Modified starch/lactic acid oligomer reactivity blended full biological decomposition plastics and preparation thereof

A technology of modified starch and oligomers, applied in the direction of flexible covering, plant protection cover, transportation and packaging, etc., can solve the problem of heat drawing of sheets and films of reactive blends without modified starch/lactic acid oligomers problems such as stretching research, time-consuming, and energy consumption needs to be further reduced, to achieve the effect of hard performance characteristics, avoiding high energy consumption, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

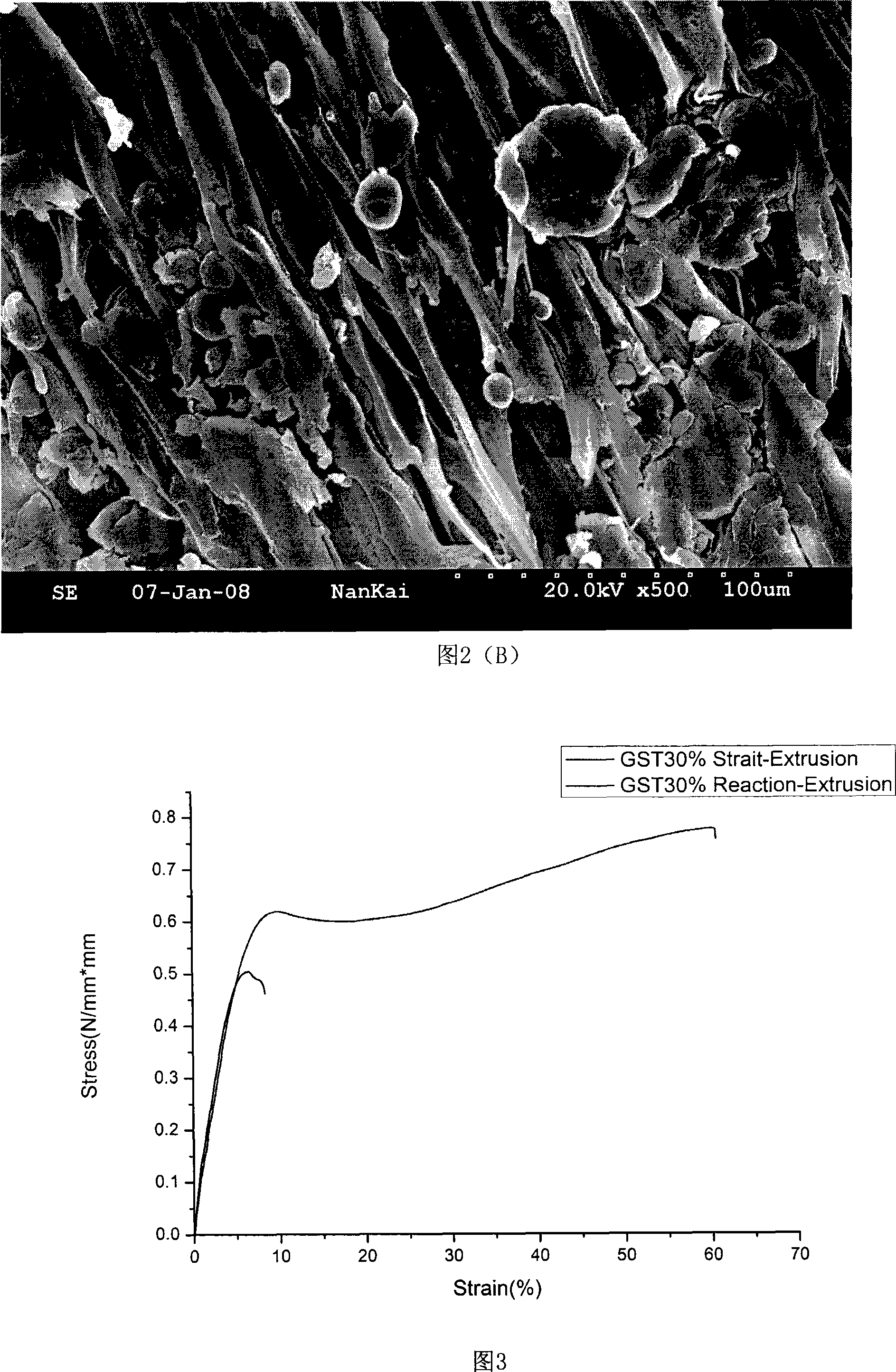

[0043] Weighed 9.0 g of etherified starch (DST) and 21.0 g of polylactic acid oligomer (PLA) with a viscosity-average molecular weight of 45,000, which were dried in a vacuum oven, respectively, and put them into a rotary reactor (Heidolph, Germany). The reaction was carried out for 6 hours under vacuum condition, the degree of vacuum was less than 20mmHg, and the rotational speed of the reactor was 90rmp.

[0044] The obtained product was extruded in a single-screw extruder, and the four-stage temperature control was: 100°C, 160°C, 165°C, 120°C, the rotation speed was 25rmp, and the residence time in the screw was 10min. The mechanical properties of the obtained product were measured after thermal stretching at 70°C.

Embodiment 2

[0046] Weigh 9.0g of acylated starch (GST) and 21.0g of polylactic acid oligomer (PLA) with a viscosity-average molecular weight of 45,000, which are dried in a vacuum oven, and add them to the rotary reactor, program the temperature to 130°C, and continue to react under vacuum conditions 6h, the vacuum degree is less than 20mmHg, and the reactor speed is 90rmp.

[0047] The obtained product was extruded in a single-screw extruder, and the four-stage temperature control was: 100°C, 160°C, 165°C, 120°C, the rotation speed was 25rmp, and the residence time in the screw was 10min. The mechanical properties of the obtained product were measured after thermal stretching at 70°C.

[0048] Embodiment 1,2 mechanical properties see table 1 for details

[0049] Table 1 embodiment 1,2 mechanical performance test comparison

[0050]

Embodiment 3

[0059] Weigh 6.0g of etherified starch (DST) and 24.0g of polylactic acid oligomer (PLA) with a viscosity-average molecular weight of 45,000, which are dried in a vacuum oven, and add them to the rotary reactor, program the temperature to 130°C, and continue to react under vacuum conditions 6h, the vacuum degree is less than 20mmHg, and the reactor speed is 90rmp.

[0060] The obtained product was extruded in a single-screw extruder, and the four-stage temperature control was: 100°C, 160°C, 165°C, 120°C, the rotation speed was 25rmp, and the residence time in the screw was 10min. The mechanical properties of the obtained product were measured after thermal stretching at 70°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com