Water electrolysis gas production device and method

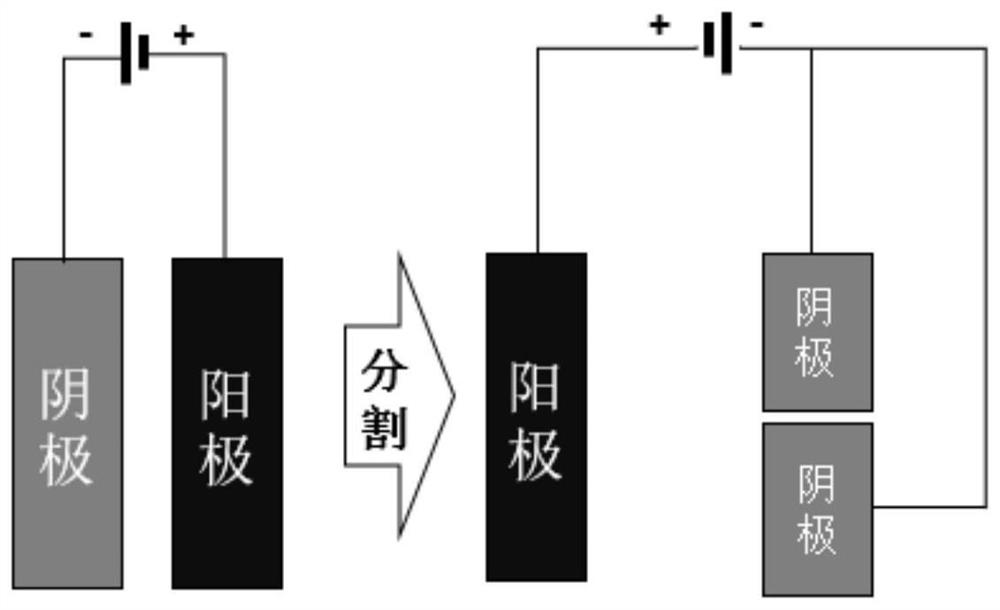

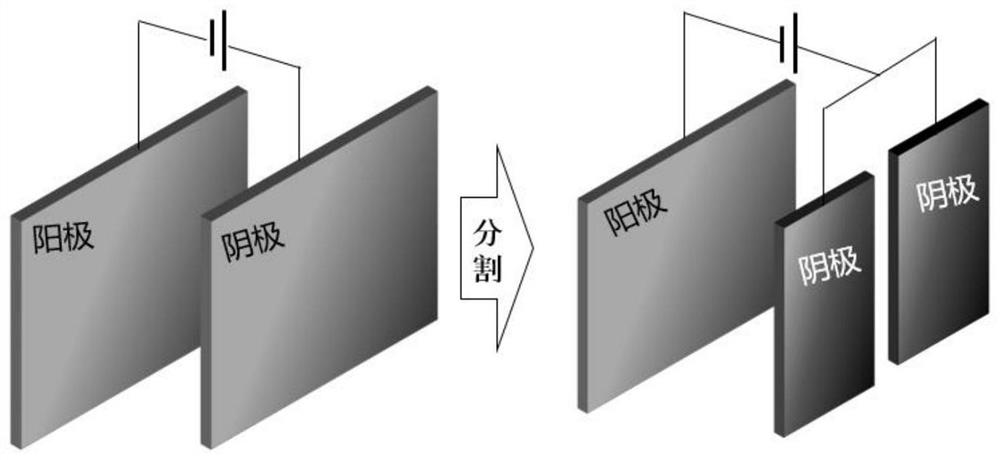

A technology for electrolyzing water and gas devices, which is applied in the electrolysis process, electrolysis components, cells, etc., and can solve problems such as increased pressure difference of the diaphragm, high pressure in the cathode electrolysis chamber, and rupture of the diaphragm.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

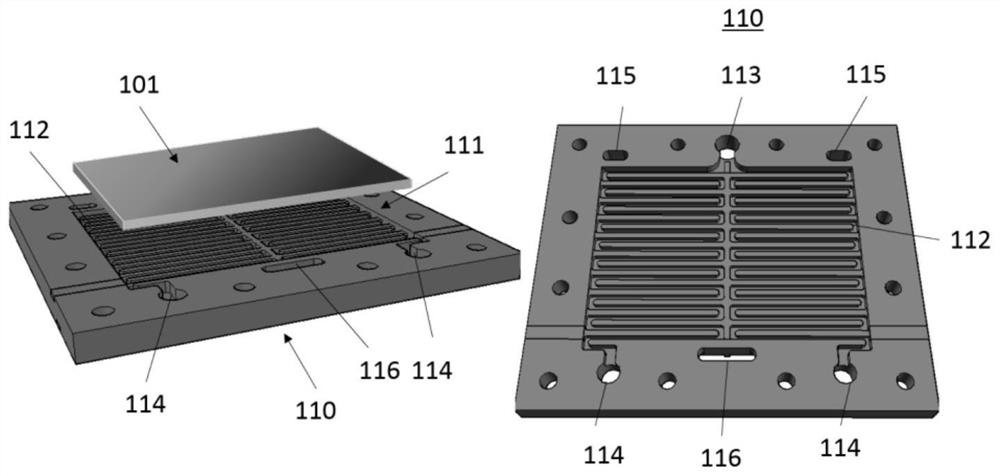

[0107] like image 3 , 4 and Image 6 As shown, the electrolyzed water gas generating device 10 provided in this embodiment includes a plurality of electrolyzed water gas generating units 100 connected in series. Specifically, it includes a first electrolyzed water gas generating unit 100a, a second electrolyzed water gas generating unit 100c, and a middle electrolyzed water gas generating unit 100b.

[0108] like Figure 7 As shown, two adjacent electrolyzed water gas generating units 100 connected in series are connected to the anode plate 110 through their respective cathode plates 120 , and are integrally formed into a bipolar plate 105 . That is, one side of the bipolar plate 105 has the same structure as the cathode plate 120 , and the other side has the same structure as the anode plate 110 . This arrangement is convenient for assembling a plurality of electrolyzed water gas generating units 100 into one body. The structure of the device obtained after assembly is ...

no. 2 example

[0120] This embodiment is basically the same as the first embodiment, the difference is only in the location of the electrolyte inlet pipe and outlet pipe, and the structure of the first electrolyzed water gas generating unit 100a and the second electrolyzed water gas generating unit 100c.

[0121] like Figure 9 and Figure 10 As shown, in the device provided in this embodiment, two catholyte water outlet pipes 106, one catholyte water inlet pipe 107, two anolyte water inlet pipes 108, and one anolyte water outlet pipe 109 are all arranged on a bipolar plate 105 on the peripheral wall, the bipolar plate 105 is named as the middle plate 150, and the structure of the middle plate 150 is as follows Figure 11 shown.

[0122] The anolyte outlet 113 , the anolyte inlet 114 , the first through hole 115 and the second through hole 116 are not provided on the anode plate 110 of the first electrolyzed water gas generating unit 100 a. The catholyte outlet 123 , the catholyte inlet 1...

no. 3 example

[0124] This embodiment is basically the same as the first embodiment, the difference is only in the location of the electrolyte inlet pipe and outlet pipe, and the structure of the first electrolyzed water gas generating unit 100a and the second electrolyzed water gas generating unit 100c.

[0125] like Figure 12 and Figure 13 As shown, in the device provided in this embodiment, two catholyte outlet pipes 106 and one anolyte outlet pipe 109 are arranged on the anode plate of the first electrolyzed water gas generating unit 100a, and the first electrolyzed water gas generating unit 100a The anode plate 110 is not provided with an anolyte inlet 114 and a second through hole 116 . Two anolyte water inlet pipes 108 and one catholyte water inlet pipe 107 are arranged on the cathode plate 120 of the second electrolyzed water gas production unit 100c, and the cathode plate 120 is not provided with the catholyte outlet 123 and the fourth through hole 126.

[0126] It should be no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com