Separation and recycle system for water-containing organic waste liquid and organic solvents as well as recycle method

A technology for separation and recovery of organic waste liquid, applied in chemical instruments and methods, organic chemistry, semi-permeable membrane separation, etc., can solve the problems of high policy threshold, long construction period, scattered demand, etc., to avoid accumulation and improve safety. , space saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

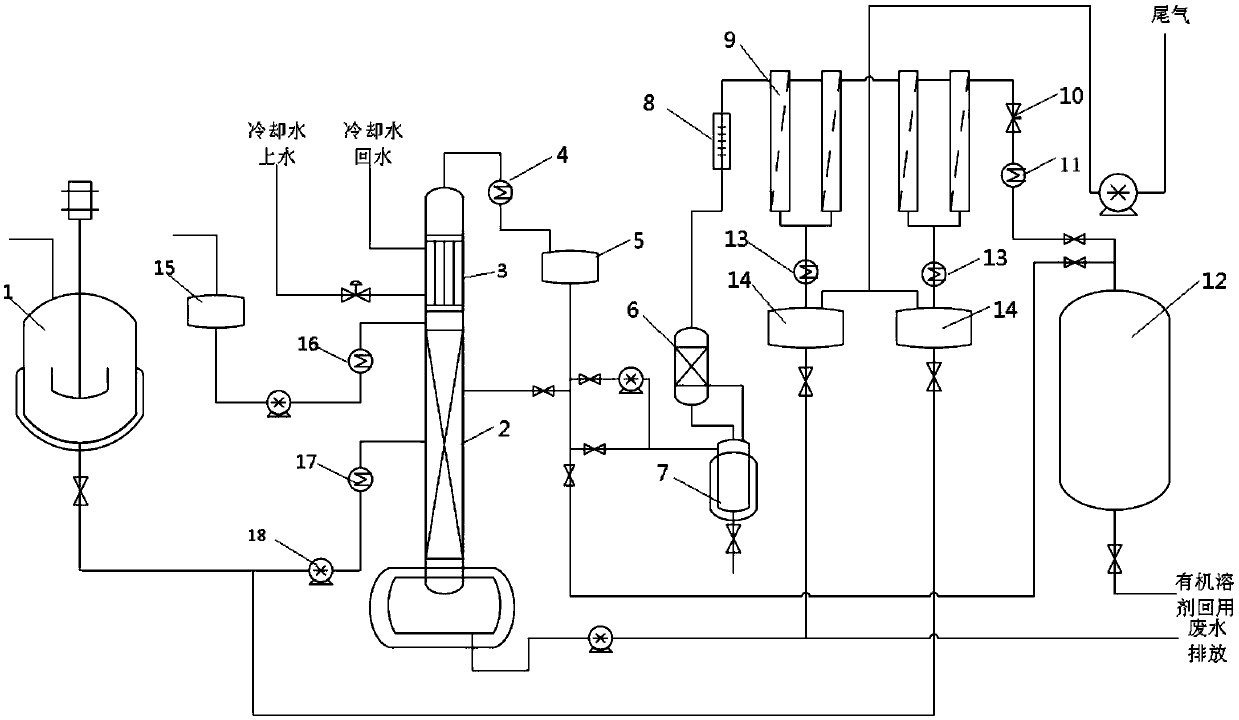

[0058] The separation and recovery system is composed of a rectification system and a pervaporation membrane separation system connected through process pipelines;

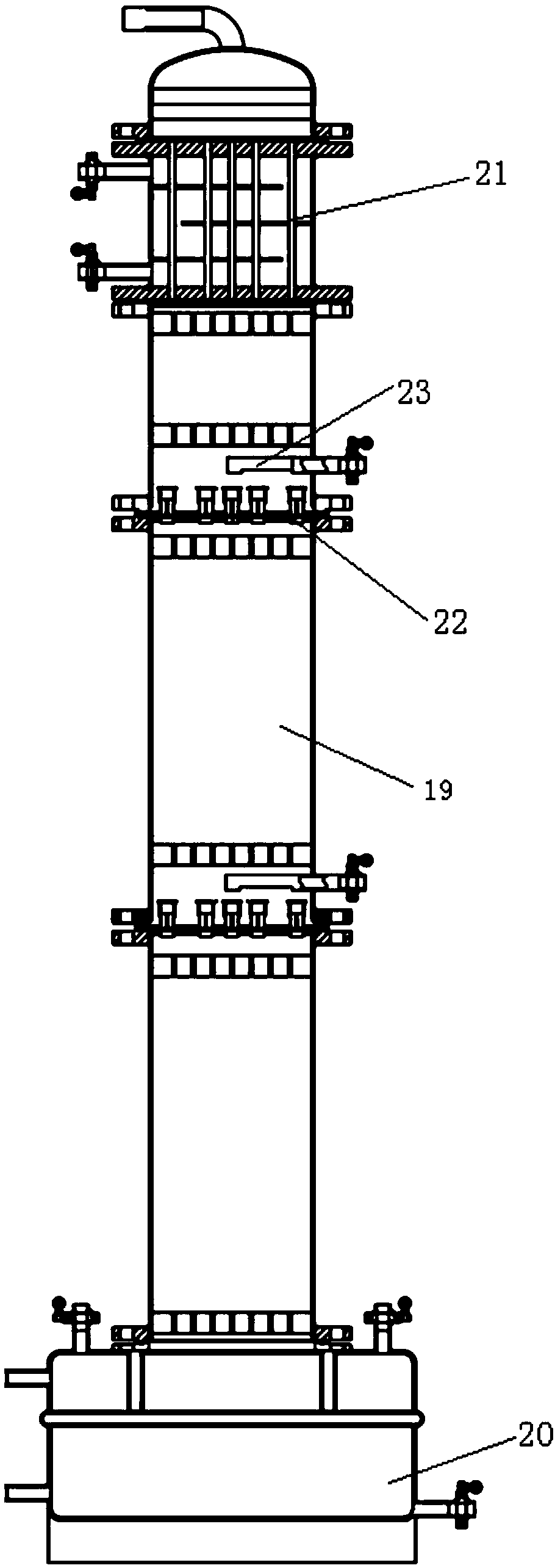

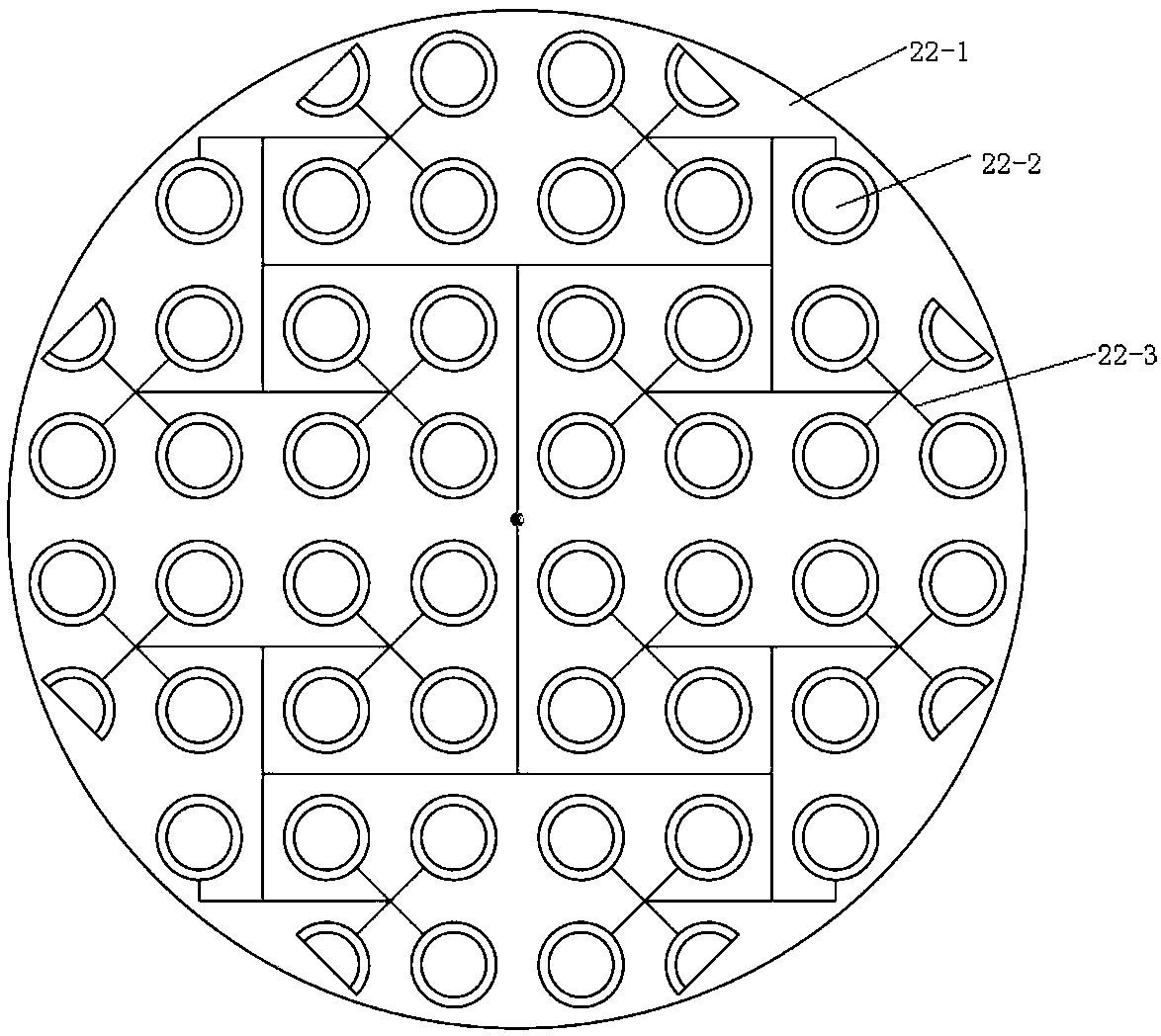

[0059] The rectification system comprises a conditioning tank 1, a rectification tower 2, a partial condenser 3, a total condenser 4 and a product receiving tank one 5, and the outlet of the conditioning tank is communicated with the feed port of the rectification tower , the partial condenser is arranged in the column body at the top of the rectification tower, the total condenser is arranged at the top of the rectification tower, and is used to condense the low-boiling components that are not condensed by the partial condenser, and the outlet of the total condenser is arranged A split pipeline, so that a part of the condensed product enters the product receiving tank 1, and a part of it flows back into the rectifying tower;

[0060] The pervaporation membrane separation system comprises a vaporizer 7, a vapor-li...

Embodiment 2

[0064] Embodiment 2 acetonitrile-water separation

[0065] Taking the acetonitrile waste liquid in the peptide industry as an example to illustrate the operation method of a small solvent recovery device. Peptide industry acetonitrile waste liquid (mixed solvent) comprises about 10~15% wt. acetonitrile and 85~90% wt. A small amount of high boiling point substances. The mixed solvent enters the rectification tower continuously at a flow rate of 100L / h (mass flow: 90.73kg / h) through the pump. The top of the rectification tower adopts a built-in condenser, and the feeding amount of circulating water is controlled according to the temperature at the top of the tower, and the temperature at the top of the tower is The control is 88.4°C, the pressure is 0.15MPa, the mass flow rate of the gas phase produced at the top of the tower is 17kg / h, the mass composition of acetonitrile is 80.1%wt., and the mass composition of water is 19.9%wt.; the temperature of the tower kettle is control...

Embodiment 3

[0067] Example 3 THF-water separation

[0068] Taking the tetrahydrofuran (THF) waste liquid of a pharmaceutical company as an example to illustrate the operation method of a small solvent recovery device, the THF waste liquid contains about 20-25% wt. THF and 75-80% wt. water (in this example, 20% wt. THF, 80% wt. of water as an example), in addition to containing a small amount of high boiling point substances and a small amount of insoluble impurities. After the THF waste liquid is filtered to remove the insoluble impurities, it is continuously pumped into the rectification tower at a flow rate of 100L / h (mass flow: 98.78kg / h). The top of the rectification tower uses a built-in condenser, and the cycle is controlled according to the temperature The amount of water fed, the temperature at the top of the tower is controlled at 97.8°C, the pressure is controlled at 0.3MPa, the mass flow rate of the gas phase produced at the top of the tower is 22kg / h, the mass composition of T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com