Crystallizer for hydrolyzing carnallite

A technology of crystallizer and carnallite, which is applied in the field of salt chemical industry, can solve unsolvable problems and achieve the effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

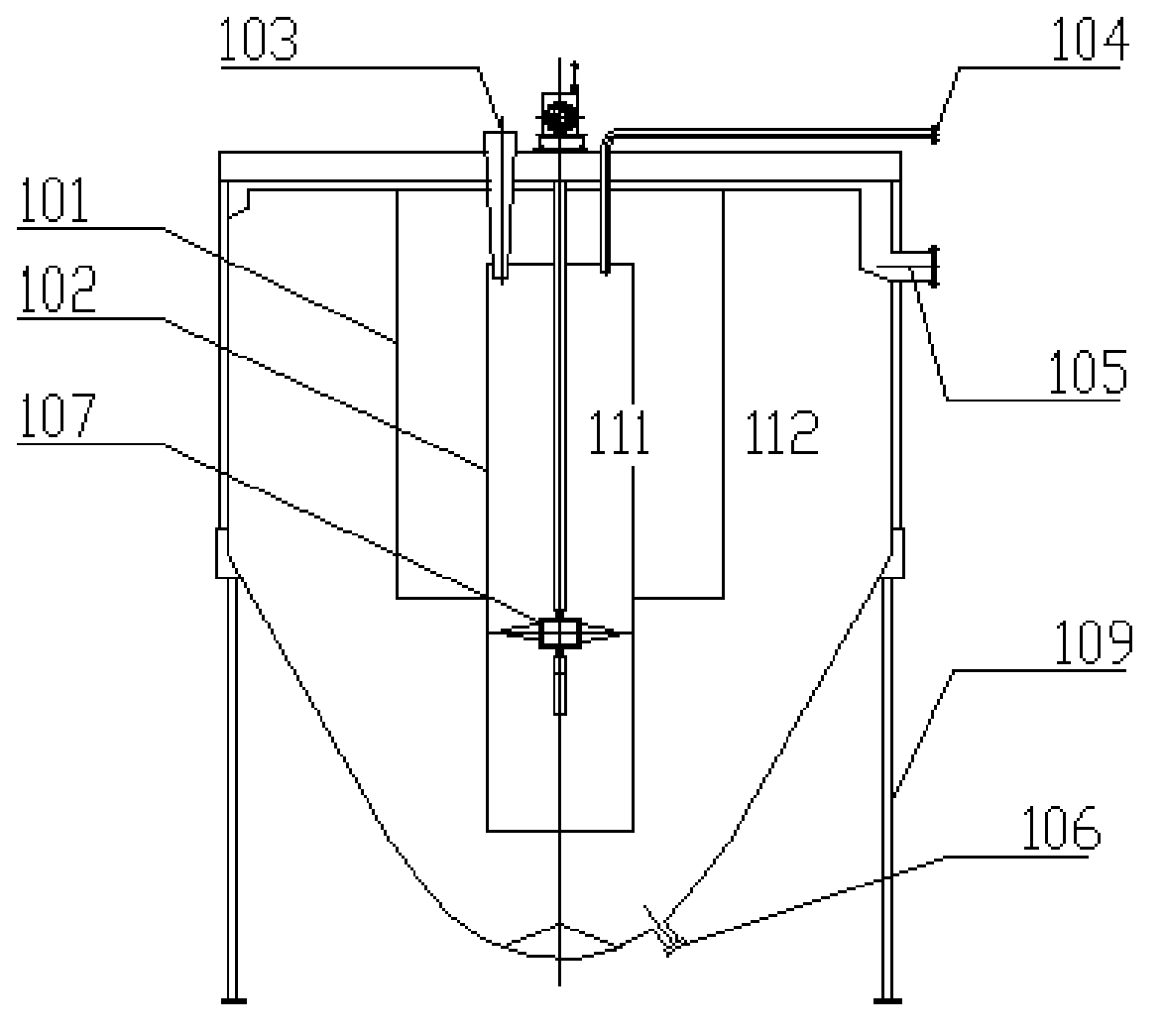

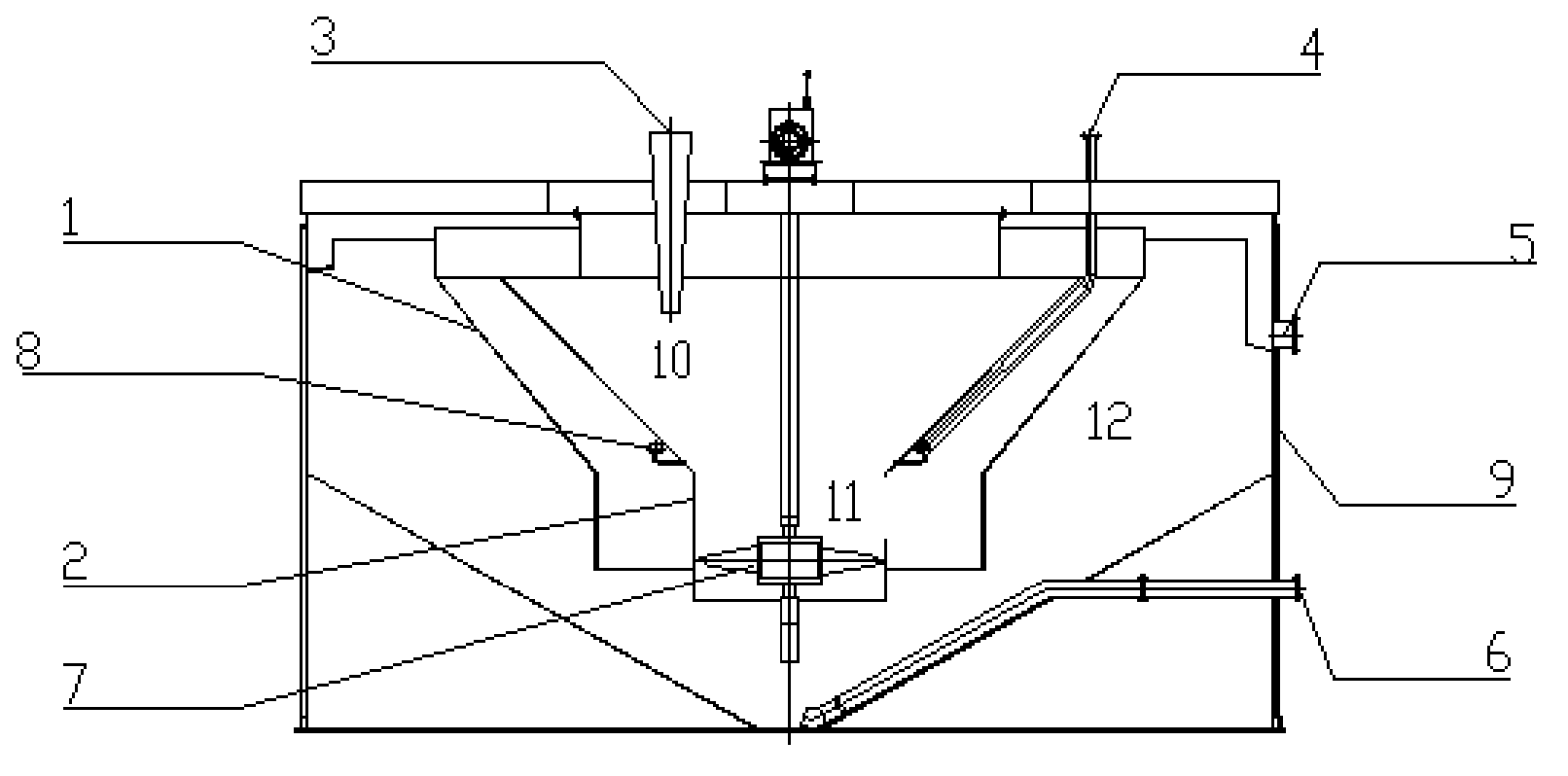

[0045] Embodiment 1: Crystallizer for hydrolysis of carnallite

[0046] The structure of the crystallizer is attached as figure 2 As shown, it includes a housing 9, an inner cylinder 2 and an outer cylinder 1 arranged in the housing 9, a carnallite inlet 3 and a mother liquor inlet 4 communicated with the inner cylinder 2, and a decomposition liquid outlet 5 is arranged on the upper part of the housing 9 , the product outlet 6 is set at the bottom of the housing 9, the inner cylinder 2 is located in the outer cylinder 1 and is coaxial with the outer cylinder 1, and a stirring device is provided at the bottom of the inner cylinder 2; it is characterized in that the inner cylinder 2 and The longitudinal cross-sectional shape of the outer cylinder 1 is that the upper part is an inverted cone, while the lower part is rectangular; the distance between the bottom of the inner cylinder 2 and the bottom of the elliptical cone shell is greater than the distance between the bottom of t...

Embodiment 2

[0054] Example 2: Crystallizer for hydrolysis of carnallite

[0055] The implementation of this embodiment is the same as that of Example 1, except that the angle between the inverted tapered side of the outer cylinder 1 and the extended line of the rectangular side is 40°, and the angle between the inverted tapered side of the inner cylinder 2 and the extended line of the rectangular side The angle is 50°, and the included angle between the shell side wall of the crystallizer and the shell bottom is 70°.

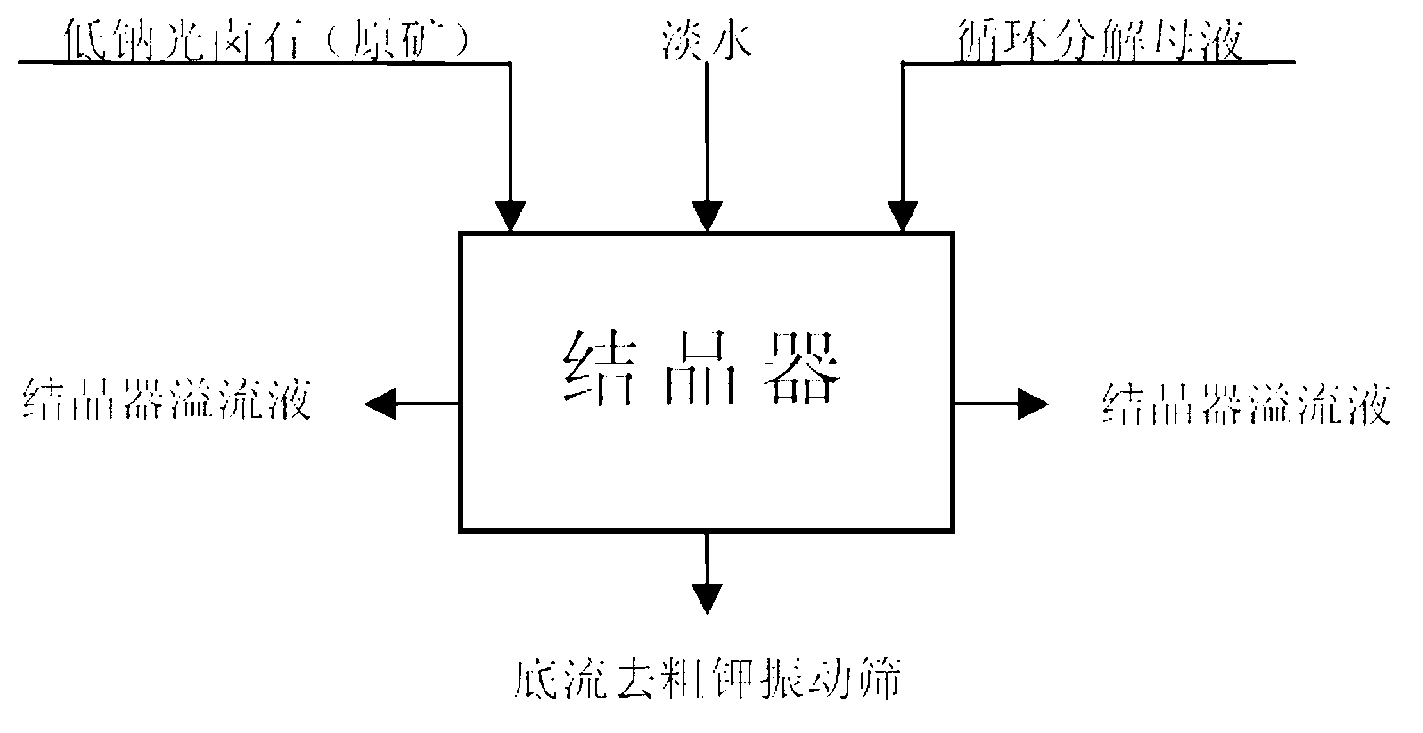

[0056] Use this embodiment crystallizer, according to appendix image 3 The process flow and the steps described in the instructions are carried out under the following conditions for carnallite hydrolysis: the processing capacity of low-sodium carnallite is 450t / h, and the underflow flow rate is controlled at 340m 3 / h, the underflow concentration is 28% (volume ratio). Adopt my country's existing analysis standard or literature data to analyze relevant components in low...

Embodiment 3

[0057] Example 3: Crystallizer for hydrolysis of carnallite

[0058] The implementation of this embodiment is the same as that of Example 1, except that the included angle between the inverted tapered side of the outer cylinder 1 and the extended line of the rectangular side is 38°, and the included angle between the inverted tapered side of the inner tube 2 and the extended line of the rectangular side The angle is 40°, and the included angle between the shell side wall of the crystallizer and the shell bottom is 57°.

[0059] Use this embodiment crystallizer, according to appendix image 3 The process flow and the steps described in the instruction manual carry out the hydrolysis of carnallite under the following conditions: the processing capacity of low-sodium carnallite is 380t / h, and the flow rate of the underflow is controlled at 360m 3 / h, the underflow concentration is 32% (volume ratio). Adopt my country's existing analysis standard or literature data to analyze re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mouth diameter | aaaaa | aaaaa |

| Mouth diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com