Patents

Literature

686 results about "Low sodium" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low Sodium Salt Composition

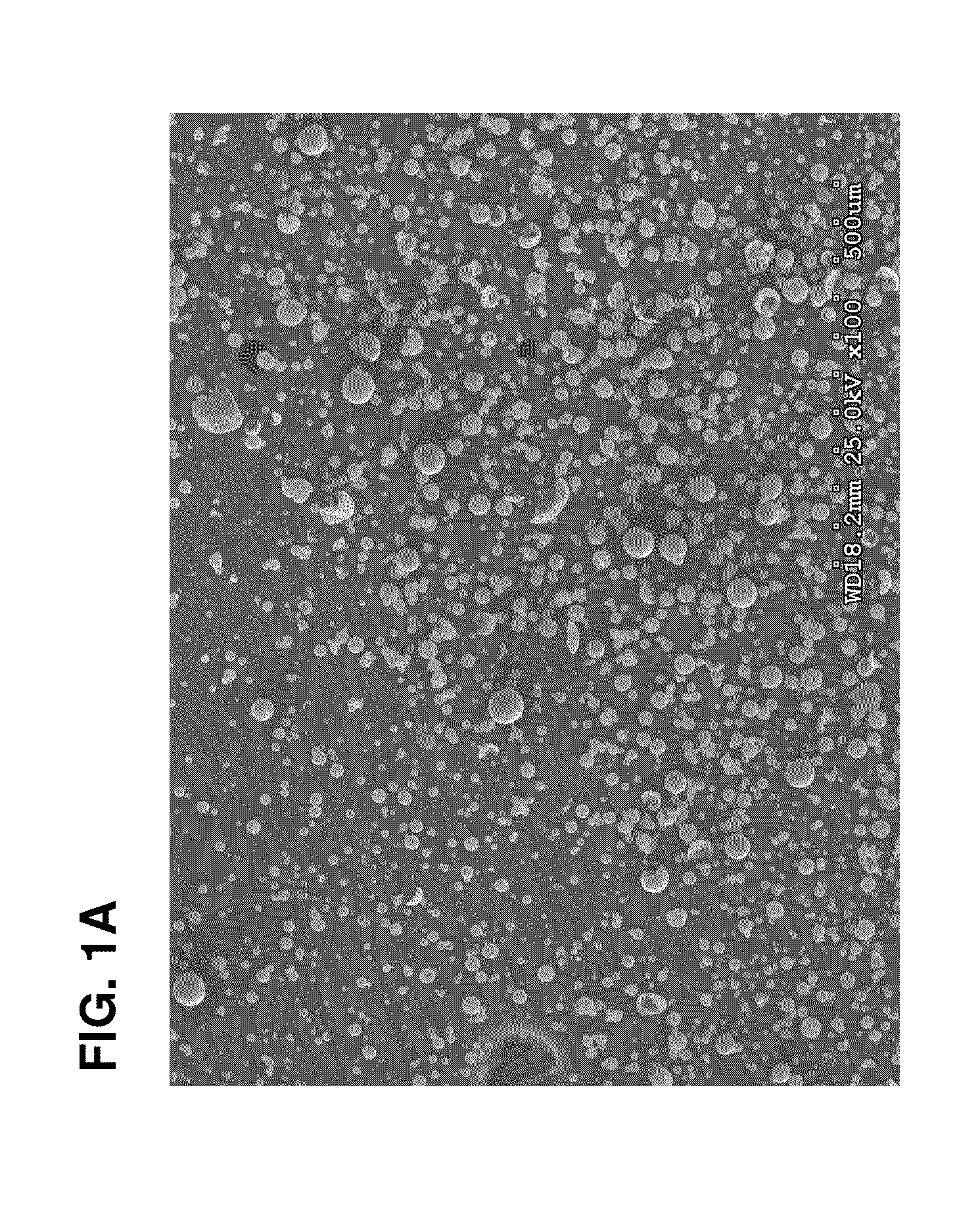

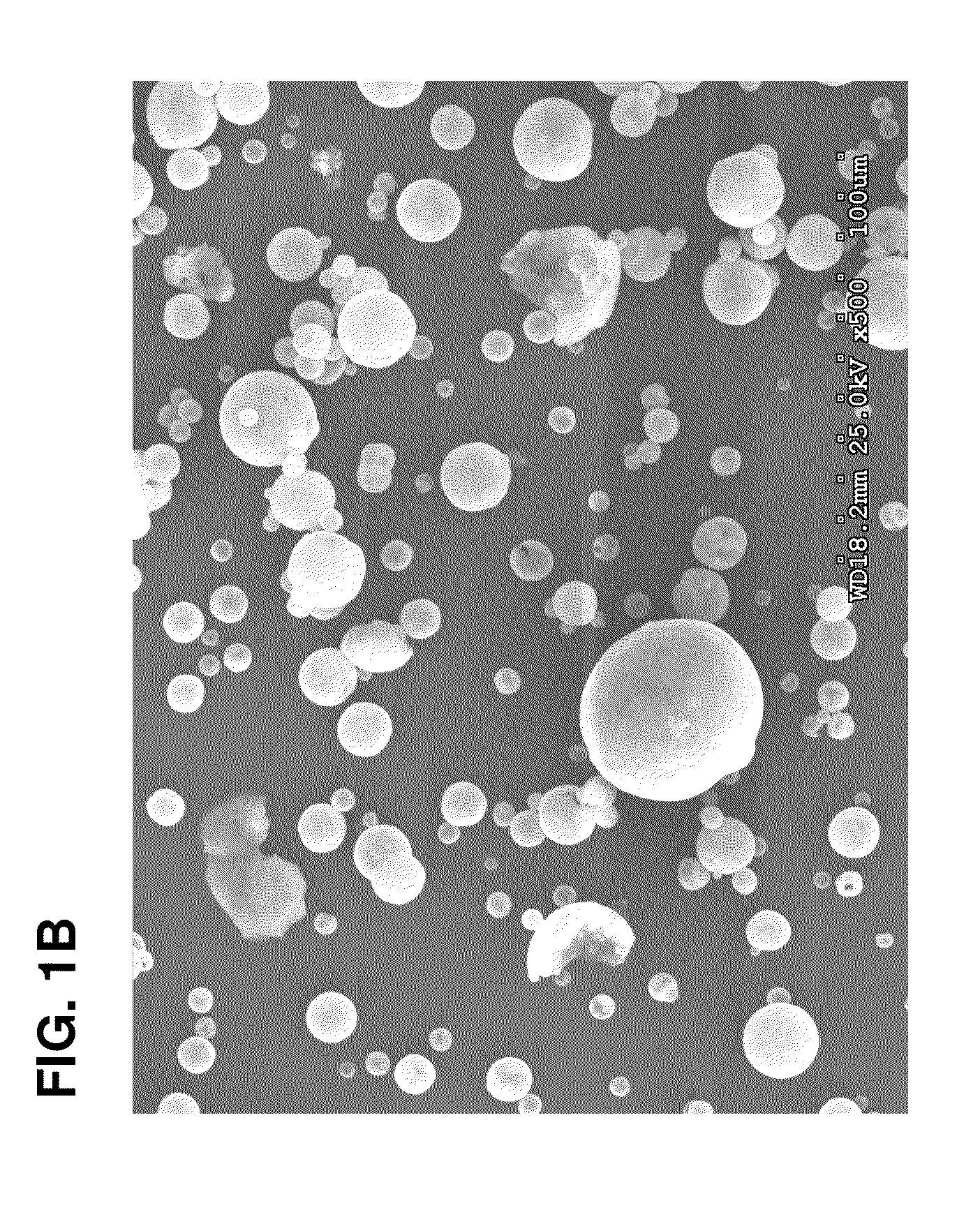

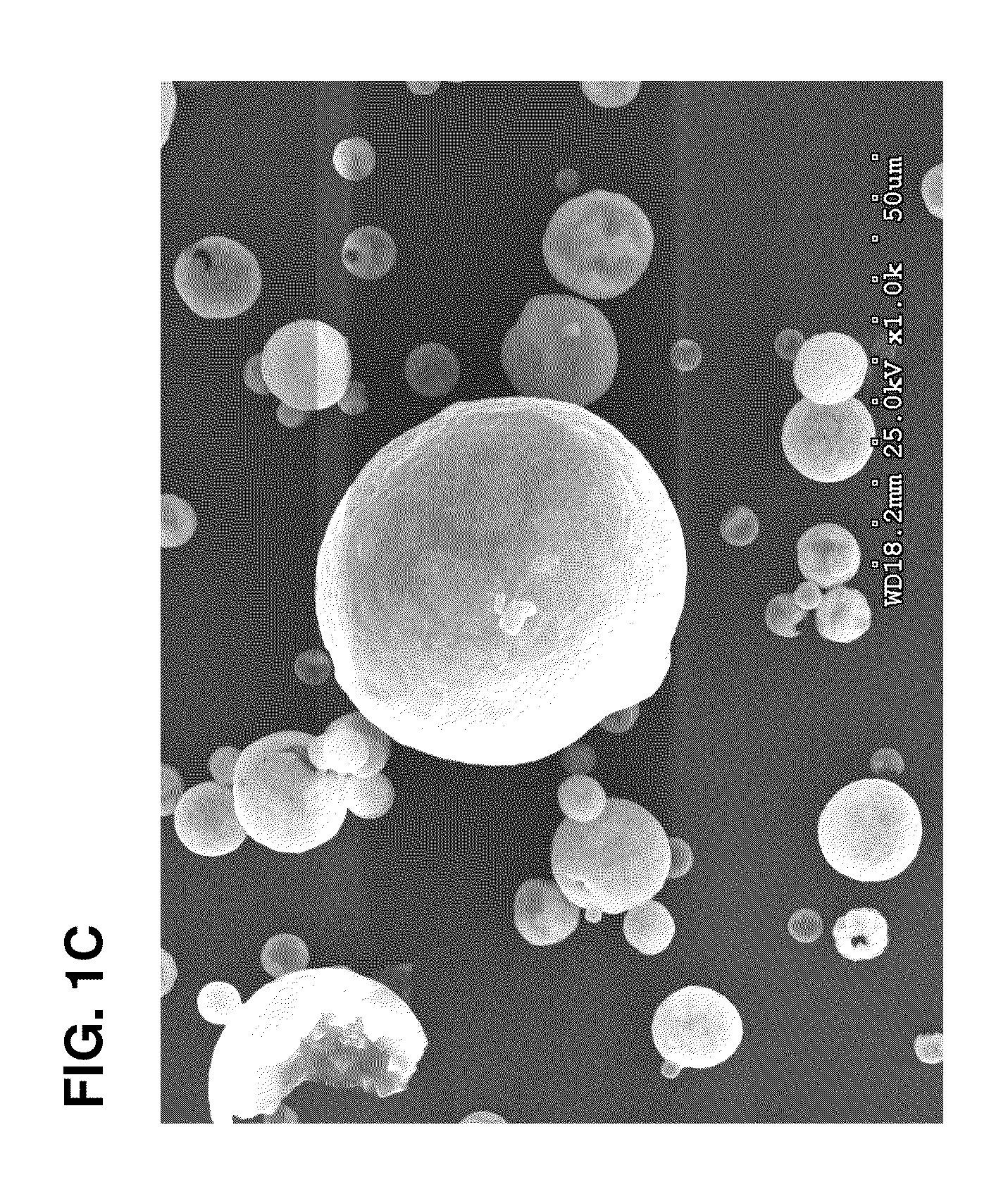

The present invention relates to a low sodium salt composition and the methods used to make it. In particular, the invention relates to the combined processing of sodium and potassium chloride to produce a low sodium salt composition. The low sodium salt composition includes sodium chloride and a modified chloride salt composition. The modified chloride salt composition includes a homogenous amalgamation of chloride salts, food grade acidulant, and carrier.

Owner:S & P INGREDIENT DEV

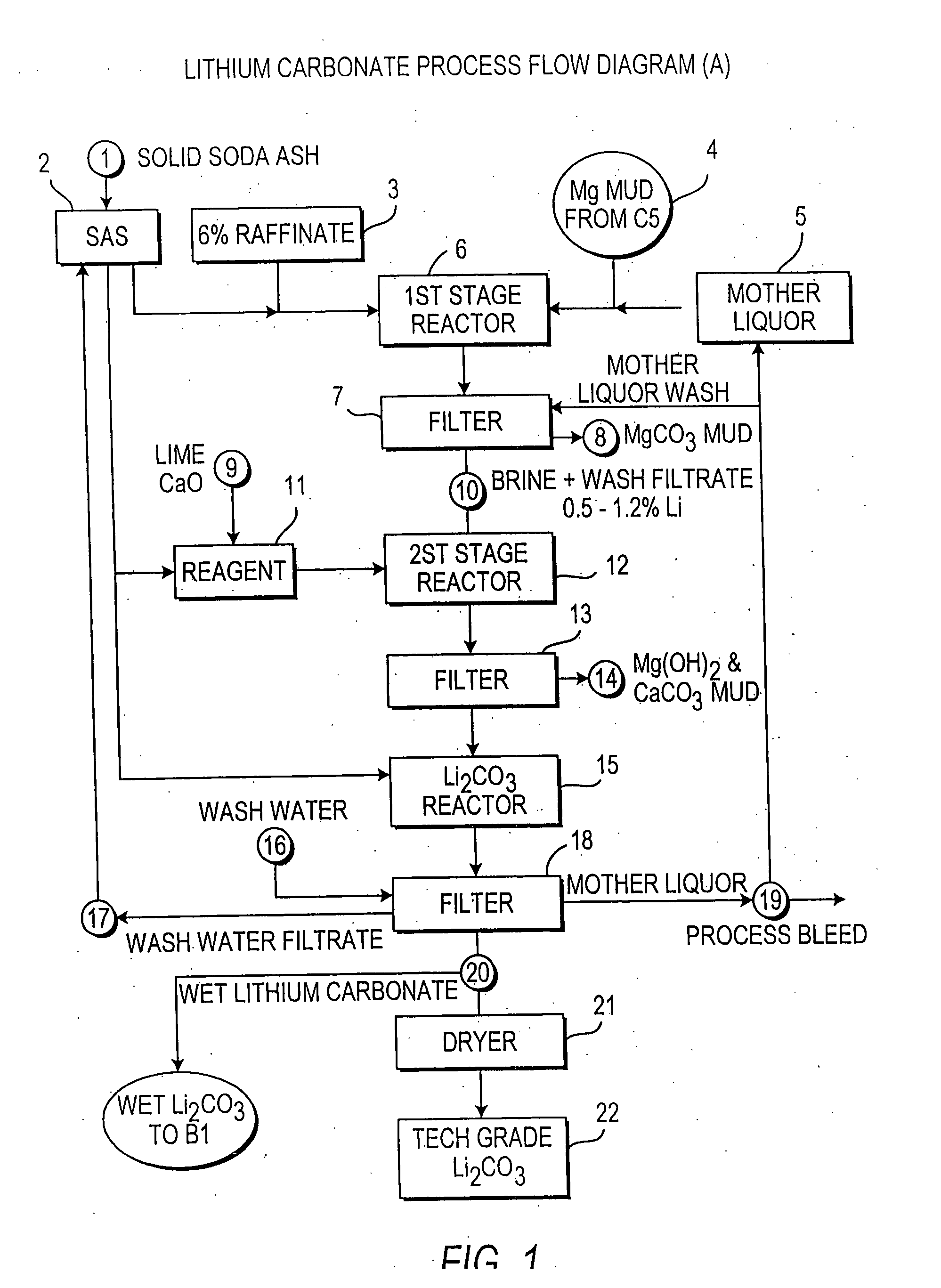

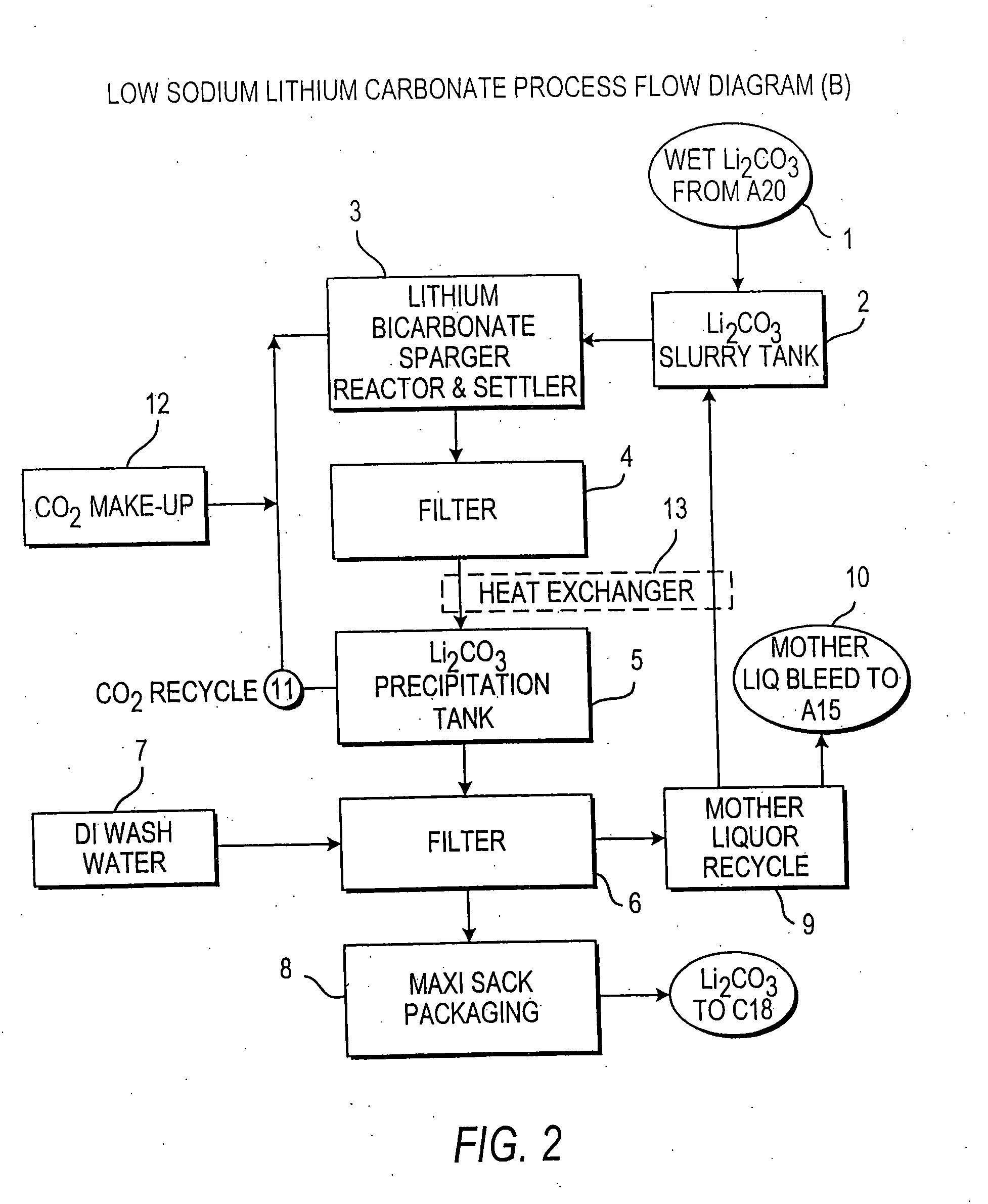

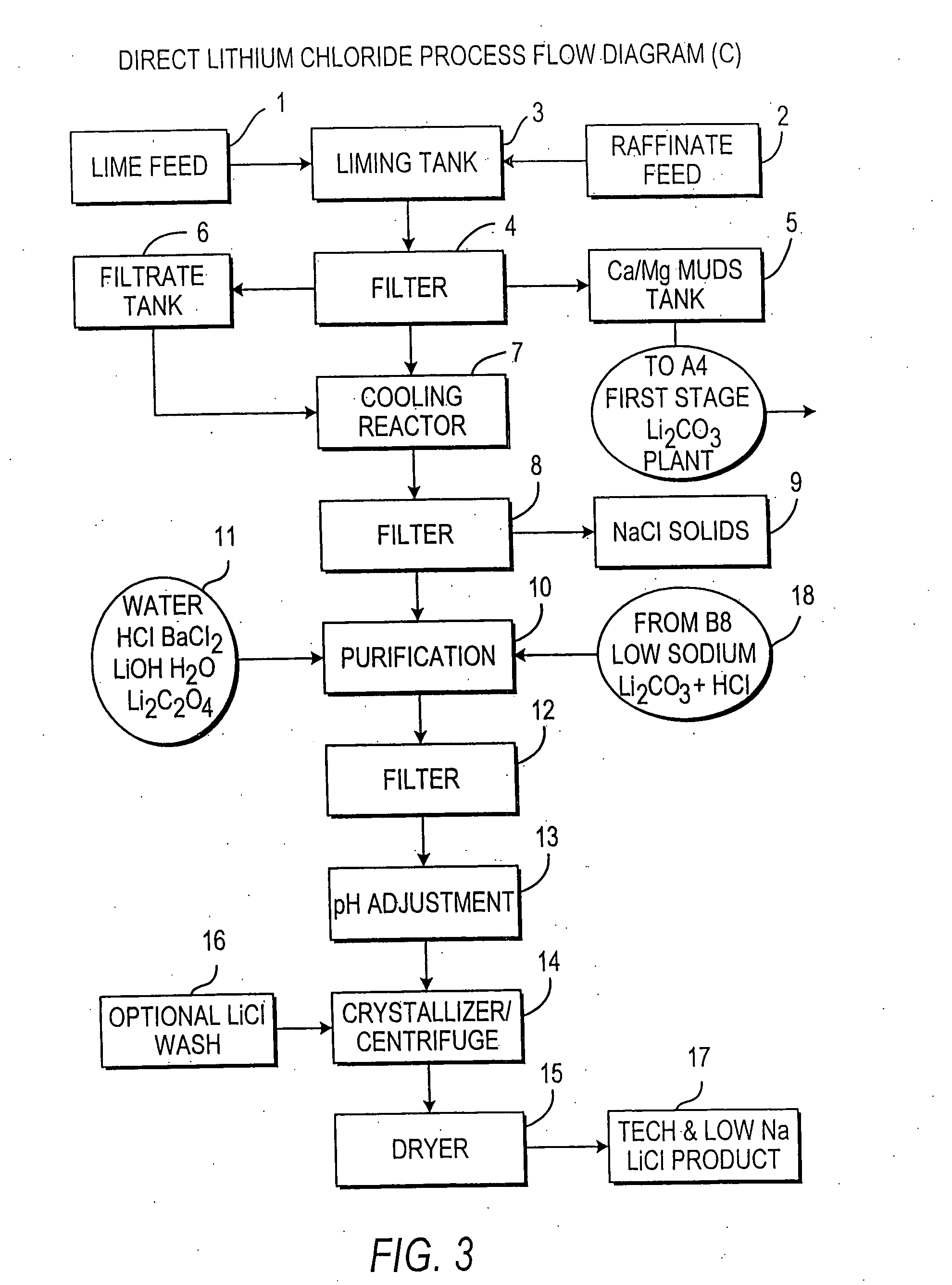

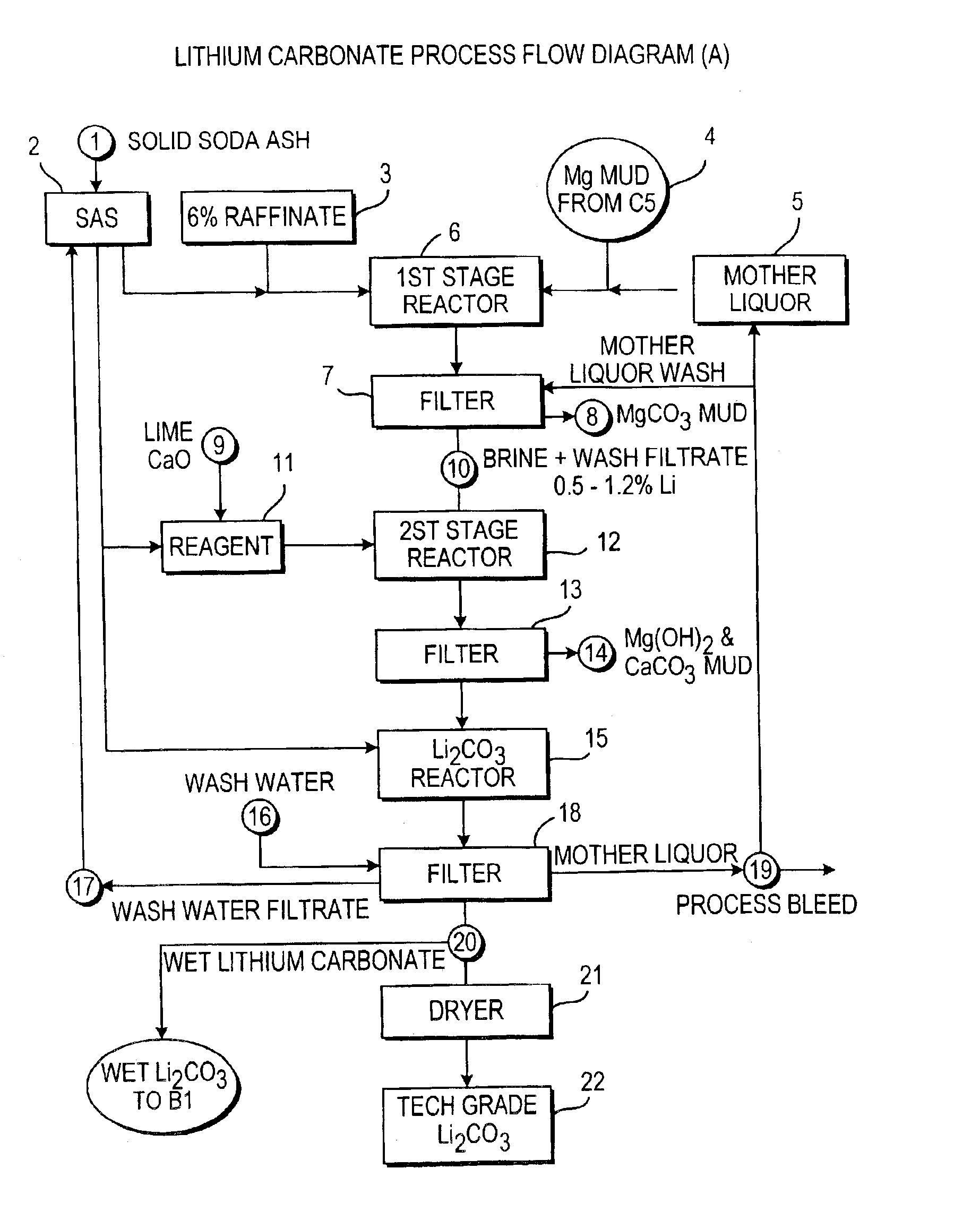

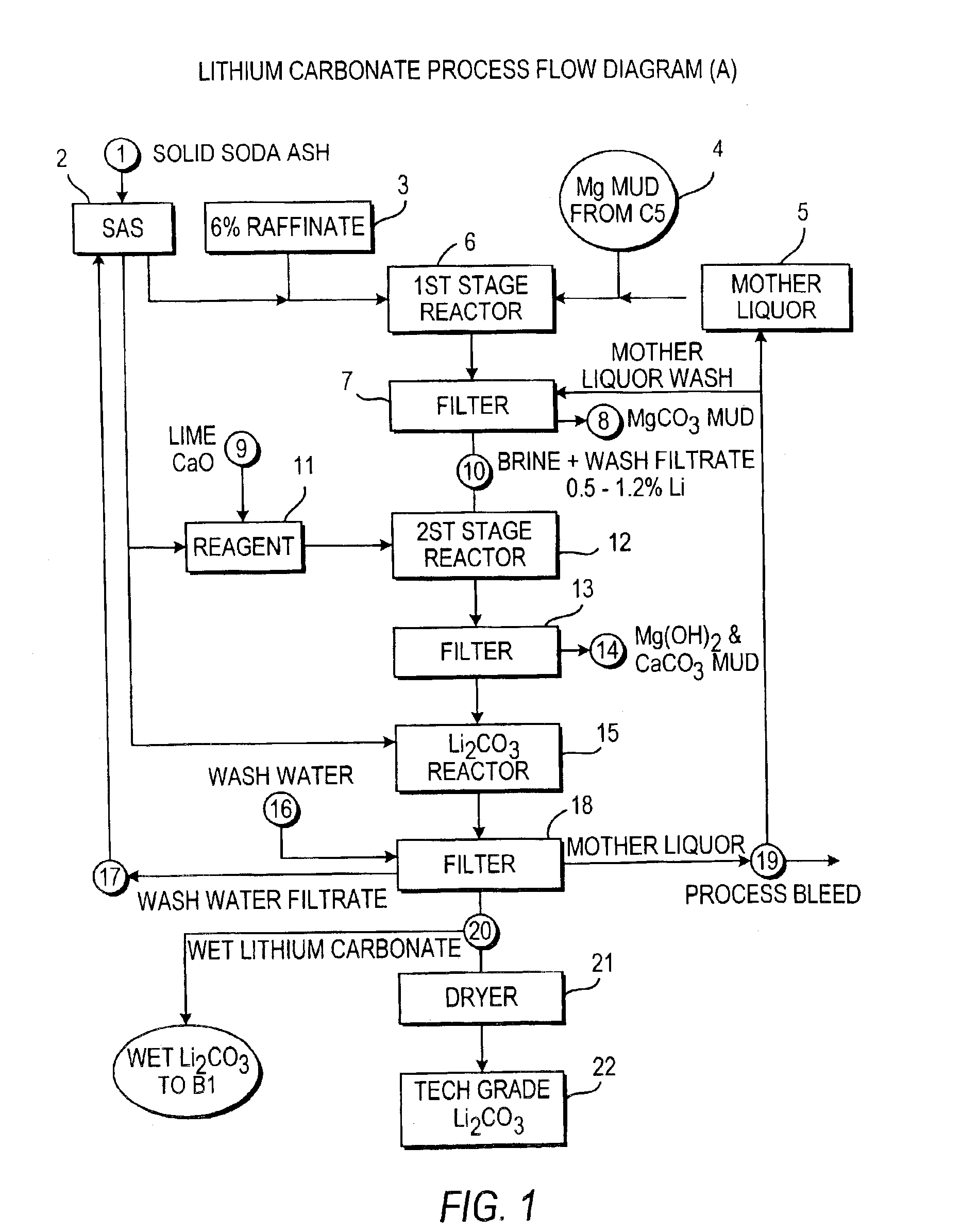

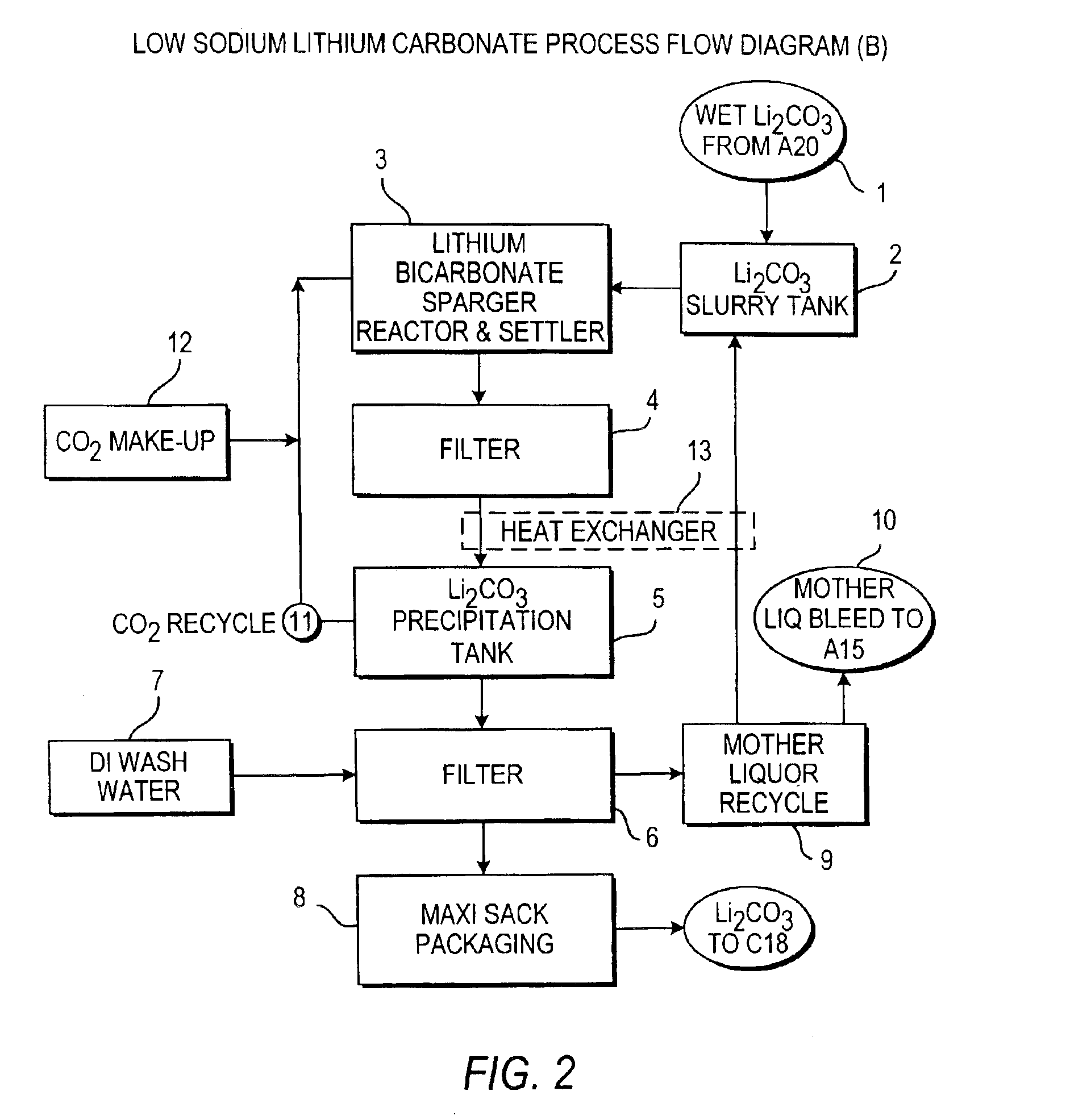

Production of lithium compounds directly from lithium containing brines

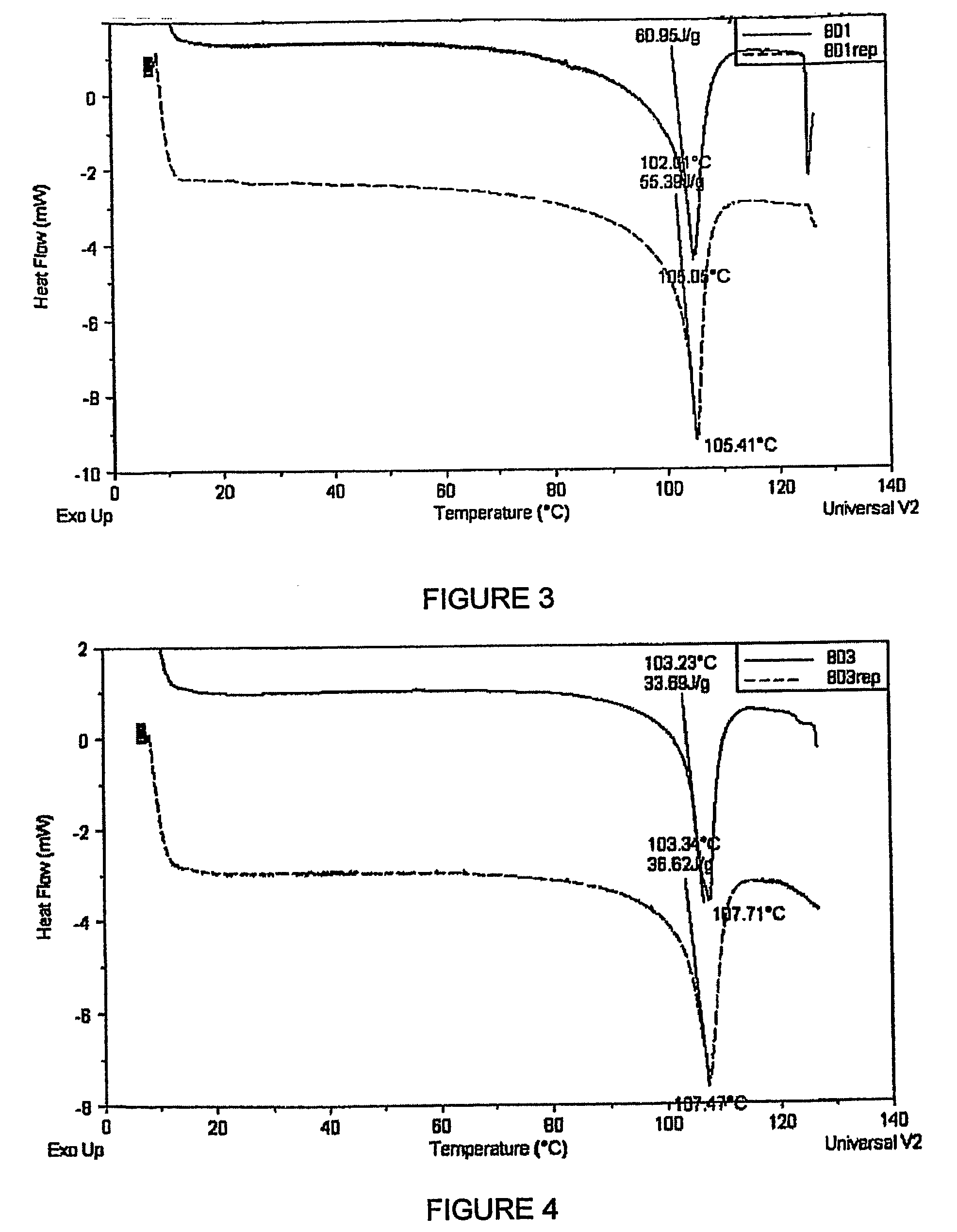

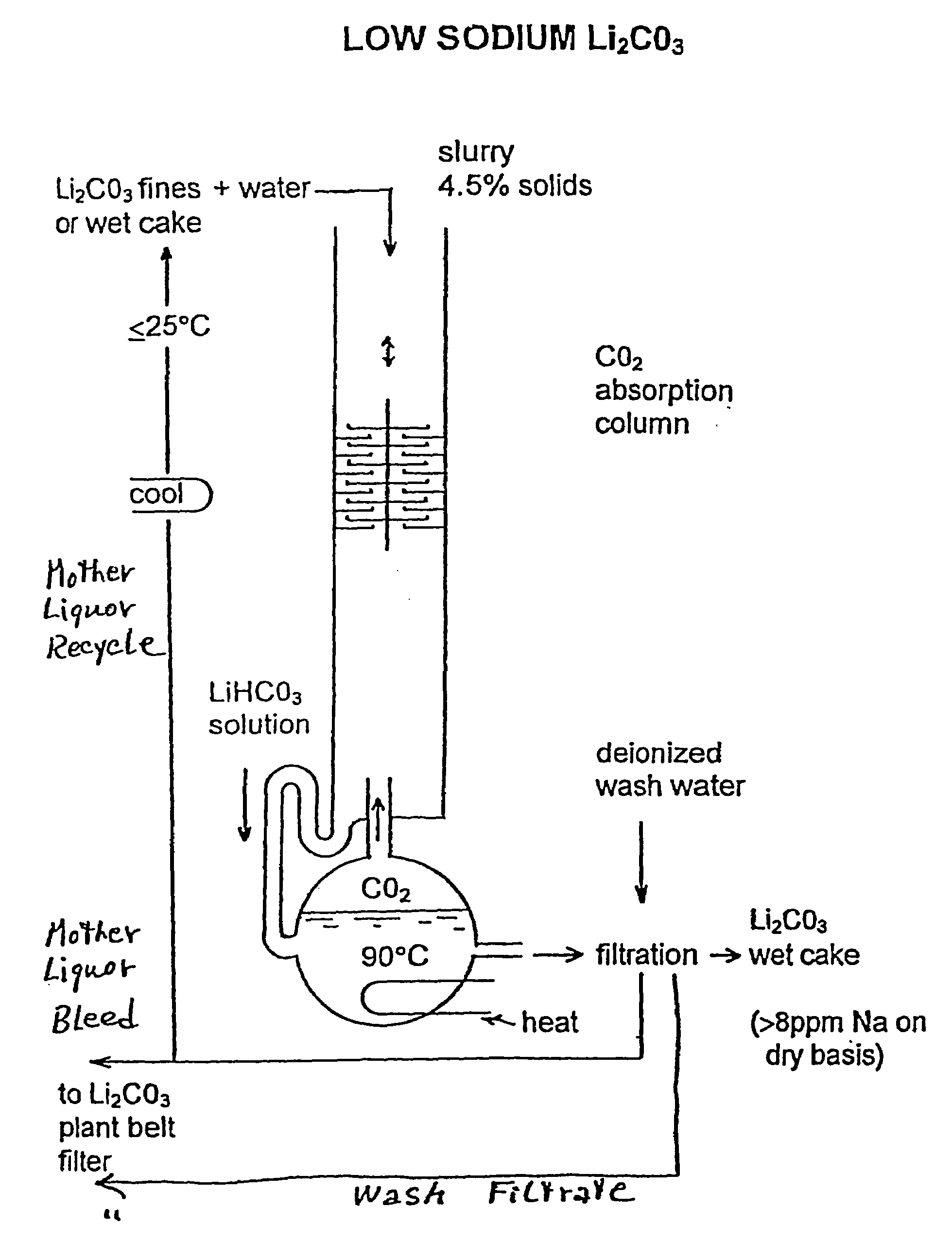

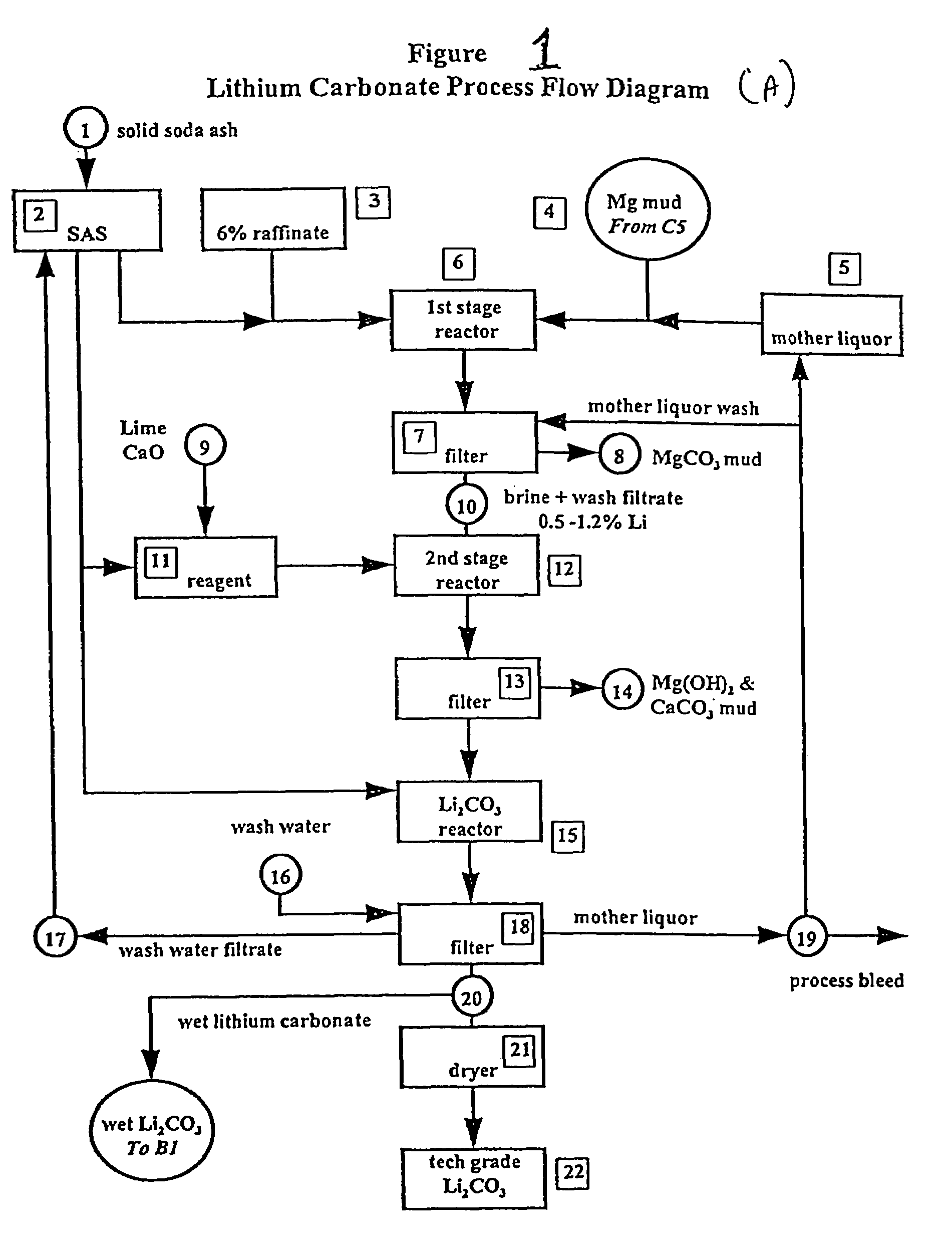

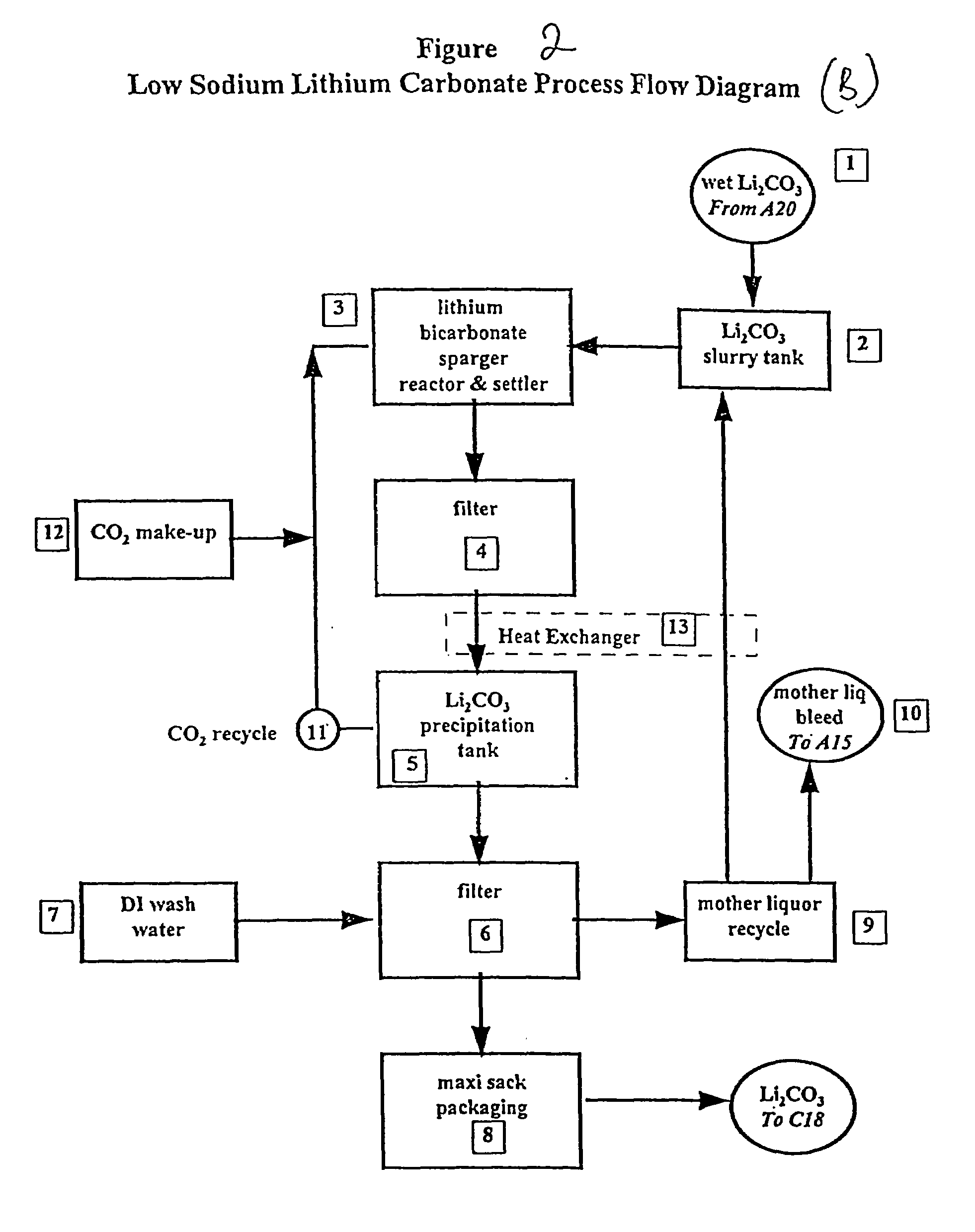

InactiveUS20060115396A1Promote absorptionConstant liquid volumeCalcium/strontium/barium carbonatesCalcium/strontium/barium sulfatesLithium chlorideLithium carbonate

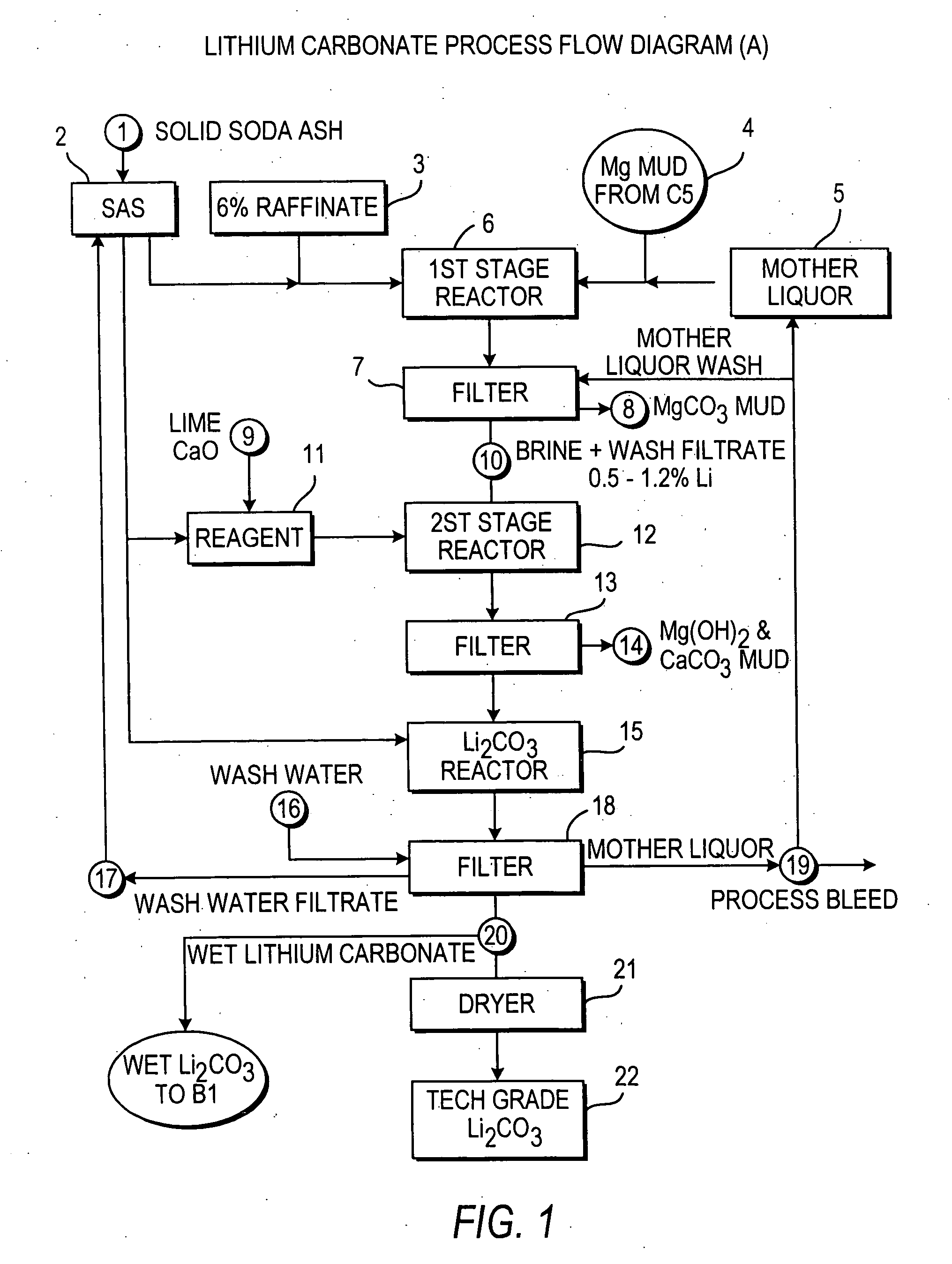

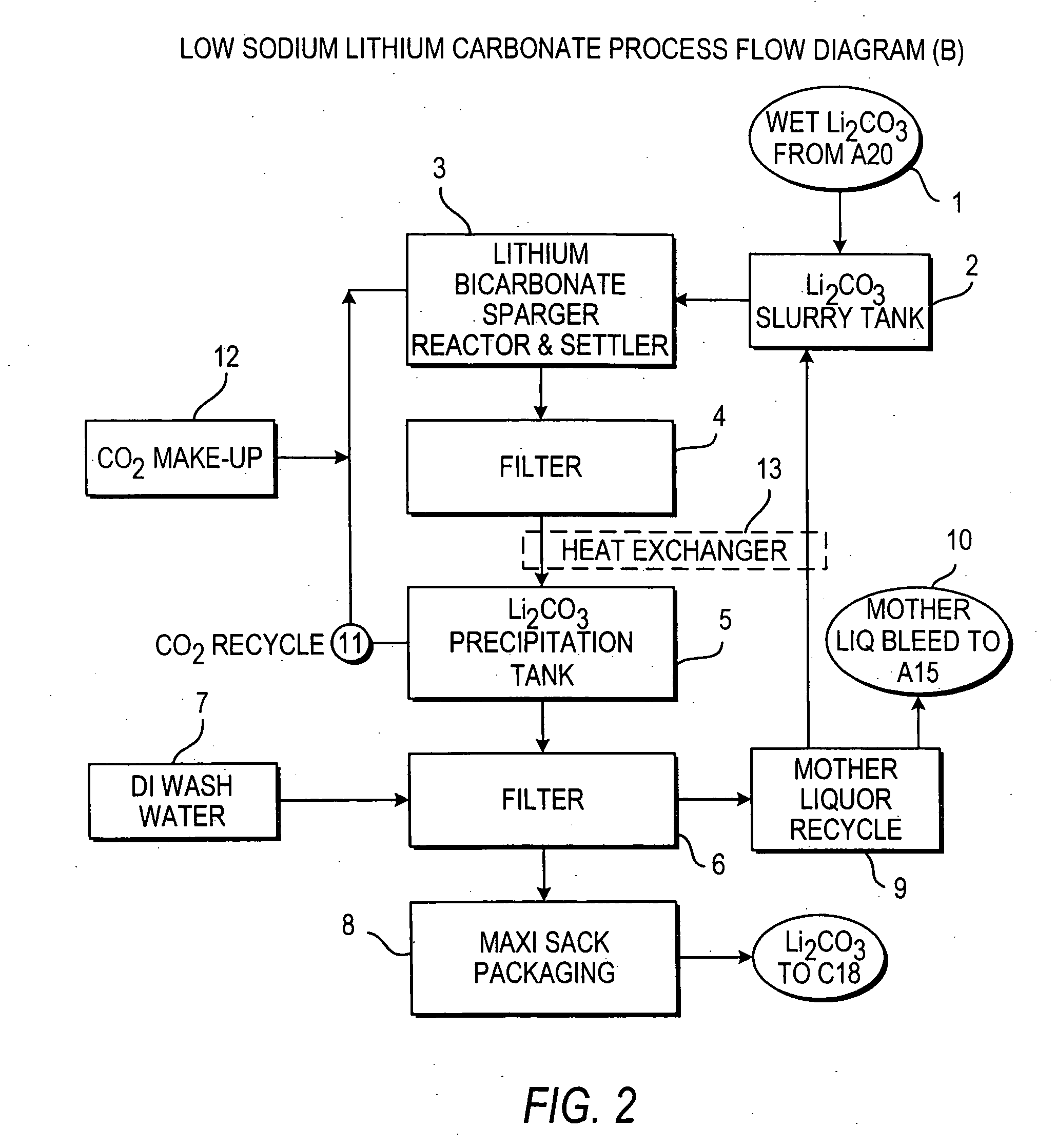

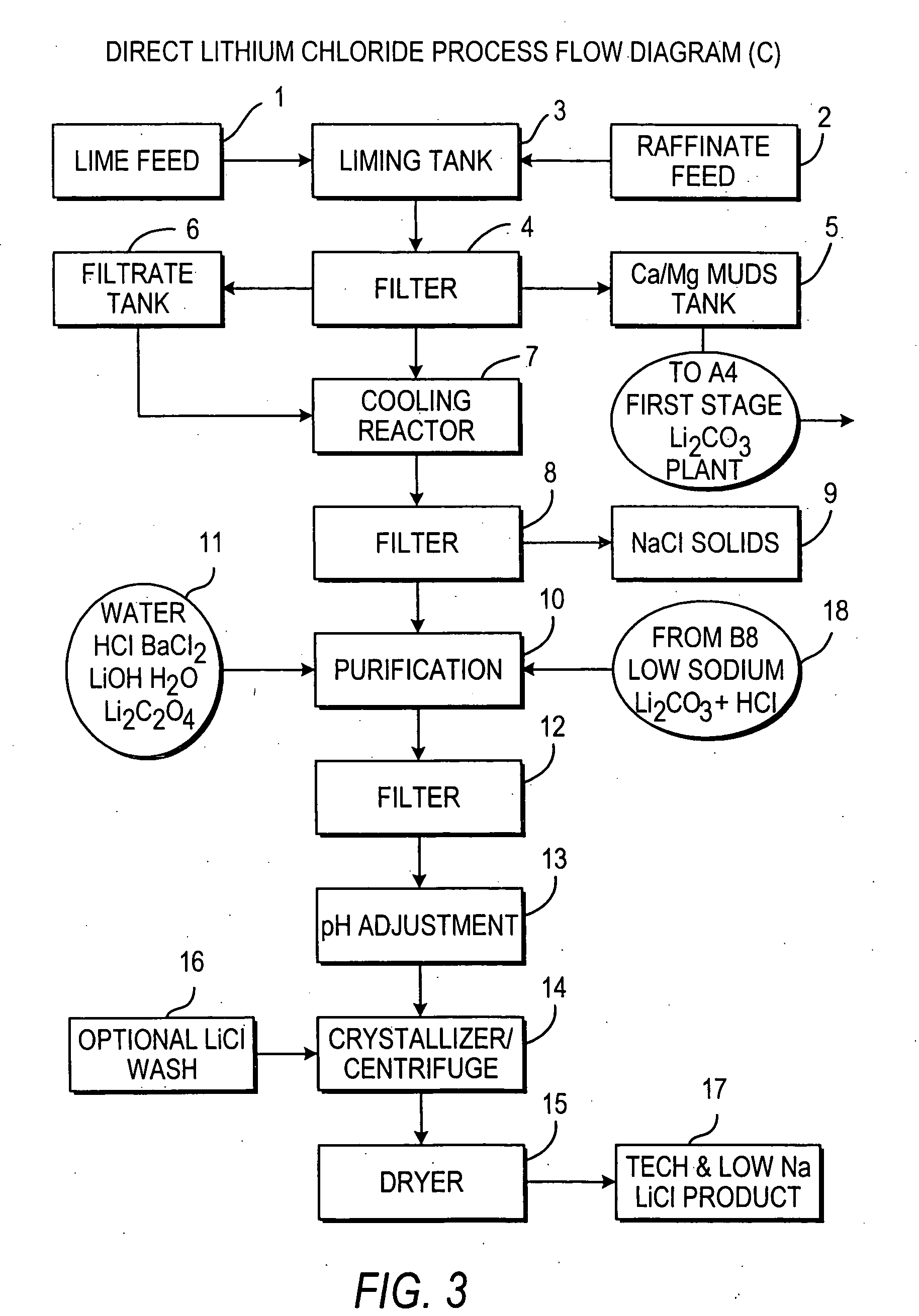

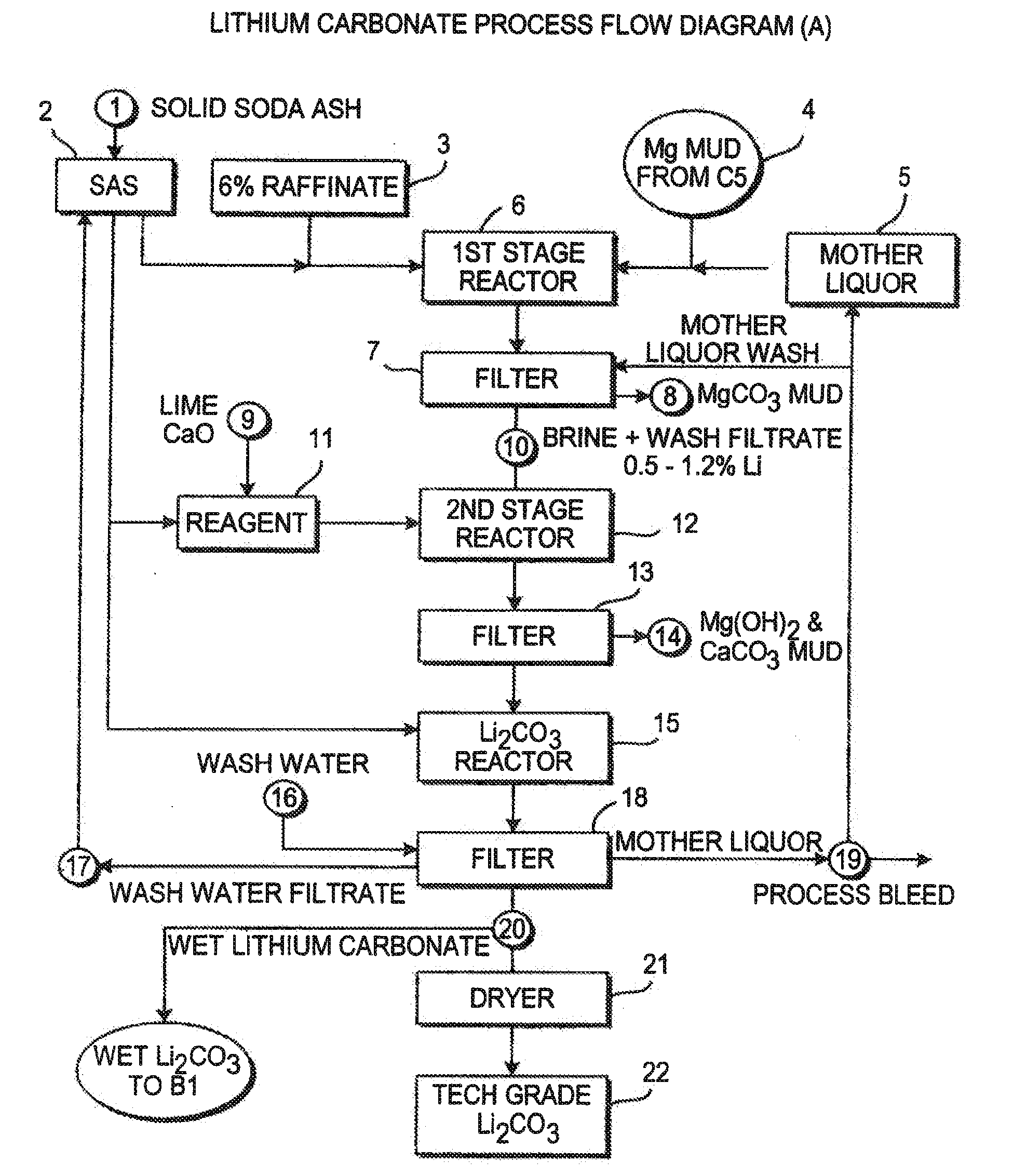

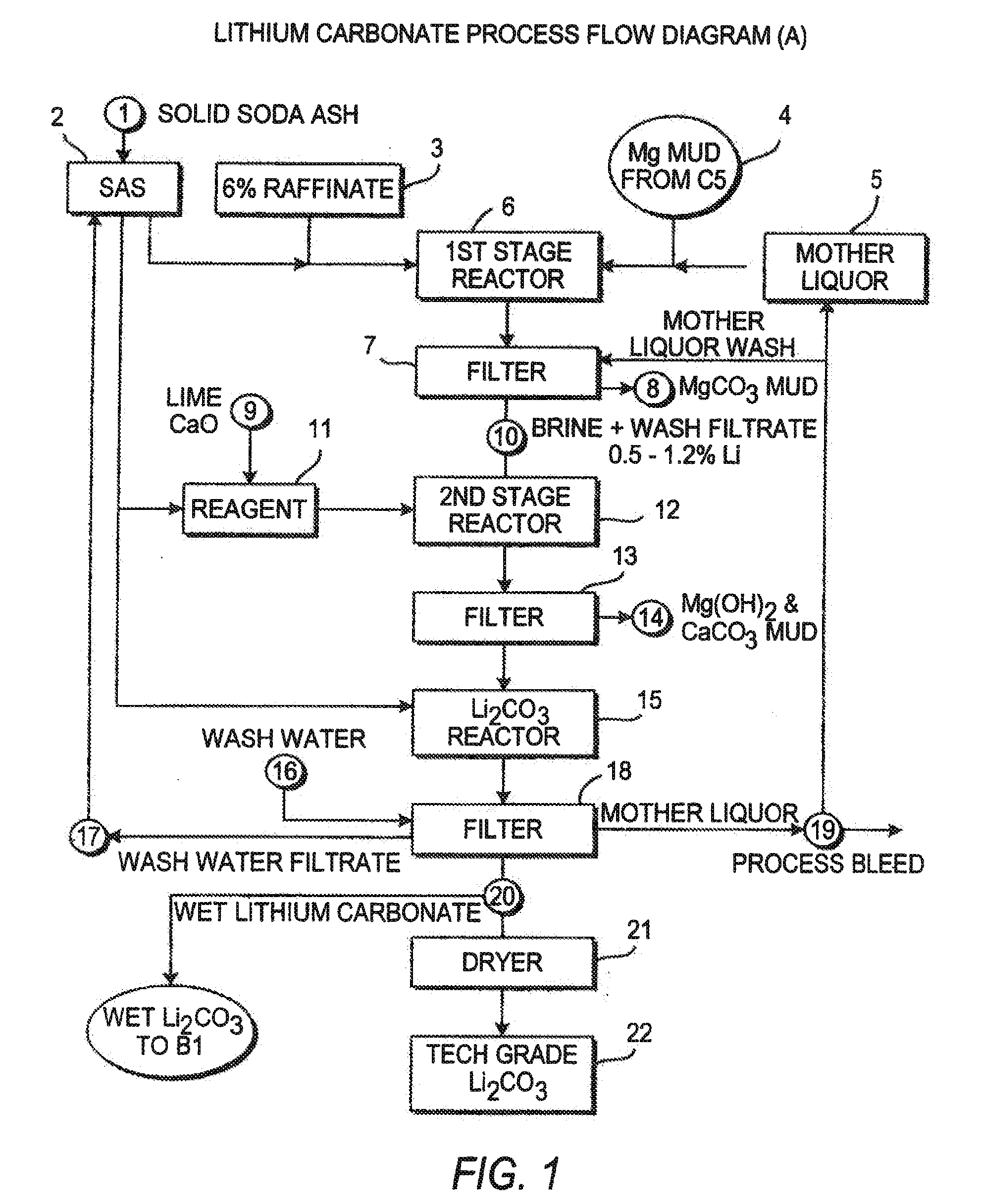

Methods and apparatus for the production of low sodium lithium carbonate and lithium chloride from a brine concentrated to about 6.0 wt % lithium are disclosed. Methods and apparatus for direct recovery of technical grade lithium chloride from the concentrated brine are also disclosed.

Owner:BORYTA DANIEL ALFRED +2

Liquid low-sodium silicate electrolyte used for a storage battery and manufactured by magnetization process, and the usage thereof

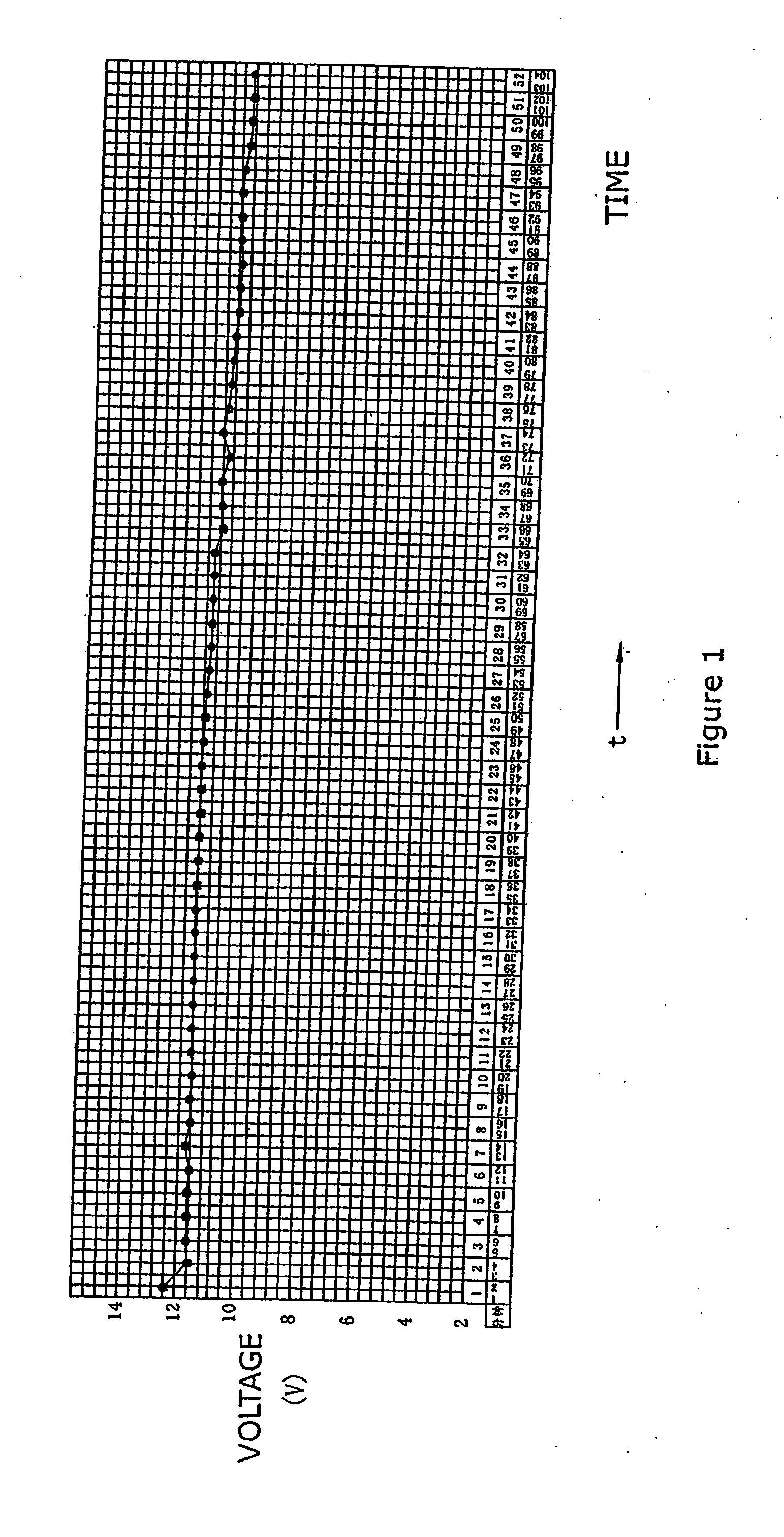

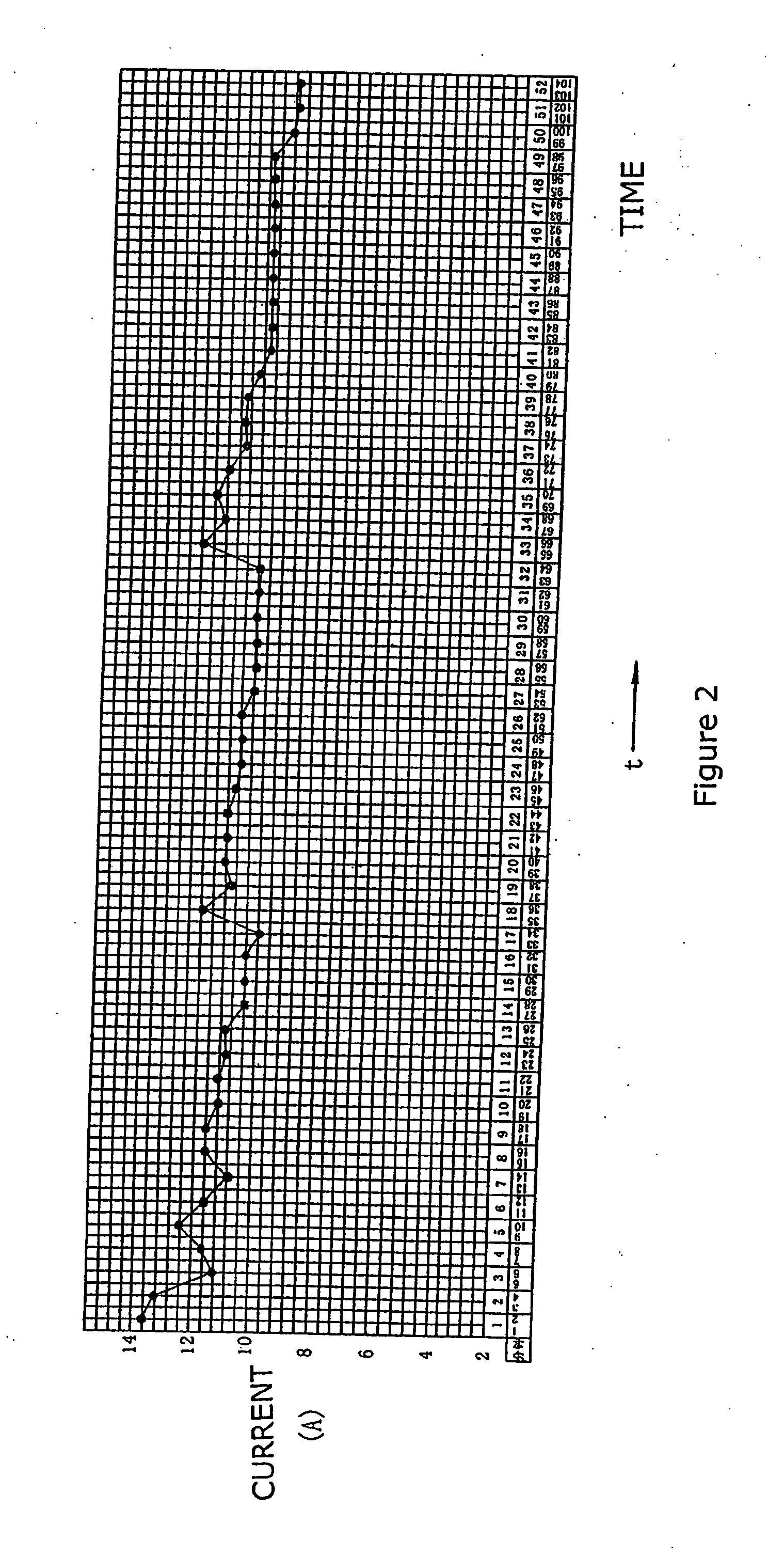

InactiveUS20080044726A1Improve liquidityHigh viscosityOther chemical processesMagnetic paintsMagnetizationBiological activation

A liquid low concentration sodium-containing silicate solution as electrolyte for lead-acid storage batteries and its applications, is prepared by mixing a silica gel containing 40˜60 wt % SiO2, the weight units of such a silica gel are 5˜15; add 15-25 weight units water and stir until the concentration of the mixture is 0.65˜0.85 0Be′ measured by a Baum densimeter, adjusting the pH value of this mixture to 1-4 using inorganic acid and magnetizing the mixture under 1000-6000 Gauss magnetic field for 5-10 minutes, stir the magnetized mixture until the viscosity of the mixture is less than 0.02 poise and finally obtain a liquid low concentration sodium-containing silicate solution. The electrolyte can be used as electrolyte or activation solution for common or special lead-acid storage batteries.

Owner:LIDU WANG

Stable sodium-free or low-sodium aqueous solution of agreeable saltiness taste

A stable sodium-free aqueous seasoning solution of agreeable salty taste, adapted as a substitute for common salt in cooked and uncooked foodstuffs, containing purified water, an organic acid, a potassium salt, a calcium salt, and a magnesium salt. The mineral solution provides a dietary supplementation of magnesium, calcium, and potassium—indispensable minerals of a diet—to which colorants, natural essences and artificial essences (singly or in combination), and low concentrations of sodium chloride may be added.

Owner:REV

Production of lithium compounds directly from lithium containing brines

InactiveUS20110123427A1Reduce in quantityPromote absorptionVarying alkali metal carbonate water contentRubidium/caesium/francium compoundsLithium chlorideLithium carbonate

Methods and apparatus for the production of low sodium lithium carbonate and lithium chloride from a brine concentrated to about 6.0 wt % lithium are disclosed. Methods and apparatus for direct recovery of technical grade lithium chloride from the concentrated brine are also disclosed.

Owner:ROCKWOOD LITHIUM INC

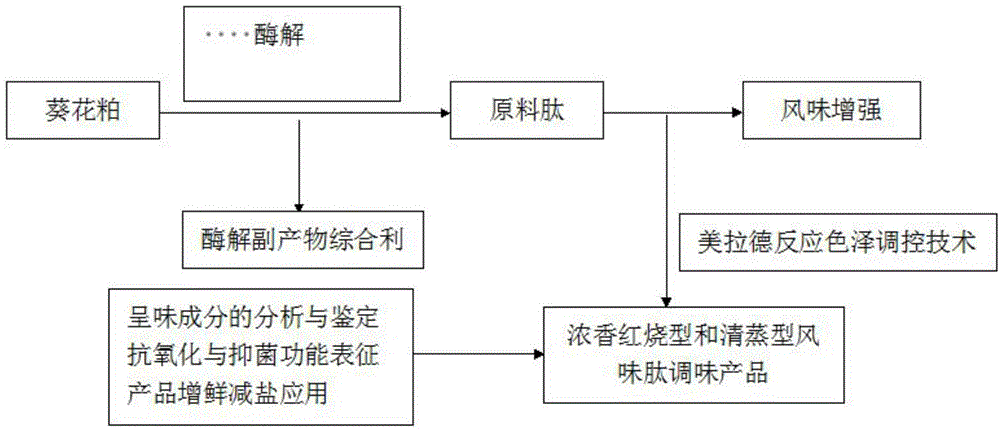

Complex flavouring with function of adding saltiness, adding freshness and containing less sodium

ActiveCN101243861AReduce sodium chloride contentSimplify cooking operationsFood shapingFood preparationCooking processLow sodium

The invention discloses a low-sodium functional compound seasoning which can increase the taste of salty and savory. The invention is characterized in that the low-sodium salt is the main raw material on the basis of which one or a plurality of functional nutrients that can increase the taste of savory and salty, and one or a plurality of savory materials are added; then after mixing, stirring, and granulating, the compound seasoning is made. The compound comprises 20 to 80 portions weight of low-sodium salt, 10 to 30 portions weight of functional nutrient and 3 to 15 portions weight of savory materials. Therefore, the compound seasoning has the advantages of effectively reducing the ingestion of NaCI, outstanding flavoring effect and nutrient function. What's more, the invention can be operated simply for the taste of salty, savory and delicious can be got at a time in the process of cooking.

Owner:上海东南清宫食品工业有限公司

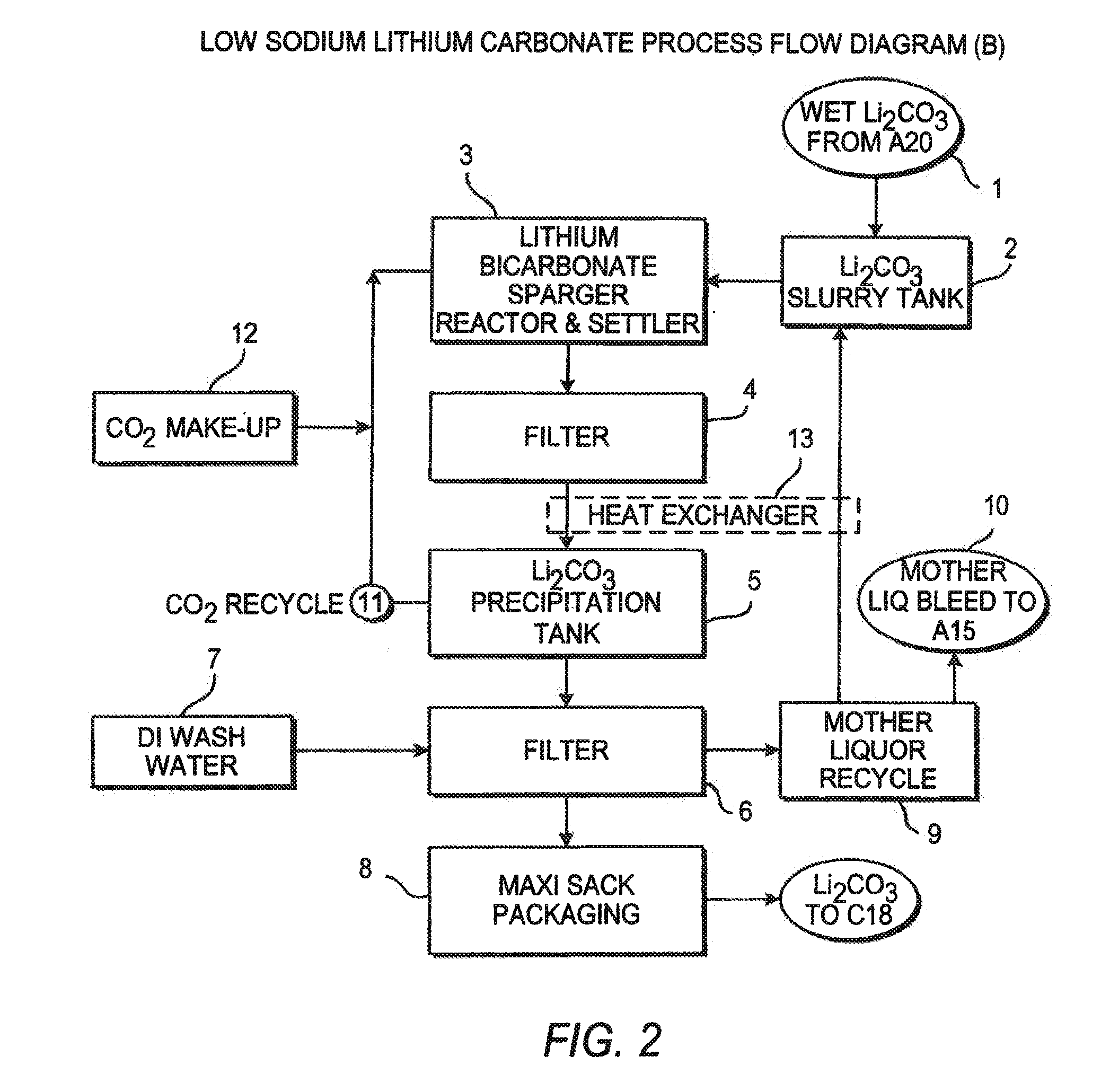

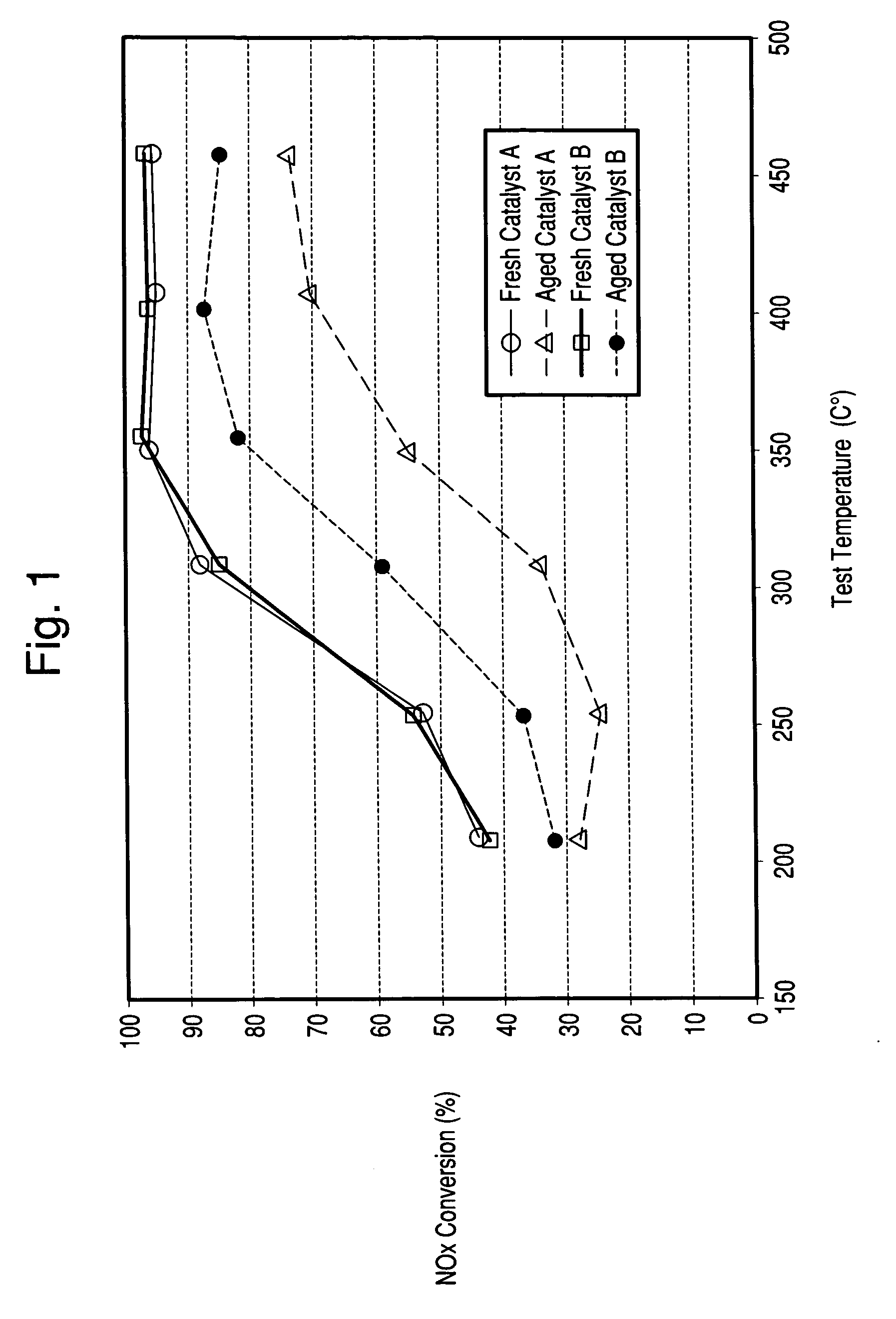

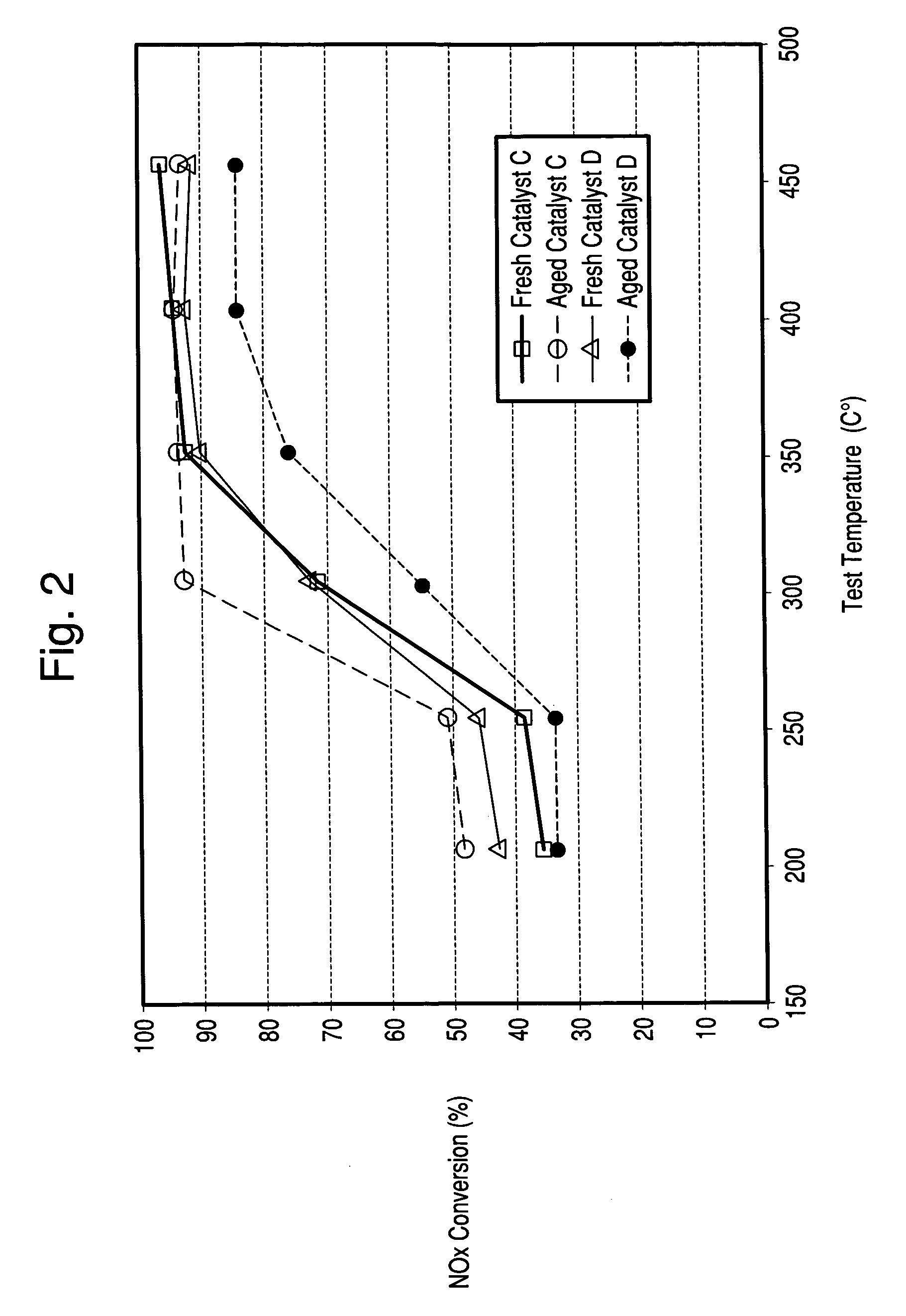

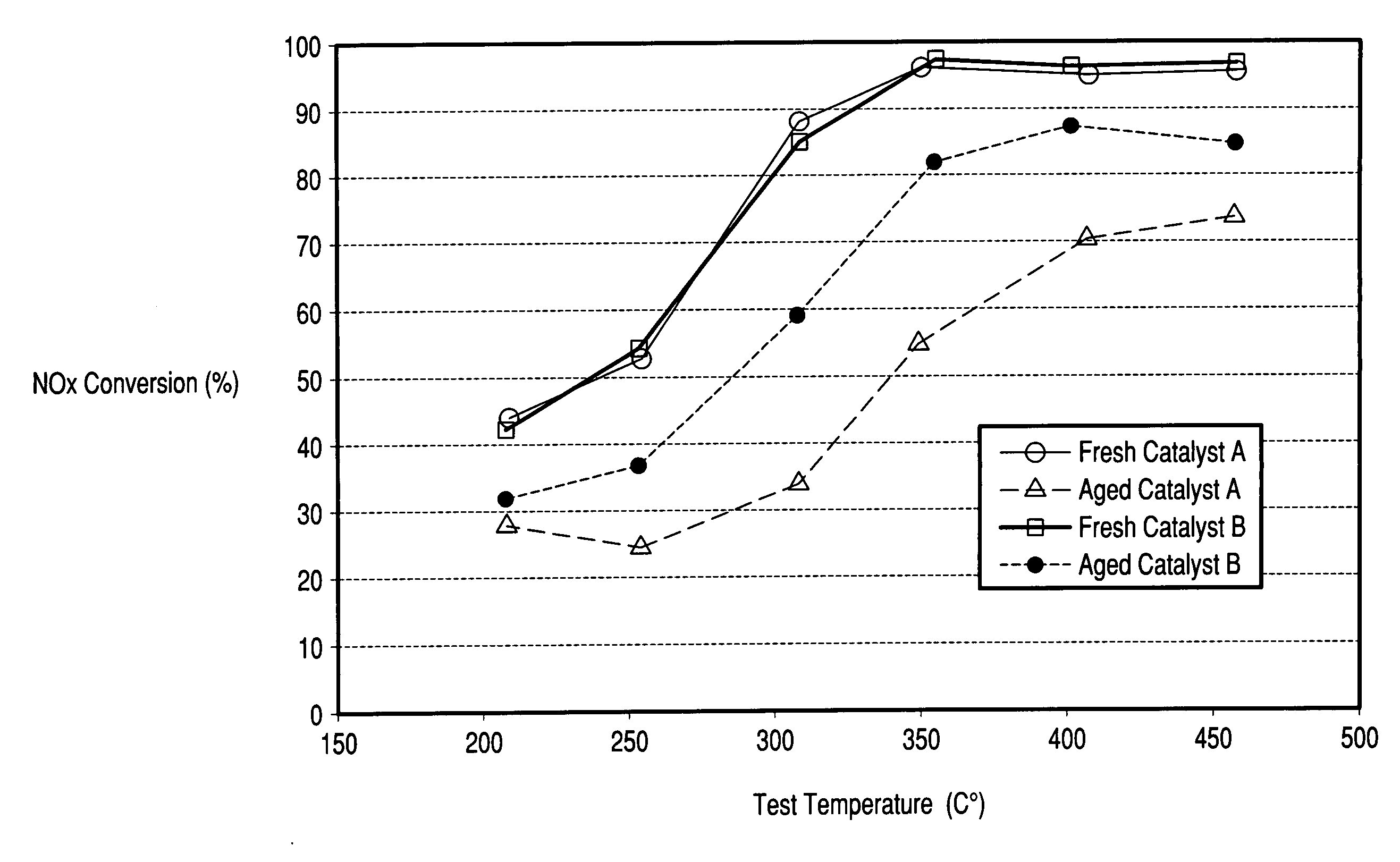

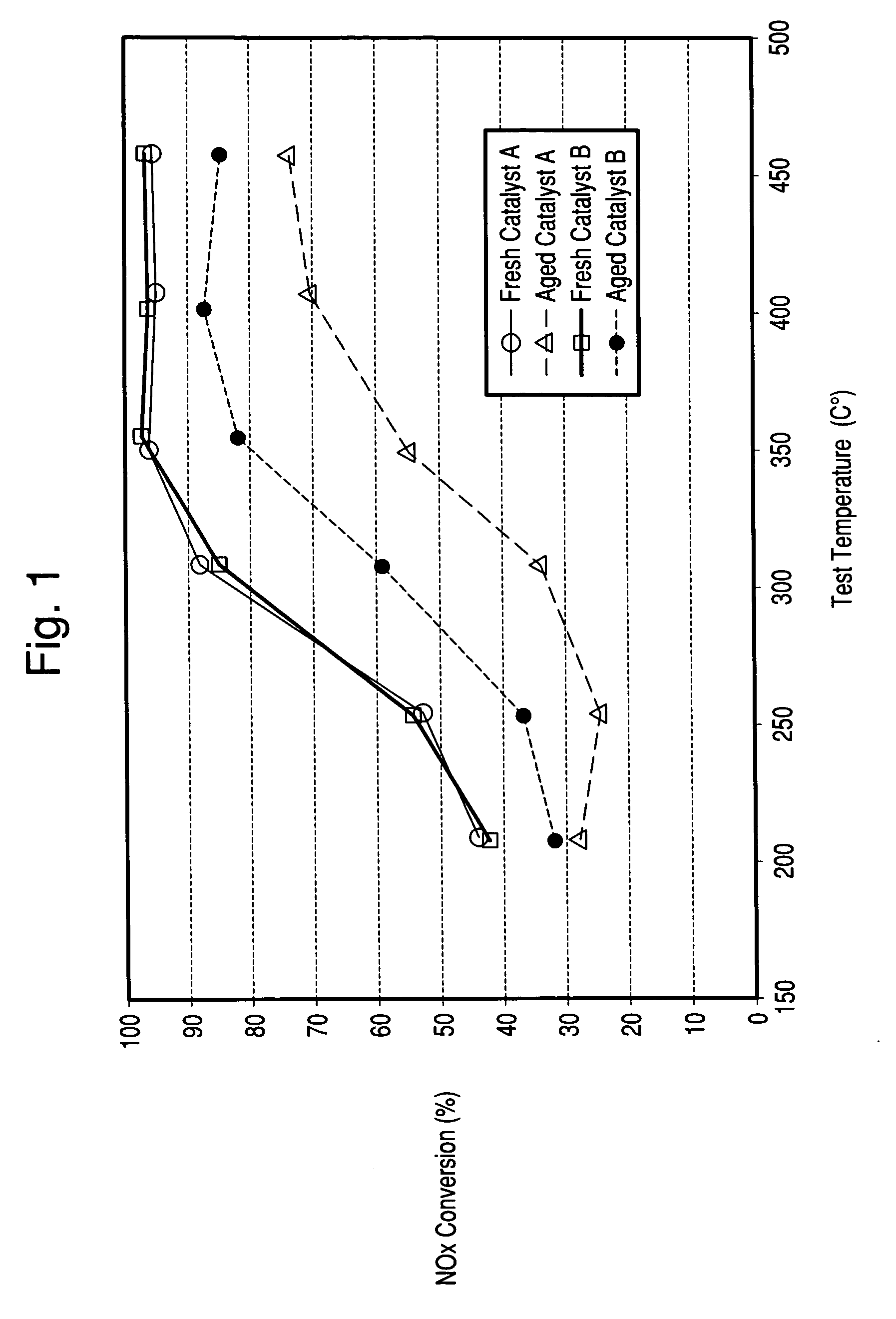

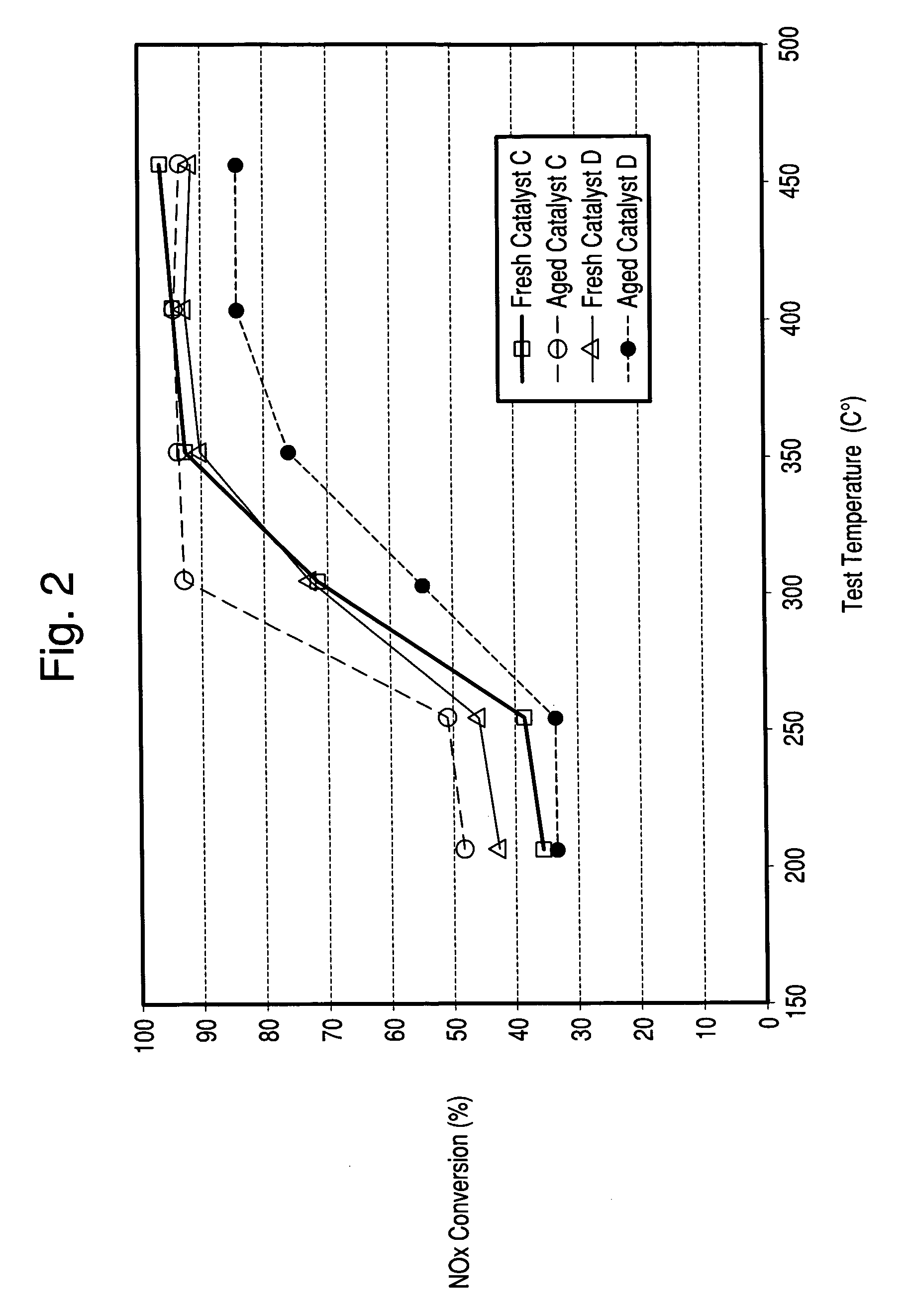

Zeolite catalyst with improved NOX reduction in SCR

InactiveUS20070134146A1Improved selective catalytic reductionImprove performanceNitrous oxide captureAluminium compoundsIon exchangeLow sodium

The present invention is directed to a novel metal-promoted zeolite catalyst, a method of producing the catalyst and a method of using the catalyst for the selective catalytic reduction of NOx with improved hydrothermal durability. The novel metal-promoted zeolite is formed from a low sodium zeolite and is hydrothermally treated after metal ion-exchange.

Owner:BASF CORP

Production of lithium compounds directly from lithium containing brines

InactiveUS20070160516A1Promote absorptionConstant liquid volumeCrystallization separationCarbonate/bicarbonate preparationLithium chlorideLithium carbonate

Methods and apparatus for the production of low sodium lithium carbonate and lithium chloride from a brine concentrated to about 6.0 wt % lithium are disclosed. Methods and apparatus for direct recovery of technical grade lithium chloride from the concentrated brine are also disclosed.

Owner:ROCKWOOD LITHIUM INC

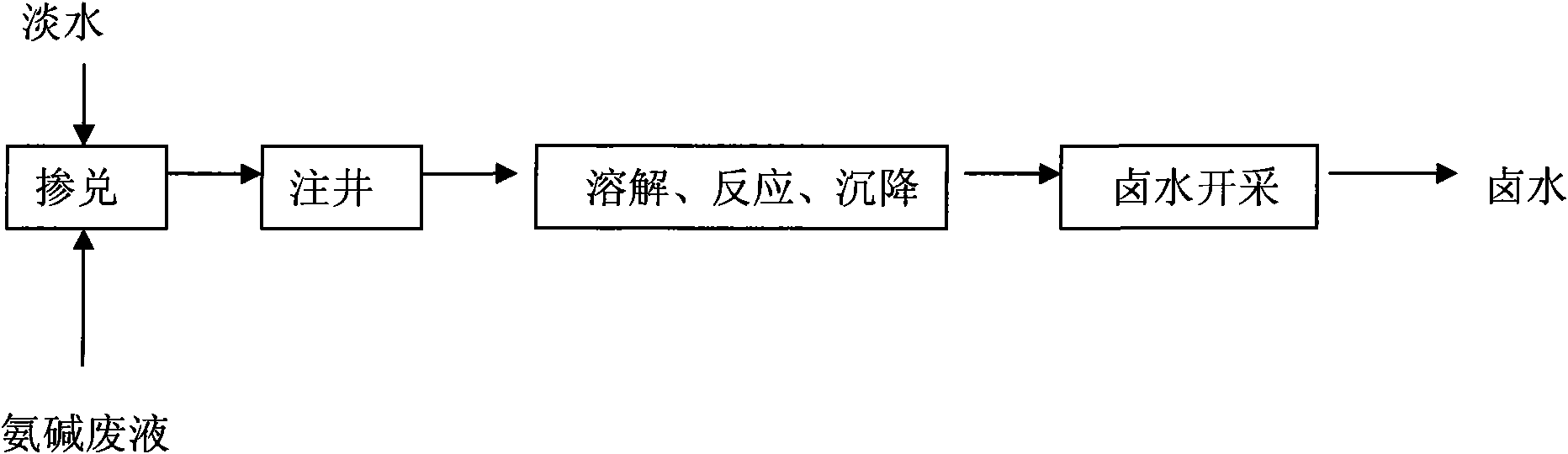

Resource recycling method of waste ammonium alkali liquid for well injection and brine extraction of sodium sulfate type salt mine

ActiveCN101629484AAchieve reuseImprove protectionFluid removalAlkali metal chloridesChemical industrySulfate

The invention discloses a resource recycling method of waste ammonium alkali liquid for well injection and brine extraction of a sodium sulfate type salt mine, which comprises the following steps: injecting waste ammonium alkali liquid under the salt mine instead of fresh water directly or after being added with fresh water, dissolving rock salt to from mine brine, and extracting the mine brine after natural sedimentation. In the invention, the waste ammonium alkali liquid is used for the sodium sulfate type salt mine, the waste ammonium alkali liquid is injected under the salt mine for brine extraction directly or after being added with water to obtain high-quality brine with low sodium sulfate content, thereby not only the sodium sulfate content in the brine is reduced, but also NaCl in the waste ammonium alkali liquid is recycled, the resource recycling of the waste ammonium alkali is achieved, and the emission of wastes is reduced. The prepared brine can be used in vacuum salt manufacturing, brine alkali manufacturing, mine brine air-cured salt manufacturing and other chemical industries.

Owner:江苏省制盐工业研究所有限公司 +1

Low-sodium salt composition

The present invention includes low-sodium salt compositions, Modified Potassium Chlorides and methods of making the same. The low-sodium salt compositions include NaCl, KCl, a cereal flour modifier or modifiers and a food grade acidulant, with the end product preferably having a Na / K ratio of from about 0.1 to about 9.0, more preferably from about 0.4 to about 3, even more preferably from about 0.6 to about 1.5 and most preferably about 1.0. The salt compositions of the present invention can be made by drum drying, extrusion cooking and agglomeration procedures. The preferred procedure includes a two step process: the production of a Modified KCl (MPC) in Step 1, in which KCl is preferably mixed with rice flour and citric acid in a drum drying process, followed by Step 2, in which the MPC is blended and / or co-ground with NaCl in any desired ratio, preferably 50 / 50, which gives a Na / K ratio of about 1 (i.e. 20% sodium and 20% potassium). This 2-step technique not only masks the bitterness associated with KCl, but also preserves the natural taste / flavor of NaCl in the final product. It is also cost-effective since only the KCl and the modifier are processed in Step 1, which is the most costly part of the overall process.

Owner:S&P DEV

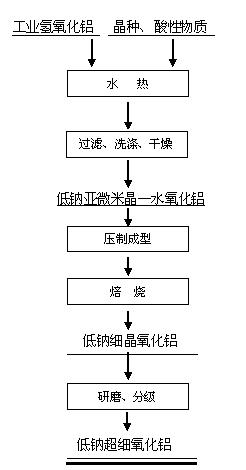

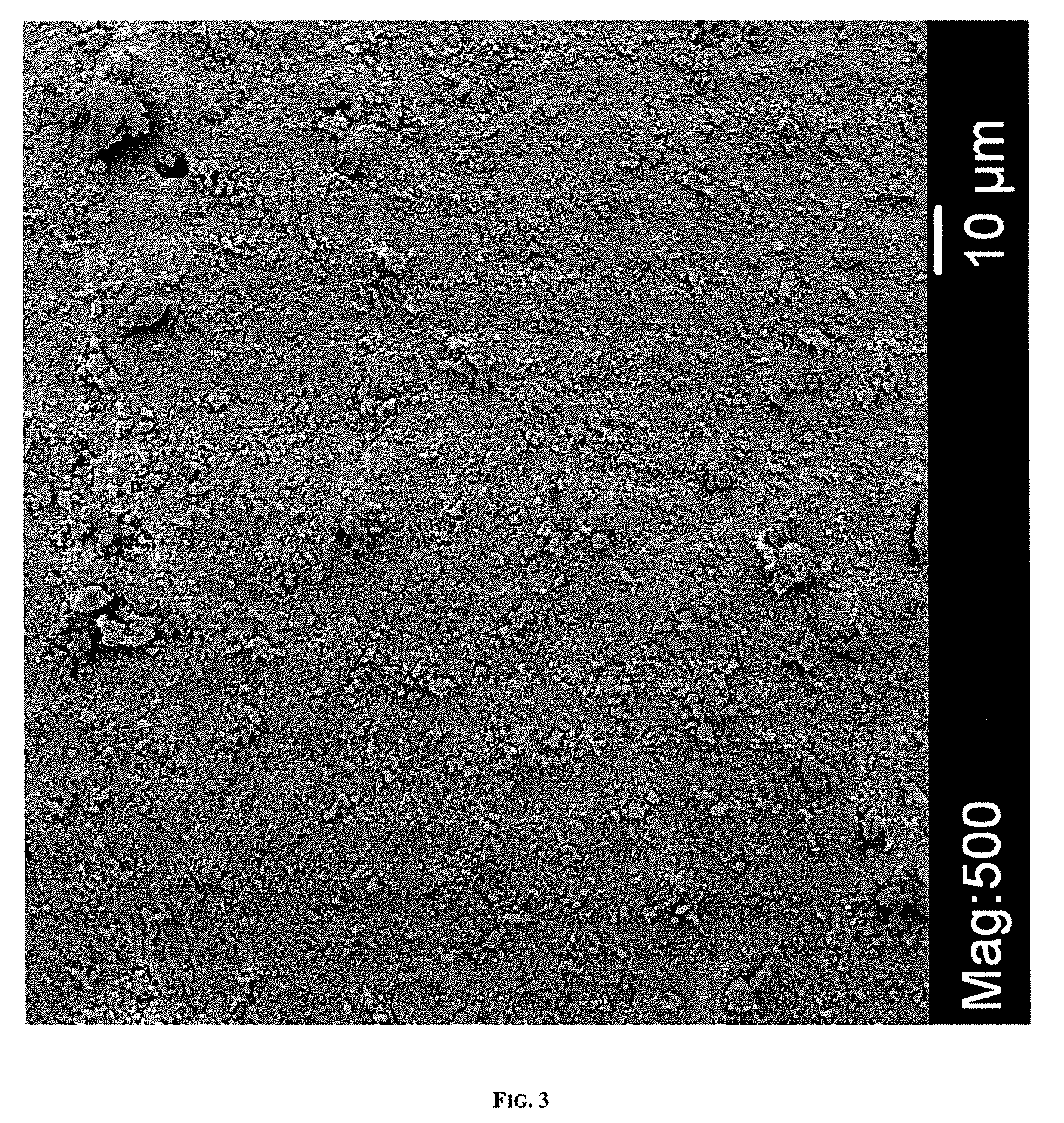

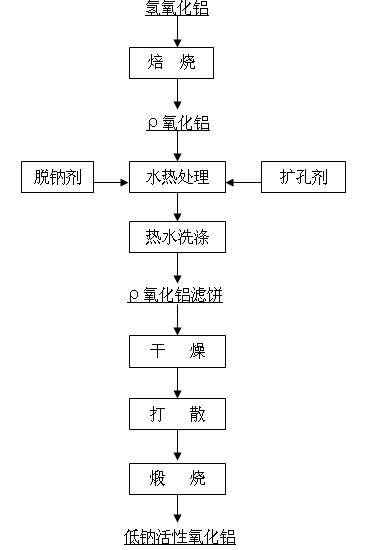

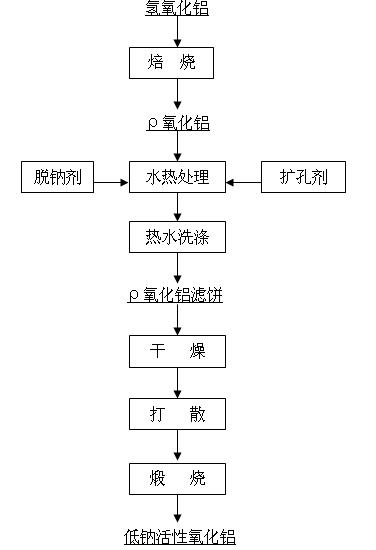

Preparation method of low-sodium fine grain alumina

InactiveCN102320638AWide variety of sourcesSimple production processAluminium oxide/hydroxide preparationBoehmiteLow sodium

The invention relates to a preparation method of low-sodium fine grain alumina, in particular to a preparation method of low-sodium submicro grain alumina used for electronic ceramics, microcrystalline ceramics, fine polishing, catalyst carriers and the like. The preparation method is characterized by taking industrial aluminium hydroxide as a raw material in the preparation process and comprising the following steps of: firstly carrying out hydrothermal phase inversion processing on aluminium hydroxide to obtain low-sodium fine grain alumina monohydrate with sodium oxide content being less than 500ppm; briquetting the obtained low-sodium fine grain alumina monohydrate, and then roasting to obtain low-sodium fine grain alumina; and finally grinding and grading, thus obtaining low-sodium submicro alumina. The preparation method of low-sodium fine grain alumina has the advantages of simple production process, wide raw material sources, low production cost, environment friendliness and the like, and can combine with the existing alumina production process and equipment to carry out hydrothermal processing, thus effectively simplifying the production process and lowering the production cost. The method is ideal for preparing ultra-low-sodium boehmite and alumina.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

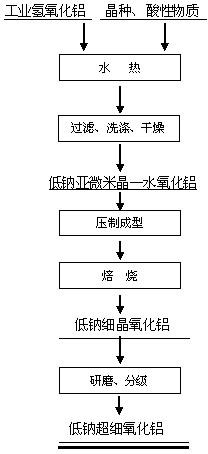

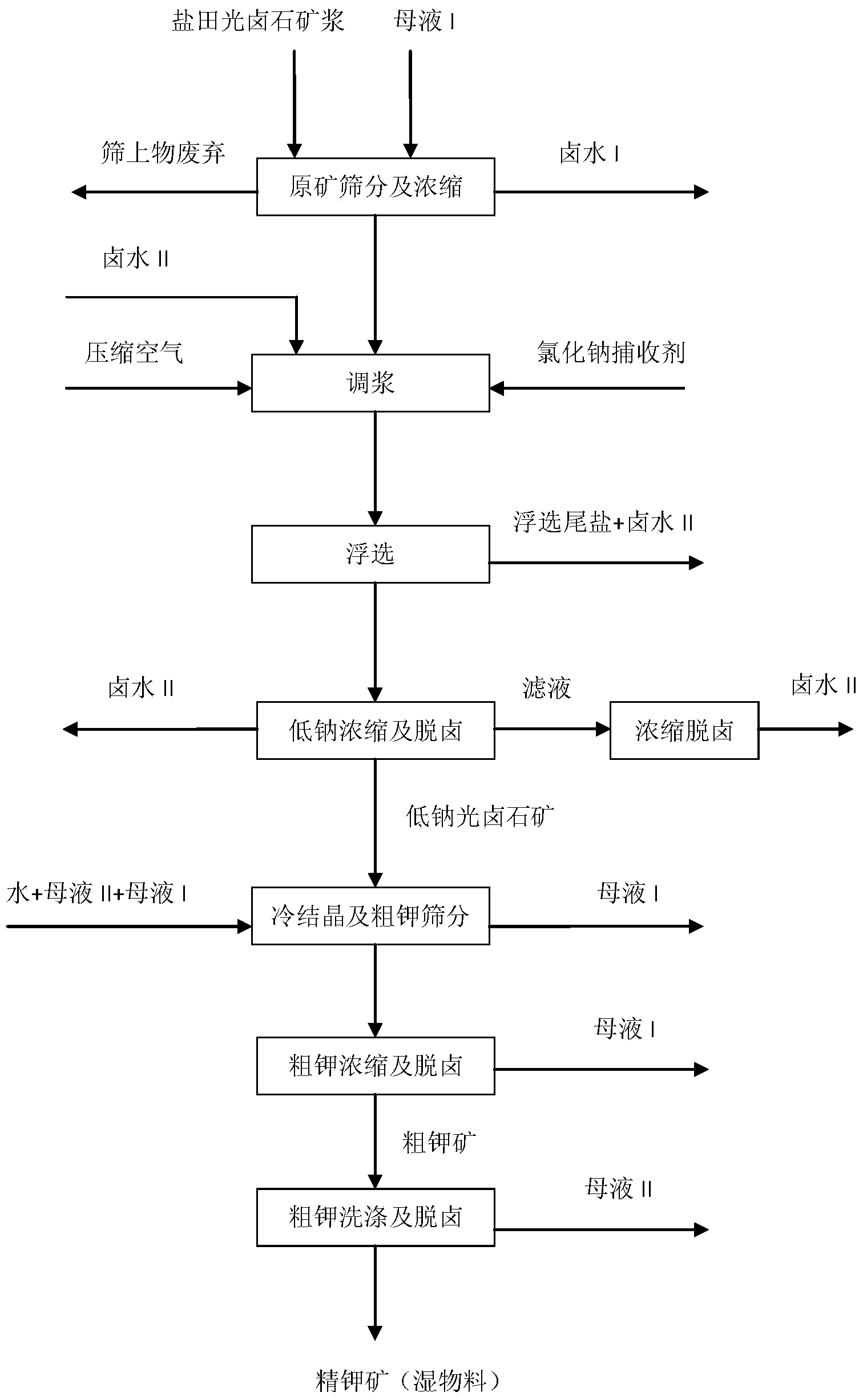

High-grade potassium chloride production system and method thereof

ActiveCN104058427ARaise the gradeReduce dosageAlkali metal chloridesAlkali metal halide purificationChemistryLow sodium

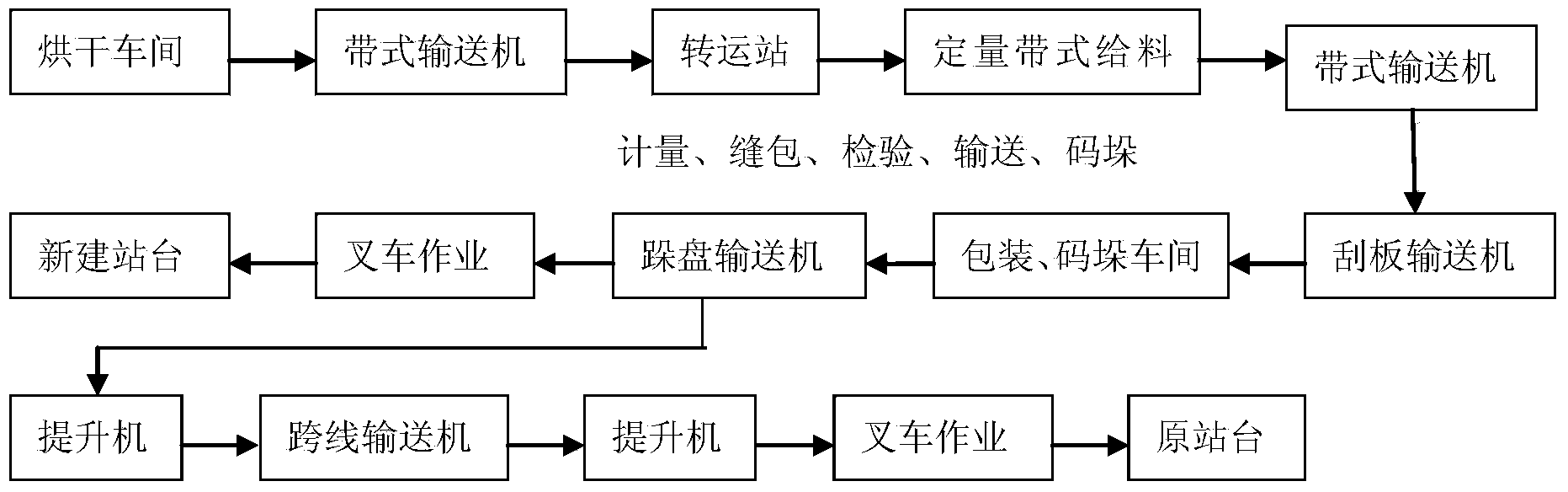

The invention discloses a high-grade potassium chloride production system and a method thereof. The system comprises a raw ore screening and concentrating system, a size mixing system, a floatation system, a low sodium concentration and dehalogenation system, a cold crystallization and thick potassium screening system, a thick potassium concentration and dehalogenation system, a refined potassium washing and dehalogenation system, a piling and filtering storage stock ground system, a breaking and conveying system and a drying cooling, packing, stacking and line crossing conveying system, and all the systems are sequentially connected and are arranged in a three-dimensional mode. Materials enter a next system in a self-flowing mode. An automatic dosing, automatic water adding and dehalogenation device is adopted, a spiral screen type centrifugal machine is used for replacing a horizontal belt type filter, and other technology improvements are adopted, so that the potassium chloride grade is improved to 98 percent from 95 percent, the piling and filtering technology is adopted in the system so that the natural gas using amount can be saved, production operation is convenient, and equipment operation is stable.

Owner:ЦИНХАЙ СОЛТ ЛЕЙК ИНДАСТРИ ГРУП КО ЛТД

Harmless and comprehensive utilization method for vanadium-extraction liquid leached residue

The invention relates to a harmless and comprehensive utilization method for vanadium-extraction liquid leached residue (in particular, low-sodium roasted vanadium-extraction liquid leached residue). The method is characterized by comprising the following steps of: taking the vanadium-extraction liquid leached residue as a raw material, extracting the valuable elements, such as vanadium, aluminum, ferrum, phosphorus and the like by carrying out a series of treatments, such as acid leaching, ion exchange, stripping liquid purification, ammonium polyvanadate precipitation, ammonium polyvanadate pyrolysis, and aluminum-ferrum-phosphorus precipitation for a solution obtained after carrying out ion exchange, wherein the liquid leached residue can be harmless and can have chemical stability; and then, mixing the chemical stability with a limestone crushed material and cement, grinding, moistening by using water, then, briquetting, stripping and carrying out natural curing to form a baking-free brick which meets the requirements of the GB6566-2001 on decorative materials.

Owner:HUAIHUA HONGFA RESOURCE COMPREHENSIVE UTILIZATIONTECH

Zeolite catalyst with improved NOx reduction in SCR

InactiveUS7704475B2Improved selective catalytic reductionImprove performanceNitrous oxide captureAluminium compoundsIon exchangeLow sodium

Owner:BASF CORP

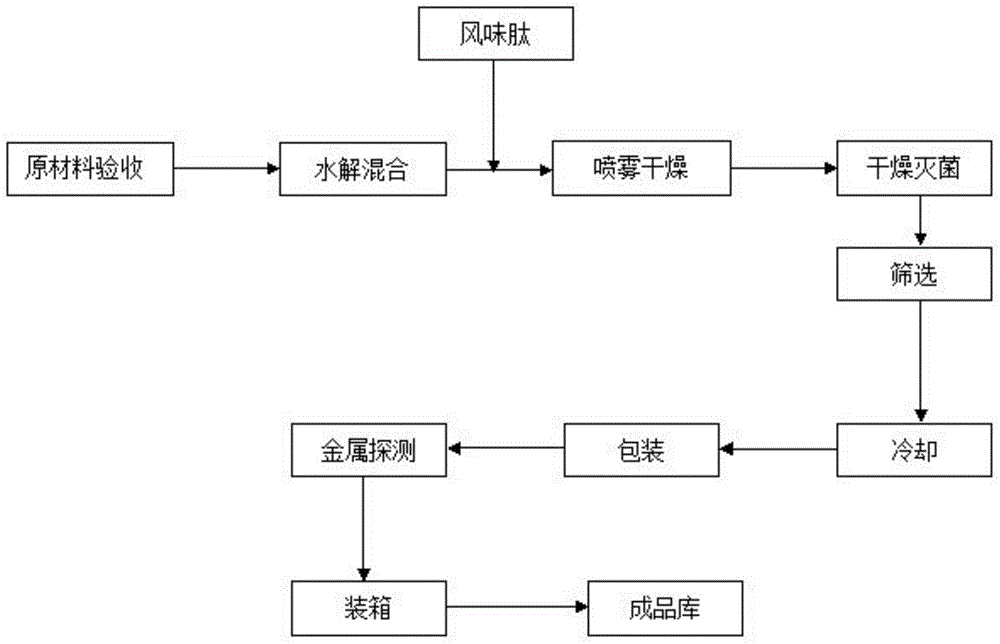

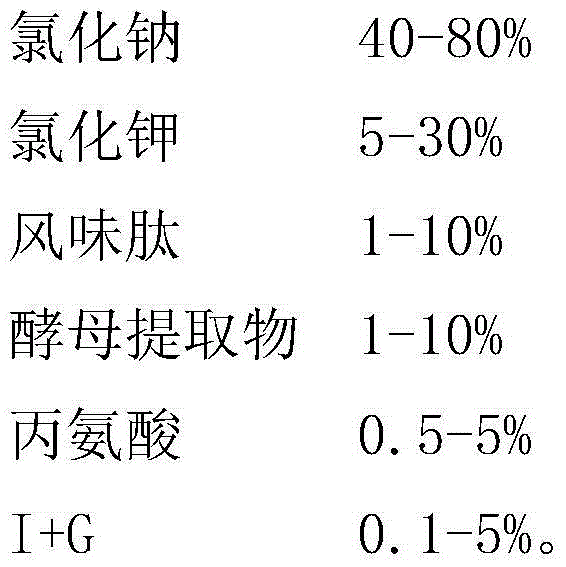

Flavored low-sodium seasoning salt

ActiveCN104643006AHigh nutritional valuePromote emptyingYeast food ingredientsFood ingredient functionsPotassiumYeast cell extract

The invention provides flavored low-sodium seasoning salt. The flavored low-sodium seasoning salt is characterized by being prepared from the following raw materials in percentage by weight: 40 to 80% of sodium chloride, 5 to 30% of potassium chloride, 1 to 10% of flavored peptide, 1 to 10% of a yeast extract, 0.5 to 5% of alanine, and 0.1 to 5% of I+G. The flavored low-sodium seasoning salt can reduce the use quantity of salt but remain the salt taste, thus the intake of sodium can be reduced; the salt is technically reduced; in addition, the fresh is increased; with the adoption of the salt, aginomoto can be saved, and the health can be conditioned.

Owner:安徽强旺生物工程有限公司

Preparation method of superfine low-sodium alpha-alumina powder with high activity

The invention discloses a preparation method of superfine low-sodium alpha-alumina powder with high activity. Industrial aluminum hydroxide is taken as a raw material; alkali is removed and adsorbed by adding an acid; a compound mineralizer is added to calcine; the superfine low-sodium alpha-alumina powder with high activity, of which the mean grain size D50 is 0.2-1.0micron, is obtained by combining dry ball milling with wet ball milling; the sodium content is 0.01%-0.05%; and the content of the alpha phase is 97%-99%. The problems that the alpha-alumina is high in sodium content, uneven in grain size, poor in sintering activity and the like are solved, special requirements of high-performance ceramic, grinding and polishing materials and the like are met, and the method has the advantages of being simple in process, environmentally friendly, low in cost and the like, and is suitable for large-scale production.

Owner:广西朗琨科技有限公司

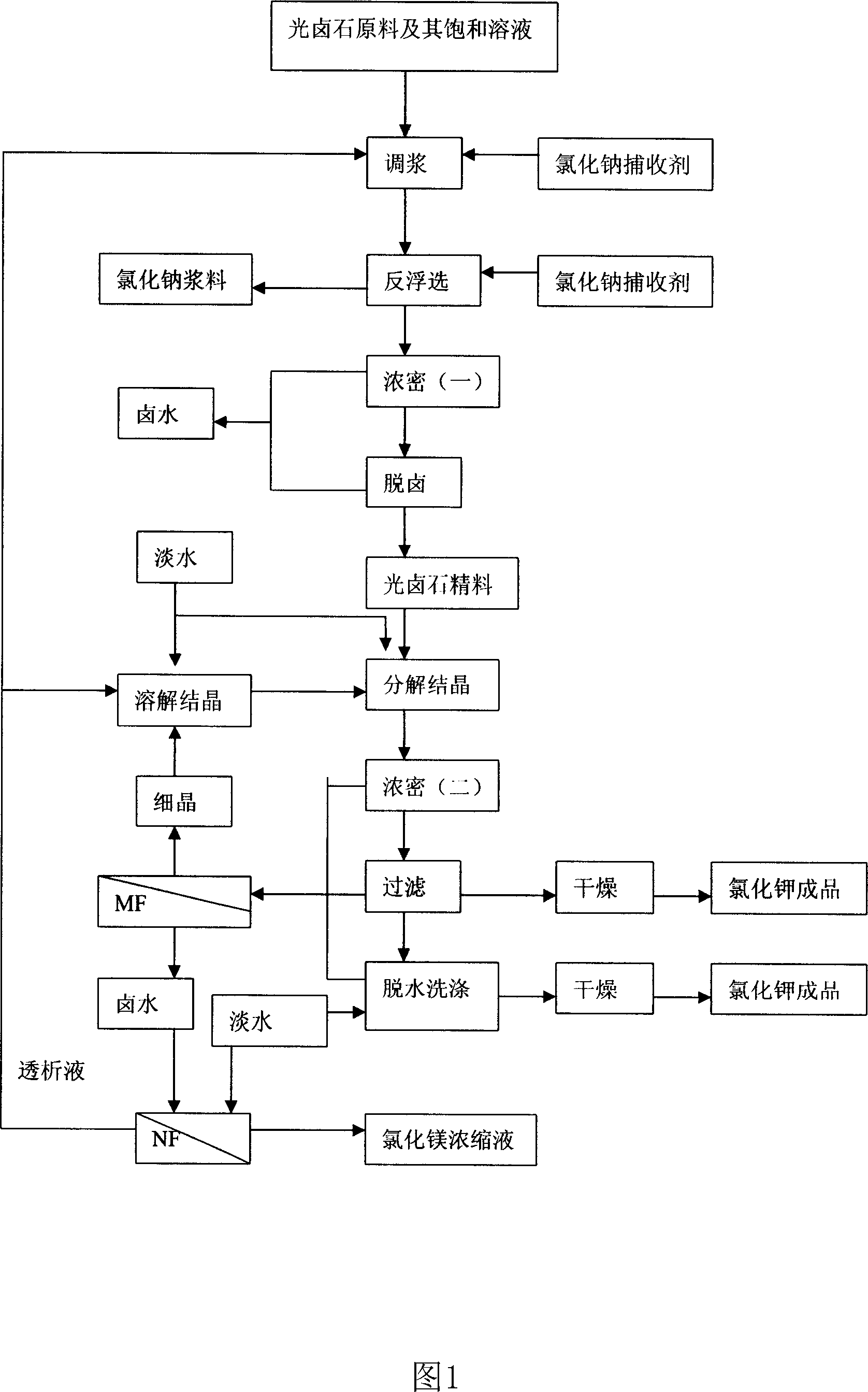

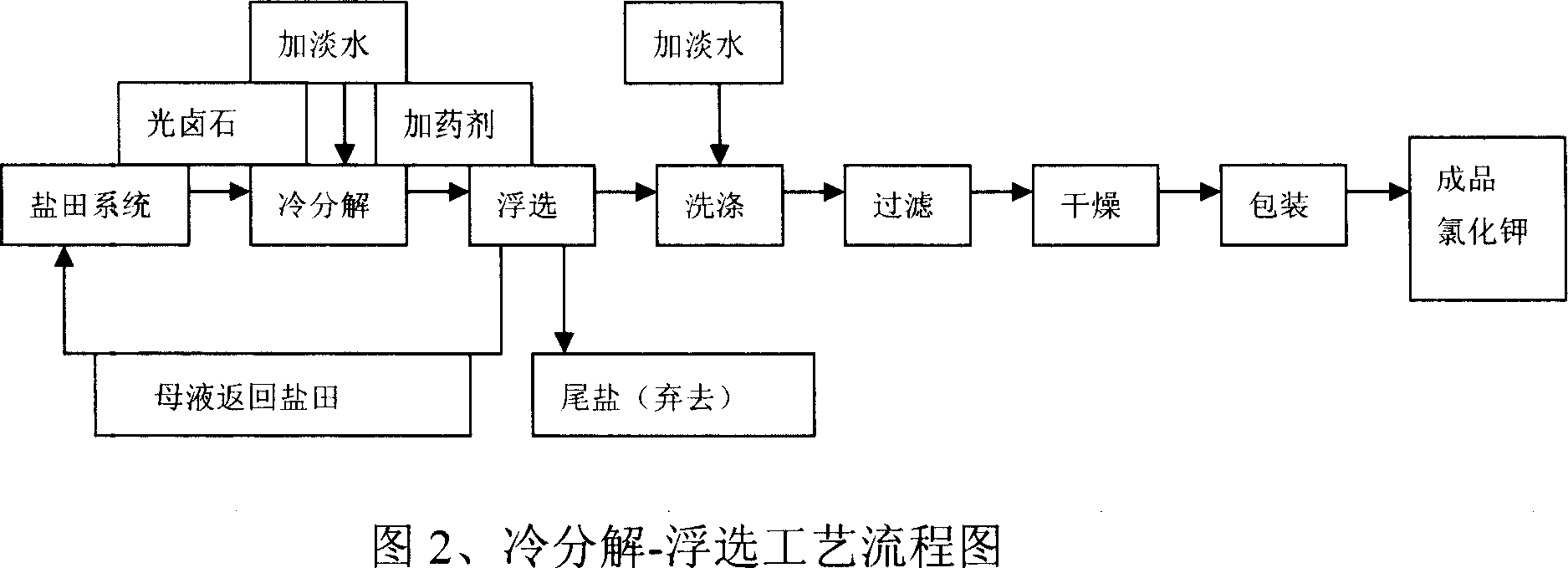

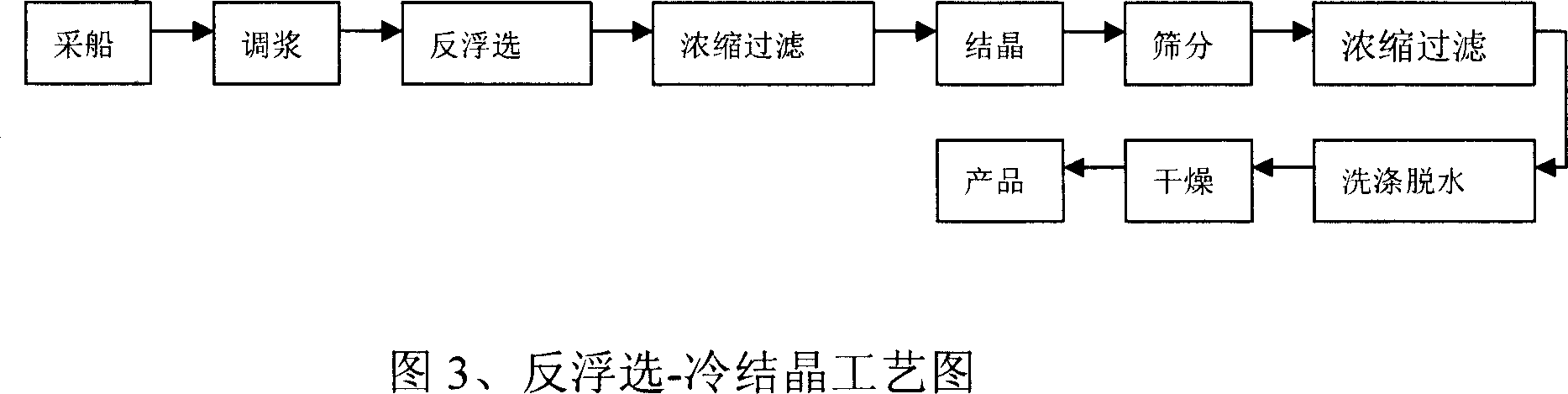

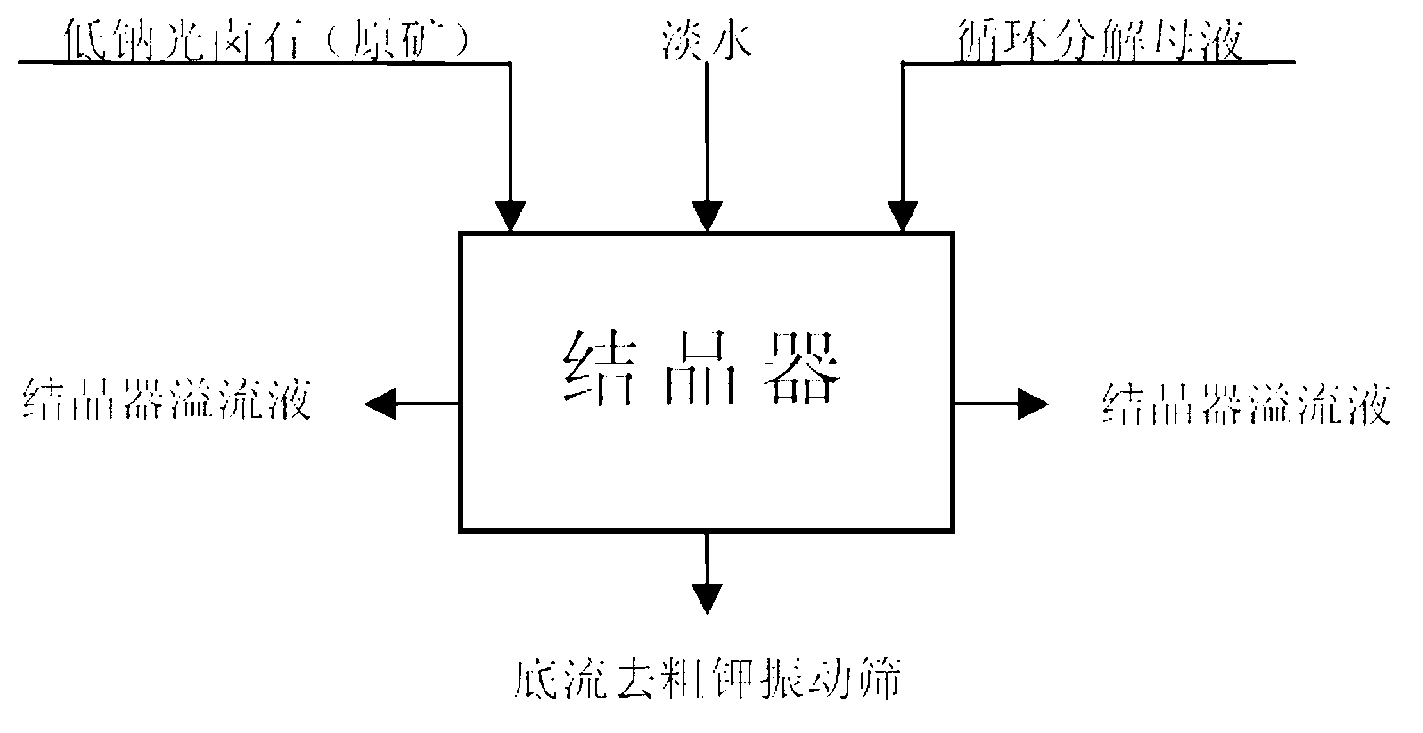

Reverse floatation-cold crystallization process for producing potassium chloride

InactiveCN101066769ALarge particlesQuality improvementAlkali metal chloridesAlkali metal halide purificationGranularityFresh water

The reverse floatation and cold crystallization process for producing potassium chloride includes the following four steps: 1. reverse floatation to prepare low sodium carnallite; 2. decomposing low sodium carnallite in fresh water, crystallizing, centrifugally filtering and drying to prepare potassium chloride product; 3. microporous membrane filtering to recover fine potassium chloride crystal, dissolving, returning to potassium chloride crystallizer for secondary crystallization to prepare potassium chloride; and 4. returning the bittern for reuse. The process has potassium chloride yield up to 80 %, great potassium chloride crystal granularity and high product quality, and is suitable for industrial production.

Owner:陈颖

Method for Producing a Low Sodium Salt Composition

The present invention relates to a low sodium salt composition and the method used to make it. More particularly, the invention relates to a two step method of making a salt composition. The first step includes contacting a chloride salt with a modifier to form a chloride salt product, mixing the product with a carrier to form a modified chloride salt solution, and spray drying the modified chloride salt solution. The second step includes contacting the dried modified chloride salt with sodium chloride, and grinding the mixture to form a salt composition. The composition includes a combination of sodium chloride and carrier modified chloride salt.

Owner:S & P INGREDIENT DEV

Preparation method of low-sodium active aluminum oxide

InactiveCN102070169AReduce manufacturing costLarger than surfaceCatalyst carriersAluminates/aluminium-oxide/aluminium-hydroxide purificationSlurryHeat treating

The invention relates to a preparation method of low-sodium active aluminum oxide, in particular to a preparation method of active aluminum oxide used as catalyst carrier for cleaning automobile tail gas. The method is characterized by comprising the following steps: roasting aluminum hydroxide to obtain an intermediate product rho aluminum oxide, adding a sodium removal agent and a pore expanding agent to carry out hydrothermal treatment, filtering the treated slurry, washing with hot pure water, drying, dispersing the dried product with a dispersion machine, and calcining to obtain active aluminum oxide. In the method provided by the invention, any one or more than two of nitric acid, acetic acid and citric acid is / are used as the sodium removal agent to wash the intermediate product after the roasting of aluminum hydroxide, thereby lowering the sodium content. The low-sodium active aluminum oxide prepared from aluminum hydroxide has the advantages of larger specific surface, multiple pores, high pore volume, simple preparation method and lower production cost.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Production method of chemical reagent potassium chloride

InactiveCN105668591AHigh recovery rateHigh purityAlkali metal chloridesAlkali metal halide purificationFiltrationPotassium

The invention discloses a production method of the chemical reagent potassium chloride, which comprises: (1) raw ore screening; (2) slurry mixing; (3) flotation; (4) low-sodium concentration and dehalogenation; Crystallization and screening of crude potassium; (6) concentration and dehalogenation of crude potassium; (7) washing and centrifugal dehydration; (8) re-dissolving; (9) two-stage filtration; (10) re-crystallization; (11) dehydration and separation. The process of the present invention not only increases the recovery rate of potassium chloride to over 62%, but also effectively removes soluble impurities and insoluble matter in the crude potassium chloride product with a purity of 95%, thereby increasing the purity of the potassium chloride product to over 99%. The process of the invention can be operated continuously, has no pollution to the environment, and is easy to realize industrialization.

Owner:SHANGHAI GUANCHUN FINE CHEM TECH CO LTD

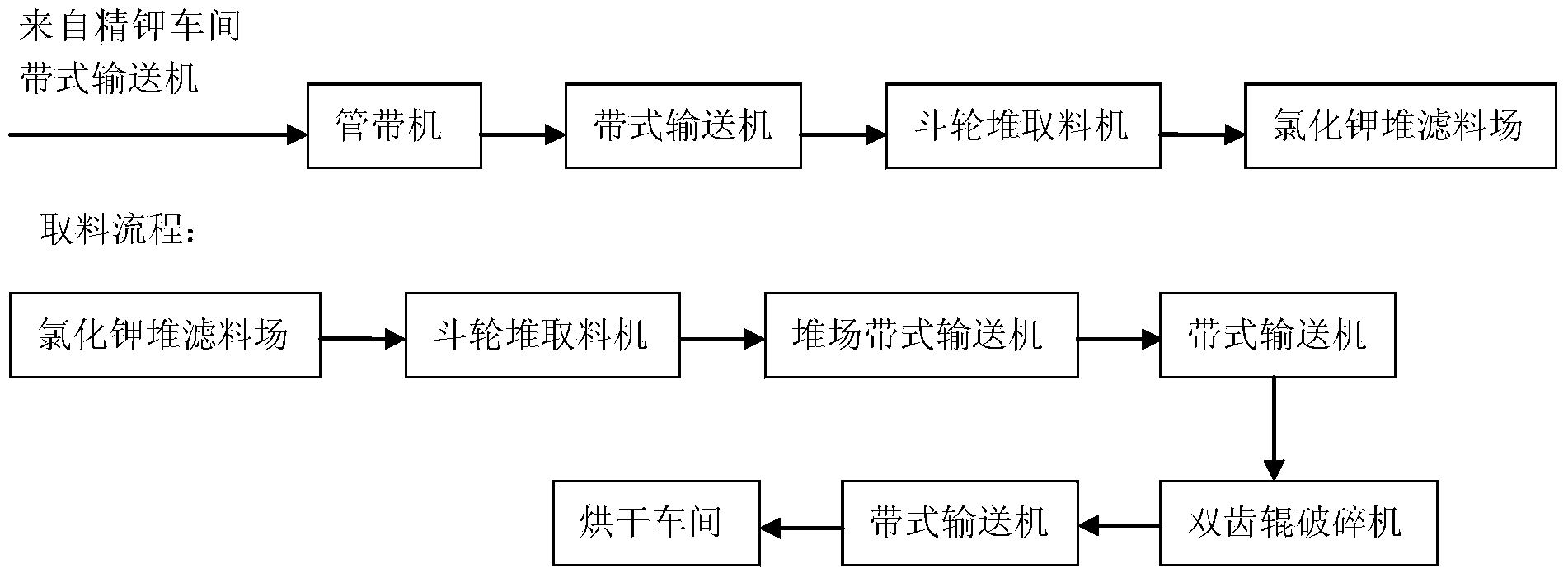

Preparation method of ultrafine low-sodium alpha-alumina micropowder

ActiveCN103332718AReduce sodiumLower firing temperatureAluminium oxide/hydroxide preparationAluminium hydroxideTechnical grade

The invention relates to a preparation method of ultrafine low-sodium alpha-alumina micropowder, and belongs to the technical field of abrasive polishing and sintered body materials. The preparation method of ultrafine low-sodium alpha-alumina micropowder is provided for realizing the reduction of the content of sodium in a raw material aluminum hydroxide, so the sintering temperature is reduced, and the uniformity of the crystal grain granularity of a product is guaranteed. A technical scheme adopted in the invention is characterized in that the preparation method of ultrafine low-sodium alpha-alumina micropowder comprises the following steps: 1, precursor treatment: adding pure water to industrial-grade aluminum hydroxide to prepare a uniform slurry, and adding an acid for sodium removal; 2, calcining: adding the treated aluminum hydroxide to a chloride mineralizer, uniformly mixing, and calcining at 1100-1350DEG C for 1-8h to obtain alpha-alumina; and 3, grinding: crushing the obtained calcining product alpha-alumina to the original grain size in order to obtain alpha-alumina micropowder.

Owner:晋城市富基新材料股份有限公司

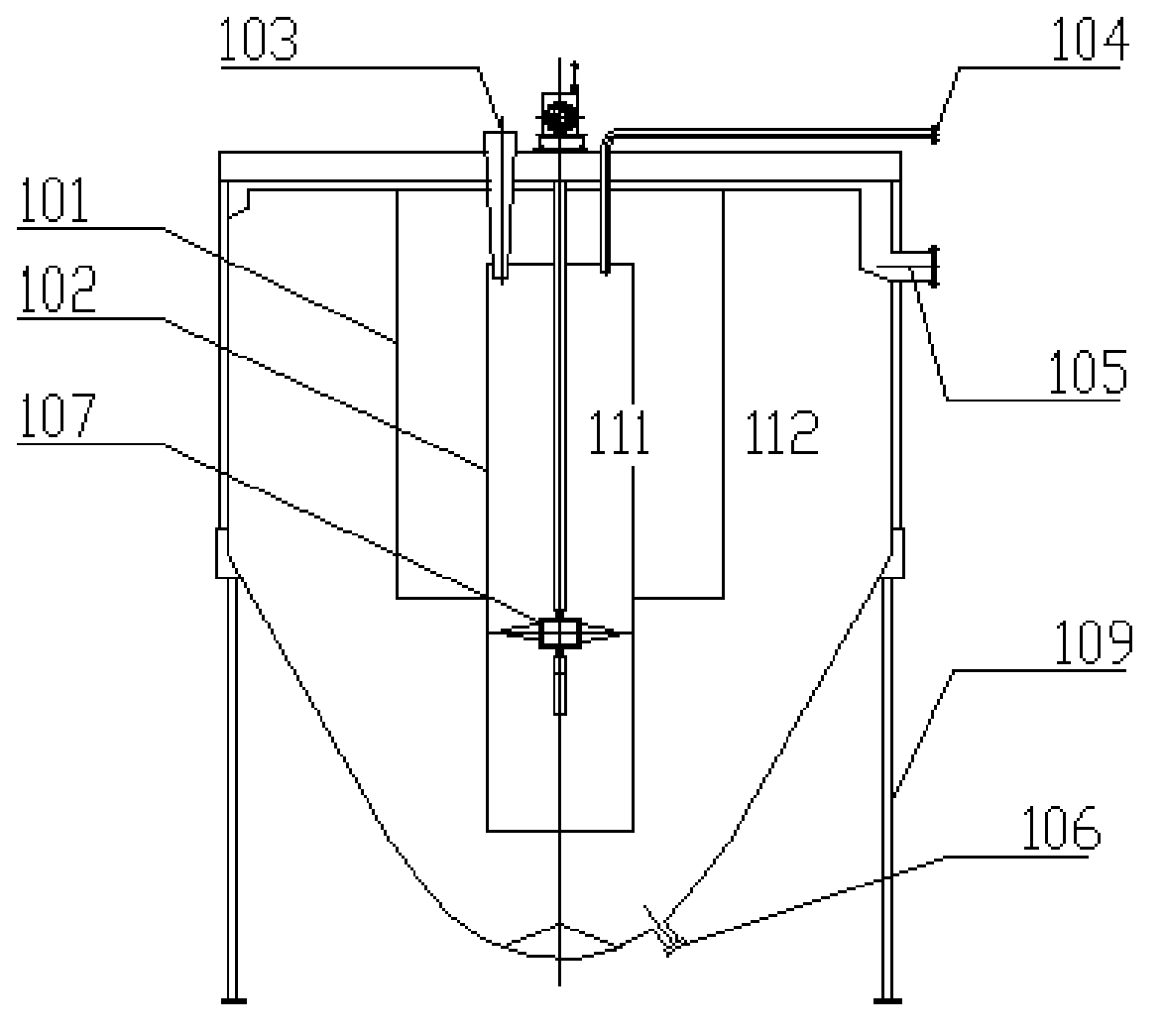

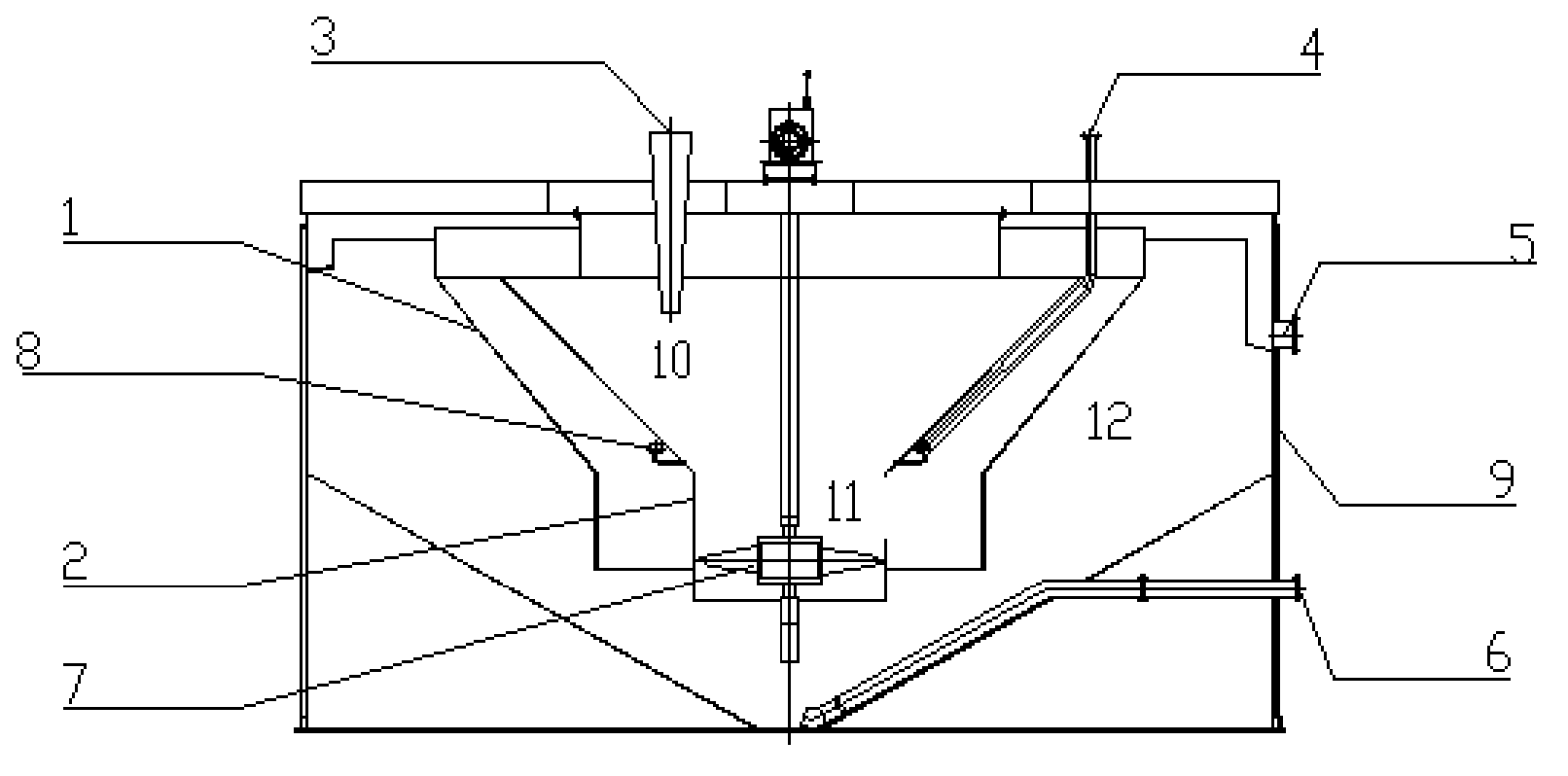

Crystallizer for hydrolyzing carnallite

ActiveCN103073030AIncrease contact areaSolve the problem of overflow from the upper part of the inner cylinder to the bottom of the crystallizer without sufficient mixing and decompositionAlkali metal halide formation shapeDecompositionChloride

The invention relates to a crystallizer for hydrolyzing carnallite. The crystallize comprises an inner cylinder, an outer cylinder, a mother solution distributor, a stirring paddle, a crystallizer cylinder body, a low-sodium carnallite inlet, a mother solution inlet, a decomposition liquid outlet and a product outlet. According to the crystallizer, the remaining time of low-sodium carnallite in a dissolving region can be prolonged, and the problem that low-sodium carnallite is not fully mixed and decomposed and then overflows to the bottom of the crystallizer from the upper part of the inner cylinder in the existing crystallizer is solved; and generated potassium chloride particles can grow above 0.2mm in particle size to ensure that solid potassium chloride is easily dewatered and dried, and washing water and heat energy required by drying are saved.

Owner:ЦИНХАЙ СОЛТ ЛЕЙК ИНДАСТРИ ГРУП КО ЛТД

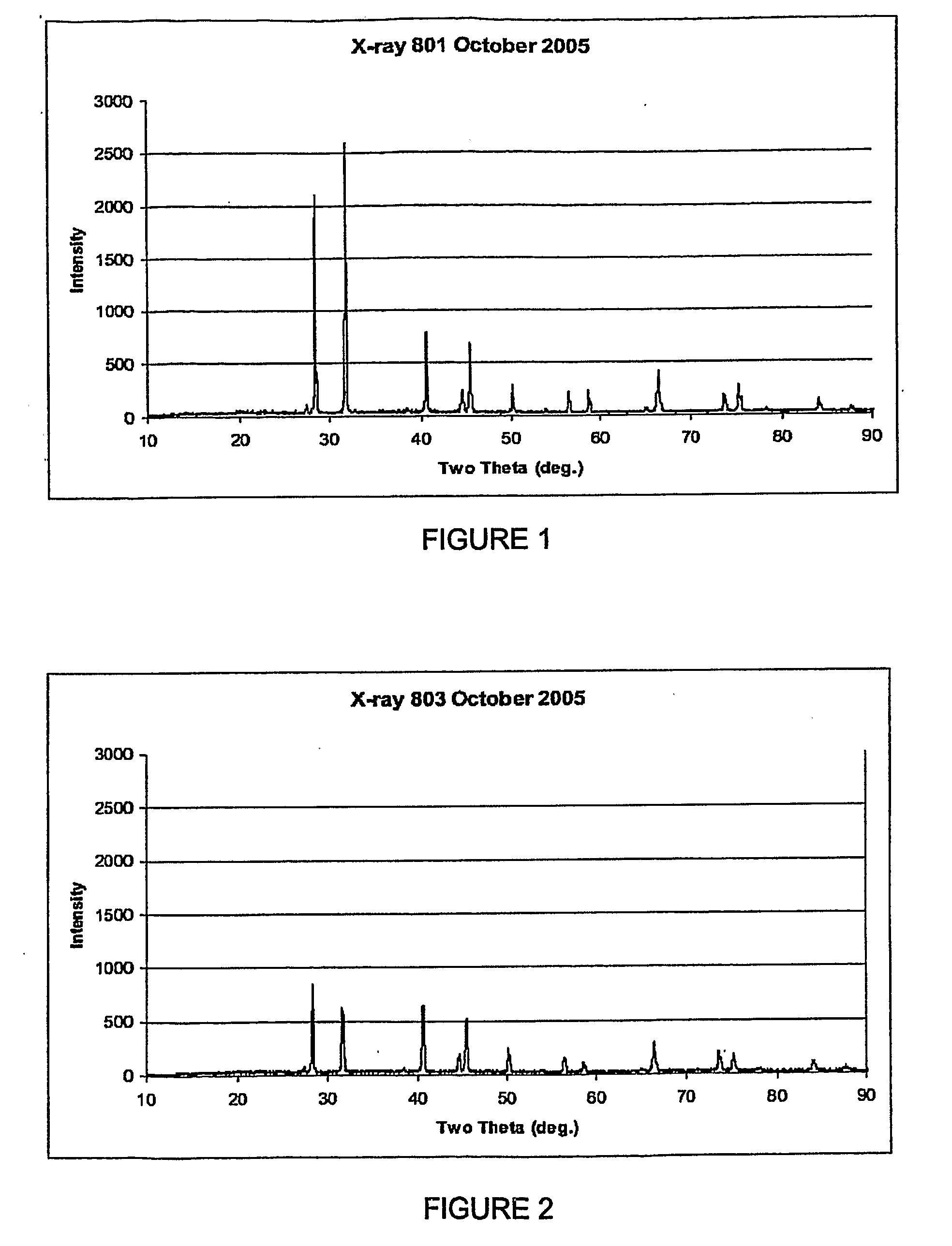

Fast synthesis process of high-crystallinity zeolite molecular sieve

InactiveCN1417116AShort synthesis cycleHigh crystallinityPentasil aluminosilicate zeoliteIon contentMolecular sieve

High-crystallinity H-type zeolite molecular sieve is synthesized through the fast process including: adding dropwise mixed solution B comprising Al2(SO4)3.18H2O, water and concentrated sulfuric acid to mixed solution A comprising water glass and deionized water while stirring drastically; adding fatty amine and inorganic ammonia solution to form gel mixture; sealing, ageing, crystallizing, cooling, solid-liquid separation, washing to filter cake pH value of 8-9, drying, calcining and HCl exchange. The process has the advantages of short synthesis period, high crystallinity, low organic template agent content in crystallized zeolite and low sodium ion content.

Owner:SYNFUELS CHINA TECH CO LTD

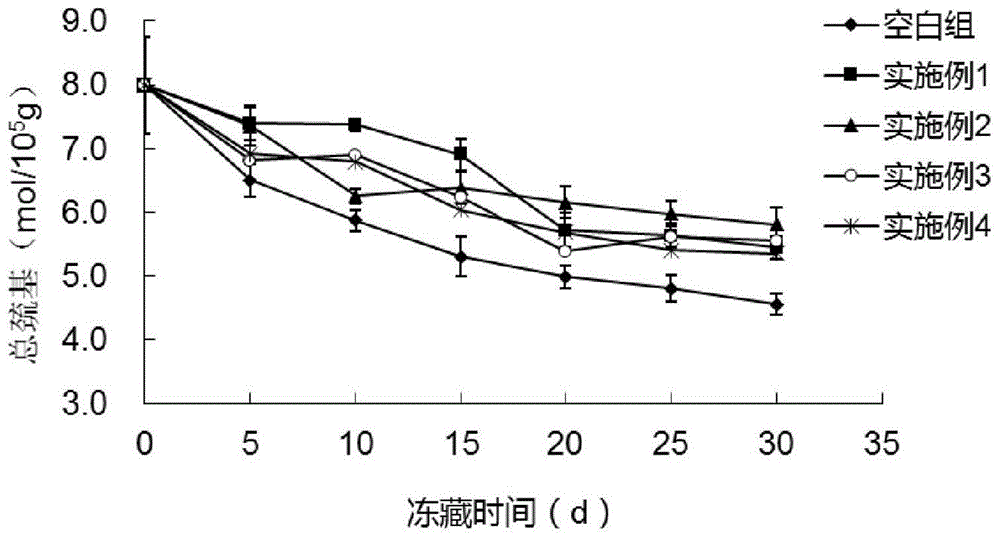

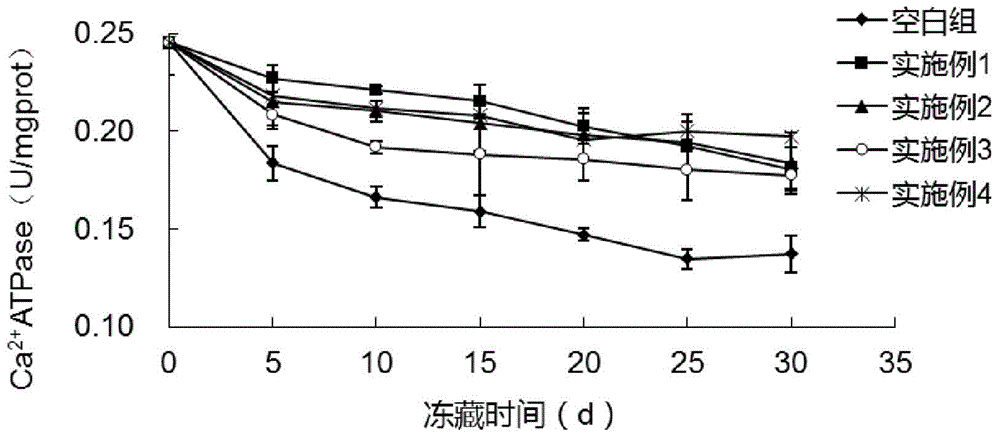

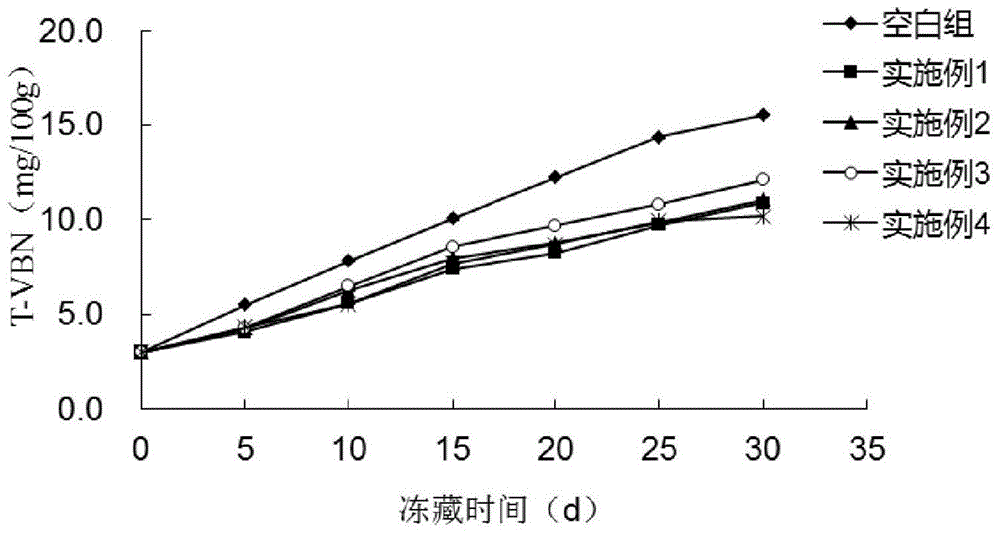

Method for improving quality of frozen freshwater fish surimi

InactiveCN104939149AGuaranteed high ionic strengthReduce intakeFood ingredient functionsFood preparationSodium ascorbateAntibacterial activity

The invention relates to a method for improving quality of frozen freshwater fish surimi. The method comprises the following steps: pretreating a raw material fish, and collecting meat; alternatively bleaching the meat with a sodium carbonate solution and clean water; adding 2.5% of a low sodium salt mixture for blending; adding the following components in percentage by weight in chopping and stirring processes: 60-70% of fish meat, 10-15% of starch, 5-8% of a fishbone enzymatic product, 0.4-0.7% of a composite antifreeze agent, 0.08-0.12% of a composite antibacterial agent, 0.02-0.04% of tea polyphenol, 0.01-0.012% of TBHQ, 0.015-0.02% of L-sodium ascorbate and 10-18% of icy water; subsequently forming; and freezing, thereby obtaining a frozen fish surimi product with improved quality. By adopting the method, not only are the water retention property, oxidation resistance and antibacterial activity of the fish surimi in the machining process improved, but also the nutrient value of the fish surimi can be increased, so that the fish surimi product can be relatively applicable to industrial production and preservation.

Owner:汪兰

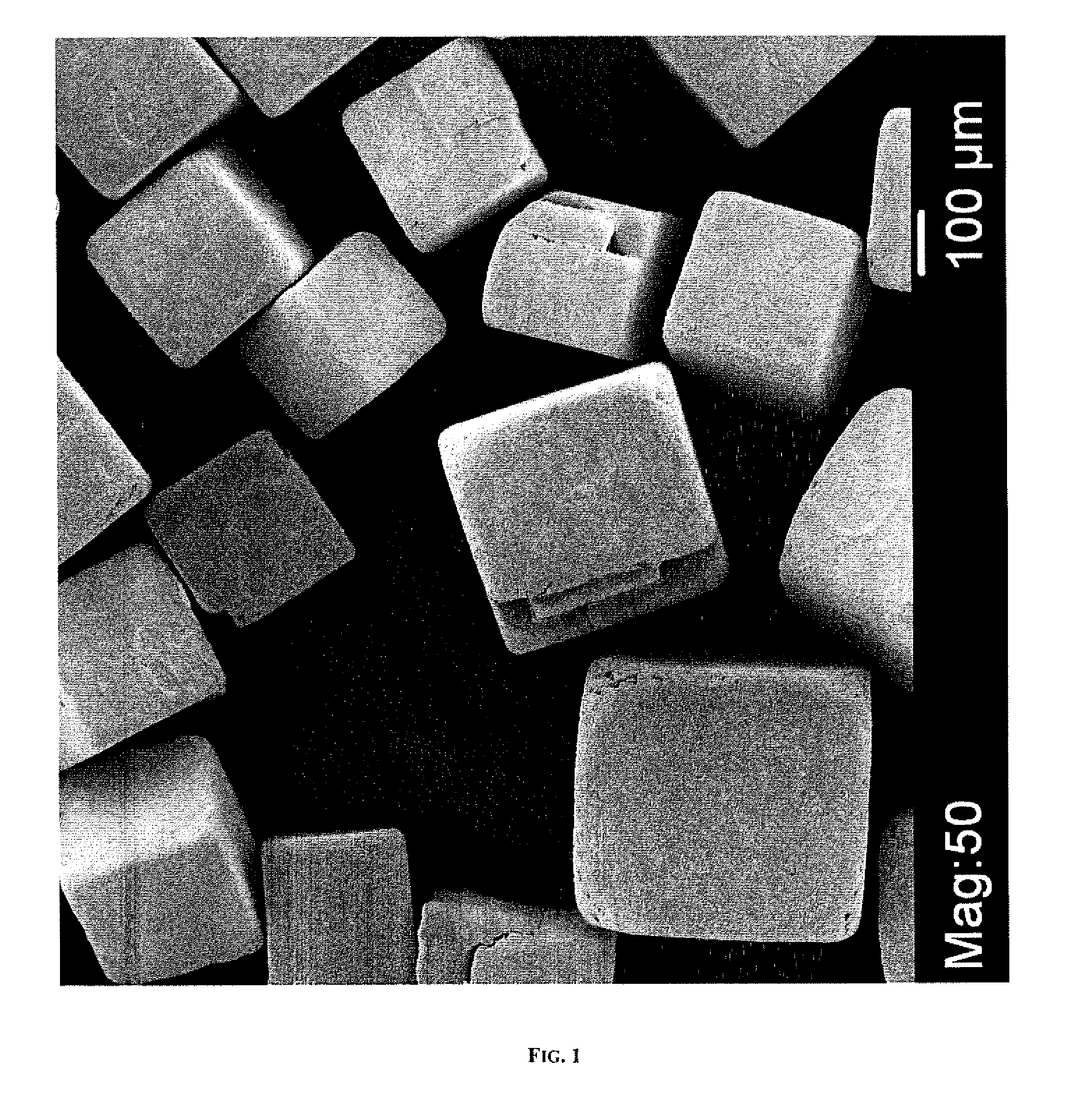

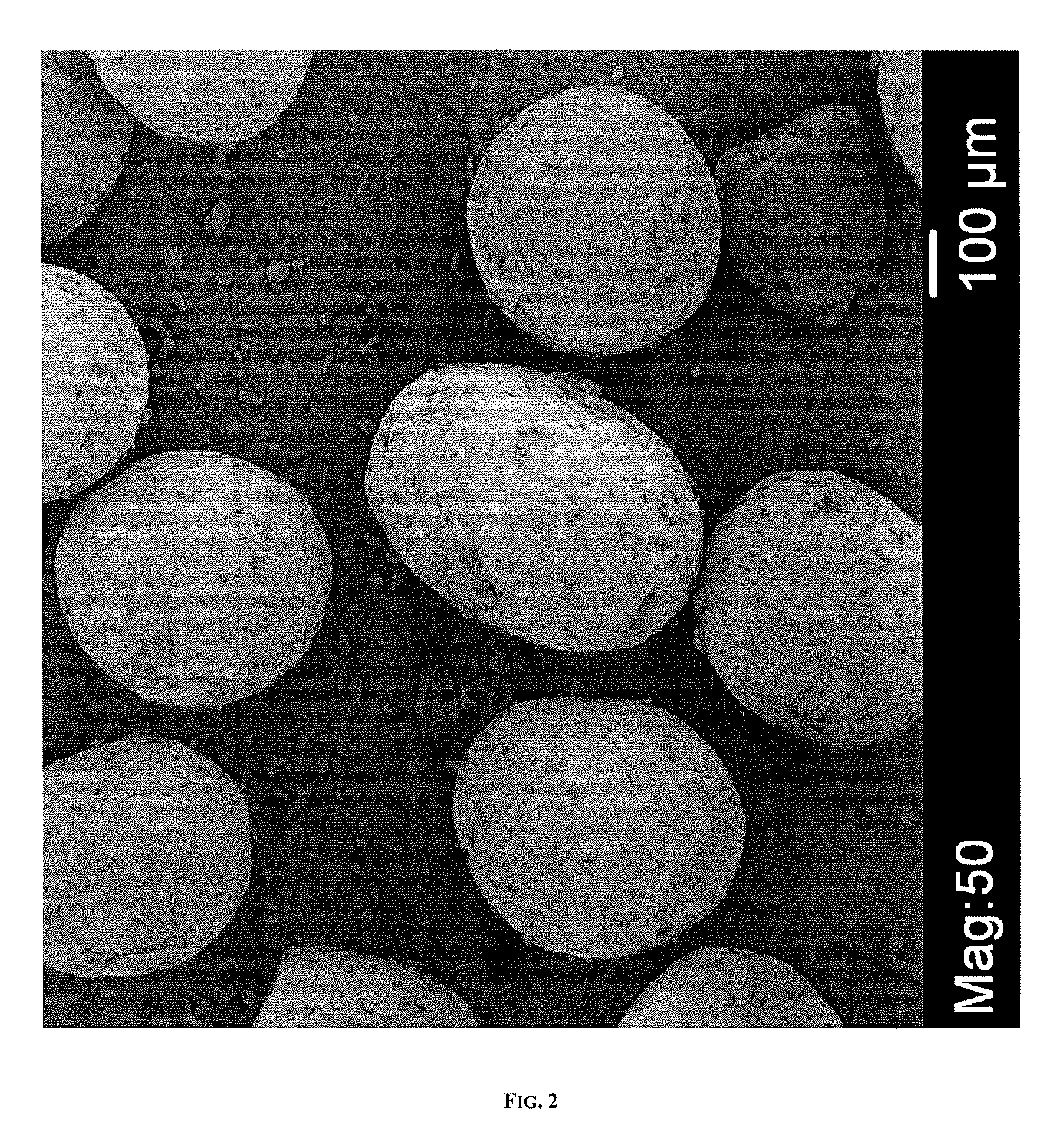

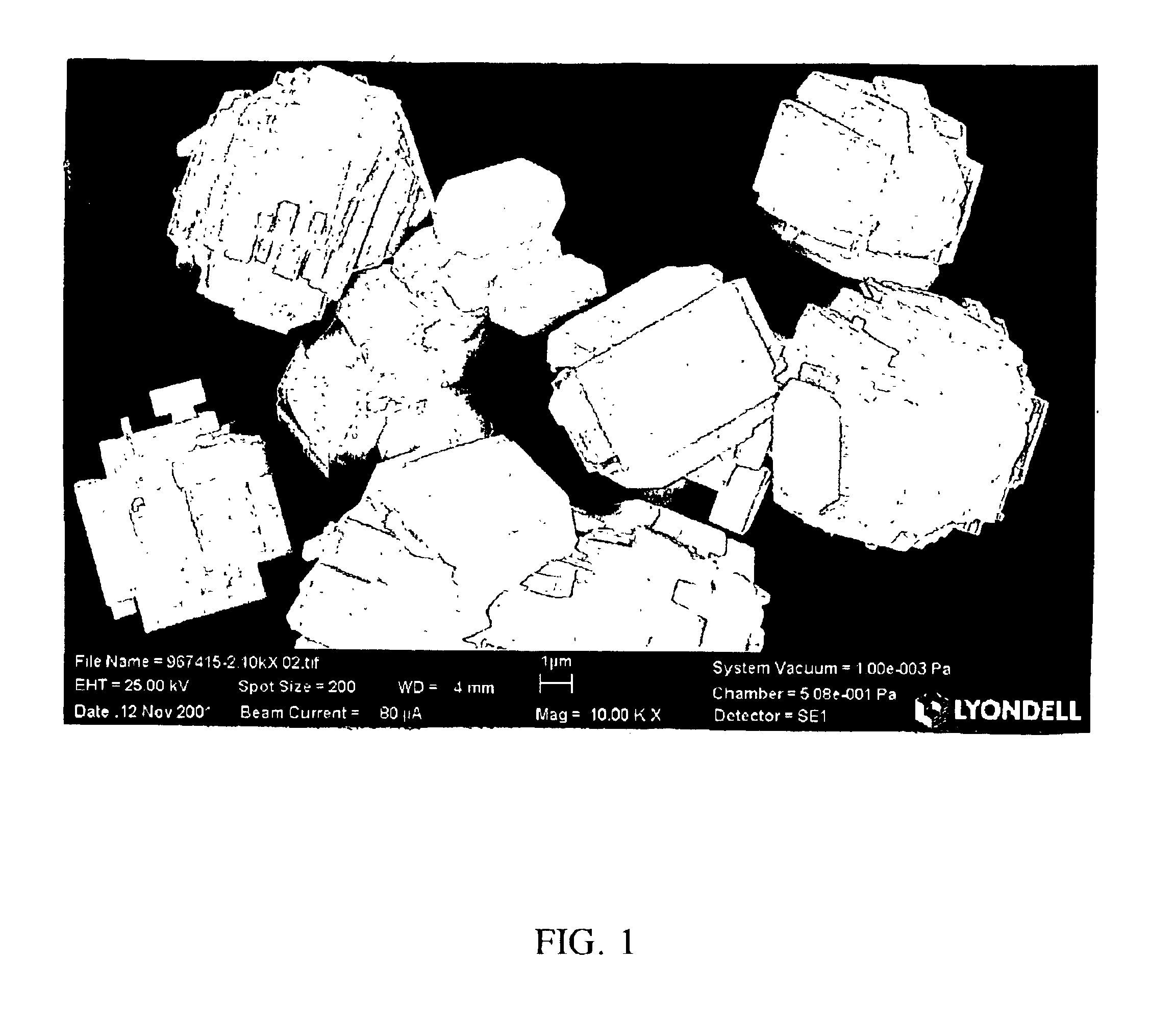

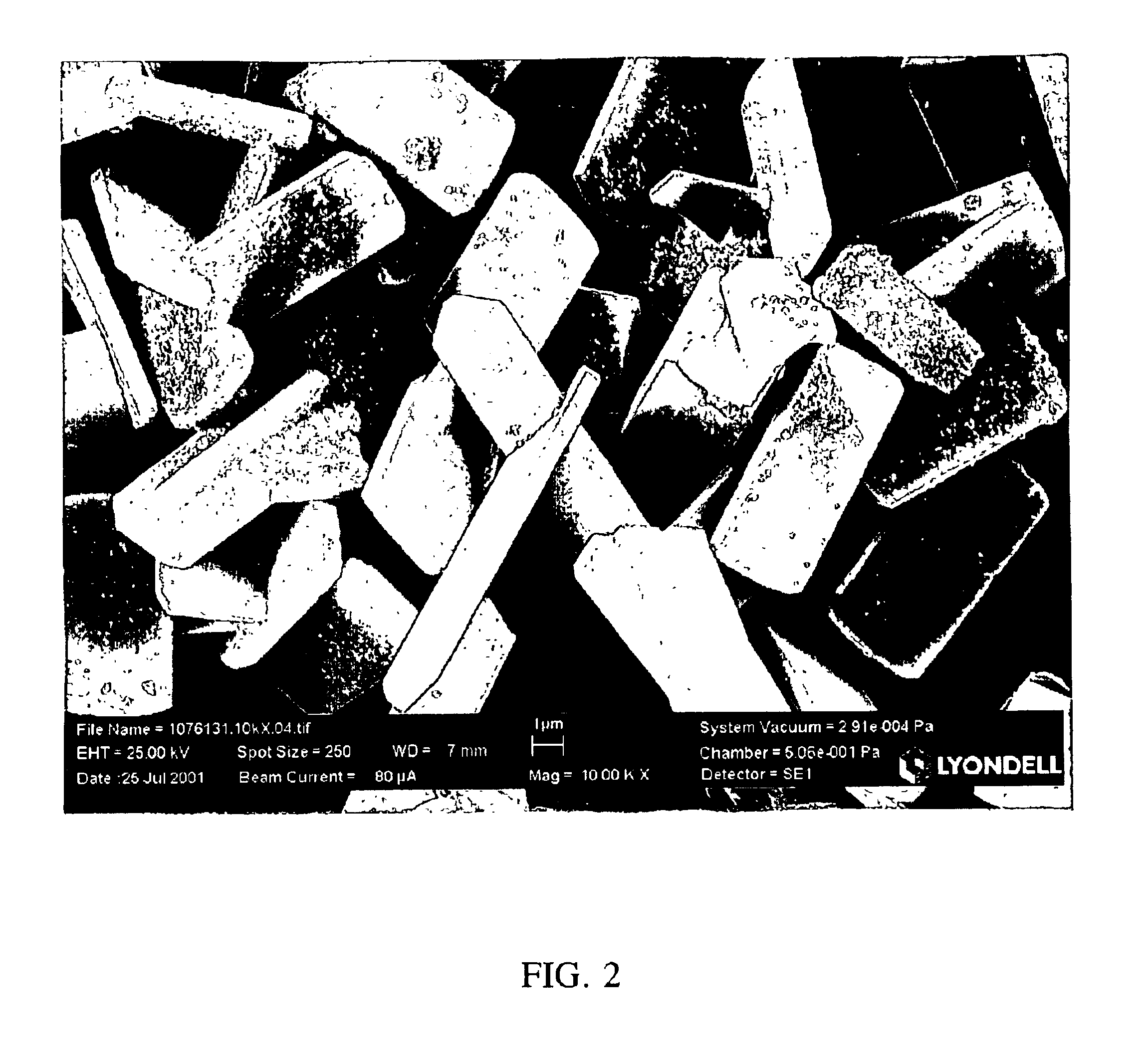

Process for direct oxidation of propylene to propylene oxide and large particle size titanium silicalite catalysts for use therein

InactiveUS6960671B2Avoid excessive additionOrganic chemistryMolecular sieve catalystsTitaniumSilicon dioxide

Large crystals of titanium silicalite or intergrowths of intergrown smaller crystals, having a mean particle size greater than 2 μm, have been found catalytically effective at commercially reasonable rates for the epoxidation of olefins in the presence of hydrogen peroxide. Crystals synthesized with a silica source having a low sodium content exhibit high levels of production and selectivity. The crystals have a low attrition rate and are easily filterable from a product stream.

Owner:LYONDELL CHEM TECH LP

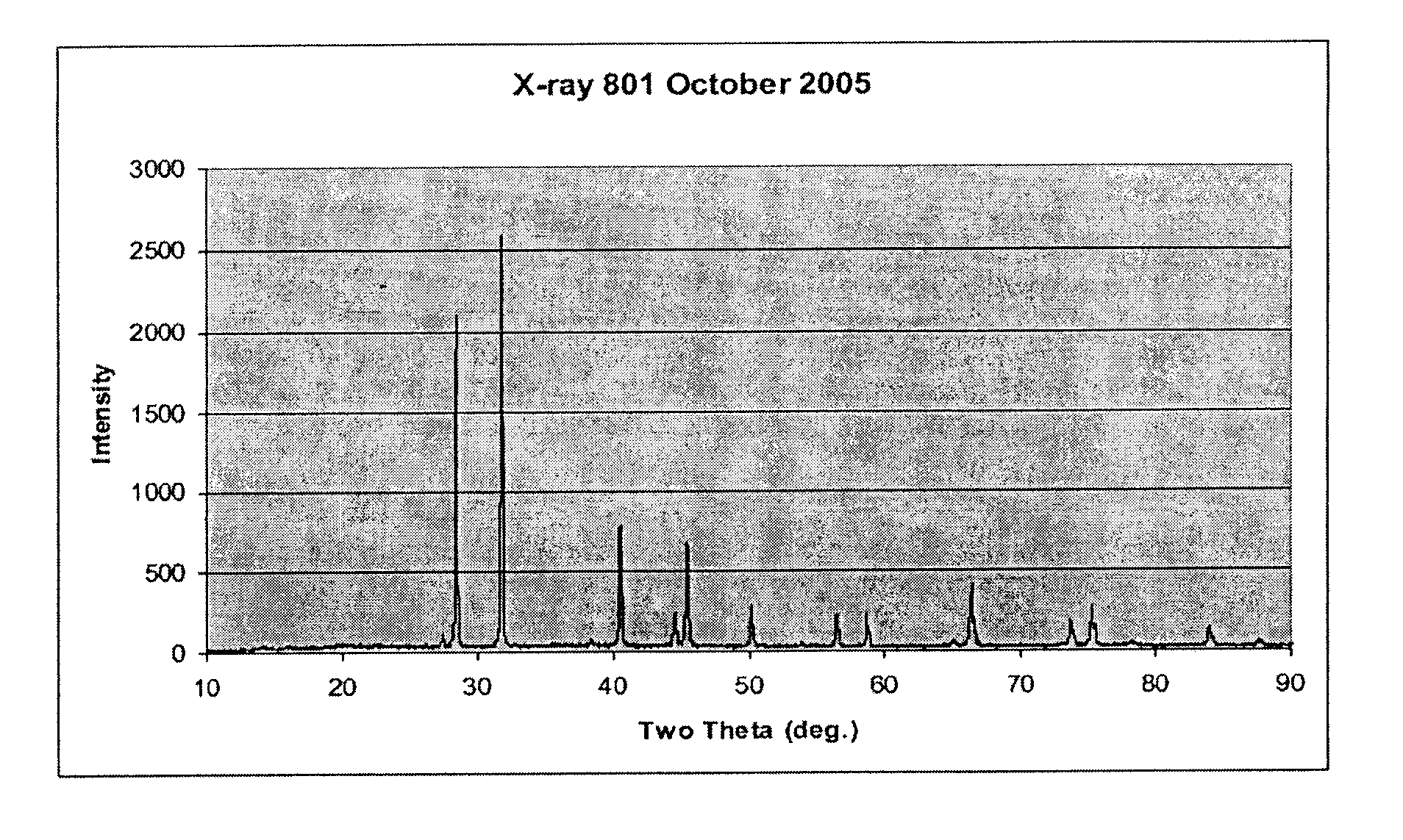

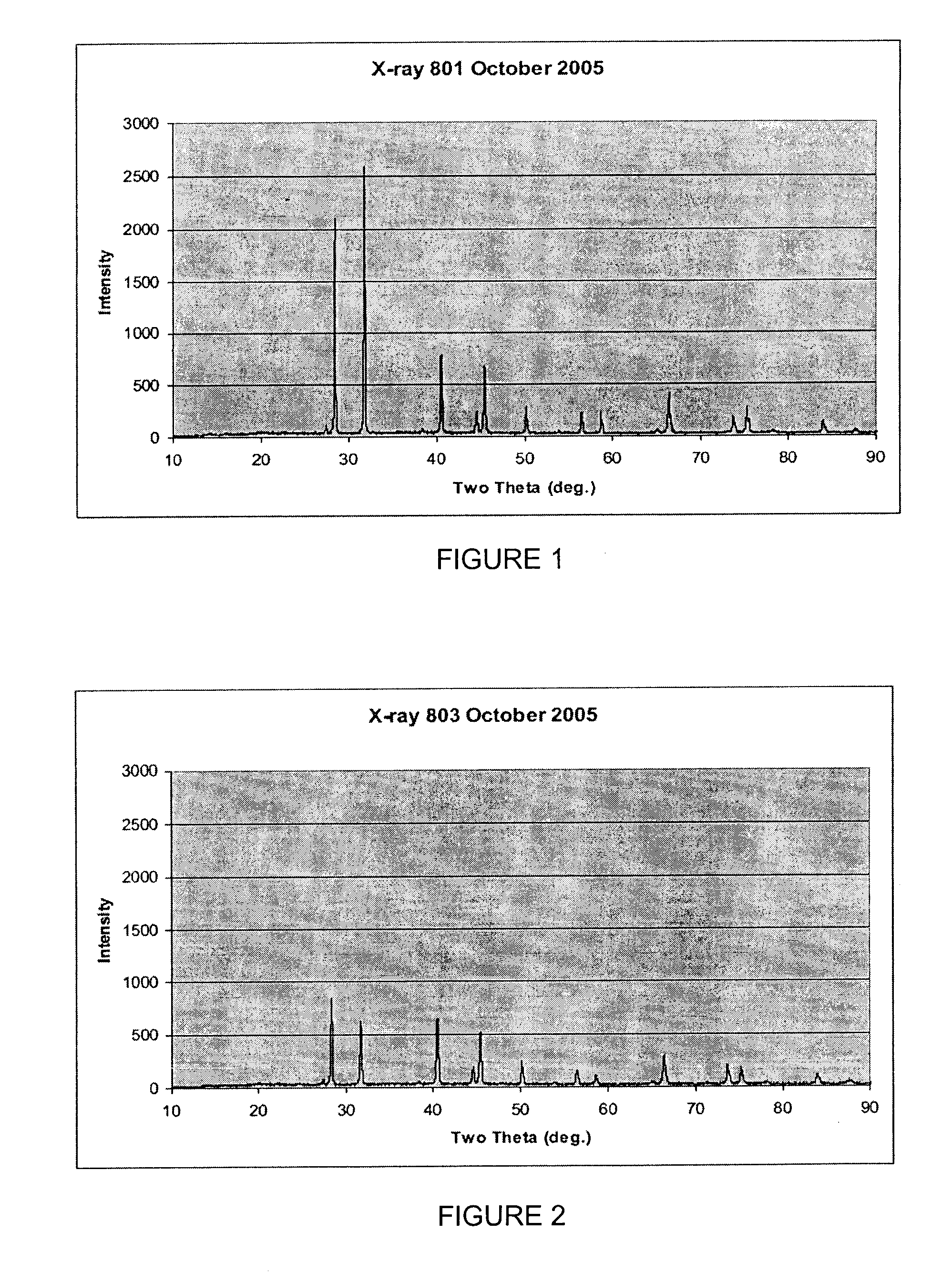

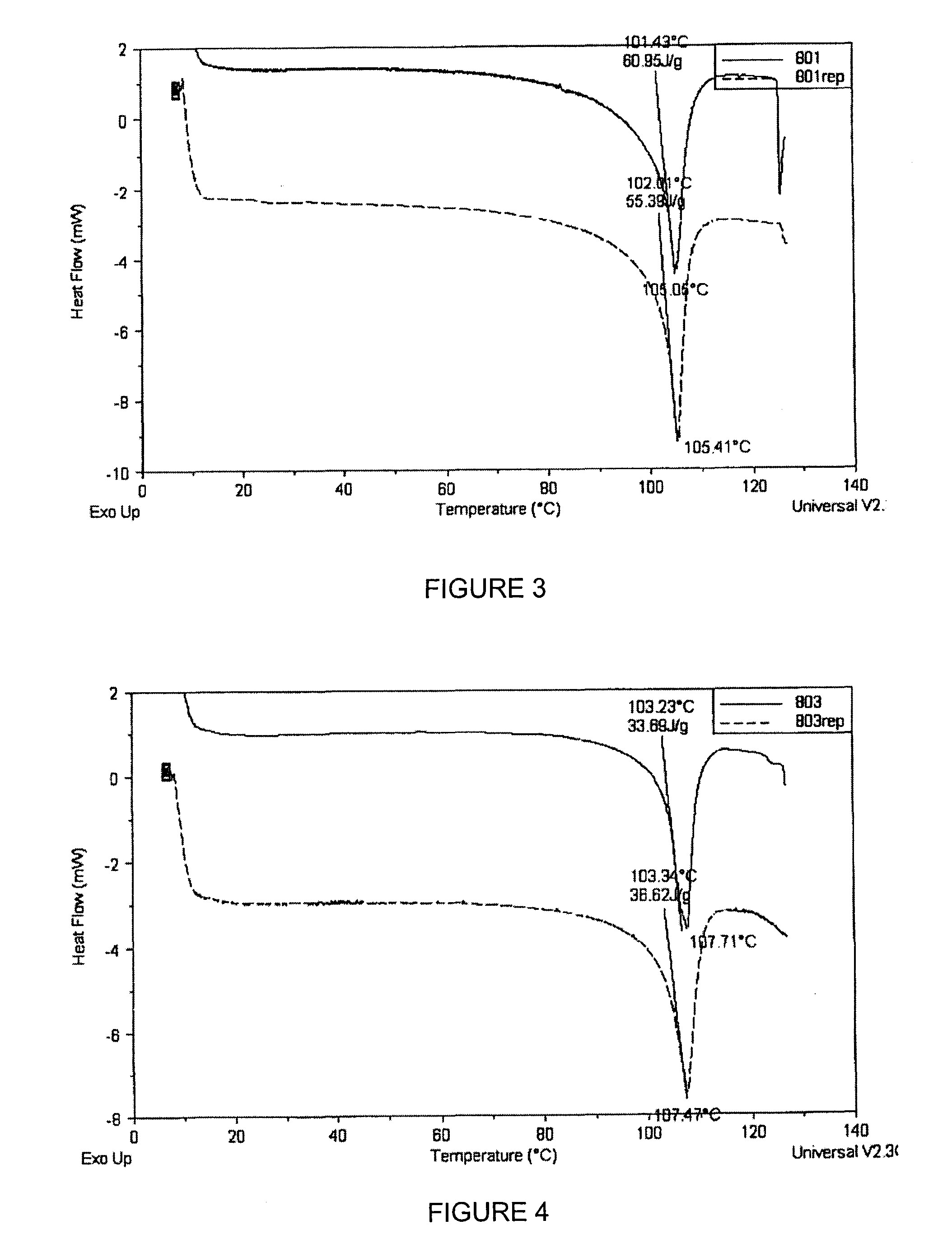

Low-sodium salt composition

ActiveUS20090117254A1Preserves natural tasteGreat tasteDough treatmentFood preparationSalt substituteFood grade

Low-sodium salt compositions / substitutes, Modified Potassium Chlorides (MPCs) and methods of making the same. The salt compositions / substitutes preferably include NaCl, KCl and a modifier(s), preferably a cereal flour such as rice flour. A food grade acidulant is preferably included. The composition / substitute will preferably have a Na / K ratio of from about 0.1 to about 9.0, most preferably about 1.0. MPCs preferably include KCl and a modifier(s), preferably a cereal flour such as rice flour. A food grade acidulant is preferably included. The salt compositions / substitutes and MPCs are preferably made by drum drying, extrusion cooking or agglomeration procedures. The MPC is preferably blended and / or co-ground with unmodified NaCl in any desired ratio, preferably 50 / 50, which gives a Na / K ratio of about 1 (i.e. 20% sodium and 20% potassium), to cost-effectively provide a salt substitute without modifying the NaCl.

Owner:S & P INGREDIENT DEV

Recovery of lithium compounds from brines

InactiveUS6936229B1Reduce in quantityCalcium/strontium/barium carbonatesCrystallization separationLithium chlorideLithium carbonate

Methods and apparatus for the production of low sodium lithium carbonate and lithium chloride from a brine concentrated to about 6.0 wt % lithium are disclosed. Methods and apparatus for direct recovery of technical grade lithium chloride from the concentrated brine are also disclosed.

Owner:ROCKWOOD LITHIUM INC

Color function seasoning low-sodium liquid salt and preparing method thereof

InactiveCN104000166AReduce intakePrevent morbidityNatural extract food ingredientsFood ingredient functionsSalt contentPlant Sources

The invention relates to a color function seasoning low-sodium liquid salt formula and a preparing method of color function seasoning low-sodium liquid salt. Low-sodium liquid salt mother liquor is used as main raw materials of the low-sodium liquid salt. The low-sodium liquid salt mother liquor comprises (according to the mass percent in the mother liquor salt content total quantity) 60%-80% of sodium chloride, 15%-30% of potassium chloride and 5%-15% of magnesium chloride. The low-sodium liquid salt further comprises a plant source function component with the adding quantity (according to the mass added into 100 mL of low-sodium liquid salt mother liquor) is 0.5%-10%. Optimization technologies such as mixing, homogenization, sterilization and filling are carried out, and color function seasoning low-sodium liquid salt products with function component activity being maintained to the maximum degree are prepared. A controllable-quantity liquid packaging container is used, the salt can be easily and evenly blended into food, the problem that solid salt is dissolved slowly, so that excessive adding or uneven dispersing may happen is solved, and accordingly eating is convenient and flexible. Compared with traditional solid salt production, during a production process of the liquid salt, a large amount of equipment needed for salt drying can be reduced, energy loss is lowered, and waste water discharging is lowered.

Owner:CHINA AGRI UNIV

Method for reducing content of sodium in aluminum hydroxide

InactiveCN102020302AReduce sodiumGood application effectAluminates/aluminium-oxide/aluminium-hydroxide purificationFire retardantLow sodium

The invention relates to a method for reducing the content of sodium in aluminum hydroxide, in particular to a method for preparing low-sodium aluminum hydroxide (Na2O is less than 0.1 percent) serving as a fire retardant or a raw material for calcining low-sodium aluminum oxide. The method is characterized by comprising the following steps of: after homogenizing the aluminum hydroxide by using pure water, performing hydro-thermal treatment, and filtering, washing and drying to obtain low-sodium aluminum hydroxide powder. In the method, the aluminum hydroxide prepared by a Bayer process or a sintering process is subjected to the hydro-thermal treatment, so that adherent alkali and lattice alkali in the aluminum hydroxide are dissolved in the water, and the low-sodium aluminum hydroxide powder is obtained by processes of solid-liquid separation, washing, drying and the like, wherein the powder can be used as the fire retardant or the raw material for calcining the low-sodium aluminum oxide. The method has the advantages that a process is simple, industrialization is easy to realize and the like, so the using performance of the aluminum hydroxide fire retardant can be improved effectively, and the low-sodium aluminum hydroxide can be used as the raw material for calcining low-sodium alpha-aluminum oxide.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Production of lithium compounds directly from lithium containing brines

InactiveUS6921522B2Promote absorptionConstant liquid volumeCalcium/strontium/barium carbonatesCalcium/strontium/barium sulfatesLithium chlorideLithium carbonate

Methods and apparatus for the production of low sodium lithium carbonate and lithium chloride from a brine concentrated to about 6.0 wt % lithium are disclosed. Methods and apparatus for direct recovery of technical grade lithium chloride from the concentrated brine are also disclosed.

Owner:ROCKWOOD LITHIUM INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com