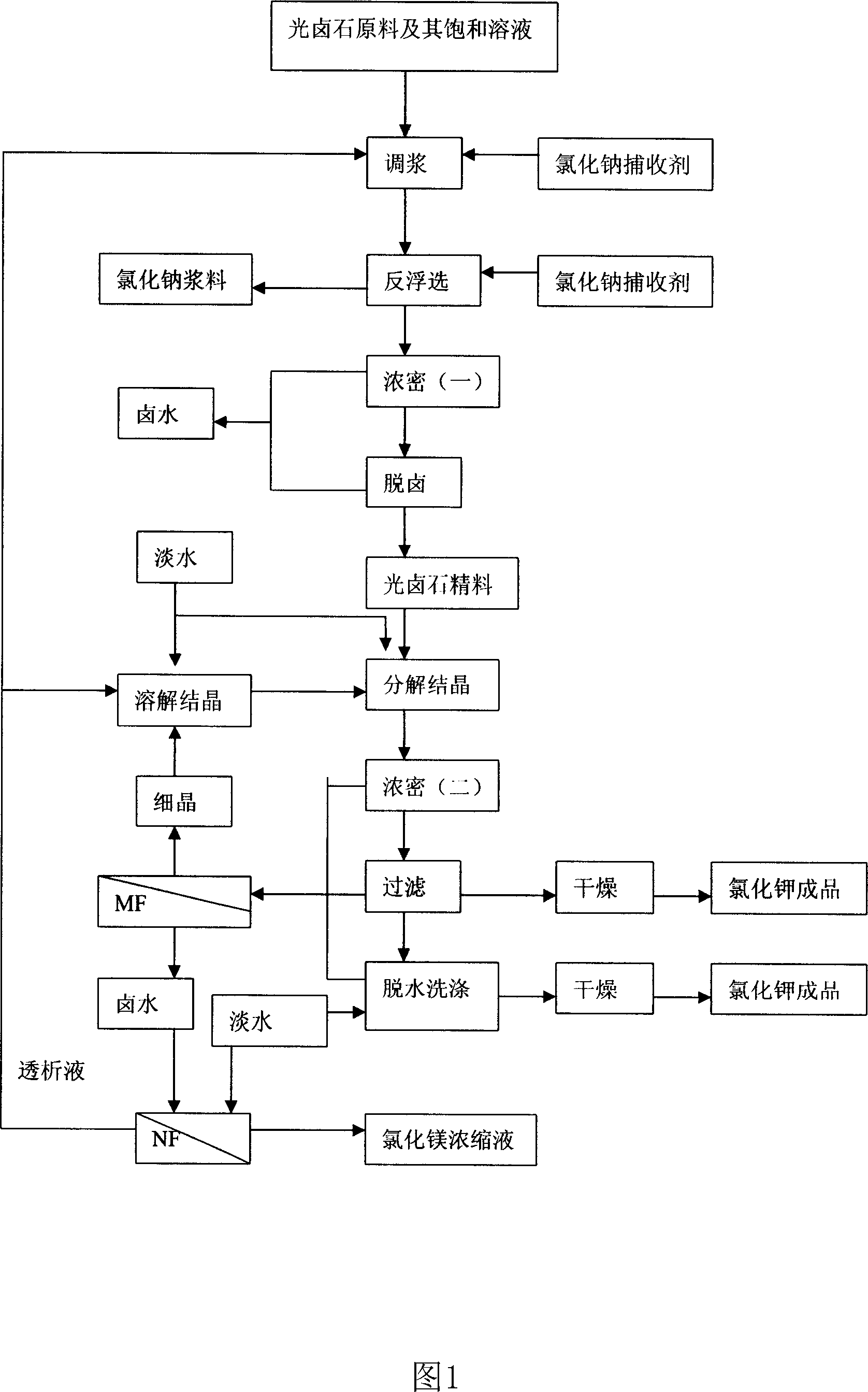

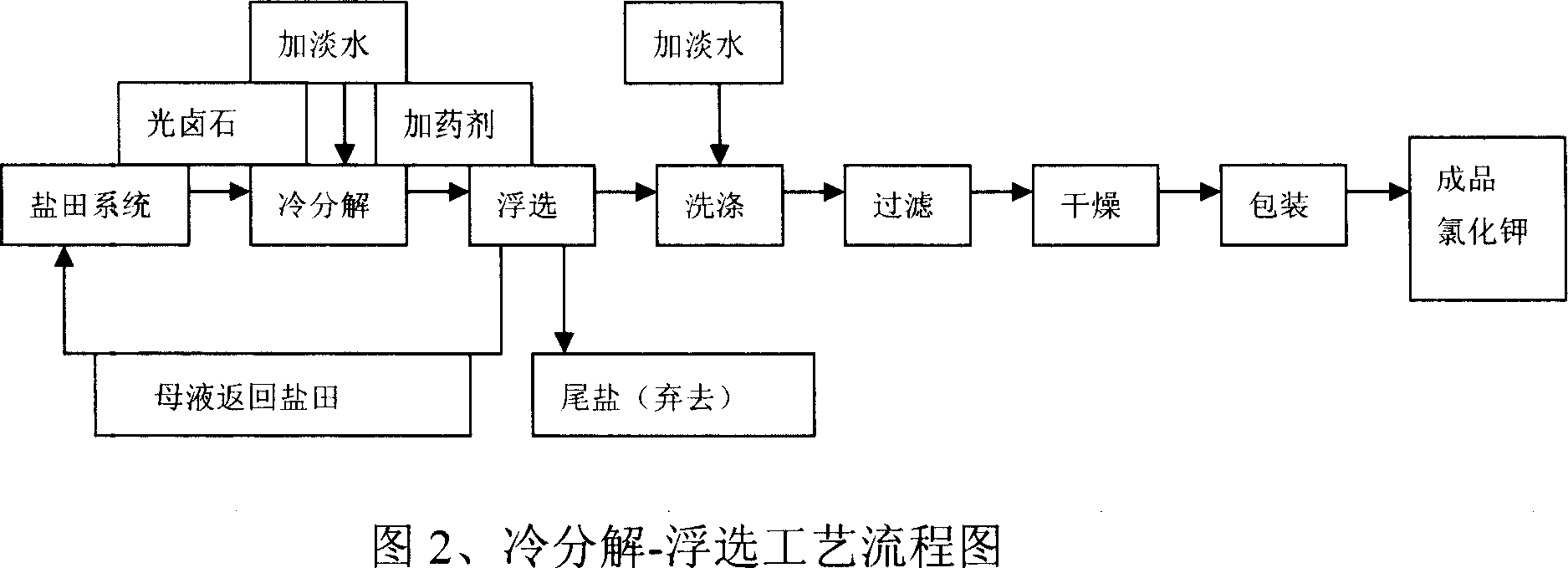

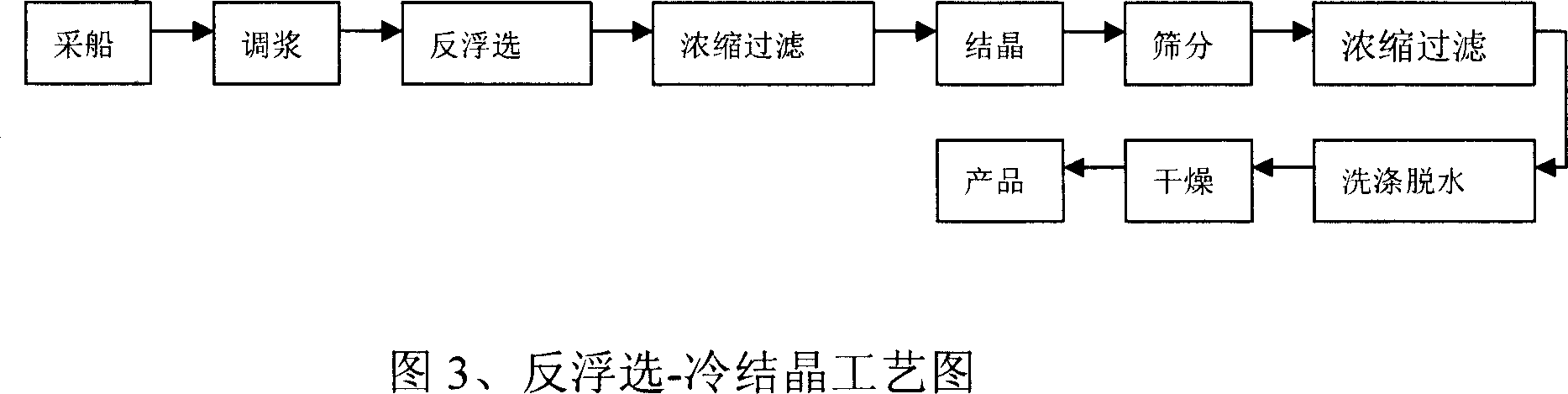

Reverse floatation-cold crystallization process for producing potassium chloride

A production method and technology of potassium chloride, applied in the direction of alkali metal chloride, alkali metal halide purification, etc., can solve the problems of poor product quality, low utilization rate of potassium chloride, etc., achieve high product quality, prevent high-concentration excessive The formation of saturated solution, the effect of large grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Take by weighing 300 kilograms of carnallite raw materials (carnallite contains potassium chloride 21.7%, magnesium chloride 27.7%, sodium chloride 18%) through screening, add in the saturated solution of 1 ton of carnallite for slurrying, then add 30 grams of carnallite Fatty amide sodium chloride flotation agent reverse flotation twice, then carry out sedimentation and concentration (thickness one), filter and separate and remove most of sodium chloride to prepare carnallite containing sodium chloride less than 6% (carnallite essence Material) 260 kg (carnallite contains potassium chloride 25.7%, magnesium chloride 32.2%, sodium chloride 5.8%). 260 kilograms of carnallite are decomposed and crystallized with 195 kilograms of fresh water, then sedimentation and concentration (thickness two), filtration and separation to obtain 49 kilograms of potassium chloride semi-finished products and 406 kilograms of slurry, and 45.2 kilograms of potassium chloride finished products...

Embodiment 2

[0045] Take by weighing 300 kilograms of carnallite raw materials (carnallite contains potassium chloride 21.7%, magnesium chloride 27.7%, sodium chloride 18%) through weighing, add the saturated solution of 1 ton of carnallite (this saturated solution uses the chlorine of recovery Potassium chloride dialysate is prepared by adding carnallite), then add 120 grams of fatty amide sodium chloride flotation agent for reverse flotation twice, then carry out sedimentation and concentration (thick one), filter and separate to remove most of the sodium chloride Prepared 279 kg of refined carnallite (carnallite concentrate) containing less than 6% sodium chloride (purified carnallite contains potassium chloride 26.2%, magnesium chloride 32.2%, sodium chloride 5.6%). 279 kilograms of carnallite are decomposed and crystallized with 200 kilograms of fresh water, then sedimentation and concentration (dense two), filter and separate to obtain 57 kilograms of potassium chloride semi-finished ...

Embodiment 3

[0049] Take by weighing 300 kilograms of carnallite raw materials (carnallite contains potassium chloride 21.7%, magnesium chloride 27.7%, sodium chloride 18%) through screening, add the saturated solution of 750 kilograms of carnallite (this saturated solution uses the chlorine of recovery Potassium chloride dialysate is prepared by adding carnallite), then add 90 grams of fatty amide sodium chloride flotation agent for reverse flotation twice, then carry out sedimentation and concentration (thick one), filter and separate to remove most of the sodium chloride Prepared 282 kg of refined carnallite (carnallite concentrate) containing less than 6% sodium chloride (purified carnallite contains potassium chloride 26.5%, magnesium chloride 32.1%, sodium chloride 5.7%). 282 kilograms of carnallite are decomposed and crystallized with 200 kilograms of fresh water, then sedimentation and concentration (thickness two), filtration and separation to obtain 58 kilograms of potassium chlor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com