Oil-saving ignition method for fault coal and pulverized coal burner applying method

A pulverized coal burner, the technology of the burner, which is applied in the direction of the burner, burner, combustion ignition, etc. of burning powder fuel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

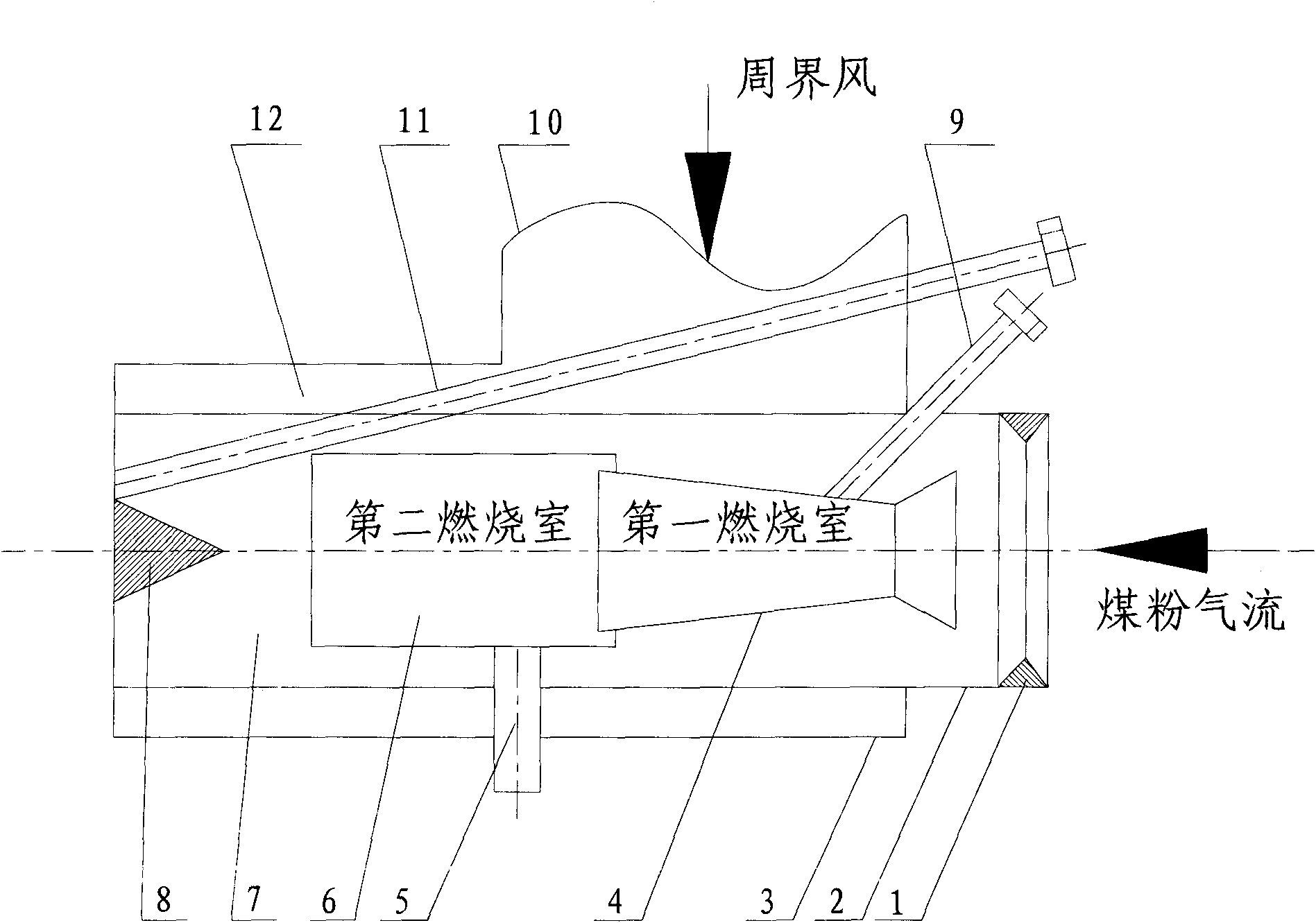

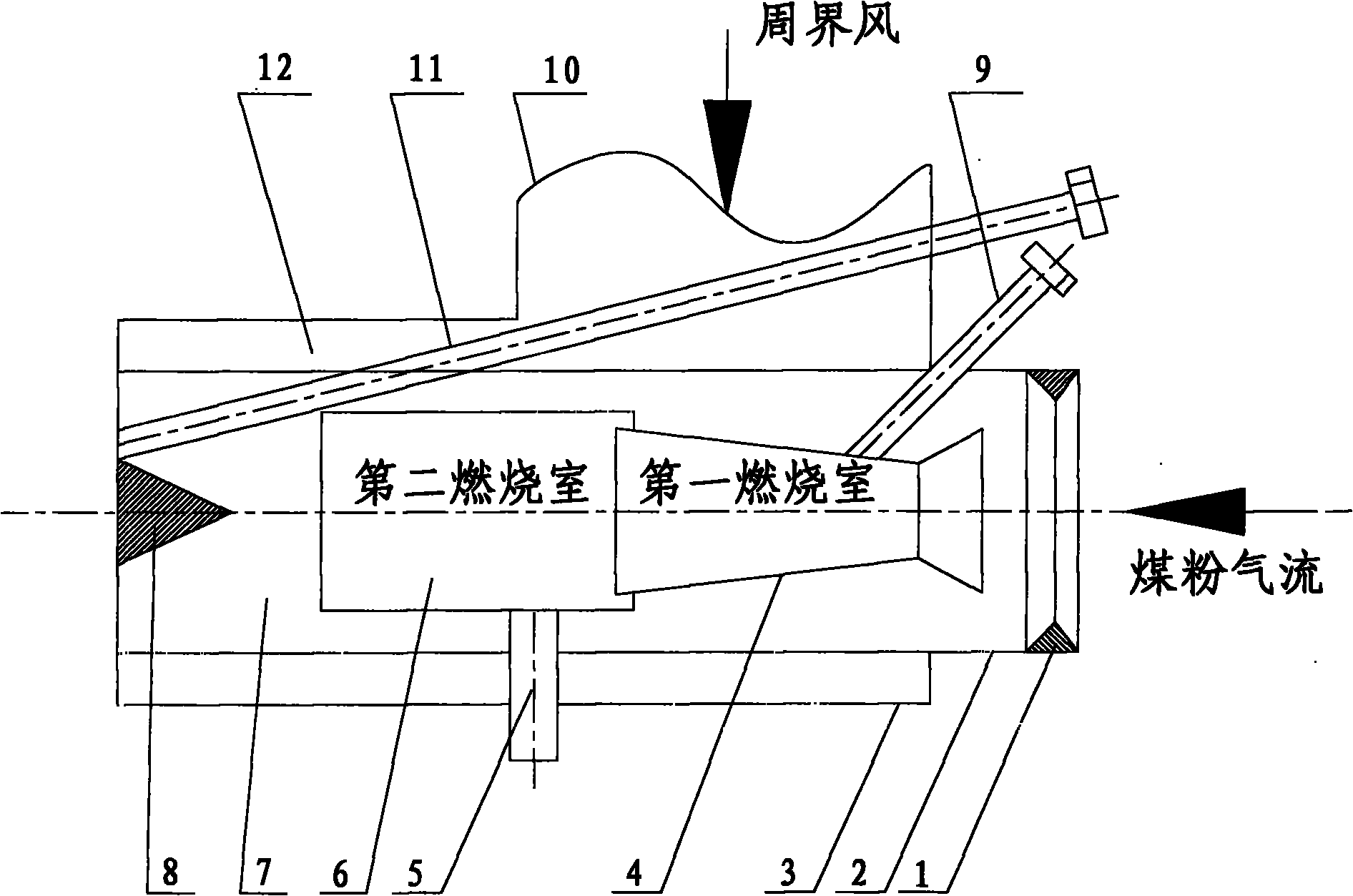

[0018] Such as figure 1 As shown, the pulverized coal burner of the present invention includes a pulverized coal concentration ring 1, a pulverized coal burner 2, a peripheral air cooling jacket 3, a primary combustion chamber 4, a secondary combustion chamber 6, and a tertiary combustion chamber 7, and the section is a triangular strip blunt body 8, main oil gun 9, air inlet 10, auxiliary oil gun 11; combustion chamber 4, 6, 7 is located on the axis of pulverized coal burner 2, and main oil gun 9 is inserted into a In the first-stage combustion chamber 4, the auxiliary oil gun 11 is inserted from the rear to the side of the blunt body 8 at the flame outlet of the pulverized coal burner 2, and the peripheral wind cooling jacket 3 is set on the outside of the pulverized coal burner 2. The imported fresh air cools the pulverized coal burner 2 shell.

[0019] In addition, in order to ensure the reliable operation of the pulverized coal burner, a flame monitoring device 5 is also...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com