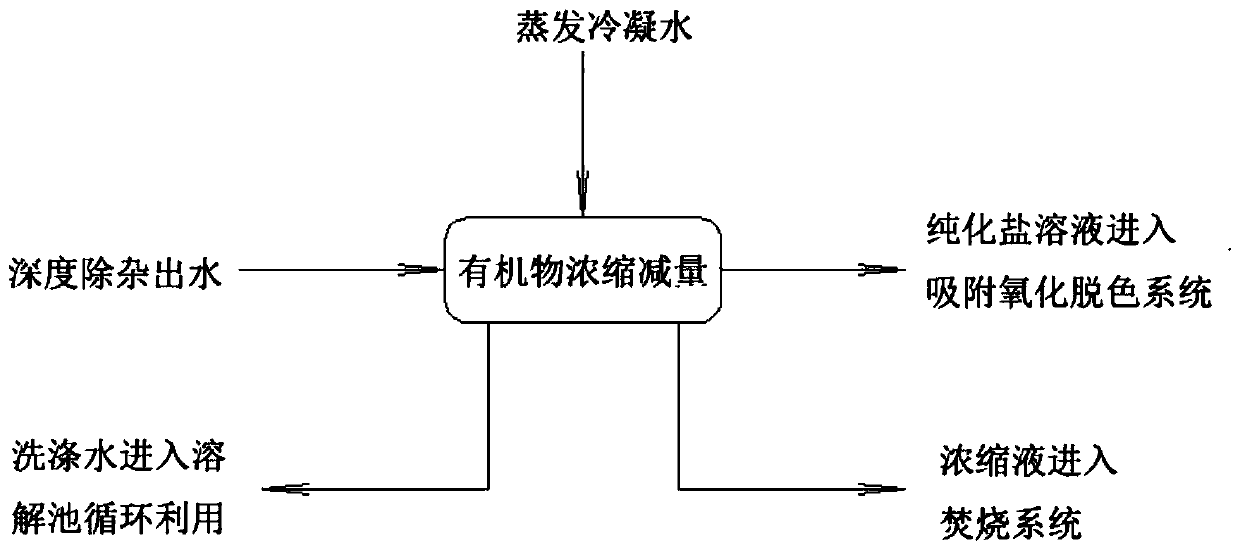

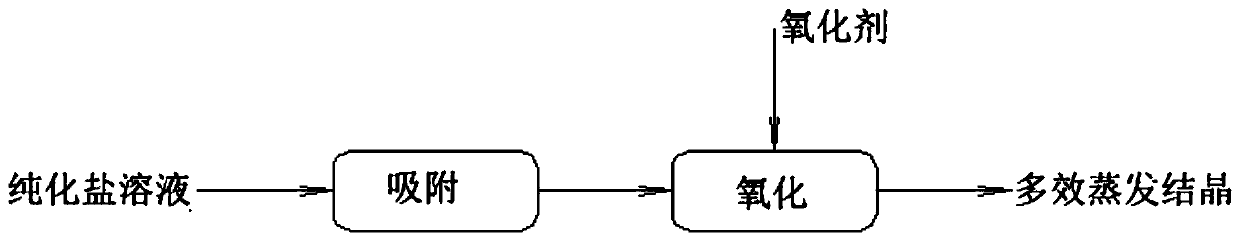

Industrial waste salt resourceful treatment method and equipment

PendingCN110844922AEfficient use ofReduce difficultyAlkali metal nitrate purificationAlkali metal sulfite/sulfate purificationEnvironmental engineeringCrystallization temperature

The invention provides an industrial waste salt resourceful treatment method and equipment. The method comprises the following steps: sequentially dissolving industrial waste salt, chemically pre-removing impurities, deeply removing impurities, concentrating and reducing organic matters, and carrying out adsorption oxidation decolorization and multiple-effect evaporative crystallization to respectively obtain sodium sulfate, sodium chloride and sodium nitrate crystals; wherein the crystallization temperature of the sodium sulfate is 75-85 DEG C; the crystallization temperature of sodium chloride is 60-70 DEG C; and the crystallization temperature of sodium nitrate is 45-55 DEG C. According to the industrial waste salt resourceful treatment method provided by the invention, the organic matters and other impurities in the industrial waste salt are firstly removed by adopting the steps, then salt separation and crystallization are realized by controlling the temperature in the evaporationprocess, and the industrial waste salt is obtained by utilizing the difference of three-phase co-saturation points of the sodium chloride, sodium nitrate and sodium sulfate at different temperaturesand the solubility of each salt. And the purity and whiteness of the sodium chloride, sodium nitrate and sodium sulfate obtained by salt separation crystallization all reach industrial-grade standards, and the sodium chloride, sodium nitrate and sodium sulfate can be directly applied.

Owner:GO HIGHER ENVIRONMENT GRP CO LTD

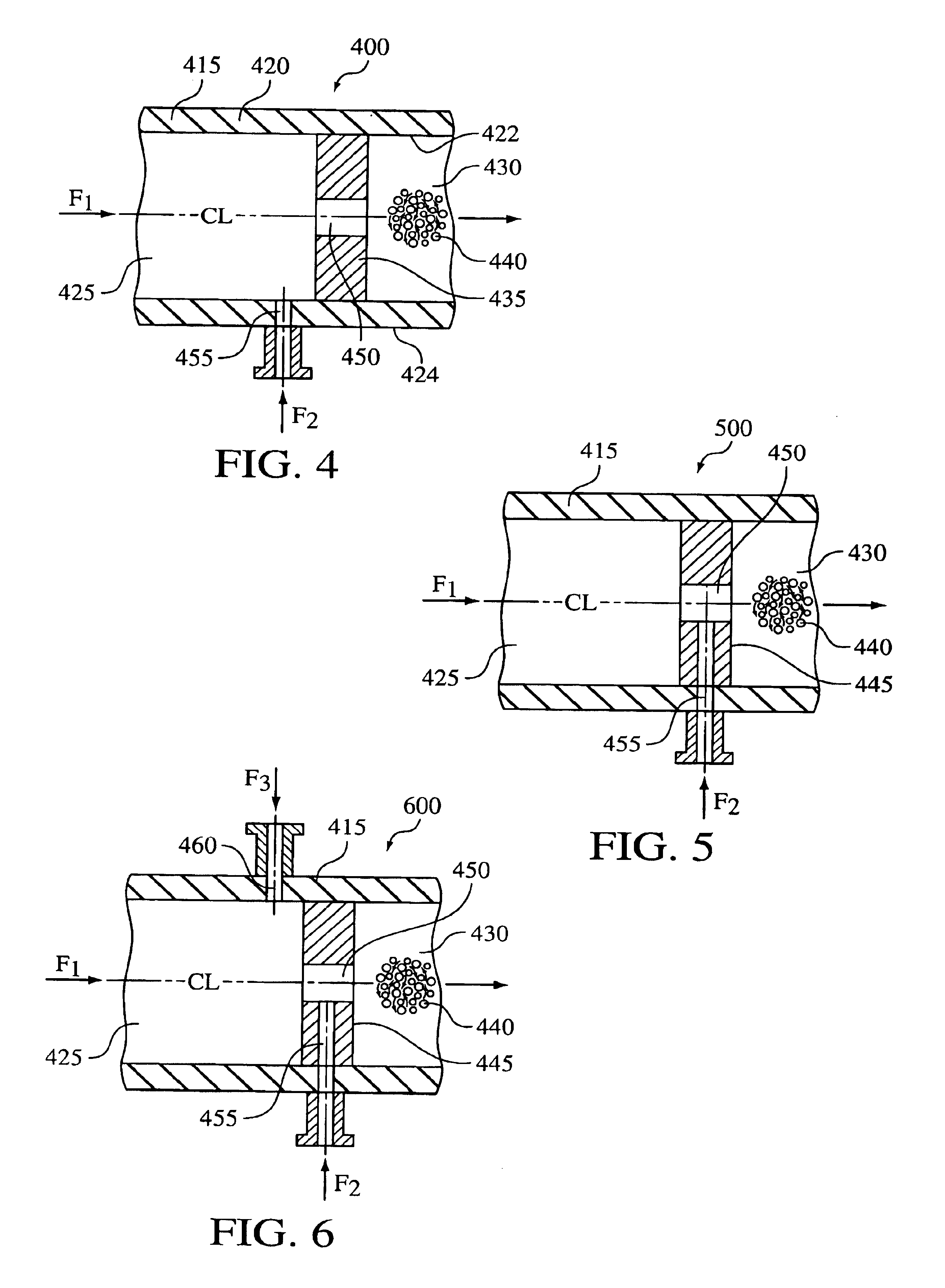

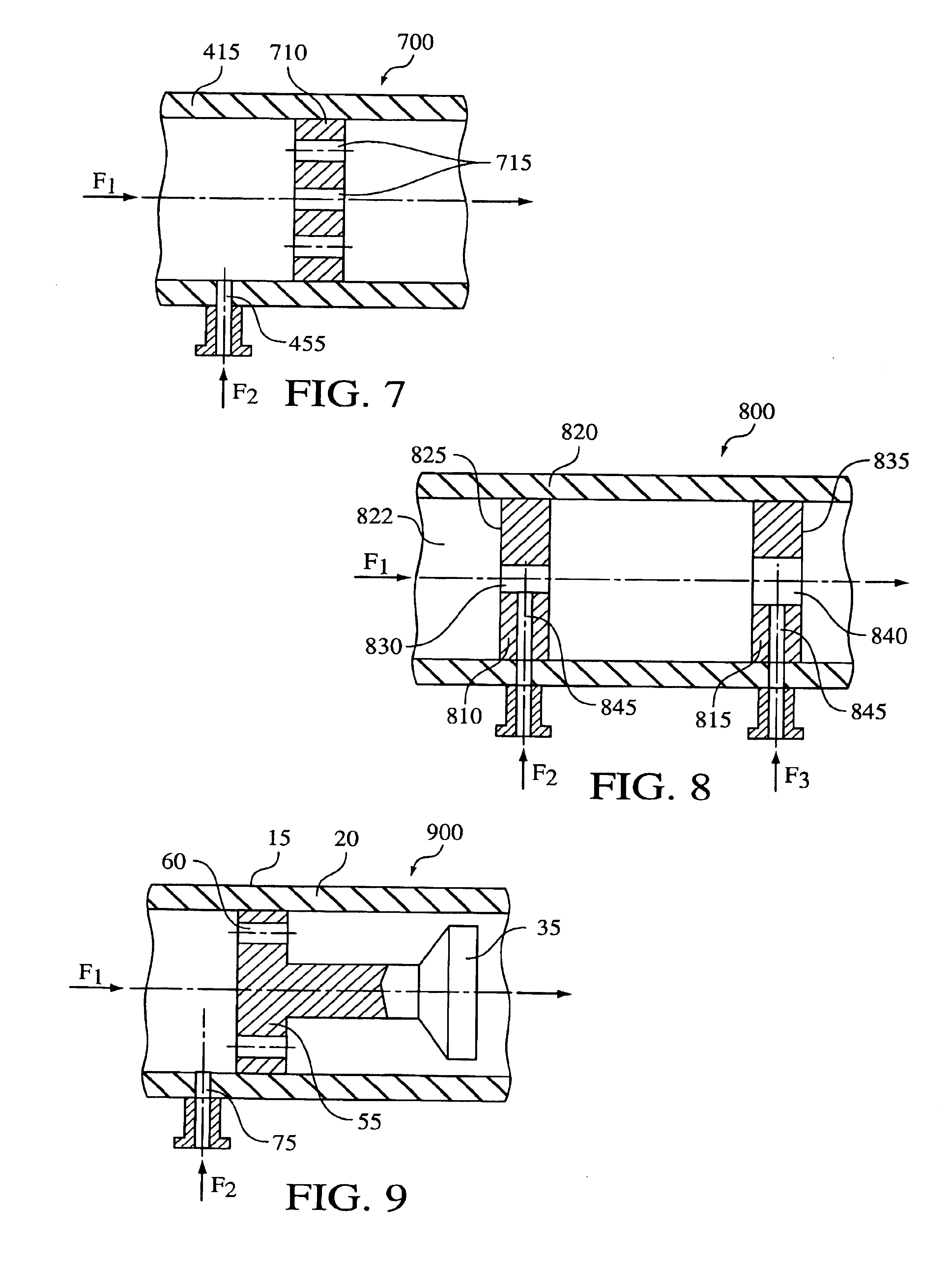

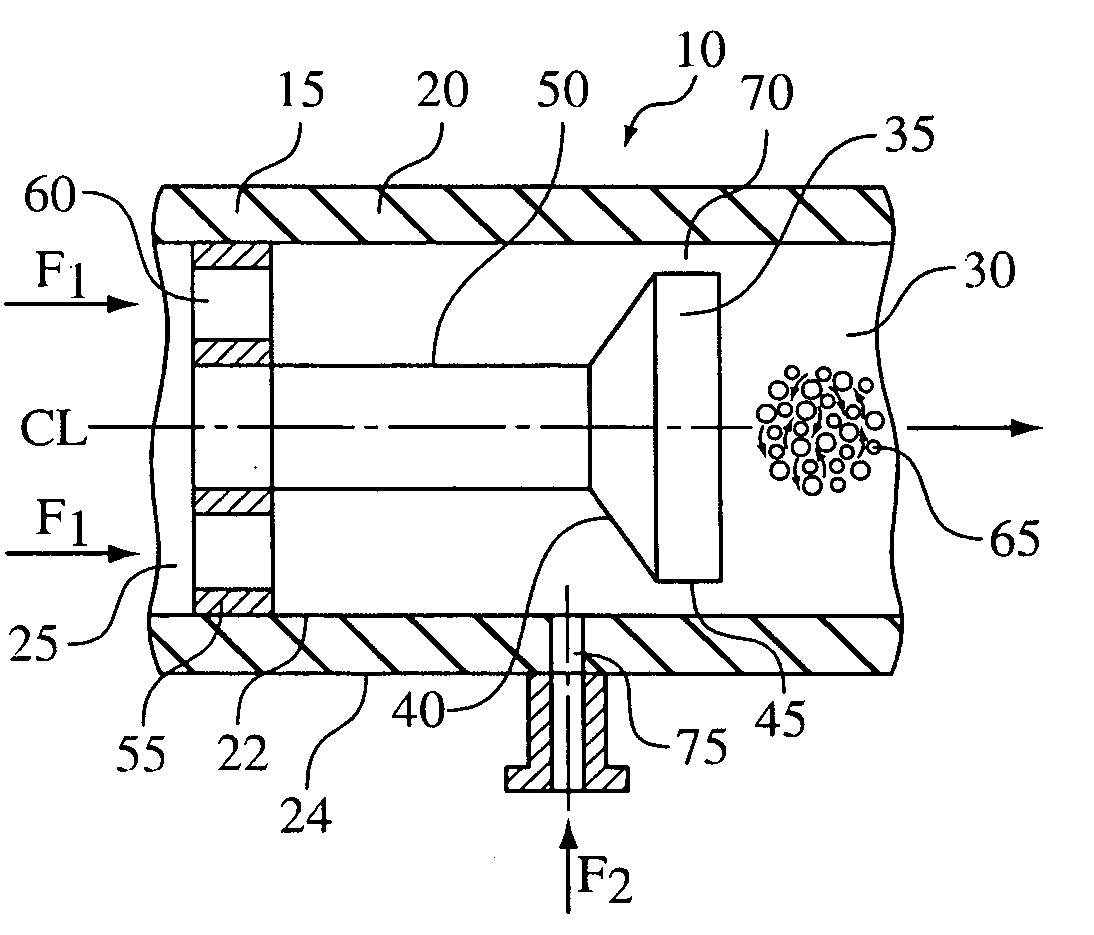

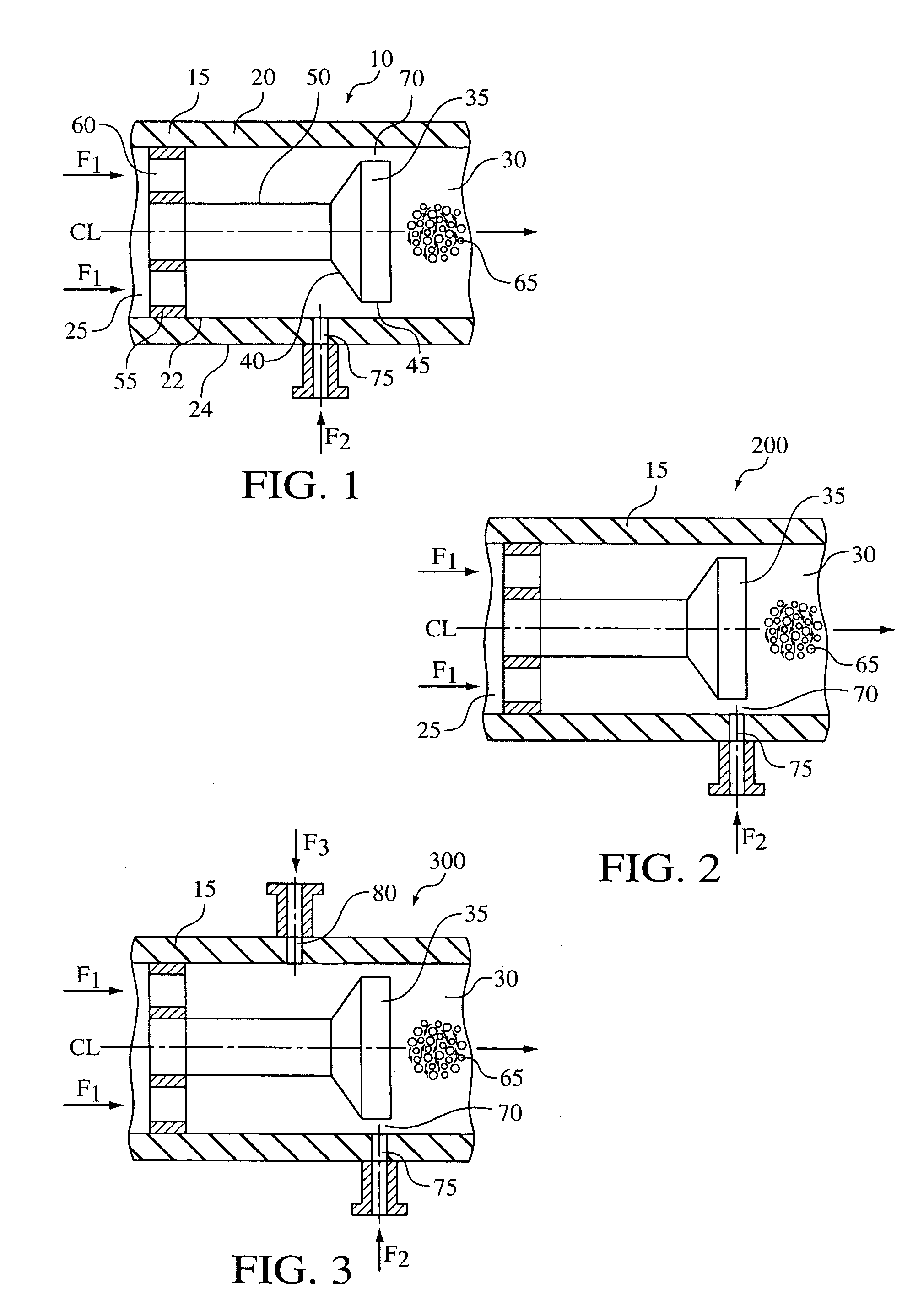

Hydrodynamic cavitation crystallization device and process

A device and process for crystallizing a compound using hydrodynamic cavitation comprising the steps of mixing at least one stream of a solution of such compound to be crystallized with at least one stream of an anti-solvent and passing the mixed streams at an elevated pressure through a local constriction of flow to create hydrodynamic cavitation thereby causing nucleation and the direct production of crystals.

Owner:CAVITECH HLDG

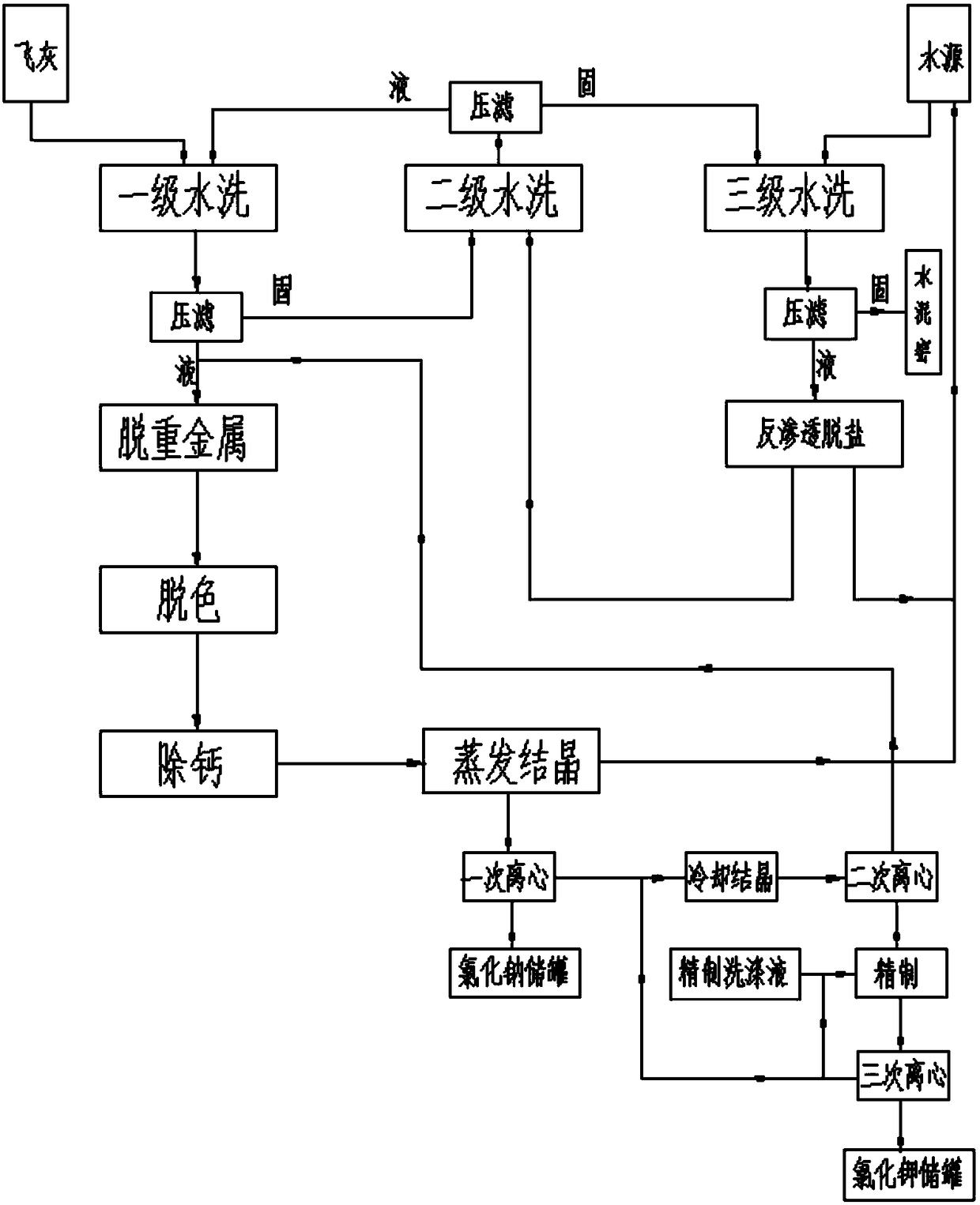

Waste fly ash washing water recycling treatment process and equipment

InactiveCN109095531AReduce generationThe production reachesChemical industryWater/sewage treatment by heatingPotassiumEvaporation

The invention discloses a waste fly ash washing water recycling treatment process which comprises the following steps: waste fly ash washing water preheating, evaporation and concentration, forced-circulation evaporation, concentrated solution circulation, sodium chloride crystallization, sodium salt-separating mother solution circulation and potassium chloride crystallization. Separation of sodium chloride and potassium chloride in the waste fly ash washing water is realized, the sodium chloride salt and potassium chloride salt are respectively obtained, production of solid wastes and hazardous wastes is reduced, the resource recovery effect is achieved, and the process is high in degree of automation, possible in continuous operation and high in production efficiency. In addition, a mechanical steam re-compression technique with energy conservation is used in the process, the energy consumption for evaporating one ton of water only accounts for 1 / 6-1 / 5 of that of a conventional evaporator, high thermal efficiency and low energy consumption can be achieved, pollutants can be reduced, and environment pollution can be avoided. The invention further discloses equipment of the process, dependency to boiler equipment can be reduced, environment pollution can be reduced, energy conservation and environment protection can be achieved, a high equipment automation degree can be achieved, and the process adopts equipment with continuous operation and production and is high in efficiency and low in operation cost.

Owner:SHENZHEN SUNEVAP TECH

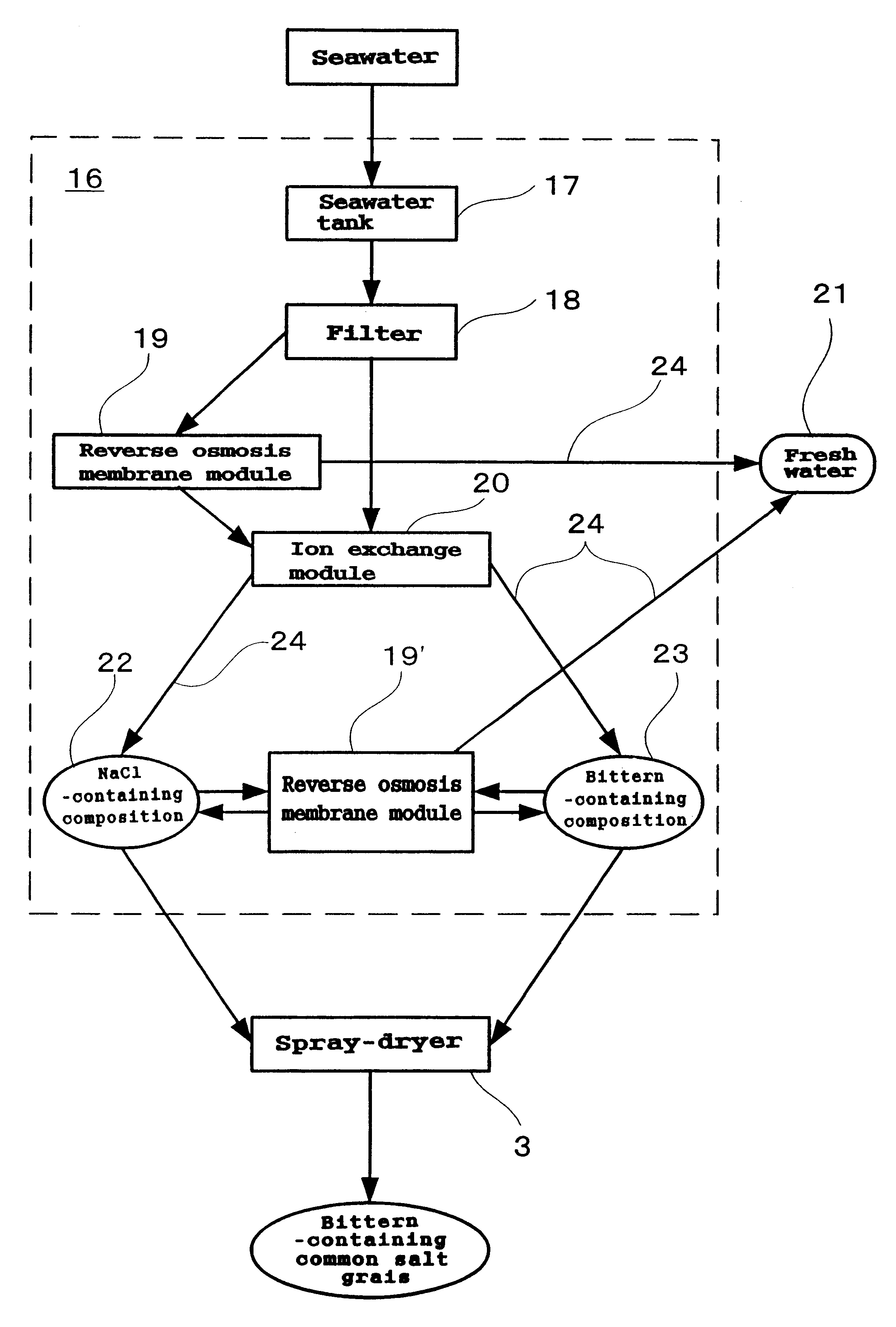

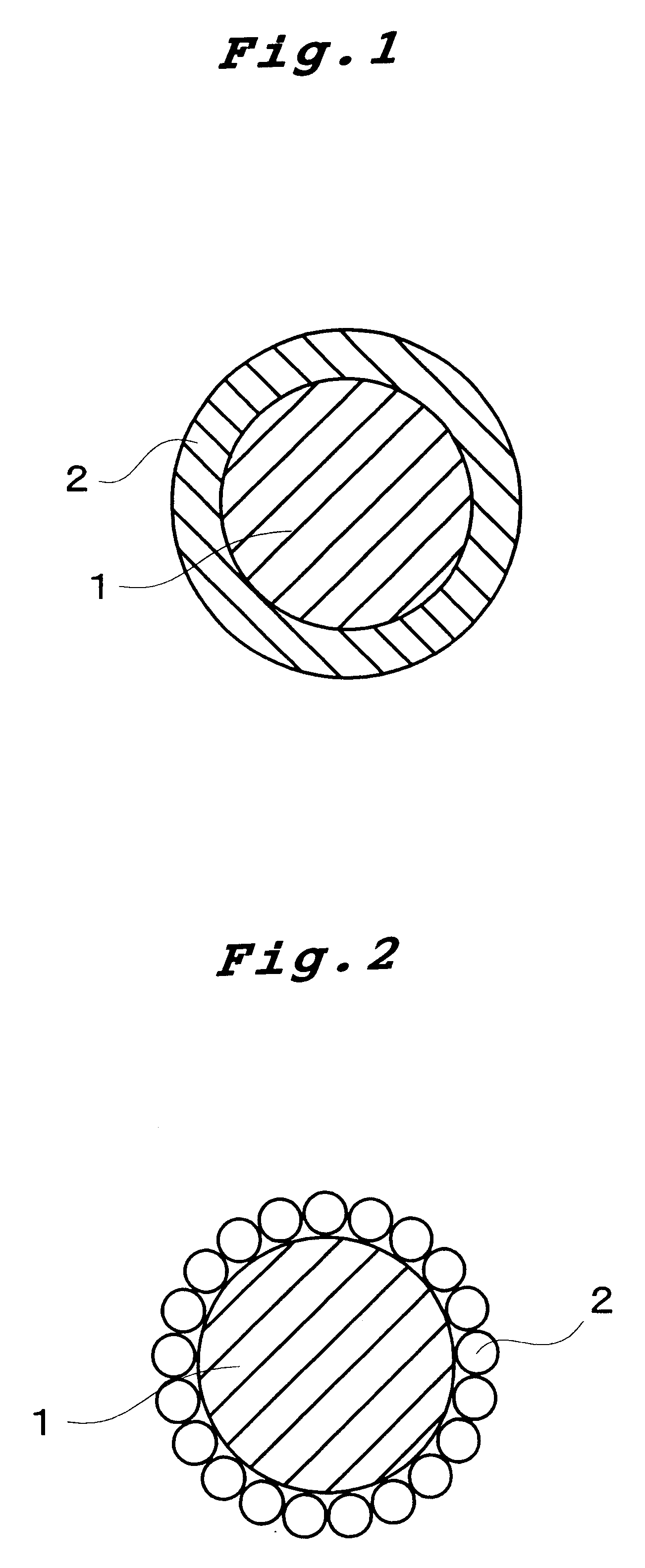

Bittern-containing common salt grains and process for preparing the same

InactiveUS6599565B1Efficient use ofEasy to operateGranule coatingPretreated surfacesIon exchangeSalt water

The invention provides a common salt having the rounded-off savory taste of natural common salt and yet a reduced tendency toward deliquescence and coagulation and a process for producing the same. The invention further provides a method for fractional recovery of freshwater and raw materials for the above common salt from seawater in connection with the production of the same common salt. The common salt of the invention is a bittern-containing granular common salt with each of its grains consisting of a core comprised of a bittern-containing composition optionally containing NaCl and, as covering the grain, a coating layer comprised of a NaCl-containing composition optionally containing CaSO4 or bittern. The method for fractional recovery of freshwater and raw materials for the above common salt from seawater according to the invention comprises a step of treating seawater with a reverse osmosis membrane to fractionate it into freshwater and a salt-containing water and subjecting the salt-containing water to an ion exchange treatment to fractionate it into a NaCl-containing composition and a bittern-containing composition or a step of subjecting seawater to an ion exchange treatment to fractionate it into an aqueous NaCl-containing solution and an aqueous bittern-containing solution and subjecting each of the aqueous NaCl-containing solution and aqueous bittern-containing solution to a reverse osmosis membrane treatment to fractionate it into freshwater and either a NaCl-containing composition or a bittern-containing composition.

Owner:UMAI

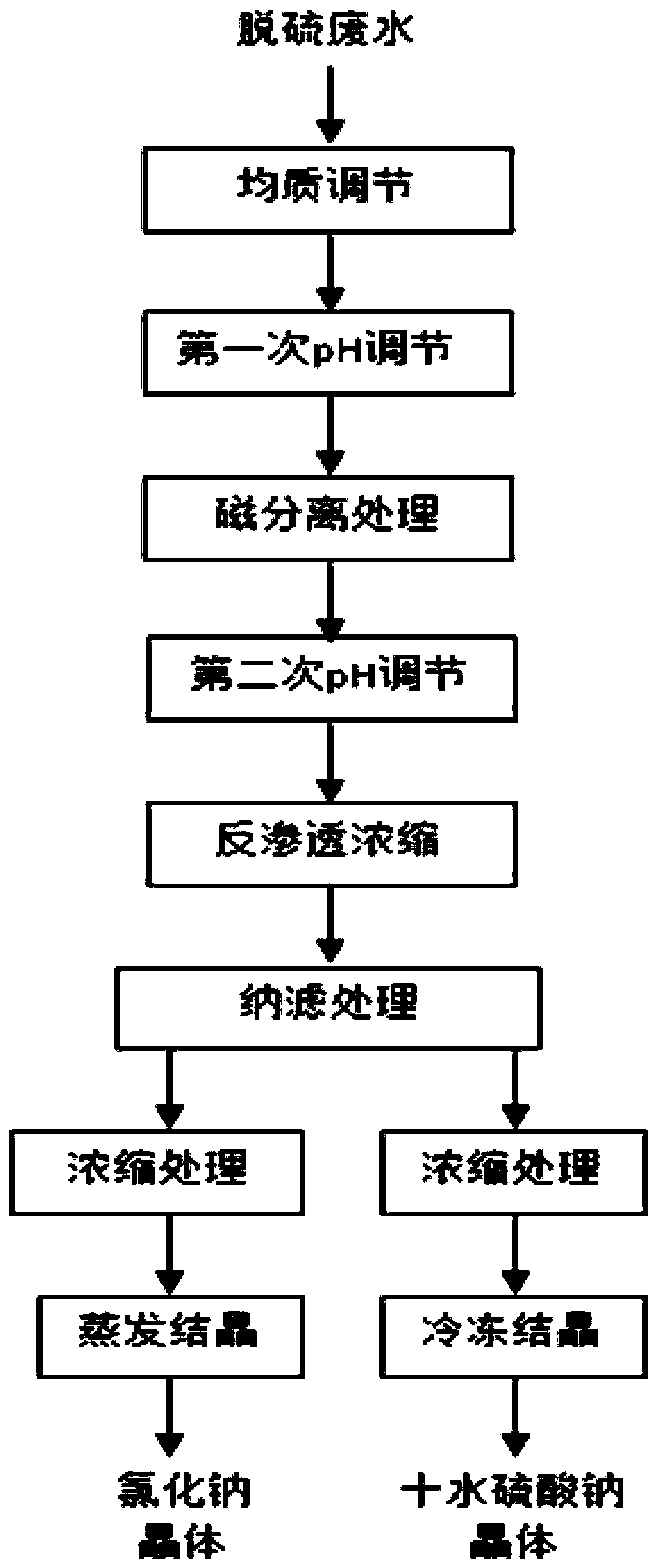

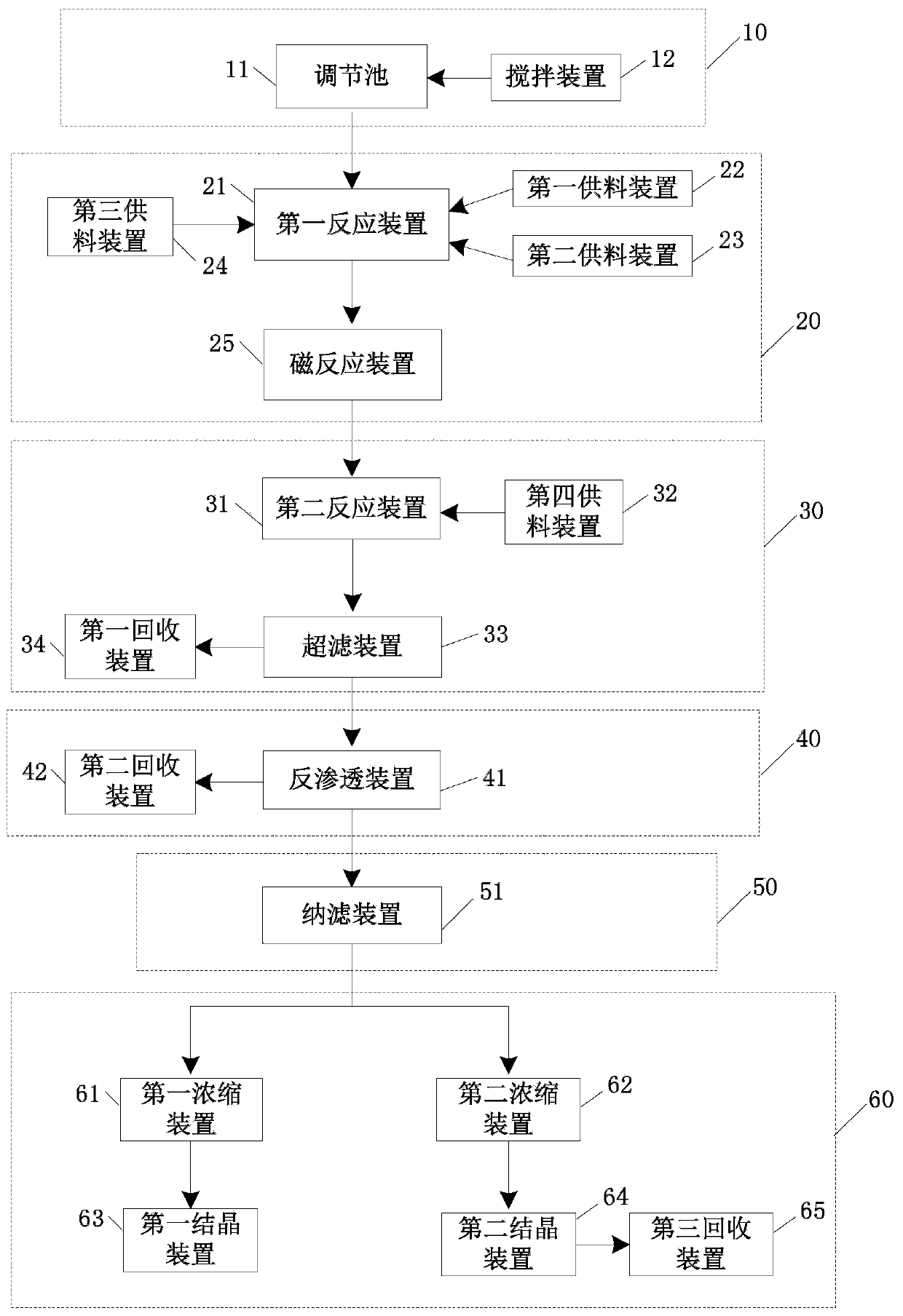

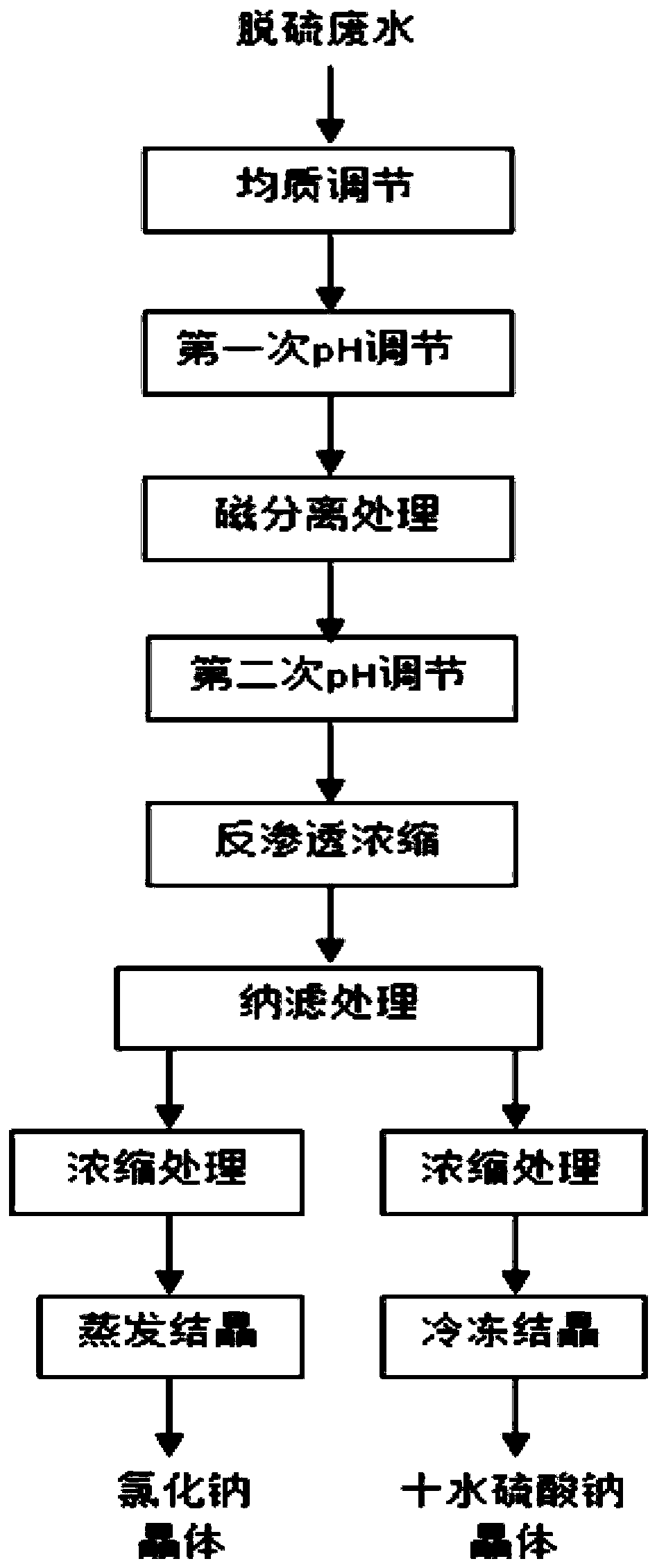

Desulfurization wastewater quality-divided crystallization processing method and processing device

PendingCN109970267ARealize fractional crystallizationReduce usageAlkali metal sulfites/sulfates preparation formWater contaminantsUltrafiltrationFiltration

The invention provides a desulfurization wastewater quality-divided crystallization processing method and a processing device. Desulfurization wastewater contains sodium chloride and sodium sulfate. The method comprises following steps: adjusting the pH of desulfurization wastewater to 9-12 for the first time, adding an organic sulfur agent and iron ore particles into adjusted desulfurization wastewater, carrying out magnetic separation to obtain precipitates and supernate; adjusting the pH of the supernate to 6.5-7.5 for a second time, carrying out ultrafiltration to obtain concentrated water; subjecting the concentrated water to a reverse osmosis treatment to obtain a reverse osmosis concentrated solution; subjecting the reverse osmosis concentrated solution to a nano filtration treatment to obtain nano filtration producing water and nano filtration concentrated water; subjecting the nano filtration producing water to a concentration treatment and a crystallization treatment in sequence to obtain sodium chloride crystals; and subjecting the nano filtration concentrated water to a concentration treatment and a crystallization treatment in sequence to obtain sodium sulfate decahydrate crystals. Solved are the problems that in conventional desulfurization wastewater quality-divided crystallization processing, the effect is influenced by heavy metal ions, and the salt crystallization amount is large.

Owner:CHINA ENFI ENGINEERING CORPORATION

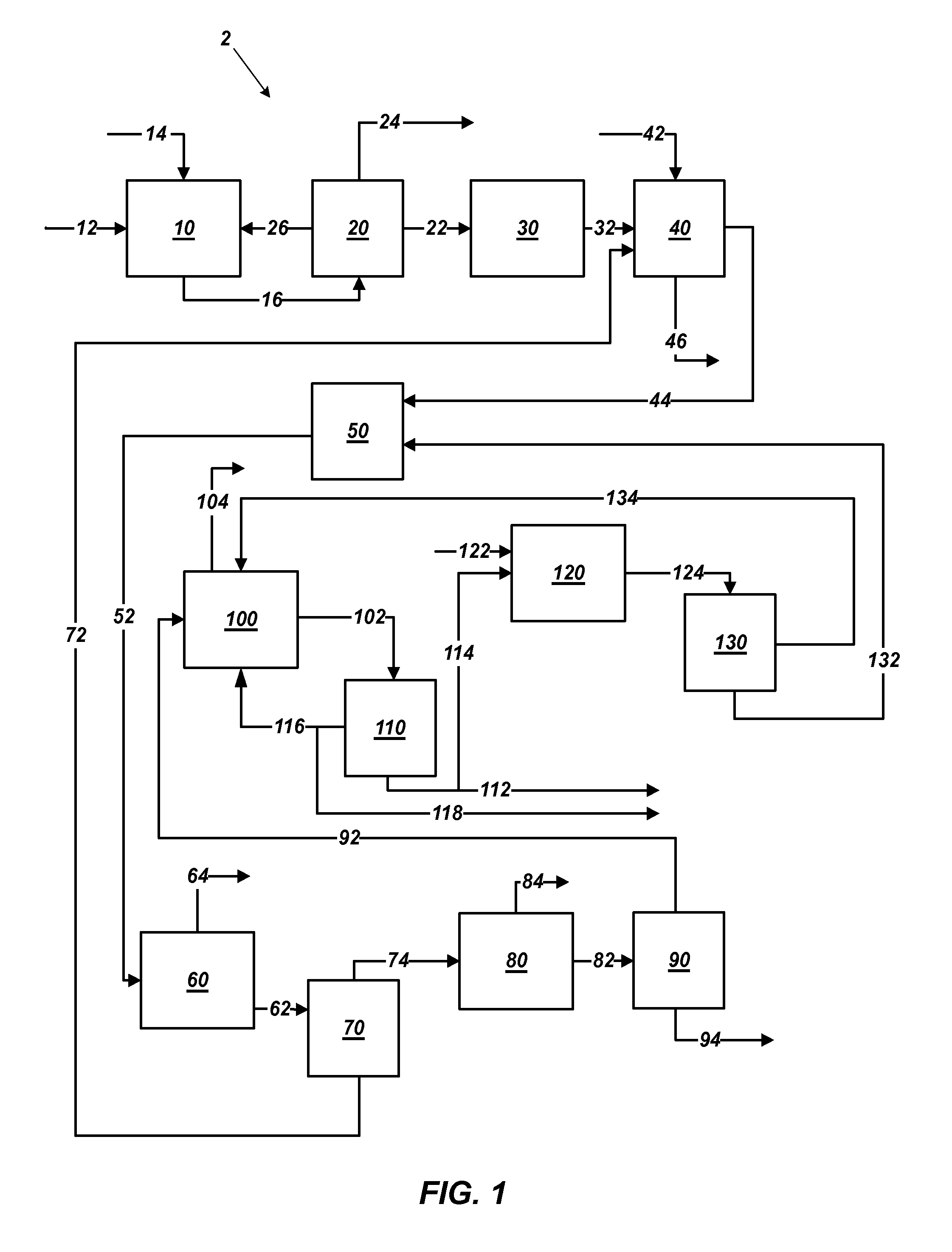

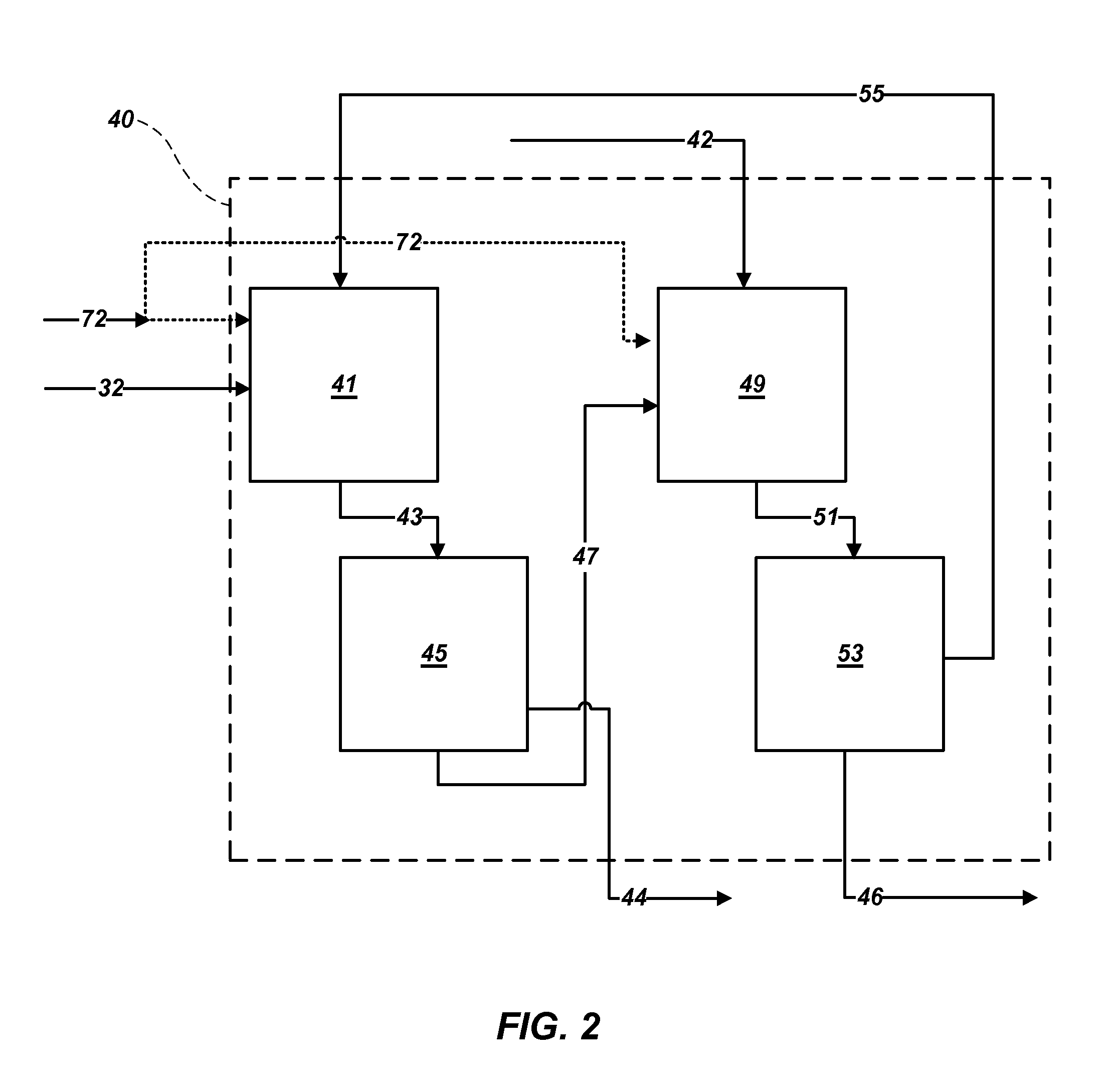

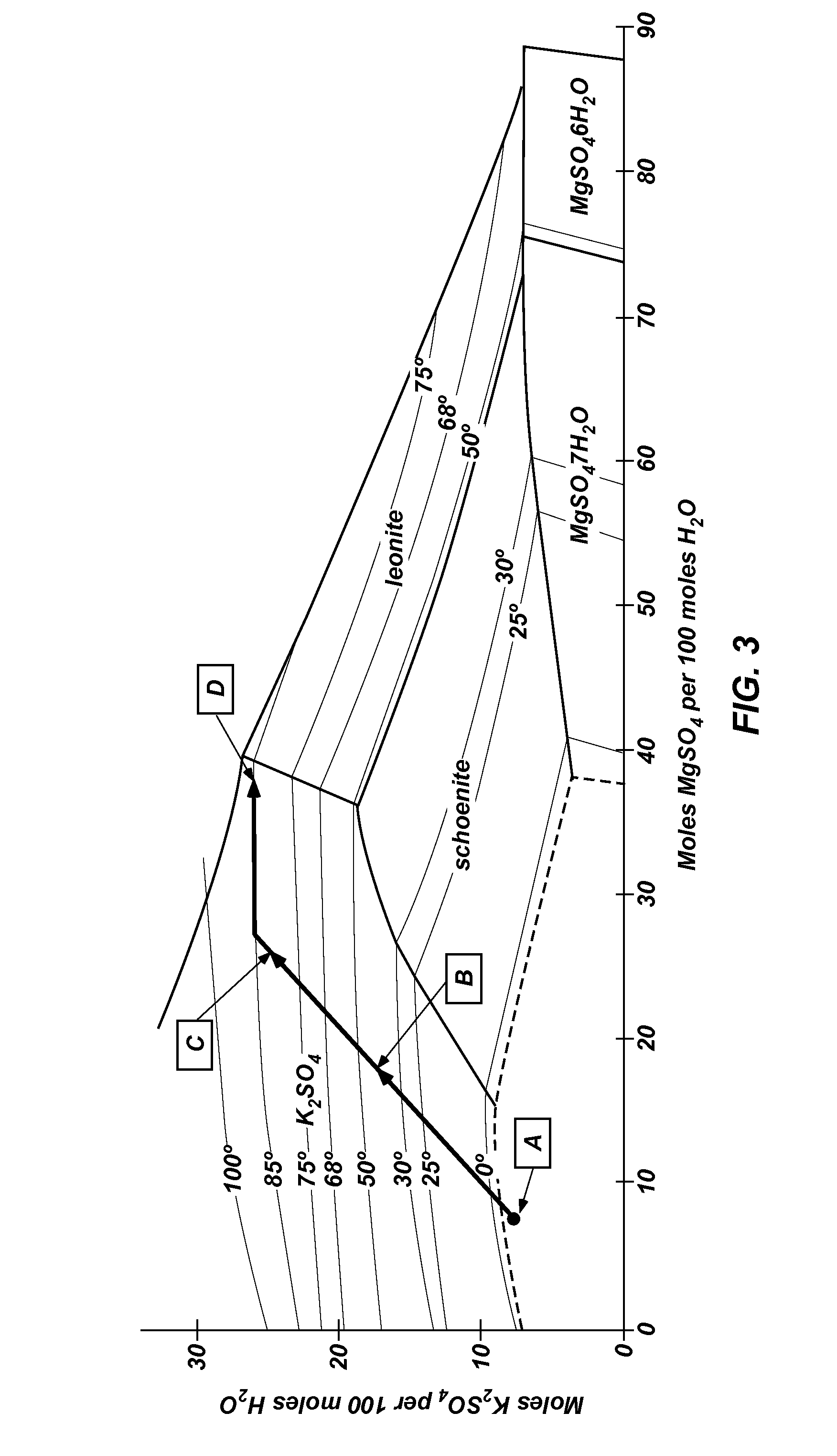

Methods of processing polyhalite ore, methods of producing potassium sulfate, and related systems

ActiveUS8551429B2Limit economic riskLess energyChemical/physical/physico-chemical processesAlkali metal oxides/hydroxidesWater solublePotassium sulfate

Methods of forming potassium sulfate include calcining polyhalite ore particles to convert the polyhalite ore particles to a water-soluble composition. At least a portion of the water-soluble composition is dissolved in an aqueous medium to form an aqueous solution comprising K+, Mg2+, and SO42− ions and a calcium-containing solid. The calcium-containing solid is separated from the aqueous solution to form a filtrate comprising K+, Mg2+, and SO42− ions. A potassium-containing salt is dissolved in the filtrate to increase the concentration of K+ and SO42− ions to from a concentrated liquor, and K2SO4 is crystallized from the concentrated liquor. A system for processing polyhalite ore includes a countercurrent leaching apparatus, a first mix tank, an evaporator, and at least one crystallizer.

Owner:INTERCONTINENTAL POTASH CORP USA

Process for synthesizing a compacted product

ActiveUS20100040882A1Speed up the processIncrease productionCeramic shaping apparatusGlass/slag layered productsPotassiumMoisture absorption

Owner:KARNALYTE RESOURCES

Process for the time recovery of sulphate of potash (SOP) from sulphate rich bittern

InactiveUS8182784B2Eliminate DPA losses in gypsumPromote recoveryChemical industryAlkali metal carbonates shape formationSulfateAqueous solution

The present invention relates to a process for the recovery of sulphate of potash (SOP) from bittern. Kainite is obtained by fractional crystallization of the bittern. Kainite is converted into schoenite with simultaneous removal of NaCl and the filtrate (SEL) is used for production of KCl. Schoenite is reacted with aqueous KCl to yield SOP and the filtrate (KEL) is recycled in the kainite to schoenite conversion step. The production of KCl from SEL is carried out with the aid of dipicrylamine (DPA). Lime is treated with DPA in water for the production of highly soluble Ca (DPA)2, which in turn treated with SEL to produce insoluble K(DPA). K(DPA) is treated with HCl to produce KCl and insoluble DPA, which can be recycled for the production of Ca (DPA)2. The aqueous KCl thus obtained is treated with schoenite to prepare SOP. The KEL obtained along with SOP is recycled to generate schoenite.

Owner:COUNCIL OF SCI & IND RES

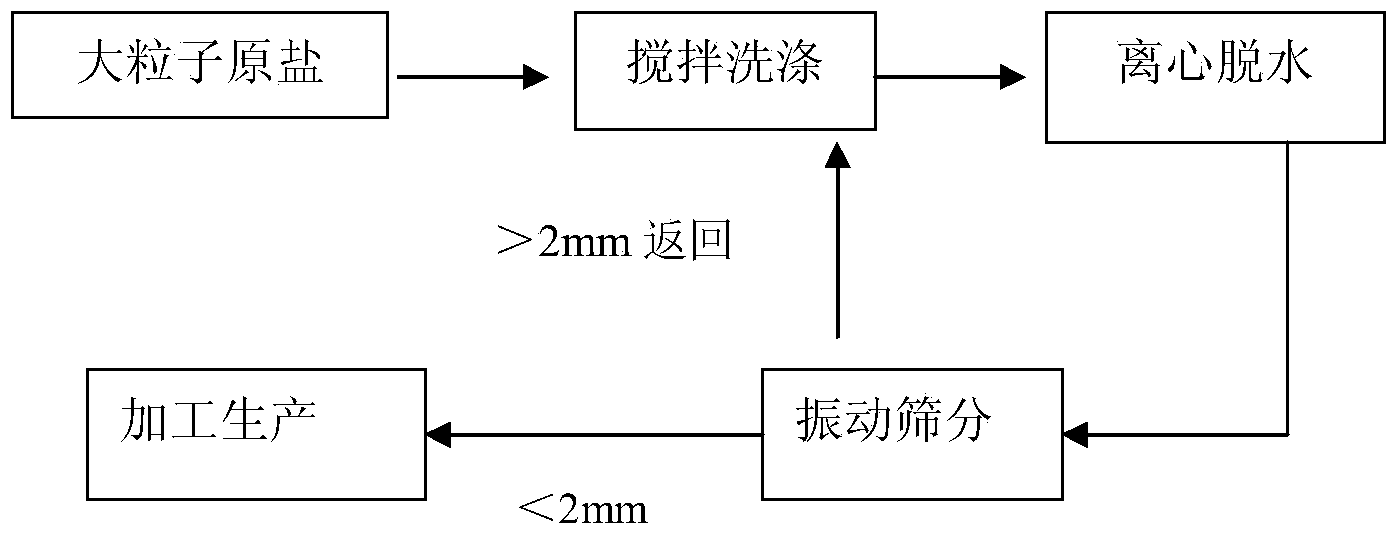

Process for efficiently producing fine-particle salt

InactiveCN104003423AIncrease profitReduce in quantityAlkali metal chloridesAlkali metal halide formation shapeGranularityCentrifugation

The invention relates to a process for efficiently producing fine-particle salt. The process is characterized by comprising the following steps of washing: adding saturated brine into the raw material salt, washing and stirring sufficiently, wherein the solid-liquid ratio of the raw material salt to saturated brine is 1.5-9; centrifuging: centrifuging washed salt slurry obtained in step (1) by a centrifuge for dewatering to obtain the centrifuged and dewatered product of which the water content is less than or equal to 5%; sieving: sieving the centrifuged and dewatered product in step (2) of which the granularity is less than 2.0mm, and enabling the centrifuged and dewatered product of which the granularity is greater than 2.0mm to return back to the centrifuged salt slurry tank again in step (2) and centrifuging again. The process disclosed by the invention has the advantages that since the large-particle salts are used as the raw material, and the innovative washing, centrifugation and sieving steps are integrated, the processing steps of solar salt is effectively reduced; due to no need of a pulverizer, the equipment investment is saved, the installation power is reduced by more than 10%, the production operations are simple, the utilization rate of the raw material is high, the number of needed workers is small and the process for producing and processing salt is worthy to be popularized and applied.

Owner:浙江绿海制盐有限责任公司

Process for recovery of low sodium salt from bittern

InactiveUS6890509B2Calcium/strontium/barium sulfatesAlkali metal carbonates shape formationEvaporationChloride

A new process for recovery of Low Sodium Salt from bittern has been described in the present invention, the said process comprising desulphatation of bittern (by-product of salt industry), evaporation of bittern in solar pans and processing of solid mixture with water to produce a mixture of sodium and potassium chlorides and optionally preparing “free flowing” and iodized, by known techniques.

Owner:COUNCIL OF SCI & IND RES

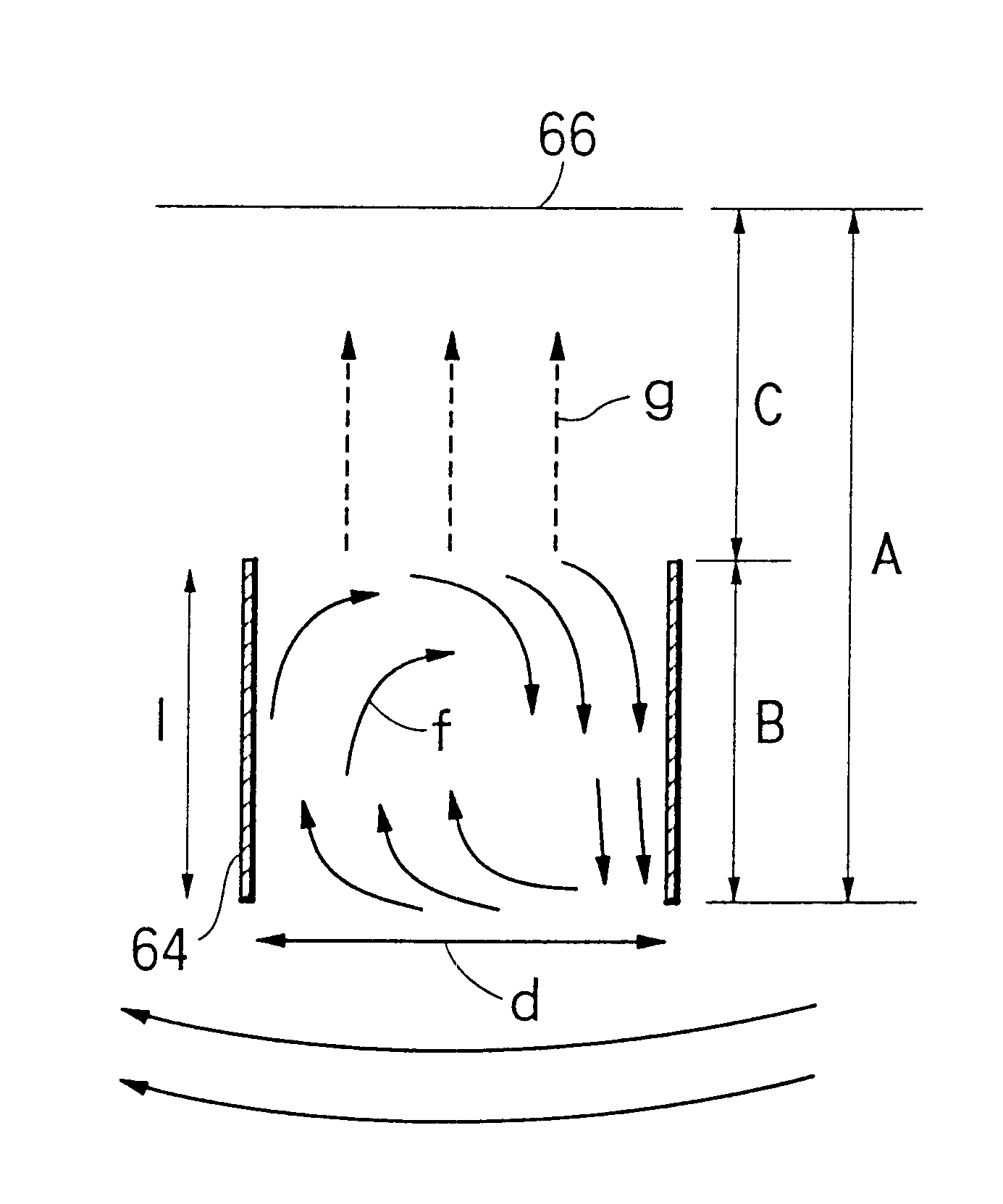

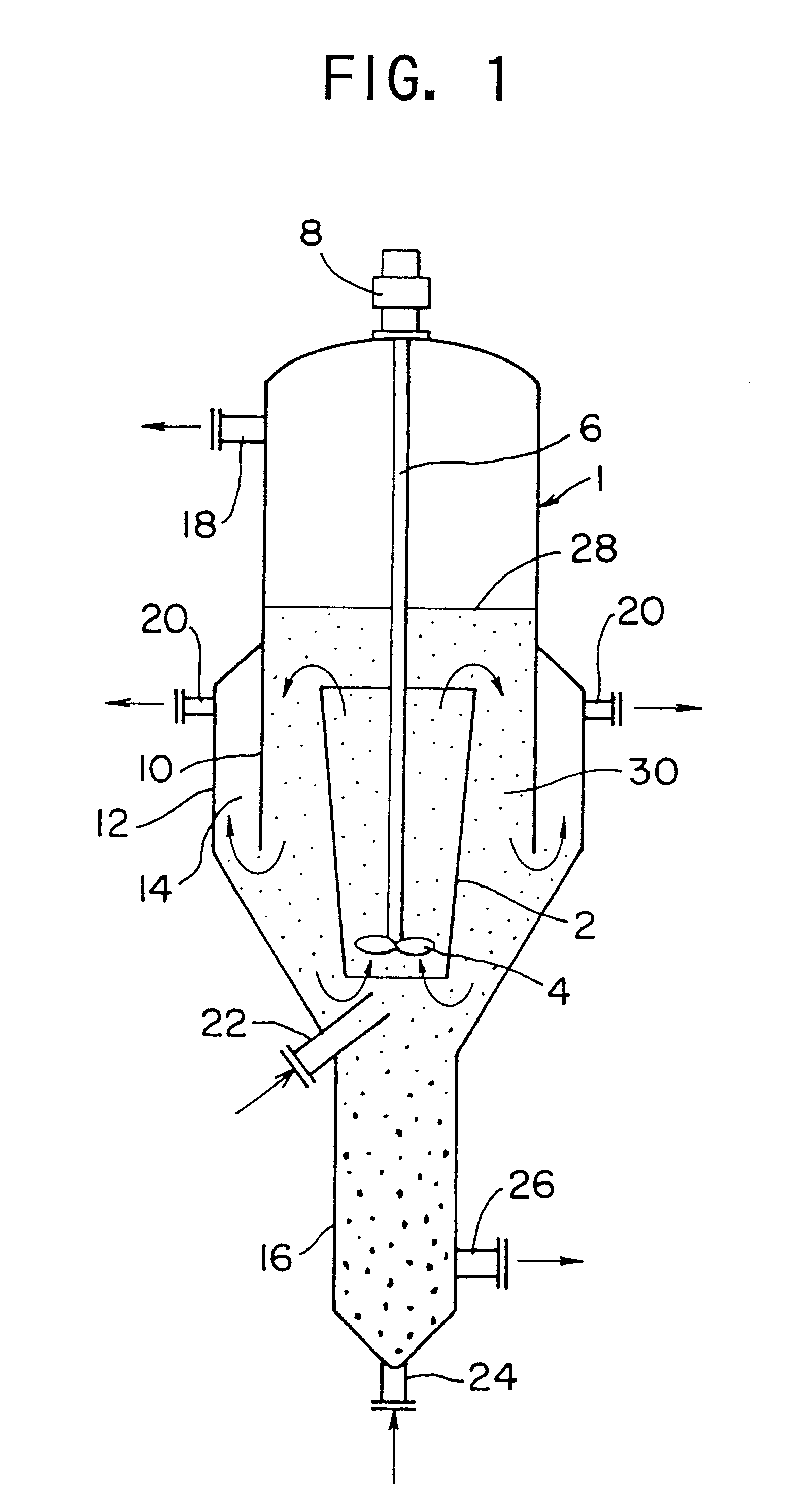

Apparatus and method for crystallization

InactiveUS6334878B1From normal temperature solutionsAlkali metal carbonates shape formationSlurryEngineering

An apparatus for crystallization, which contains a crystallization vessel, a seed supplying device, a feed solution supplying device and a tube baffle disposed within the crystallization vessel. The tube baffle is provided with a crystallization portion in an inner area and a lower area thereof, and the tube baffle and the crystallization vessel define a classification portion there between. The apparatus further contains an agitating fan for agitating the seed crystals and the feed solution, and a plurality of plate baffles disposed within the classification portion which define a buffer portion and a gravitational settling portion. The apparatus further contains a device for generating a rising velocity of a slurry containing fine crystals in the gravitational settling portion by discharging the slurry so that the rising velocity of the slurry is greater than a settling velocity of the fine crystals and an outlet for discharging the crystallized material.

Owner:AJINOMOTO CO INC

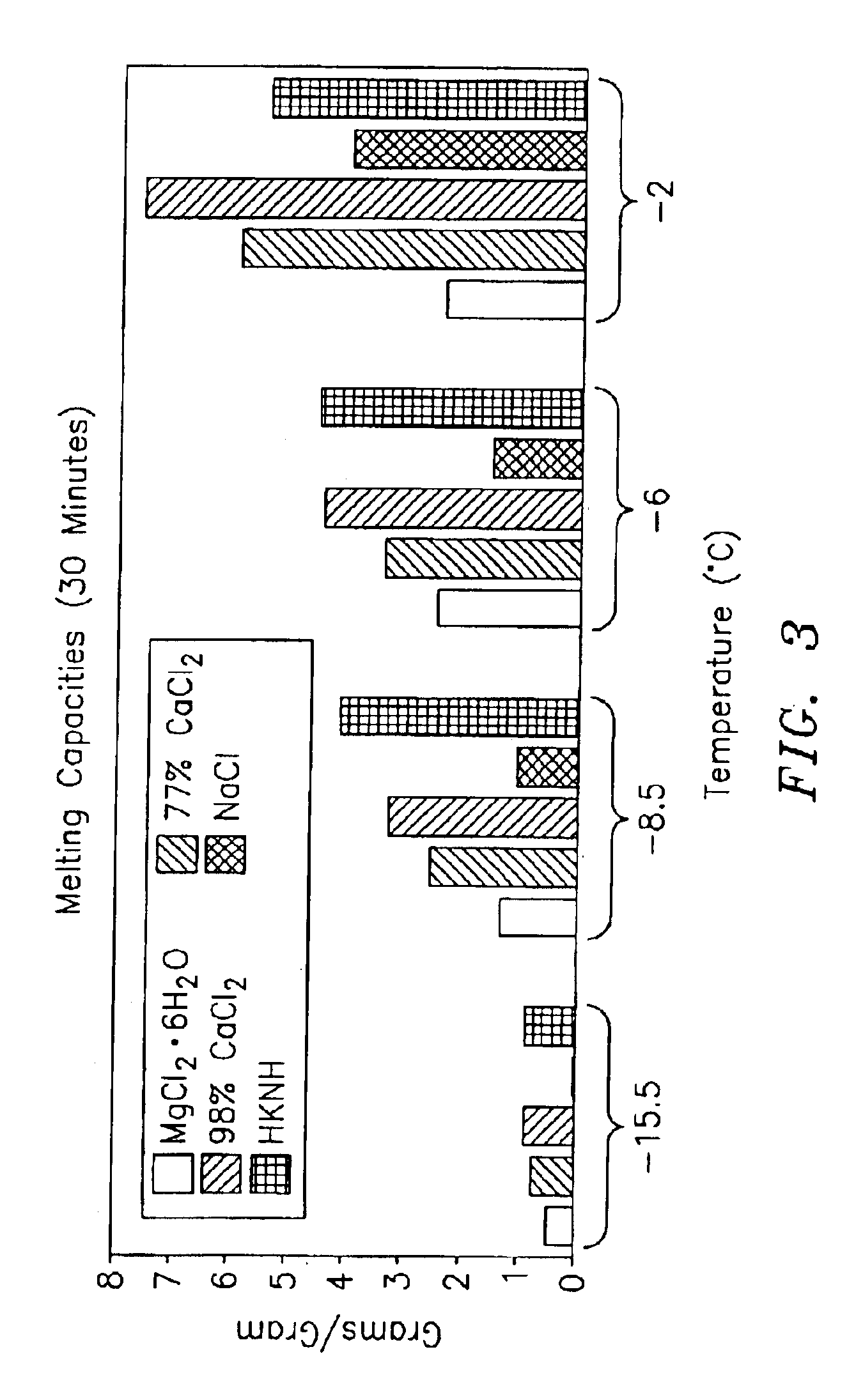

Snow and ice-melting granules and method for preparing same

Snow and ice-melting granules prepared from compacted blends of salts of alkali and / or alkaline earth metals and a method for preparing such granules, are provided. The inventive granules have improved mechanical properties and, as such, are not readily reduced to a powder when subjected to mechanical loadings during transit and storage. In a preferred embodiment, the inventive granules employ one or more corrosion inhibitors homogeneously distributed throughout the granules.

Owner:GRO WELL BRANDS INC

Popular searches

Electrical/wave energy microorganism treatment Water Crystallization regulation/control Electrical/wave energy enzyme treatment Single crystal growth details Crystallization auxillary selection Semiconductor/solid-state device manufacturing Chemical/physical processes Glucose production After-treatment apparatus

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com