Patents

Literature

68 results about "Thermal dissolution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermal dissolution is a method of liquefaction of solid fossil fuels. It is a hydrogen-donor solvent refining process. It may be used for the shale oil extraction and coal liquefaction. Other liquids extraction processes from solid fuels are pyrolysis and hydrogenation. Compared to hydrogenation, the process of thermal dissolution has milder conditions, simpler process, and no consumption of catalyst.

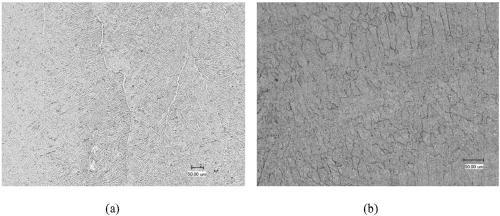

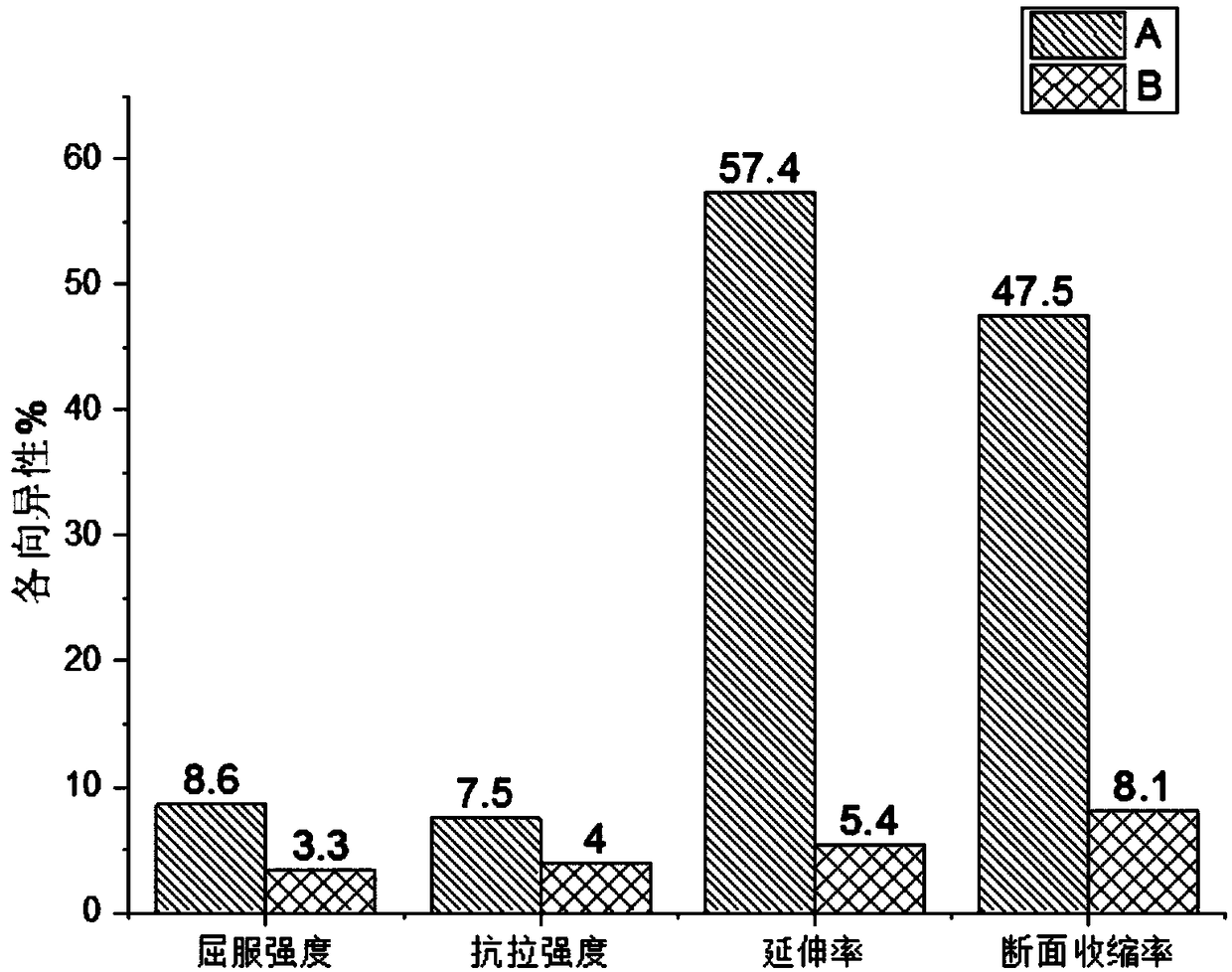

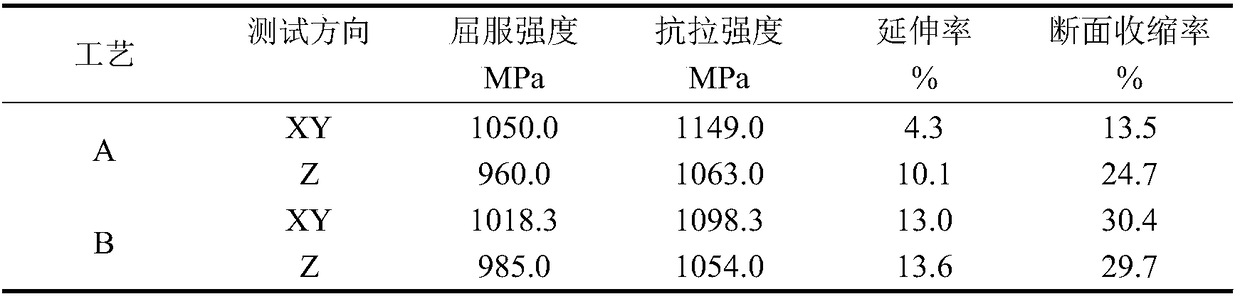

Method for utilizing boron alloying metamorphism to reduce anisotropy of TC4 additive manufacturing

InactiveCN109226743AGrain equiaxation and refinementReduce anisotropyAdditive manufacturing apparatusIncreasing energy efficiencyTi 6al 4vSedimentation

The invention discloses a method for utilizing boron alloying metamorphism to reduce anisotropy of TC4 additive manufacturing. The method includes the following steps of S1, drying Ti-6Al-4V-0.05B alloy powder under a vacuum environment at 120 DEG C for 8 hours; S2, using a laser additive manufacturing device for conducting laser melting, covering and forming on the alloy powder dried in step S1 under a protective atmosphere of inert gas to obtain a formed sample component; S3, conducting thermal dissolution and aging treatment on the formed component under argon protection of the inert gas. By using a new material obtained by alloying boron and TC4 in the method for laser melting, covering and sedimentation, boron effectively inhibits generation of thick preliminary cylindrical crystals in a TC4 titanium alloy during forming and facilitates isometry and refining of TC4 titanium alloy grains, the structure is more uniform, and the anisotropy of conventional mechanical performance is controlled within 10%. A new approach is provided for laser additive manufacturing of the TC4 titanium alloy.

Owner:XI AN JIAOTONG UNIV

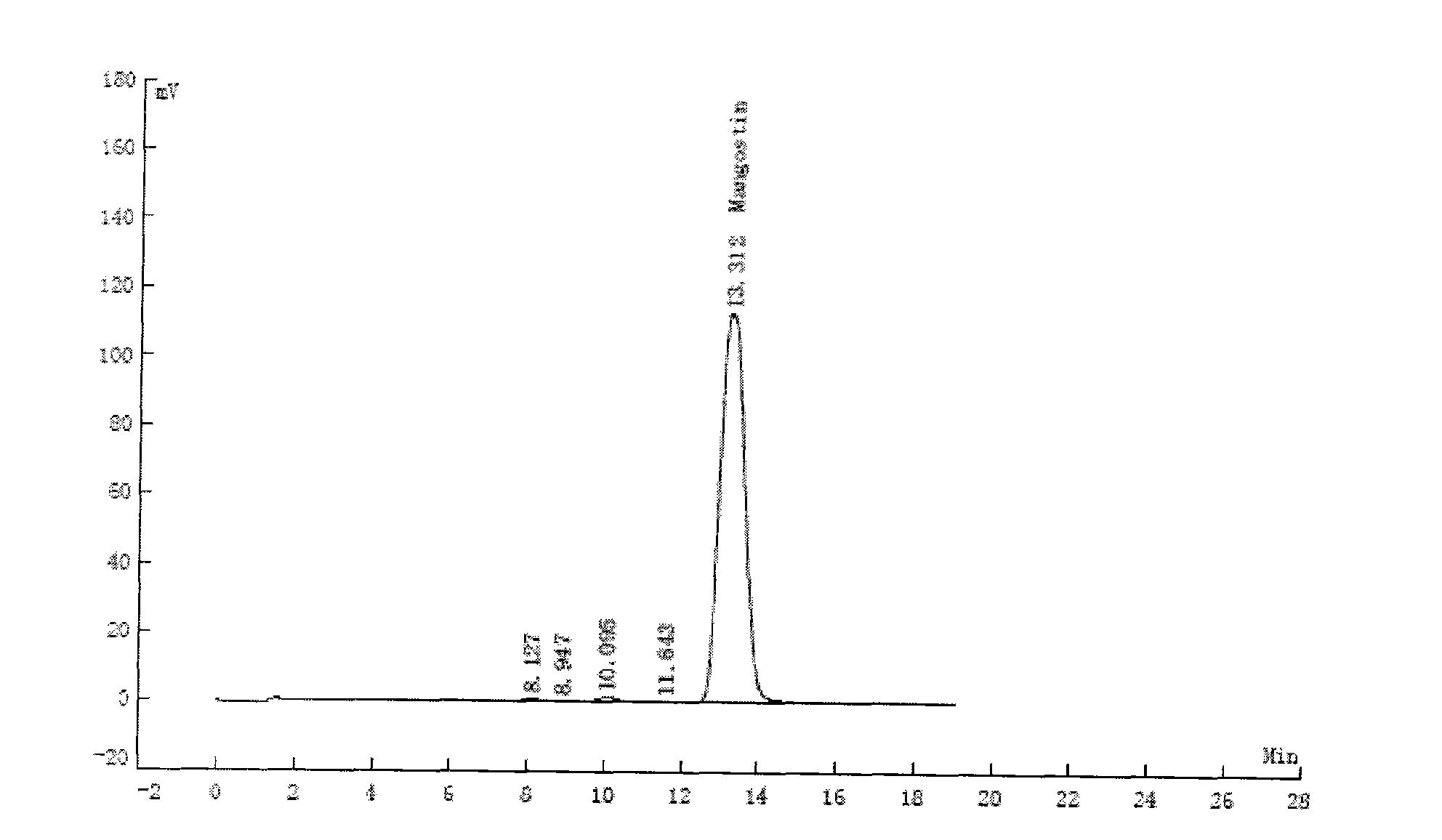

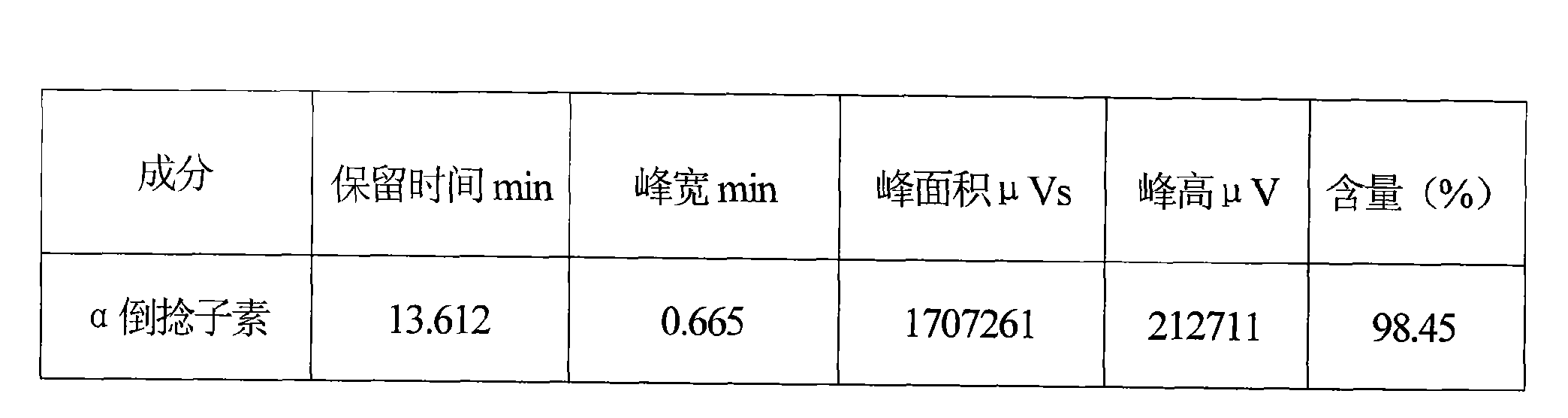

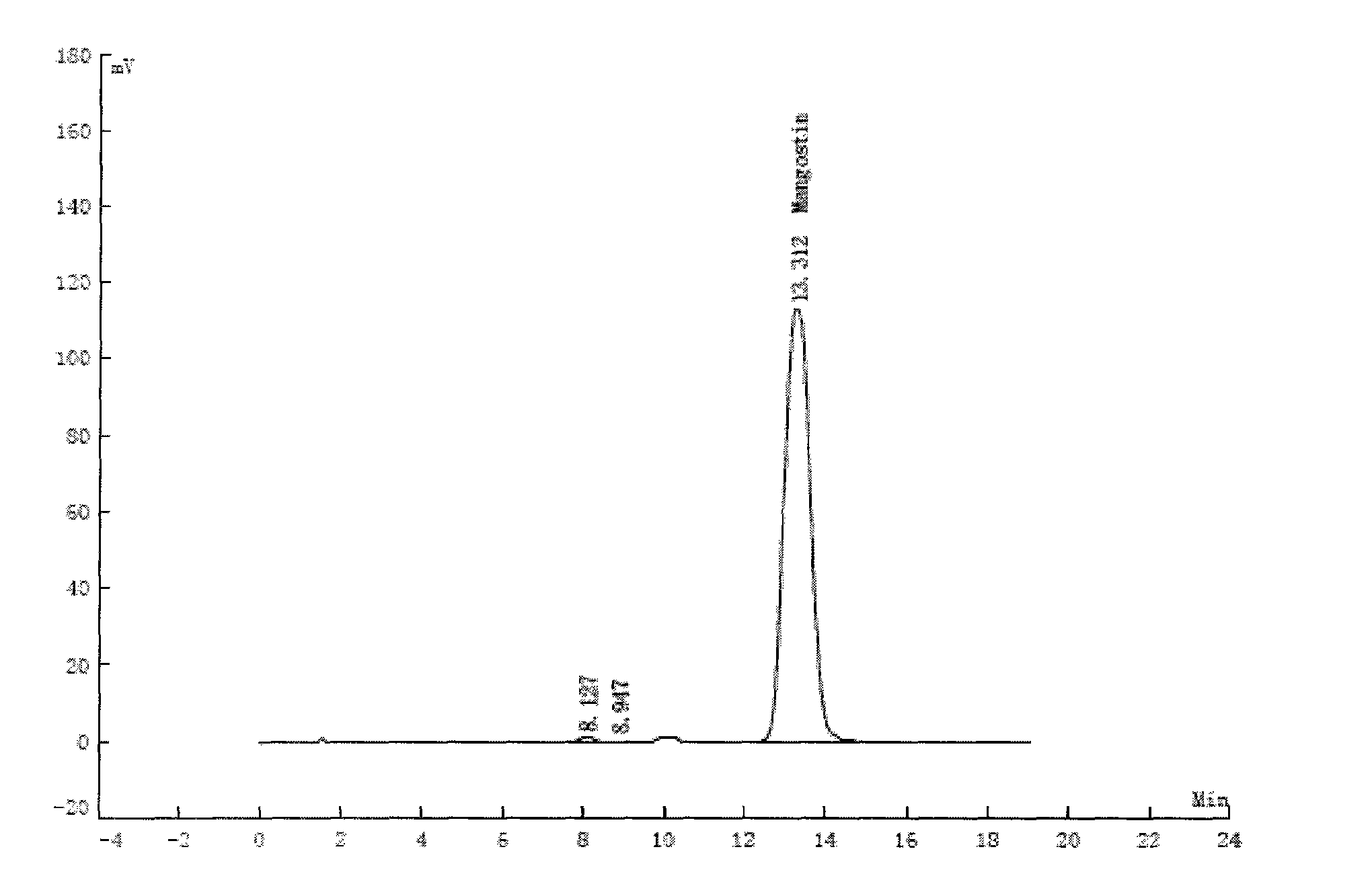

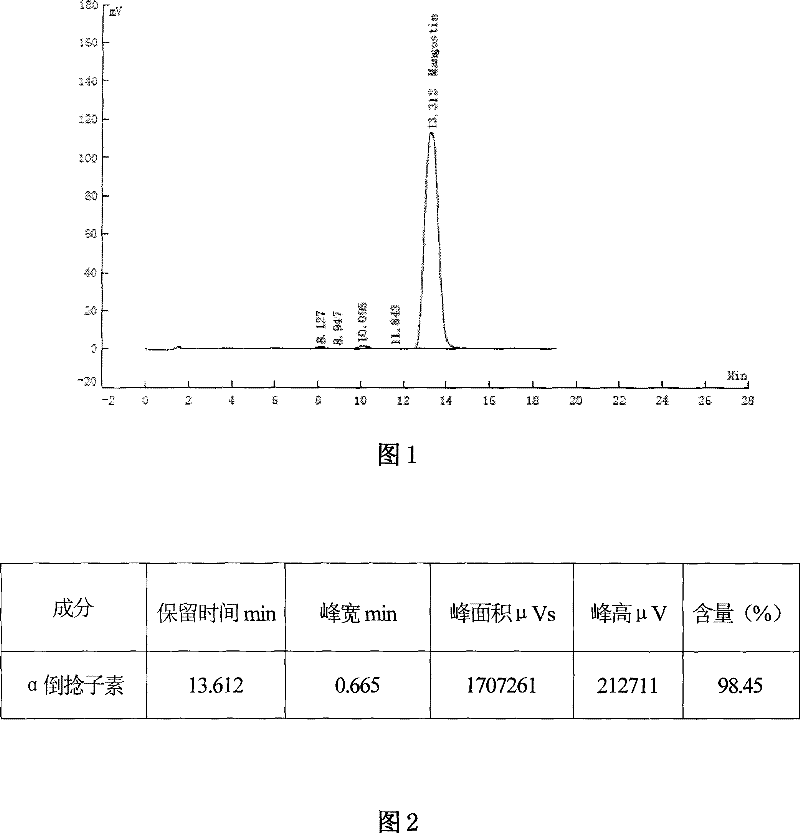

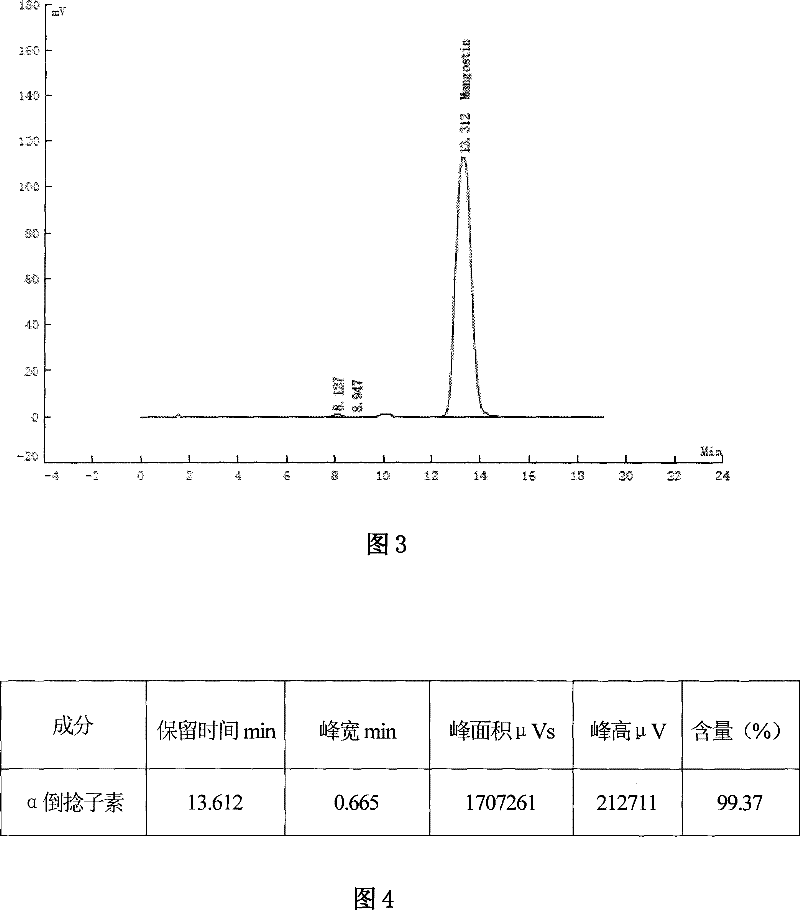

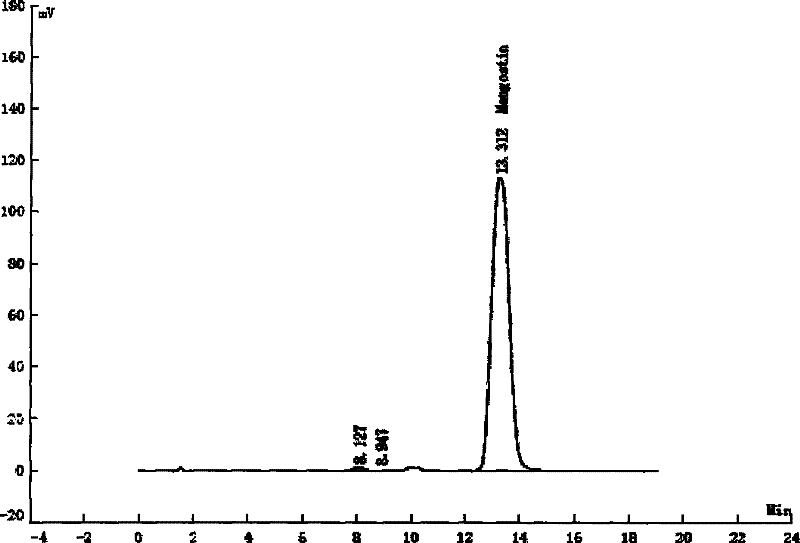

Method for extracting alpha-mangostin from mangosteen fruit peel

ActiveCN101525328ASimple processSimple chromatographic processOrganic chemistryPlant ingredientsAlpha mangostinOrganic solvent

The invention relates to a method for extracting alpha-mangostin from a mangosteen fruit peel. The method comprises the following realization steps: (I) extracting the mangosteen fruit peel; (II) concentrating an extracting solution; mixing the extracting solution of every time and concentrating under reduced pressure to obtain a concentrated solution; (III) leaching the solution; (IV) carrying out silica gel column chromatography; (V) carrying out coarse crystallization; and (VI) carrying out recrystallization: adding a primary crystal into an organic solvent with the volume of 1 to 5 times to carry out thermal dissolution; placing the solution after finishing the thermal dissolution, reducing the temperature to a room temperature, carrying out recrystallization, and controlling the crystallization time to between 10 and 20 hours; and filtering and centrifugating a recrystallization liquid, drying the liquid in vacuum to obtain the 98 percent alpha-mangostin. The method has the advantages of simple process and short operation time.

Owner:SHAANXI JIAHE PHYTOCHEM

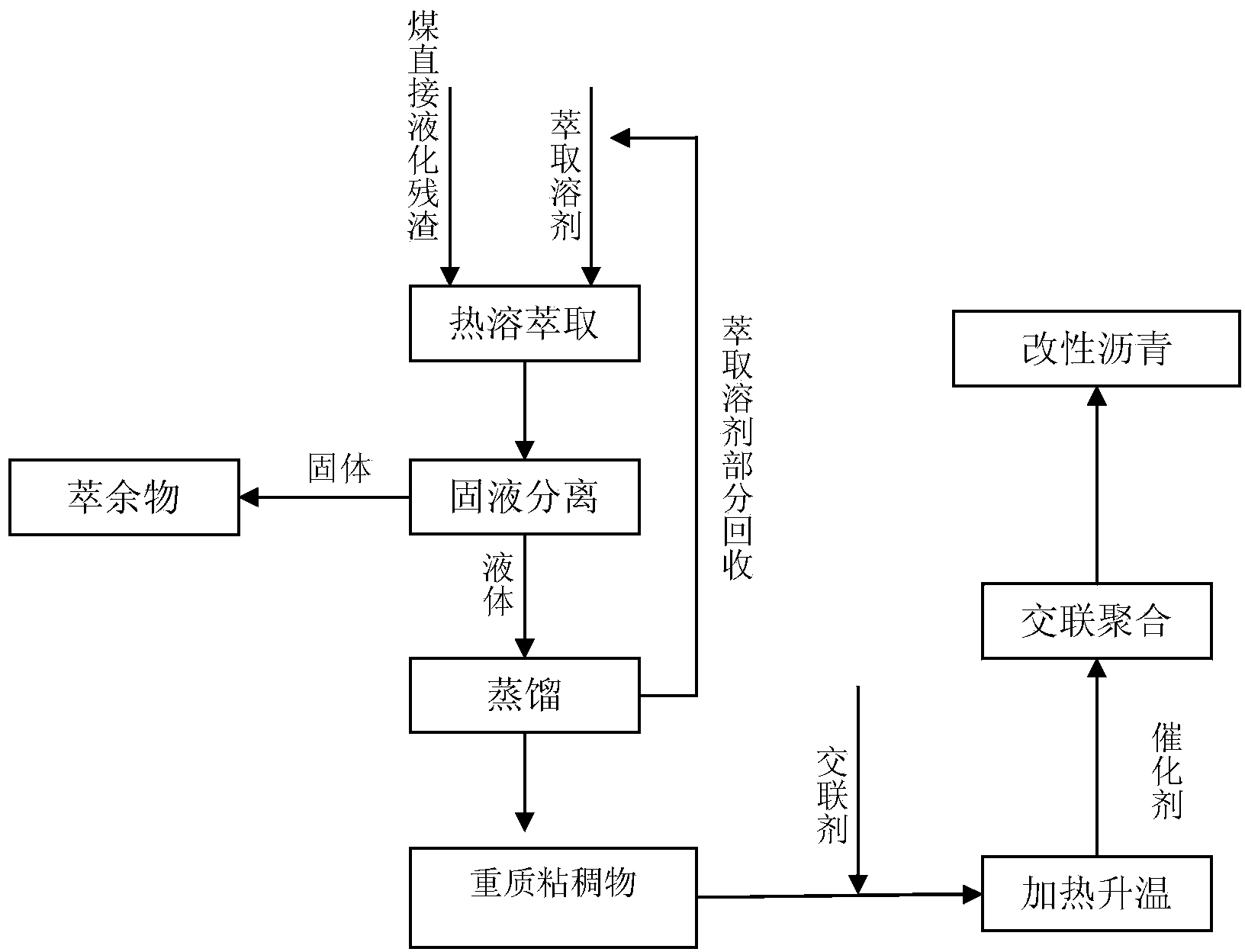

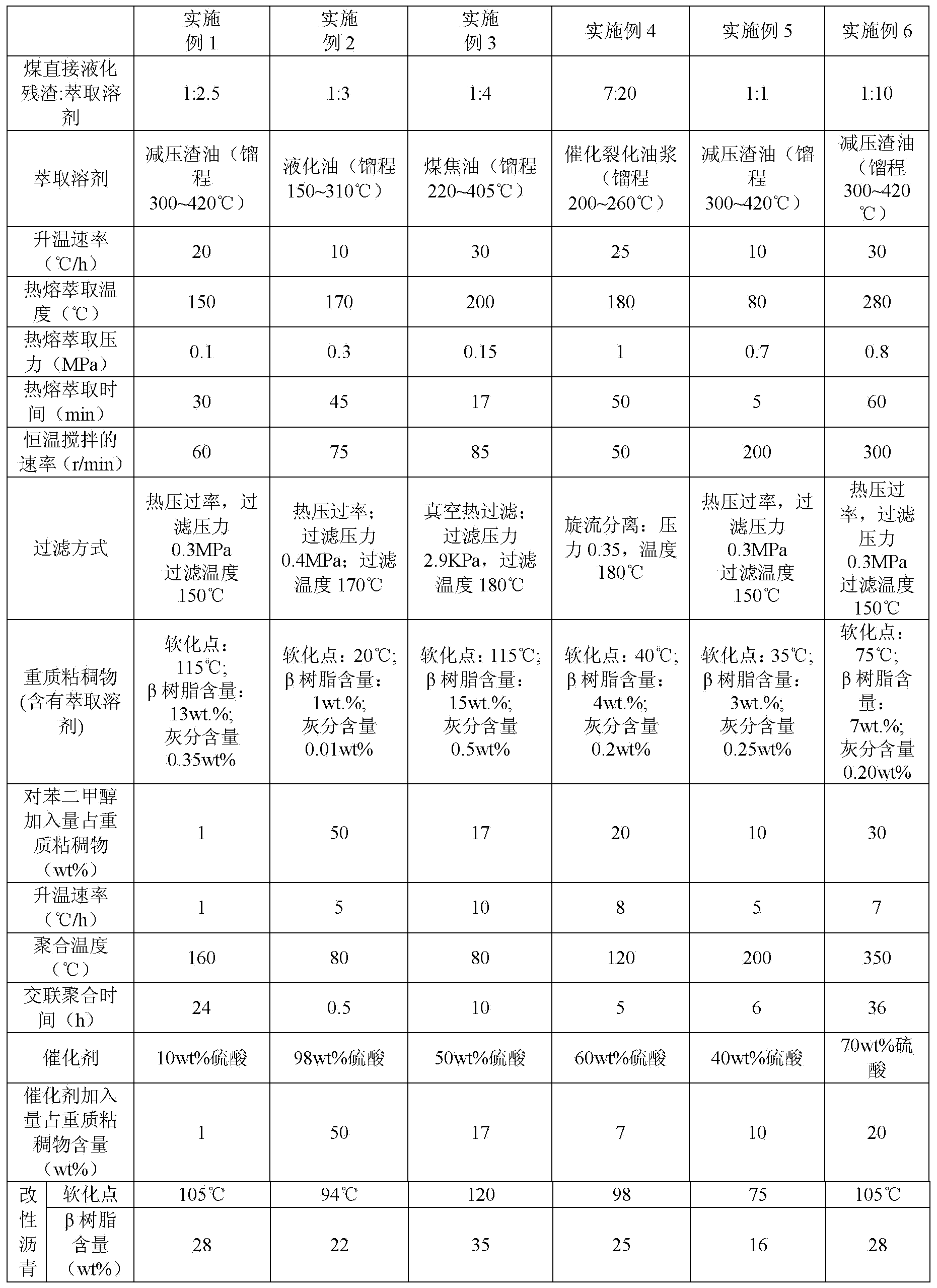

Modified asphalt, method for preparing modified asphalt by using direct liquefied coal residue in normal pressure continuous mode and application of modified coal residue

ActiveCN103756703AHigh Beta Resin ContentImprove adhesionWorking-up pitch/asphalt/bitumen by selective extractionWorking-up pitch/asphalt/bitumen by chemical meansCross-linkDistillation

The invention discloses modified asphalt, a method for preparing the modified asphalt by using direct liquefied coal residues in a normal pressure continuous mode, and an application of the modified asphalt. The method comprises the following steps: 1, adding an extracting solvent into the direct liquefied coal residues for performing thermal dissolution extraction, solid-liquid separation and solvent recycling treatment in sequence so as to obtain a heavy dope with the extracting solvent; 2, adding a cross-linking agent into the heavy dope, stirring and mixing so as to obtain a first mixture; 3, adding a catalyst into the first mixture, heating at normal pressure to perform cross-linking polymerization so as to obtain the modified asphalt. According to the method, the modes that in the prior art, the direct liquefied coal residues are directly prepared into high-temperature asphalt firstly and subsequently heavy oil is added to perform cross-linking polymerization to modify the asphalt are abandoned, but the cross-linking agent is directly added into the heavy dope with the extracting solvent after distillation to polymerize at normal pressure so as to obtain a modified asphalt product with a low softening point and high beta resin content, and the modified asphalt is suitable for being used as middle / high-temperature binding asphalt and a raw material of dipping asphalt.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

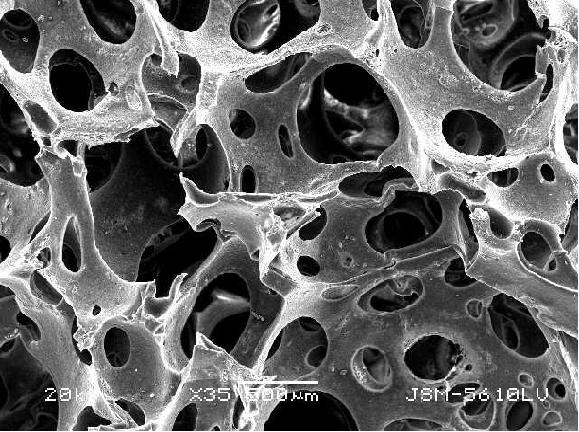

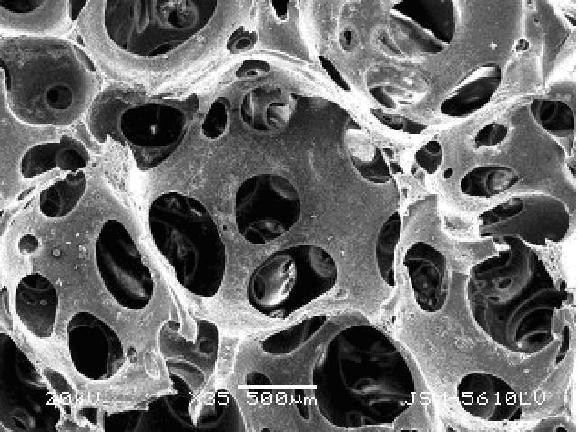

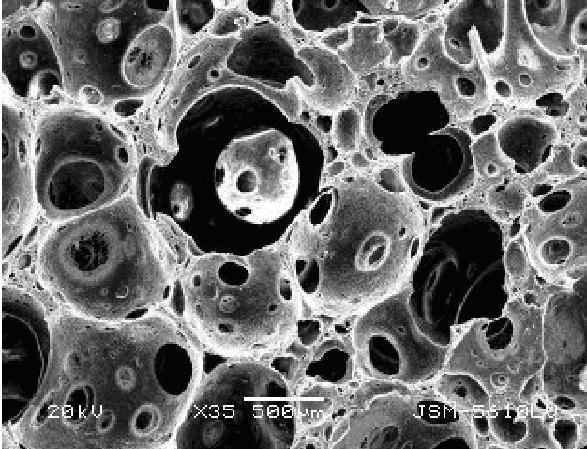

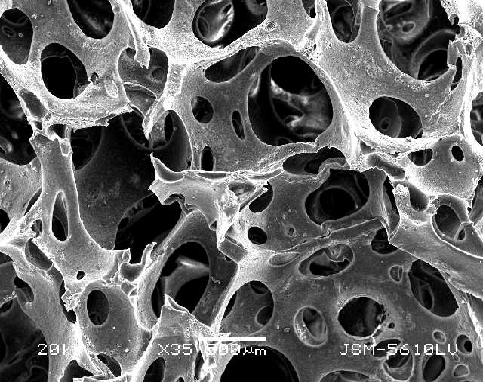

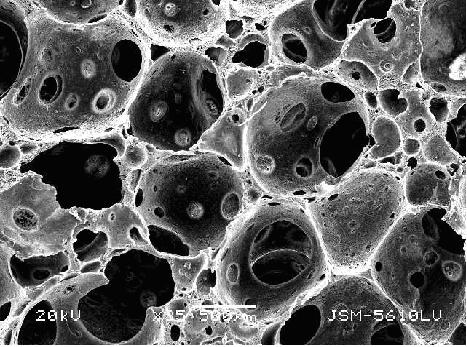

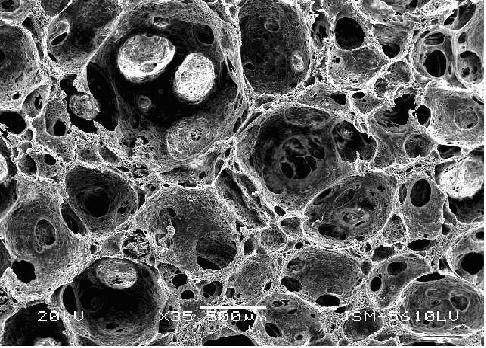

Succinyl-chitosan/polyvinyl alcohol composite sponge and preparation method thereof

ActiveCN101974189AGood flexibilityIncrease elasticityAbsorbent padsProsthesisPolymer scienceBiocompatibility Testing

The invention relates to a succinyl-chitosan / polyvinyl alcohol composite sponge. The composite sponge is prepared with succinyl-chitosan and polyvinyl alcohol as the raw materials and comprises the following raw materials by weight: 0.5-2% of succinyl-chitosan, 9-10% of polyvinyl alcohol, 9-13% of inorganic acid, 10-17% of formaldehyde, 3-5% of foaming agent and the balance water. A preparation method of the composite sponge comprises thermal dissolution, acetalization and foaming of polyvinyl alcohol and compositing of polyvinyl alcohol and succinyl-chitosan. During preparation, the polyvinyl alcohol which undergoes complete alcoholysis or incomplete alcoholysis and has degree of polymerization of 1700-2000 is selected as the raw material, the succinyl-chitosan and the polyvinyl alcohol are mixed in water and heated and dissolved, then acid, formaldehyde and the foaming agent are added to the mixture to be blended and the mixture is heated and formed in an oven, thus obtaining the composite sponge. The method can prepare the composite sponge with higher water absorbing capacity, better flexibility and viscoelasticity and good biocompatibility and the advantages of low cost, environmental protection and simple process, and the obtained material can be applied to treating wound cavity infection, burns, skin grafting, etc.

Owner:山东医正源生物医药科技有限公司

Silicon recovery method

ActiveCN102515186AHigh extraction rateHigh recovery rateAlkali metal silicatesSlagEnvironmental engineering

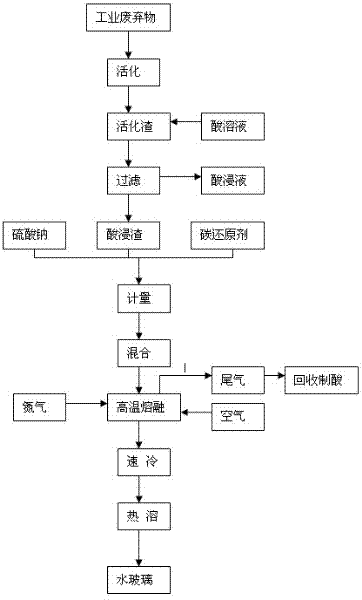

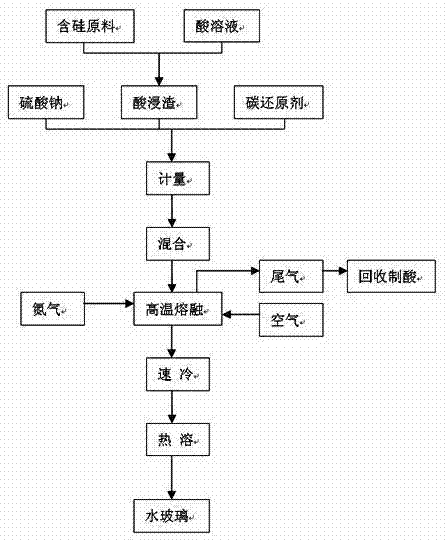

The invention discloses a silicon recovery method, which comprises: taking an industrial waste as a raw material, using an acid solution for acid leaching, filtering, and washing, then adding anhydrous sodium sulfate into an acid leaching residue, employing carbon as a reducing agent, and conducting high temperature fusion reaction so as to obtain sodium silicate, which is then subjected to thermal dissolution or high temperature water dissolution, thus obtaining water glass. The method of the invention has the characteristics of high silicon recovery rate, fewer residue, reasonable resource utilization, and adjustable water glass modulus ranging from 1 to 3.5, provides a new for industrial waste acid leaching slag silicon provides a new technological route for silicon extraction from the acid leaching residue of an industrial waste, and is conducive to resource comprehensive application of industrial wastes.

Owner:KUNMING UNIV OF SCI & TECH +1

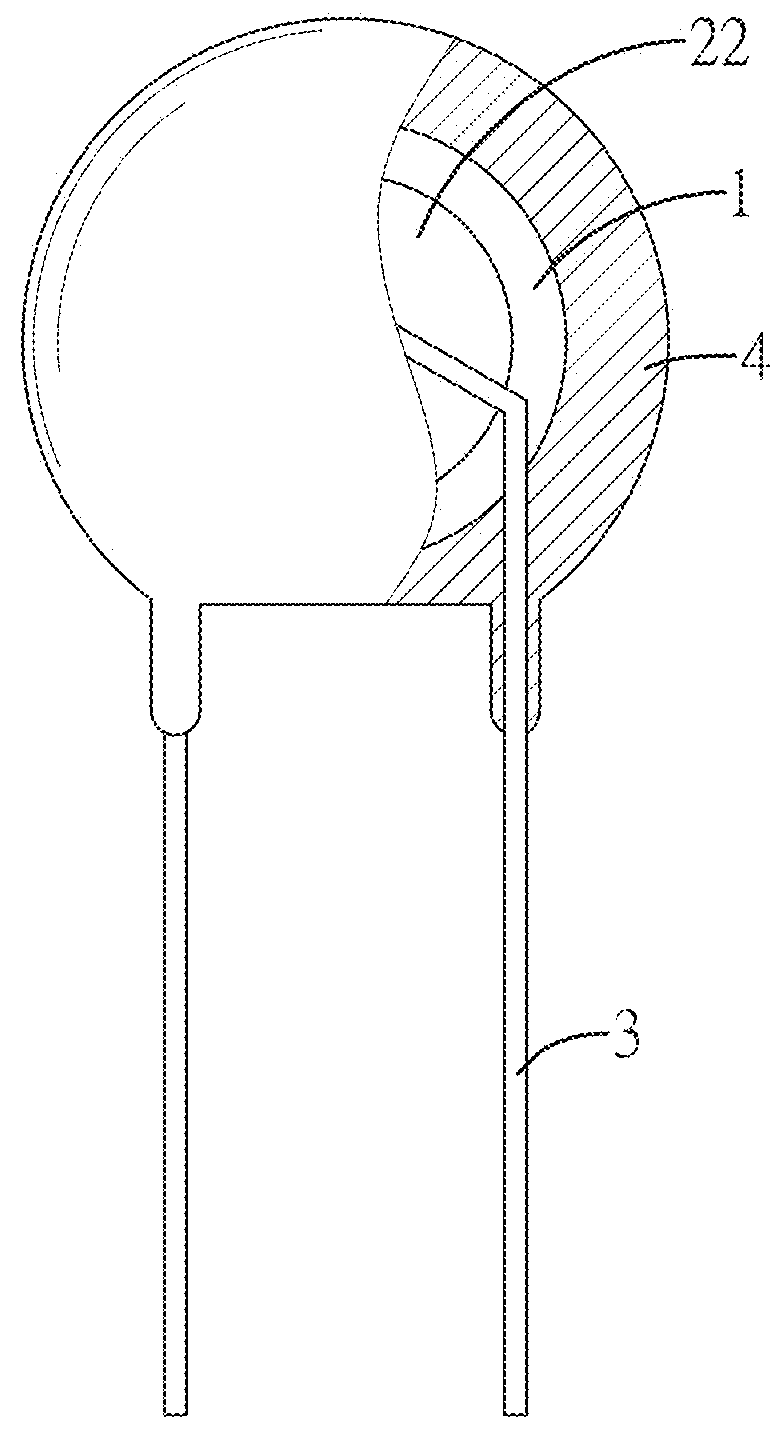

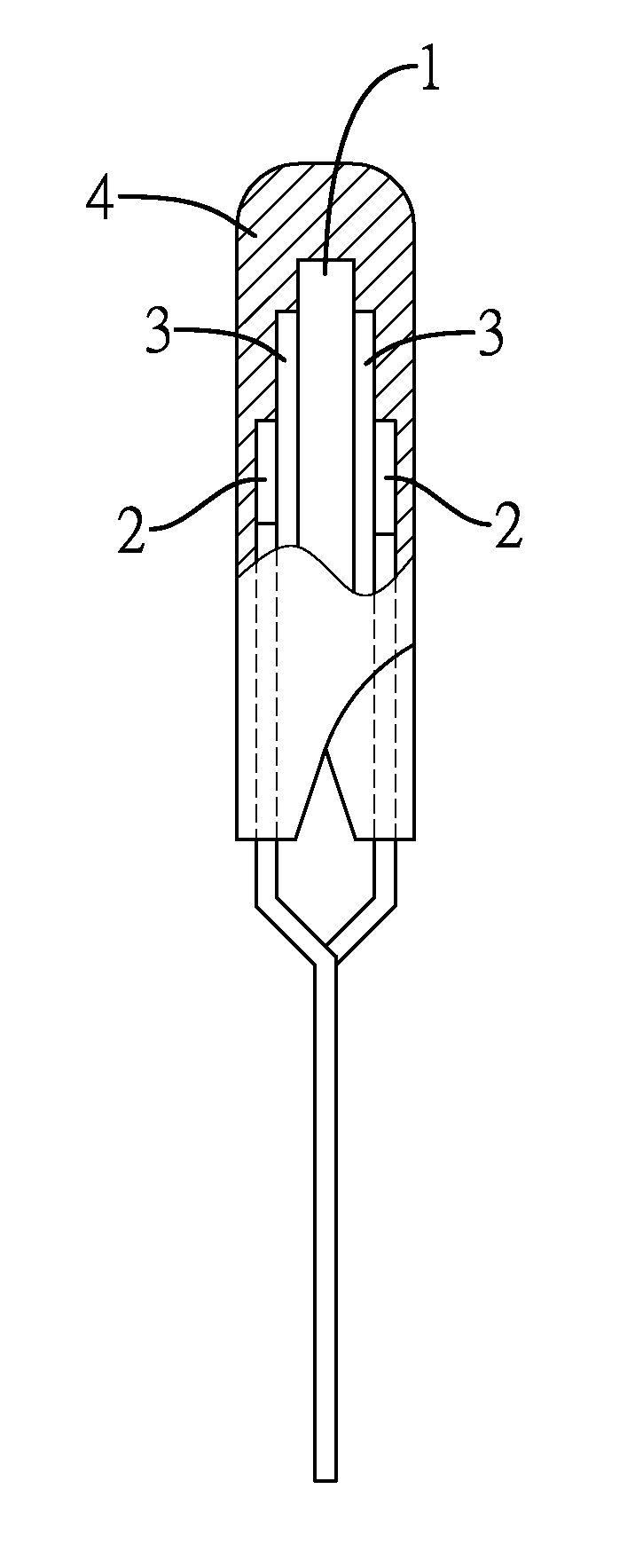

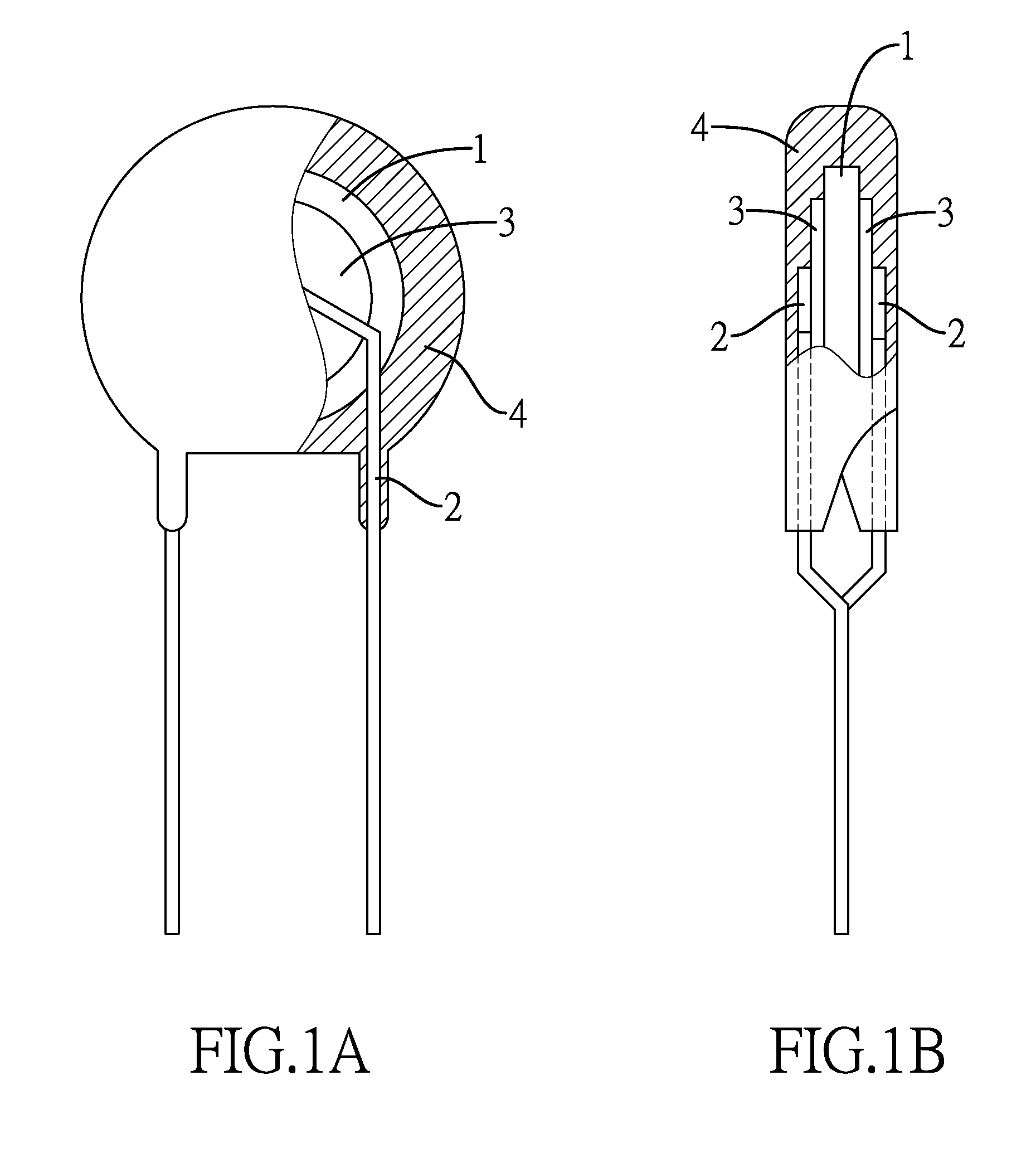

Electrode component with pretreated layers

ActiveUS20160035466A1Enhanced ohmic contact resistanceLow heat generationResistor terminals/electrodesCurrent responsive resistorsSilver electrodeOrganic solvent

An electrode component with pretreated layers includes a ceramic substrate, two pretreated layers formed on two opposite surfaces of the ceramic substrate, two electrode layers respectively formed on the two pretreated layers, two pins respectively connected to the electrode layers, and an insulating layer enclosing the ceramic substrate, the pretreated layers, the electrode layers, and portions of the two pins. The pretreated layer formed between the ceramic substrate and the electrode layer replaces the fabrication means for conventional silver electrode layer to provide good binding strength between the ceramic substrate and the electrode layer. Besides same electrical characteristics for original products, the electrode component can get rid of the use of precious silver in screen printed silver electrode and avoid pollution caused by evaporation and thermal dissolution of organic solvent while lowering the ohmic contact resistance between the electrode layer and the ceramic substrate.

Owner:THINKING ELECTRONICS INDAL

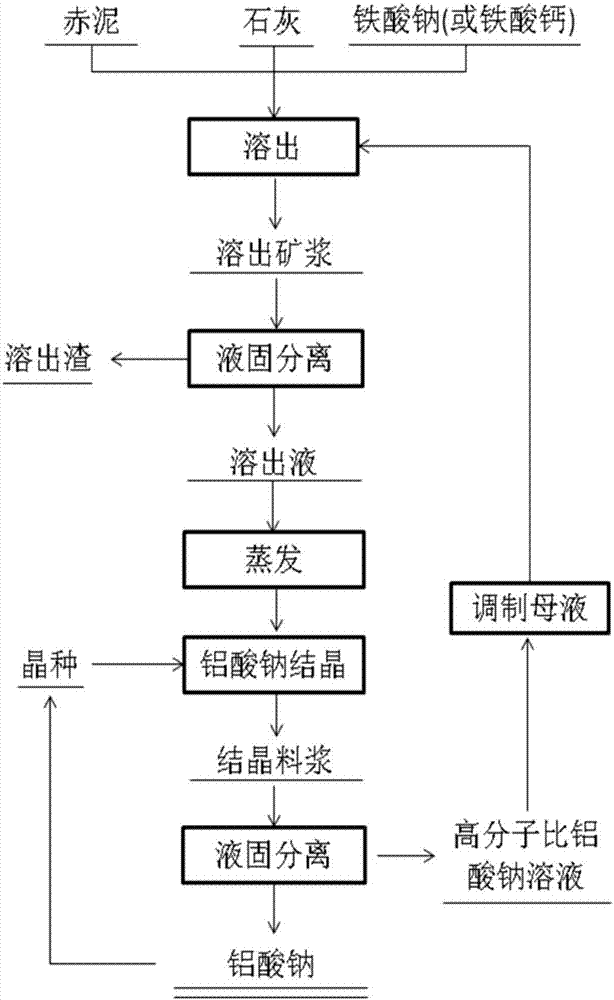

Method for producing sodium aluminate by treating Bayer-process red mud through andradite one-step alkali thermal method

InactiveCN107244683AAchieve recyclingLow alkali contentSilicon compoundsAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationAndraditeAdhesive

The invention relates to a method for producing sodium aluminate by treating Bayer-process red mud through an andradite one-step alkali thermal method. The method comprises the following steps: S1: mixing the red mud, sodium ferrite or calcium ferrite, active lime and a circulating mother solution to prepare raw material ore pulp; S2: carrying out alkali thermal dissolution reaction on the raw material ore pulp; after reacting, obtaining dissolved-out ore pulp; S3: diluting the dissolved-out ore pulp to obtain a diluting solution; carrying out liquid-solid separation on the diluting solution to obtain dissolved-out dreg and a dissolved-out solution; S4: after evaporating the dissolved-out solution, adding a crystal seed, crystallizing and carrying out solid-liquid separation to obtain a sodium aluminate solid and a high-molecular-ratio sodium aluminate solution; S5: blending the high-molecular-ratio sodium aluminate solution to prepare the circulating mother solution used in step S1. According to the method provided by the invention, aluminum oxide and sodium oxide in the red mud are recycled so that the alkali content in the dissolved-out dreg is reduced to be 0.5 percent or below and the red mud can be used as raw materials including cement, concrete, an iron-melting adhesive and the like; the method provided by the invention can be used for consuming a lot of the red mud so that the recycling of the red mud is realized and the green utilization effect of resources is realized.

Owner:NORTHEASTERN UNIV

Method of extracting beta-sitosterol from n-pentanol solvent crystallization

The invention discloses a method of extracting beta-sitosterol from n-pentanol solvent crystallization. Under certain temperature, alcohol of 95 percent with 7 times the amount of crude sterols is used to carry out thermal dissolution on the crude sterols; impurities are filtered through micropores; filter liquor is pumped into a cold separation reactor be filtered after being cooled to 10 DEG C; a filter cake and the alcohol are added into a reactor according to the mass ratio of 3 : 1, fully mixed and filtered; n-pentanol and the filter cake with the mass ratio of 3 to 5 : 1 are added into the reactor, temperature then rises to 40 DEGC plus / minus 2 DEG C, and the n-pentanol and the filter cake are fully mixed keeping the temperature unchanged; the steps are repeated to ensure that content of the beta-sitosterol in the filter cake achieves above 90 percent, and then the filter cake is dried in vacuum, crashed, sieved and packaged into a finished product. Compared with other solvent methods, the invention has high product yield and low cost. Solvent mixture is used in other solvent methods, while the invention uses single solvent n-pentanol having easy recovery and simple operation.

Owner:SHANXI TIANWEI BIOLOGICAL PRODS

Method for extracting alpha-mangostin from mangosteen fruit peel

ActiveCN101525328BSimple processSimple chromatographic processOrganic chemistryPlant ingredientsAlpha mangostinOrganic solvent

The invention relates to a method for extracting alpha-mangostin from a mangosteen fruit peel. The method comprises the following realization steps: (I) extracting the mangosteen fruit peel; (II) concentrating an extracting solution; mixing the extracting solution of every time and concentrating under reduced pressure to obtain a concentrated solution; (III) leaching the solution; (IV) carrying out silica gel column chromatography; (V) carrying out coarse crystallization; and (VI) carrying out recrystallization: adding a primary crystal into an organic solvent with the volume of 1 to 5 times to carry out thermal dissolution; placing the solution after finishing the thermal dissolution, reducing the temperature to a room temperature, carrying out recrystallization, and controlling the crystallization time to between 10 and 20 hours; and filtering and centrifugating a recrystallization liquid, drying the liquid in vacuum to obtain the 98 percent alpha-mangostin. The method has the advantages of simple process and short operation time.

Owner:SHAANXI JIAHE PHYTOCHEM

Foam drainage agent with resistance to high-content gas condensate and resistance to high mineralization and preparation method of foam drainage agent

ActiveCN110819327AGood foam stabilityImprove liquid carrying capacityDrilling compositionActive agentFluorocarbon

The invention discloses a foam drainage agent with resistance to high-content gas condensate and resistance to high mineralization and a preparation method of the foam drainage agent, and belongs to the technical field of materials for gas well mining in oil-gas fields. The foam drainage agent includes the following raw material components: in percent by mass, 20-35% of a zwitterionic surfactant,1-5% of a fluorocarbon surfactant, 1-5% of an anionic surfactant, 1-5% of cocinic acid monoethanolamide and the balance water. The preparation method comprises the steps: performing weighing, stirring, mixing and heating, and performing dissolution so as to obtain the foam drainage agent finished product. Through arrangement of the specific raw materials and the ratios, good resistance to high-content gas condensate and resistance to high mineralization are achieved, and it is ensured that the foam drainage agent can have excellent capacity of foam generation, foam stabilization and liquid carrying under the conditions of high-content gas condensate and high mineralization; and meanwhile, the foam drainage agent has a wide range of raw material sources, low price, a simple production technology, low requirements of equipment and environments and large-scale production.

Owner:CHINA PETROLEUM & CHEM CORP +1

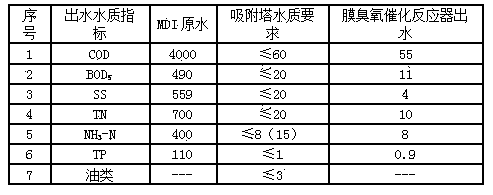

Regeneration method and device used for deactivation catalyst layer of membrane ozone catalytic reactor

InactiveCN103752354AEfficient regenerationExtended service lifeSemi-permeable membranesCatalyst regeneration/reactivationPtru catalystPhysical chemistry

The invention relates to a regeneration method and a device used for a membrane module deactivation catalyst layer in a membrane ozone catalytic reactor. The regeneration method comprises the steps of firstly, introducing air, heating and roasting to remove residual organic pollutants in a membrane module; then carrying out hot dissolution for 5-20 minutes by adopting mixed liquor of nitric acid and hydrochloric acid, and removing metal oxide attached to a membrane catalytic layer; after atomizing 5%-30% modified Mn-Si-Ti catalyst suspension, sucking under negative pressure to enable the modified Mn-Si-Ti catalyst suspension to enter a membrane supporting body, and loading the inner surfaces of holes of the suspension; and finally removing a modified Mn-Si-Ti catalyst adsorbed on the surface of a membrane separation layer by spraying and washing, and after immersing the outer surface of the membrane module into 15%-25% modified Ni-Co catalyst suspension for 5-10 minutes, drying the obtained sample at 80-150 DEG C to obtain the regenerative catalytic membrane module. By utilizing the regeneration method and the device for the deactivation catalyst provided by the invention, the deactivation catalyst can be effectively regenerated, the service life is prolonged, and the operating cost is reduced.

Owner:TIANJIN ACADEMY OF ENVIRONMENTAL SCI

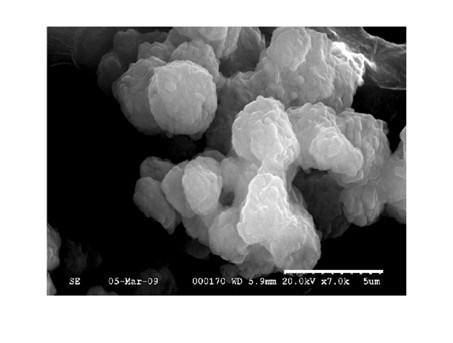

Nickel-based high dispersion emulsion catalyst, preparation method and application thereof

PendingCN109289932AAvoid the problem of high energy consumption for water removalImprove operational efficiencyOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbon oil crackingNickel saltPolymer science

The invention discloses a nickel-based high dispersion emulsion catalyst, a preparation method and application thereof. The preparation method comprises the steps of: (1) heating and dissolving a hydrophilic surfactant and a nickel salt in a 0.3-3 times mass of deionized water; (2) putting an oleophylic surfactant and wax oil into a condenser, performing heating to 50-80DEG C, and conducting stirring under a rotating speed of 1000-4000r / min; and (3) when the oil phase reaches a required temperature, adding the water phase slowly into the container, performing shearing dispersion under a constant temperature condition for 5~15min, and then conducting cooling to room temperature, thus obtaining the nickel-based high dispersion emulsion catalyst. The deionized water introduced into the catalyst prepared by the invention has no need for removal, the problem of large water removal energy consumption in a slurry bed hydrogenation process of the previous water-soluble catalysts can be avoided, the operation efficiency is improved, and the catalyst also has the advantages of good dispersion effect in raw materials, high hydrogenation activity, good coke suppression effect and high coal conversion rate.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Gelatin/polyvinyl alcohol composite sponge and preparation method thereof

InactiveCN101974190AImprove mechanical propertiesStrengthening can increase the pore size of the composite spongeAbsorbent padsProsthesisPolymer scienceBiocompatibility Testing

Owner:樊李红

Method for recovering ruthenium from benzene hydrogenation prepared cyclohexene catalyst

InactiveCN108396145ASimple preparation processEasy to operateProcess efficiency improvementHypochloriteDistillation

The invention discloses a method for recovering ruthenium from a benzene hydrogenation prepared cyclohexene catalyst. The method comprises the following steps that alkali fusion treatment is carried out on the catalyst by adopting a conventional method, and thermal dissolution by adopting water is carried out; then an oxidizing agent is added to carry out distillation reaction, and the generated ruthenium tetroxide gas is absorbed by an acidic solution; and the absorption liquid is subjected to concentrated and drying to obtain a ruthenium trichloride product. According to the method, the distillation reaction liquid is returned and used for the alkali fusion heat treatment step without wastewater discharge; and excessive chlorine generated in the distillation reaction is recovered by adopting a dilute alkali liquid, and the generated hypochlorite is returned and used for distillation reaction, so that the utilization rate of raw materials is improved.

Owner:LUXI CATALYST

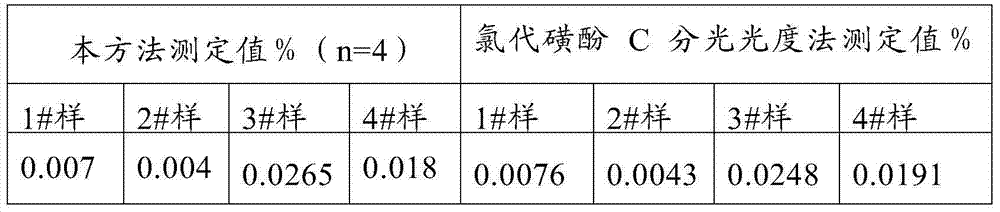

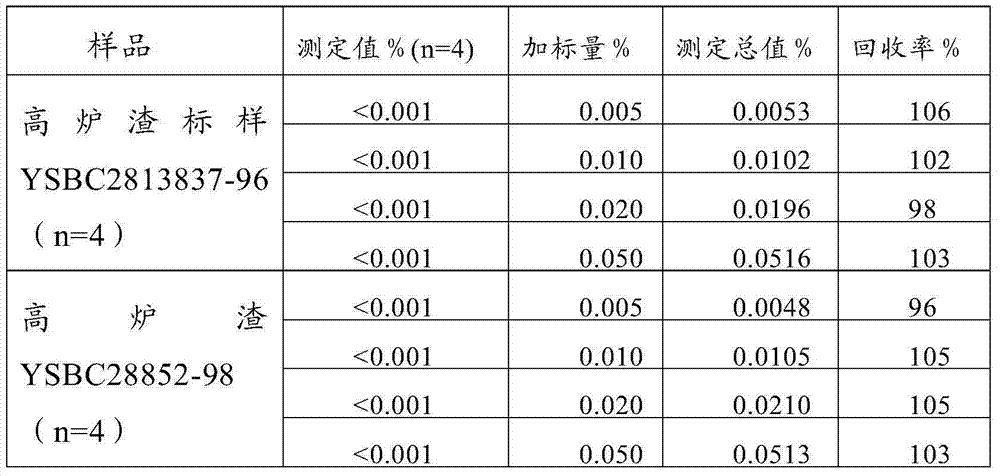

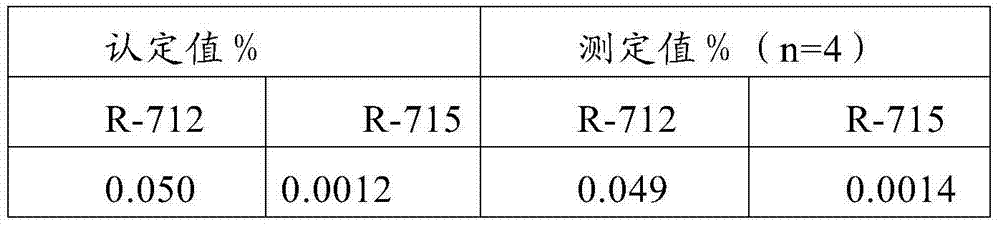

Method of measuring micro-amount niobium in steelmaking blast furnace slag

InactiveCN104764794AHigh sensitivityImprove applicabilityMaterial analysis by electric/magnetic meansSteelmakingNiobium

The invention discloses a method of measuring micro-amount niobium in steelmaking blast furnace slag. The method includes steps: (1) preparing standard work solutions of niobium in different concentrations; (2) introducing an inductively coupled plasma source mass spectrometer to measure the signal intensity of to-be-test ions and draying calibration curves of the standard work solutions of niobium; (3) weighing a blast furnace slag sample and successively adding nitric acid, hydrochloric acid and hydrofluoric acid to dissolve the sample; (4) preparing a blank sample added with the nitric acid, the hydrochloric acid and the hydrofluoric acid without addition of the blast furnace slag sample, adding perchloric acid to generate smoke for expelling residual hydrofluoric acid, and cooling the blank sample to room temperature; (5) adding a water solution of tartaric acid and hydrochloric acid to an electric heating plate for heating and dissolving salts, cooling the solution to room temperature and moving the solution to a volumetric flask; (6) adding a cesium standard solution and performing a constant volume operation with high-purity water; (7) introducing the blast furnace slag sample solution and the blank sample solution into the inductively coupled plasma source mass spectrometer and measuring the signal intensity of the to-be-test ions; and (8) calculating the content of niobium in the sample solution according to the 93Nb standard work solution calibration curve being known in concentration.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

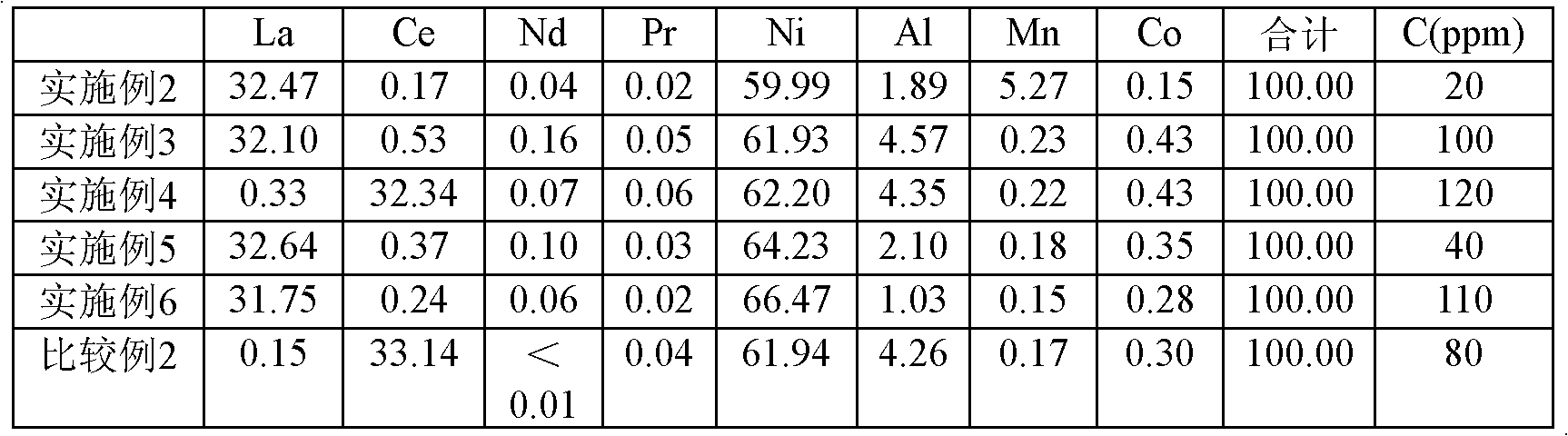

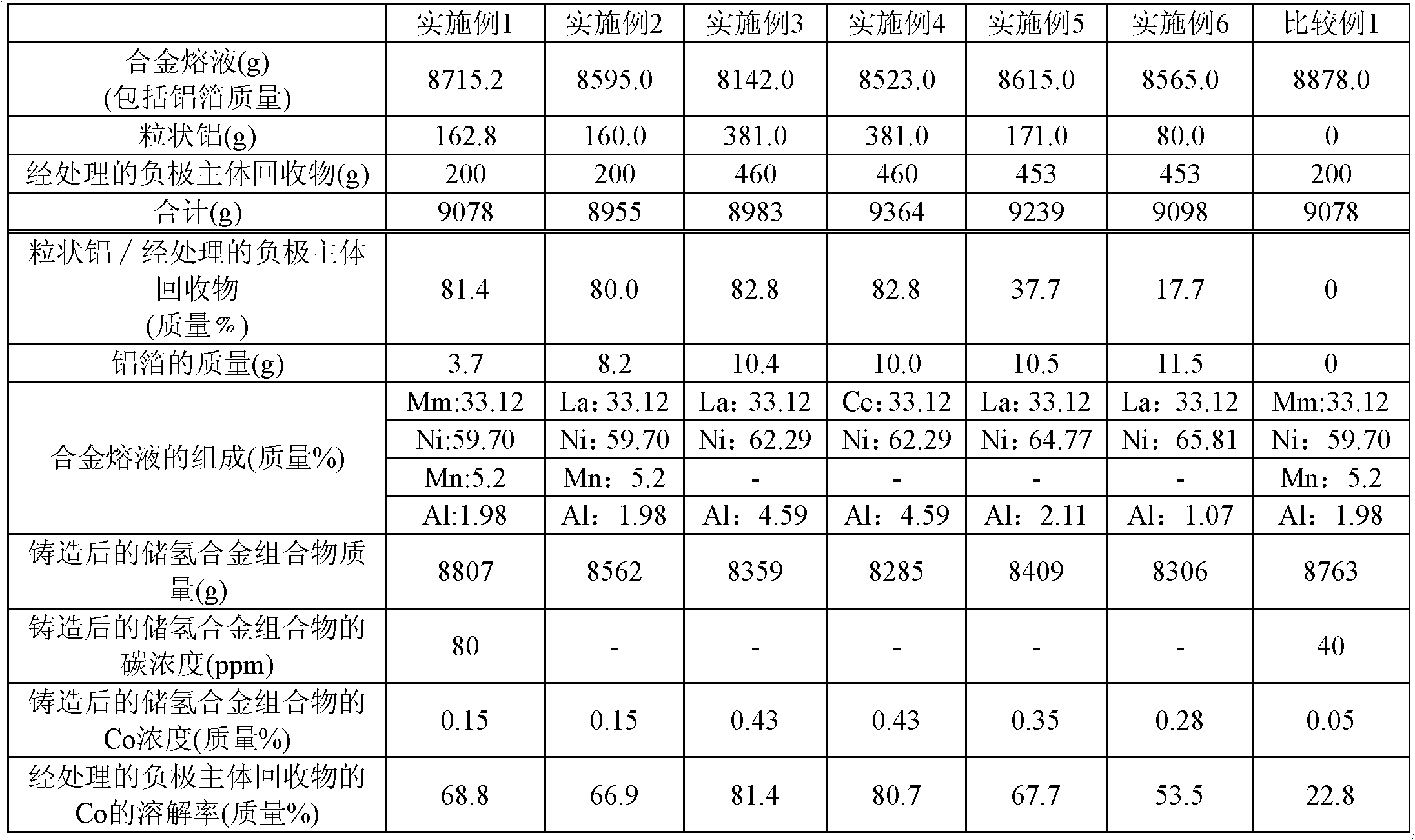

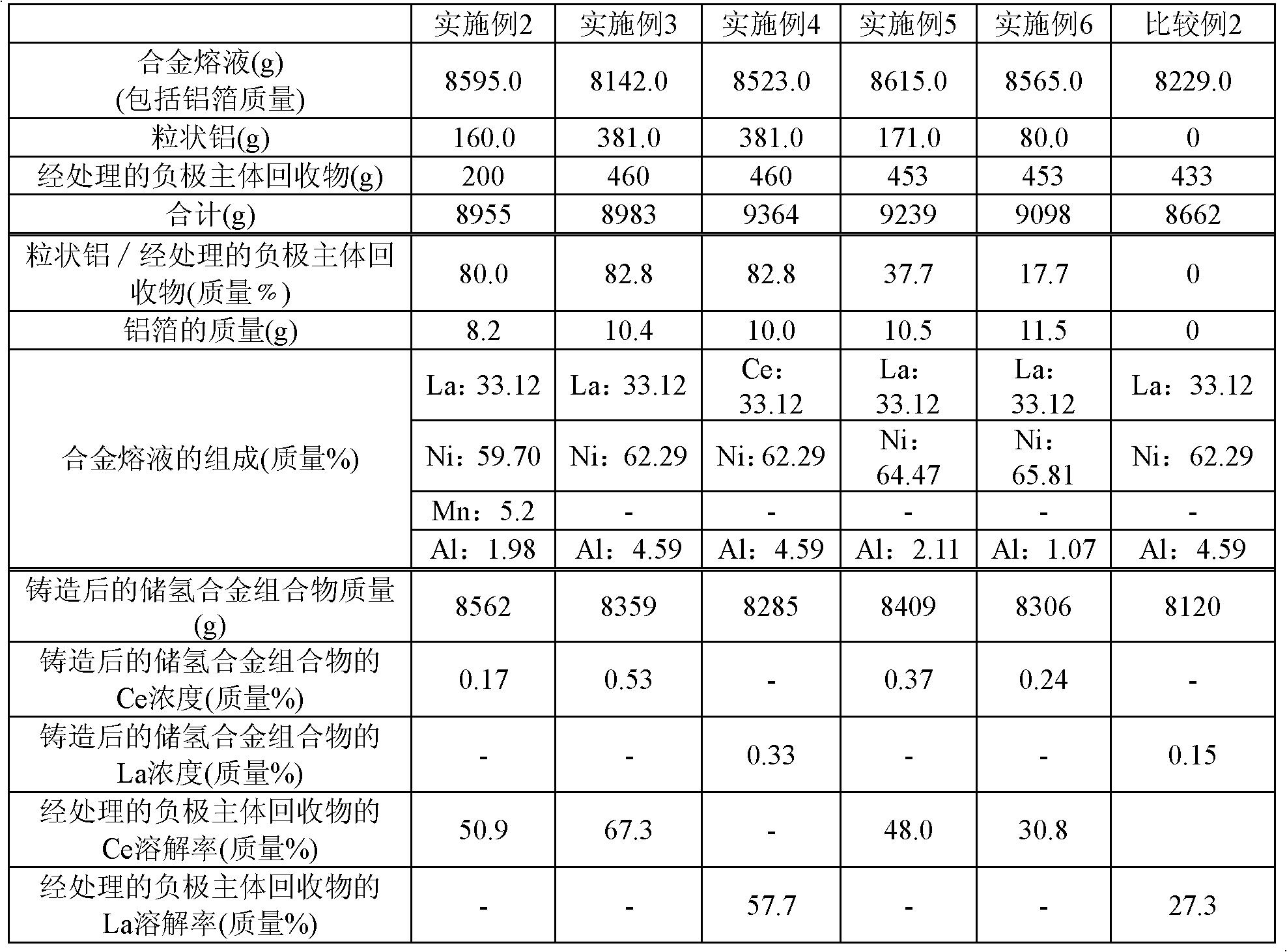

Process for production of hydrogen-storing alloy composition

ActiveCN102576919AImprove dissolution efficiencyHydrogenAlkaline accumulator electrodesNickel–hydrogen batteryThermal dissolution

Disclosed is a method which can increase the dissolution efficiency in the thermal dissolution of a negative electrode active material or a composition mainly composed of the negative electrode active material that has been collected from a waste nickel-hydrogen battery, by introducing the negative electrode active material or the composition into a molten product of an alloy of an element constituting the negative electrode active material. The dissolution efficiency of the negative electrode active material or the composition mainly composed of the negative electrode active material can be increased dramatically by adding aluminum to the molten product of the alloy simultaneously with or subsequent to the addition of a negative electrode main collection product.

Owner:MITSUI MINING & SMELTING CO LTD

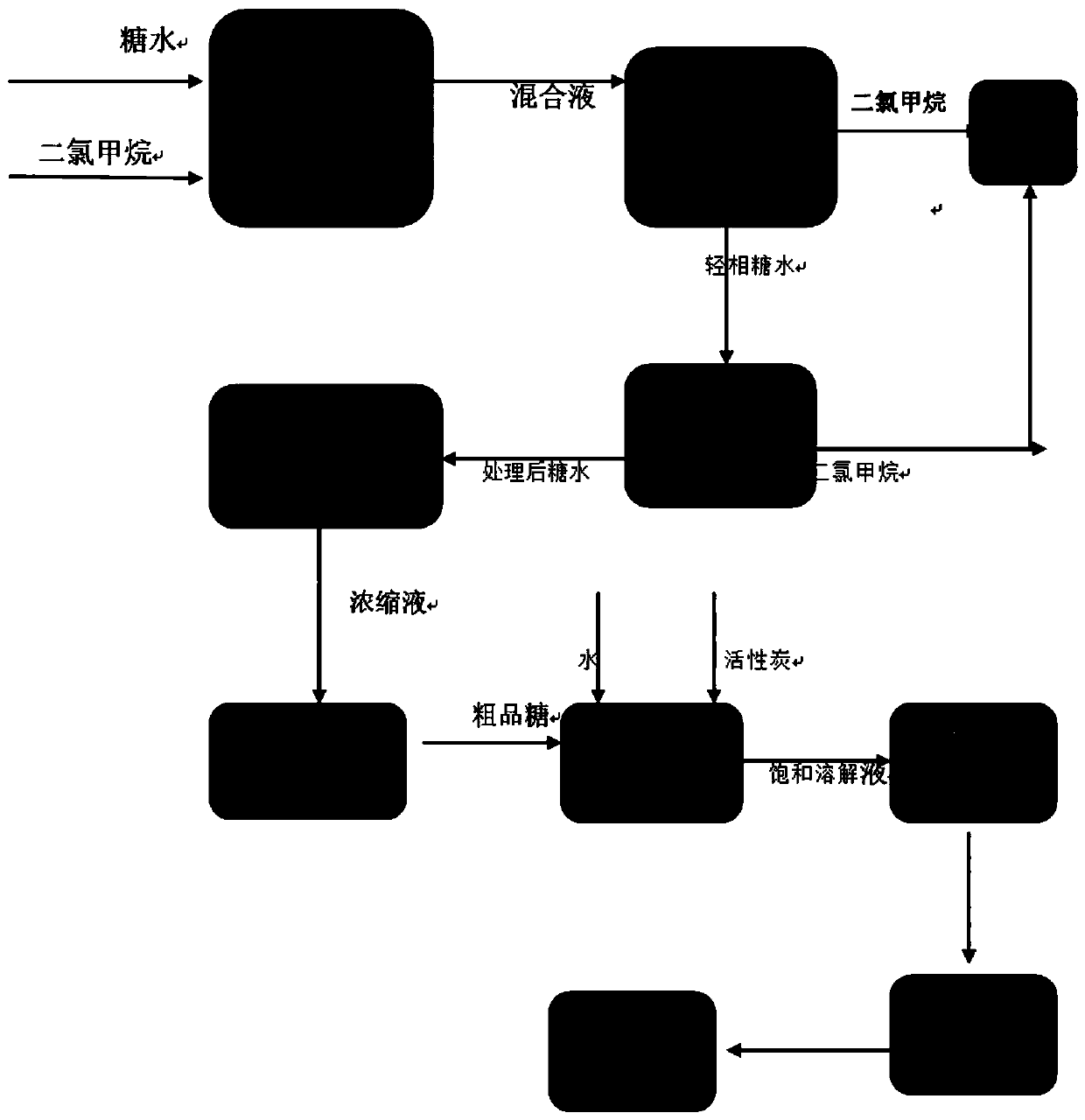

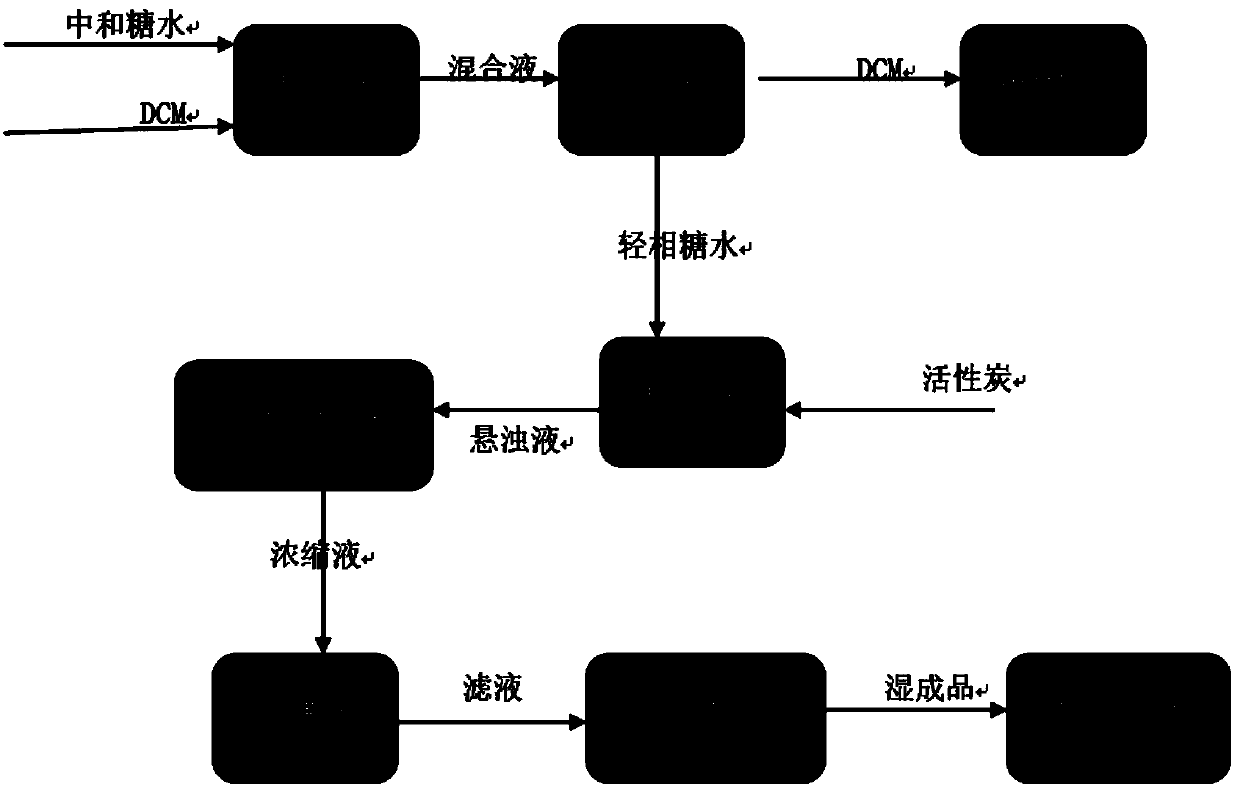

Acesulfame optimized crystallization process

InactiveCN110818654APromote crystallizationReduce duplicationOrganic chemistryActivated carbonProcess engineering

The invention relates to an acesulfame optimized crystallization production process; the acesulfame optimized crystallization method comprises the steps: directly adding a certain amount of activatedcarbon into reversely extracted sweet water, mixing to form a turbid liquid sweet water state, directly carrying out MVR concentration with mixed sweet water, carrying out high-temperature filtrationon the concentrated solution, freezing, crystallizing and drying to obtain a finished product. The production process has the advantages that a novel optimized crystallization process is adopted, so that the production operation is simplified, the operation flow is shortened, the labor intensity of workers is reduced, and the freezing load is reduced; compared with an original traditional production process, the production process has the advantages of optimizing new crystal crystallization, removal, heat dissolution, decolorizing, freezing and other operations, simplifying the operation, shortening the flow, reducing the labor intensity, saving a large amount of electricity and steam, and improving the product quality.

Owner:ANHUI JINGHE IND

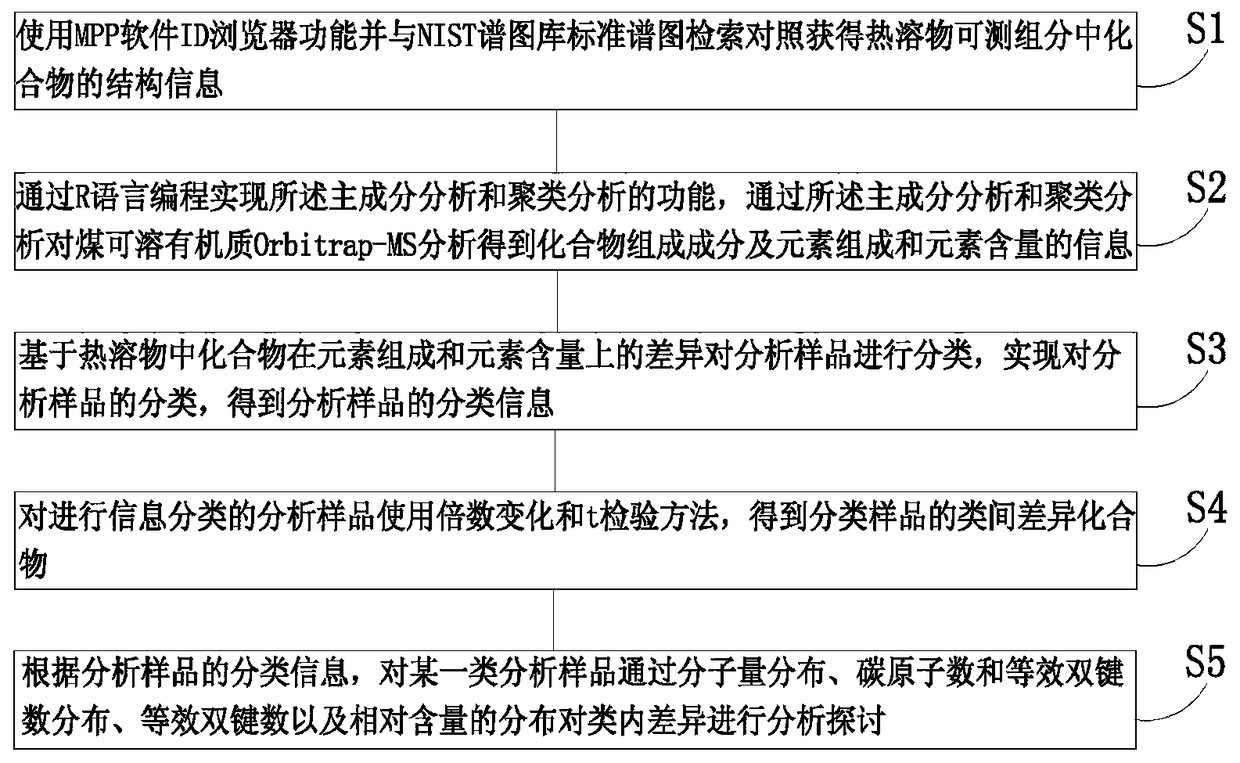

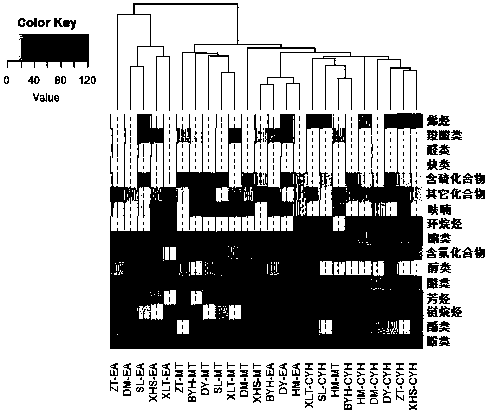

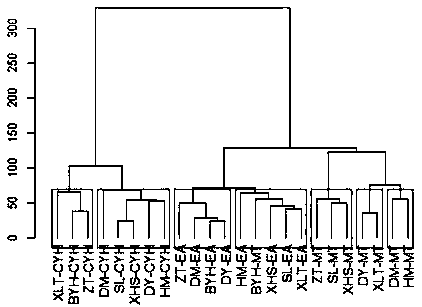

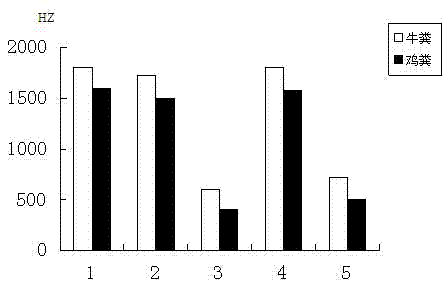

Stoichiometric analysis method for coal soluble organic matter

InactiveCN109100411AQuick analysisEasy to analyzeMaterial analysis by electric/magnetic meansMetrologyPrincipal component analysis

The invention discloses a stoichiometric analysis method for coal soluble organic matter. The method is used for performing effective and comprehensive analysis on GC / MS data, TOF-MS data and Orbitrap-MS data of the coal soluble organic matter. Firstly, an ID browser function of Mass Profiler Professional (MPP) software is used, and retrieval and comparison with standard spectrograms of a NationalInstitute of Standards and Technology (NIST) spectral library is performed to acquire structural information of compounds in measurable components of thermal dissolution matter, and subsequently principal component analysis and hierarchical cluster analysis of mass spectrometric data are realized by using R language programming in turn to study information of compound group composition and element composition, wherein the information of compound group composition and element composition is acquired by Orbitrap MS analysis of the coal soluble organic matter; sample classification information is acquired based on differences in the element composition and content of the compounds in the thermal dissolution matter; based on classification, compounds which are different among classes are acquired by using changes in multiples and t inspection; and intra-class differences are studied through molecular weight distribution, the number of carbon atoms and distribution of the number of equivalent double bonds, and the number of equivalent double bonds and distribution of relative content. The method can achieve comprehensive and efficient characterization and statistical analysis of the complex coal molecular structure at the molecular level.

Owner:CHINA UNIV OF MINING & TECH

Technique for preparing sodium dimethyl 5-sulfoisophthalate

ActiveCN103992250ASupporting coordinationClosely connectedSulfonic acids salts preparationSocial benefitsActivated carbon

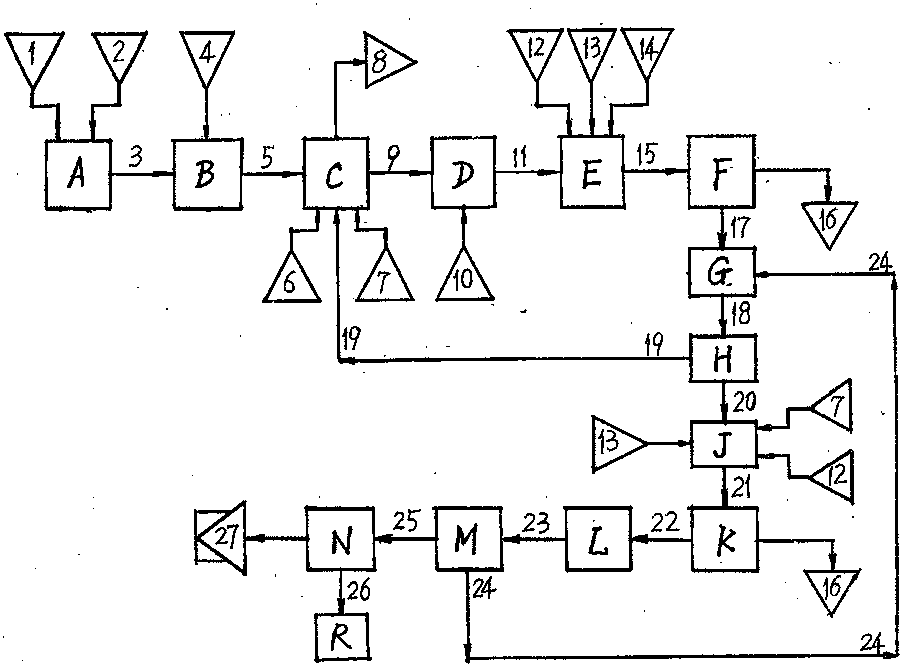

The invention relates to a technique for preparing sodium dimethyl 5-sulfoisophthalate. A sulfonation kettle (a), an esterification kettle (B), an extraction kettle (C), a back washing kettle (D), a decolorization / impurity suction kettle (E), a filter (F), an intermediate crystallizing kettle (G), a centrifugal dehydrator (H), a thermal dissolution kettle (J), a fine filter (K), a terminal crystallizing kettle (L), a secondary dehydrator (M) and a drying machine (N) are used as technological equipment; and m-phthalic acid (1) and fuming sulfuric acid (2) are used as main raw materials. In the technical process of all steps, methanol (4), deionized water (7), a sodium carbonate solution (10), activated carbon (12), oxydol (13), compressed air (14), deionized water (7) and activated carbon (12) are sequentially added into related equipment according to the technical requirements to prepare the sodium dimethyl 5-sulfoisophthalate finished product (27) at specific temperature and time under technological conditions of the technical process of all the steps. The finished product has the advantages of high purity, good quality, low cost and high yield, relieves the environmental pollution, and has favorable economic and social benefits.

Owner:SHANDONG JINSHENG NEW MATERIAL TECH

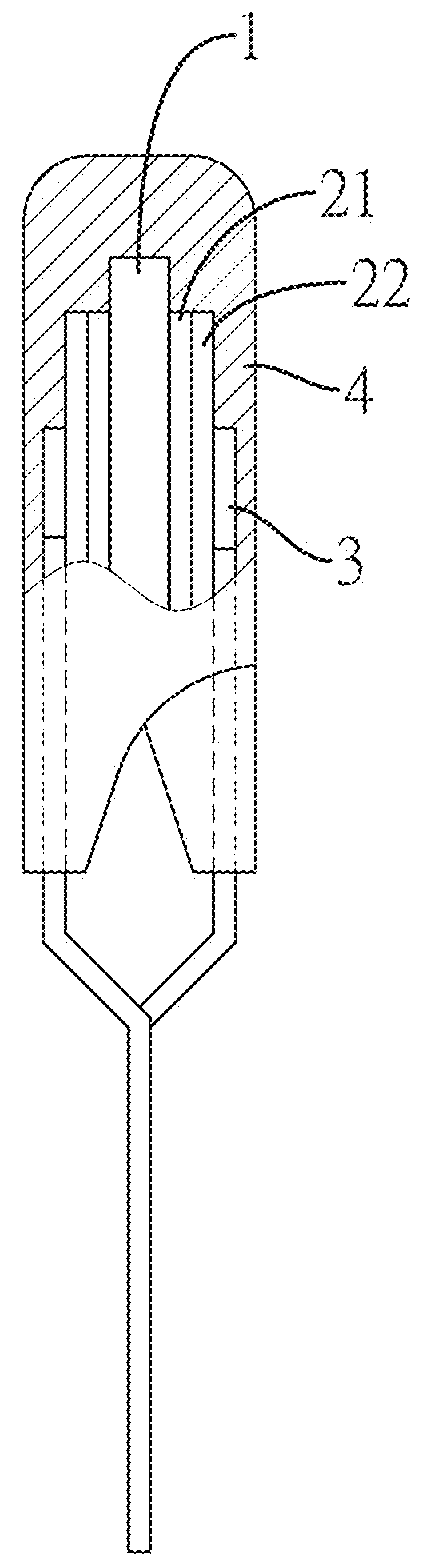

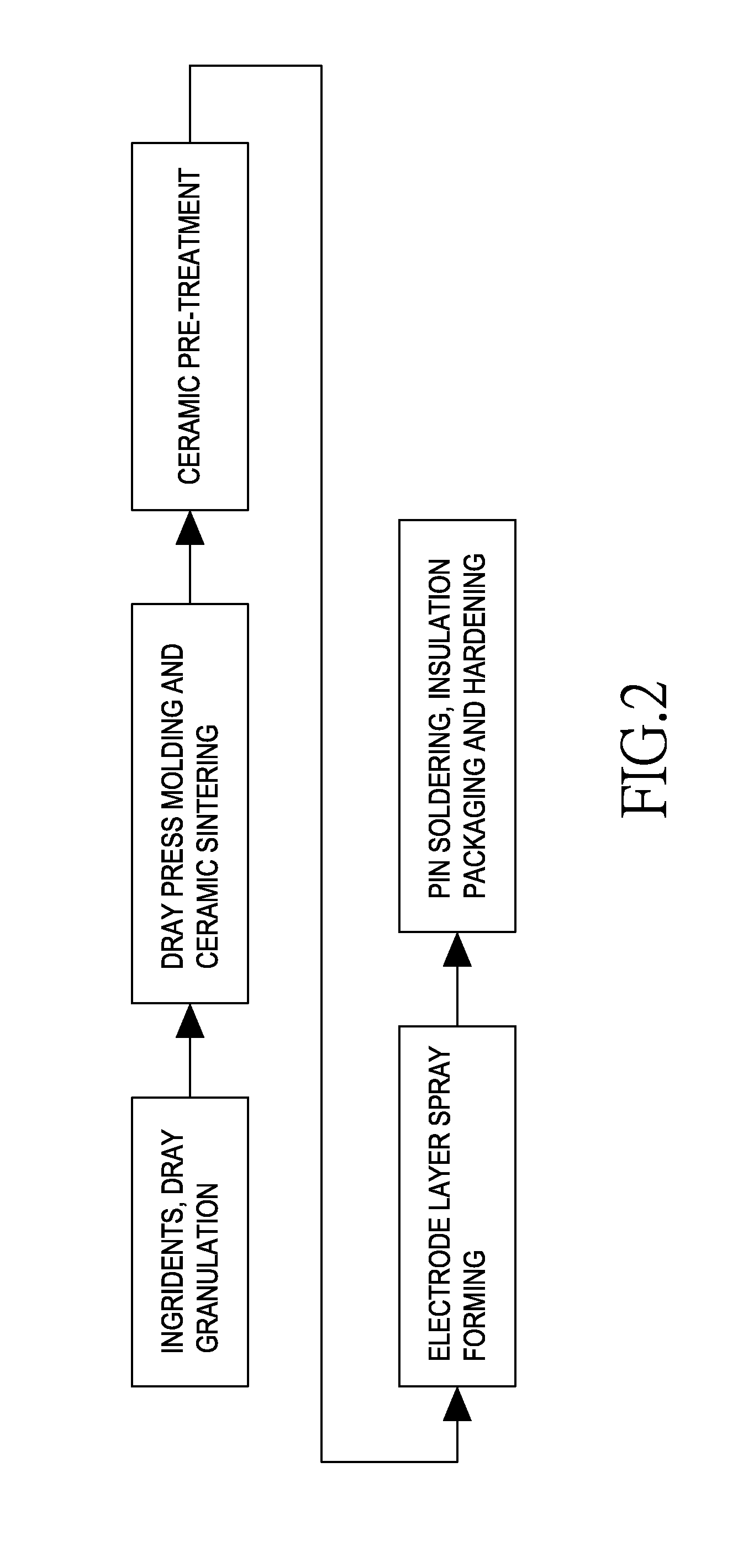

Electrode component and method for fabricating the same

ActiveUS20160086699A1Low production costReduce riskEnvelope/housing resistor manufactureCurrent responsive resistorsMetallic materialsEvaporation

An electrode component includes a ceramic substrate, two electrode layers formed on two opposite surfaces of the ceramic substrate, two pins respectively connected to the two electrode layers, and an insulating layer enclosing the ceramic substrate, the electrode layers and a portion of each pin. Each electrode layer is formed of two or more base metal materials or alloys thereof, and the concentrations of the base metal materials progressively vary across the electrode layer. Accordingly, the production cost is lowered, environmental pollution caused by evaporation and thermal dissolution of organic solvent can be prevented, risk of separable electrode interface at high-voltage discharge is mitigated, and the fabrication process of the electrode layer is shortened while maintaining bonding strength between the electrode layers and the ceramic substrate and solderability between the electrode layers and the pins.

Owner:THINKING ELECTRONICS INDAL

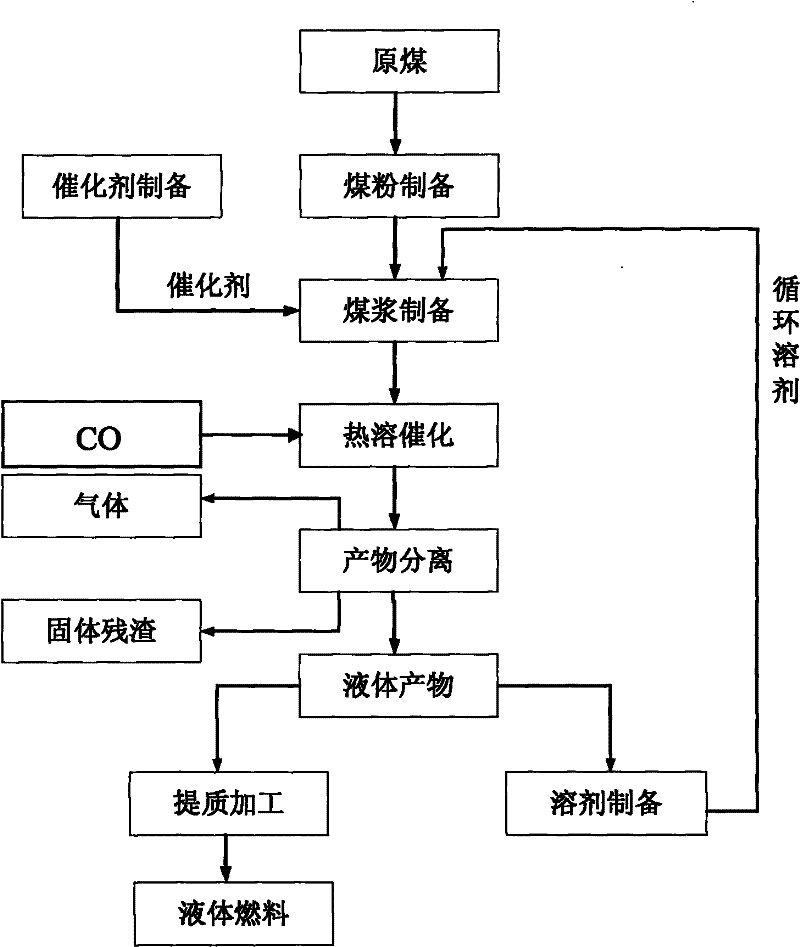

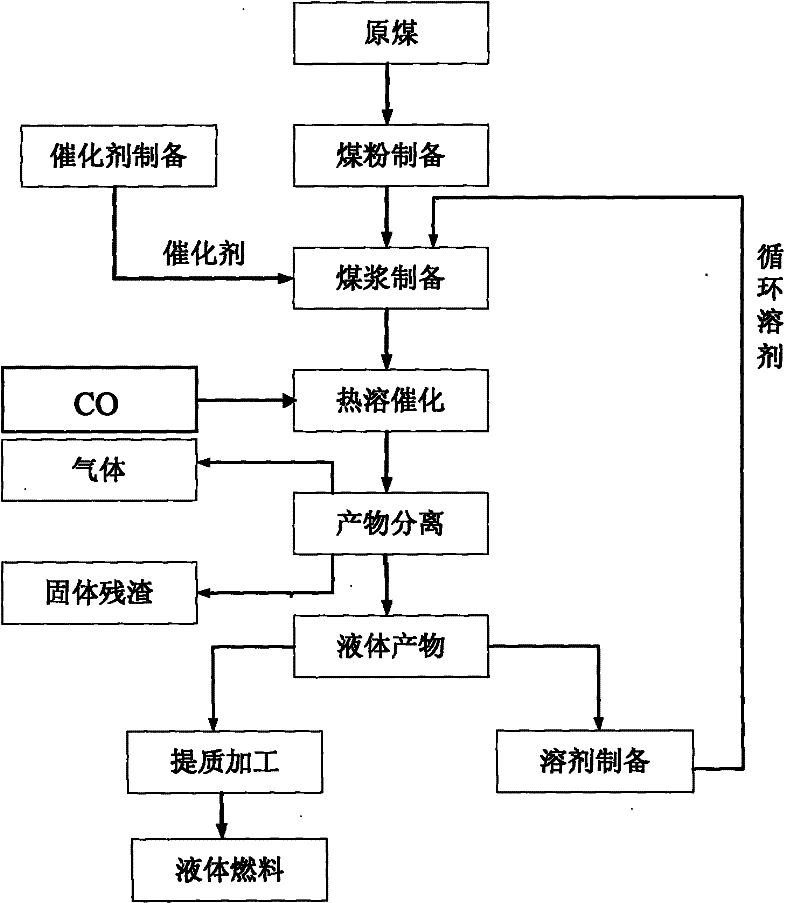

Lignite solubilizing and catalytic liquefaction method in non-hydrogen atmosphere

InactiveCN102191075AMild reaction conditionsSimple operation processLiquid hydrocarbon mixture productionChemical reactionHydrogen atmosphere

The invention belongs to the technical field of coal chemical processing and discloses a lignite solubilizing and catalytic liquefaction method in non-hydrogen atmosphere. The method comprises the following steps: preparing coal powder, preparing coal slurry, performing thermal dissolution and catalysis, and separating the thermal dissolution liquefied product, wherein in the coal powder preparation step, the water content of coal powder is no less than 8w%; and in the thermal dissolution and catalysis step, CO gas is introduced. In the method, CO is used as medium, thus the solvent can be optimized and the quality of liquefaction oil can be increased; H2O required by the reaction comes from the lignite with rich water, thus the limit on the water of lignite can be lowered, the heating drying of lignite can be eliminated and the energy consumption can be reduced; the water production rate in the liquefaction of lignite can be reduced, thus water pollutions can be reduced; the chemical reaction is utilized to generate active hydrogen which is easy to react with coal, thus the yield of liquefaction oil can be increased and coal is easy to dissolve; and CO is used to remove partial oxygen and sulfur in the coal structure and the consumption of hydrogen can be reduced. The operational process is simple, safe and stable, the localization degree of equipment is high, the investment is low and the cost is low.

Owner:ZHAOQING SHUNXIN COAL CHEM TECH

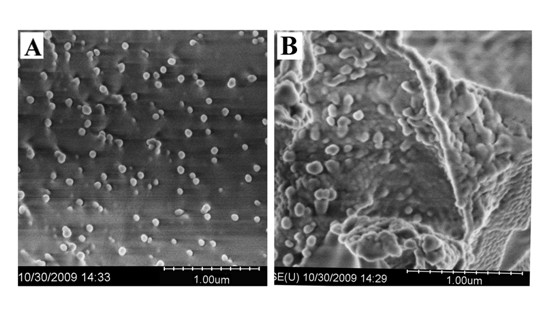

Solid-phase nano micelle and preparation method thereof

InactiveCN102198086AImprove cohesionImprove stabilityPharmaceutical delivery mechanismMacromolecular non-active ingredientsSolubilityWater insoluble

The invention discloses a 'solid-phase nano micelle' as well as a preparation method and application thereof as a carrier for water-insoluble medicines, wherein the solid-phase nano micelle comprises a small molecular surfactant which has the molecular weight below 10000Da, is solid and small in aqueous solubility at body temperature and has the Krafft point not lower than the body temperature. The solid-phase nano micelle is prepared by thermal dissolution-spray drying. At the temperature higher than the Krafft point, the surfactant has high water solubility, an encapsulated drug exists in aform of micelle, and at the body temperature or room temperature, the water solubility is reduced, the micelle exists in a form of solid-phase nano particles. The preparation can significantly improve the solubility of insoluble medicines, and offers proper releasing features to the insoluble medicines in order to enhance the bioavailability of the insoluble medicines.

Owner:SHANGHAI JIAOTONG UNIV SCHOOL OF MEDICINE

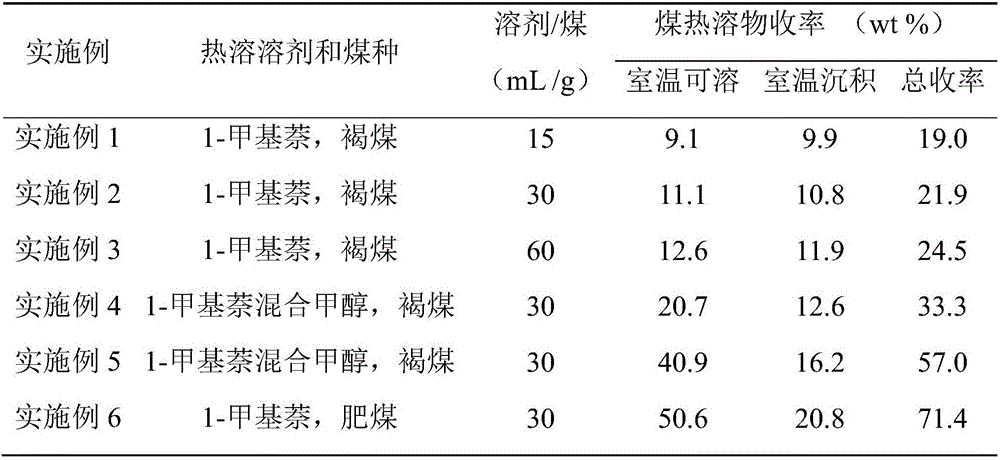

Ultrasound-assisted classification preparation method of lignite extracts and residues

The invention discloses an ultrasound-assisted classification preparation method of lignite extracts and residues, and belongs to the field of coal chemical industry. The preparation method particularly comprises the steps that lignite is mixed with an organic solvent, ultrasound-assisted thermal dissolution treatment is conducted under an inert gas atmosphere at 360 DEG C, a lignite and organic solvent mixture subjected to thermal dissolution treatment is centrifuged at room temperature and washed with a thermal dissolution solvent, the organic solvent in a centrifugal washing solution is separated and recycled, and room-temperature soluble lignite extracts and residues are obtained; solid residues are subjected to centrifugal washing again with an N,N-dimethylformamide solvent at room temperature, and room-temperature deposited lignite extracts and residues are obtained. According to the ultrasound-assisted classification preparation method of the lignite extracts and residues, the yield of the lignite extracts and residues is high, classification preparation for the lignite extracts and residues is achieved, in the preparation process, no specific thermal filtration separation processing equipment is needed, the dose of the thermal dissolution solvent is small, the process is simple, the cost is low, the method is suitable for industrial production, and classification extraction of the lignite extracts and residues is beneficial for subsequent processing and utilization of the lignite extracts and residues.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

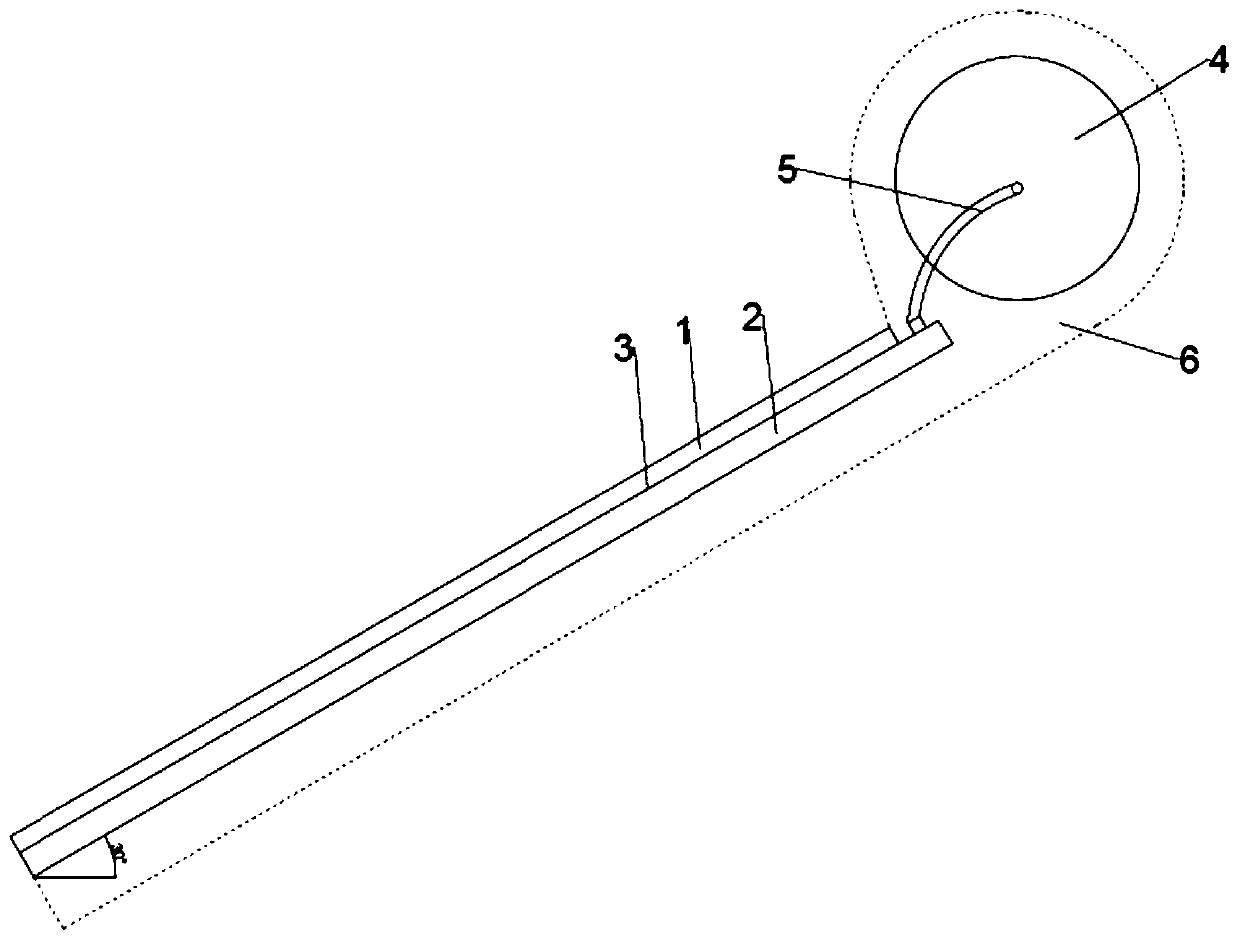

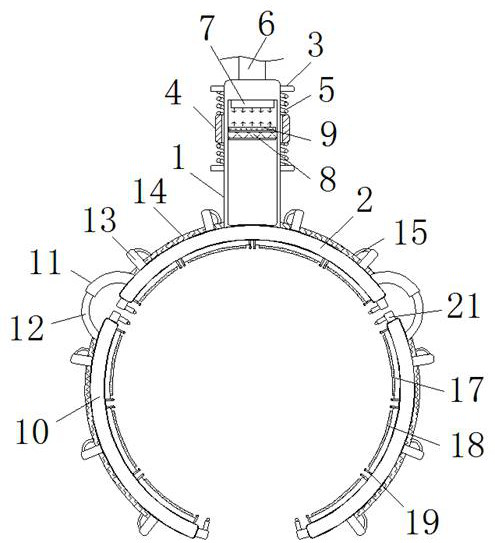

Solar photovoltaic and photo-thermal composite heat collection device

ActiveCN110108044ANovel structureFavorable for large-scale commercial applicationsSolar heating energySolar heat storageEvaporationEngineering

The application discloses a solar photovoltaic and photo-thermal composite heat collection device, wherein a heat collection panel is arranged under a photovoltaic panel; the heat collection panel andthe photovoltaic panel are adhered by a thermal dissolution method; the heat collection panel is an evaporation zone of a separated panel heat collection pipe and is constituted through combination of two aluminum plates; a semi-circular micro-channel gravity assisted heat pipe structure is processed by a gas expansion method; a heat storage tank is installed above the heat collection panel, is equivalent to a condensation section and has a horizontal three-layer casing structure, and a small cylinder is formed in the center for flowing of working medium steam; a cylinder outside a steam cylinder is filled with water as a heat storage material, and the heat storage material is used for heat exchange of the steam in the steam cylinder; and the outmost cylinder of the casing is filled withparaffin as a supplementary heat storage materials, and the outer surface of the steam cylinder is closely winded with a copper spiral pipe used as a cold water pipe. In this way, efficiency of heat collection and heat storage is high; an extra power pump is not needed during system running; the heat exchange working medium can flow by a tap water pipe system or a high water tank, so energy consumption is reduced and heat exchange effects can be improved significantly; and commercial application prospect is broad.

Owner:SUNSHORE SOLAR ENERGY IND +1

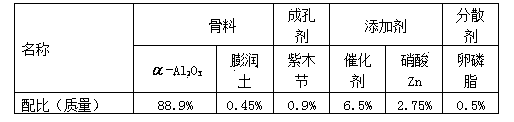

Preparation method of thorium dioxide foil

InactiveCN106935297AImprove surface qualityImprove flatnessNuclear energy generationReactors manufacturePolyvinyl alcoholMicrometer

The invention belongs to the technical field of reactor simulated fuel pellets and particularly relates to a preparation method of thorium dioxide foil. The method includes: compacting thorium dioxide powder, wherein pressure is 80-90MPa, and pressure maintaining time is 20-25 seconds; adding 0.3% binder polyvinyl alcohol into deionized water to perform heat dissolution, boiling to allow polyvinyl alcohol to be completely dissolved in the deionized water, mixing the solution with granulated thorium dioxide, and crushing and sieving mixed powder, wherein final particle size is controlled to be 150-300 micrometers; using die pressing and cold pressing molding to form the thorium dioxide foil, wherein the inner diameter of the female die of a forming die is a cylindrical structure, forming pressure is 9-11T, pressure maintaining time is 15-20 seconds, the distance between the formed foil and the upper end face of the female die is 20-25mm, and the sintering of the thorium dioxide foil includes a low-temperature heat preservation stage, a medium-temperature heat preservation stage and a high-temperature heat preservation stage. The preparation method has the advantages that difficulties that a green body is difficult in demoulding, the green body breaks and green body edges fall off are solved, and the thorium dioxide foil green body good in surface quality is obtained.

Owner:CHINA NUCLEAR BAOTOU GUANGHUA CHEM IND

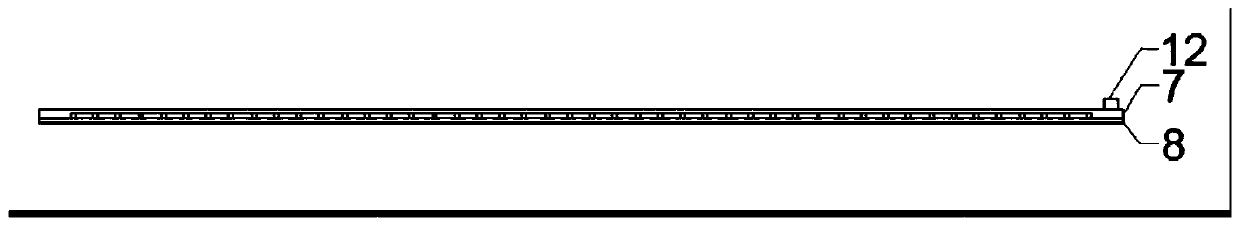

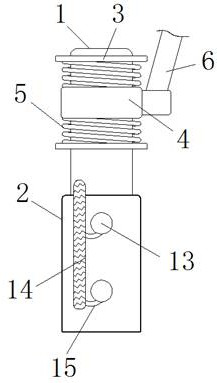

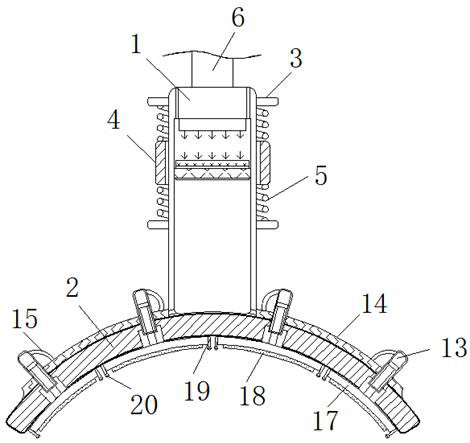

Thermal dissolution dredging processing mechanism for chemical oil stain waste discharge pipeline

The invention discloses a thermal dissolution dredging processing mechanism for a chemical oil stain waste discharge pipeline. The thermal dissolution dredging processing mechanism comprises a hollowpipe, an electromagnet, a heating element, an outer cylinder and a motor, wherein the lower end of the hollow pipe is fixedly connected to the center of the top of a main positioning clamp, spring bodies are fixed between the upper end and the lower end of a damping ring and limiting rings, a pushing handle is fixedly connected to the outer wall of the damping ring, auxiliary positioning clamps are arranged at the edge ends of the main positioning clamp, single-way pipes and threaded hoses are fixed to the outer wall of the main positioning clamp and the outer walls of the auxiliary positioning clamps correspondingly, and the threaded hoses communicate with the interior of the hollow pipe, the interior of first connecting pieces and the interior of second connecting pieces. The thermal dissolution dredging processing mechanism for the chemical oil stain waste discharge pipeline is directly suitable for the exterior of a pipeline, can well move the pipelines with different thicknesses in a wrapping mode, achieves the rapid dissolution dredging effect of accumulated blocked oil stains in the pipeline, and improves the use dredging efficiency and convenience of the pipeline.

Owner:东营威联化学有限公司

Method for preparing rubber powder from waste and old tires through thermal dissolution and depolymerization

ActiveCN105542817AHigh value-added utilizationThermosolution Polymerization High EfficiencyPigmenting treatmentProductsDepolymerizationEvaporation

The invention discloses a method for preparing rubber powder from waste and old tires through thermal dissolution and depolymerization, belonging to the technical field of comprehensive utilization of waste and old tires. The method comprises the following steps: selecting an ionic liquid and a hydrogen supplying solvent capable of highly efficiently depolymerizing the structures of the waste and old tires, adding the waste and old tires, the ionic liquid and the hydrogen supplying solvent into a reaction vessel and carrying out thermal dissolution and depolymerization under mild conditions; eluting out obtained reaction products with tetrahydrofuran and then carrying out filtering so as to obtain a mixed solution of a tetrahydrofuran soluble substance, tetrahydrofuran, the ionic liquid and tertralin and residues, wherein the mixed solution may be subjected to rotary evaporation to recover the solvent so as to obtain a mixture; and adding water into the mixture and carrying out precipitation and filtering so as to obtain rubber powder and a mixed solution of the ionic liquid and tertralin, wherein the mixed solution of the ionic liquid and tertralin can be repeatedly used. The method is simple and clean, carries out thermal dissolution and depolymerization on the waste and old tires, catalyzes thermal dissolution and depolymerization of the tires into the rubber powder and carbon black, and realizes high-added-value utilization of the waste and old tires.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

A type zeolite and preparation method thereof

InactiveCN101811703BImprove performanceHigh yieldSolid waste disposalAluminosilicate zeolite type-ASodium aluminateProcess engineering

The invention provides an A type zeolite and a preparation method thereof. The invention solves the problems of high manufacture cost and complex process step of the A type zeolite in the prior art and the technical problems of reduced performance stability of the generated zeolite and difficult control of zeolite quality when the combustion ash, such as paddy husk ash, bagasse ash, diatomite, and the like are adopted as raw materials. The A type zeolite is prepared from burning ash, the main component of which is SiO2, as a raw material in an alkaline solution through hydrothermal reaction. The method comprises the following steps of: hydrothermally dissolving the burning ash in the alkaline solution; adding sodium metaaluminate for crystallization; washing in water, filtering and dryingto obtain the A type zeolite. The method has shorter reaction time, high crystallizing speed, more favorable and stable performance of the generated A type zeolite and obvious economic benefit, obviously reduces the production cost, simplifies the preparation step, and improves the yield and the market competition of products.

Owner:杨辉

Grading preparation method of coal thermal dissolution substance

InactiveCN106422404ASimple processLow costSolid fuelsSolid solvent extractionN dimethylformamideOrganic solvent

The invention provides a grading preparation method of a coal thermal dissolution substance and belongs to the field of coal chemical industry. The preparation method comprises specific steps as follows: coal and an organic solvent are mixed, a mixture is subjected to thermal dissolution treatment at the temperature of 360 DEG C in the atmosphere of inert gas, the coal and organic solvent mixture after the thermal dissolution treatment is centrifuged at the room temperature and washed with a thermal dissolution solvent, the organic solvent in a centrifugal washing solution is separated and recovered, and the coal thermal dissolution substance which is soluble at the room temperature is obtained; solid residues are subjected to centrifugal washing again with an N,N-dimethylformamide solvent at the room temperature, and the coal thermal dissolution substance deposited at the room temperature is obtained. The grading preparation method of the coal thermal dissolution substance realizes grading preparation of the coal thermal dissolution substance, requires no specific hot-filtration separation processing equipment in a preparation process, adopts a simple technology, and is lower in cost and applicable to industrial production, and grading extraction of the thermal dissolution substance is further helpful for follow-up processing and utilization of the coal thermal dissolution substance.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Sodium sulfide solution purification process

InactiveCN101353159AFull wash recoveryContinuous uninterrupted operationAlkali metal sulfides/polysulfidesContinuous/uninterruptedFiltration

The invention relates to an alkali liquor purification process method in a sodium sulphide production course. The alkali liquor purification process method comprises a thermal dissolution process, a centrifugal settlement and separation process, a filtration process. By adopting the alkali liquor purification process of the invention, equipment can be simplified, in particular, continuous and uninterrupted operation can be realized; the working efficiency is greatly improved, in particular, the product quality is greatly improved; meanwhile, residual alkali in sludge can be fully washed and recovered; the process is shortened, and quantitative automatic switch control can be realized easily on schedule; and the situations of leaking and polluting environment can be reduced.

Owner:金贤琴

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com