Patents

Literature

43 results about "Mass composition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mass percent composition is also known percent by weight. It is abbreviated as w/w%. For a solution, mass percent equals the mass of an element in one mole of the compound divided by the molar mass of the compound, multiplied by 100%.

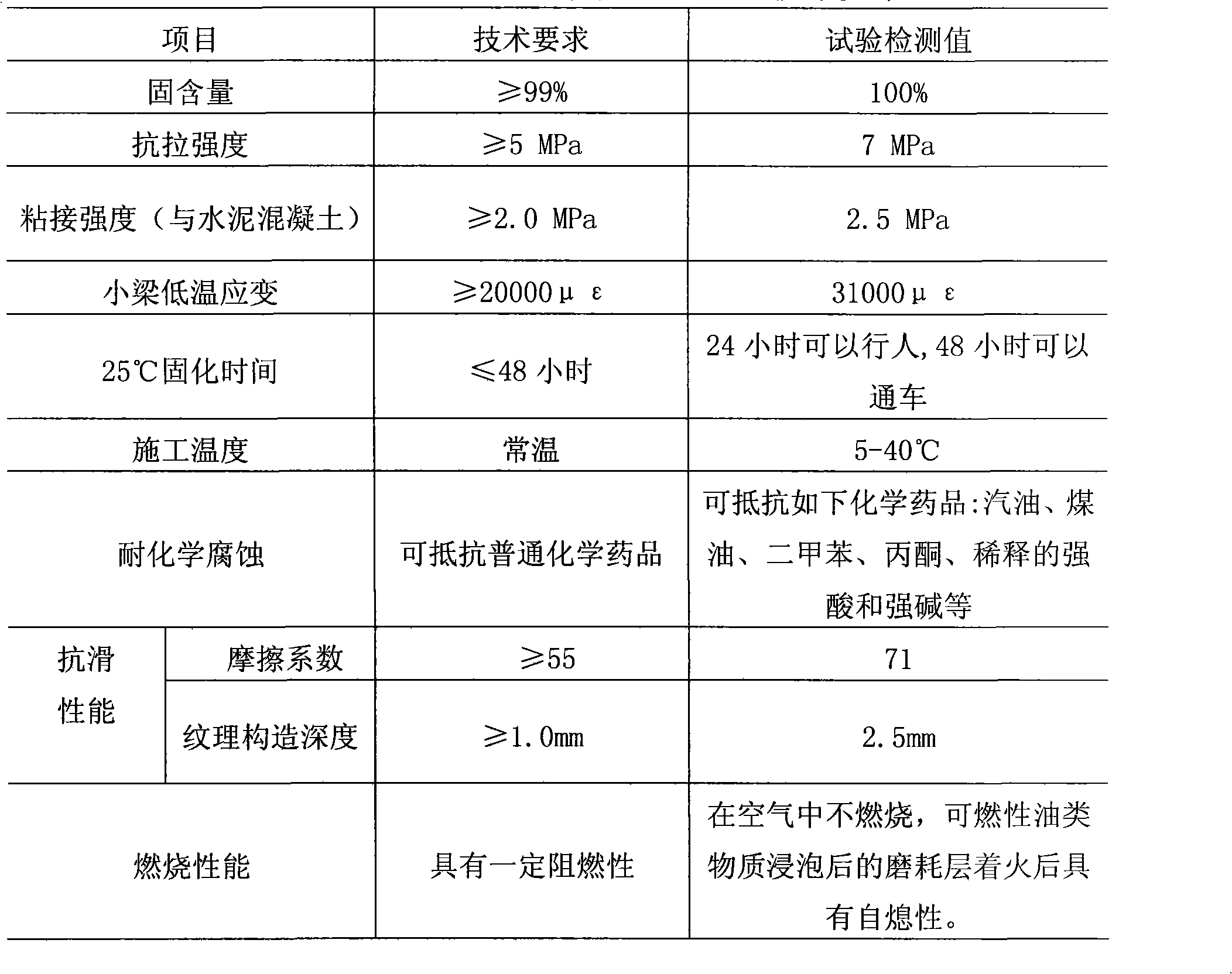

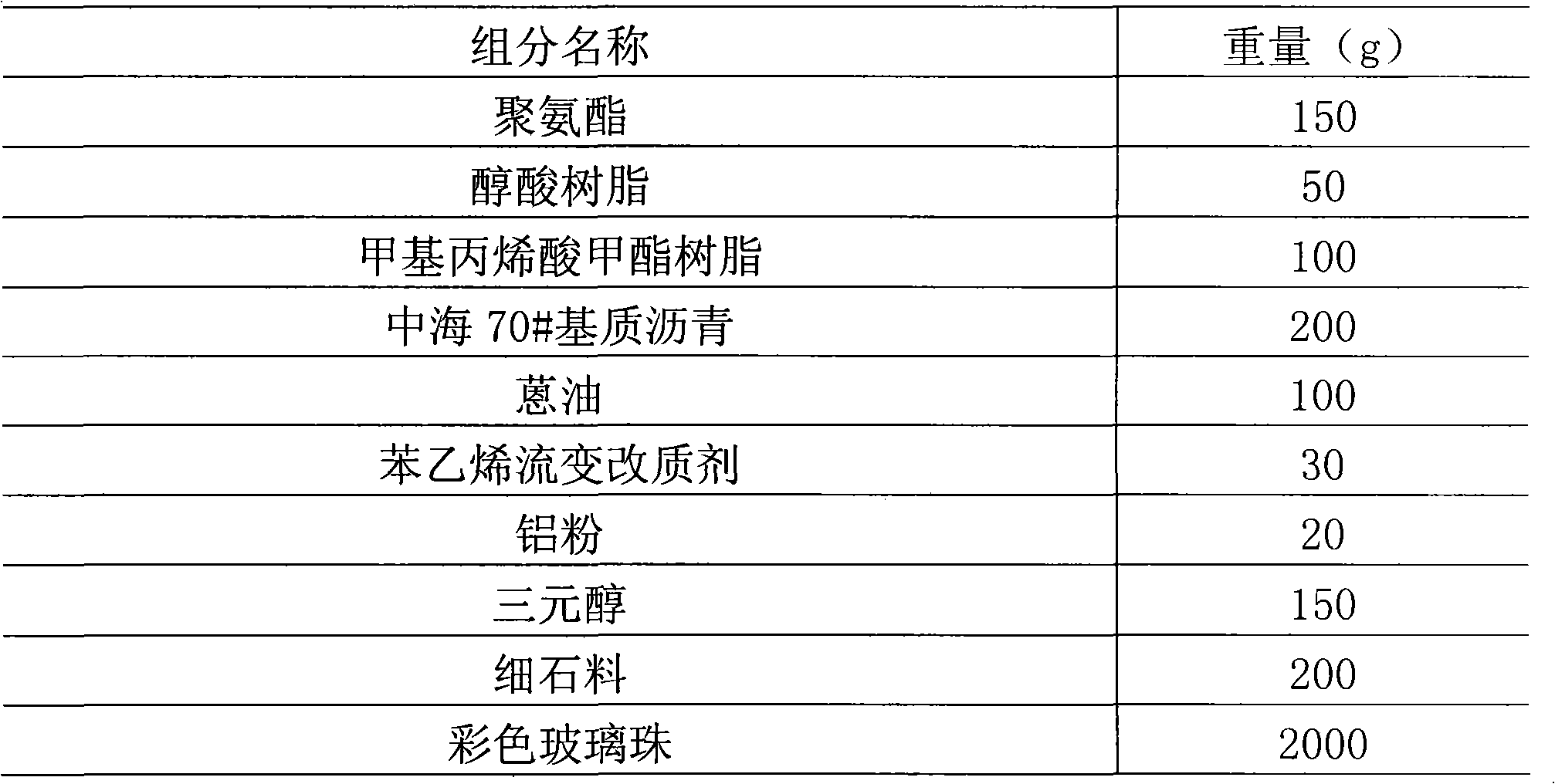

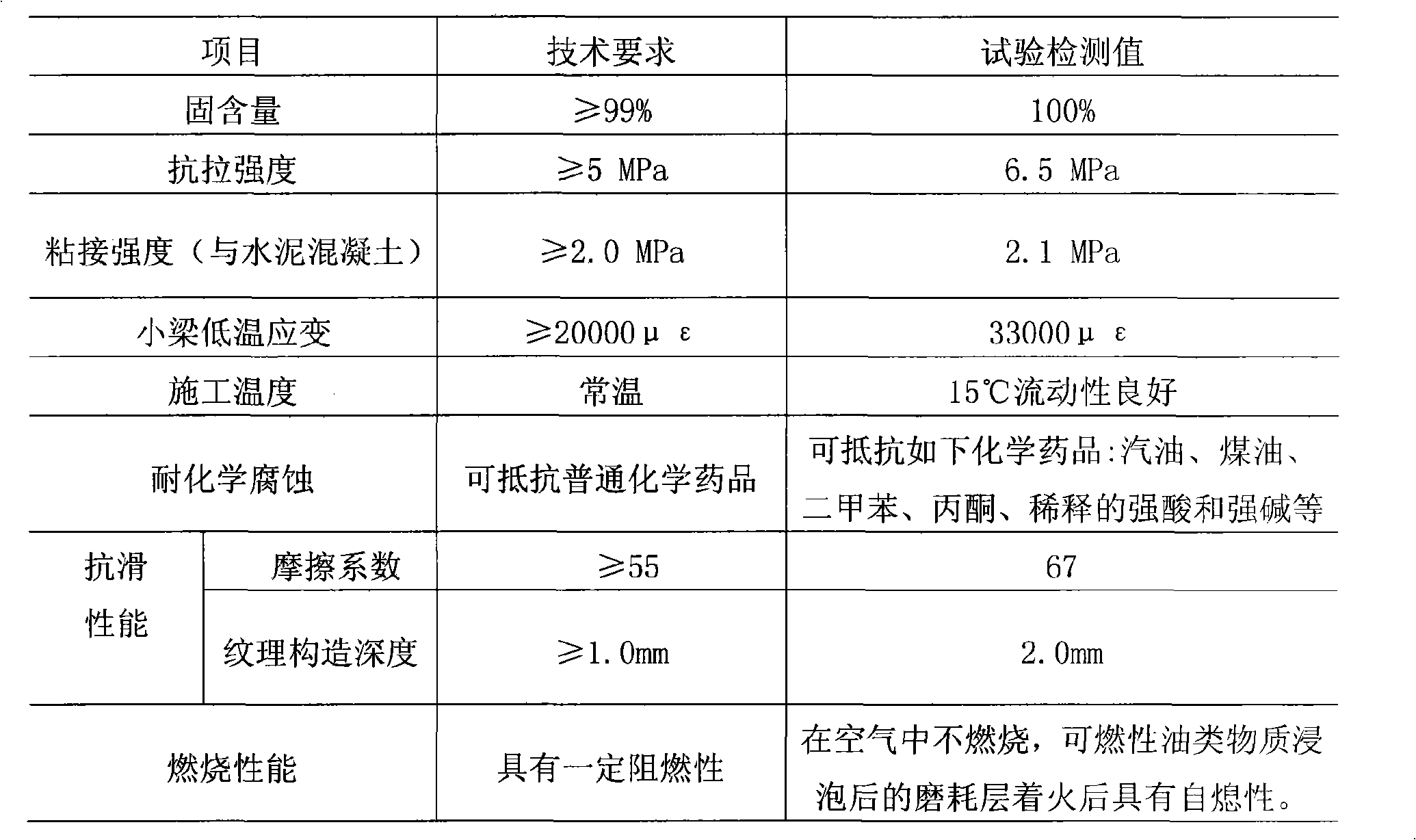

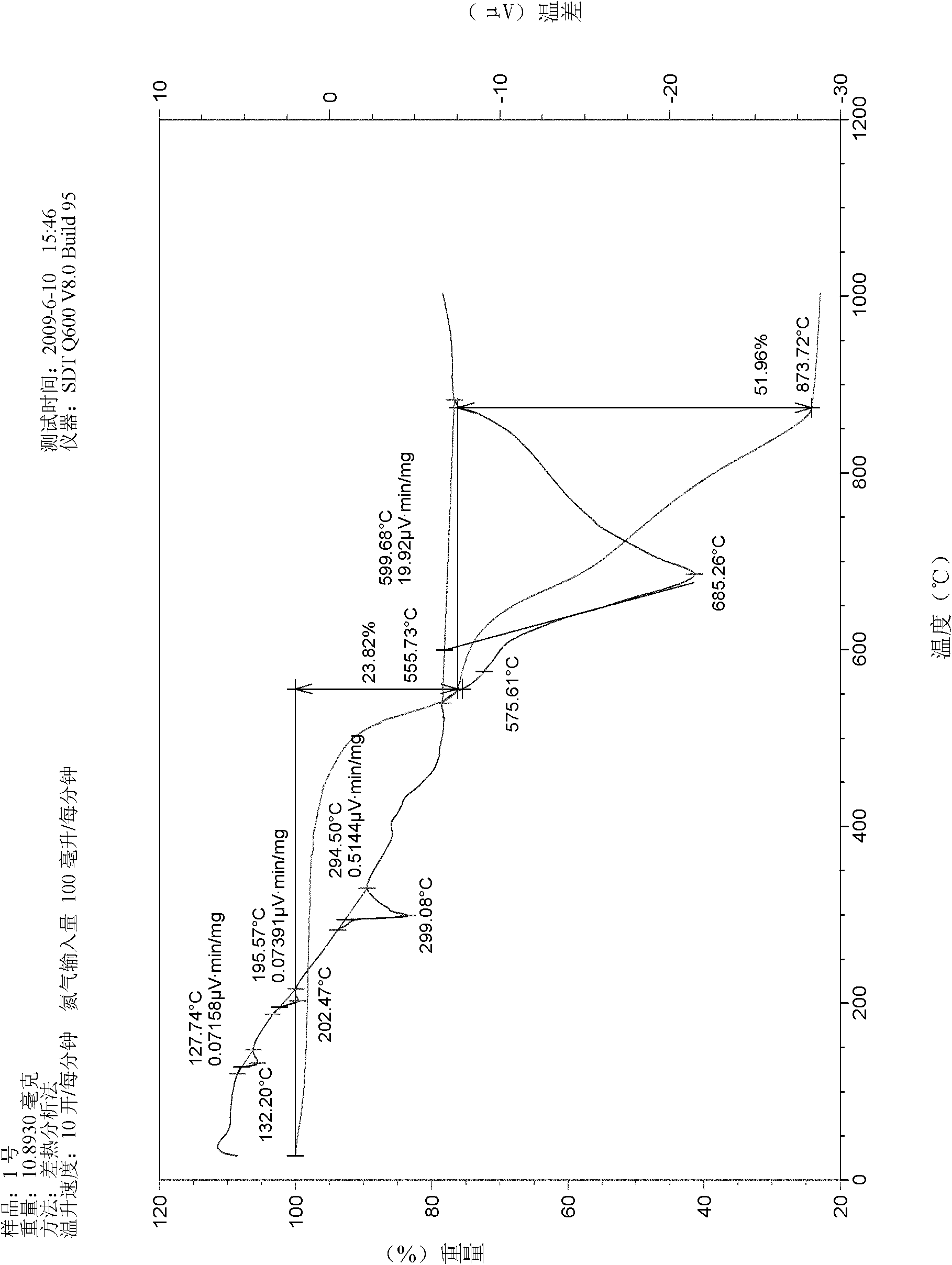

High-elasticity color antiskid wearing layer

The invention relates to a road surface structure of a road project. The mass composition of the invention is that: 0-20 parts of polyurethane,0-20 parts of alkyd, 0-20 parts of methyl-methacrylate resin, 20-50 parts of substrate pitch,10-20 parts of compatiblizing agent, 2-5 parts of rheological agent, 1-5 parts of ultraviolet aging resisting agent, 10-30 parts of curing agent, 10-20 parts of gravel and 50-200 parts of colorful wear-resistant rubble. The invention is characterized by simple formula, easy manufacture, strong adhesive capacity, good antiskid capacity, and good low-temperature property and does not crack in cold areas of the northern. The structure can be applied to laying the surface of the tunnel (especially the tunnel surface 200-300m away from the entrance and exit of the tunnel), bridge, airport pavement, bending section of the senior road and the repair of the used cement concrete pavement.

Owner:重庆市智翔铺道技术工程有限公司

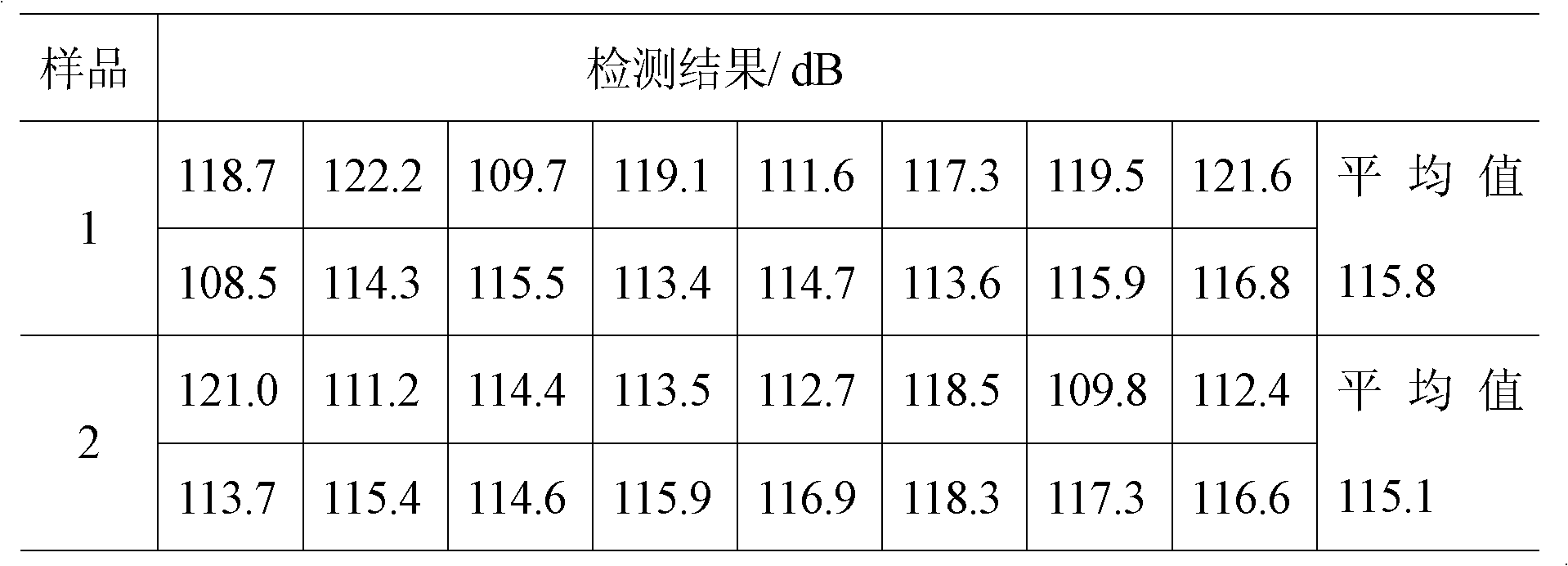

Sulfur-free and pearlite-free firecracker reagent and preparation method thereof

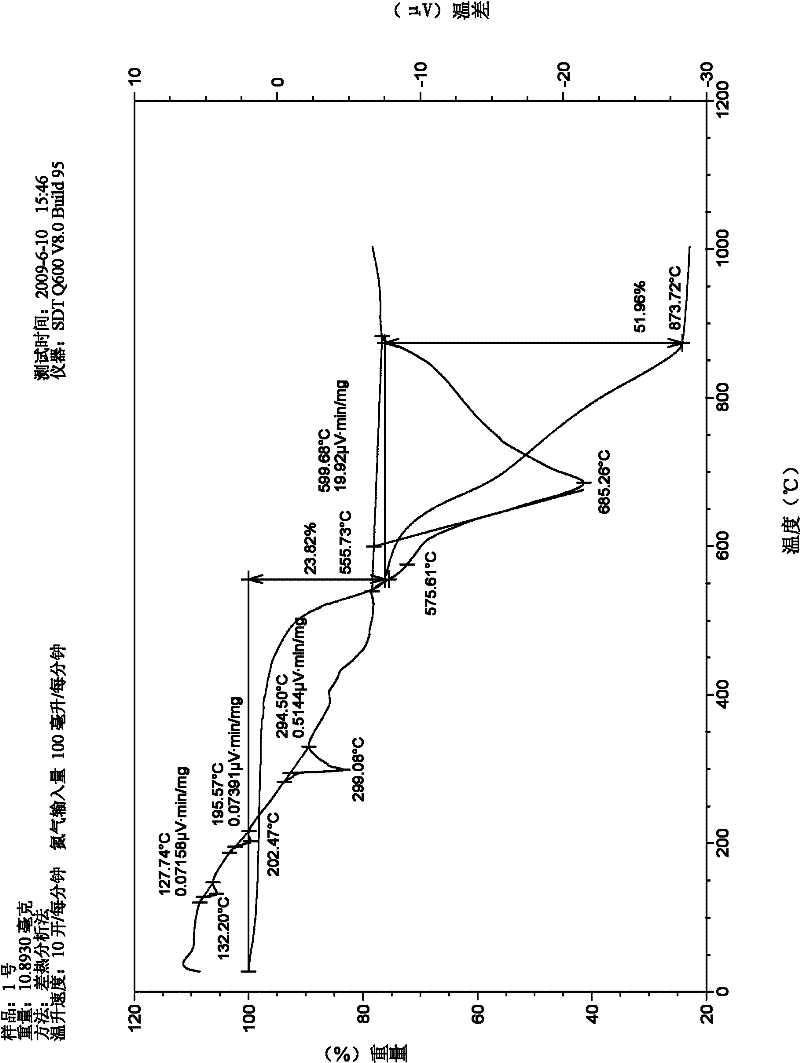

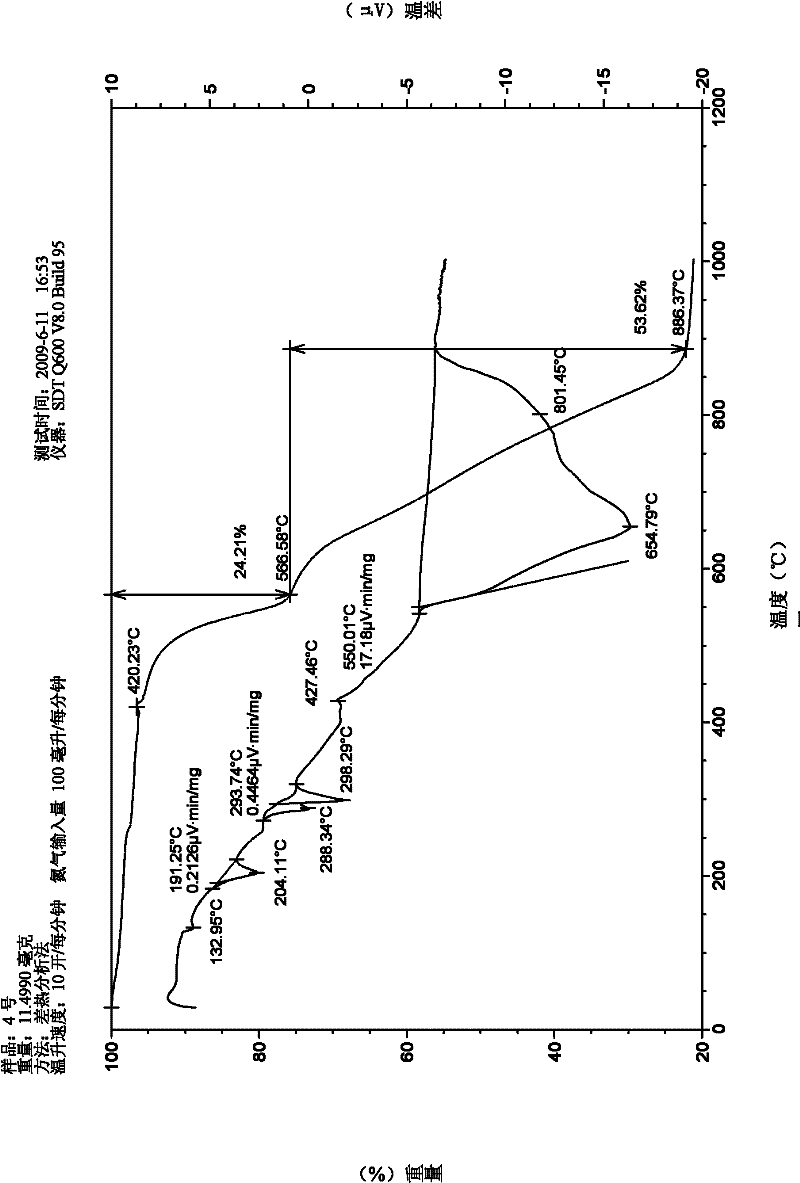

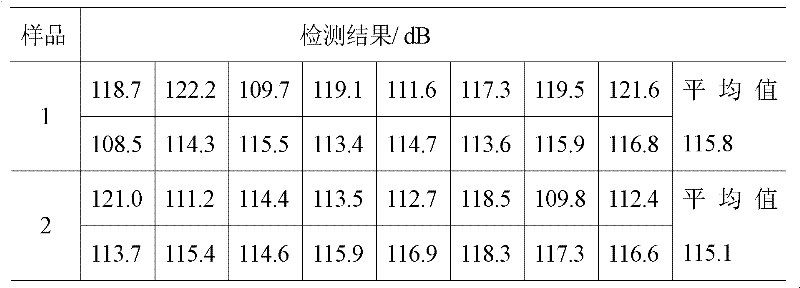

The invention discloses a sulfur-free and pearlite-free firecracker reagent and a preparation method thereof. The reagent comprises the following mass components: 35-65 percent of A component and 35-65 percent of B component, wherein the A component comprises the mass compositions: a mixture formed by 20-50 percent of potassium perchlorate, 0-30 percent of potassium nitrate and 30-50 percent of barium nitrate and a complexing agent occupying 1-5 percent of the mixture, and the B component comprises the mass compositions: 50-80 percent of aluminum powder, 10-25 percent of charcoal powder and 10-25 percent of organic foaming powder. The burning rate of a firecracker prepared from the reagent is more than 98 percent, the sound level value is no less than 100dB and is no more than 140dB, the time the gas product pressure rises from 0.69MPa to 2.07MPa is 1.74ms, a pH value of the pyrotechnic composition is 5-9, the moisture is no more than 1.5 percent, the hygroscopicity is no more than 2.0 percent, the thermal stability is 75 DEG C plus / minus 2 DEG C, the firecracker has no decomposition phenomenon under the condition of 48h, the friction sensitivity is no more than 40 percent, and the impact sensitivity of the pyrotechnic composition is no more than 0 percent. The key is that the reagent reduces the environmental pollution without harm to human bodies and has great application prospect.

Owner:HUNAN VOCATIONAL INST OF SAFETY TECH +1

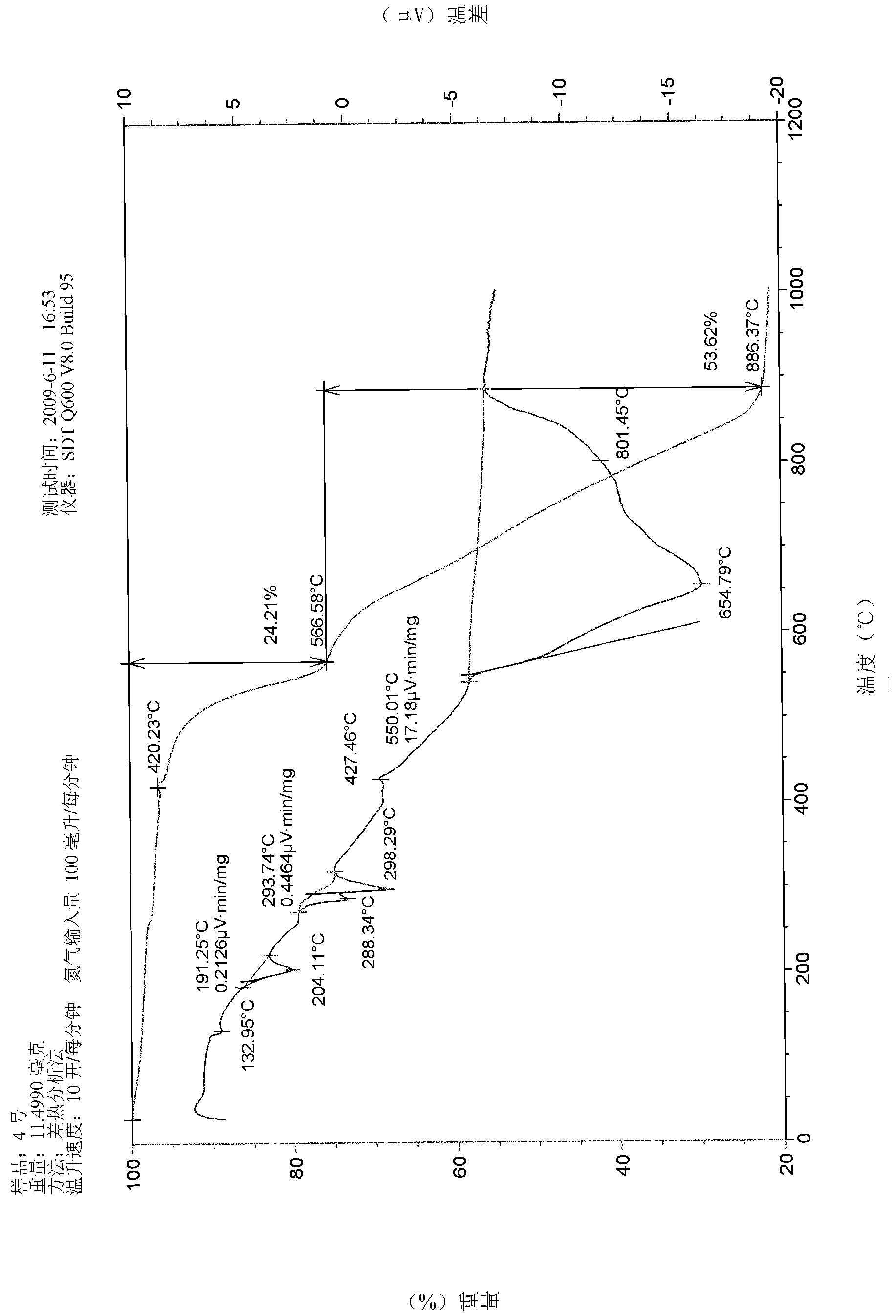

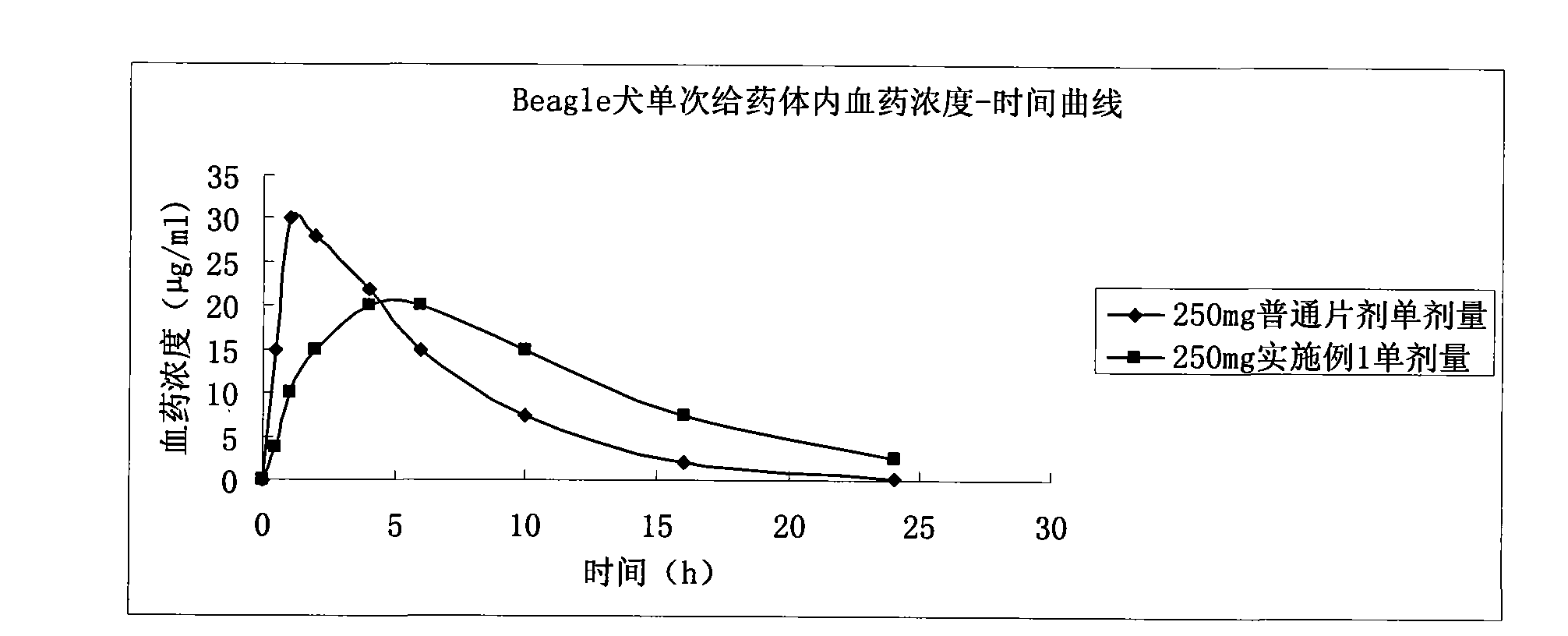

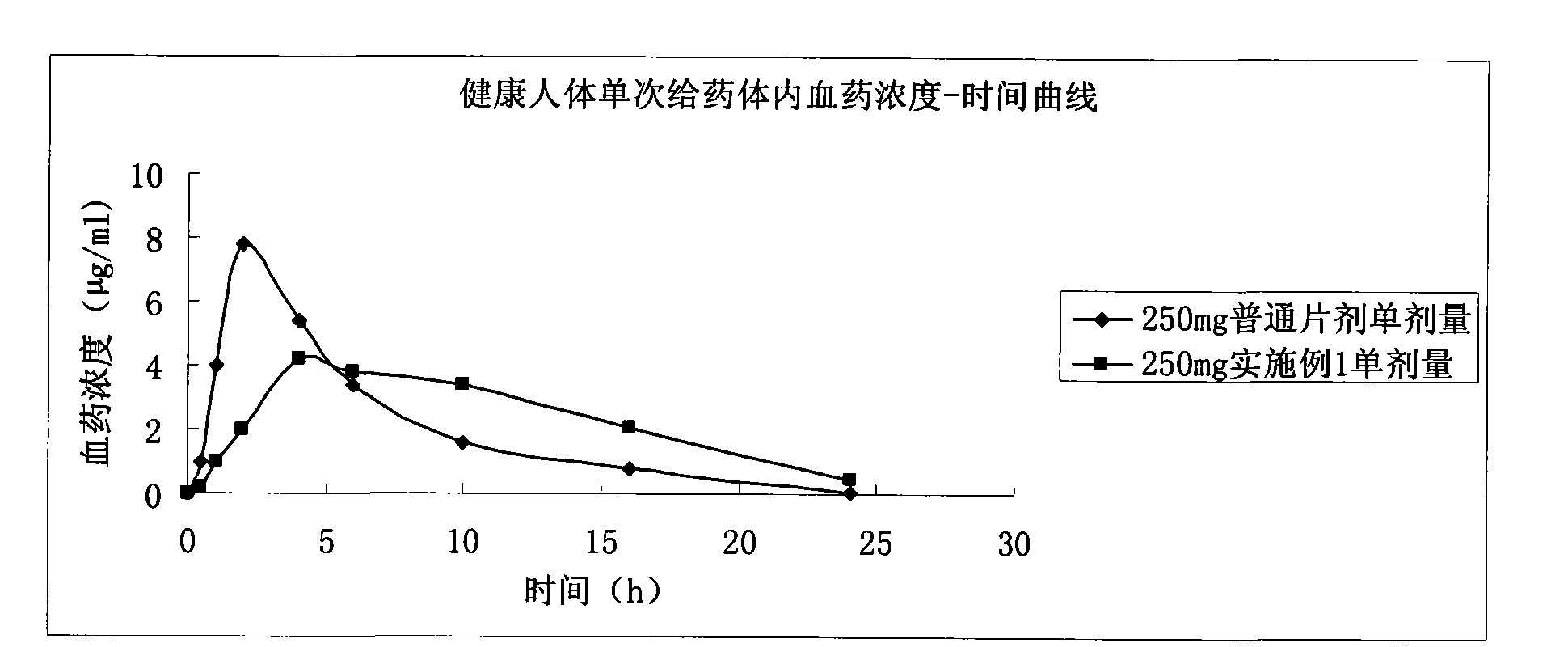

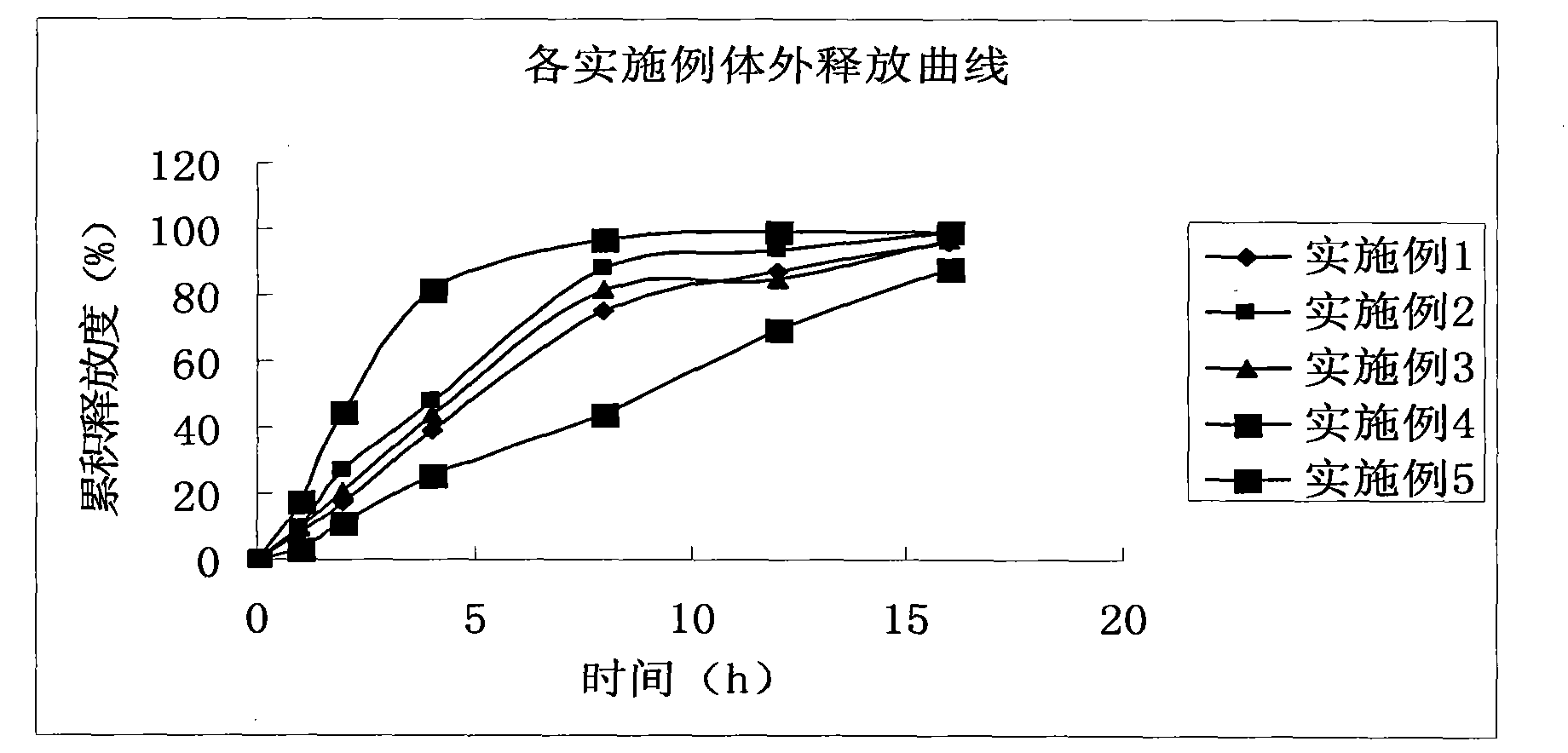

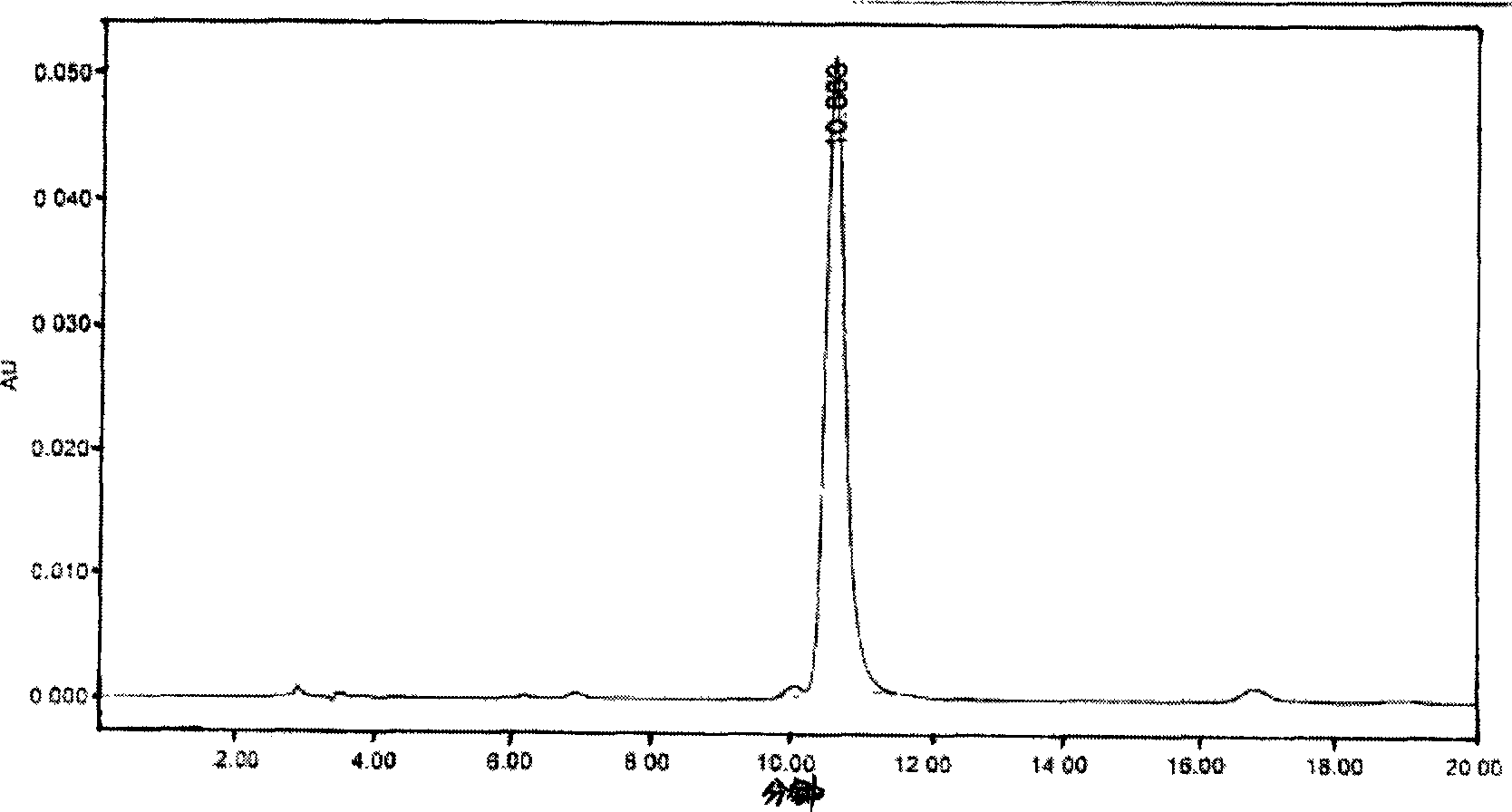

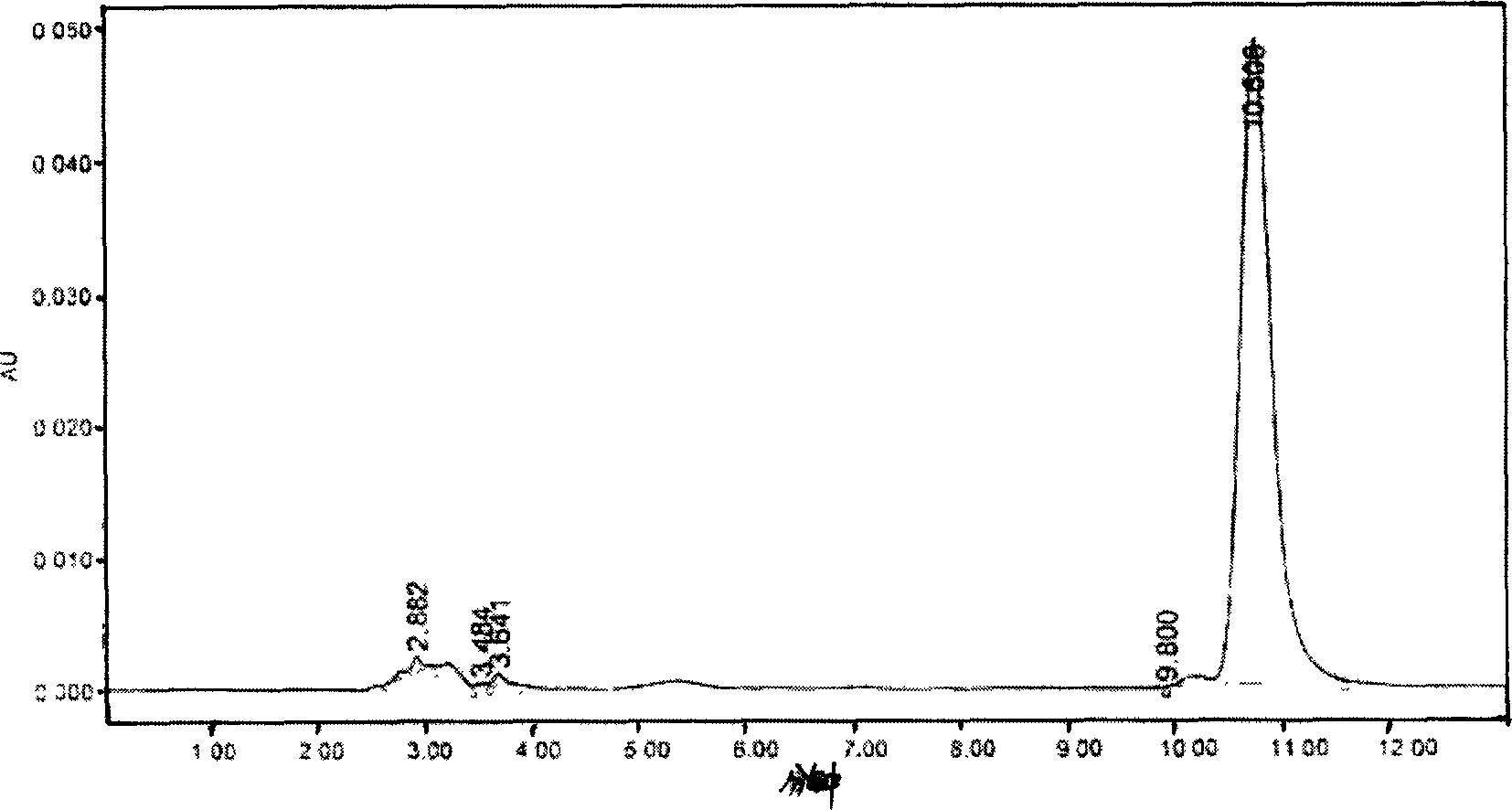

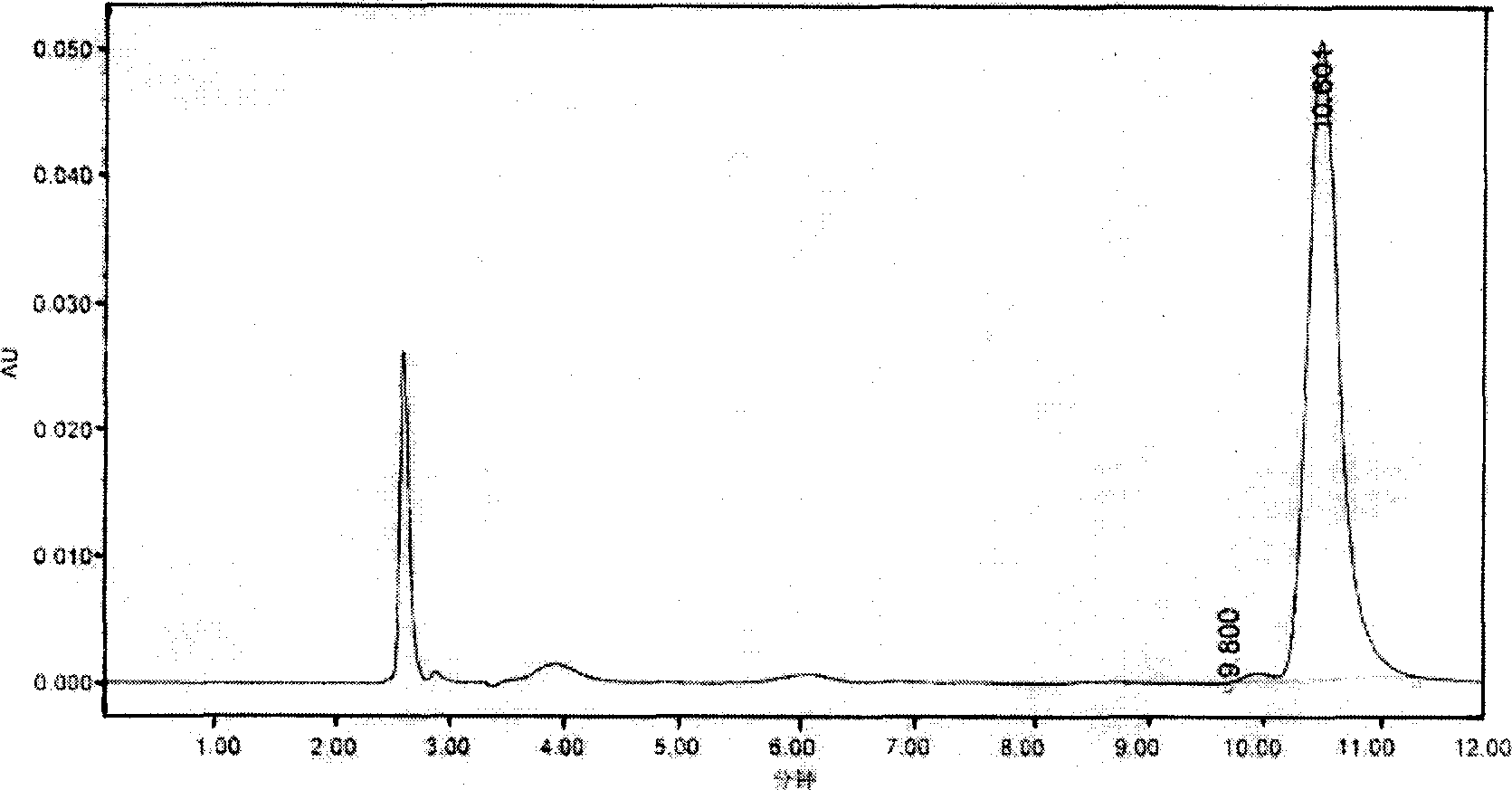

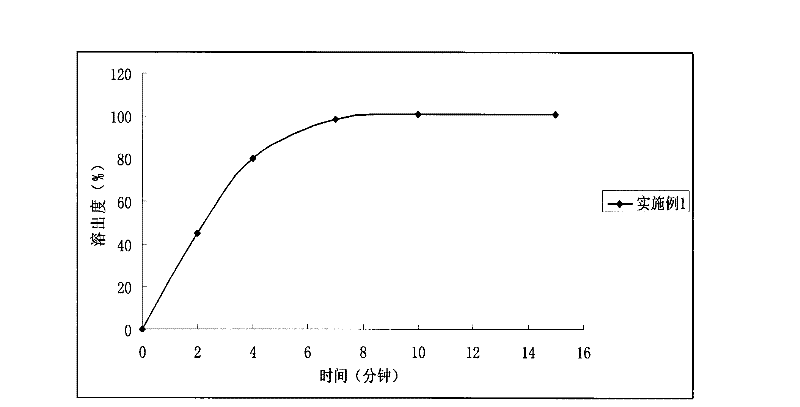

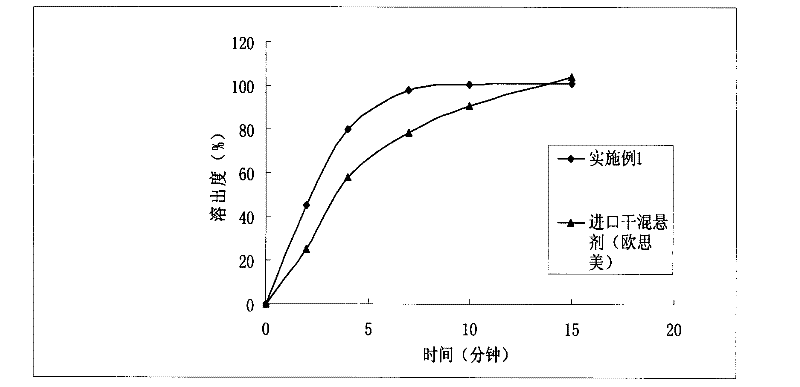

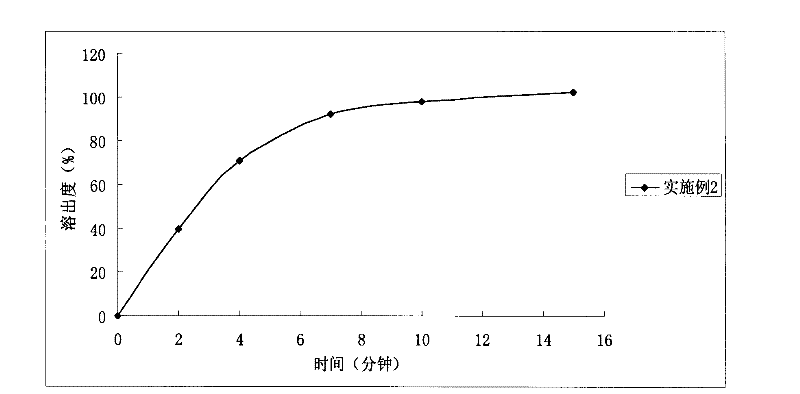

Levetiracetam slow release pellet capsule preparation and preparation method thereof

InactiveCN101647789AImprove liquidityReduce or eliminate irritationNervous disorderPharmaceutical delivery mechanismMass compositionSide effect

The invention relates to a levetiracetam slow release pellet capsule preparation and a preparation method thereof. The levetiracetam slow release pellet capsule preparation comprises the following components in percentage by mass: 50-70 percent of levetiracetam, 15-30 percent of blank pellet, 5-10 percent of hydroxypropylmethyl cellulose or polyvidone, 7-15 percent of ethylcellulose or acrylic resin, 1-8 percent of talc powder and 0.5-2 percent of cataloid. The preparation method comprises the following steps: coating levetiracetam fine powder on the blank pellet by a binding agent to be madeinto a medicine-contained pellet; coating an isolating layer on the medicine-contained pellet; coating a slow release coating film on the medicine-contained pellet coated with the isolating layer to prepare a slow release pellet; and mixing the slow release pellet, the talc powder and the cataloid and filling the mixture into a capsule. The levetiracetam is made into the slow release capsule preparation by a pellet and slow release technology, and the slow release preparation can stabilize blood medicine concentration, reduce the generating frequency and degree of the side effect and fundamentally solve the problems of great influence on a tablet by gastric pyloric sphincter and big differences of gastric emptying individuals.

Owner:天津药物研究院药业有限责任公司

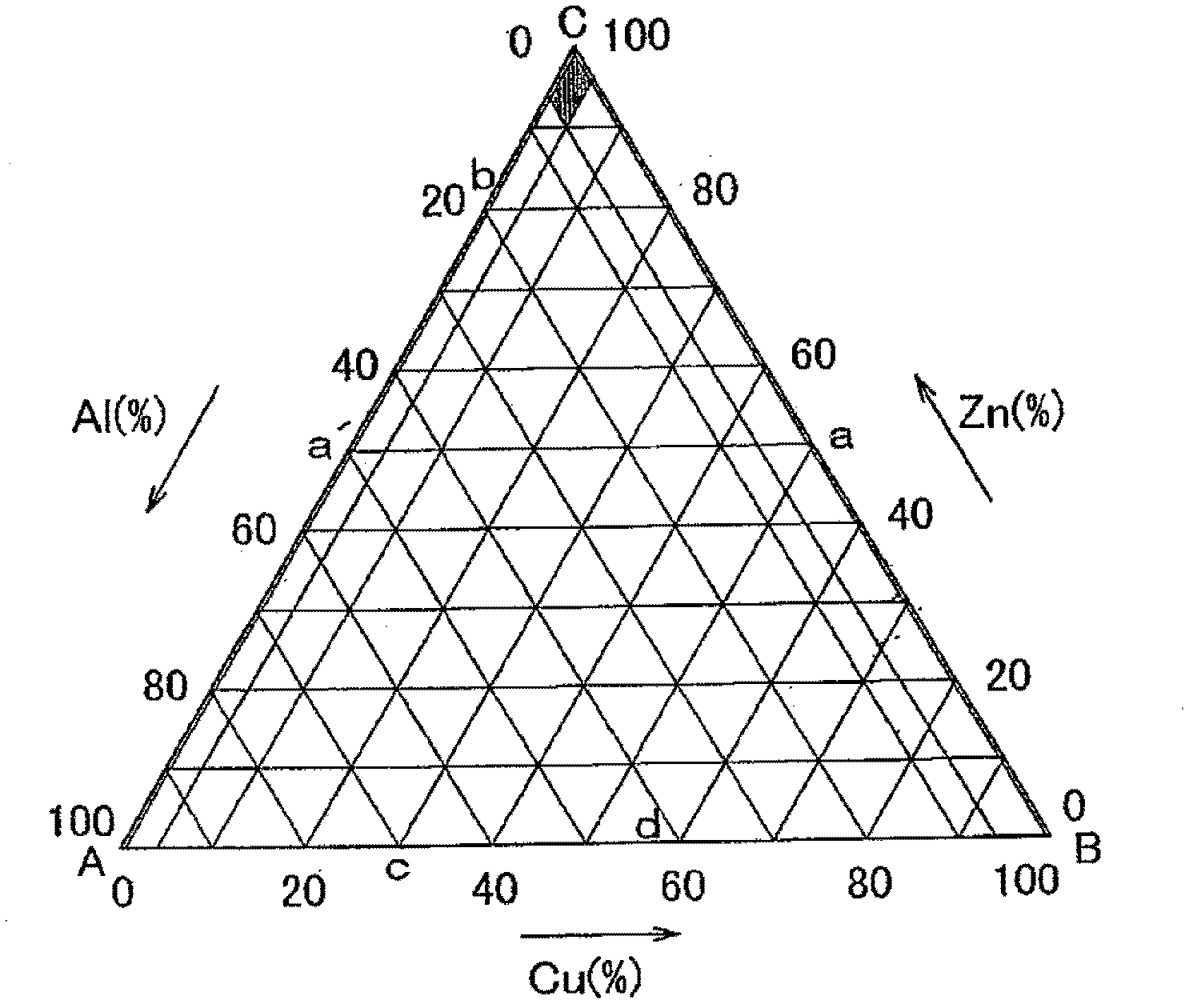

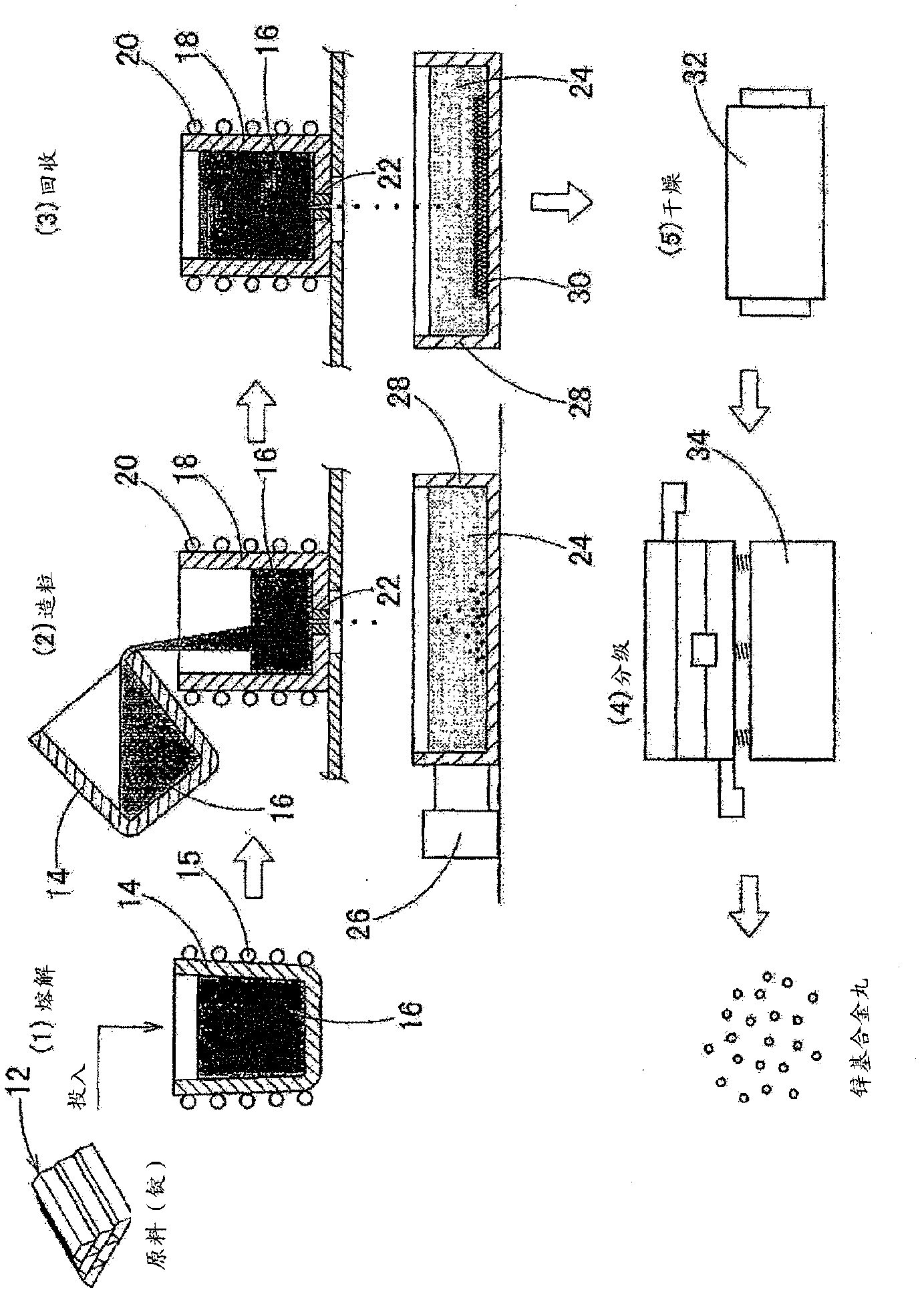

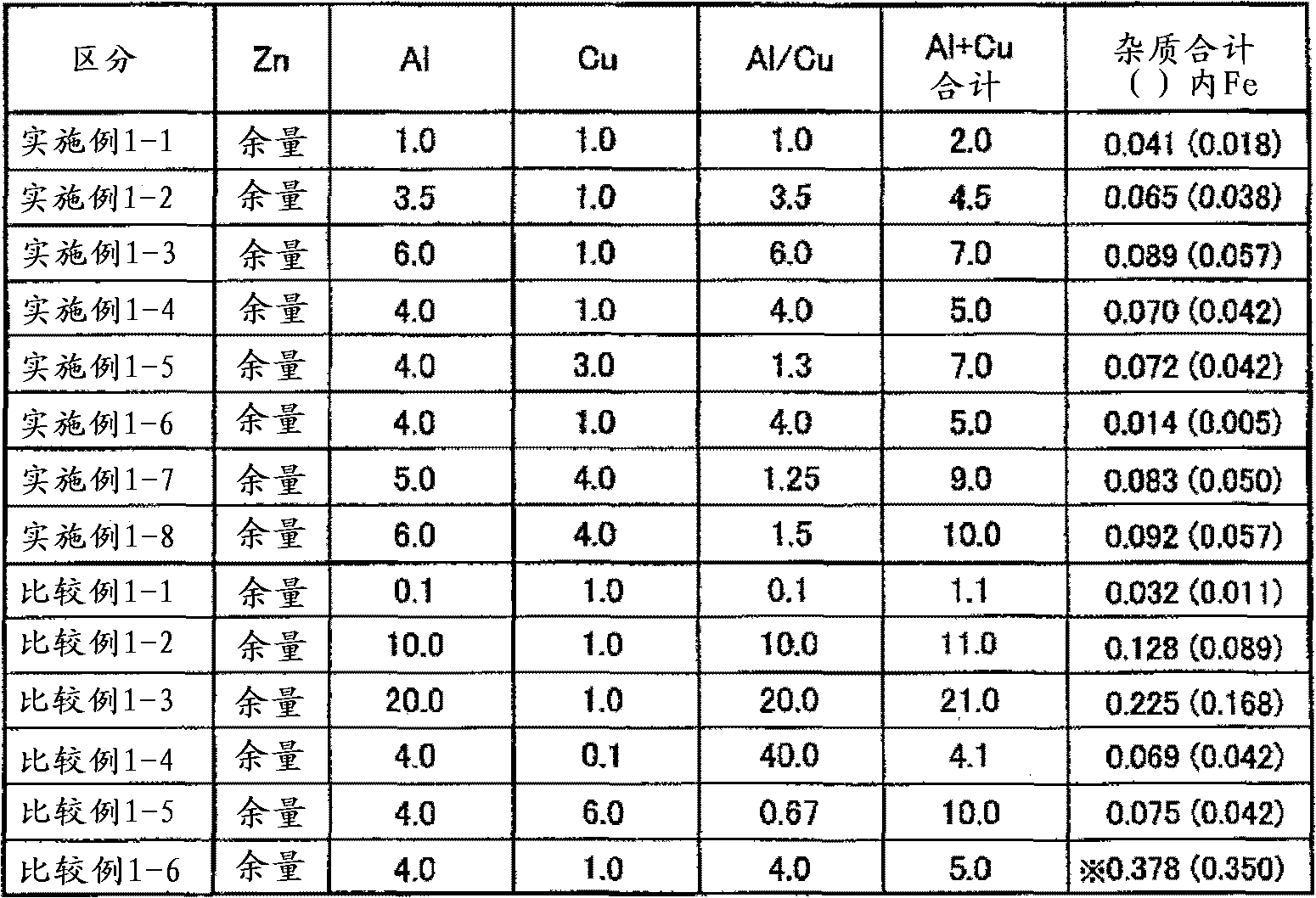

Zinc-based alloy shots

ActiveCN102574274AReduce consumptionReduce generationAbrasion apparatusMass compositionDust explosion

Provided are zinc-based alloy shots which, without risk of dust explosion, are capable of high performance deburring and abrasion cleaning through shot blasting and application of compressive residual stress through shot peening, with low quantities of shots consumed by shot projection. The zinc-based alloy shots include a three-component zinc-based alloy shot wherein 0.5 - 6.5 mass % Al, 0.5 - 4.5 mass % Cu are contained as additional elements, the mass composition ratio of Al to Cu (Al / Cu) is 1.0 - 13.0, the total amount (Al + Cu) is 1.5 - 10.5 mass %, and the Vickers hardness is 90 - 190 HV; and a four-component zinc-based alloy shot wherein 0.5 - 6.5 mass % Al, 0.5 - 4.5 mass % Cu, 0.01 - 0.2 mass % Mg are contained as additional elements, the mass composition ratio of Al to Cu (Al / Cu) is 1.0 - 13.0, the total additional amount (Al + Cu) is 1.5 - 8.0 mass %, and the Vickers hardness is 90 - 190 HV.

Owner:SINTOKOGIO LTD

Composite propolis capsule health-care food

A combined propolis capsule health-care food consists of the following mass compositions of the components respectively as follows: propolis powder (35-50 shares, with the purity more than 90 percent), bee pollen (35-50 shares, with the purity more than 98 percent), and the adjuvant material (10-15 shares). The combined propolis capsule health-care food provided by the present invention adds bee pollen into the propolis, thereby enriching the nutrition, adding the functions, and improving both the nutritional value and the grade of effect of food therapy. The combined propolis capsule health-care food provided by the present invention contains flavone biologically active substances, amino acids and multiple trace elements, thereby having obvious effects to adjust the blood pressure, the blood lipid level and the blood glucose, helping the recovery of heart diseases, diabetes and prostate diseases, and having the functions to prevent the kidneys, foster the face, resist the tiredness, and enhance the human immunity. The prescription contains no water, ethanol or elements of western medicines, while the content of effective material is higher, and only low dosage is needed with low cost, without any side effect or toxic effect in long-term usage. The present invention is a health-care food with good health-care effects and convenient taking.

Owner:白万钧

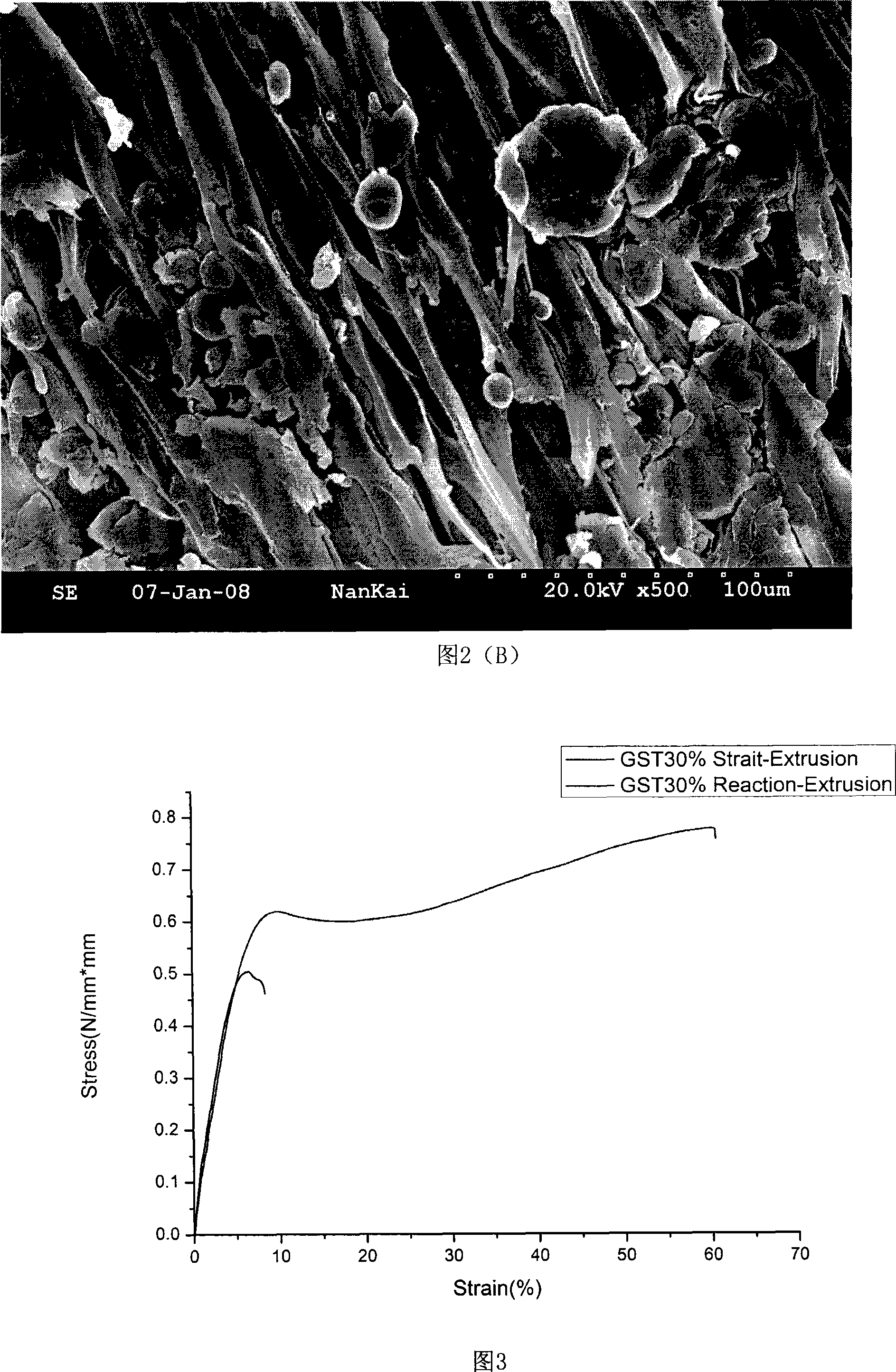

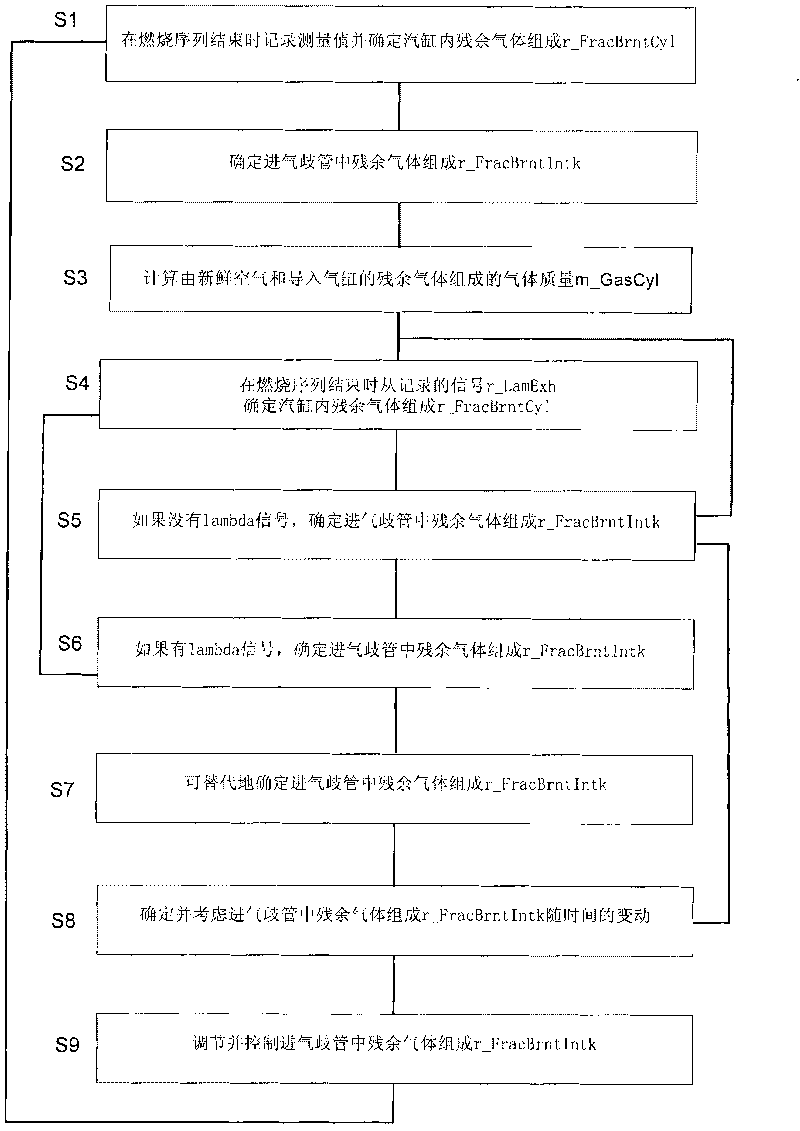

Modified starch/lactic acid oligomer reactivity blended full biological decomposition plastics and preparation thereof

The invention discloses a modified starch / lactic acid oligomer reactive blending total biolysis plastic. The modified starch / lactic acid oligomer reactive blending total biolysis plastic comprises plastic master batch that is used as raw material and an accessory ingredient. Mass composition of the plastic master batch: 2-50 portions of modified starch and 2-70 portions of lactic acid oligomer. The lactic acid oligomer that is synthesized by a one-step method is selected to go through continuous coextrusion together with the modified starch that has low cost by a solid phase condensation method, then auxiliary homotaxial or double-axis is provided for strengthening thermal stretch, thus obtaining the total biolysis plastic that has performance characteristics of being hard and tenacious and low price. The production cost, tensile strength, elongation at break and Young modulus of the total biolysis plastic are better than the existing relevant total biolysis plastic. The total biolysis plastic prepared by the invention can be applied in developing green consumables of high-tech electronic products, disposable packing materials, hotel articles, agricultural mulching film and so on, thus realizing greening of high-tech industries, releasing white pollution and saving deficient petroleum resource.

Owner:TSINGHUA UNIV +1

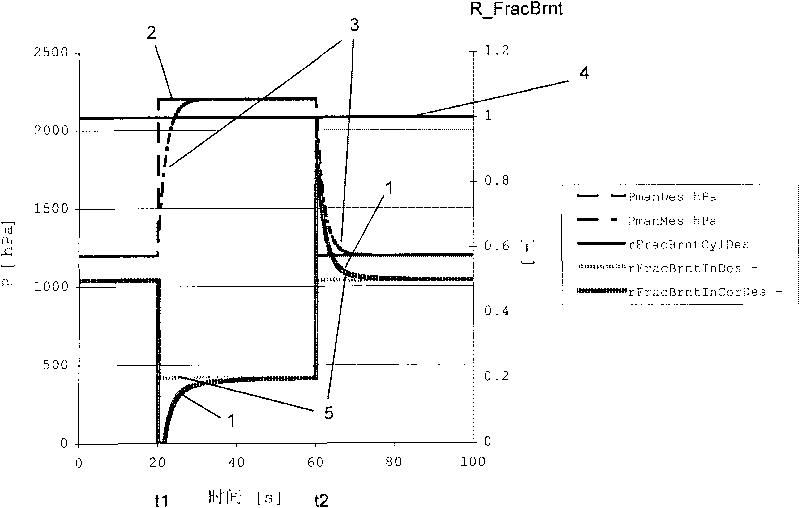

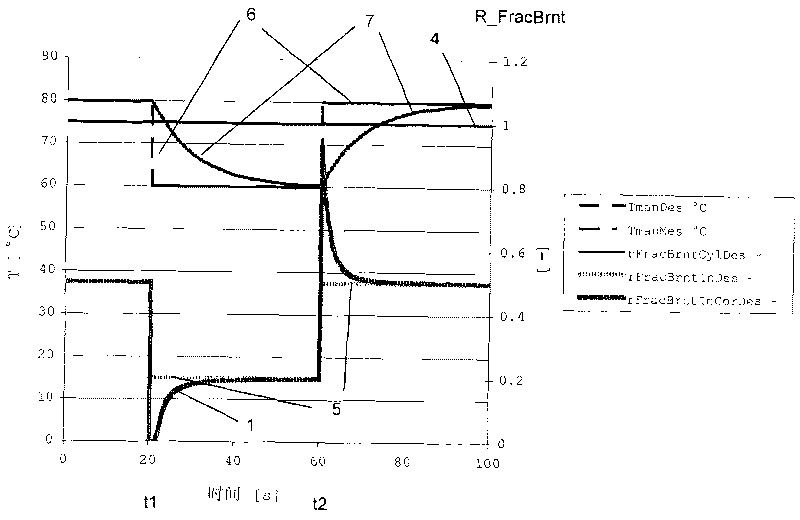

Residual gas composition control of internal combustion engine with exhaust gas recirculation

InactiveCN101737180AElectrical controlNon-fuel substance addition to fuelMass compositionGas composition

The present invention relates to a method for adjusting and / or controlling the exhaust gas recirculation of internal combustion engine through adjusting the composition of residual gas. The engine comprises at least one cylinder, an intake manifold, and an exhaust gas system with exhaust gas recirculation. The method comprises determining and / or detecting the mass of fuel required in the filling process of each cylinder and the mass of air-gas mixture. According to the invention, the residual gas mass composition (r-FracBrntIntk) in the intake manifold is adjusted and / or controlled with a mode that a required preset and / or presettable residual gas mass flow (r_end) is obtained in each cylinder. In the adjustment and / or control, the injection fuel mass (m_FuInj) which is determined and / or detected in each cylinder before the combustion process is considered. The method of the invention can realize utilization which is more effective than recirculation exhaust and more sufficiently combustion.

Owner:FORD GLOBAL TECH LLC

A heavy rare earth-free sintered NdFeB

InactiveCN108987017AInhibit growthImprove coercive forceInductances/transformers/magnets manufactureMagnetic materialsMass compositionRare earth

The invention relates to the field of permanent magnetic materials and discloses a heavy rare earth-free sintered NdFeB. The raw material comprisesa main phase alloy and an auxiliary phase alloy. Themass composition of the elements in that main phase alloy is PraNdbTMcFe100-a-b-c-dBd, wherein TM is one or more of Nb, Al, Cu, Co, Ni, Ga, Zr; 27 <= a, b <= 32, 0 <= c <= 10, 0.7 <= d <= 1. 1, the rest is Fe and inevitable impurities; The mass composition of the elements in the auxiliary phase alloy is NdmFen alloy, m+n=1; The mass of the auxiliary phase alloy is 0.5%-4wt% of that of the main phase alloy. The invention can make the performance of the Nd-Fe-B magnet reach the magnetic performance which can be achieved by adding 1-3wt% of dysprosium into the Nd-Fe-B magnet prepared by the traditional process without using the heavy rare earth.

Owner:ZHEJIANG DONGYANG DMEGC RARE EARTH MAGNET CO LTD

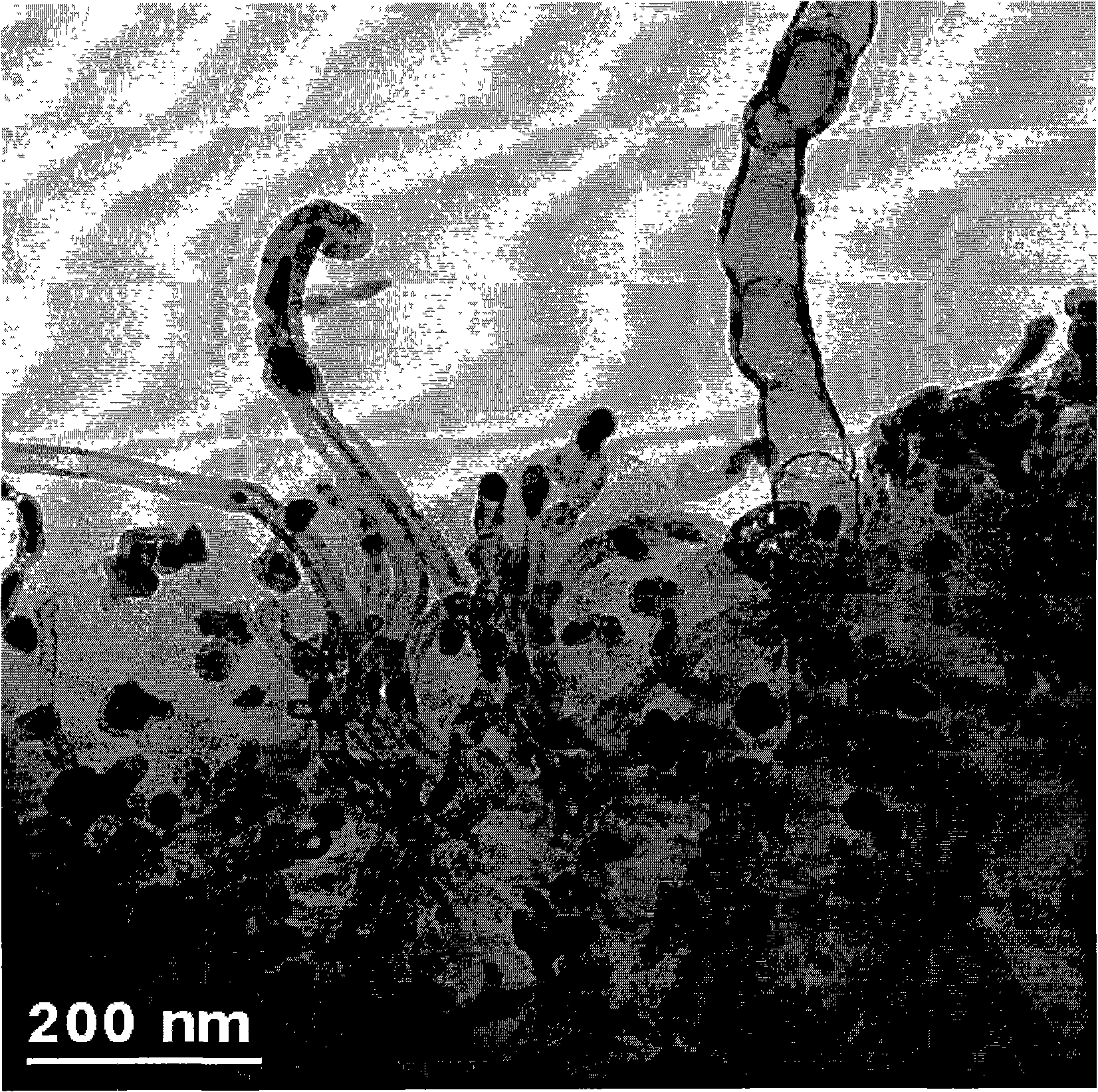

Nitrogen doping carbon nanometer-tube and LiFePO4 composite nanometer conductive material as well as preparation method thereof

InactiveCN101325258ASmall particle sizeStable charging and discharging performanceNon-metal conductorsElectrode manufacturing processesMass compositionConductive materials

The invention relates to a nitrogen-doped carbon nano-tube / LiFePO4 composite nano-sized conducting material and the preparation method which comprises the following steps: A) the mass composition of the nitrogen-doped carbon nano-tube / LiFePO4 composite nano-sized conducting material is as follows: a1CNx:b1LiFePO4, wherein the value of a1 is in the range of 0.01-0.20, and the value of b1 is in the range of 0.80-0.99; and B) the preparation method comprises the following steps: mixing lithium sources, iron sources and phosphor sources at the raw material ratio of Li:a2Fe:b2P, wherein a2 is in the range of 0.93-1.03, and b2 is in the range of 0.93-1.03, stirring in the distilled water, then, oven-drying under the protection of inert gases, calcining at 550 DEG C to 950 DEG C in the atmosphere of Ar or N2 while introducing organic amine, allowing reaction for 0.5 to 12 hours to obtain the final nitrogen-doped carbon nanotube / LiFePO4 composite nano-sized conducting material. The nitrogen-doped carbon nano-tube / LiFePO4 composite nano-sized conducting material has the advantages of low cost, good electrical conductivity and high stability of high-current charge / discharge performance.

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY

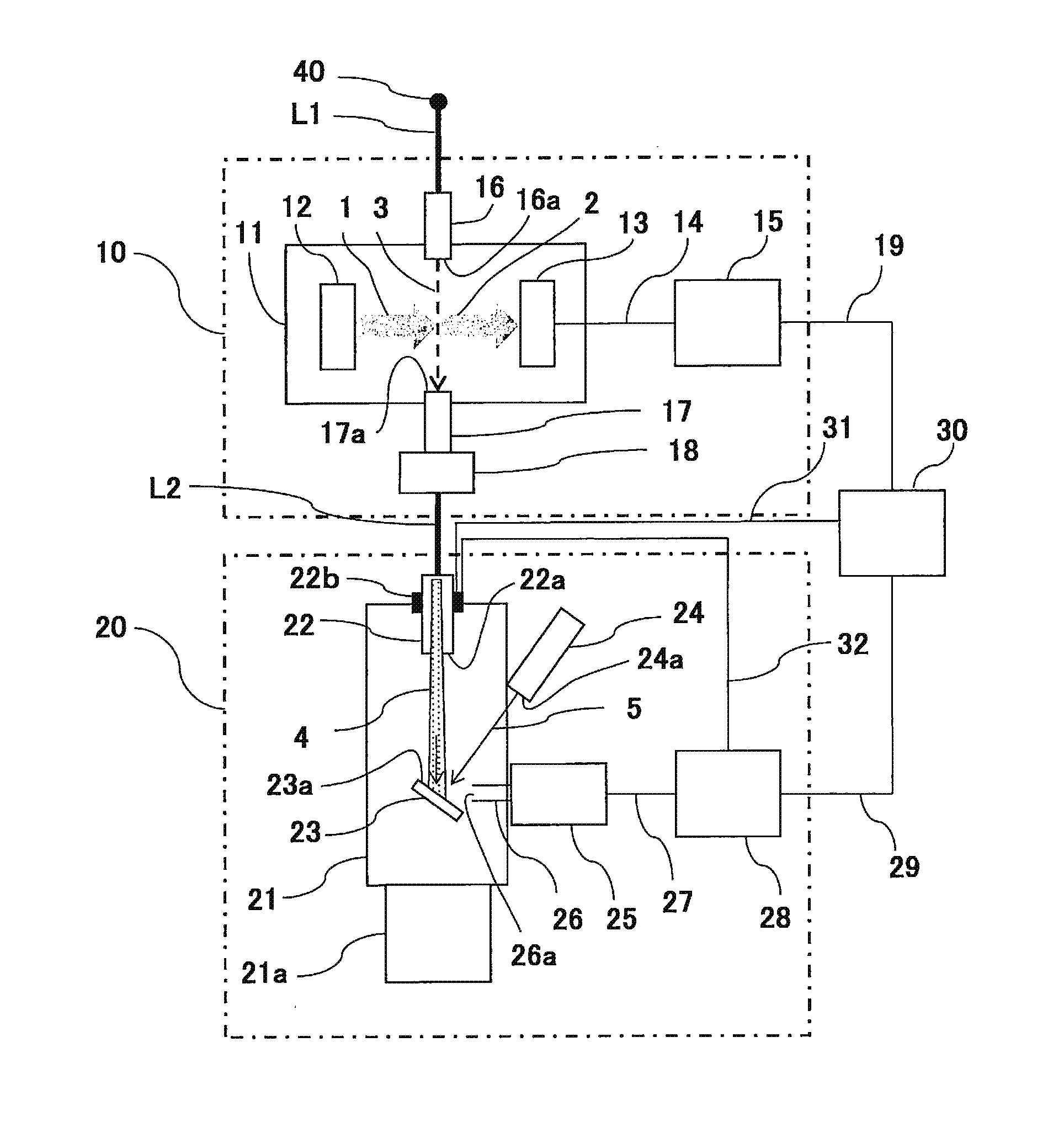

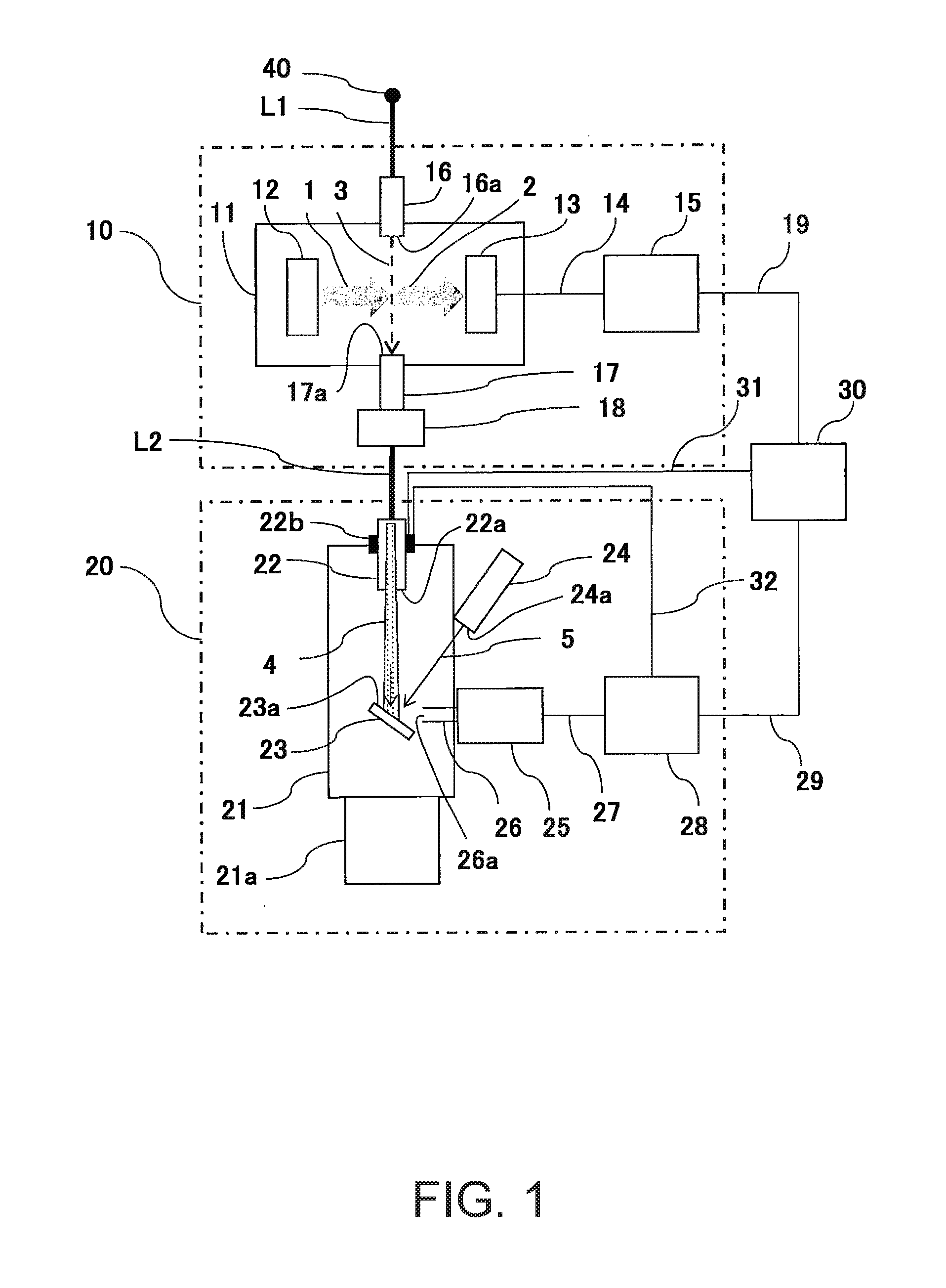

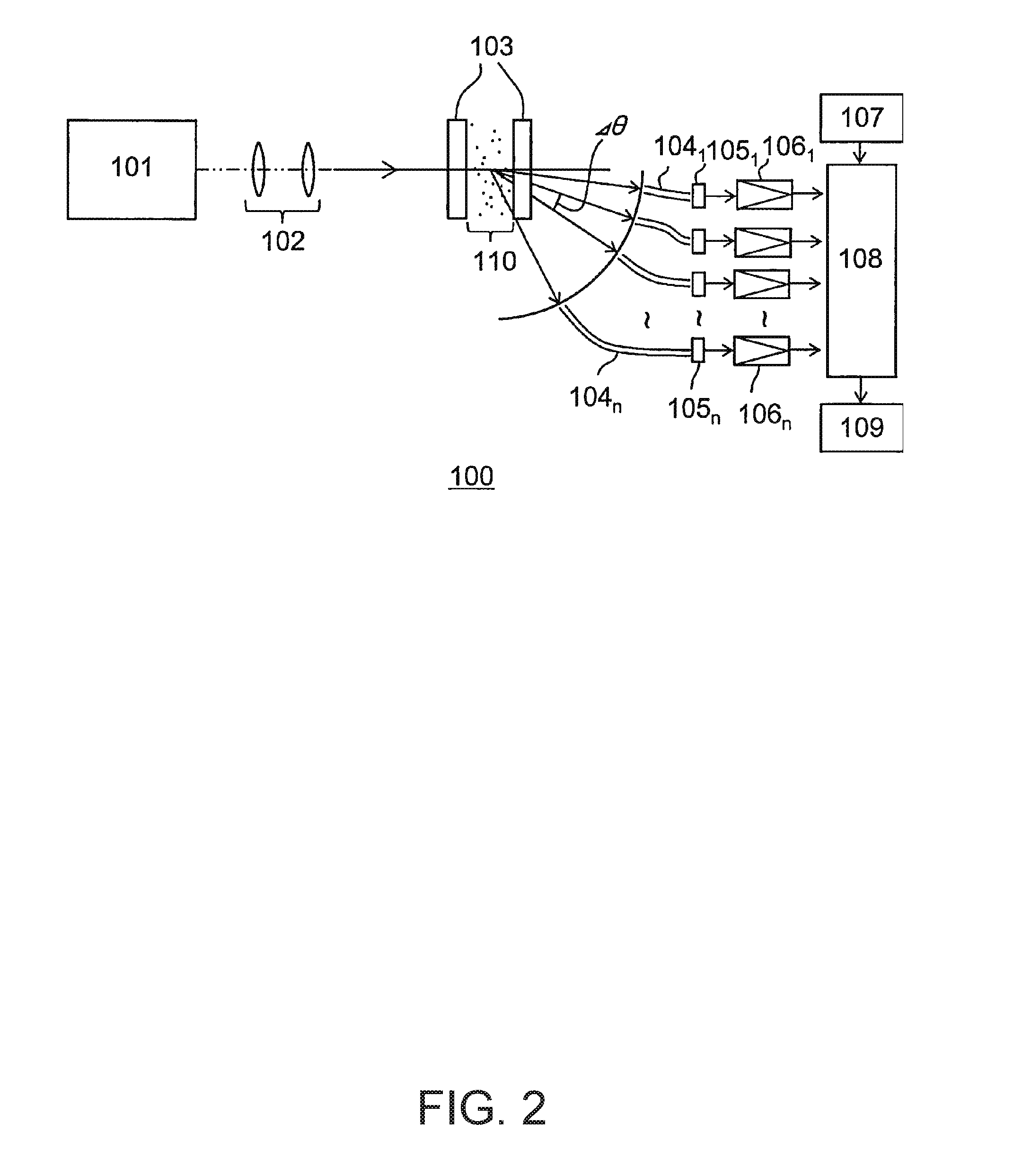

Multifunctional particle analysis device and method of calibrating the same

InactiveUS20160377539A1Reduce effortEasily accurately analyzeAnalysing gaseous mixturesScattering properties measurementsMass compositionParticle physics

A multifunctional particle analysis device includes a particle measuring device and a particle composition analysis device. Calibration particles for which at least the number, size, and composition thereof are known are input to the particle measuring device and the particle composition analysis device and analyzed. The sensitivity of the particle measuring device is calibrated in accordance with the number and size of the calibration particles as measured by the particle measuring device, and the sensitivity of the particle composition analysis device is calibrated in accordance with the mass composition of the calibration particles as measured by the particle composition analysis device. Moreover, the irradiation axis of particles that enter the particle composition analysis device relative to a capturing unit is calibrated in accordance with a state in which the calibration particles are captured on the capturing unit of the particle composition analysis device.

Owner:FUJI ELECTRIC CO LTD

Breviscapine injection liquid and its preparing process

InactiveCN1732970ASolve the stability problem of high-dose useImprove stabilityOrganic active ingredientsMetabolism disorderMass compositionActivated carbon

The invention discloses a breviscapine injection liquid and its preparing process, wherein each 1000 weight parts of the Breviscapine injection comprises, Breviscapine 0.5-0.9 part, sodium thiosulphate 0.01-2 parts, glucose 50-100 parts, ethylenediaminetetraacetic acid disodium salt 0.01-1 part, adsorbing with activated charcoal 0.1-0.3 part, and balancing water for injection.

Owner:HANGZHOU MINSHENG PHARM CO LTD

Pranoprofen in-situ gelling eye drop and preparation method thereof

InactiveCN102885768AFix stability issuesResolution timeOrganic active ingredientsSenses disorderMass compositionPatient compliance

A pranoprofen in-situ gelling eye drop is disclosed. The pranoprofen in-situ gelling eye drop comprises the components by mass percent: 0.1% of pranoprofen, 1%-40% of thickening agent, 0.03%-1.0% of pH adjusting agent, 0.01%-0.03% of bacteria inhibitor, 0.005%-0.2% of antioxidant, 0.01%-0.05% of chelating agent, and 0.1%-4.0% of solubilizing agent. The pranoprofen in-situ gelling eye drop disclosed by the invention has the characteristics that a material (e.g., poloxamer 407 and sodium alginate) with good biocompatibility and having the feature of temperature sensitivity, pH sensitivity or ion sensitivity is used as a matrix, the eye drop is administered in vitro under a solution state, phase change occurs immediately at the administered site in vivo in accordance with different environments inside and outside human body, so as to form in-situ gel; and the eye drop is convenient to use, high in bioavailability and long in residence time and results in good compliance of patients. The invention further discloses a preparation method of the pranoprofen in-situ gelling eye drop.

Owner:JIANGSU JIBEIER PHARMA

High dielectric constant stress control material

InactiveCN1901102AChange the potential distributionUniform electric fieldRubber insulatorsPower cables with screens/conductive layersMass compositionStearic acid

This invention relates to a high dielectric constant stress control material characterizing that its mass composition includes: raw rubber: 100, stearic acid: 0.5-1.2, nm-ZnO: 5-10, TiO2: 6-10, olefin oil: 15-25, carbon black: 20-30, coupler: 2-3, sulfur: 2-3, dioxide DIPB: 3-4, accelerant TMTD: 2-3, and mixing and injection molding technics are applied to process it, which is advantaged that it can be prepared to a resistance-capacitance stress tube to control the stress of the cut place of shield of the cable to alter the potential distribution of the cable insulation surface so as to uniform the electric field and the break through phenomenon will not happen since field strength of this place is uniformly distributed.

Owner:江苏宇诚业基电气设备有限公司

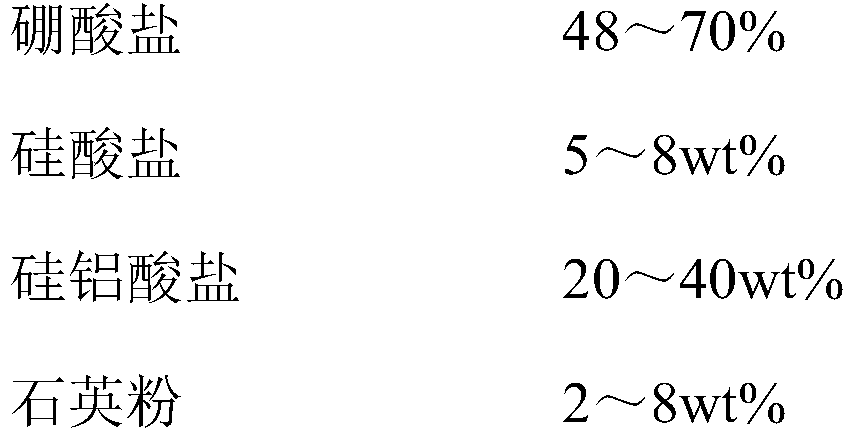

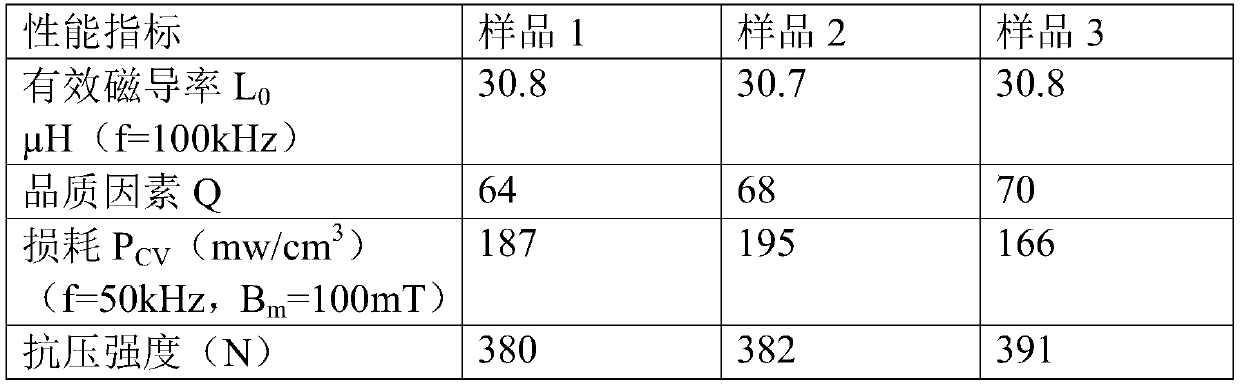

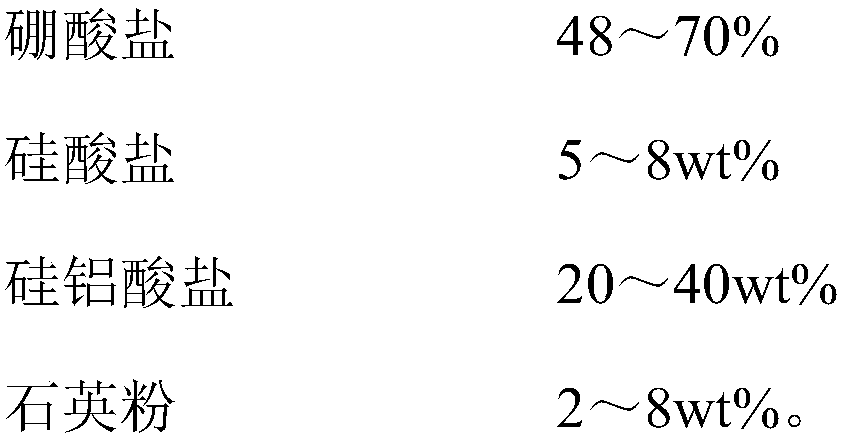

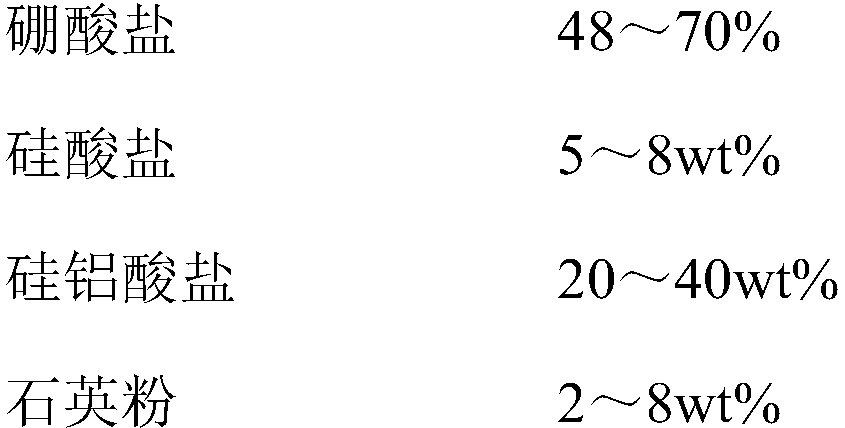

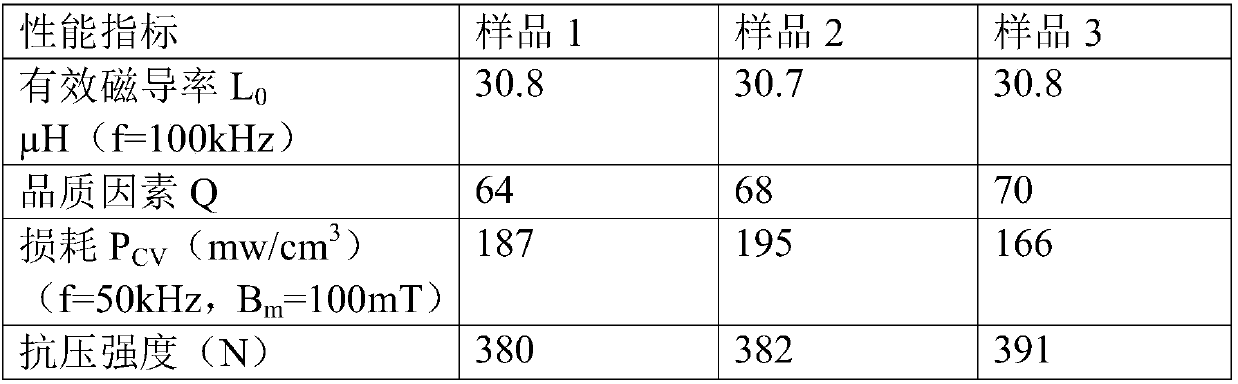

A kind of insulating all-inorganic adhesive for metal soft magnetic powder core and using method thereof

ActiveCN107845474BSolve the problem of high temperature resistanceOvercome the disadvantage of high lossInorganic material magnetismMass compositionPotassium

The invention discloses an insulating full inorganic binder for metal soft magnetic powder core and belongs to the technical field of magnetic material preparation. The insulating full inorganic binder is composed of borate, silicates, aluminosilicates and quartz; the mass compositions are: 48 to 70% borate, 5 to 8 wt% silicate, 20 to 40wt% aluminosilicates, 2 to 8 wt% quartz powder, wherein the borate is anhydrous sodium tetraborate powder; the silicate is sodium silicate powder; the aluminosilicates are two or more selected from talc, kaolin, albite, mica and potassium feldspar. The heat resistance temperature of the insulating full inorganic binder of the invention reaches 1000 DEG C; the invention can significantly improve the mechanical strength of the magnetic powder core, and the prepared magnetic powder core has comprehensive excellent magnetic properties and mechanical properties. The present invention is particularly suitable for iron-based magnetic powder cores and can significantly improve its high frequency performance and quality factors.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

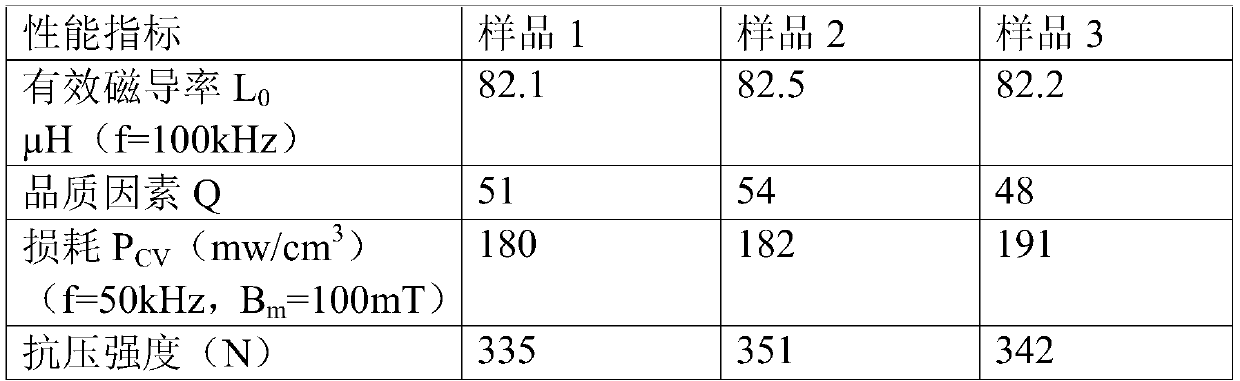

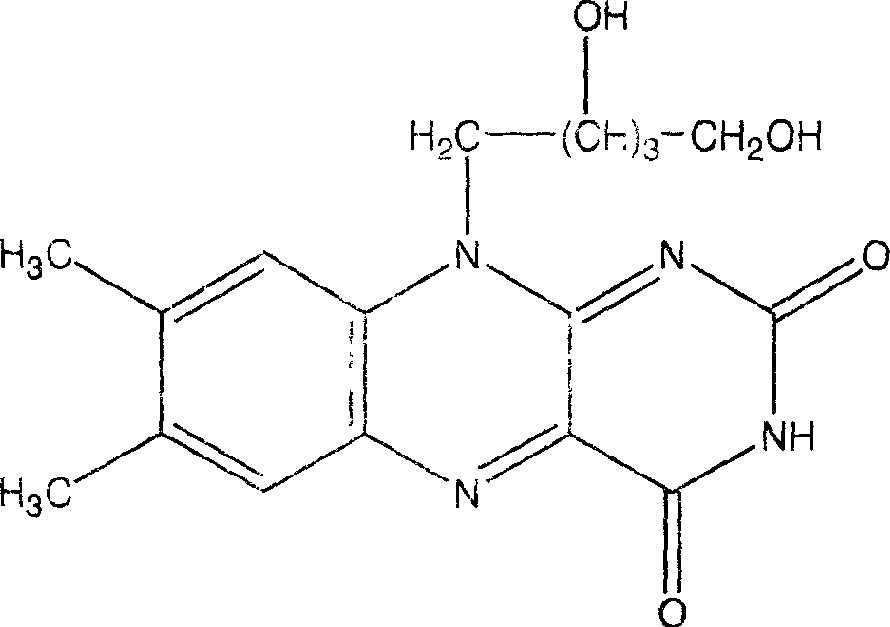

Free radicle production method and uses of lactochrome and its derivative composition dark reaction

InactiveCN1605253AGrowth inhibitionNot easy to develop resistanceBiocideAnimal repellantsMass compositionDisease

The present invention is the method of utilizing the dark reaction of riboflavin and its derivative and its application. Riboflavin and its derivative is dispersed in the surfactant micelle solution and mixed with reductant with lower redox potential to obtain free radical generating dark reaction composition. The composition has the mass composition of riboflavin and its derivative to surfactant micelle solution to reductant with lower redox potential of 1 to 10-3000 to 0.1-20. Under dark condition, the composition can generate great amount of free radicals to suppress the growth of fungi effectively with less resistance. The present invention may be used as medicine for preventing and treating microbe caused diseases and diseases of crops, and may be also used in preparing bactericide and preparation for degrading dark environment pollutant. The present invention lays foundation of the wide application of riboflavin and its derivative.

Owner:山东省生物信息工程技术研究中心 +1

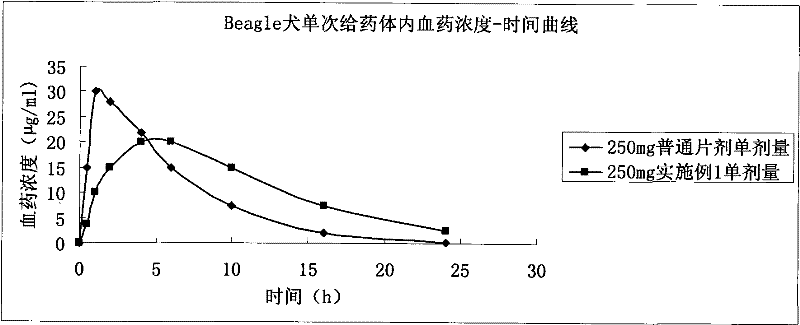

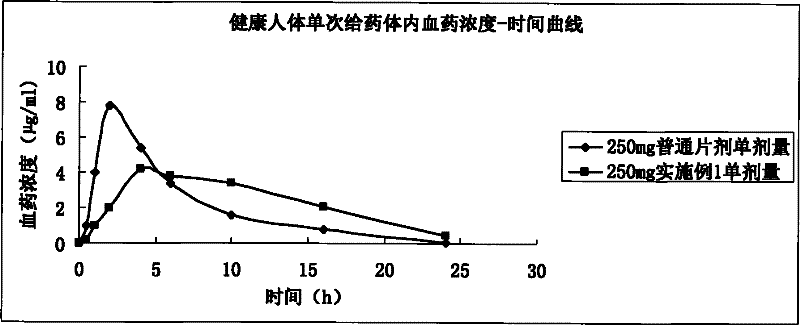

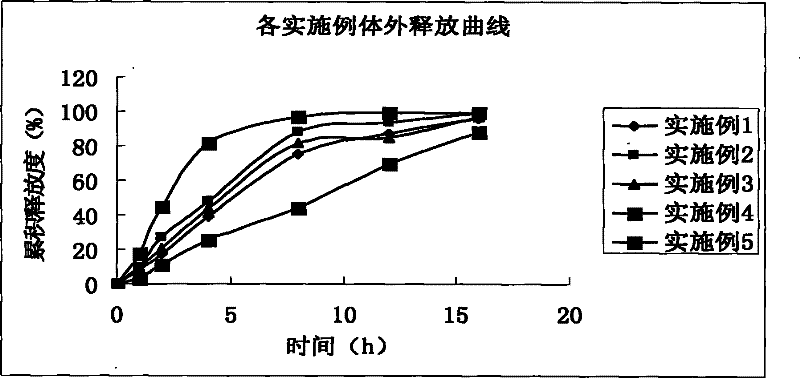

Levetiracetam slow release pellet capsule preparation

InactiveCN101647789BImprove liquidityReduce or eliminate irritationNervous disorderPharmaceutical delivery mechanismMass compositionSustained release pellets

The invention relates to a levetiracetam slow release pellet capsule preparation and a preparation method thereof. The levetiracetam slow release pellet capsule preparation comprises the following components in percentage by mass: 50-70 percent of levetiracetam, 15-30 percent of blank pellet, 5-10 percent of hydroxypropylmethyl cellulose or polyvidone, 7-15 percent of ethylcellulose or acrylic resin, 1-8 percent of talc powder and 0.5-2 percent of cataloid. The preparation method comprises the following steps: coating levetiracetam fine powder on the blank pellet by a binding agent to be madeinto a medicine-contained pellet; coating an isolating layer on the medicine-contained pellet; coating a slow release coating film on the medicine-contained pellet coated with the isolating layer to prepare a slow release pellet; and mixing the slow release pellet, the talc powder and the cataloid and filling the mixture into a capsule. The levetiracetam is made into the slow release capsule preparation by a pellet and slow release technology, and the slow release preparation can stabilize blood medicine concentration, reduce the generating frequency and degree of the side effect and fundamentally solve the problems of great influence on a tablet by gastric pyloric sphincter and big differences of gastric emptying individuals.

Owner:天津药物研究院药业有限责任公司

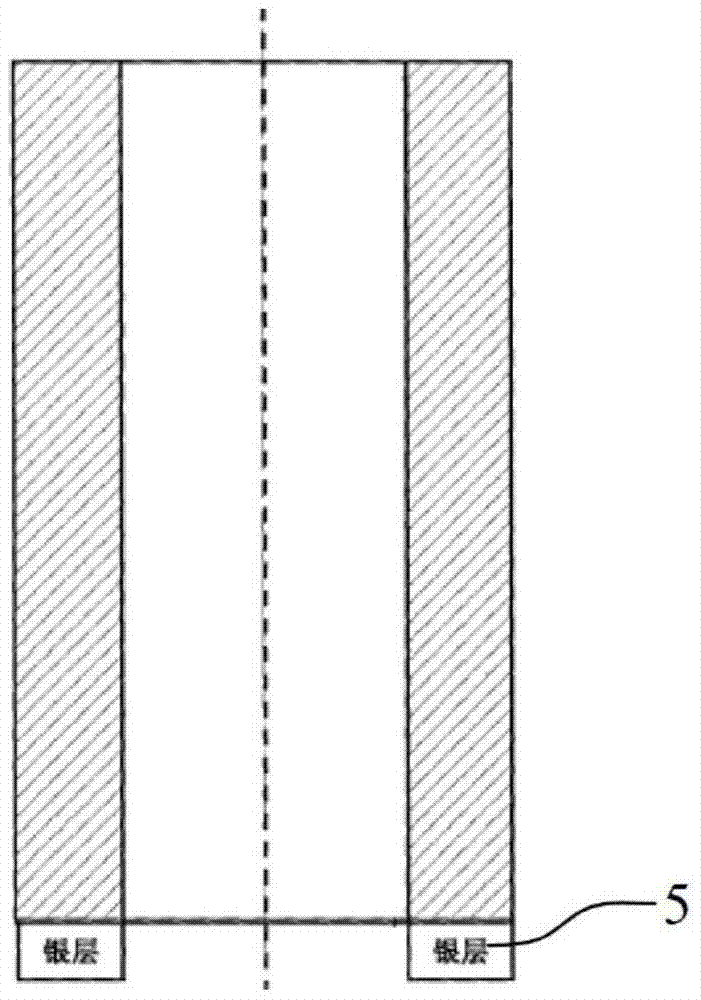

Microwave Dielectric Resonator

The invention discloses a microwave dielectric resonator, comprising a cavity and a dielectric resonator, the dielectric resonator is a cylinder with a through hole; the dielectric resonator is composed of the following components in mass percentage: calcium carbonate, Aluminum oxide, neodymium oxide, titanium dioxide; one end of the dielectric resonator is coated with a silver layer, and the other end of the dielectric resonator is welded in the cavity; the cavity is composed of the following components in mass percentage: alumina 95~ 96%, calcium carbonate 2~3%, lanthanum oxide 0.8~1.5%, samarium oxide 0.2~0.5%; the relative dielectric constant of the cavity is 9.5; the surface roughness of the inner wall of the cavity is about 0.8; the cavity The internal wall is covered with a metal layer through sputtering or electroless plating. The microwave dielectric resonator of the invention has a high Q value, and the tuning range can reach 7%-10% at a specified frequency. The general tuning range of the TE mode resonator is 3%-4%.

Owner:江苏灿勤科技股份有限公司

Insulating full inorganic binder for metal soft magnetic powder core and use method thereof

ActiveCN107845474AHigh strengthReduce eddy current lossInorganic material magnetismMass compositionPotassium

The invention discloses an insulating full inorganic binder for metal soft magnetic powder core and belongs to the technical field of magnetic material preparation. The insulating full inorganic binder is composed of borate, silicates, aluminosilicates and quartz; the mass compositions are: 48 to 70% borate, 5 to 8 wt% silicate, 20 to 40wt% aluminosilicates, 2 to 8 wt% quartz powder, wherein the borate is anhydrous sodium tetraborate powder; the silicate is sodium silicate powder; the aluminosilicates are two or more selected from talc, kaolin, albite, mica and potassium feldspar. The heat resistance temperature of the insulating full inorganic binder of the invention reaches 1000 DEG C; the invention can significantly improve the mechanical strength of the magnetic powder core, and the prepared magnetic powder core has comprehensive excellent magnetic properties and mechanical properties. The present invention is particularly suitable for iron-based magnetic powder cores and can significantly improve its high frequency performance and quality factors.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

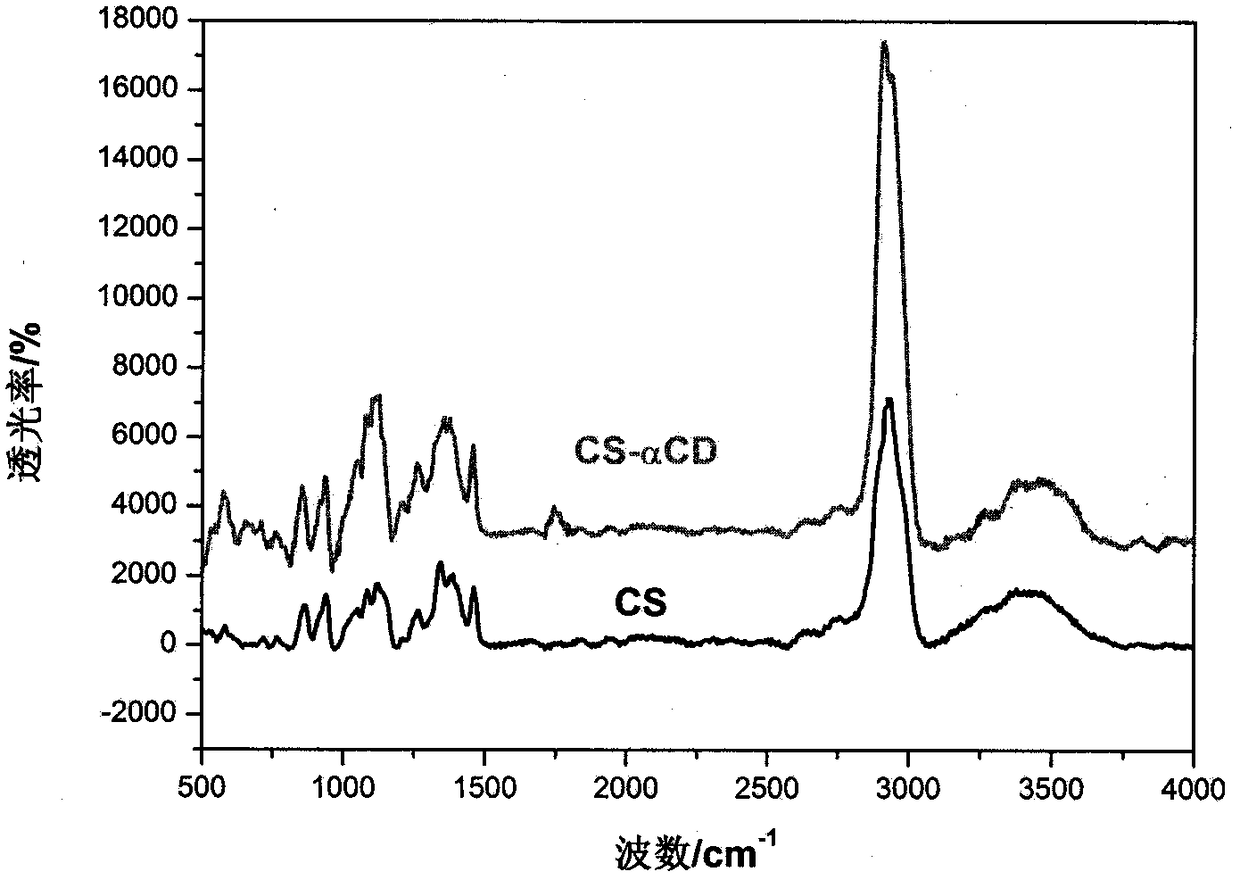

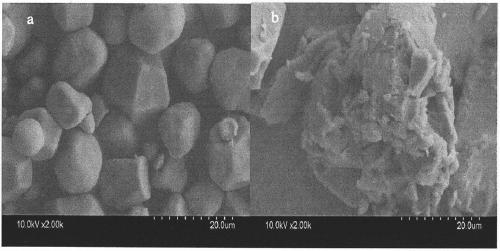

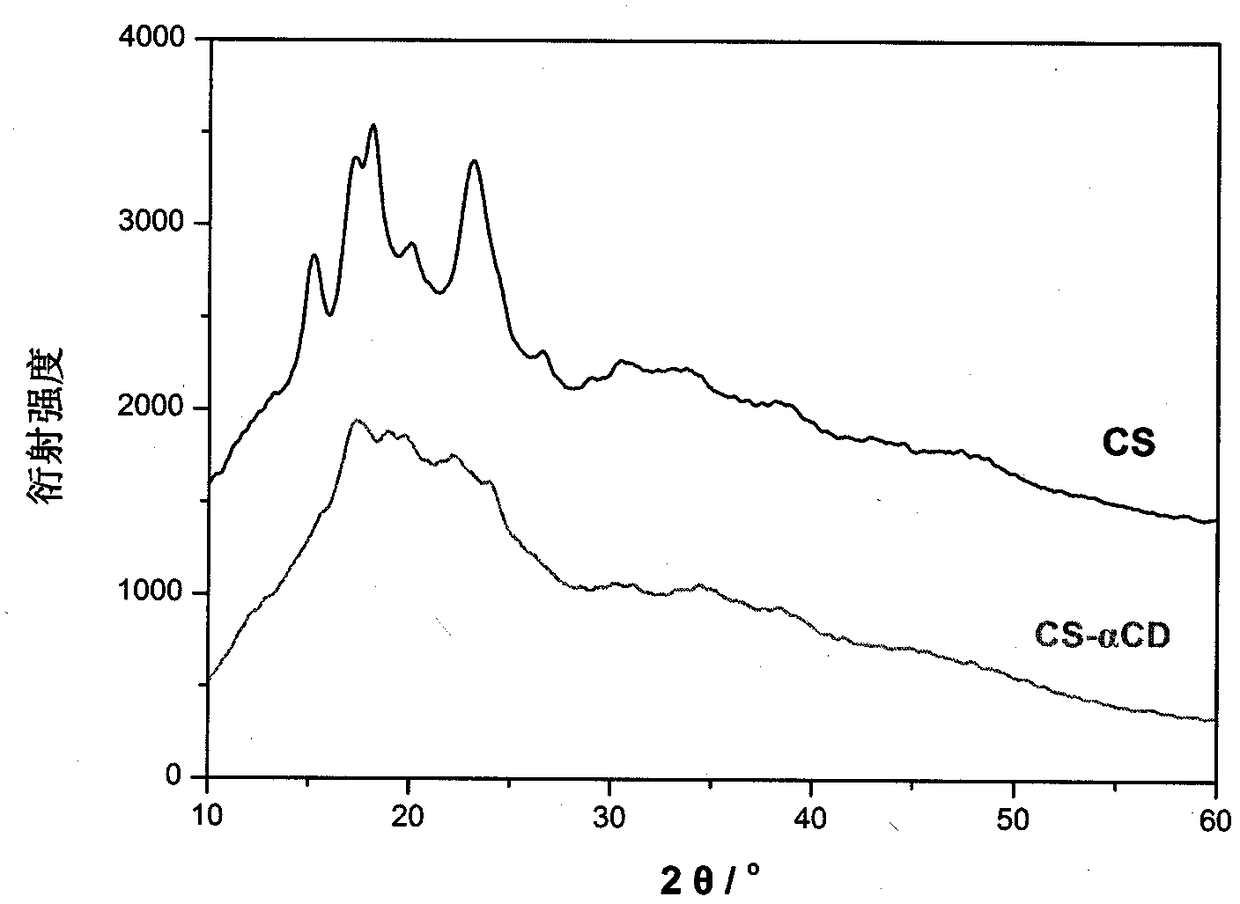

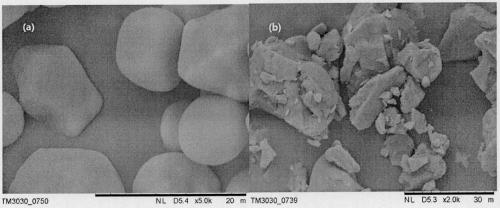

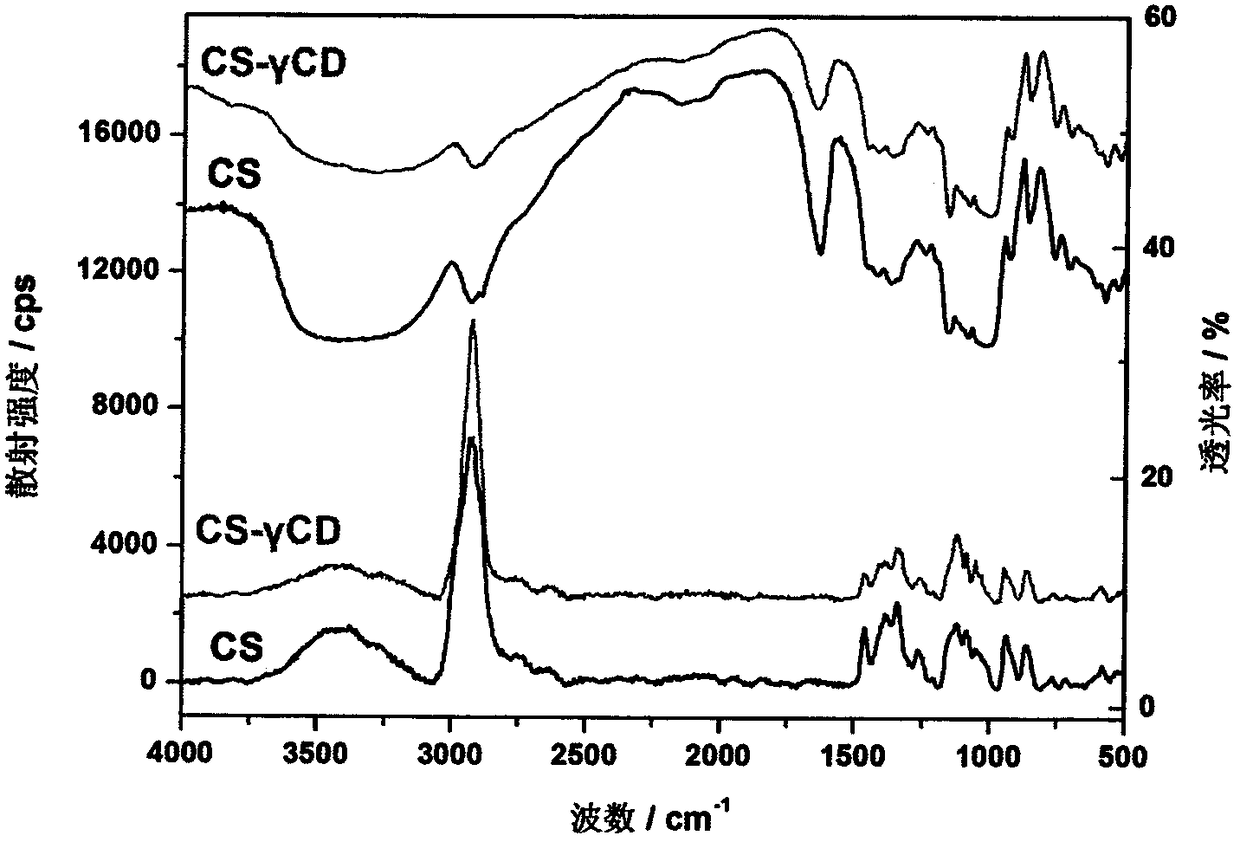

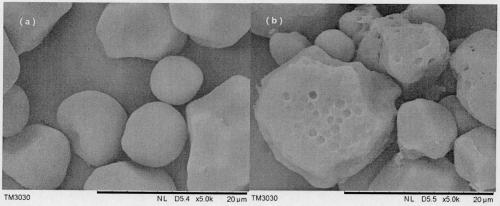

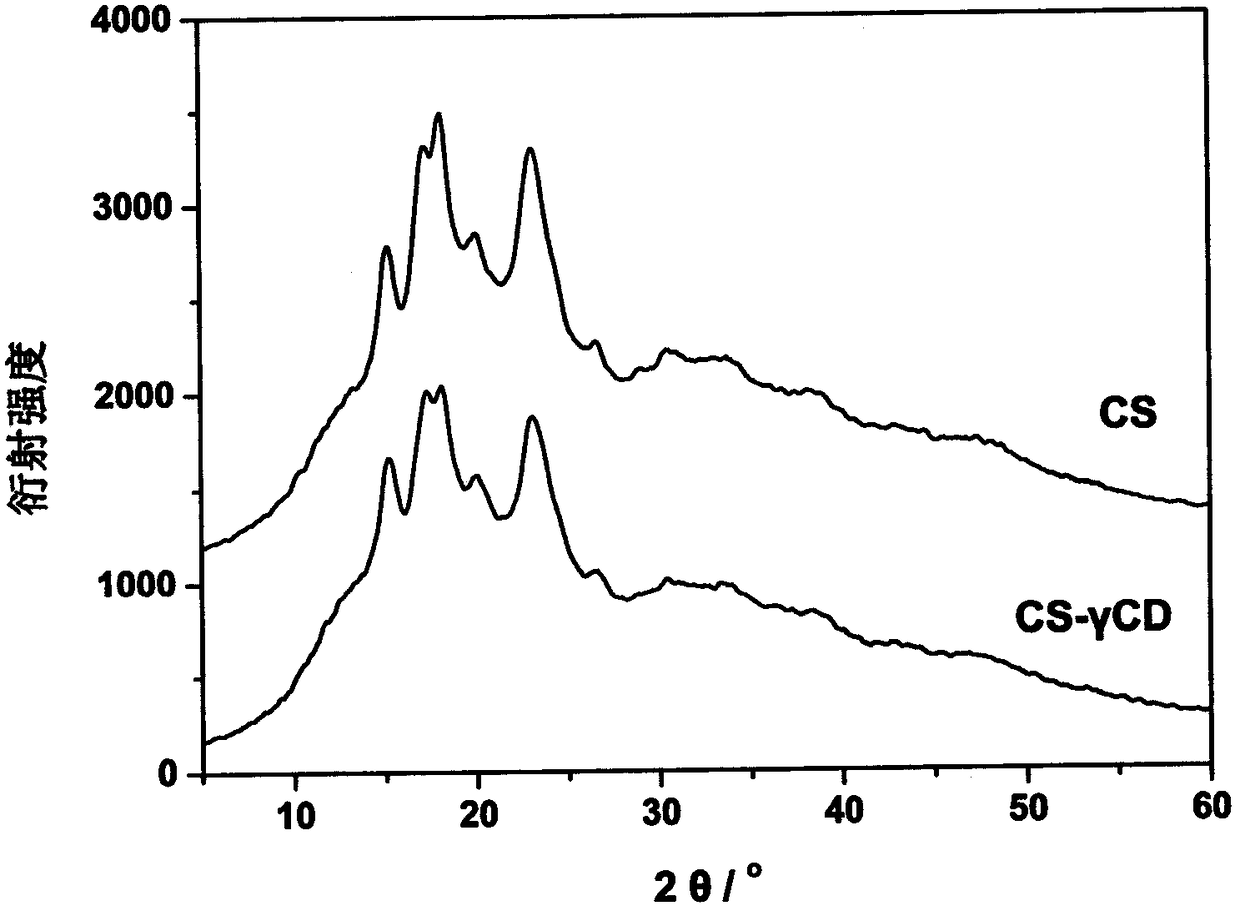

Alpha-cyclodextrin modified starch slurry and preparation method thereof

InactiveCN109293789AImprove physical and chemical propertiesImprove solubilityFibre typesWater bathsMass composition

The invention relates to the technology for modified starch slurry for textiles, and in particular, relates to alpha-cyclodextrin immobilized starch and a preparation method thereof. The alpha-cyclodextrin immobilized starch is characterized by comprising the raw materials of the starch in parts by mass: 50 parts of corn starch, 50 parts of alpha-cyclodextrin, 20 parts of malic acid, 7.5 parts ofsodium hypophosphite and 300 parts of deionized water. The technical scheme to solve the technical problems of the preparation method comprises that the preparation method of the alpha-cyclodextrin immobilized starch (CS-[alpha]CD) is designed; the preparation method adopts the raw material mass composition of the acetylated corn starch and the following technological steps: (1) preparing a starchsuspension from the corn starch, [alpha]-cyclodextrin and 200 parts of deionized water, transferring to a 500 mL three-neck flask, placing in a 85 DEG C water bath pot, turning on a condensing device, heating and gelatinizing for 30 min, then adding 100 parts of a solution containing malic acid and sodium hypophosphite with the weight part through a constant pressure dropping funnel, stirring evenly, transferring the mixture into a 120 DEG C oven, carrying out reaction for 2 h and taking out the mixture; and (2) after the reaction is finished, taking out the product, crushing, washing twice with deionized water, washing twice with 75% ethanol, and centrifuging and drying to obtain the sample [alpha]-cyclodextrin immobilized starch, namely CS-[alpha]CD.

Owner:TIANJIN POLYTECHNIC UNIV

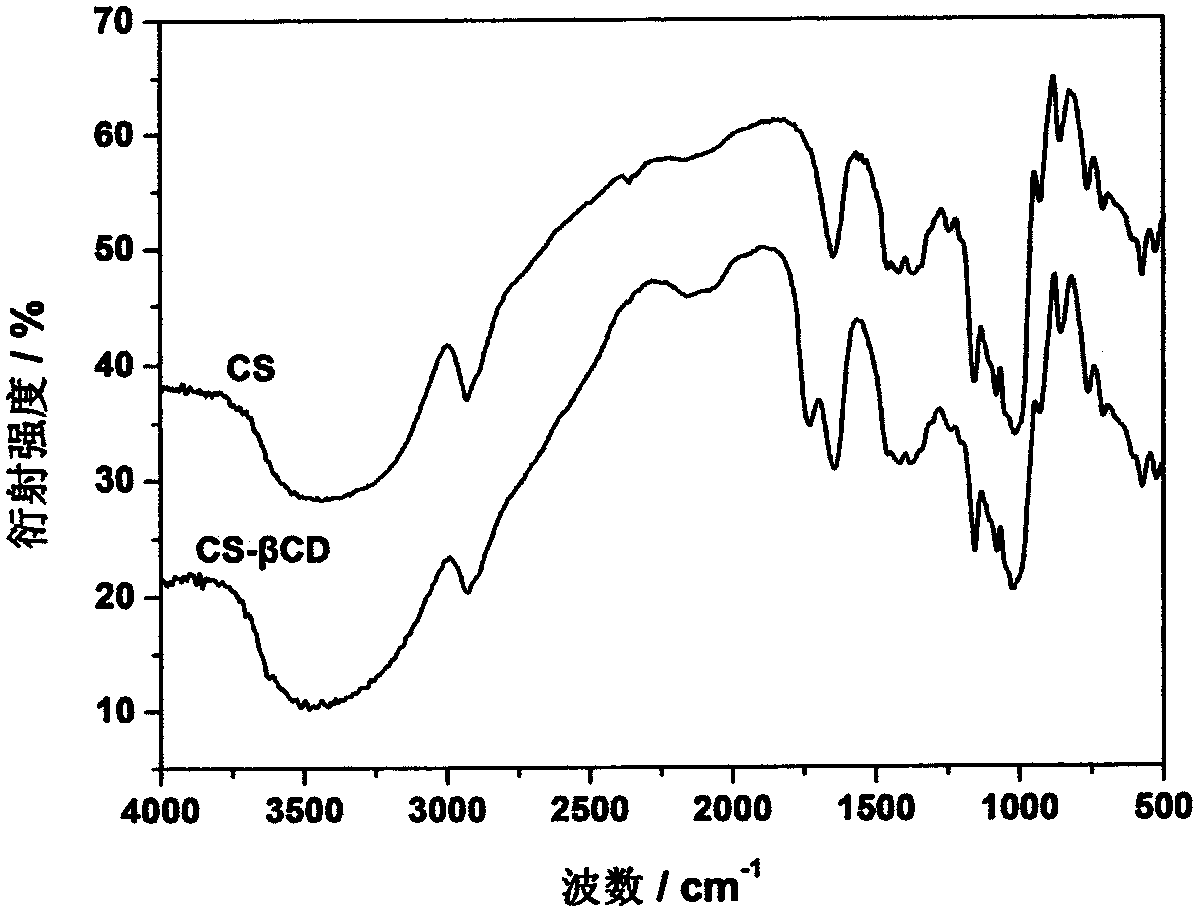

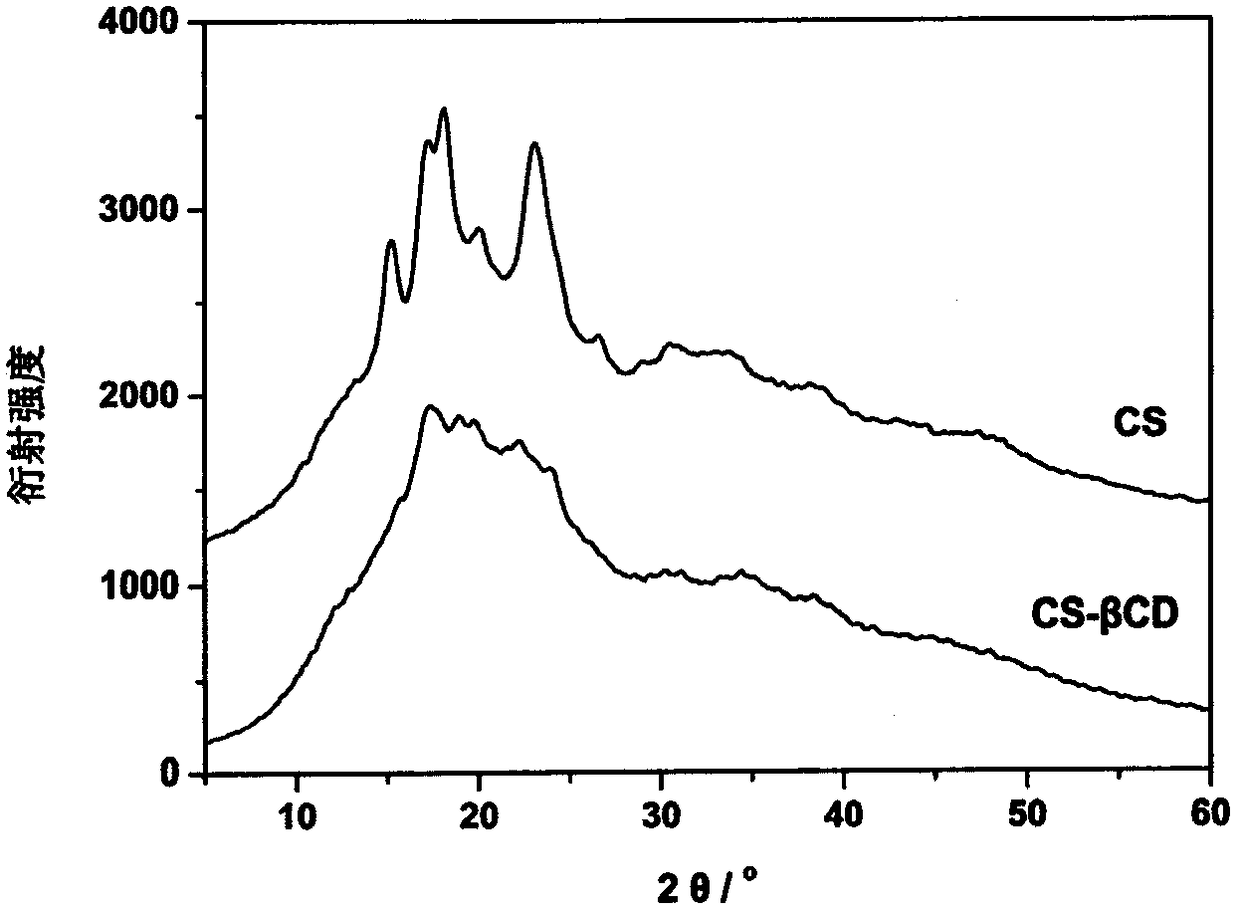

CD (cyclodextrin) modified starch dye adsorbent and preparation method thereof

InactiveCN108993422AWide variety of sourcesEasy to makeOther chemical processesWater contaminantsWater bathsMass composition

The invention discloses a natural polymer adsorbent beta-CD (cyclodextrin) immobilized starch (CS-beta CD). The adsorbent is characterized in that the starch comprises raw materials in parts by mass as follows: 100 parts of native starch, 234 parts of beta-CD, 400 parts of distilled water, 20 parts of citric acid and 5 parts of sodium hypophosphite. The invention also provides a preparation methodof the starch. The method adopts the raw material mass composition of the beta-CD immobilized starch and comprises the following process steps: (1) a suspension is prepared from 100 parts of corn starch, 234 parts of beta-CD and 400 parts of the distilled water, transferred into a three-neck flask and then heated and gelatinized for 30 min in a water bath at 85 DEG C; then 20 parts of the distilled water, 20 parts of citric acid and 5 parts of sodium hypophosphite are added, and the substances are stirred uniformly; the obtained mixture is transferred into a drying oven at 120 DEG C and subjected to a reaction for 2 h; (2) after the reaction, a product is taken out, crushed, washed three times with 40% ethanol and dried centrifugally, and the sample beta-CD immobilized starch, namely, CS-beta CD is obtained.

Owner:TIANJIN POLYTECHNIC UNIV

Aqueous Dispersion and Additives for Fracturing Work

InactiveUS20160264851A1Performed simply simply and flexiblyDrilling compositionMass compositionCarboxylic acid

The aqueous dispersion of the present invention is an aqueous dispersion in which a biodegradable resin composition (C) in the form of a fine solid is dispersed in an aqueous medium, and the biodegradable resin composition (C) comprises a copolymer (A) comprising a constituent unit (a-1) derived from a polyvalent carboxylic acid and a constituent unit (a-2) derived from a hydroxycarboxylic acid, and a biodegradable resin (B), and wherein the mass composition ratio [(A) / (B)] of the copolymer (A) to the biodegradable resin (B) is 1 / 99 to 100 / 0 provided that the total amount of the copolymer (A) and the biodegradable resin (B) is 100.

Owner:MITSUI CHEM INC

CD (cyclodextrin) modified starch dye adsorbent and preparation method thereof

InactiveCN108993421AWide variety of sourcesEasy to makeOther chemical processesWater contaminantsMass compositionSorbent

The invention discloses a natural polymer adsorbent, namely, a gamma-CD (cyclodextrin) immobilized starch adsorbent. The adsorbent is characterized in that starch comprises raw materials by mass as follows: 100 parts of corn starch, 1000 parts of aqueous NaCl solution (wNaCl%=2.5), 15 parts of gamma-CD and 10 parts of ECH. The invention also provides a preparation method of the starch adsorbent. The method adopts the raw material mass composition of the gamma-CD immobilized starch and comprises the following process steps: (1) a starch suspension is prepared from the corn starch and the aqueous NaCl solution in parts and transferred into a three-neck flask, and pH is regulated by a 30% NaOH solution to be 10; then ECH in parts is added (dropwise three times in a reaction process), a refluxcondensation device is connected, and a continuous reaction is performed at 50 DEG C for 6 h; (2) after the reaction, a product is cooled to room temperature, pH is regulated by a 3N hydrochloric acid solution to be 6.5-7, the product is precipitated with absolute ethyl alcohol, and a crude product is obtained by centrifugal separation; the crude product is washed centrifugally three times with 65 / 35 ethanol water, dried in vacuum at 50 DEG C, ground and crushed, and gamma-CD immobilized starch, namely, CS-gamma CD is obtained.

Owner:TIANJIN POLYTECHNIC UNIV

Pickling material recipe of hot and spicy mustard pickled goose livers and manufacturing method thereof

The present invention mainly provides a stewed foie gras stewed with spicy mustard and its preparation method, which is composed of the following ingredients and quality: Formula 1: mustard 20-40g, dried pepper 20-40g, rock sugar 20-40g, grass fruit 6-10g , pepper 15‑25g, cinnamon 6‑10g, bay leaves 6‑10g, sesame paste 20‑40g, Luo Han Guo 1‑3, cumin 4‑6g, licorice 6‑10g, ginger 15‑25g, rock sugar 30‑50g, Rice wine 20‑40 grams. Recipe 2: Star anise 6-10g, tomato 100-200g, salt 10-20g, clove 1-3g, angelica dahurica 2-6g, oil consumption 10-20mL, dark soy sauce 30-50mL, cooking wine 40-60mL. The invention also provides a preparation method of spicy mustard stewed foie gras. The invention has the advantages that: the marinated material prepared by the stewed formula has a special taste, is sweet and not greasy, smells good, tastes delicious, and has both a spicy taste and a unique choking taste of mustard.

Owner:任大伏

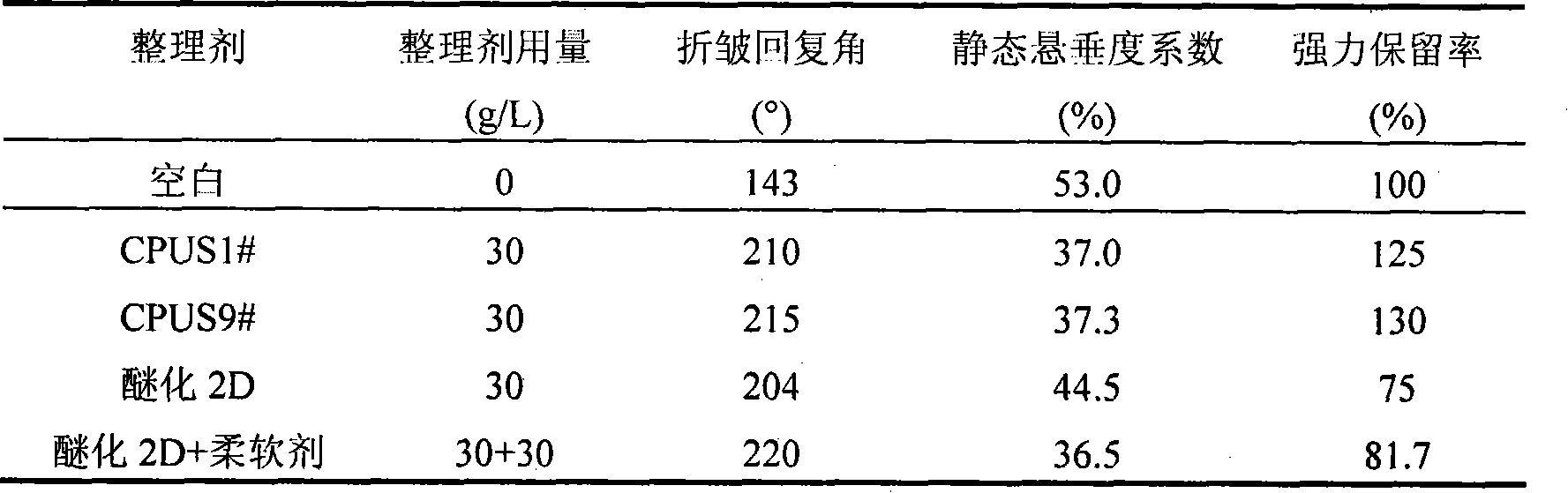

Cationoid polyurethane and modified silicon oil composite water dispersion, preparation and applications

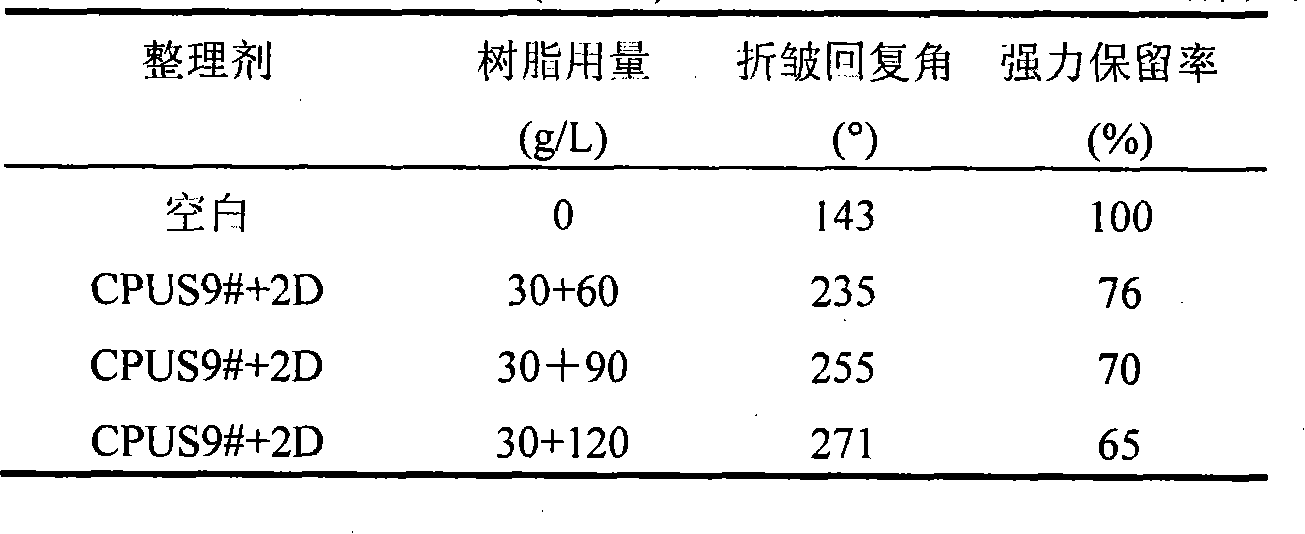

InactiveCN101307180BGood adhesionIncreased durabilityFibre treatmentMass compositionRoom temperature

The invention relates to a cationic polyurethane and modified silicone oil composite nano aqueous dispersion and a preparation method and an application thereof. The dispersion particles of the dispersion are compounded with cationic polyurethane and modified silicone oil, the diameters of the dispersion particles are less than 100nm. The mass composition of the modified silicone oil in the dispersion particles is 10 to 50 percent. High molecular weight polyether glycol and cationic diol chain extender react with isophorone diisocyanate(IPDI) to form ionic polyurethane after end capping and neutralization. The ionic polyurethane and the modified silicone oil are compounded and added with water to conduct self-emulsification at the room temperature to form the polyurethane and modified silicone oil composite nano aqueous dispersion. The nano aqueous dispersion can be used as a multifunction finishing material cotton cloth and can effectively improve the crease resistant, draping property and strength conservation rate and improve the hand feeling of fabrics and hydrophilcity and hydrophobicity of the surfaces of the fabrics.

Owner:TIANJIN UNIV

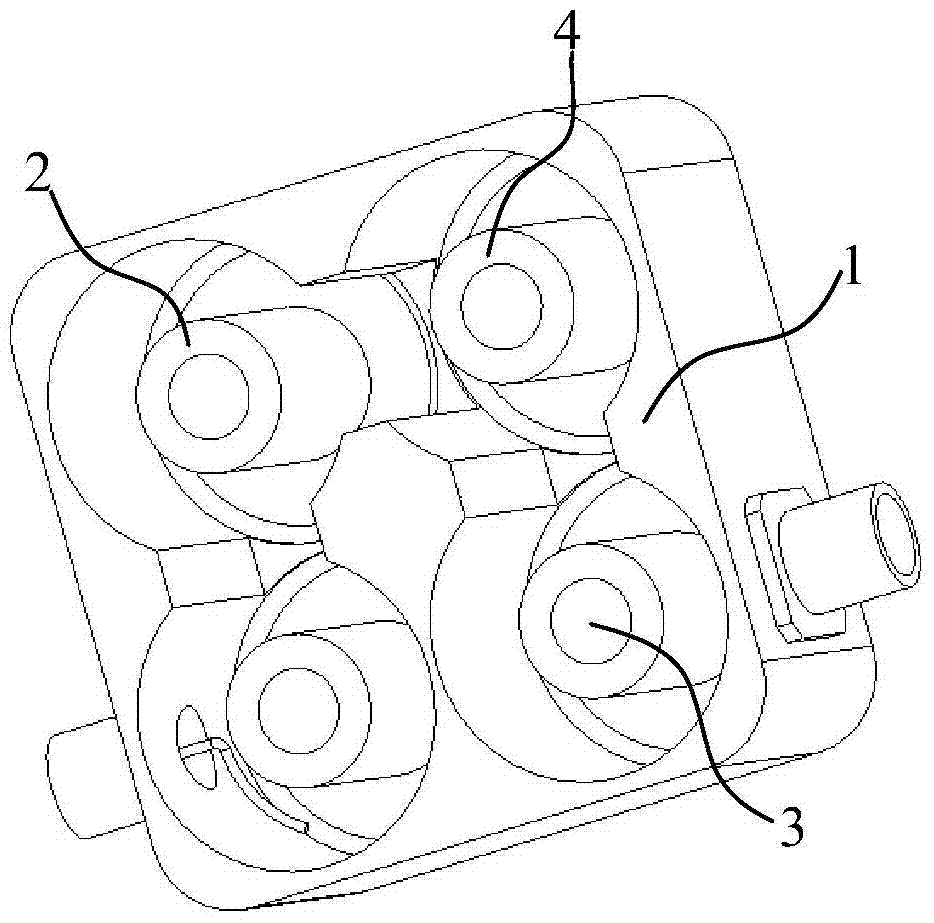

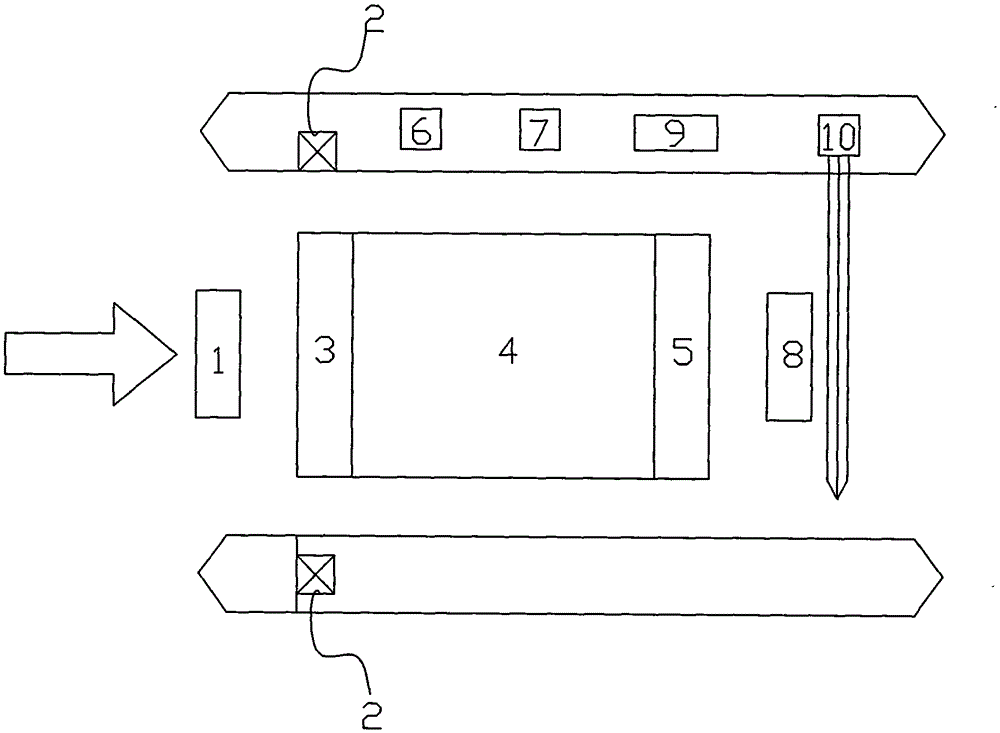

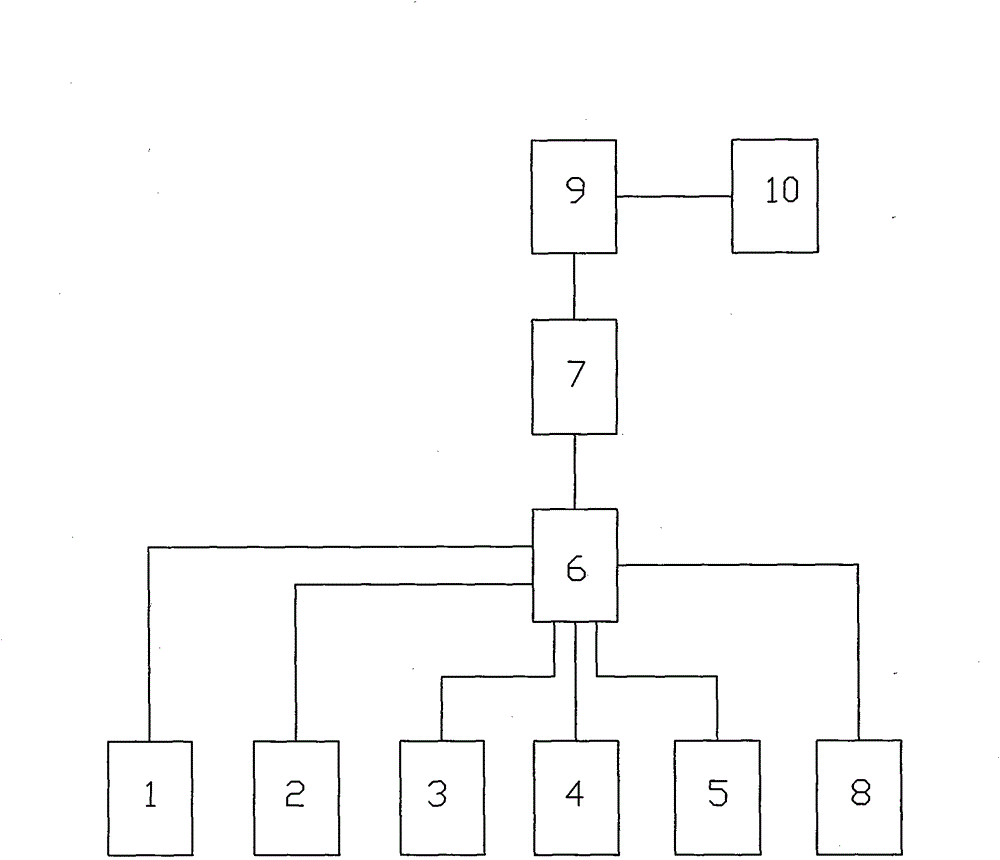

Three-stage compound weighing device

ActiveCN104089691BLess investmentShort construction periodSpecial purpose weighing apparatusMass compositionThree stage

The invention belongs to the field of expressway automobile weighing scales, and in particular relates to a three-stage composite weighing platform. The three-section composite weighing platform is composed of the first section, the second section, the third section, and the weighing sensor under the weighing platform. It is characterized in that, from left to right, the first section The rear end of the weighing platform is lapped on the front end of the second section of the weighing platform, the front end of the third section of the weighing platform is lapped on the rear end of the second section of the weighing platform, and the upper surface of the whole scale body is level and even. The recent application practice has proved that the beneficial effect of the three-stage composite weighing platform is that the investment is small, that is, it does not need to spend a lot of money to build a huge static scale, which is almost the investment basis of the axle load scale. The construction period is short, cheating prevention, quick results, and income Large, realize dynamic fast and accurate weighing, benefit the country and the people. The advantage of "low investment and dynamic, rapid and accurate weighing" makes the three-stage composite weighing device expected to replace the traditional large static scale and simple axle load scale, and is suitable for installation and use at the entrance of all congested roads.

Owner:SHANXI GUOQIANG TECH DEV

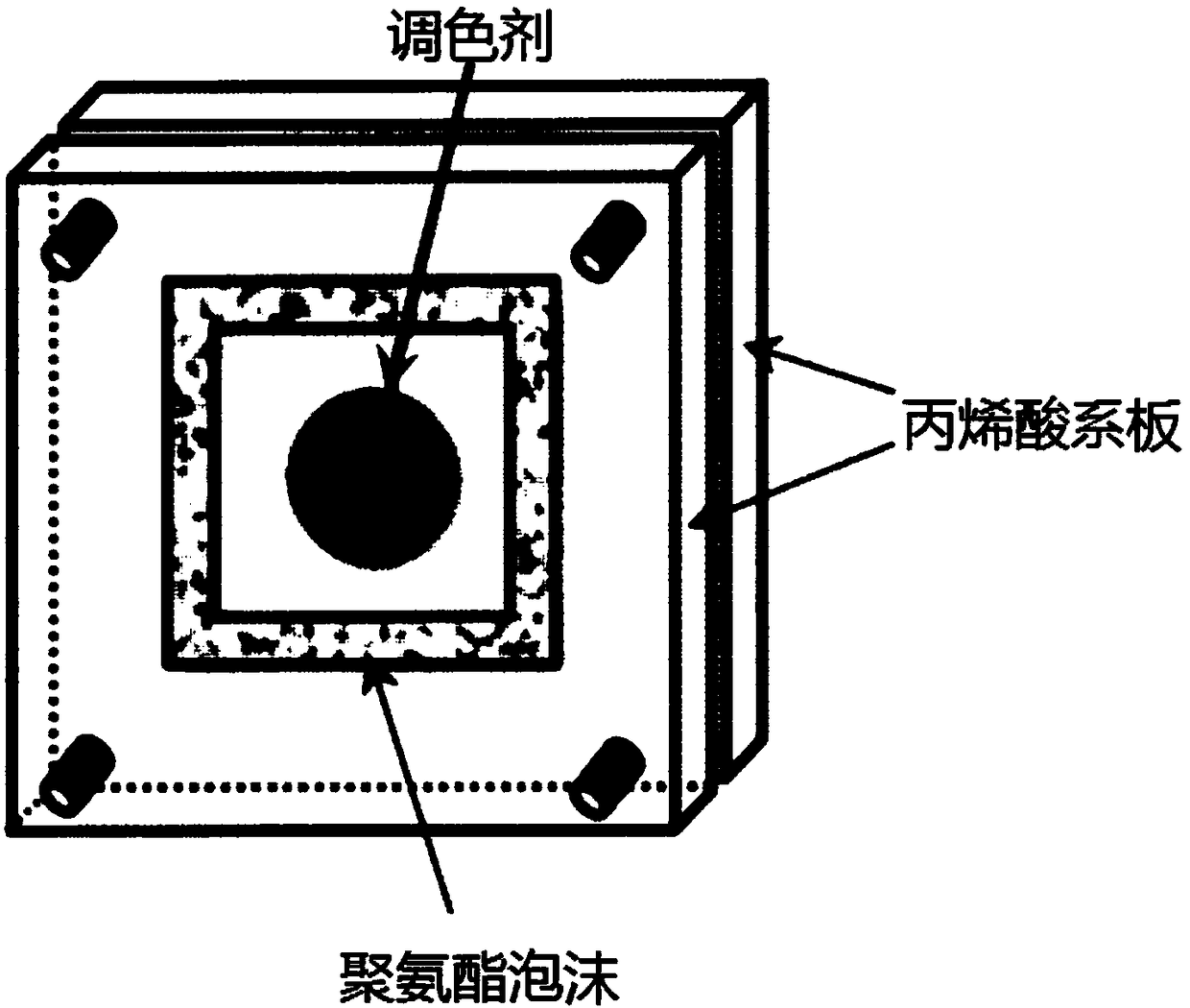

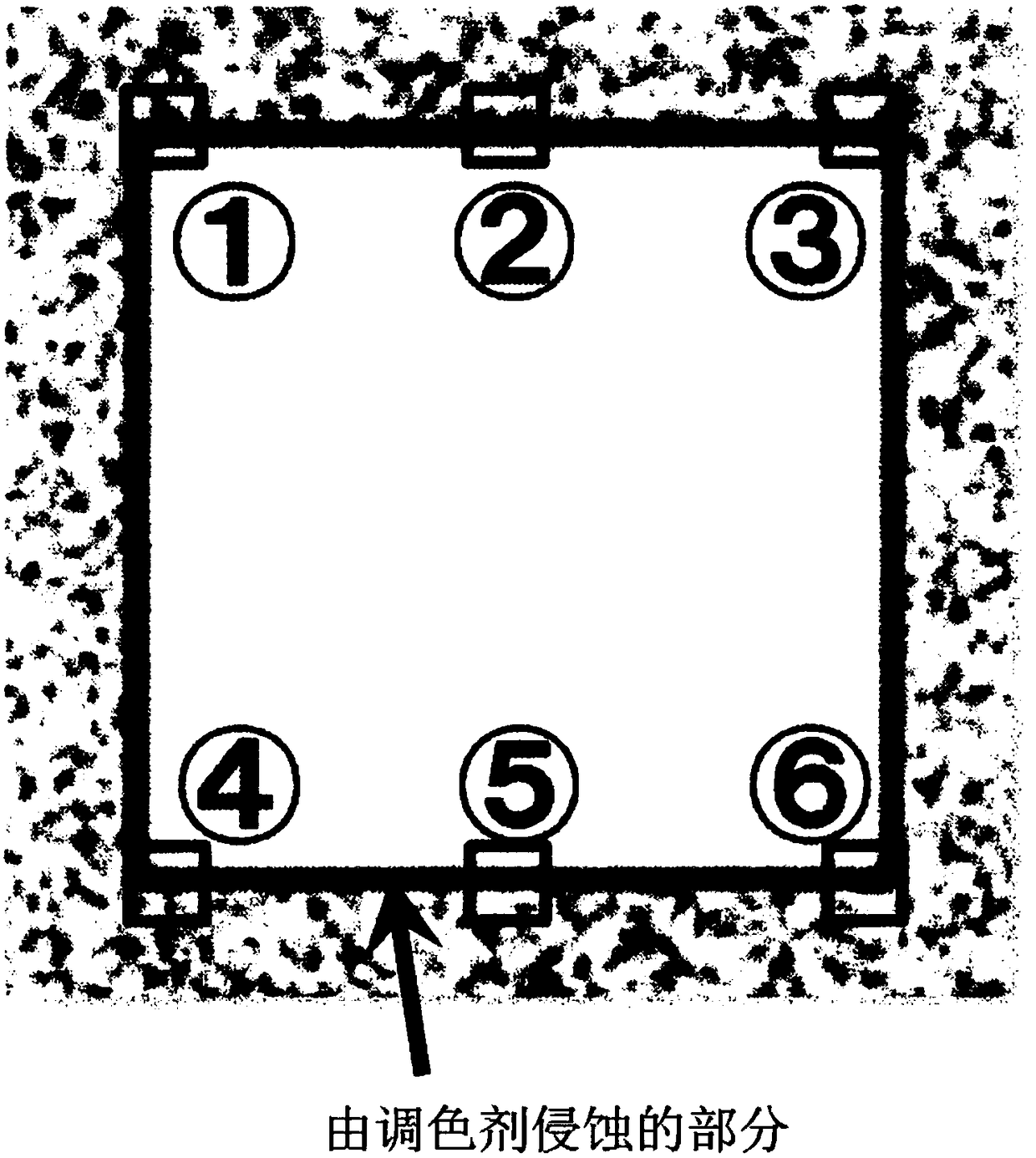

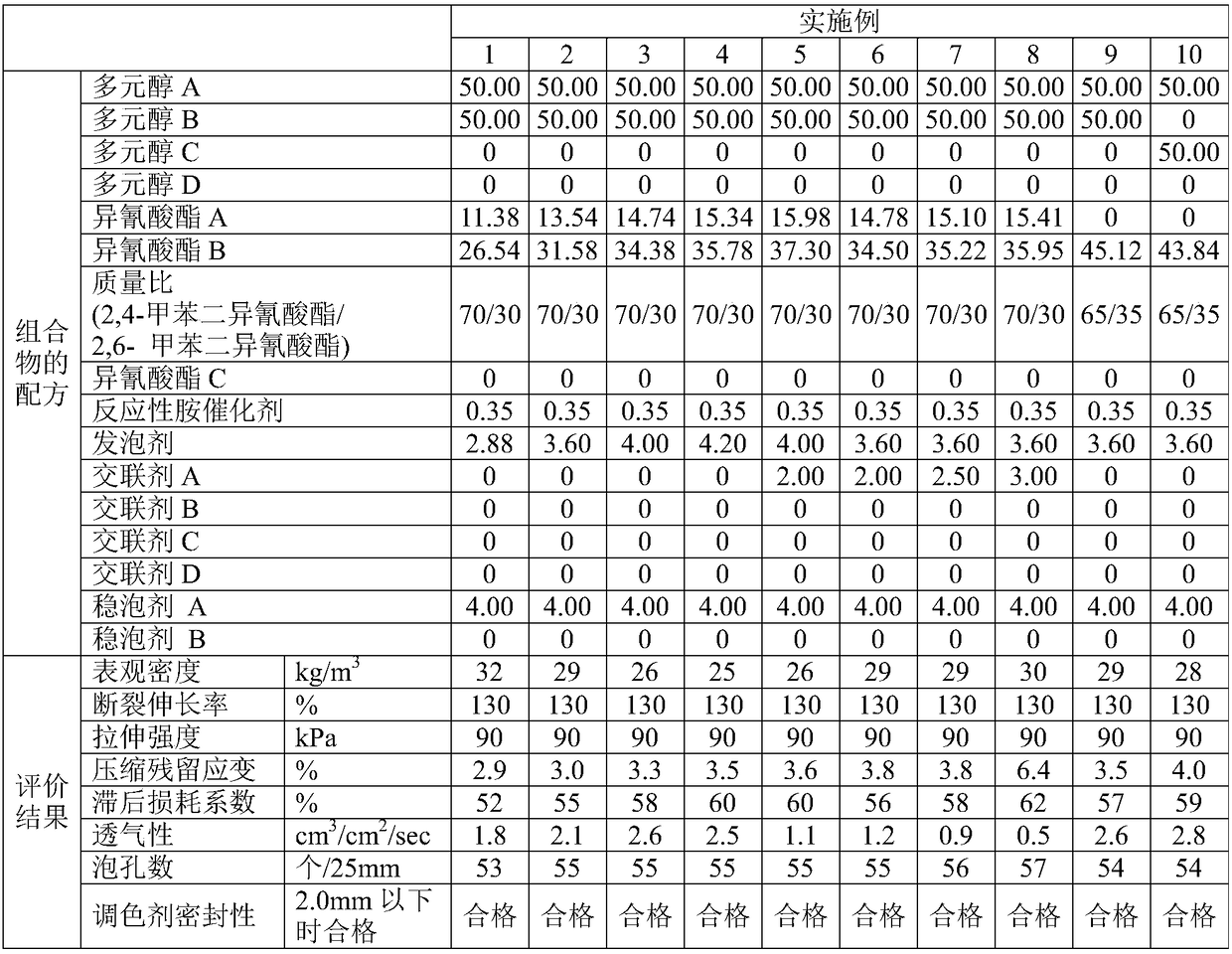

Composition for polyurethane foam

InactiveCN108473656AImprove sealingPromote recoveryElectrographic process apparatusMass compositionPolyester

The present invention provides a composition for polyurethane foam, which is obtained by blending a polyol composed of a polyester polyol and a polyether polyol, tolylene diisocyanate, a foaming agentand a foam stabilizer, and which is characterized in that: the polyester polyol contains a phthalate ester polyol; and the mass composition ratio of the tolylene diisocyanate, namely (2, 4-tolylene diisocyanate) / (2, 6-tolylene diisocyanate) is from 65 / 35 to 70 / 30. This composition for polyurethane foam enables a polyurethane foam to have enhanced tensile strength and elastic recoverability, whileensuring low air permeability and excellent toner sealability.

Owner:BRIDGESTONE CORP

Strontium ranelate orally disintegrating tablets and preparation method thereof

ActiveCN102525975AEasy to takeFast absorptionOrganic active ingredientsSkeletal disorderMass compositionMedicine

The invention relates to strontium ranelate orally disintegrating tablets and a preparation method of the tablets. The strontium ranelate orally disintegrating tablets are characterized in that the strontium ranelate orally disintegrating tablets are prepared from the following components by mass: 1-2 parts of strontium ranelate, 0.5-2 parts of filler, 0.1-0.5 parts of disintegrant, 0.02-0.2 parts of corrective, and 0.02-0.2 parts of lubricant. The preparation method comprises the following steps: sieving strontium ranelate, filler, corrective and lubricant, and mixing in a mixing machine; and selecting a proper mold, and tableting with a tableting machine to obtain strontium ranelate orally disintegrating tablets. Compared with the existing preparation, the strontium ranelate orally disintegrating tablets prepared using the method of the invention is more suitable for patients to take, increases the compliance of patients, and has the adavntages of rapid absorption, high bioavailability and the like in addition to convenience in administration. Therefore, the development of this project can obtain wide social and economic benefits.

Owner:天津药物研究院药业有限责任公司

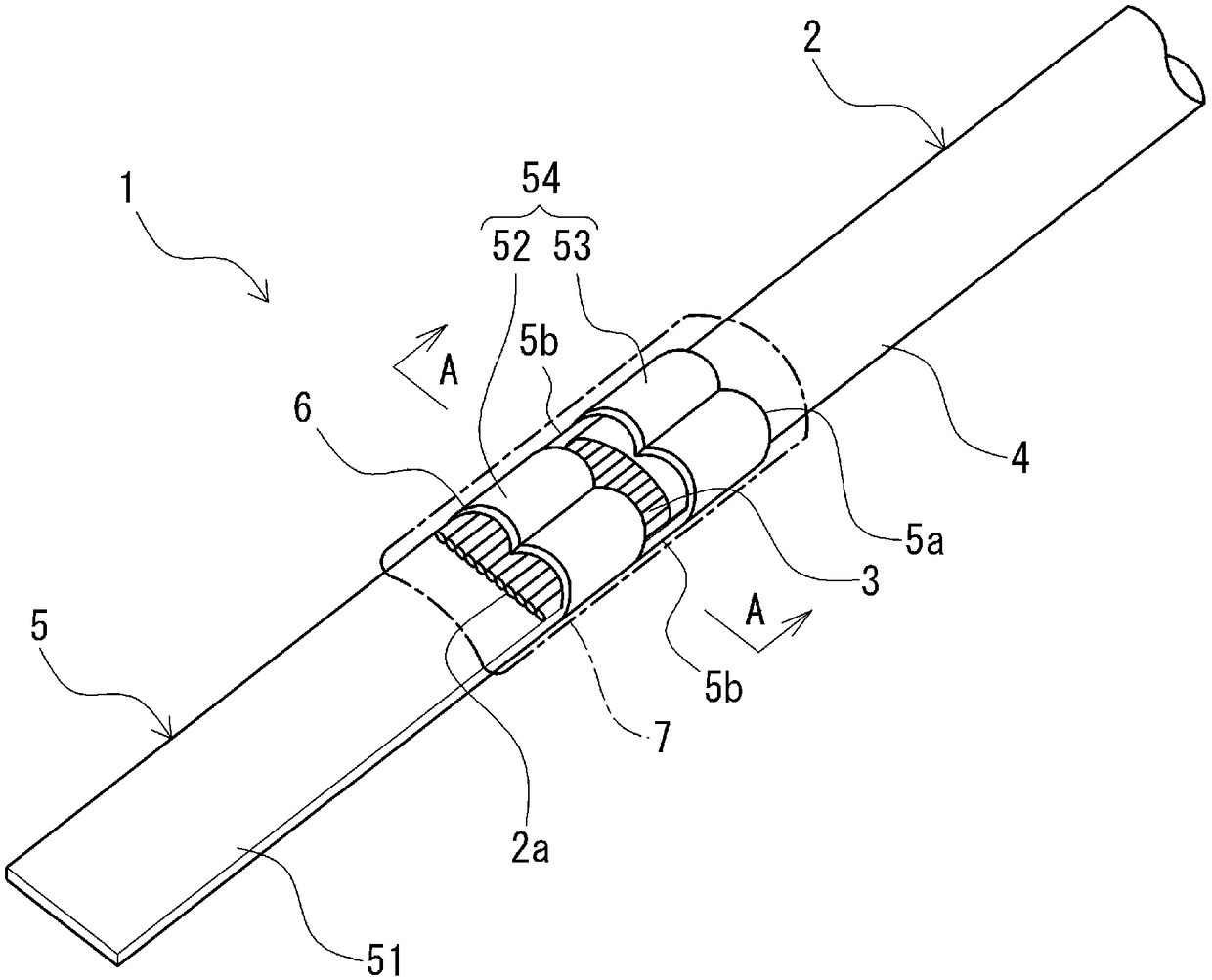

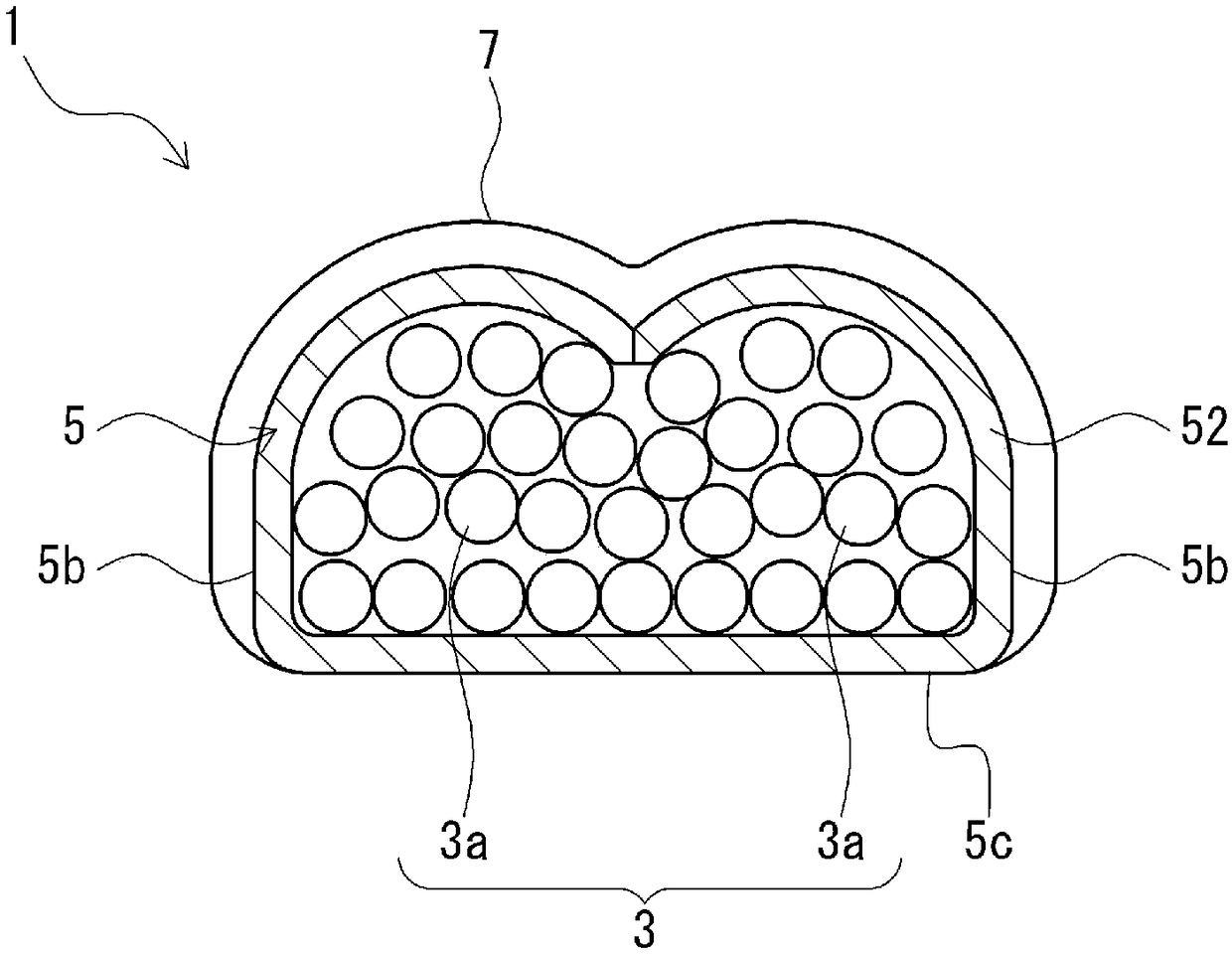

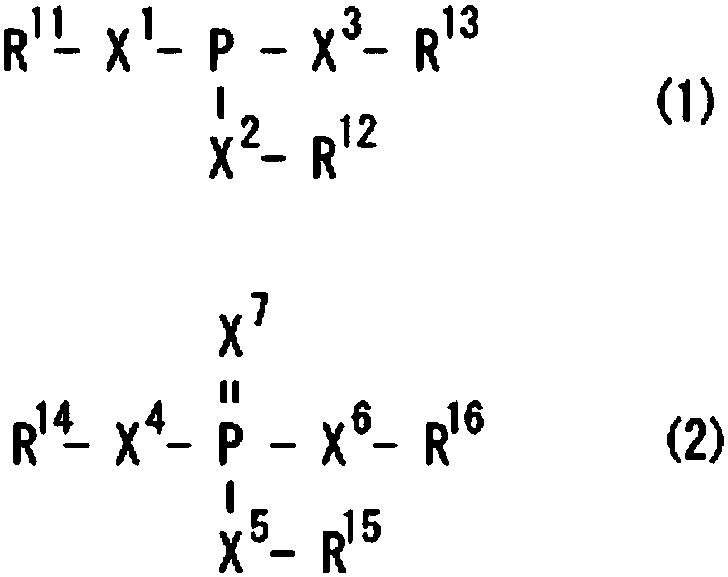

Corrosion inhibitor and covered electrical cable with terminal

ActiveCN108474120AGuaranteed anti-corrosion performanceImprove adsorption capacityCoupling contact membersInsulated cablesMass compositionElectricity

Provided is a corrosion inhibitor that, when used on a connection section of a covered electrical cable with a terminal, said covered electrical cable having a covering material that includes a plasticizer, maintains anticorrosive performance even if exposed to high temperatures. Also provided is a covered electrical cable with a terminal, the anticorrosive property of said covered electrical cable having been improved using said corrosion inhibitor. A corrosion inhibitor including a base oil (A) that has a viscosity of 30 mPa.s or greater at 100 DEG C, and a metal adsorption component (B) that includes a phosphorus compound, wherein the mass composition ratio of (A) to (B) is within the range of (A):(B)=50:50 to 98:2. A covered electrical cable 1 with a terminal, wherein a film 7 comprising the corrosion inhibitor of the present invention covers a part 6 where a terminal metal fitting 5 and an electrical cable conductor 3 are electrically connected.

Owner:AUTONETWORKS TECH LTD +3

Sulfur-free and pearlite-free firecracker reagent and preparation method thereof

The invention discloses a sulfur-free and pearlite-free firecracker reagent and a preparation method thereof. The reagent comprises the following mass components: 35-65 percent of A component and 35-65 percent of B component, wherein the A component comprises the mass compositions: a mixture formed by 20-50 percent of potassium perchlorate, 0-30 percent of potassium nitrate and 30-50 percent of barium nitrate and a complexing agent occupying 1-5 percent of the mixture, and the B component comprises the mass compositions: 50-80 percent of aluminum powder, 10-25 percent of charcoal powder and 10-25 percent of organic foaming powder. The burning rate of a firecracker prepared from the reagent is more than 98 percent, the sound level value is no less than 100dB and is no more than 140dB, the time the gas product pressure rises from 0.69MPa to 2.07MPa is 1.74ms, a pH value of the pyrotechnic composition is 5-9, the moisture is no more than 1.5 percent, the hygroscopicity is no more than 2.0 percent, the thermal stability is 75 DEG C plus / minus 2 DEG C, the firecracker has no decomposition phenomenon under the condition of 48h, the friction sensitivity is no more than 40 percent, and the impact sensitivity of the pyrotechnic composition is no more than 0 percent. The key is that the reagent reduces the environmental pollution without harm to human bodies and has great application prospect.

Owner:HUNAN VOCATIONAL INST OF SAFETY TECH +1

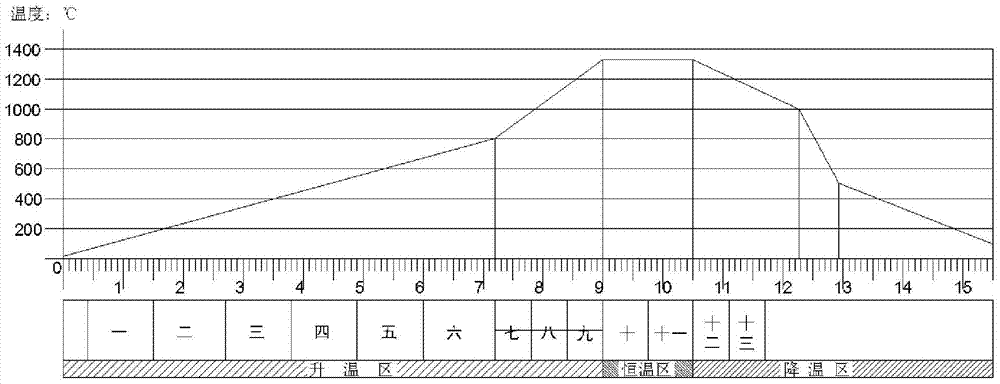

Method for rare earth 242 phase control component for growing superconducting block material

InactiveCN101319380BInhibition of alternative situationsAvoid formingPolycrystalline material growthSuperconductors/hyperconductorsMass compositionRare-earth element

The invention relates to a method for growing a superconducting bulk material by utilizing rare earth 242 phase to control the composition. A precursor is added with light rare earth 242(LRE2Ba4Cu2O9, wherein, LRE is Nd and Sm, etc.) phase powder to control the composition. The ground and sintered LRE123 and LRE242 powder are mixed and ground according to a certain ratio and are pressed into the precursor; the corresponding seed crystal is put on the top part of the precursor, and the LRE-BCO bulk material is prepared by a melt textured method. In the method, the barium-rich rare earth 242 phase powder is utilized because the fused mass composition can be adjusted in a high temperature melting state, thereby effectively suppressing the substitution situation of light rare earth elements and barium elements in the peritectic reaction process, increasing the superconducting transformation temperature of the prepared light rare earth BCO superconductor and improving other performances of the prepared light rare earth BCO superconductor.

Owner:SHANGHAI JIAO TONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com