Zinc-based alloy shots

A technology of base alloy and aluminum base alloy, which is applied in metal processing equipment, abrasives, manufacturing tools, etc., can solve the problems of high explosion lower limit concentration and low dust cloud explosion sensitivity, and achieve high explosion lower limit concentration, stable surface treatment quality, High sanding and cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

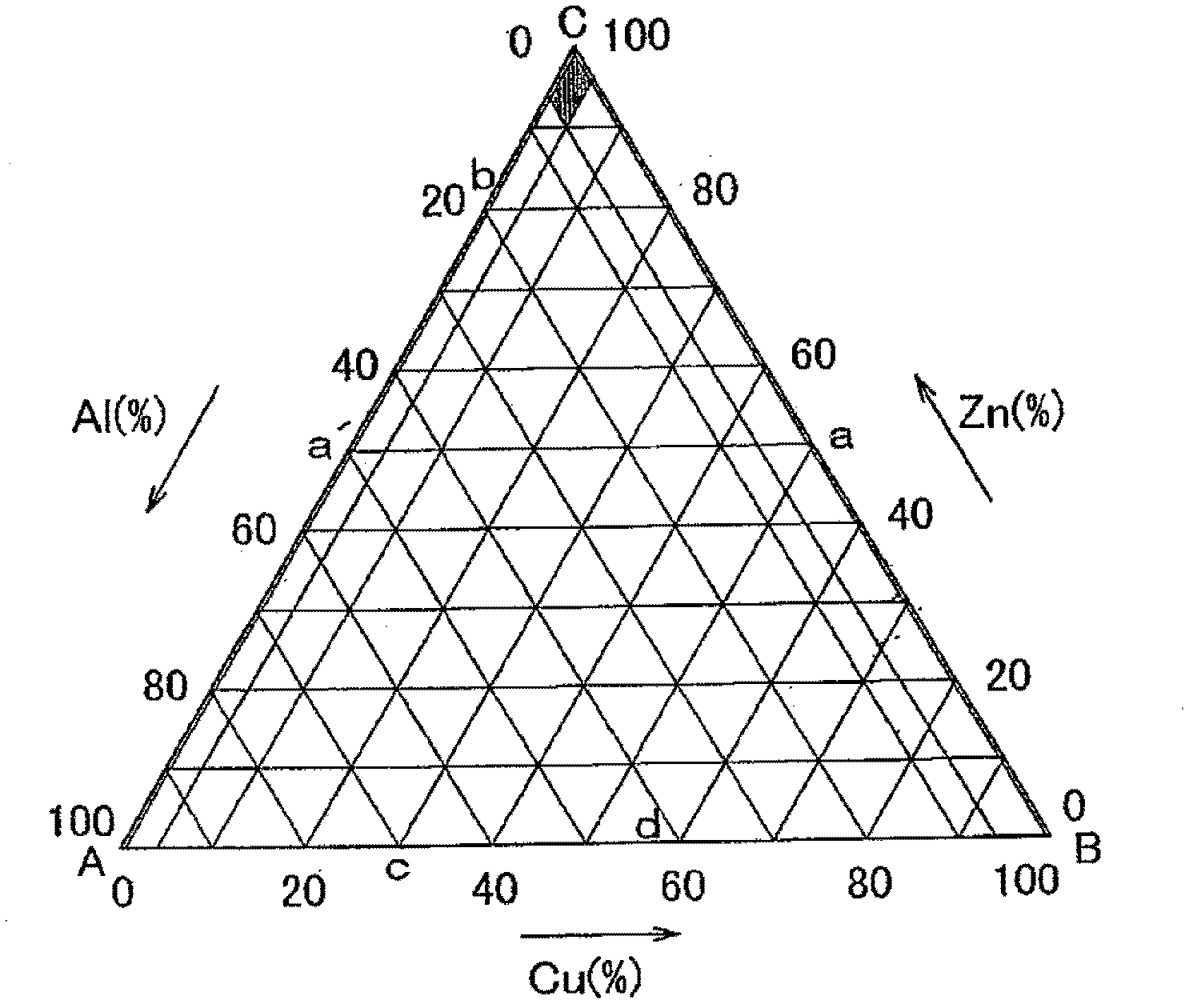

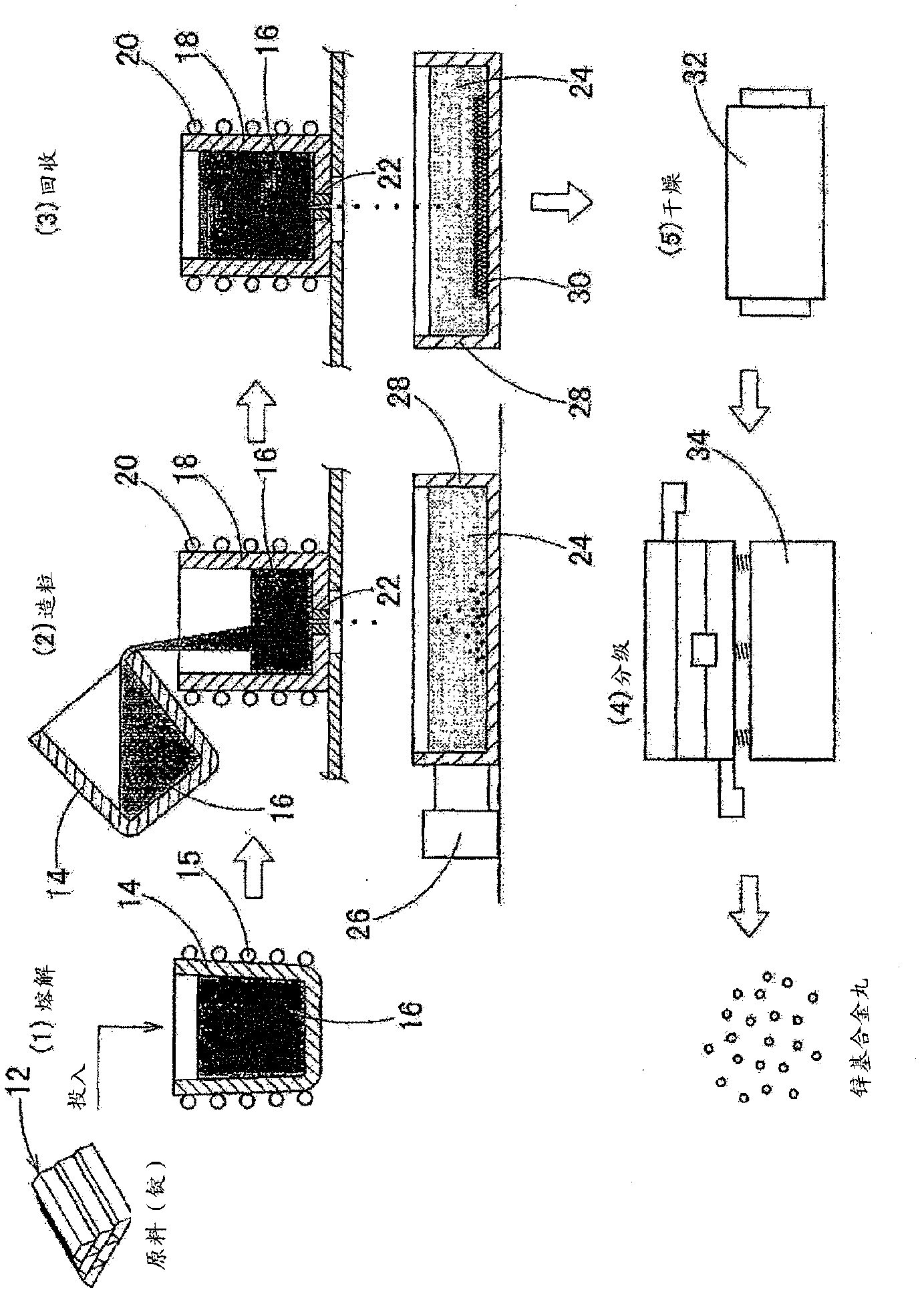

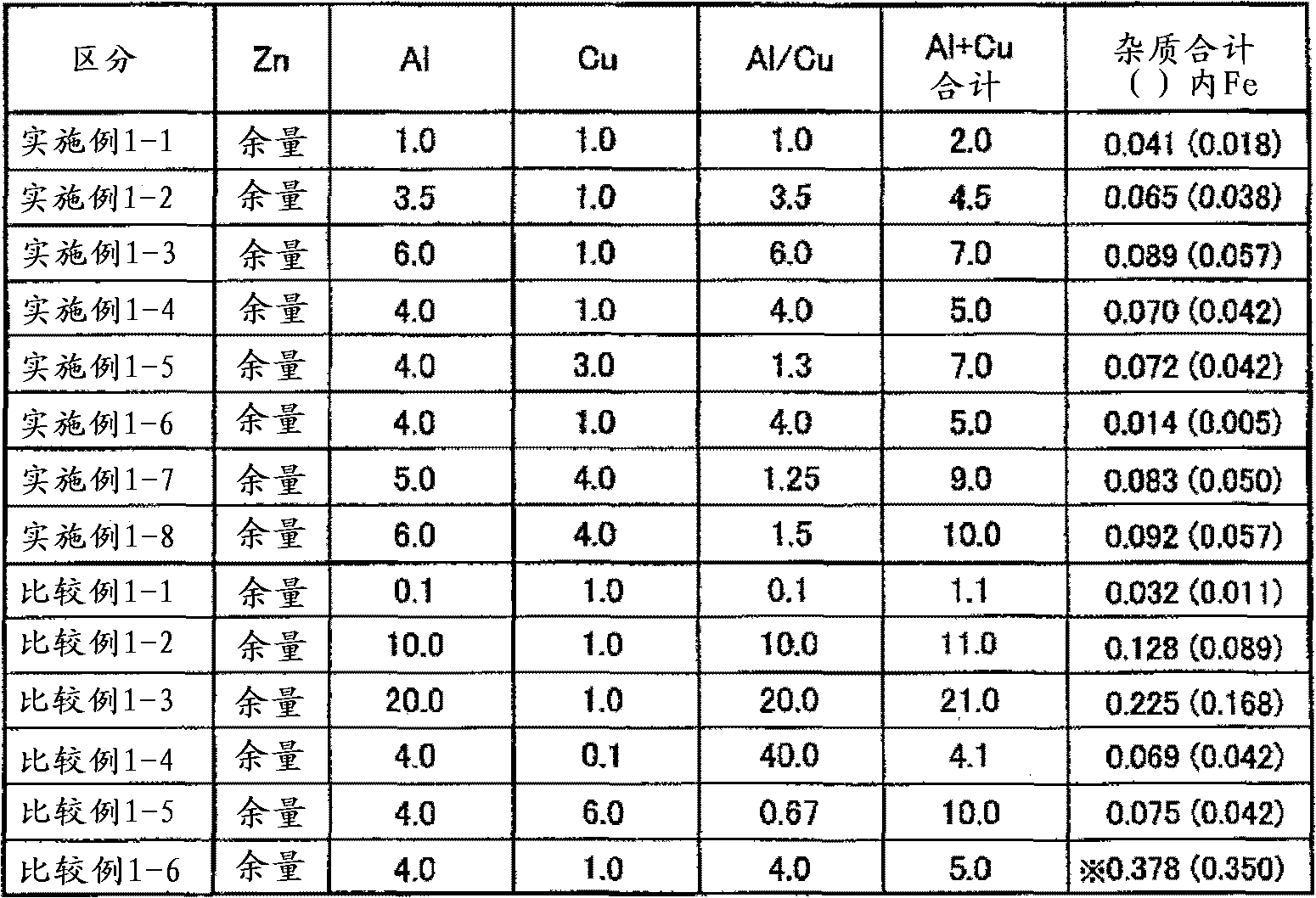

[0062] Next, examples performed together with comparative examples in order to confirm the effects of the first and second inventions will be described.

[0063] Examples 1-1 to 1-8 and Comparative Examples 1-1 to 1-6 correspond to the first invention, and Examples 2-1 to 2-3 and Comparative Examples 2-1 to 2-3 correspond to the second invention.

[0064] The following base metals (ingots) were used as raw materials for the alloying elements. The Fe content (allowable upper limit) is added together with the purity (lower limit) prescribed by JIS of each base metal. In addition, Fe of "No. 1 copper wire shavings" is an estimated value.

[0065] ·Total raw materials of alloying elements: 200kg

[0066] ·Used base metal A (example, comparative example not including embodiment 1-6, 2-3)...

[0067] Zn: common zinc base metal (JISH2107) 99.97%, Fe: 0.01%,

[0068] Al: 3 kinds of aluminum base metals (JISH2102) 99.00%, Fe: 0.80%,

[0069] Cu: No. 1 copper wire shavings (JISH210...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com