CD (cyclodextrin) modified starch dye adsorbent and preparation method thereof

A cyclodextrin and adsorbent technology, applied in chemical instruments and methods, adsorption of water/sewage treatment, water pollutants, etc., can solve the problems of complex operation, pollution, and low adsorption efficiency, and achieve simple preparation process and high adsorption effect Good, convenient and easy to implement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The present invention simultaneously designs the preparation method (abbreviation preparation method) of β-cyclodextrin-loaded starch, which adopts the composition and process steps of the raw material mass fraction of β-cyclodextrin-loaded starch of the present invention: native starch 100 parts; 234 parts of β-cyclodextrin; 400 parts of distilled water, 20 parts of citric acid, 5 parts of sodium hypophosphite.

[0027] (1) Make a suspension from the above-mentioned portions of cornstarch, β-cyclodextrin and distilled water, transfer to a three-necked flask, and gelatinize by heating in a water bath at 85° C. for 30 minutes. Then add 20 parts of distilled water containing said parts of citric acid and sodium hypophosphite, and stir evenly. The mixture was moved into an oven at 120°C and reacted for 2h.

[0028] (2) After the reaction, it was taken out and pulverized, washed three times with 40% ethanol, and centrifuged to dry to obtain the sample β-cyclodextrin immobi...

Embodiment 1

[0037] (1) Make a suspension from 50g of cornstarch, 117g of β-cyclodextrin and 200mL of distilled water, transfer it to a three-neck flask, and heat it in a water bath at 85°C for 30min to gelatinize. Then add 100 mL of distilled water containing 10 g of citric acid and 2.5 g of sodium hypophosphite, and stir well. The mixture was moved into an oven at 120°C and reacted for 2h.

[0038] (2) After the reaction, it was taken out and pulverized, washed three times with 40% ethanol, and centrifuged to dry to obtain the sample β-cyclodextrin immobilized starch, ie CS-βCD.

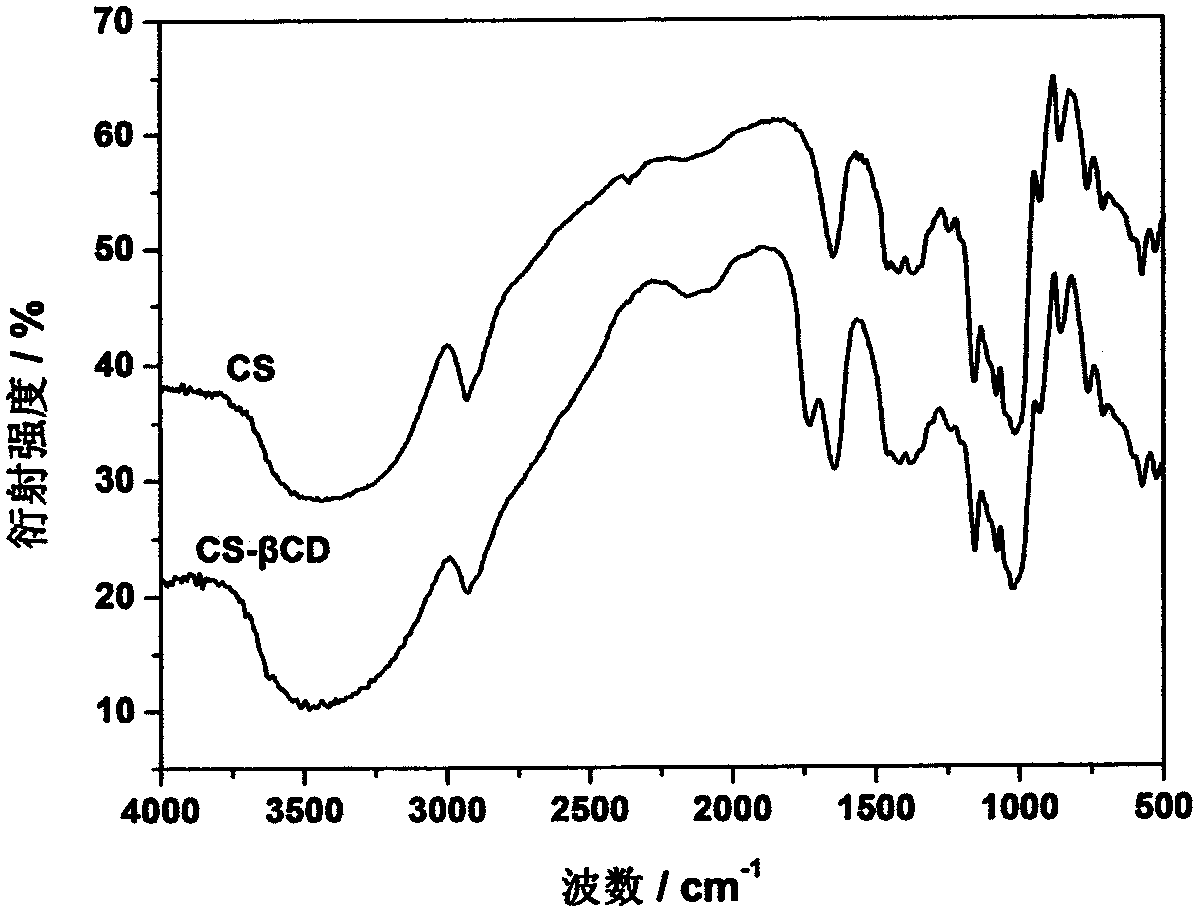

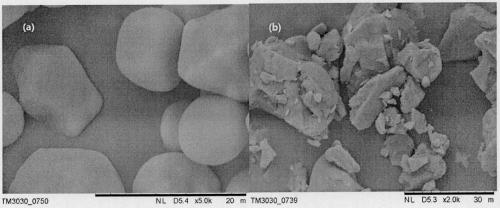

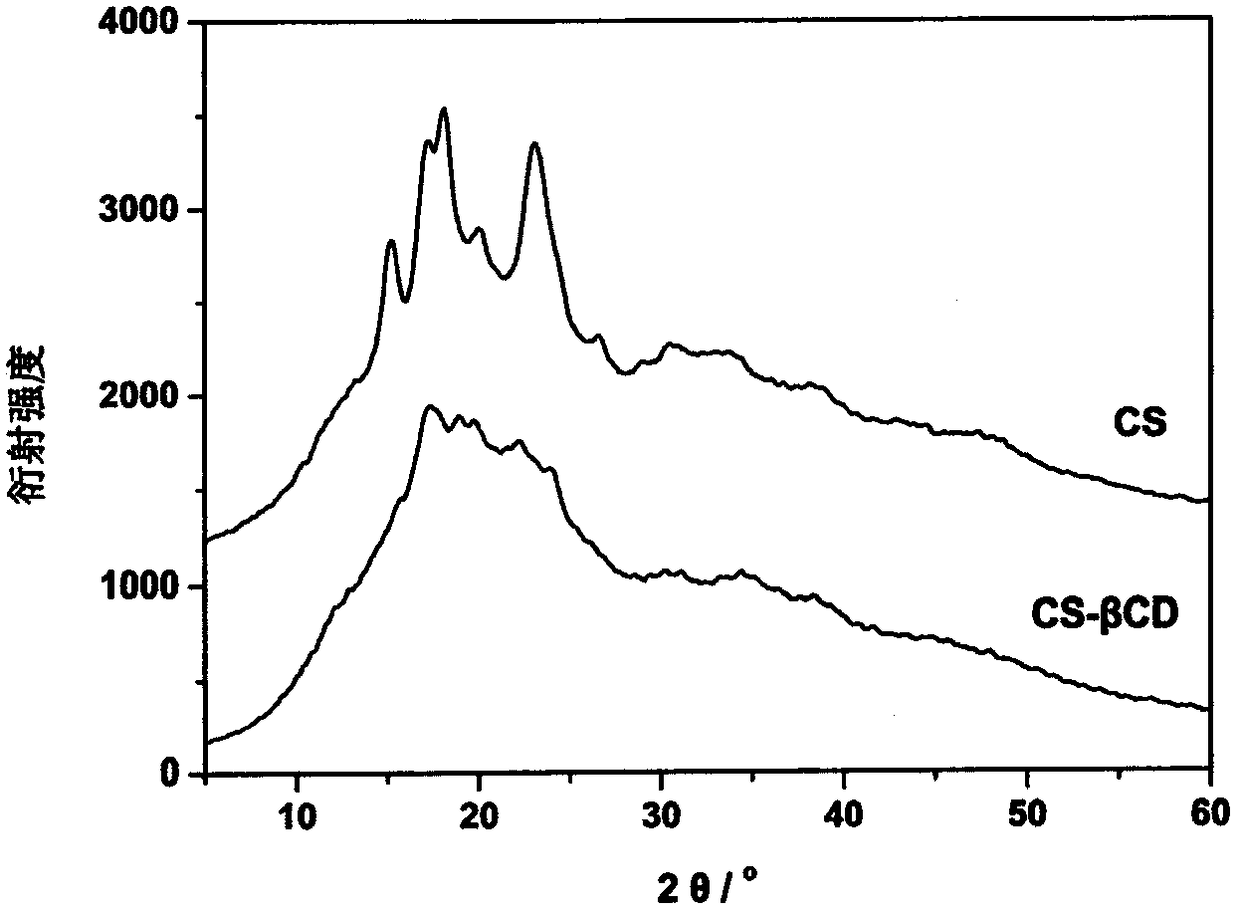

[0039] Immobilization effect test: Refer to the measurement method of CS-βCD substitution degree in the previous section to determine relevant parameters. The calculated substitution degree and carboxyl content data in this example are listed in Table 1, and the structural characterization can be found in figure 1 , figure 2 and image 3 .

Embodiment 2

[0041] (1) Make a suspension from 50g of cornstarch, 117g of β-cyclodextrin and 200mL of distilled water, transfer it to a three-neck flask, and heat it in a water bath at 85°C for 30min to gelatinize. Then add 100 mL of distilled water containing 10 g of citric acid and 2.5 g of sodium hypophosphite, and stir well. The mixture was moved into an oven at 130°C and reacted for 2h.

[0042] (2) After the reaction, it was taken out and pulverized, washed three times with 40% ethanol, and centrifuged to dry to obtain the sample β-cyclodextrin immobilized starch, ie CS-βCD.

[0043] The calculated immobilization rate of this embodiment is listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com