High-grade potassium chloride production system and method thereof

A production method and production system technology, applied in the direction of alkali metal chloride, alkali metal halide purification, etc., can solve the problems of affecting product grade and recovery rate, discontinuity, and insufficient flotation efficiency, and achieve convenient and intensive production operation. The effect of land use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

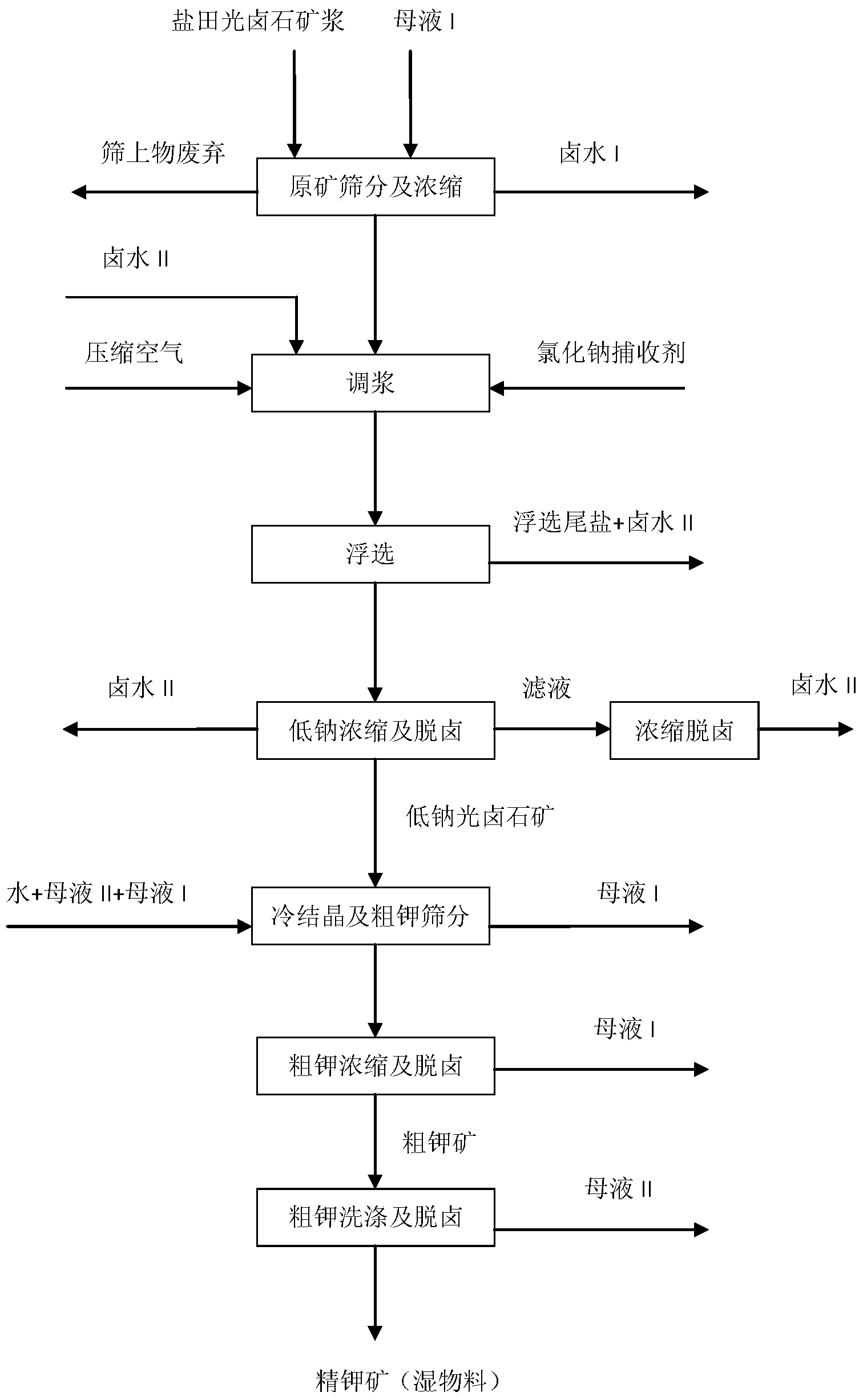

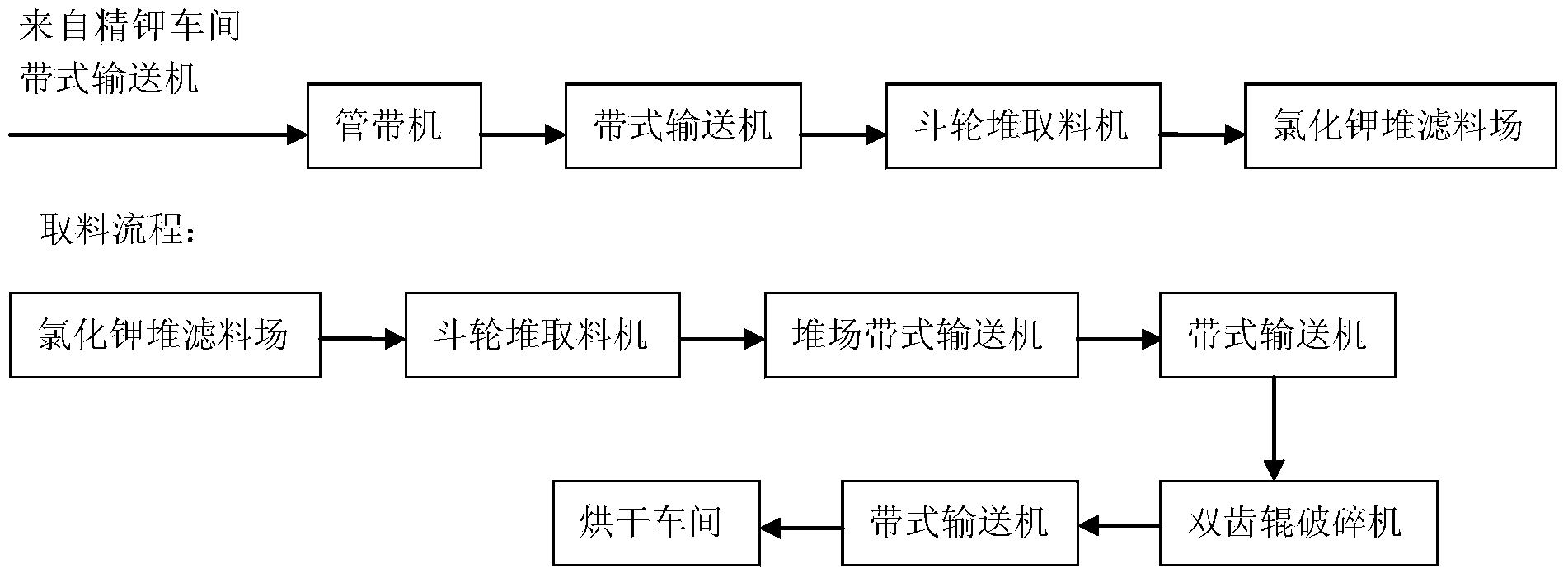

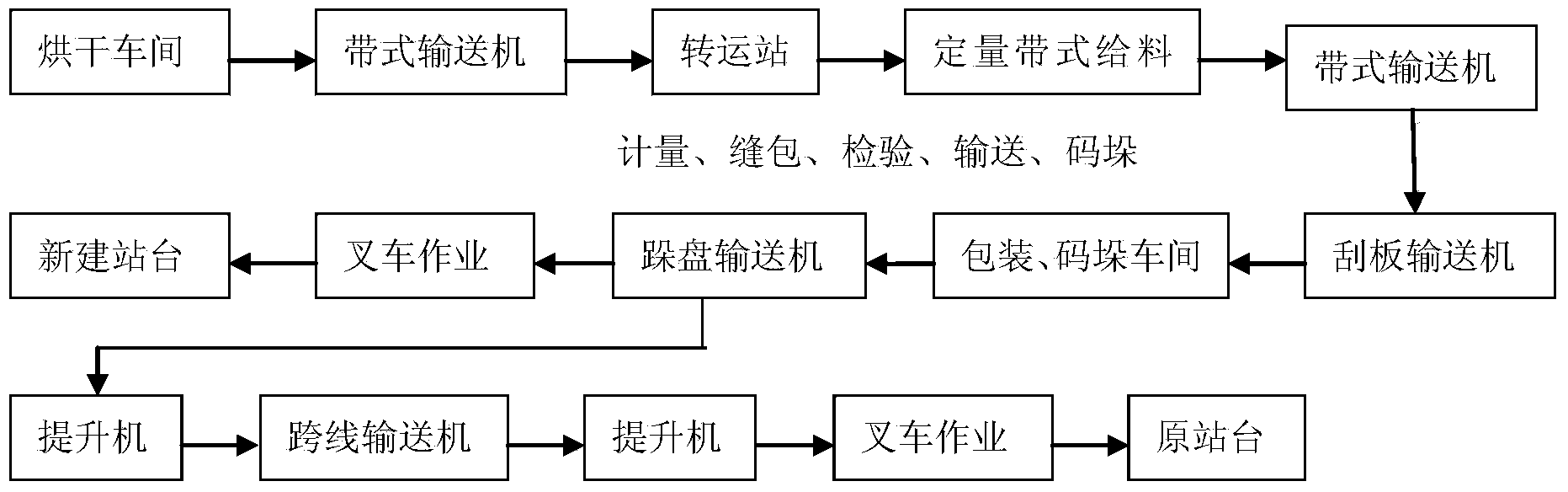

[0038] A high-grade potassium chloride production system, including raw ore screening and concentration system, pulping system, flotation system, low-sodium concentration and dehalogenation system, cold crystallization and crude potassium screening system, crude potassium concentration and dehalogenation system , refined potassium washing and dehalogenation system, heap filter storage yard system, crushing and conveying system, drying and cooling, packaging, palletizing, cross-line conveying system, each system is connected in sequence, each system device is arranged in three dimensions, and the material enters in the form of self-flow The next system has the advantage of reducing the number of pumps and saving electricity consumption;

[0039] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com