Method and system for operating molten carbonate fuel cells

A technology of molten carbonate and fuel cells, which is used in molten electrolyte fuel cells, fuel cells, fuel cell additives, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

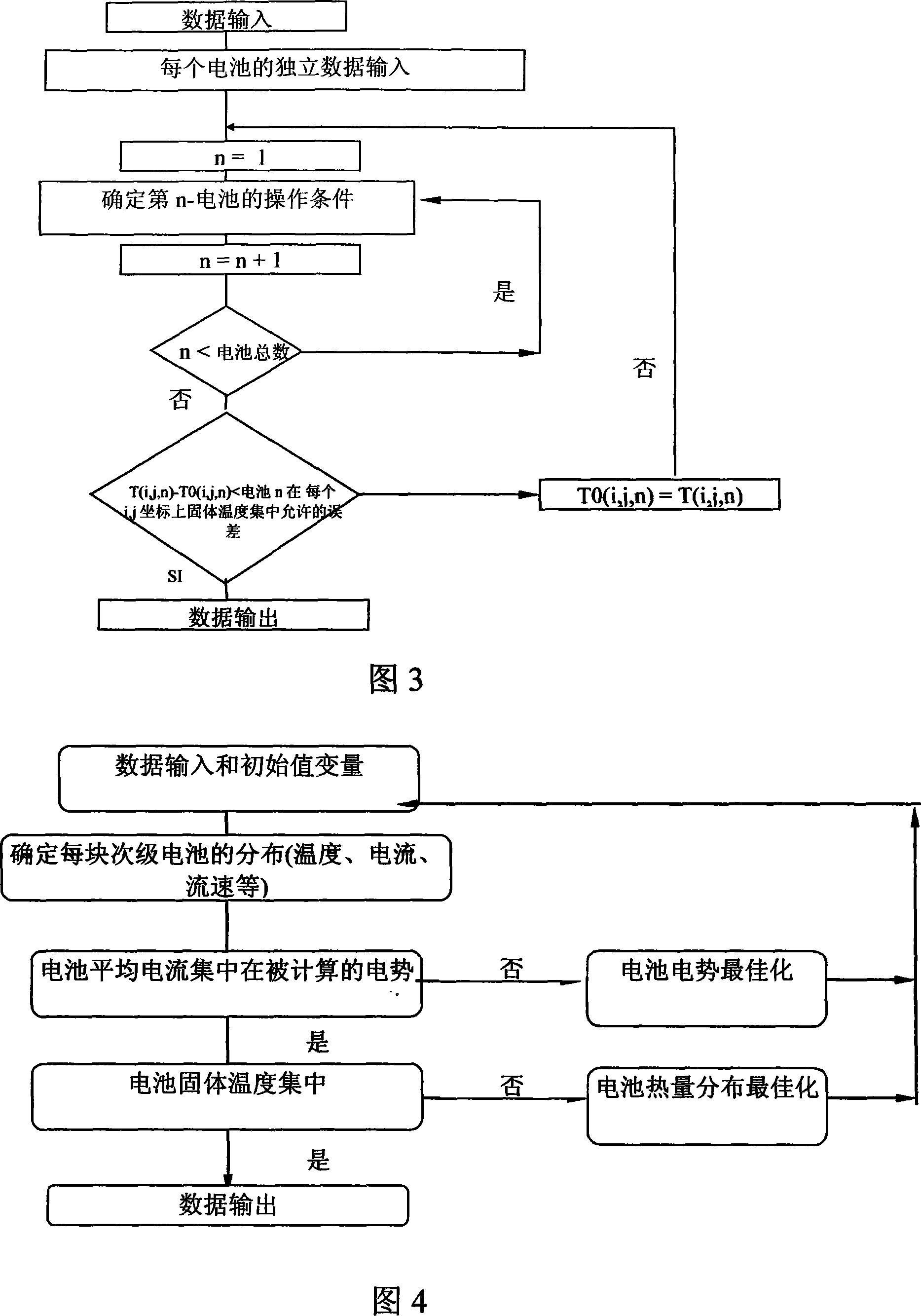

[0045] From an electrochemical point of view, molten carbonate fuel cells are innovative reactors because the chemical energy of the filled fuel is directly converted into electrical energy in the reactor. At the same time, they also have the characteristics of high yield and low environmental pollution. In order to develop a method for optimizing the performance of molten carbonate fuel cells, three steps must be passed:

[0046] 1. Evaluation of the experimental values of the tested molten carbonate fuel cells;

[0047] 2. Evaluation of local chemical, physical and electrical conditions;

[0048] Optimization of operating conditions based on obtained results and special operating constants.

[0049] The method employs steps outlined in the flowchart of Figure 16 and the following scheme:

[0050] Phase I: Evaluation of Experimental Values

[0051] The determination of the reference experimental values concerning the battery kinetics and electrochemical properties was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com