Patents

Literature

159results about How to "Lower outlet temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

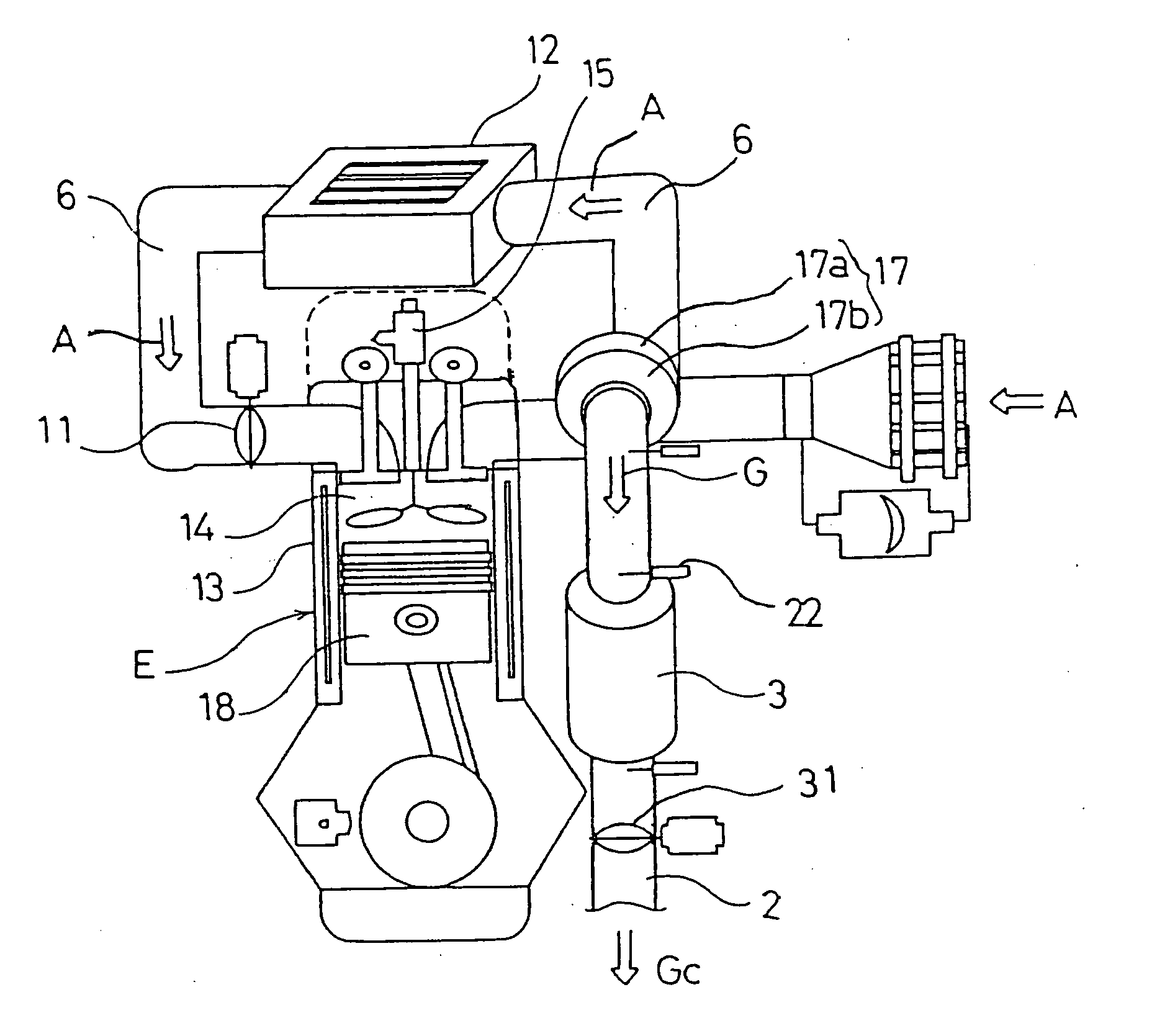

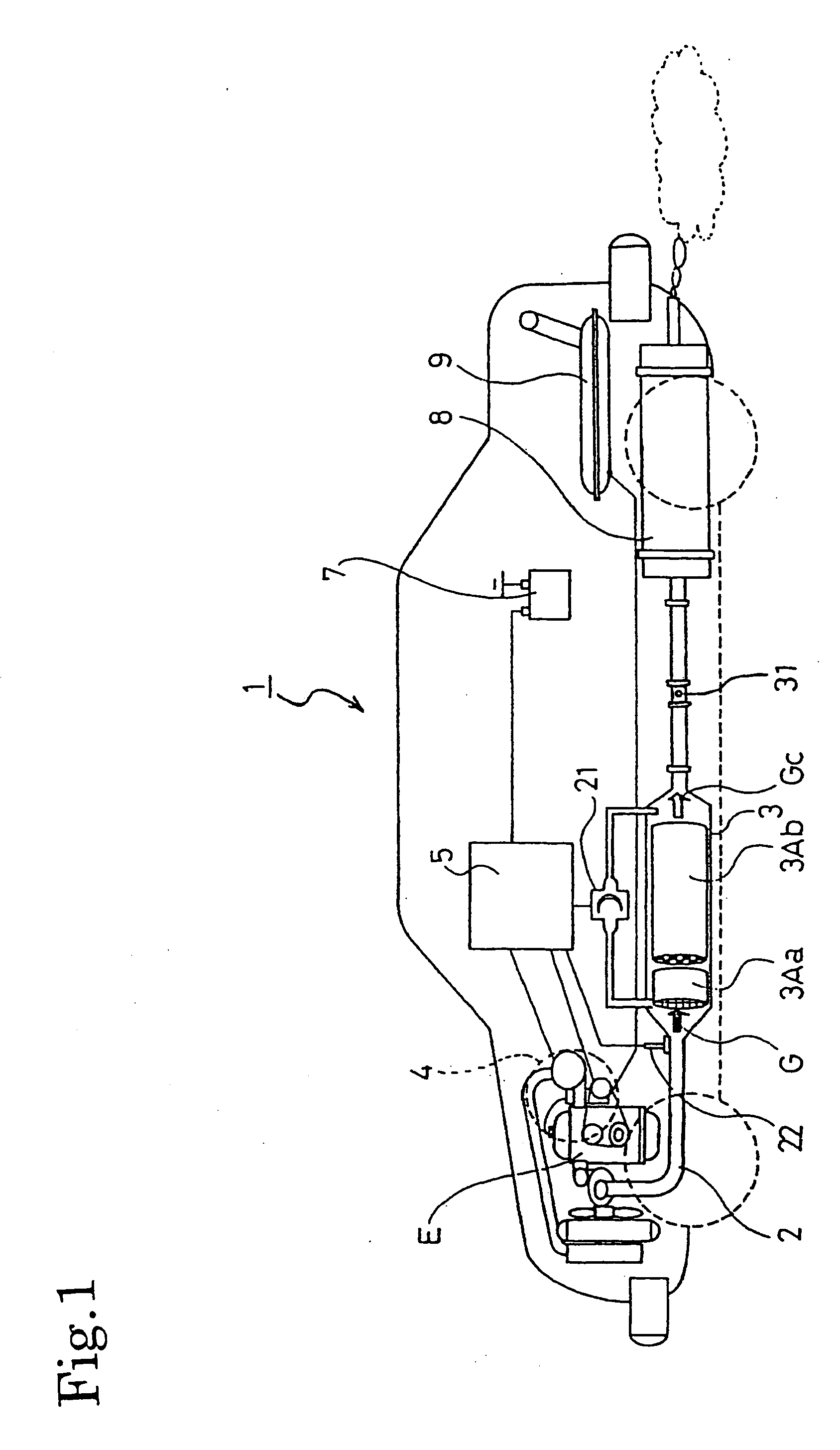

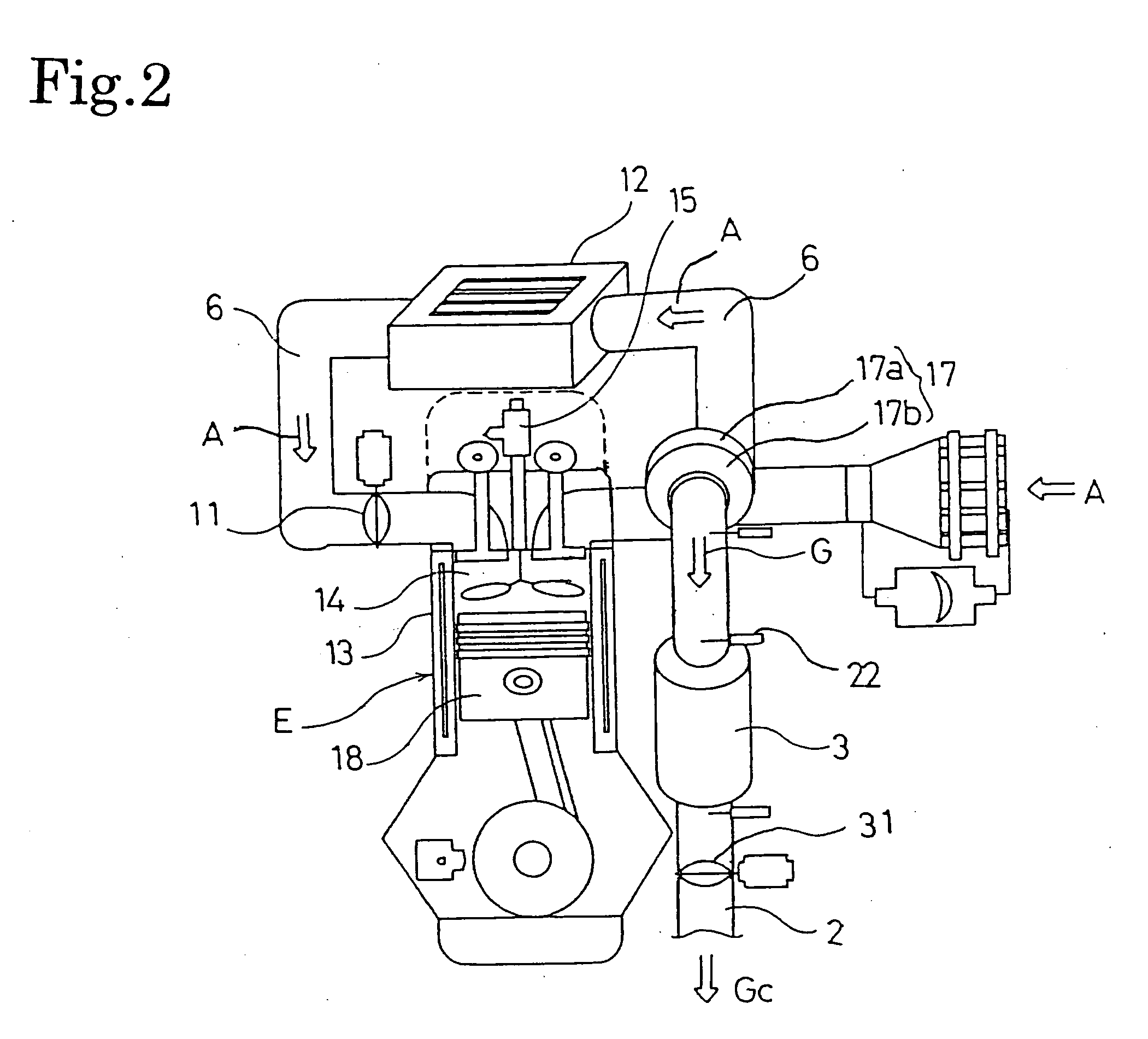

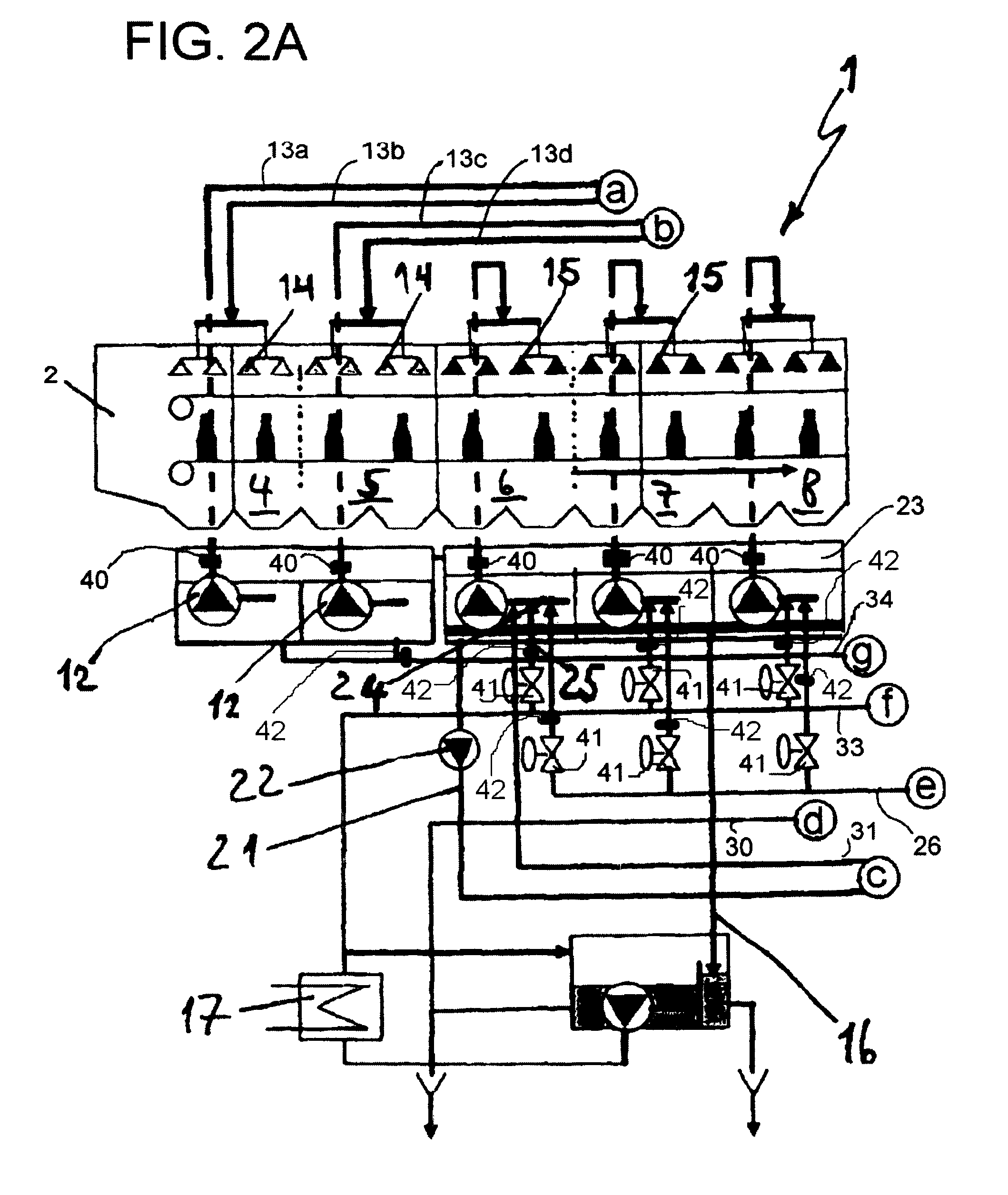

Exhaust gas purifying system

ActiveUS6966179B2Efficiently raising temperature of exhaust gasLower outlet temperatureElectrical controlInternal combustion piston enginesThrottle controlLow load

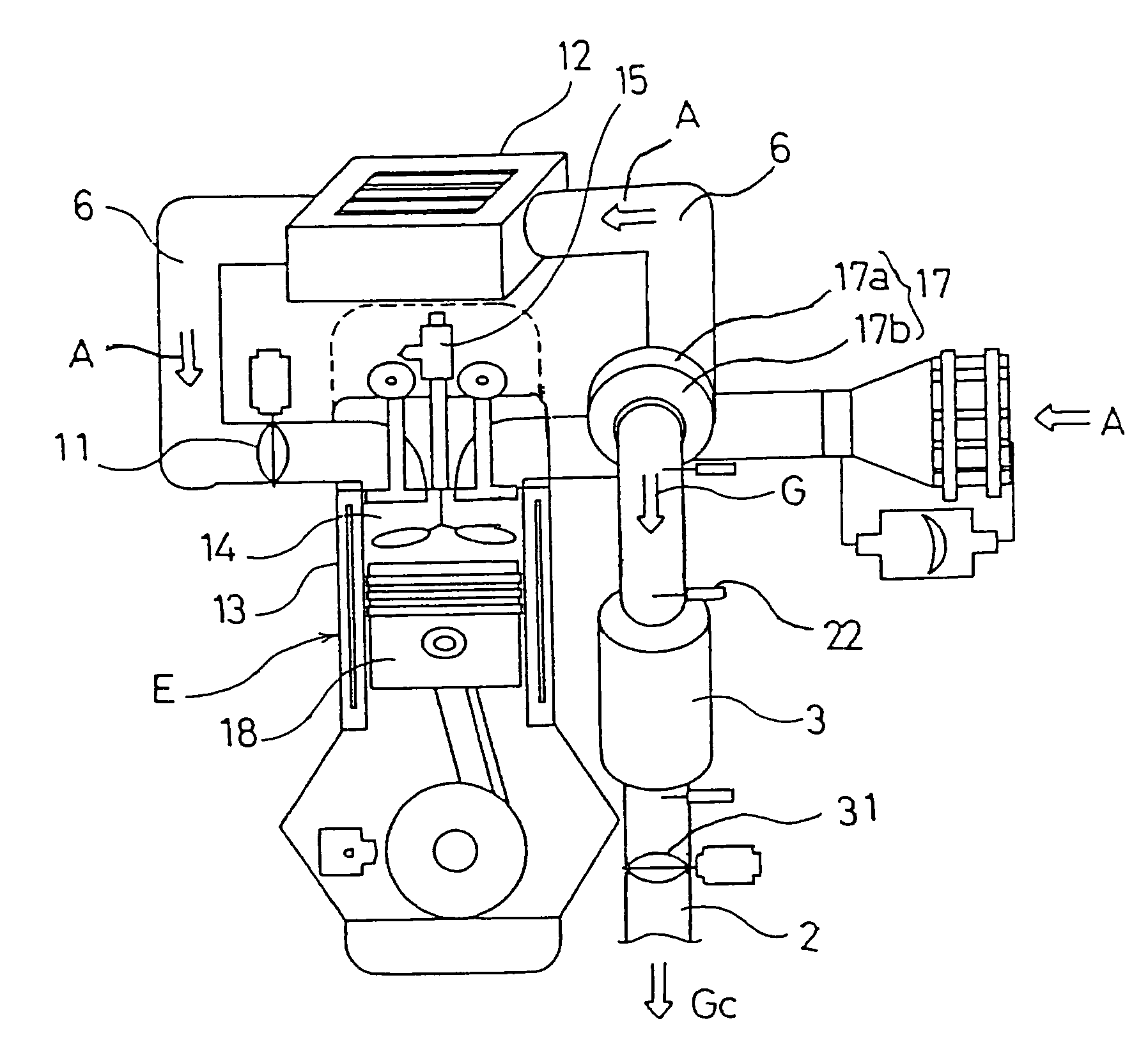

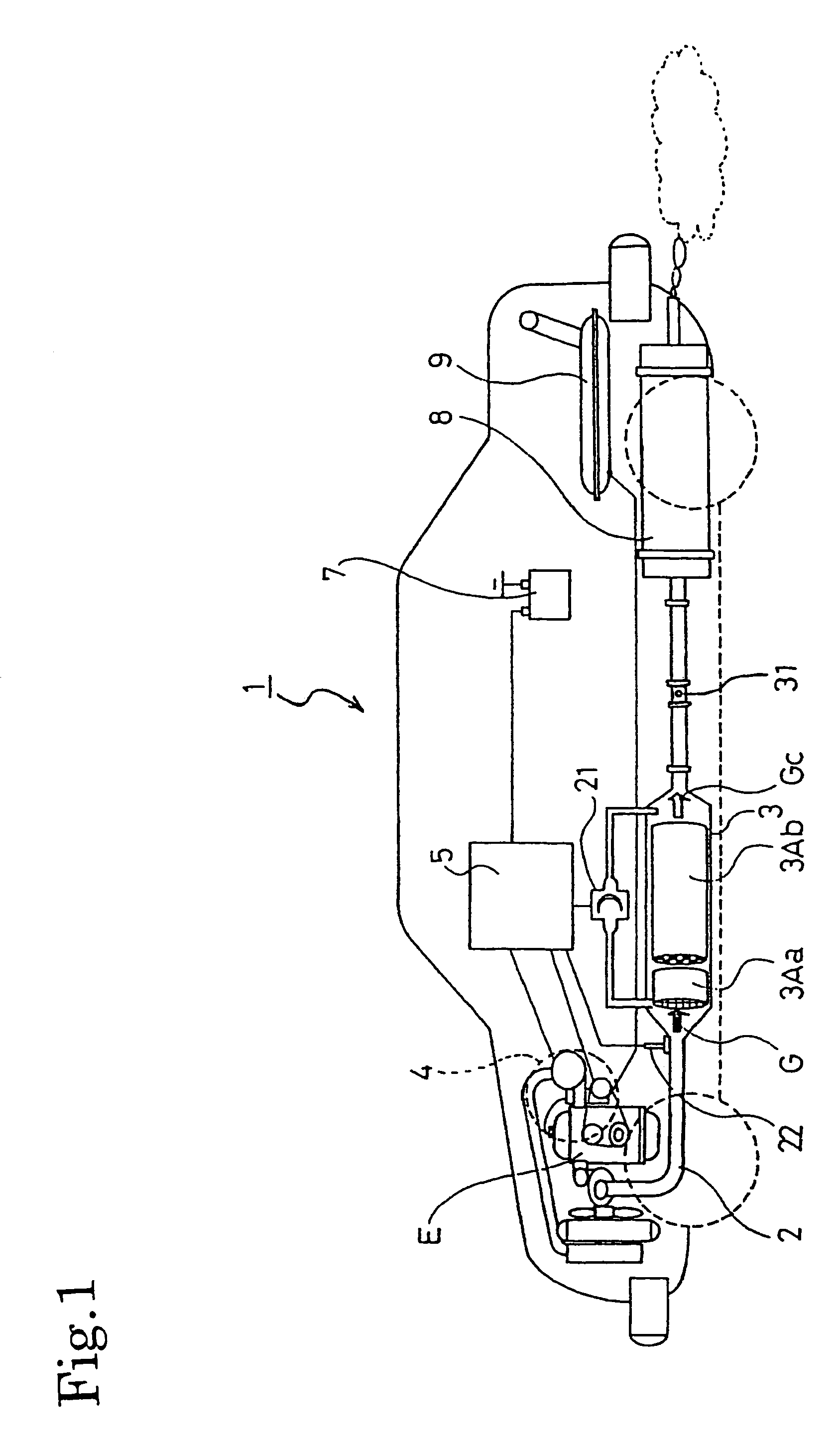

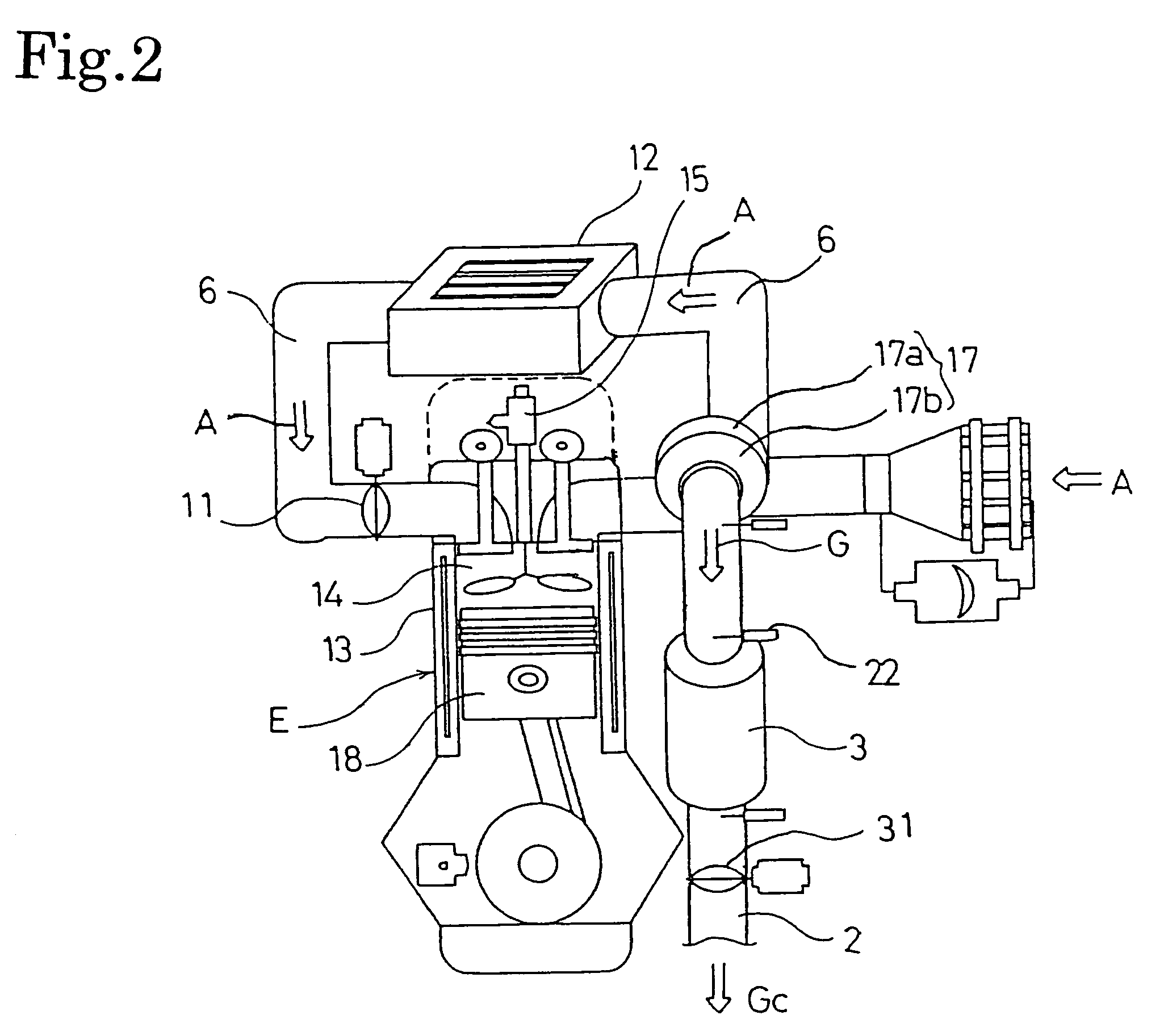

To provide an exhaust gas purifying system capable of forcibly regenerating DPF by efficiently raising the temperature of exhaust gas even when an exhaust gas temperature is very low at the time of low load and low engine speed such as an idling operation. In an exhaust purifying system (1) having an exhaust throttling valve (31) and a DPF (3) in an exhaust passage and having regeneration control means (P1) for regenerating the DPF (3), the regeneration control means (P1) is provided with an exhaust gas temperature detection means (P22), a fuel injection control means (P11), and an exhaust throttling control means (P12) and includes regeneration control for performing the exhaust gas temperature raising control through the multistage delay injection by the fuel injection control means (P11) and through the exhaust throttling of the exhaust throttling valve (31).

Owner:ISUZU MOTORS LTD

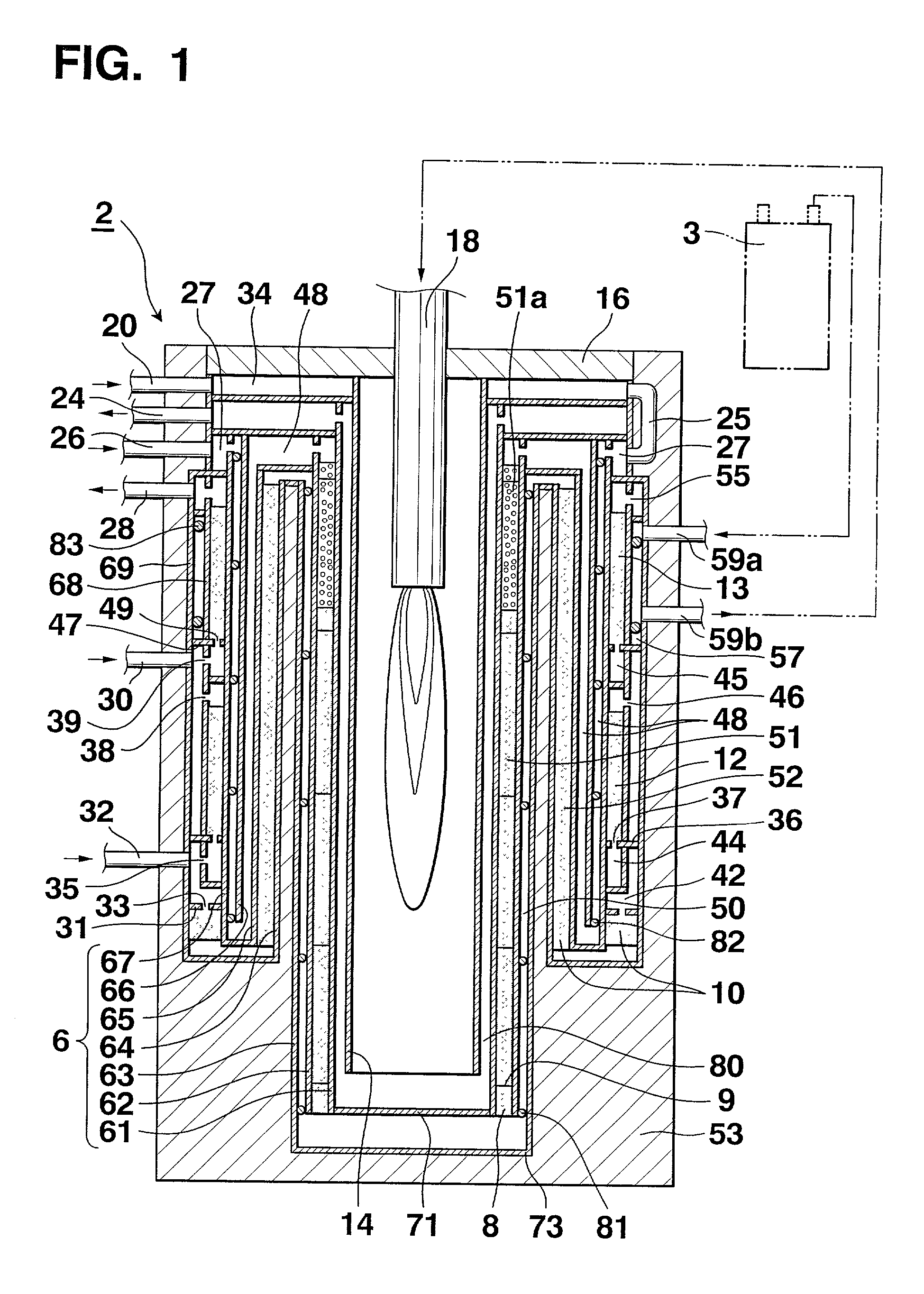

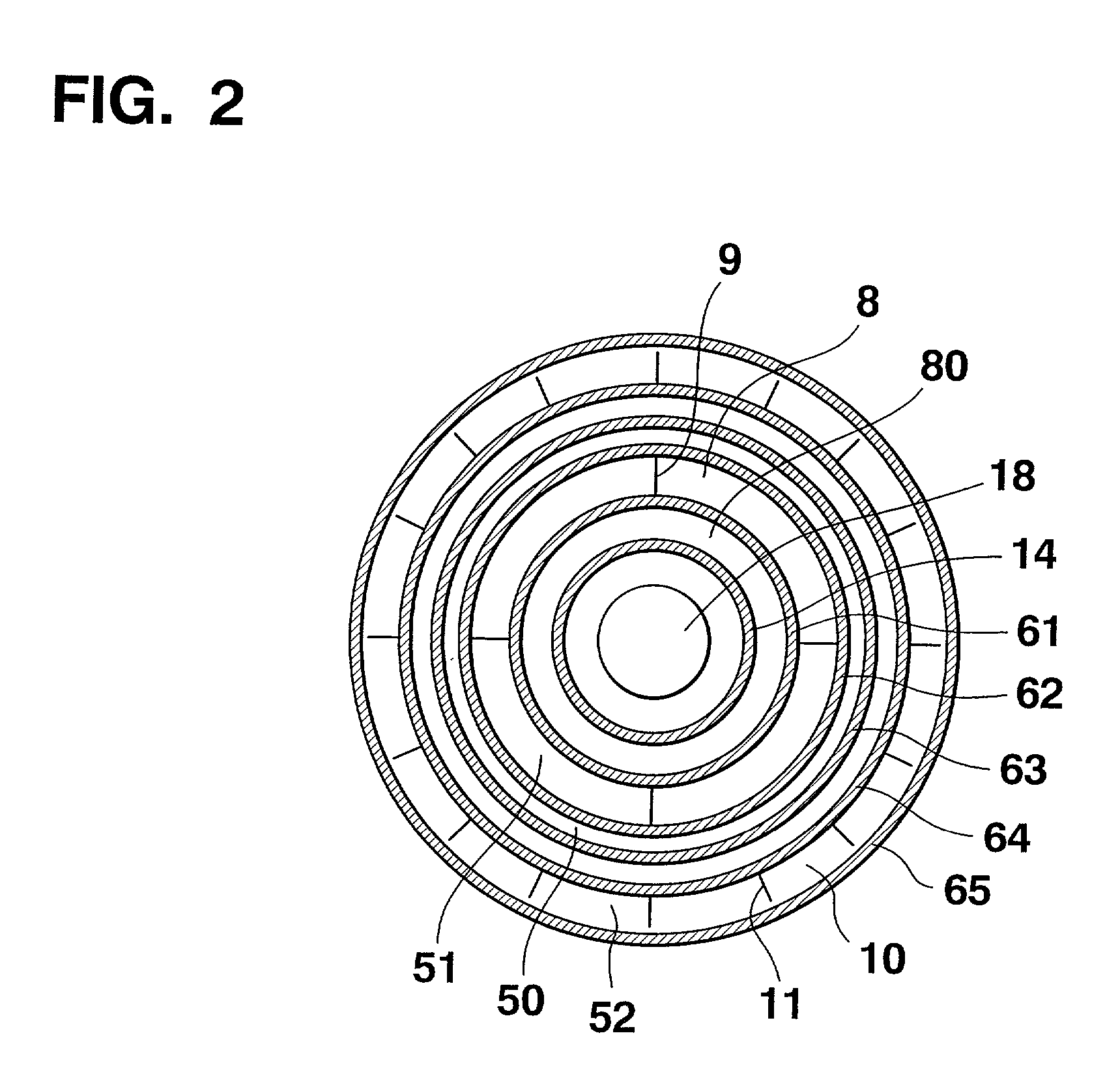

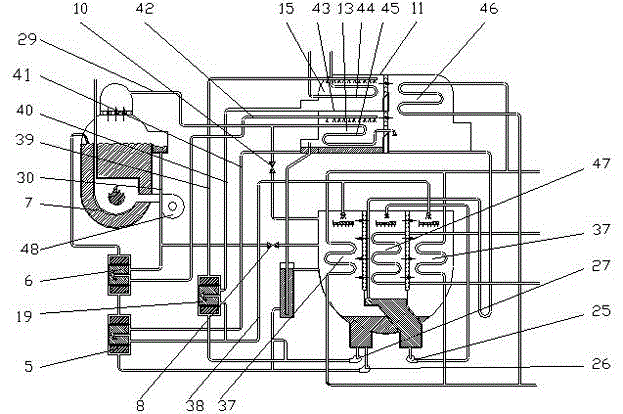

Single-pipe cylinder type reformer

InactiveUS20020042035A1Efficient executionReduce heatPhysical/chemical process catalystsHydrogen separation using solid contactCombustorEngineering

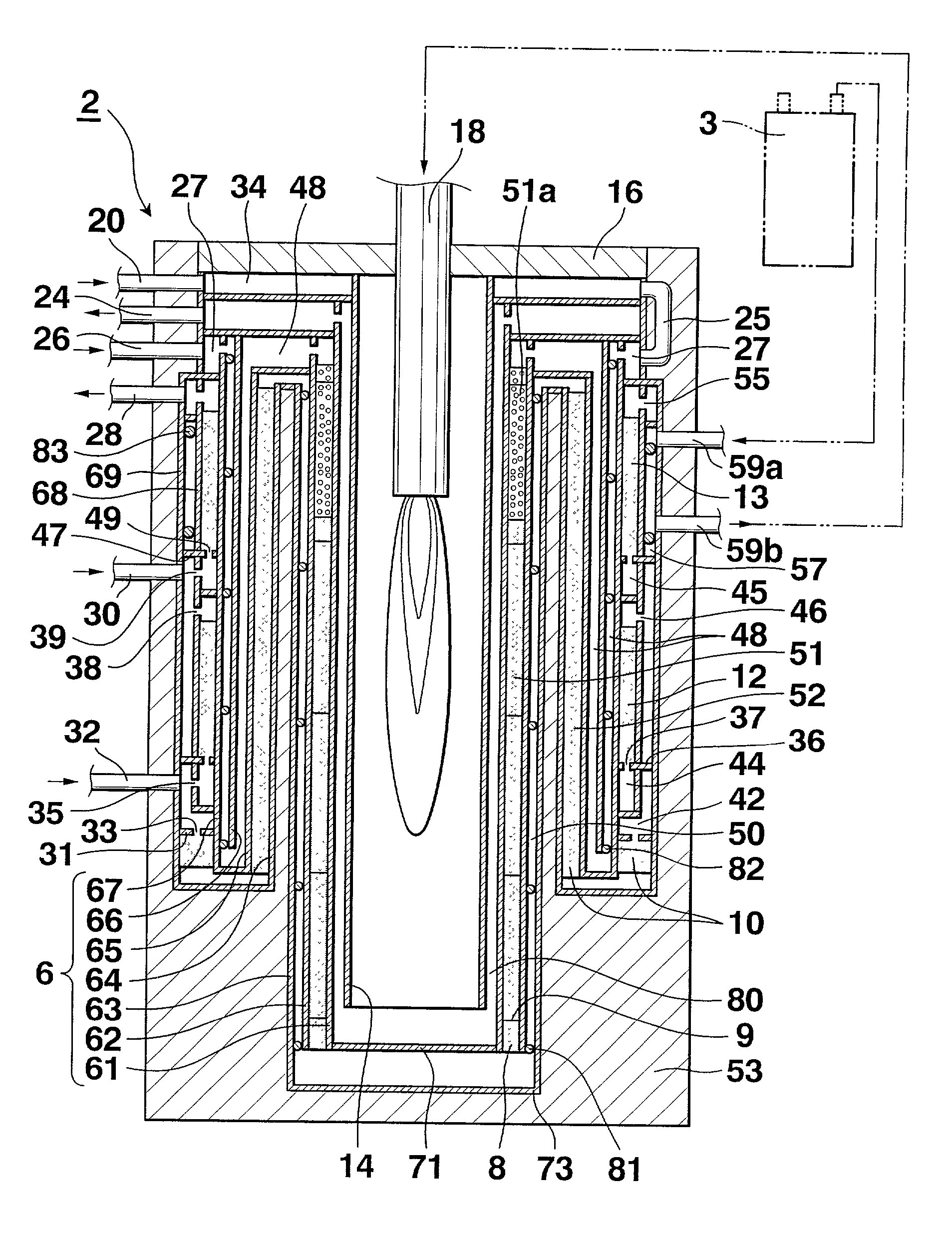

A single-pipe cylinder type reformer of the invention includes a plurality of circular cylinders standing upright coaxially, a radiation cylinder coaxially arranged inside the plurality of circular cylinders, and a burner arranged at one end of the center of the radiation cylinder, and has a reforming catalyst layer obtained by packing with a reforming catalyst at least a first gas flow path closest to the burner among a plurality of gas flow paths divided by the plurality of circular cylinders and having annular cross-sections. A pre-heat layer formed on one end side (upstream) of the reforming catalyst layer packed with the reforming catalyst is packed with a metal packing. Helical dividing means are provided in the respective gas flow paths to extend in the axial direction of the circular cylinders. The helical dividing means helically divide a gas and makes it flow through the first gas flow path.

Owner:TOKYO GAS CO LTD

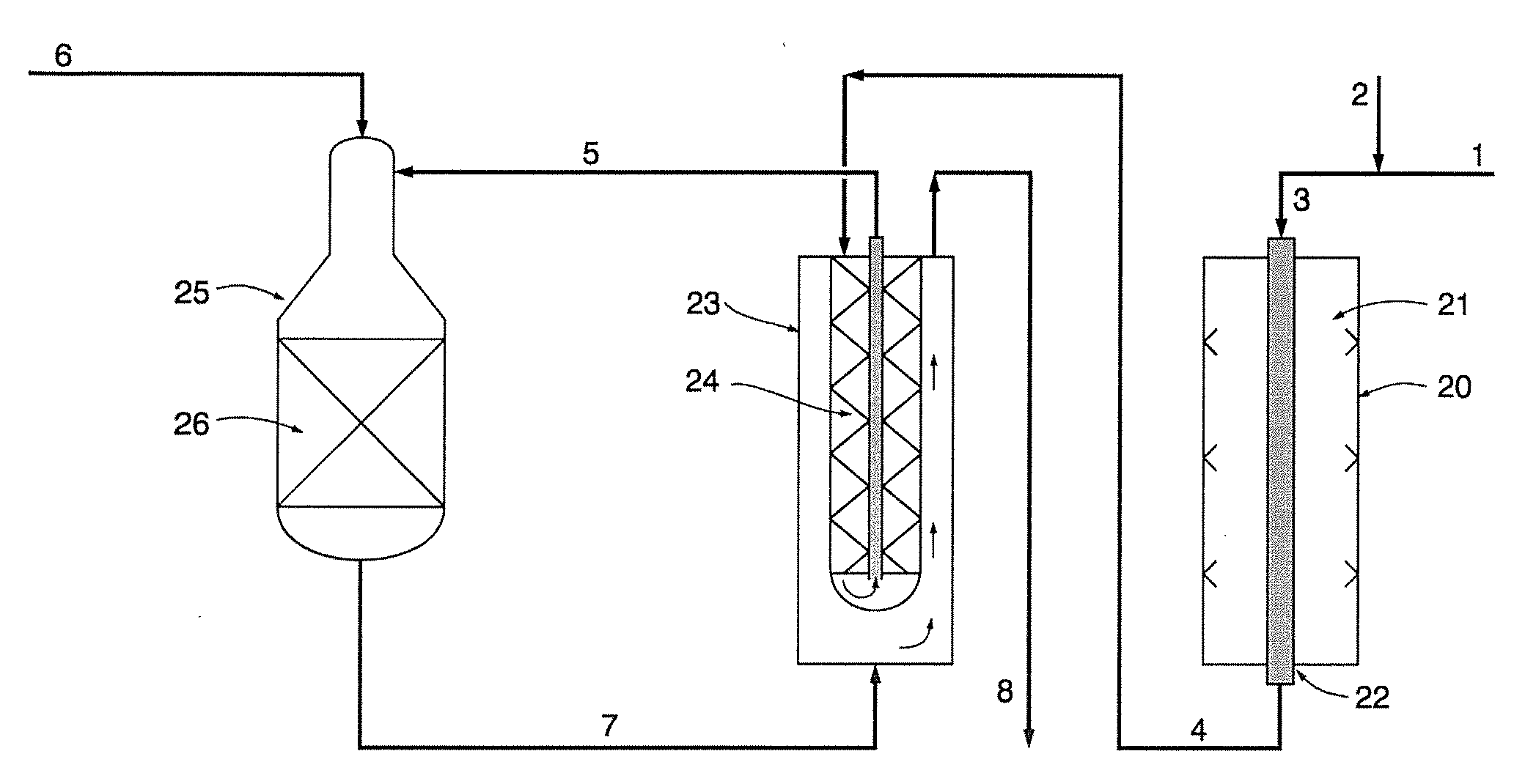

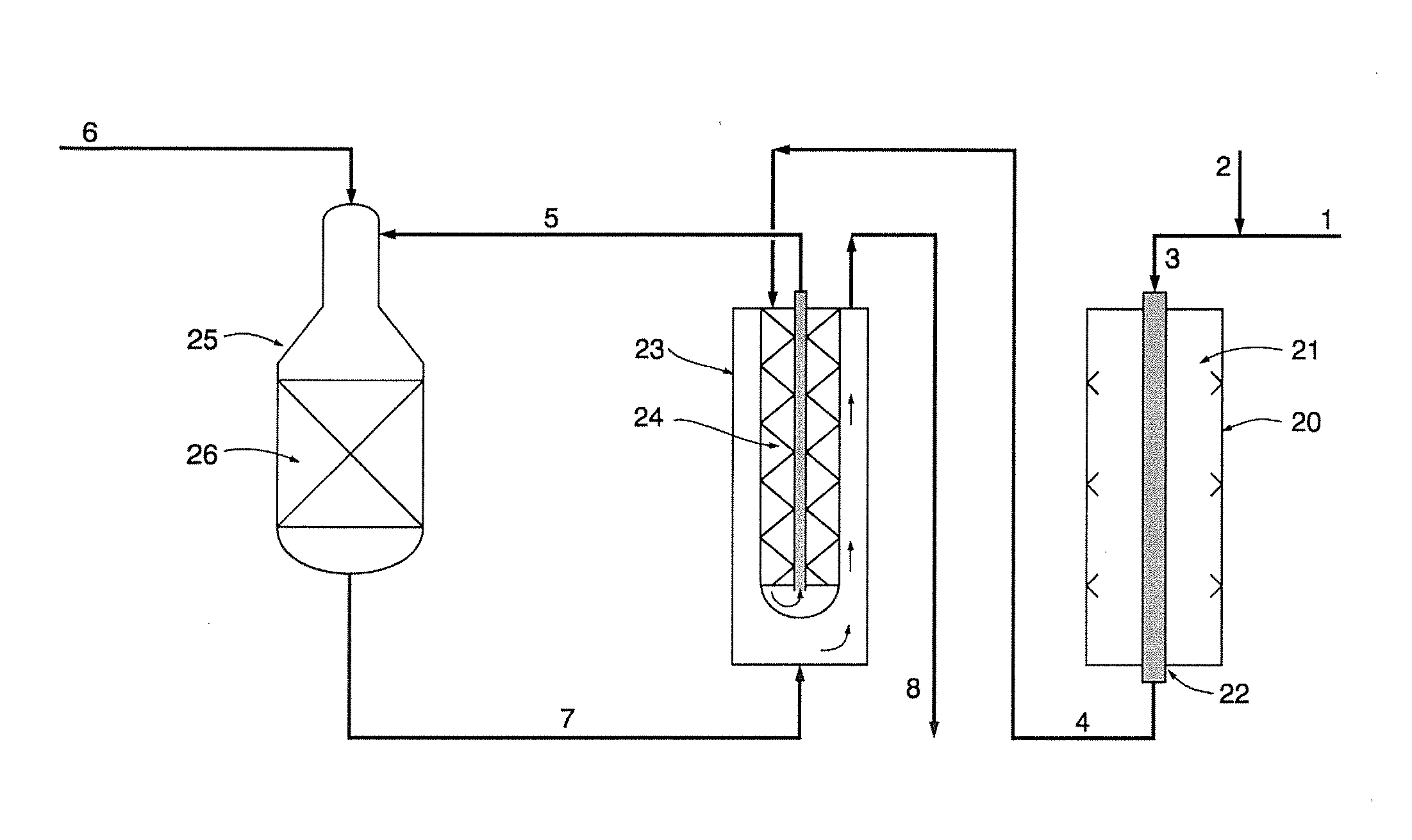

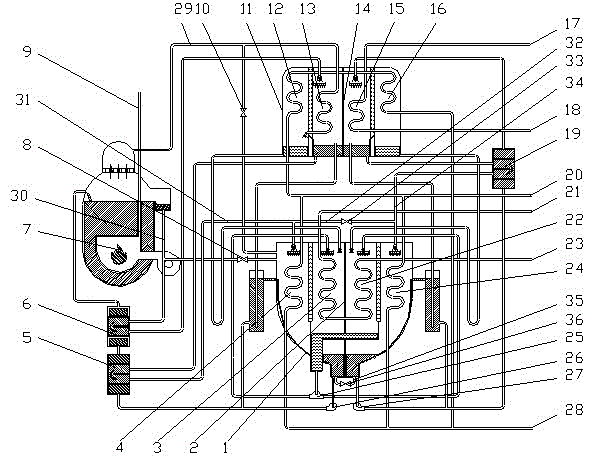

Process for reforming hydrocarbons

InactiveUS20090184293A1High propensityEliminate poisonHydrocarbon from carbon oxidesHydrogen productionHydrocarbonChemistry

The invention relates to a process for the production of synthesis gas from a hydrocarbon feedstock, wherein the entire hydrocarbon feed is passed through a radiant furnace, heat exchanger reformer and autothermal reformer in a series arrangement, and in which effluent gas from the autothermal reformer is used as heat source for the reforming reactions occurring in the heat exchange reformer.

Owner:HALDOR TOPSOE AS

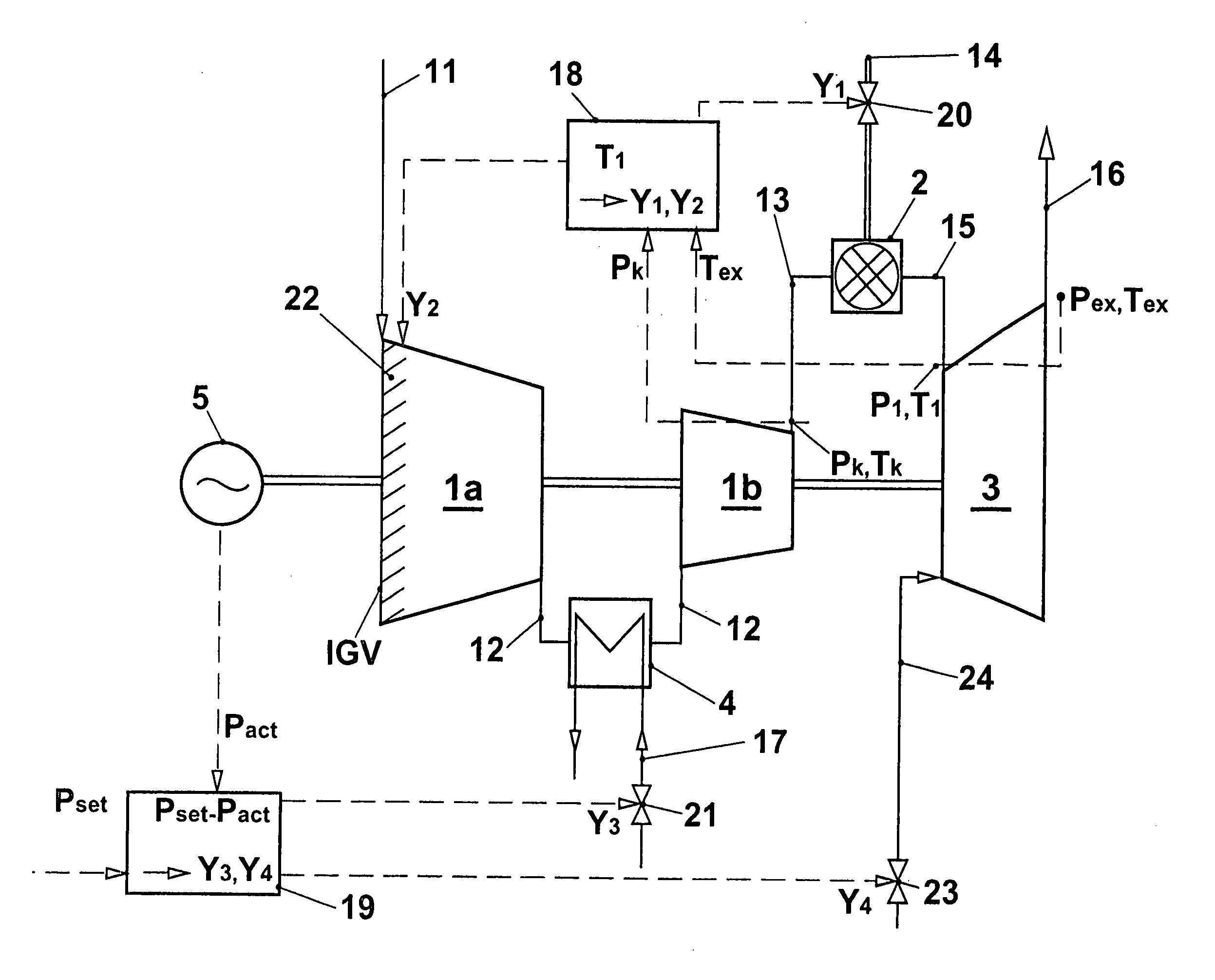

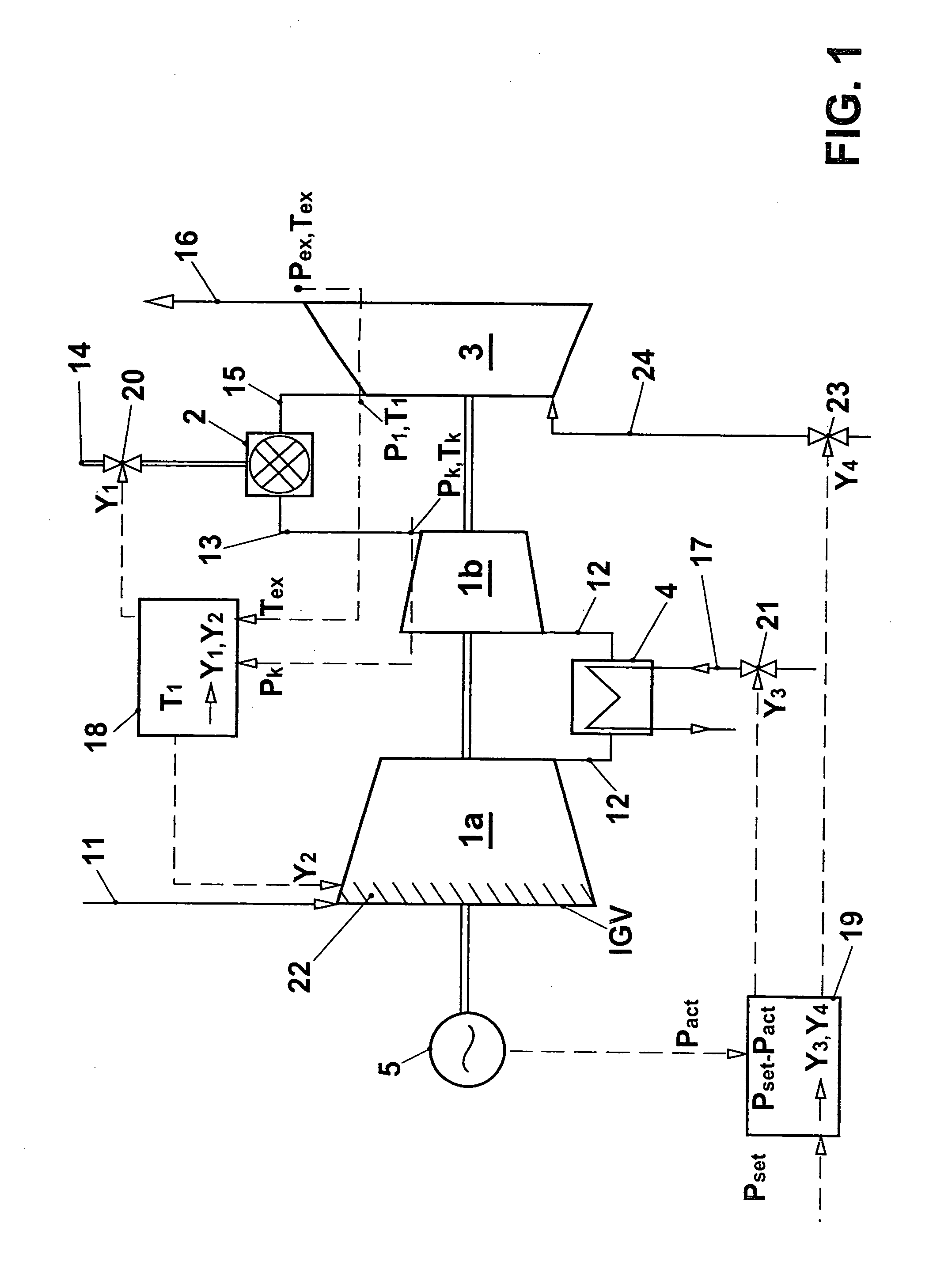

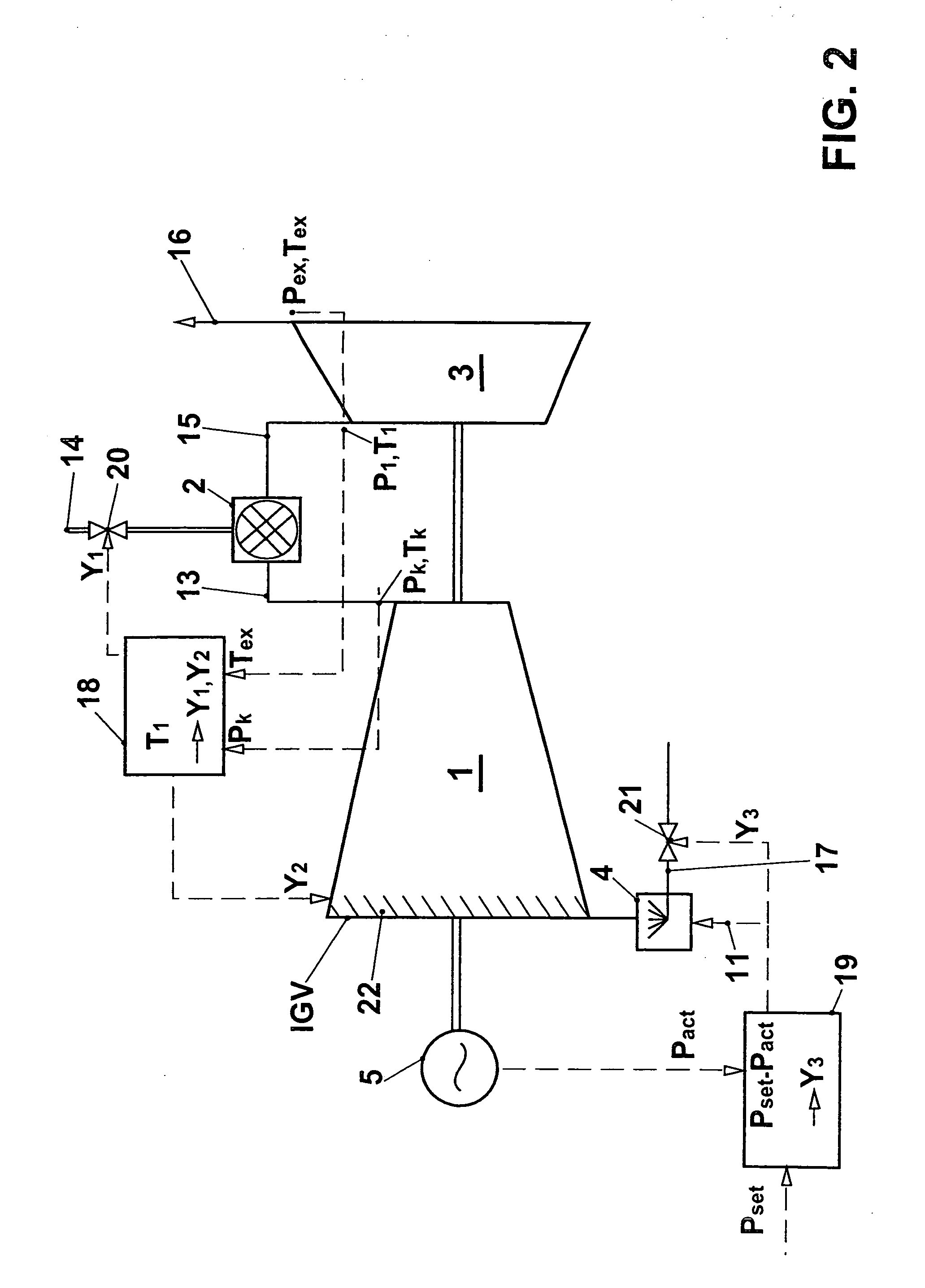

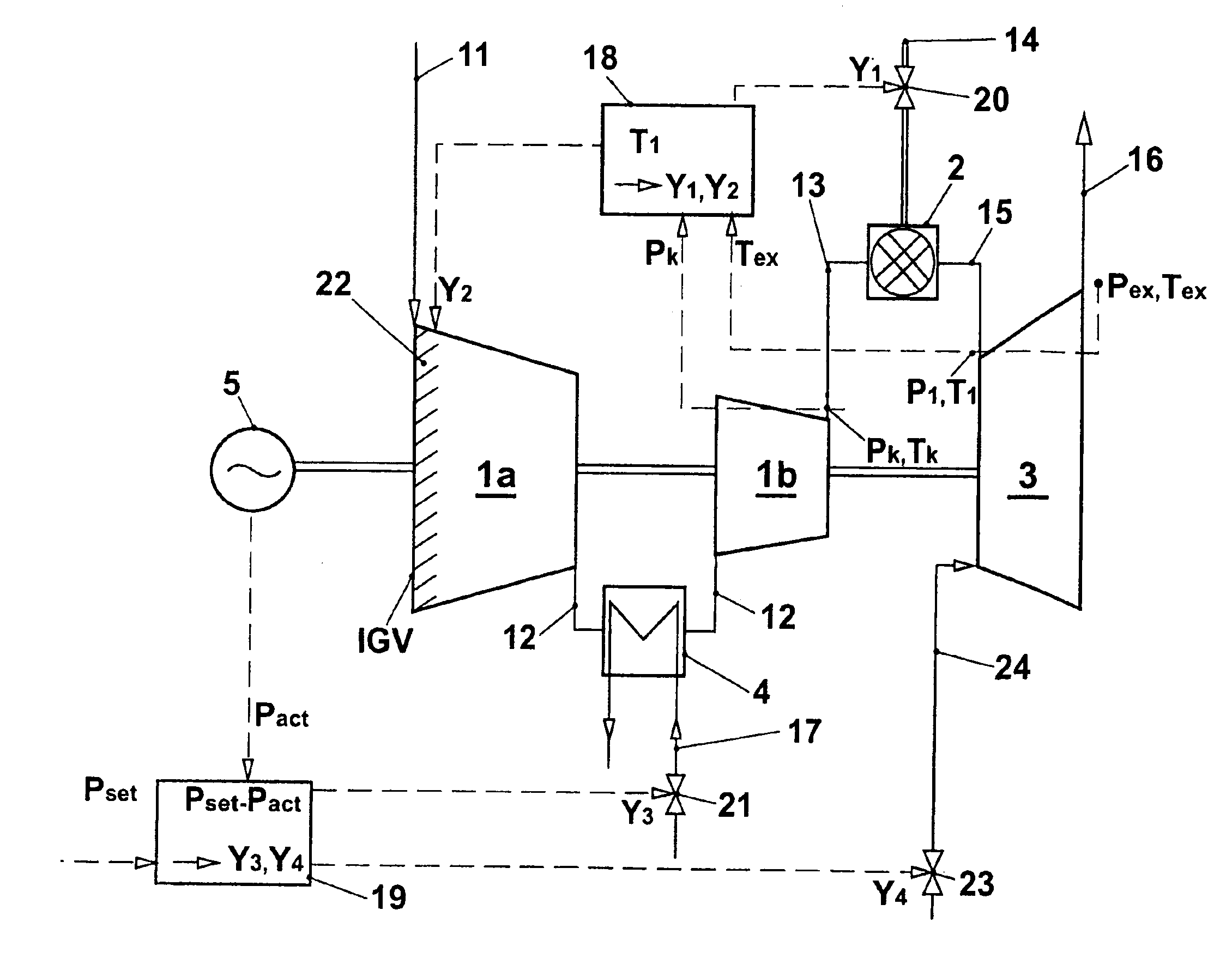

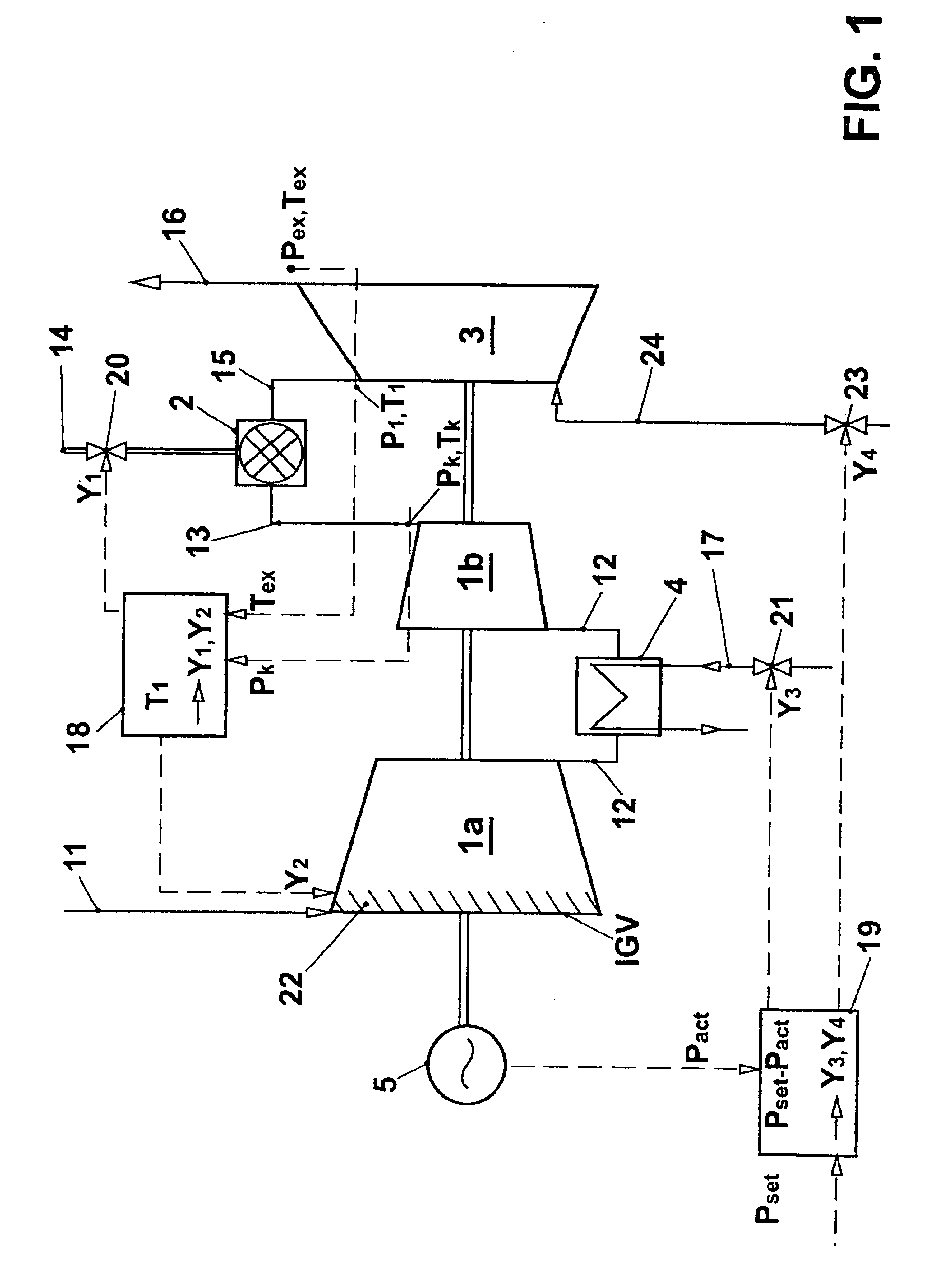

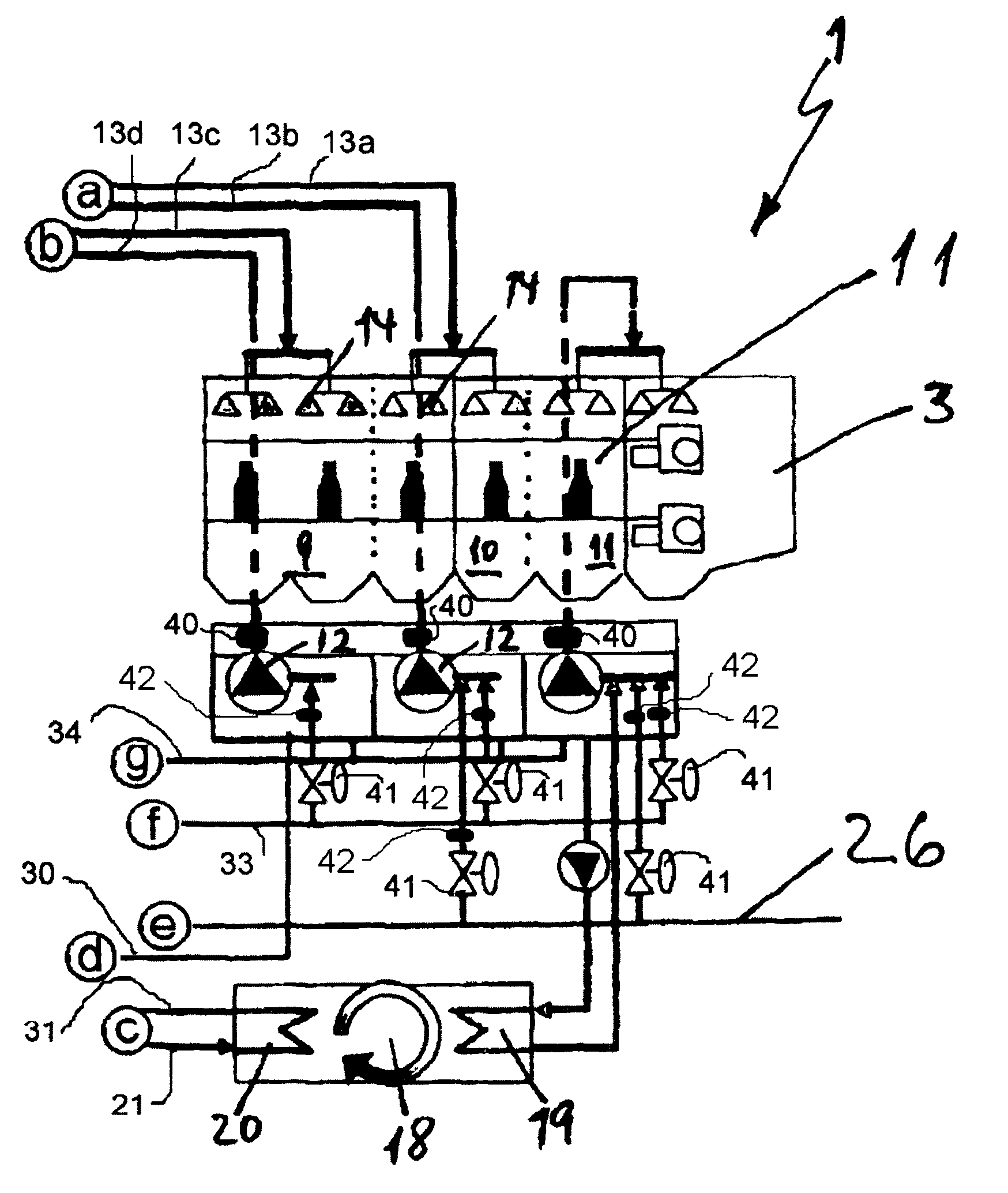

Method for operating a gas turbine group

InactiveUS20050109033A1Increase powerReduces compressor outlet temperatureEngine fuctionsGas turbine plantsCooling powerLimit value

A gas turbine group is provided with at least one cooling apparatus for cooling the working medium before and / or during the compression. The cooling power of the cooling apparatus can be adjusted by suitable means. A controller controls the cooling power of the cooling apparatus as a function of a control deviation in the useful power of the gas turbine group. The cooling controller interacts with other controllers of the gas turbine group in such a way that the gas turbine group is itself always operated at least close to its full load operating state. In this context, it is preferable for the inlet guide vane row of the compressor to be maximally open, and for the hot-gas temperature on entry into the turbines to be controlled so that it is constantly at an upper limit value.

Owner:ANSALDO ENERGIA IP UK LTD

Exhaust gas purifying system

ActiveUS20050044845A1Increase exhaust pressureImprove combustion performanceElectrical controlInternal combustion piston enginesThrottle controlLow load

To provide an exhaust gas purifying system capable of forcibly regenerating DPF by efficiently raising the temperature of exhaust gas even when an exhaust gas temperature is very low at the time of low load and low engine speed such as an idling operation. In an exhaust purifying system (1) having an exhaust throttling valve (31) and a DPF (3) in an exhaust passage and having regeneration control means (P1) for regenerating the DPF (3), the regeneration control means (P1) is provided with an exhaust gas temperature detection means (P22), a fuel injection control means (P11), and an exhaust throttling control means (P12) and includes regeneration control for performing the exhaust gas temperature raising control through the multistage delay injection by the fuel injection control means (P11) and through the exhaust throttling of the exhaust throttling valve (31).

Owner:ISUZU MOTORS LTD

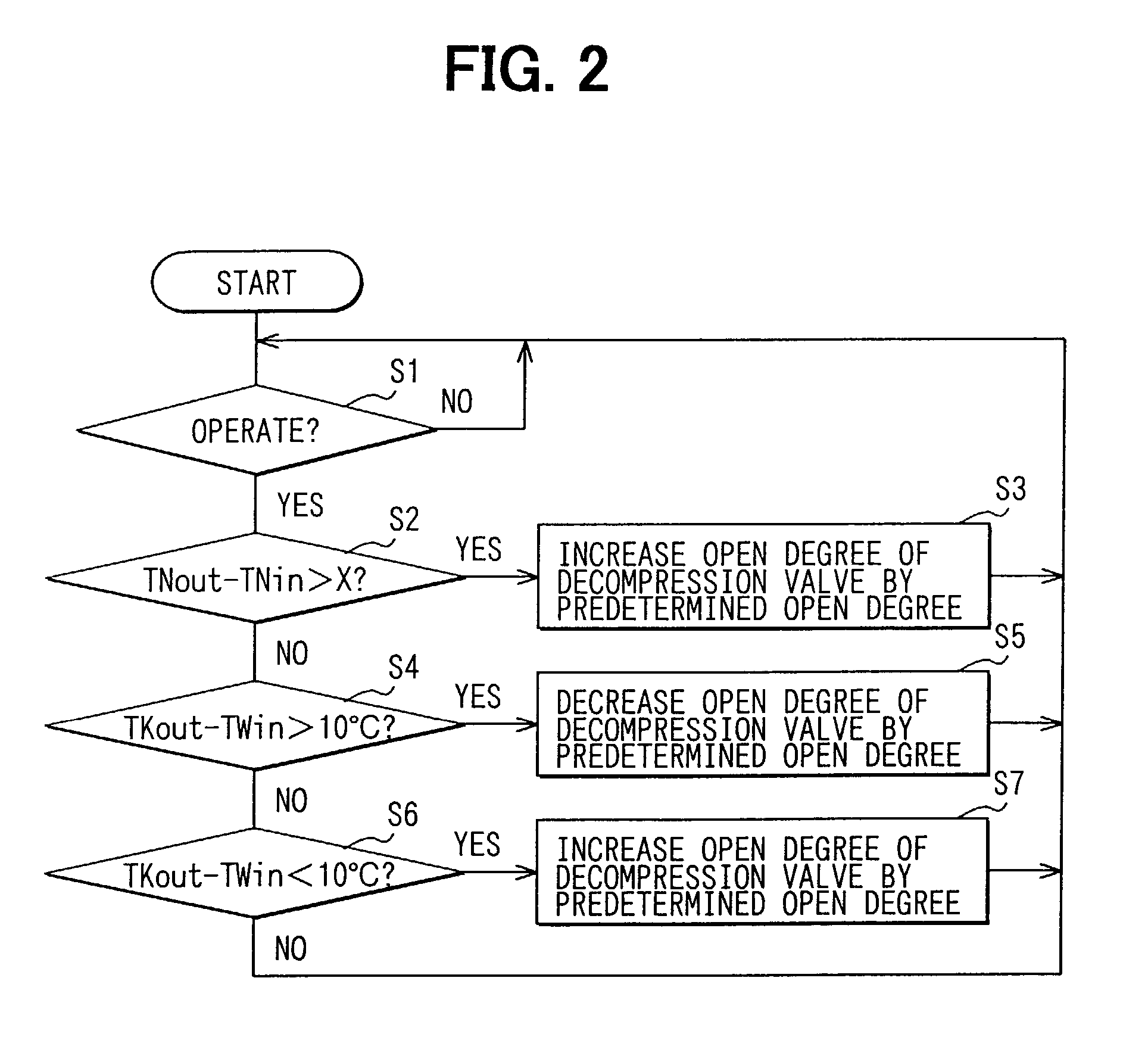

Super-critical refrigerant cycle system and water heater using the same

InactiveUS7076964B2Suppress amount of heat exchangeLower outlet temperatureCompressorHeat pumpsWater flowEngineering

Owner:DENSO CORP

Method for operating a gas turbine group

InactiveUS7104071B2Increase powerIncrease mass flowEngine fuctionsGas turbine plantsCooling powerLimit value

A gas turbine group is provided with at least one cooling apparatus for cooling the working medium before and / or during the compression. The cooling power of the cooling apparatus can be adjusted by suitable means. A controller controls the cooling power of the cooling apparatus as a function of a control deviation in the useful power of the gas turbine group. The cooling controller interacts with other controllers of the gas turbine group in such a way that the gas turbine group is itself always operated at least close to its full load operating state. In this context, it is preferable for the inlet guide vane row of the compressor to be maximally open, and for the hot-gas temperature on entry into the turbines to be controlled so that it is constantly at an upper limit value.

Owner:ANSALDO ENERGIA IP UK LTD

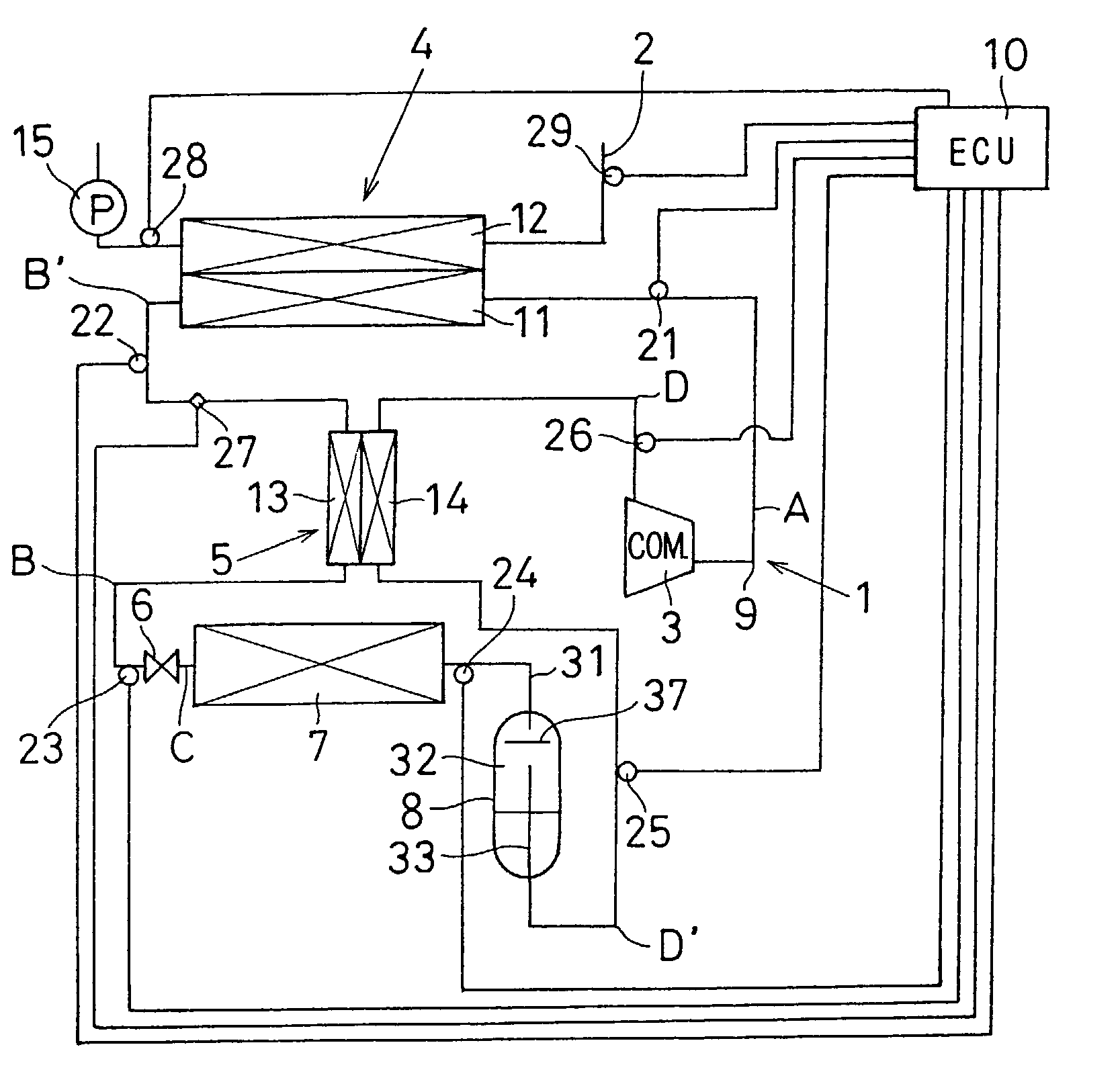

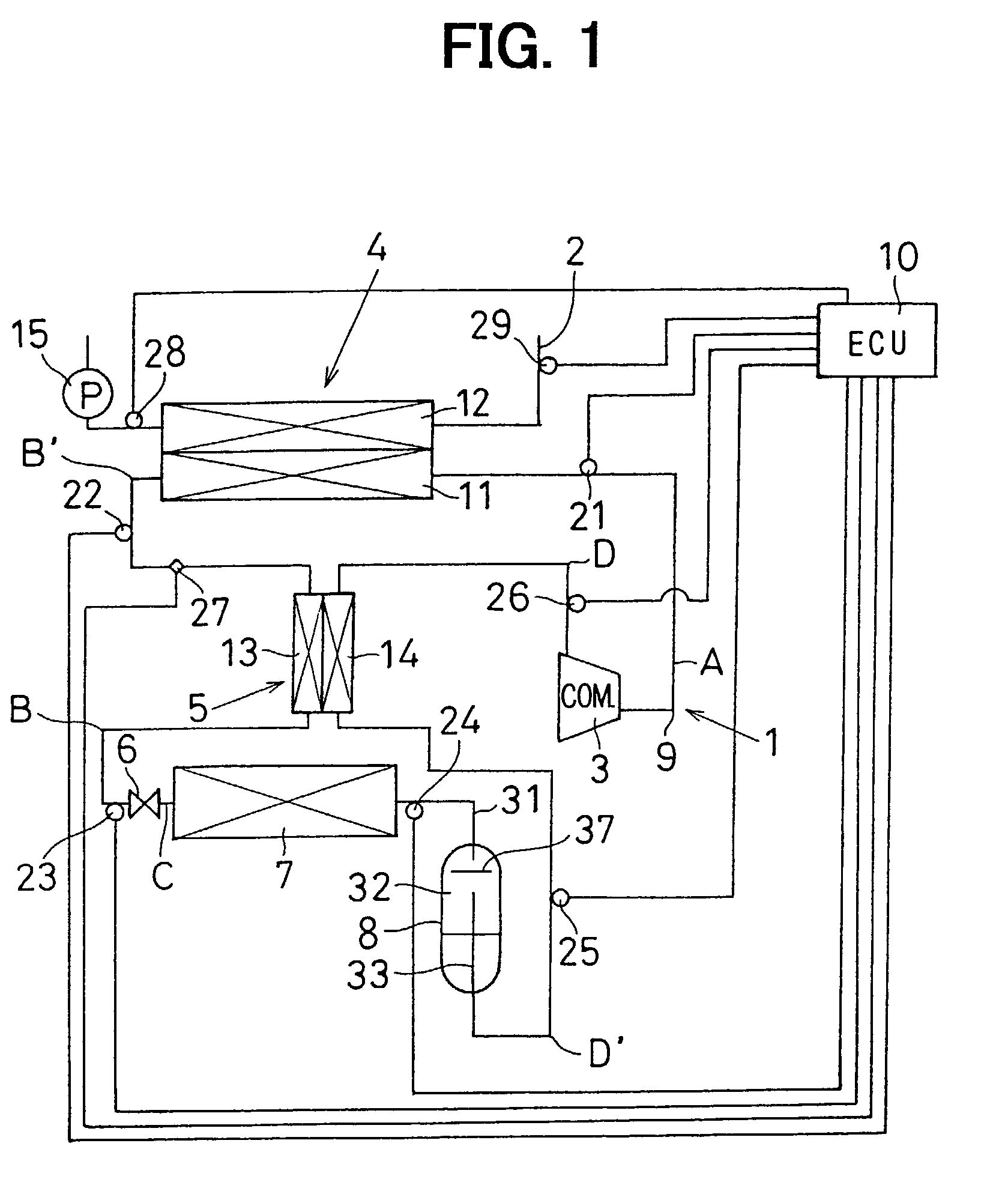

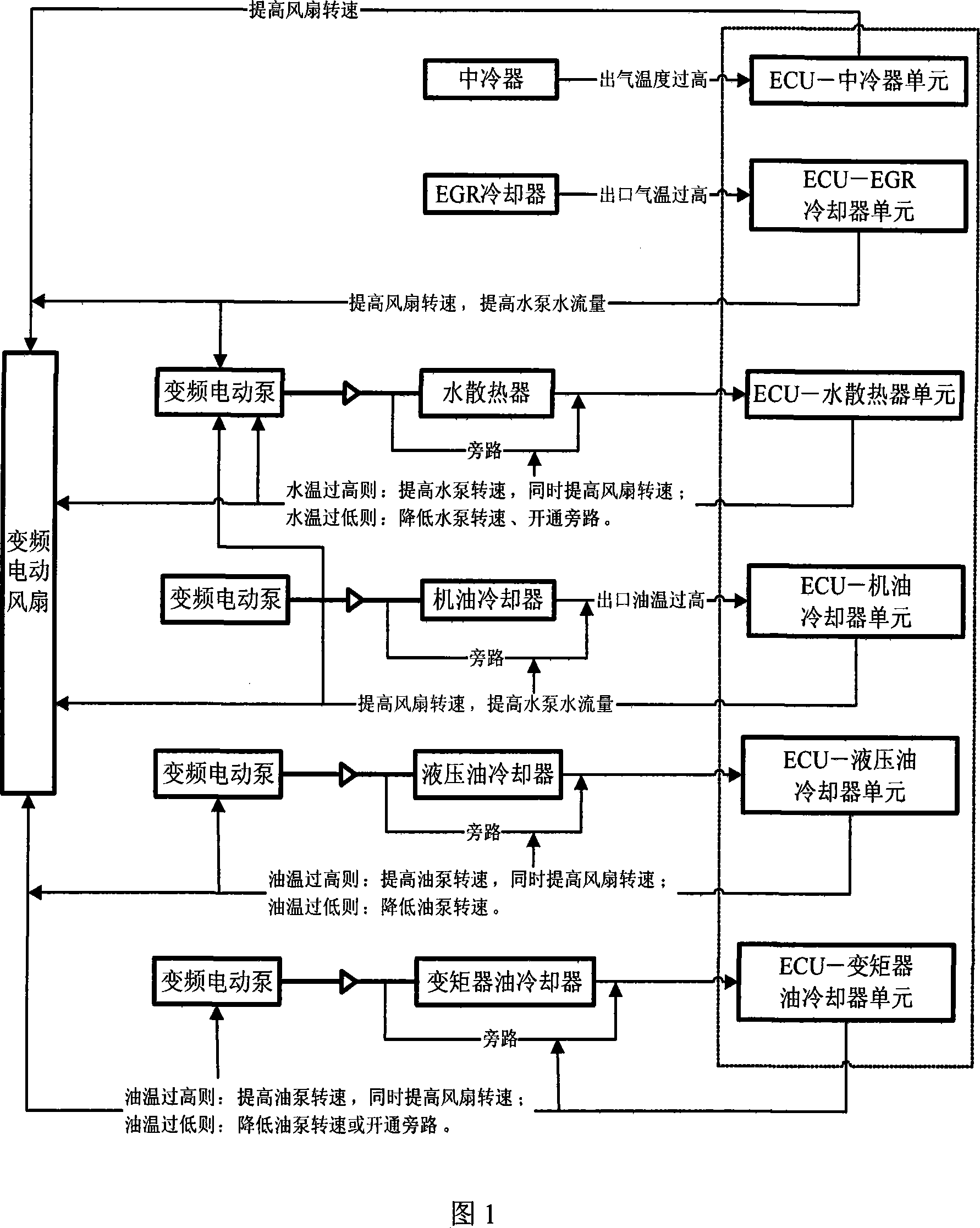

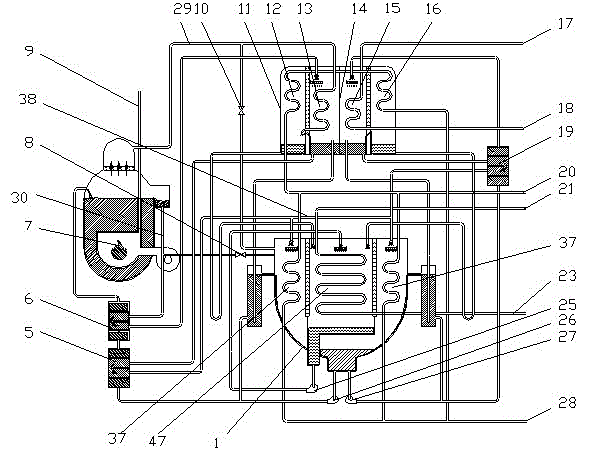

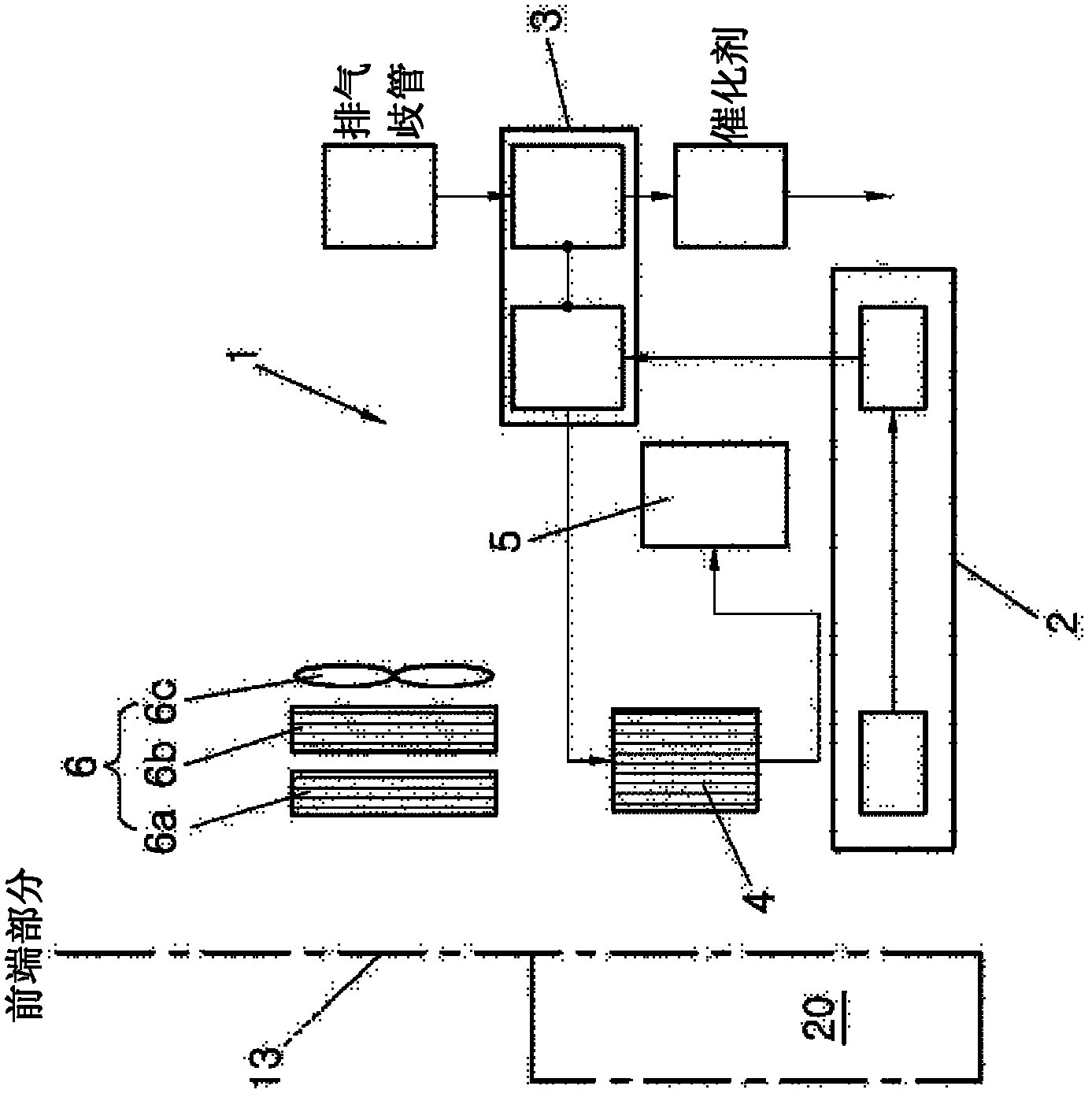

Intelligentized heat management system of propulsion plant

InactiveCN101109310ABest working condition rangeEmission reductionCoolant flow controlPositive displacement pump componentsHeat managementPollutant emissions

The invention discloses an intelligent heat management system for a power equipment, which comprises a plurality of cooling units, an electronic control unit ECU, a fan and a motorized pump, and is characterized in that the ECU can make judgment depending upon the feedback signal of the temperature of the cooling media, adjust the speed of the fan and the motorized pump, so as to control the operation temperature of the thermal media of each cooling unit to be optimal. The invention realizes the most economic oil consumption by the ECU, guarantees that the engine is always under the optimal operation state under different environments. The advantages with the invention are: 1. The invention can guarantee that the engine is always under the optimal operation condition. 2. The invention can save energy, reduce emission of pollutant, is environmental friendly. 3. Each heat exchanging unit can cool as necessary, no overhot or over cold condition will happen. 4. The intelligent heat management system for power equipments is realized completely depending upon the feedback temperature signal by the ECU.

Owner:ZHEJIANG YINLUN MACHINERY

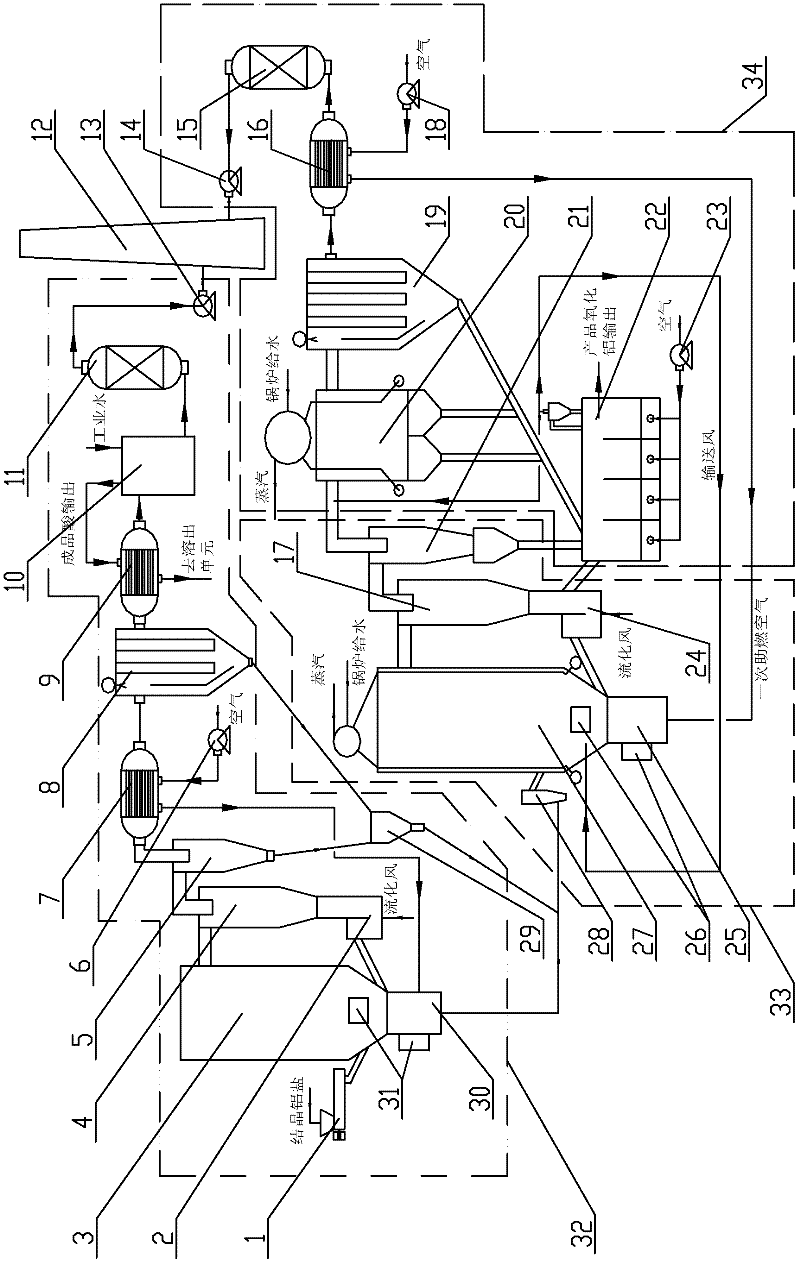

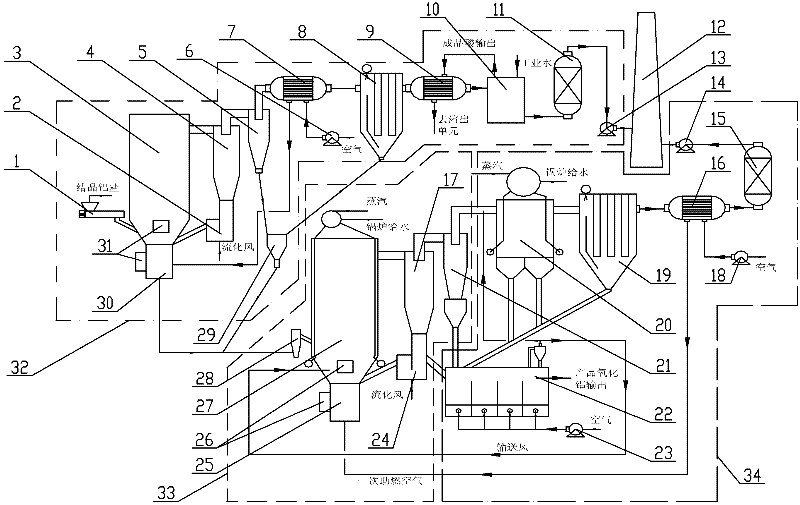

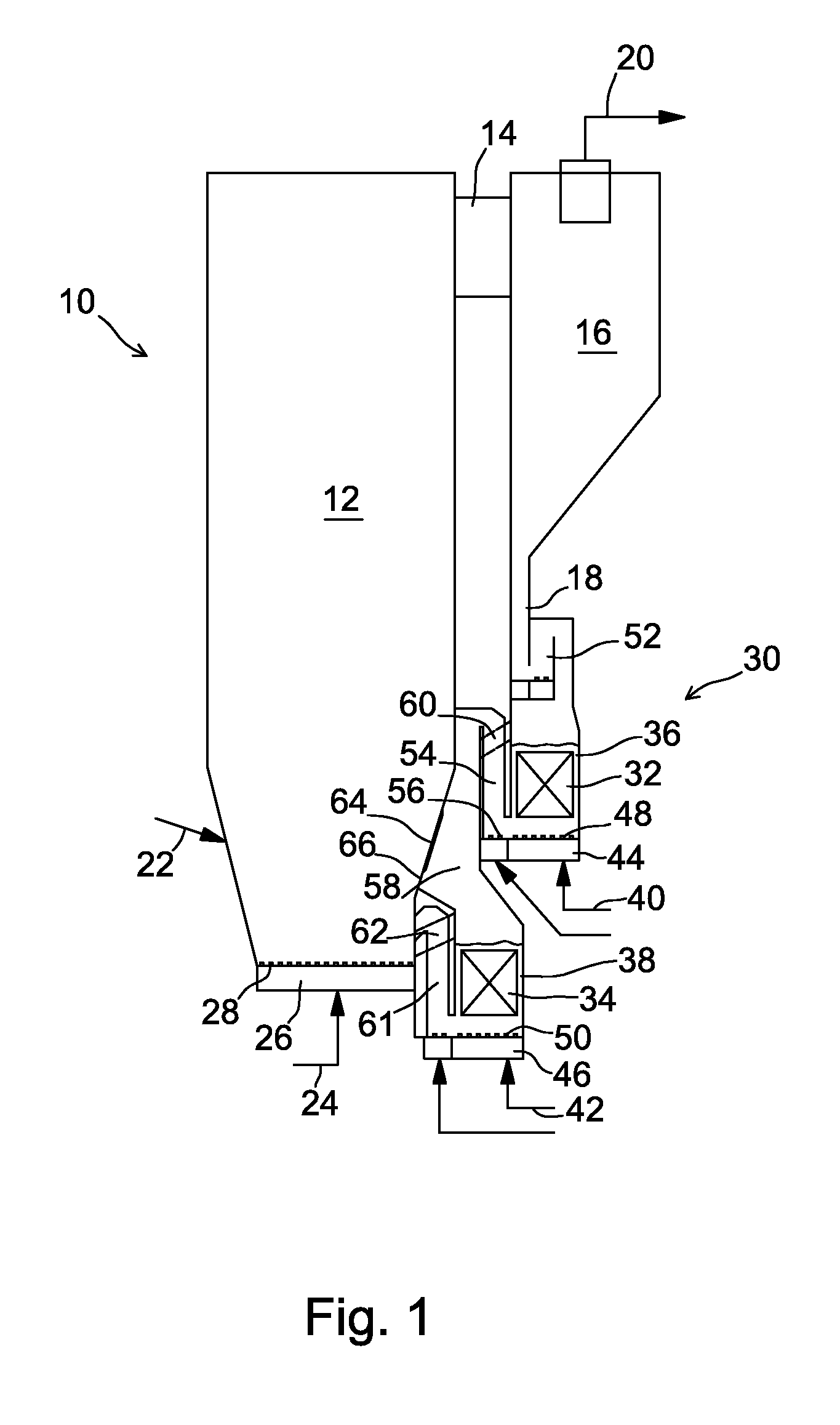

Slagging-free type and multilevel differential temperature fluidized roasting system for crystallized aluminum salt and method thereof

ActiveCN102502744ASolve the problem of large initial investmentReduce energy consumptionEnergy inputAluminium oxide/hydroxide preparationFlue gasProcess engineering

The invention provides a slagging-free type, low-energy consumption and multilevel differential temperature fluidized roasting system for crystallized aluminum salt and a method thereof. The system comprises a crystallized aluminum salt low-temperature roasting system, an aluminum oxide high-temperature finished product roasting system, a high-temperature aluminum oxide multilevel fluidized cooling and heat recovery system and a chimney. The method comprises the following steps of: reducing the outlet temperature of low-temperature roasting flue gas with large gas production rate by adopting a differential temperature multiple roasting method, so that sensible heat carried by the flue gas is greatly reduced; and carrying out reasonable cascade utilization on energy and converting fuel chemical energy inputted by a process system into effective heat of the system to a greatest extent. The slagging-free type and multilevel differential temperature fluidized roasting system has the remarkable advantages of strong adaptability to the content of attached water of the crystallized aluminum salt, good adjustment and stability, high product purity, low energy consumption, low investment, small floor area and the like.

Owner:BEIJING HANGHUA ENERGY SAVING ENVIRONMENTAL PROTECTION TECH CO LTD

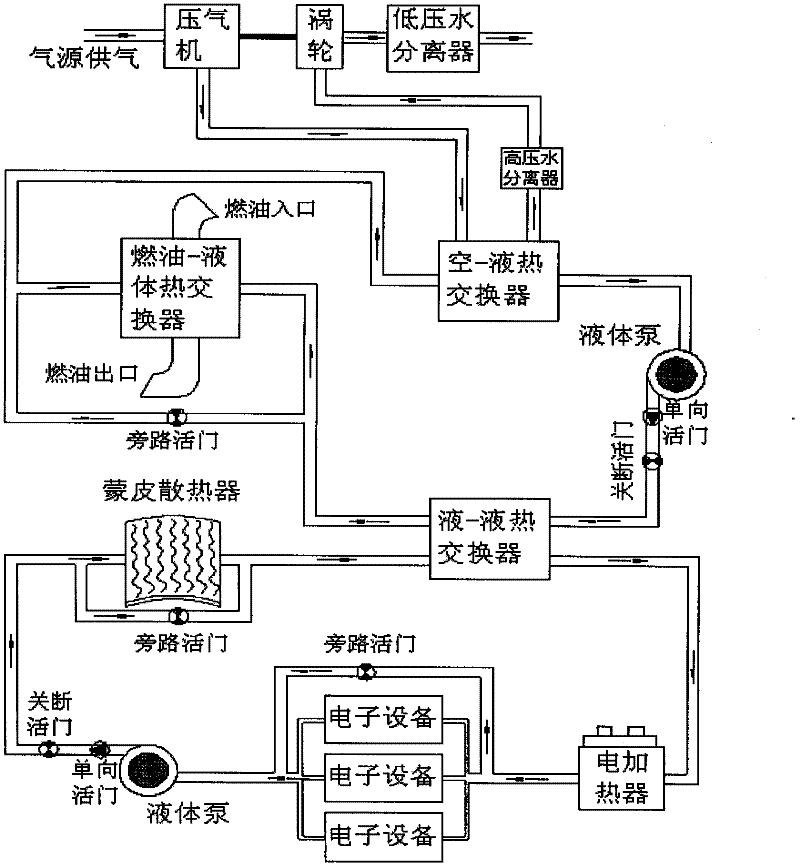

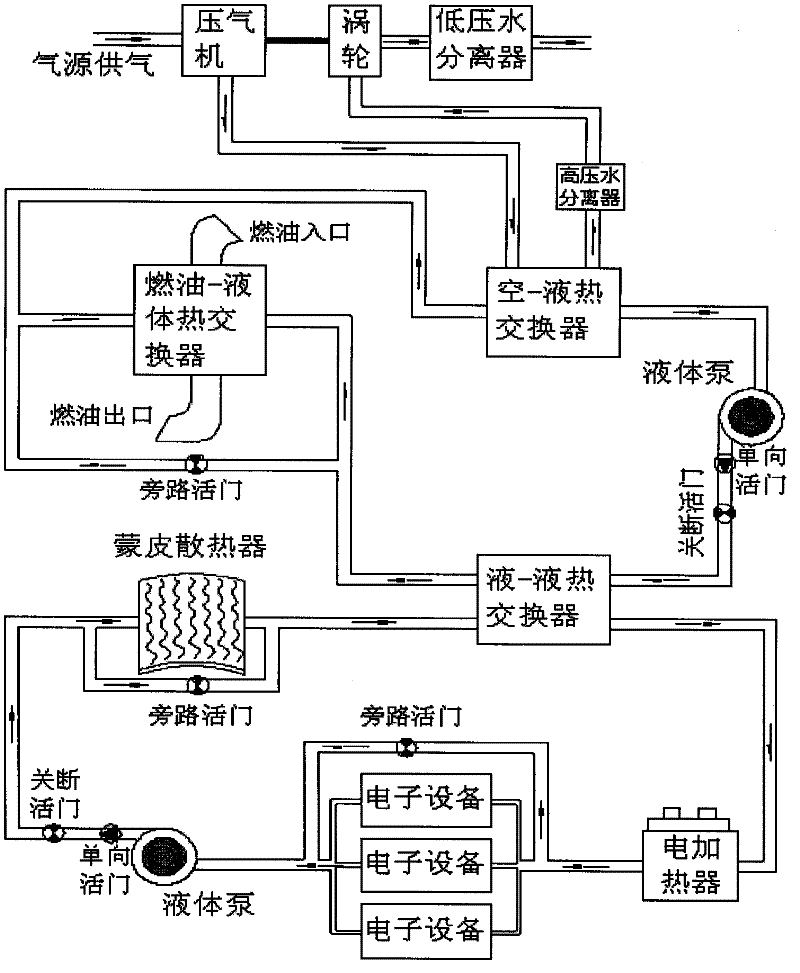

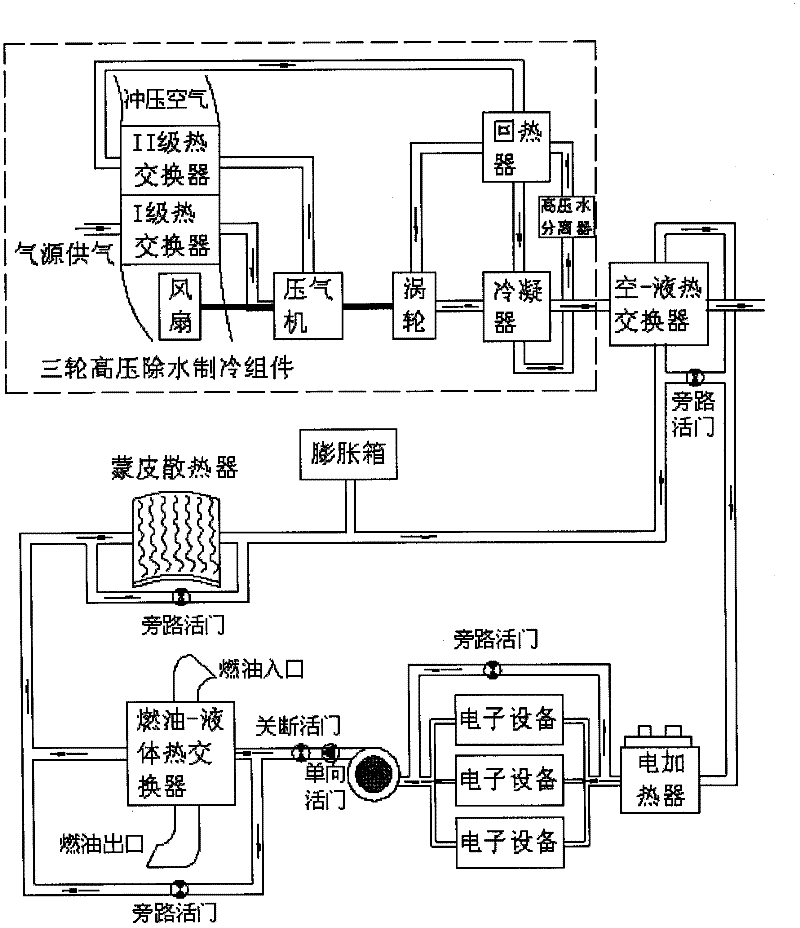

Comprehensive environmental control/liquid cold and heat energy management system for non-stamping air inlet duct

ActiveCN102381479AReduce compensatory lossesImprove water removal efficiencyAir-treatment apparatus arrangementsEnergy efficient board measuresFuel oilEngineering

The invention relates to a comprehensive environmental control / liquid cold and heat energy management system for a non-stamping air inlet duct, belonging to the field of aircraft-mounted equipment and in particular relating to an improved comprehensive environmental control / liquid cold and heat energy management system for the non-stamping air inlet duct. The system is composed of four parts of a two-wheel type high pressure water-removing refrigerating assembly, a liquid cooling system 1, a liquid cooling system 2 and a fuel oil system, wherein the high pressure water-removing refrigerating assembly and the liquid cooling system 1 are coupled through an air-liquid heat exchanger; and the air-liquid heat exchanger is located at the downstream of an air compressor outlet in the two-wheel type high pressure water-removing refrigerating assembly and is located between a fuel oil-liquid heat exchanger and a liquid pump in the liquid cooling system. The system reduces the compensation loss of the refrigerating system property, improves the water-removing and refrigerating efficiency of the refrigerating assembly, effectively reduces the influence on the flight performance of an aircraft, enhances the fuel oil efficiency of the aircraft and has good aircraft economy.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

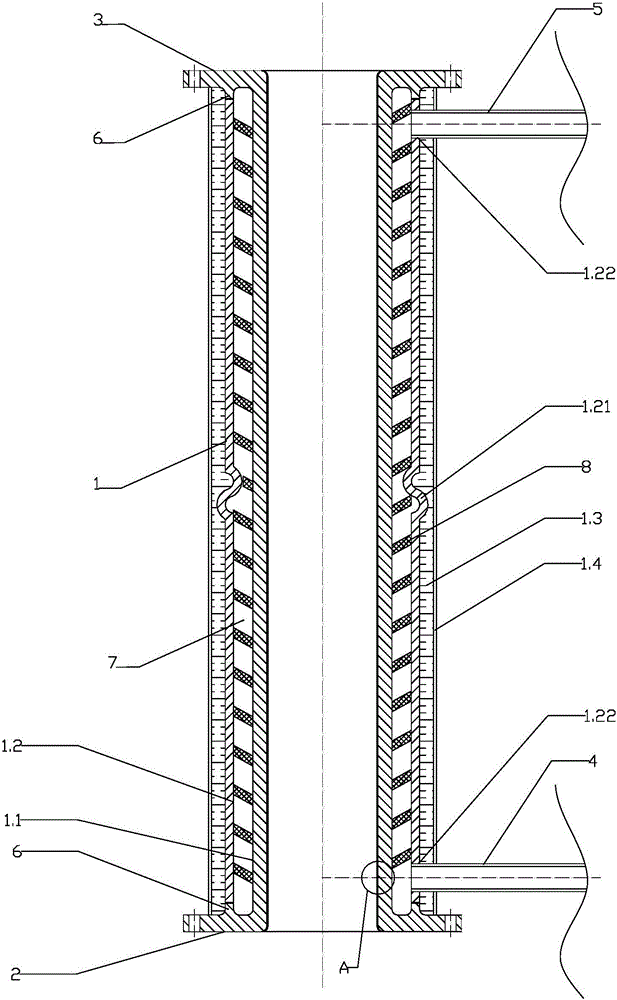

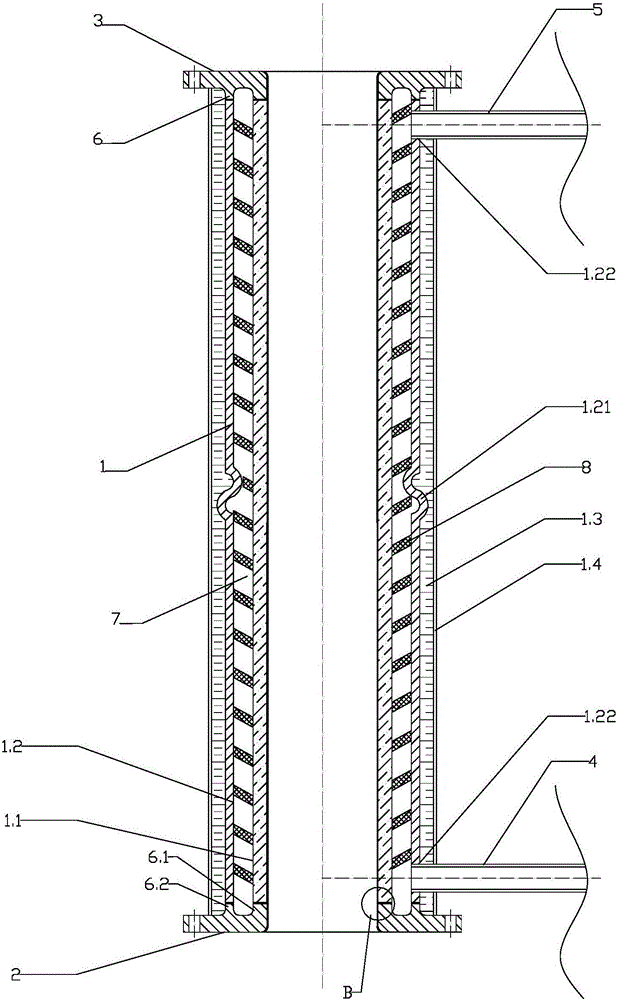

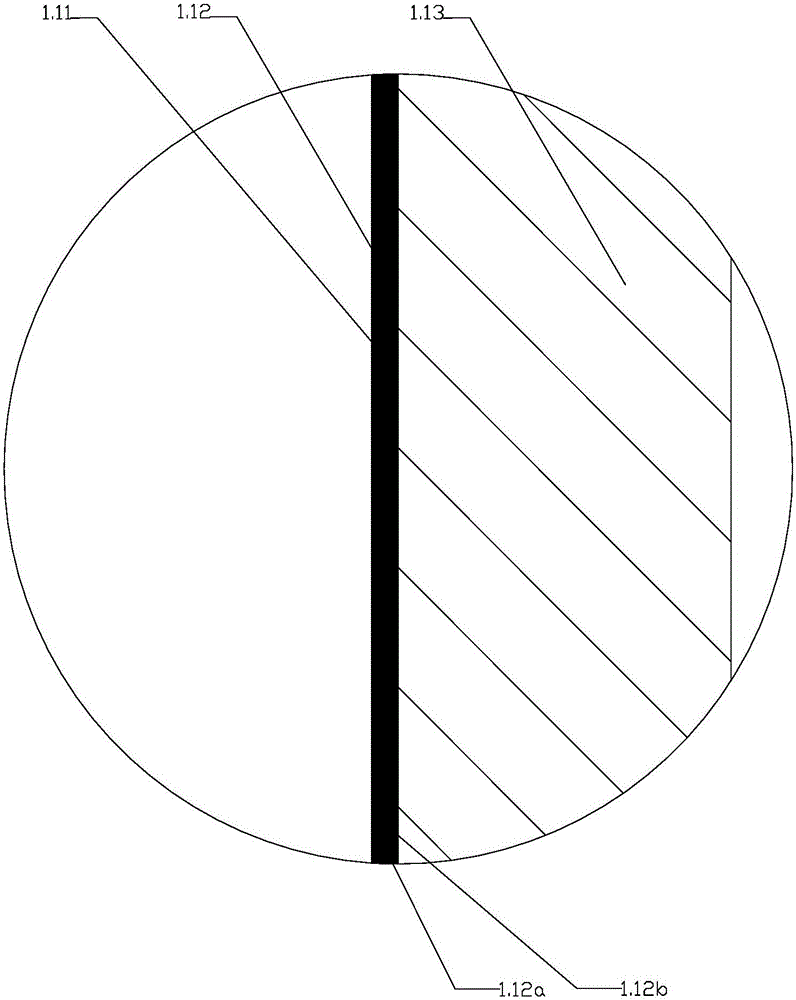

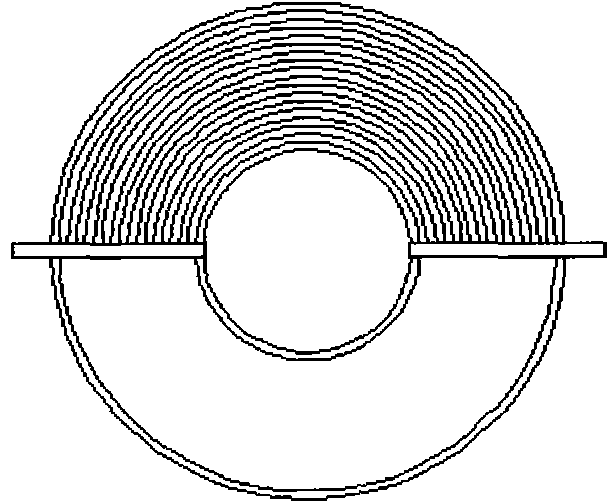

Coke oven ascension pipe raw gas evaporative cooling device and preparation method thereof

InactiveCN105043117APrevent oxidationAvoid carburizationIncreasing energy efficiencyWaste heat treatmentEngineeringCoke oven

The invention discloses a coke oven ascension pipe raw gas evaporative cooling device and a preparation method thereof. The device comprises a cooling pipe, a raw gas inlet flange and a raw gas outlet flange, wherein the raw gas inlet flange and the raw gas outlet flange are connected with the two ends of the cooling pipe respectively. The cooling pipe is sequentially composed of an inner sleeve, an outer sleeve, a heat preservation layer and a protection layer from inside to outside. Through holes are formed in the two ends of the side wall of the outer sleeve respectively. A water inlet steel pipe is installed on the through hole close to the raw gas inlet flange. A vapor outlet steel pipe is installed on the through hole close to the raw gas outlet flange. An annular expansion joint section is arranged at the portion, between the water inlet steel pipe and the vapor outlet steel pipe, of the outer sleeve. The high temperature structural strength and high temperature breakage resistant capacity of the cooling device are remarkably improved, the heat transfer behavior of the pipe wall of the inner sleeve of the cooling device is improved, the radial temperature distribution of the pipe wall is optimized, the efficient function coordination of multiple layers of materials is achieved, and the comprehensive use performance of the inner sleeve is improved; the aim of long-term efficient and stable running of the ascension pipe raw gas evaporative cooling device is finally achieved.

Owner:武汉钢铁有限公司

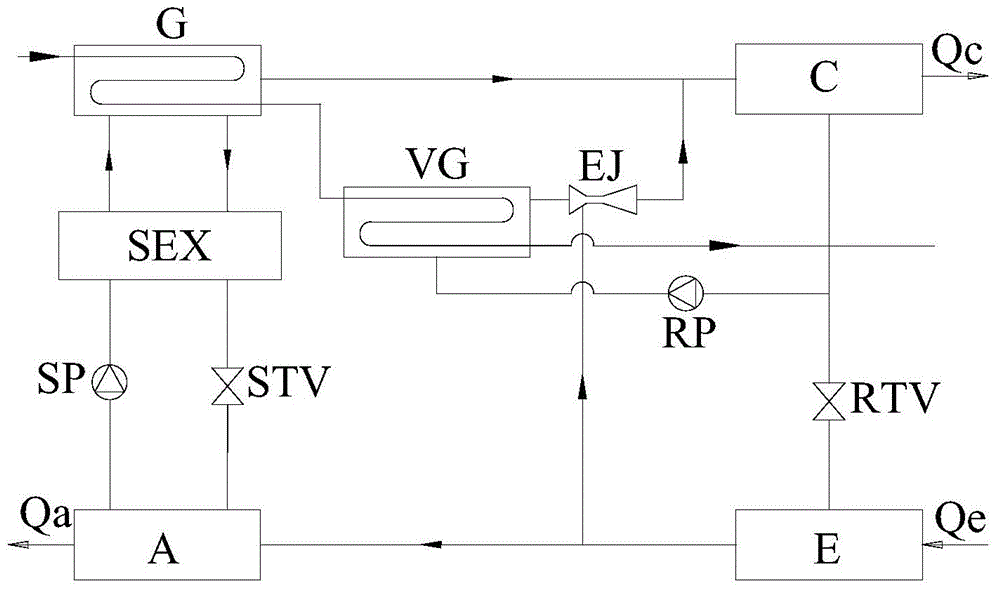

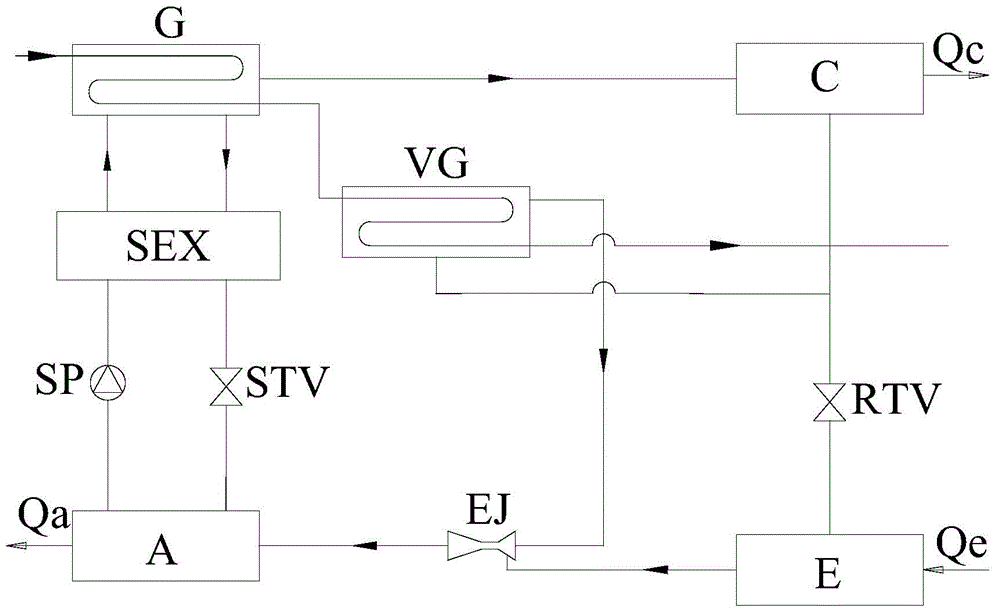

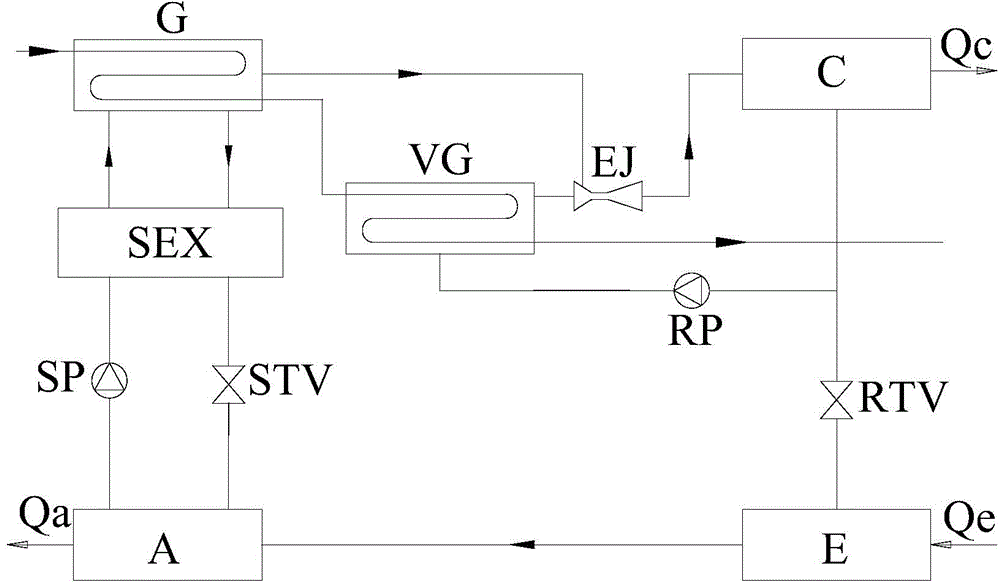

Ejection-absorbing hybrid refrigerating and heat pump unit and operating method thereof

InactiveCN104676958ALower outlet temperatureRaise the outlet temperatureHeat pumpsSteam generation plantsSteam pressureEngineering

The invention belongs to the technical field of refrigerating and heat pumps and particularly relates to an ejection-absorbing hybrid refrigerating and heat pump unit and an operating method thereof. The unit comprises generators, a condenser, an evaporator, an absorber, a solution heat exchanger, a solution pump, a solution throttle valve, a coolant throttle valve, a steam generator and a gas ejector. By providing one or multiple steam generators, outlet temperature of a high-level drive heat source of the unit can be decreased, utilization efficiency of heat and hierarchy of coolant steam pressure are increased, and the gas ejector can be conveniently set according to different pressure level; high-temperature high-pressure steam generated by the steam generator allow coolant steam to be ejected from outlets of the generators to the condenser, thereby decreasing the high-level heat source temperature of the generators; the coolant steam from an outlet of the evaporator can also be ejected to the absorber so as to enhance absorbing pressure of the absorber and reduce the size of the absorber; the coolant steam from the outlet of the evaporator can also be ejected to the condenser to increase refrigerating and heating quantity of the unit and improve comprehensive thermal performance of the unit.

Owner:BEIJING UNIV OF CIVIL ENG & ARCHITECTURE

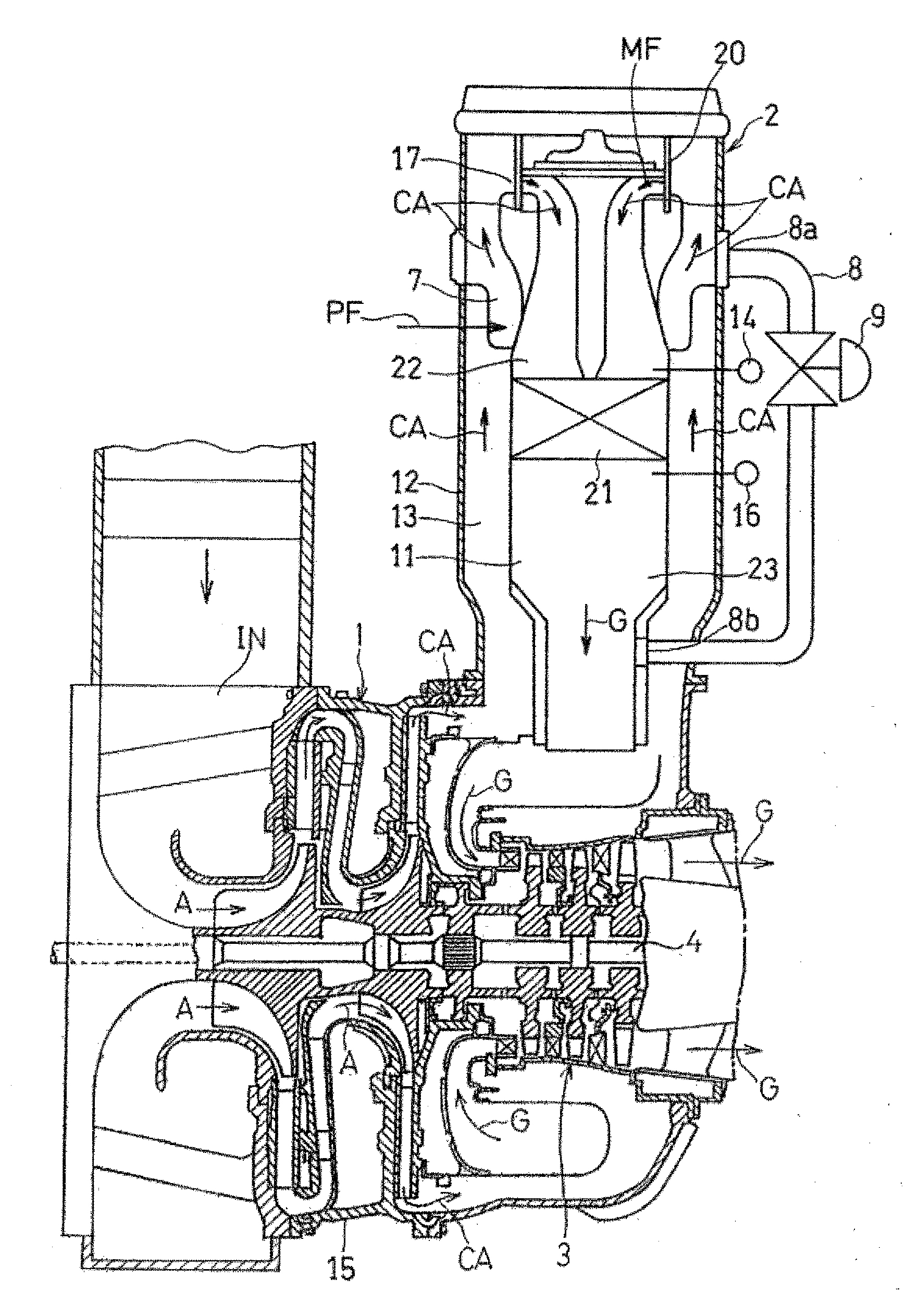

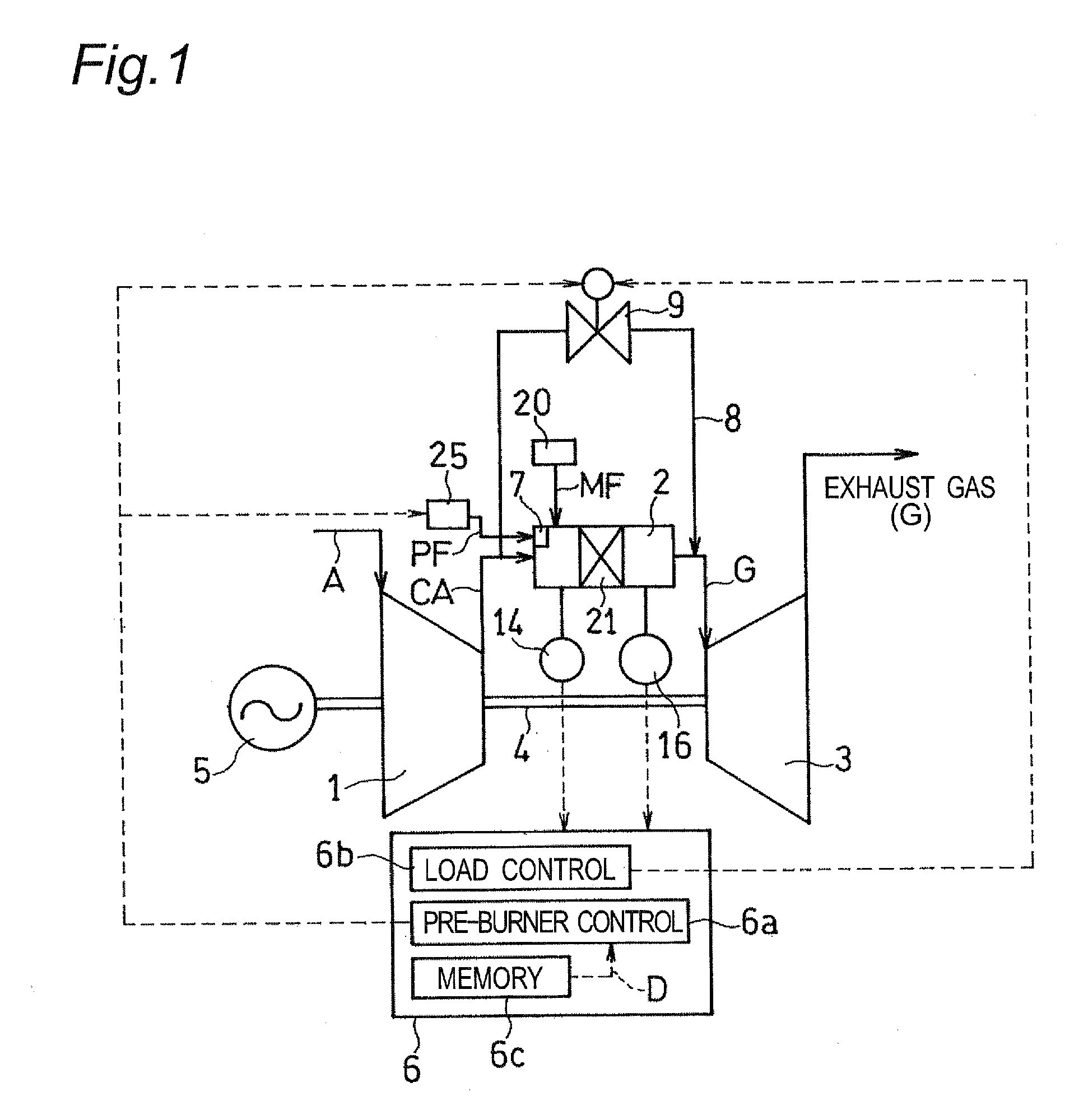

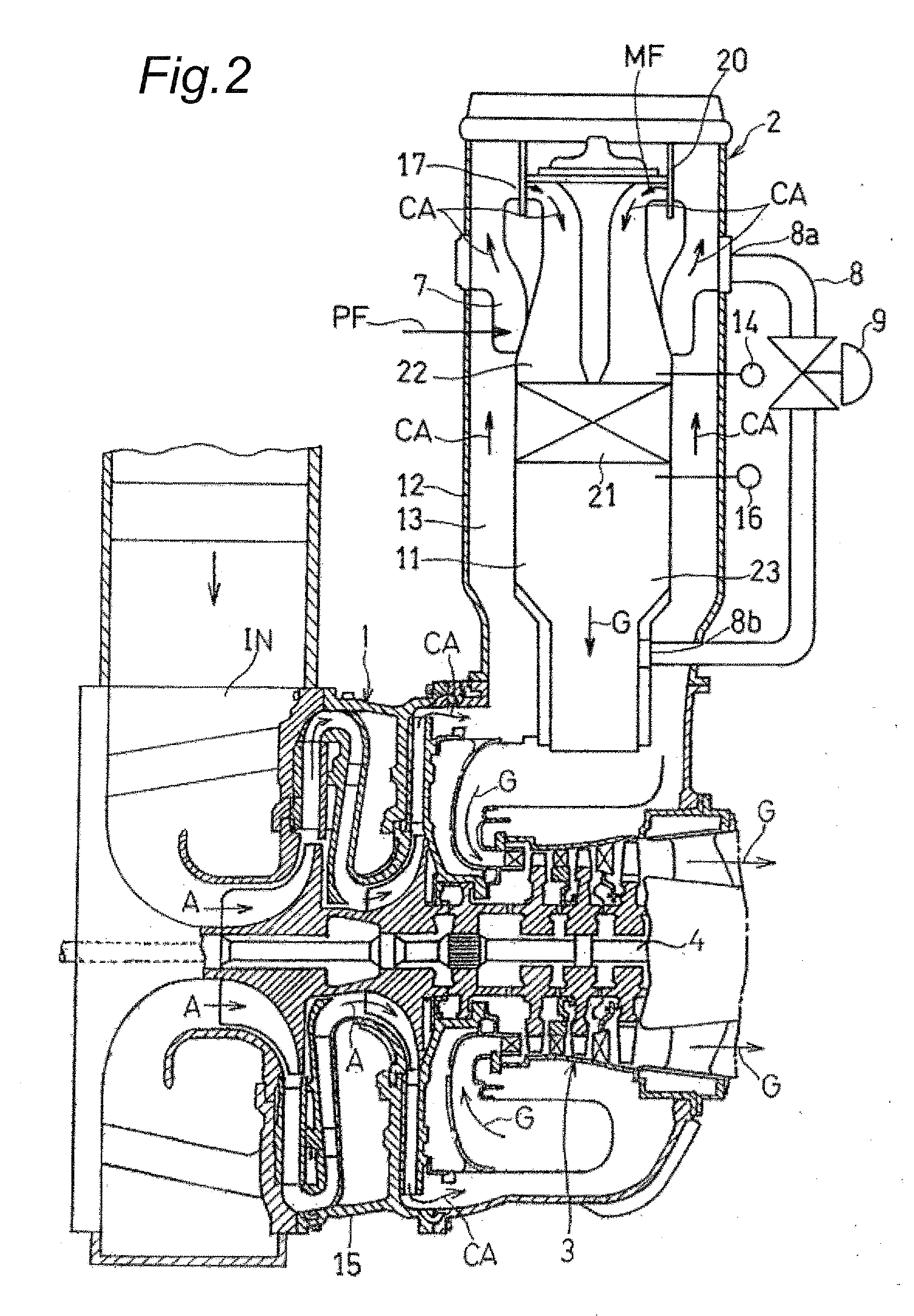

Controller for use with gas turbine engine

InactiveUS20130025254A1Reduce the amount requiredIncrease carbon monoxide concentrationFuel supply regulationContinuous combustion chamberCombustorTemperature difference

Provided is a controller for use with a gas turbine engine, which ensures a stable combustion regardless of the deterioration of the catalyst and elevated characteristics of the exhaust gas. The controller 6 is used in the engine which comprises a combustor 2 for combusting a mixture of compressed air from a compressor 1 and a fuel under the existence of catalyst, the combustor having a catalytic combustion unit 21 bearing the catalyst and a pre-burner 7 provided on an upstream side of the catalytic combustion unit with respect to a flow of the compressed air for supplying and combusting a pre-heating fuel PF with the compressed air CA. The controller comprises a memory 6c for memorizing an initial temperature difference D between inlet and outlet temperatures t1, t2 measured at inlet and outlet of the catalytic combustion unit with non-deteriorated catalyst accommodated therein, and a pre-burner control for calculating a present temperature difference between the inlet and outlet temperatures measured in an operation of the gas turbine engine and controlling an amount of the fuel to be supplied to the pre-burner according to a deterioration Δd of the catalyst which is provided by a difference between the initial and present temperature differences D and d.

Owner:KAWASAKI HEAVY IND LTD

Two-stage type hot water direct-fired single-double effect composite lithium bromide absorption refrigeration unit

InactiveCN102914079ARelieve stressReduce the temperatureEnergy efficient heating/coolingClimate change adaptationWater flowLithium bromide

The invention relates to a two-stage type hot water direct-fired single-double effect composite lithium bromide absorption refrigeration unit. The absorption refrigeration unit comprises a direct-fired high pressure generator (7), an evaporator, an absorber, a steam generator (13), a hot water generator (15), a condenser, a solution heat exchanger, a solution pump and a refrigerant pump and is characterized by comprising a single effect condenser (16) and a double effect condenser (12); the heat exchange tube bundle of the hot water generator (15) and the heat exchange tube bundle of the single effect condenser (16) are arranged in a cavity; the heat exchange tube bundle of the steam generator (13) and the heat exchange tube bundle of the double effect condenser (12) are arranged in another cavity; the cooling water flow paths of the single effect condenser (16) and the double effect condenser (12) adopt series connection flow paths; and cooling water gets into the single effect condenser (16) and gets out of the double effect condenser (12). The two-stage type hot water direct-fired single-double effect composite lithium bromide absorption refrigeration unit can be used for reducing the generation pressure of the hot water generator and the concentration of a dilute solution for hot water single effect circulation.

Owner:SHUANGLIANG ECO ENERGY SYST CO LTD

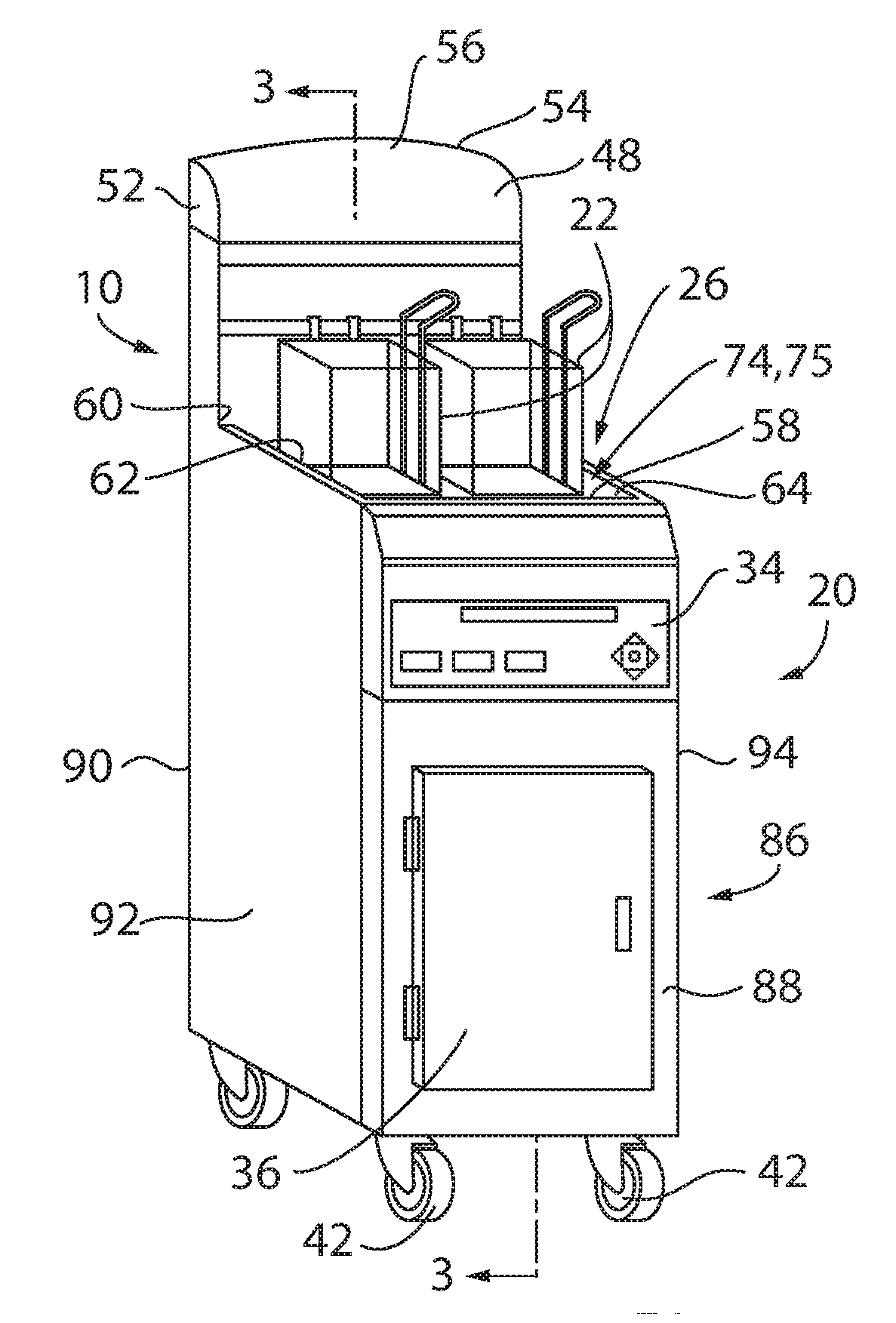

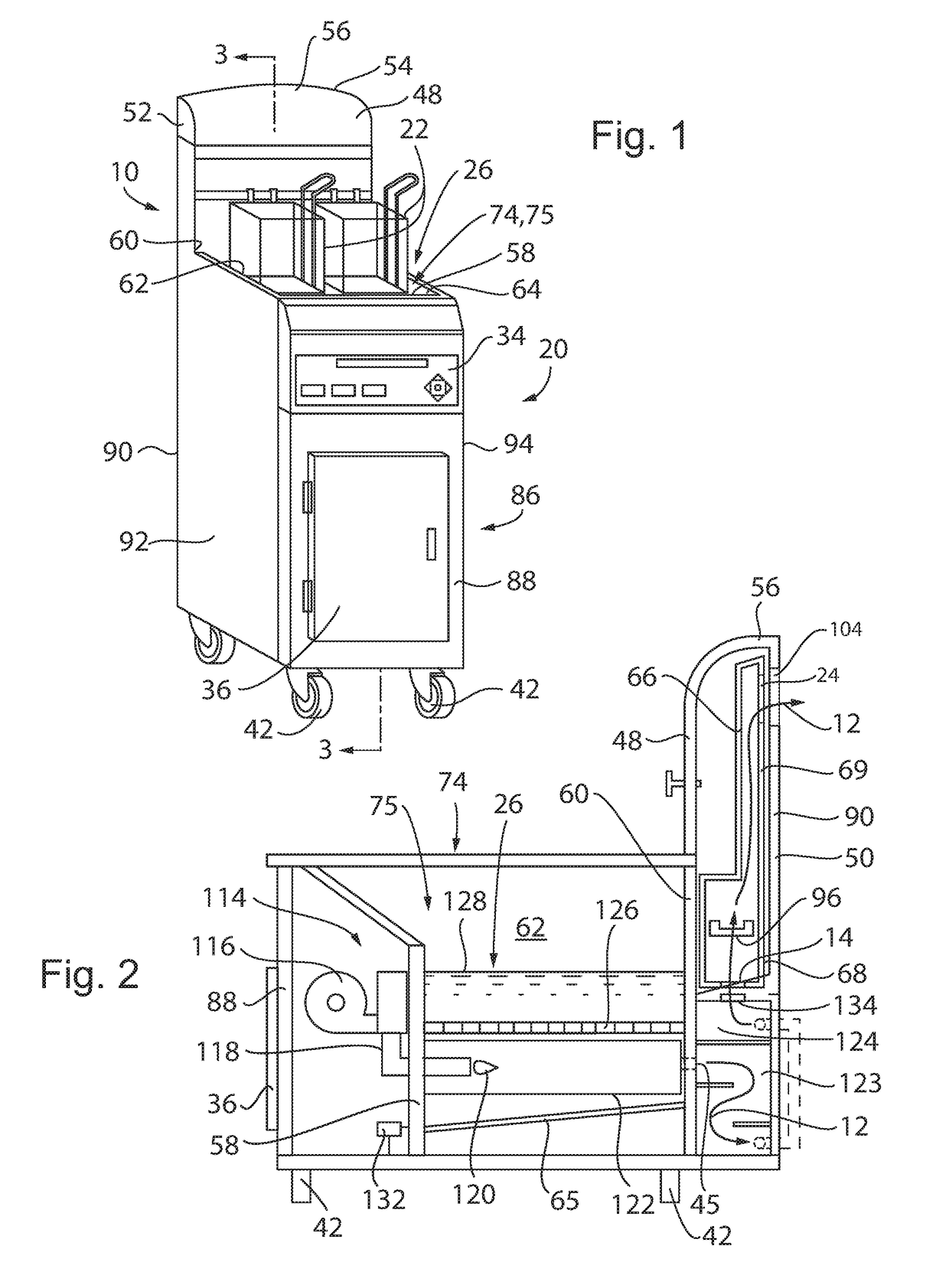

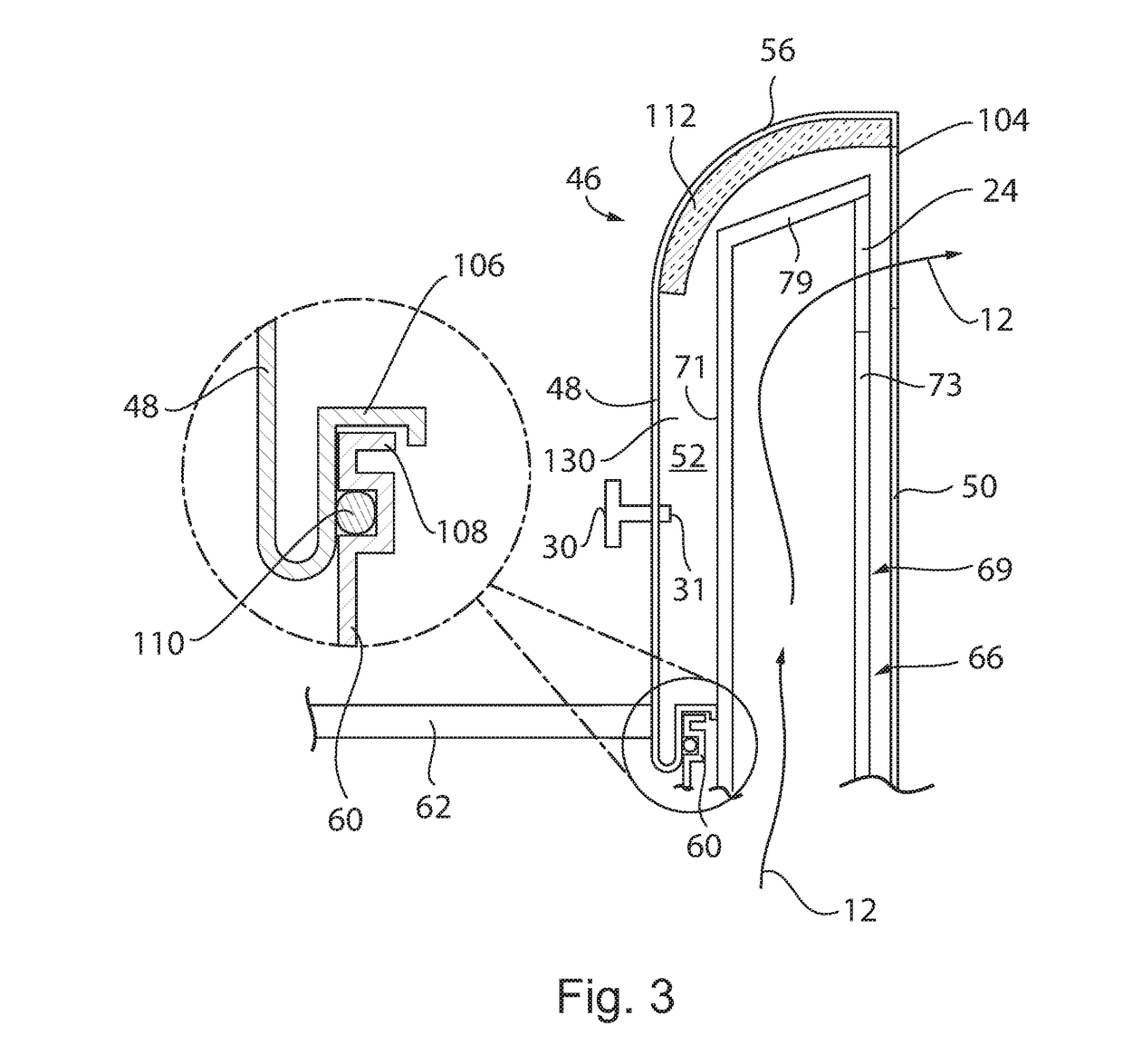

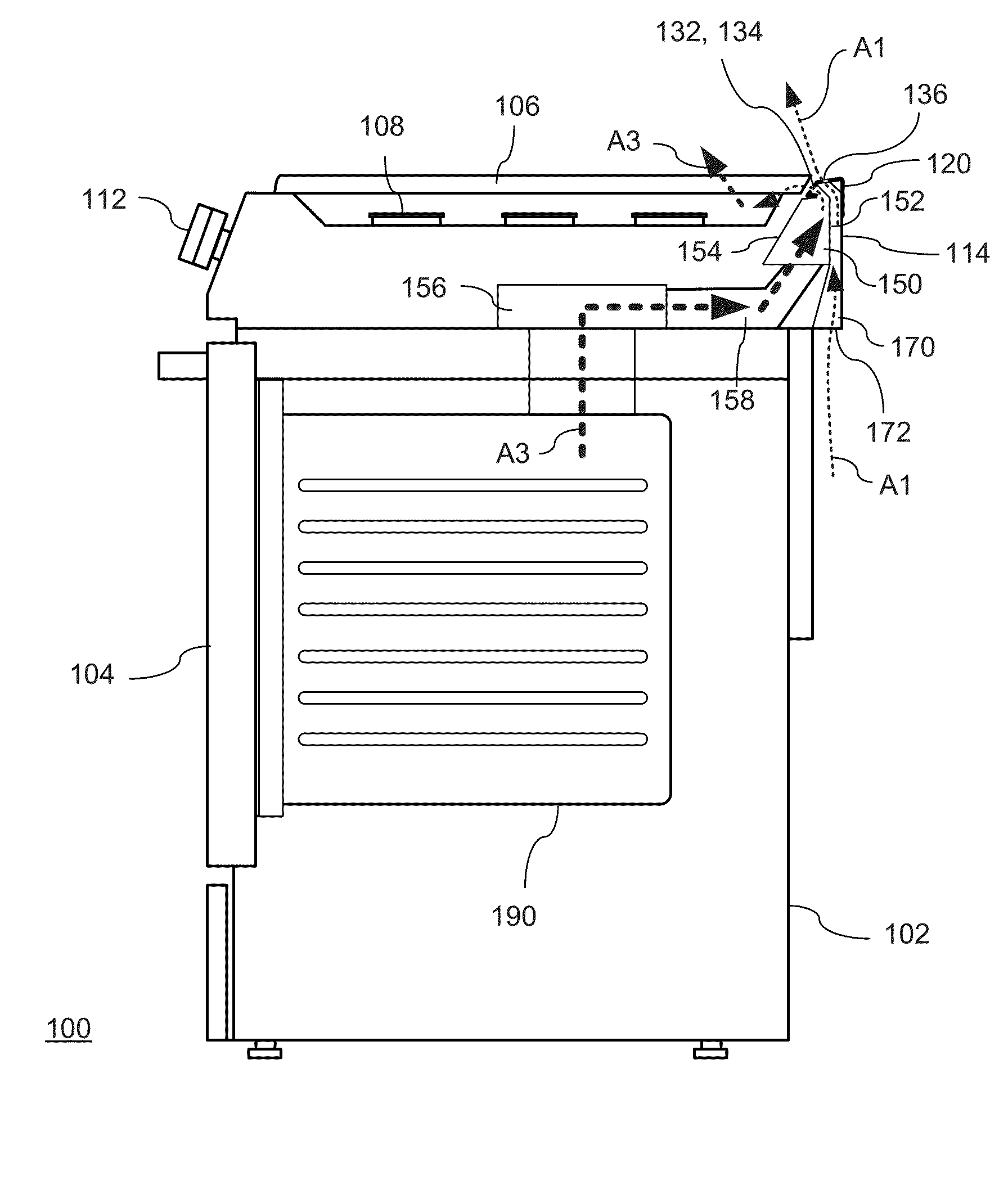

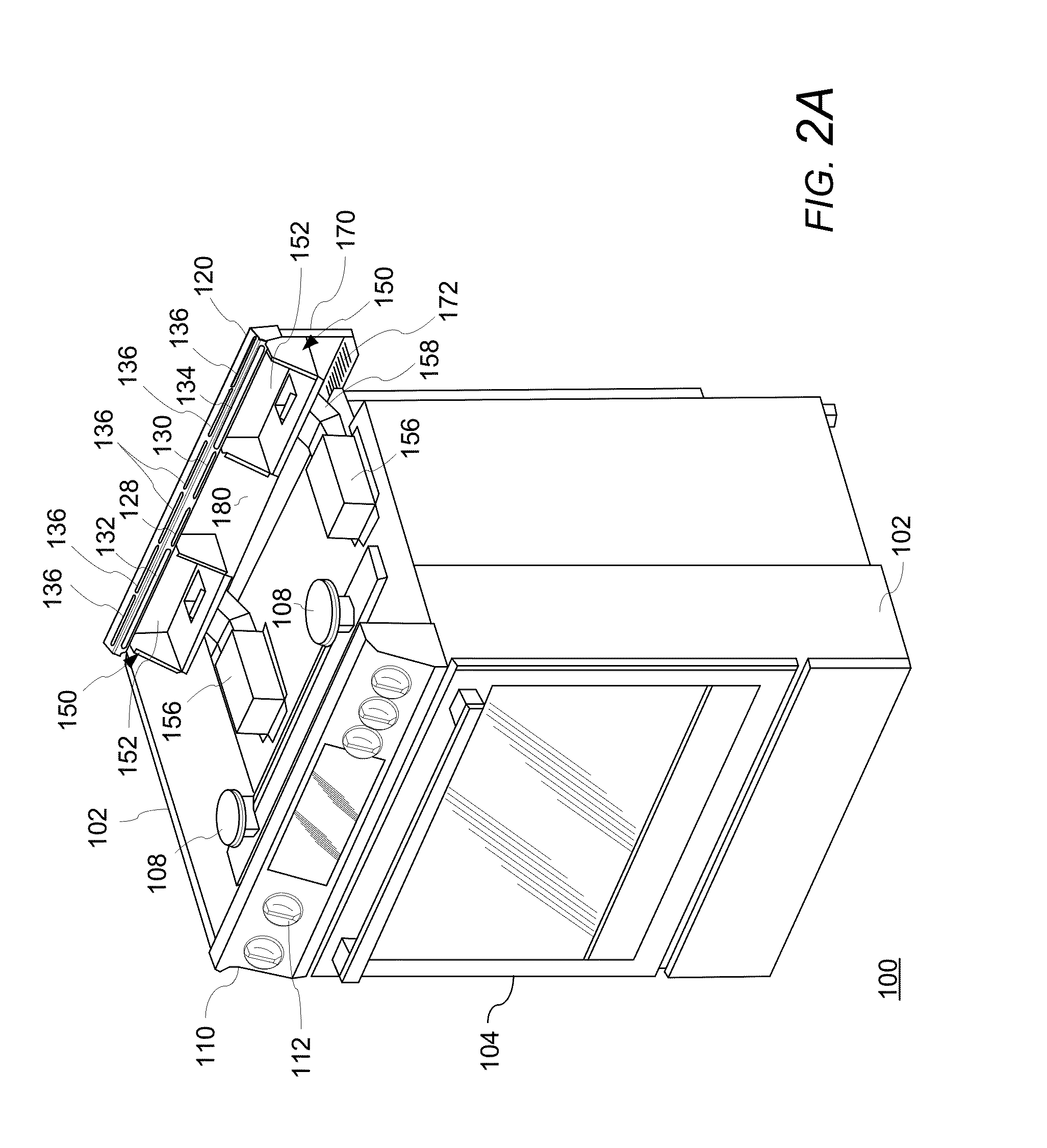

Flue Assembly and Splash Back Panel for a Cooking Appliance

ActiveUS20180289217A1Prevent “ baking-on ”Easy to cleanDomestic stoves or rangesLighting and heating apparatusForeign objectMechanical engineering

The present invention provides a deep fat fryer separating the flue from the splash back panel and with a flue opening directed not upwardly, but rearwardly from the flue. By arranging the flue opening on the rear wall, the opening is protected from grease fallback (e.g., dripping from an overhead exhaust hood) or other foreign objects falling into the opening. The splash back panel further provides a seamless curved design that is easy to clean and also insulated from the heat of the flue. A baffle installed within the flue allows the combustion products to mix, cool, and slow upon exiting the baffle opening and entering the atmosphere reducing the exit temperature and also reducing the heating of the splash back panel.

Owner:ALTO SHAAM

High thermal conductivity silica brick for coke oven and preparation method thereof

ActiveCN104119081ADense microstructureImprove thermal conductivitySilica particleCarboxymethyl cellulose

The invention relates to a high thermal conductivity silica brick for coke oven and a preparation method thereof. The high thermal conductivity silica brick for a coke oven comprises the following components by weight: 68.0%-82.0% of natural silica particles, 13.0%-26.0% of natural silica powder, 0.5%-2.0% of an additive containing dispersant, 1.5%-5.0% of siliceous non oxide, 1.0%-3.0% of a mineralization agent, and an additional binder in the weight 1.5%-3.0% of the total weight of the previous materials. The additive comprises a dispersant carboxymethyl cellulose (CMC) with granularity less than 0.088 mm and siliceous non-oxide Si with granularity less than 0.043 mm, wherein the content of Si is greater than 96 wt.%. The silica brick provided by the invention has high thermal conductivity and keeps other comprehensive excellent performances of silica brick, and can satisfy the demands of coke oven for longevity, energy saving and high efficient production.

Owner:BAOSHAN IRON & STEEL CO LTD +1

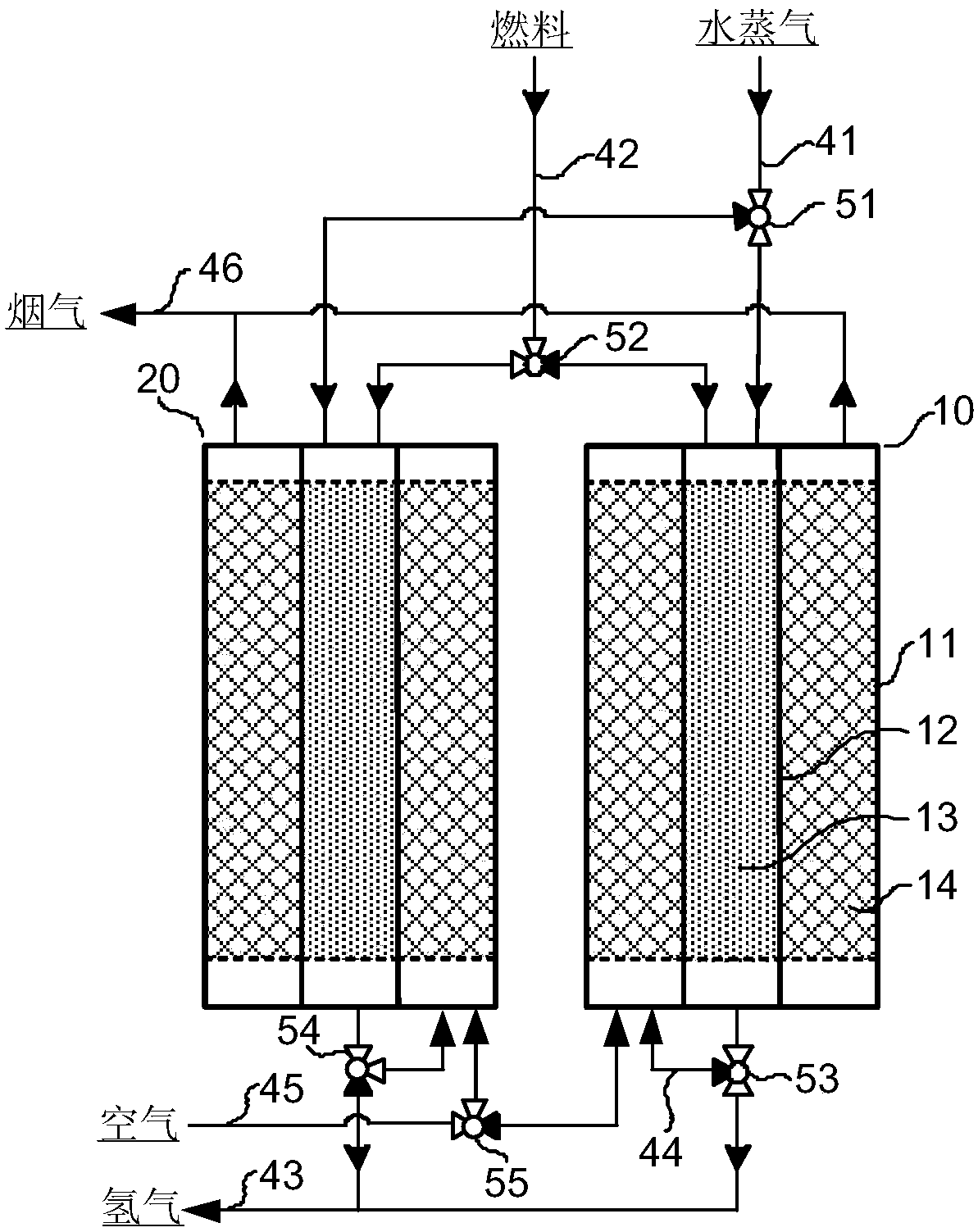

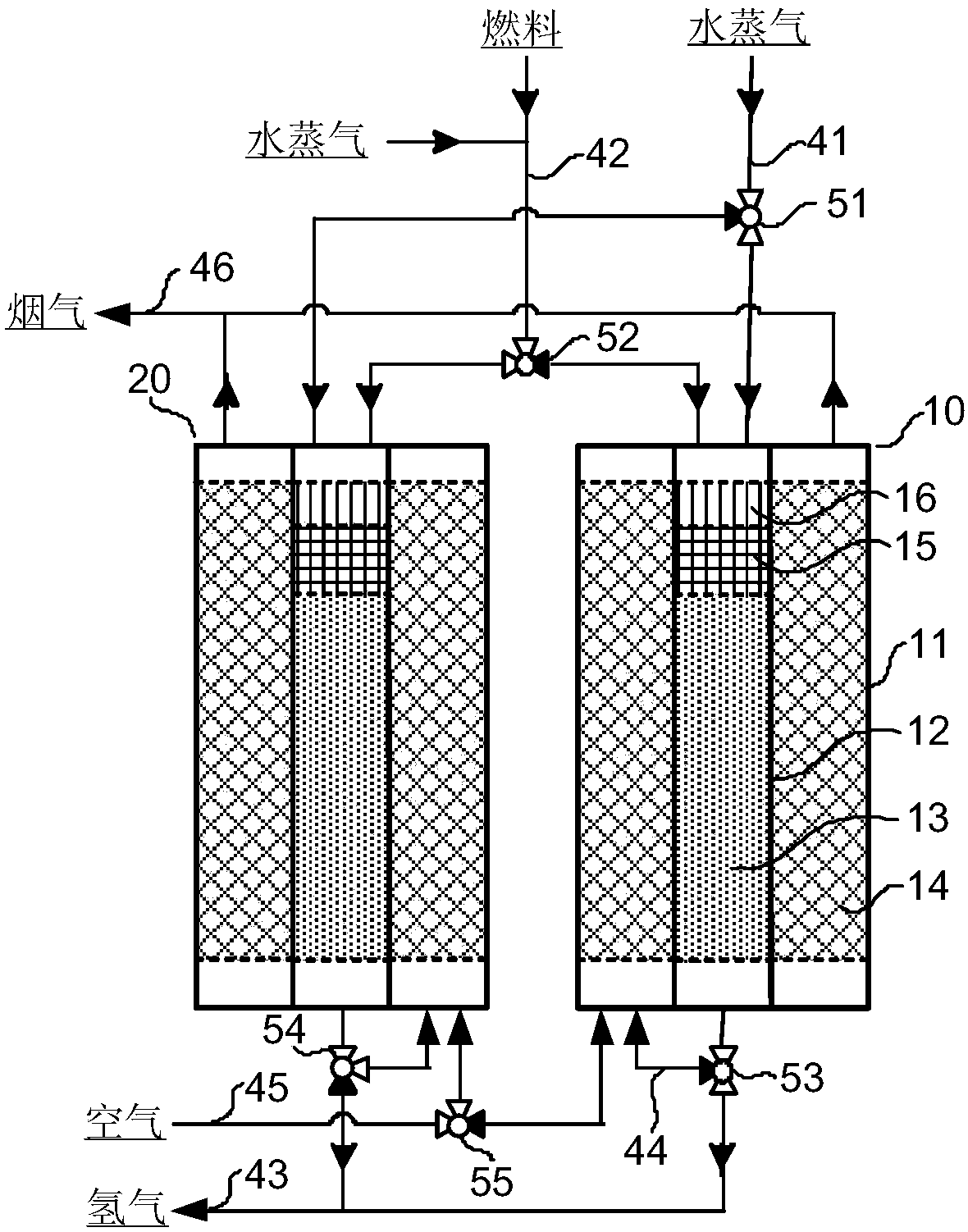

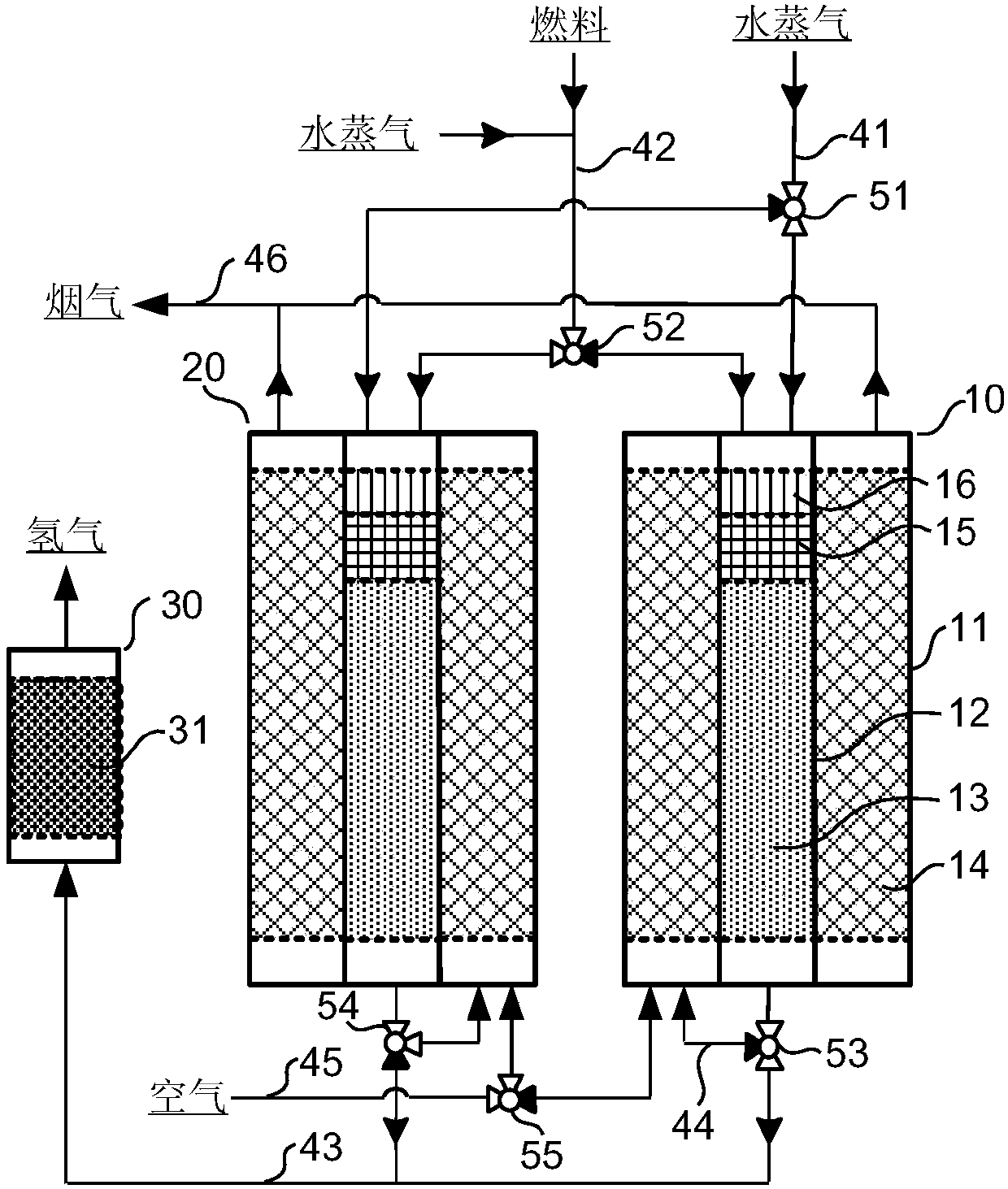

Fuel chemical chain hydrogen production system and method

PendingCN110194437ASimple processMiniaturizationHydrogenHydrogen/synthetic gas productionWater vaporMiniaturization

The invention relates to a fuel chemical chain hydrogen production system and method, the fuel chemical chain hydrogen production system comprises two identical chemical chain combustion reactors, each chemical chain combustion reactor comprises an outer pipe and an inner pipe coaxially arranged with the outer pipe, the inner pipe is filled with a first oxygen carrier, and the interlayer between the outer pipe and the inner pipe is filled with a second oxygen carrier. The upper end of the inner pipe is connected with a steam introduction pipe and a fuel introduction pipe, and the lower end ofthe inner pipe is connected with a gas outlet pipe. When steam introduced into the first chemical chain combustion reactor and a reduced oxygen carrier carry out the oxidation reaction of the oxygen carrier, a fuel introduced into the second chemical chain combustion reactor and an oxidized oxygen carrier carry out reduction reaction of the oxygen carrier. The fuel chemical chain hydrogen production system has simple process, compact reactor and easy miniaturization, and can efficiently produce pure hydrogen from a gaseous or liquid fuel.

Owner:BEIJING LIANLI ENERGY TECH CO LTD

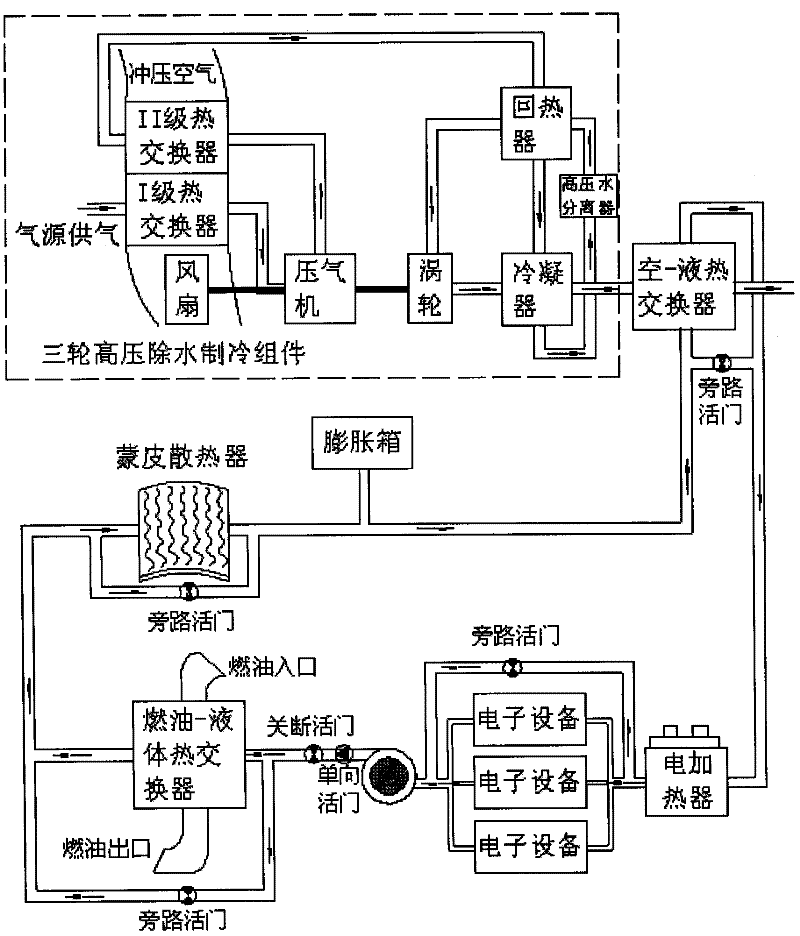

Three-wheel pressure-boosting refrigerating and liquid cooling composite thermal energy managing system

InactiveCN102390536AReduce compensatory lossesImprove water removal efficiencyAir-treatment apparatus arrangementsEnergy efficient board measuresExpansion tankJet aeroplane

The invention discloses a three-wheel pressure-boosting refrigerating and liquid cooling composite thermal energy managing system, belonging to the field of airplane airborne laser equipment, relating to an improvement on a composite environmental control / liquid cooling thermal energy managing system. The invention is composed of a three-wheel high pressure dehydrating refrigerating assembly, a liquid cooling system and a fuel system, wherein the high pressure dehydrating refrigerating assembly and the liquid cooling system are coupled by an air-liquid heat exchanger; said air-liquid heat exchanger is on downstream of the turbine in the high pressure dehydrating refrigerating assembly, and between an expansion tank and an electric heater in the liquid cooling system; the liquid cooling system and a fuel system are coupled by a liquid- fuel heat exchanger; said liquid- fuel heat exchanger is between an aircraft skin heat radiator and sov shutoff valve in the liquid cooling system. The invention lowers the compensation loss for the cooling system, and raises dehydration and cooling effect for the refrigerating assembly, and effectively lowers influence on flight performance of the aircraft, and raises the fuel efficiency of the aircraft such that the economy of the aircraft is good.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

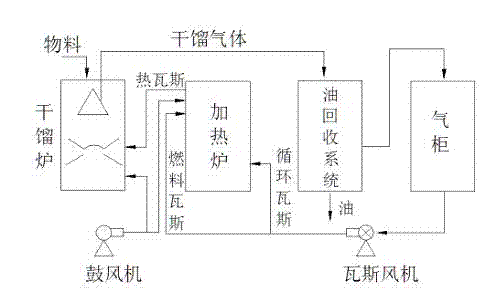

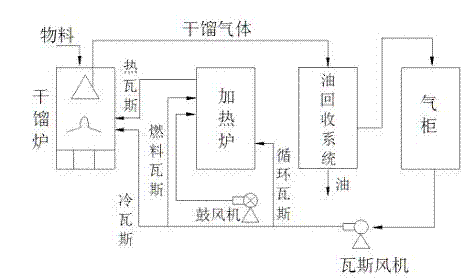

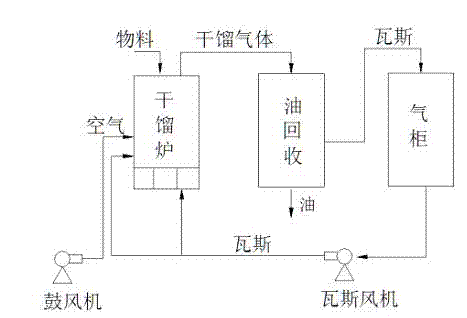

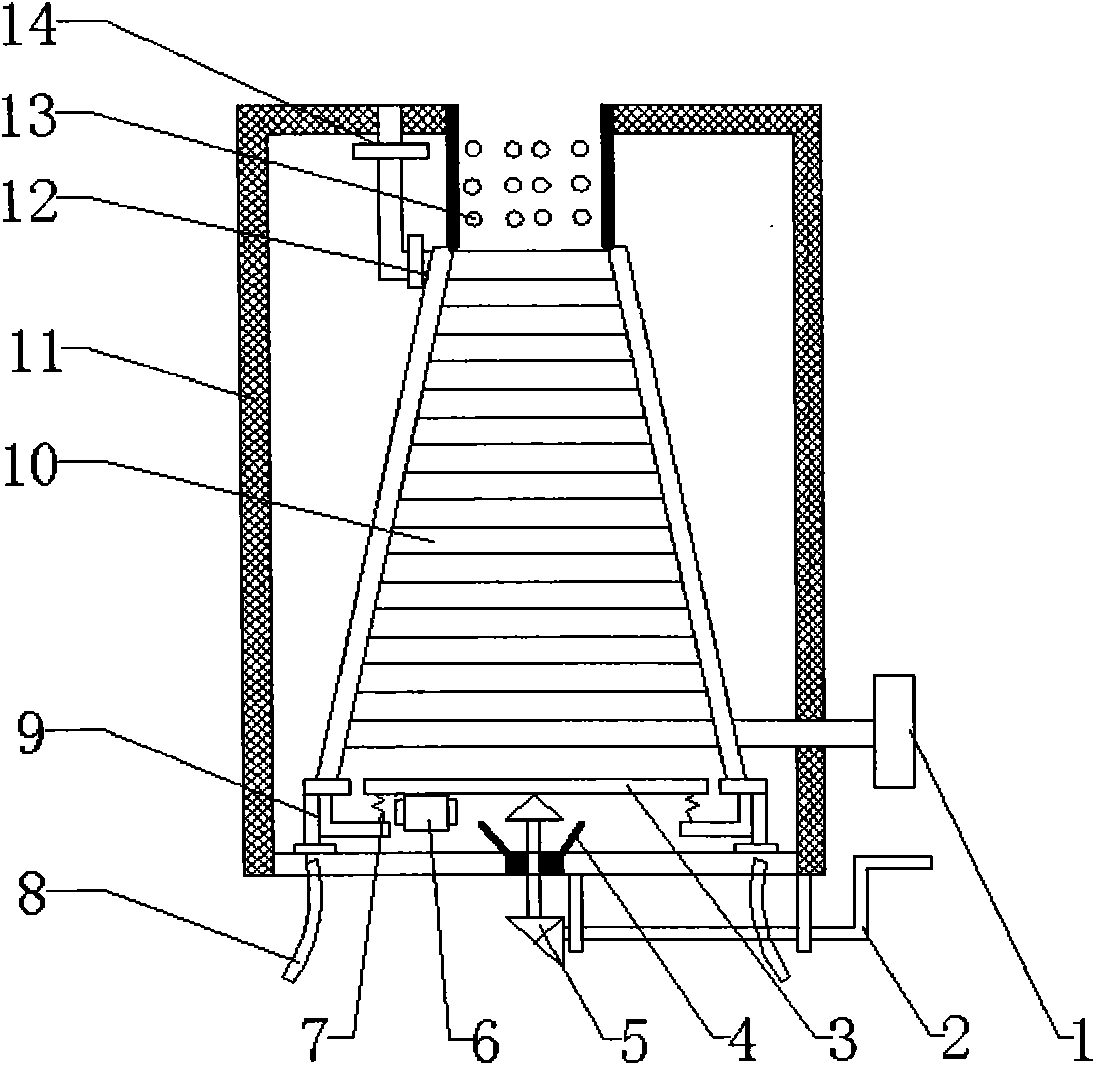

Integrated gas retort

ActiveCN102827619AReduce consumption costsLow running costEnergy inputIndirect heating destructive distillationCombustion chamberHeat carrier

The invention relates to an integrated gas retort integrating heating of a heat carrier and dry distillation of materials into the same one dry distillation unit. The integrated gas retort is characterized in that smoke gas is used as dry distillation heat carrier for indirectly heating materials; the gas retort is formed by combining a plurality of dry distillation sub units. Each dry distillation sub unit is independent, one combustion chamber corresponds to one dry distillation chamber to form one dry distillation sub unit, the upper parts of retorts comprising a plurality of dry distillation sub units are communicated, the two dry distillation sub units are separated by a smoke gas chamber, and the lower parts share one water seal tank and a tar exhaust device. The actual daily capacity of the gas retort can achieve more than 6000. The integrated gas retort is applicable to low-temperature dry distillation oil refining of materials oil sand, oil shale, coal and the like. The integrated gas retort is applicable to dry distillation and oil refining of small-particle materials, as well as various qualities of materials with low gas content, low fixed carbon content and high moisture content, and the oil recovery rate of the gas retort can achieve about 90%.

Owner:辽宁智越建设有限公司

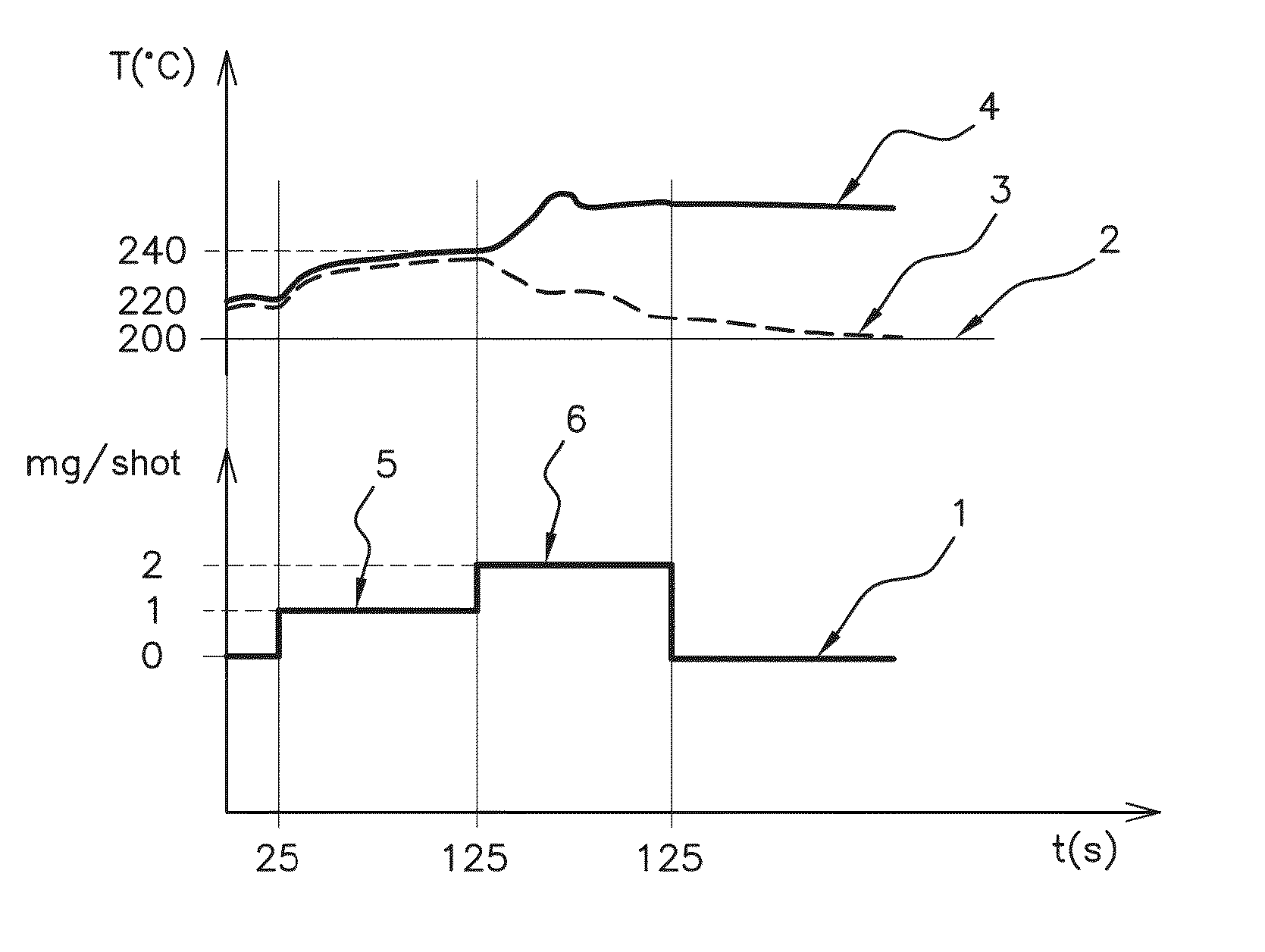

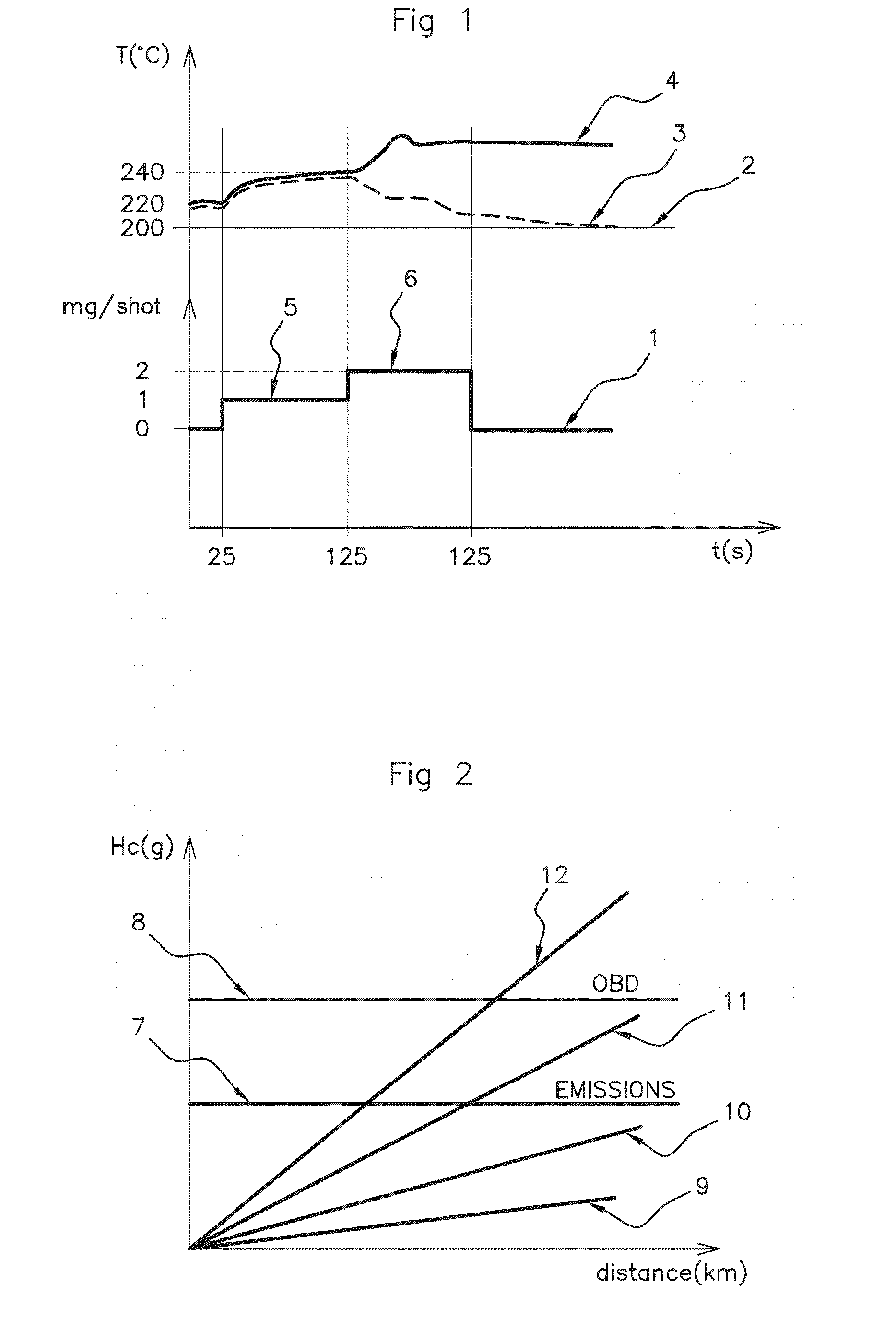

Method for monitoring an oxidation catalysis device

ActiveUS20160169076A1Relatively small errorEasy to viewElectrical controlInternal combustion piston enginesEngineeringInternal combustion engine

A method for monitoring an oxidation catalysis device or DOC arranged in an exhaust line of an internal combustion engine of a vehicle, in a predetermined range of inlet (2) and outlet (3) temperatures of the DOC, includes injecting predetermined successive quantities of fuel in stages (5, 6) into the inlet of the DOC, recording the outlet (3) temperature of the DOC after each injected quantity of fuel, recording the total quantity injected for a given stage, for which the outlet temperature (3) of the DOC begins to decrease, determining a characterization of the DOC monitored, then comparing this characterization with a test characterization of a similar DOC which has been established beforehand in order to determine a threshold degradation of the DOC monitored that is not to be exceeded.

Owner:VITESCO TECH GERMANY GMBH

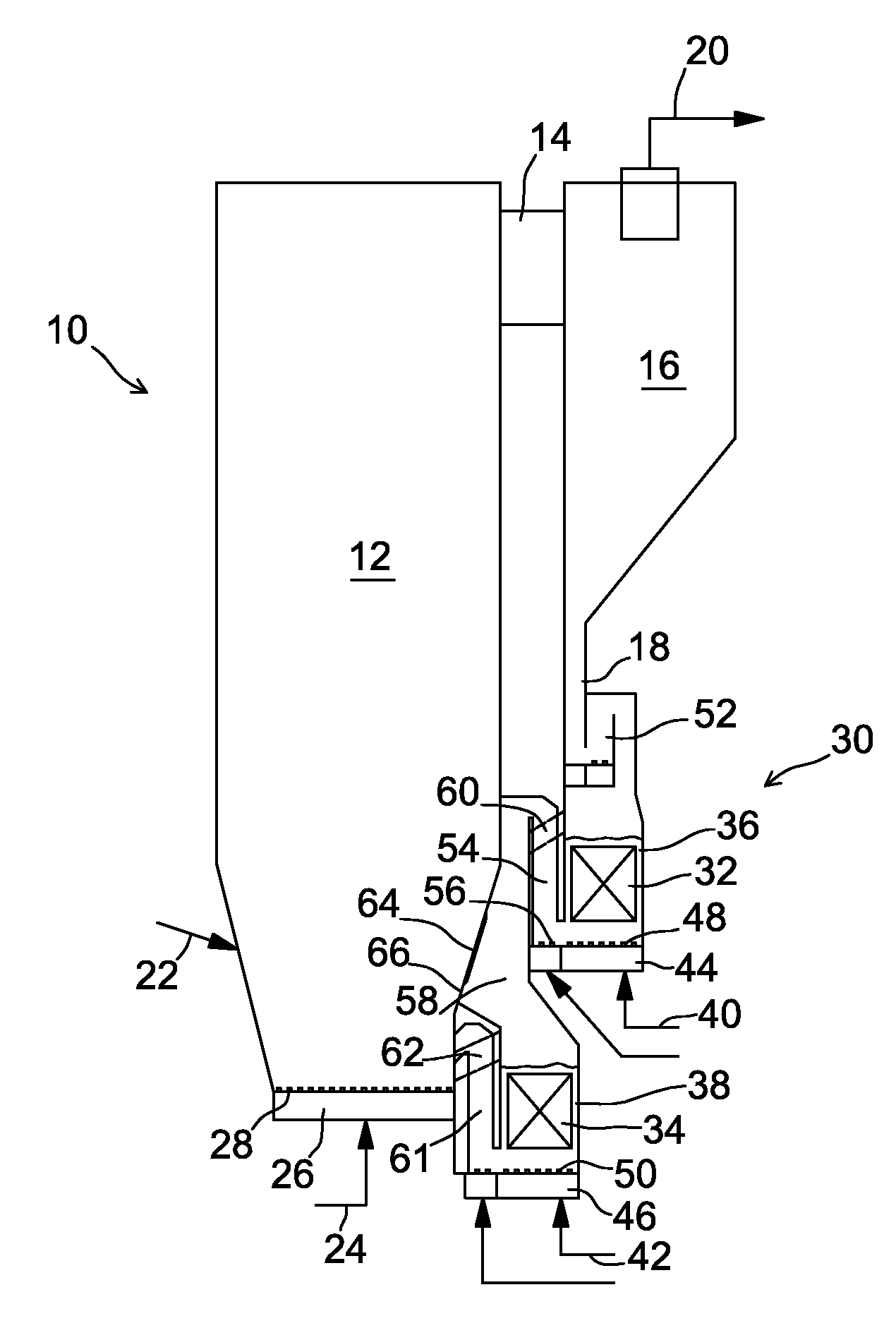

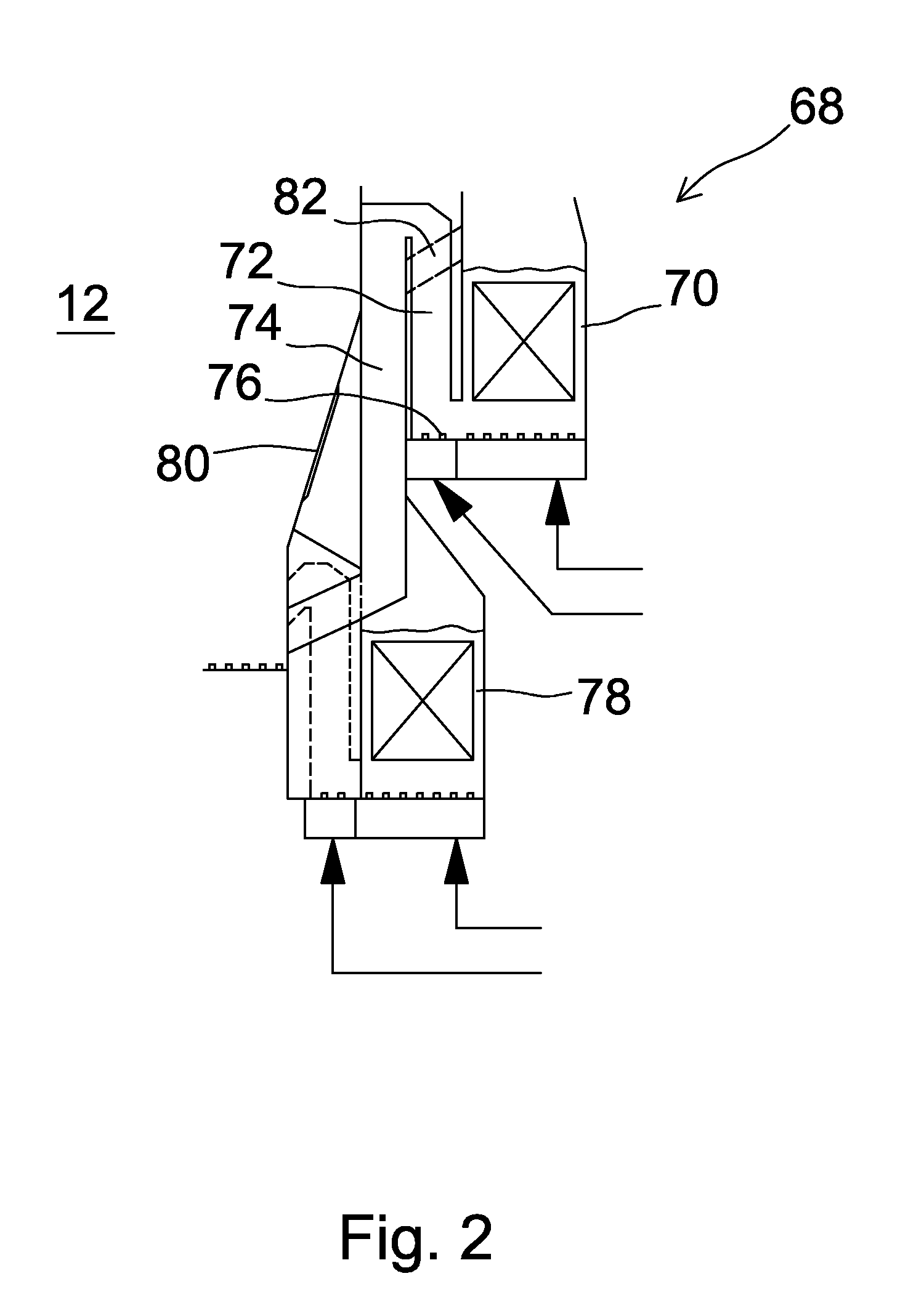

Fluidized Bed Heat Exchanger for a Circulating Fluidized Bed Boiler and a Circulating Fluidized Bed Boiler with a Fluidized Bed Heat Exchanger

ActiveUS20090293818A1Improve liquidityIncrease temperatureFluidized bed combustionFlash steam boilersInlet channelPlate heat exchanger

A heat exchanger and a circulating fluidized bed boiler with a heat exchanger including a first fluidized bed heat exchange chamber and a second fluidized bed heat exchange chamber, arranged in connection with a furnace of the circulating fluidized bed boiler, a first inlet channel for introducing hot solids from a particle separator of the external circulation of the circulating fluidized bed boiler into the first heat exchange chamber, a second inlet channel for introducing solids to the second heat exchange chamber, a first discharge for removing a first portion of the cooled solids from the first heat exchange chamber to the second inlet channel and a second discharge for removing cooled solids from the second heat exchange chamber to the furnace, the heat exchange chamber including an inlet for introducing hot solids directly from the internal circulation of the furnace to the second heat exchange chamber. The heat exchanger also preferably includes a third discharge for removing a second portion of the cooled solids from the first heat exchange chamber directly to the furnace.

Owner:FOSTER WHEELER ENERGIA OY

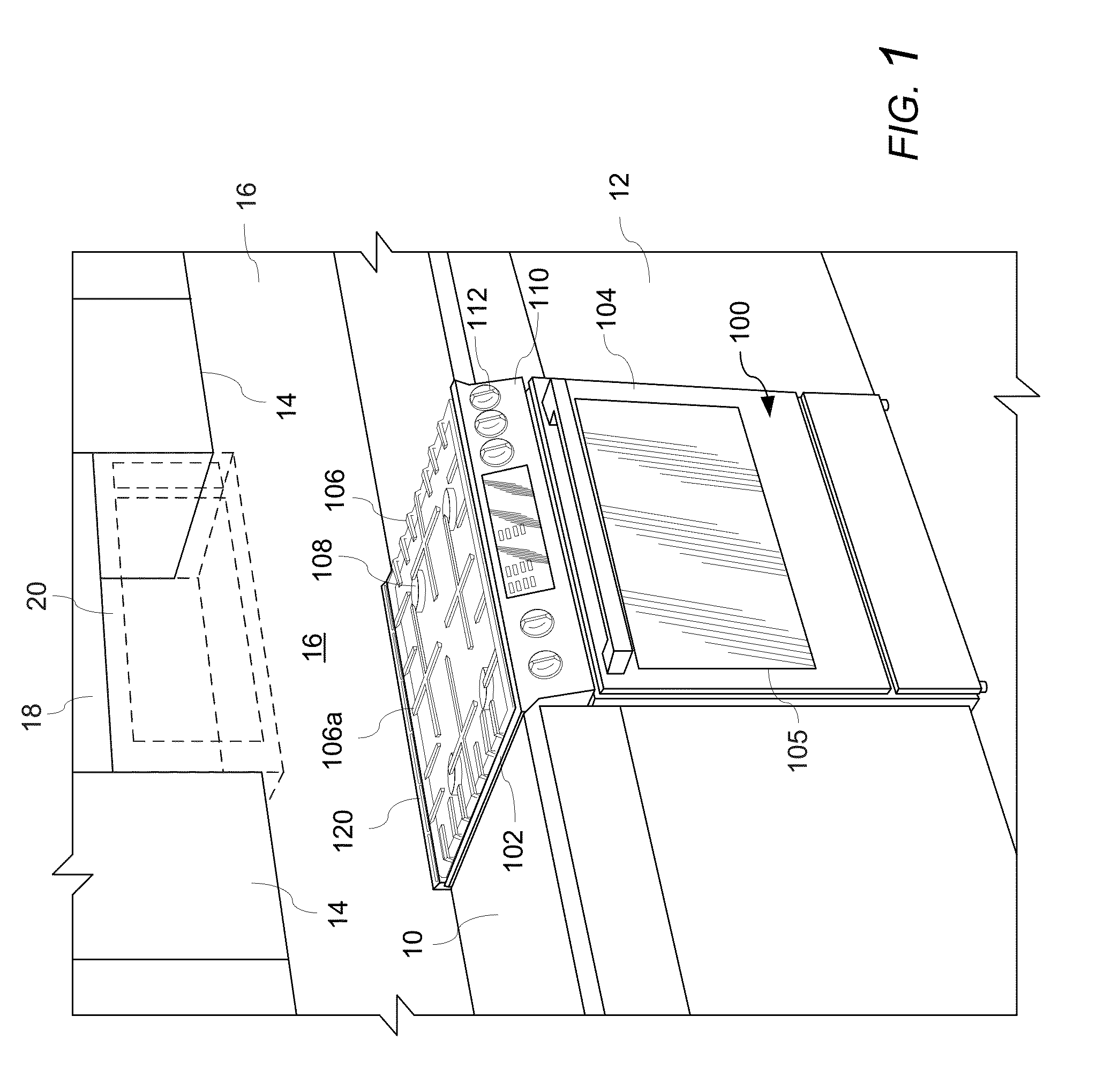

Home cooking appliance having a flue boundary

ActiveUS20150260415A1Minimize and prevent convective heat transferQuantity maximizationDomestic stoves or rangesLighting and heating apparatusFlue gasFlue

A home cooking appliance includes a housing, a cooking compartment in the housing, a flue in the housing and in fluid communication with the cooking compartment for exhausting flue gases from the cooking compartment, an exhaust outlet for exhausting the flue gases from the housing, and a flue boundary connecting the flue and the exhaust outlet, the flue boundary separating flue gases from cooling air flowing through the housing and preventing dilution of flue gases with cooling air. The housing includes a cooling rough-in box having a cooling air flow channel for cooling the rear wall of the flue boundary. The cooling rough-in box includes an opening permitting the cooling air to be drawn into the cooling air flow channel from an exterior of the housing by convection owing to heat on the rear wall of the flue boundary.

Owner:BSH BOSCH & SIEMENS HAUSGERAETE GMBH

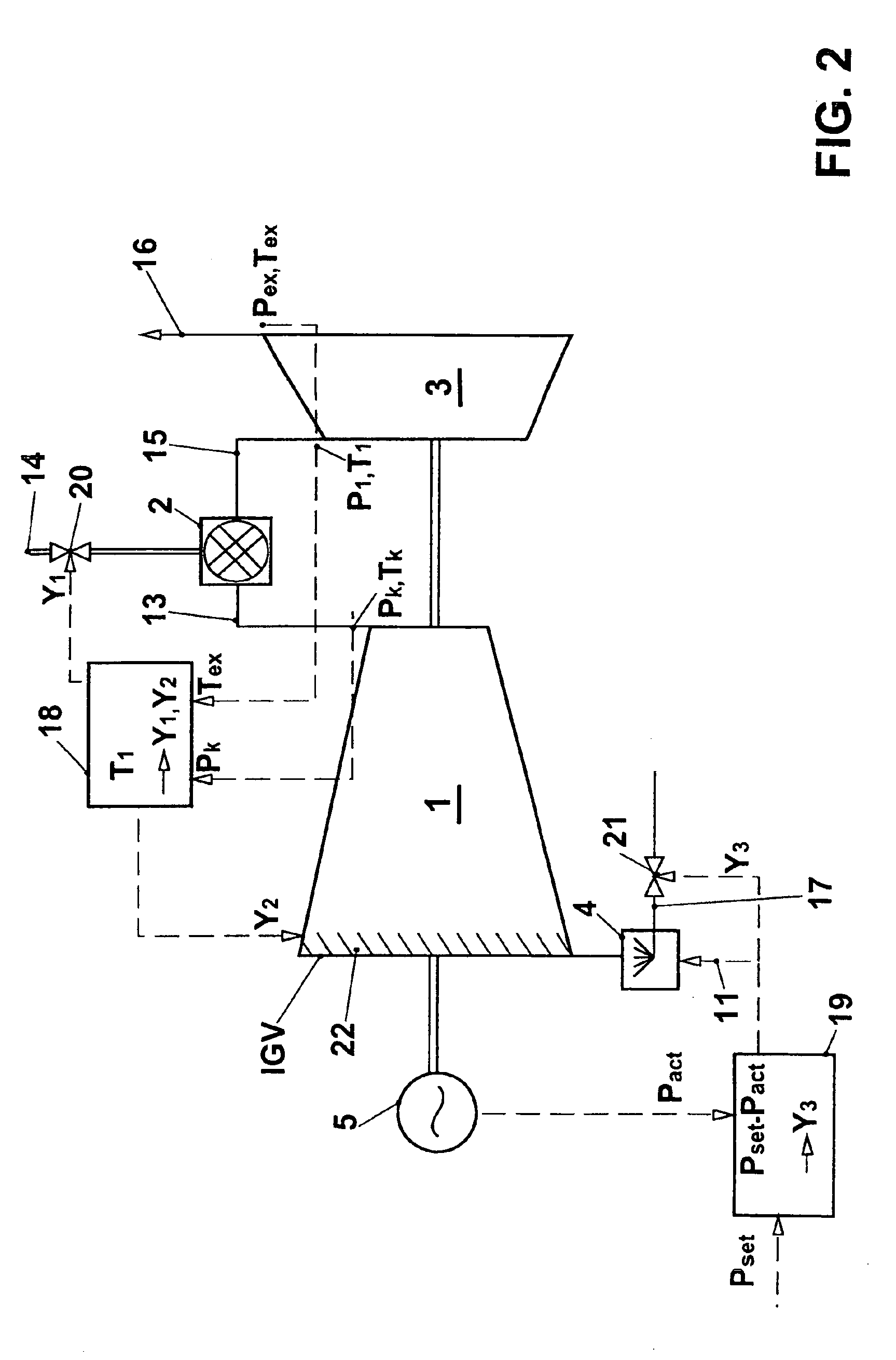

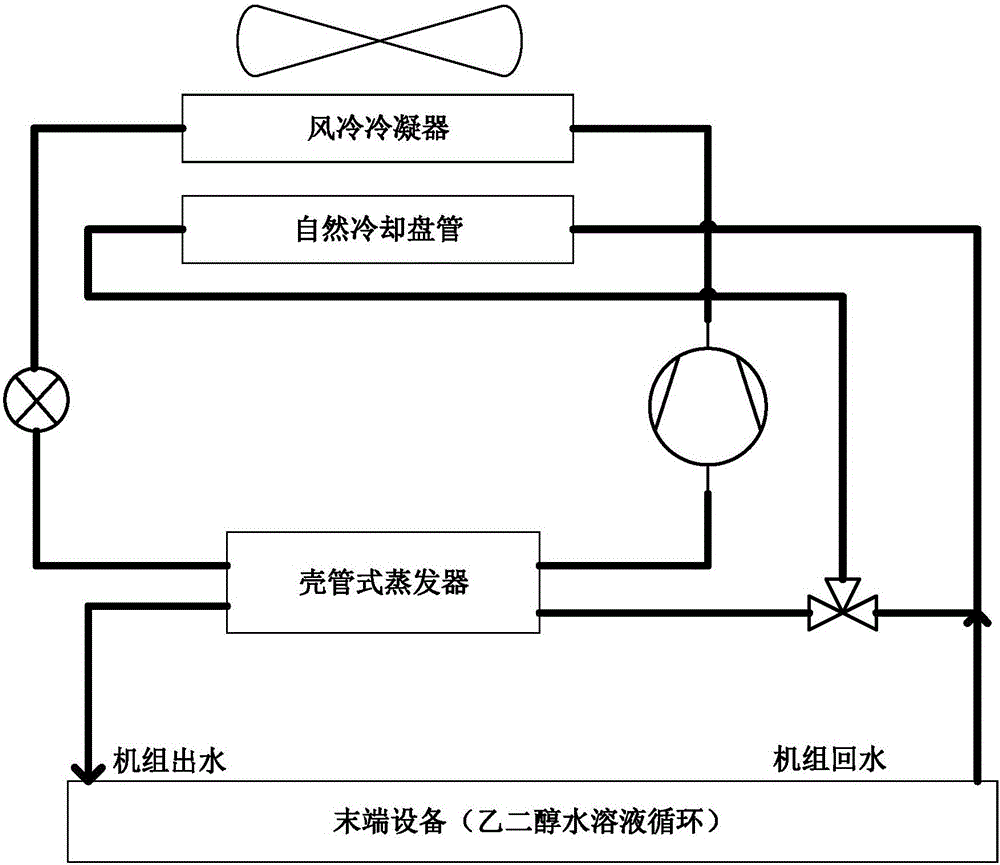

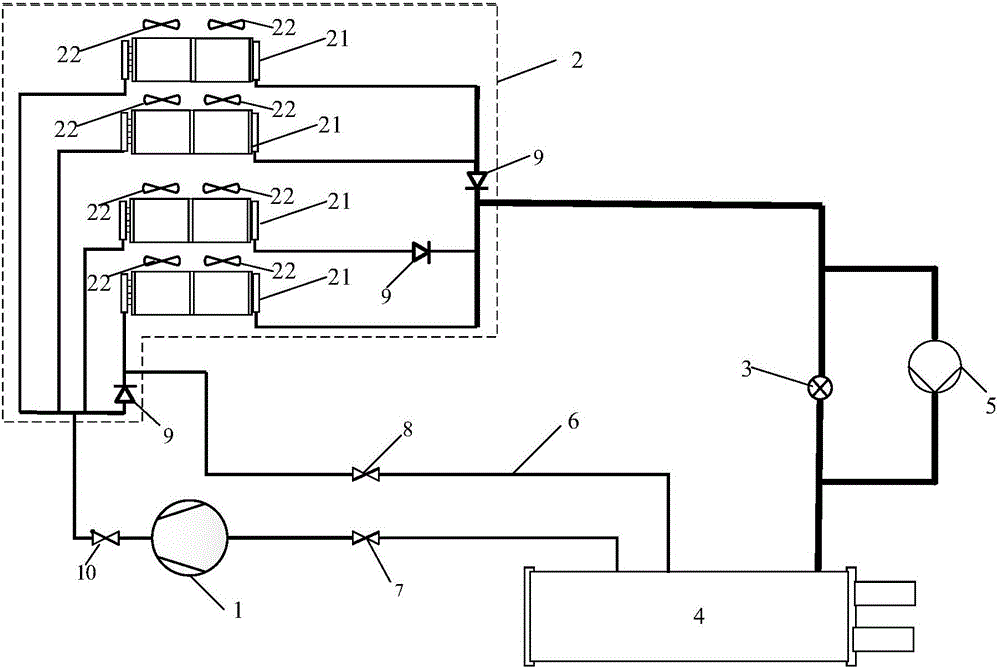

Refrigeration air-cooling unit and control method thereof

InactiveCN106225126AImprove cooling efficiencyReduce condensation areaMechanical apparatusEfficient regulation technologiesFree coolingEngineering

The invention provides a refrigeration air-cooling unit and a control method thereof. The unit comprises a steam compression circulation loop formed by the connection of a compressor (1), a condensing device (2), an expansion valve (3) and an evaporator (4) and further comprises a natural cooling circulation loop formed by the connection of a refrigerant pump (5), the condensing device (2) and the evaporator (4), wherein water is used as a refrigerating medium in the evaporator (4); and the condensing device (2) comprises a plurality of condensers (21) arranged in parallel, and the natural cooling circulation loop comprises at least one of the condensers (21). Through the refrigeration air-cooling unit and the control method thereof, the condensing area of natural cooling circulation can be effectively reduced, the outlet temperature of the condensing device is accordingly lowered, the evaporator is effectively prevented from being damaged, and the purposes and effects of preventing the freezing of the evaporator and keeping refrigerating efficiency are simultaneously realized.

Owner:GREE ELECTRIC APPLIANCES INC

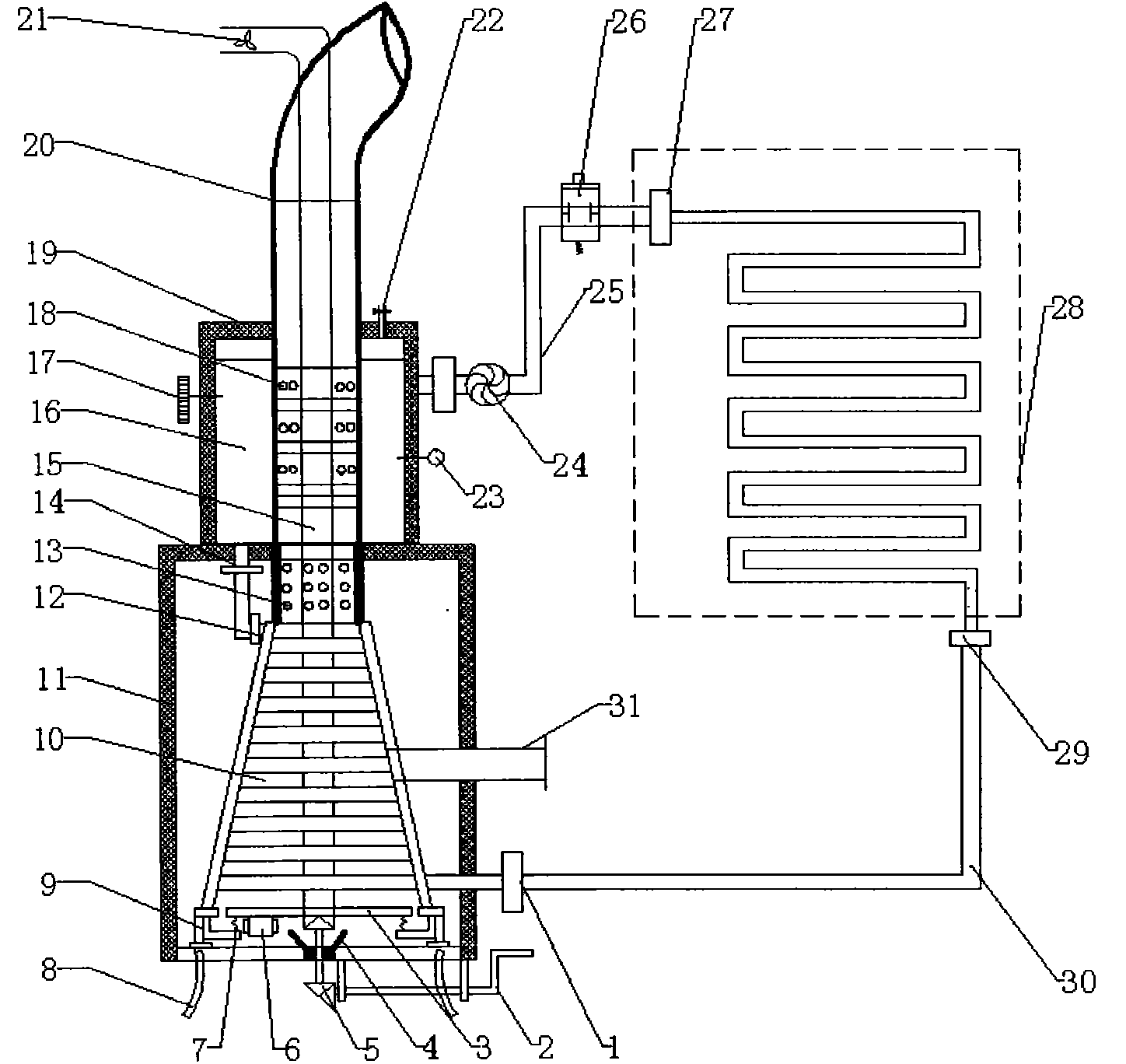

Biomass semi-gasification heating system

InactiveCN103836711ALow maintenance costAvoid harmful gasesAir supply regulationEnergy inputHeating systemProcess engineering

The invention relates to a biomass semi-gasification heating system. The biomass semi-gasification heating system comprises a biomass semi-gasification furnace, an energy-saving water tank, a heat exchanger, a chimney and an air pre-heating pipe. The biomass semi-gasification heating system organically combines the biomass semi-gasification furnace, the energy-saving water tank, the chimney, the air pre-heating pipe and the indoor heat exchanger together, the combustion and reverse combustion technology is fully used in the design of the biomass semi-gasification furnace, a water cooling wall forms a hearth, the design concept that the air pre-heating pipe conveys the needed air is adopted, the energy-saving water tank is designed into four areas, the structure that water cooling pipes are communicated with the related areas is adopted, and the design of the whole system accords with the concept of energy conservation, so that the biomass semi-gasification heating system is not only low in production, manufacturing, use and maintenance expense, but also convenient to popularize in rural areas. The biomass semi-gasification heating system overcomes the defects of a common heating furnace and a common biomass gasification heating furnace, and improves the effective use efficiency of biomass energy.

Owner:HENAN POLYTECHNIC UNIV

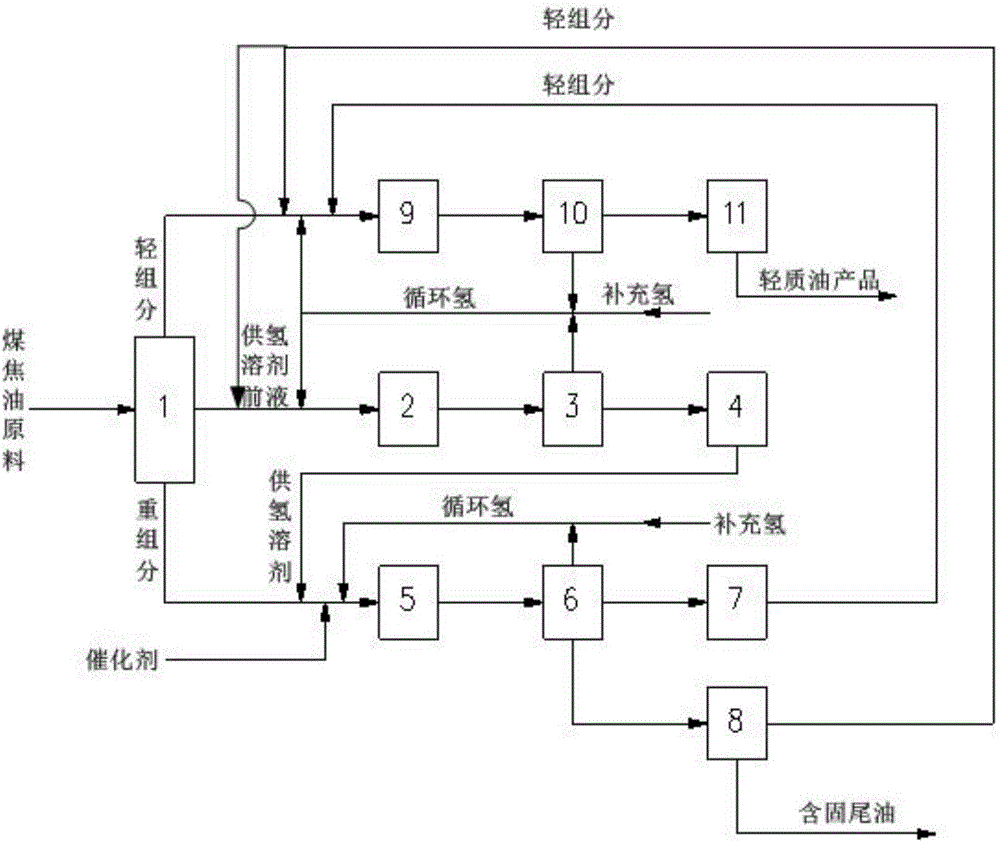

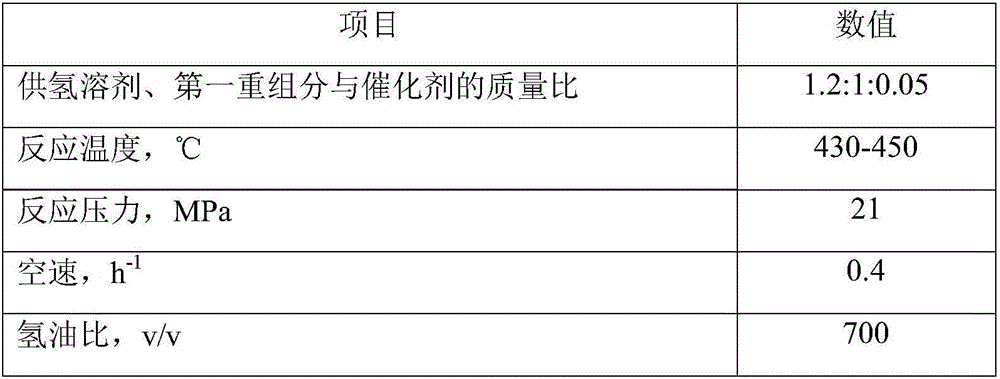

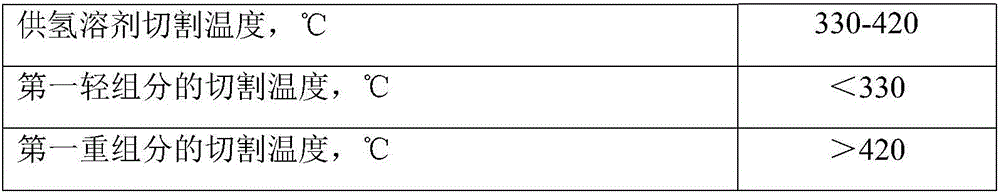

High solid content coal tar suspended bed hydrogenation system and technology

ActiveCN106635159AHigh yieldGuaranteed uptimeTreatment with hydrotreatment processesHydrocarbon oils treatment productsSolventChemistry

The invention provides a high solid content coal tar suspended bed hydrogenation system and a high solid content coal tar suspended bed hydrogenation technology. The system comprises a hydrogen supply unit; a catalyst supply unit; a coal tar segmentation unit used for segmenting high solid content coal tar into a first light component, hydrogen-donor solvent pre-solution and a first heavy component; a hydrogen-donor solvent production unit connected with the coal tar segmentation unit and the hydrogen supply unit respectively; and a catalytic hydrogenation reaction unit connected with the coal tar segmentation unit, the hydrogen-donor solvent production unit and the catalyst supply unit respectively. According to the system and the technology provided by the invention, hydrogenation depth can be significantly improved, liquefied oil productivity is increased, wall-phase coke can be effectively avoided, total quantity of coke is reduced, long-term and stable operation of the device is achieved, and gas-phase productivity can be effectively reduced and the load of a feeding heating furnace is reduced.

Owner:胜帮科技股份有限公司

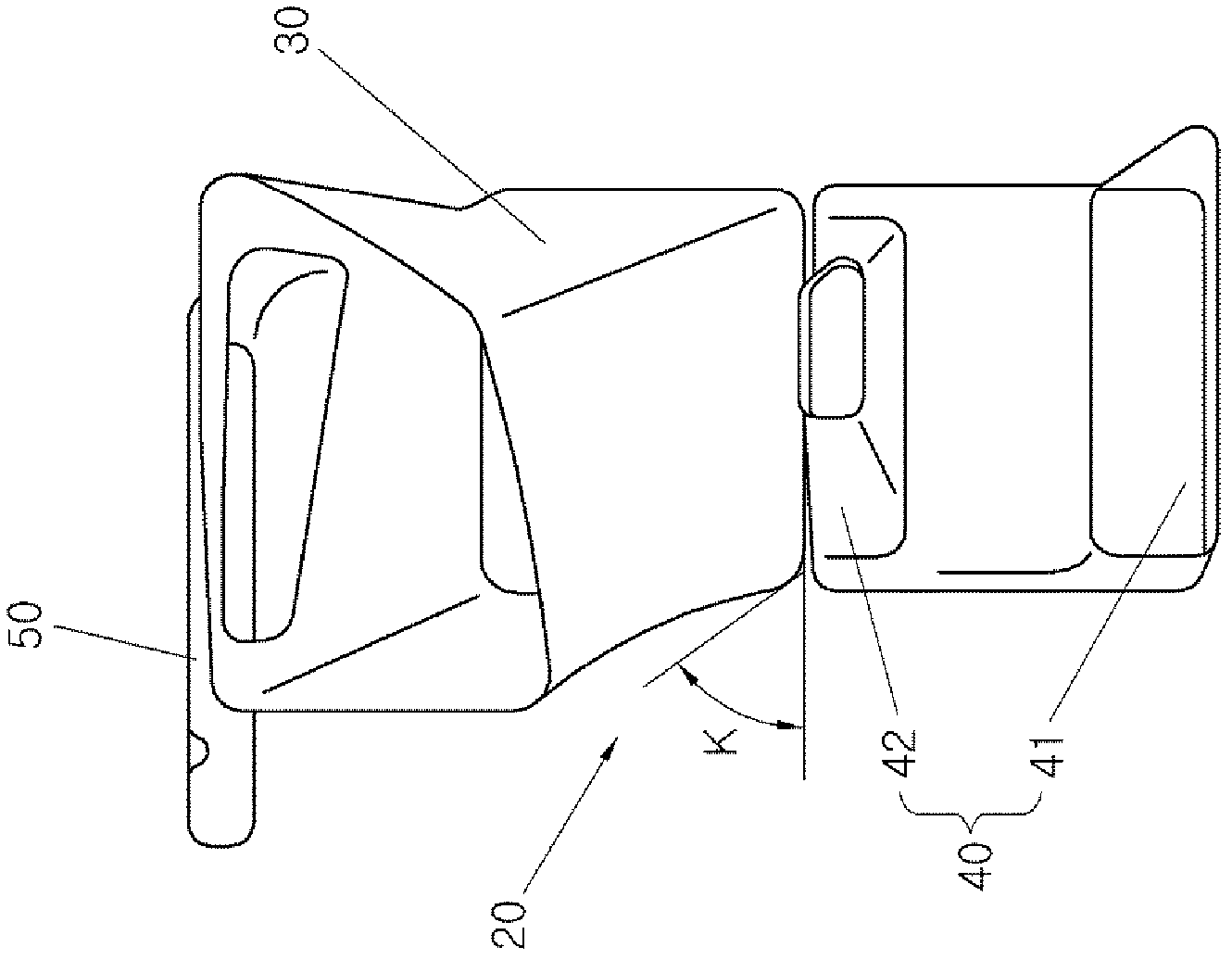

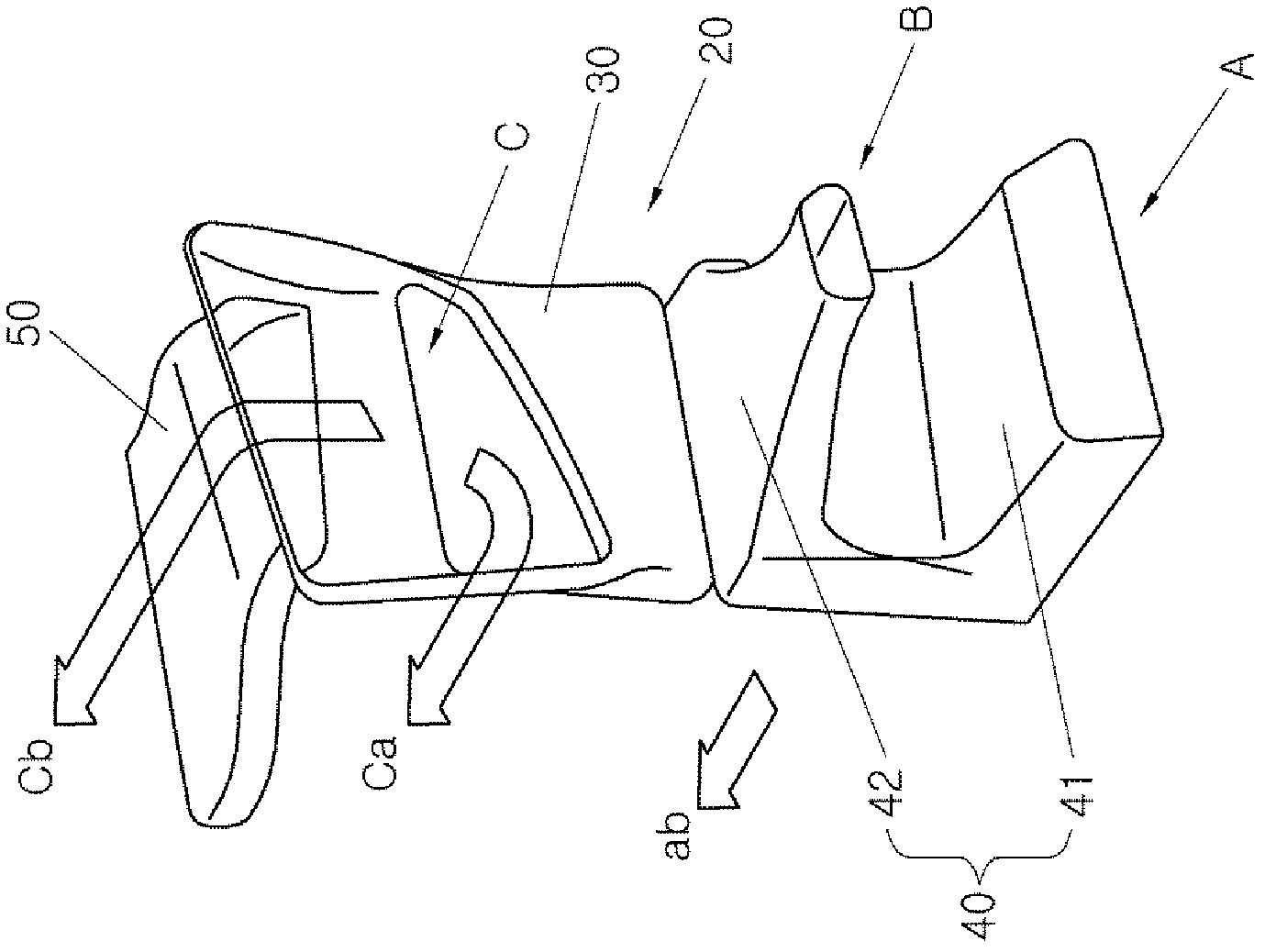

Wind flux concentration guiding device and engine room layout thereof

ActiveCN102673385AImprove cooling effectImprove efficiencyAir coolingMachines/enginesTurbochargerIntercooler

An engine room layout using a wind flux concentration guiding device, may include an intake system having an air intake, a turbocharger, and an intercooler, and may be disposed in an engine room, a cooling module having a condenser and a radiator, a main duct that introduces wind passing through a front end part forming the front of the engine room and discharges the wind to the air intake and the intercooler, a sub-duct that introduces the wind passing through the front end part from different positions and discharges the wind to the intercooler, and a diverging duct that may be connected to a wind channel of the main duct to diverge some of the wind introduced into the main duct before the wind passes out of the main duct, and send the wind to the air intake.

Owner:HYUNDAI MOTOR CO LTD +1

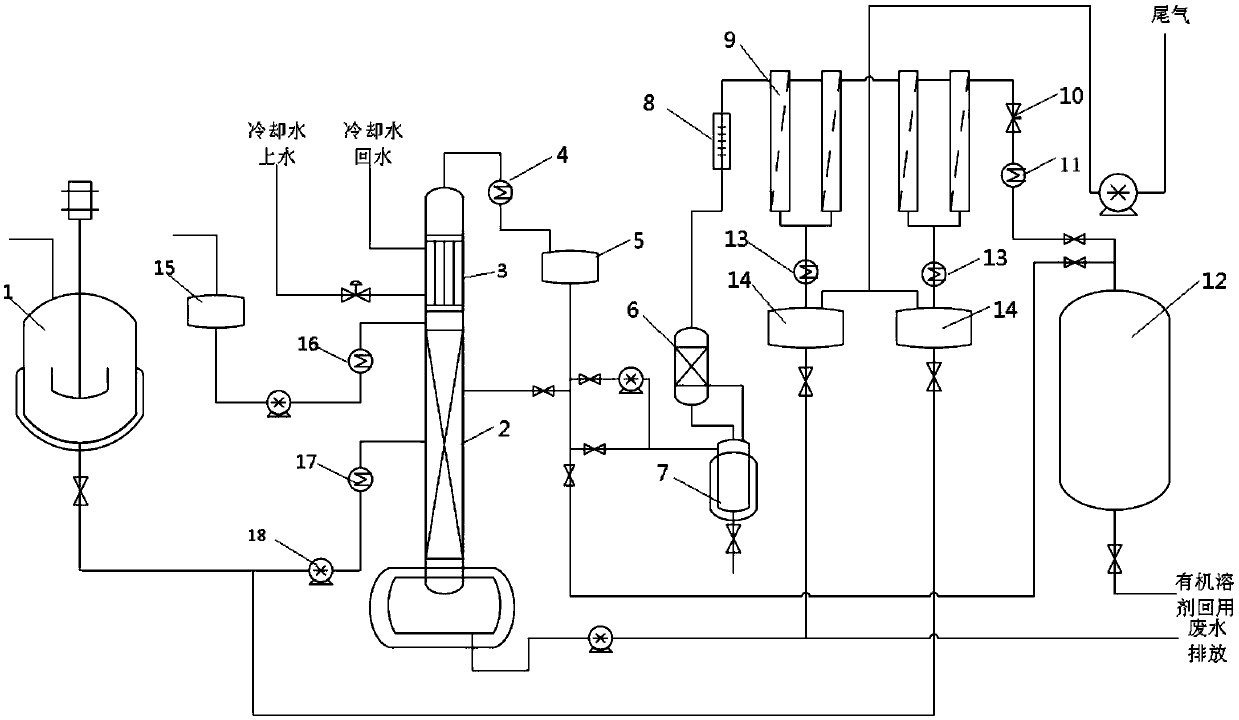

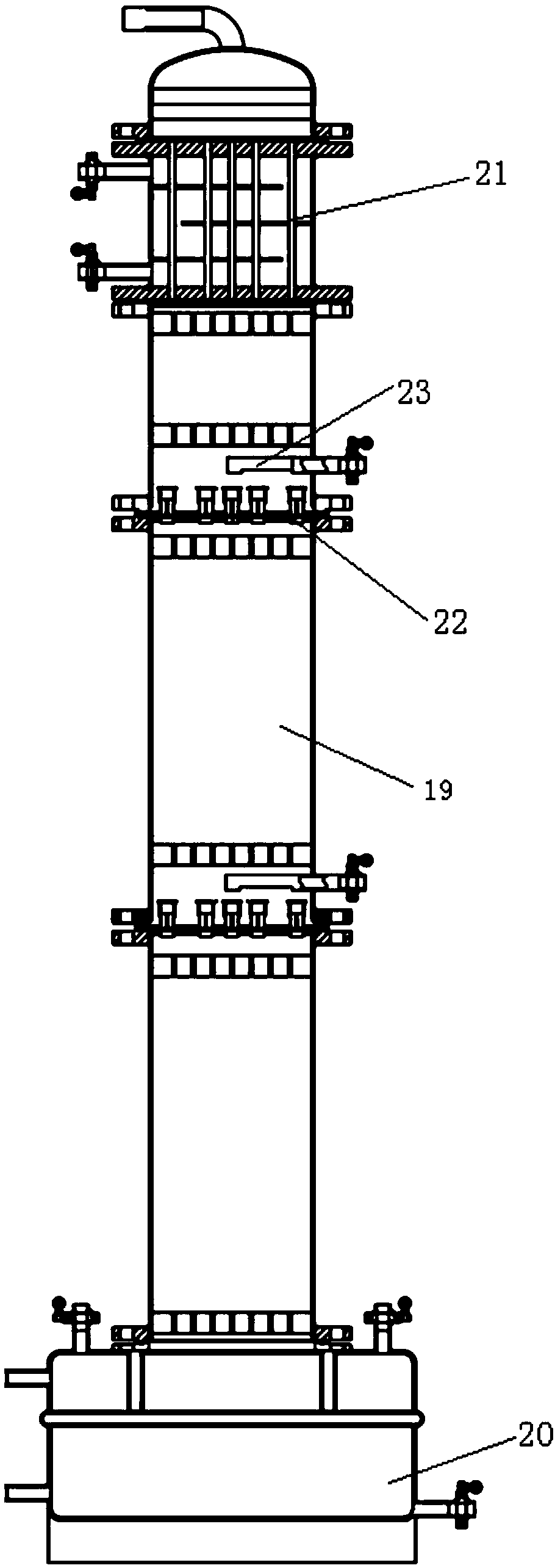

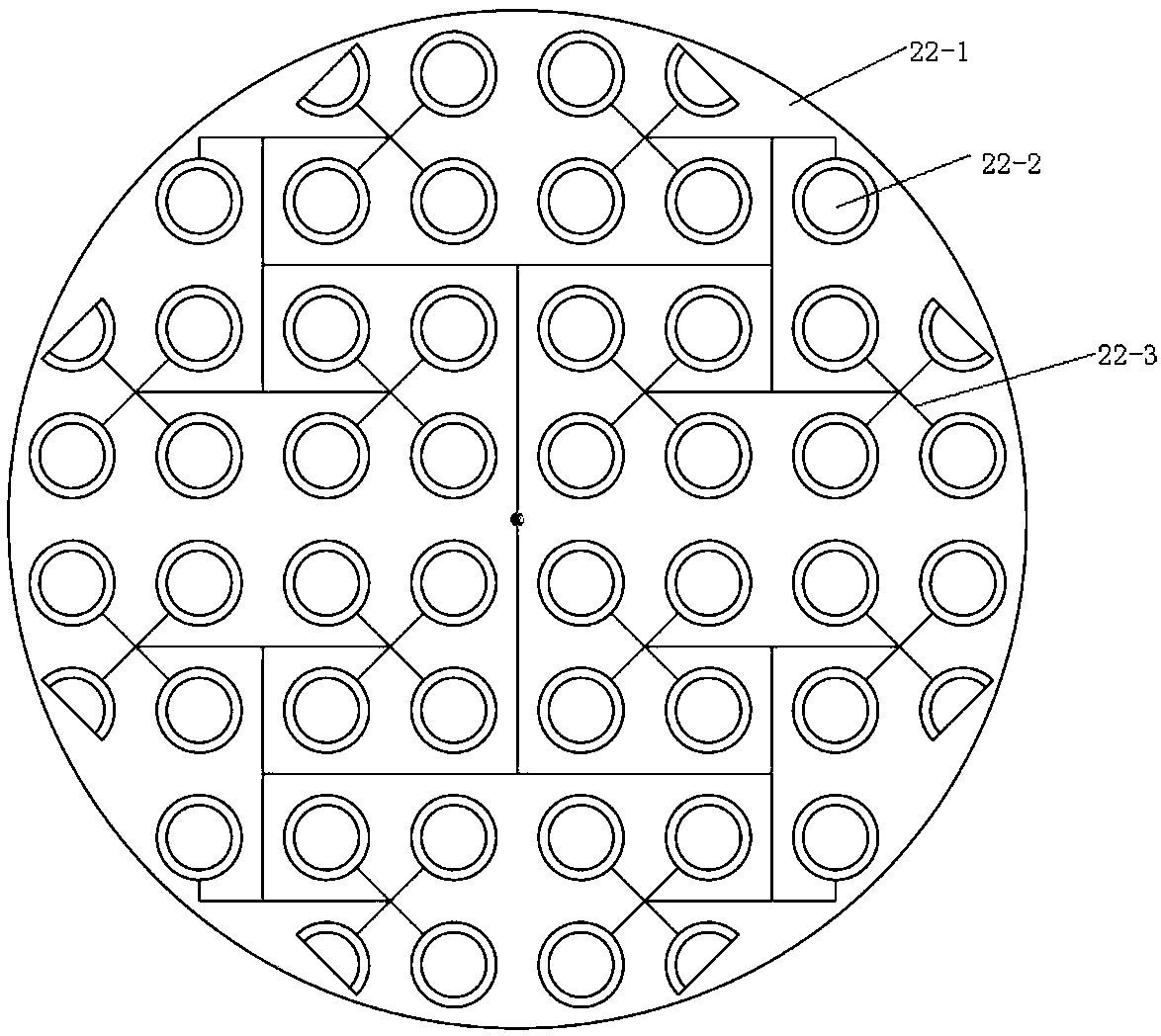

Separation and recycle system for water-containing organic waste liquid and organic solvents as well as recycle method

PendingCN109663376AAvoid accumulationEasy to separateLiquid distribution in distillationDistillationLiquid wasteRecovery method

The invention provides a separation and recycle system for water-containing organic waste liquid and organic solvents as well as a recycle method, wherein the separation and recycle system consists ofa distillation system and a pervaporation membrane separation system through process pipeline connection. A packed tower is adopted as a rectifying tower, and the material inlet of the packed tower is arranged in the center of a packed tower liquid distributor. A damping structure is arranged in the pervaporation membrane unit of the pervaporation membrane separation system. The separation and recycle system provided by the invention is suitable for online dehydration and recycle of multiple kinds of water-containing and two or more than two azeotropic or non-azeotropic organic solvents as well as for separation and reuse of the organic solvents.

Owner:CHENGDU GELAI HIGH TECH CO LTD

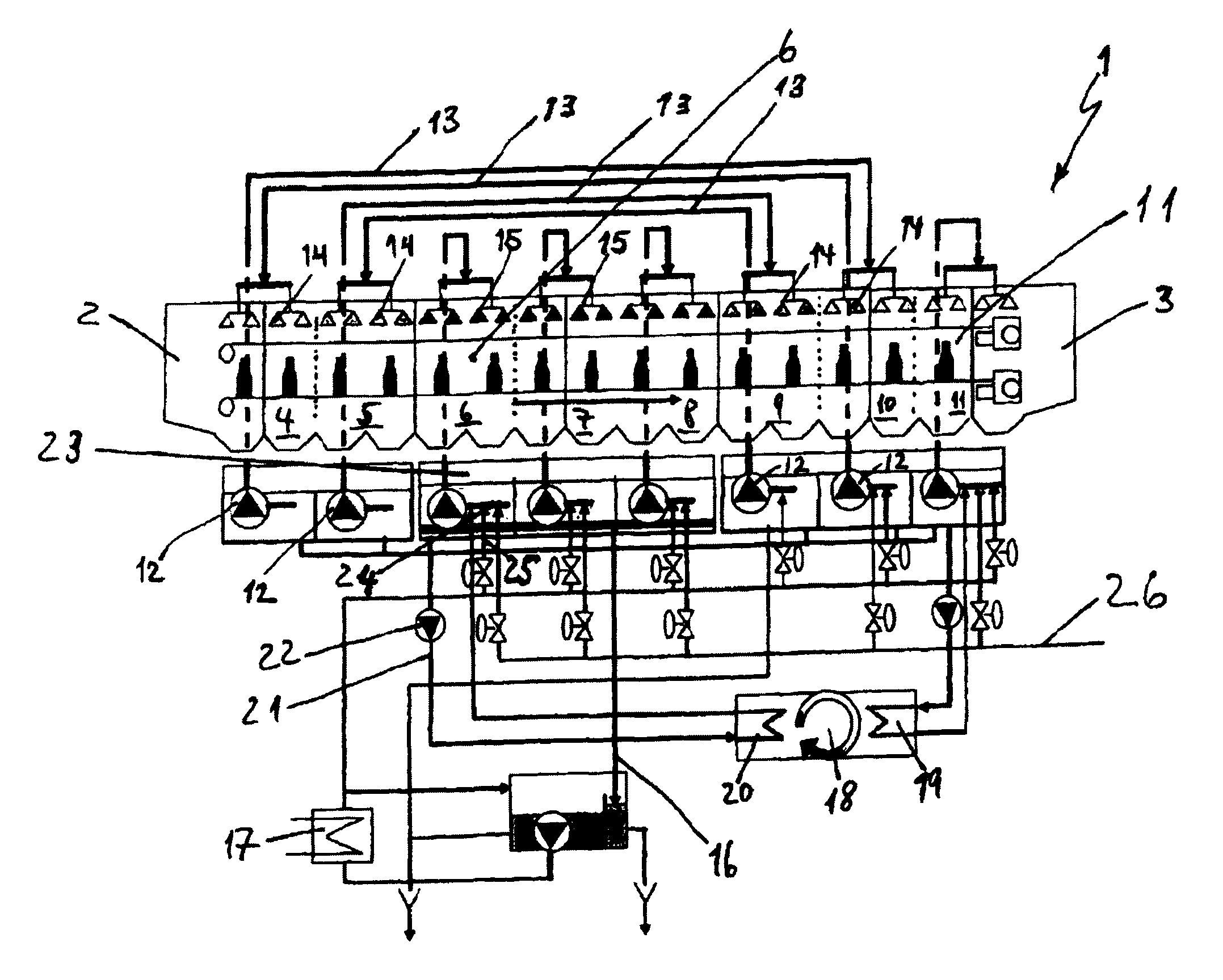

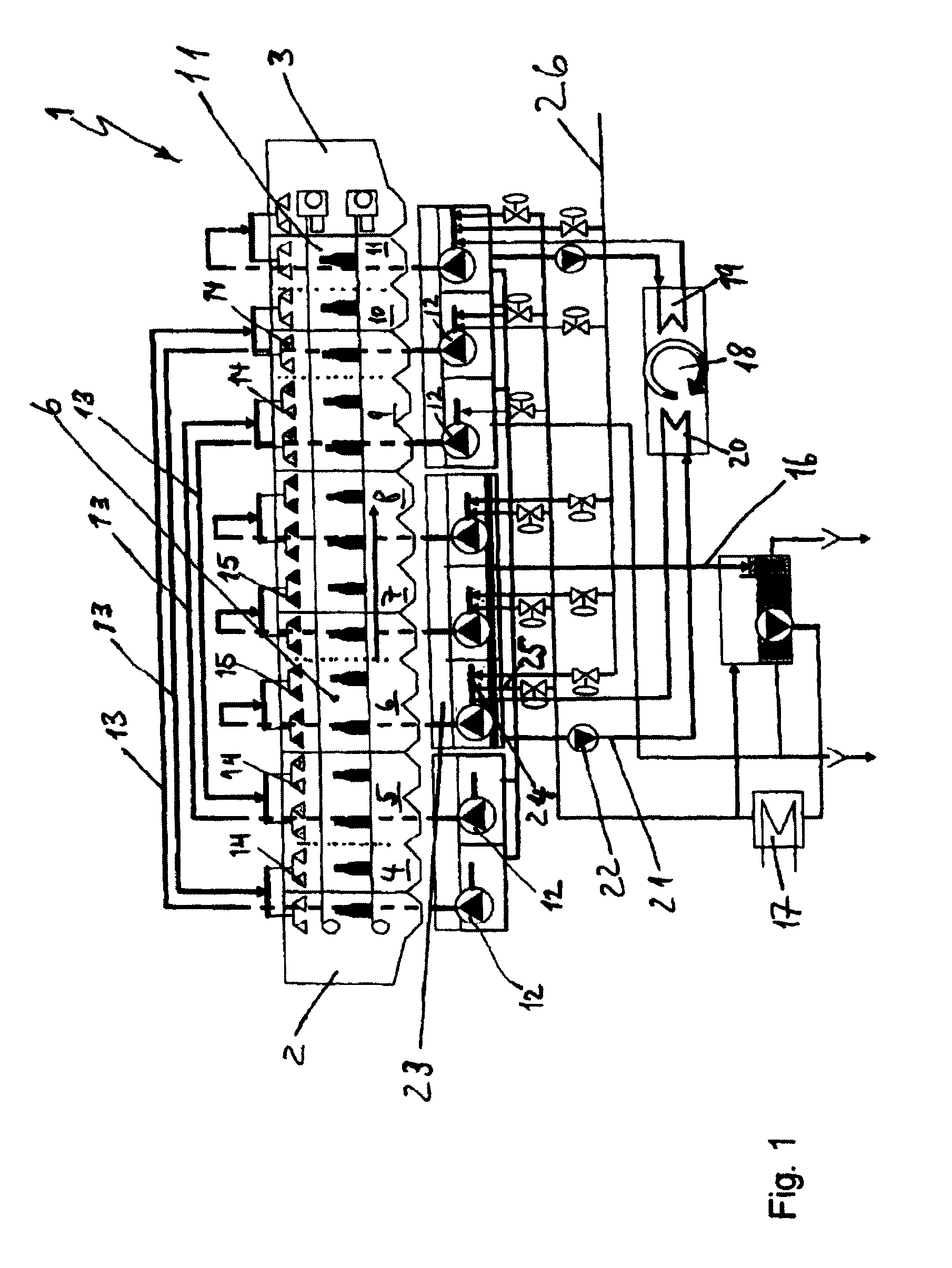

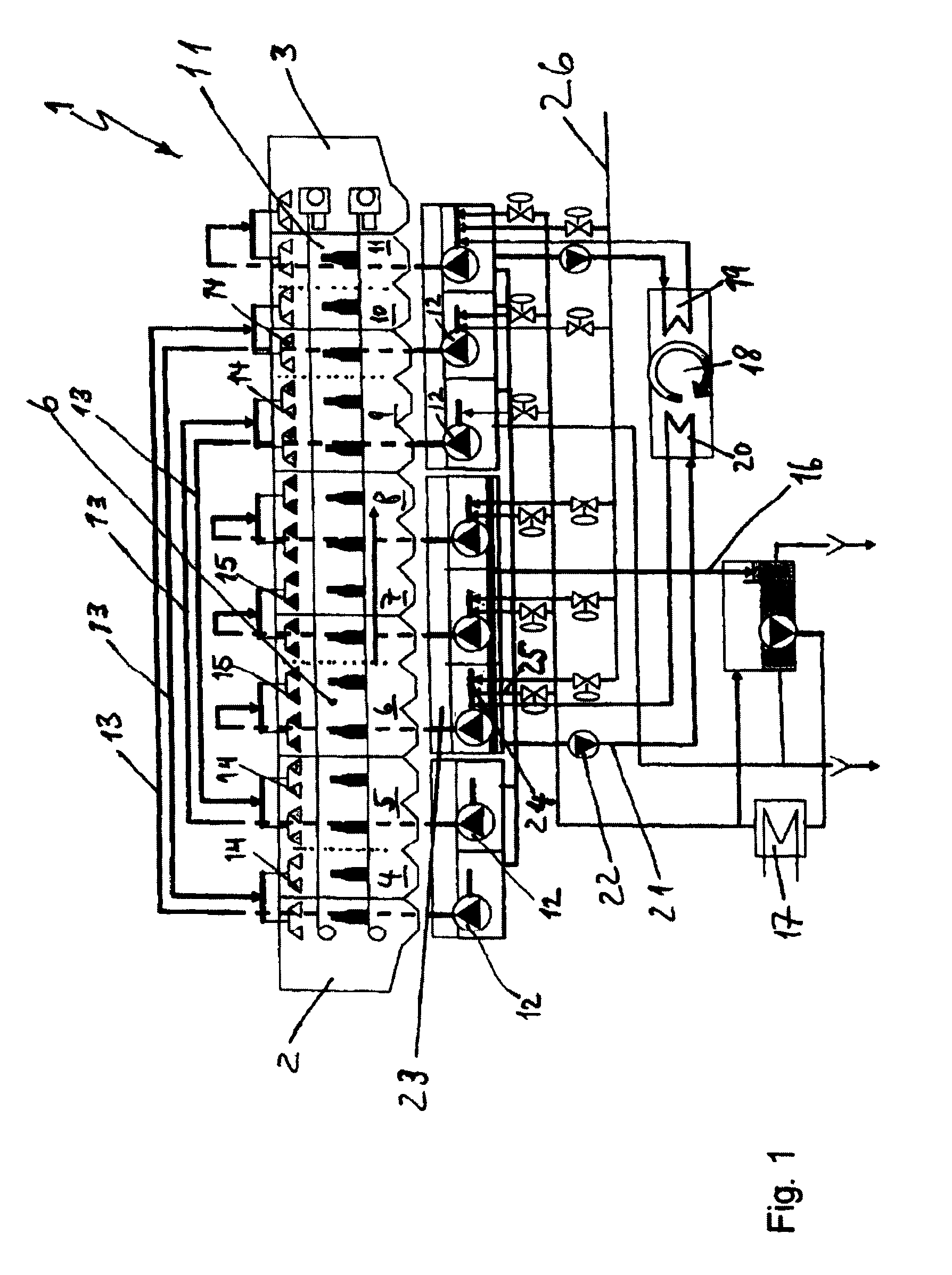

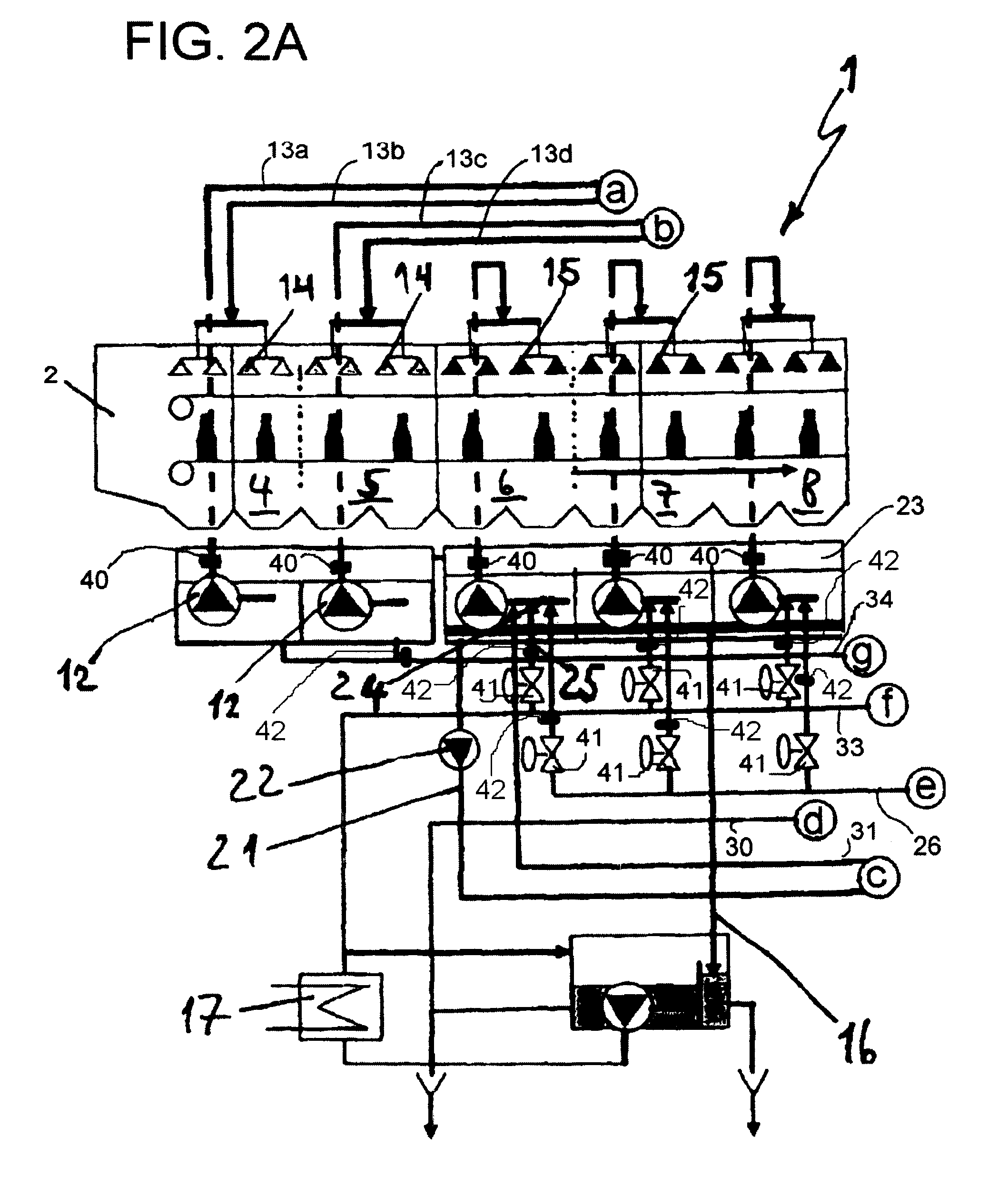

Beverage bottling plant for filling beverage bottles with a beverage bottle treatment machine and a beverage bottle treatment machine in a beverage bottling plant

A beverage bottling plant for filling beverage bottles with a beverage bottle treatment machine and a beverage bottle treatment machine in a beverage bottling plant. The abstract of the disclosure is submitted herewith as required by 37 C.F.R. §1.72(b). As stated in 37 C.F.R. §1.72(b): A brief abstract of the technical disclosure in the specification must commence on a separate sheet, preferably following the claims, under the heading “Abstract of the Disclosure.” The purpose of the abstract is to enable the Patent and Trademark Office and the public generally to determine quickly from a cursory inspection the nature and gist of the technical disclosure. The abstract shall not be used for interpreting the scope of the claims. Therefore, any statements made relating to the abstract are not intended to limit the claims in any manner and should not be interpreted as limiting the claims in any manner.

Owner:KHS GMBH

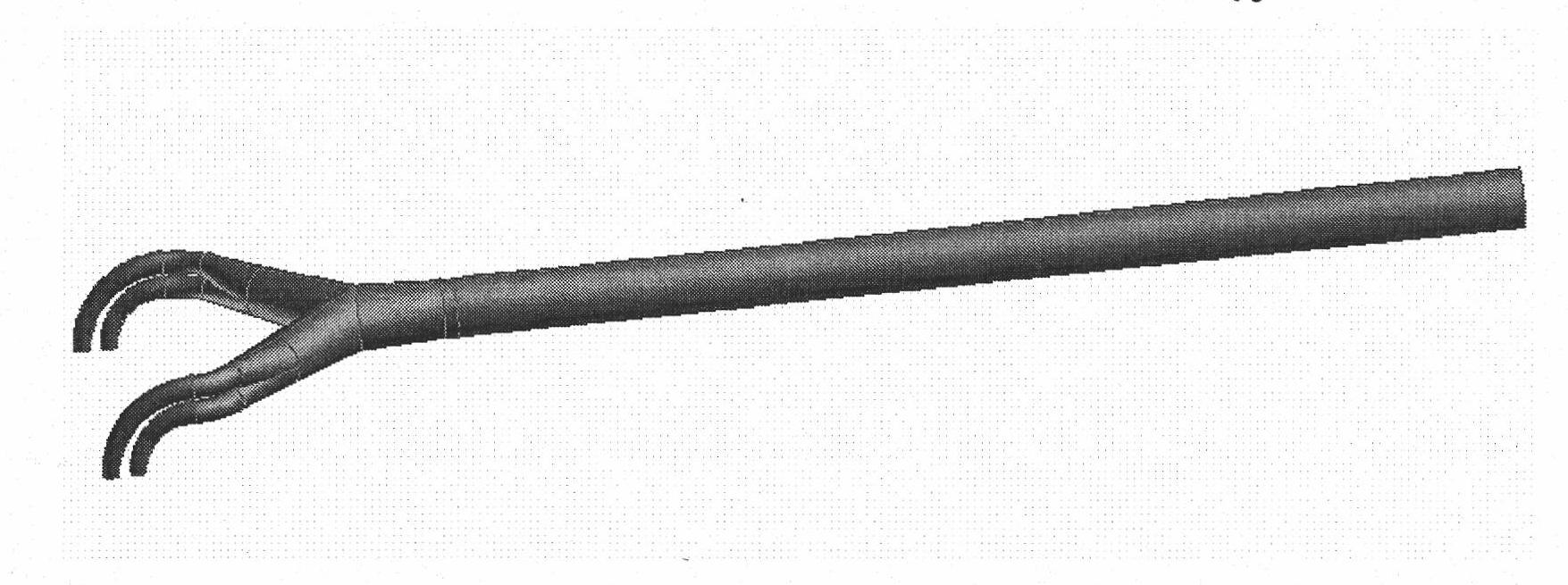

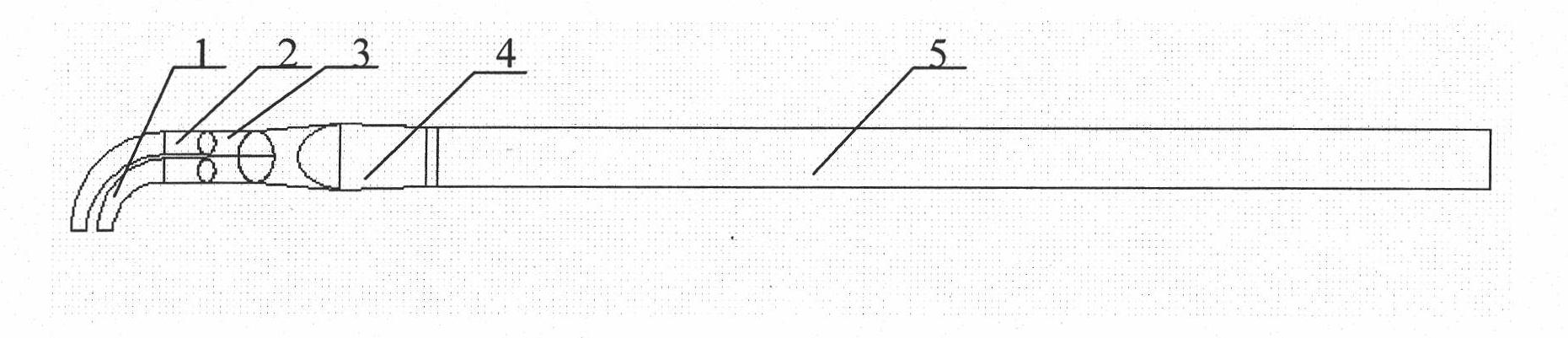

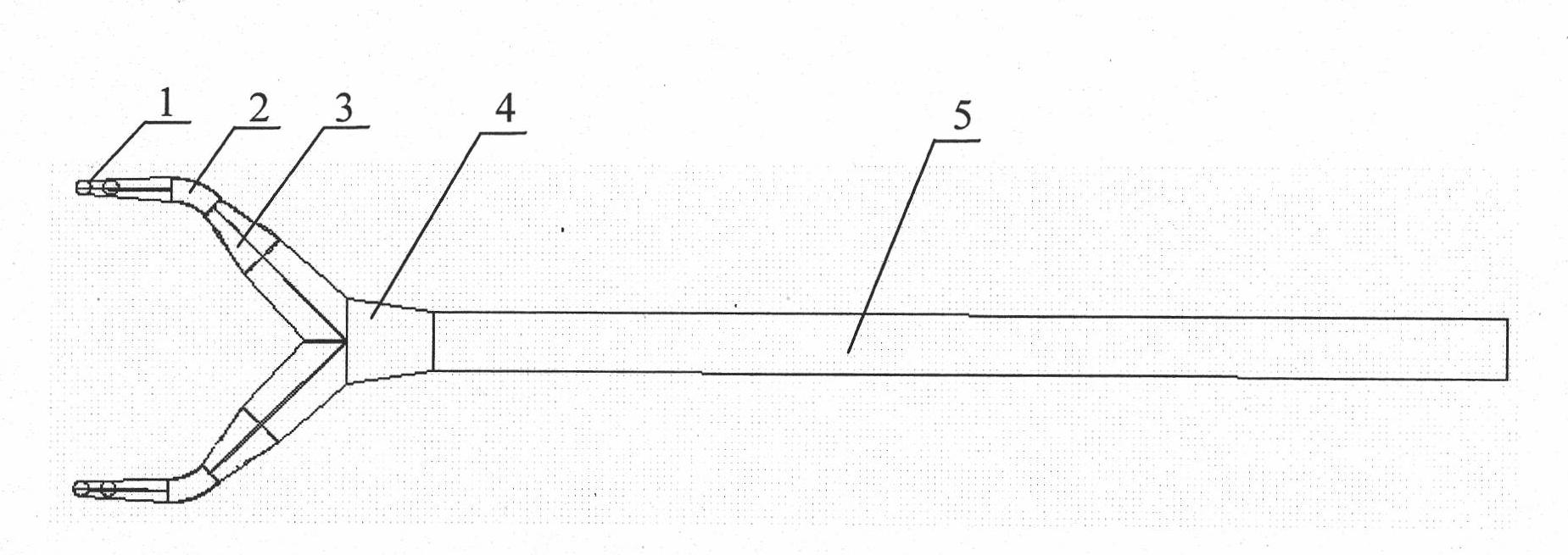

Low dropout decompression transfer line

ActiveCN101532594BSmall pressure dropGood vaporization effectDistillation separationRigid pipesLow speedPetroleum

A low dropout decompression transfer line of the invention is used in a pipeline between a vacuum furnace and a vacuum tower of an atmosphere and vacuum distillation unit in the process of oil refining and in other devices for transporting oil products with high temperature and low pressure. The low dropout decompression transfer line comprises a 90 degree extend elbow, a 30-60 degree elbow, a transition section and a low speed section; wherein, the transition section adopts a structure of progressive hole enlargement, the 90 degree extend elbow is one with the curvature radius being 3-6 times of the diameter of a bent pipe, and the transition section is structured in the way that a trousers-shaped straight tee (3) with 15-30 degree of included angle is connected with a Y-shaped straight tee (4) in the shape of trousers with 45-90 degree of included angle. The invention adopts the principle of pipe diameter extending and smooth processing at joints, reduces resistance loss in the process of flowing and pressure drop of the transfer line and optimizes vaporization effect of the oil products, thus improving distillate yield and generating appreciable economic benefits.

Owner:TIANJIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com