Alloy sacrificial anode film preventing stress corrosion cracking and preparation method thereof

A technology of stress corrosion cracking and sacrificial anode, applied in the field of alloy film, can solve the problem of no unified definition, and achieve the effect of good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

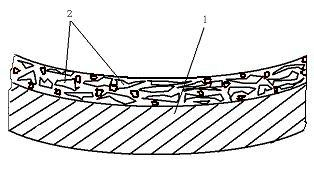

Image

Examples

Embodiment 1

[0057] Alloyed sacrificial anode film to prevent stress corrosion cracking, which contains aluminum, magnesium, titanium and rare earth elements in the zinc-based alloy, the weight percentage of each element in the zinc-based alloy is: zinc 84.022%, aluminum 14%, lanthanum 0.5% , cerium and praseodymium 0.4%, magnesium 1.0%, titanium 0.008%, iron and manganese 0.05%, carbon 0.02%.

[0058] Alloy production method: Add aluminum, magnesium, titanium and rare earth elements in batches according to different melting points in different order and time (according to the order of melting point from small to large, adding when reaching the melting point temperature) into the special smelting furnace, out of the furnace and pouring Make ingots into special molds, then heat preservation, constant temperature, and cooling in an inert gas environment, and then process them into rods of 8mm-12mm after reaching room temperature, and the rods are drawn into wires of φ2mm-3mm , the method of ...

Embodiment 2

[0061] An alloyed sacrificial anode film to prevent stress corrosion cracking, which contains aluminum, magnesium, titanium and rare earth elements in a zinc-based alloy. The weight percentage of each element in the zinc-based alloy is: zinc 83%, aluminum 15.335%, lanthanum 0.8% , cerium and praseodymium 0.2%, indium 0.05%, magnesium 0.5%, titanium 0.025%, iron and manganese 0.08%, carbon 0.01%.

[0062] Alloy manufacturing method and coating thermal spraying method are as in Example 1.

Embodiment 3

[0064] An alloyed sacrificial anode film to prevent stress corrosion cracking, which contains aluminum, magnesium, titanium and rare earth elements in a zinc-based alloy. The weight percentage of each element in the zinc-based alloy is: zinc 83.714%, aluminum 14.5%, lanthanum 0.3% , cerium and praseodymium 0.6%, indium 0.03%, magnesium 0.8%, titanium 0.018%, iron and manganese 0.03%, carbon 0.008%.

[0065] Alloy manufacturing method and coating thermal spraying method are as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com