Patents

Literature

268results about How to "Save energy consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

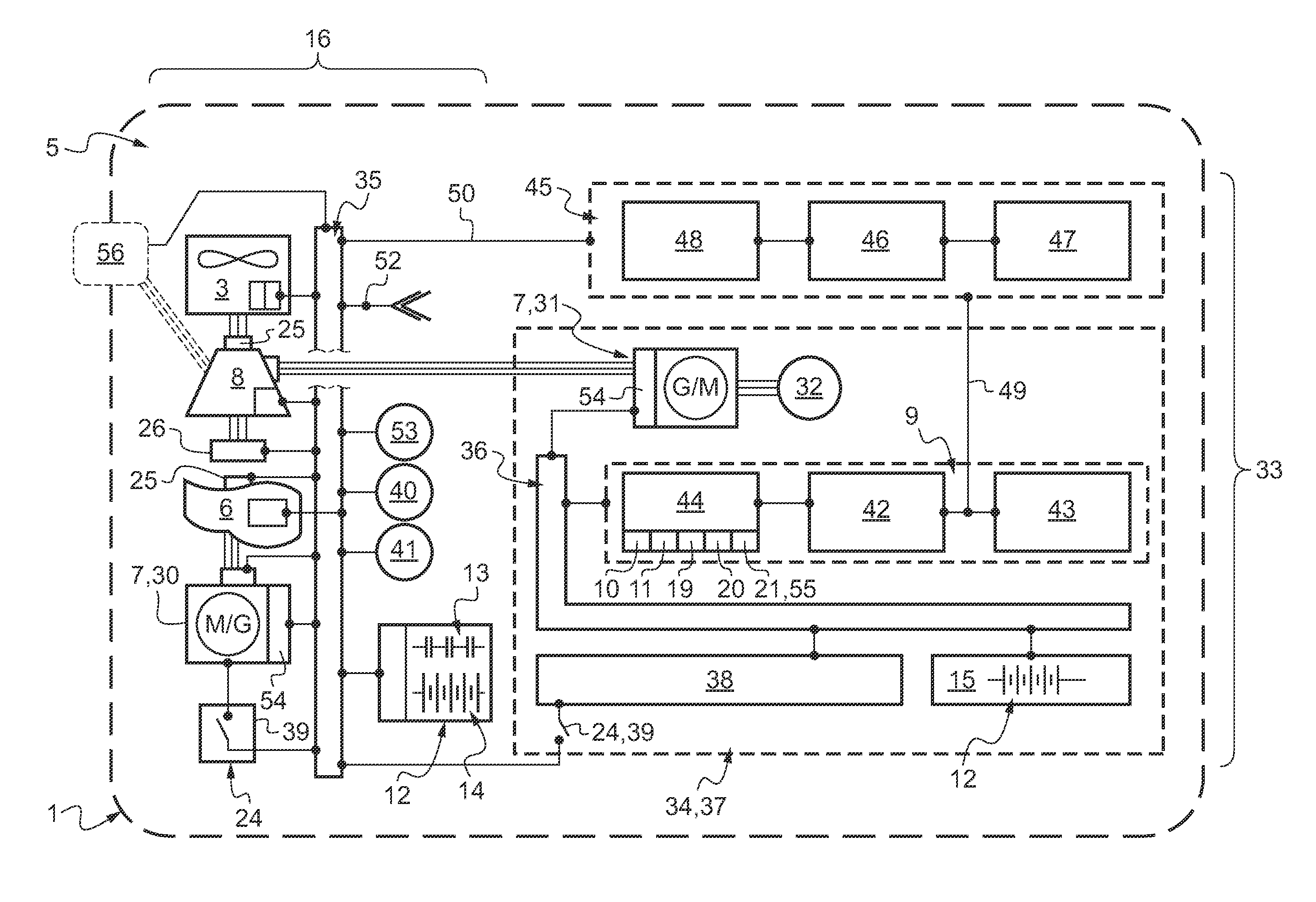

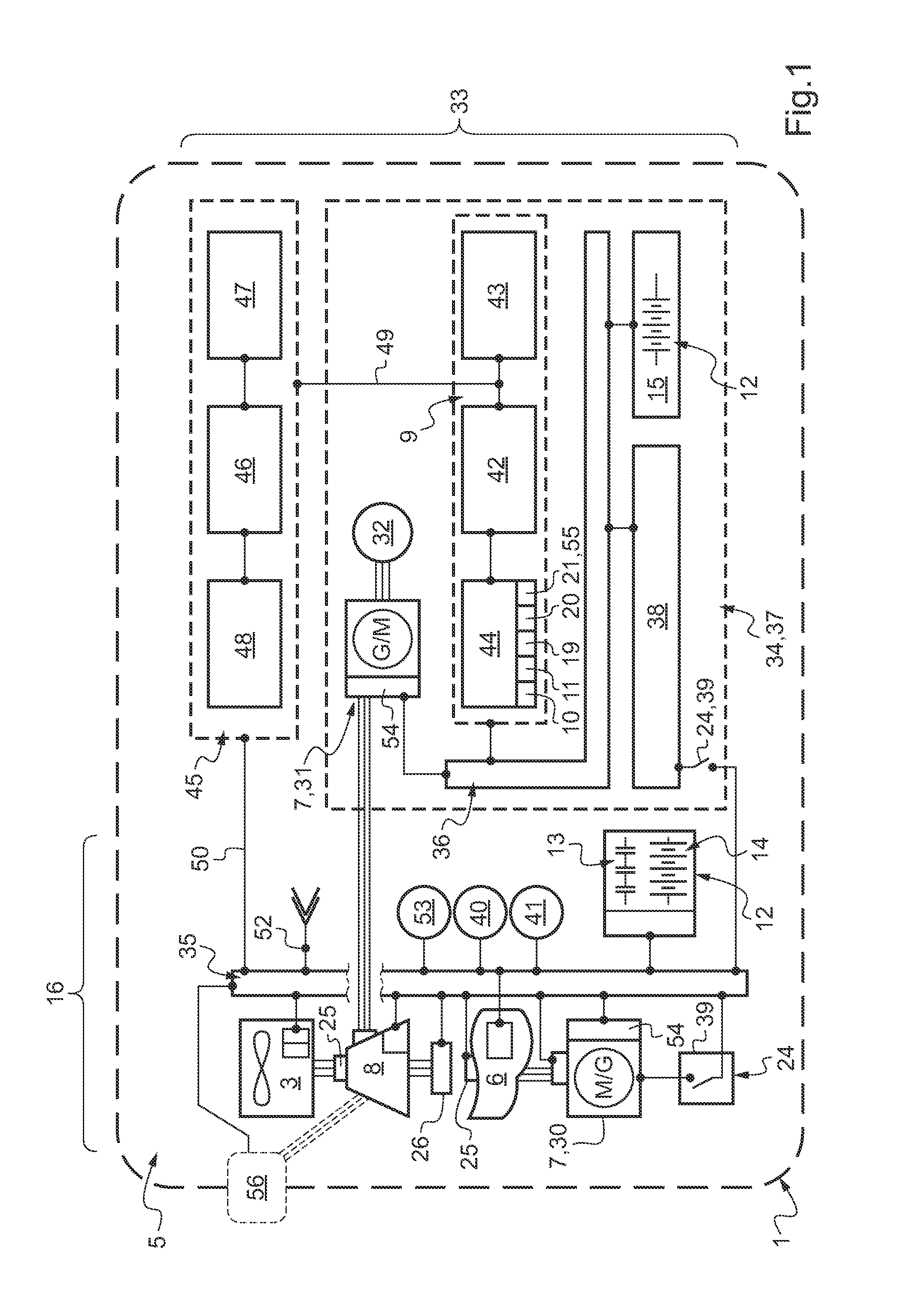

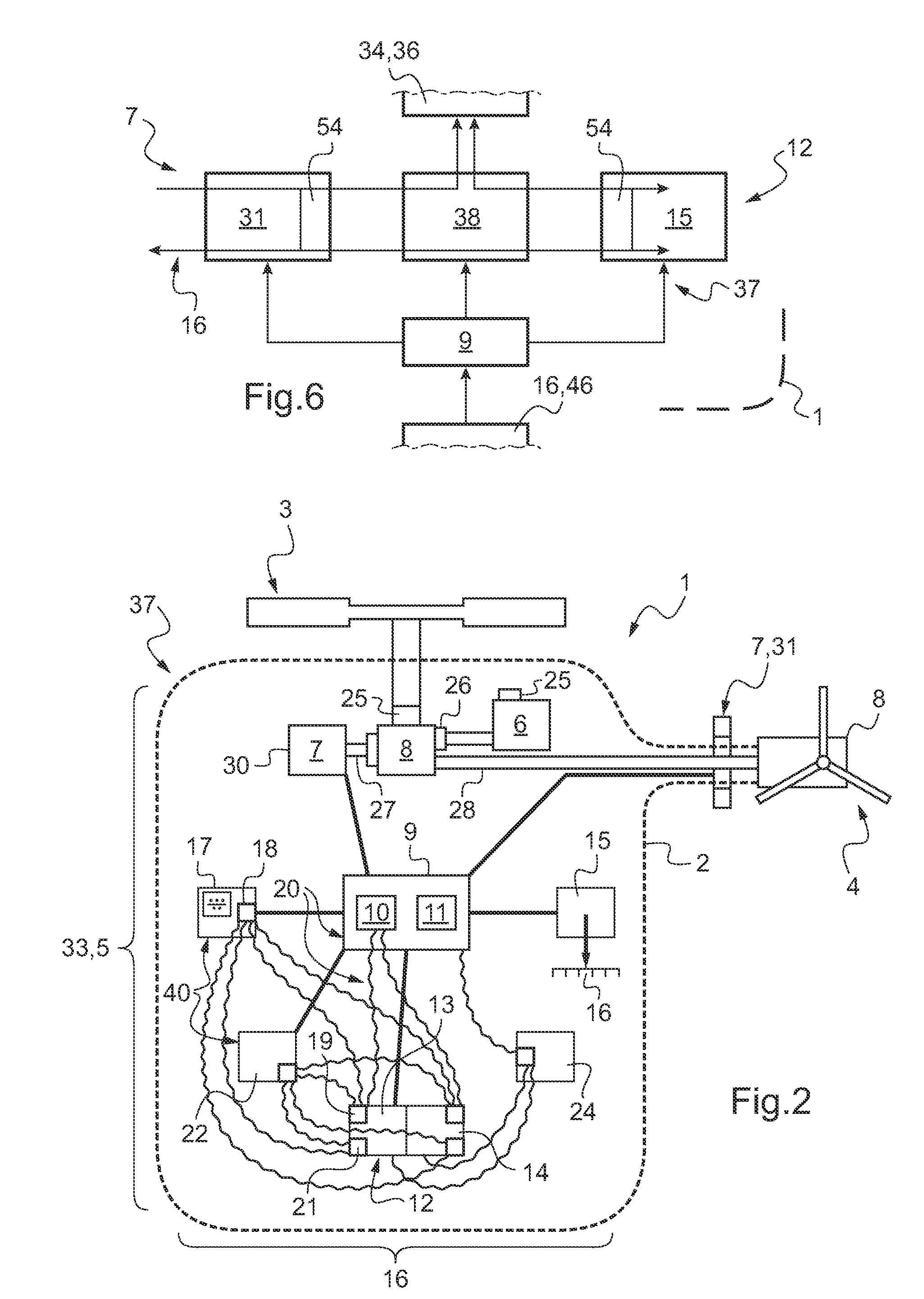

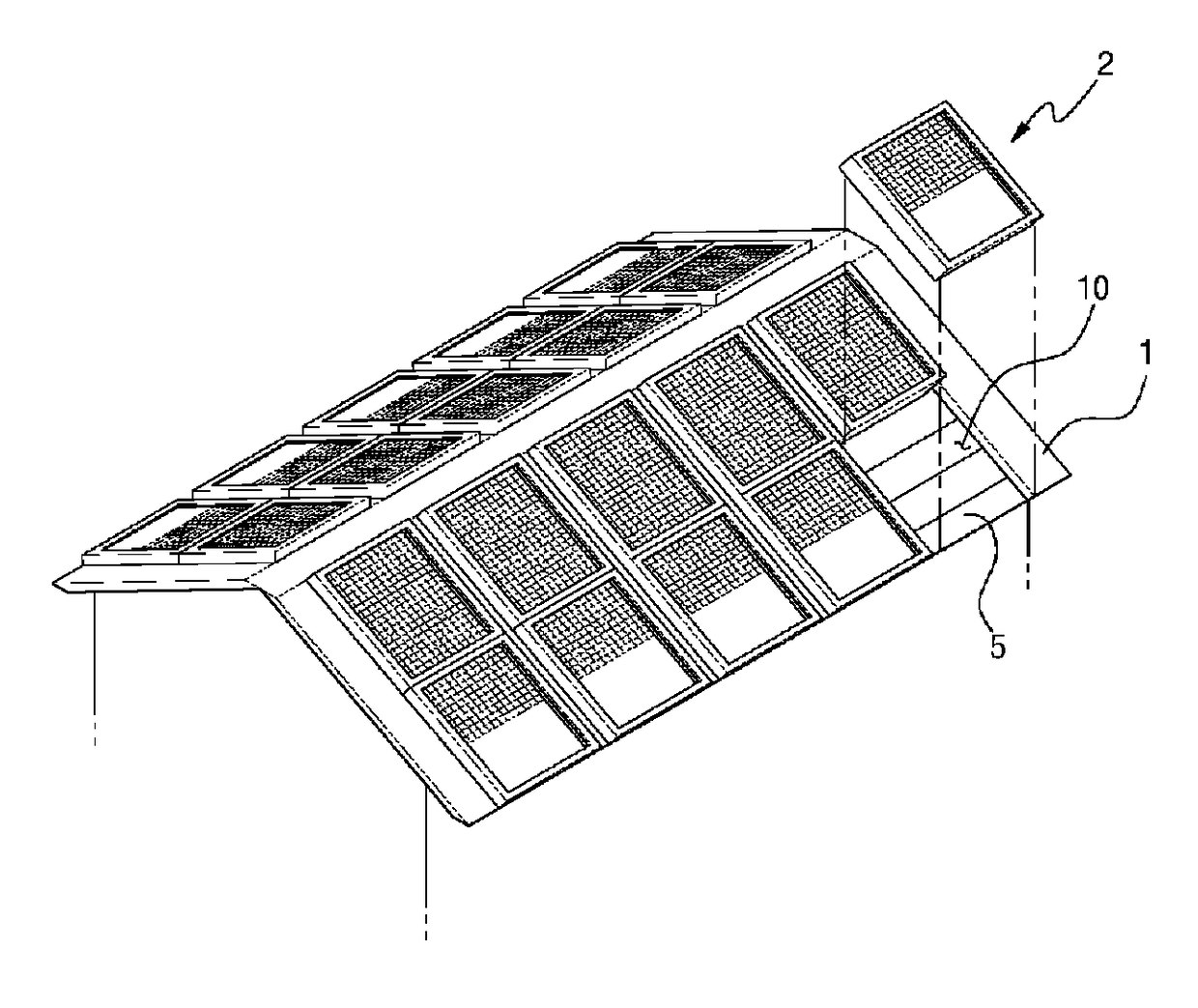

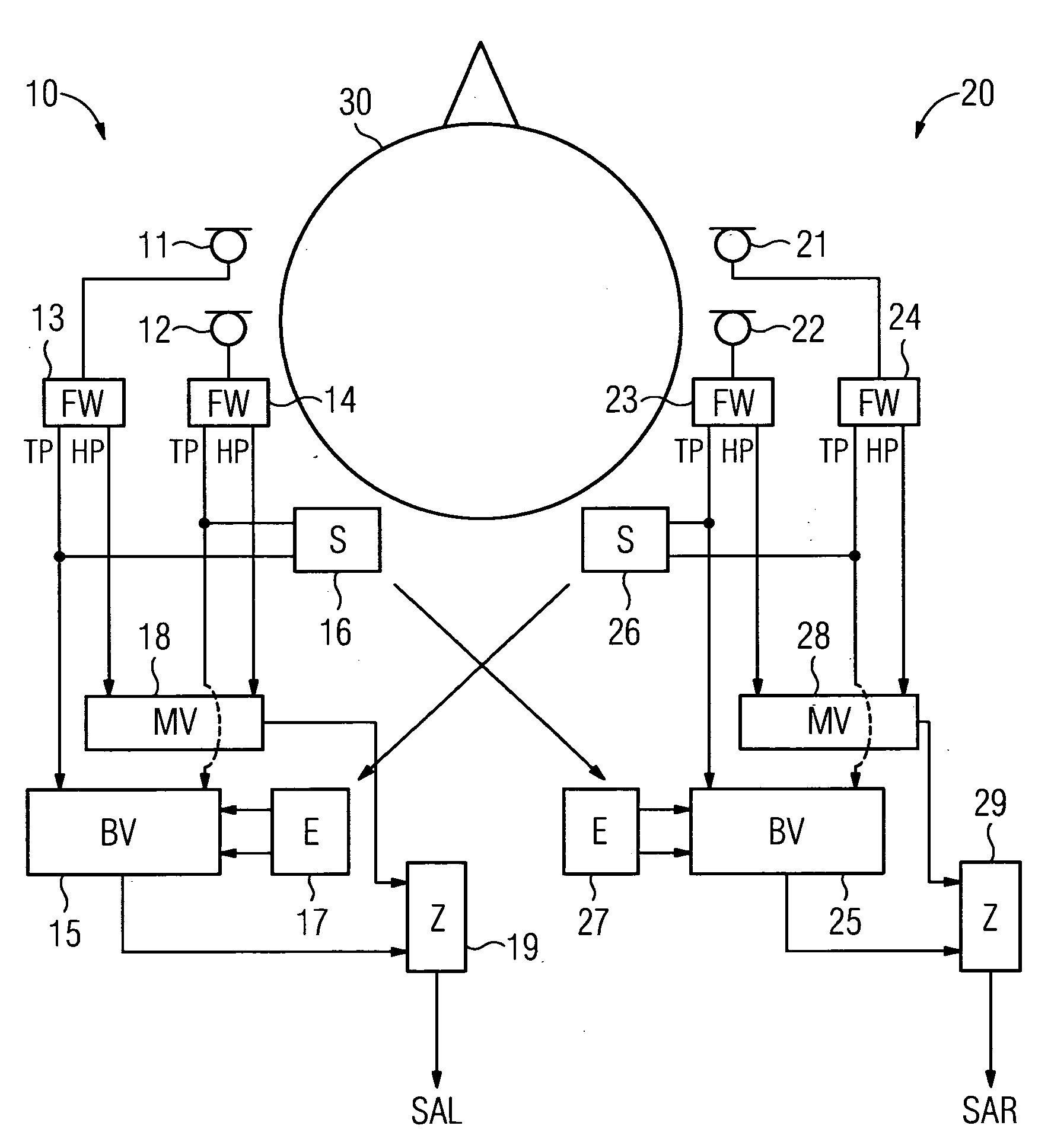

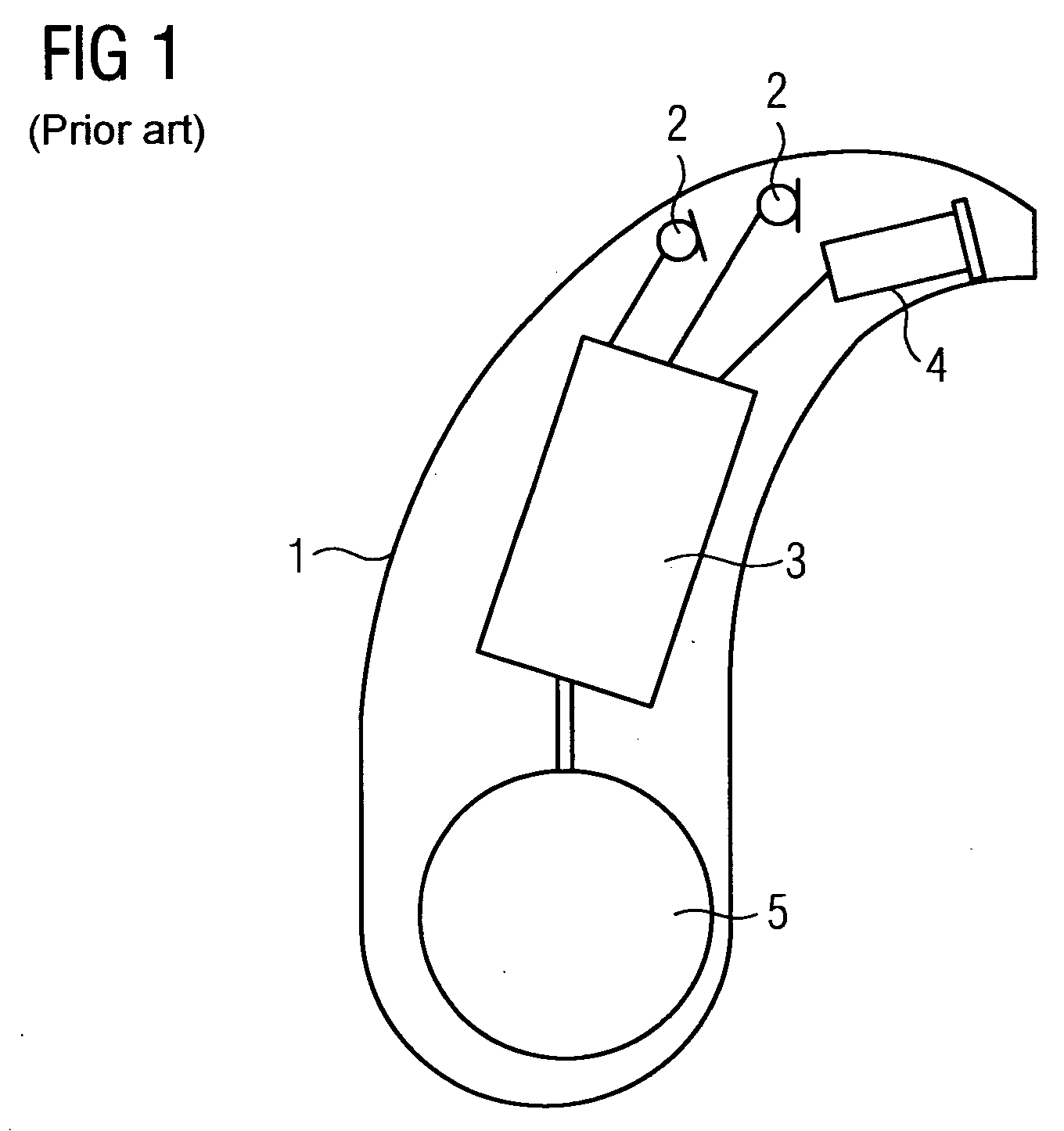

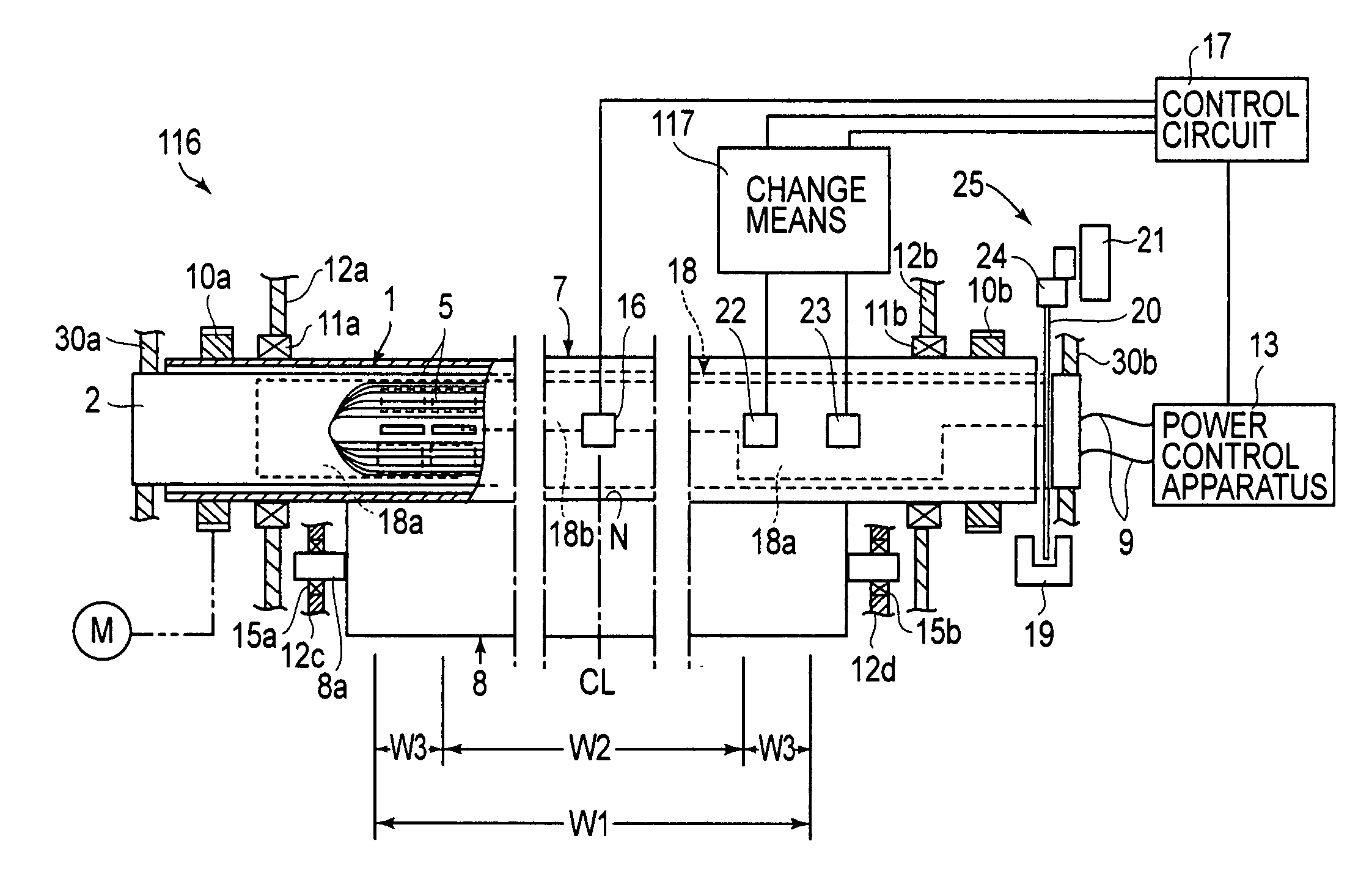

Electrical architecture for a rotary wing aircraft with a hybrid power plant

ActiveUS20120025032A1Reduce loadSave energy consumptionAircraft power plant componentsPropulsion by batteries/cellsOn boardEngineering

A hybrid power plant (5) for an aircraft (1) comprises at least: a hybrid drive system (37) having a main on-board electricity network (16) and an auxiliary electricity network (34); and a selective adaptation interface (38) arranged to enable electrical energy to be exchanged selectively between the main and auxiliary electricity networks (16; 34). At least one engine and a hybrid drive auxiliary electrical machine (7, 31) are mechanically connected to a transmission (8); said machine (7) being electrically connected to at least one auxiliary electrical bus (36) in parallel with at least one auxiliary device for delivering electric charge.

Owner:EUROCOPTER

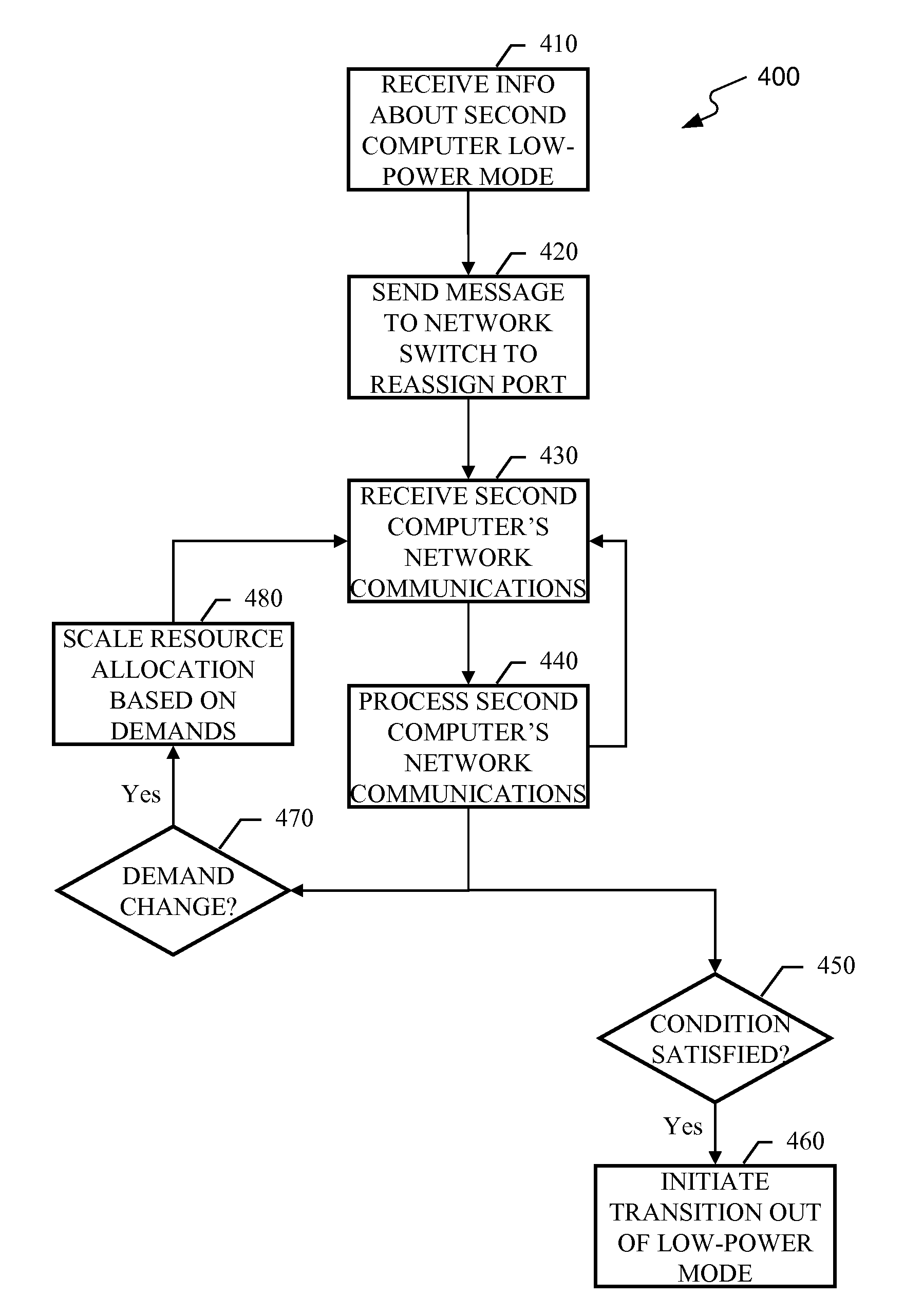

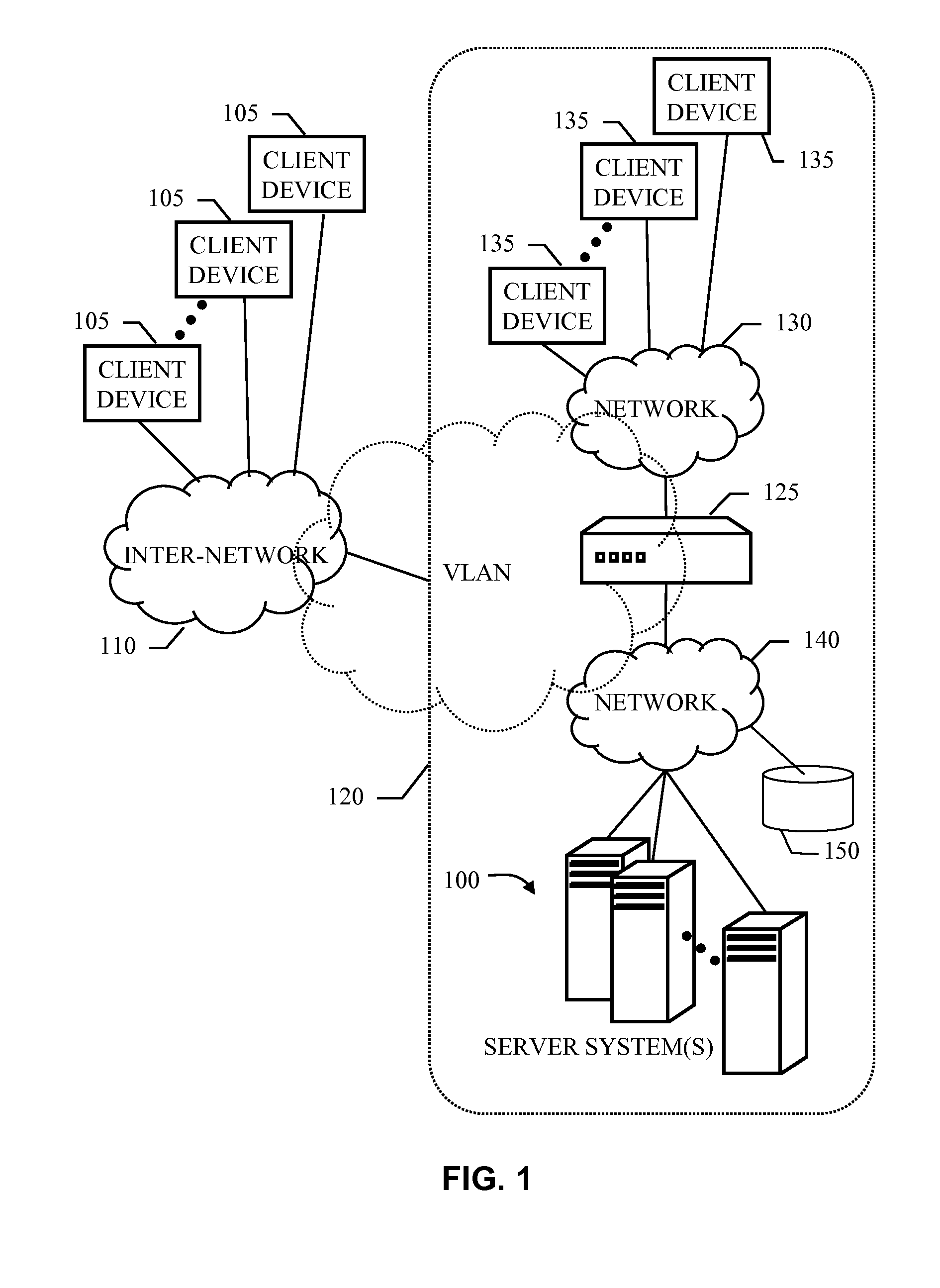

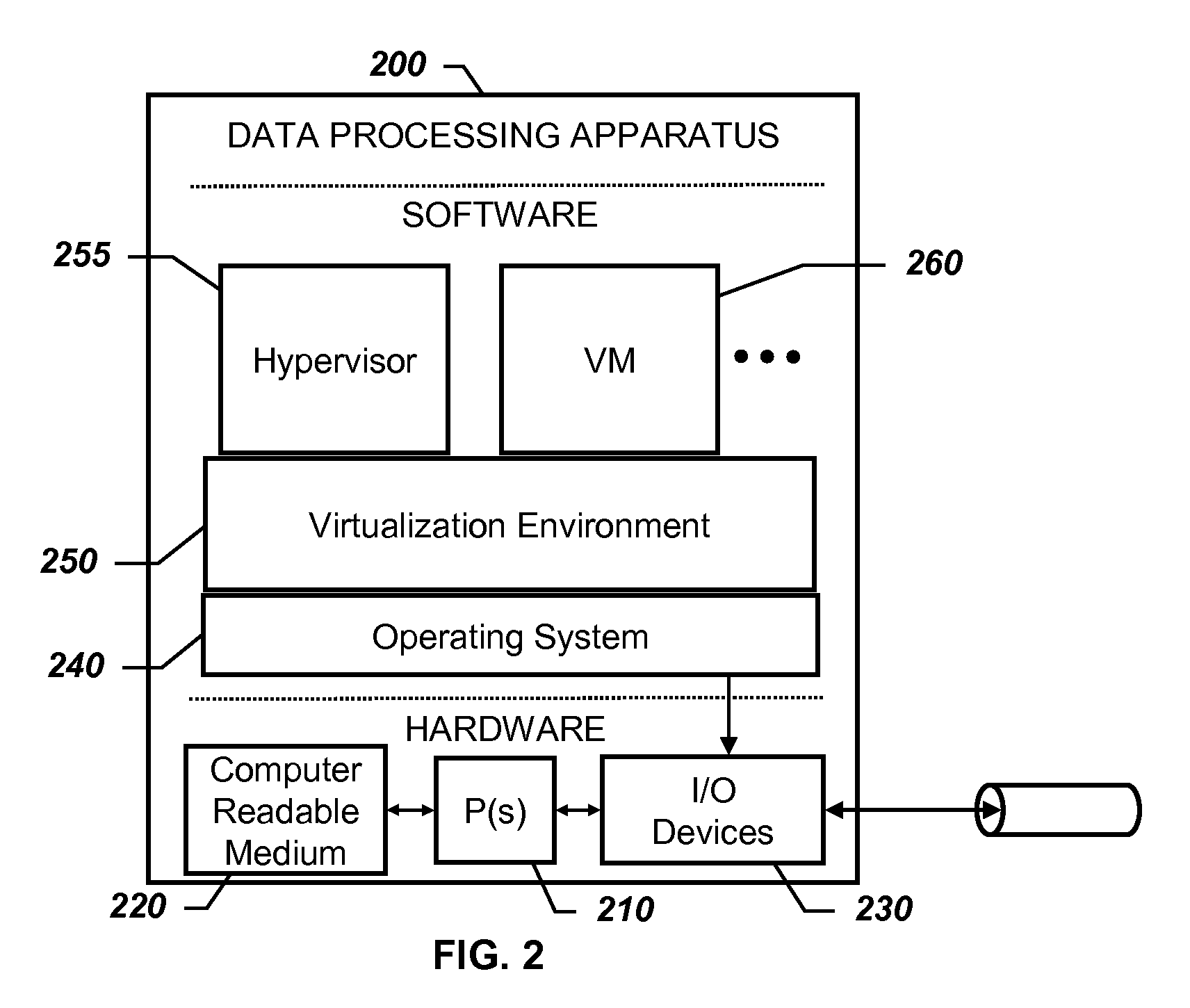

Architecture to enable energy savings in networked computers

ActiveUS20110191610A1Save substantial powerEasy to implementEnergy efficient ICTDigital data processing detailsPower modeOperation mode

This application includes systems and techniques that permit computers to remain accessible while in a low-power mode. In some implementations, the technique includes receiving at a first computer, via a computer network, information regarding a second computer transitioning to a low-power mode of operation; receiving at the first computer network communications designated for the second computer; processing at the first computer at least a portion of the network communications on behalf of the second computer without transitioning the second computer out of the low-power mode of operation, where the processing comprises processing the at least a portion of the network communications on behalf of the second computer within a virtual machine corresponding to the second computer; and initiating, via the computer network, a transition of the second computer out of the low-power mode of operation when at least one of the network communications satisfies a predetermined condition.

Owner:RGT UNIV OF CALIFORNIA

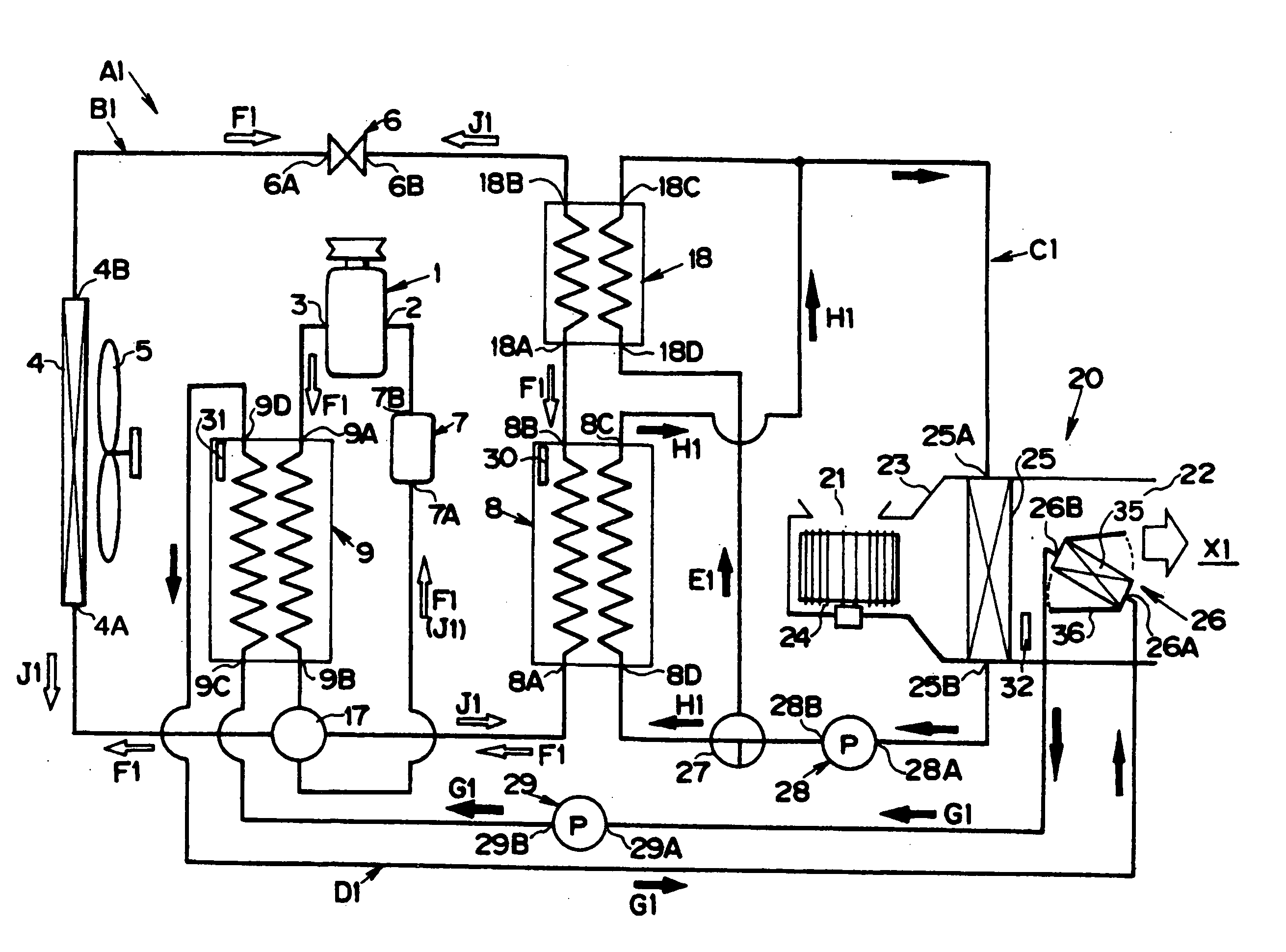

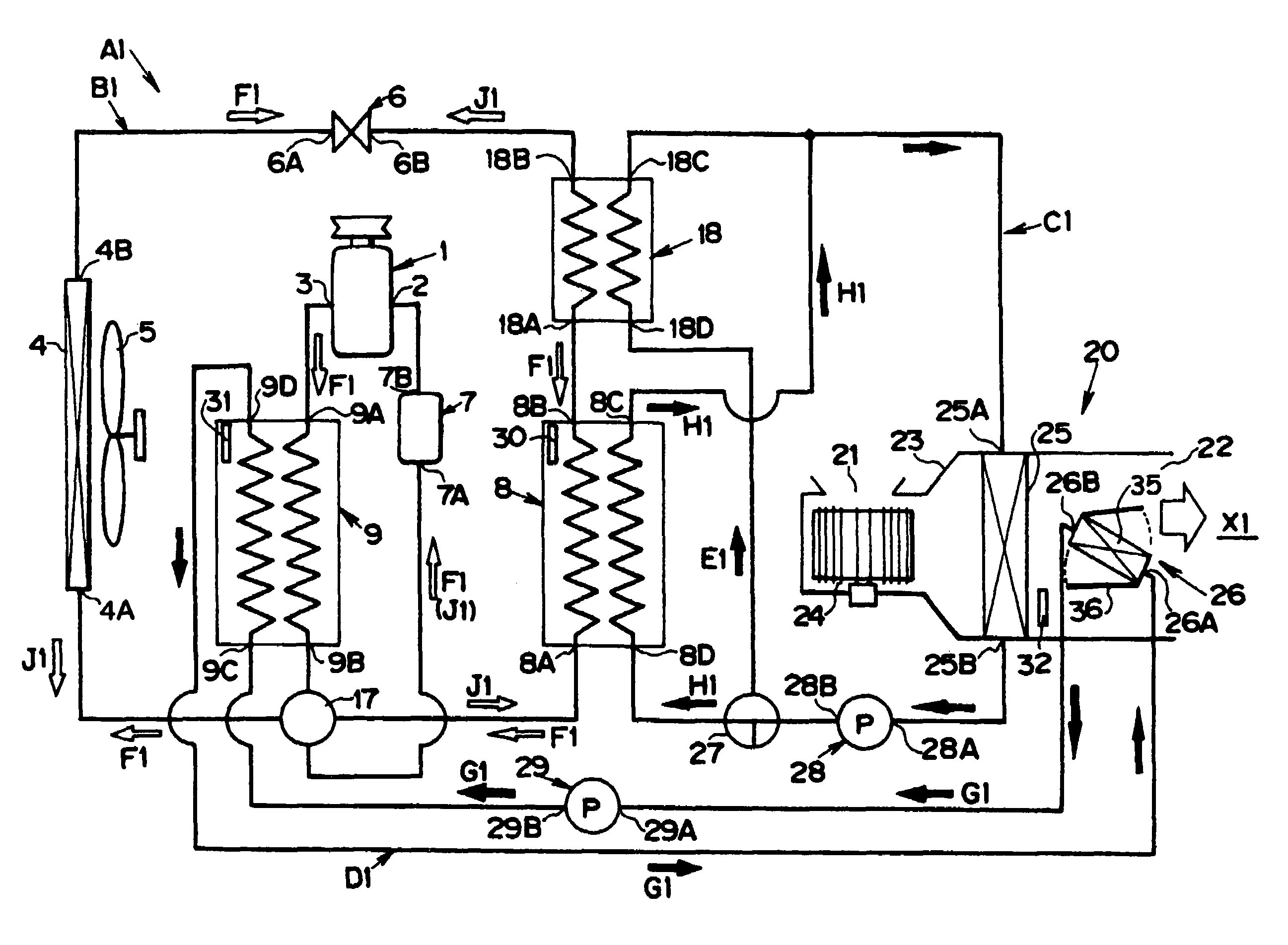

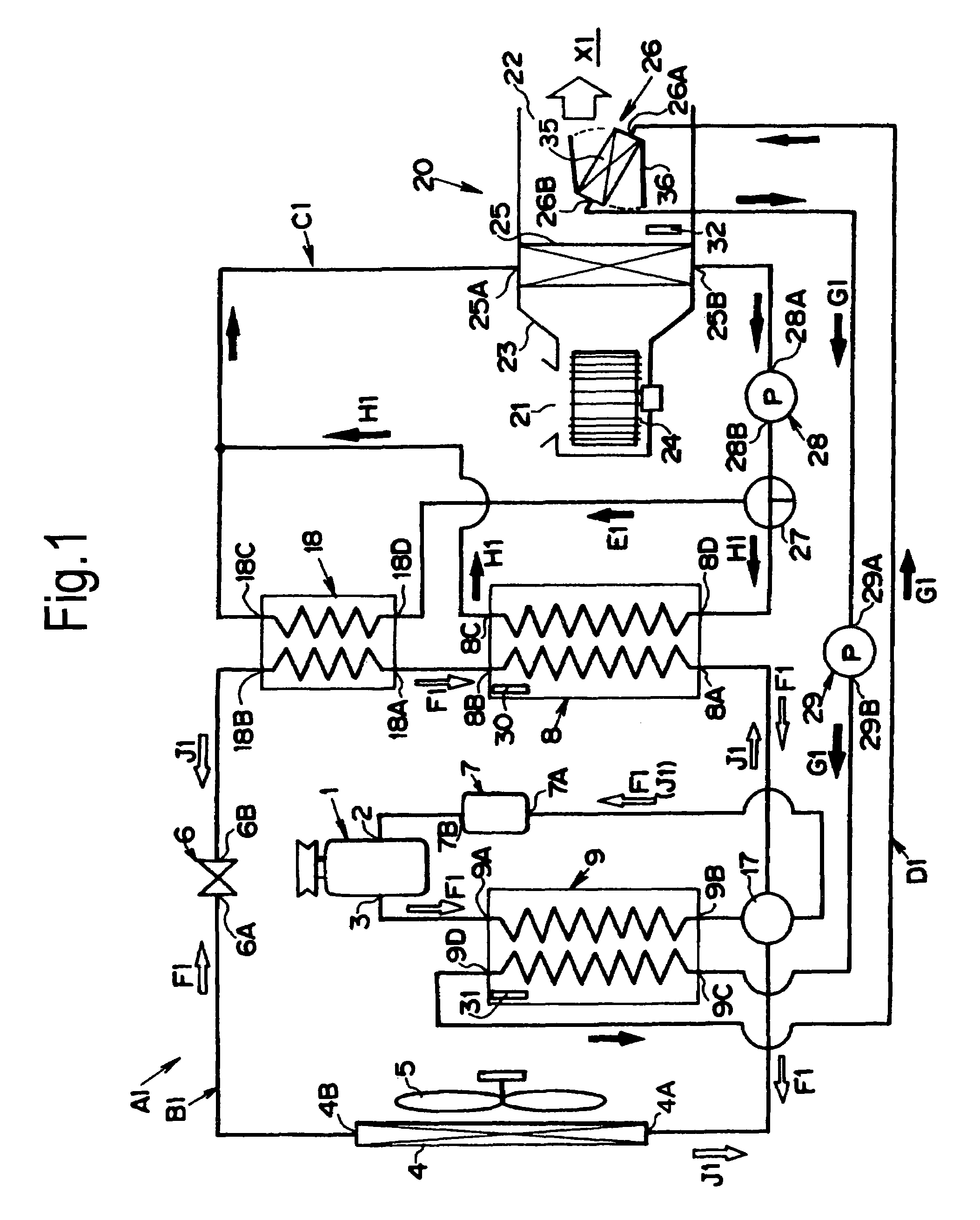

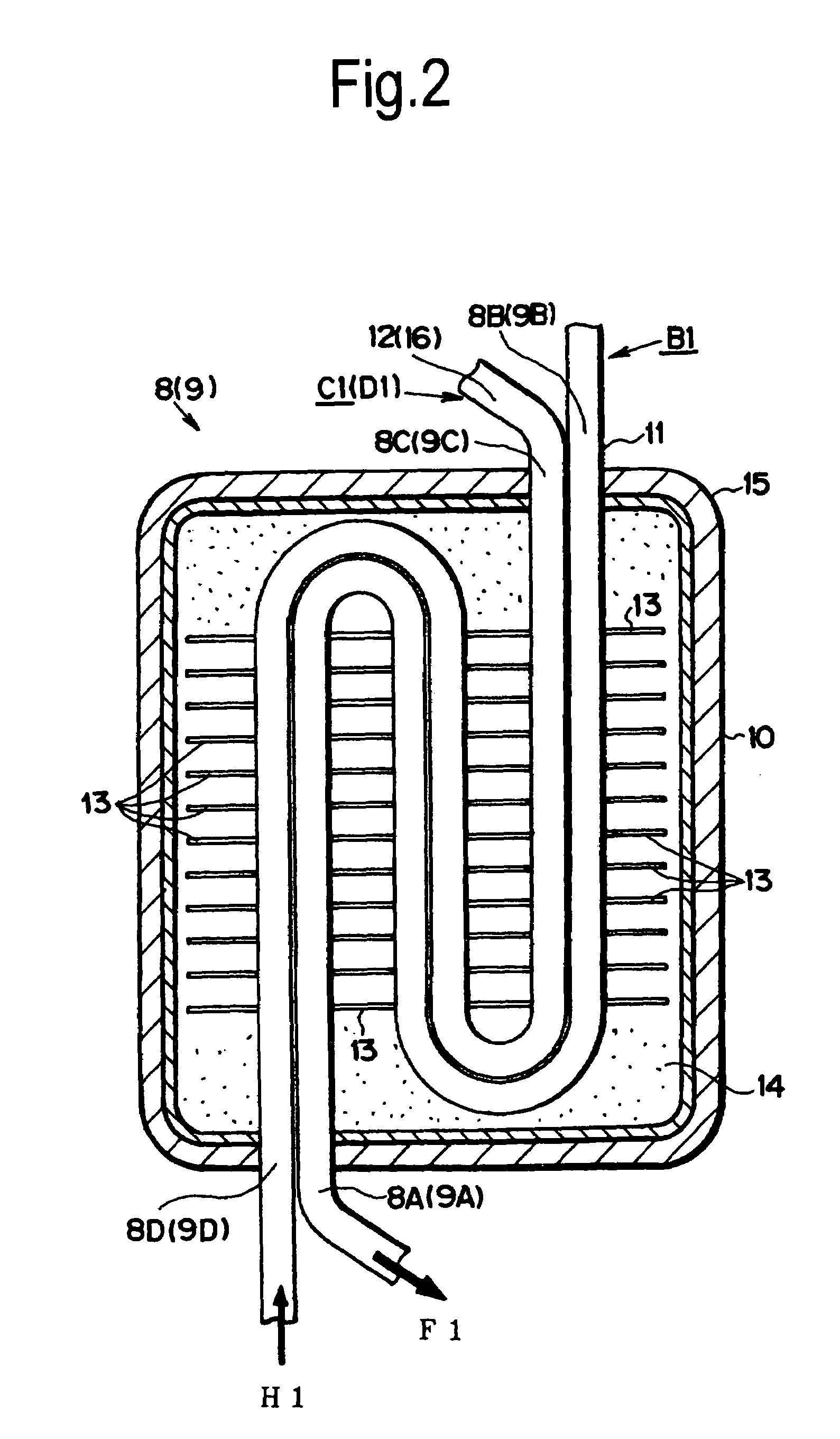

Air conditioning apparatus

InactiveUS20060032623A1Efficient heat transferImprove heat transfer efficiencyHeat storage plantsDesuperheatersEngineeringHeat exchanger

An air conditioning system for cooling or heating an air, and for feeding the heated or cooled air to predetermined portions is characterized by comprising: a first circulating circuit for circulating a first heating medium; a second circulating circuit for circulating a second heating medium; a control unit for controlling the heat for executing heat exchange between the first heating medium and the second heating medium to flow through either the heat exchanger or the first heat storing device. Moreover, an air temperature is controlled by heat of the second heating medium.

Owner:TOYOTA JIDOSHA KK

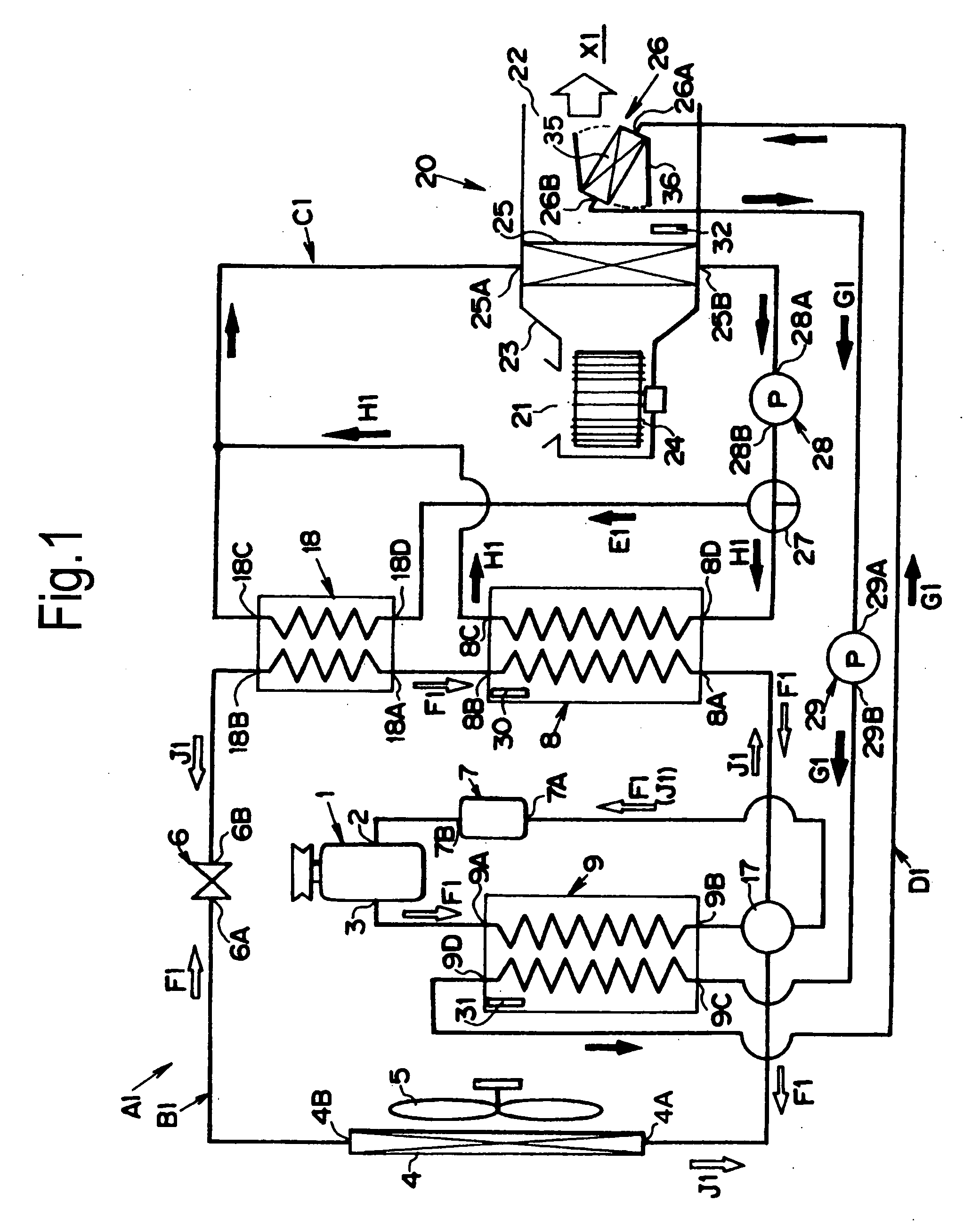

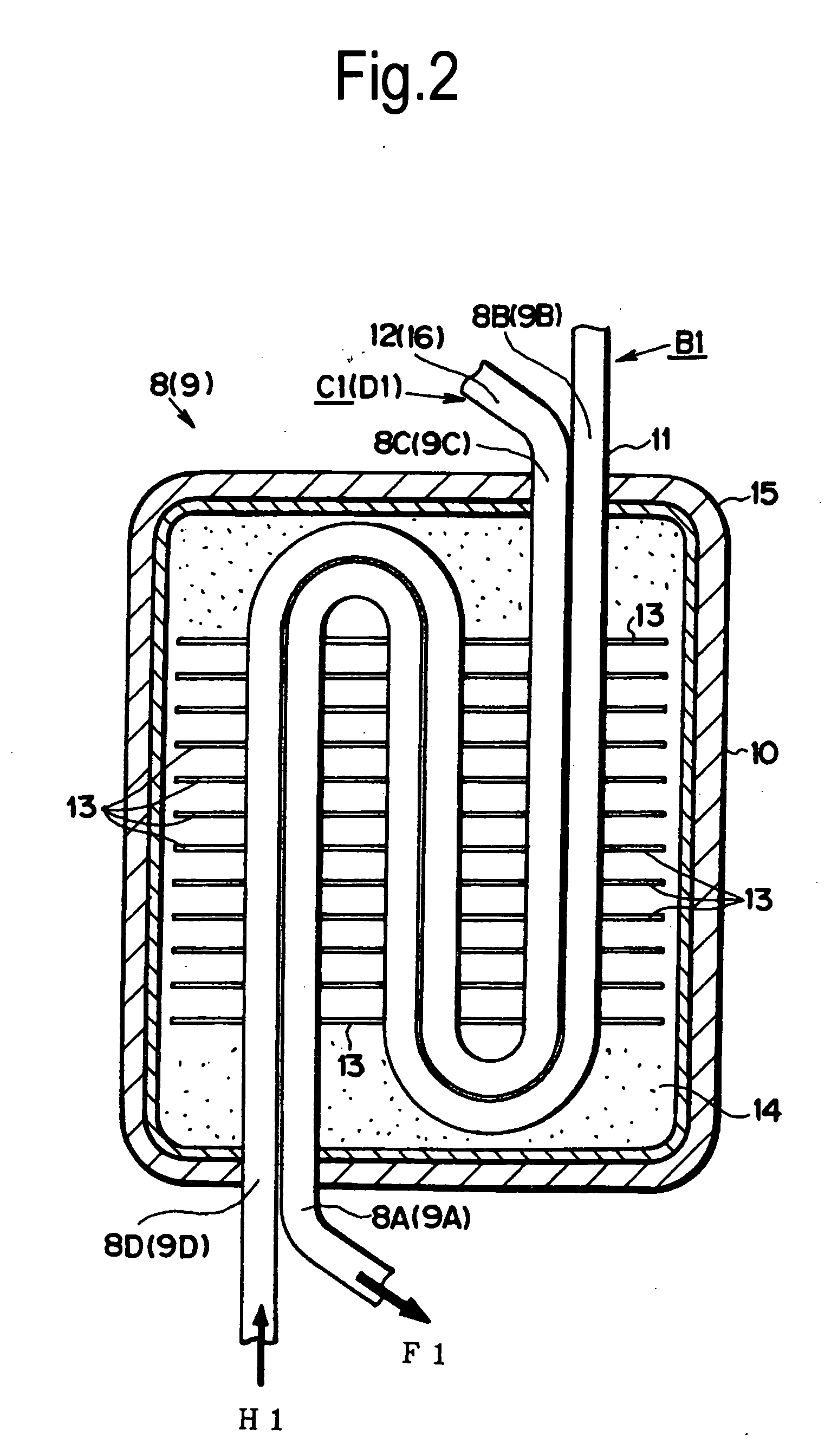

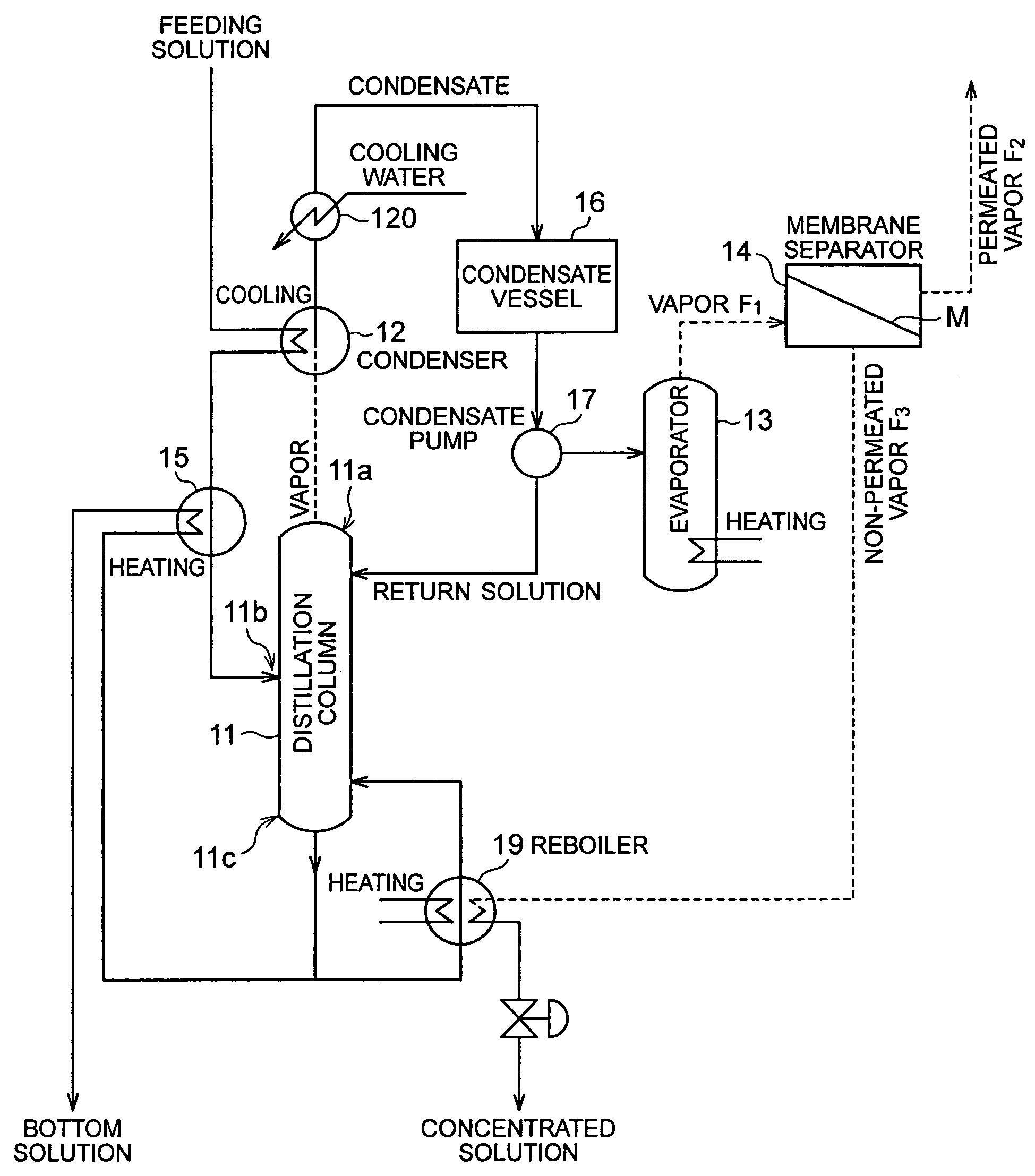

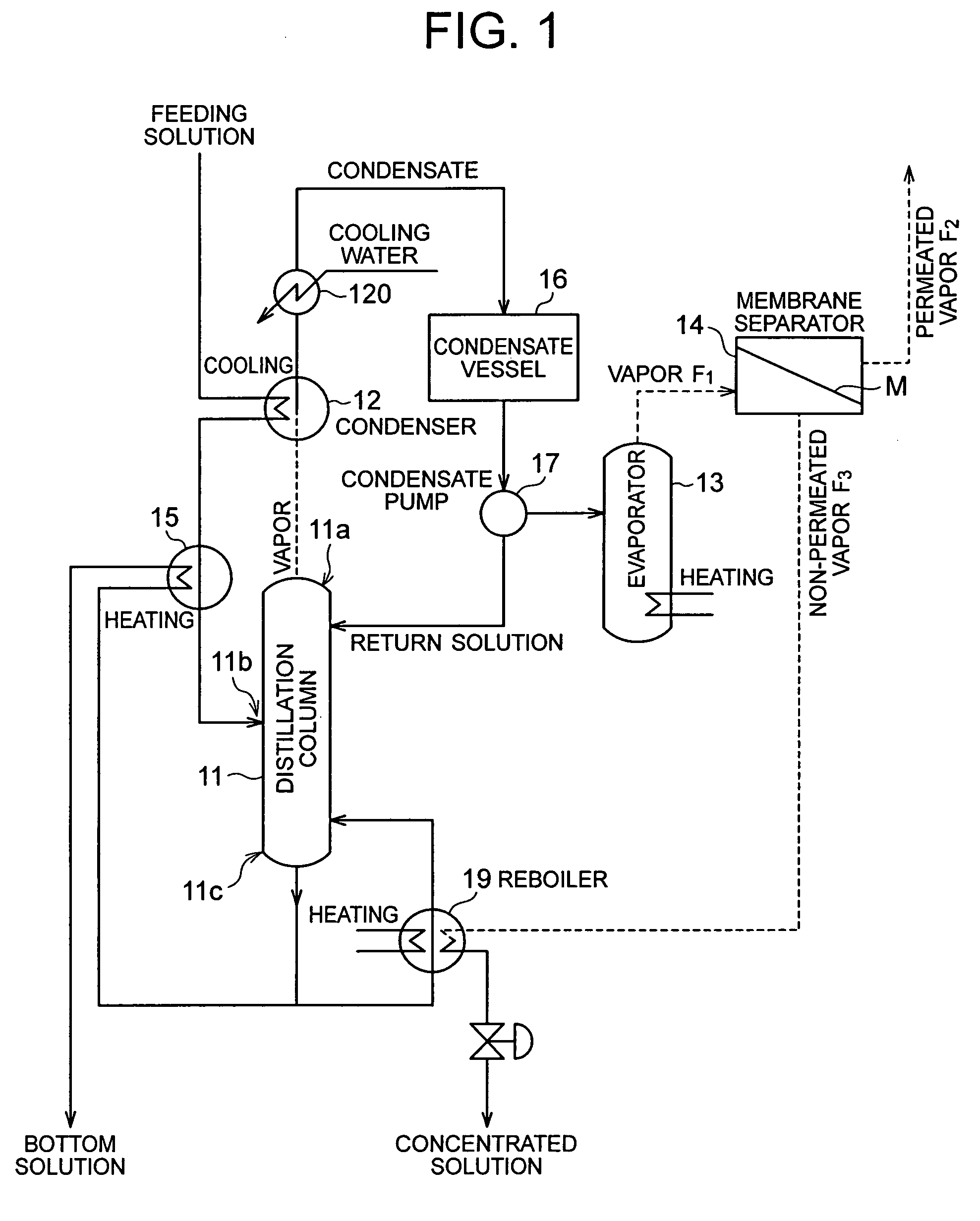

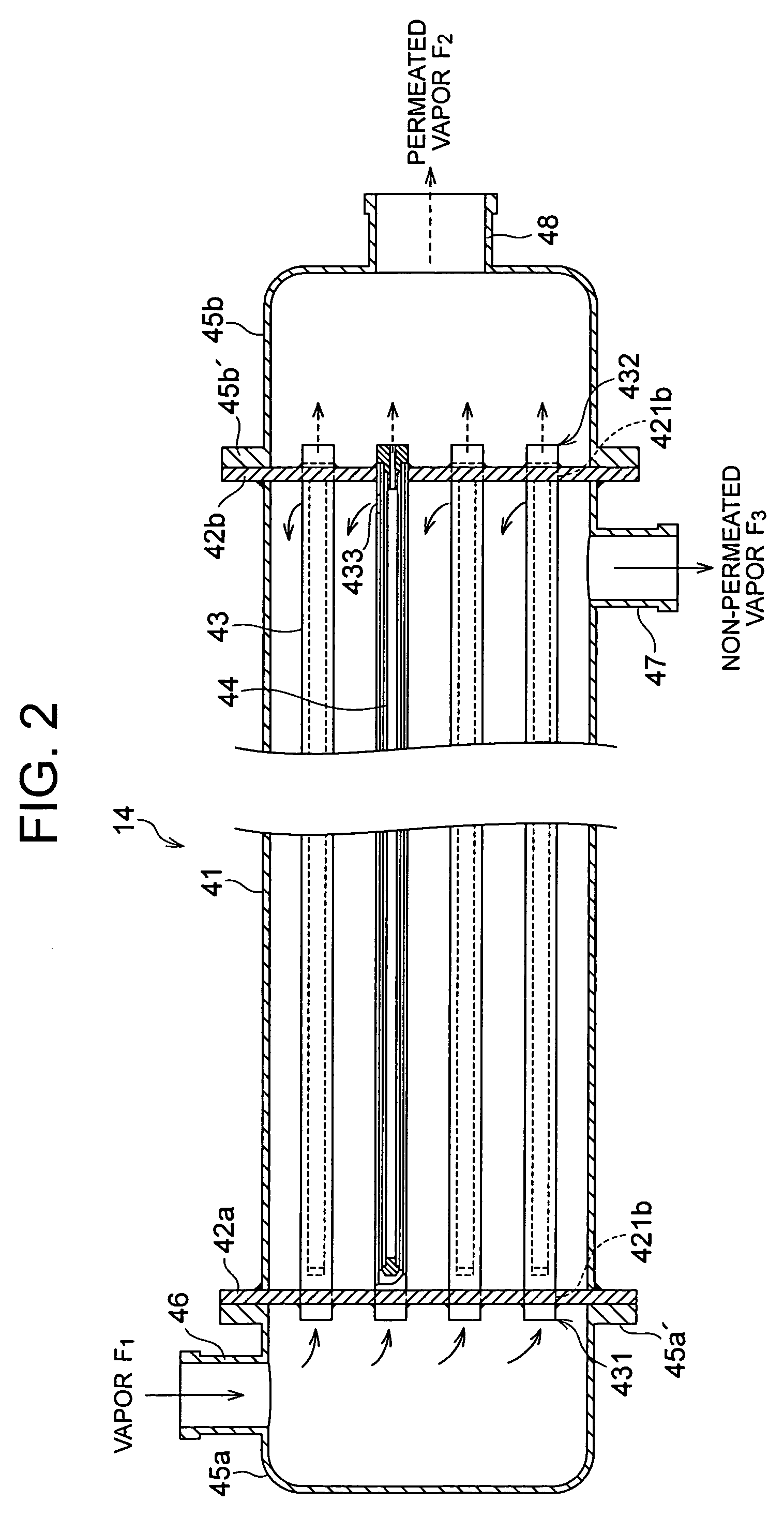

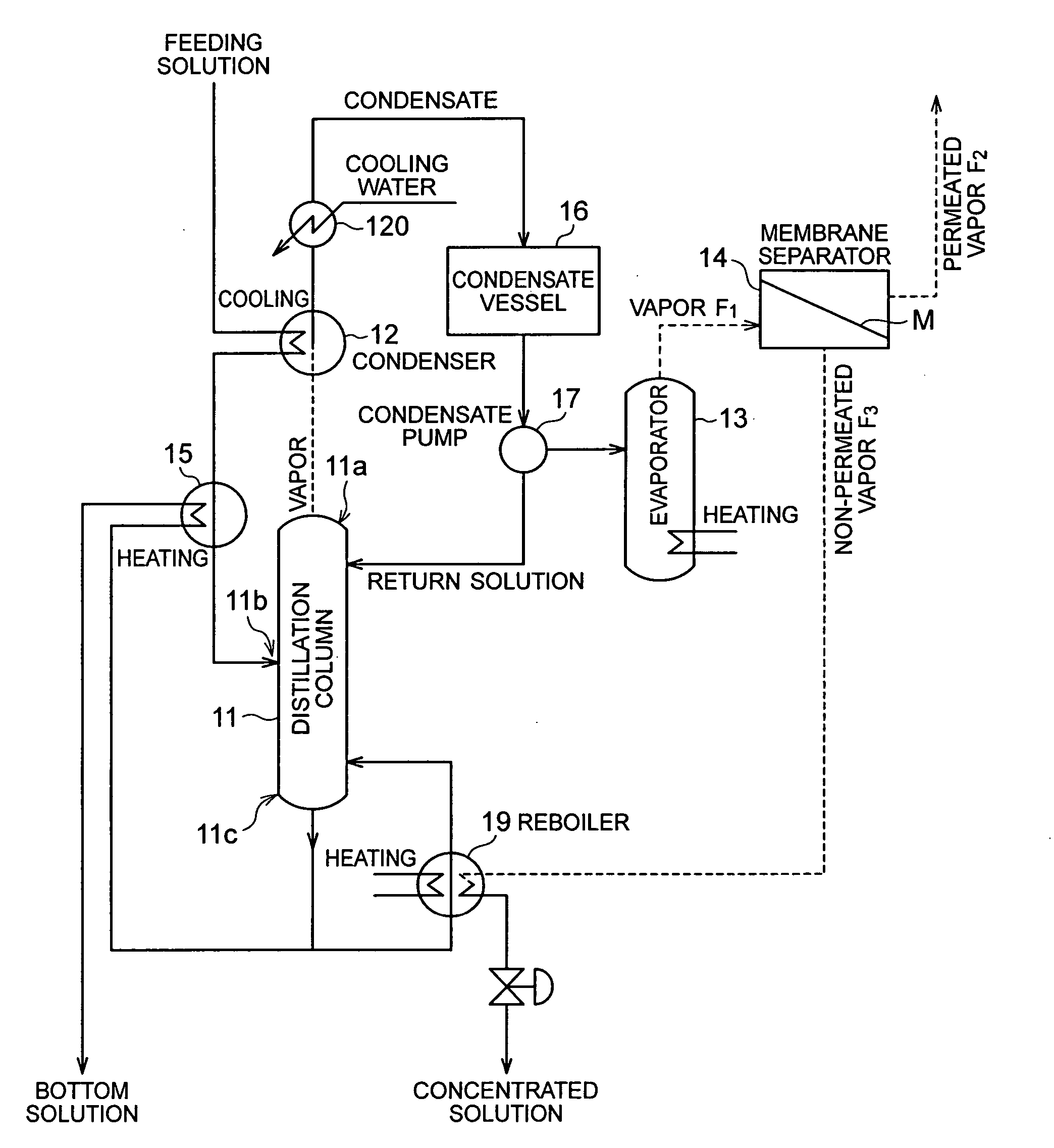

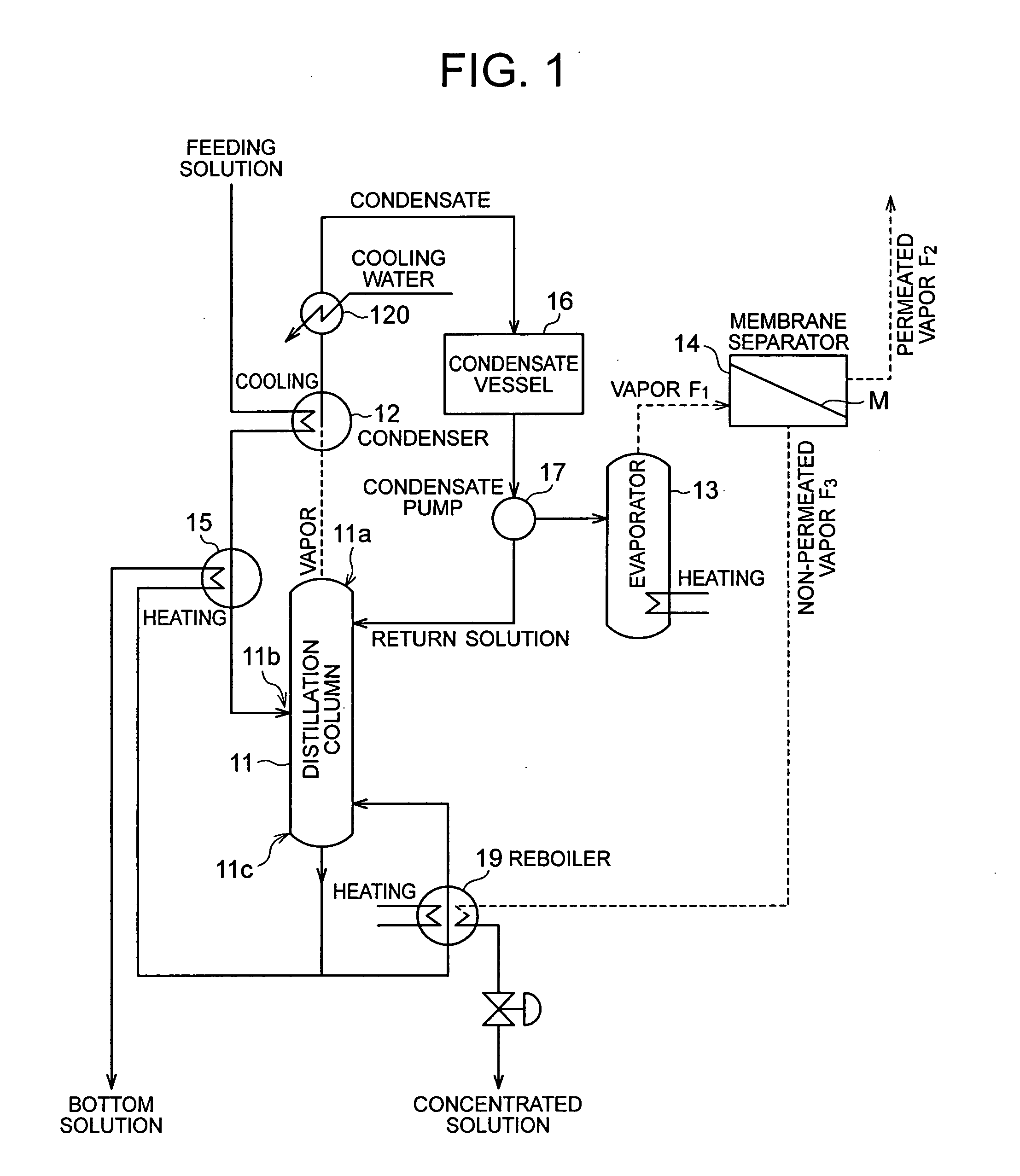

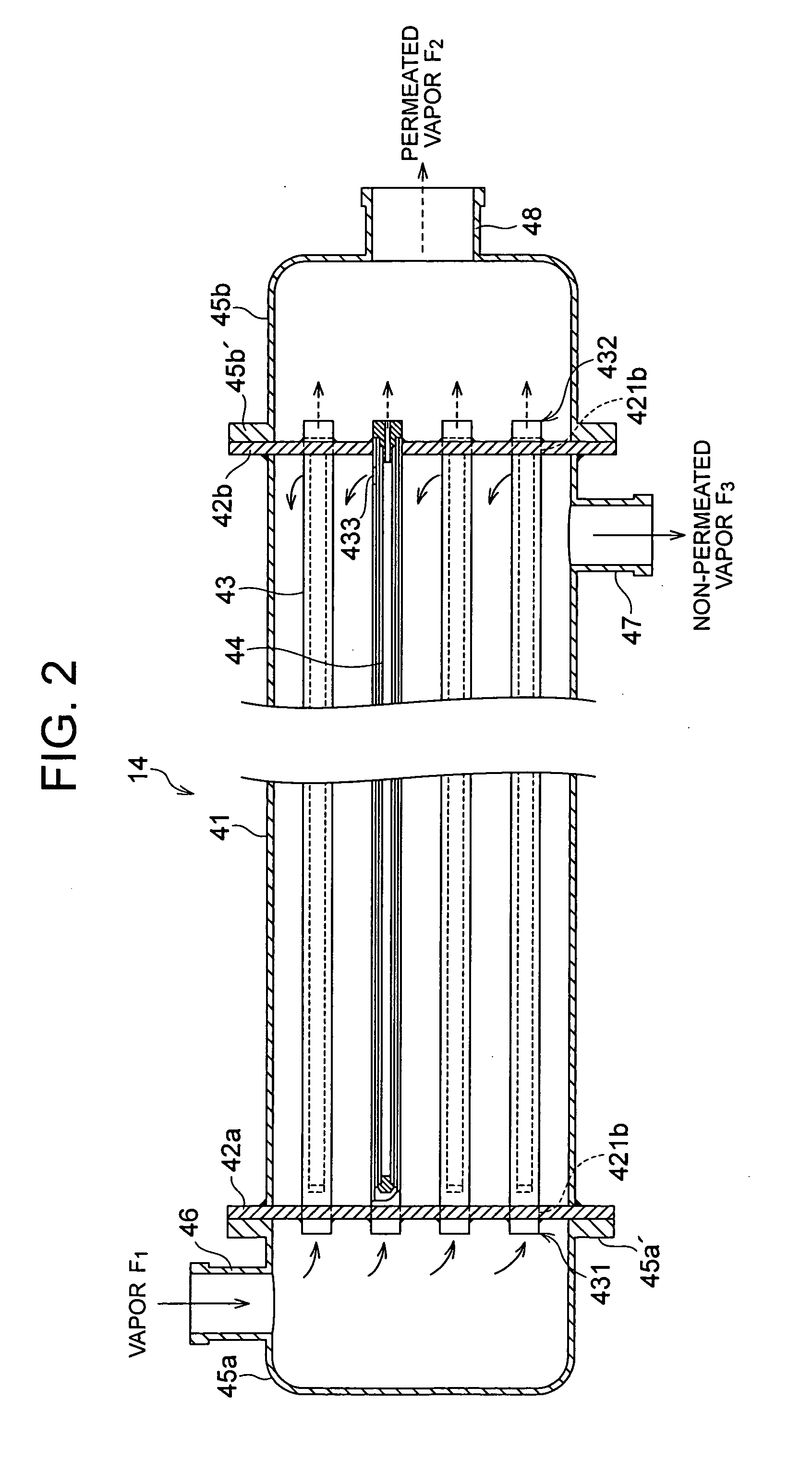

Method for concentrating water-soluble organic material

InactiveUS7594981B2Improve permeabilityIncrease operating pressureOrganic compound preparationDispersed particle separationDistillationWater soluble

A method for concentrating a water-soluble organic material wherein a mixture of the water-soluble organic material with water is distilled in a distillation column (11), and the fraction from the top (11a) of the distillation column (11) is separated by the use of a membrane separator (14) into a permeated vapor (F2) and a non-permeated vapor (F3), which comprises once condensing the fraction to form a condensate, heating the condensate in an evaporator (13) to generate a vapor (F1) having a pressure higher than the operation pressure for the distillation column (11), and introducing the vapor (F1) to the membrane separator (14), thereby separating water from the mixture.

Owner:MITSUBISHI CHEM CORP

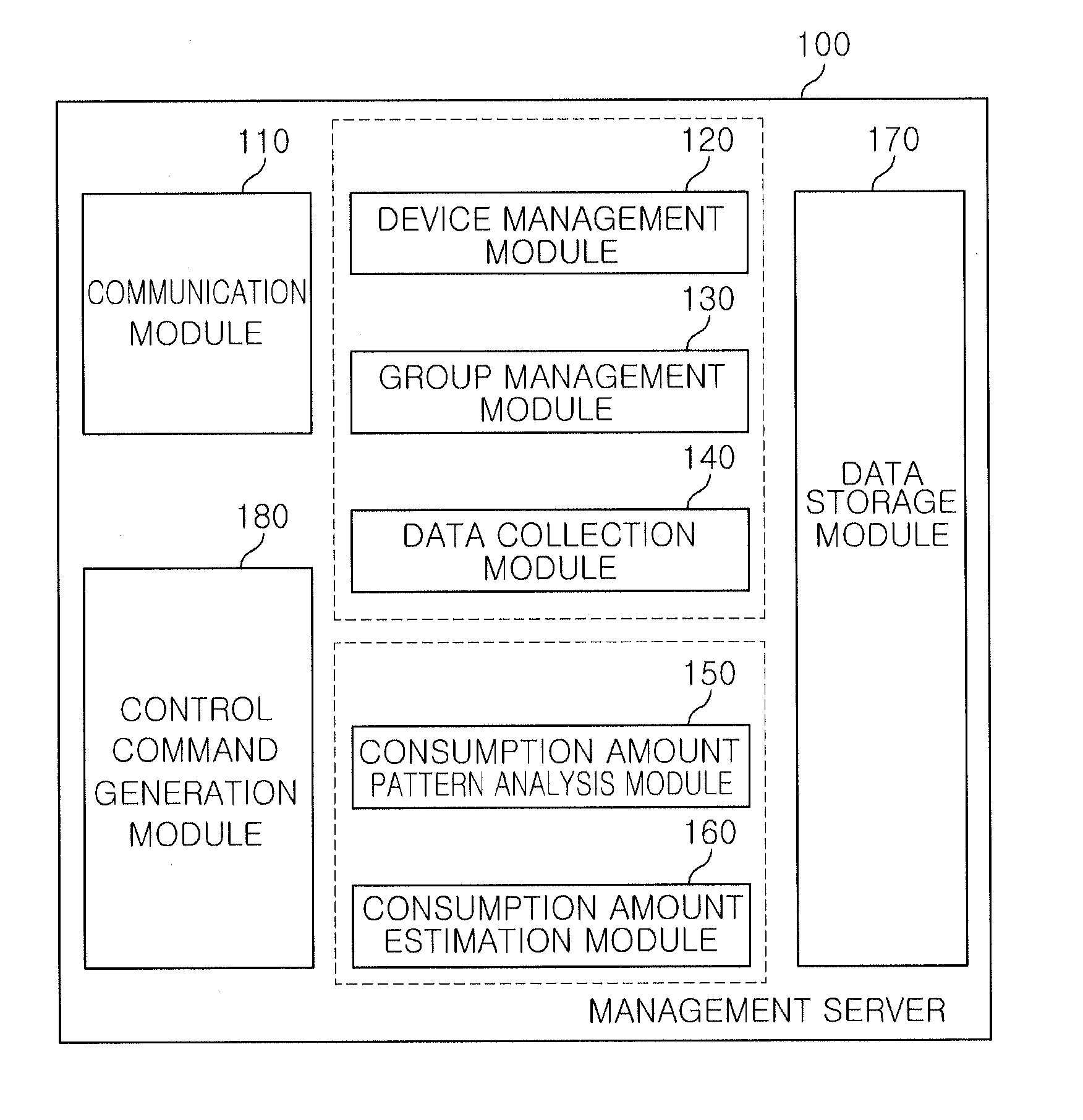

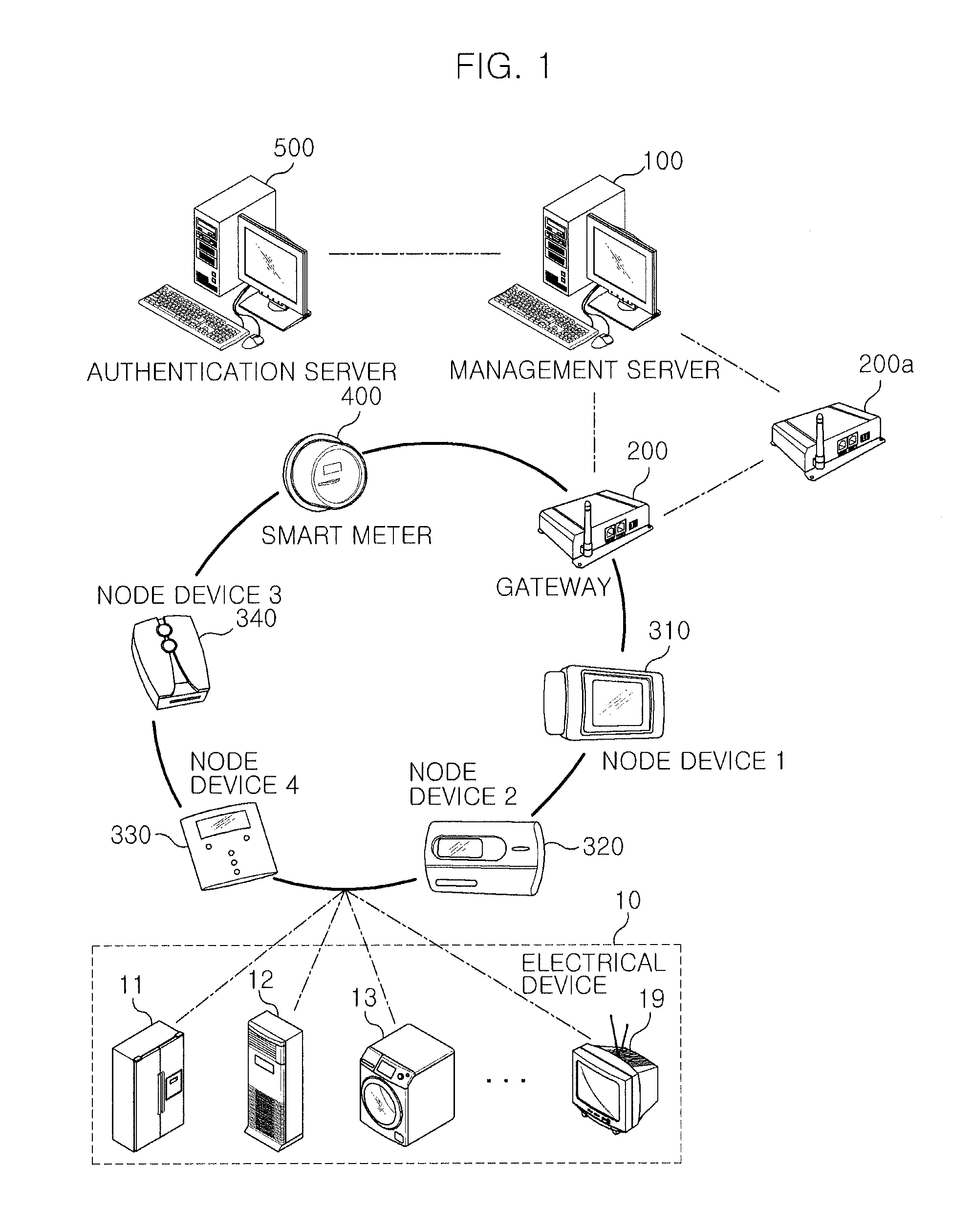

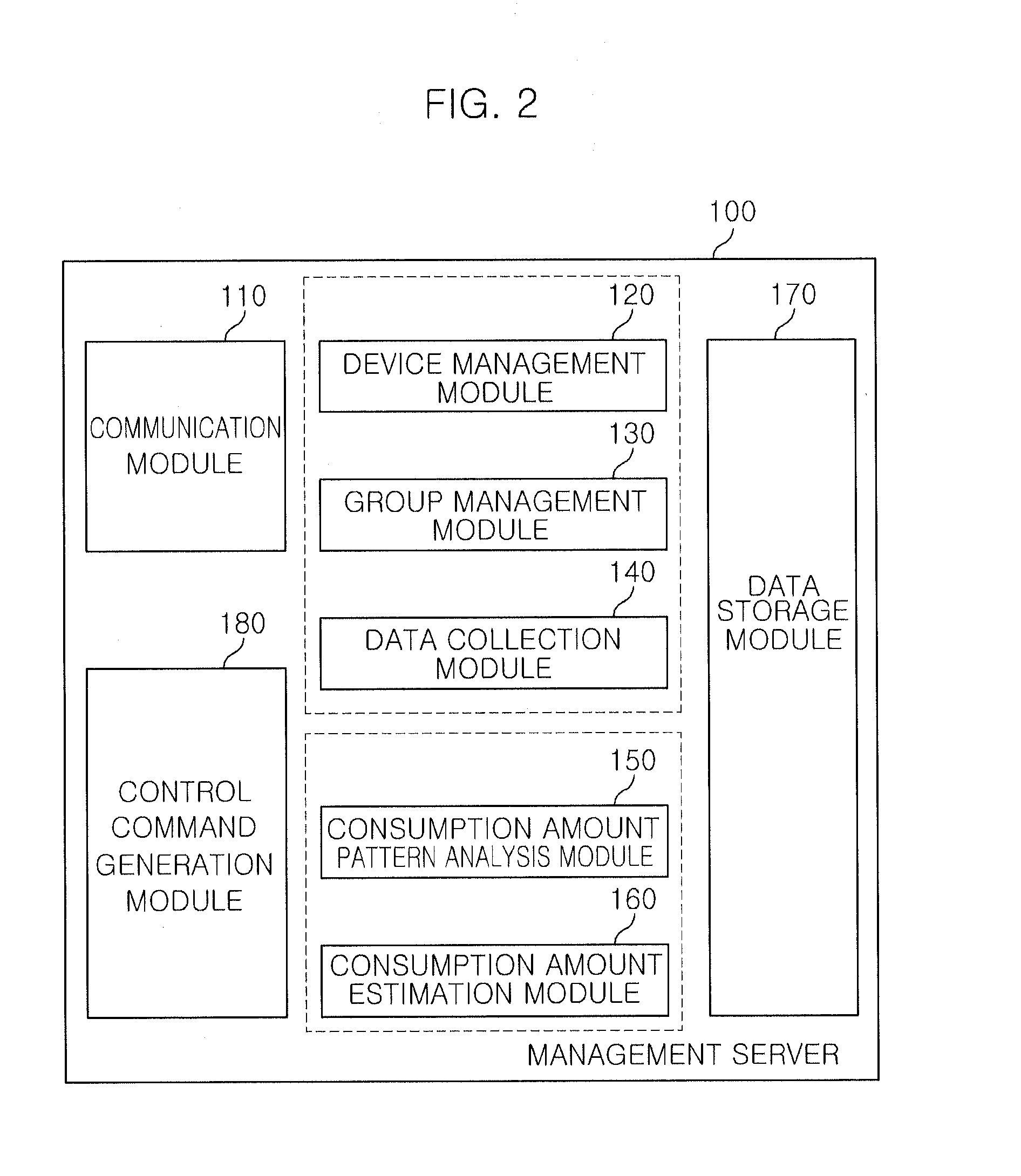

Apparatus and method for smart energy management by controlling power consumption

InactiveUS20110153107A1Save chargeSave energy consumptionLevel controlVolume/mass flow measurementAutomatic controlControl power

Disclosed are an apparatus and a method for smart energy management by controlling power consumption. Power consumption information is collected from one or more electrical device groups with a smart meter and electrical devices connected through gateways. When the method estimates that the power consumption will be larger than a threshold value, a control command is outputted to a load controller connected through the gateway and power consumption of electrical devices that belong to the electrical device using group is remotely controlled. According to an embodiment of the present invention, an energy company that produces and supplies energy can supply energy depending on a consumer's demand by using current facilities because the present invention can collect remotely energy consumption, analyze energy consumption patterns, and control automatically the energy consumption of electrical devices installed in a customer's area. The consumer who consumes energy can save the energy consumption and the charge of the energy consumption.

Owner:ELECTRONICS & TELECOMM RES INST

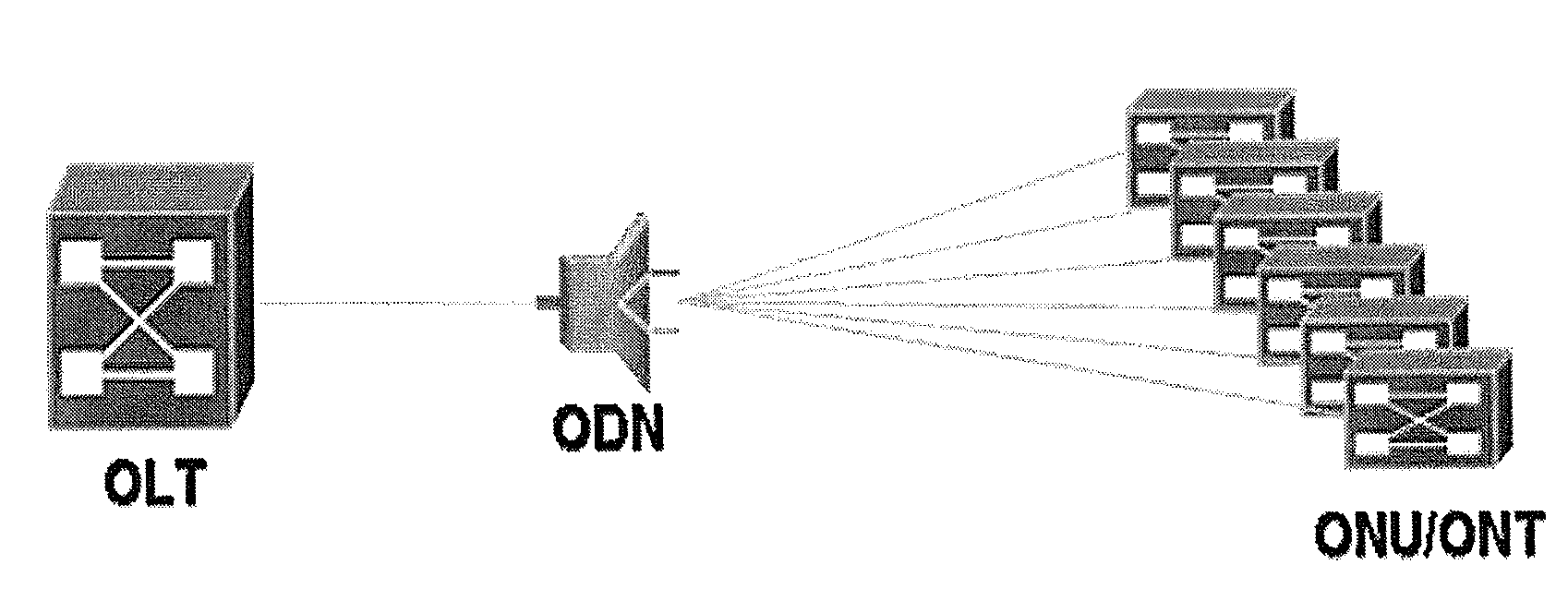

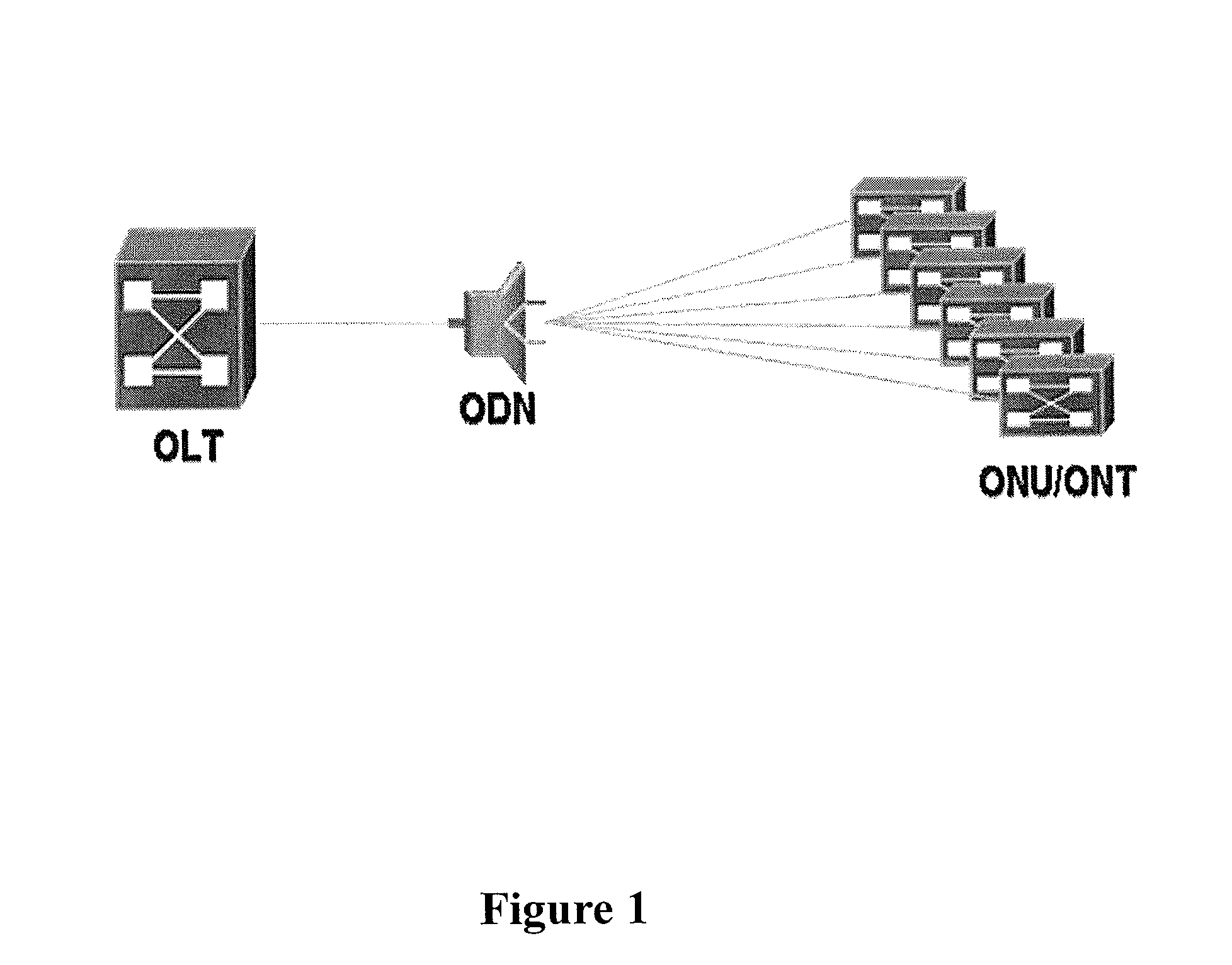

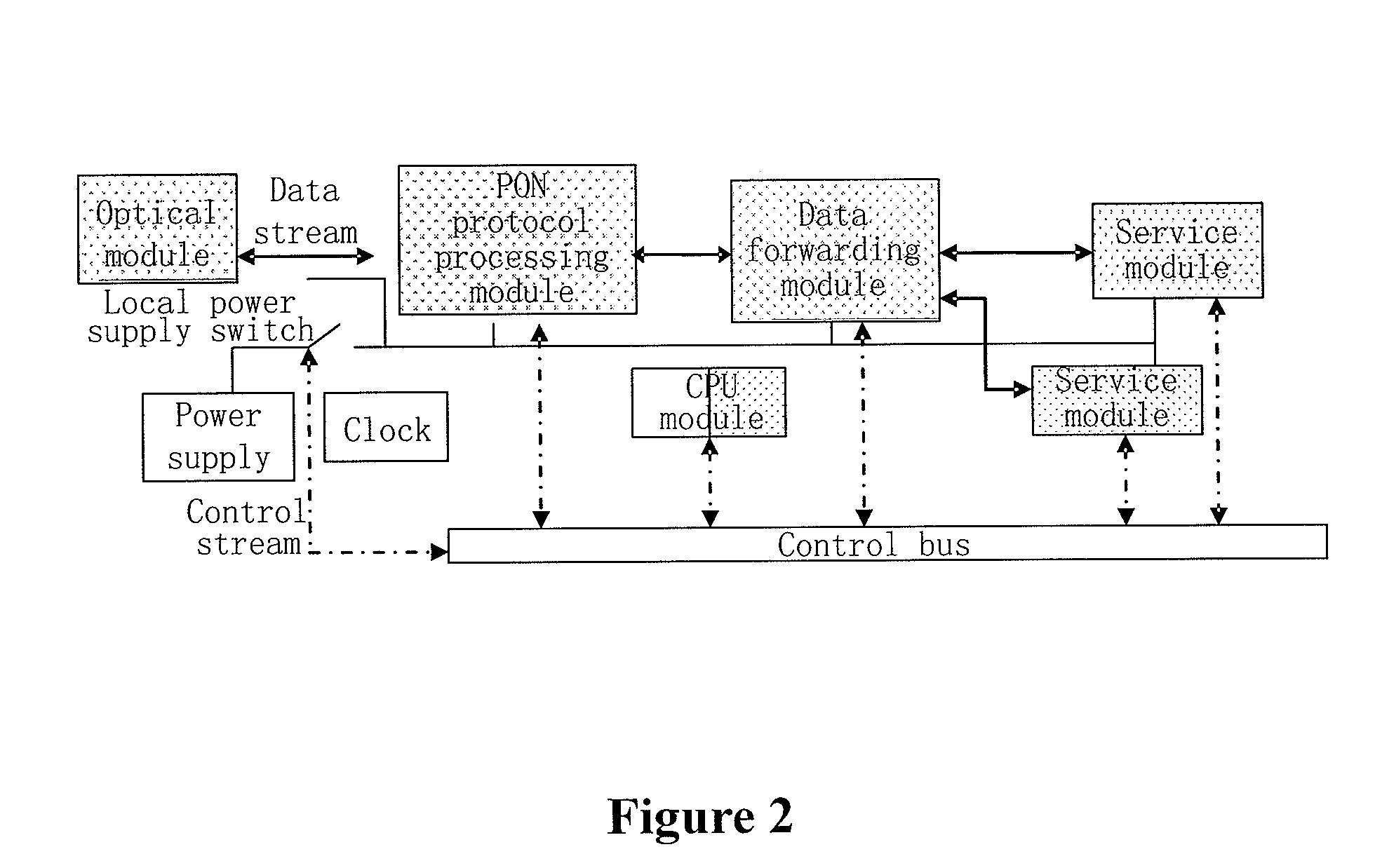

Method for operating PON user terminal and a PON user terminal

ActiveUS20080212964A1Save power consumptionReduce power consumptionMultiplex system selection arrangementsTime-division multiplexTerminal equipmentComputer science

A method for operating PON (passive optical network) user terminal and a PON user terminal equipment, when there is only few data service request in the PON, the PON user terminal operates in power saving manner which maintains low speed connection, the method comprises: a judgment condition that the PON user terminal changes to power saving state is set; the PON user terminal determines whether its own state meet the judgment condition changing to power saving state, if so, it transmits a request to change to power saving state to the OLT (optical line terminal); after the PON user terminal receives the respond that the OLT has accepted the request, it controls parts of the modules therein to change to power saving state, and intermittently switch over between power saving state and normal state. The invention allows saving power under the condition that keeps the low speed service uninterrupted, in the meanwhile alleviates the pressure of ONU terminal thermal design.

Owner:HUAWEI TECH CO LTD

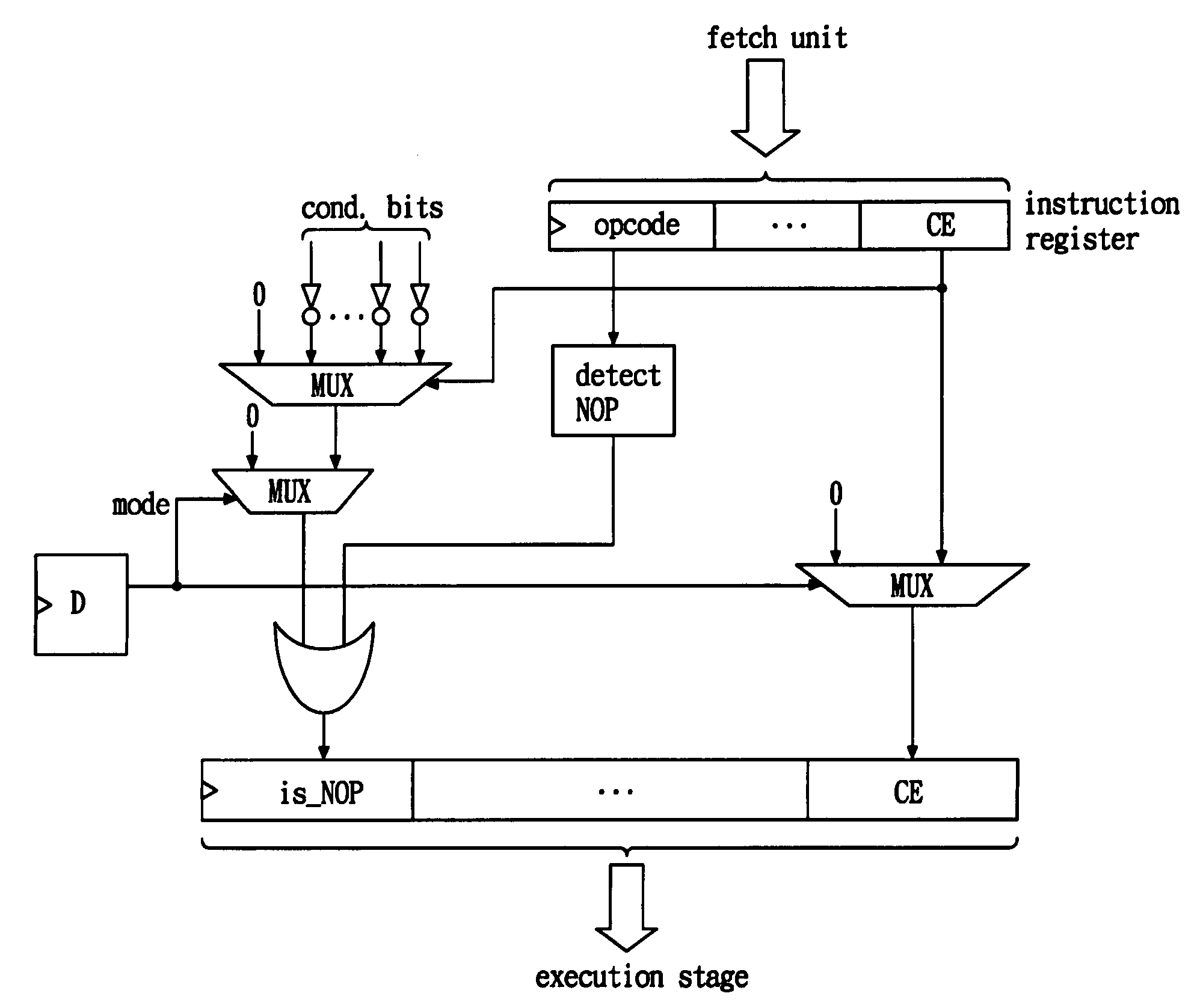

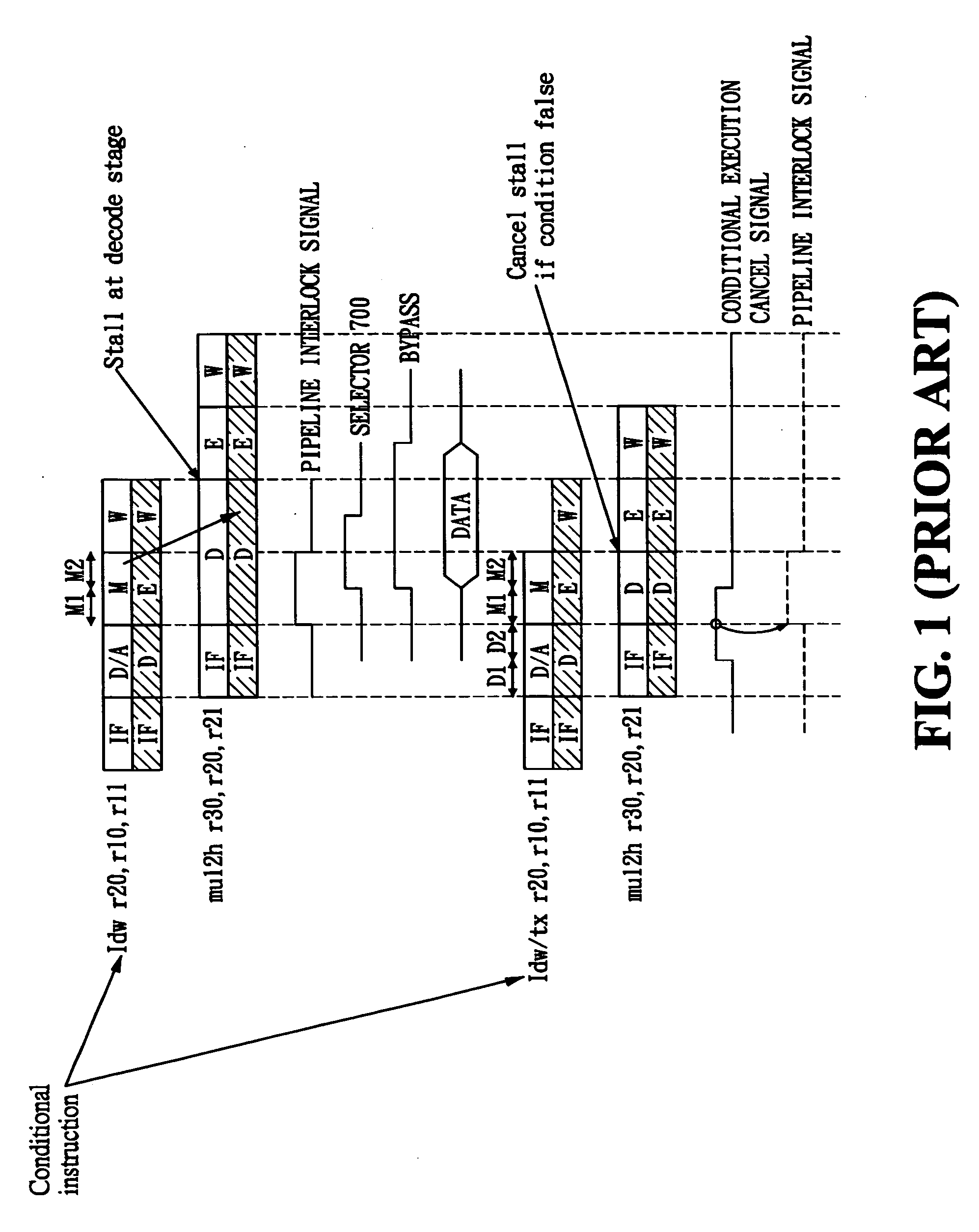

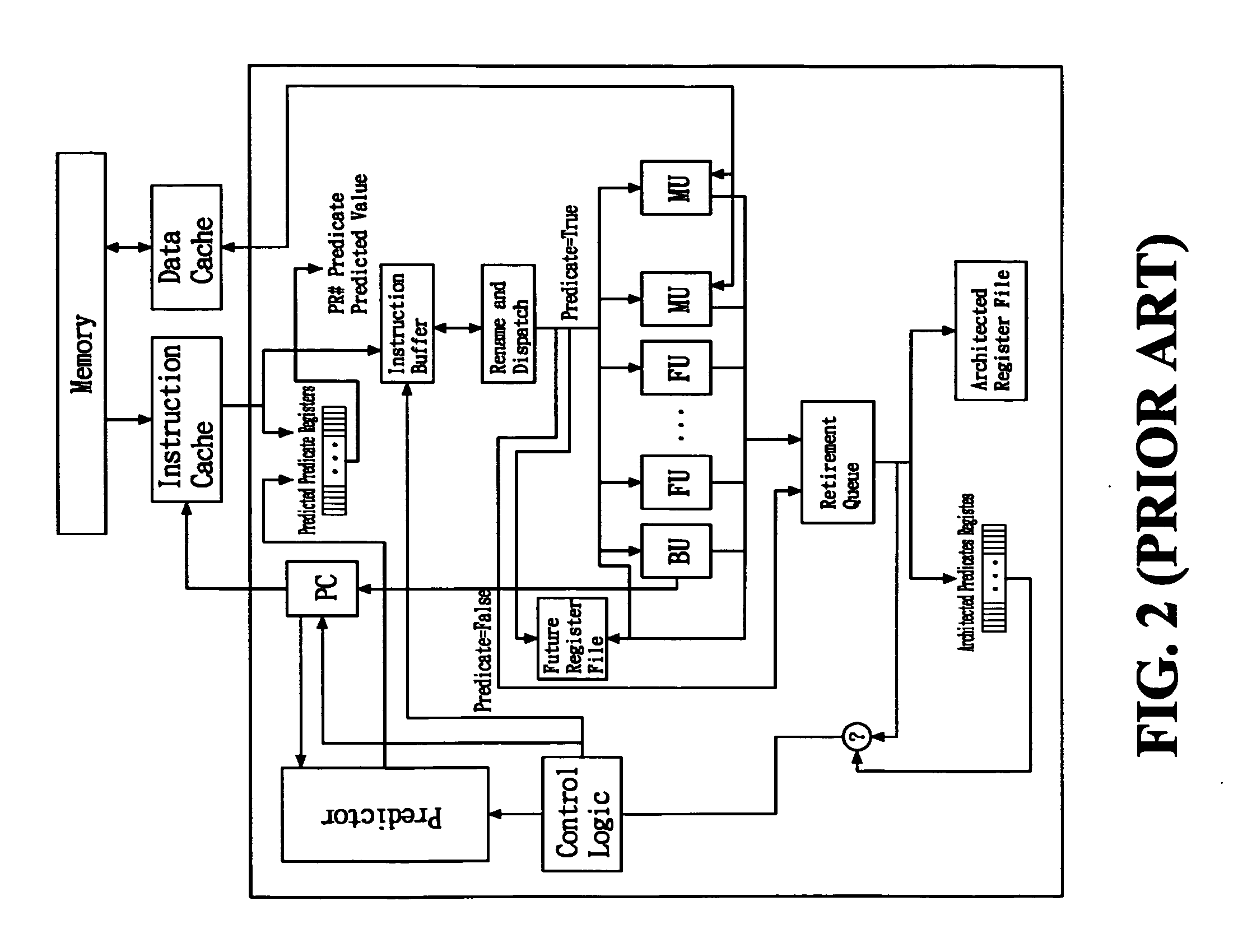

Apparatus and method for switchable conditional execution in a VLIW processor

ActiveUS20060288195A1Reduce hardware complexitySave energy consumptionDigital computer detailsSpecific program execution arrangementsConditional executionDecodes

An apparatus for switchable conditional execution in a VLIW processor is provided, comprising one or more decoders, one or more ALU with control units, and a register file. The decoders loads and decodes said instructions from a fetch unit for decoding and sending the decoded instructions to the ALU with control units for execution. The register file stores and forwards the results on result buses to the decoders. The execution of a VLIW instruction includes a fetch stage, a decode stage, plural execution stages and a write-back stage. The invention has the features of approximate ASIC timing by conditional write-back with the compiler support for the conditional write-back, condition resolved just before write-back., software selective conditional issue and conditional write-back modes, and without hardware interlock / dependence checking for the VLIW processor.

Owner:IND TECH RES INST

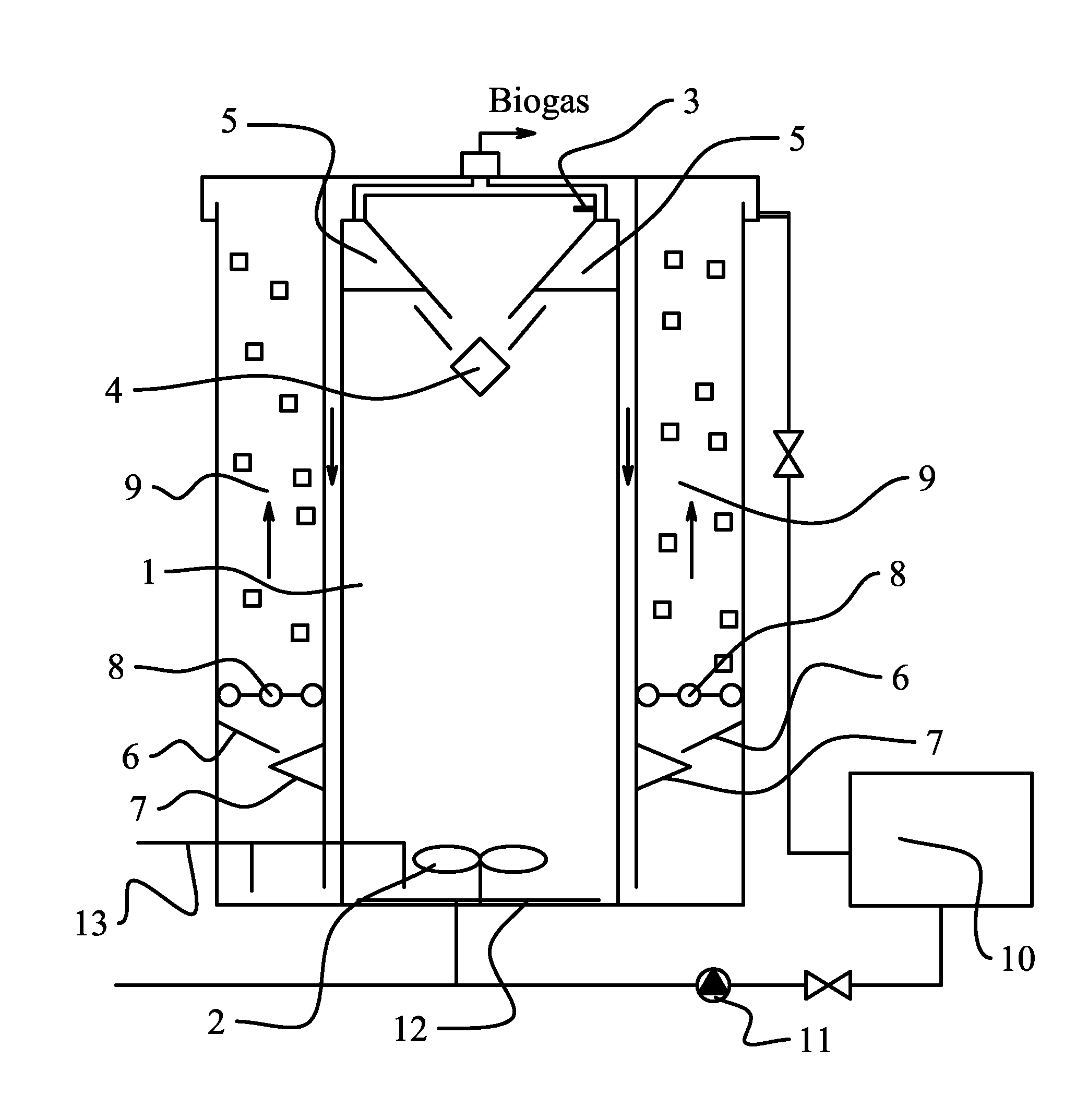

Integrated bioreactor and method of using the same for treatment of highly-concentrated organic wastewater

ActiveUS20120138527A1Increase concentrationIncrease alkalinityWater treatment parameter controlTreatment using aerobic processesRefluxPh monitors

An integrated bioreactor and its applications as well as a method for treatment of highly-concentrated organic wastewater using the same. The integrated bioreactor with a concentric columnar structure includes an inner layer and an outer layer, in which the inner layer is an upflow anaerobic sludge blanket (UASB) and the outer layer is a moving bed biofilm reactor (MBBR). The effluent of the MBBR is recycled into UASB via a reflux pump mounted between a water tank and the integrated bioreactor. A water outlet of the UASB is arranged with an on-line pH monitor and a mechanical agitation device is arranged on the top of a bottom water distributor. The bioreactor is low in cost, features friendly maintenance, stable operation, and high degree of automation, and can be applied under low temperature.

Owner:NANJING UNIV

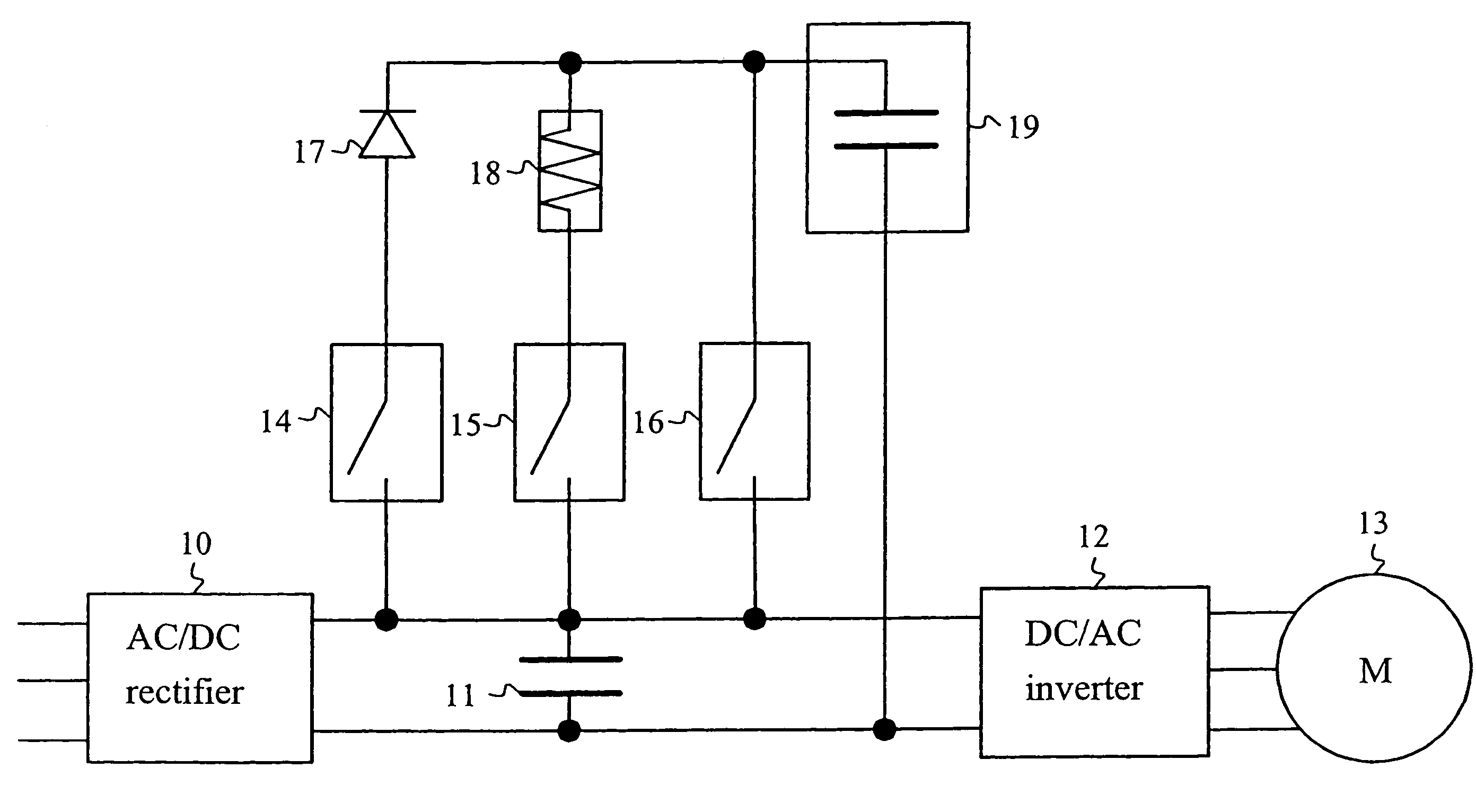

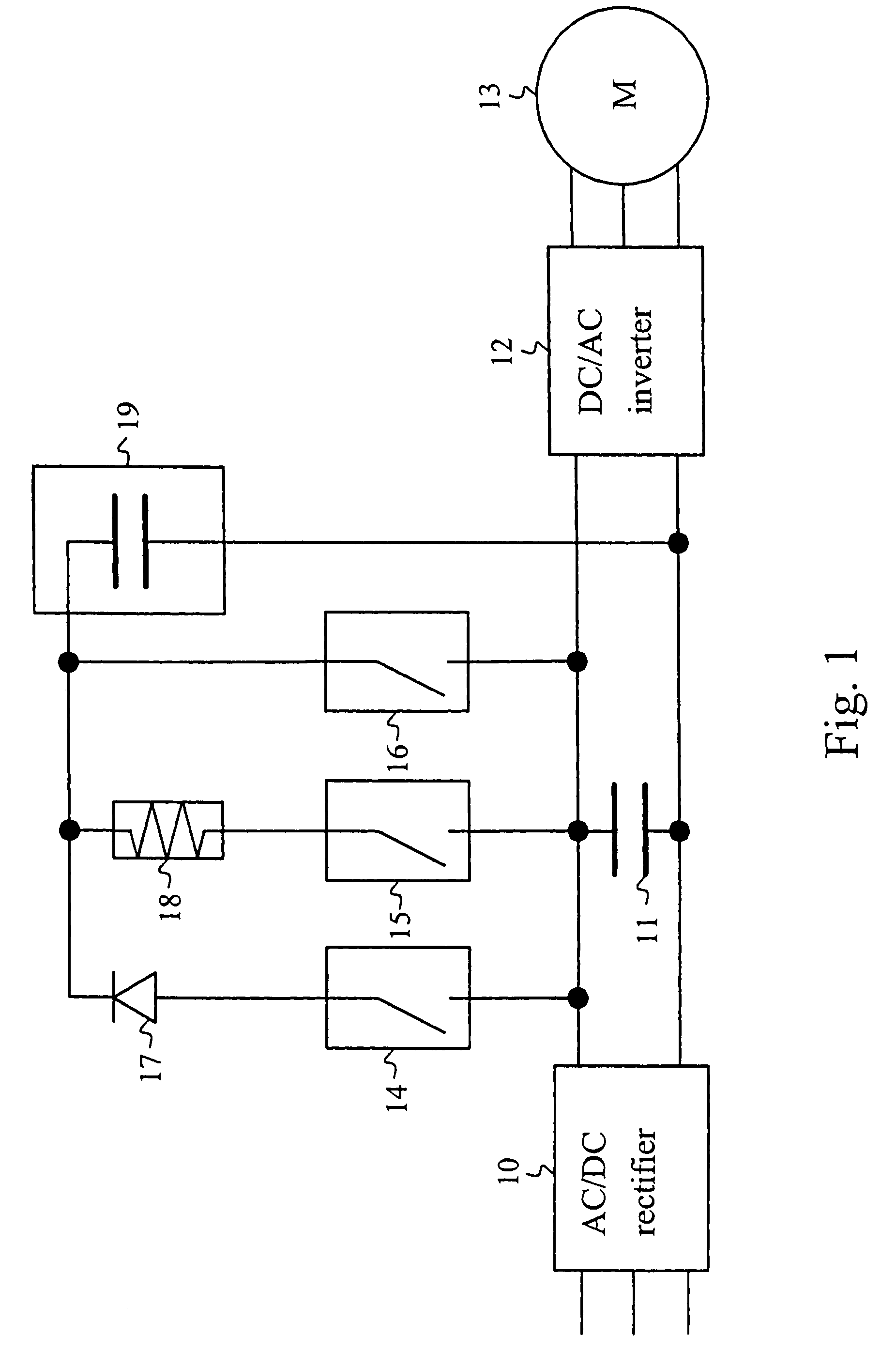

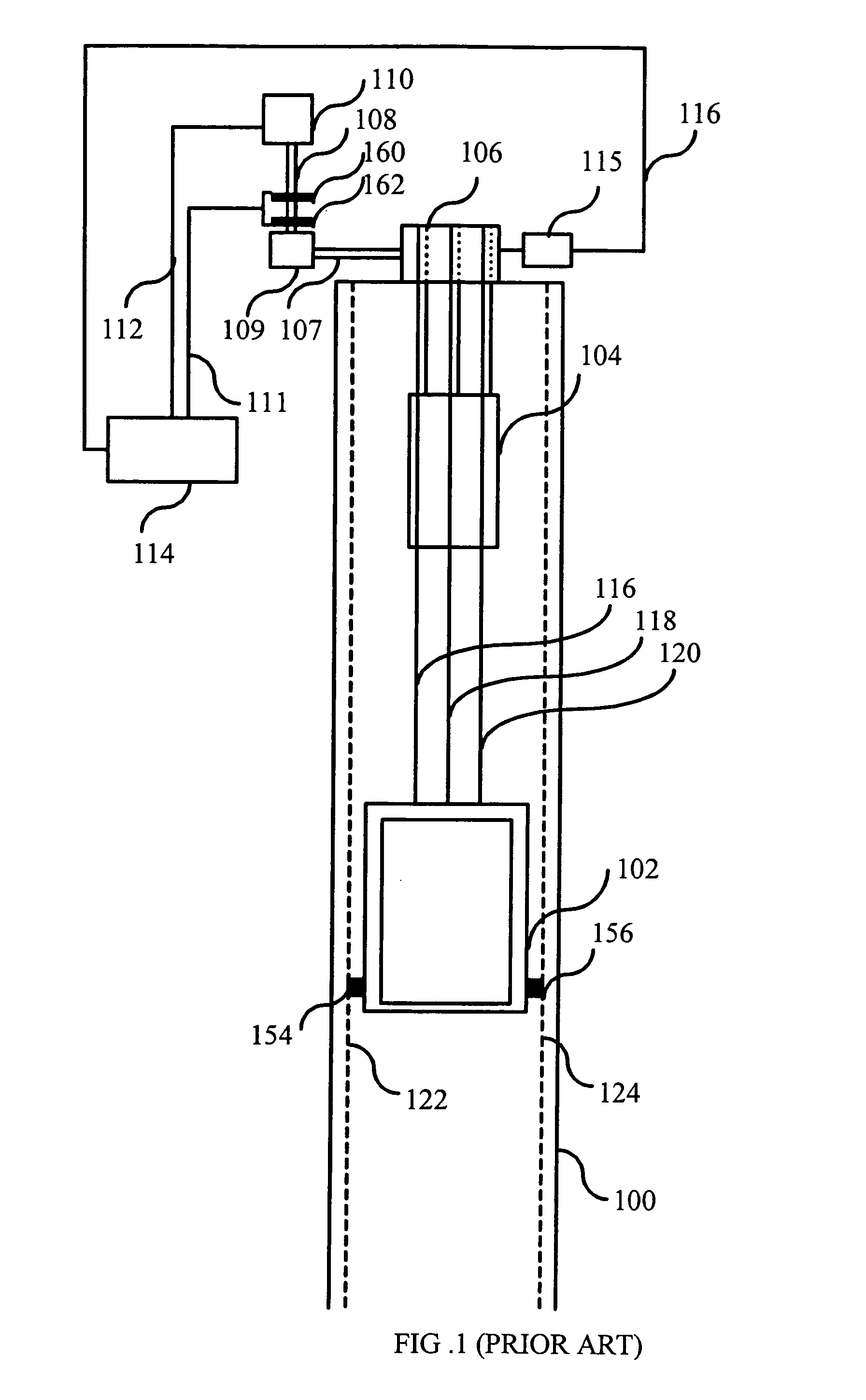

Elevator system using a supercapacitor as a backup power source

ActiveUS7331426B2Save energy consumptionEconomical and reliableMultiple dynamo-motor startersDynamo-electric converter controlEngineeringEnergy depletion

An elevator system uses a supercapacitor to store electric energy. Furthermore, the supercapacitor can be used as a source of reserve power in emergency situations, such as power failures. The supercapacitor is connected together with three switching branches to a rectified signal of the power supply of the motor. By closing and opening the switches, the supercapacitor can be charged when the motor load is small. When the motor load is large or when the power supply fails, the electric energy contained in the supercapacitor can be discharged for use by the motor. In an emergency, the motor drives the elevator at a speed lower than normal, and therefore a supply voltage lower than normal is sufficient. Also, energy obtained from braking of the elevator can be stored in the supercapacitor, which has a storage capacity of considerable magnitude as compared to an ordinary capacitor. By applying the invention, the energy consumption of the elevator can be reduced because the waste energy obtained from the power supply can be stored and utilized when more energy is needed.

Owner:KONE CORP

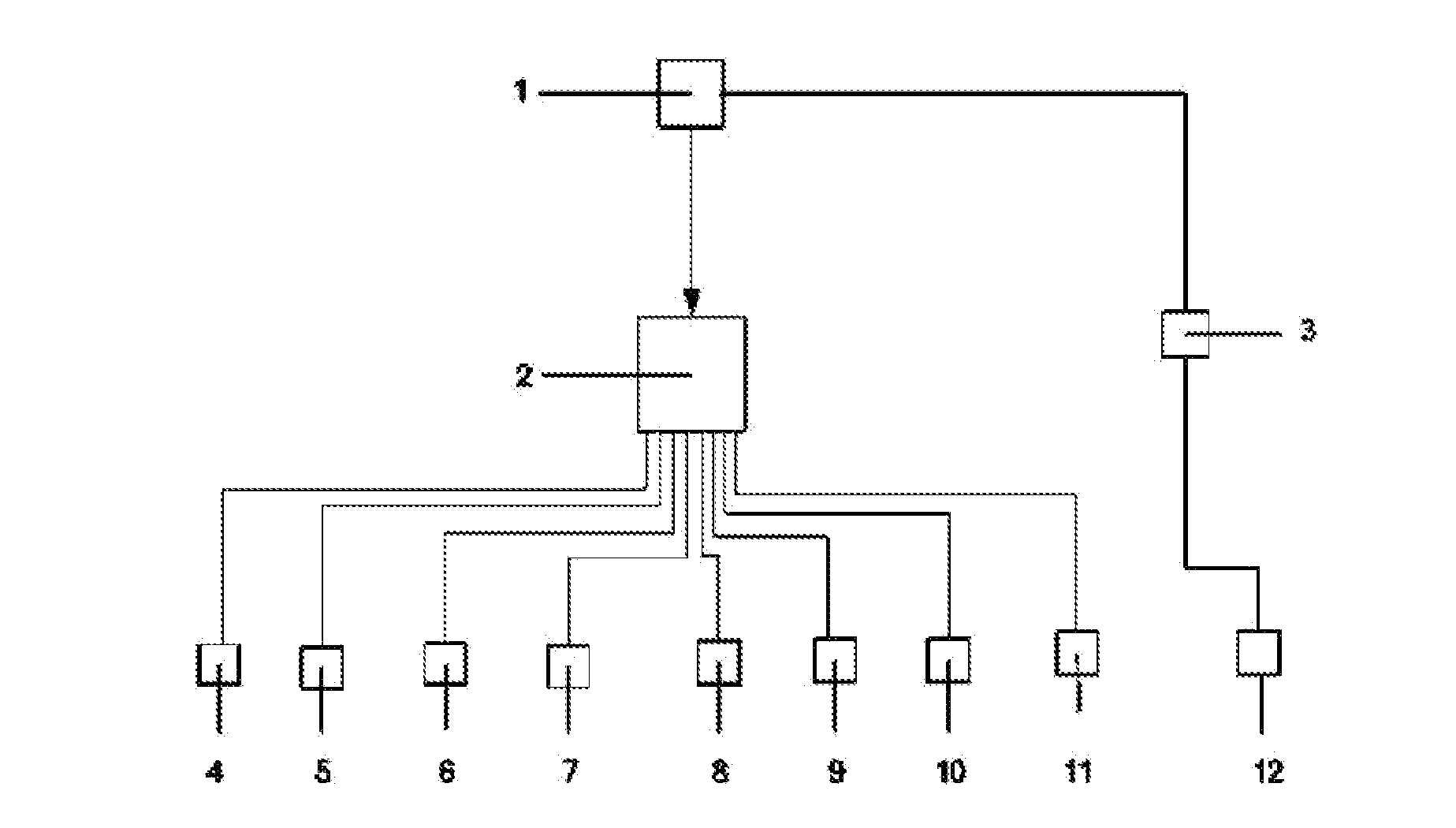

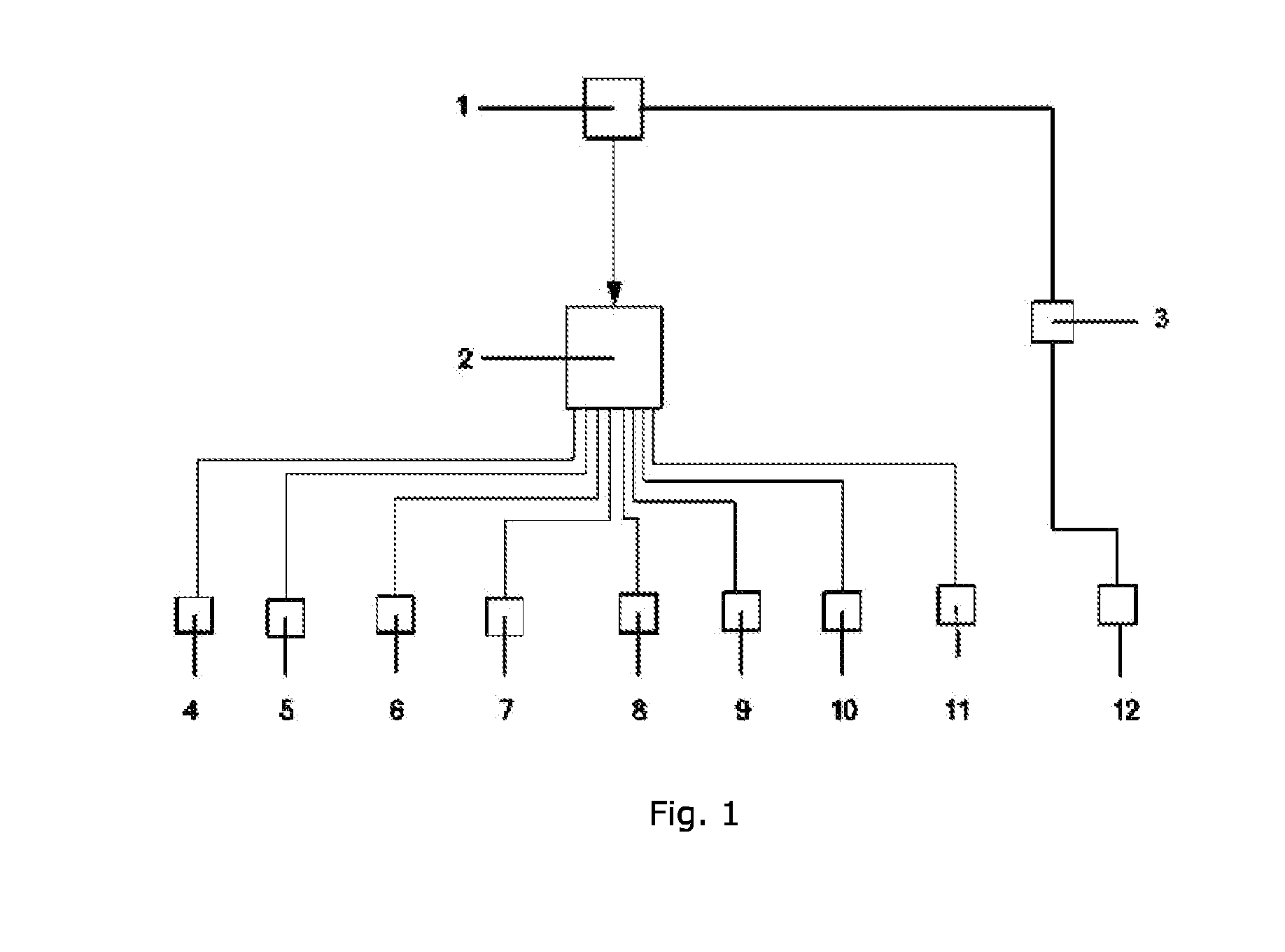

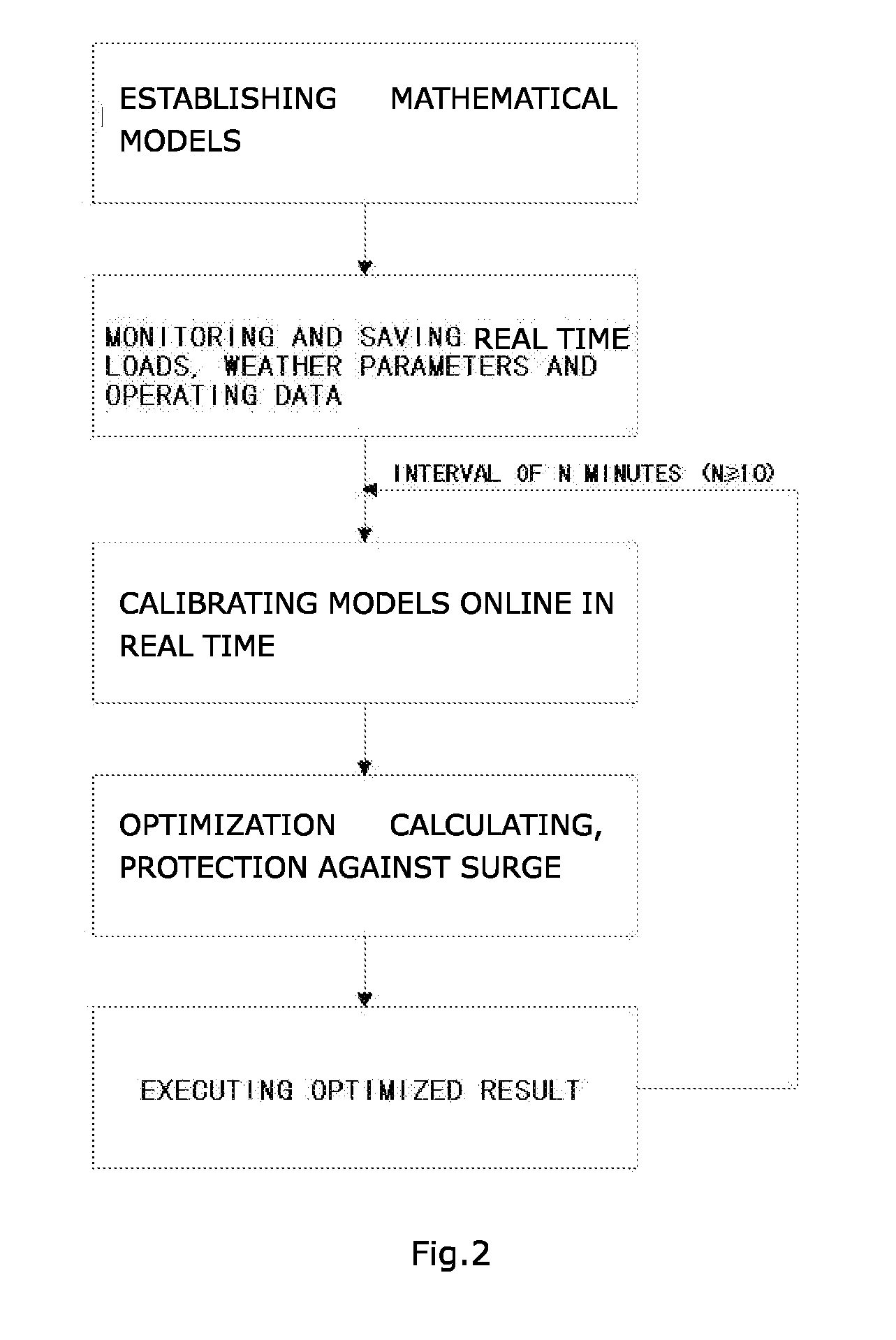

Energy-saving optimized control system and method for refrigeration plant room

ActiveUS20130167560A1Improve energy efficiencySave energy consumptionMechanical apparatusSpace heating and ventilation safety systemsRefrigeration plantOutdoor temperature

An energy-saving optimized control system for a chiller plant room comprises an industry control computer (1), a flow sensor (4), a temperature sensor (5), an outdoor temperature and humidity sensor (6), a three-phase active power transmitter (7), a water pump variable speed driver (9) and a cooling tower fan variable speed driver (10), which are respectively connected with a programmable controller (2), wherein the programmable controller (2) communicates with the industrial control computer (1) through an industrial Ethernet; and an RS485 communication interface module (3) is connected with chillers and communicates with the industrial control computer (1) through a ModBus protocol. An energy-saving optimized control method for a chiller plant room is also provided. By establishing a mathematical model of the relationship between the energy consumption and operation parameters of each equipment in the refrigeration plant room and combining the real-time cooling loads and weather parameters, the operating state of each equipment is adjusted so as to reach the lowest operating energy consumption of the whole chiller plant room under the premise of meeting the cooling loads.

Owner:WELDTECH TECH SHANGHAI

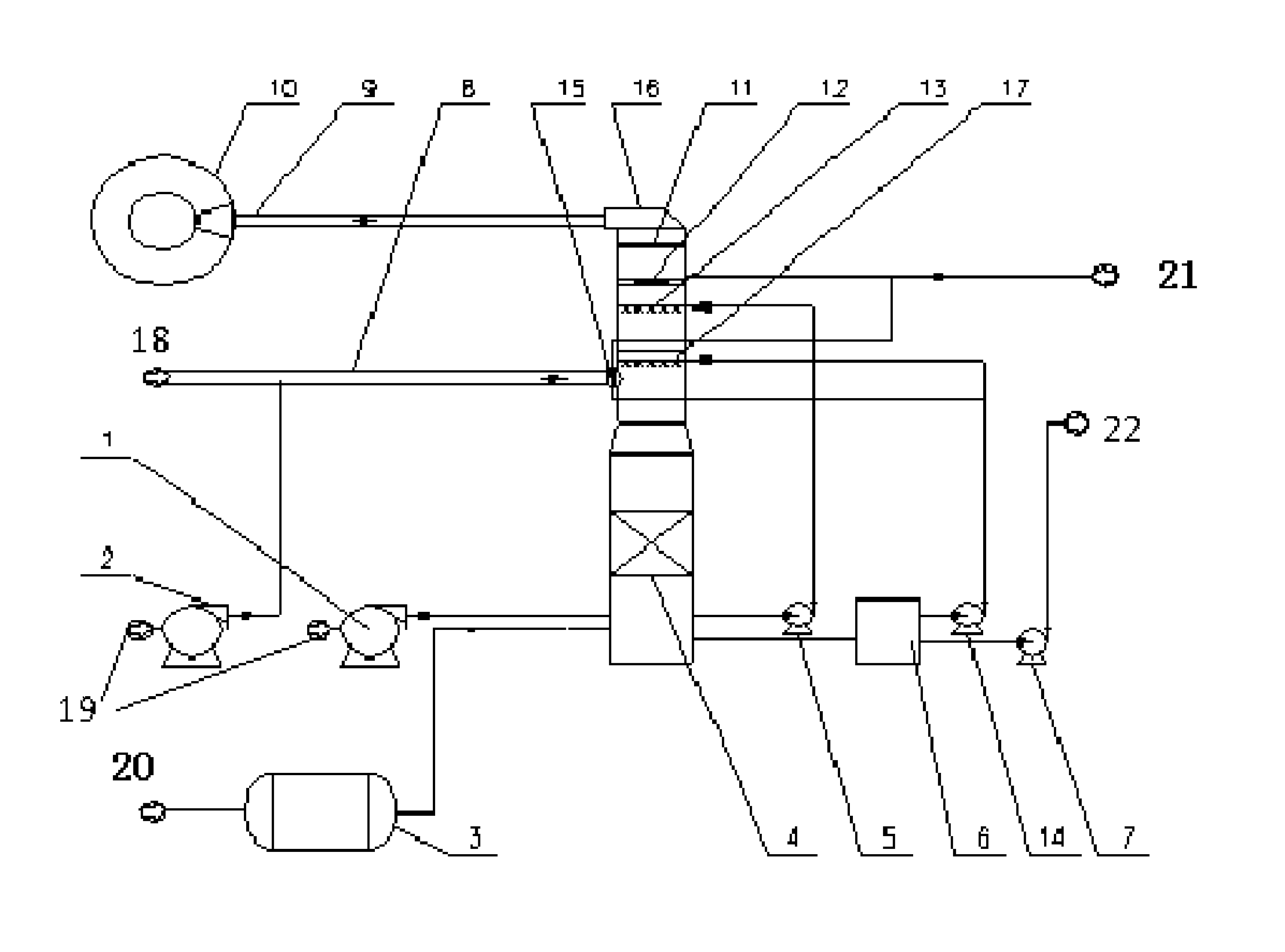

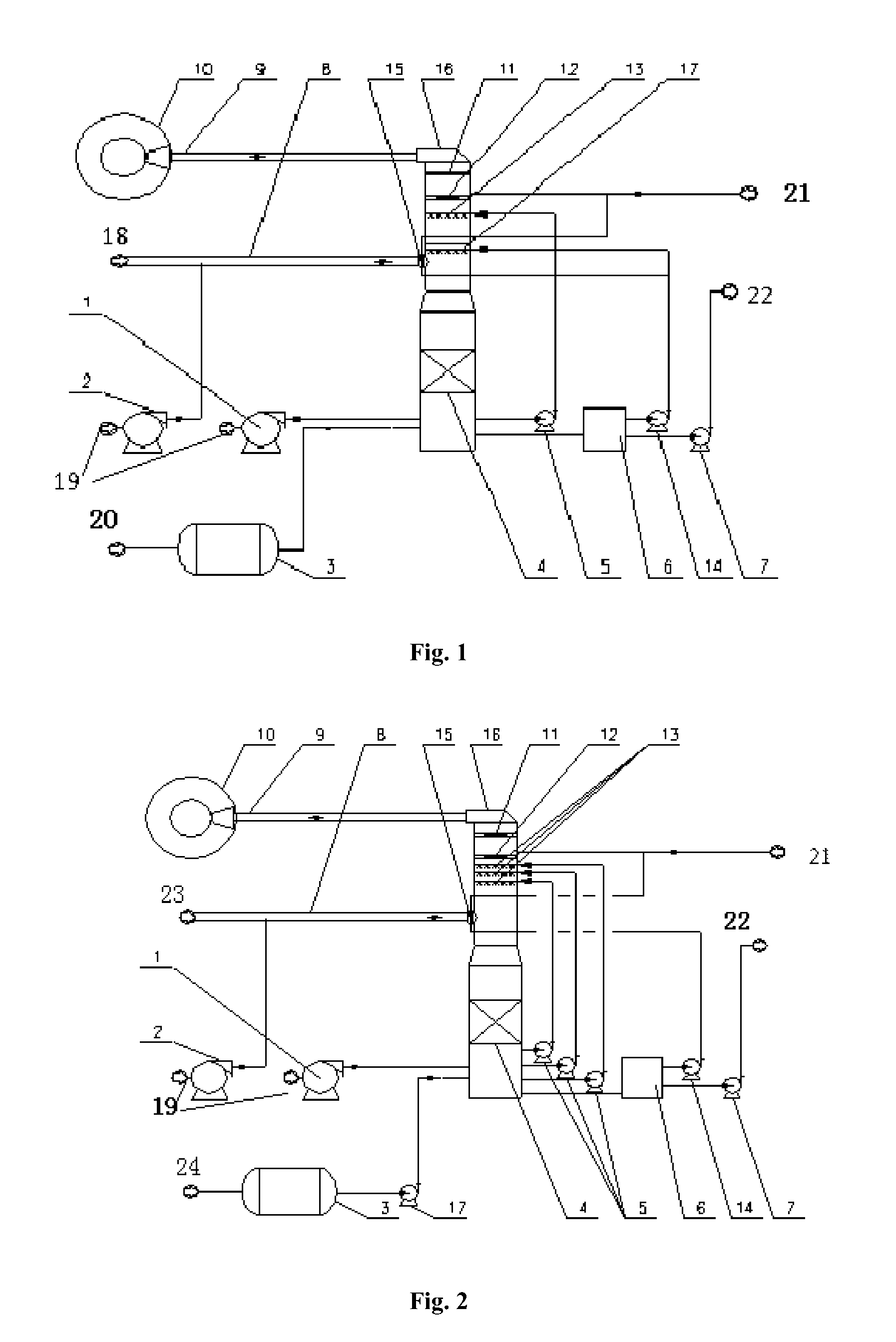

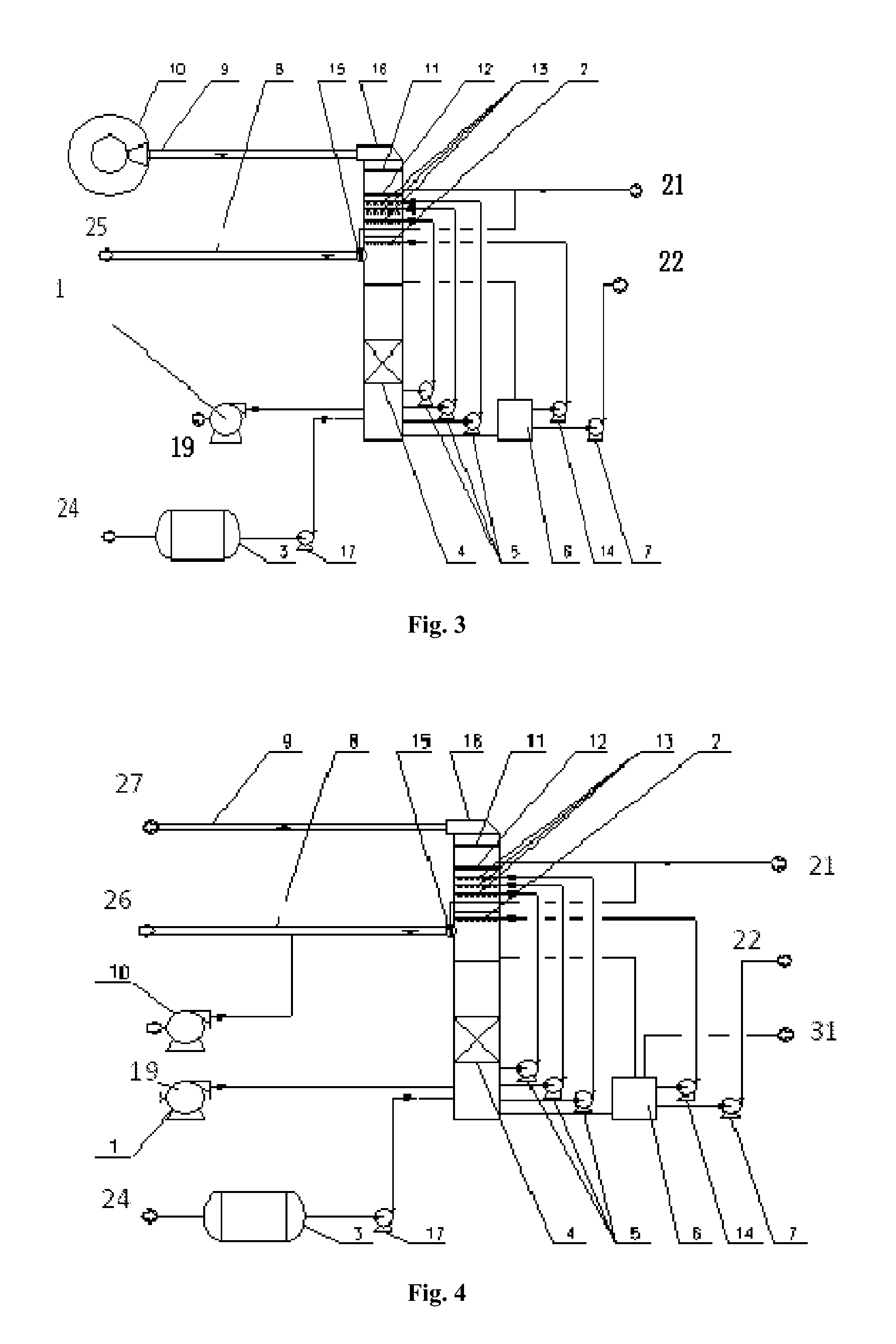

Flue gas-treating method and apparatus for treating acidic tail gas by using ammonia process

ActiveUS9370745B2Improve desulfurization efficiencyEffectively control the ammonia slip and the aerosol generationGas treatmentDispersed particle separationFlue gasAmmonia storage

Owner:JIANGNAN ENVIRONMENTAL PROTECTION GRP INC

Air conditioning apparatus

InactiveUS7669647B2Increase fuel consumptionImpact engine loadOther heat production devicesHeat storage plantsEngineeringAir conditioning

An air conditioning system for cooling or heating an air, and for feeding the heated or cooled air to predetermined portions is characterized by comprising: a first circulating circuit for circulating a first heating medium; a second circulating circuit for circulating a second heating medium; a control unit for controlling the heat for executing heat exchange between the first heating medium and the second heating medium to flow through either the heat exchanger or the first heat storing device. Moreover, an air temperature is controlled by heat of the second heating medium.

Owner:TOYOTA JIDOSHA KK

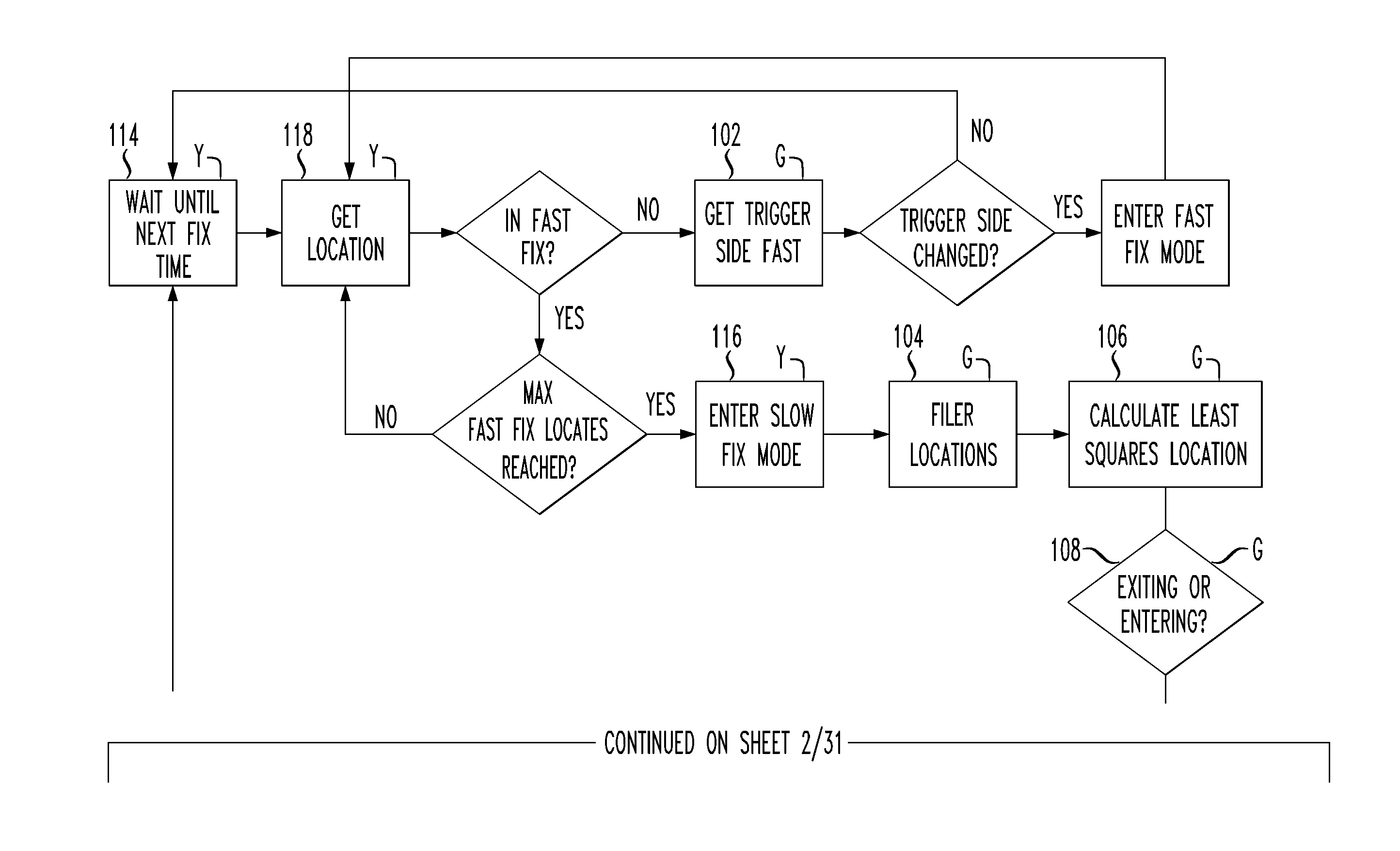

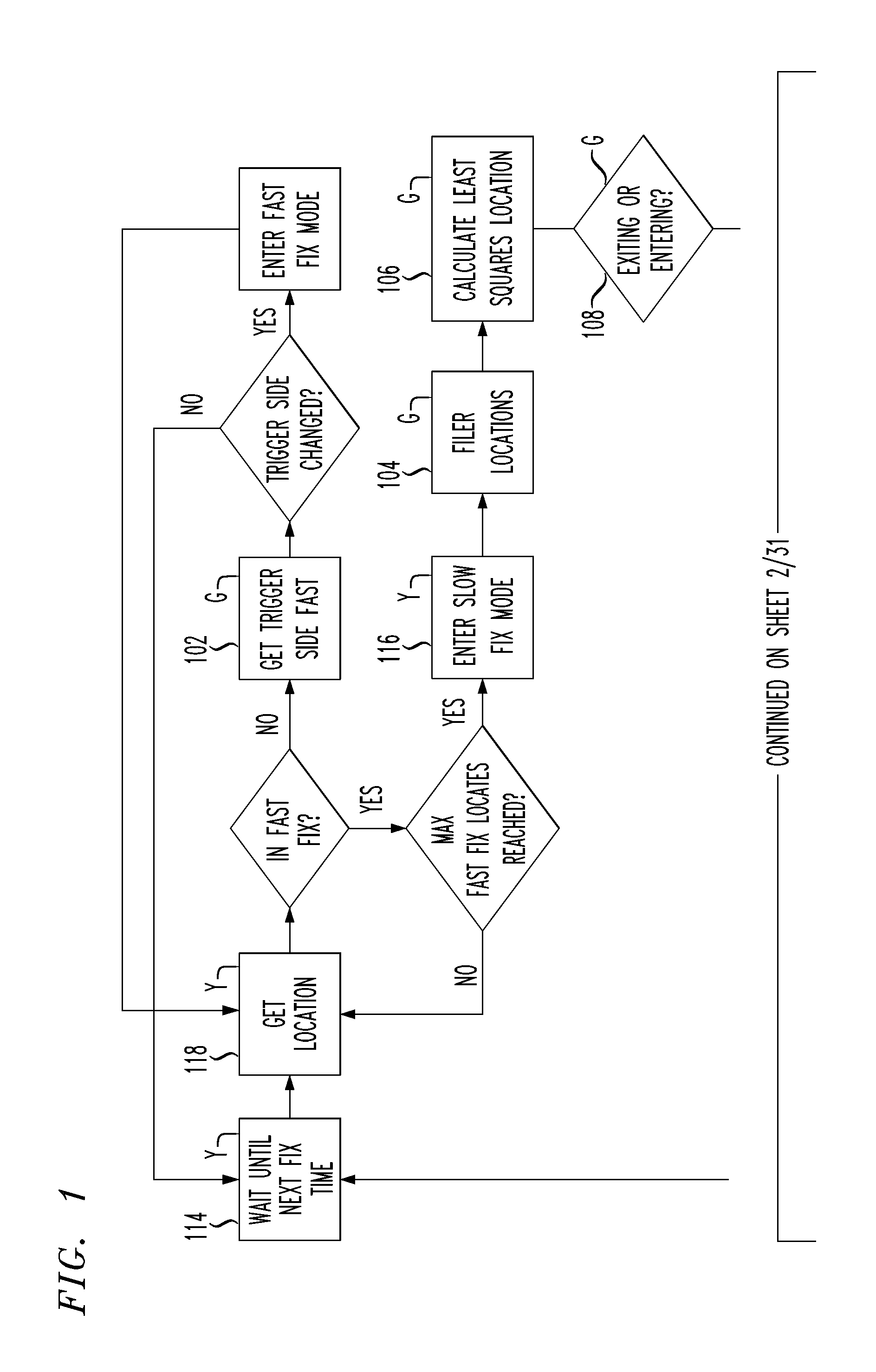

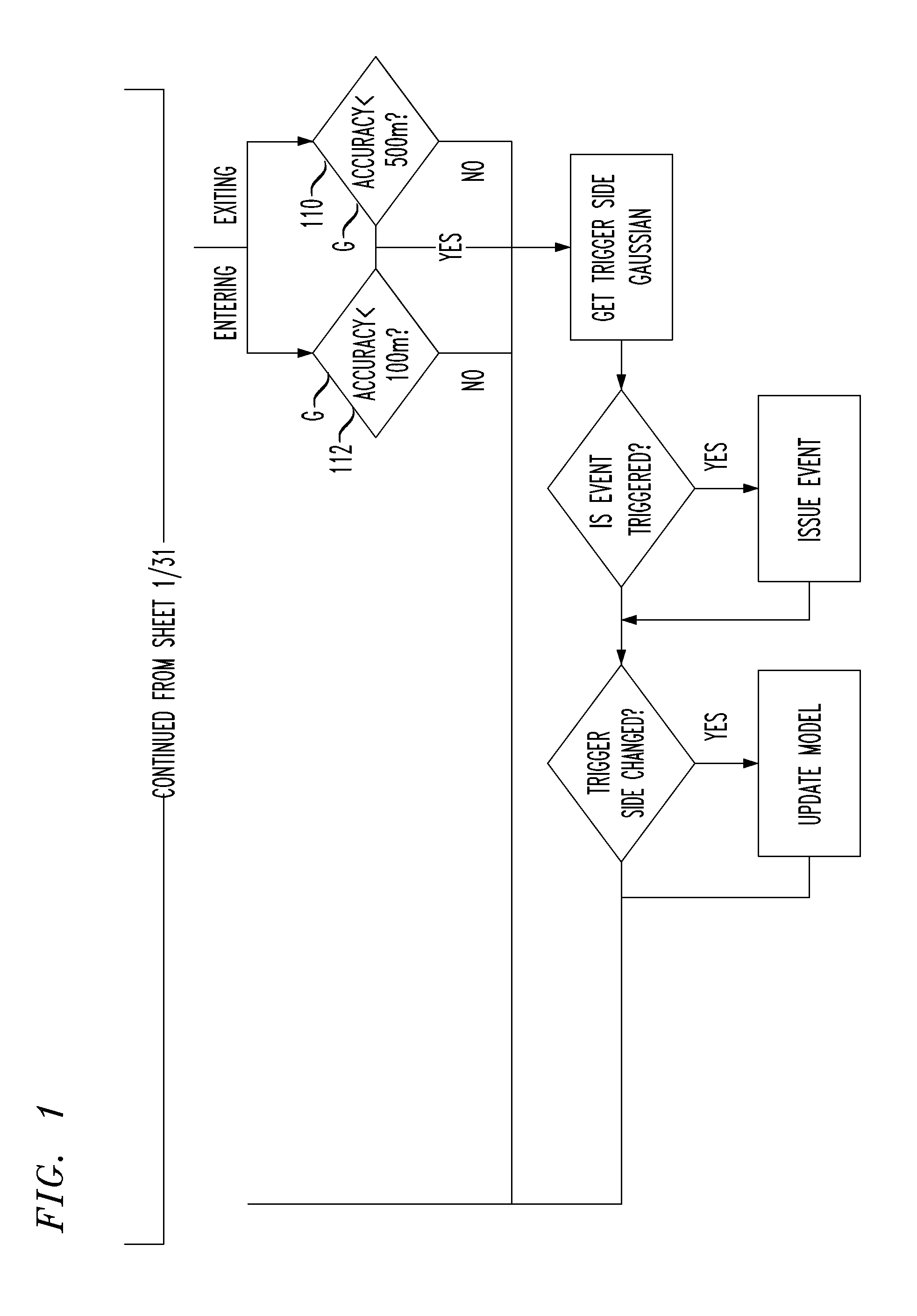

Geofence with kalman filter

InactiveUS20130331128A1Save energy consumptionIncrease probabilityPower managementPosition fixationPoint of entryLeast squares

A least squares geofence method that minimizes trigger misfires caused by data variability and location blunders and minimizes delayed / missed entry triggers generated under urban or indoor conditions. The least squares geofence method uses a weighted least squares (LS) model to compute a location estimate for a target device. A LS location estimate is used to determine if a target device is located inside or outside a predefined geofence. The present invention additionally comprises a Kalman filter geofence method that further improves the accuracy of entry / exit geofence triggers. A Kalman filter geofence method uses a Kalman filter to filter location data retrieved for a target device. Filtered location data is used to determine if a target device is located inside or outside a predefined geofence. A Kalman filter geofence method estimates velocity and heading information for a target device to generate accurate entry / exit geofence triggers for devices in fast moving mode.

Owner:TELECOMM SYST INC

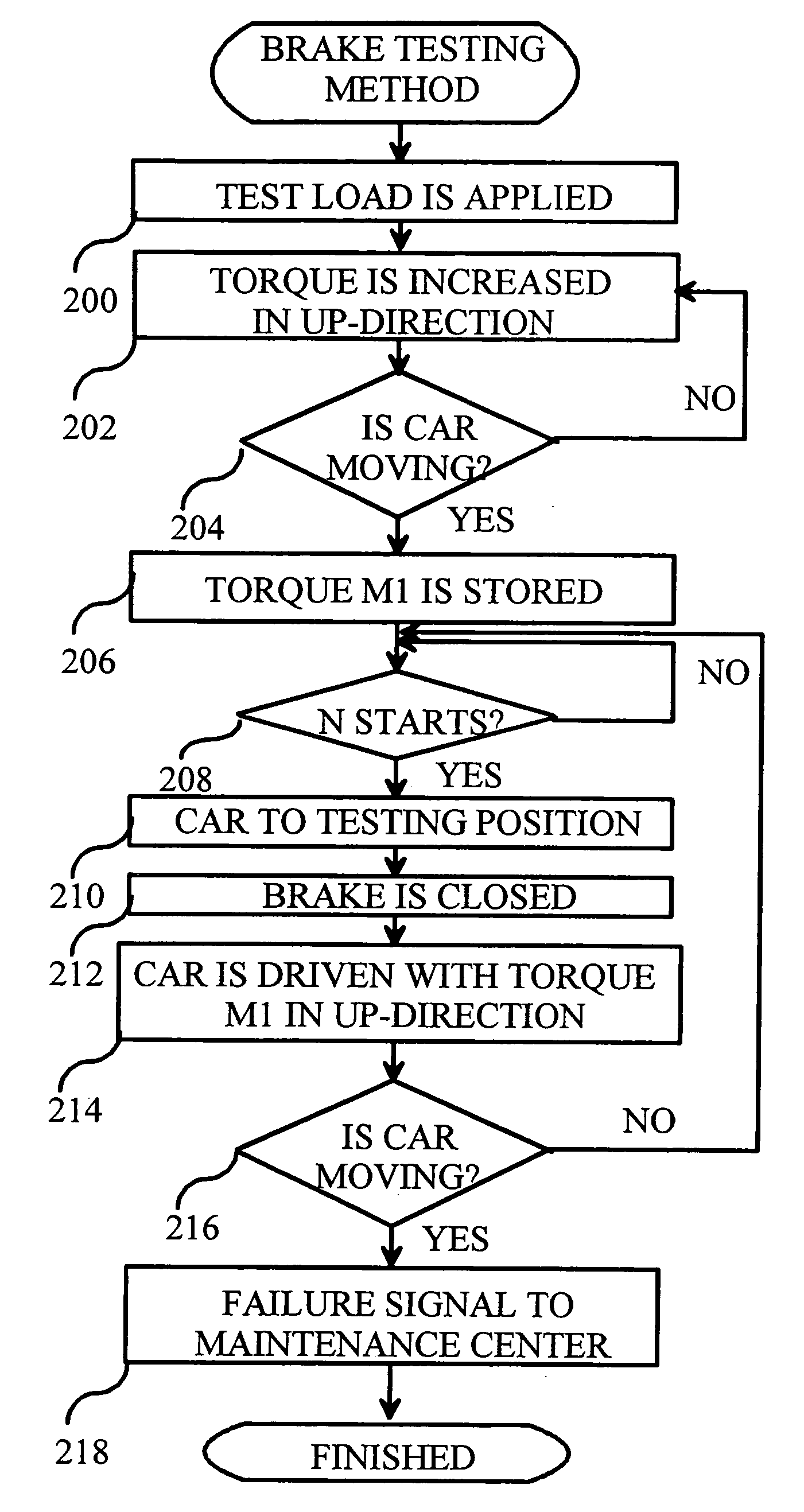

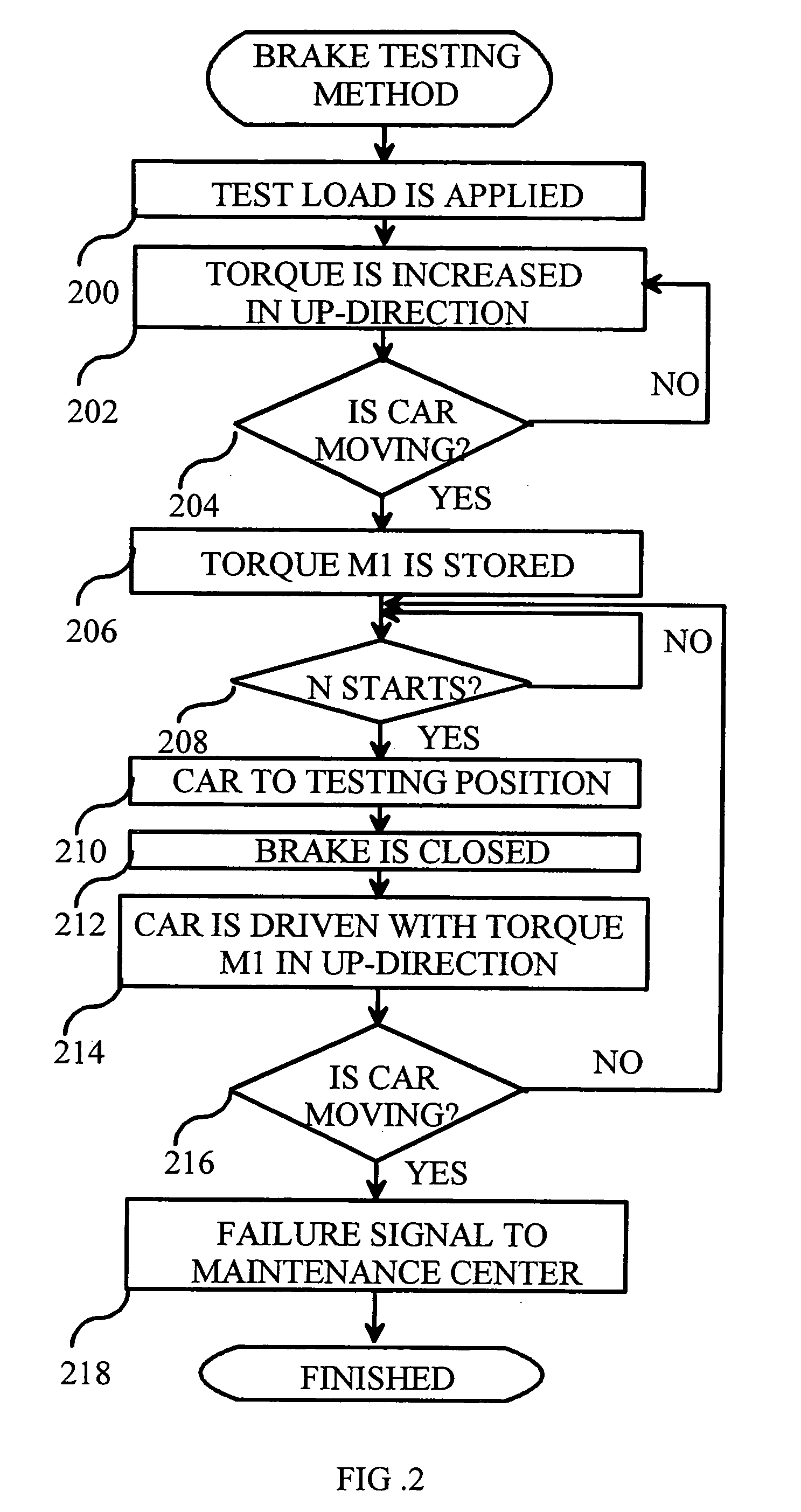

Elevator arrangement

ActiveUS7222698B2Reduce riskSave energy consumptionStructural/machines measurementElevatorsEngineeringAutomotive engineering

The present invention relates to a method and a system for testing the condition of the brakes of an elevator. In the method, a test weight is set to apply to the drive machine of the elevator, by means of which weight a first torque required for driving the elevator car in the upward direction is measured. At least one of the brakes of the elevator is closed. Next, the empty elevator car is driven in the upward direction with the force of the aforesaid first torque and a check is carried out to detect movement of the elevator car. If a movement of the elevator car is detected, then the aforesaid at least one brake of the elevator is regarded as defective. The method of the present invention makes it possible to check the operativeness of the brakes of the elevator without separate maintenance visits.

Owner:KONE CORP

Method for concentrating water-soluble organic material

InactiveUS20060070867A1Improve permeabilityIncrease operating pressureSemi-permeable membranesOrganic compound preparationDistillationWater soluble

A method for concentrating a water-soluble organic material wherein a mixture of the water-soluble organic material with water is distilled in a distillation column (11), and the fraction from the top (11a) of the distillation column (11) is separated by the use of a membrane separator (14) into a permeated vapor (F2) and a non-permeated vapor (F3), which comprises once condensing the fraction to form a condensate, heating the condensate in an evaporator (13) to generate a vapor (F1) having a pressure higher than the operation pressure for the distillation column (11), and introducing the vapor (F1) to the membrane separator (14), thereby separating water from the mixture.

Owner:MITSUBISHI CHEM CORP

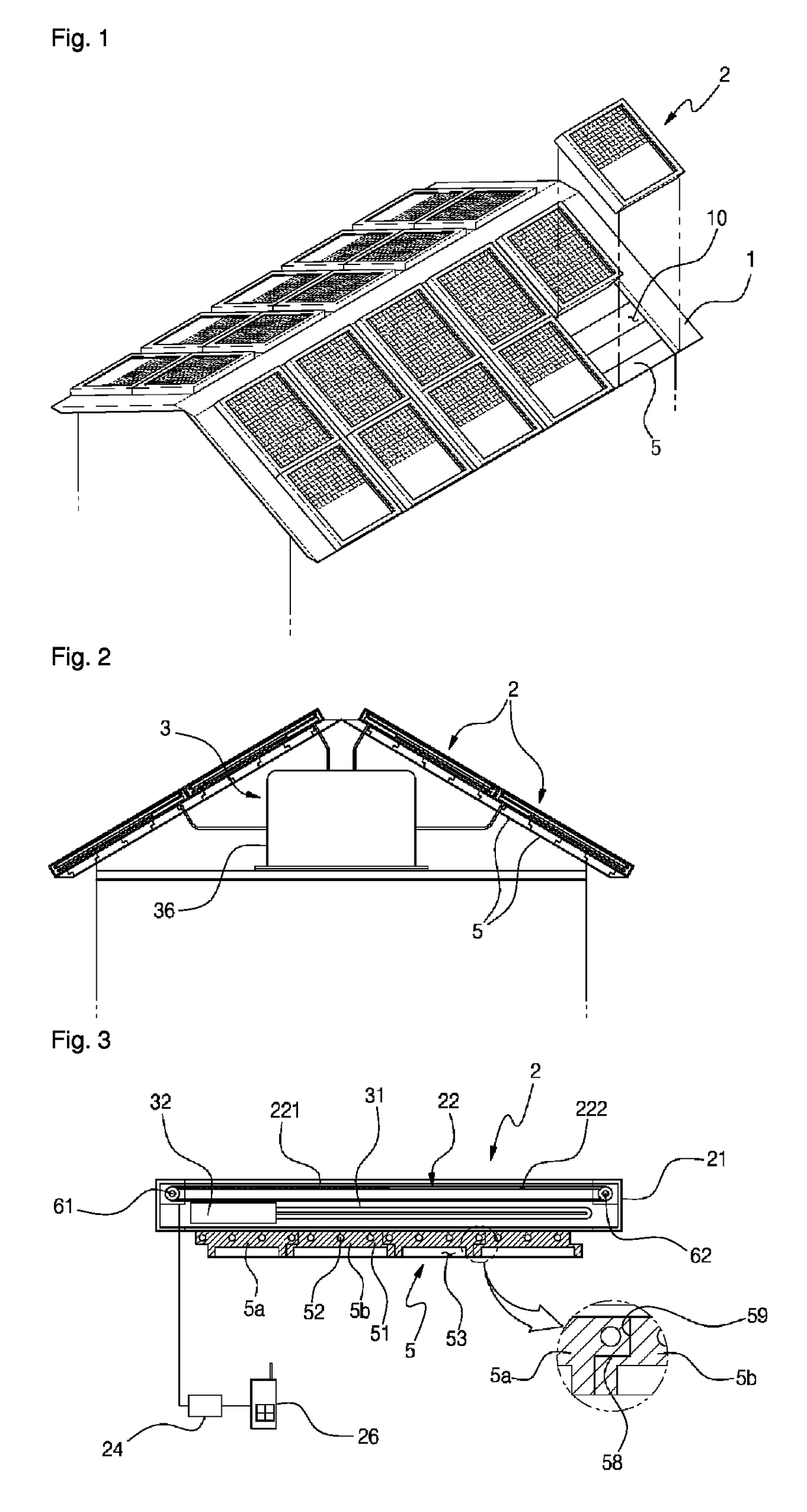

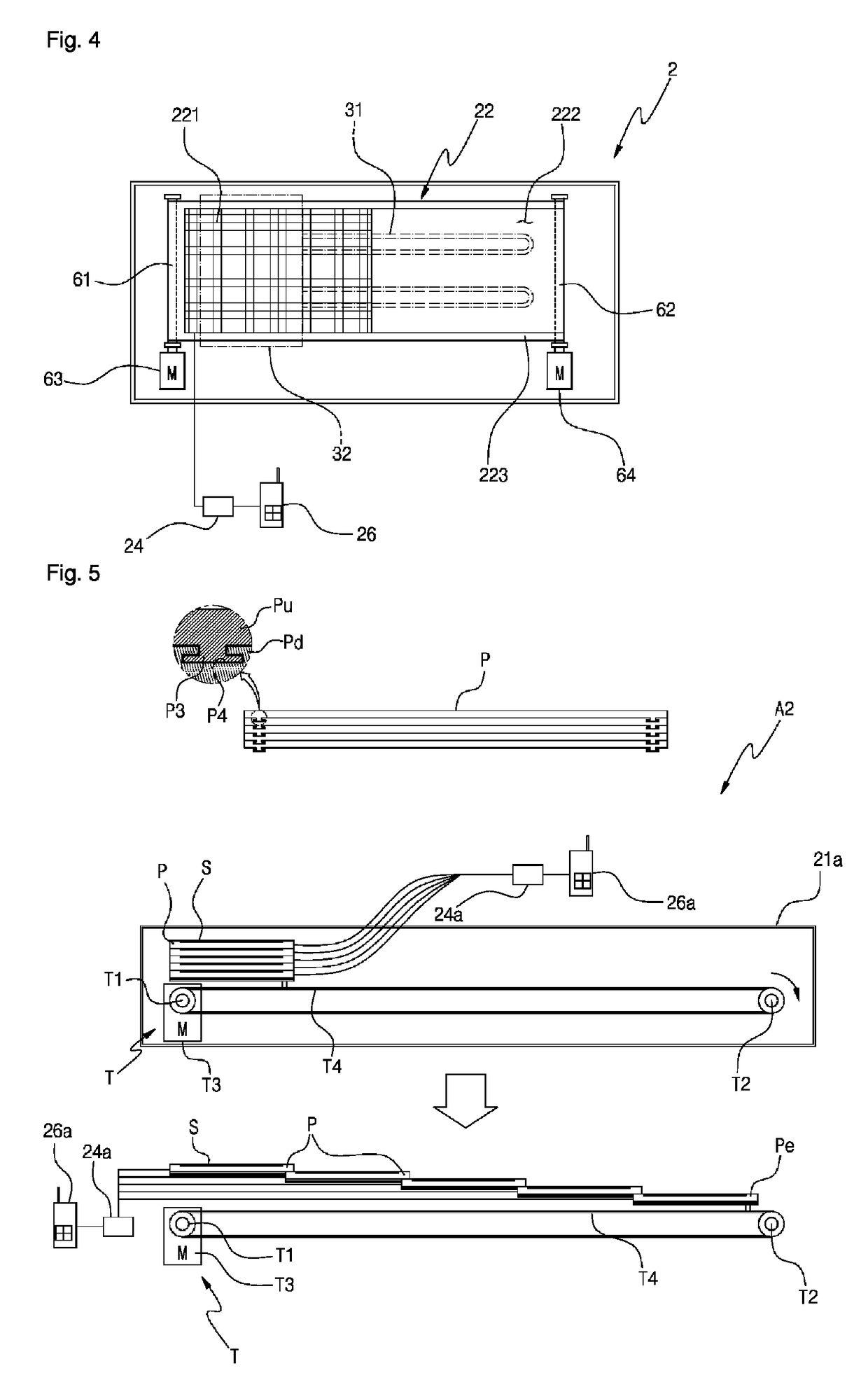

Heating and power generating apparatus using solar energy

ActiveUS9711672B2Save energy consumptionProtect environmentPhotovoltaic supportsSolar heating energyElectricityThermal water

Owner:WANG TZENG CHYUAN

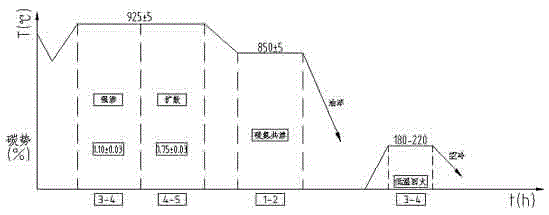

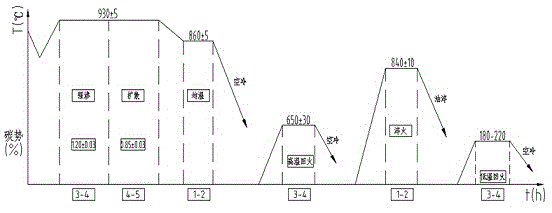

Automobile transmission gear heat treatment method

ActiveCN104894506AAvoid early crackingAlleviate the problem of bulky carbidesSolid state diffusion coatingFatigue IntensityHigh carbon

The invention discloses an automobile transmission gear heat treatment method. The method includes the steps of carburization, carbonitriding, quenching, cleaning, low temperature tempering and air cooling. The carburization technique is combined with the carbonitriding technique, abrasion resistance, fatigue strength and corrosive resistance are improved by a layer of highly hard nitride layer obtained on the carburized layer on the surface of a gear, and comprehensive performance of a product is good; meanwhile, the problems of massive carbide appearing under the high carbon potential state and network carbide appearing in the cooling process are avoided, and early-age cracking of the surface of the gear is avoided; moreover, by the method, the technological process is simplified, heating and cooling links and discharge links are reduced, carburization deformation and quenching deformation are reduced, generation of black structures is reduced as well, and anti-fatigue performance is guaranteed; finally, by the method, production cycle is shortened greatly, energy consumption is lowered, and production efficiency is improved highly.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

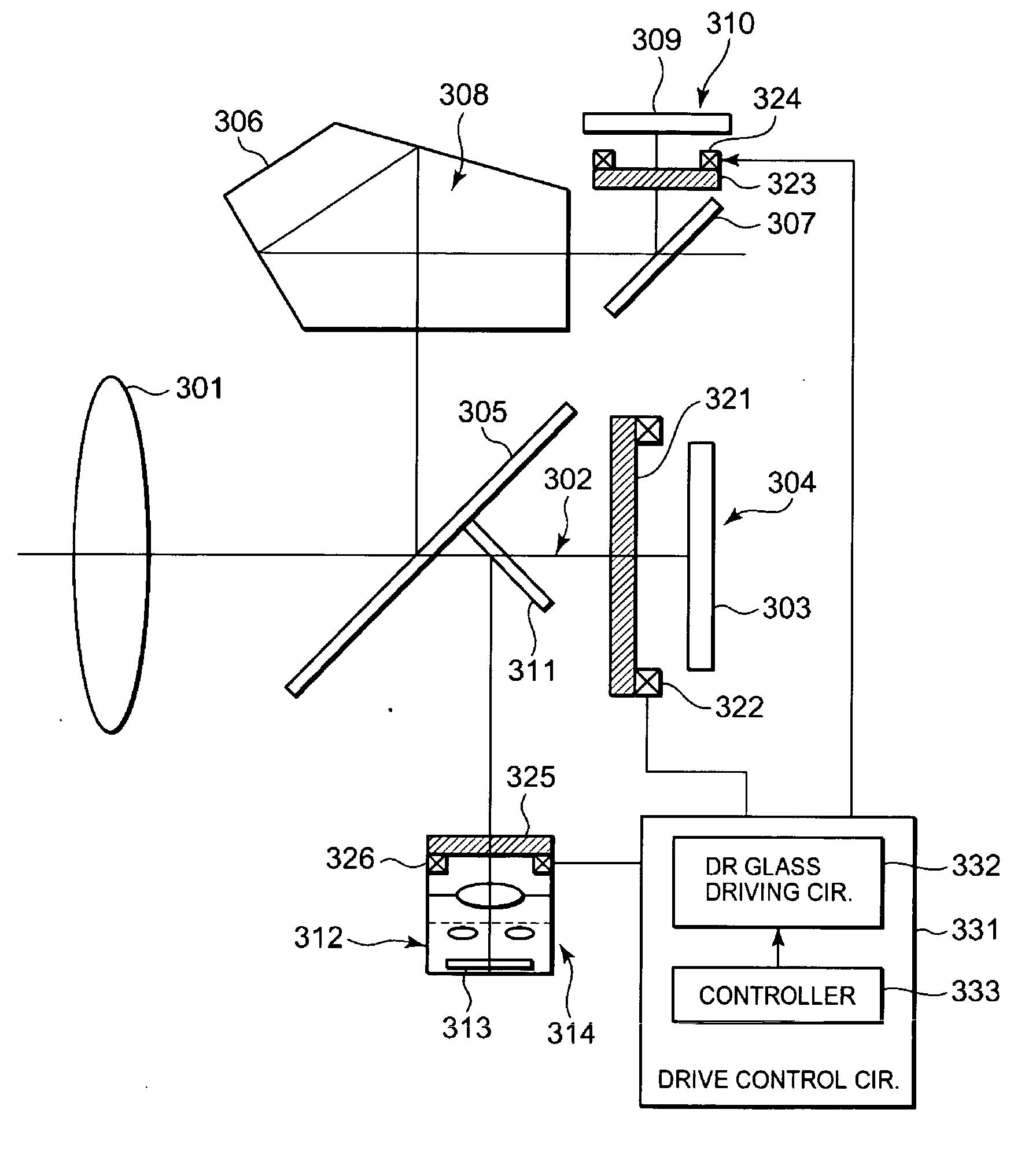

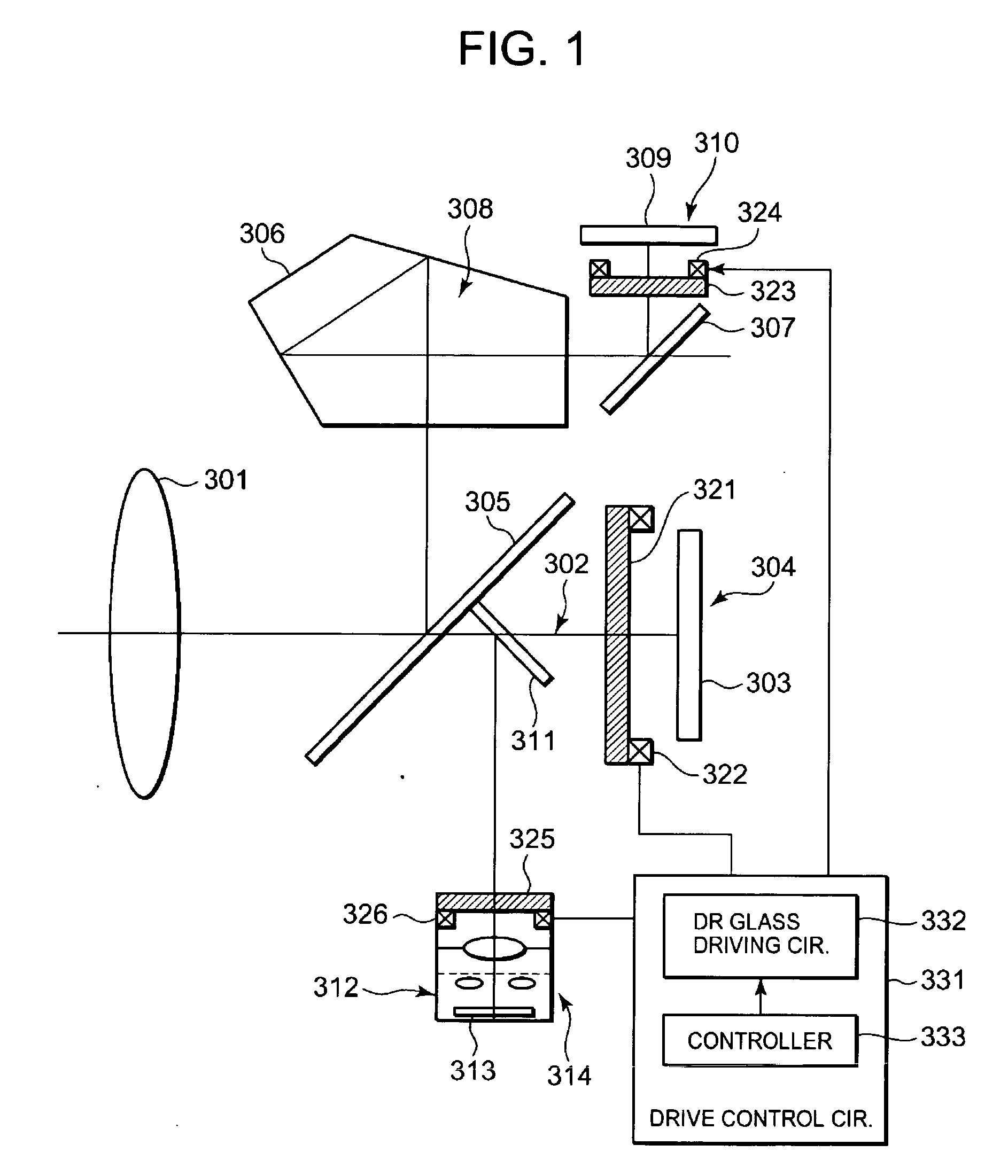

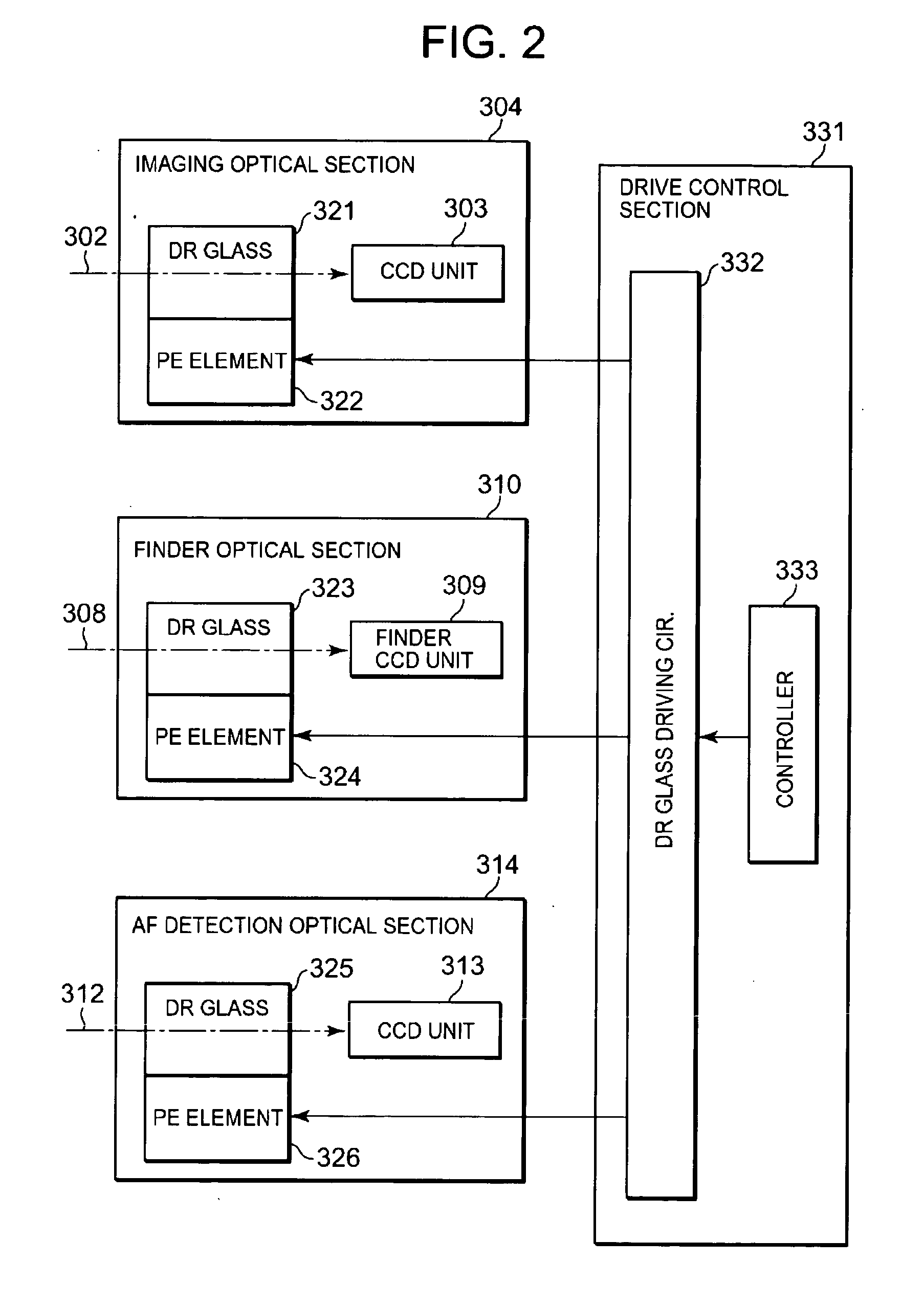

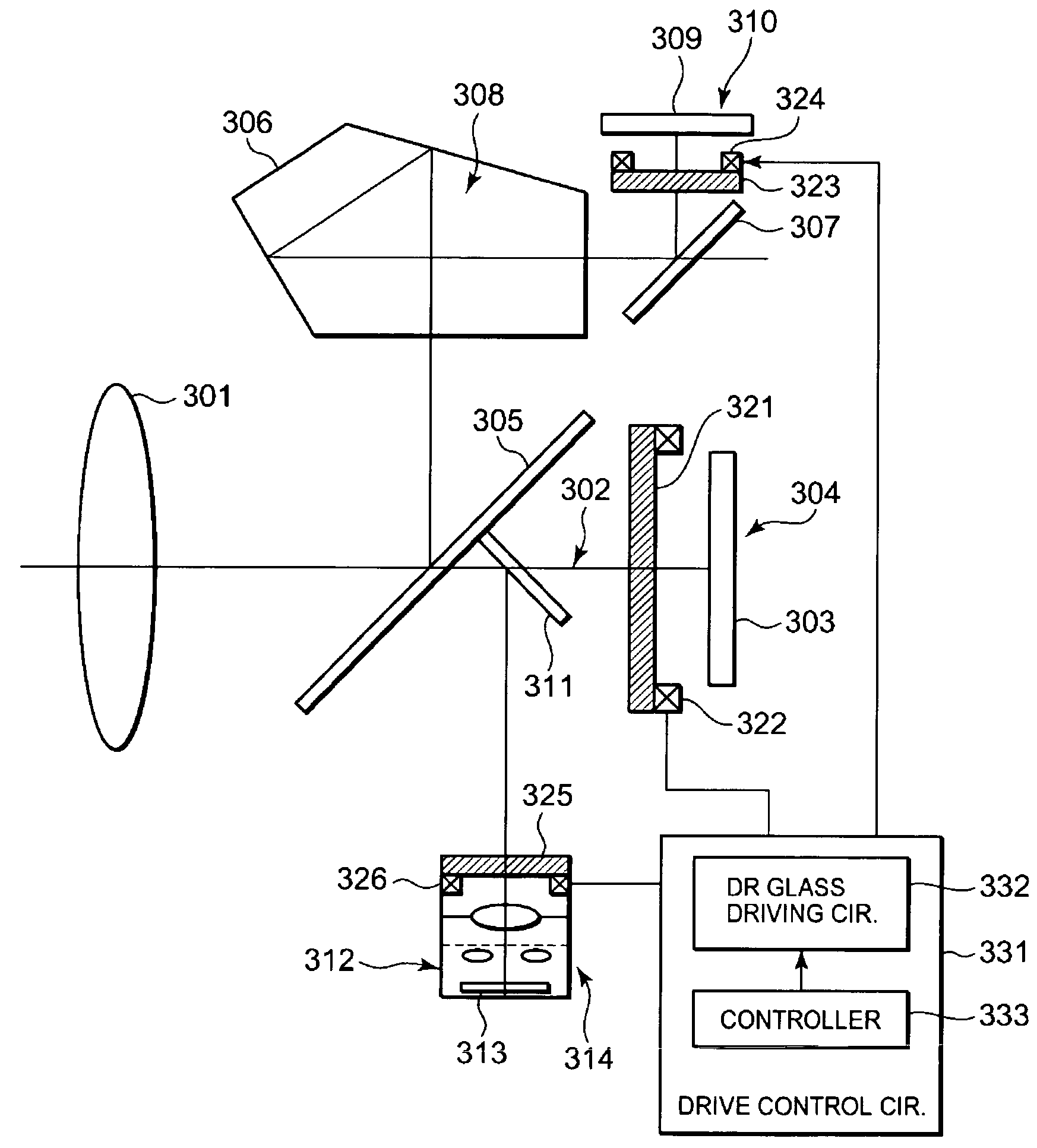

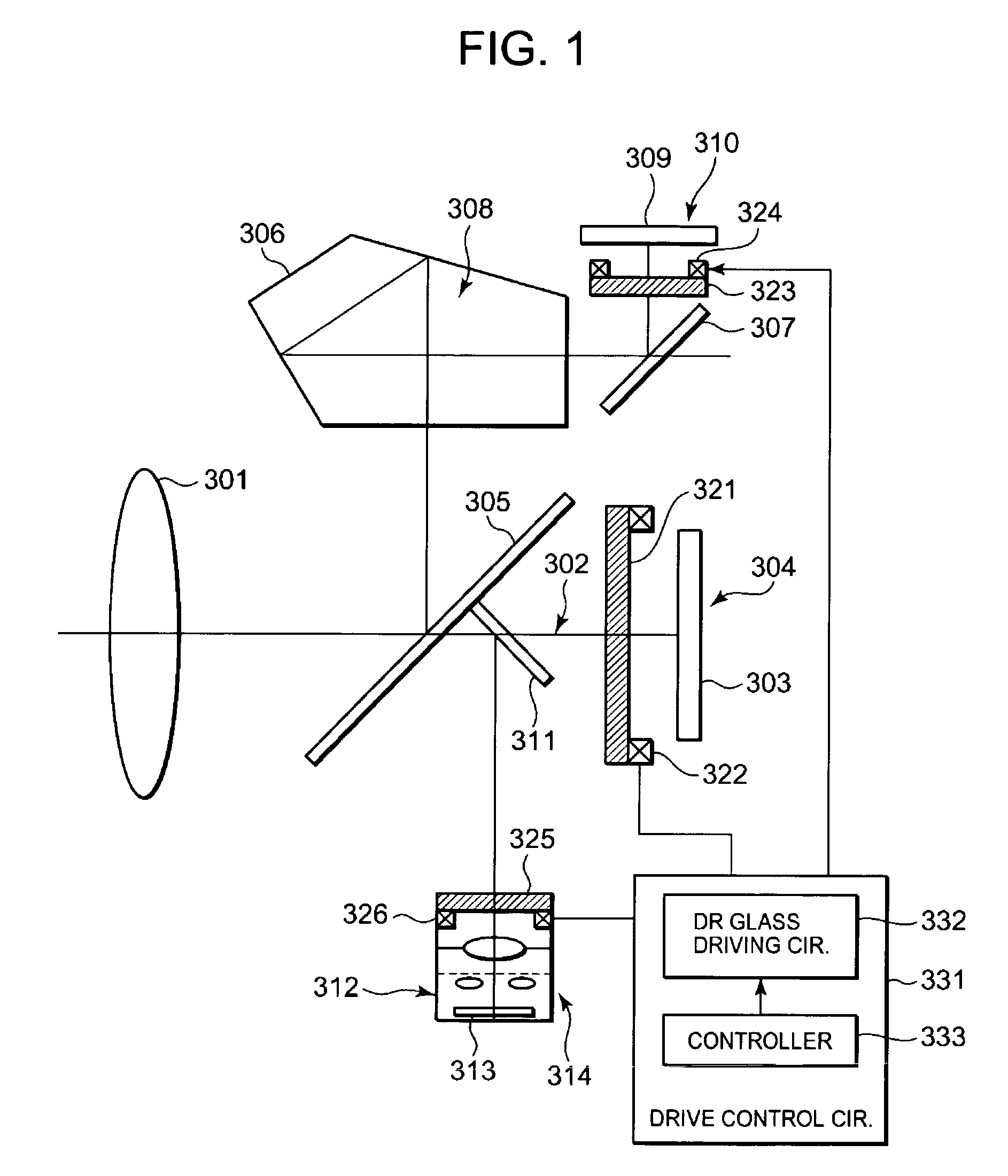

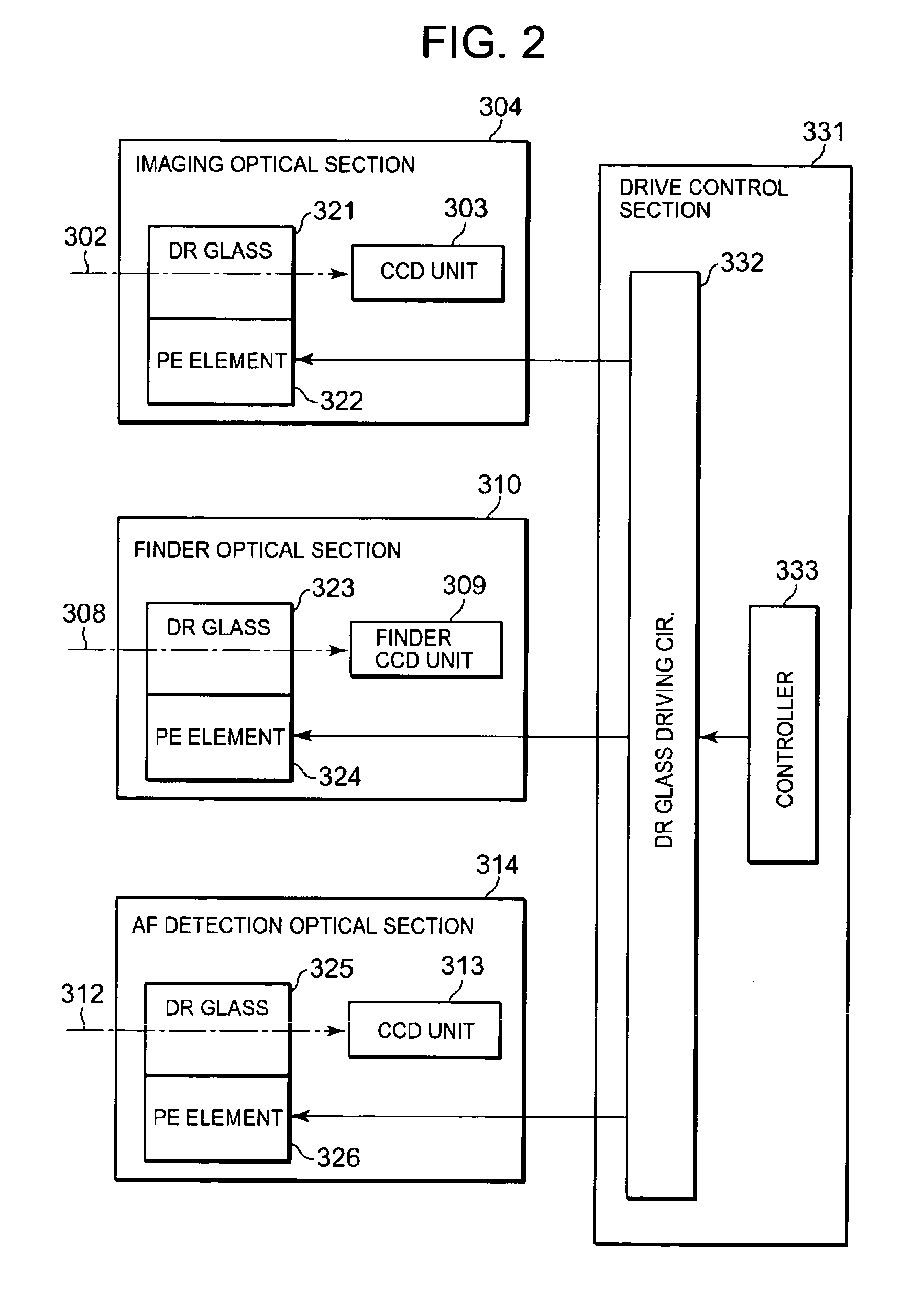

Optical apparatus with dust reduction capability

InactiveUS20060207290A1Low costSave energy consumptionTelevision system detailsCharging furnaceResonanceVoltage

The present invention realizes efficient dust removal in an optical apparatus in such a manner that a single circuit drives a plurality of dust reduction optical elements to vibrate. When the optical elements have different resonance frequencies, it can be configured such that the vibration exciting frequency can be changed in a range including the resonance frequencies of all the optical elements. In this case, the optical element driven can also be switched according to the change in frequency so that only the optical element having a resonance frequency close to the driving frequency will be driven. Alternatively, it can be configured such that the driving time or applied voltage can be changed according to the characteristics of the optical element driven.

Owner:OLYMPUS CORP

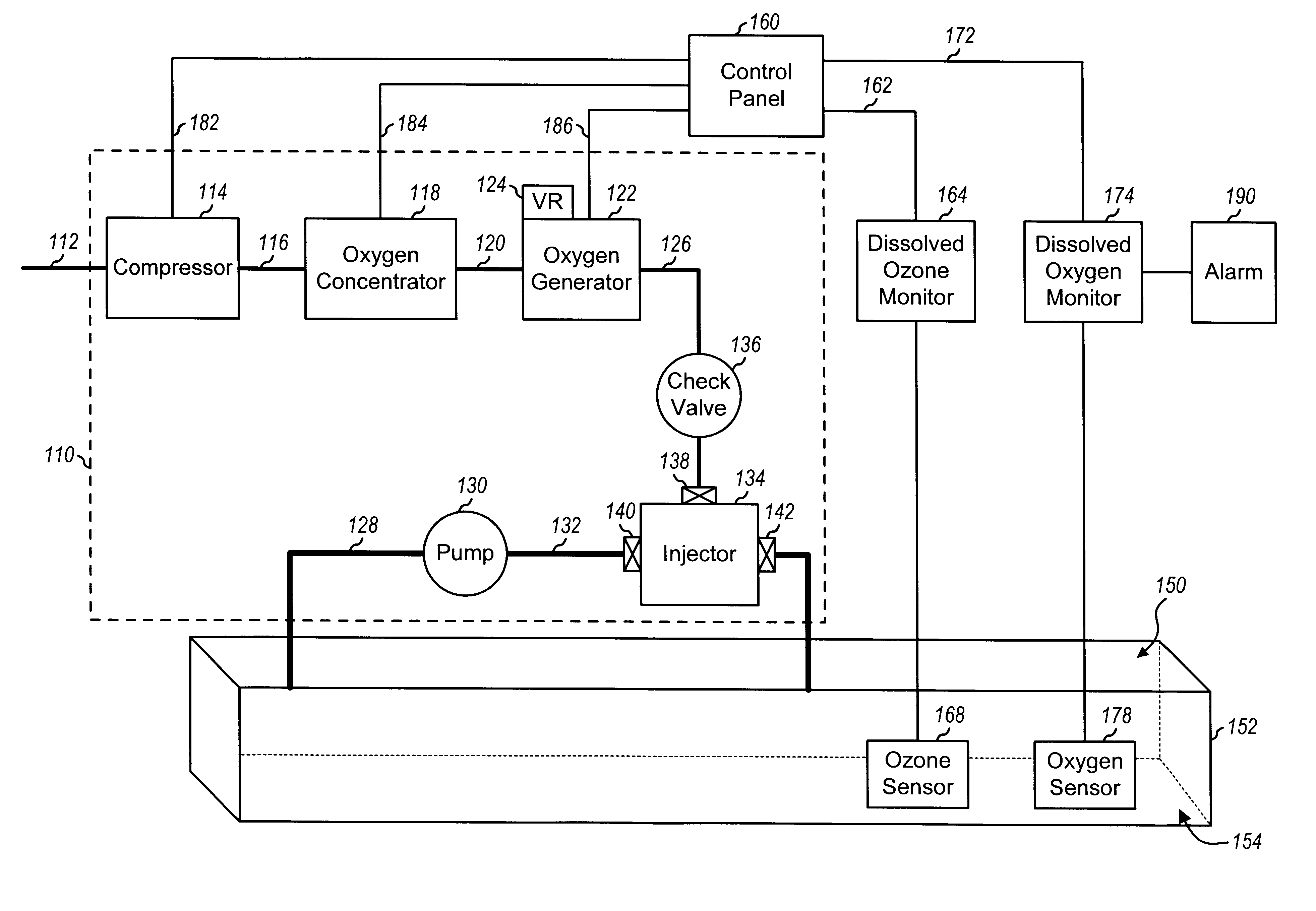

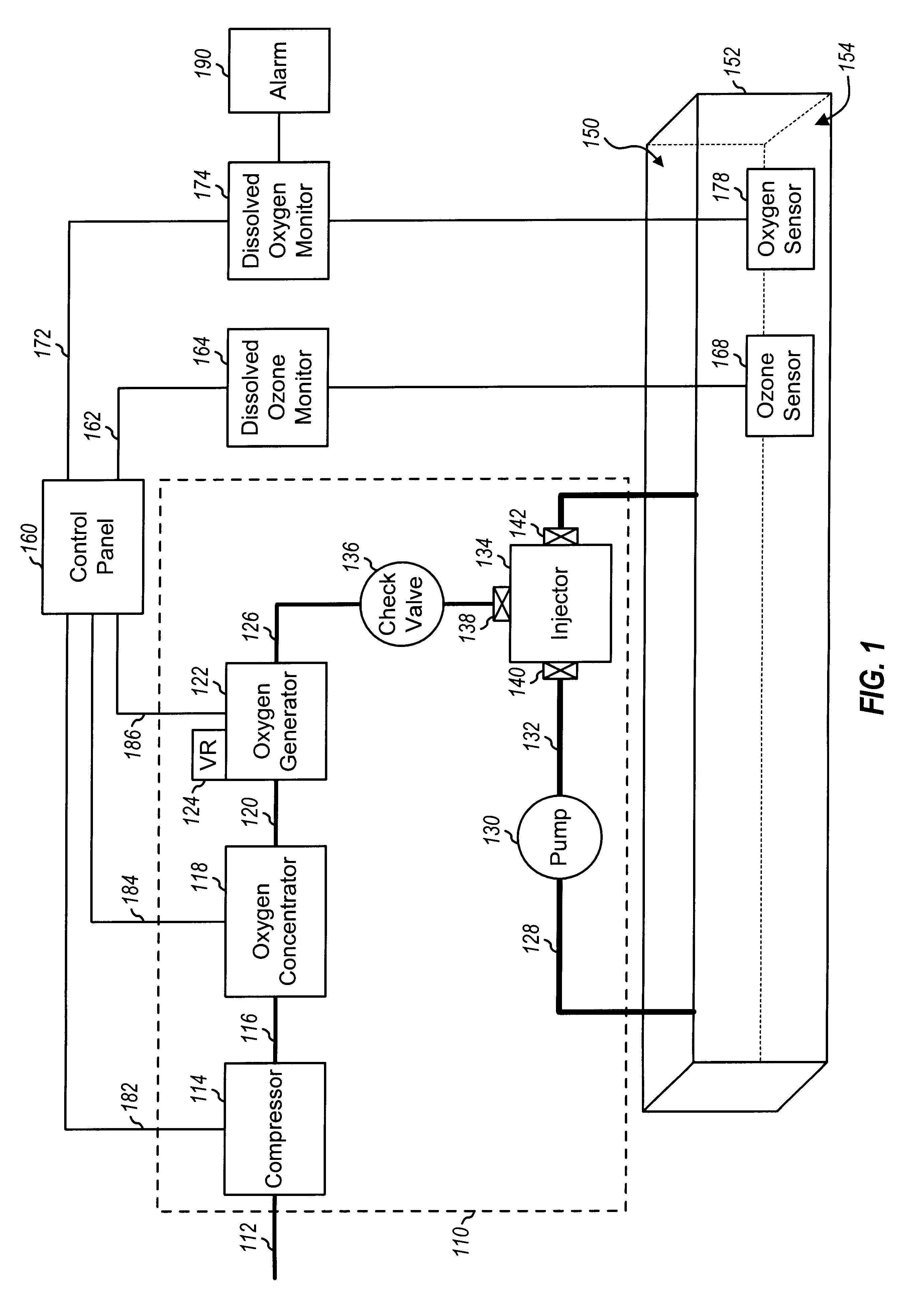

Method for inactivating red tide algae and harmful dinoflagellates

InactiveUS6235206B1Increase oxygen supplyIncrease oxygen contentWater/sewage treatment by magnetic/electric fieldsWater/sewage treatment by substance additionOzone generatorWater source

A method and system for inactivating harmful organisms (e.g., red tide algae and dinoflagellates). The method includes the steps of supplying ambient air to a conditioning unit to generate conditioned air; passing the conditioned air to an ozone generator to generate ozone; mixing the ozone with water, from a water source, that contains the harmful organisms to generate ozonated water; delivering the ozonated water back to the water source to achieve dilution of the harmful organisms; at least partially isolating the water source from external water to prevent quick dilution of the ozonated water; and continually circulating water in the water source through the mixing step. The harmful organisms are inactivated by exposure to the ozone.

Owner:ETECH INC

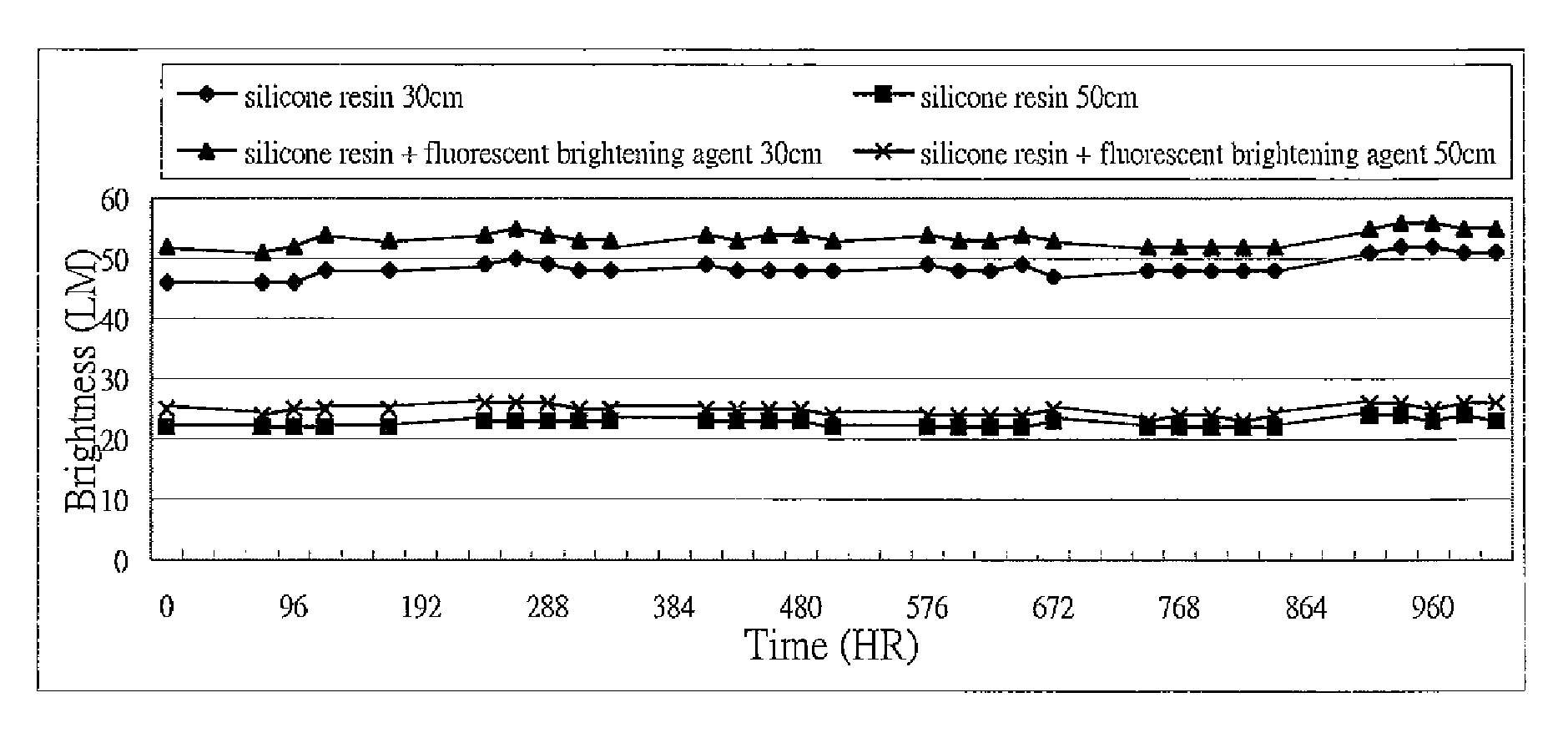

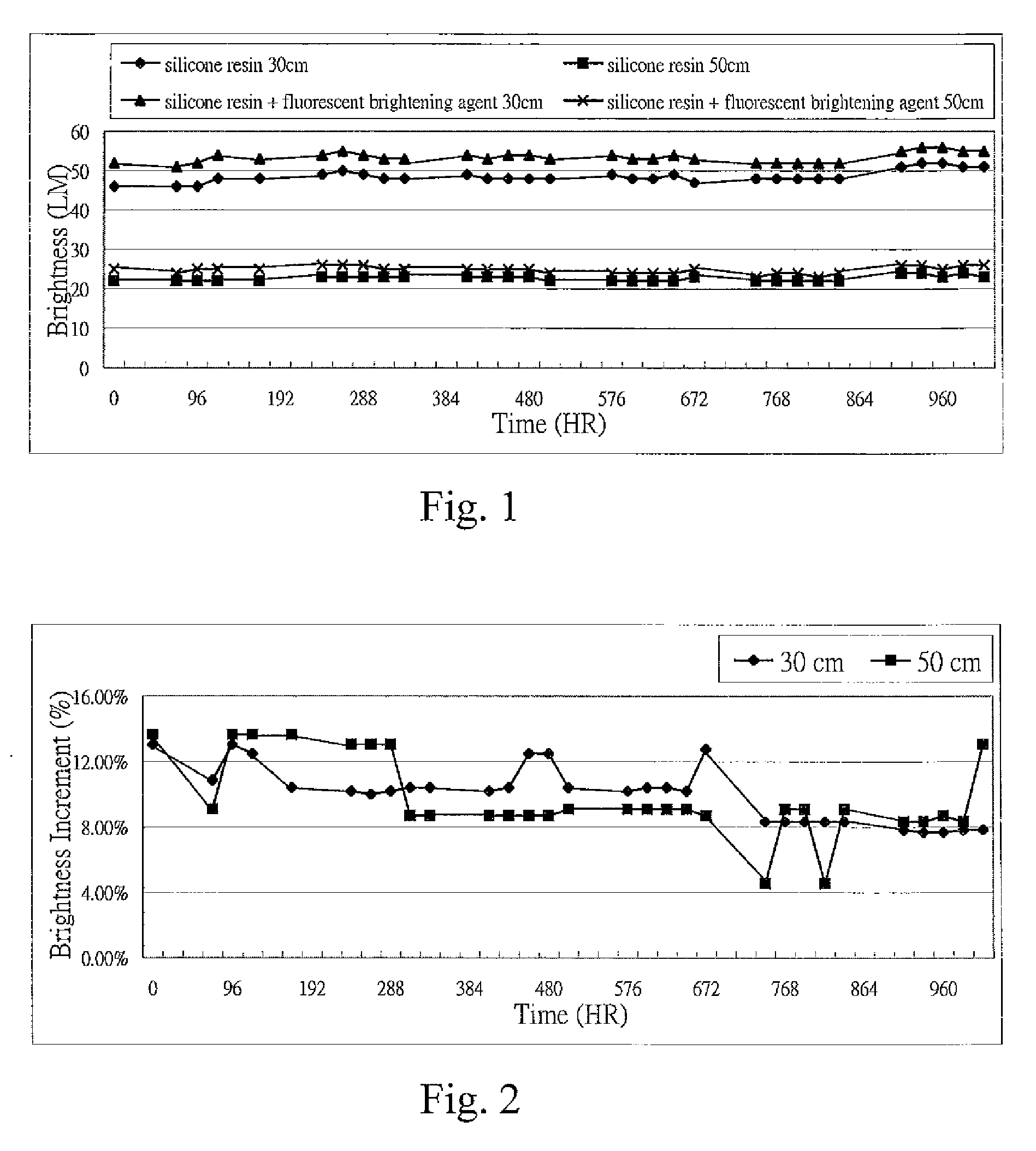

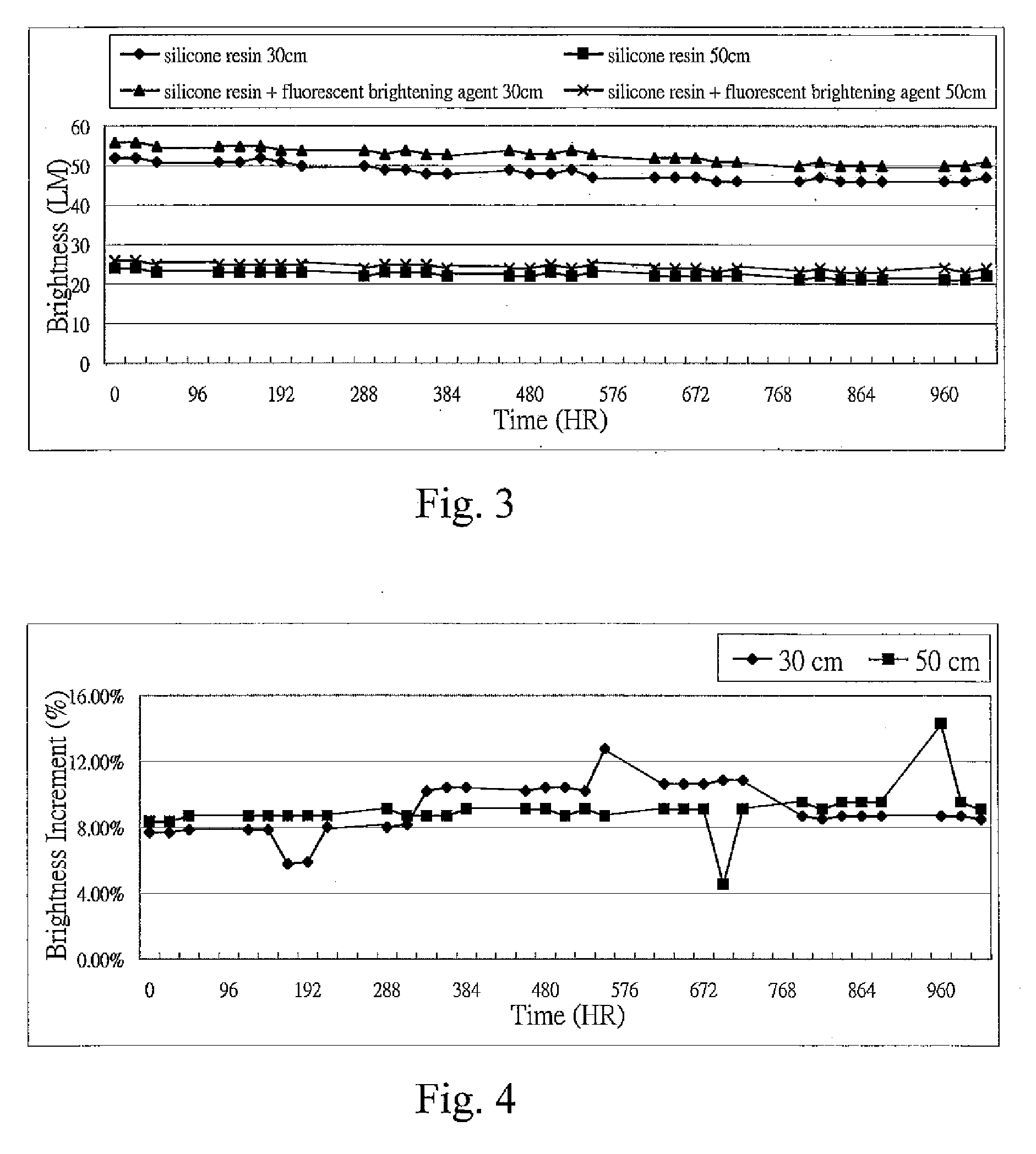

Light-enhanced element

InactiveUS20090129053A1Increase brightnessHigh luminous efficiencyLuminescent compositionsSpectral modifiersFluorescenceLength wave

The present invention provides a light-enhanced element including a transparent element including a fluorescent brightening agent, wherein the fluorescent brightening agent can absorb the first light emitted by a light-emitting element and subsequently emits the second light having a wavelength longer than that of the first light.

Owner:LUMINOSO PHOTOELECTRIC TECH

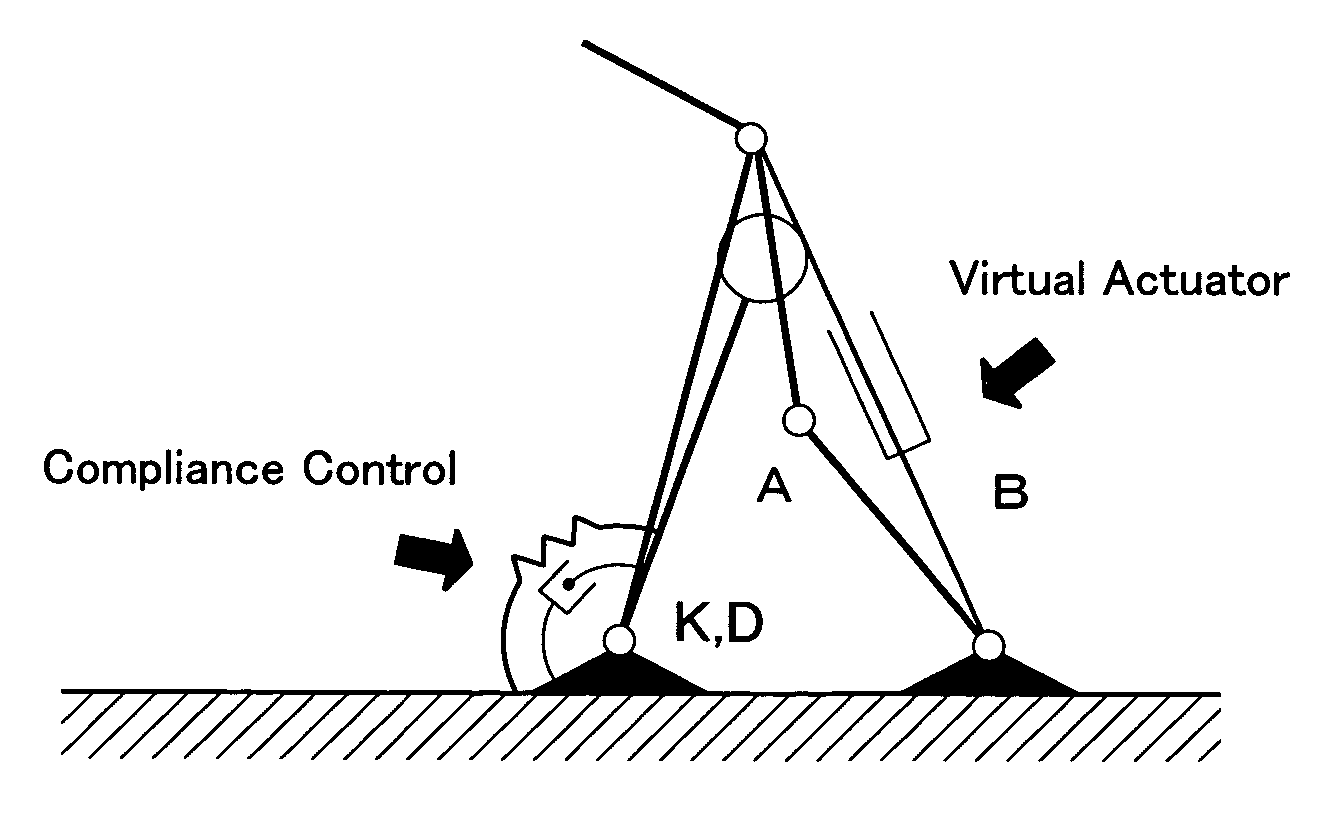

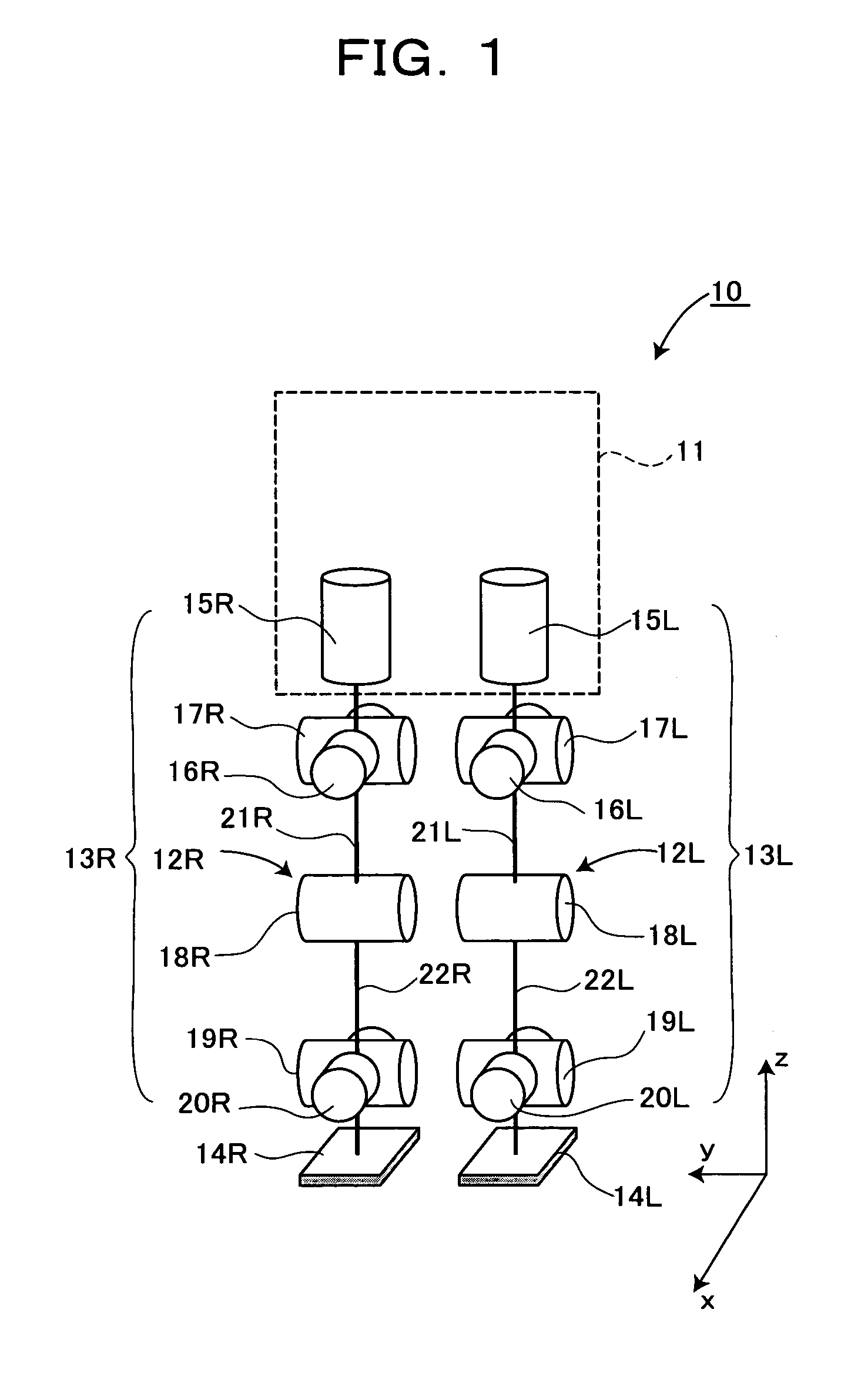

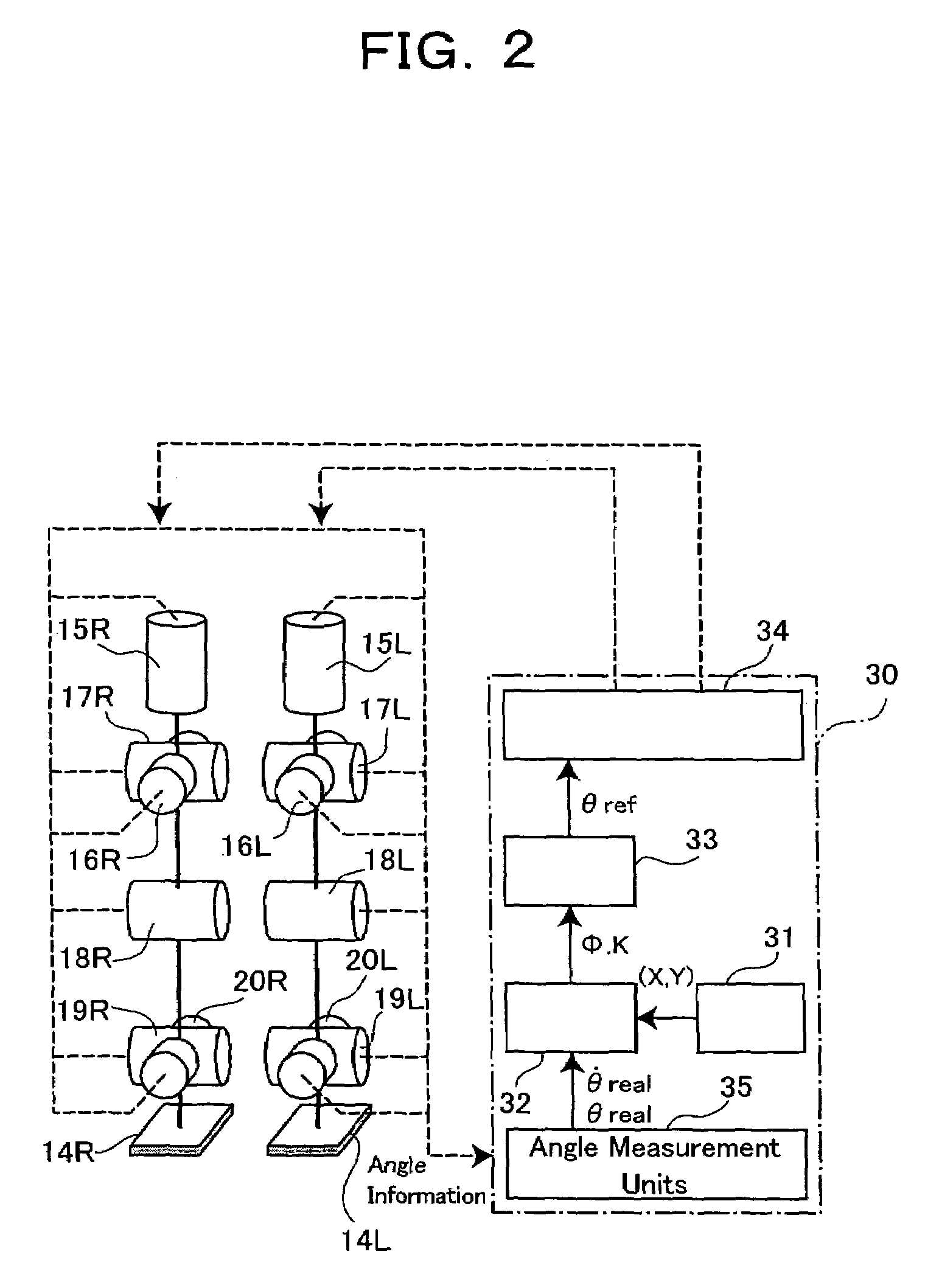

Biped walking mobile system, its walk controller, and walk control method therefor

InactiveUS6992456B2Improve walking stabilityDefects can be eliminatedProgramme-controlled manipulatorComputer controlPower modeEngineering

The present invention provides a biped (two-footed) walking mobile system, its walk controller, and walk control method therefore, which are to realize enhancing an walk stability, as well as a consumed energy saving. A walk controller (30) of a biped walking mobile system forms a gait data by a gait forming part (33) based on parameters from a gait stabilizing part (32), and drive-controls drive means of respective joint portions (15L, 15R–20L, 20R) of each leg portion based on said gait data. In this case, the walk controller (30) is so constituted as to selectively witch a powered mode to conduct ordinary drive-control and a passive mode to drive-control the drive means similarly with passive joints, whereby drive-controlling respective joint portions. The walk controller (30) preferably switches the drive and passive modes with respect to, for example, joint portions of knee and foot portions, or switches to the powered mode for kick-up and landing during walking motion, and to the passive mode for a free foot state.

Owner:JAPAN SCI & TECH CORP

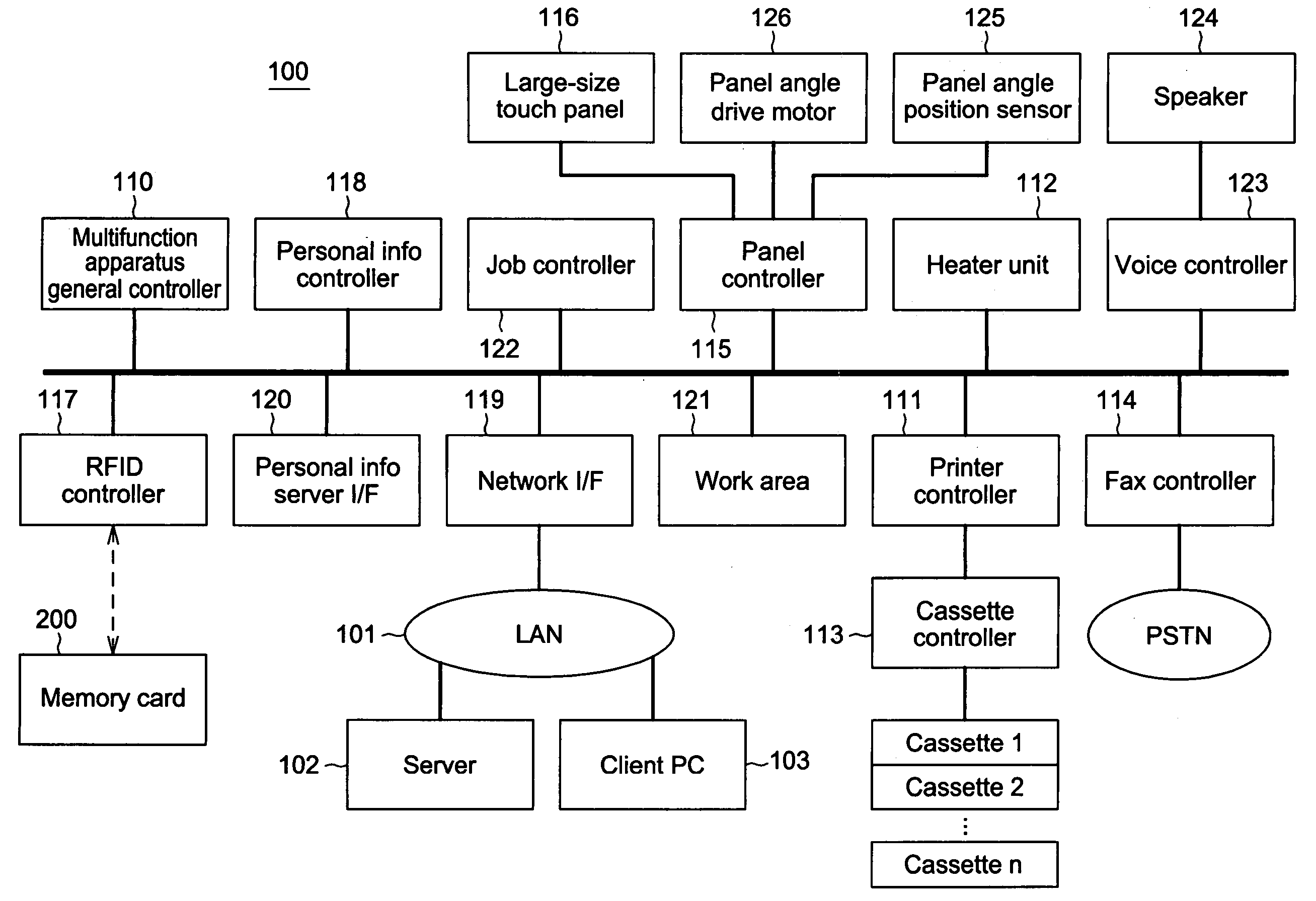

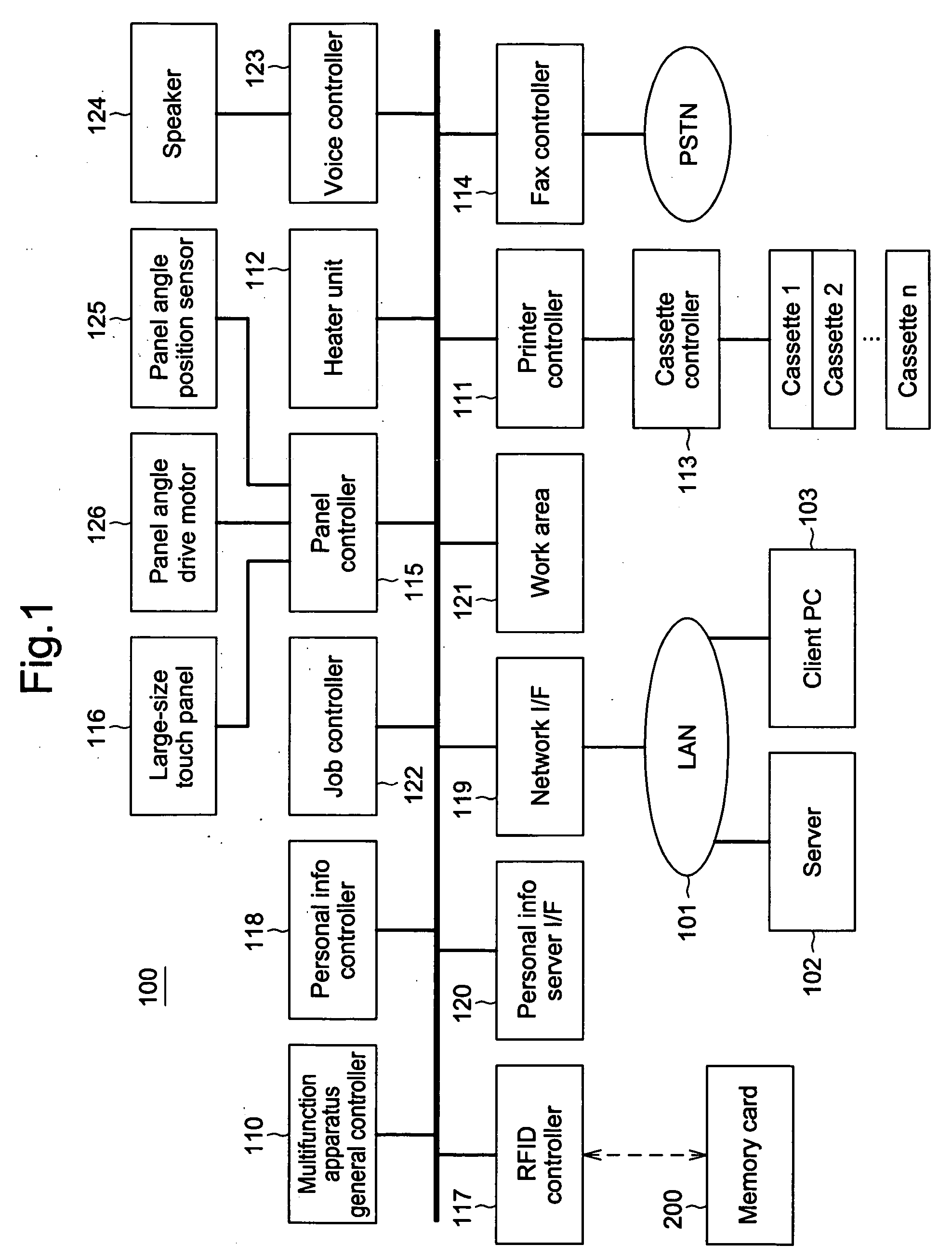

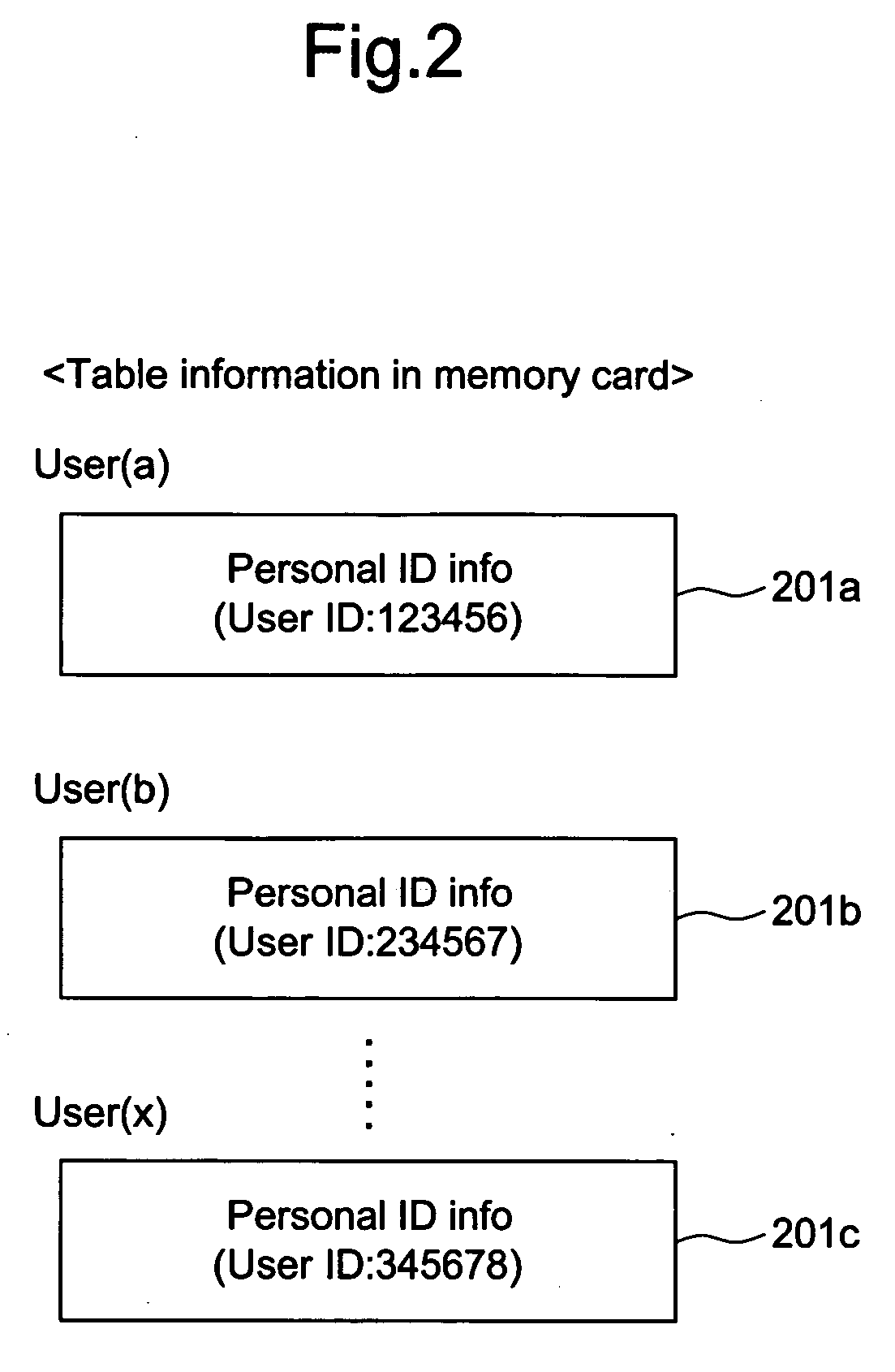

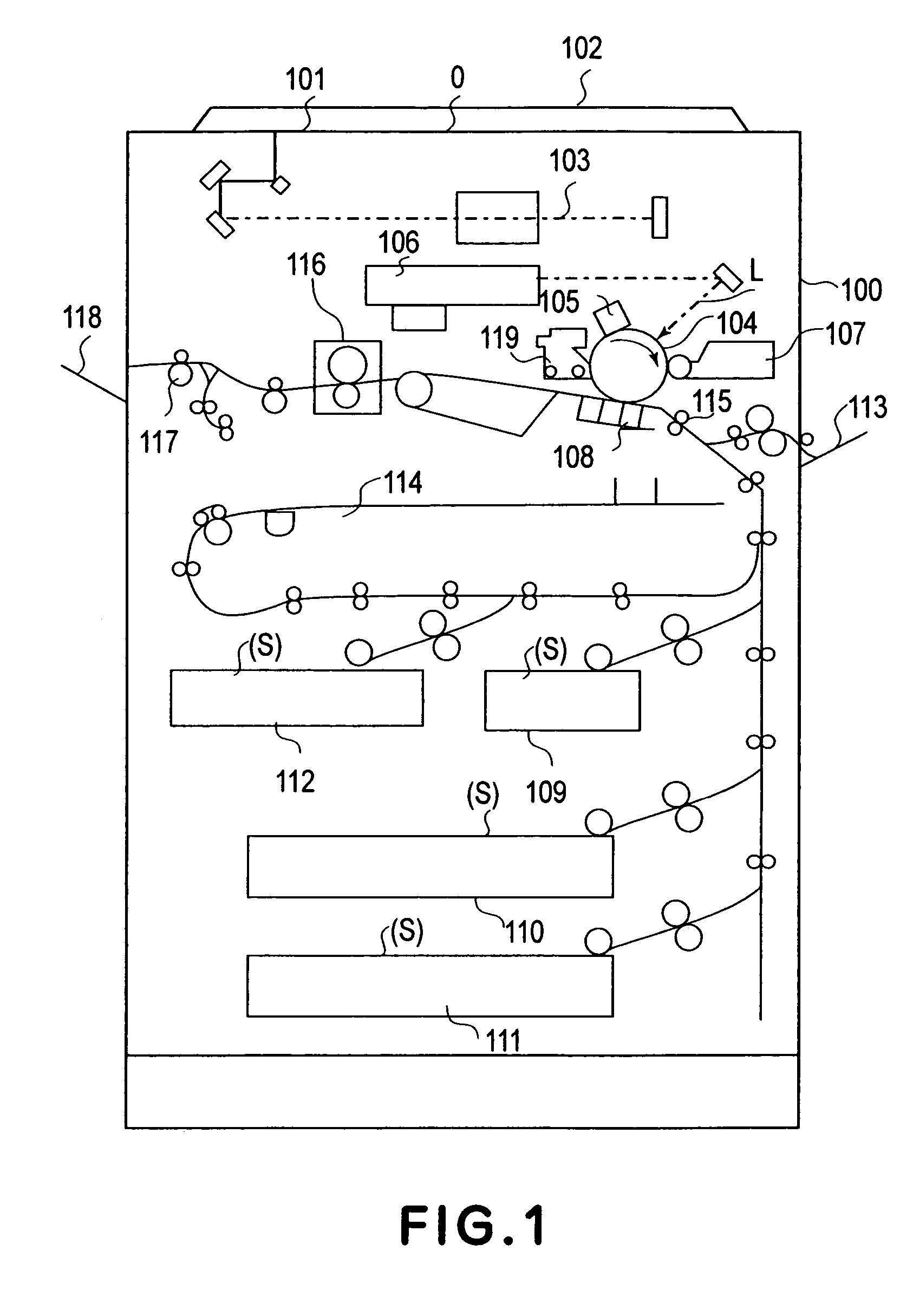

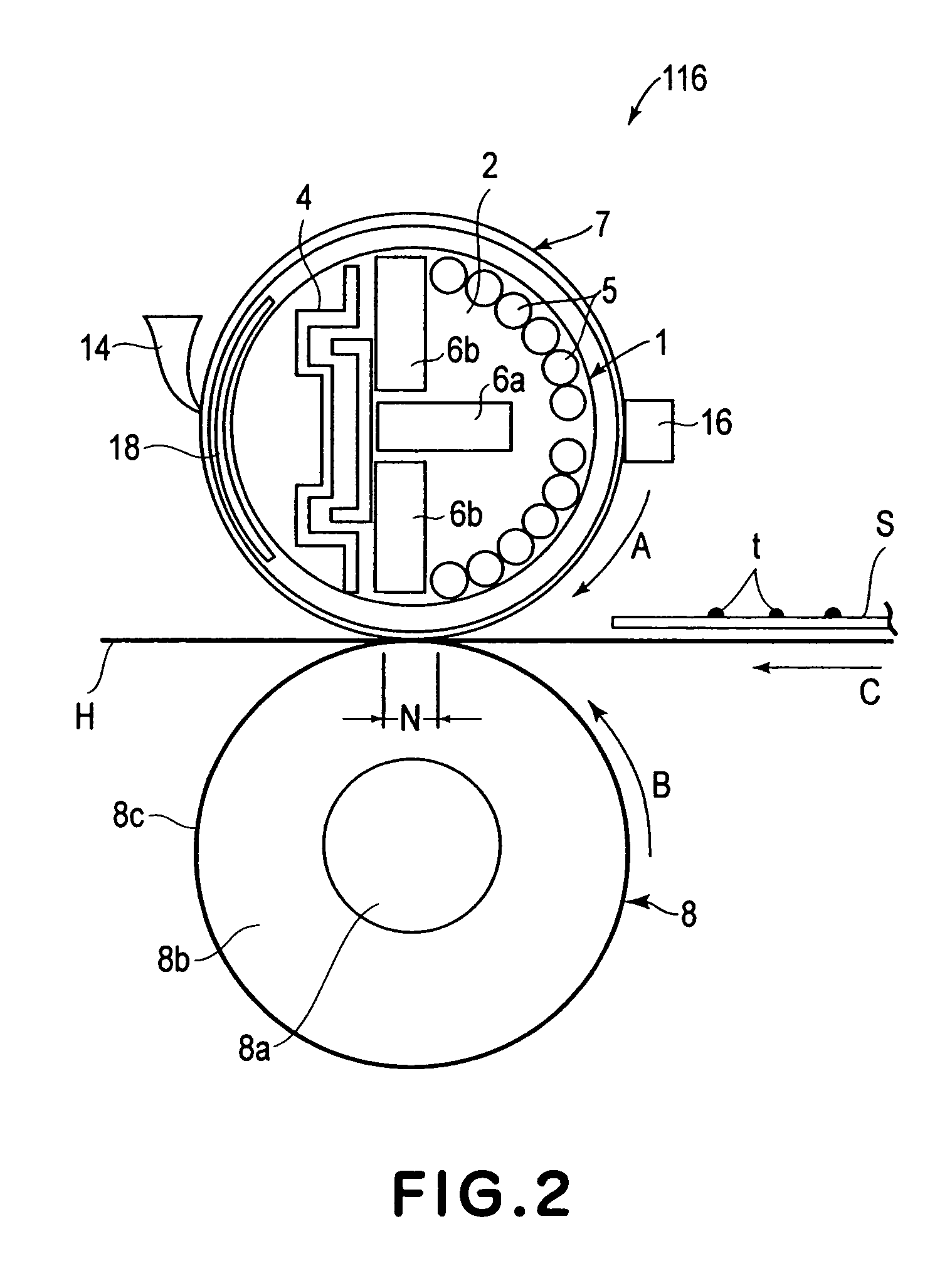

Multifunction apparatus

InactiveUS20050190707A1Shorten time periodSave energy consumptionElectrographic process apparatusLine-transmissionUser authenticationNormal mode

A multifunction apparatus according to the present invention transmits an electromagnetic wave signal to a memory card carried by a user who enters a detection area, scans identification information of the user for user authentication, and starts a warm-up operation immediately after the authentication. Accordingly, the time period spent by the user starting from the user's arrival at the multifunction apparatus until the completion of the warm-up operation is shortened. In addition, the multifunction apparatus determines whether the user remains in the detection area after a job is completed, and transitions from a normal mode to an energy-save mode when it is determined that the user is not remaining in the detection area, the normal mode being in a state where sufficient electrical power is supplied for a job execution, the energy-save mode being in a state where the power supply is decreased compared to the normal mode.

Owner:PANASONIC CORP

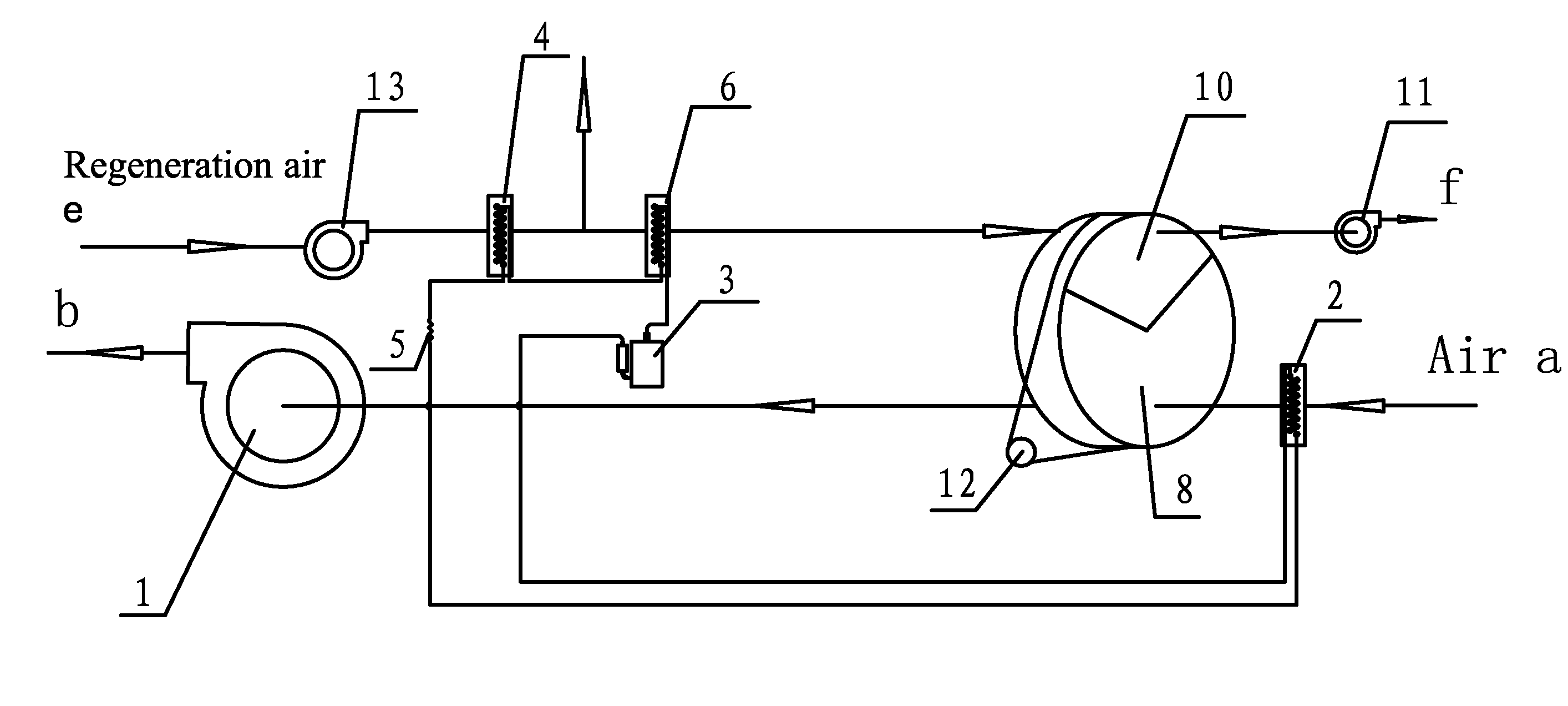

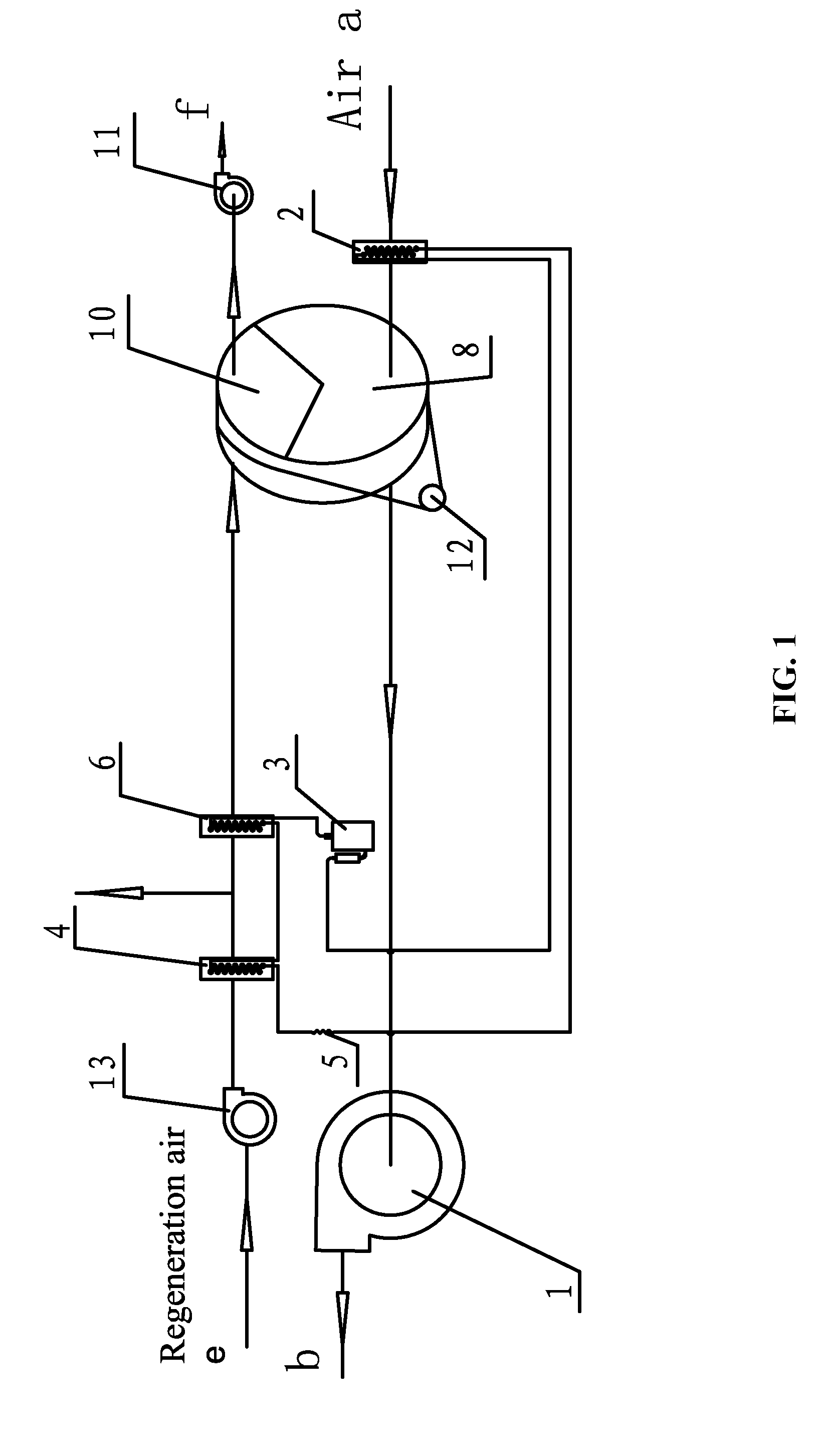

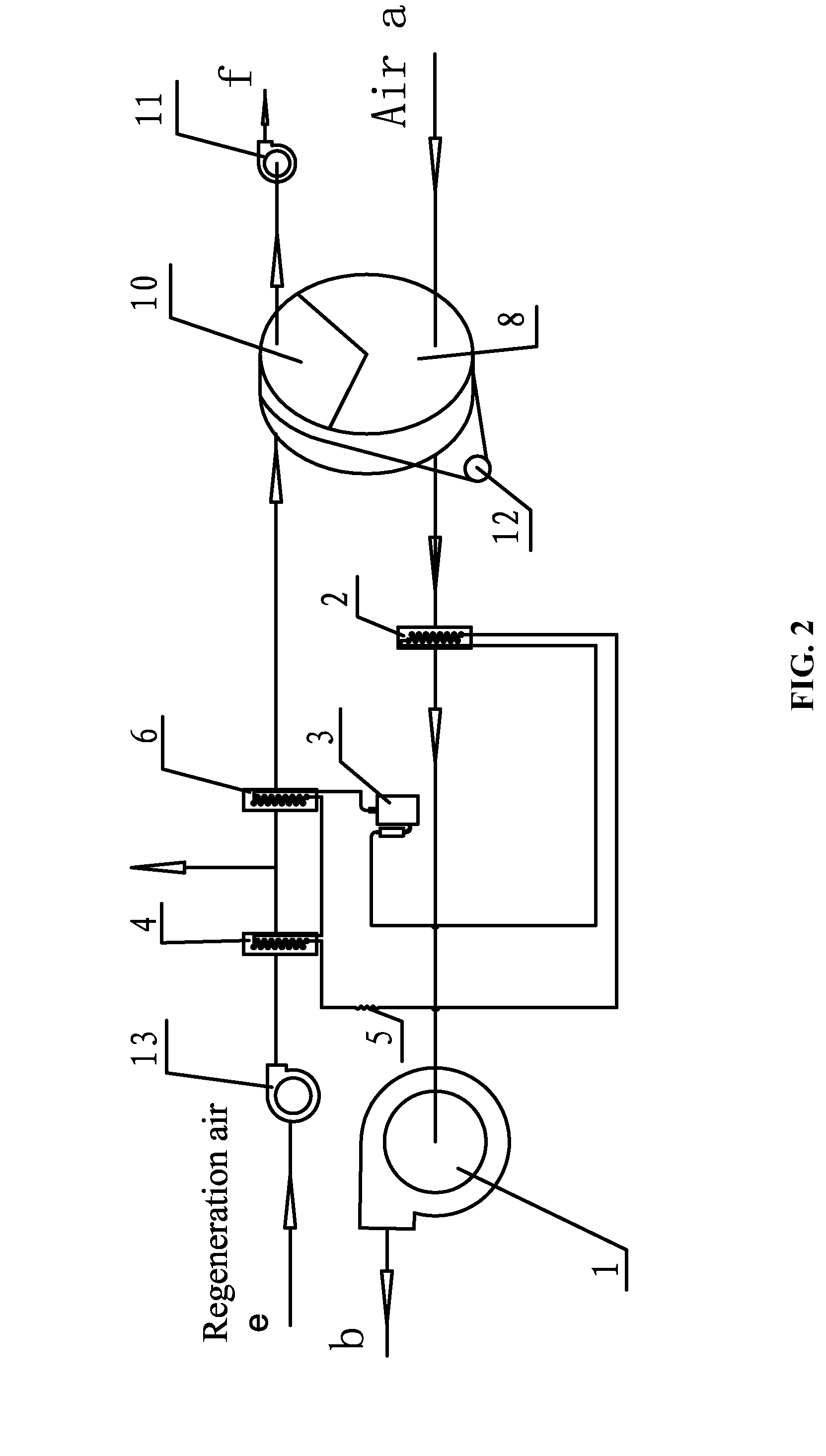

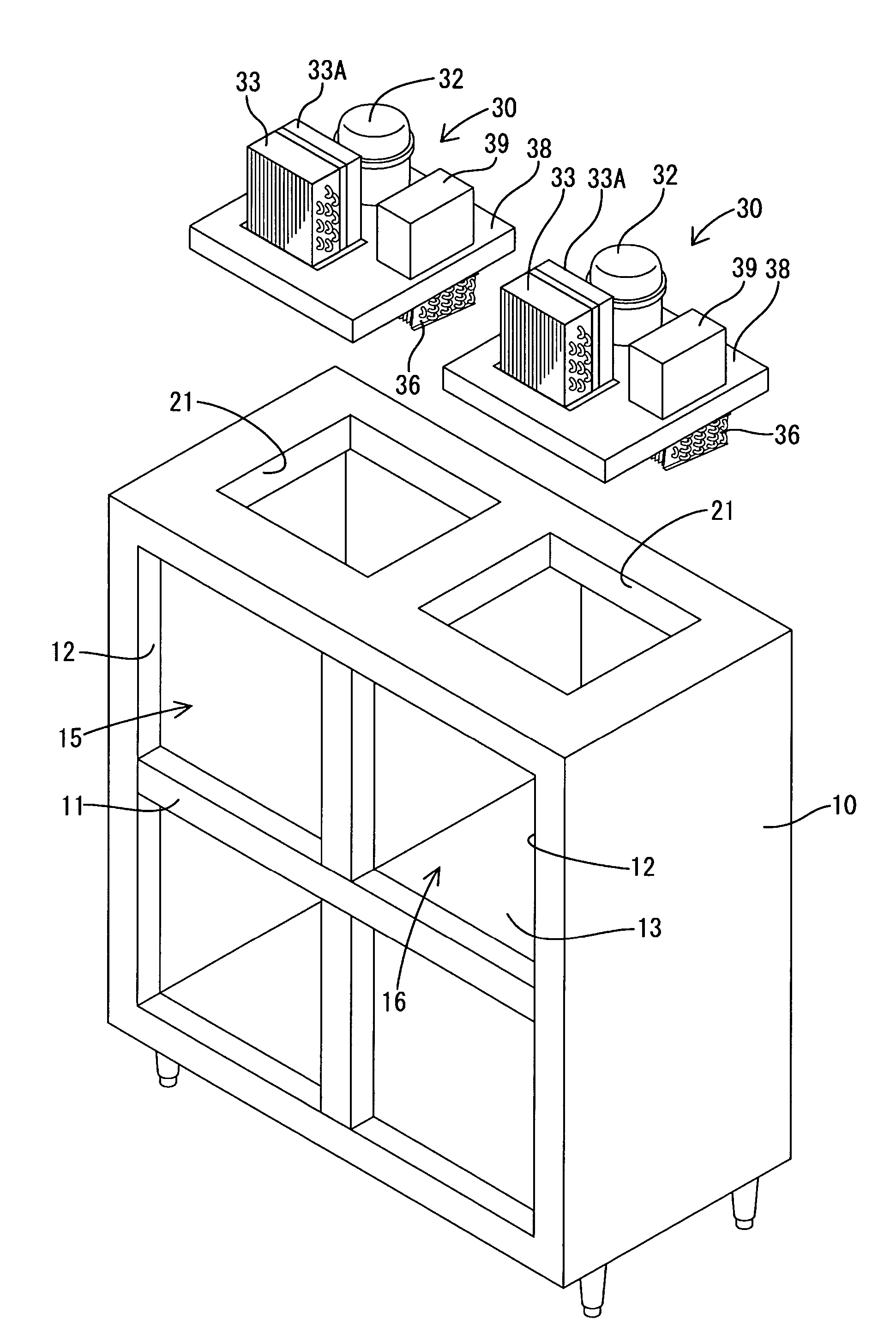

Coupled air-conditioning device

ActiveUS20140165637A1Save energy consumptionEasy loadingLighting and heating apparatusDispersed particle separationProcess regionGas cooler

A coupled air-conditioning device including a dehumidification system and a vapor compression-type refrigeration system which are connected through a pipeline. The vapor compression-type refrigeration system is a closed circuit including an evaporator, a compressor, a condenser and an expansion valve. The dehumidification system includes a desiccant-wheel with a regeneration area and a processing area, a processing air blower, a regeneration air blower and an electric motor driving the desiccant-wheel to rotate. The processing air blower and the regeneration air blower are provided with an exhaust port. The condenser includes a phase-change condensation heat exchanger and a refrigerant gas cooler. The refrigerant gas cooler operates to cool the overheated refrigerant discharged from the compressor into a saturated refrigerant in gas state, employing a structural form of a tube-fin heat exchanger comprising a heat exchange tube and a fin piece.

Owner:MA JUN

Optical apparatus with dust reduction capability

InactiveUS7580628B2Save energy consumptionAchieve dust removalCharging furnaceTelevision system detailsResonanceEngineering

The present invention realizes efficient dust removal in an optical apparatus in such a manner that a single circuit drives a plurality of dust reduction optical elements to vibrate. When the optical elements have different resonance frequencies, it can be configured such that the vibration exciting frequency can be changed in a range including the resonance frequencies of all the optical elements. In this case, the optical element driven can also be switched according to the change in frequency so that only the optical element having a resonance frequency close to the driving frequency will be driven. Alternatively, it can be configured such that the driving time or applied voltage can be changed according to the characteristics of the optical element driven.

Owner:OLYMPUS CORP

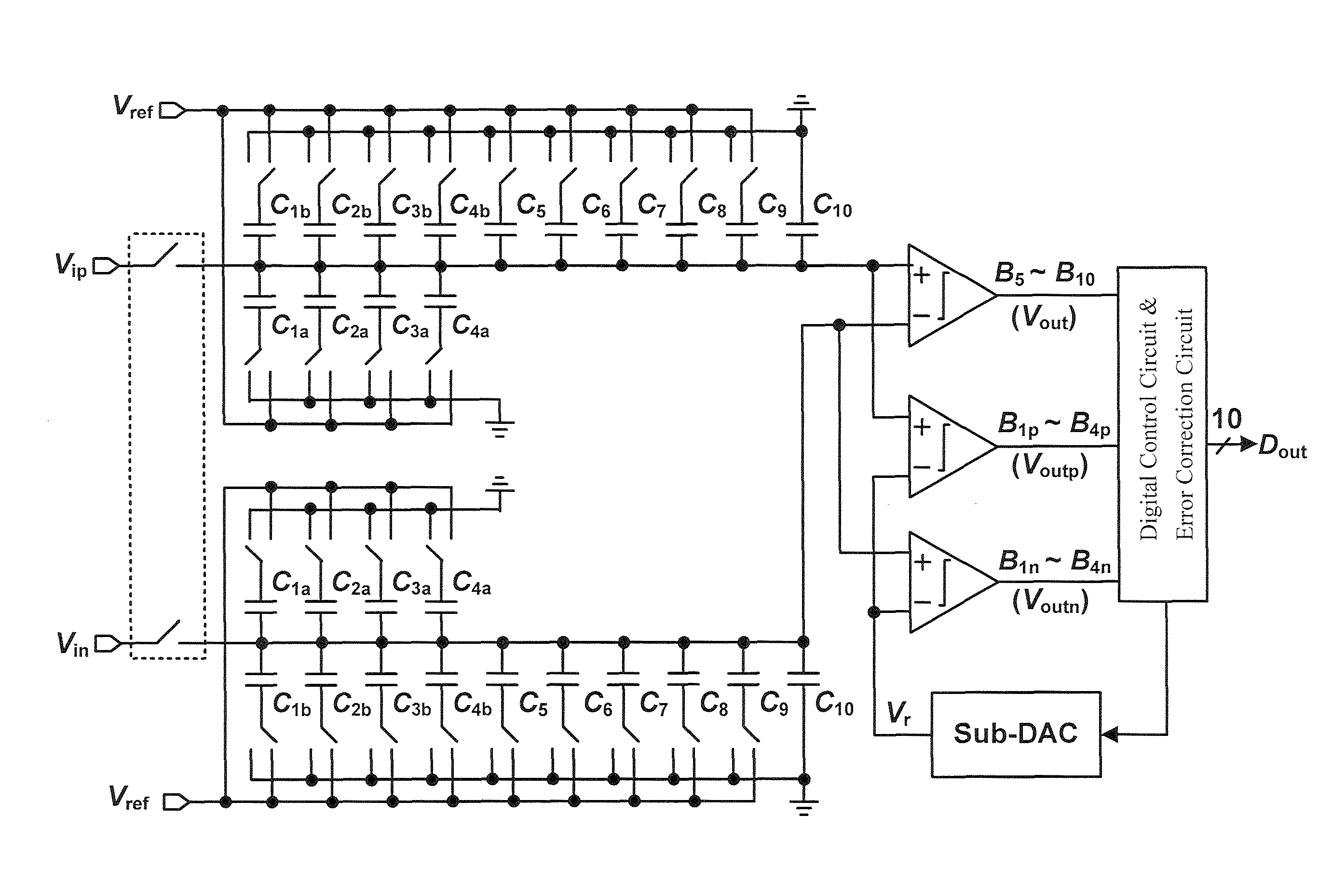

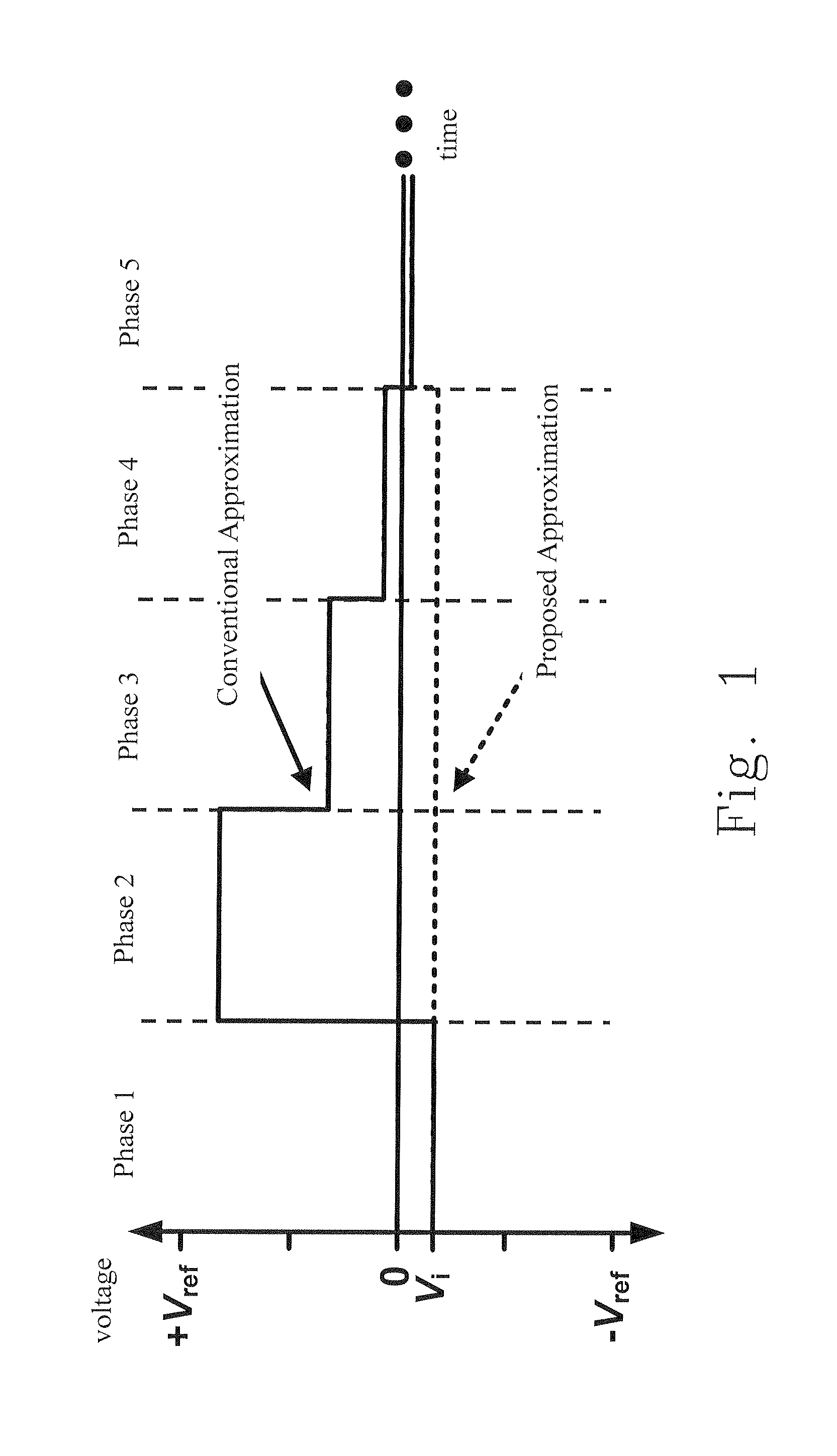

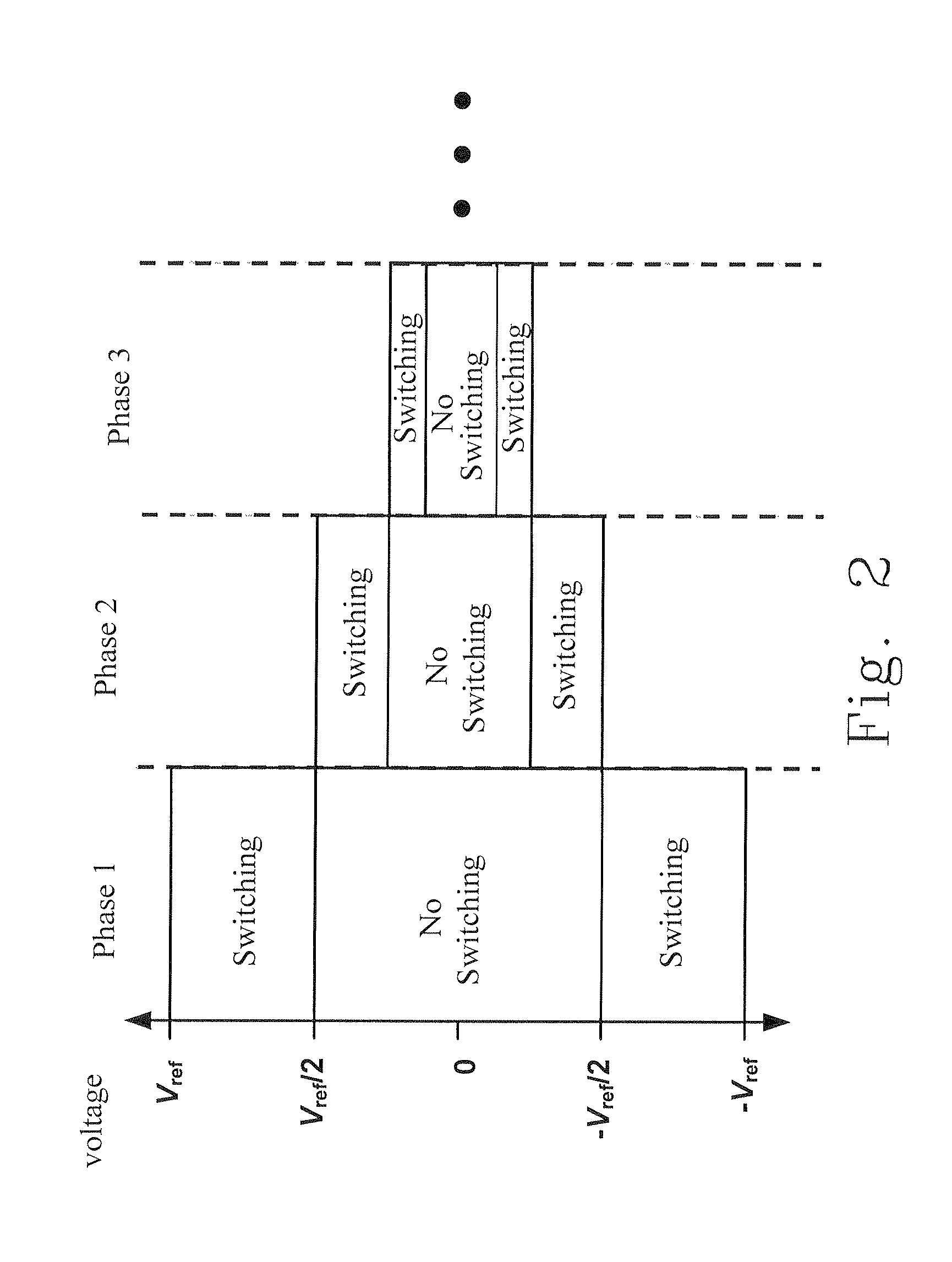

Successive approximation analog-to-digital converter having auxiliary prediction circuit and method thereof

ActiveUS8416116B2Save energy consumptionImprove circuit efficiencyPower saving provisionsElectric signal transmission systemsA d converterEngineering

Owner:NAT CHENG KUNG UNIV

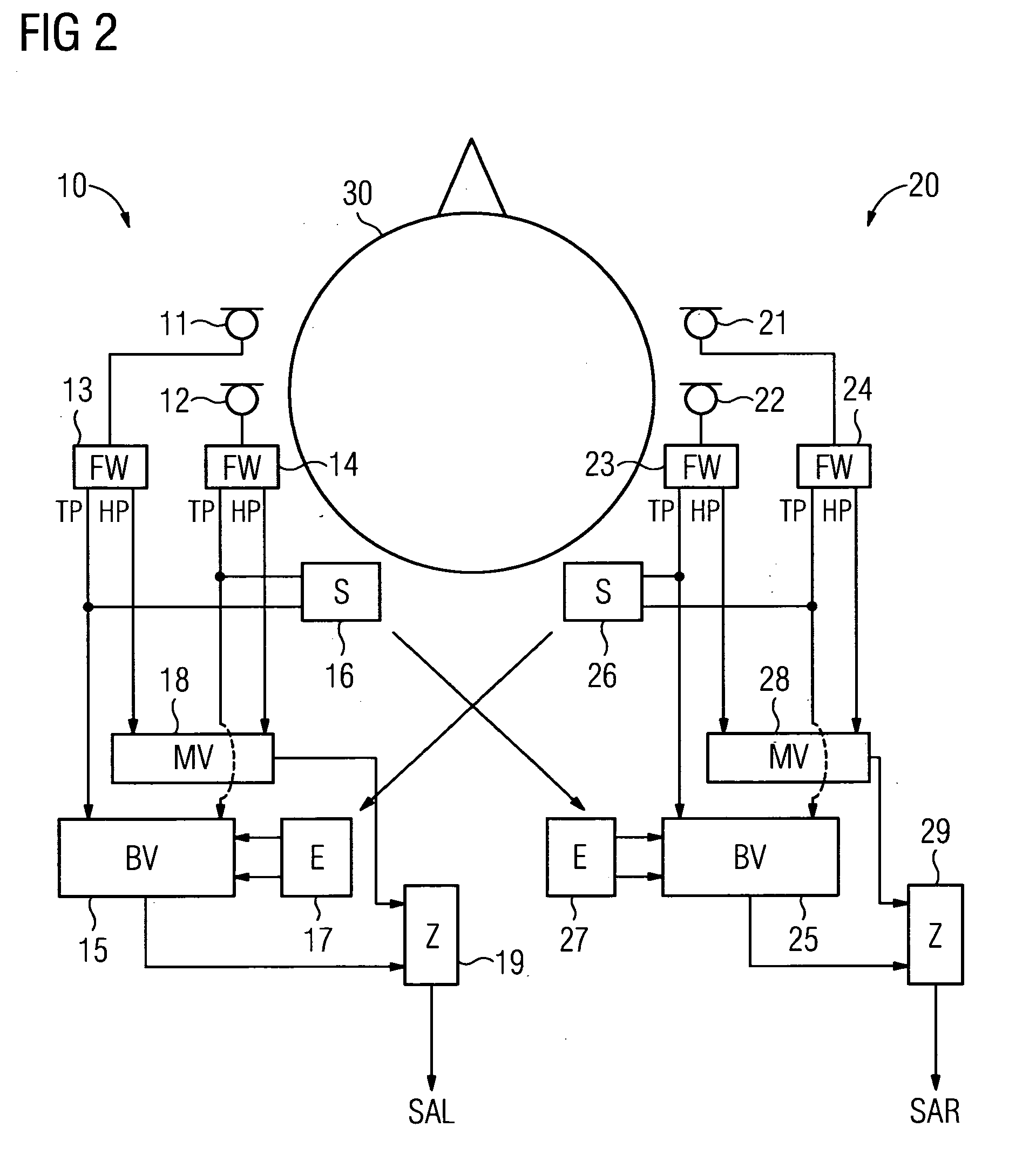

Hearing system with partial band signal exchange and corresponding method

ActiveUS20090238385A1Improve binaural supplyFacilitate transmissionMicrophonesElectrical transducersFrequency spectrumAuditory system

A binaural supply with a hearing system is to be enabled, whereby the computing outlay and energy consumption are to be kept as minimal as possible. A hearing system comprising a first hearing apparatus including a first signal input facility and a first communication facility and a second hearing apparatus including a second signal input facility, a second communication facility for receiving a signal from the first communication facility and a second signal processing facility for processing signals from the second signal input facility and the second communication facility are provided to form a common output signal. The signal transmitted from the first to the second communication facility corresponds to a real spectral part of the overall frequency spectrum of the first input signal. As only one part of the overall spectrum is transmitted and / or binaurally processed, the computing outlay and energy consumption is reduced.

Owner:SIVANTOS PTE LTD

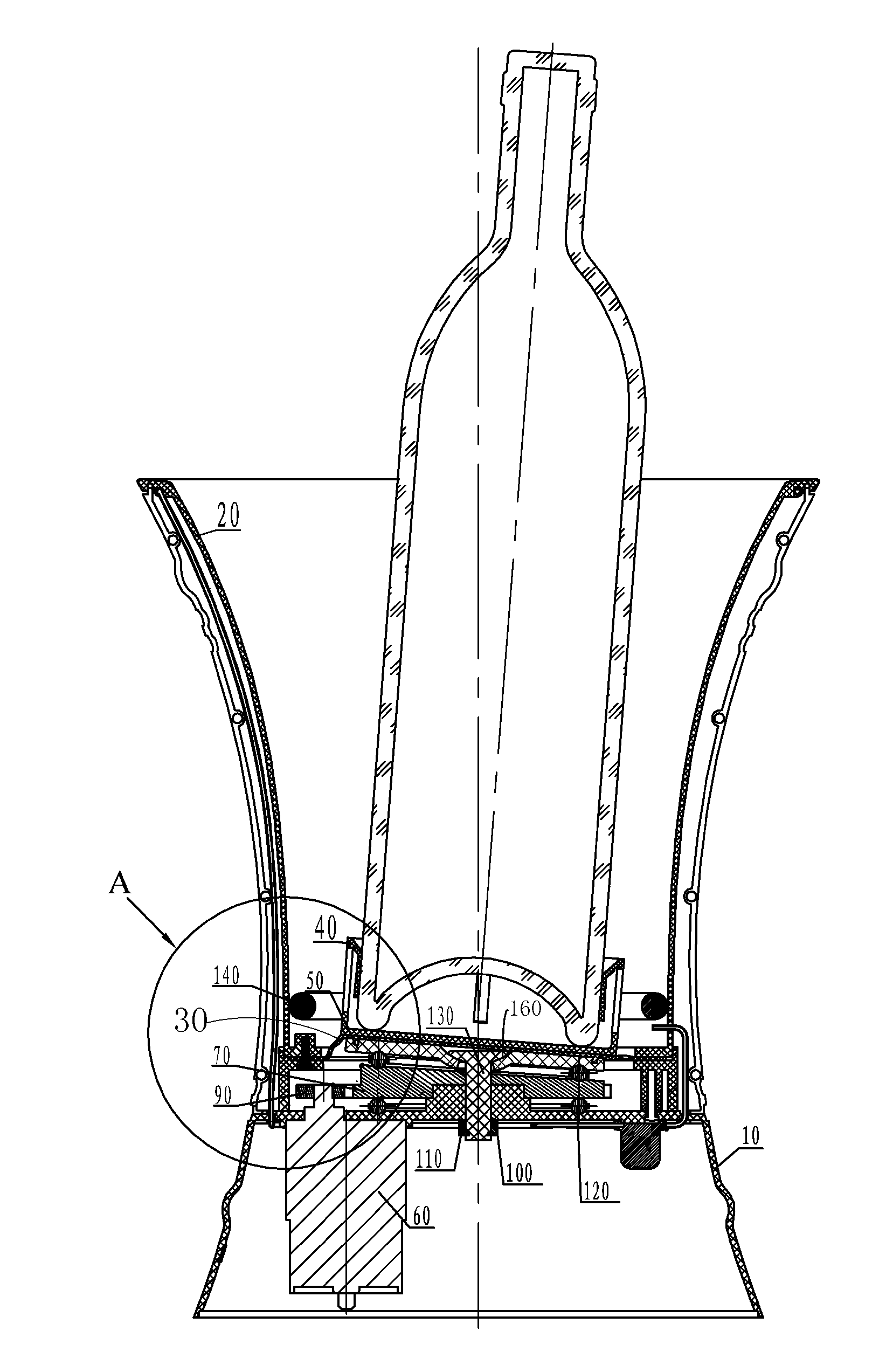

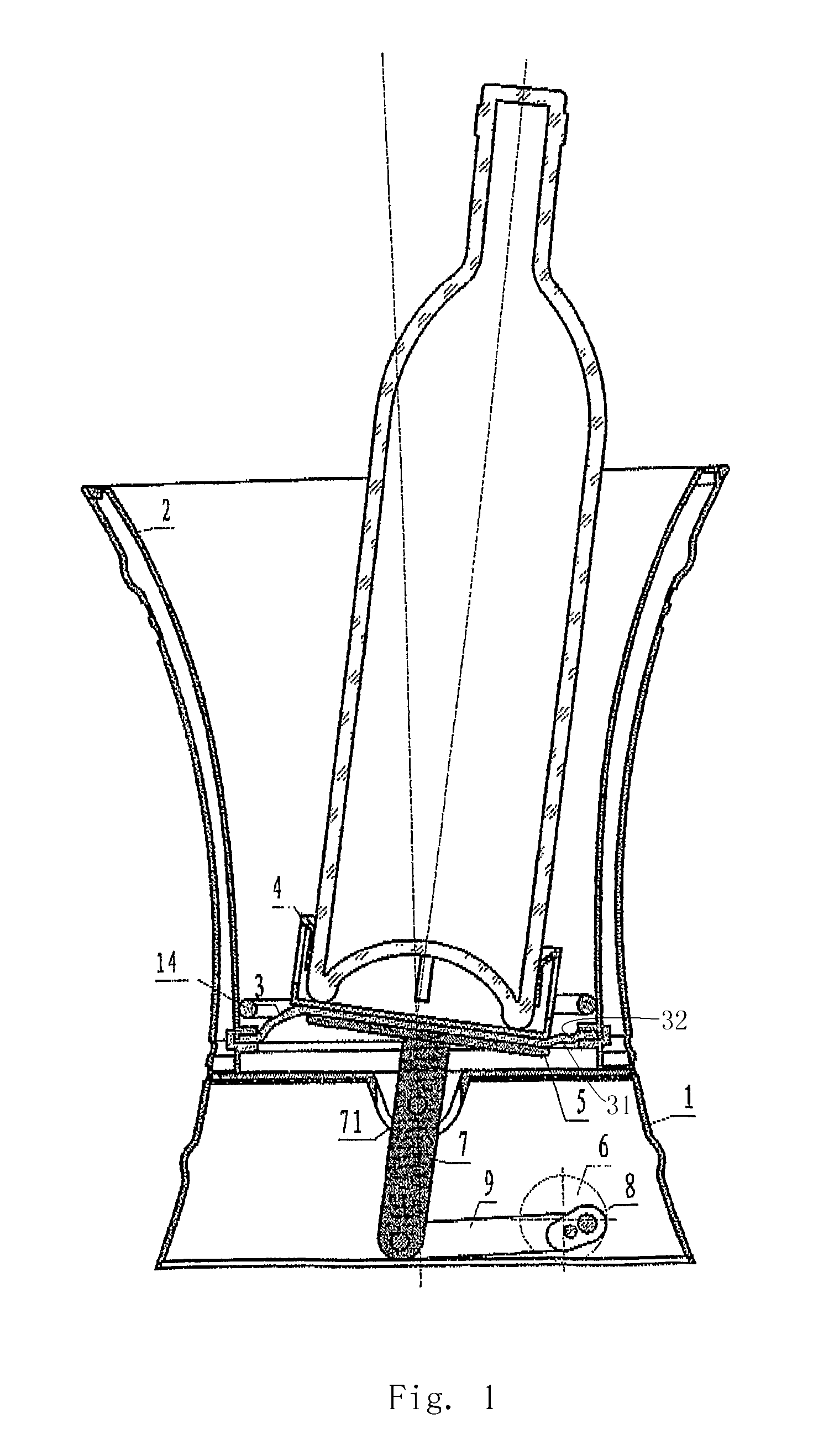

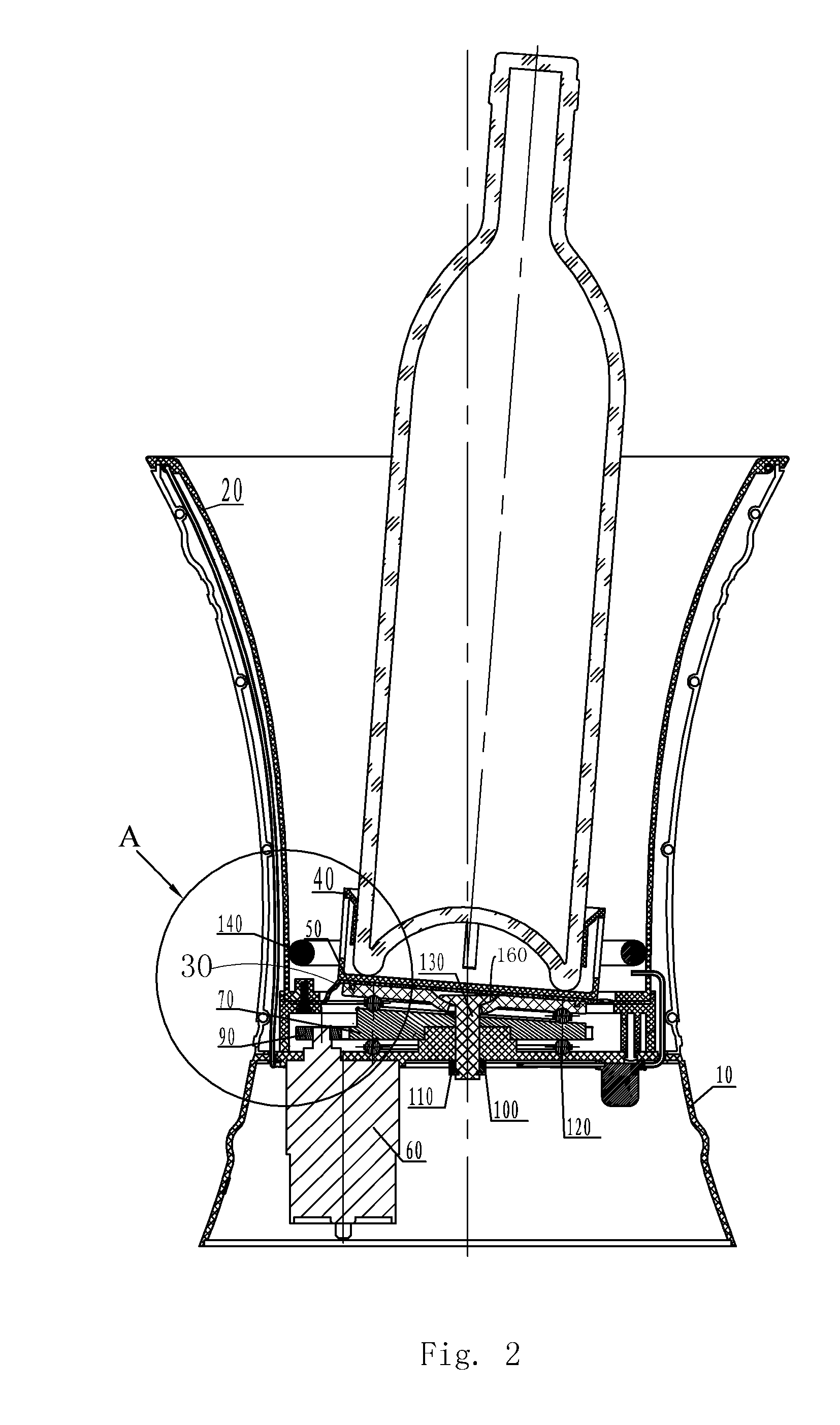

Drink swinging apparatus

InactiveUS8132960B2Promote breathingIncrease appetiteRotating receptacle mixersShaking/oscillating/vibrating mixersWine bottleEngineering

A shaker is disclosed which is driven by a motor through a swing mechanism so as to swing a wine bottle, for example, drink within the bottle such as wine. The shaker comprises a base, a container, and a bottle seat disposed at a bottom in the container for receiving a bottle body, characterized in that the drink shaker further comprises a swing mechanism disposed in the base and driven by the motor through a conversion mechanism, and the swing mechanism is capable of driving the bottle seat to swing rightward and leftward in a plane or in different planes.

Owner:ZHUANG MIN

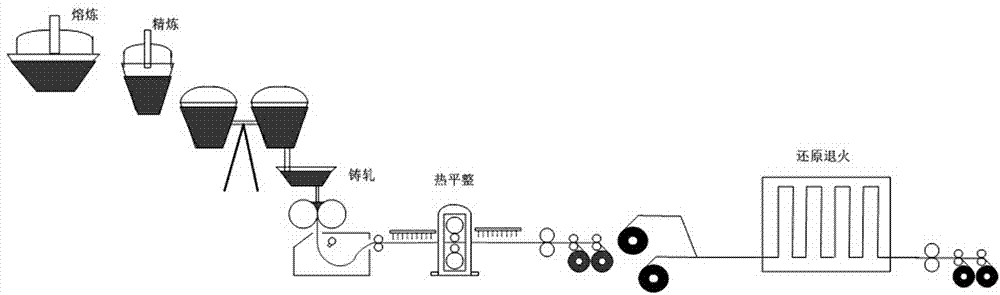

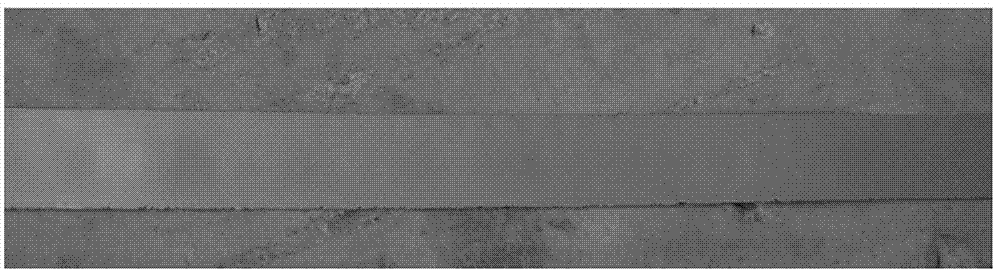

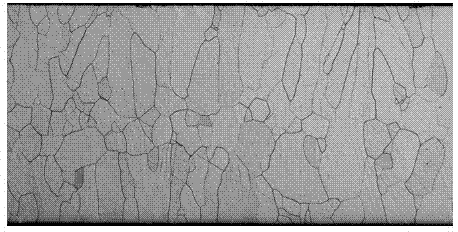

Method for producing hot-rolled pickling-free plate by combining thin-strip continuous casting with reducing annealing

The invention belongs to the technical field of material metallurgy, and particularly relates to a method for producing a hot-rolled pickling-free plate by combining thin-strip continuous casting with reducing annealing. The method specifically includes the steps: obtaining refining molten steel, preparing a cast-rolling strip blank, uncoiling a cast-rolling thin strip after thermal leveling for reducing annealing, removing scale on the surface of the cast-rolling thin strip in a reduction section, and adopting H2 atmosphere condition to protect reduction, wherein reduction temperature is 800-1100 DEG C and reduction time is 10-30min; adopting H2 and N2 atmosphere for protection in a high-temperature annealing section, wherein reduction temperature is 500-1000 DEG C and reduction time is 1-5min, realizing texture and performance control of the thin strip, and obtaining a thin-strip steel product. By the technical scheme, the cast-rolling thin strip is free of pickling and is directly subjected to reducing annealing, so that cold-rolled pickling process is omitted, pre-oxidation process before continuous annealing can be completely abolished, continuity of thin strip production process can be greatly improved, production efficiency is improved, production cost is lowered, discharging of pollutants like waste acid is reduced, and great economic benefit and social benefit are created.

Owner:NORTHEASTERN UNIV LIAONING

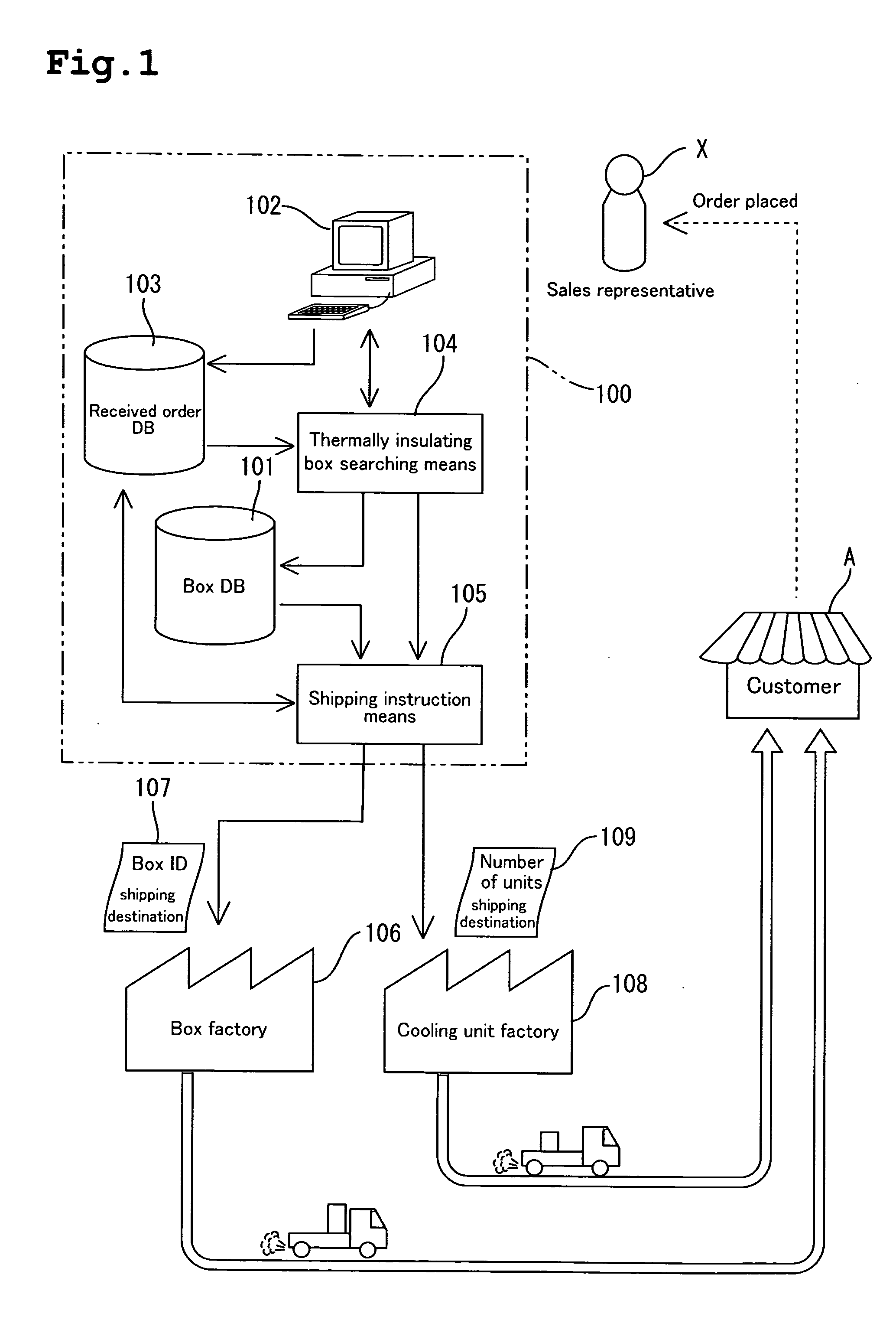

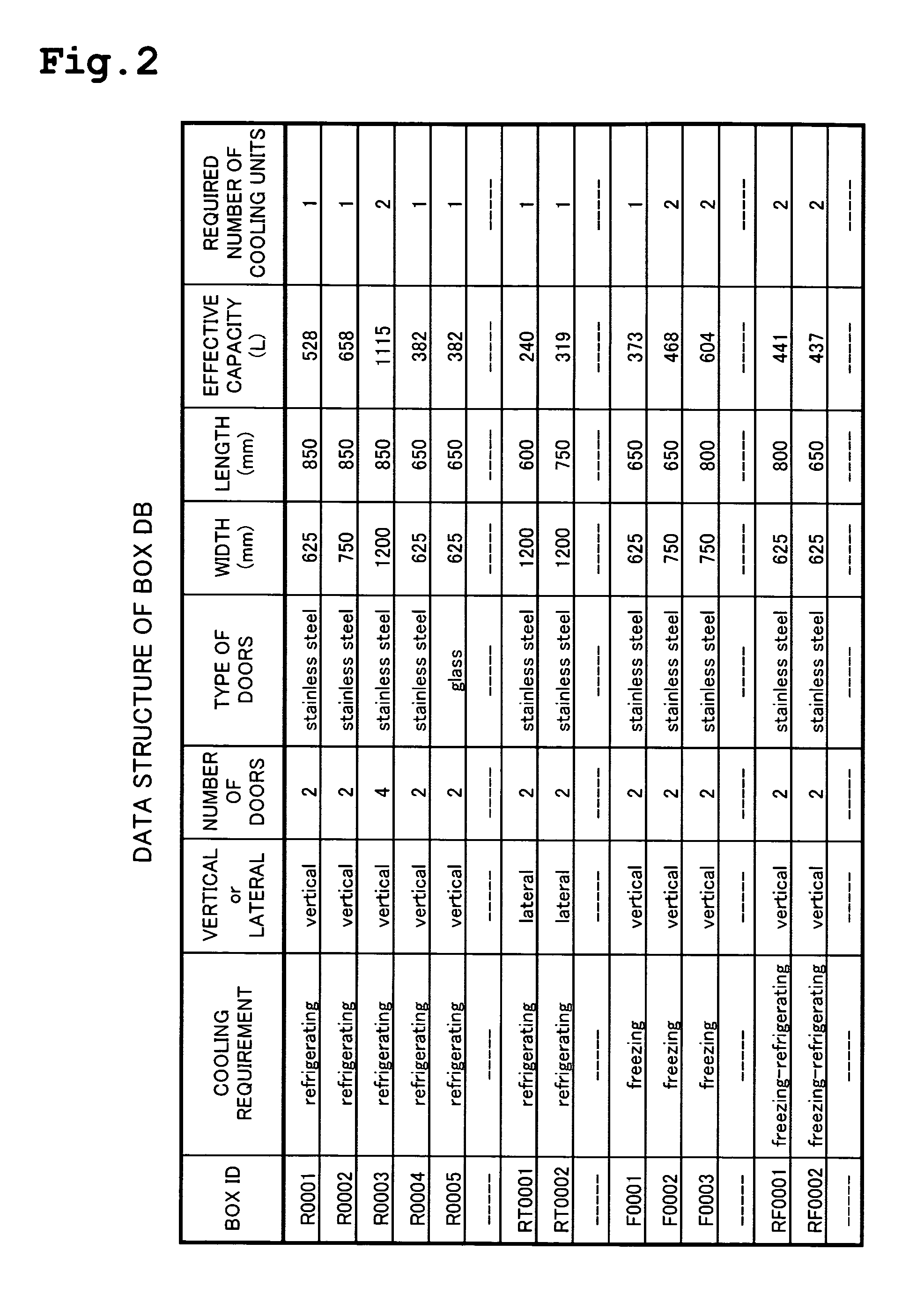

Method of manufacturing refrigerated repositories and sales management system for refrigerated storage

InactiveUS20050092012A1Increase freedomSave energy consumptionShow cabinetsFluid circulation arrangementCool storageCooling capacity

A method of manufacturing cooling storage units and a sales management system is to be provided for the same permitting the exclusion of a made-to-order production system which indispensably requires pre-shipment cooling tests. Thermally insulated boxes of different predetermined sets of specifications, each usable as a freezer, a refrigerator, or a freezer-refrigerator, and cooling units so fabricated as to have a prescribed cooling capacity for any one of the group of thermally insulated boxes are made ready in advance. One thermally insulated box, meeting the specified requirements from the group of thermally insulated boxes, and a matching cooling unit are transported to the installation site of the cooling storage unit. The thermally insulated box and the cooling unit are combined at the installation site to constitute the cooling storage unit.

Owner:HOSHIZAKI ELECTRIC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com