Patents

Literature

60results about How to "Improve ignitability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

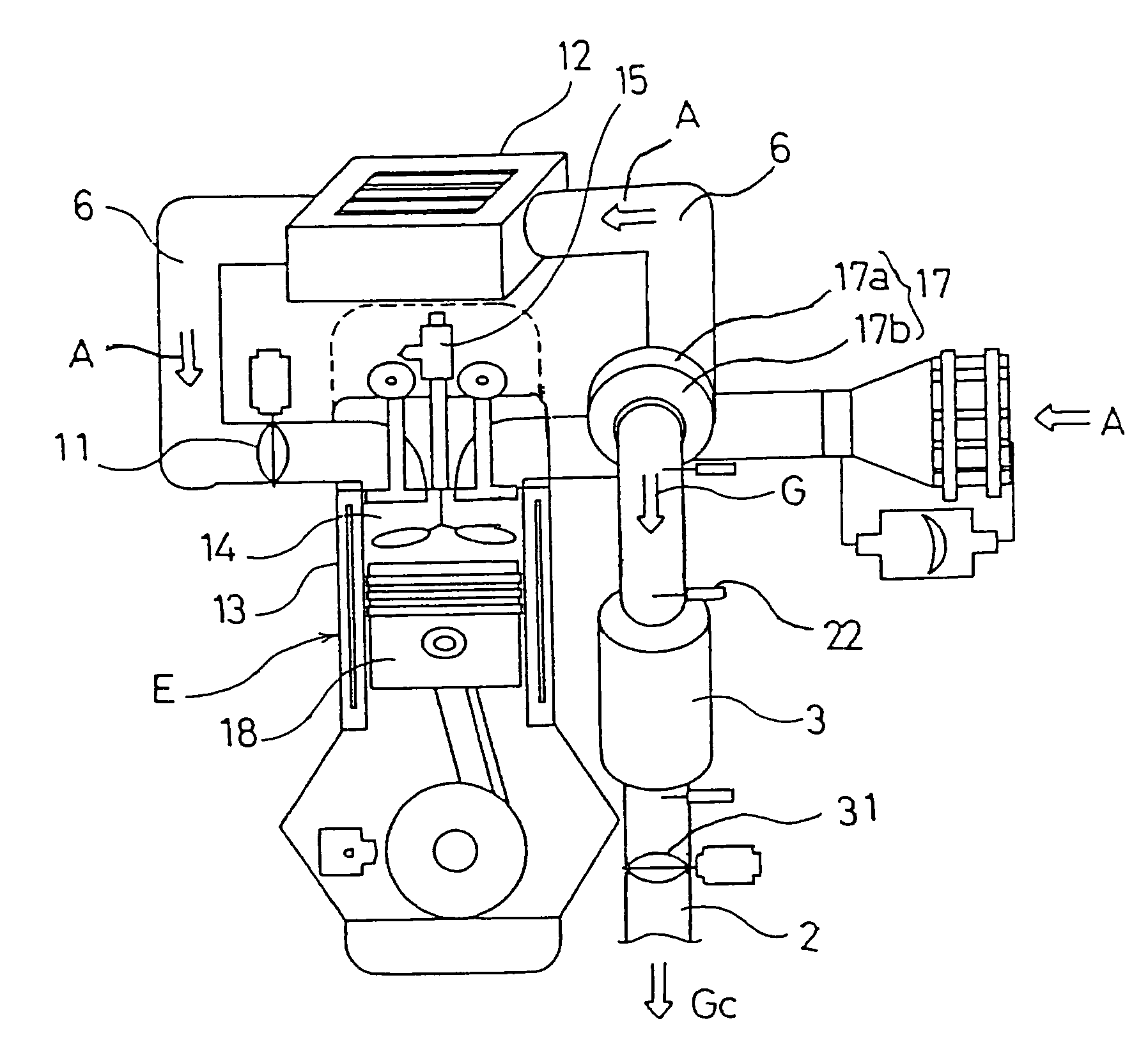

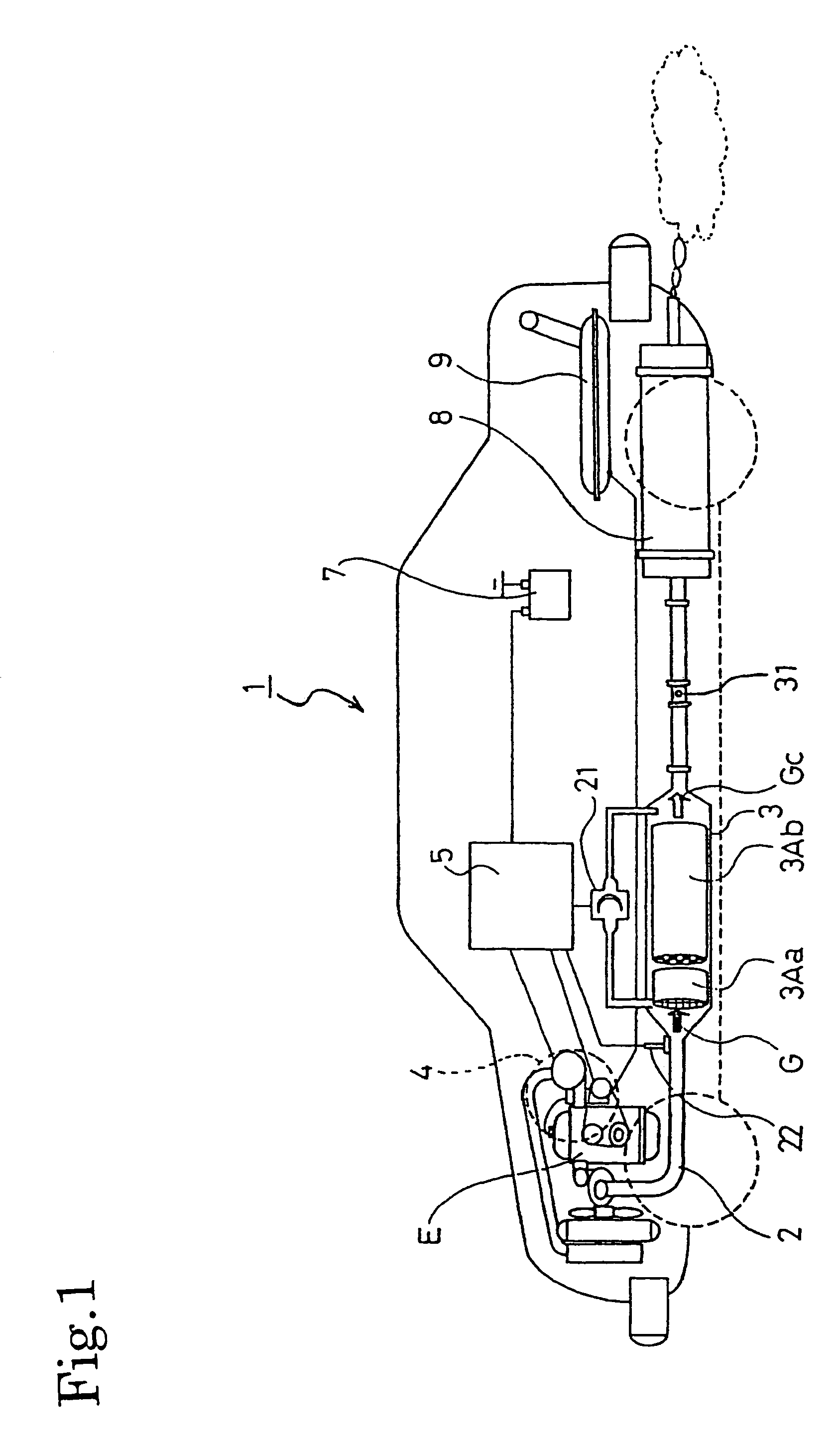

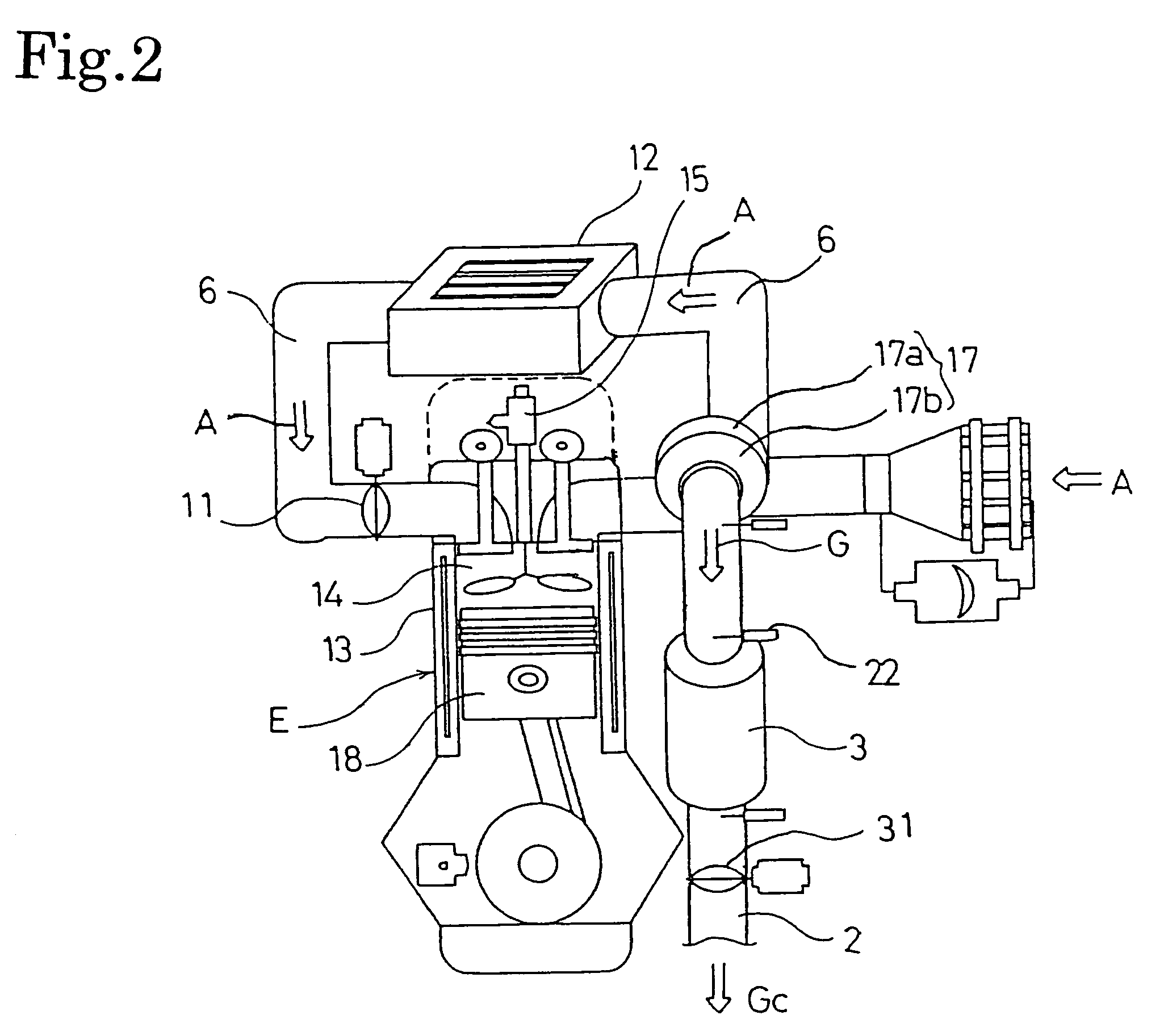

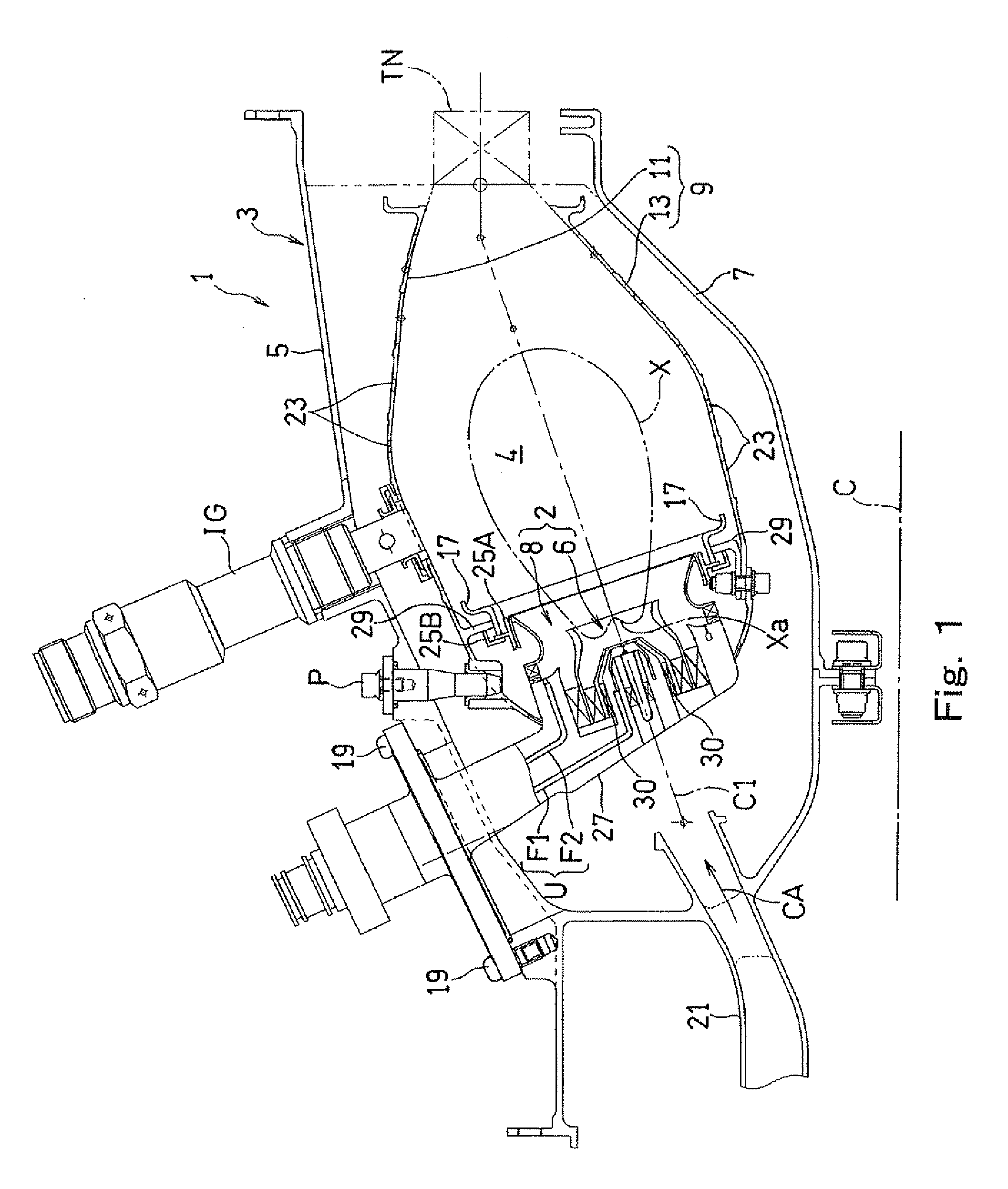

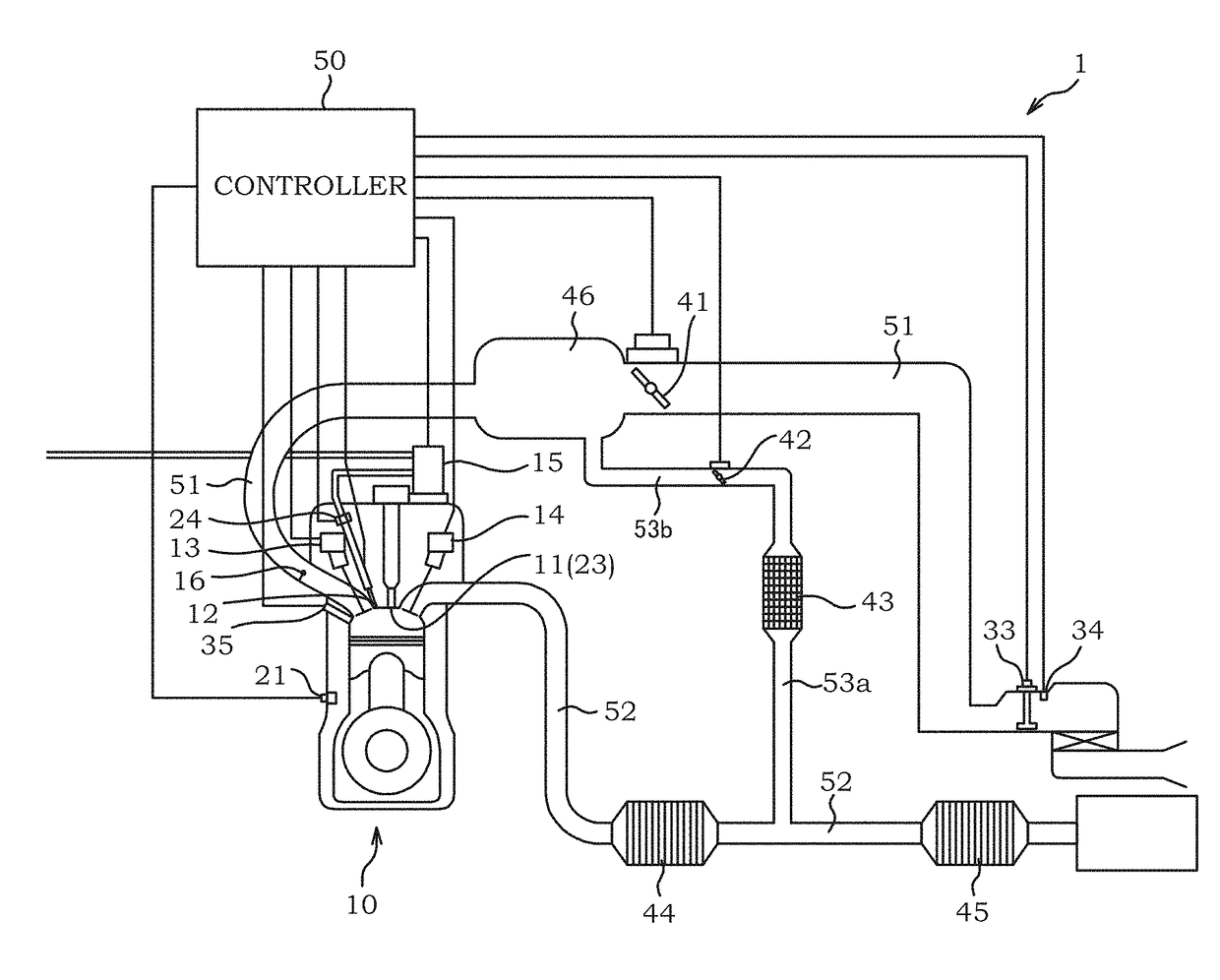

Exhaust gas purifying system

ActiveUS6966179B2Efficiently raising temperature of exhaust gasLower outlet temperatureElectrical controlInternal combustion piston enginesThrottle controlLow load

To provide an exhaust gas purifying system capable of forcibly regenerating DPF by efficiently raising the temperature of exhaust gas even when an exhaust gas temperature is very low at the time of low load and low engine speed such as an idling operation. In an exhaust purifying system (1) having an exhaust throttling valve (31) and a DPF (3) in an exhaust passage and having regeneration control means (P1) for regenerating the DPF (3), the regeneration control means (P1) is provided with an exhaust gas temperature detection means (P22), a fuel injection control means (P11), and an exhaust throttling control means (P12) and includes regeneration control for performing the exhaust gas temperature raising control through the multistage delay injection by the fuel injection control means (P11) and through the exhaust throttling of the exhaust throttling valve (31).

Owner:ISUZU MOTORS LTD

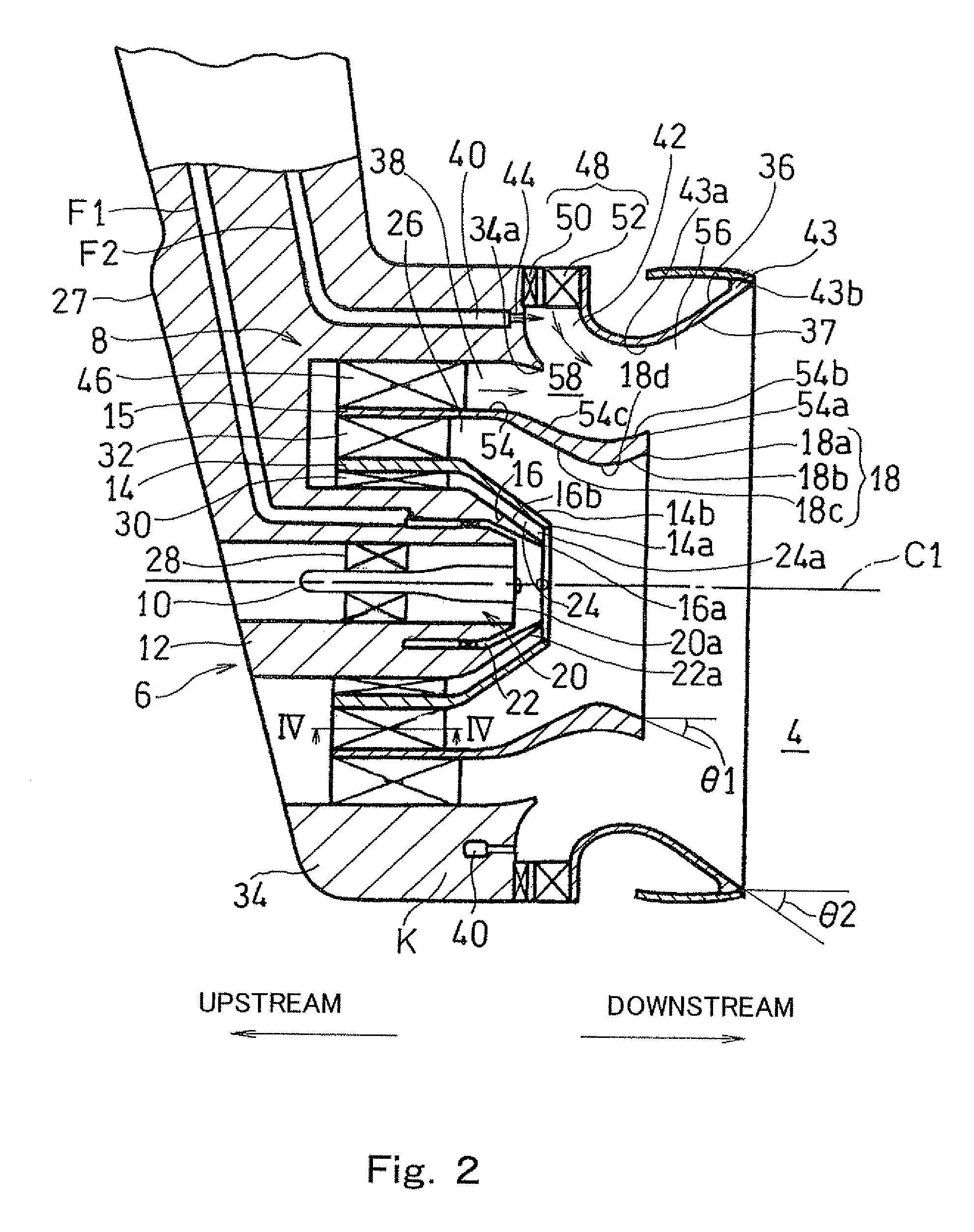

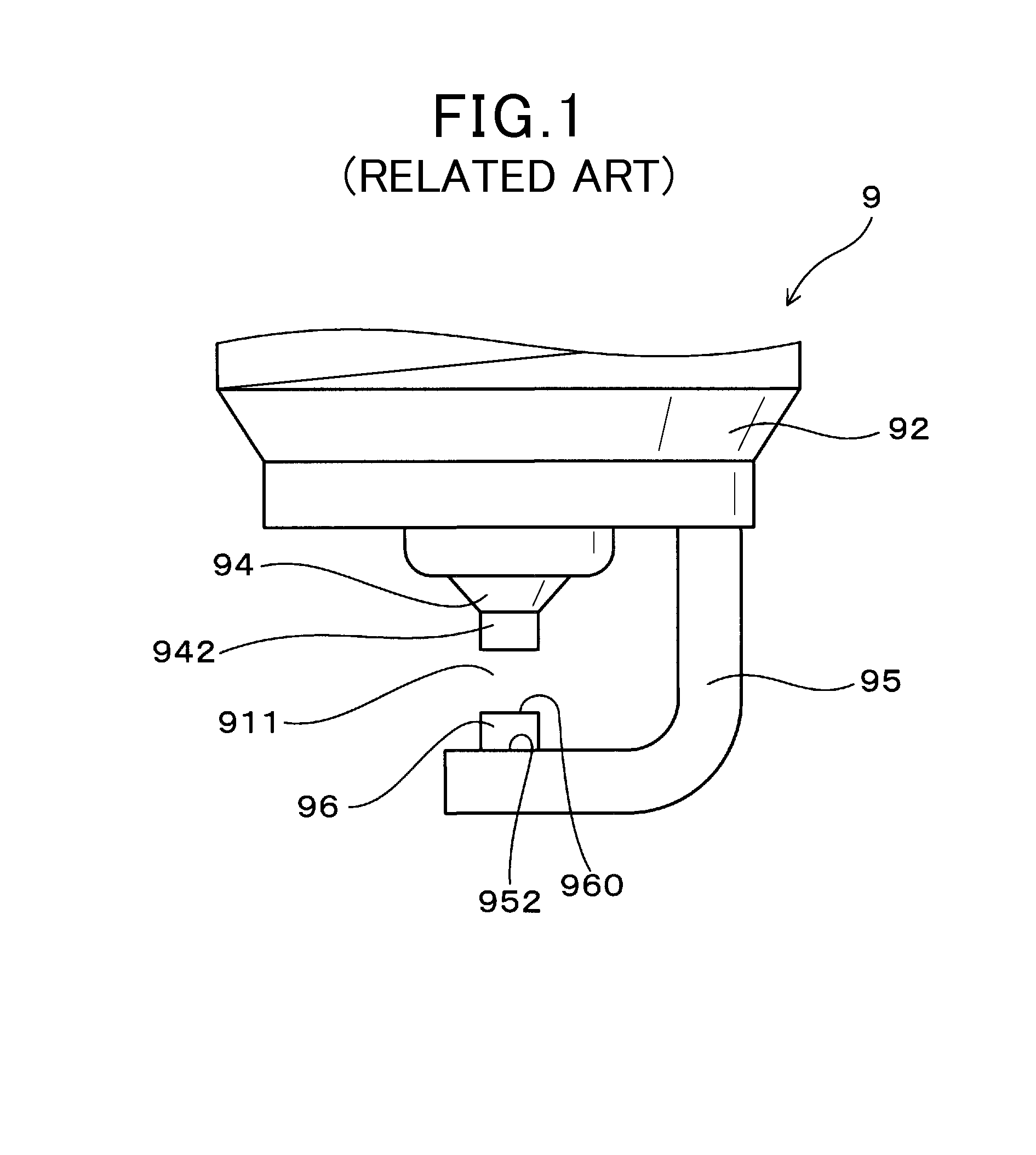

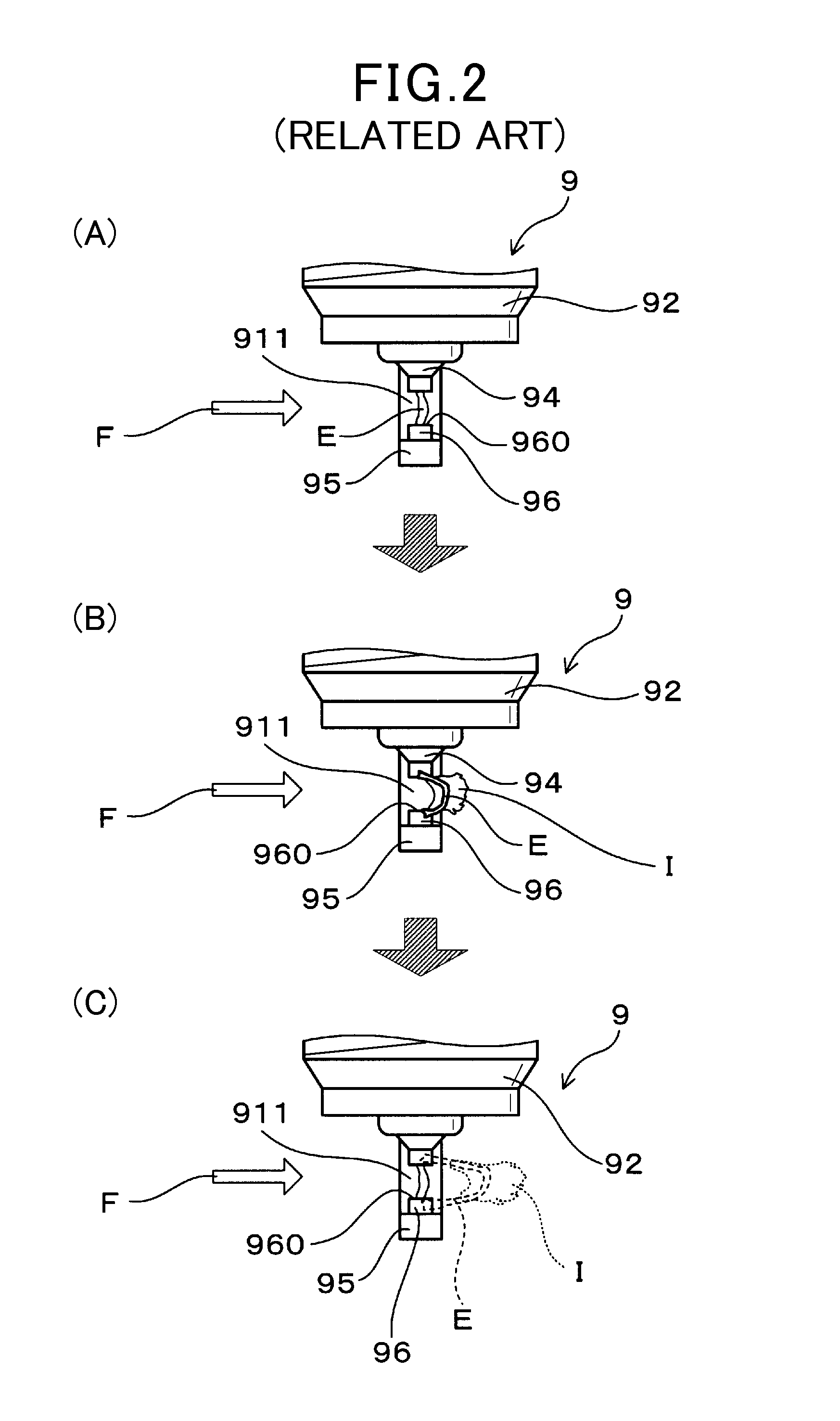

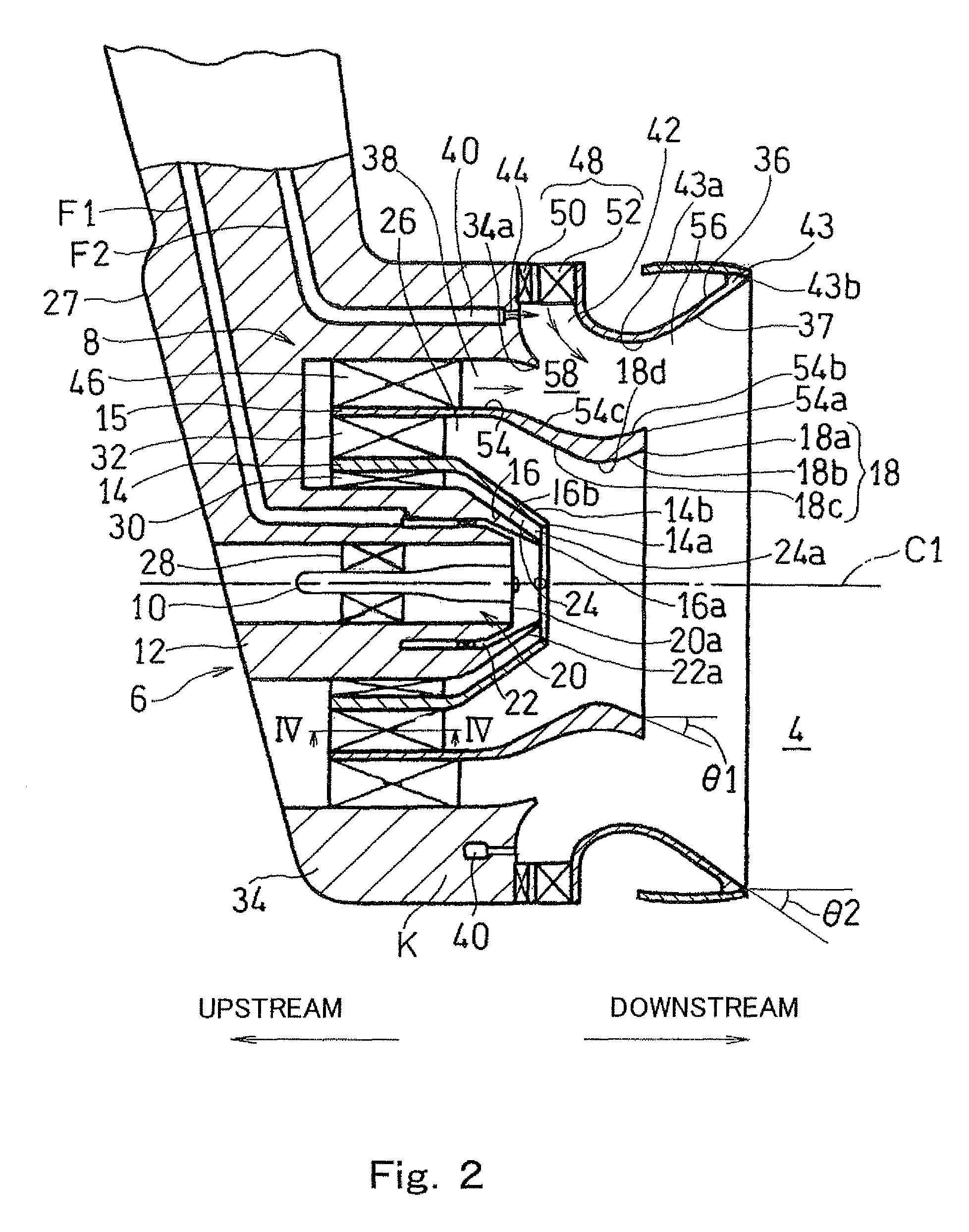

Fuel injector

ActiveUS20120305673A1Deteriorating combustion efficiencyAvoid interferenceContinuous combustion chamberMachines/enginesInjectorCombustion chamber

A fuel injector includes: a pilot injector configured to spray fuel so as to form a first combustion region in a combustion chamber; and a main injector provided coaxially with the pilot injector so as to surround the pilot injector and configured to supply a fuel-air mixture that is a mixture of the fuel and air to form a second combustion region in the combustion chamber, wherein the pilot injector includes: a center nozzle configured to eject air jet flowing straight in an axial direction on a central axis of the pilot injector; an inside swirler provided on a radially outer side of the center nozzle and configured to cause inflow air to swirl around the central axis; and a pilot fuel injecting portion configured to inject the fuel from between the center nozzle and the inside swirler to air flow in the center nozzle.

Owner:KAWASAKI HEAVY IND LTD +1

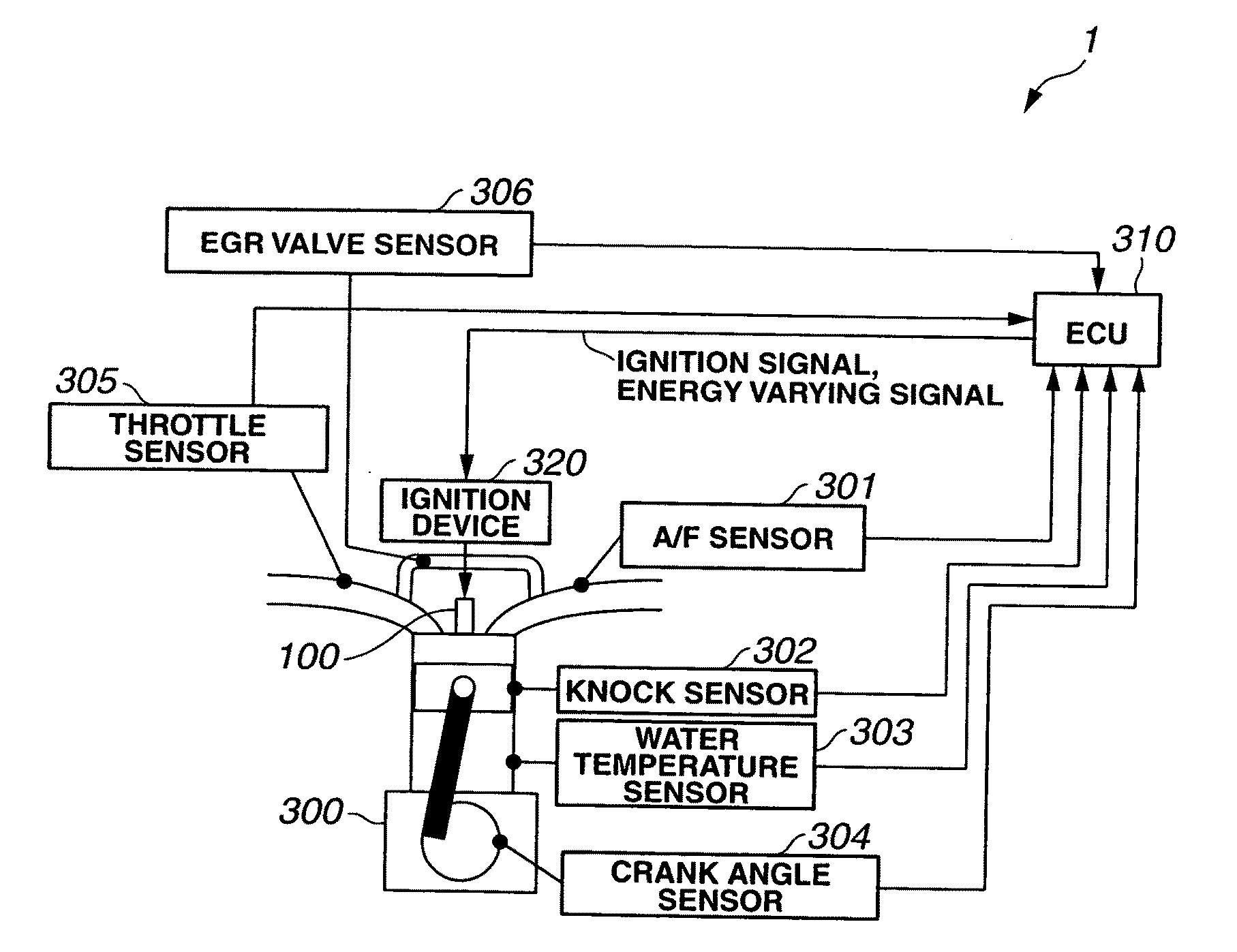

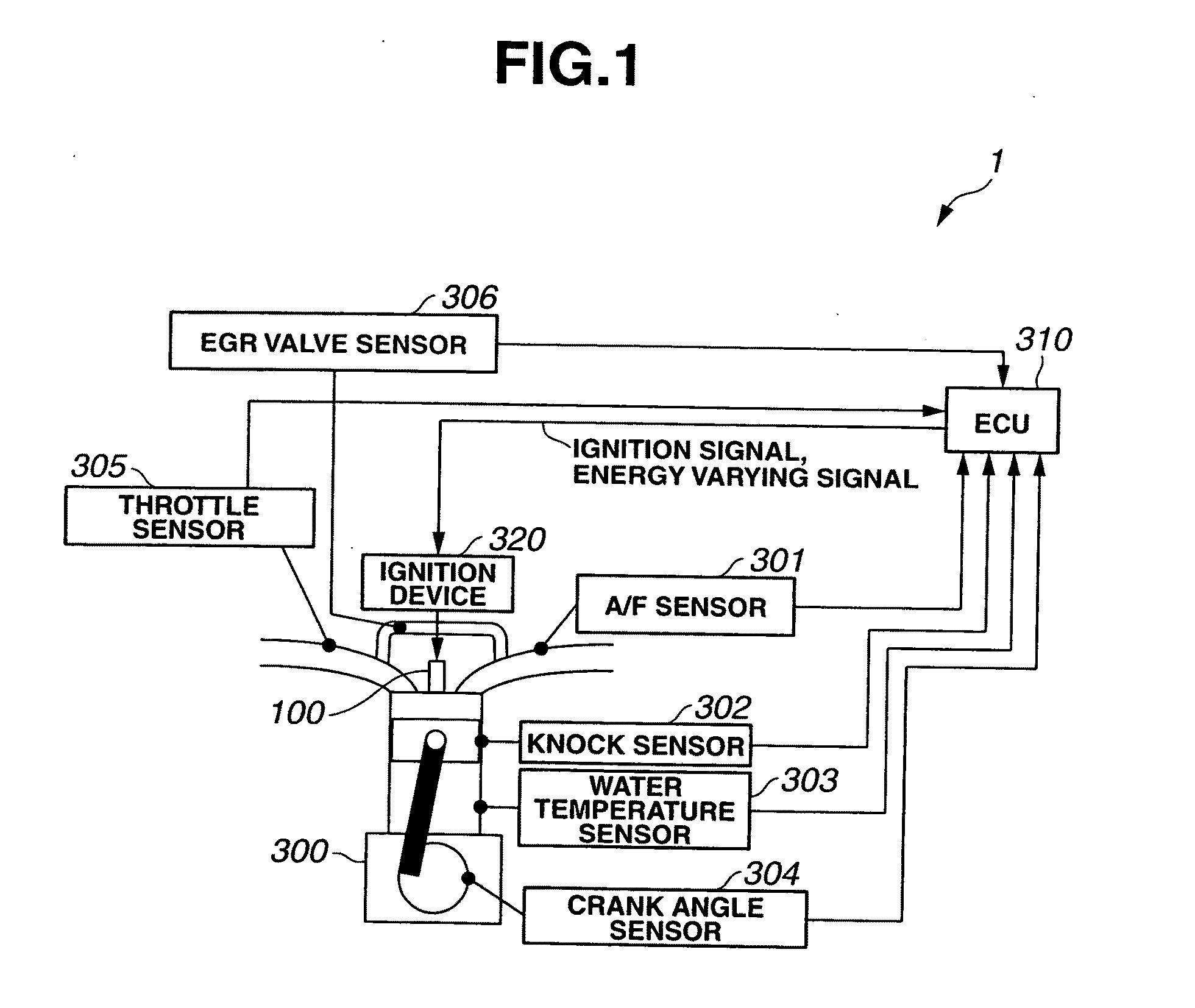

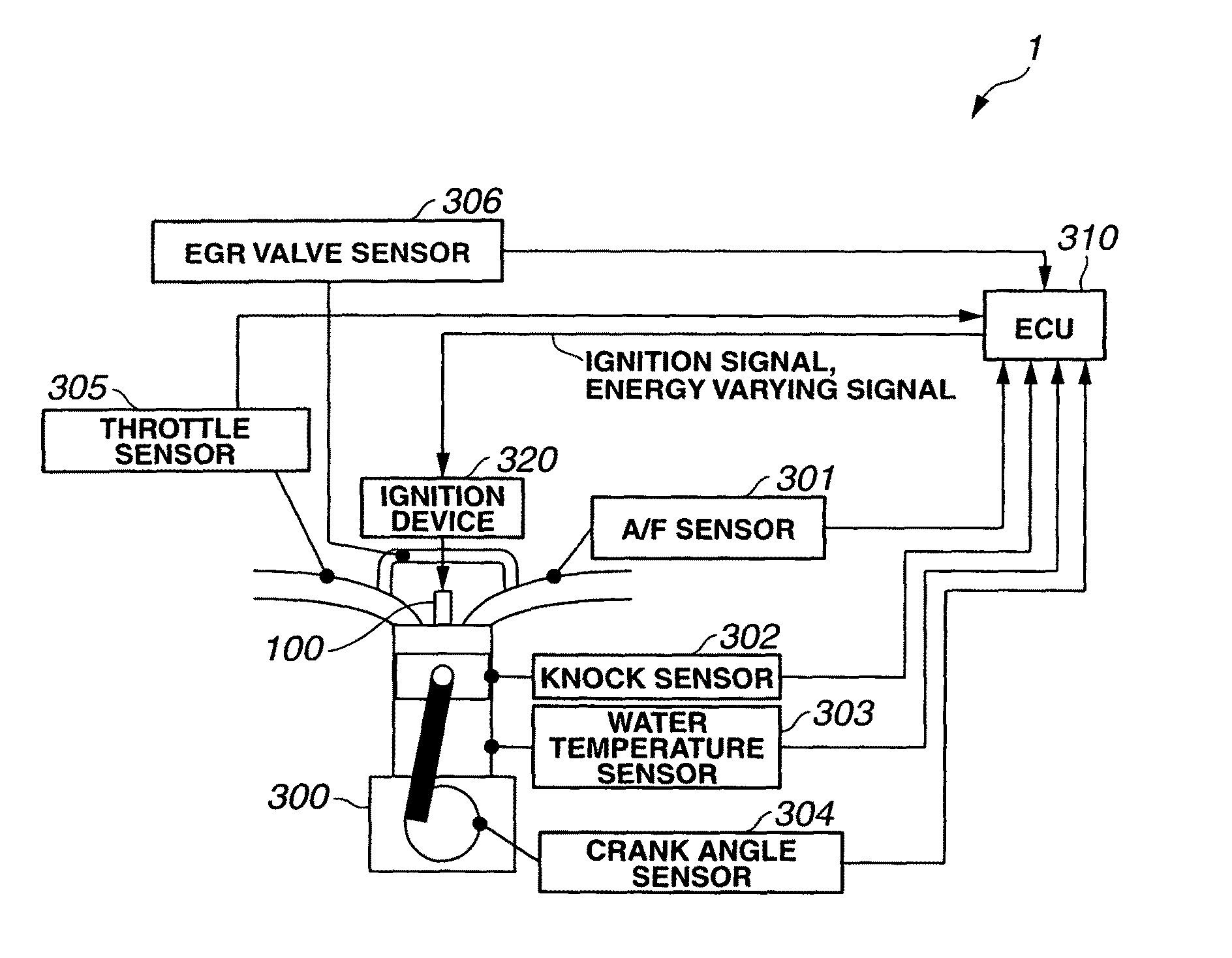

Plasma jet ignition plug ignition control

InactiveUS20100132666A1Easy to controlAdjustable quantitySparking plugsCombustion enginesIgnition coilIgnition control

A control system for controlling the ignition of a plasma-jet spark plug provided in an internal combustion engine senses an operating condition of the internal combustion engine, and determines an ignition mode of the plasma-jet spark plug in accordance with the sensed operating condition. The control system performs an ignition control of breaking down the insulation across a spark discharge gap by applying a first electric power to the plasma-jet spark plug, and producing plasma in the vicinity of the spark discharge gap by applying a second electric power to the spark discharge gap in a state of dielectric breakdown. The control system performs this ignition control according to the ignition mode determined as mentioned above.

Owner:NGK SPARK PLUG CO LTD

Propellants and explosives with flouro-organic additives to improve energy release efficiency

InactiveUS6843868B1Economical to manufactureWidespread , cost effective useExplosivesHalogenEnvironmentally friendly

A non- / low-toxic, non-hypergolic, propellant formulation generally comprising metal nanoparticles, such as boron, aluminum, or carbon, and one or more fluoro-polymers mixed in in particulate form. The present invention takes advantage of the increased surface area provided by nano-sized metallic particles to enhance the metal's combustion efficiency, or ignitability. The inclusion of fluoro-polymers also aids in increasing the combustion efficiency of the metallic nanoparticles due to the presence of halogenic oxidizers. The thermal degradation of a halogenated fluoro-polymer additive in the propellant combustion zone serves to release halogens, thereby improving the combustion of the metallic nanoparticles and increasing the propulsion system's energy output. The present invention's formulation is safe to store and handle, environmentally-friendly, and may be economically manufactured to provide for widespread, cost-effective use.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

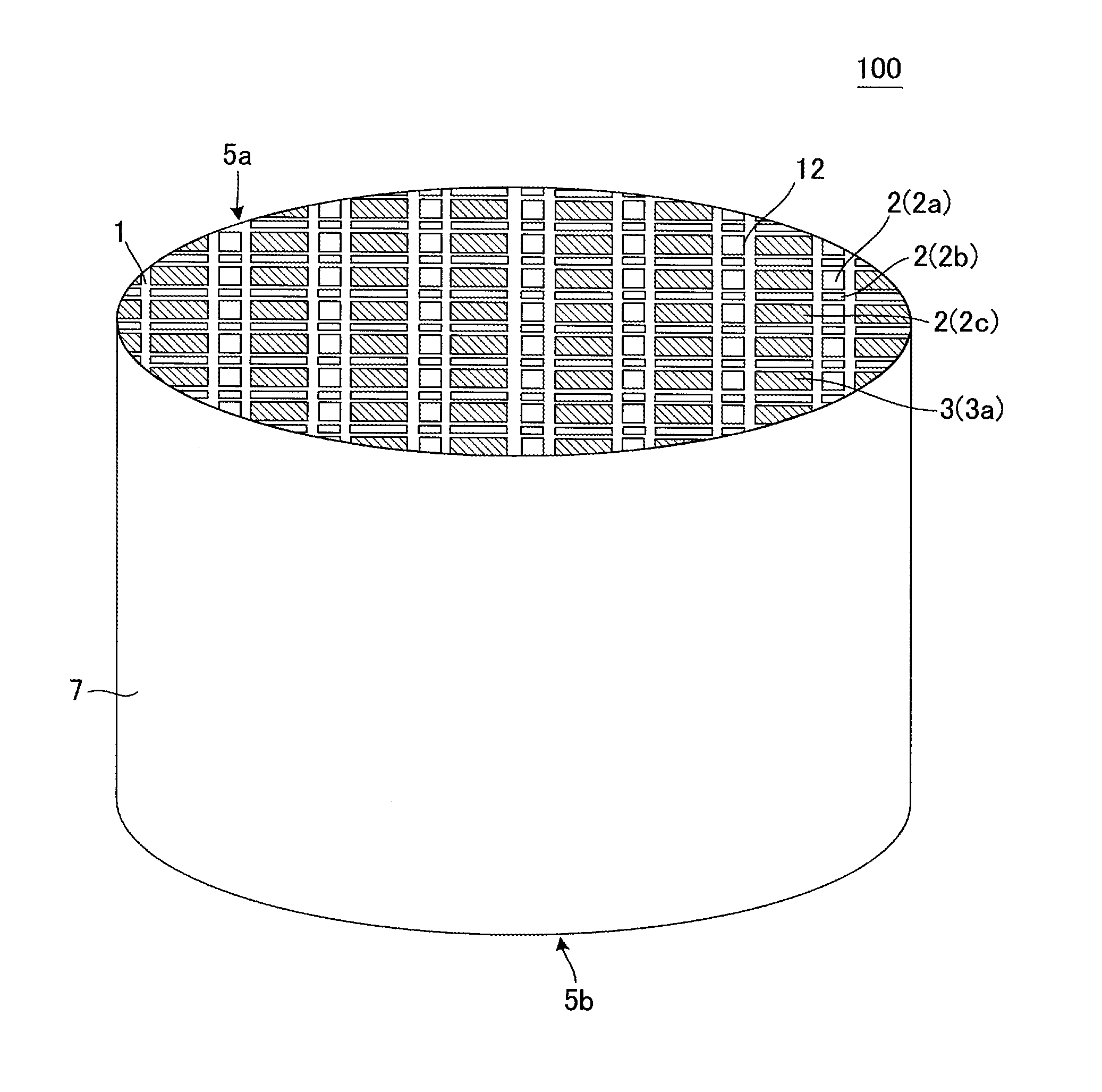

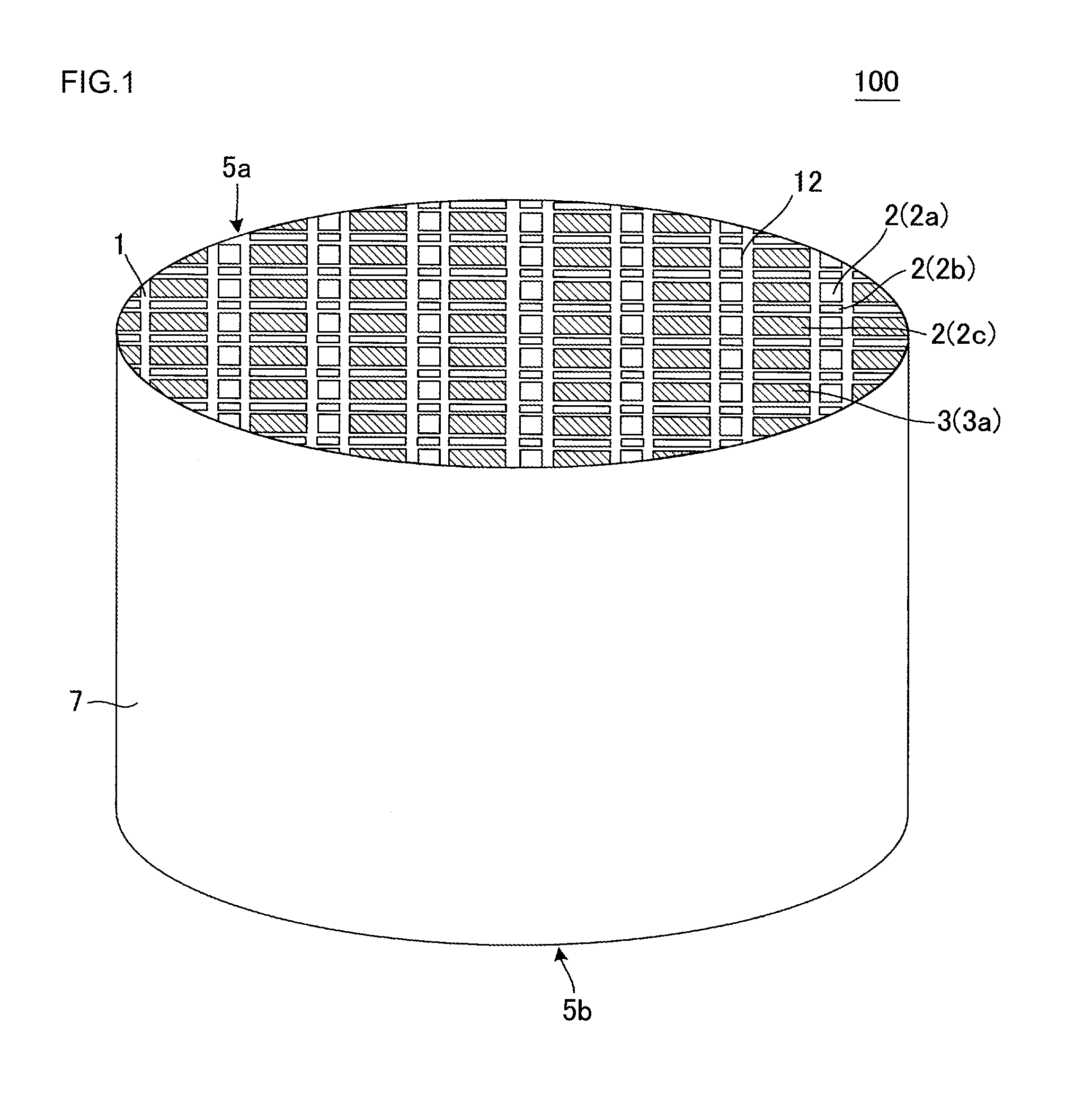

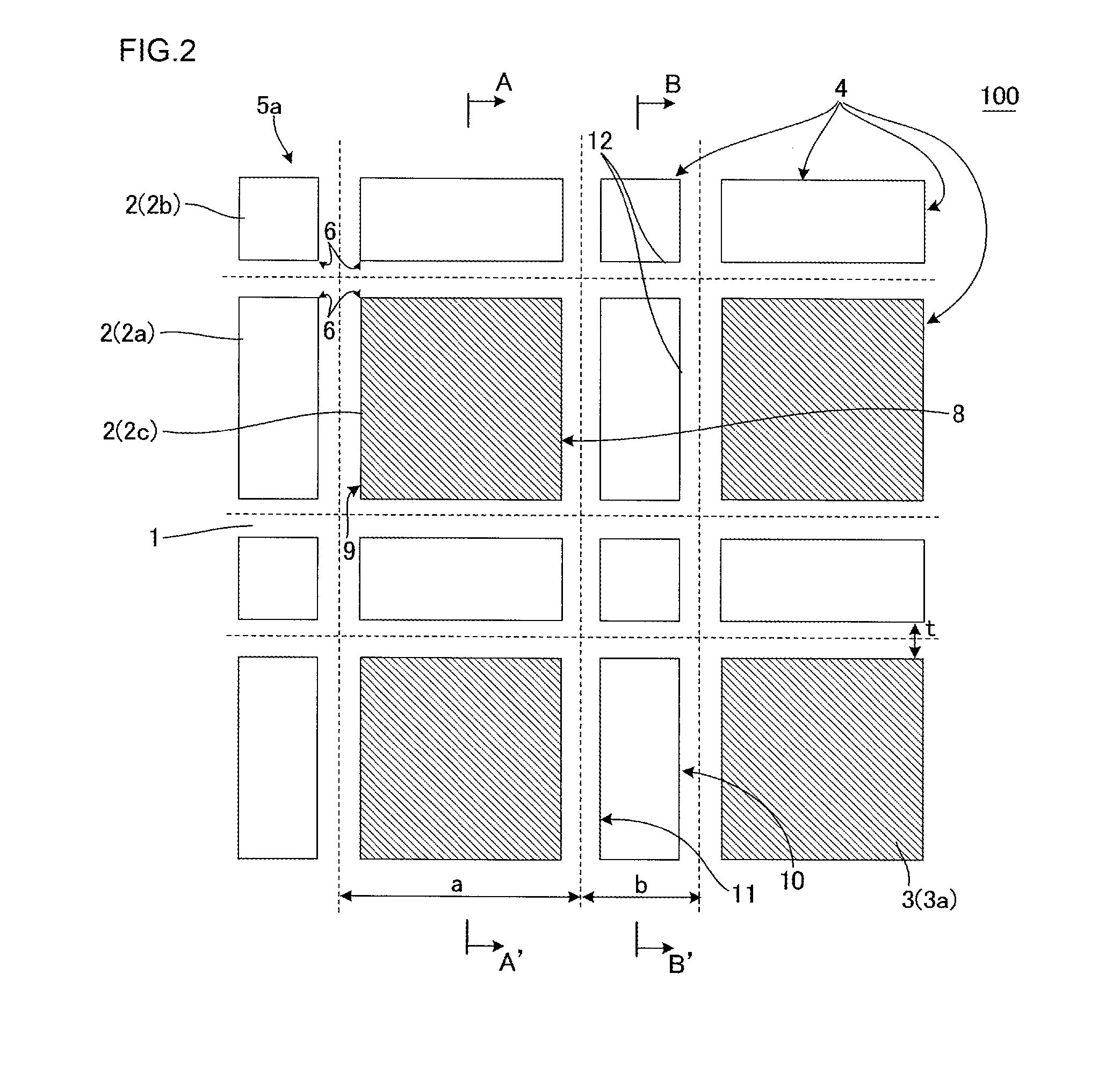

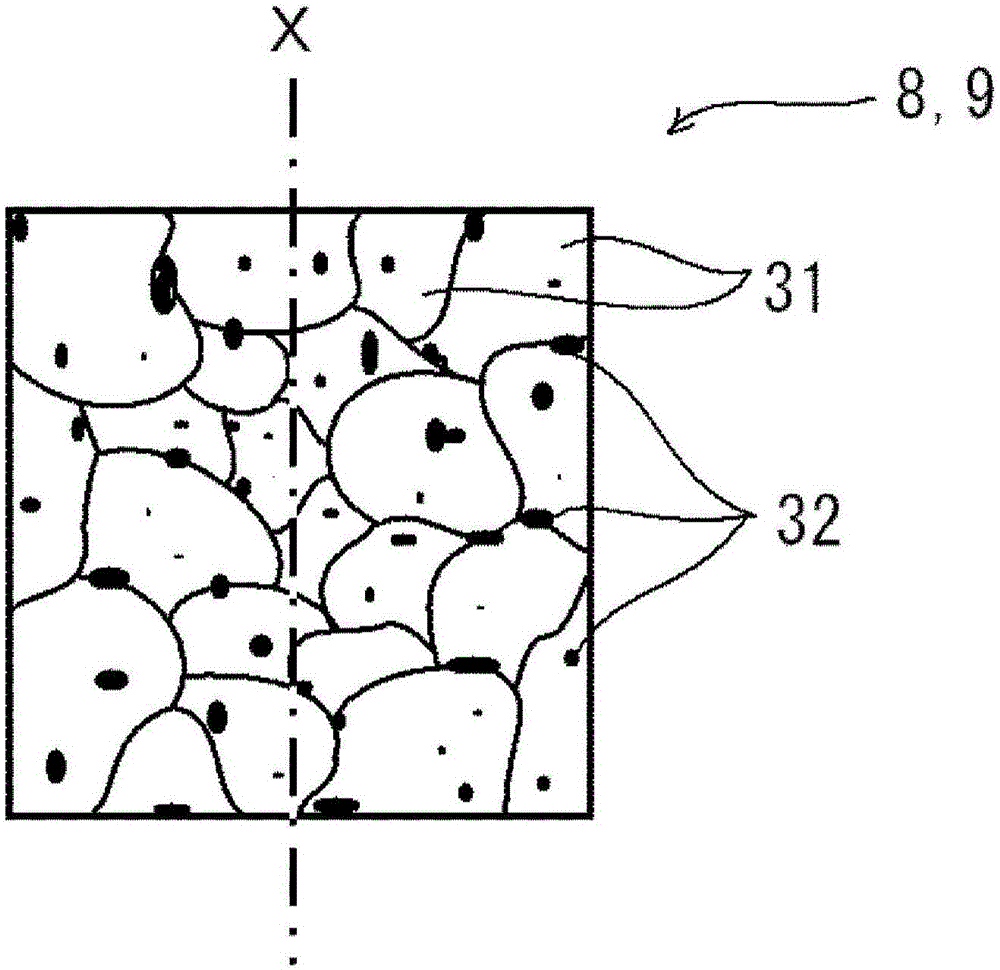

Honeycomb filter

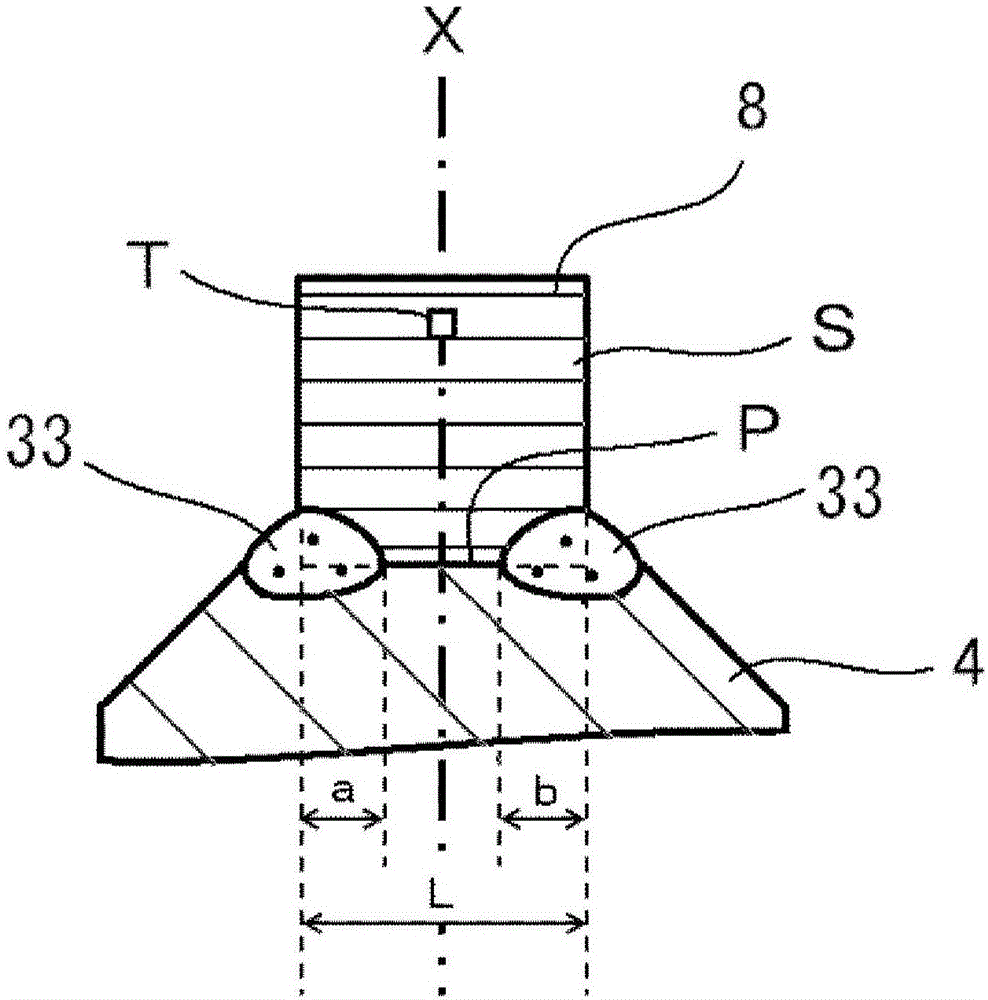

ActiveUS20160067653A1Efficiently regenerateImprove ignitabilityCombination devicesGas treatmentHoneycombUnit volume

In a cross section perpendicular to a central axis direction of the honeycomb substrate, cells are arranged so that a periphery of an inlet plugged cell is surrounded with four rectangular outlet plugged cells and four square outlet plugged cells, and in the cross section, a partition wall center distance a, a partition wall center distance b and a partition wall thickness t satisfy the following equation (1). Additionally, an amount of a catalyst per unit volume of partition walls which is loaded onto the partition walls defining the rectangular outlet plugged cells and the inlet plugged cells is larger than an amount of a catalyst per unit volume of the partition walls which is loaded onto the partition walls defining the rectangular outlet plugged cells and the square outlet plugged cells.0.95<b / at<1.90 (1)

Owner:NGK INSULATORS LTD

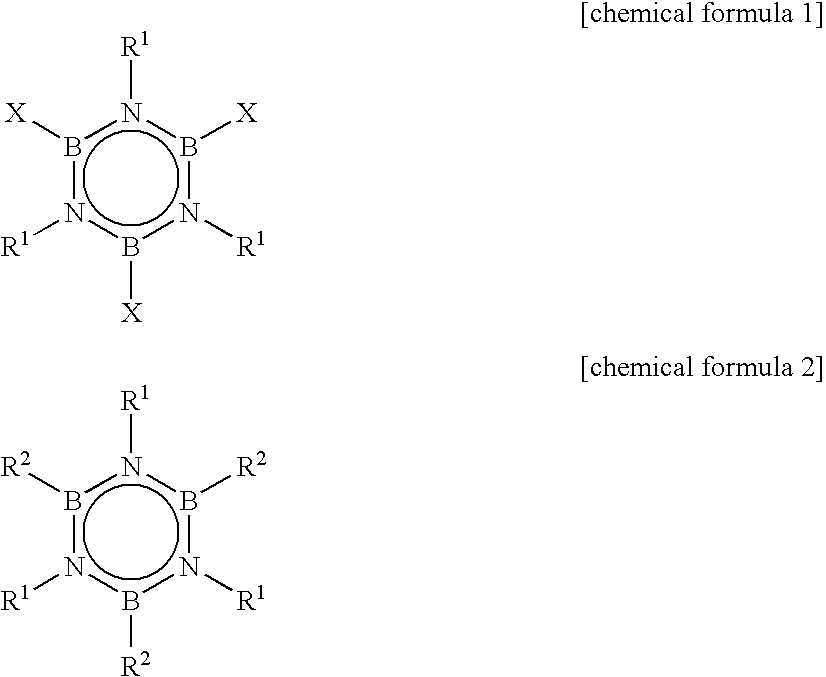

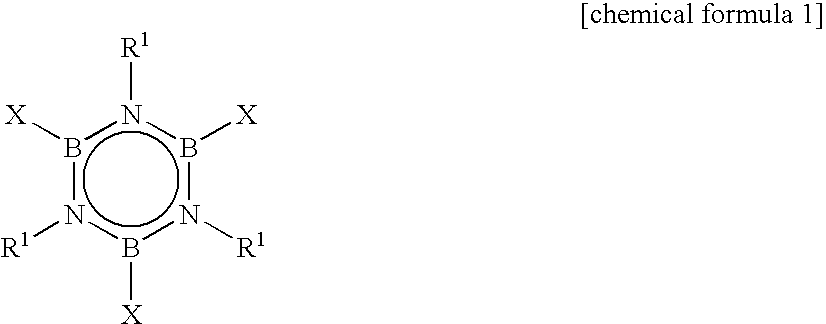

Alkylborazine compound and production method for the same

InactiveUS20050177002A1Boiling pointImprove flammabilitySilicon organic compoundsGroup 3/13 element organic compoundsHalogenDistillation

In the process of synthesizing alkylborazine compound represented by the chemical formula 2, by a reaction of a halogenated borazine compound represented by the chemical formula 1 with a Grignard reagent, thus synthesized alkylborazine compound is washed with water, or subjected to sublimation purification or distillation purification at least three times, and / or subjected to distillation purification at least twice. In the formulas, R1 independently represents alkyl group; R2 independently represents alkyl group; and X represents halogen atom.

Owner:NIPPON SHOKUBAI CO LTD

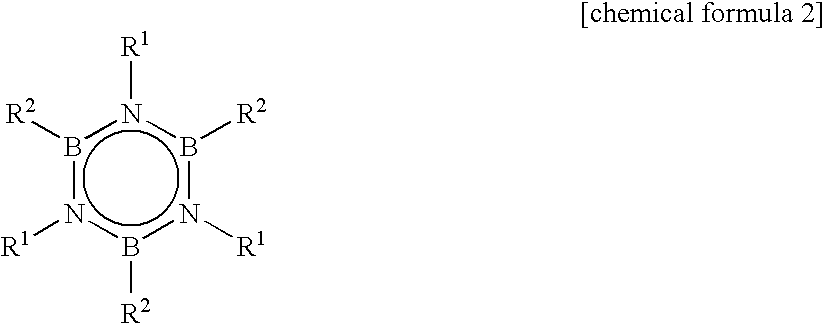

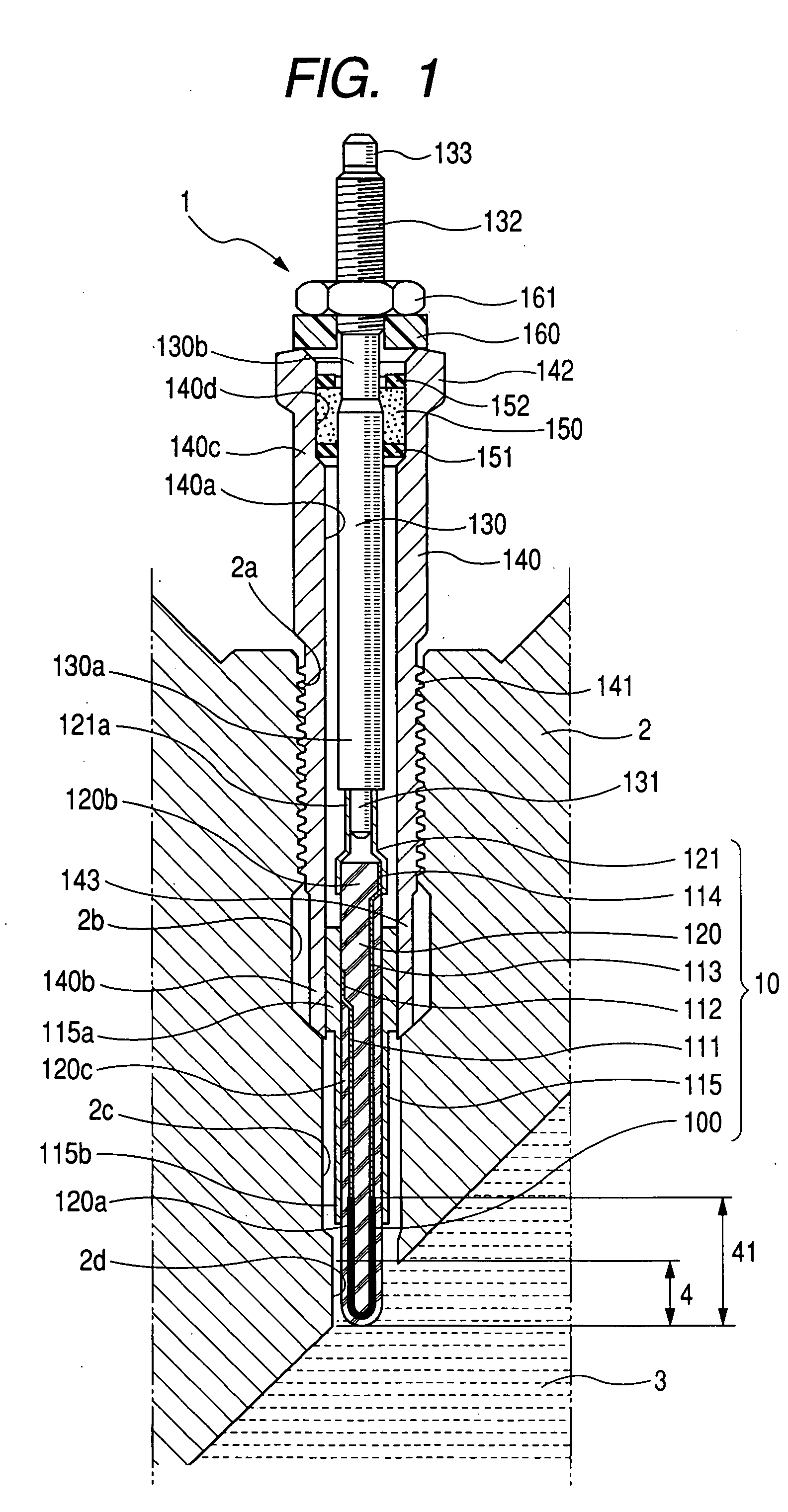

Glow plug and method of manufacturing the same

InactiveUS20080302777A1Reduce power consumptionHighly reliable mannerIncandescent ignitionMachines/enginesElectrical resistance and conductanceCombustion chamber

A glow plug and related manufacturing method are disclosed. The glow plug includes a heating section for heating a combustion chamber of an engine for promoting an ignition. The heating section includes a ceramic heating element developing a heat when applied with electric power, a ceramic insulating support body embedded with the heating element, and a pair of lead wires connected to the heating element and having terminal portions exposed to a surface of the insulating body. The heating element has a positive temperature coefficient of resistance and includes: (a) initial resistance R20 equal to or greater than 0.3Ω and equal to or less than 0.65Ω; (b) heating resistance R1200 equal to or greater than 0.7Ω and equal to or less than 1.3Ω; and (c) temperature coefficient of resistance R1200 / R20 equal to or greater than 2.0 and equal to or less than 4.0.

Owner:DENSO CORP

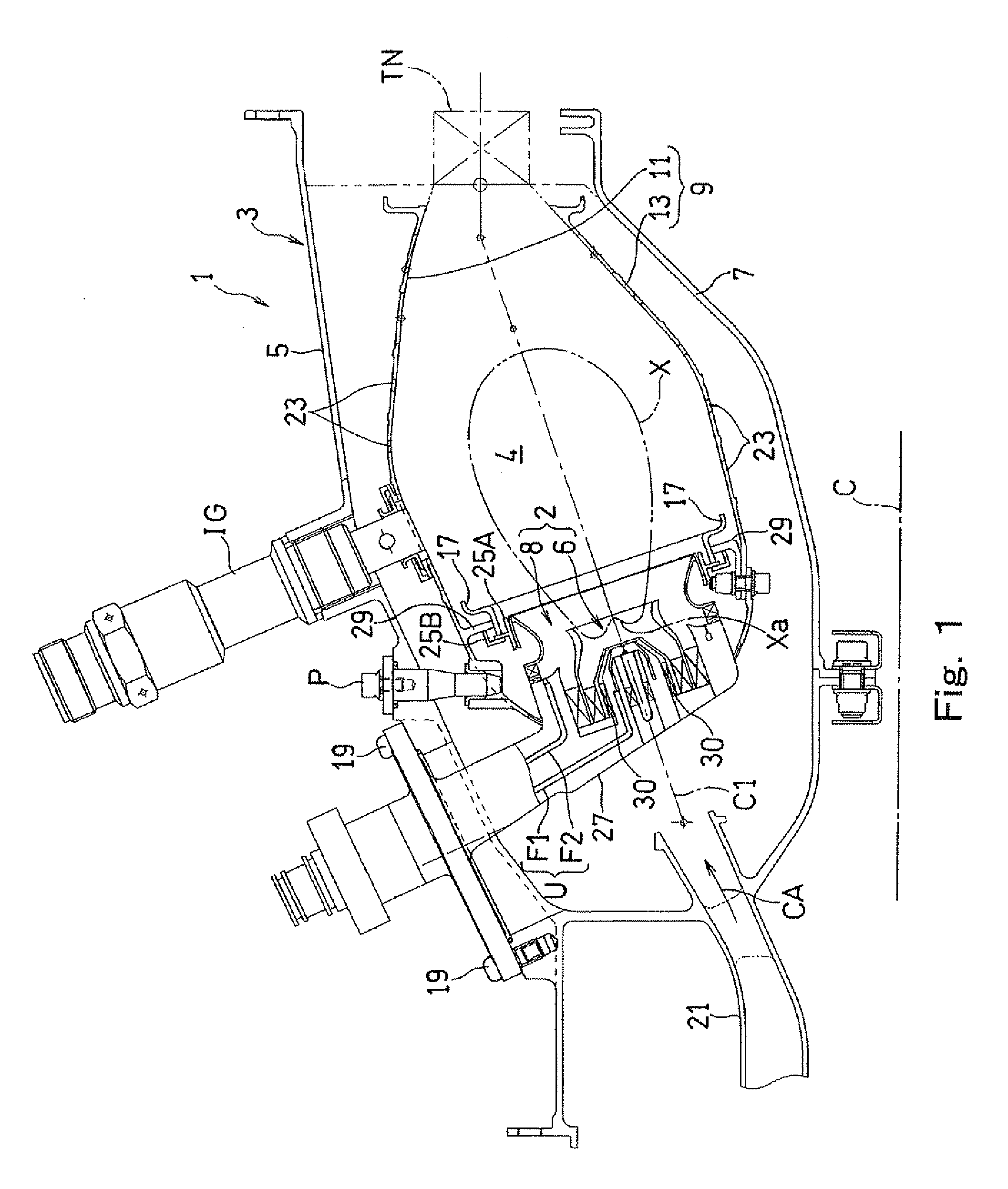

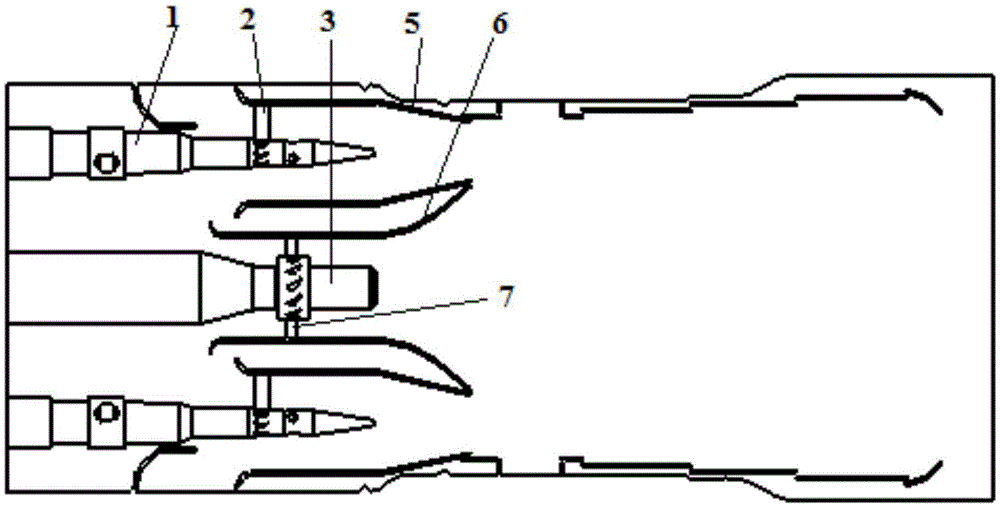

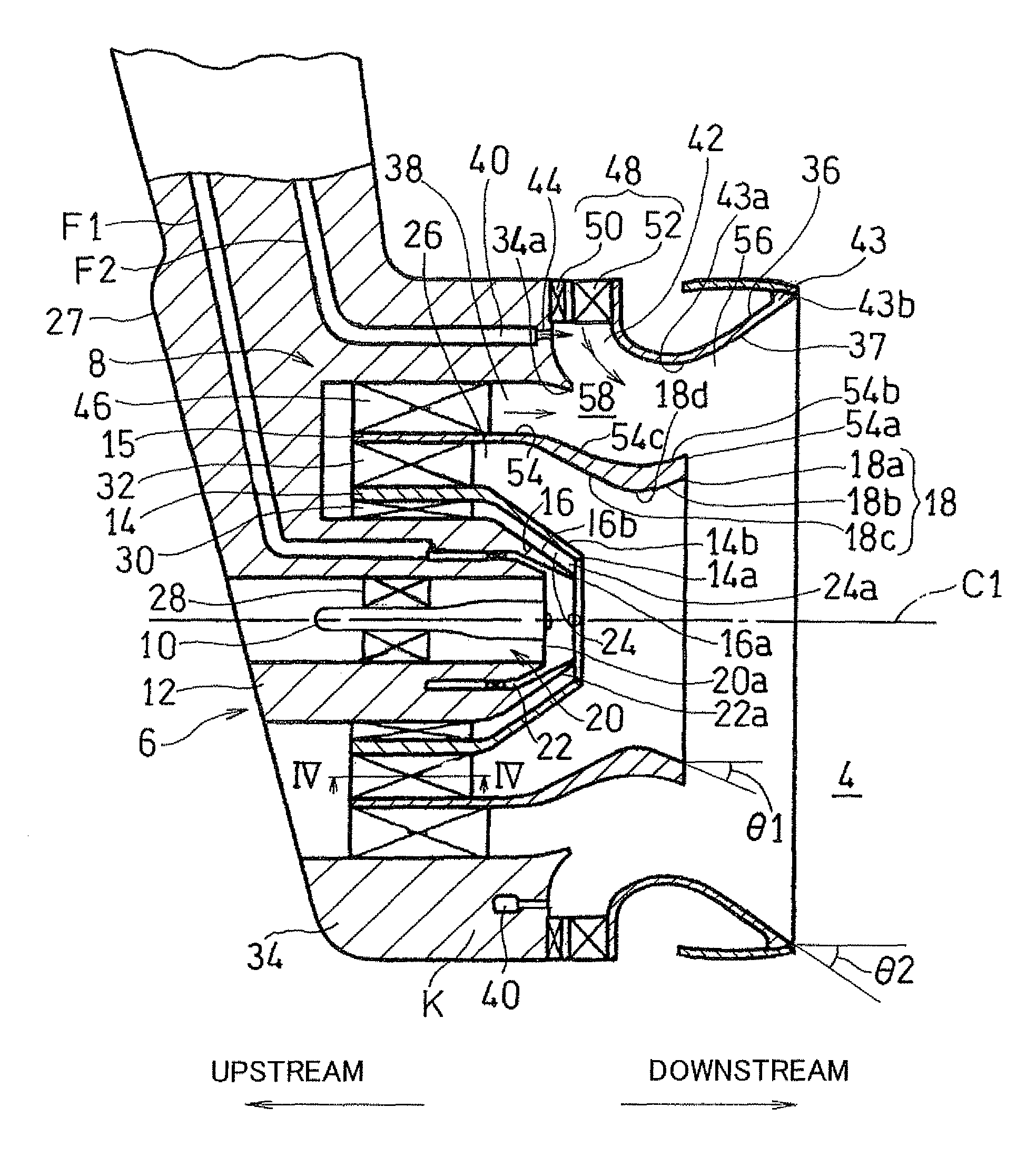

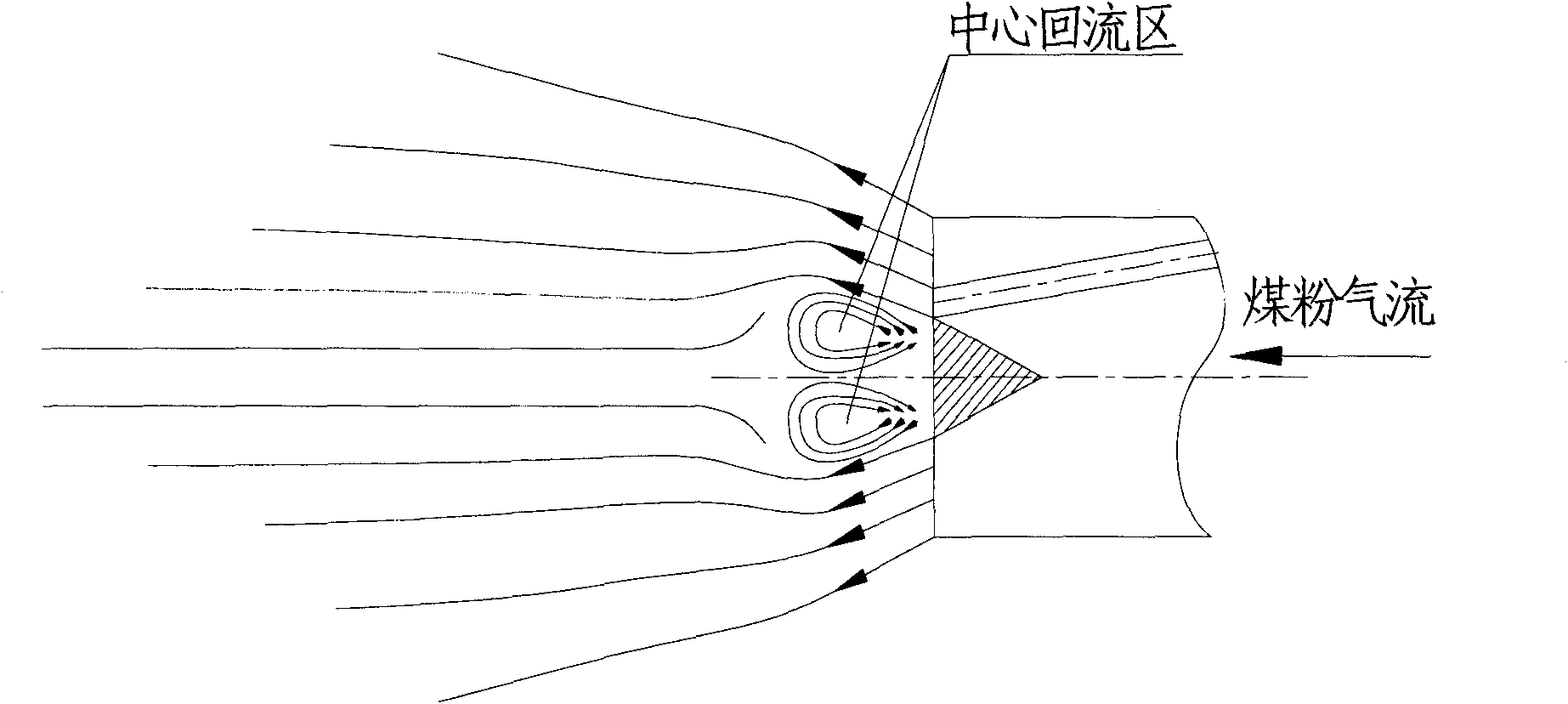

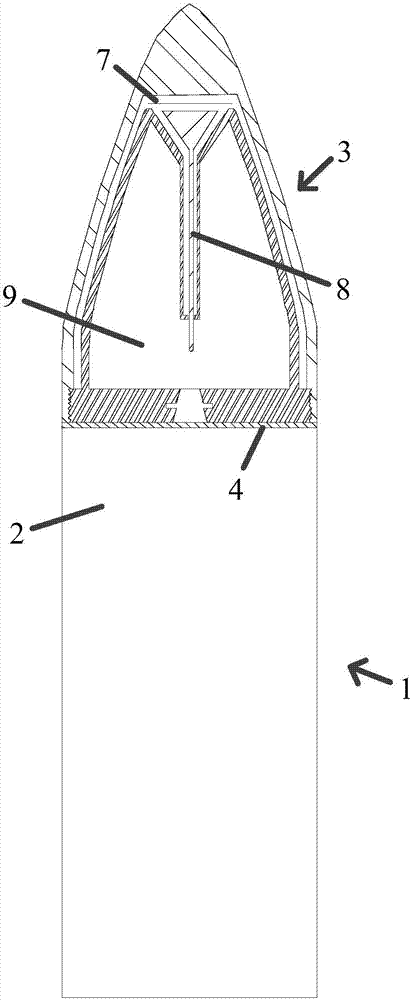

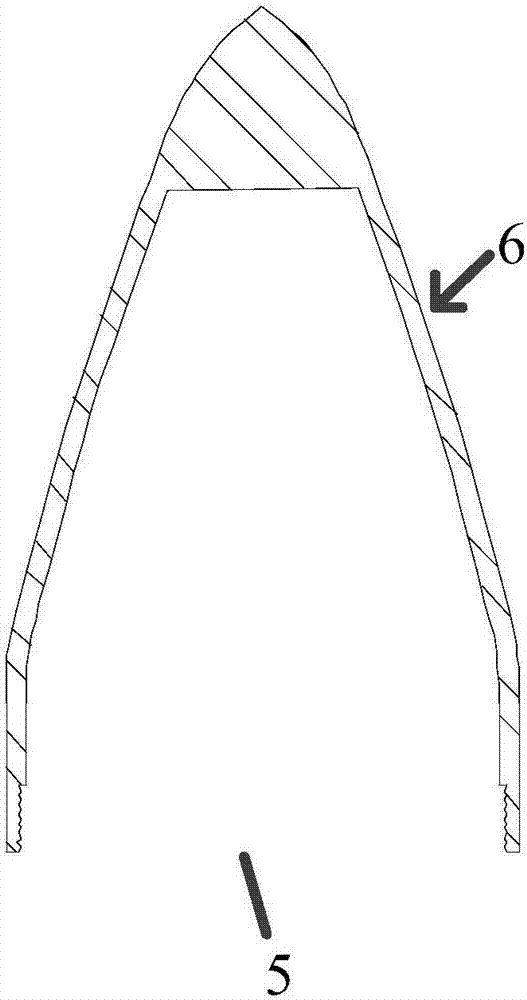

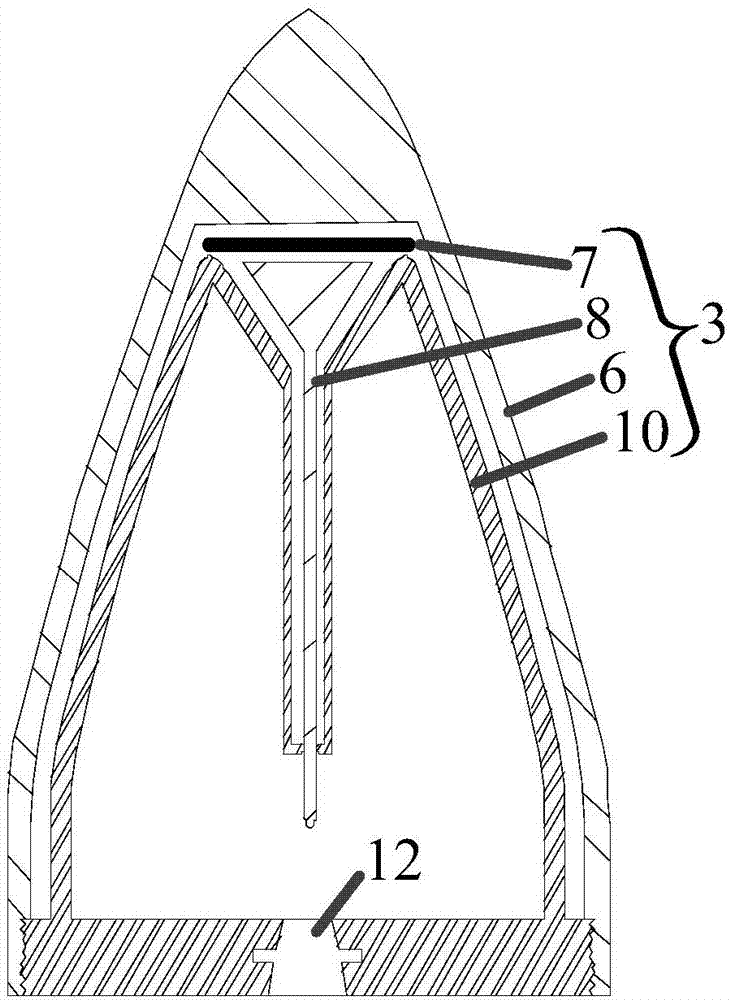

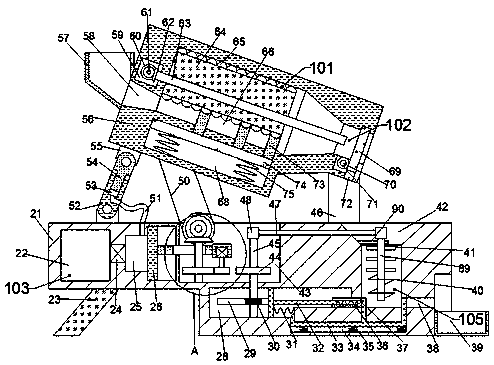

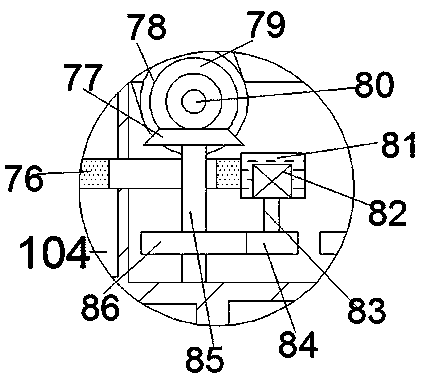

Head design of combustion chamber of twin-stage premixing ground-based gas turbine

InactiveCN105650680AImprove combustion efficiencyImprove ignitabilityContinuous combustion chamberCombustion chamberEngineering

The invention provides a head design of a combustion chamber of a twin-stage premixing ground-based gas turbine. The basic structure of the head comprises a central vortex tube, a crescent-shaped flame stabilizer and an outside annular vortex tube, wherein the central vortex tube is provided with double hydrocyclones; the crescent-shaped flame stabilizer is arranged at the down stream of the central vortex tube; and the outside annular vortex tube surrounds the central vortex tube. According to the design, a full-premixing combustion mode of the head is adopted mainly, so that the emission of NOx is reduced; air entering from a central value grade vortex tube of the head firstly passes through the first hydrocyclone, and then is mixed with ejected fuel; when a mixture flows out of the central vortex tube, the mixture is mixed and enhanced by the second hydrocyclone; at the same time, the hydrocyclone further prevents tempering; the central value grade premixed fuel forms a stable ignition source on the flame stabilizer; and the premixed fuel flowing out of the outside main burning stage is ignited, burning is carried out stably and mildly, and uniform combustion is achieved. The design can guarantee that the ground-based gas turbine can keep low emission of NOx and stable combustion on operating conditions of all loads.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Firework type extinguishant and extinguisher thereof

InactiveCN1333067AImprove ignitabilityIgnition lag period shortenedFire extinguisherOrganic acidOxidizing agent

The composition of fire-extinguishing agent is made of (wt%) 40-65% of oxidant, 10-20% of fuel, 20-40% of catalyst, 0-5% of additive and 3-7% of combustion speed regulator, in which the oxidant is ammonium nitrate, the fuel is a compound whose molecular formula is CnH2n-2On-1 (n=5-7), and the catalyst is one of nitrates or mixture of more than two kinds of them, and the combustion speed regulatoris chloride, inorganic acid salt and organic acid salt. Said invented fire extinguisher includes exhaust chamber, cooling chamber and charging chamber, said three portions are made into cylindrical form. Said exhaust chamber includes filtering screen and nozzle on the filtering screen, the cooling chamber includes includes at least 6 layers of sieve plates, on the plate the screen for holding cooling agent is laid, and the charging chamber also is equipped with a starter made of chemical initiating agent. Its combustion speed is high, it does not pollute environment, and is extensive in application.

Owner:松全才 +1

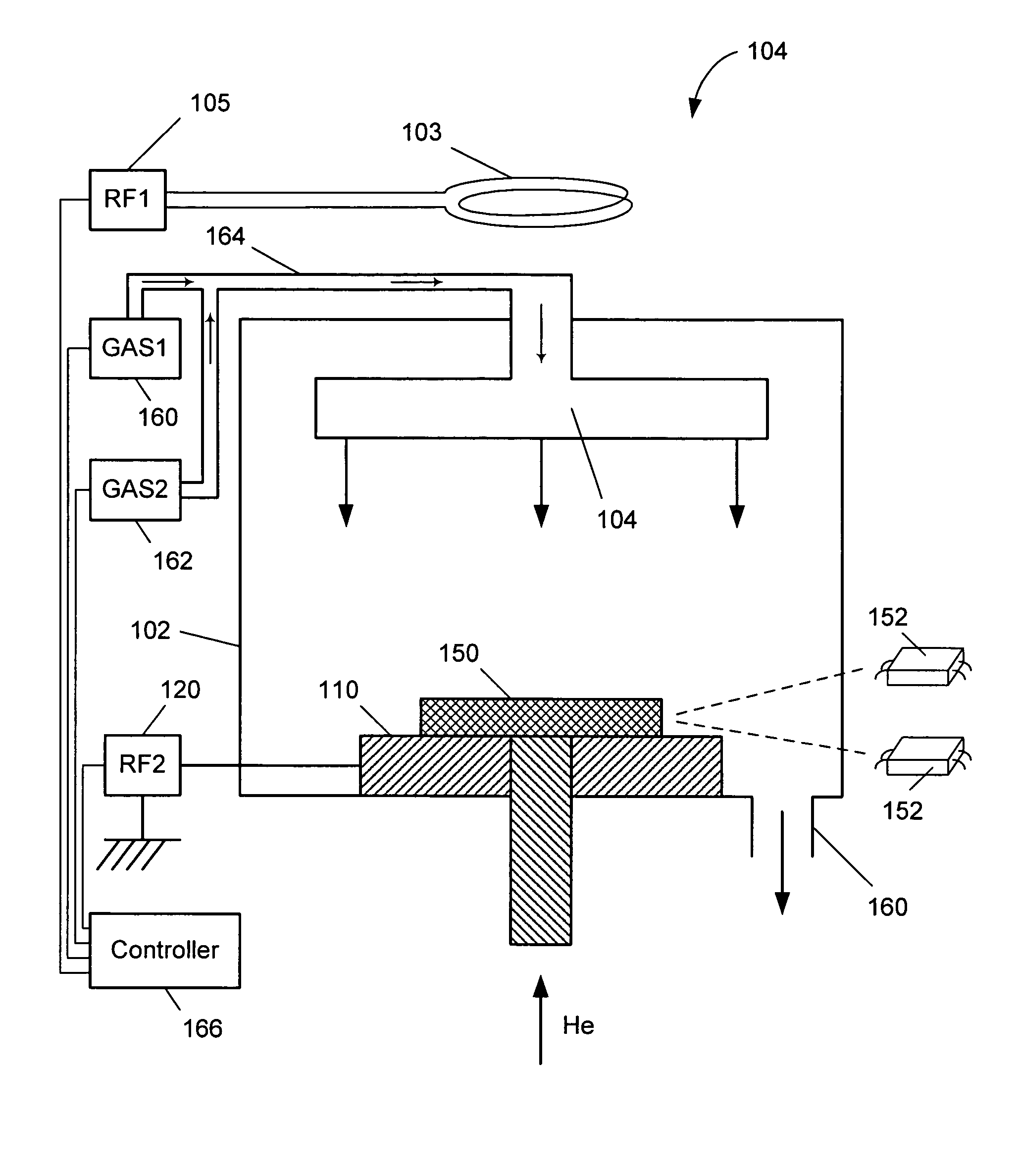

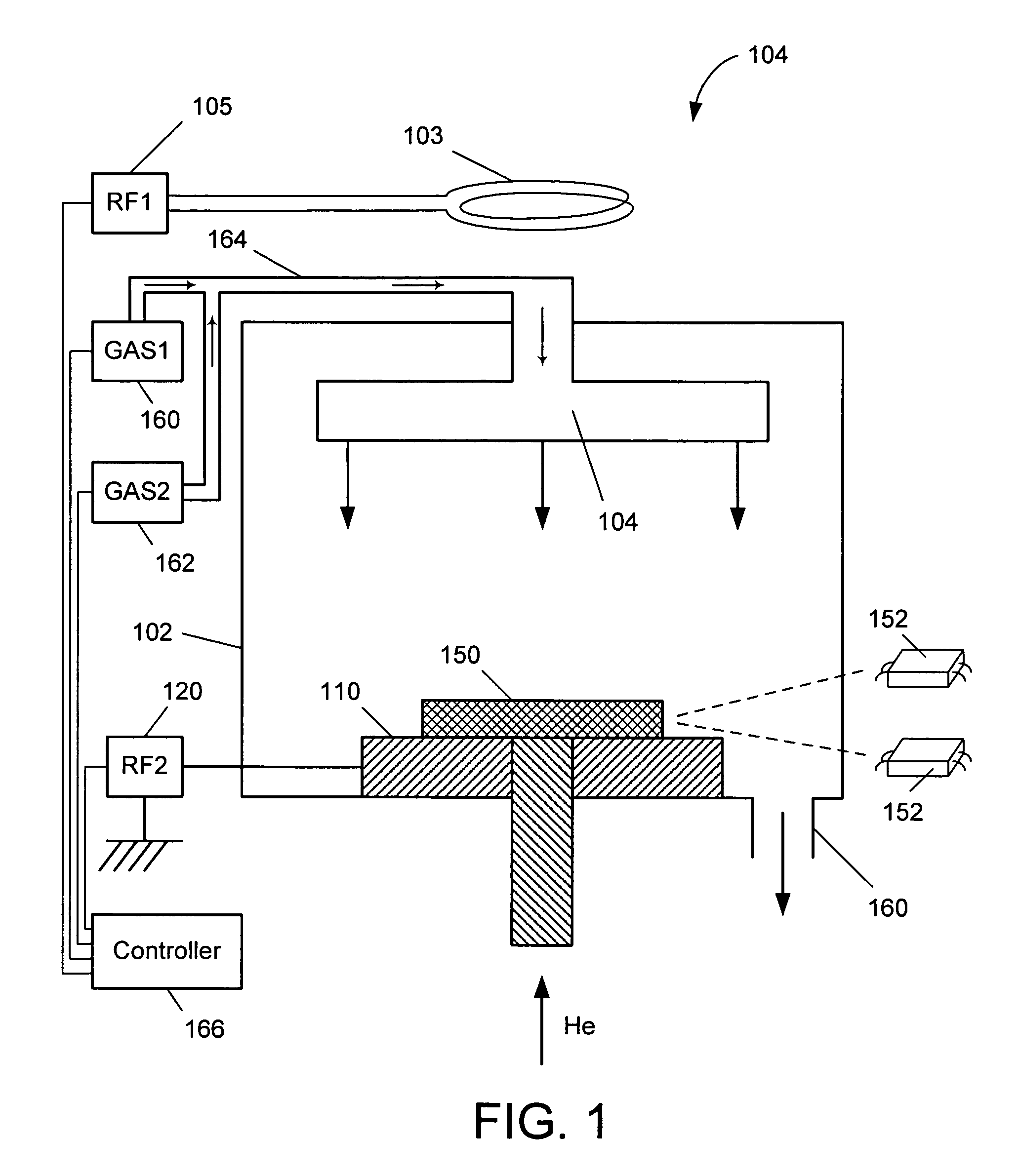

Method to improve ignition in plasma etching or plasma deposition steps

InactiveUS7279429B1Improve flammabilityImprove ignition reliabilityElectric discharge tubesDecorative surface effectsPlasma depositionEngineering

In one embodiment, the present invention relates to a method for increasing the ignition reliability of a plasma in a plasma reactor, the method comprising: supplying a source gas to the plasma reactor, the source gas comprising: (a) at least one reactive compound; and (b) at least one ignition gas, wherein the at least one ignition gas increases the ignitability of the source gas as compared to the ignitability of the source gas lacking the at least one ignition gas.

Owner:ADVANCED MICRO DEVICES INC

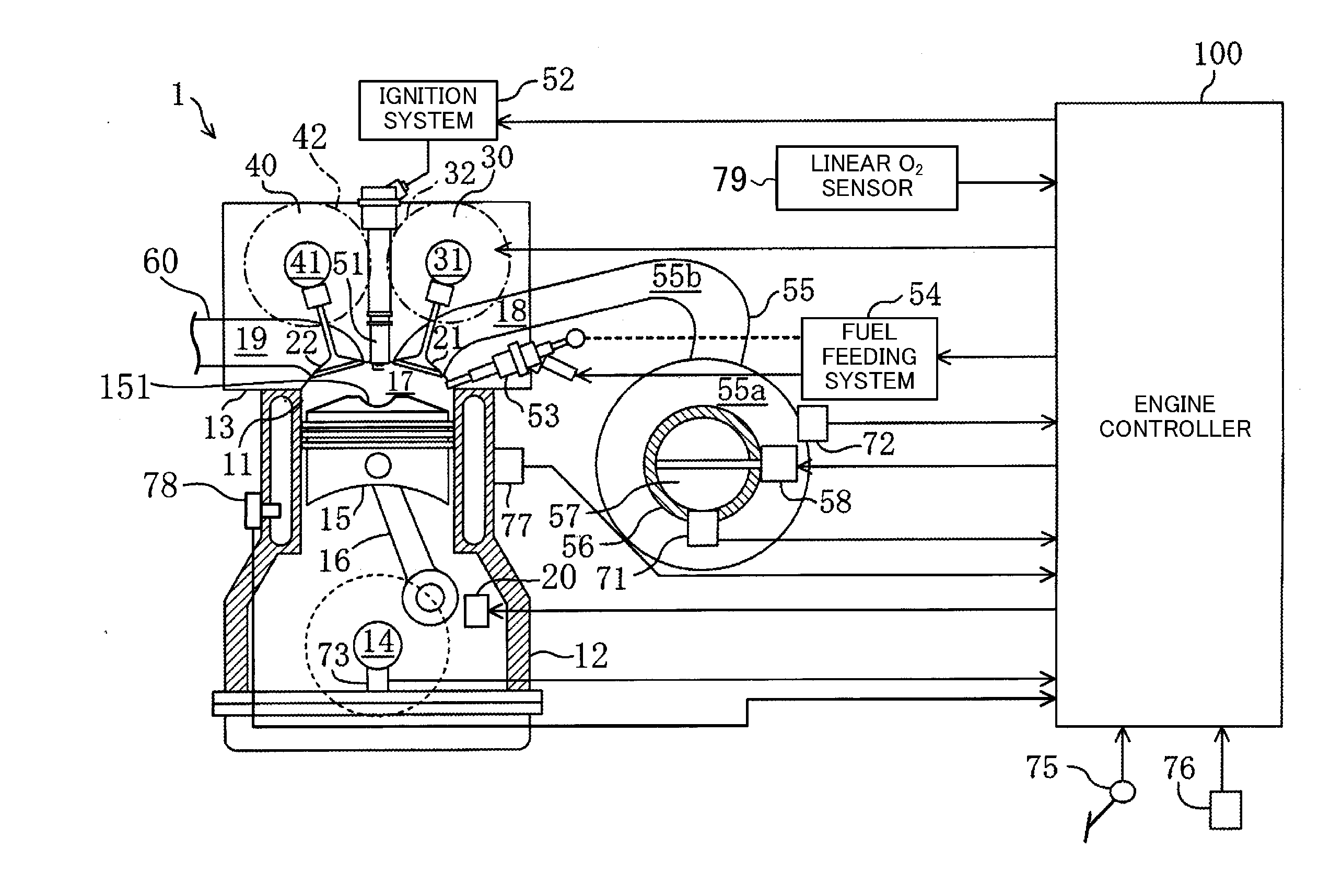

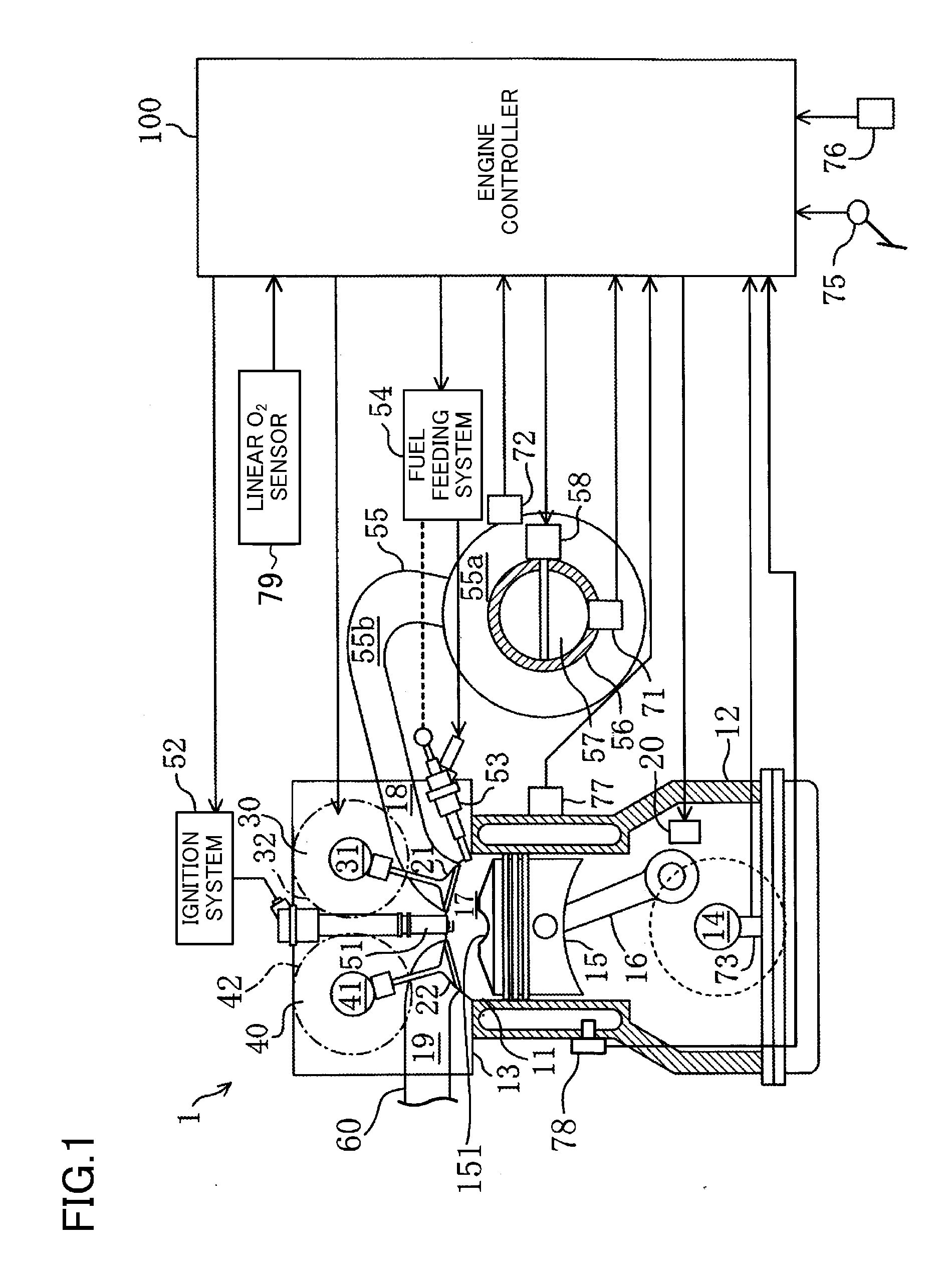

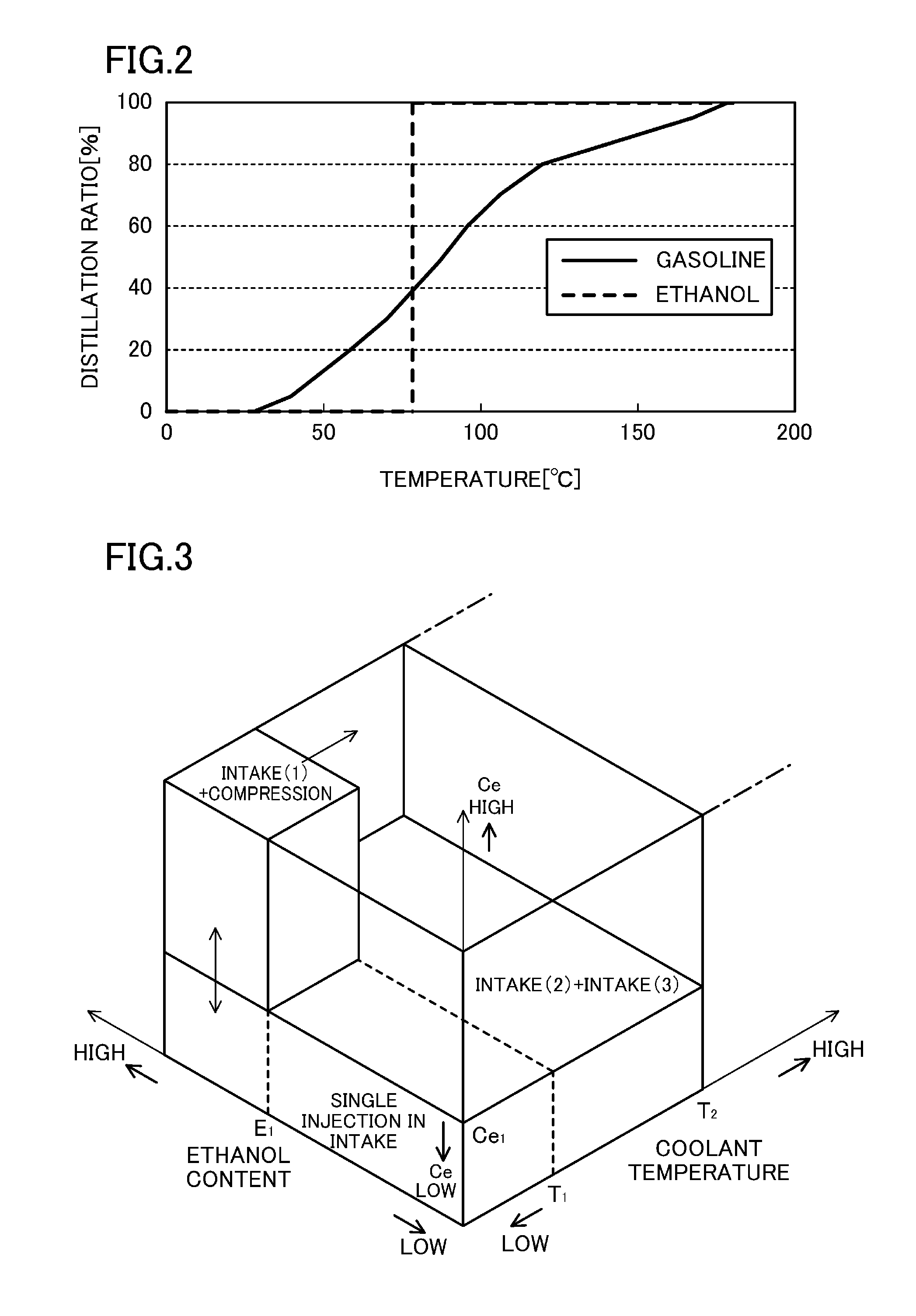

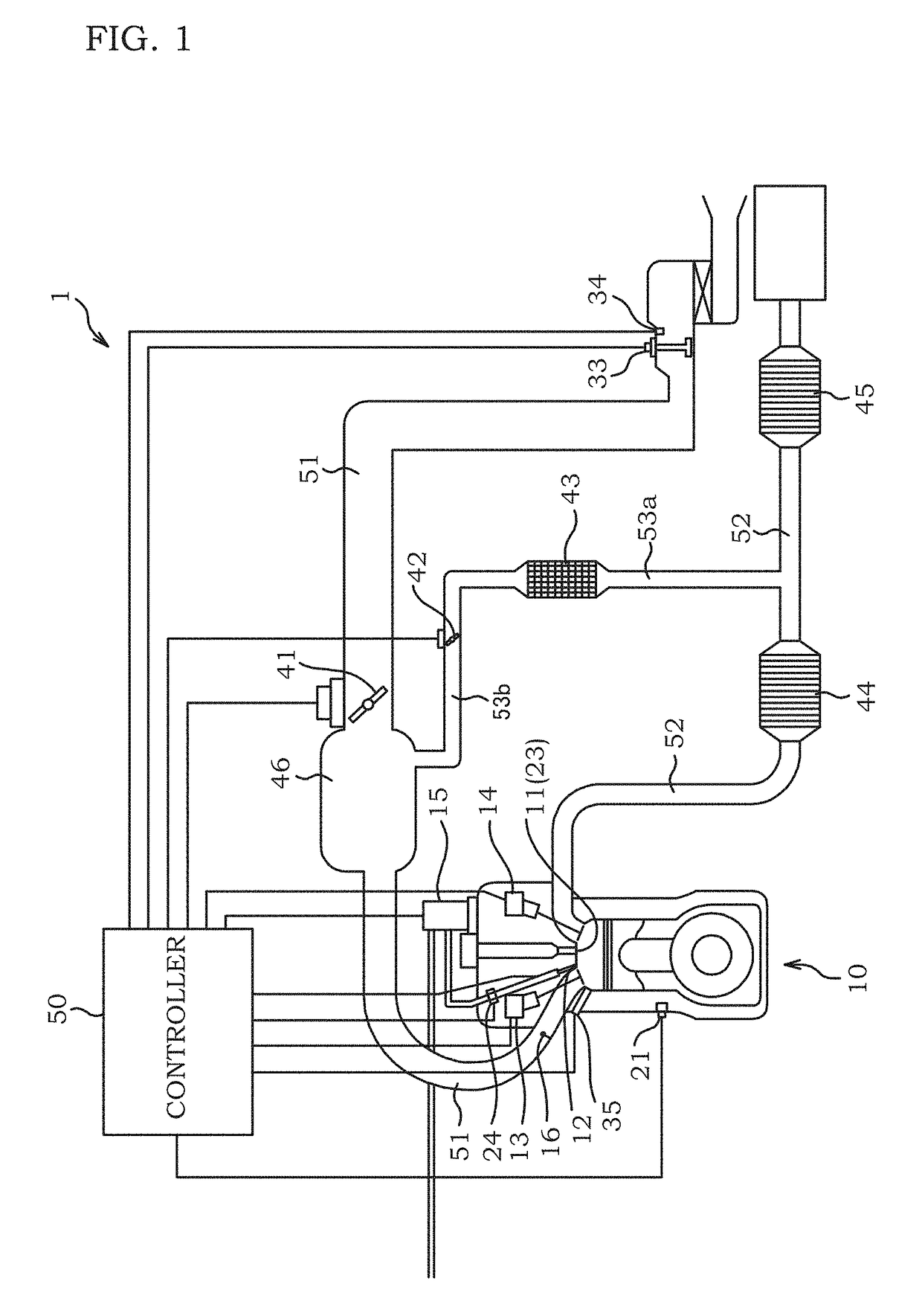

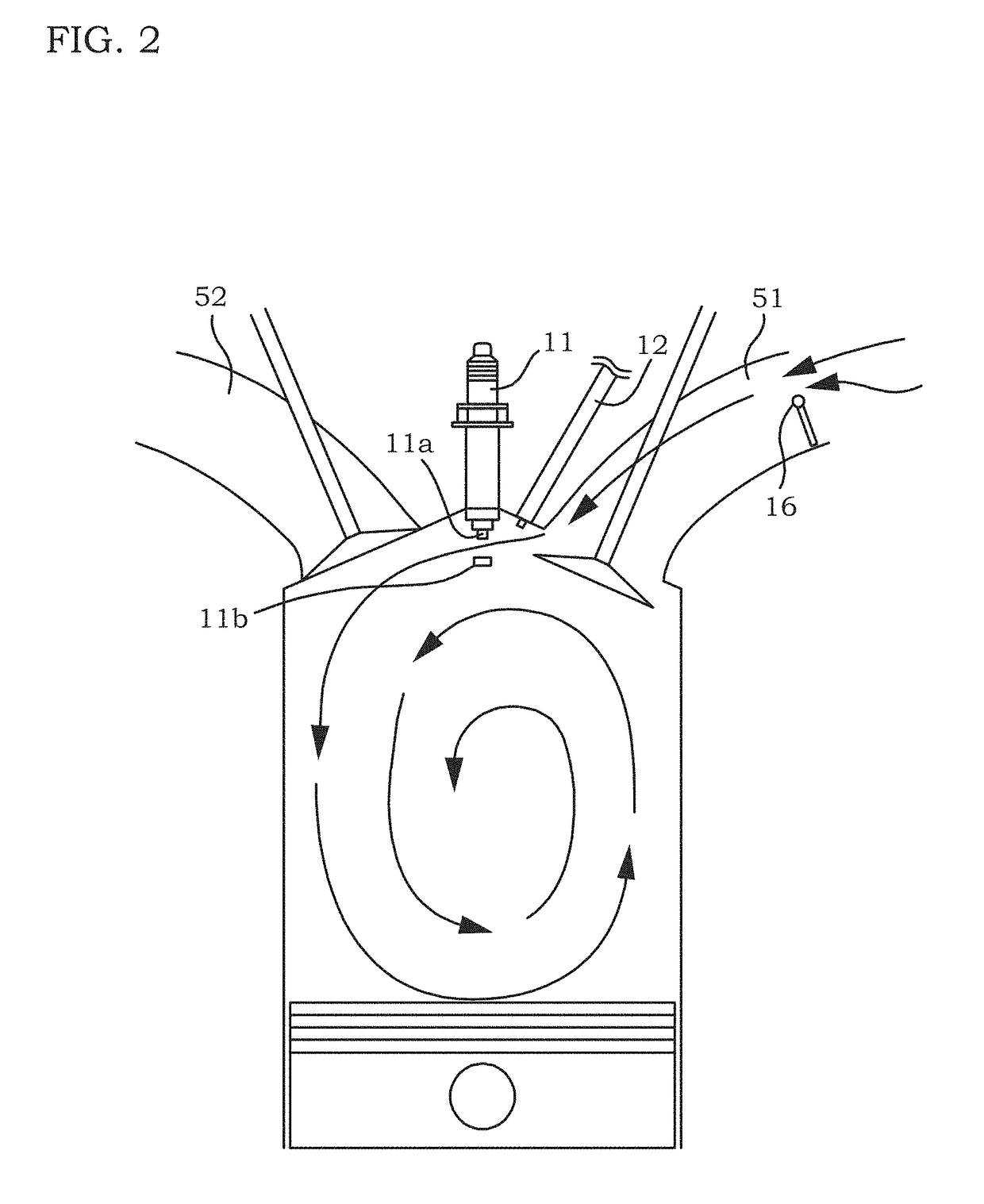

Control device for spark-ignition engine

InactiveUS20160341145A1Improve homogeneityGeneration of smoke is reduced and avoidedElectrical controlInternal combustion piston enginesEngineeringControl theory

A controller (an engine controller 100) allows a fuel to be fed into a cylinder 11 within a range from an intake stroke to a compression stroke, if an engine body (an engine 1) is at a low temperature which is equal to or below a predetermined temperature and is under a load which is equal to or greater than a predetermined load. The controller instructs a fuel injection valve 53 to inject a greater amount of the fuel during the compression stroke than during the intake stroke if the content of an unconventional fuel in the fuel is higher than a predetermined level, and to inject a greater amount of the fuel during the intake stroke than during the compression stroke if the content of the unconventional fuel in the fuel is equal to or lower than the predetermined level.

Owner:MAZDA MOTOR CORP

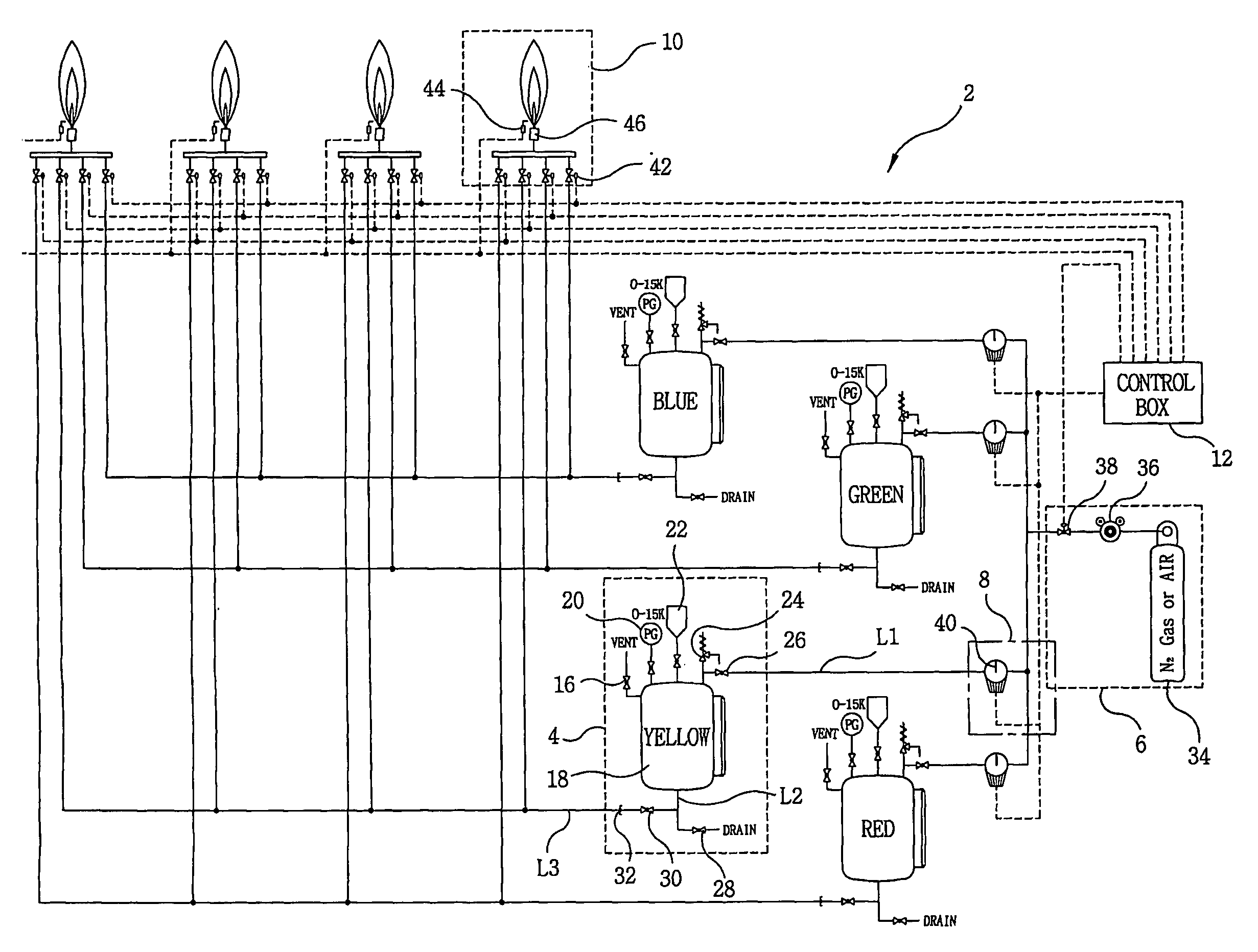

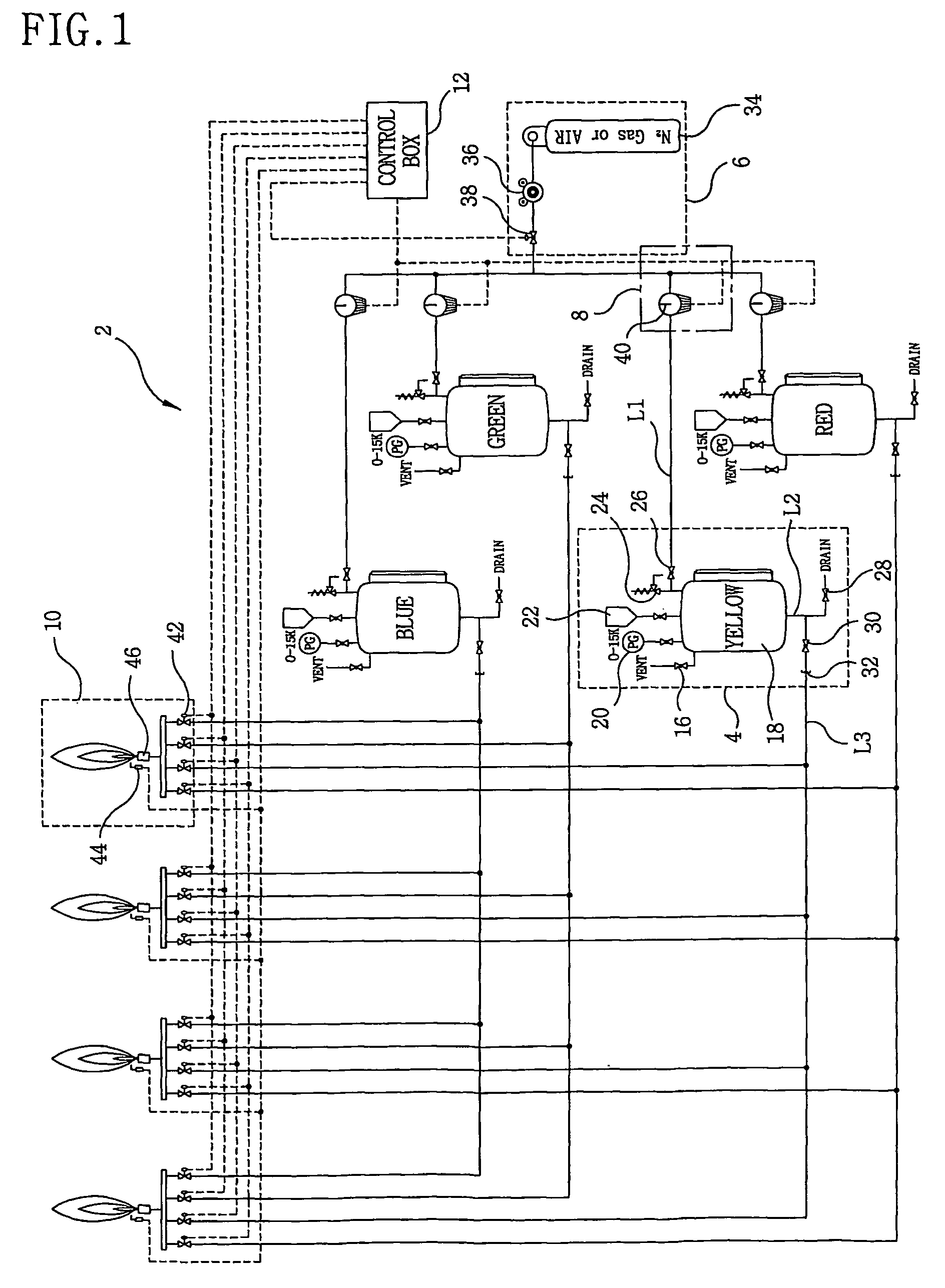

Fuel composition and a device for colored flames

InactiveUS20060096164A1Enhanced colored flame presentationImprove flammabilityLiquid fuel feeder/distributionLiquid carbonaceous fuelsEngineeringHydrocarbon

The present invention is related to a fuel composition for colored flames and an appropriate combustion device for using such composition which provides a fuel composition for colored flames with improved inflammability, realization of colored flames and persistency by having alcohol of low ignition point as a fuel, by adding a compound having an ester structure and by adding a fire power enhancer including at least 3 higher hydrocarbon. Also, the present invention provides a combustion device wherein the fuel composition is injected in fog so as to enhance ignition power when rendering colored flames by injecting through an injection nozzle and igniting, the size of flames can be controlled by adjusting pressure, and color of the flames injected through each injection nozzle portion can be realized in different colors respectively by a control device.

Owner:HWALIM TECHNOLOGICAL

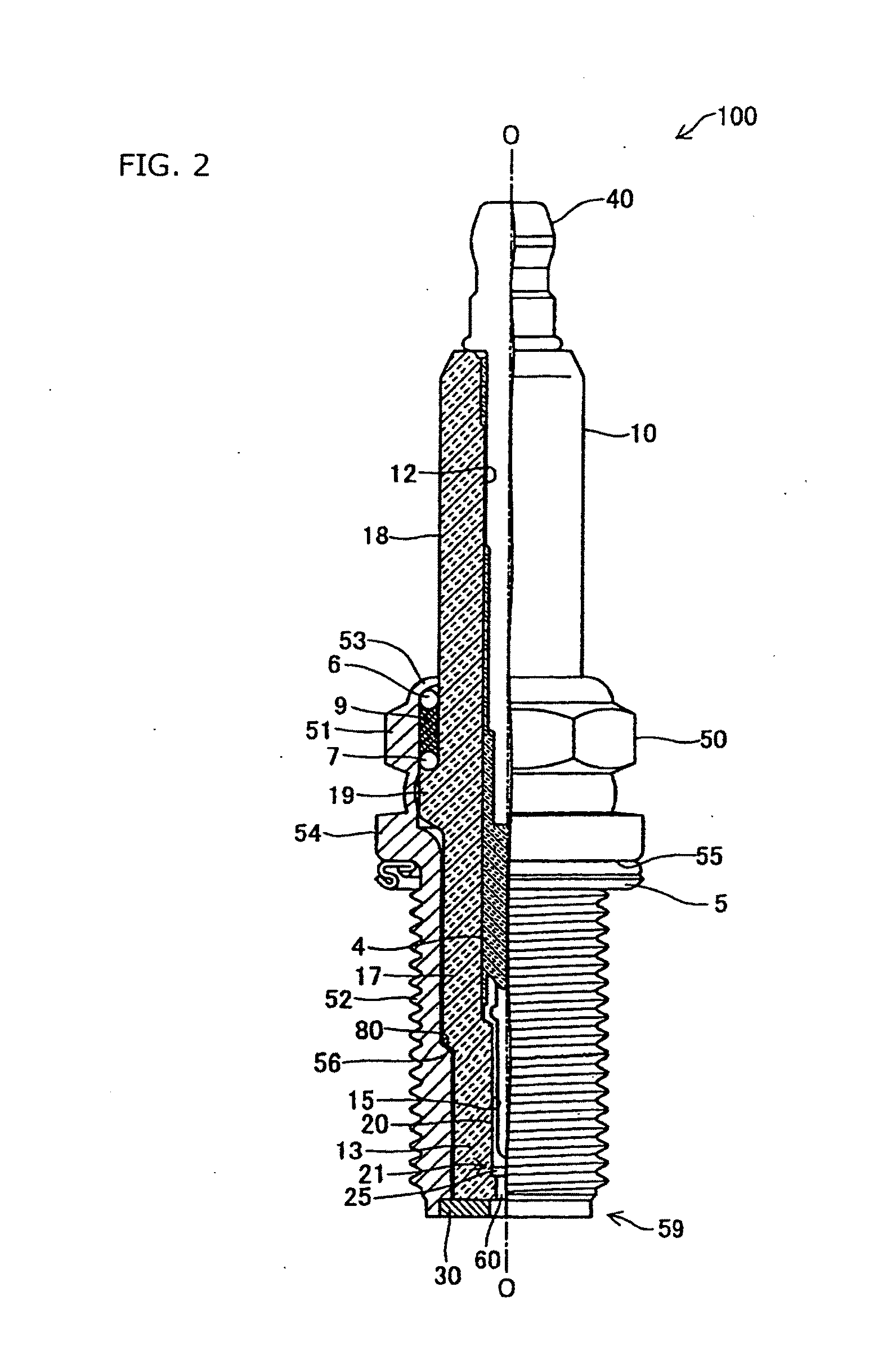

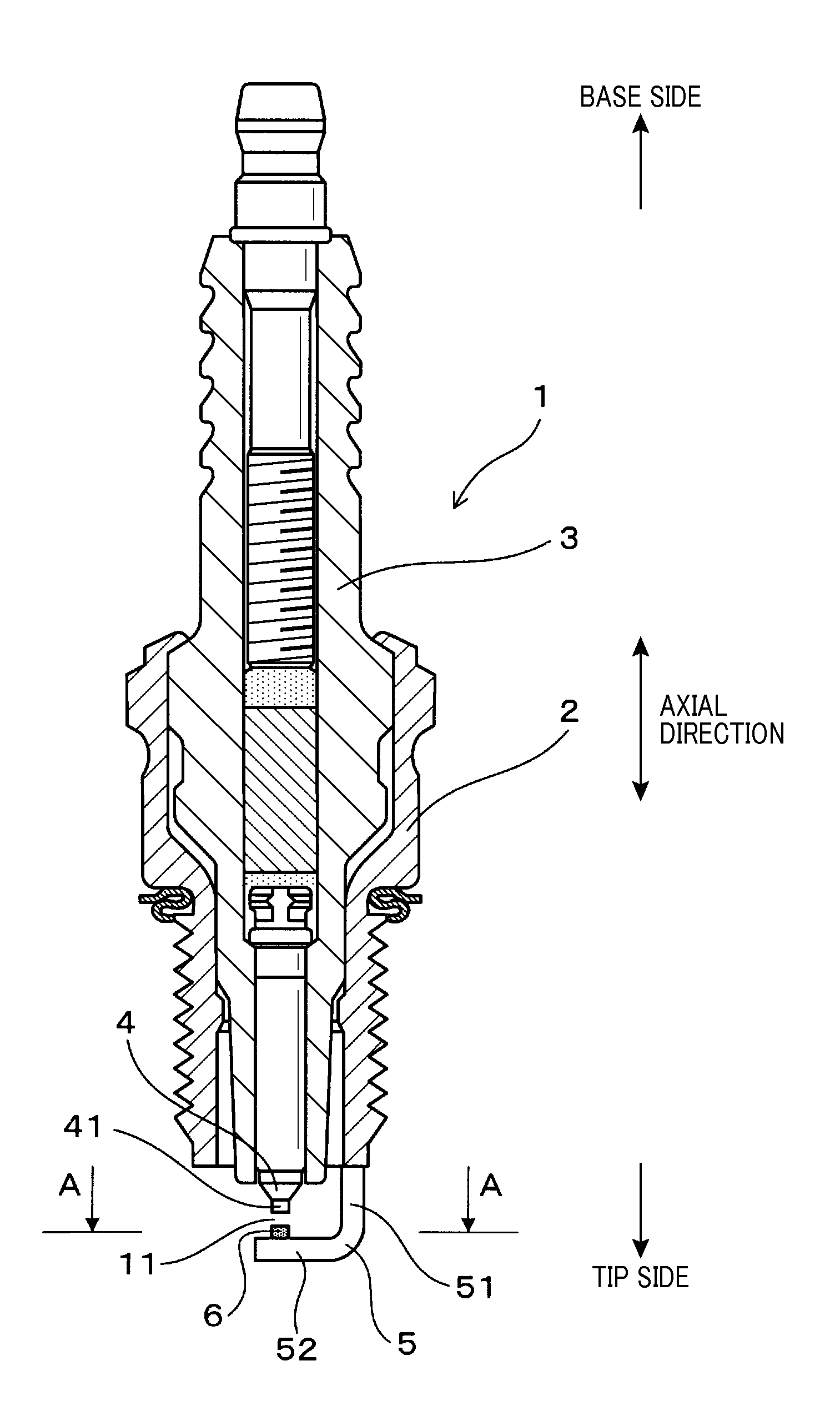

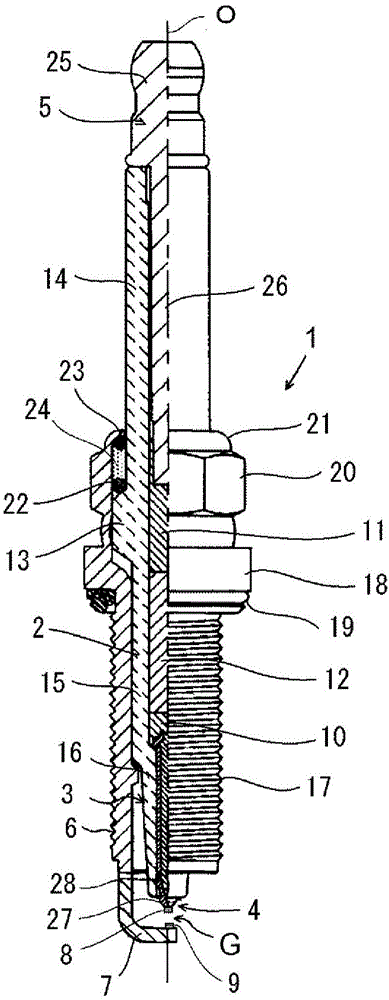

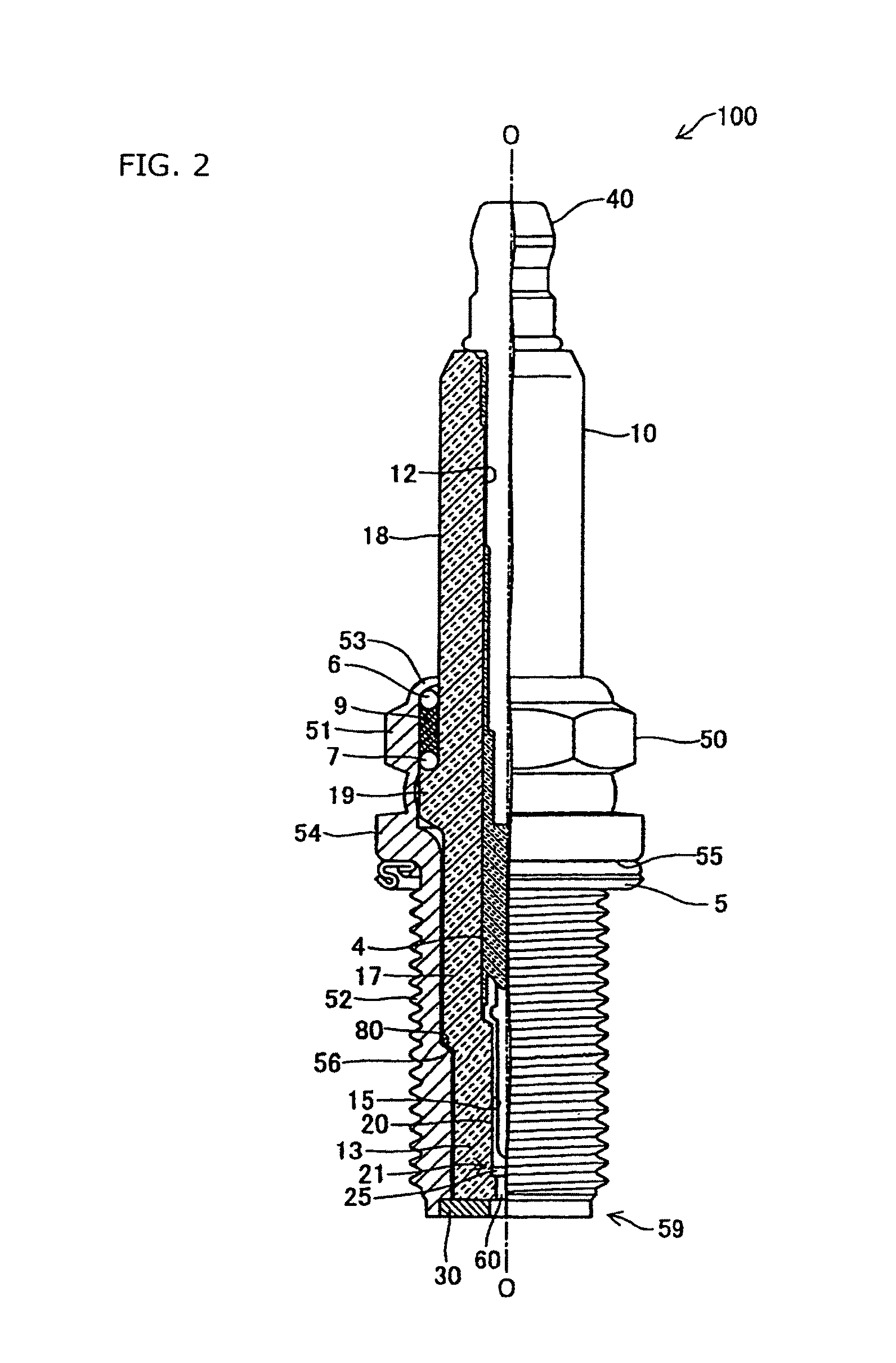

Spark plug for internal combustion engines and mounting structure for the spark plug

ActiveUS20140265816A1Prolong lifeWear minimizationSparking plugsMachines/enginesCombustionEngineering

A spark plug for an internal combustion engine is provided, which includes a housing, an insulation porcelain, a center electrode and a ground electrode. At least one of a tip portion of the center electrode and an opposing portion of the ground electrode is provided with a projection portion. At least one of the projection portions has a cross section perpendicular to the axial direction of the plug, the cross section having a minimum curvature radius portion and being in a specific shape that satisfies a predetermined requirement. The requirement is that, when a first straight line, a first line segment and a second straight line are provided, and when the cross section is divided into a first region and a second region by the second straight line, the second region has an area larger than the area of the first region.

Owner:DENSO CORP

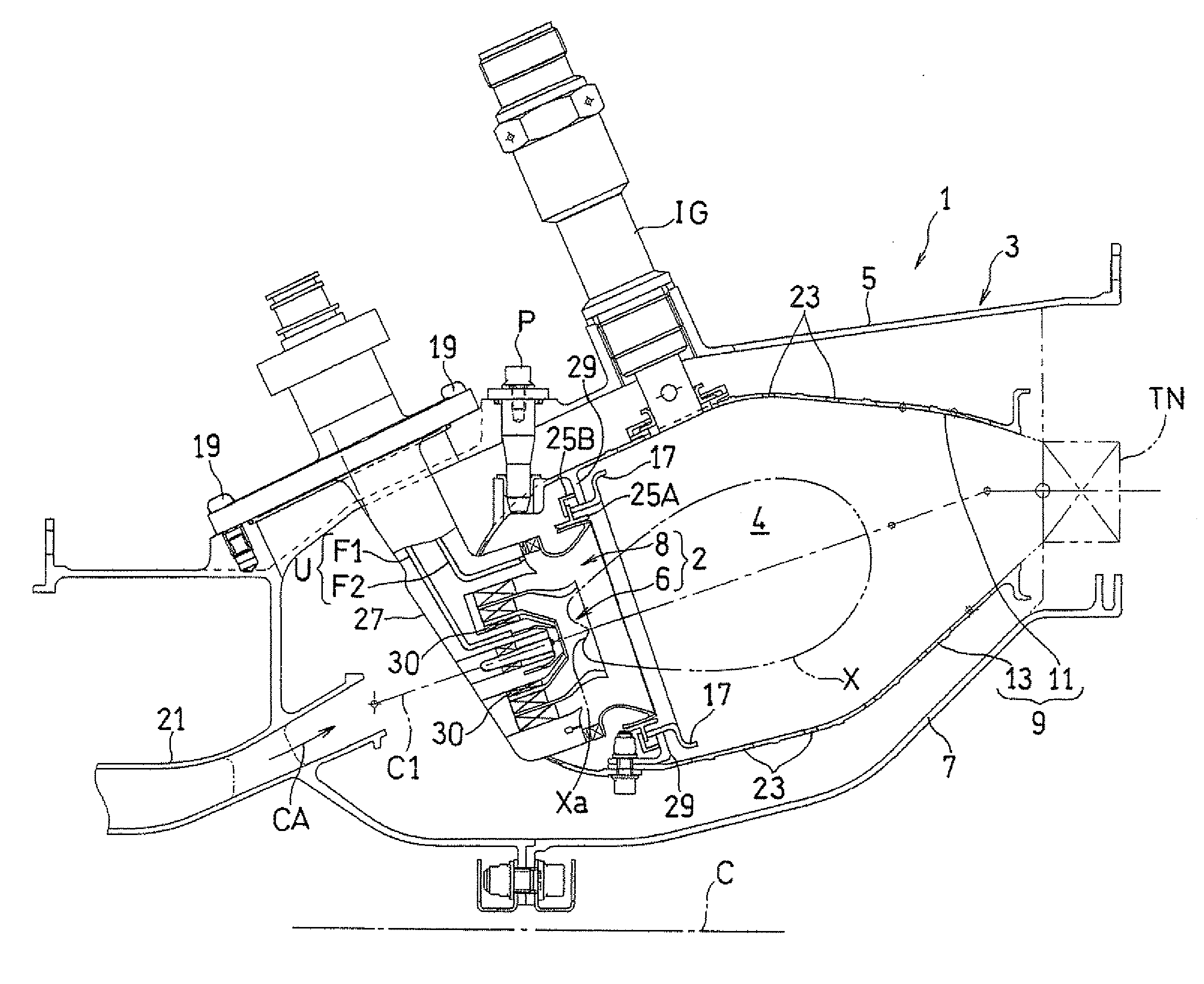

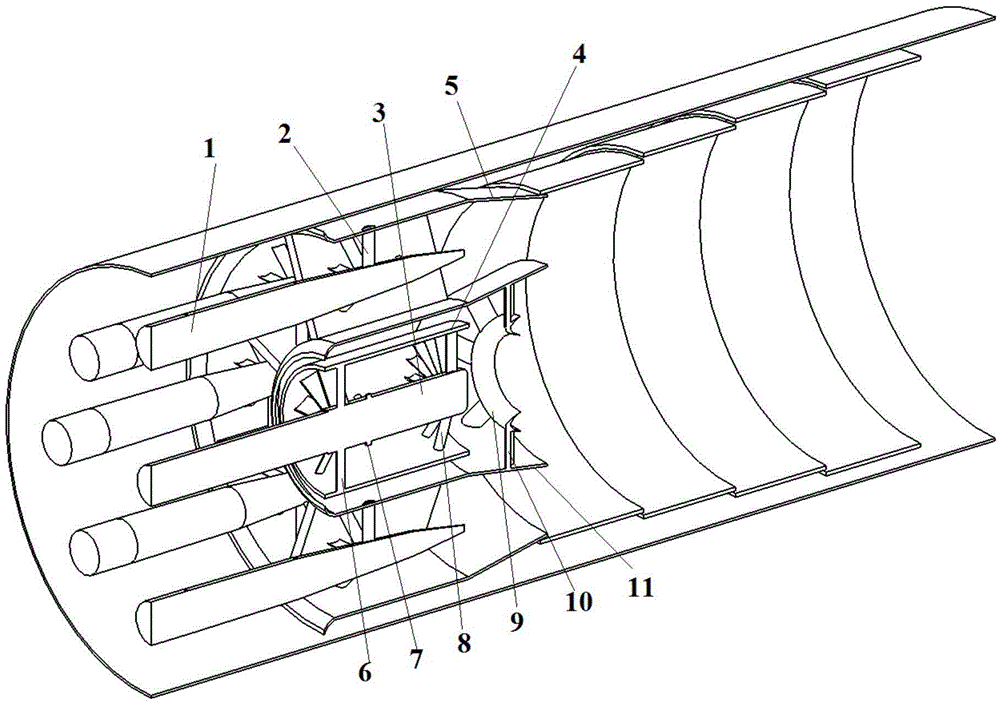

Pilot fuel injector with swirler

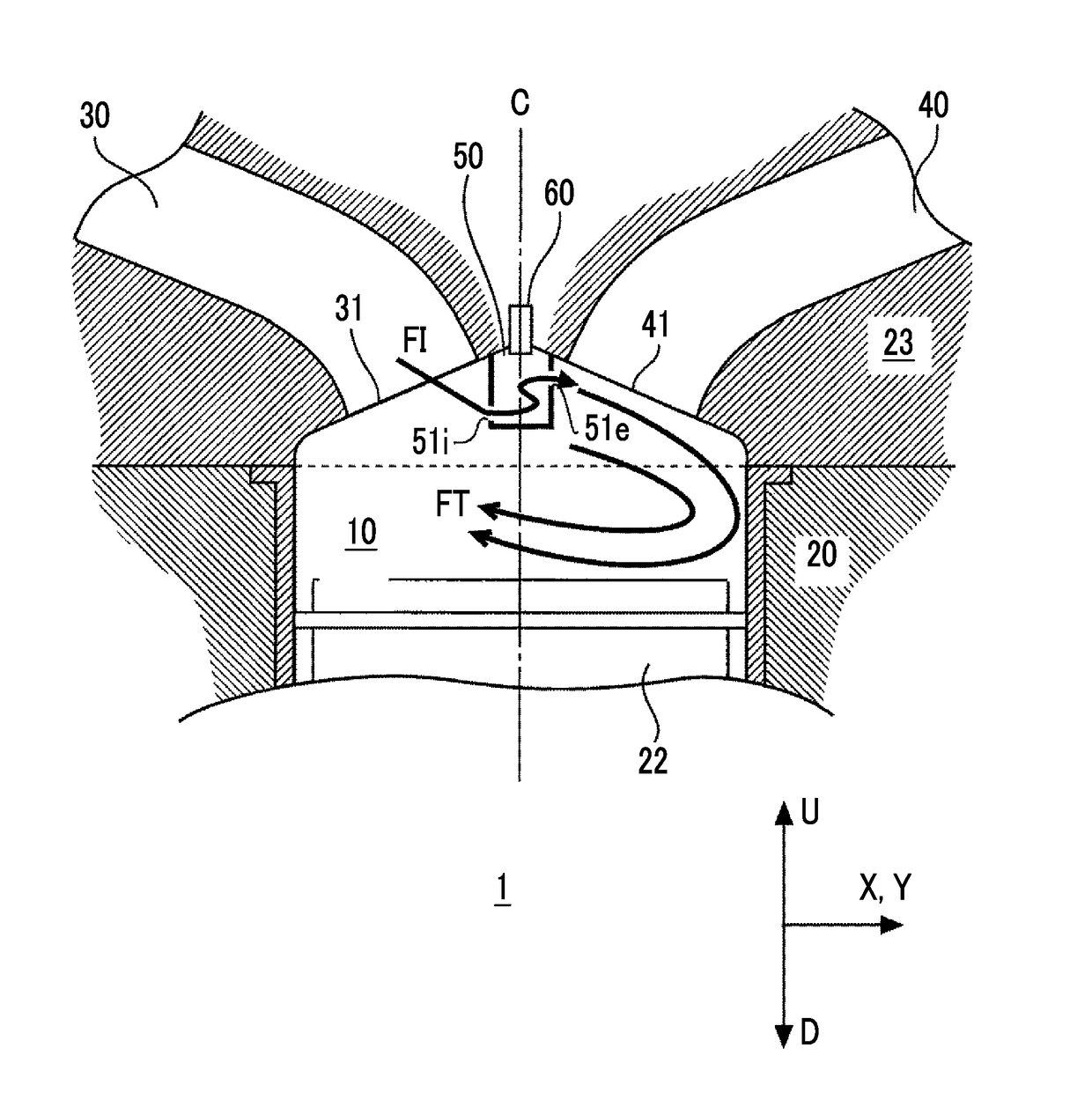

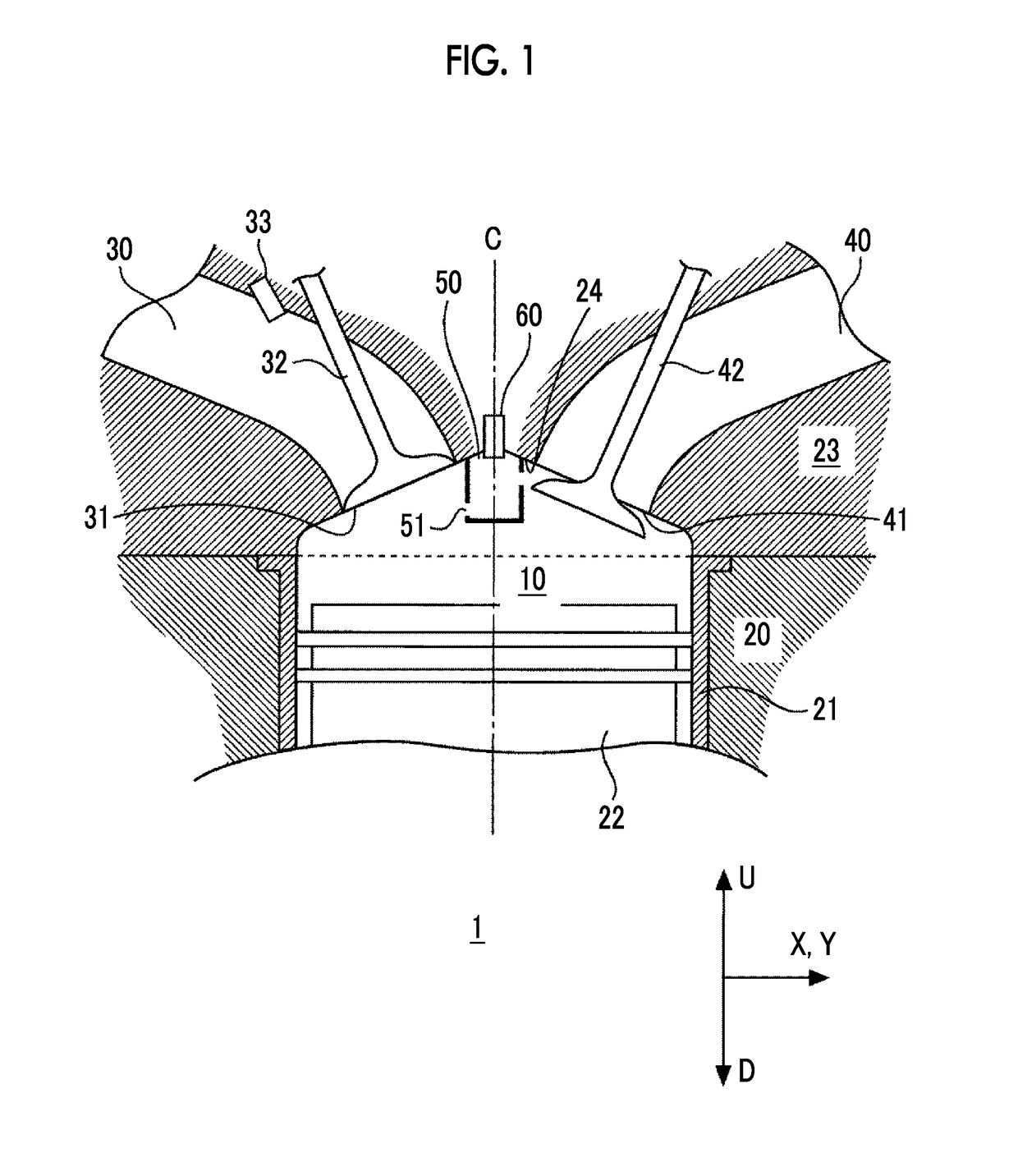

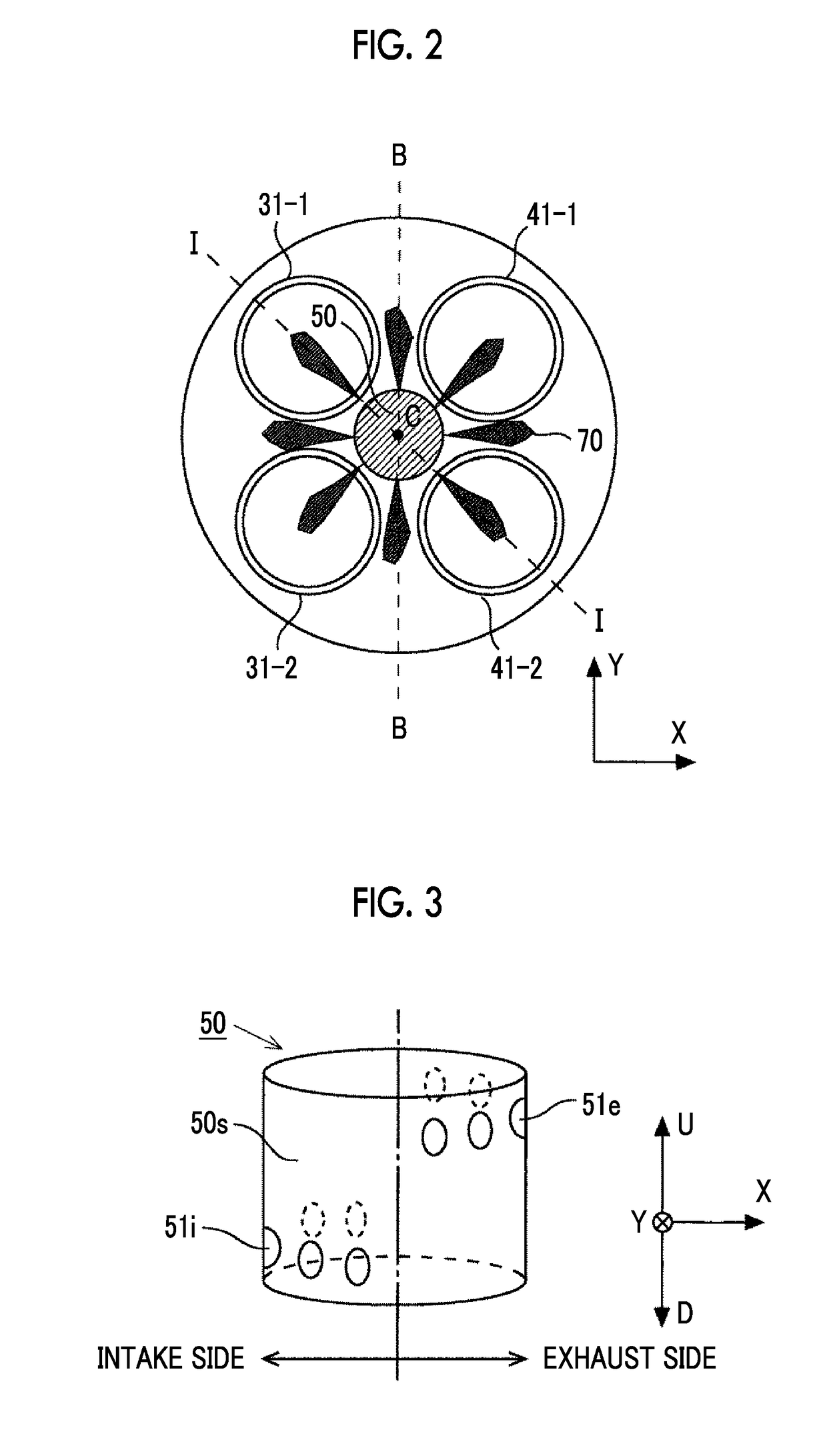

ActiveUS9366442B2Improve efficiencyImprove ignitabilityContinuous combustion chamberMachines/enginesCombustion chamberMain injector

A fuel injector includes: a pilot injector configured to spray fuel so as to form a first combustion region in a combustion chamber; and a main injector provided coaxially with the pilot injector so as to surround the pilot injector and configured to supply a fuel-air mixture that is a mixture of the fuel and air to form a second combustion region in the combustion chamber, wherein the pilot injector includes: a center nozzle configured to eject air jet flowing straight in an axial direction on a central axis of the pilot injector; an inside swirler provided on a radially outer side of the center nozzle and configured to cause inflow air to swirl around the central axis; and a pilot fuel injecting portion configured to inject the fuel from between the center nozzle and the inside swirler to air flow in the center nozzle.

Owner:KAWASAKI HEAVY IND LTD +1

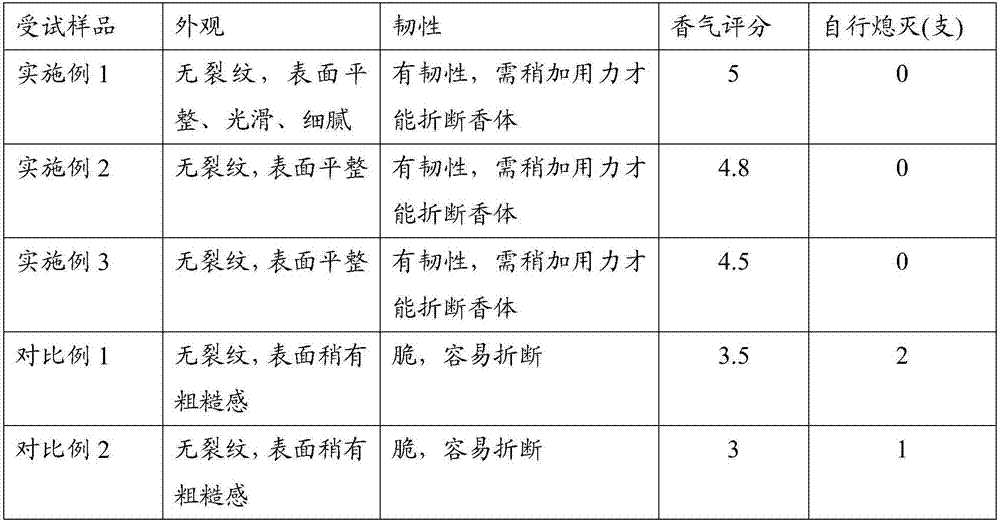

Novel applications of cow dung and incense products containing cow dung

InactiveCN107232949ARecovery from fatiguePrevent diseaseDeodrantsReligious equipmentChemistryCow dung

The invention provides applications of dry cow dung in preparation of incense products. The invention further provides the incense products containing the dry cow dung and a manufacturing method of the incense products. According to the technical scheme, dry cow dung is adopted as the main component for preparing the incense products such as incense sticks for the first time, and thus a novel utilization way is developed for cow dung.

Owner:敖格友

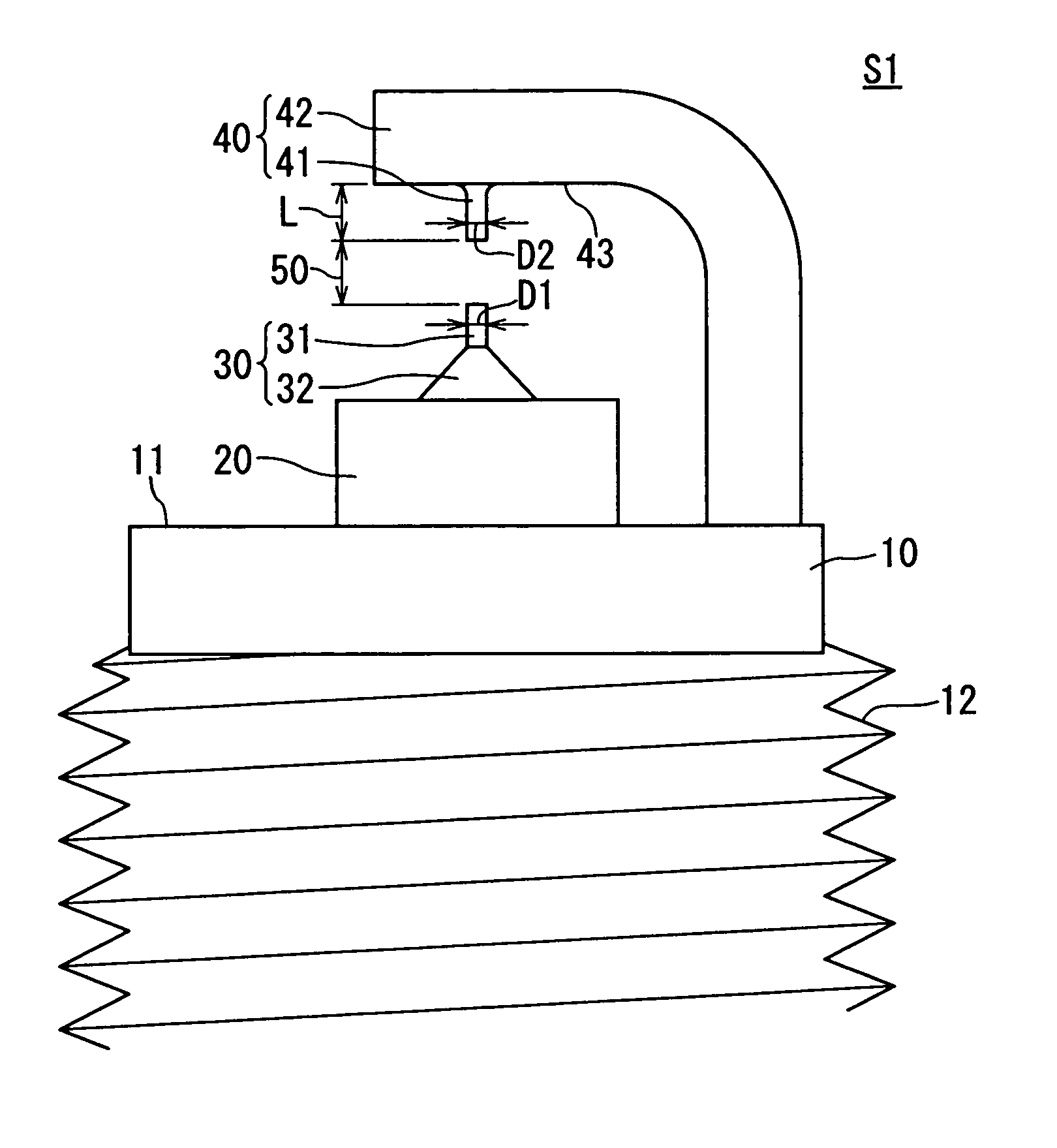

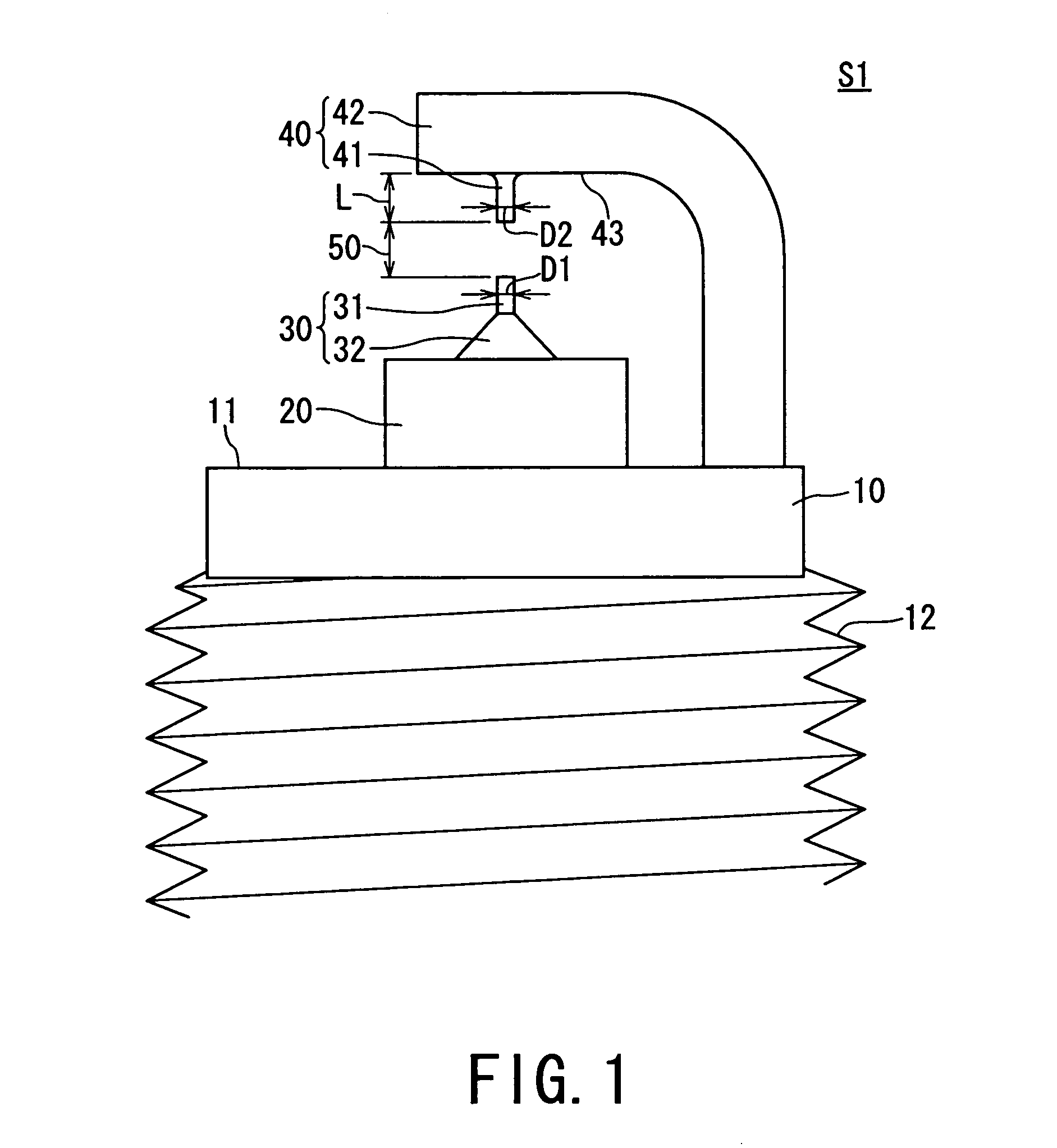

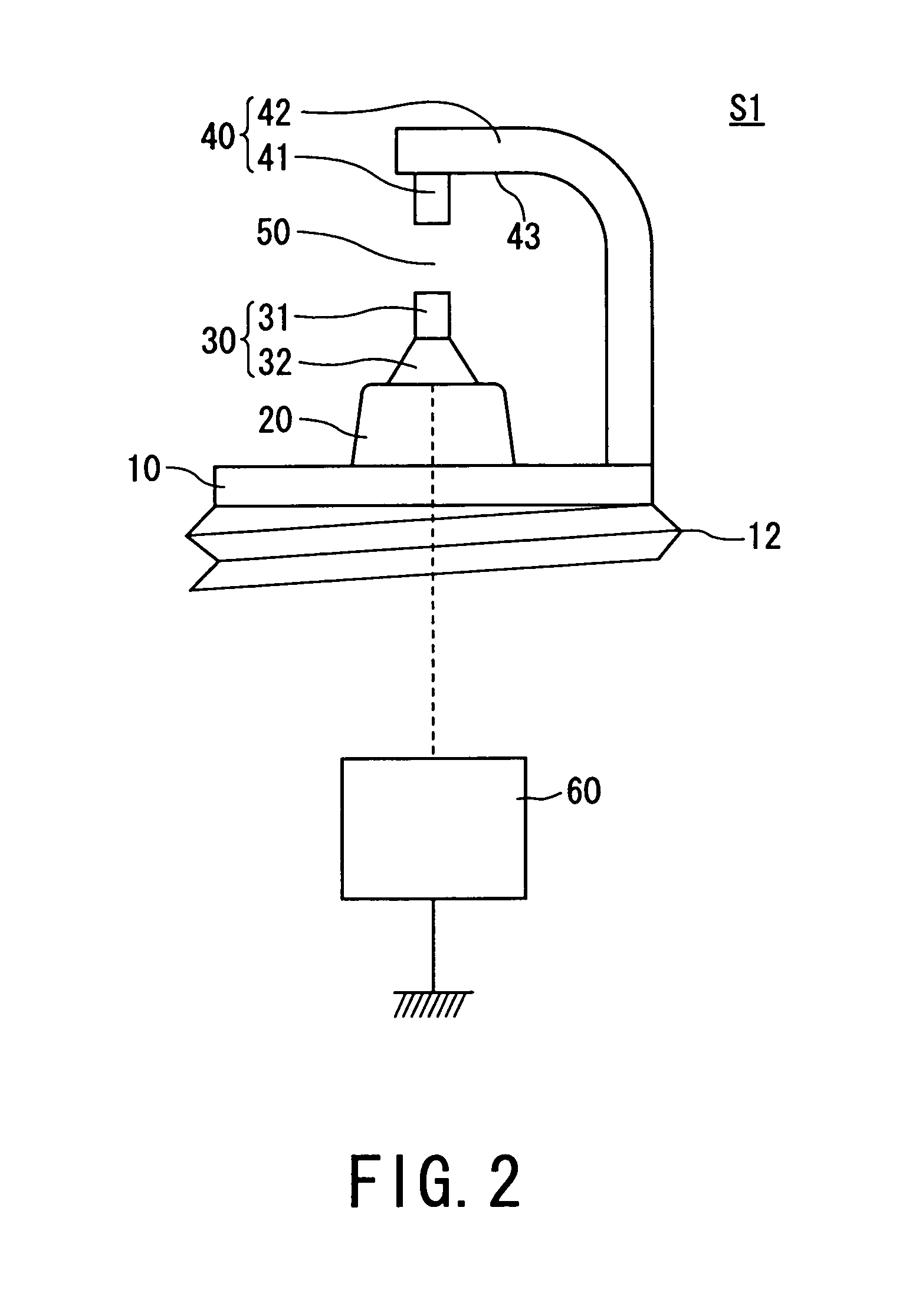

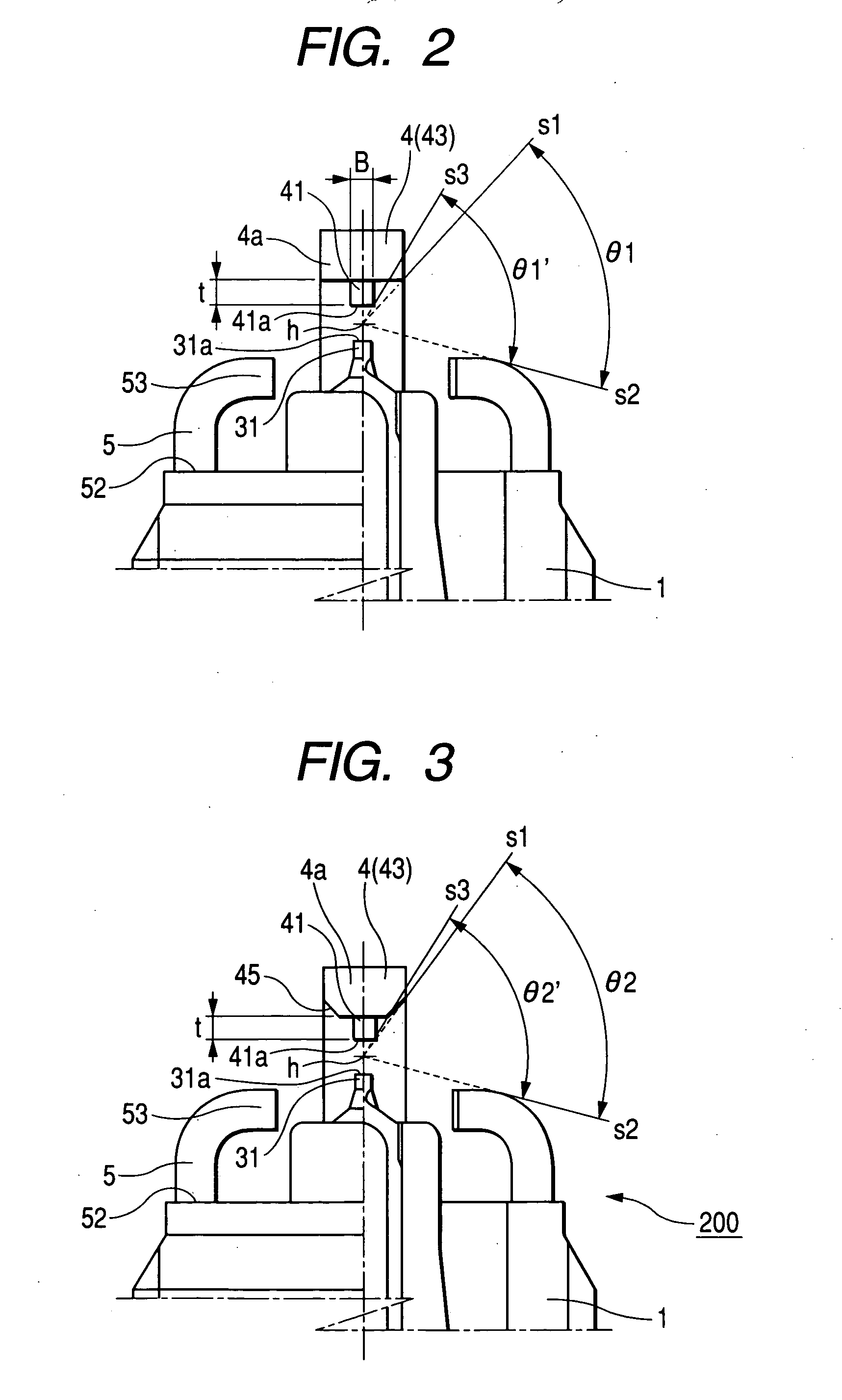

Spark plug and ignition apparatus using same

InactiveUS7086363B2Low ignition energySave energy consumptionSparking plugsGenerator generated ignition energyEngineeringSpark plug

A power-saving type of ignition apparatus is provided with a spark plug of which electrodes (30, 40) are regulated in their shapes to lower an amount of energy required for its ignition. To face to a tip (31) of a center electrode (30) extending from a mounting bracket (10), a cylindrical protrusion (41) is built on one surface (43) of an earth electrode (40). The protrusion extends toward the center electrode to form a discharge gap (50) between the protrusion and the tip of the center electrode. Both of the tip of the center electrode and the protrusion of the earth electrode are 2.3 [mm] or less in each diameter (D1, D2), thus an amount of energy required for ignition being limited to 17 [mJ] or less.

Owner:DENSO CORP +1

Spark plug

ActiveCN106030942AExcellent consumptionIncreased durabilitySparking plugs manufactureEngineeringPerovskite

The objective of the present invention is to provide a spark plug having excellent durability by providing a central electrode and / or a grounding electrode with a tip having excellent resistance to spark-wear under high-temperature environment. The spark plug is provided with a central electrode and a grounding electrode disposed with a gap from the central electrode, said spark plug being characterized in that: there is a tip forming the gap on the central electrode and / or the grounding electrode; the tip has a metal matrix, whereof the main constituent is Ir, and oxide particles containing at least one species of oxide having a perovskite structure represented by the general formula ABO3 (where A is at least one species selected from the group 2 elements of the periodic table, and B is at least one species selected from the metal elements); and the proportion of the surface area occupied by the oxide particles upon observation of the cross section of the tip is 1% to 13% inclusive.

Owner:NGK SPARK PLUG CO LTD

Internal combustion engine

ActiveUS20180230895A1Strengthen tumble flowImprovement in combustibilitySparking plugsInternal combustion piston enginesPistonEngineering

An internal combustion engine includes: a main combustion chamber; an intake port connected to the main combustion chamber; an exhaust port connected to the main combustion chamber; a sub-chamber; and a spark plug in the sub-chamber. The sub-chamber is provided between the intake opening portion and the exhaust opening portion and connected to the main combustion chamber through a plurality of communication holes. The communication holes include a first communication hole provided on the intake opening portion side, and a second communication hole provided on the exhaust opening portion side. The first communication hole is closer to a piston than the second communication hole is. The first communication hole is inclined to be closer to the piston as the first communication hole is positioned toward the inside from the outside of the sub-chamber.

Owner:TOYOTA JIDOSHA KK

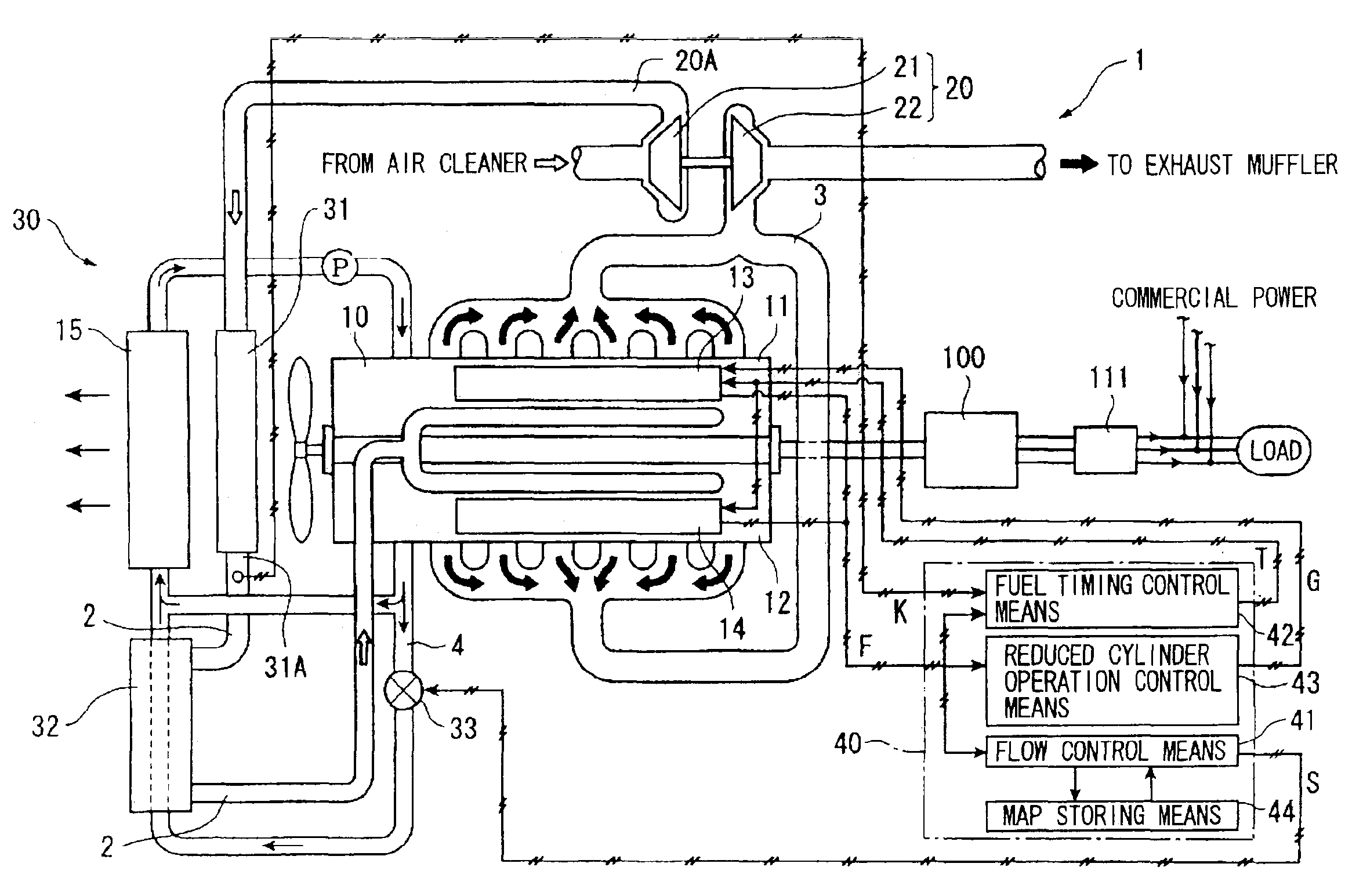

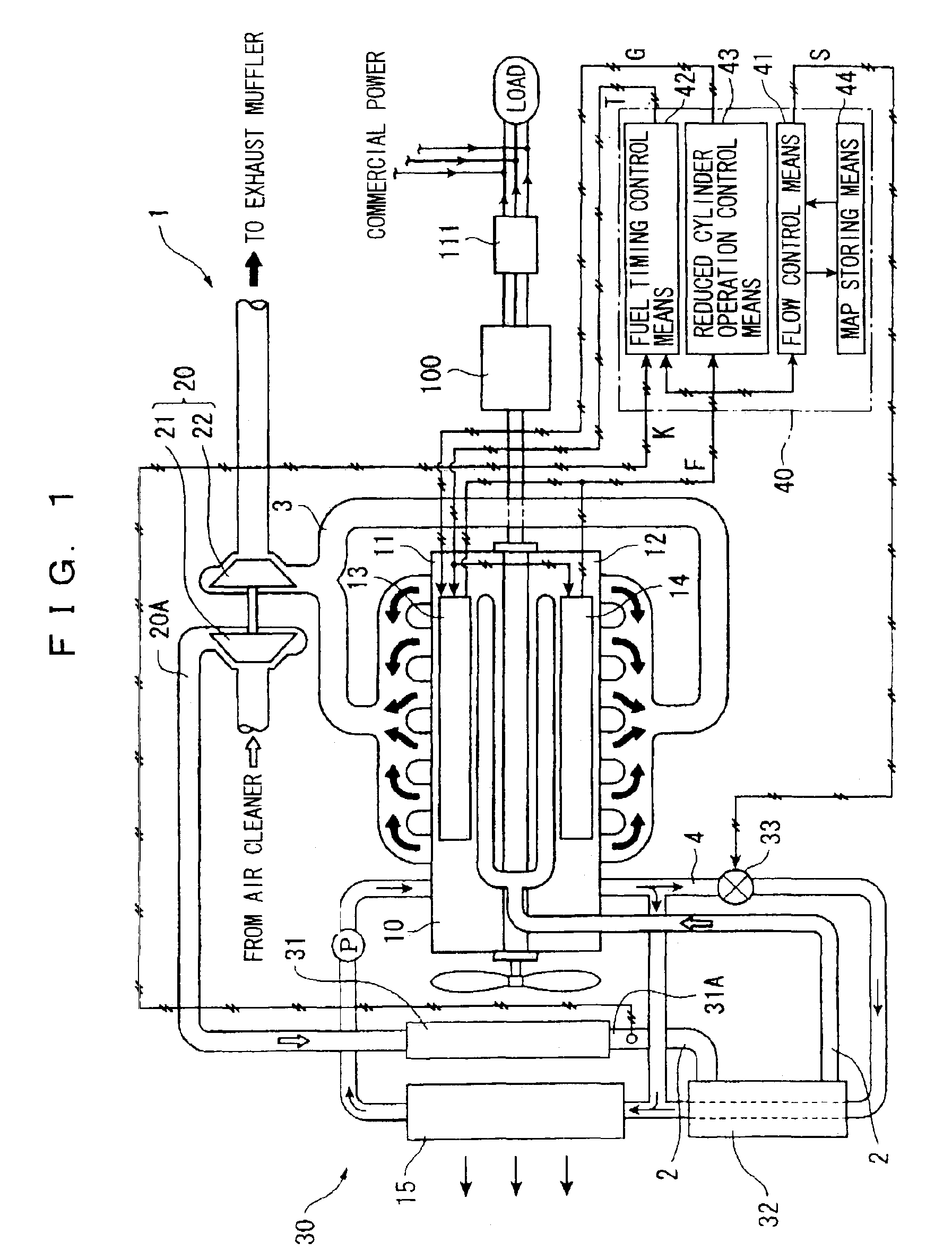

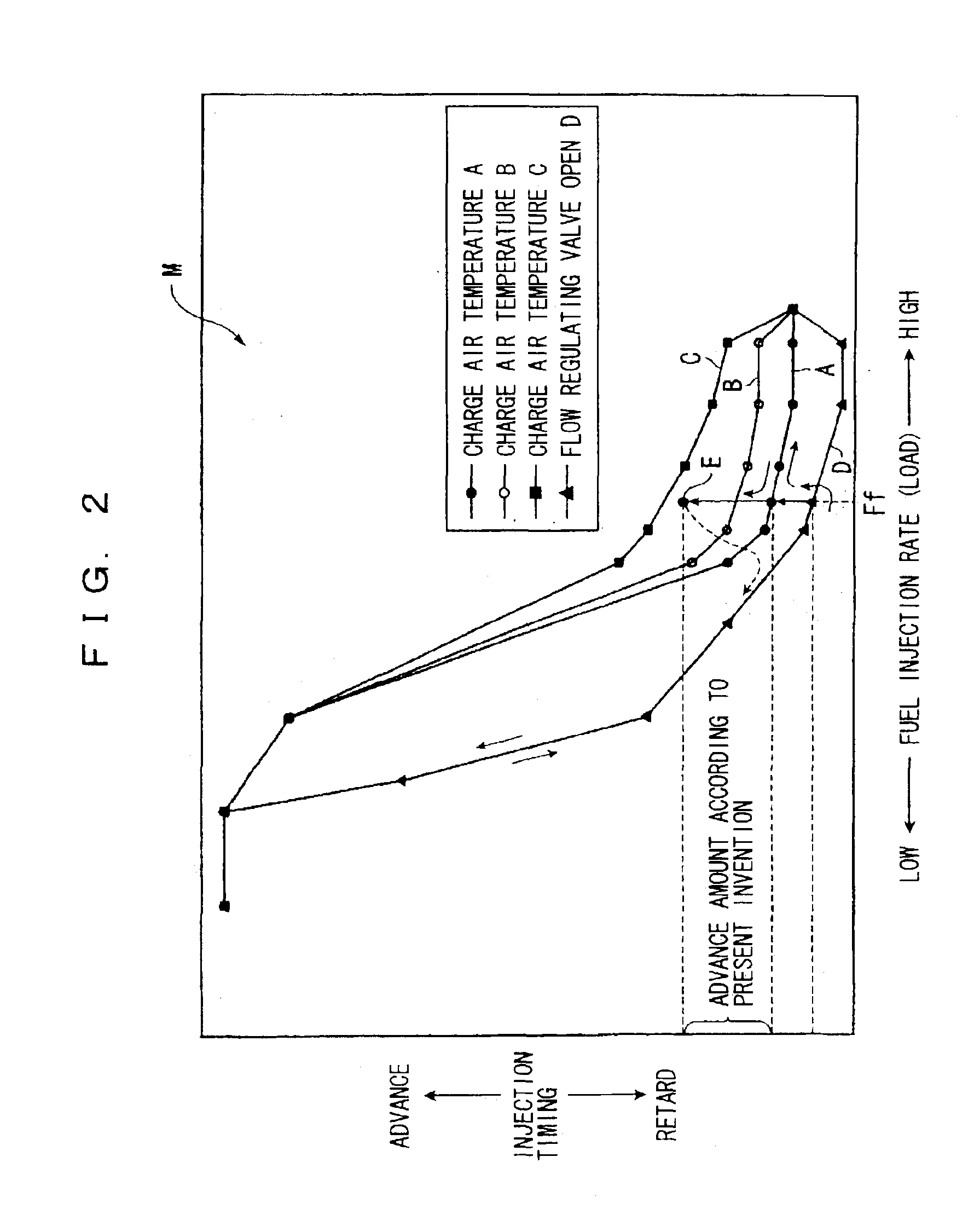

Diesel engine

InactiveUS6935307B2Easy to solveReduce engine loadLiquid coolingElectrical controlLow loadDiesel engine

A diesel engine capable of favorably preventing the generation of white smoke even when an engine load is shifted from a high load side to a low load side. For this purpose, a diesel engine (1) includes fuel injection timing control means (42) for controlling fuel injection timing, the fuel injection timing control means (42) advances the fuel injection timing by predetermined time when an engine load becomes a predetermined load (Ff) or lower in an engine stopping step of stopping the diesel engine while gradually reducing the engine load.

Owner:KOMATSU LTD

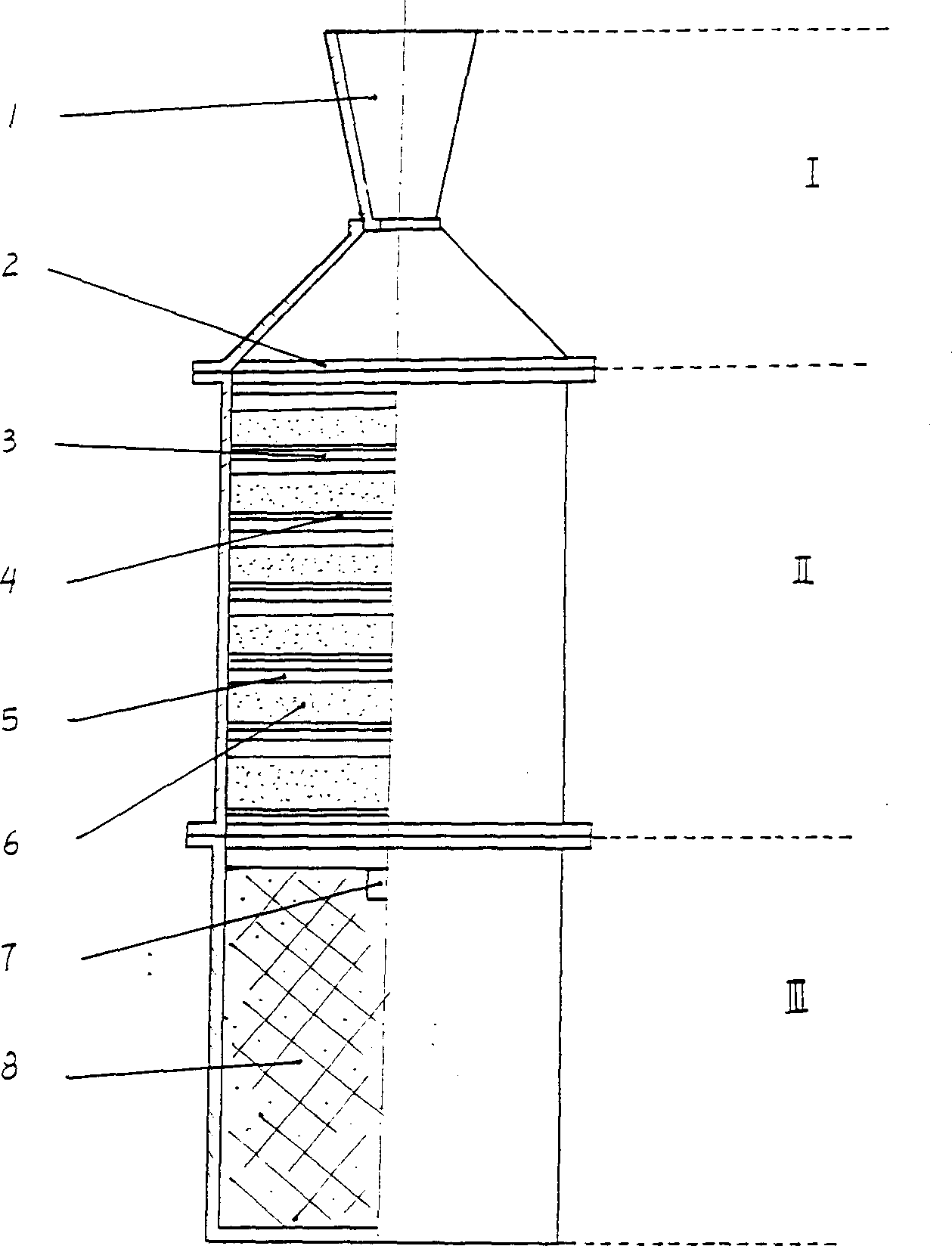

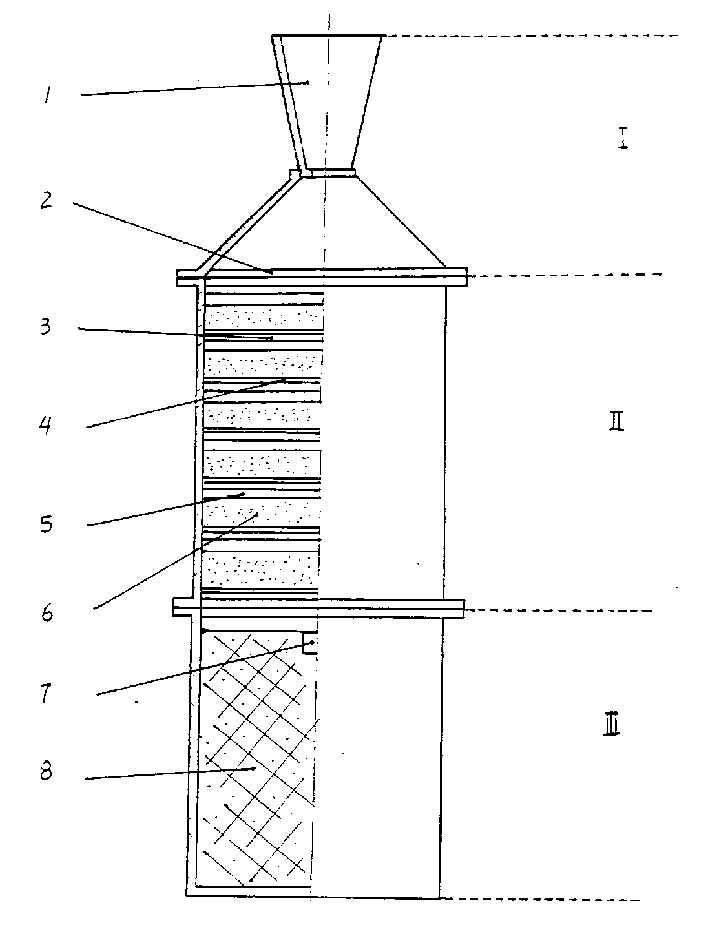

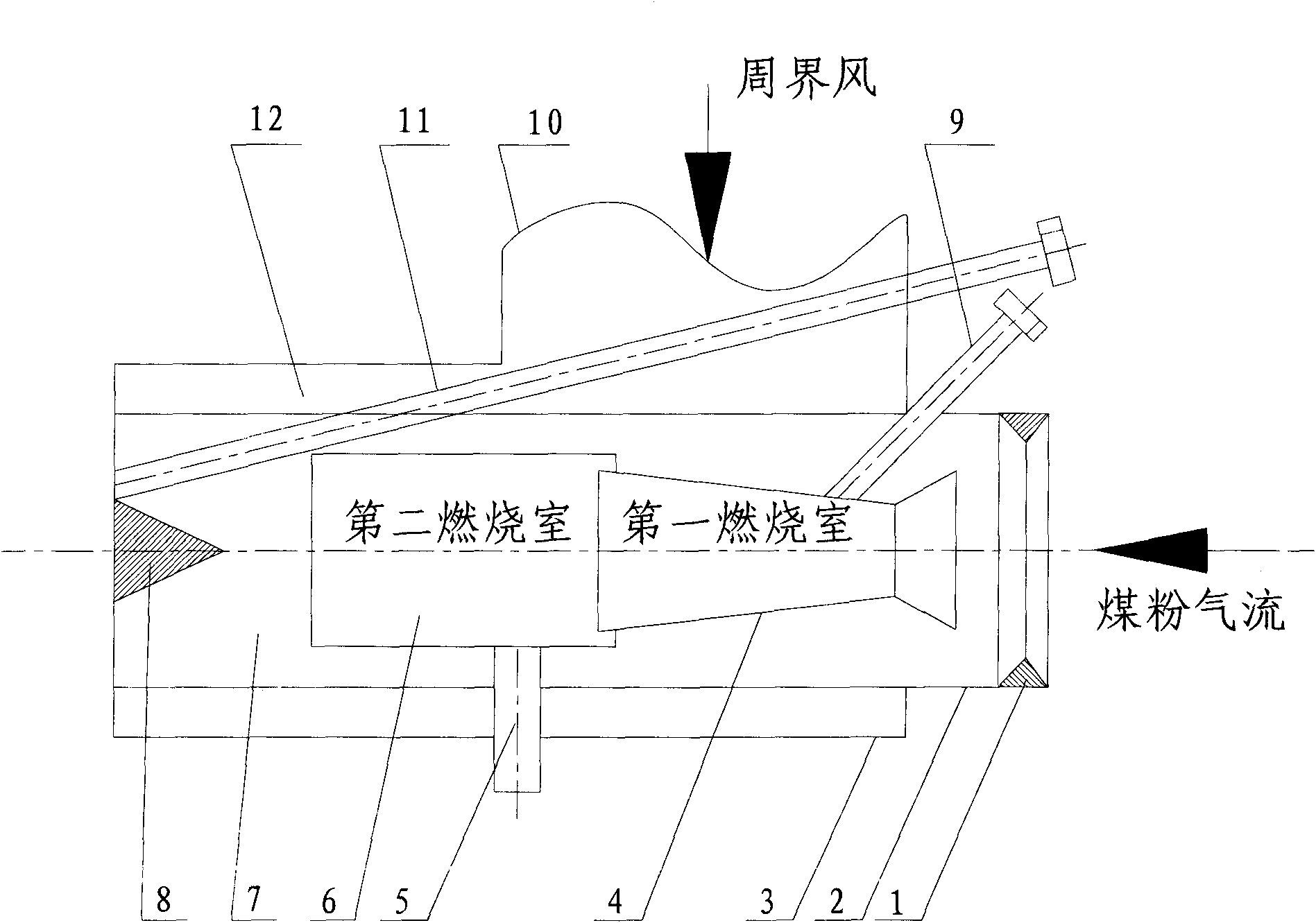

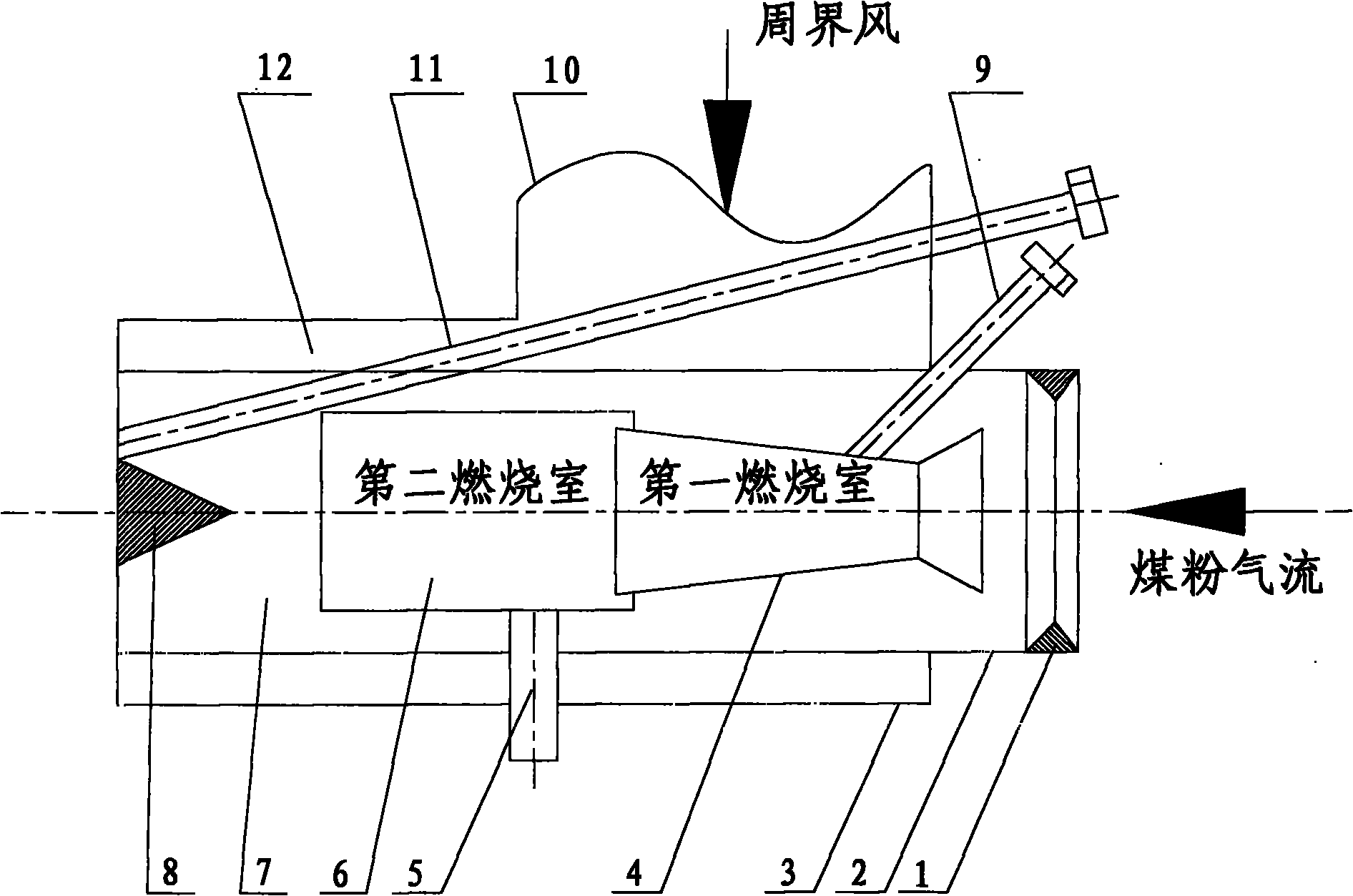

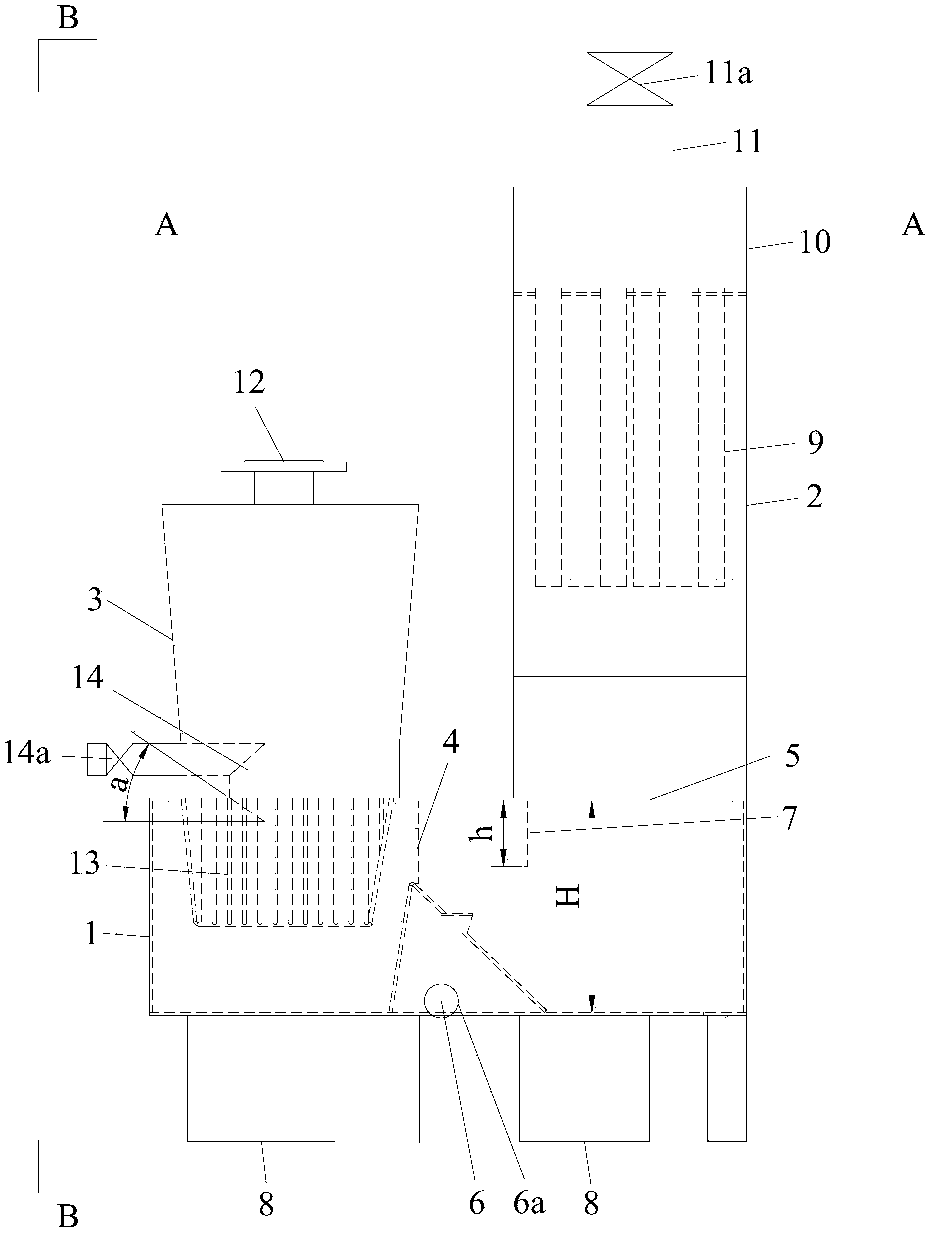

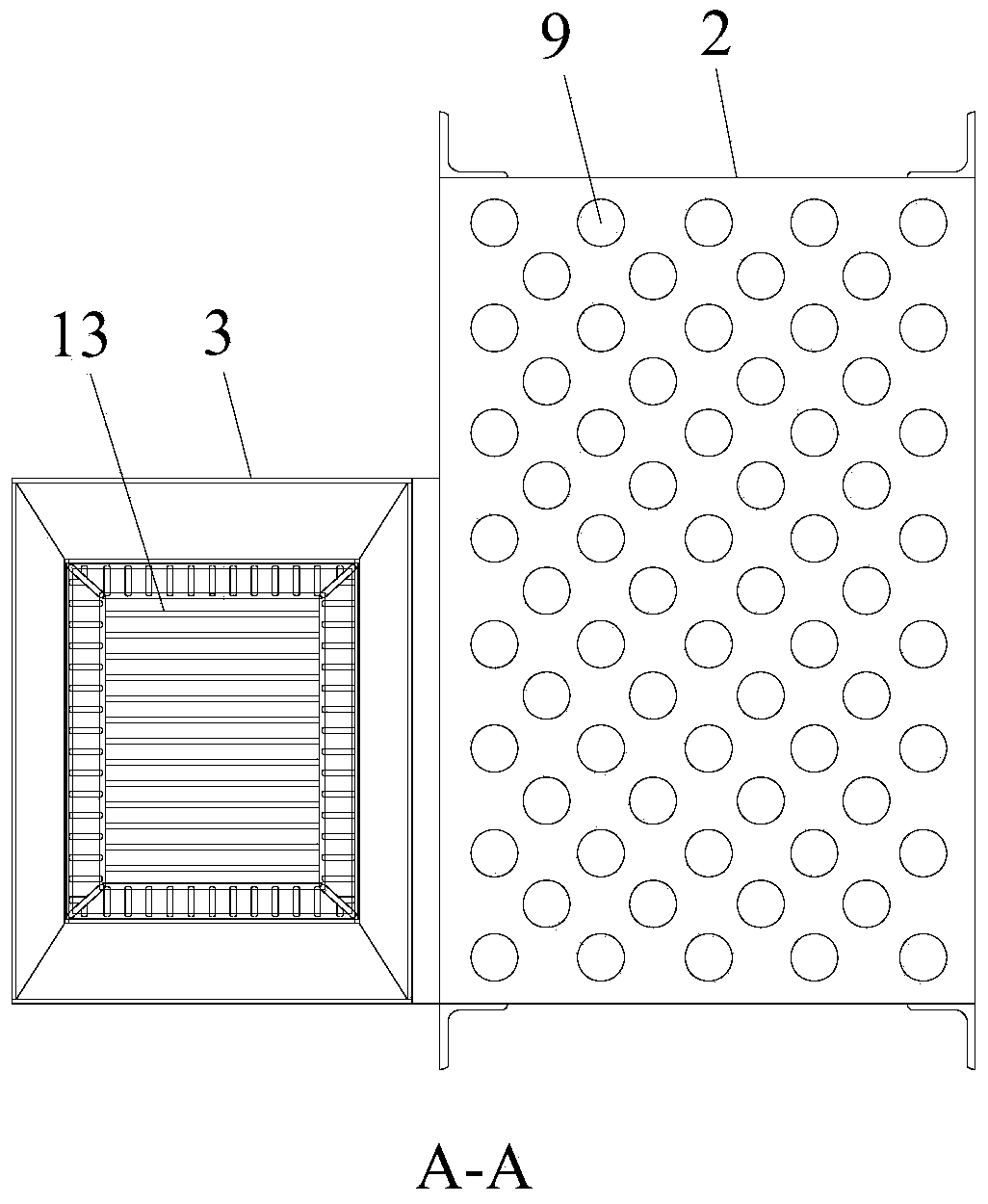

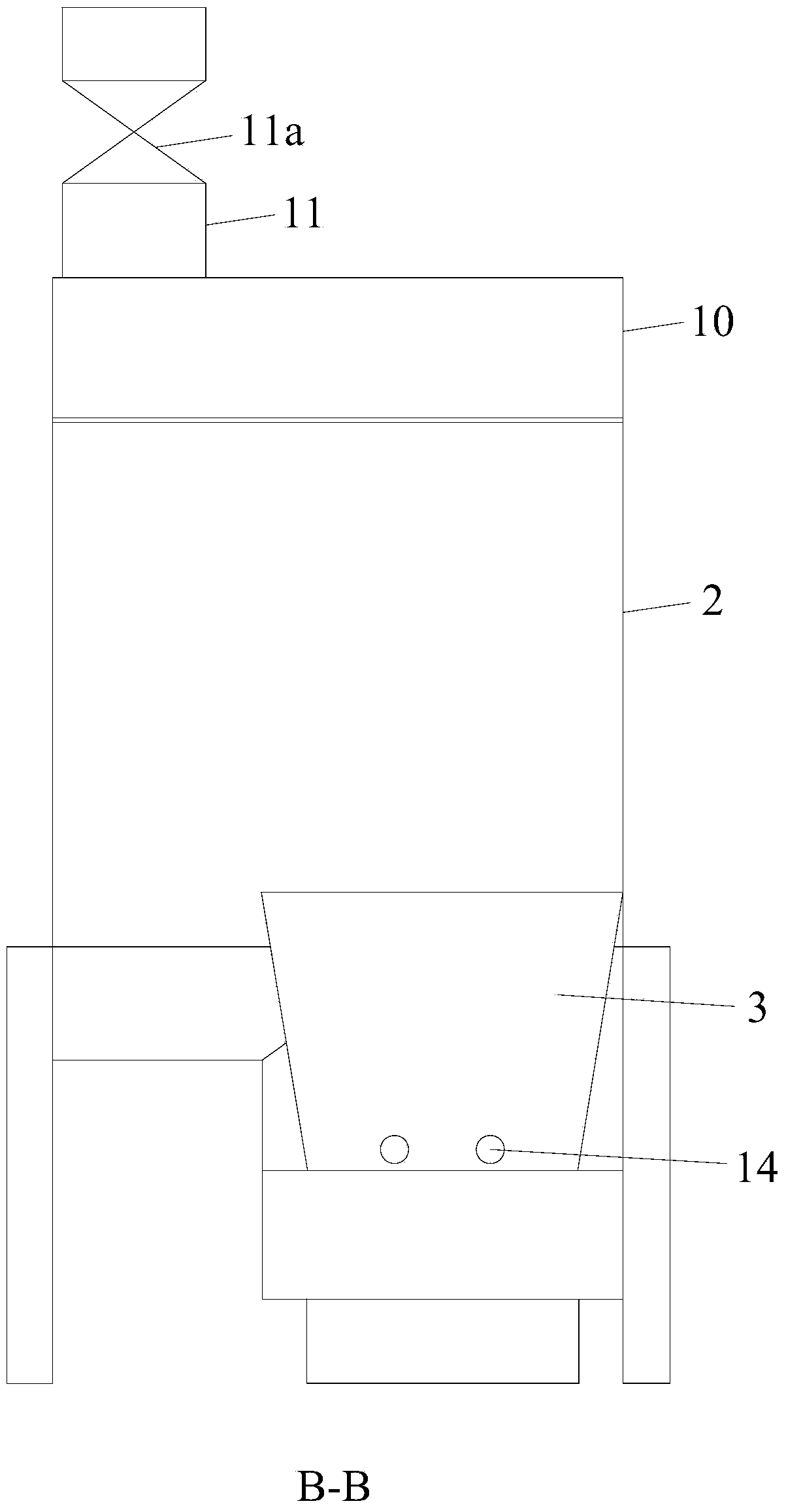

Oil-saving ignition method for fault coal and pulverized coal burner applying method

InactiveCN101782239AImprove ignitabilityReliable heatingPilot flame ignitersPulverulent fuel combustion burnersCombustion chamberCombustor

The invention discloses an oil-saving ignition method for fault coal and a pulverized coal burner applying the method. In the method, pulverized coal streams are ignited by using a small amount of fuel oil in the pulverized coal burner and at the outlet of the pulverized coal burner, and flames of the pulverized coal streams replace atomized torch flames of a big oil gun in the traditional ignition mode. The burner comprises a shell; a composite chamber and a main oil gun are arranged in the shell; an auxiliary oil gun is also arranged in the shell, and is arranged in a certain lower-level chamber at the rear end of the first-level chamber; and the pulverized coal body heated in the burner moves to the auxiliary oil gun and then is ignited by the auxiliary oil gun so as to form stable pulverized coal stream flames. The auxiliary oil gun is arranged at the rear end of the main oil gun in the burner, and the distance between the two oil guns is long enough, so the pulverized coal body can be reliably heated to the degree suitable for ignition and then is reliably ignited so as to achieve good oil-saving effect.

Owner:艾佩克斯科技(北京)有限公司

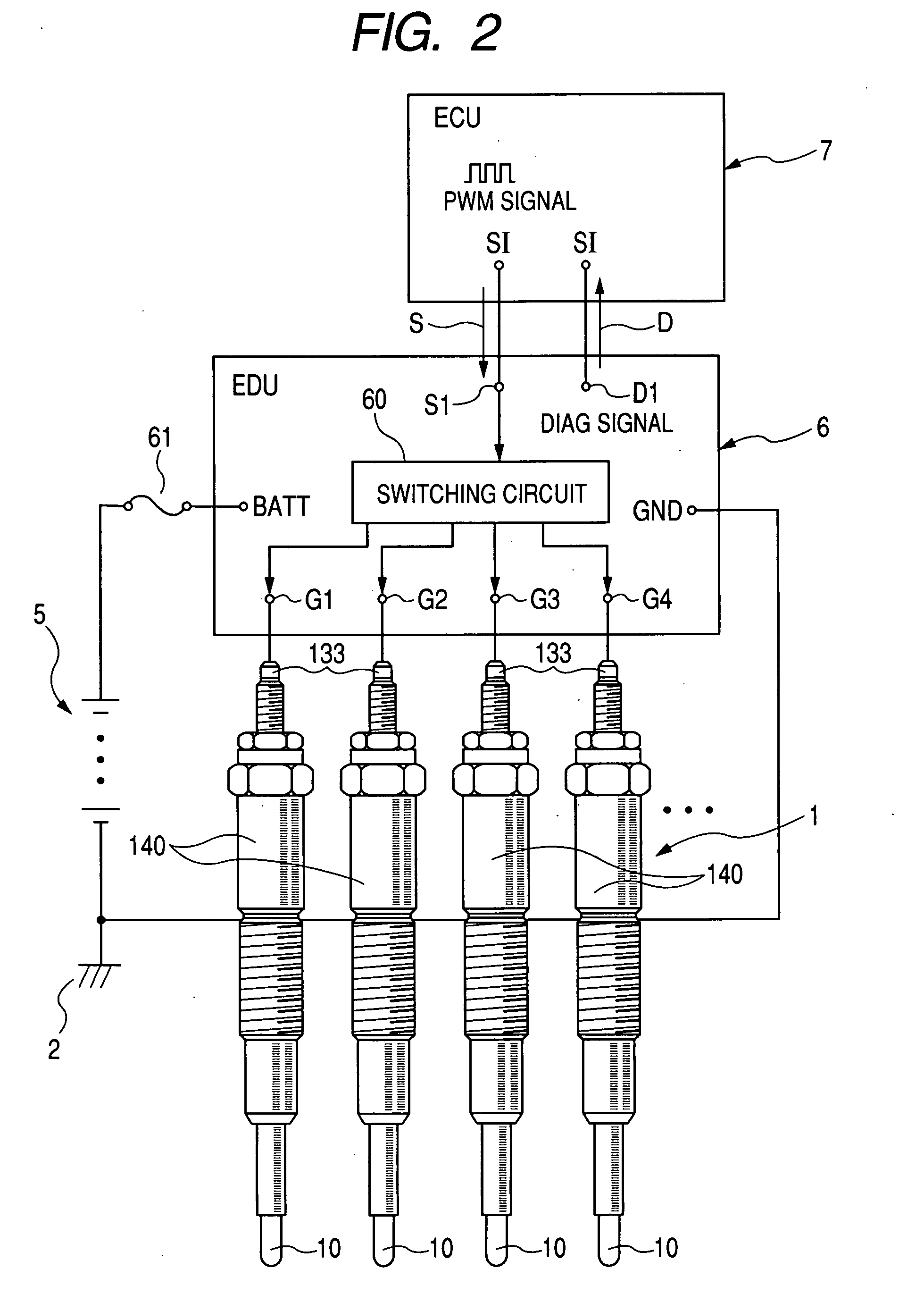

Plasma jet ignition plug ignition control

InactiveUS8316823B2Increased durabilityImprove ignitabilitySparking plugsCombustion enginesPlasma jetElectricity

A control system for controlling the ignition of a plasma-jet spark plug provided in an internal combustion engine senses an operating condition of the internal combustion engine, and determines an ignition mode of the plasma-jet spark plug in accordance with the sensed operating condition. The control system performs an ignition control of breaking down the insulation across a spark discharge gap by applying a first electric power to the plasma-jet spark plug, and producing plasma in the vicinity of the spark discharge gap by applying a second electric power to the spark discharge gap in a state of dielectric breakdown. The control system performs this ignition control according to the ignition mode determined as mentioned above.

Owner:NGK SPARK PLUG CO LTD

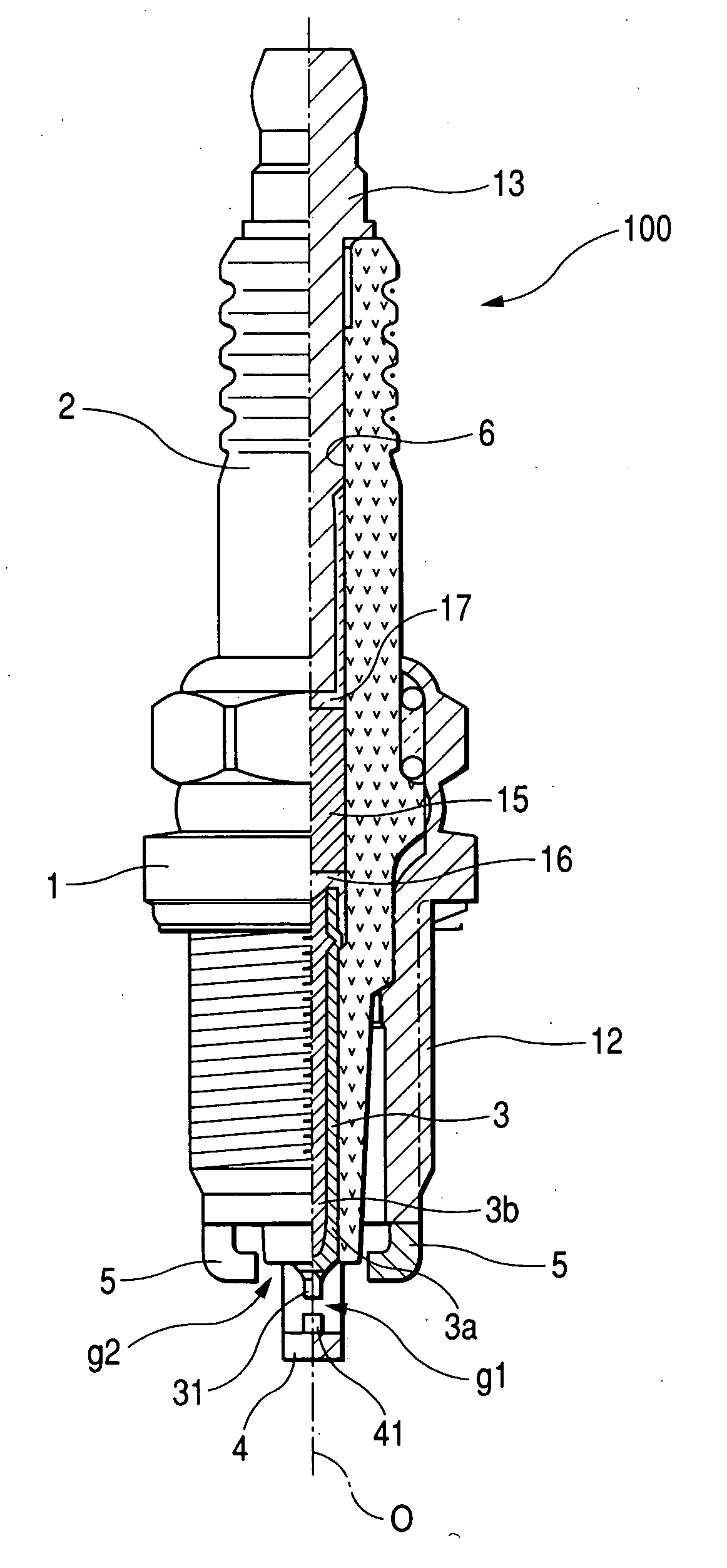

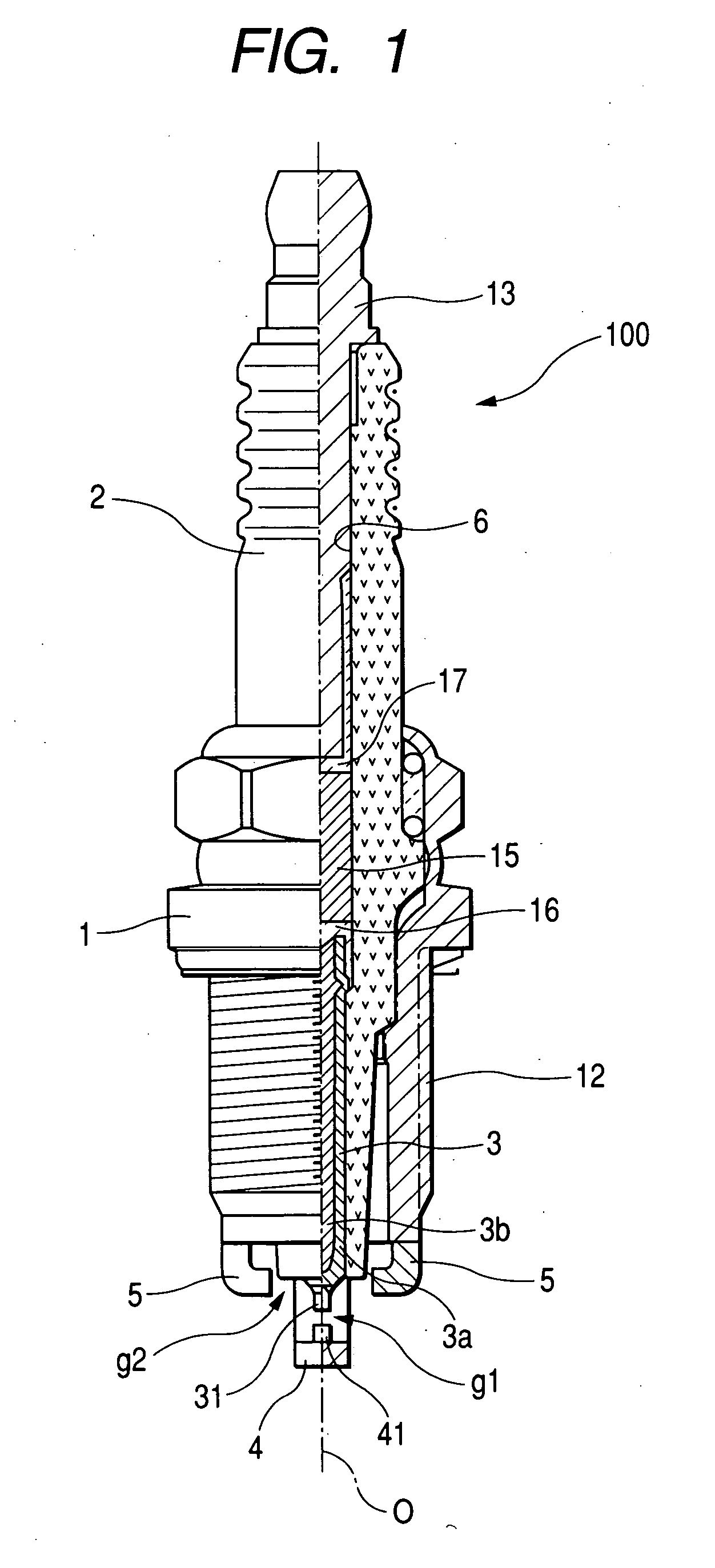

Spark plug

InactiveUS20050184633A1Efficiently growImprove ignitabilitySparking plugsEngineeringElectrical and Electronics engineering

A spark plug including an insulator having an axial hole in an axial direction of the spark plug; a center electrode disposed in a tip end side of the axial hole of the insulator; a metal shell surrounding the insulator; a first ground electrode including a first ground electrode body having one end joined to the metal shell, and a noble metal tip joined to an inner side face of another end portion of the first ground electrode body and disposed opposite a tip end face of the center electrode across a first discharge gap. One end of the second ground electrode is bonded to the metal shell, and the another end is disposed opposite a side peripheral face of said center electrode or a side peripheral face of said insulator across a second discharge gap. Furthermore, the spark plug is characterized as having a distance t and an included angle θ as defined herein.

Owner:NGK SPARK PLUG CO LTD

Gas generator ignition agent and preparation method thereof, and gas generator for vehicle safety airbag

ActiveCN108456126AImprove ignitabilityIncrease gas production ratePedestrian/occupant safety arrangementExplosive working-up apparatusStart timePotassium

The invention provides a gas generator ignition agent and a preparation method thereof, and a gas generator for a vehicle safety airbag. The gas generator ignition agent contains a fuel, an oxidant, abinder and an additive, wherein the additive is an oxazole-based energy-containing ionic compound. According to the present invention, by adding 5-aminotetrazole nitrate to a boron / potassium nitrateignition agent, on the basis of the ensuring of the combustion heat and the combustion temperature of the agent, the high-temperature and high-pressure gas amount can be increased, the output pressureof the ignition agent can be increased, and the output performance of the ignition pipe can be increased, such that the pressure starting time of the gas generator is advanced to less than 2 ms, andthe pressure value at 10 ms is increased by about 20 Kpa so as to improve the gas generating performance of the gas generator.

Owner:BYD CO LTD

Transmitting body capable of achieving secondary acceleration

ActiveCN107270781AAvoid the problem of low acceleration kinetic energyImprove flight stabilityProjectilesIsolation layerEngineering

The invention provides a transmitting body capable of achieving secondary acceleration. The transmitting body comprises a main transmitting body and a transmitting head. An inner cavity of the main transmitting body is internally provided with first-level power media. The transmitting head is arranged at the front end of the main transmitting body, and a heat isolation layer is arranged between the transmitting head and the main transmitting body. The transmitting head comprises a bullet head shell with an installing port, a double gold piece, a heat conduction motivating rod and a power chamber, wherein the double gold piece is arranged in an inner cavity of the bullet head shell through the installing port, and second-level power media are contained in the power chamber. The power chamber is provided with a splicing structure detachably connected with the bullet head shell. One end of the heat conduction motivating rod is connected with the second-level power media, and the other end of the heat conduction motivating rod is opposite to the double gold piece. A gap is formed between the double gold piece and the heat conduction motivating rod. The double gold piece is deformed due to heating and is connected with the heat conduction motivating rod. The problems that in the prior art, a transmitting body cannot achieve interval sub-level ignition boosting, and the stability and shooting precision of bullets are poor are solved, and the problem that users cannot change the firing range of the bullets is solved.

Owner:来安县永阳知识产权运营有限公司

Control method and control device of internal combustion engine

ActiveUS20180328262A1Improve ignitabilityImprove flammabilityElectrical controlInternal combustion piston enginesAirflowExternal combustion engine

In a control method of an internal combustion engine including a fuel injection valve having a plurality of injection holes and adapted to directly inject a fuel into a cylinder and an ignition plug adapted to generate a plug discharging channel, after fuel injection is performed, spark ignition is performed while turbulence in an air flow is generated by the fuel injection by an ignition plug disposed so that a discharging region is sandwiched by fuel sprays injected from the two adjacent injection holes and located within a range where the turbulence in the air flow is generated.

Owner:NISSAN MOTOR CO LTD +1

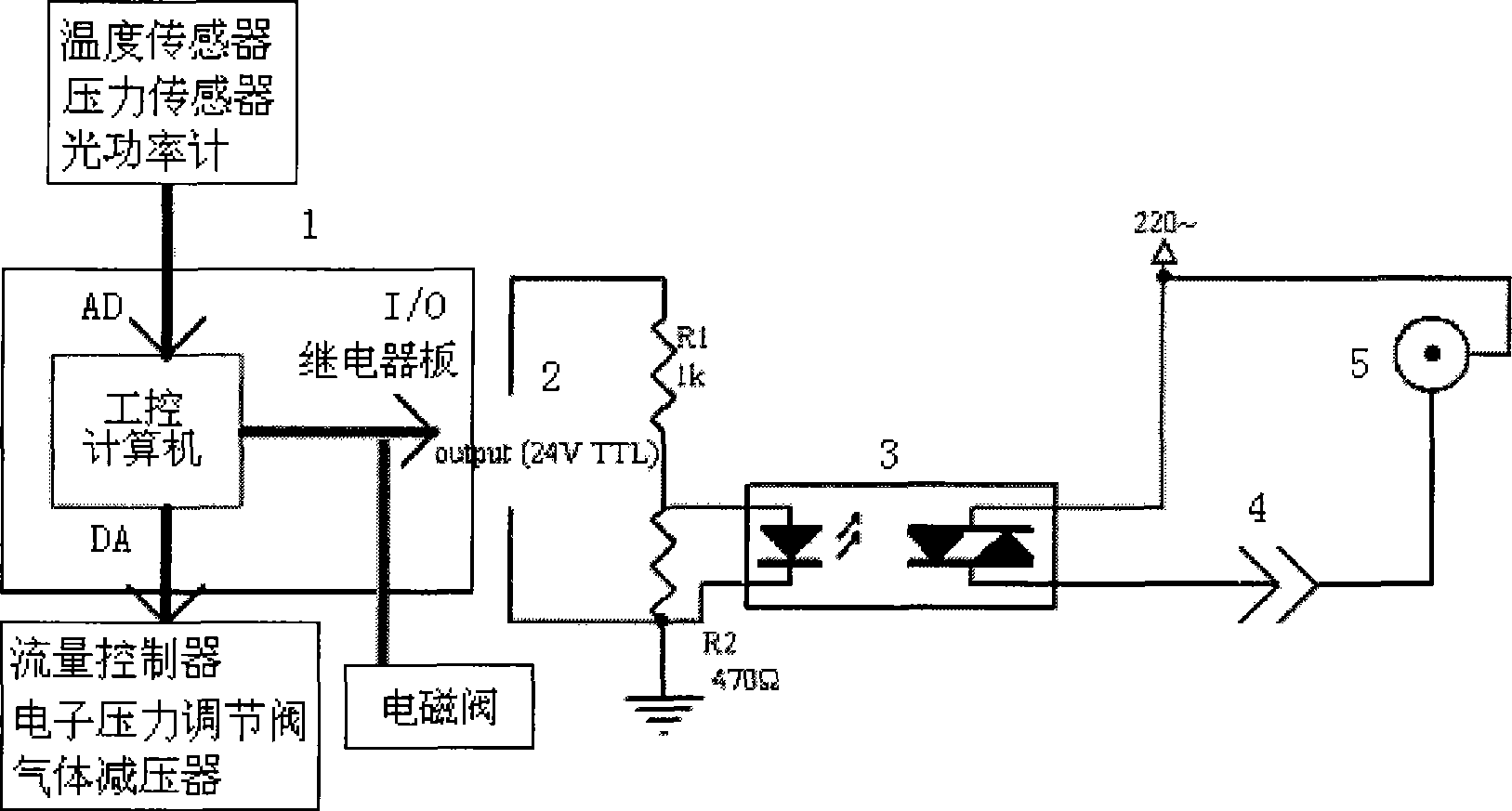

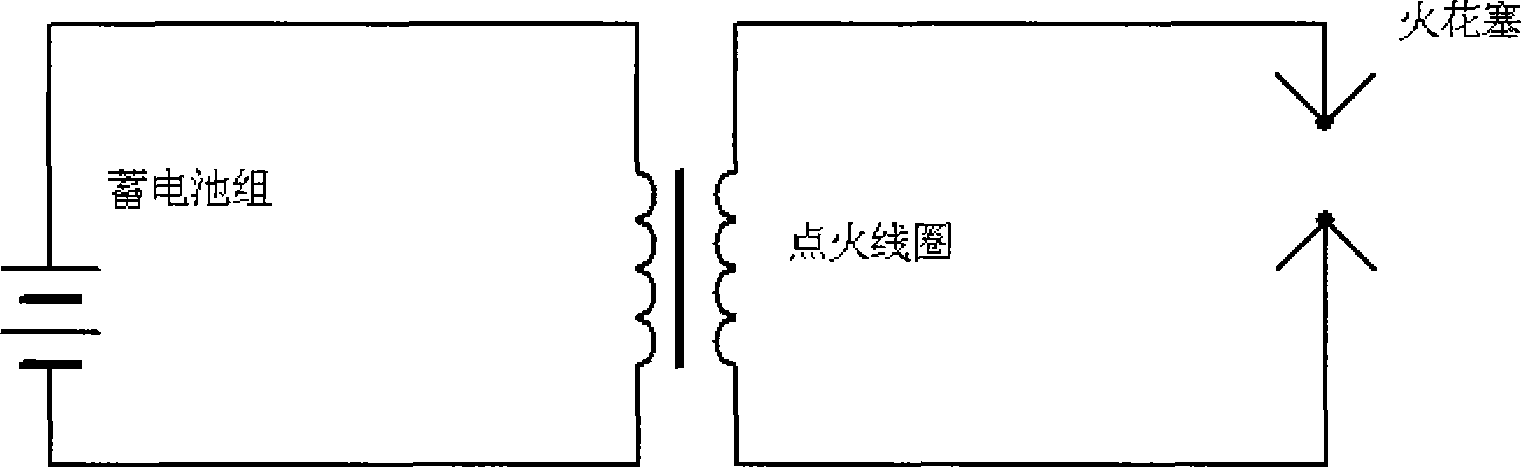

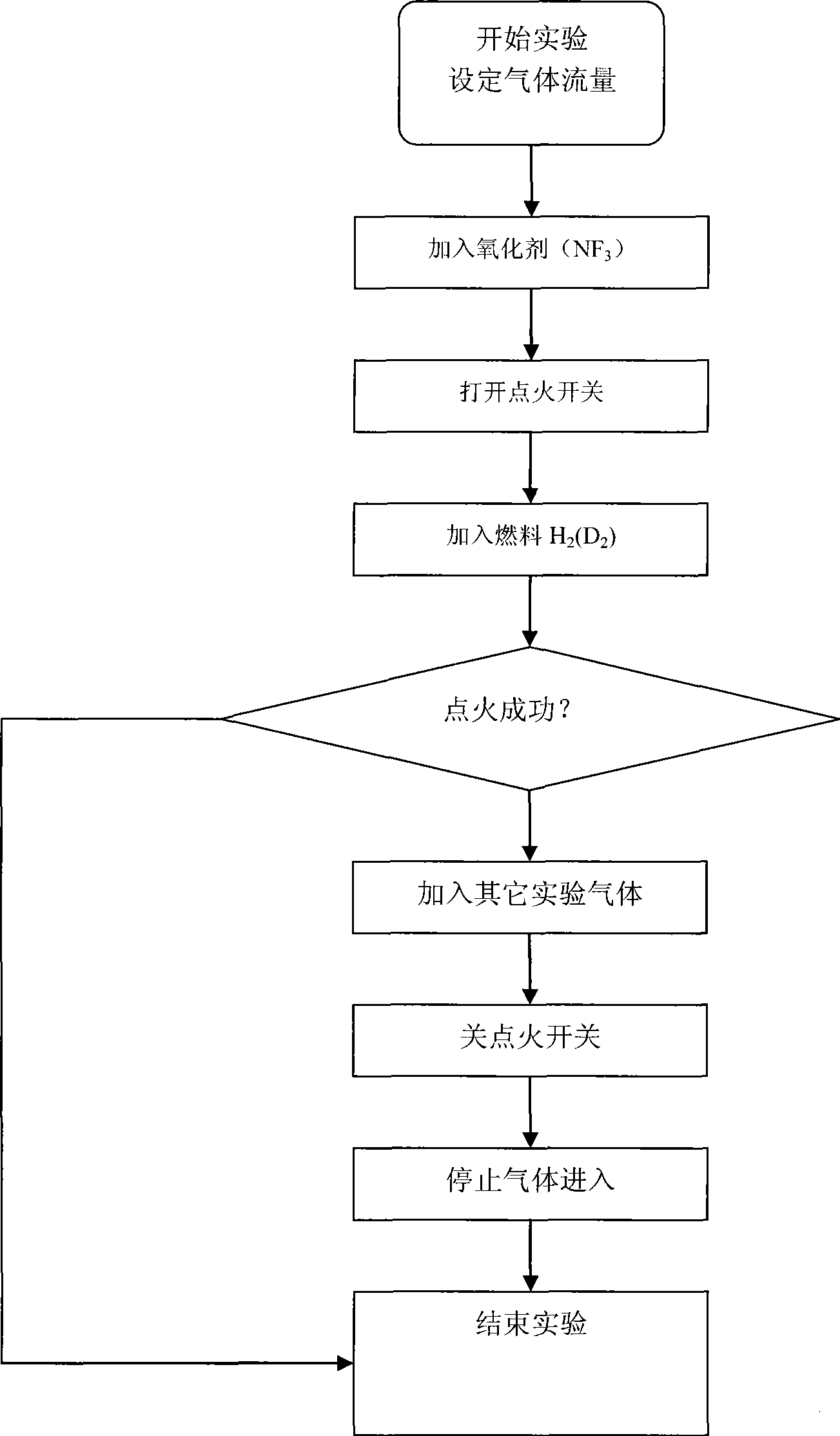

Ignition control device and control method for combustion driving full gas phase iodine laser burning chamber

InactiveCN101394060AImprove securityLow costComputer controlExcitation process/apparatusAutomotive engineeringCombustion chamber

The invention relates to an ignition control device of a combustion-driven all gas-phase iodine laser combustion chamber and a control method. The device is provided with a data acquisition controller; the control voltage output by the controller is connected with a spark device through a voltage regulator and a drive circuit; then the spark device is connected to a spark plug through a conductive wire; and a control program is stored in the data acquisition controller. The method comprises the steps of presetting the amount of the gas-flow rate; introducing an oxidant into the combustion chamber according to the preset flow rate; starting an ignition switch, and igniting a fire maker; introducing fuel into the combustion chamber according to the preset flow rate; judging whether the ignition is successful according to the changes of the temperature and the pressure as well as the illumination condition of the combustion chamber; if the ignition is successful, adding other experimental gases; stopping the ignition switch, and stopping igniting the fire maker; stopping introducing the gas into each pipeline; and finishing the experiment. The invention has the advantages of simple structure, low cost, convenient operation, high efficiency, safety and good ignition effect, and ensures that the gas ignition implementation of the combustion chamber is simple in an ordinary laboratory.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Machine-made bamboo charcoal processing device

ActiveCN110561577AUniform particle sizeGuaranteed qualityCane mechanical workingWood working apparatusCombustionElectric machinery

Owner:东至县森茂炭业有限公司

Self-suction environment-friendly gasification inverse combustion heating furnace

InactiveCN104019444AReal-time adjustment of combustion operating loadCompact structureSolid fuel combustionCombustion apparatusCombustion chamberSlag

The invention discloses a self-suction environment-friendly gasification inverse combustion heating furnace. The self-suction environment-friendly gasification inverse combustion heating furnace comprises a combustion chamber, a heat exchange chamber and a gasification chamber. The combustion chamber is arranged horizontally, the gasification chamber and the heat exchange chamber are vertically distributed above the combustion chamber, and therefore a U-shaped furnace body structure for gasification sectional combustion is formed. A turbulent flow baffle extends downwards from the position, close to a first channel, of the inner side of a top plate of the combustion chamber, and the positions, corresponding to the gasification chamber and the heat exchange chamber, of the bottom of the combustion chamber are respectively provided with a slag pit. An air supply port is formed in the combustion chamber, a smoke discharging pipeline enabling negative pressure to be formed in the U-shaped furnace body structure is arranged at the top of the heat exchange chamber, a gasification agent supply port is formed inside the gasification chamber, and the air supply port, the smoke discharging pipeline and the gasification agent supply port are provided with valves used for regulating and controlling operating conditions of the U-shaped furnace body structure together. The self-suction environment-friendly gasification inverse combustion heating furnace is simple in structure, convenient and rapid to operate, high in combustion efficiency, low in environment pollution, and capable of reducing investment cost and operating cost.

Owner:GUANGDONG EMICRONET NEW ENERGY TECH

Fuel composition and a device for colored flames

InactiveUS7556658B2Enhanced colored flame presentationImprove flammabilityLiquid fuel feeder/distributionLiquid carbonaceous fuelsEngineeringHydrocarbon

Owner:HWALIM TECHNOLOGICAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com