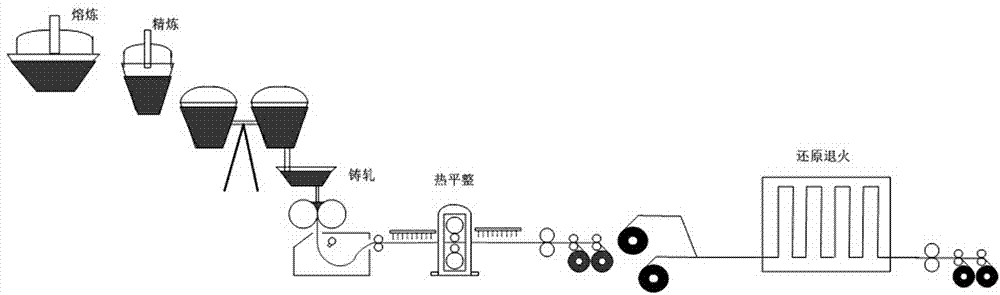

Method for producing hot-rolled pickling-free plate by combining thin-strip continuous casting with reducing annealing

A pickling-free, thin strip technology, applied in the field of material metallurgy, to achieve the effect of ensuring adhesion, huge economic and social benefits, and improving high strength and plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

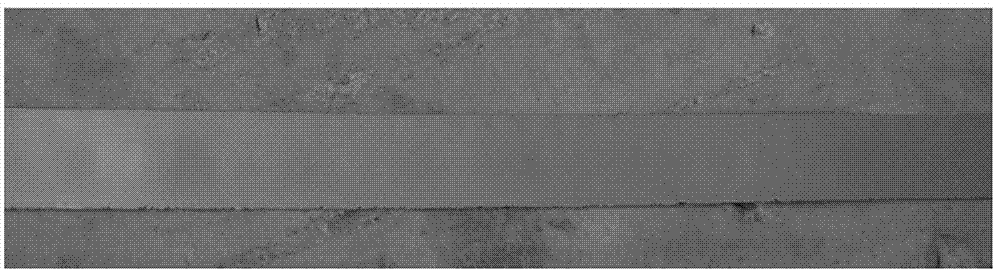

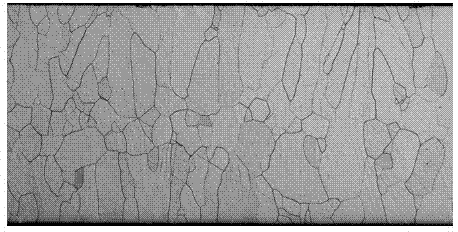

Examples

Embodiment 1

[0029] (1) Smelting and refining:

[0030] According to the composition ratio of the thin strip, by weight percentage, it is C: 0.003%, Si: 0.03%, Mn: 0.22%, Al: 0.02%, S: 0.004%, P: 0.007%, and the rest is Fe ingredients, put into the smelting furnace Smelting in the smelting furnace, when the temperature of the molten steel in the smelting furnace is 1590°C, add a slag remover, and then carry out refining to obtain refined molten steel;

[0031] (2) Preparation of cast-rolled strip:

[0032] The beryllium copper casting roll with coating protection on the surface is used to carry out twin-roll thin strip casting and rolling of the refined molten steel. The pouring temperature of the refined molten steel is 1550°C, the casting and rolling speed is 40m / min, and the preset roll gap is 0.9 mm, protected by inert gas argon during the flow of molten steel to obtain a cast-rolled strip with a thickness of 1.1 mm, and the oxide scale on the surface of the cast-rolled strip is contr...

Embodiment 2

[0038] (1) Smelting and refining:

[0039] According to the composition ratio of the strip, by weight percentage C: 0.04%, Si: 0.04%, Mn: 0.3%, Al: 0.025%, S: 0.006%, P: 0.009%, the balance is Fe ingredients, put into the smelting furnace Smelting in the smelting furnace, when the temperature of the molten steel in the smelting furnace is 1560°C, add a slag remover, and then carry out refining to obtain refined molten steel;

[0040] (2) Preparation of cast-rolled strip:

[0041] The beryllium copper casting roll with coating protection on the surface is used to carry out twin-roll strip casting and rolling of the refined molten steel. The starting temperature of the refined molten steel is 1520°C, the casting and rolling speed is 25m / min, and the preset roll gap is 2mm. , inert gas argon protection is used during the flow of molten steel to obtain a cast-rolled strip with a thickness of 2.1 mm, and the oxide scale on the surface of the cast-rolled strip is controlled at 7 μm...

Embodiment 3

[0048] (1) Smelting and refining:

[0049] According to the composition ratio of thin strip, by weight percentage C: 0.004%, Si: 2.91%, Mn: 0.2%, Al: 0.01%, S: 0.016%, the balance is Fe batching, puts into smelting furnace and smelts, when When the temperature of molten steel in the smelting furnace is 1650°C, add a slag remover, and then carry out refining to obtain refined molten steel;

[0050] (2) Preparation of cast-rolled strip:

[0051] The beryllium copper casting roll with coating protection on the surface is used to carry out twin-roll thin strip casting and rolling of the refined molten steel. The pouring temperature of the refined molten steel is 1600 ℃, the casting and rolling speed is 10m / min, and the preset roll gap is 2.0 mm, protected by inert gas argon during the flow of molten steel to obtain a cast-rolled strip with a thickness of 2.1 mm, and the oxide scale on the surface of the cast-rolled strip is controlled at 7 μm;

[0052] (3) Thermal leveling:

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com