Regeneration method and device used for deactivation catalyst layer of membrane ozone catalytic reactor

A technology of ozone catalysis and reactor, applied in chemical instruments and methods, catalyst regeneration/reactivation, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem that there are no relevant research reports on catalyst regeneration methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

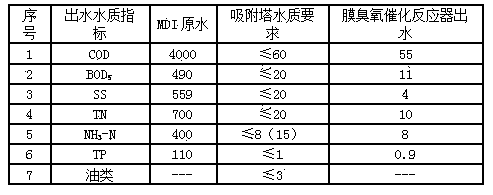

[0083] A method for regenerating deactivated catalytic membrane components of a membrane ozone catalytic reactor, comprising:

[0084] (1) Firstly, air is introduced and baked at 600°C to remove organic pollutants remaining in the membrane module;

[0085] (2) Then use a mixture of 66% nitric acid and 37% hydrochloric acid to heat dissolve at 100°C for 5 minutes to remove the metal oxide attached to the catalytic layer of the membrane; the molar ratio of nitric acid to hydrochloric acid is 1:3;

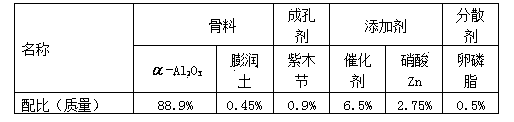

[0086] (3) After the modified Mn-Si-Ti catalyst suspension with a mass concentration of 10% (w / w) is atomized, it is sucked under negative pressure to make it enter the membrane support and load the inner surface of its pores;

[0087] (4) Finally, remove the modified Mn-Si-Ti catalyst adsorbed on the surface of the membrane separation layer by spraying and rinsing, and immerse the outer surface of the membrane module in the modified Ni-Co catalyst suspension with a mass concentration...

Embodiment 2

[0099] A method for regenerating deactivated catalytic membrane components of a membrane ozone catalytic reactor, comprising:

[0100] (1) First, air is introduced and baked at 850°C to remove organic pollutants remaining in the membrane module;

[0101] (2) Then use a mixture of 66% nitric acid and 37% hydrochloric acid to heat dissolve at 160°C for 5-20 minutes to remove the metal oxides attached to the catalytic layer of the membrane; the molar ratio of nitric acid to hydrochloric acid is 3:1

[0102] (3) After the modified Mn-Si-Ti catalyst suspension with a mass concentration of 30% (w / w) is atomized, it is sucked under negative pressure to make it enter the membrane support and load the inner surface of its pores;

[0103] (4) Finally, remove the modified Mn-Si-Ti catalyst adsorbed on the surface of the membrane separation layer by spraying and rinsing, and immerse the outer surface of the membrane module in the modified Ni-Co catalyst suspension with a mass concentratio...

Embodiment 3

[0115] Apparatus for deactivating catalytic membrane modules in membrane ozone catalytic reactors (see figure 1 ), including the organic residue removal device of the deactivated membrane module and the regeneration recovery device of the deactivated membrane module; among them

[0116] Inactivated membrane module organic residue removal device: mainly composed of air compressor, temperature control heater and roasting box, the connection between temperature control heater and roasting box is: The heating electrode is regulated so that the temperature in it reaches the set value; the air compressor is connected to the air inlet in the roasting box through the air guide tube, so that the air enters the roasting box to provide an oxygen source for the oxidation, and through the deactivation The membrane module is placed in a closed device, and the temperature and time are controlled to bake in the baking box, so that the organic pollutants remaining in the membrane module are o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com