Patents

Literature

293 results about "Zinc based alloy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Zinc Alloys. zinc-base alloys containing mainly aluminum, copper, or magnesium (see Table 1). Zinc alloys are characterized by a low melting point and good flowability; they are readily worked by pressure and cutting and are easily welded and soldered.

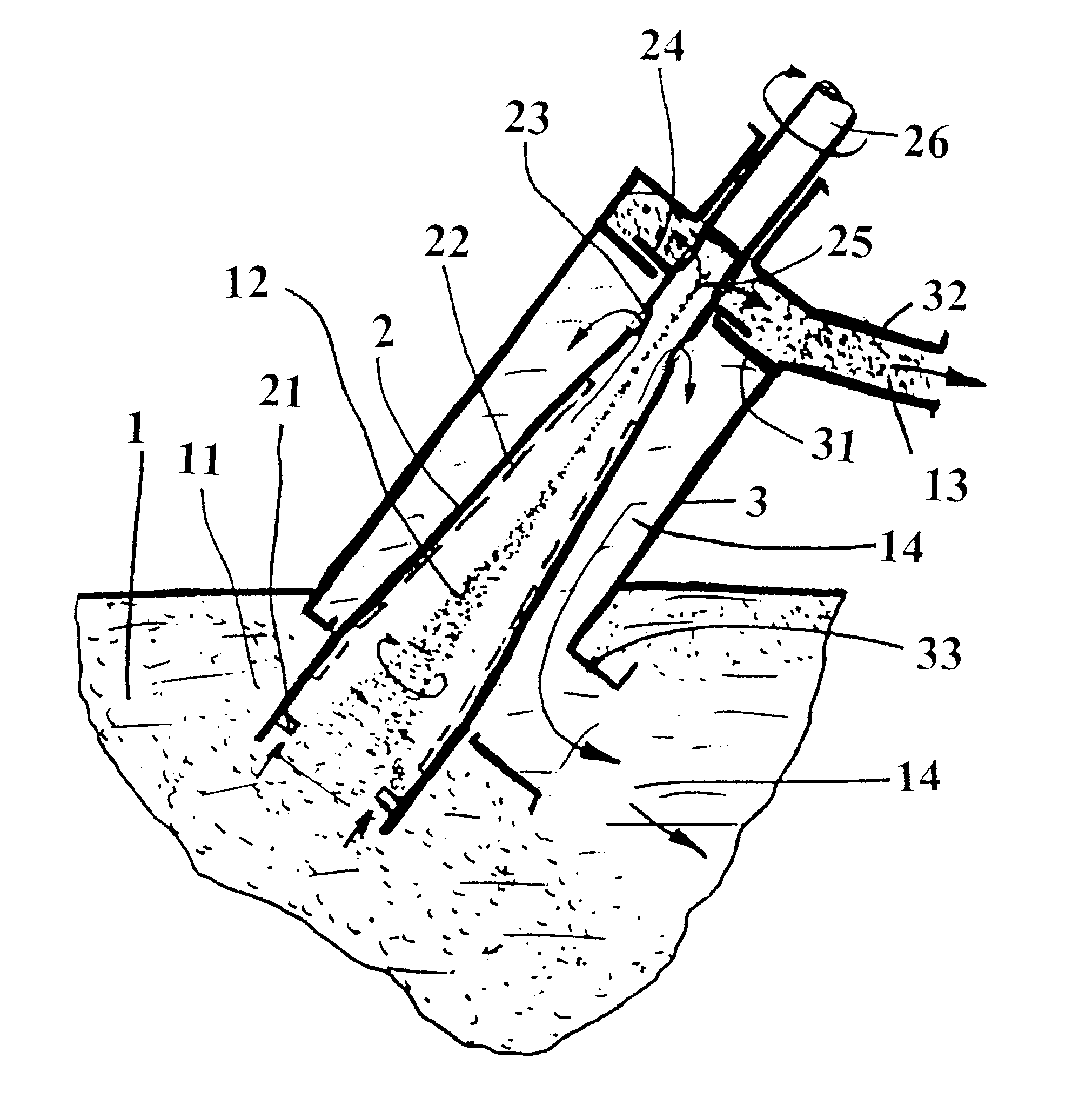

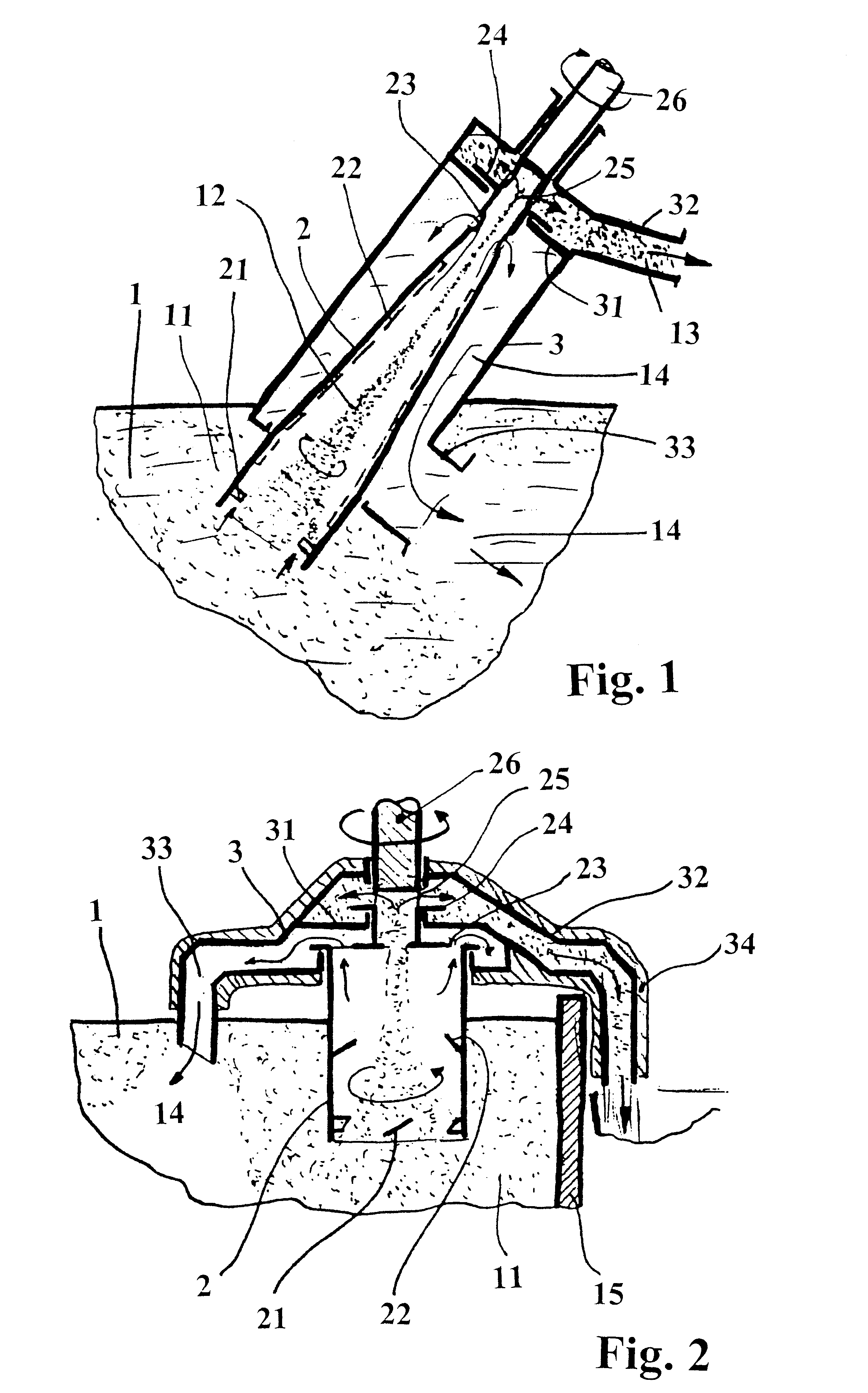

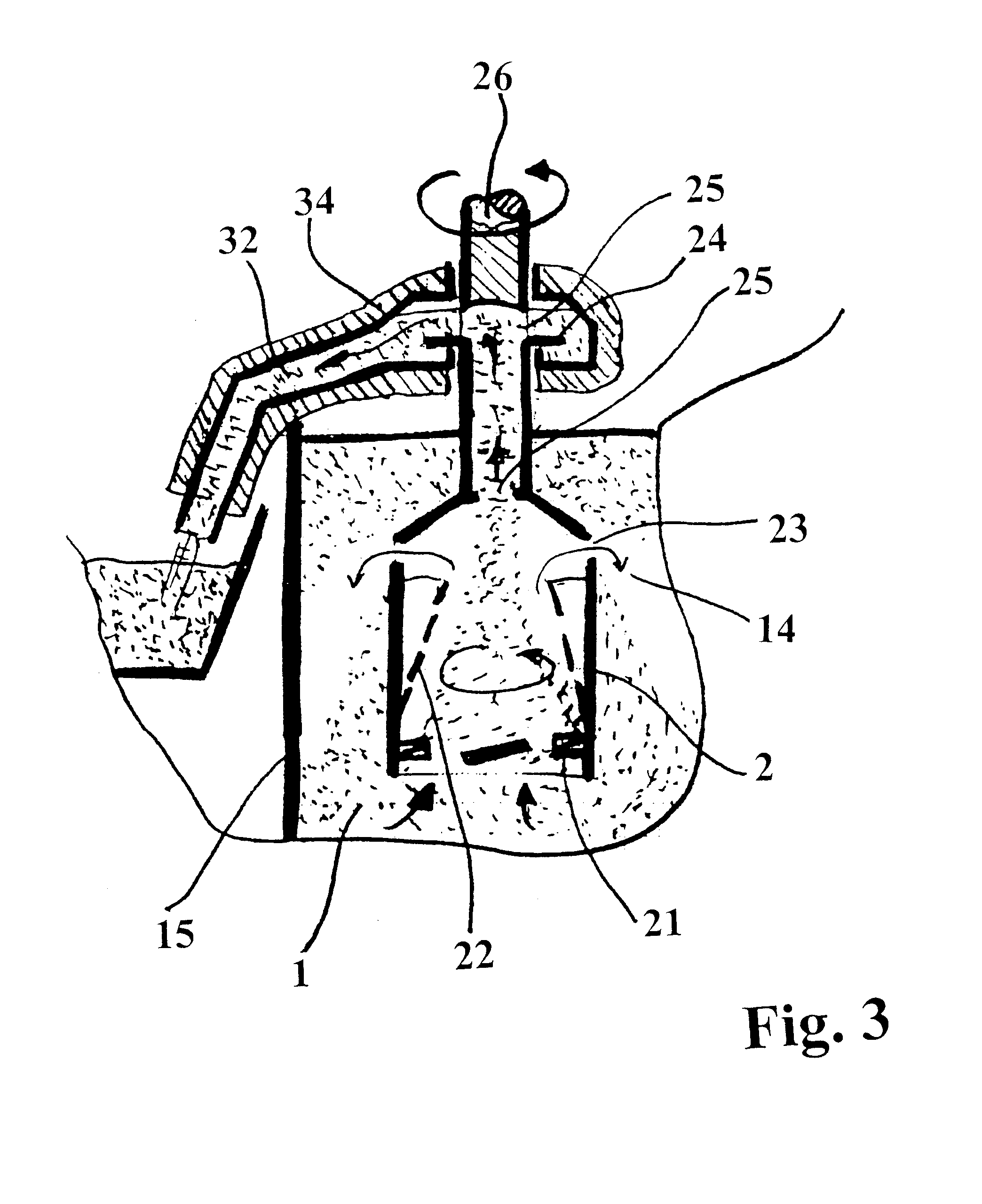

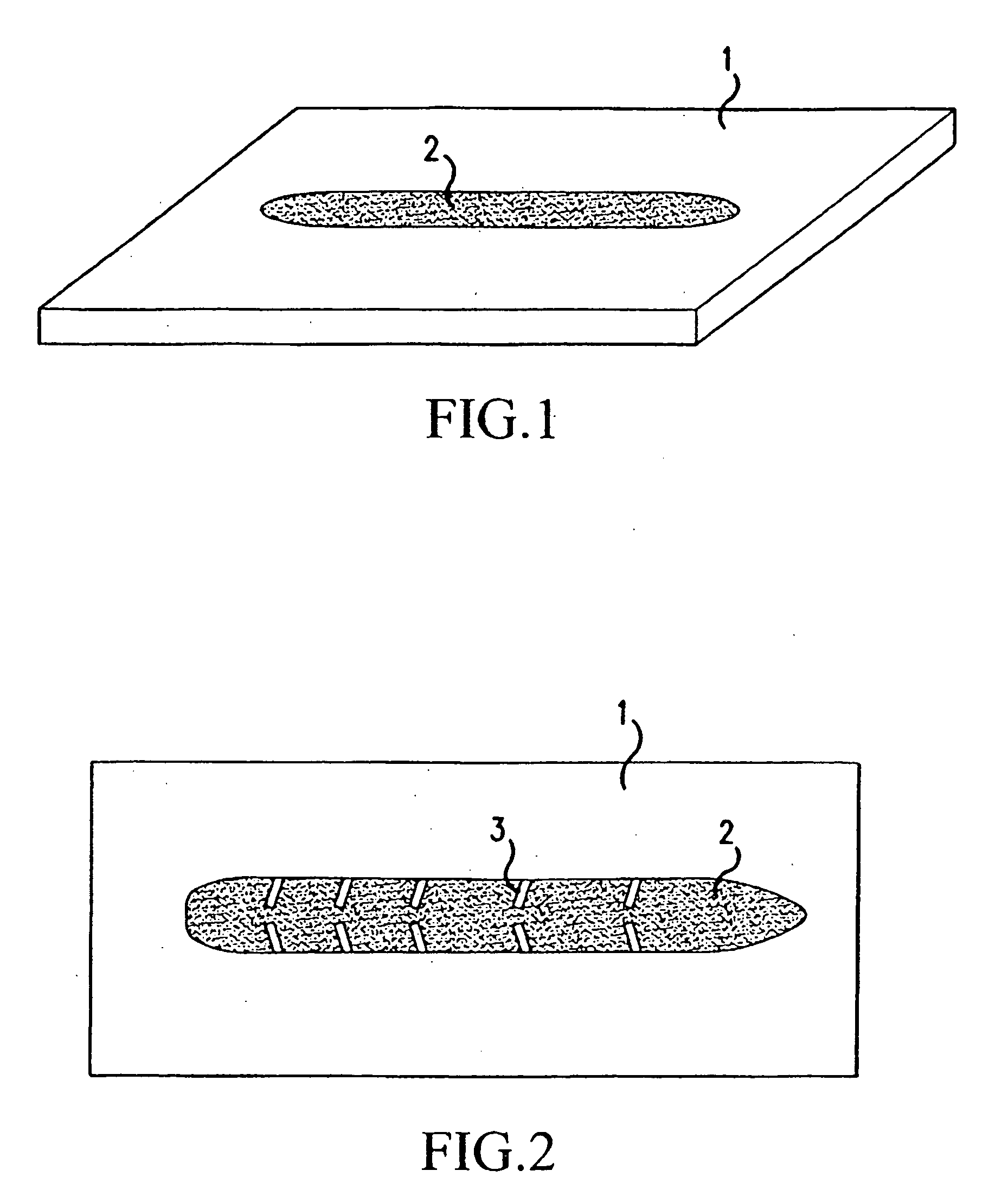

Process for precipitating compounds from zinc metal baths by means of a hollow rotary body that can be driven about an axis and is dipped into the molten zinc

InactiveUS6364930B1High acceleration of the metalRapid and highly effective separationHot-dipping/immersion processesSpecific fluid pumpsZinc metalLiquid metal

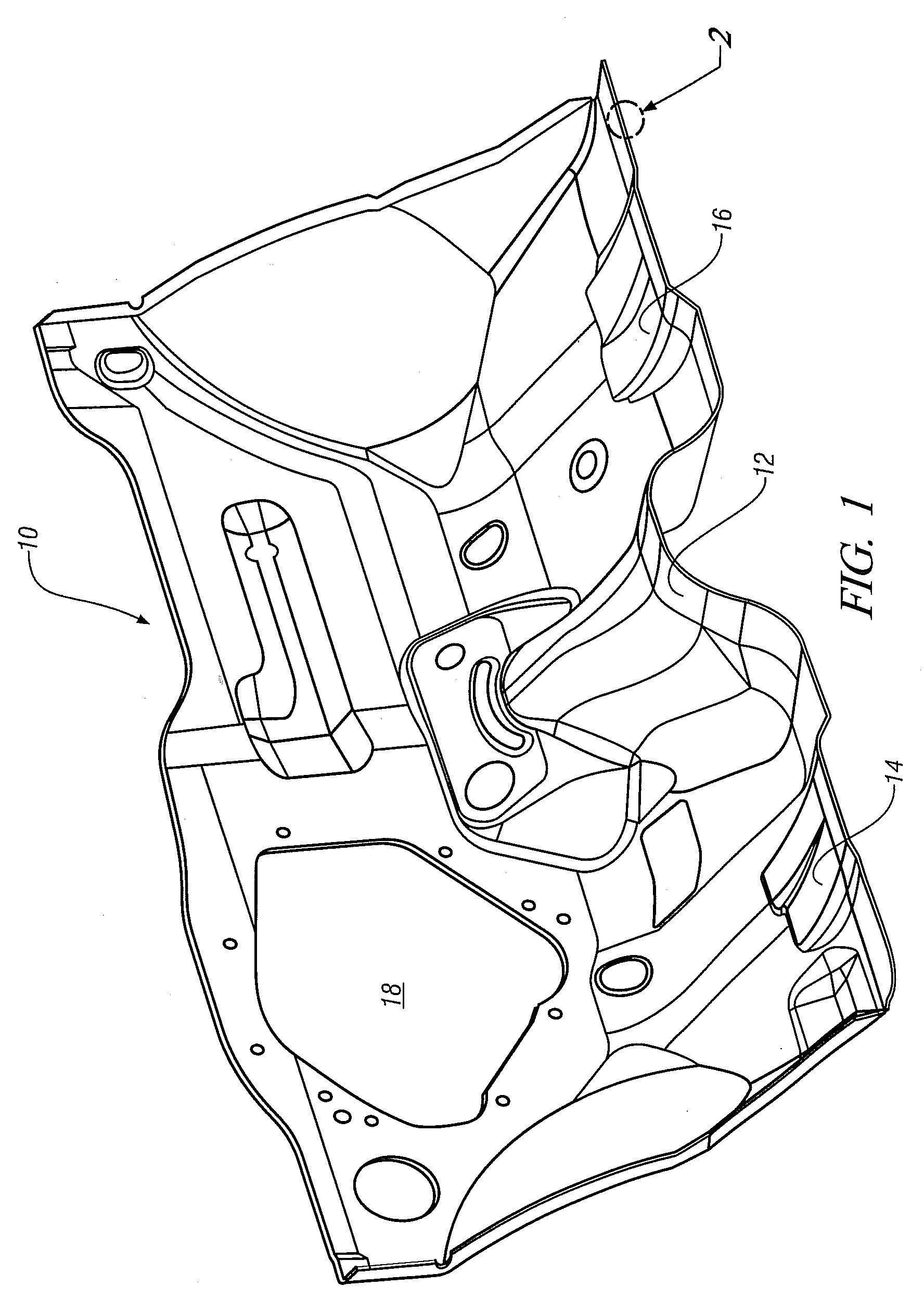

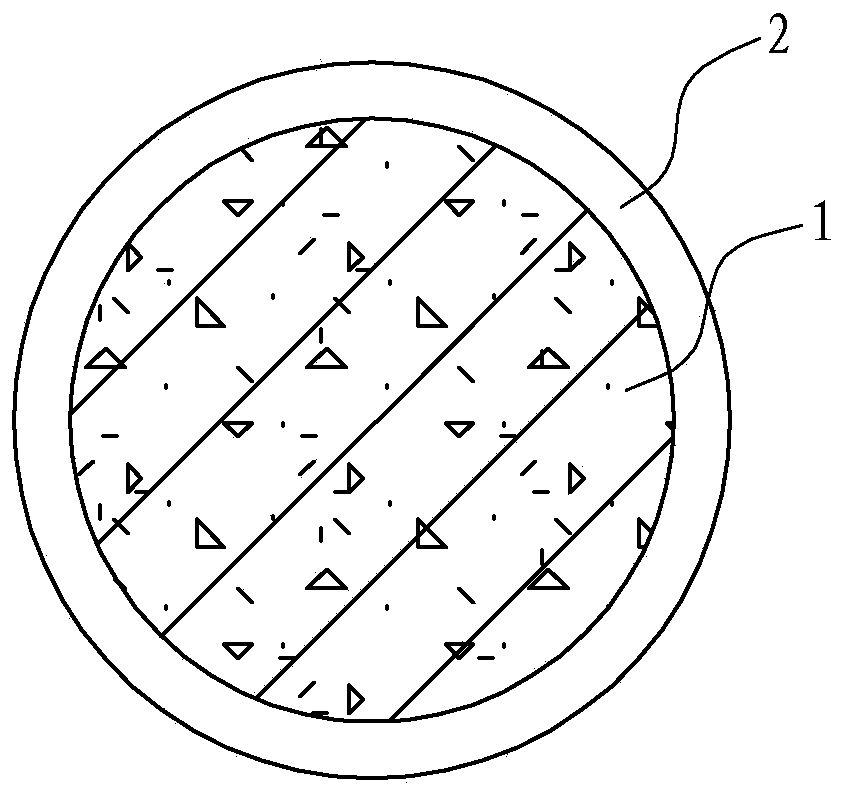

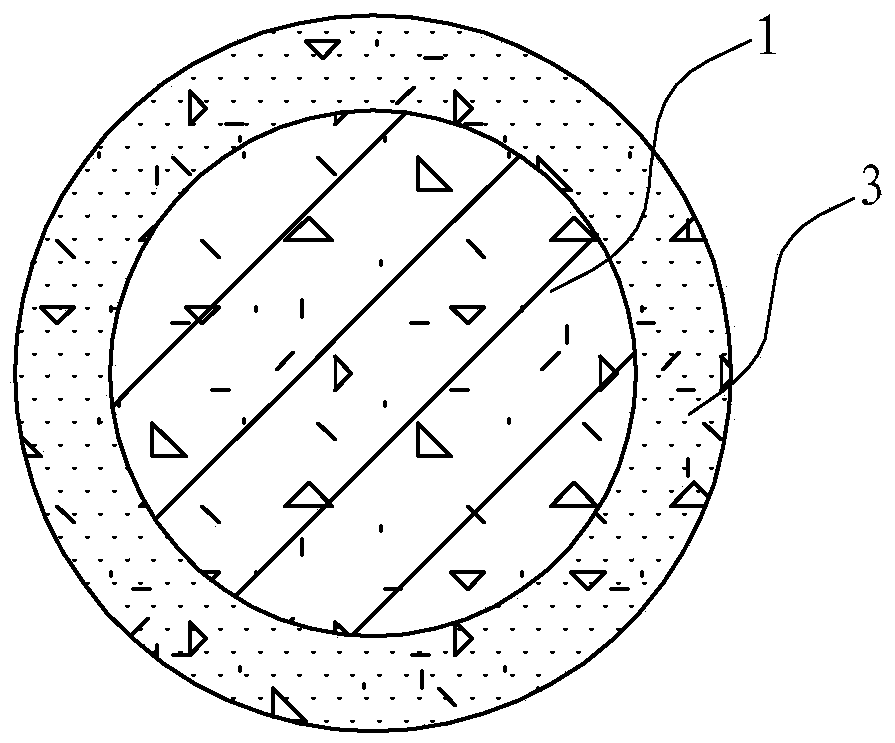

A process and device are disclosed for precipitating solid compounds from the liquid zinc or liquid zinc-based alloys of a metal bath. According to the disclosed process, partial amounts of the metal phase containing the compound(s) are exposed to an acceleration higher than the acceleration due to gravity and at least partially dissociated thereby into fractions containing heavier and / or lighter components. The molten mass depleted of solid compounds is returned to the metal bath and the part of the molten mass enriched with the desired compounds is discharged. The disclosed device is substantially characterized in that a hollow rotary body (2) is introduced into the molten mass (1). The hollow rotary body (2) can be driven about an axis and is fitted in the submerged or lower area with conveyor means (21) which project into the cavity. In its discharge or upper area, the hollow rotary body (2) is provided with at least one discharge opening (23) for the depleted molten mass (14) eccentrically arranged in its wall and with at least one further discharge opening (25) for the liquid metal enriched with the desired compounds centrally arranged and / or eccentrically arranged on the discharge side. At least one of the upper molten mass discharge openings (23, 24) in the rotary body (2) opens into a discharge area of a housing (3) which at least partially surrounds the rotary body (2).

Owner:ANDRITZ PATENTVERW GES

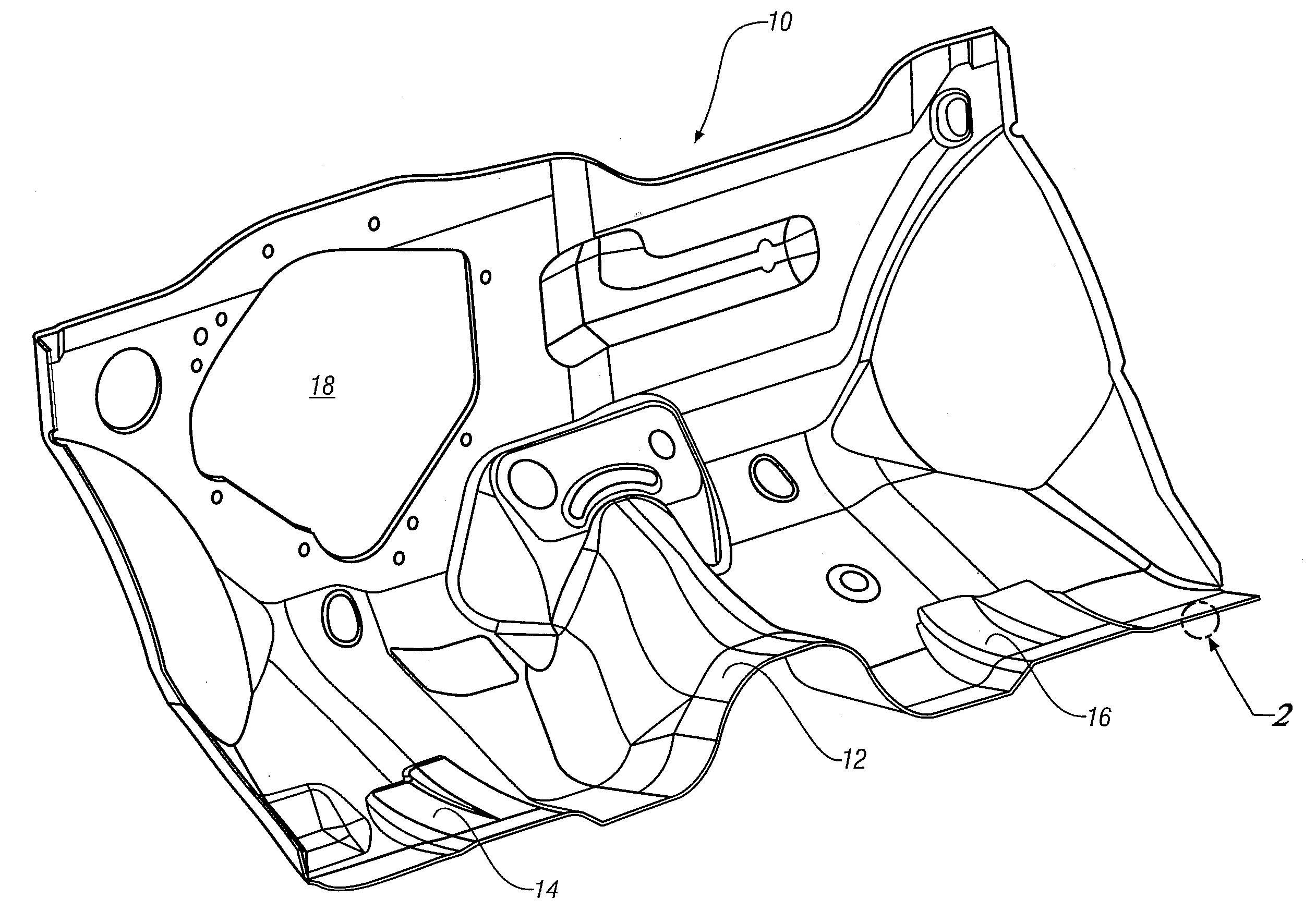

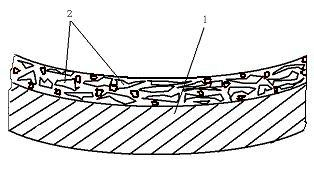

Corrosion resistant laminated steel

InactiveUS20100035080A1Improve corrosion resistanceEasy to shapeMetallic material coating processesThin material handlingSheet steelSolderability

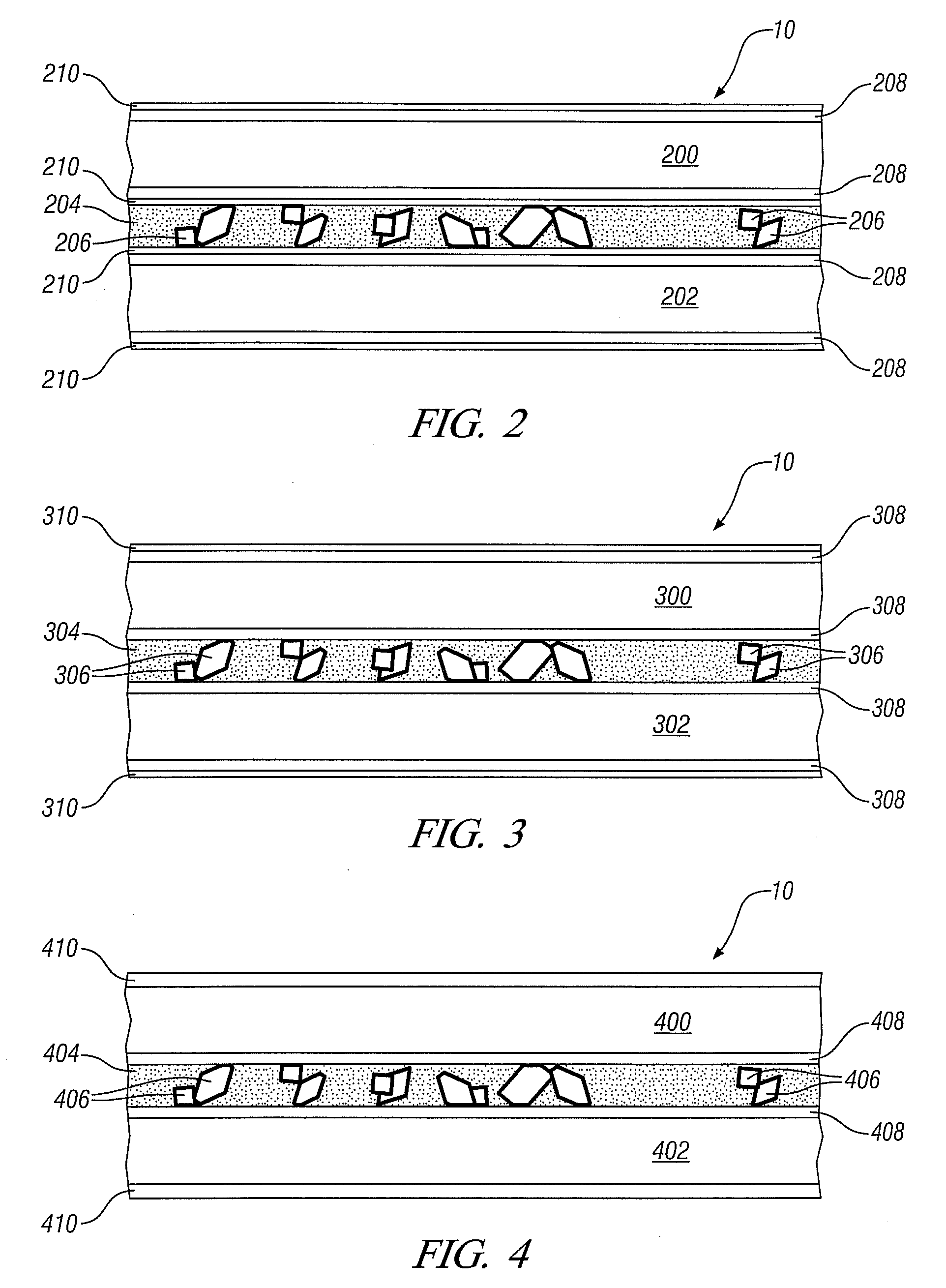

Outer steel sheet-viscoelastic core laminates are often subject to corrosion in moisture-containing environments. Zinc-based alloys of aluminum, or of aluminum and magnesium, may be beneficially applied to the inner faces of the steel sheets or to both the inner and outer sheet faces. Substantially pure zinc coatings may be applied over the zinc-based alloys or over an otherwise bare outer steel sheet surface. Combinations of such zinc-based alloy coatings and substantially pure zinc coatings improve the corrosion resistance of the steel sheet-polymer core laminates while maximizing weldability and paintability.

Owner:GM GLOBAL TECH OPERATIONS LLC

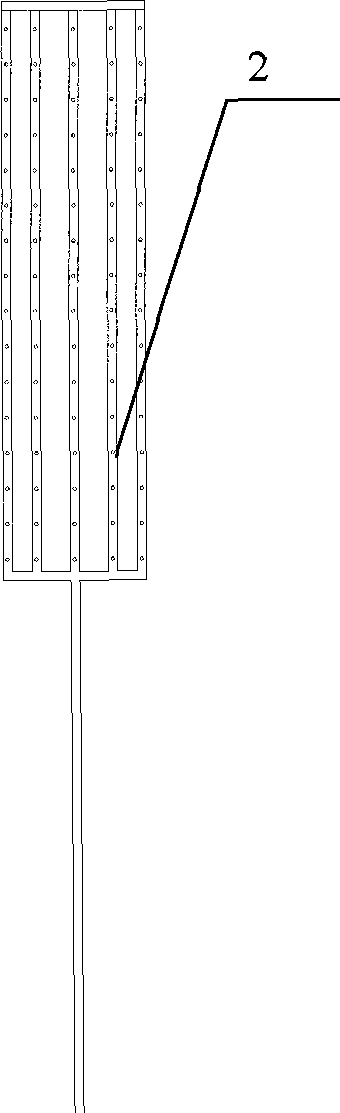

Process of making zinc-base alloy wire and rod with high strength and high toughness

The present invention relates to process of making zinc-base alloy wire and rod with high strength and high toughness. The production process includes the steps of providing zinc-base alloy material with Al content not less than 10 wt%, smelting, heat preservation and extruding at 300-450 deg.c, drawing, heat treatment at 150-300 deg.c for 30-120 min, and quenching. The production process can obtain zinc-base alloy wire and rod of different sizes for producing various mechanical parts, such as screw, nut, pull rod, wire, etc.

Owner:NINGBO POWERWAY ALLOY MATERIAL

High-accuracy zinc base alloy electrode wire and preparing method thereof

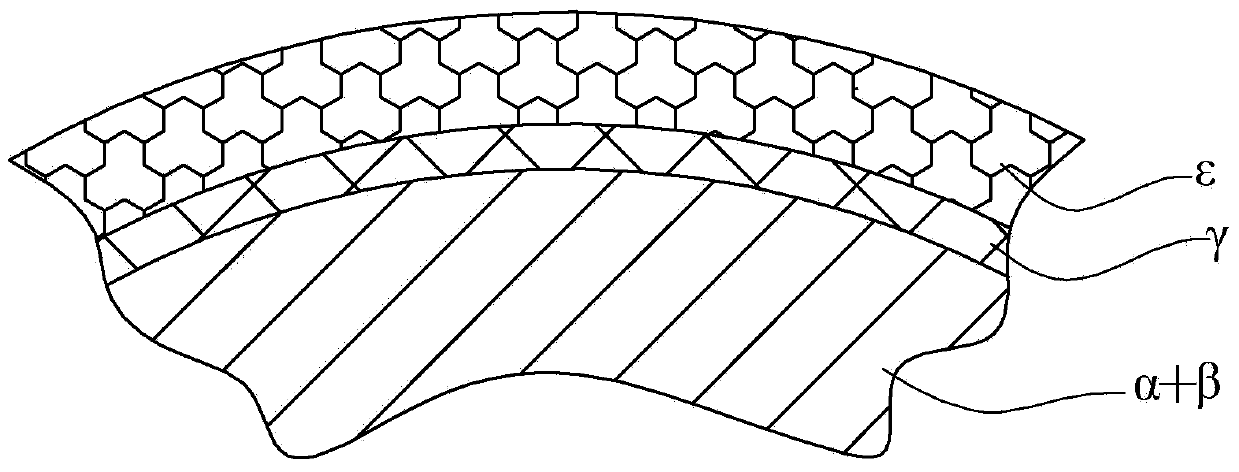

ActiveCN104191056AGood for taking awayCutting discharge mitigationElectrical-based machining electrodesSurface finishImpurity

The invention relates to a high-accuracy zinc base alloy electrode wire. Components in a shell layer comprise, by weight, 70.5%-95% of Zn, 2.5%-27% of Cu, 0.02%-4.0% of X, 0.002%-0.4% of Y and inevitable impurities brought in by raw materials. X is any two kinds of metal from Ni, Ag, Cr, Si and Zr, the content ranges of the two kinds of metal are both 0.01%-2.0%, Y is any two kinds of elements of Ti, Al, Co, B and P, and the content range of the two elements are both 0.001%-0.2%. The epsilon phase content in the shell layer structure is over 80% by weight, the balance is a gamma phase or an eta phase, and epsilon phases are evenly distributed on the surface of core materials. Meanwhile, the invention relates to a preparing method of the electrode wire. Compared with the prior art, a metal workpiece subjected to cutting processing by the electrode wire is high in surface smoothness and good in surface quality, accordingly, cutting accuracy is high, meanwhile, the electrode wire preparing technology is simple, operability is high, the number of manufacturing steps is small, and large-scale and automatic production can be achieved easily.

Owner:NINGBO BODE HIGHTECH CO LTD

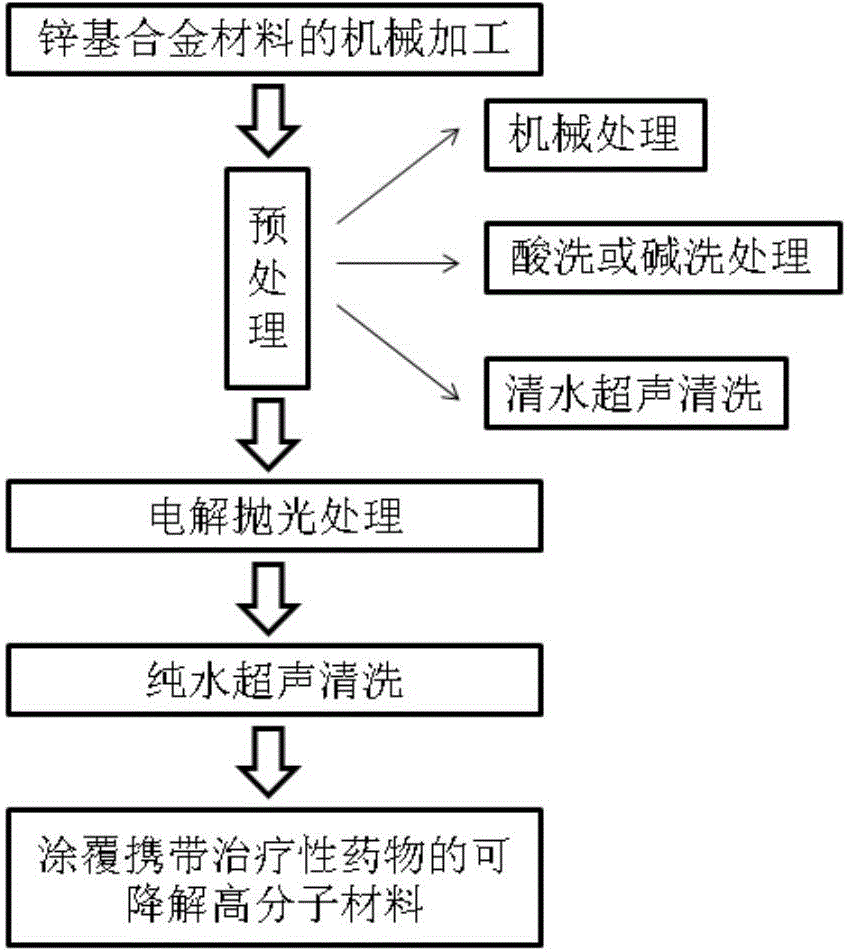

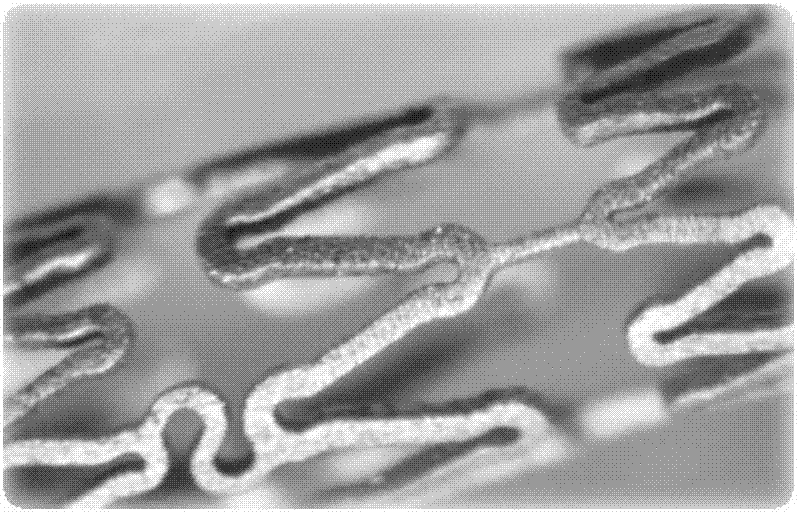

Degradable zinc-based alloy bracket and preparation method thereof

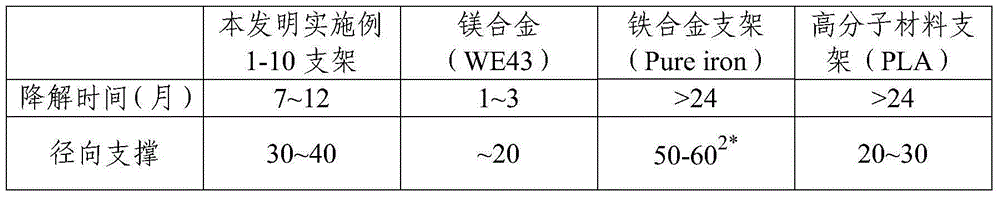

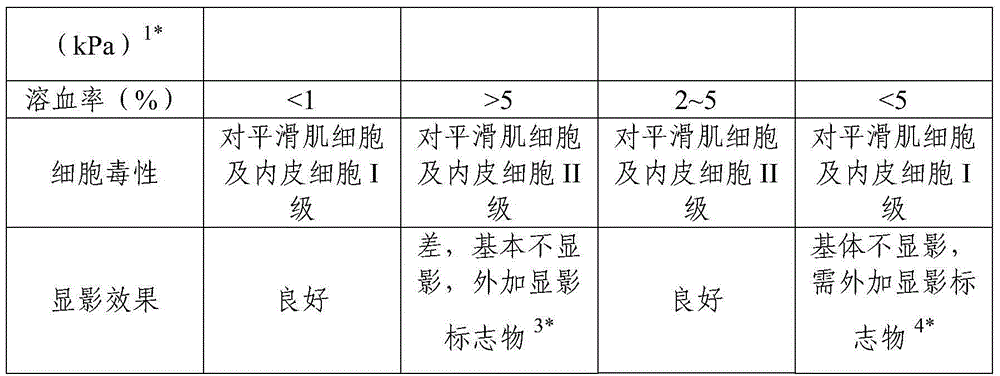

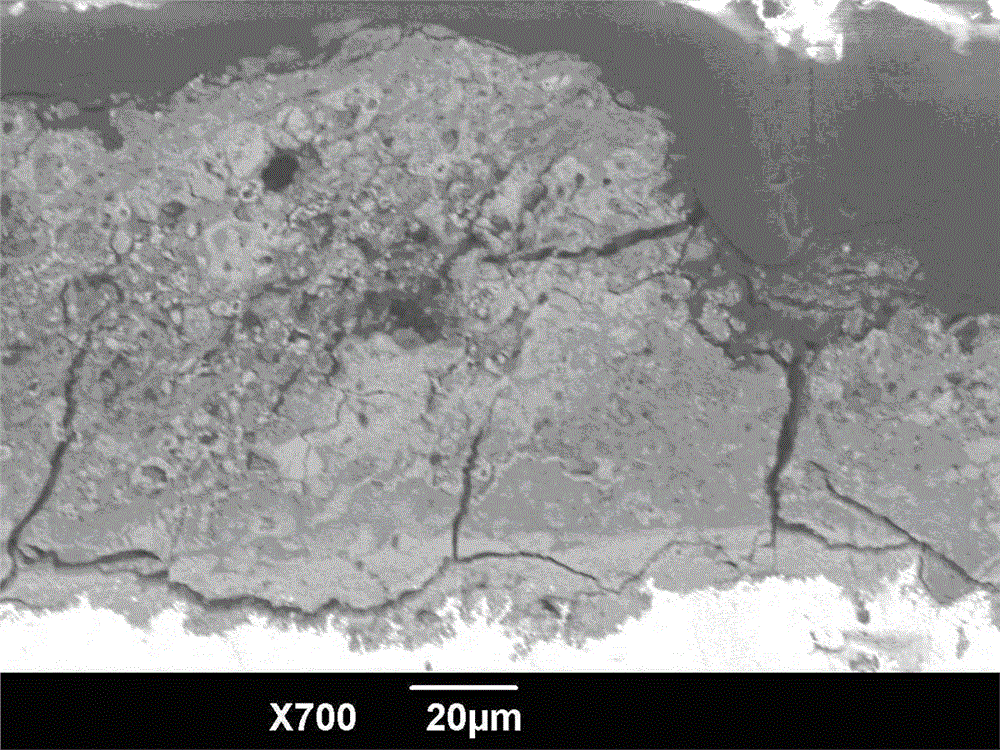

ActiveCN104857570AGood flexibilityEasy to place for interventionCoatingsProsthesisPercent Diameter StenosisBiocompatibility Testing

The invention relates to a degradable zinc-based alloy bracket and a preparation method thereof. The bracket includes a degradable zinc-based material bracket substrate; the surface of the bracket substrate is provided with a degradable polymer eluting coating containing treatment drug; the bracket substrate is a cylindrical mesh structure. The preparation method includes: 1) processing the degradable zinc-based material to be a bracket substrate; 2) performing the surface pretreatment on the bracket substrate; 3) performing electrochemical polishing treatment on the bracket substrate; 4) after the treatment, coating a degradable high polymer material carrying with treatment drug on the surface of the bracket. For the substrate material zinc alloy has excellent corrosive resistance, the bracket provided by the invention keeps good supporting property after implanting for 4 months above; the substrate surface is coated with the polymer coating with good biocompatibility, thus the improved compatibility of the zinc-based alloy is good for the coverage of endothelial cells at the surface of the bracket; the drug release can be controlled, and drug burst release is reduced, so that the drug can be released slowly and sustainably with a certain concentration, so as to reduce the local inflammation, restenosis and stent thrombosis risk after implanting the bracket.

Owner:LEPU MEDICAL TECH (BEIJING) CO LTD

Alloy austenitic-bainite ductile iron worm gear and preparation process thereof

ActiveCN101736190AEasy to controlImprove yieldPortable liftingGearing elementsAfter treatmentFerrosilicon

The invention relates to an alloy austenitic-bainite ductile iron worm gear and a preparation process thereof. The worm gear comprises the following components in percentage by weight: 3.5 to 3.9 percent of C, 2.3 to 2.9 percent of Si, less than or equal to 0.4 percent of Mn, less than or equal to 0.035 percent of P, less than or equal to 0.03 percent of S, 0.2 to 0.3 percent of Mo, 0.3 to 0.6 percent of Cu, 0.2 to 0.5 percent of Ni and the balance of iron. The preparation process comprises the following steps: smelting the components, taking a rare earth magnesium alloy as a spheroidizing agent and ferrosilicon as an inoculating agent, and casting a blank after treatment; roughly machining the blank of the worm gear, heating and isothermally quenching to obtain a proper amount of retained austenite; and finishing a gear to prepare the alloy austenitic-bainite ductile iron worm gear. The worm gear has the advantages to high fatigue resistance, high pitting resistance, lower density than steel, small deformation and the like, and is suitable for replacing a worm gear on a valve electric actuator made of a copper alloy or zinc base alloy (ZA27) so as to obviously reduce production cost.

Owner:YANGZHOU ELECTRIC POWER EQUIP MFG FACTORY CO LTD +2

Fine-grained zinc-based alloy for die and preparation process thereof

InactiveCN103320651AMeet the mechanical performance requirementsExtended service lifeMedium frequencySemi solid

The invention provides a fine-grained zinc-based alloy for a die and a preparation process thereof. The invention is characterized in that the fine-grained zinc-based alloy for the die is composed of a matrix alloy, intermediate alloys, an alterant and a scouring agent and comprises 12.5 to 16.5% of Al, 8 to 12.5% of Cu, 0.01 to 0.05% of Mg, 0.10 to 0.25% of Ti, 0.01 to 0.03% of B, 0.3 to 0.7% of Zr, 1 to 3% of Si, 0.4 to 0.8% of Mn, 0.2 to 0.8% of Re and 0.4 to 0.5% of ZnCl2, with the balance being Zn, wherein Re comprises, by mass, 45 to 55% of Ce, 10 to 20% of La, 7 to 15% of Y and 4 to 10% of Gd. The preparation process comprises the following steps: fusing the alloys in a crucible resistance furnace or a medium-frequency induction melting furnace; preparing a semi-solid zinc-based alloy through electromagnetic stirring; carrying out casting after temperature drops to 550 DEG C; and carrying out water cooling or air cooling. Compared with the prior art, the invention has the following advantages: the fine-grained zinc-based alloy for the die has the following mechanical properties at normal temperature, i.e., sigma b of 492.6 MPa, delta s of 1.42% and HBR of 168; even at a high temperature of 200 DEG C, sigma b reaches 216 MPa and delta s reaches 26%, completely according with the requirement of a common injection die for the mechanical property sigma b of 120 to 150 MPa at the temperature of 200 DEG C.

Owner:江苏新亚特钢锻造有限公司

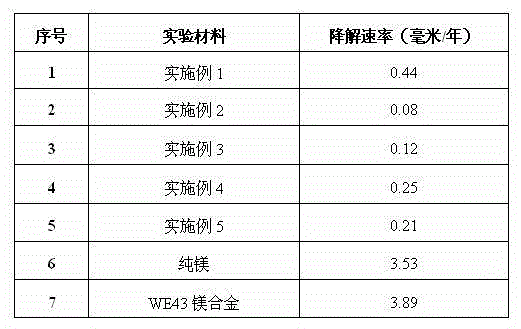

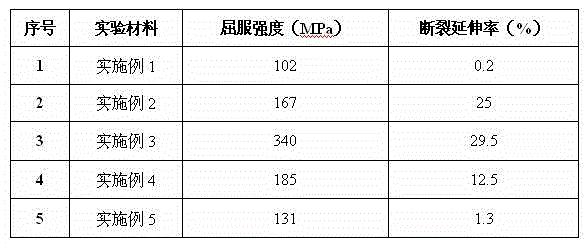

Degradable corrosion-resistant high-toughness Zn-Fe zinc alloy for human body and application thereof

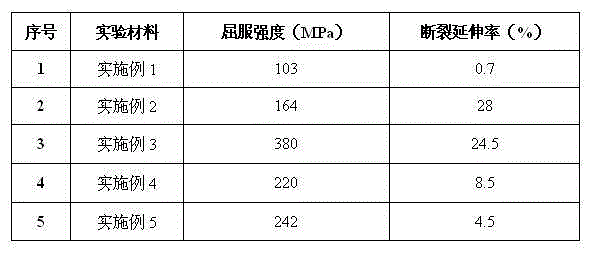

ActiveCN104689369ALow costImprove corrosion resistanceSuture equipmentsProsthesisZinc alloysUltimate tensile strength

The invention provides a degradable corrosion-resistant high-toughness Zn-Fe zinc alloy for a human body and application thereof and relates to the field of medical implant materials. The corrosion-resistant high-toughness Zn-Fe zinc alloy provided by the invention is aimed at overcoming the defects in the prior art and has the advantages that the cost of adding materials is low, the strength is high, the plasticity is good, the degradation rate is controllable, and meanwhile, the Zn-Fe zinc alloy can be degraded by human bodies. The zinc alloy contains a Zn element and a Fe element, wherein the mass percent of Zn element is 90-99.998%, and the mass percent of Fe element is 0.002-10%. According to the zinc alloy provided by the invention, the cost of the added materials is low, degradation products of all ingredients of a prepared alloy material can be degraded through human body metabolism, the corrosion resistance is far higher than that of a magnesium alloy, the degradation rate is greatly lowered, a longer-time mechanical support can be provided, and the strength and toughness of the alloy material are good.

Owner:XIAN ADVANCED MEDICAL TECH

Degradable corrosion-resistant high-toughness Zn-Fe-X zinc alloy for human body and application thereof

ActiveCN104689378ALow costImprove corrosion resistanceSuture equipmentsProsthesisAdditive ingredientZinc alloys

The invention provides a degradable corrosion-resistant high-toughness Zn-Fe-X zinc alloy for a human body and application thereof and relates to the field of medical implant materials. The zinc alloy contains a Zn element, a Fe element and an X element, wherein the X element is at least one of Mg, Ca and Sr, the mass percent of Zn element is 89.92-99.997%, the mass percent of Fe element is 0.002-10%, and the mass percent of X element is 0.001-0.08%. According to the zinc alloy provided by the invention, the cost of added materials is low, degradation products of all ingredients of a prepared alloy material can be degraded through human body metabolism, the corrosion resistance is far higher than that of a magnesium alloy, the degradation rate is greatly lowered, a longer-time mechanical support can be provided, and the strength and toughness of the alloy material are good.

Owner:XIAN ADVANCED MEDICAL TECH

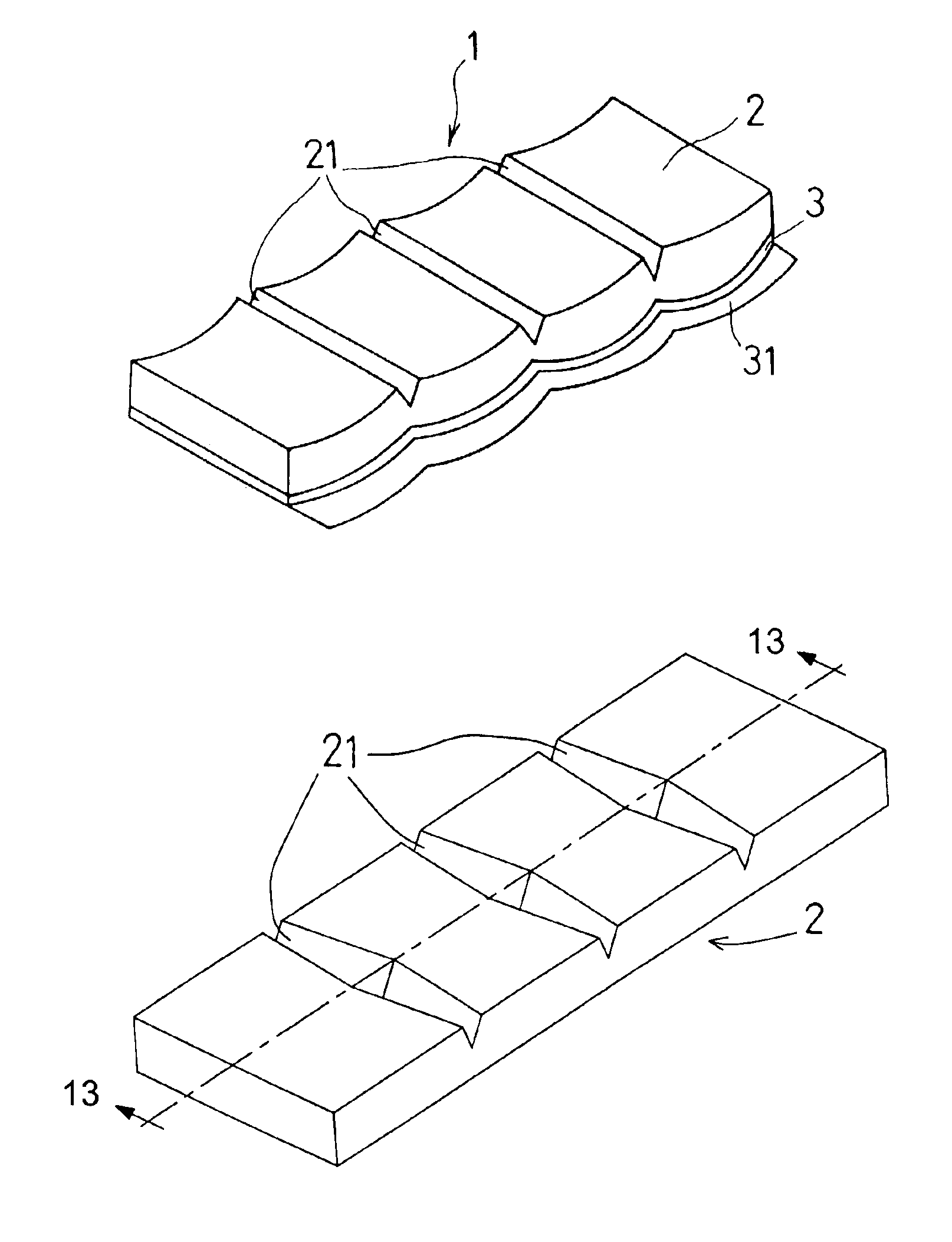

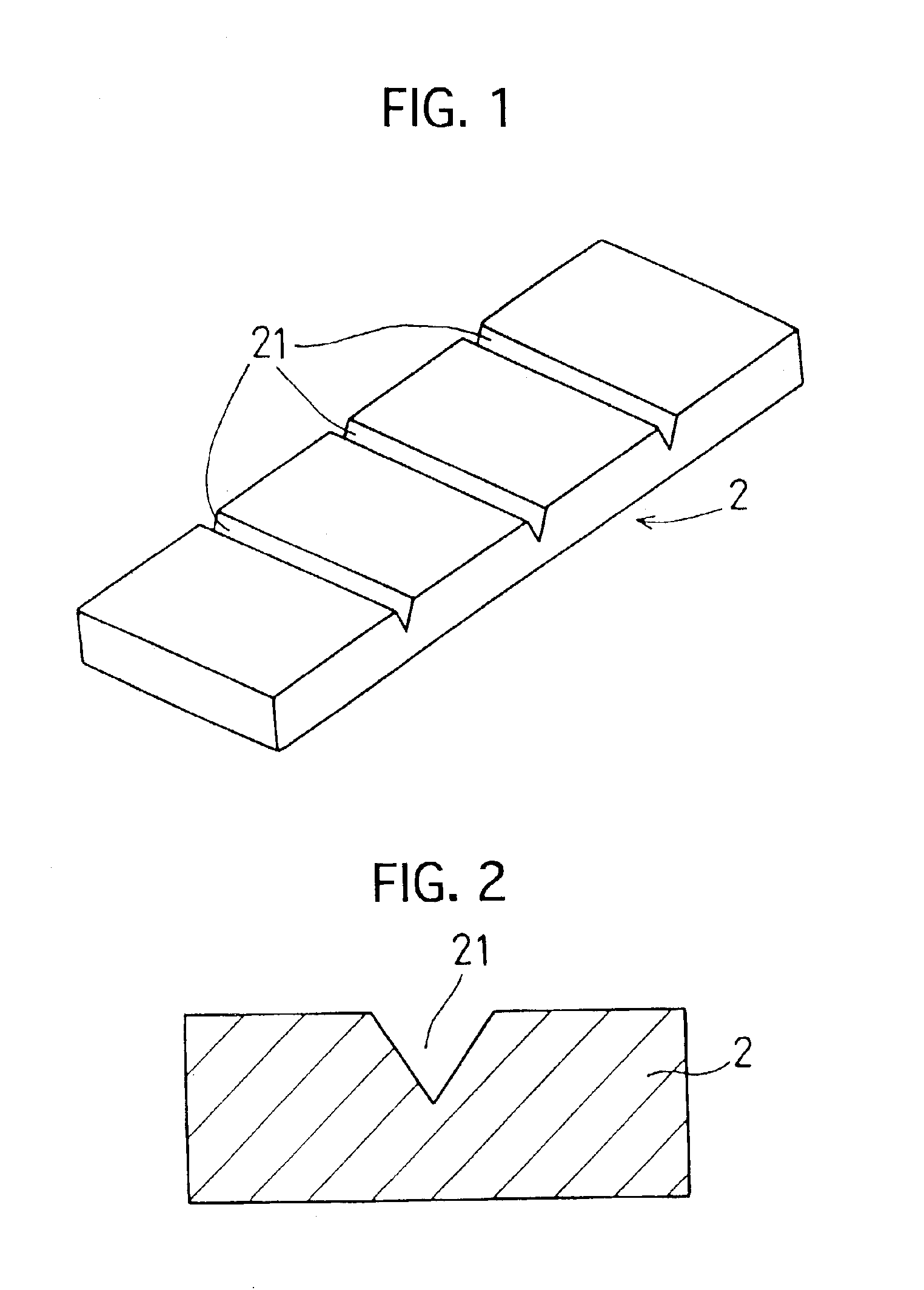

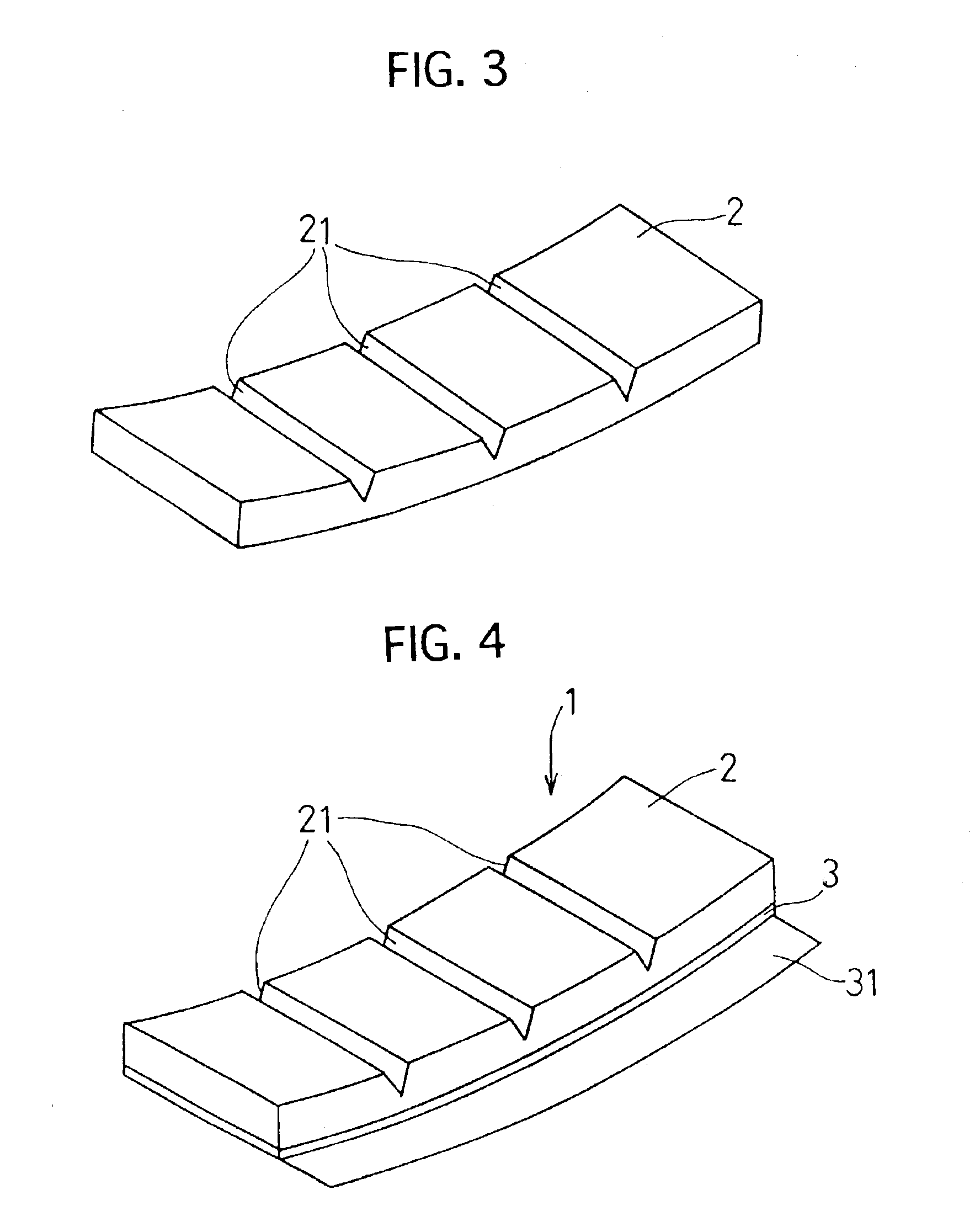

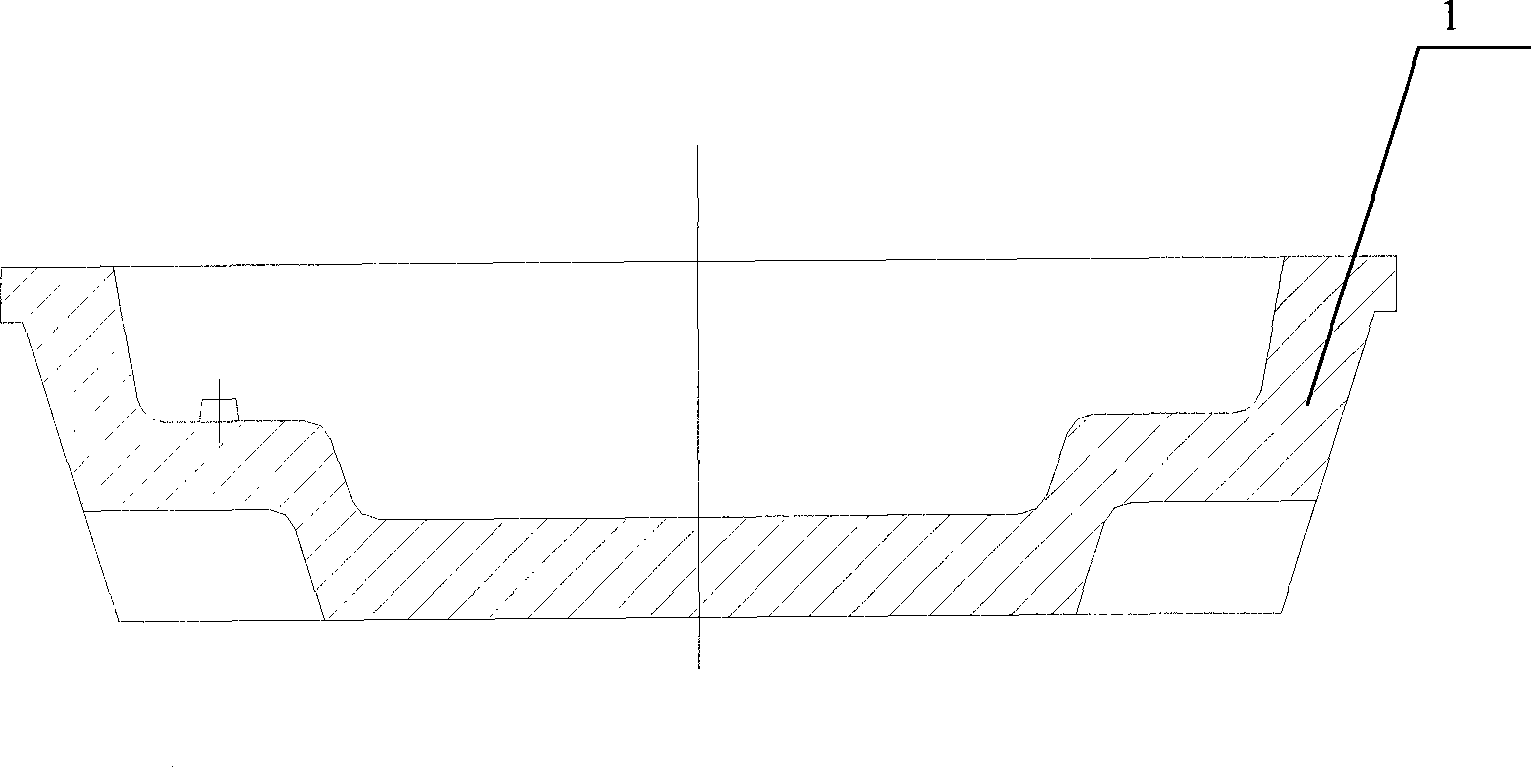

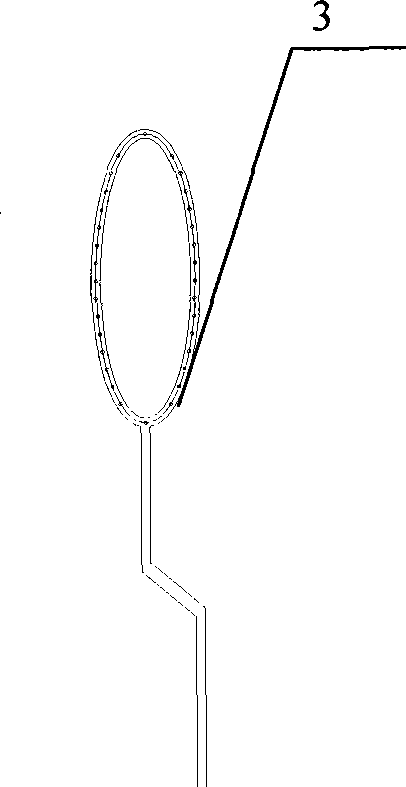

Wheel balance weight and process for manufacturing the same

A wheel balance weight includes a weight and an installation member. The weight is composed of at least one member selected from the group consisting of zinc and a zinc-based alloy, is formed as a substantially strip shape having a substantially uniform thickness, and has opposite surfaces and at least a groove. The groove is formed in at least one of the opposite surfaces of the weight, and crosses in the width-wise direction of the weight. The installation member is adapted for installing the weight to a rim in a wheel. Since the weight is composed of zinc or a zinc-based alloy, environments are inhibited from being polluted when the wheel balance weight is abolished. Moreover, it is possible to manufacture the wheel balance weight at reduced costs and install it to wheels with ease.

Owner:HONDA MOTOR CO LTD +1

Casting method and device for ingot metal

ActiveCN101428334ADelay surface curing timeAvoid the problem of shrinkage cavityIngotZinc based alloy

The invention relates to a casting method and a device for ingot metal such as aluminum, silver, zinc and zinc-based alloy ingot. The invention adopts the method that the molten metal is cast into an ingot mold at first, then at least one surface of the ingot is heated and insulated during the solidification process, to ensure that the cooling speed thereof is greatly reduced and less than that of the other surfaces of the ingot, and the heating is not stopped until the volume of the molten metal in the center of the ingot during the cold shrinkage process is fully compensated by the molten metal on the surface. The device comprises a casting mechanism and a die, the die adopts a vessel with an opening, an insulating cover for covering the opening is also arranged on the die, and a heating device is arranged in the insulating cover. The invention can be used for ingot metal such as aluminum, silver, zinc ingot, zinc-based alloy ingot and the like cast by the die with the opening. The invention ensures that the volume of the surface can be compensated till the volume everywhere in the ingot metal is completely filled and shrunk through delaying the hardening time of one surface of the ingot metal; therefore, the influencing factors of formation of the internal shrinkage hole are radically eliminated, and the effect of eliminating the internal shrinkage hole is realized.

Owner:ZHUZHOU SMELTER GRP

High-strength simple-cutting zine-base alloy and preparation process thereof

The invention discloses a high-strength easy-cutting zinc-based alloy and preparing method, which comprises the following parts: 2. 5-2. 65% copper, 0. 45-0. 60% magnesium,0. 20-0. 35% aluminium,0. 01-0. 06% lanthanum,0. 15-0. 20% cerium, and residual zinc. The invention affirms the strength and cutting property of alloy effectively, which saves power and simplifies the technique.

Owner:CENT SOUTH UNIV

Alloy sacrificial anode film preventing stress corrosion cracking and preparation method thereof

The invention relates to an alloy film, in particular to an anticorrosive alloy plated film. The invention also relates to a preparation method of an alloy. An alloy sacrificial anode film for preventing stress corrosion cracking is made of an aluminum, magnesium, titanium and rare-earth element-containing zinc-based alloy. As a CPF metal coating of the invention has triple corrosion prevention forms different from the conventional corrosion prevention form by using a single metal, namely a capture effect, a self-sealing effect and a static bed effect, the alloy sacrificial anode film has the corrosion prevention effect (making the best use of the circumstances) different from the past. Simultaneously, as the bonding of a metal thermal spray coating and a steel substrate is semi-molten metallurgical bonding and mechanical bond bonding, the bonding force is greater than that of an organic coating and the steel substrate. By adopting a special sealing agent, the alloy sacrificial anode film can bear a potential voltage of -1.33v, and has high oil resistance, high alkali resistance and high adhesion, and does not generate cathodic disbanding due to bubbling caused by OH<-> or H<+> generated by cathodic reaction under the coating.

Owner:大连天凡防腐工程有限公司

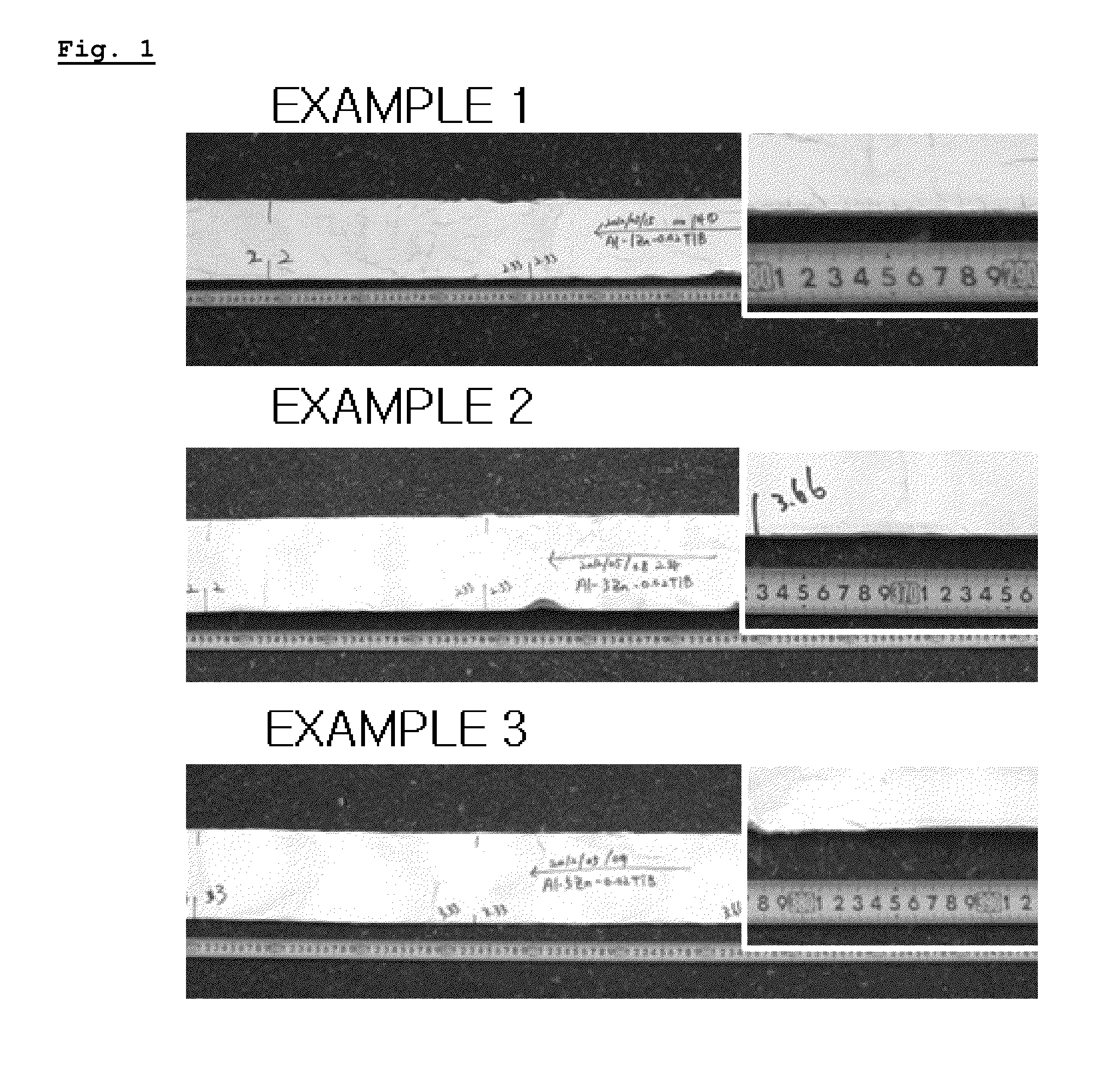

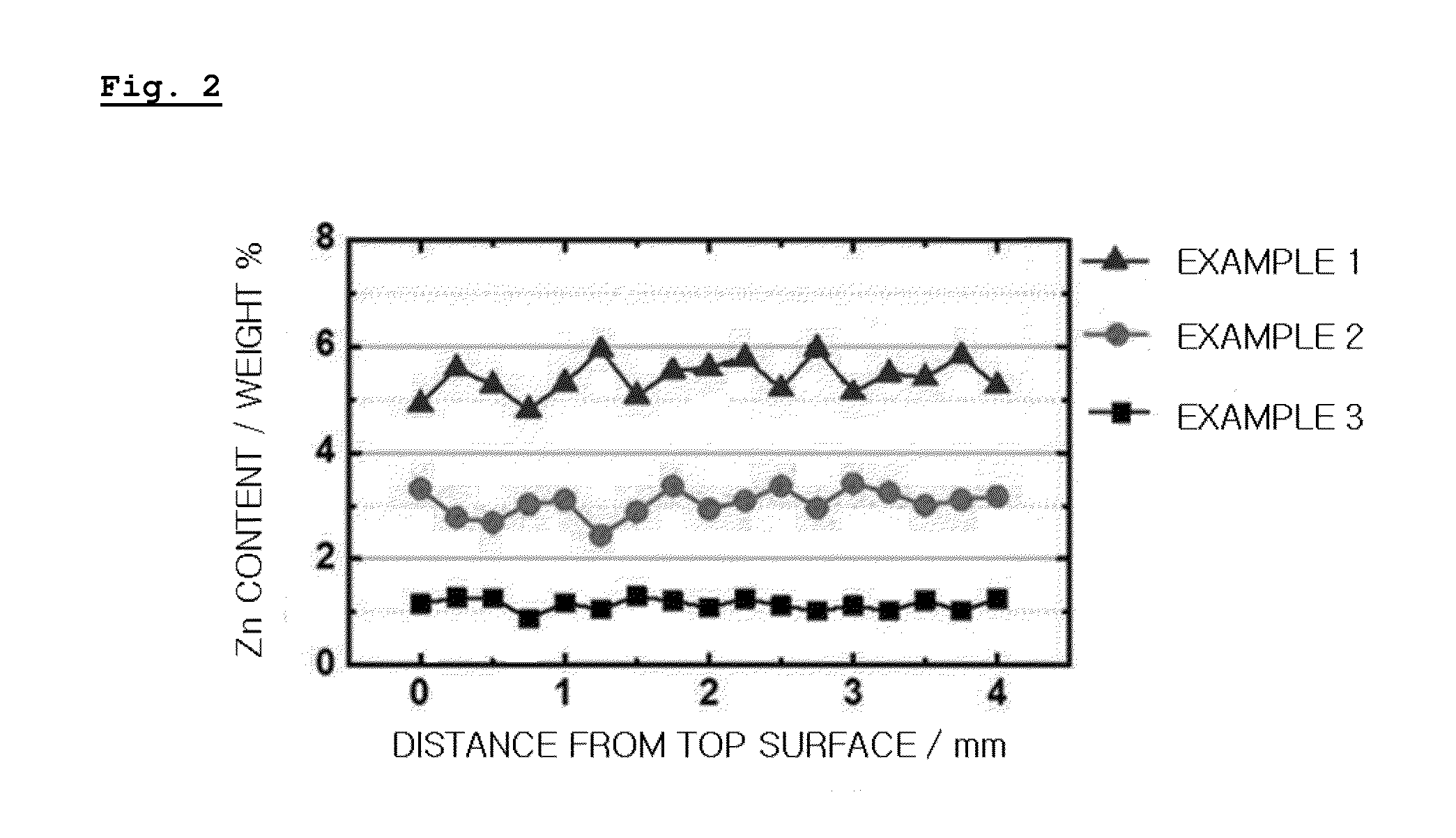

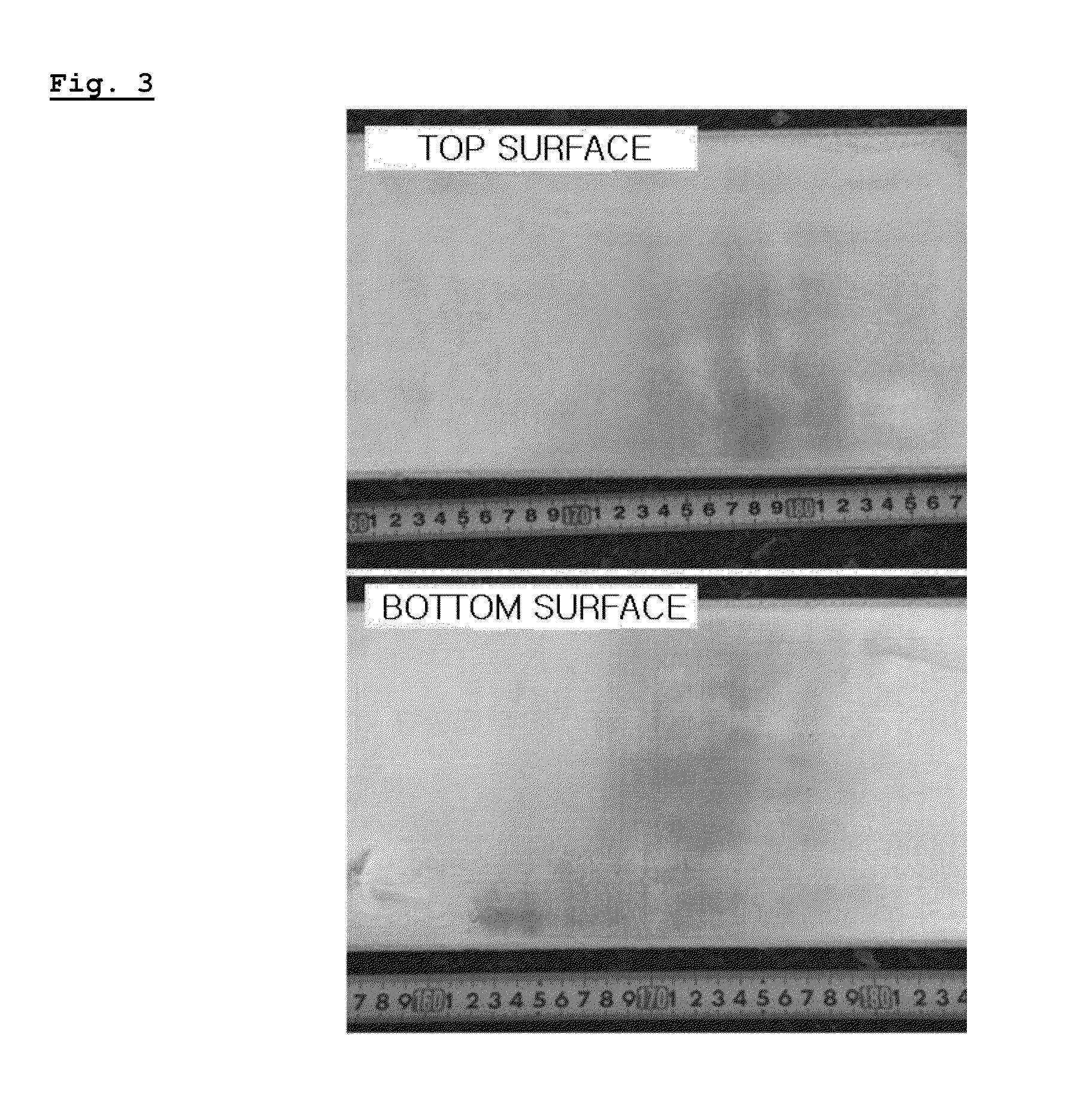

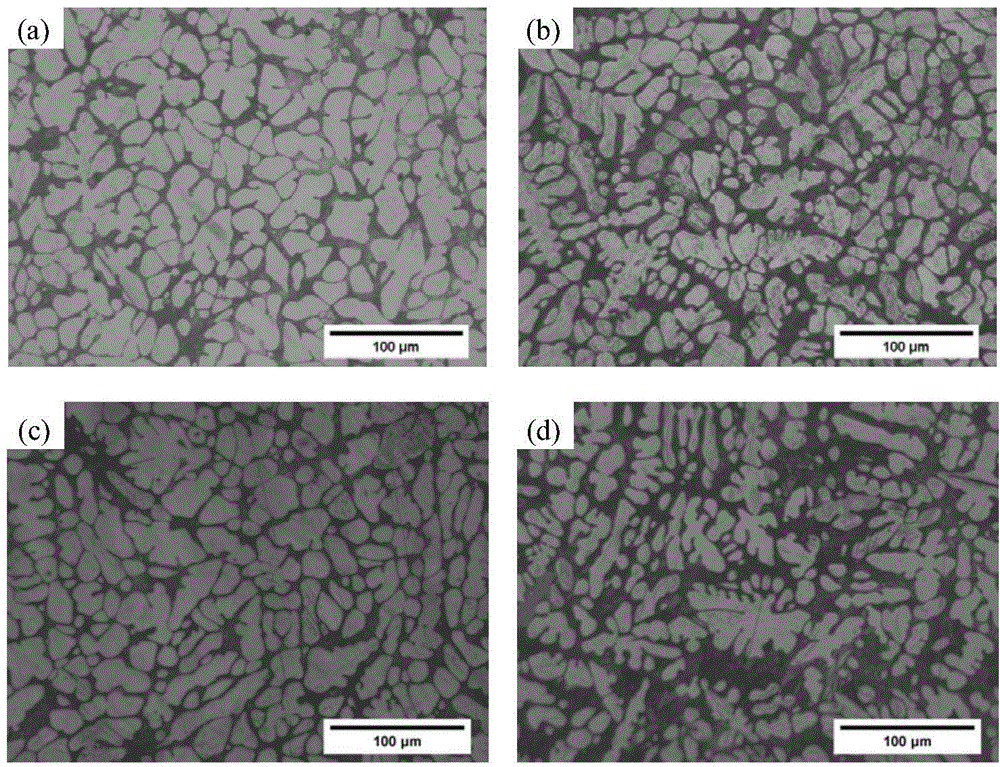

Method Of Manufacturing Aluminum-Zinc-Based Alloy Sheet Using Twin-Roll Casting And Aluminum-Zinc-Based Alloy Sheet Manufactured Thereby

Provided are a method of manufacturing an aluminum-zinc-based alloy sheet using twin-roll casting and an aluminum-zinc-based alloy sheet manufactured thereby. Specifically, a method of manufacturing an aluminum-zinc-based alloy sheet, including preparing a melt by melting elements corresponding to an aluminum alloy including 0.5 wt % to 10 wt % of zinc, inevitable impurities and aluminum as a balance (step 1); and twin-roll casting by introducing the melt prepared in step 1 between a pair of rotating cooling rolls (step 2), and an aluminum-zinc-based alloy sheet manufactured thereby are provided.The present invention may manufacture an aluminum-zinc-based alloy sheet, in which twin-roll casting is known to be difficult due to a wide solid-liquid coexistence region, by twin-roll casting by using cooling rolls having high thermal conductivity and controlling a reduction force by the rotational speed of the rolls.

Owner:KOREA INST OF MATERIALS SCI

High corrosion resistant non-water soluble nano anticorrosive paint in zinc based

InactiveCN1563229AWith metallic lusterStrong corrosion resistanceAnti-corrosive paintsEpoxy resin coatingsAlcoholSolvent based

A non water-soluble and zinc based nanoanticorrosion coating material is prepared by using flaky zinc powder or zinc based alloy powder as raw material; adding trace amount of nanometal powder material; using lipid and alcohol as solvent; adding resin, coupling agent, floatting agent and curing agent of amine for forming solvent type of nanoanticorrosion paint. The prepared coating material can be used as both of basic paint or surface paint with strong adhesive force, metal gloss and decorative function.

Owner:KUNMING HENDERA SCI & TECH

Weld Joint Formed with Stainless Steel-Based Weld Metal for Welding a Zinc-Based Alloy Coated Steel Sheet

ActiveUS20090158889A1Improve corrosion resistanceIncreased durabilityElectric discharge heatingWelding/cutting media/materialsCrack resistanceAlloy coating

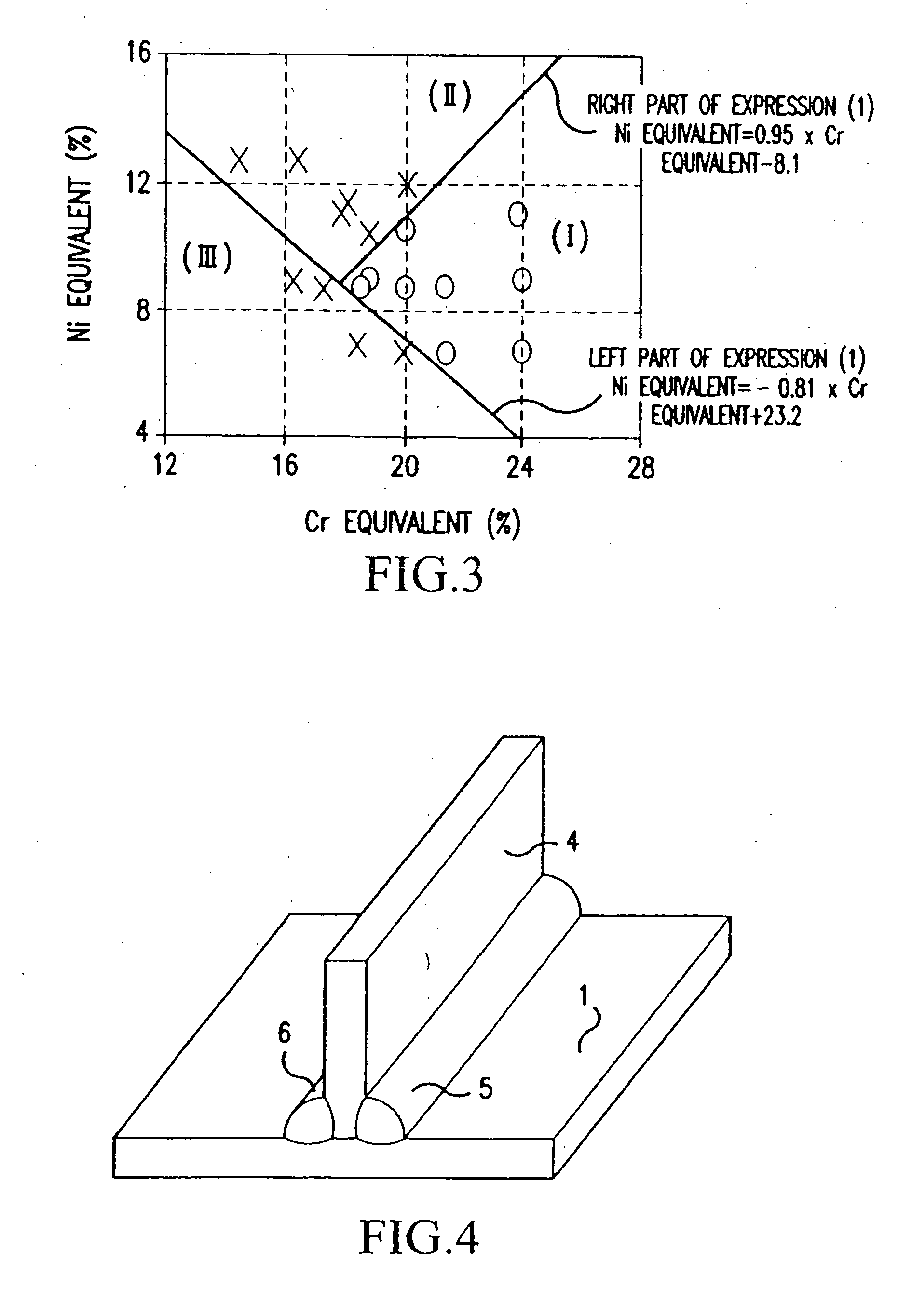

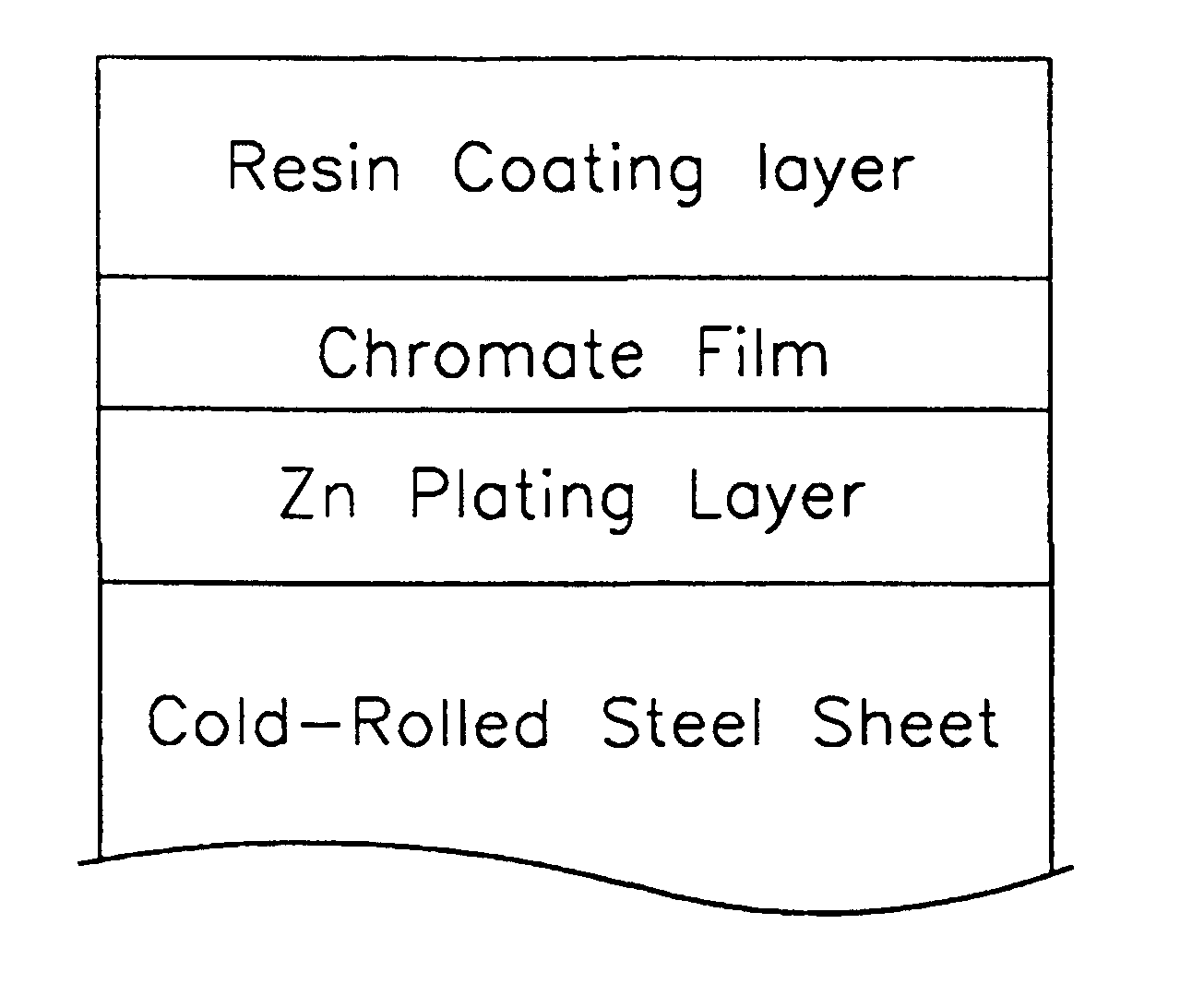

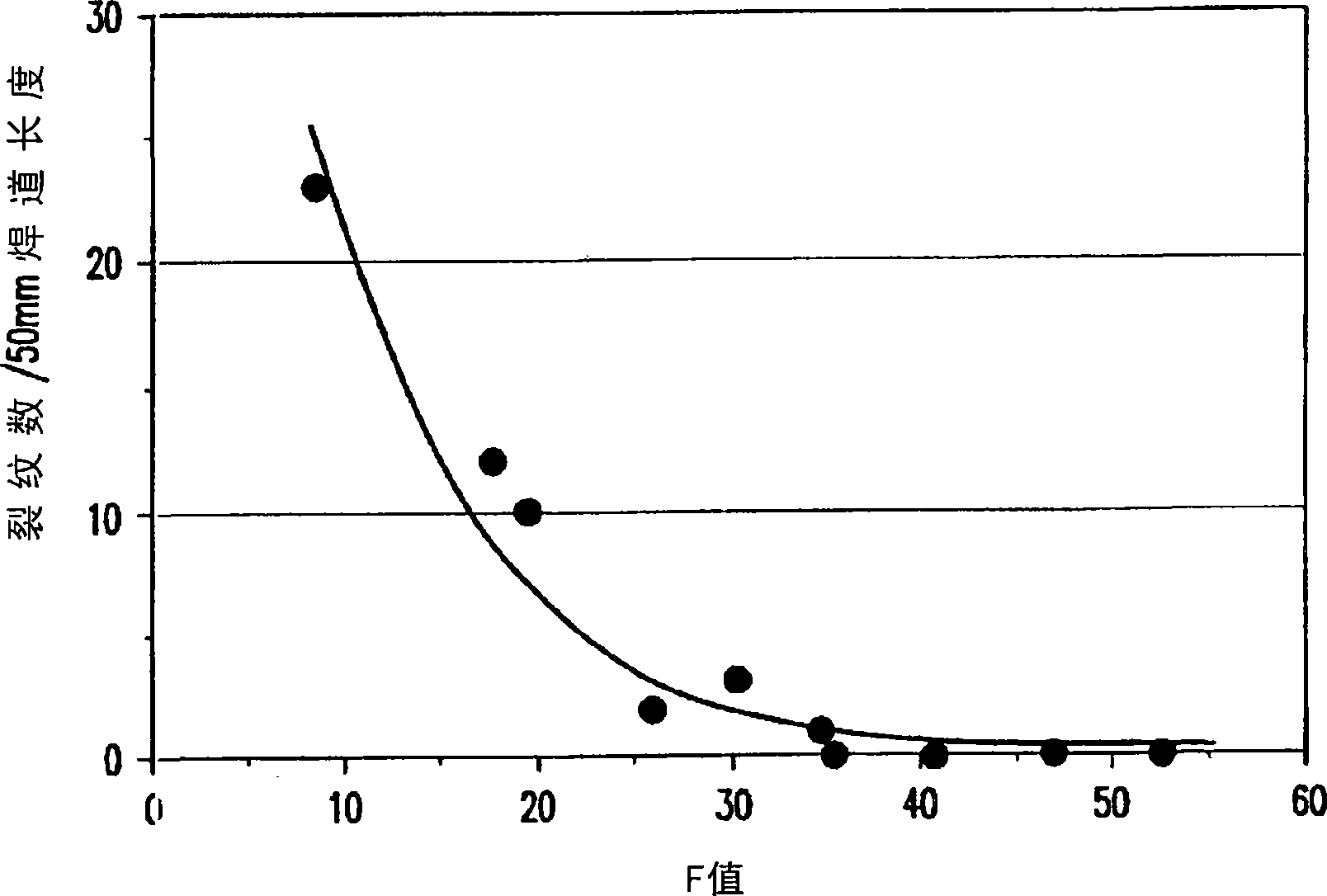

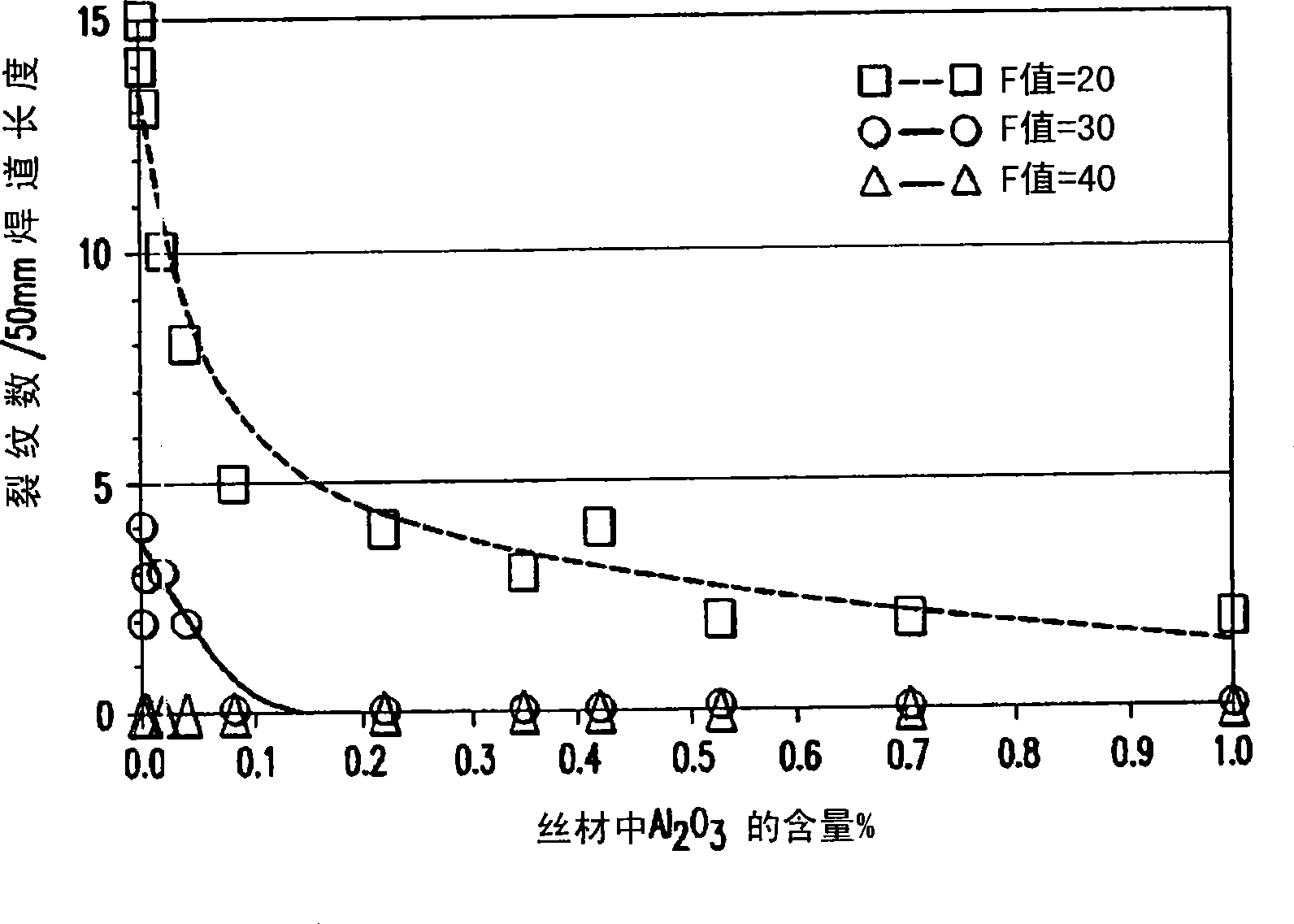

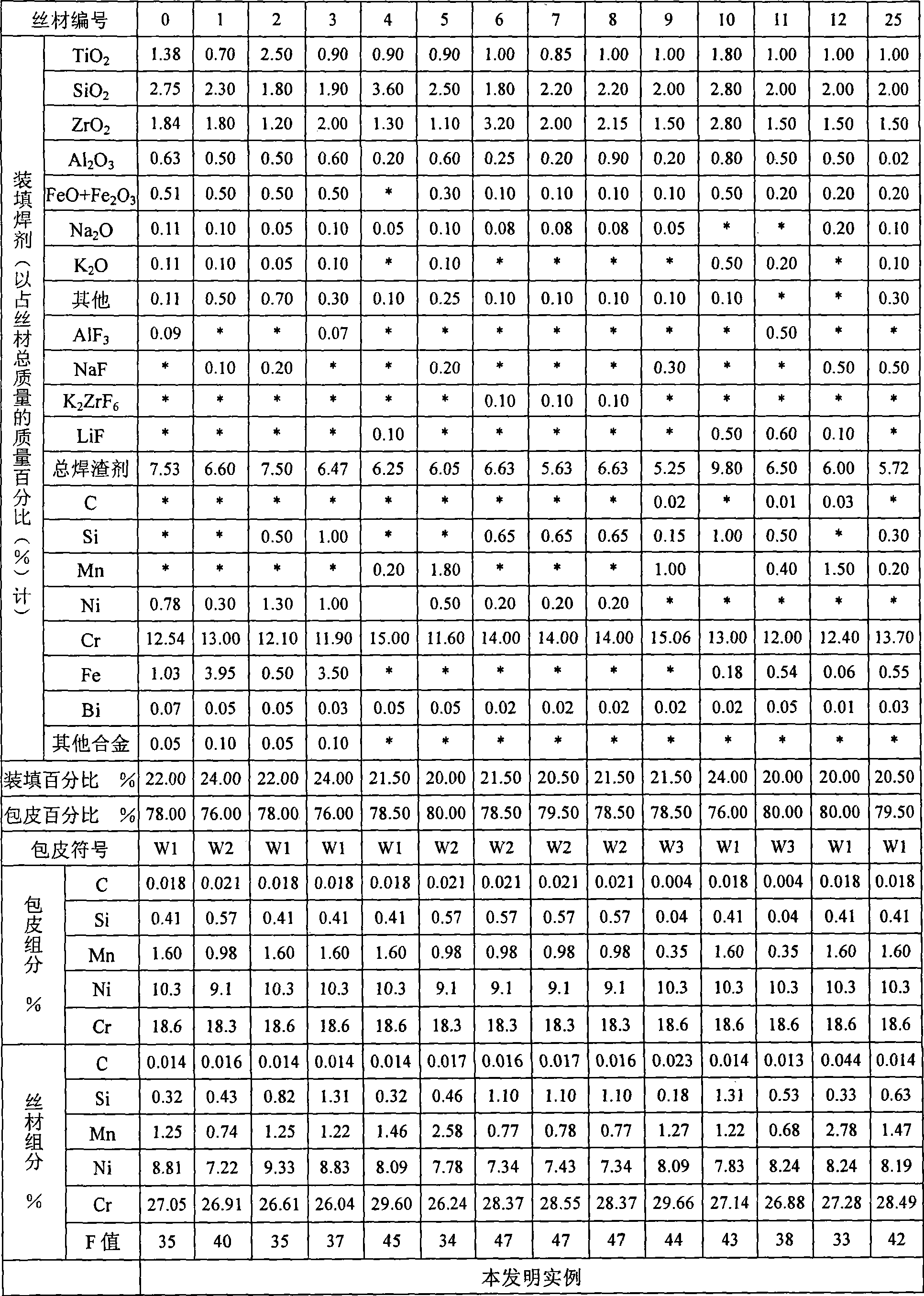

Disclosed are a weld joint and a stainless steel-based weld metal composition for the weld joint. The composition and weld joint made therefrom are suitable for welding a zinc-based alloy coated steel sheet. The weld is excellent in corrosion resistance and liquid-metal embrittlement crack resistance. This is accomplished by inhibiting liquid-metal embrittlement cracks of the stainless-steel-based weld metal when the zinc-based alloy coating steel sheet is welded using the stainless-steel-based weld metal. The weld joint comprises a welded portion of weld metal made of stainless-steel-based components, the weld metal containing in mass percent (%): C: 0.01-0.1; Si: 0.1-1; Mn: 0.5-2.5; Ni: 5-11; and Cr: 17-25, and the balance being iron and residual impurities, wherein the following expression are met: −0.81×Cr equivalent+23.2≦Ni equivalent≦0.95×Cr equivalent−8.1 . . . (1); Ni equivalent=Ni+30×C+0.5×Mn+30×N . . . (2); Cr equivalent=Cr+Mo+1.5×Si . . . (3).

Owner:NIPPON STEEL CORP

Surface-treated steel sheet for fuel tanks and method of fabricating same

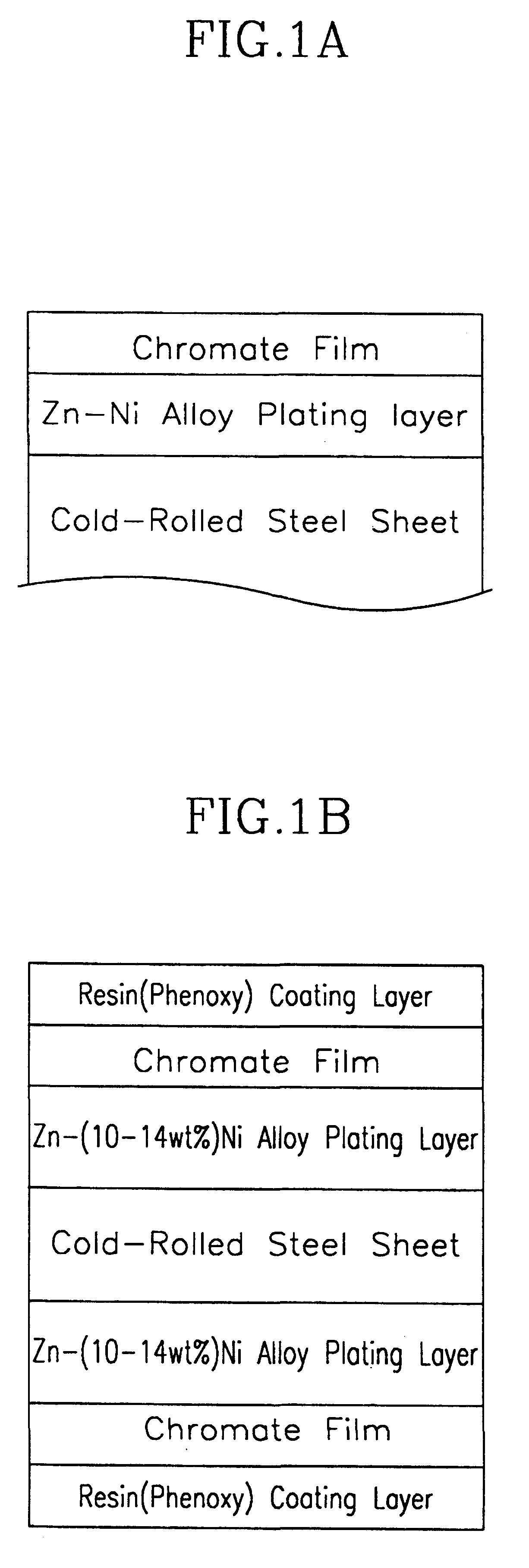

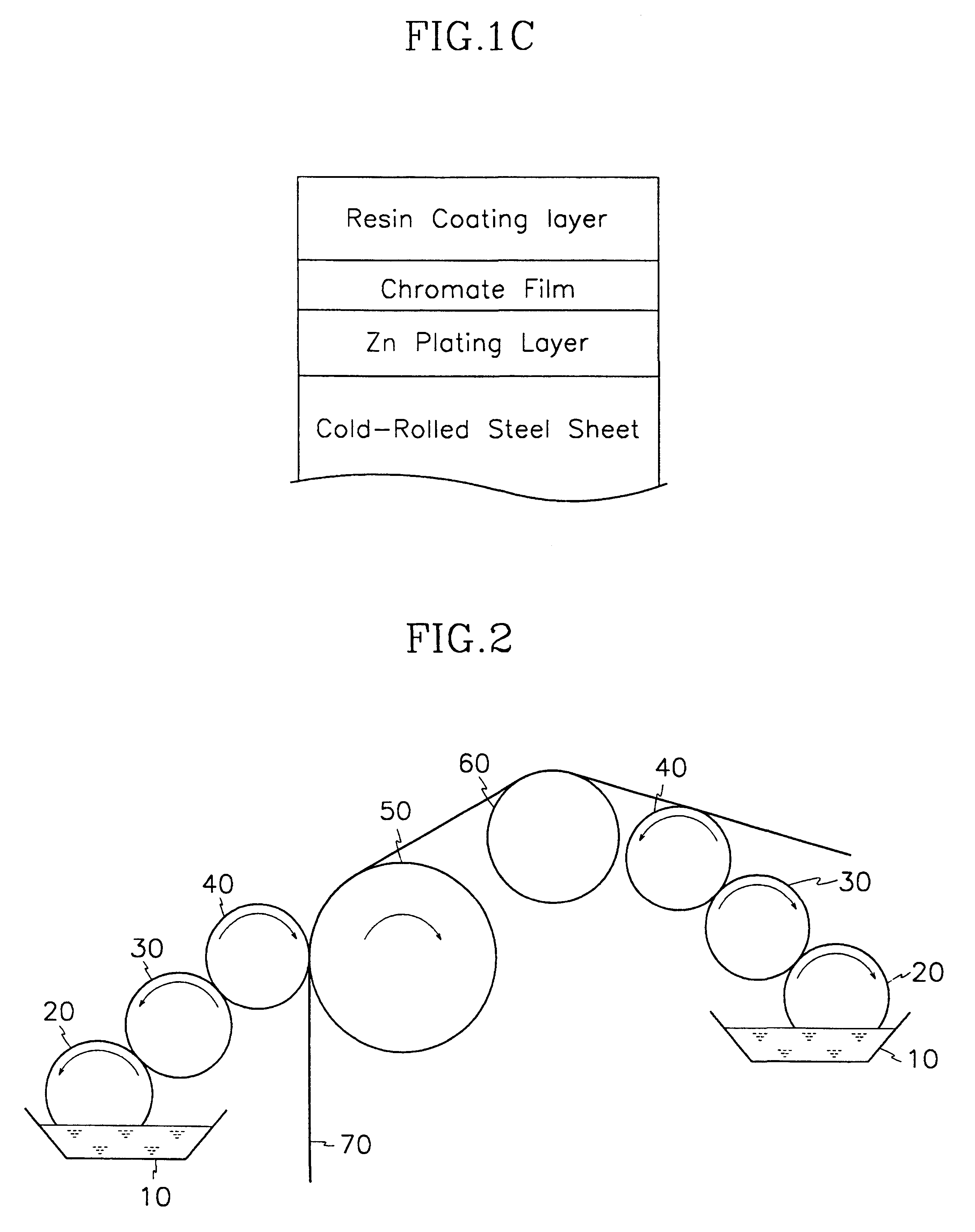

InactiveUS6387538B1Improve cosmetic corrosion resistance and fuel corrosion resistanceImprove featuresLiquid surface applicatorsWax coatingsEpoxyColloidal silica

Owner:POHANG IRON & STEEL CO LTD

Preparation method for zinc-based alloy specially-shaped tube

The invention relates to a preparation method for zinc-based alloy specially-shaped tube. The preparation method for zinc-based alloy specially-shaped tube comprises the following steps of: (1) establishing a constitutive equation and a working diagram by adopting a high-temperature compression test, so as to obtain deformation conditions suitable for processing zinc alloy; (2) performing a finite element numerical simulation on zinc alloy porthole die extrusion, so as to optimize die structure and extrusion process; (3) heating a zinc alloy ingot blank in an induction furnace, and then performing hot extrusion by selecting the optimized die structure and process parameters, so as to obtain a specially-shaped tube blank with an approximate final size; (4) performing fixed short core rod pulling, so as to obtain the specially-shaped tube with a finished size; (5) performing cleaning and heat treatment; and (6) straightening, so as to obtain the finished tube. The method disclosed by the invention is short in process, high in material utilization rate, low in cost, high in added value, and suitable for large-scale production; and the prepared zinc-based alloy specially-shaped tube can be used for replacing a part of brass specially-shaped tubes, plays a promotion role on relief for the copper resource shortage of China to a certain extent, and has economic benefits and social benefits to a certain extent.

Owner:GRIMAT ENG INST CO LTD

Method for directly welding aluminum and non-coating steel

InactiveCN101804499AReduce production processLow costArc welding apparatusWelding/cutting media/materialsMaterials processingSoldering

The invention relates to a method for directly welding aluminum and non-coating steel, belonging to the technical fields of material processing and manufacturing engineering. The method is characterized in that when heterogeneous metals which are the aluminum and the steel are welded, the surface of the steel is not needed to be plated with intermediate layer metal or coated with soldering flux in advance; tungsten electrode gas shielded welding or melting electrode gas shielded welding technique is adopted, and a welding wire obtained by the technique is a flux-cored wire which is filled with soldering flux inside zinc base alloy material; the welding wire contains the aluminum with the mass percent of 0.1-30%; the filled soldering flux is cesium aluminum tetrafluoride with the mass percent of 10-20%; and the method can realize direct welding between the aluminum as well as aluminium alloy and the non-coating steel. The method has the advantages that a manufactured aluminum-steel heterogeneous metal joint has the tensile strength which is more than 80% of the tensile strength of aluminium alloy parent metal; and the method has simple technique, saves the energy consumption, reduces the manufacturing process and the cost, and is widely applied to welding between heterogeneous metal products, namely, between aluminum as well as aluminium alloy and iron-based materials such as the non-coating steel, cast iron and the like.

Owner:DALIAN UNIV OF TECH

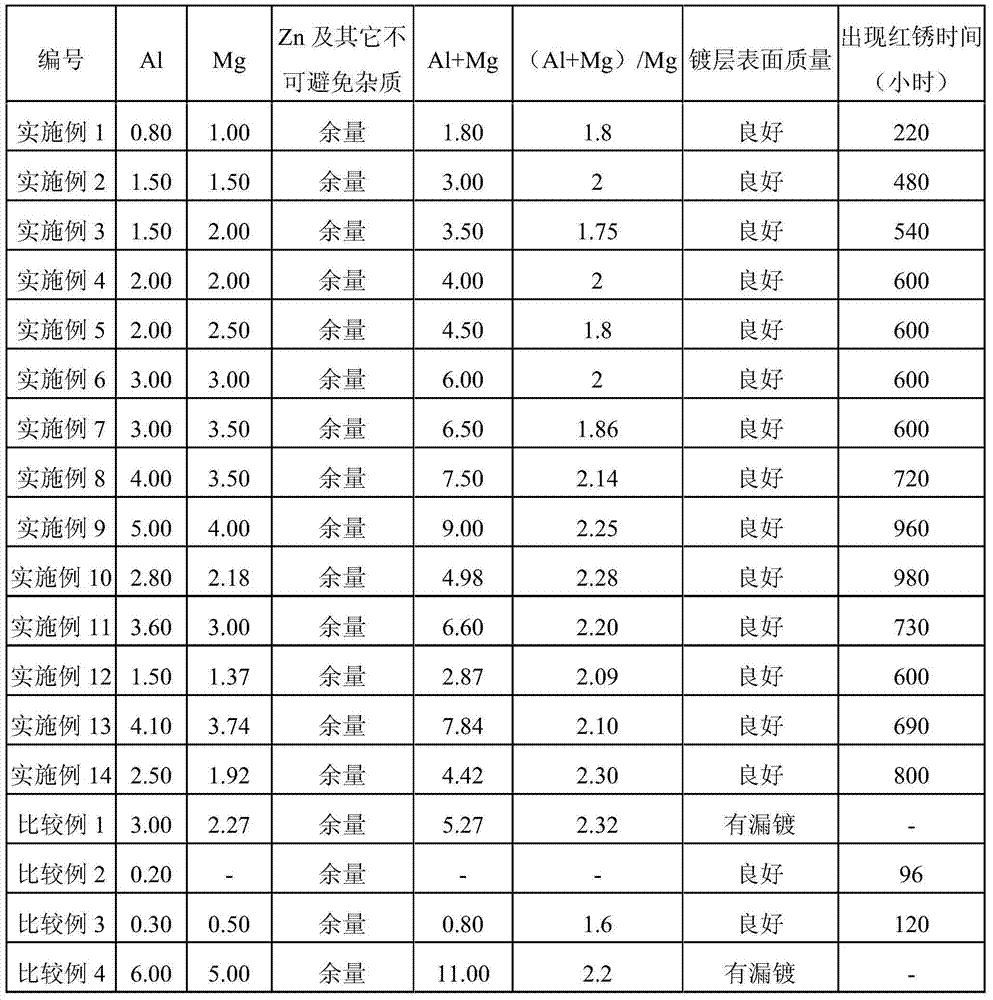

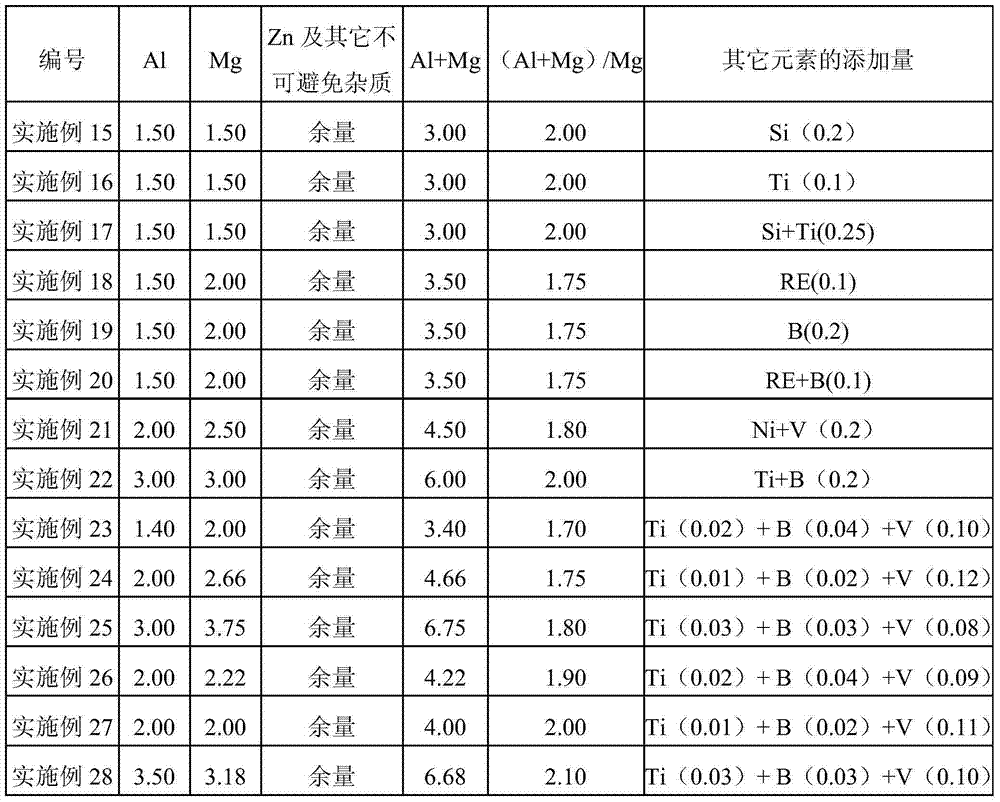

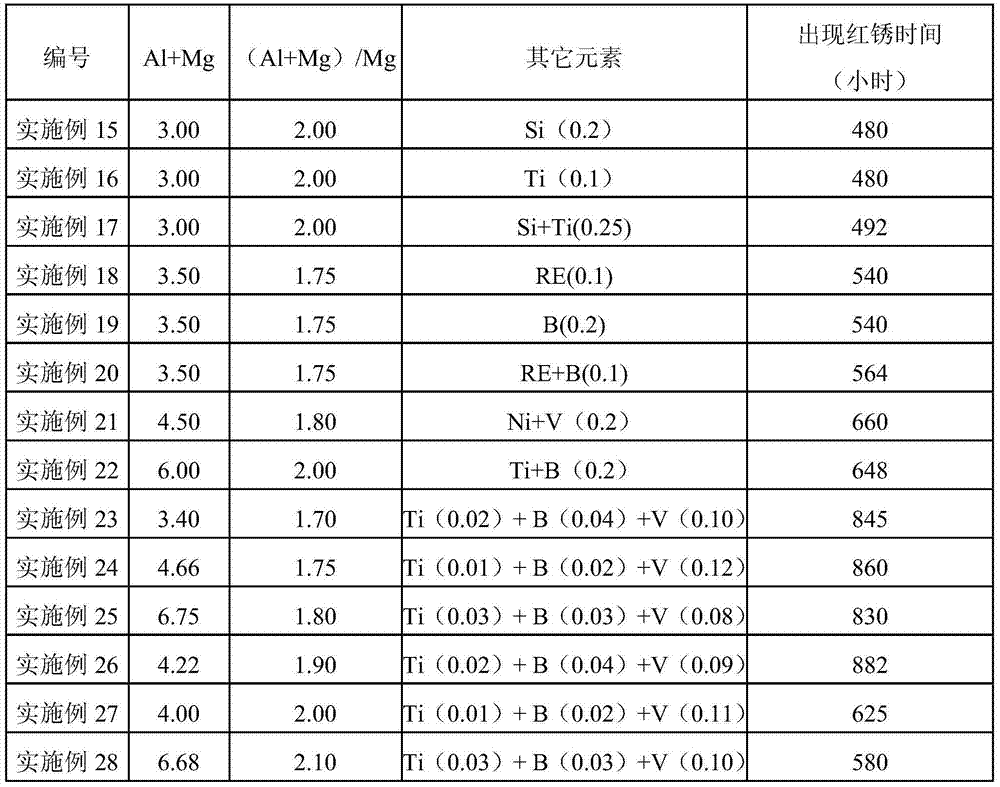

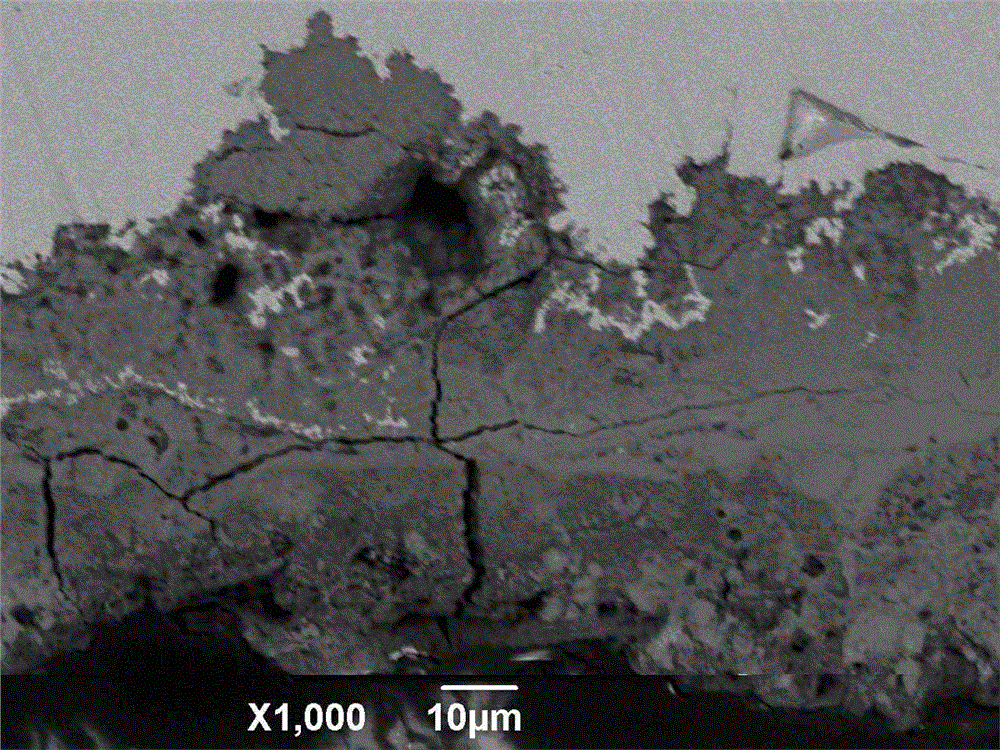

Plating solution for continuous hot dipping of steel strips and dipping method thereof

InactiveCN104498850AImprove corrosion resistanceHot-dipping/immersion processesImpurityZinc based alloy

The invention relates to plating solution for continuous hot dipping of steel strips and a dipping method thereof. The plating solution for continuous hot dipping of steel strips disclosed by the invention comprises 0.5-5wt% of Al, 1-4wt% of Mg, and the balance of Zn and inevitable impurities, wherein the contents of Al and Mg meet the following conditions: (Al+Mg) / Mg is 1.70-2.30. The plating solution for continuous hot dipping of steel strips and the dipping method thereof provided by the invention are suitable for the hot dipping of different varieties of steel strips, and moreover, the corrosion resistance of the zinc-based alloy plating layers prepared by virtue of the plating solution can be greatly improved.

Owner:CHINA IRON & STEEL RES INST GRP +1

Corrosion-resistant and high-strength and toughness Zn-Fe-Li-based zinc alloy capable of being degraded in human body and application of corrosion-resistant and high-strength and toughness Zn-Fe-Li-based zinc alloy

The invention discloses a corrosion-resistant and high-strength and toughness Zn-Fe-Li-based zinc alloy capable of being degraded in a human body and an application of the corrosion-resistant and high-strength and toughness Zn-Fe-Li-based zinc alloy, relates to field of medical implantation materials, and provides the corrosion-resistant and high-strength and toughness Zn-Fe-Li-based zinc alloy which is low in cost of added materials, high in strength, good in plasticity and controllable in degradation rate, has non-expanding and non-migrating degradation products and can be simultaneously degraded in the human body against the defects in the prior art. The zinc alloy comprises Zn, Fe and Li elements, wherein the content of the Zn element in mass percentage is 80-99.997%, the content of the Fe element in mass percentage is 0.002-10%, and the content of the Li element in mass percentage is 0.001-10%. The cost of the materials added into the zinc-based alloy disclosed by the invention is low, the degradation products of various components in the prepared alloy material can be degraded in the human body by metabolism, the corrosion resistance is much higher than that of a magnesium alloy, the degradation speed is greatly reduced, the mechanical support can be provided for a longer time, and the alloy material has good strength and toughness.

Owner:XIAN ADVANCED MEDICAL TECH

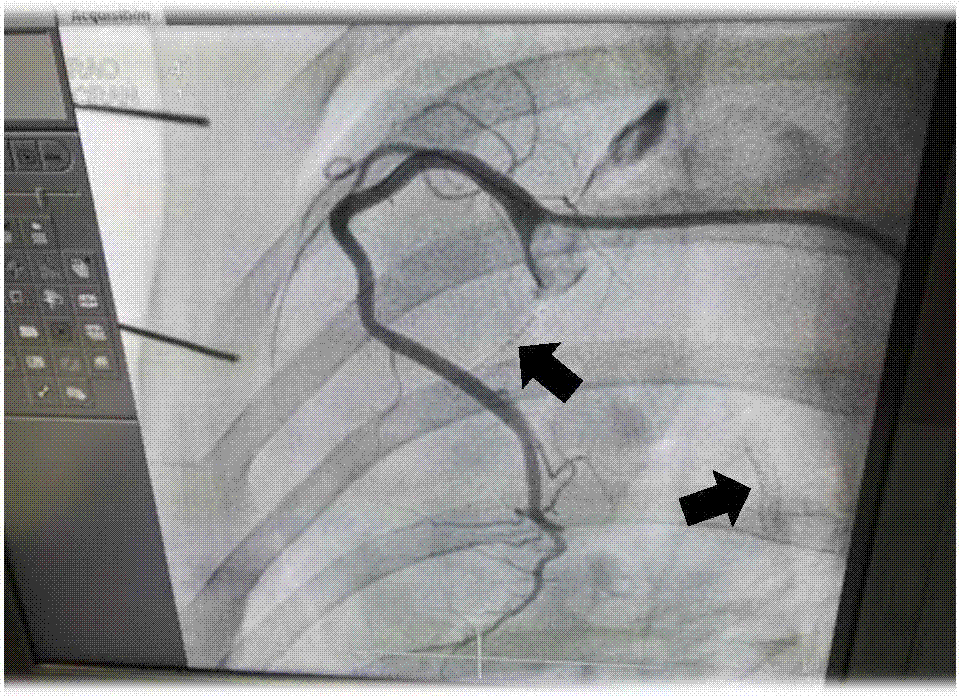

Medical degradable implantable metal material

ActiveCN107496993AGood non-toxicGood biocompatibilitySurgeryTissue regenerationCoronary heart diseaseMetallic materials

The present invention relates to the field of medical materials, and provides an implantable metal material capable of being degraded in vivo. The invention discloses a multi-element zinc alloy comprising Zn, Cu, Ti, Mg and the like, wherein the multi-element zinc alloy comprises, by mass, 0-4.5% of Cu, 0-1.5% of Ti, 0-1.5% of Mg, and the balance of Zn, and can further contain 0-2% of Mn, 0-3% of Ag and the like, wherein Mg, Cu and Mn are essential elements of human body, and Ti and Ag are non-toxic elements, such that the introduction of toxic alloying elements is avoided. According to the present invention, the multi-element zinc-based alloy is prepared by selecting the high-purity raw material or intermediate alloy, the high-performance billet is obtained through processing, and the obtained product has advantages of good mechanical property, uniform corrosion and strong controllability, can meet the requirements of medical devices on safety and mechanical property, can be used in vascular stents, lumen stents, orthopedic implants, surgical suture devices and other devices, and is preferentially used for preparing degradable stents for the interventional therapy of coronary heart diseases and the temporary supporting of body lumens stenosis.

Owner:LEPU MEDICAL TECH (BEIJING) CO LTD

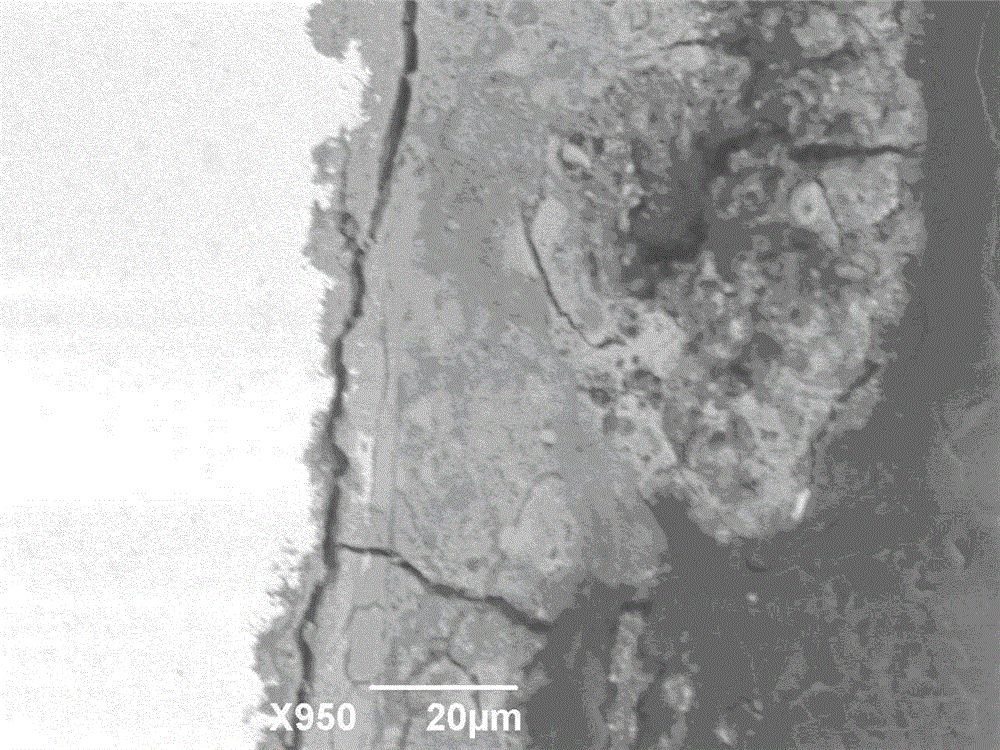

Degradable zinc base alloy implant material and preparation method and application thereof

ActiveCN106890356AReduced activityRegulation of degradation rateSurgeryTissue regenerationOrthopedic departmentInternal fixation

The invention discloses a degradable zinc base alloy implant material and a preparation method and application of the degradable zinc base alloy implant material. The degradable zinc base alloy implant material comprises 0.01 wt%-14 wt% of Fe, 0 wt%-13 wt% of functional elements and the balance of Zn according to mass percentage. In the preparation, Zn, Fe and the functional elements are evenly mixed, and the mixture is placed in a high-purity graphite crucible, and smelted under the atmosphere of mixed gases SF6 and CO2, so as to obtain the degradable zinc base alloy implant material. The mechanical properties of the zinc base alloy implant material are remarkably improved, the implant material is easy to process and form, the properties like strength and plasticity meet the basic requirements of the body implant material of an intravascular stent, an orthopedic internal fixation system and the like; the introduction of the functional elements further enables the product to achieve the certain effects of resisting bacteria, maintaining and inducing angiogenesis, repairing bones, promoting calcification and being beneficial for recovery of body functions.

Owner:SHANDONG RIENTECH MEDICAL TECH +1

Stainless steel wire with flux core for welding zinc coated steel sheets

A stainless steel wire having a flux core for welding zinc-based alloy coated steel sheet having an outer metal sheath coating a core of flux wherein in total having in mass (%) as percentage to the total mass of the wire: C: 0.01- 0.05 %, Si: 0.1- 1.5 %, Mn: 0.5- 3.0 %, Ni: 7.0- 10.0 %, Cr: 26.0- 30.0 %, wherein an F value defined as a function of the above components ranges from 30 to 50, the flux further having a slag formation agent in mass (%) as percentage to the total mass of the wire: TiO2: 0.6- 2.6 %, SiO2: 1.8- 3.8%, ZrO2: 1.0- 3.5%, and optionally Al2O3: 0.1- 1.0%, wherein the slagformation agent in total is less than 10%, and the wire further containing Fe and residual impurities.

Owner:NIPPON STEEL CORP

Method for preparing zinc base alloy

The invention relates to a method for preparing zinc base alloy, comprising the following steps: firstly respectively preparing Al-Cu alloy, Al-Mn alloy and Al-Ti-B alloy; and then adding the Al-Cu alloy, the Al-Mn alloy, the Al-Ti-B alloy, rare-earth metal and metal Mg into molten metal Zn; after all the substances are melted, slagging, slagging off, casting to form an ingot, and cooling to obtain the zinc base alloy, wherein the Re in the zinc base alloy Zn-Al-Mg-Cu-Re-Mn-Ti-B is the rare-earth metal. By utilizing the preparation method provided by the invention, the temperature can be effectively lowered, thus lowering the requirements on energy and equipment; and meanwhile, the zinc base alloy prepared by the preparation method provided by the invention has excellent mechanical property.

Owner:湖南株冶环保科技有限公司

Degradable medical implant metal material and preparation method thereof

ActiveCN105986146AGood mechanical propertiesImprove corrosion resistanceZinc alloysMechanical property

The invention relates to a biological medical degradable zinc-based alloy. The biological medical degradable zinc-based alloy is characterized in that a zinc alloy system is composed of Zn, Mg, Ca and Mn and comprises, by mass, 0 to 1.5% of Mg, 0 to 0.5% of Ca and 0 to 0.2% of Mn, with the balance being Zn, wherein Mg is not equal to 0. The zinc-based alloy prepared in the invention avoids introduction of unfavorable elements, has good mechanical properties, excellent corrosion resistance and strong corrosion failure controllability, and can meet requirements for biological safety and comprehensive mechanical properties of a biomaterial in the field of medical instruments.

Owner:LEPU MEDICAL TECH (BEIJING) CO LTD

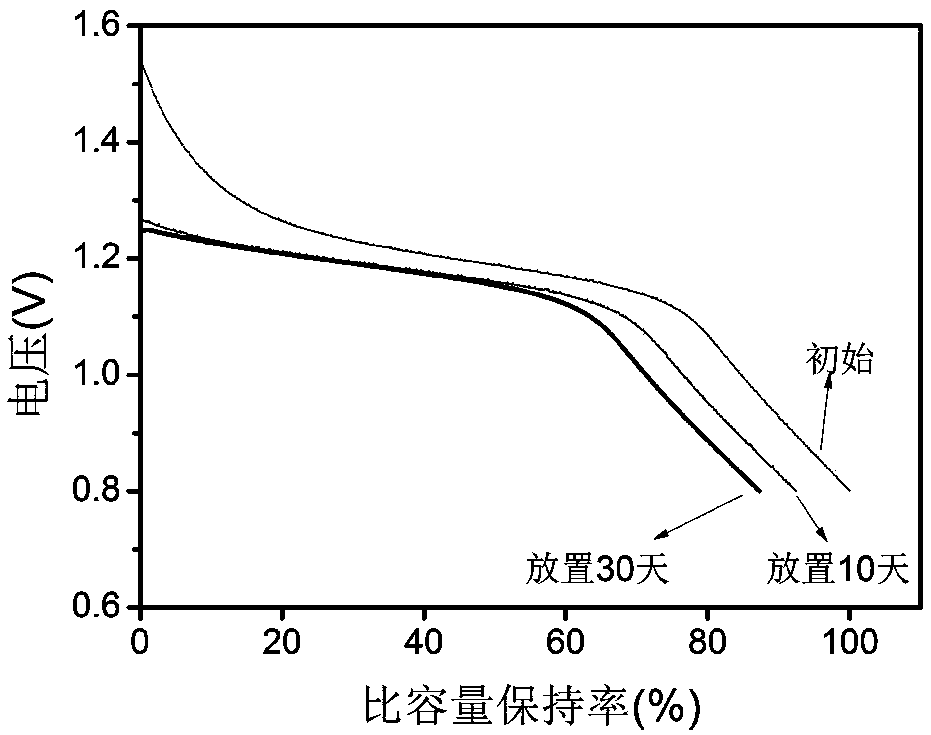

Water-phase electrolyte system zinc iodine secondary battery and preparation method thereof

ActiveCN107666015AImprove Coulombic efficiencyEnsure safetyCell electrodesSecondary cellsChemical reactionHigh energy

The invention discloses a water-phase electrolyte system zinc iodine secondary battery and a preparation method thereof. The battery comprises a positive electrode, a negative electrode, a water-phaseelectrolyte and a diaphragm. The positive electrode is a composition material containing iodine, the negative electrode is pure zinc or zinc base alloy, and the water-phase electrolyte is a zinc saltwater solution. When the battery works, reversible chemical reaction between zinc and iodine is carried out, so that the battery is essentially different from a zinc ion battery on the basis of reversibly embedding or separating a zinc ion in / from a positive electrode material. The built zinc iodine secondary battery has a simple structure, good safety, high energy density, low material cost, environment protection, and a better application prospect.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

Corrosion-resistant and high-strength and toughness Zn-Fe-RE-based zinc alloy capable of being degraded in human body and application of corrosion-resistant and high-strength and toughness Zn-Fe-Li-based zinc alloy

ActiveCN104651664ALow costImprove corrosion resistanceSuture equipmentsProsthesisZinc alloysUltimate tensile strength

The invention discloses a corrosion-resistant and high-strength and toughness Zn-Fe-RE-based zinc alloy capable of being degraded in a human body and an application of the corrosion-resistant and high-strength and toughness Zn-Fe-RE-based zinc alloy, relates to field of medical implantation materials, and provides the corrosion-resistant and high-strength and toughness Zn-Fe-RE-based zinc alloy which is low in cost of added materials, high in strength, good in plasticity and controllable in degradation rate, has non-expanding and non-migrating degradation products and can be simultaneously degraded in the human body against the defects in the prior art. The zinc alloy comprises Zn, Fe and RE elements, wherein the content of the Zn element in mass percentage is 82-99.997%, the content of the Fe element in mass percentage is 0.002-10%, and the content of the RE element in mass percentage is 0.001-8%. The cost of the materials added into the zinc-based alloy disclosed by the invention is low, the degradation products of various components in the prepared alloy material can be degraded in the human body by metabolism, the corrosion resistance is much higher than that of a magnesium alloy, the degradation speed is greatly reduced, a mechanical support can be provided for a longer time, and the alloy material has good strength and toughness.

Owner:XIAN ADVANCED MEDICAL TECH

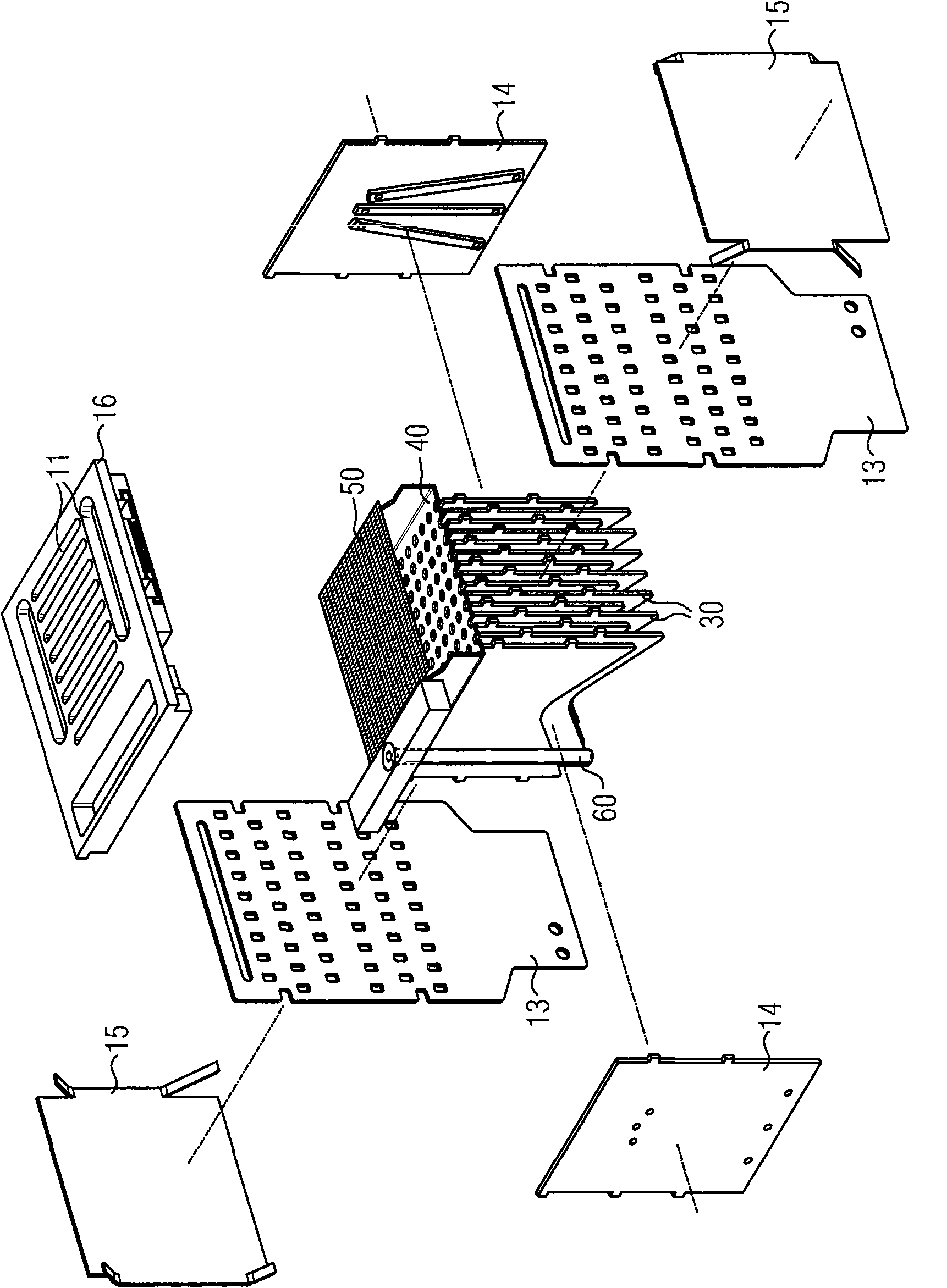

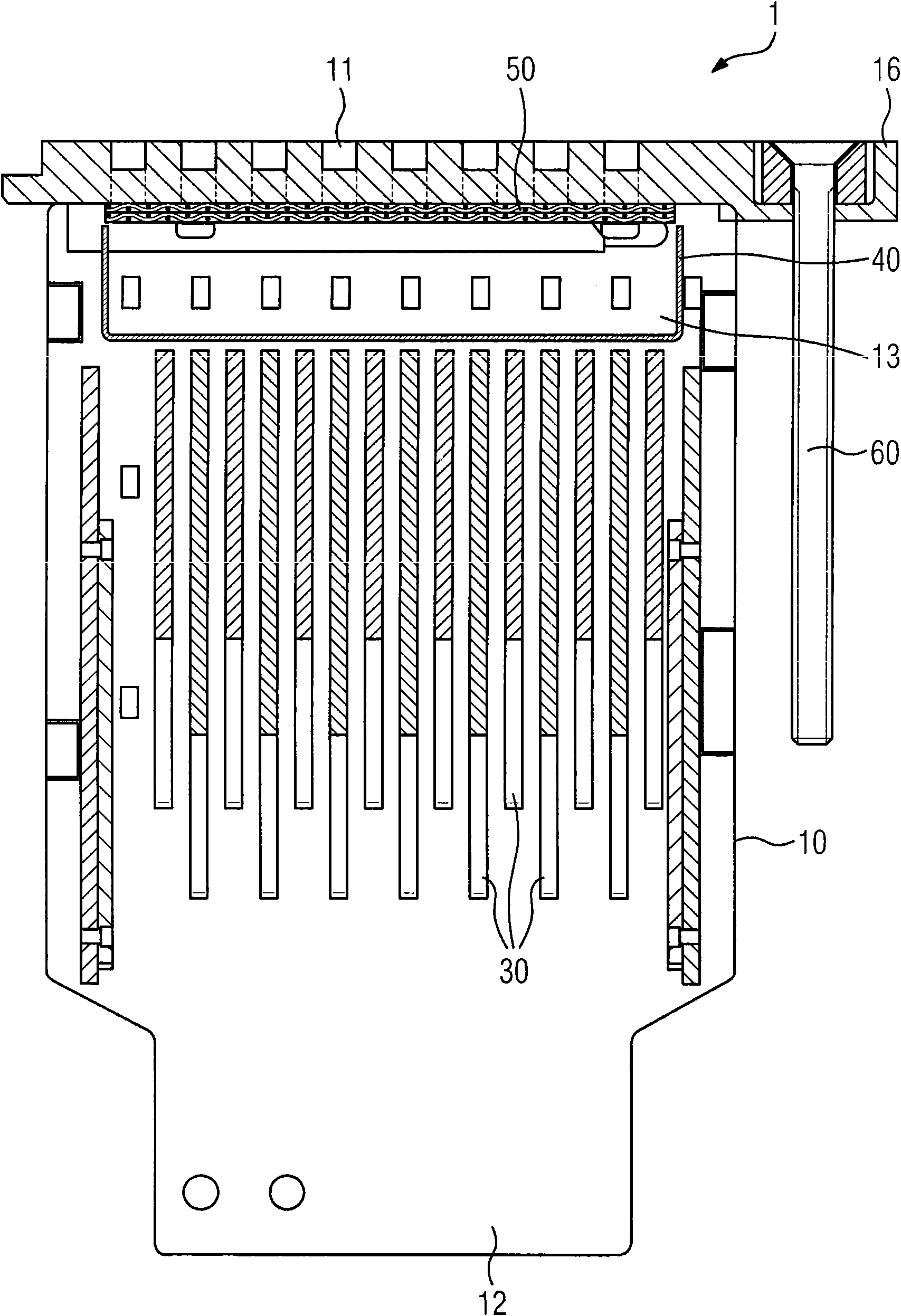

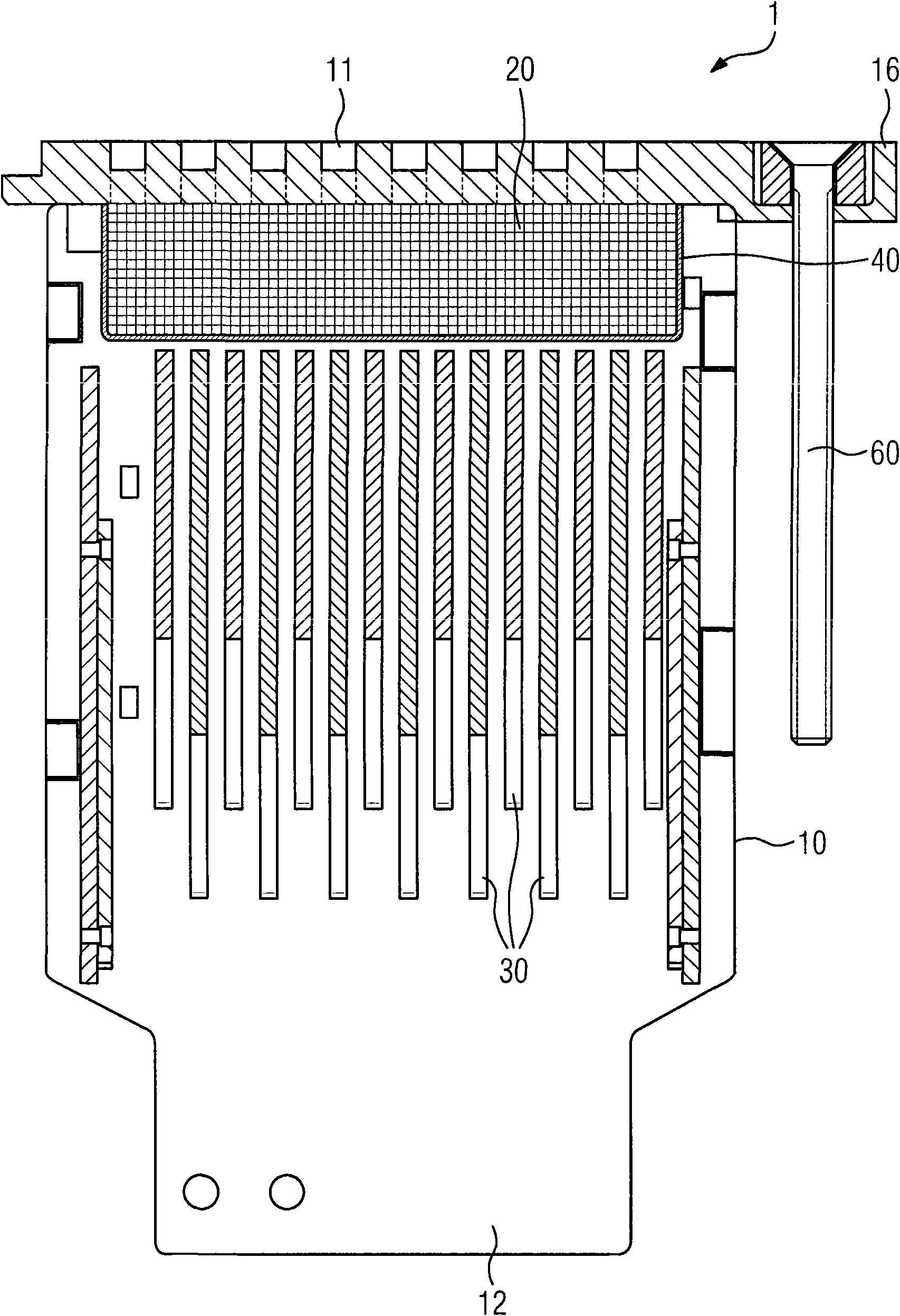

Circuit breaker with switching gas cooling

The invention relates to a circuit breaker comprising at least one housing having at least one opening, and at least one pair of contacts located in the housing, the contacts of the pair of contacts being mobile in relation to each other for opening and closing an electric circuit. The invention is characterized in that an open-pore metal foam (20) is interposed between at least one of the pairs of contacts and at least one housing opening (11), the metal foam being electrically insulated from the current-carrying elements of the circuit breaker (1). The invention further relates to the use ofan open-pore metal foam (20), produced of a zinc base alloy or aluminum base alloy, as a cooling structure for the dissipation of heat from switching gases that are produced by an electric switchingprocess.

Owner:SIEMENS AG

Surfacing welding electrode with anti liquid zinc and aluminium-containing zinc-base alloy corrosion

InactiveCN1528554AGood resistance to zinc liquid corrosionLow wettabilityArc welding apparatusWelding/cutting media/materialsRare earthRutile

The invention discloses a build-up welding rod resistant to the corrosion of liquid state Zn and Al-Zn based alloy, composed of rutile, marble, fluorite, feldspar, mica, Cr powder, silicon iron, ferromanganese, molybdenum-iron, aluminium iron, Ni powder, titanium pigment, ferrotitanium and rare earth. It heightens Si content (Si>2%), and adds in Cr to prohibit zinc-iron alloying reaction, increases Mn content to reduce the soakage of Zn liquid to steel base, and increases Ni and Cr to effectively reduce Al-Zn liquid containing zinc-iron alloying reaction. It reasonably selects Si, Mn, Ni, Cr, Mo, etc in the deposited metal to make the deposited metal have good Zn liquid corrosion resistance. It is applied to the corrosion resisting of 0-7% Al containing Zn liquid and liquid Zn based alloy. Its life of built-up welding layer is 3-50 times of low-carbon (C<0.03%), low silicon (Si<0.03%) steels.

Owner:陈冬

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com