Circuit breaker with switching gas cooling

A technology of circuit breakers and casings, applied in the field of circuit breakers, can solve problems such as the influence of circuit breaker manufacturing prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] about in figure 1 and figure 2 The conventional circuit breaker shown in has been described with reference to the prior art.

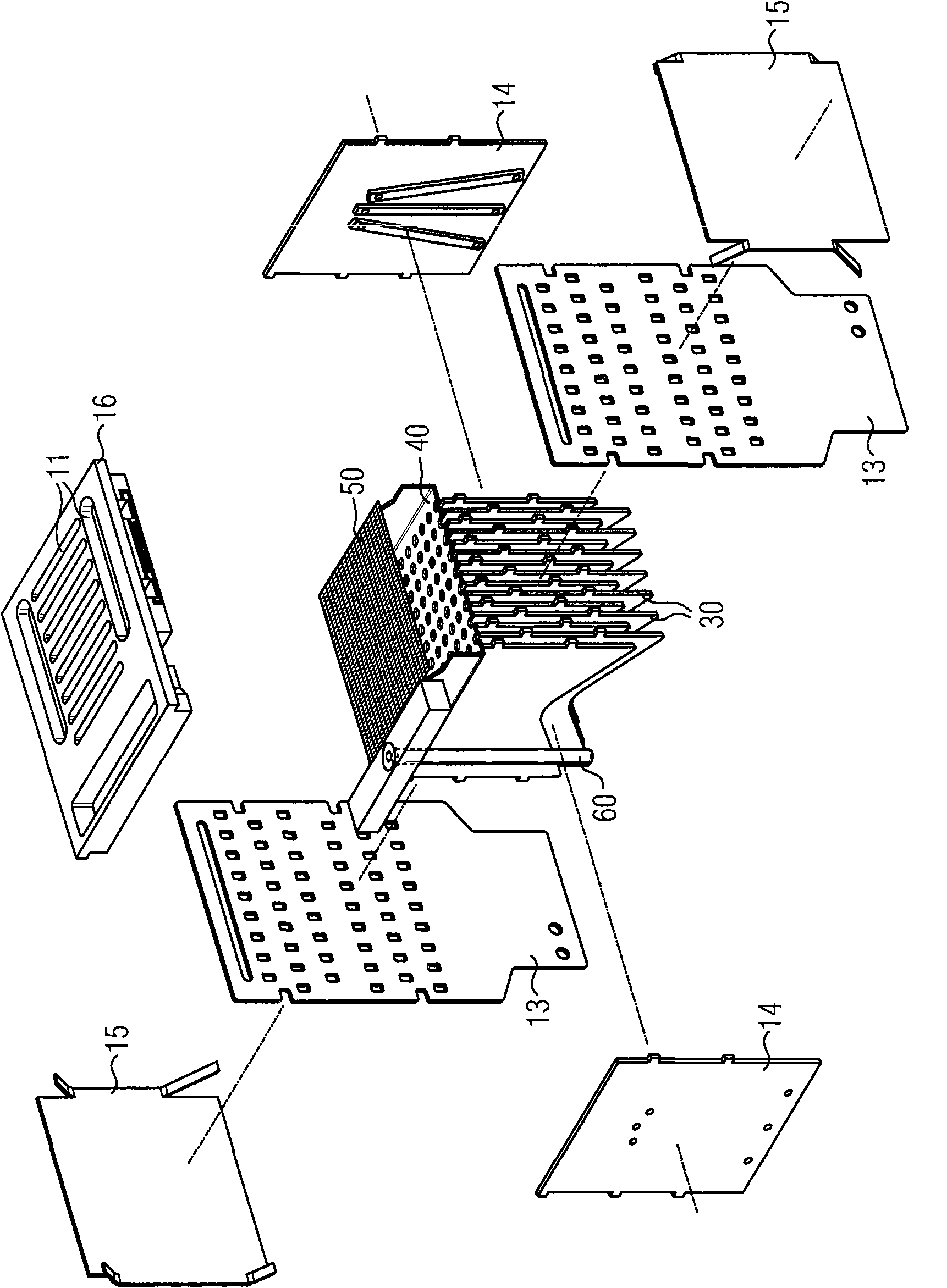

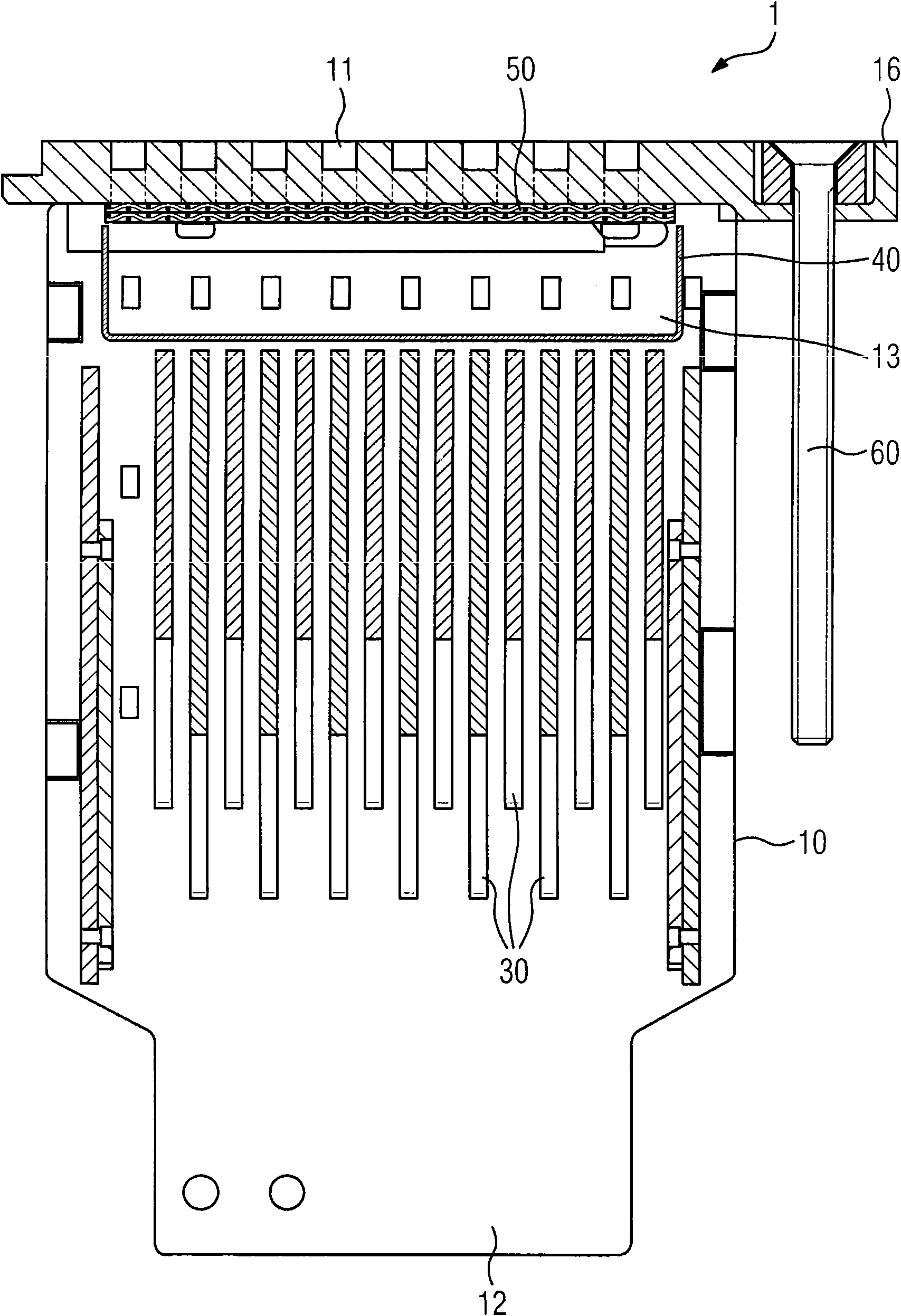

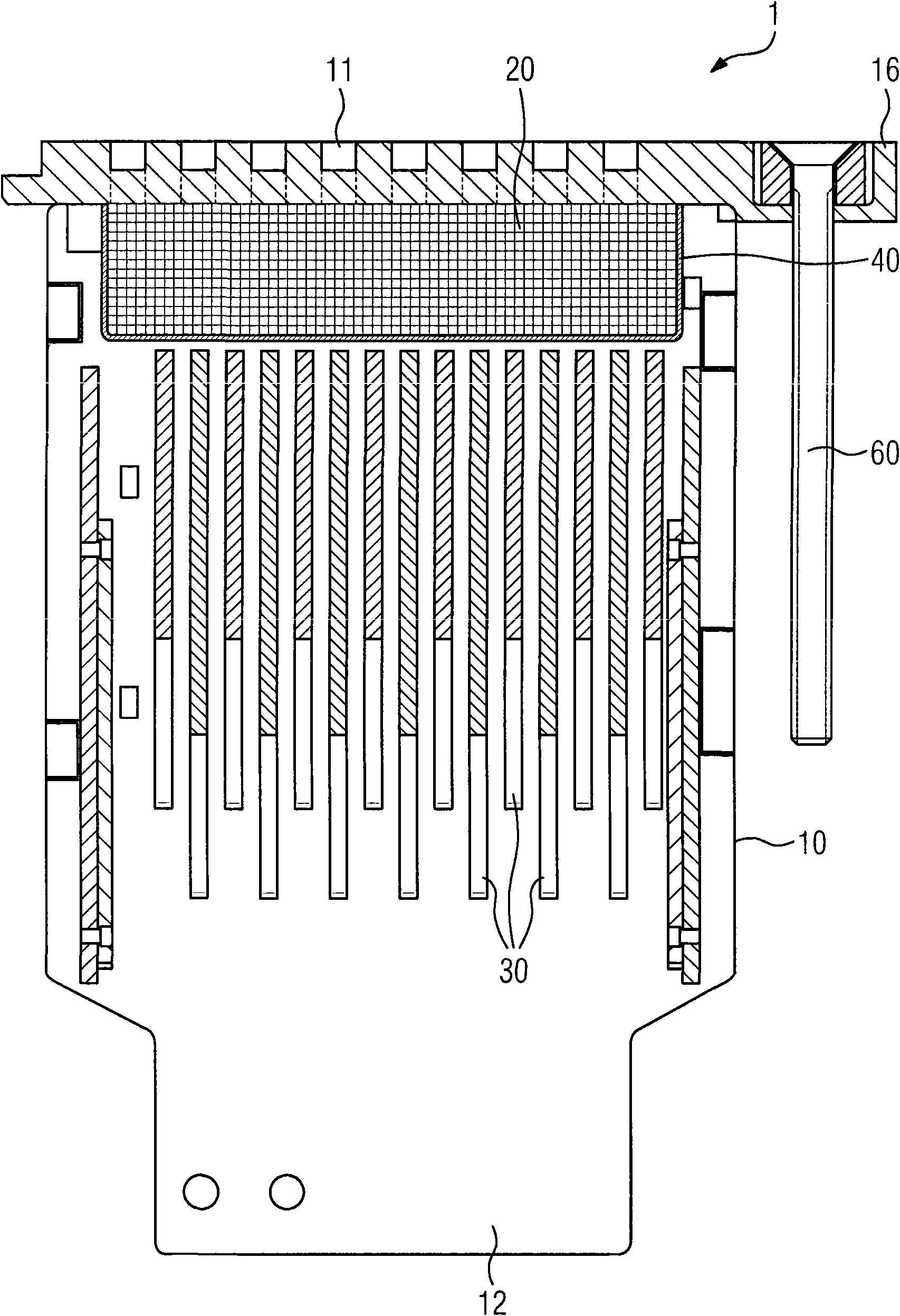

[0032] exist image 3 In the embodiment shown in , the external dimensions of the circuit breaker 1 according to the present invention are basically defined by the housing 10 and the top cover 16 fixed thereon, wherein the top cover 16 can be regarded as the housing constituting the surface of the circuit breaker a part of. The entire housing 10 is fastened via the cover 16 by means of fastening screws 60 , for example in the distribution system.

[0033] A switching chamber 12 is formed in the housing 10 of the circuit breaker 1 , in which the contacts (not shown) of the circuit breaker 1 which are movable relative to each other are arranged. Arranged parallel to one another above the switching chamber 12 are a plurality of arc extinguishing plates 30 which serve to reduce the arc that occurs between the contacts when the contacts are ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com