Patents

Literature

583 results about "Corrosion resistant alloy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A corrosion-resistant alloy (CRA) is an alloy consisting of metals such as: When combined, such metals can promote corrosion resistance more than other components like carbon steel. This type of alloy offers reliable protection from corrosion, eradicating the need for expensive maintenance and repair.

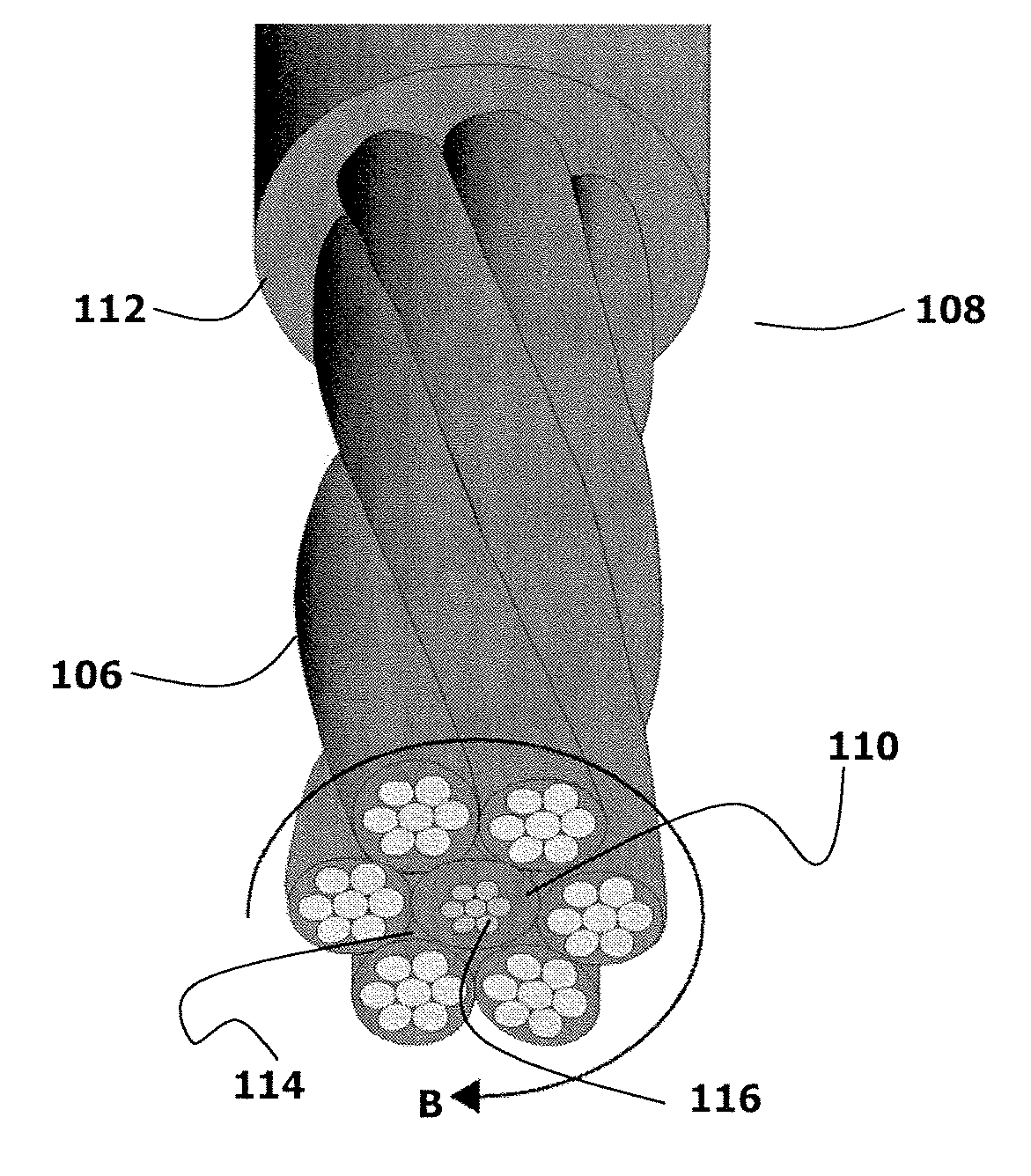

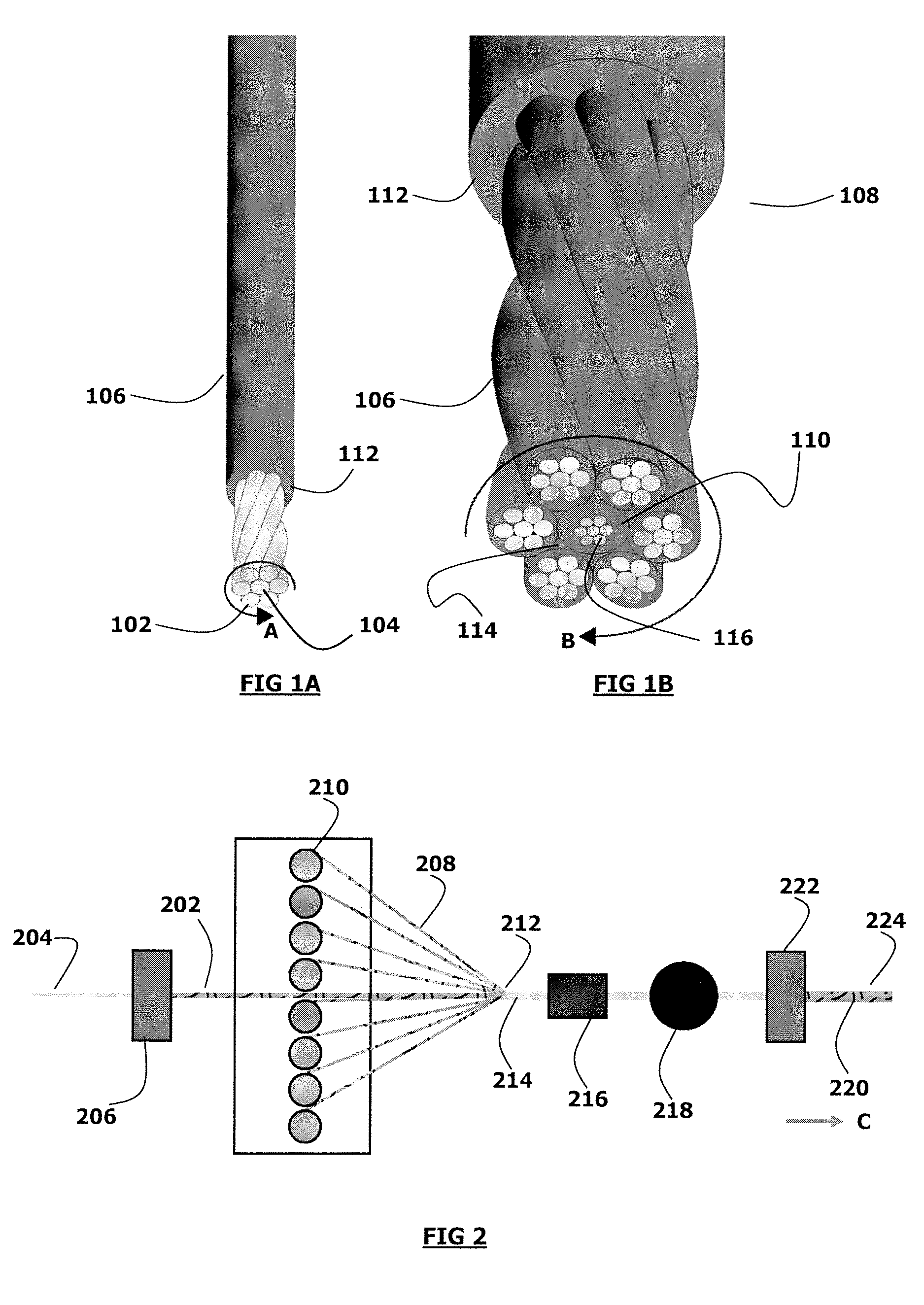

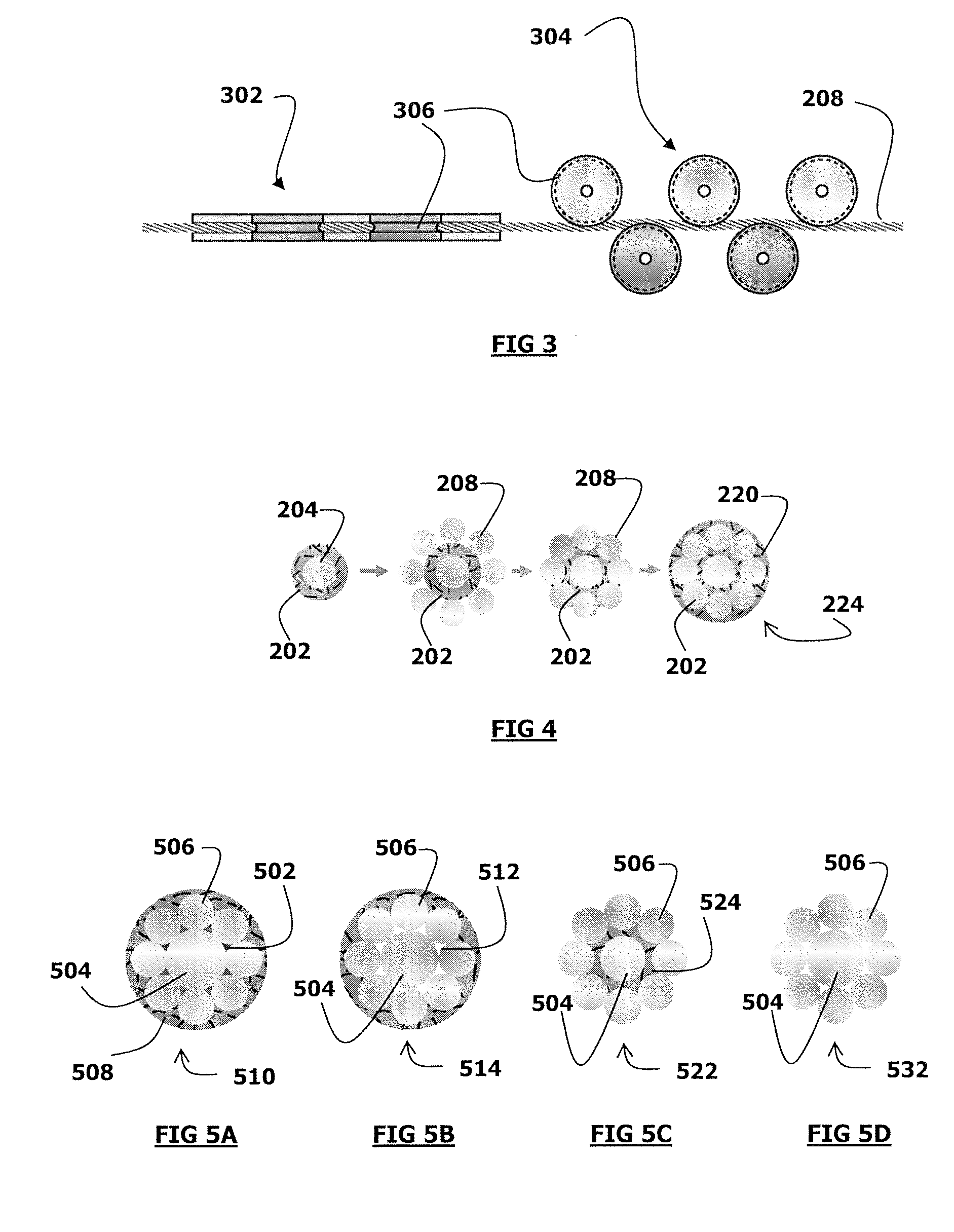

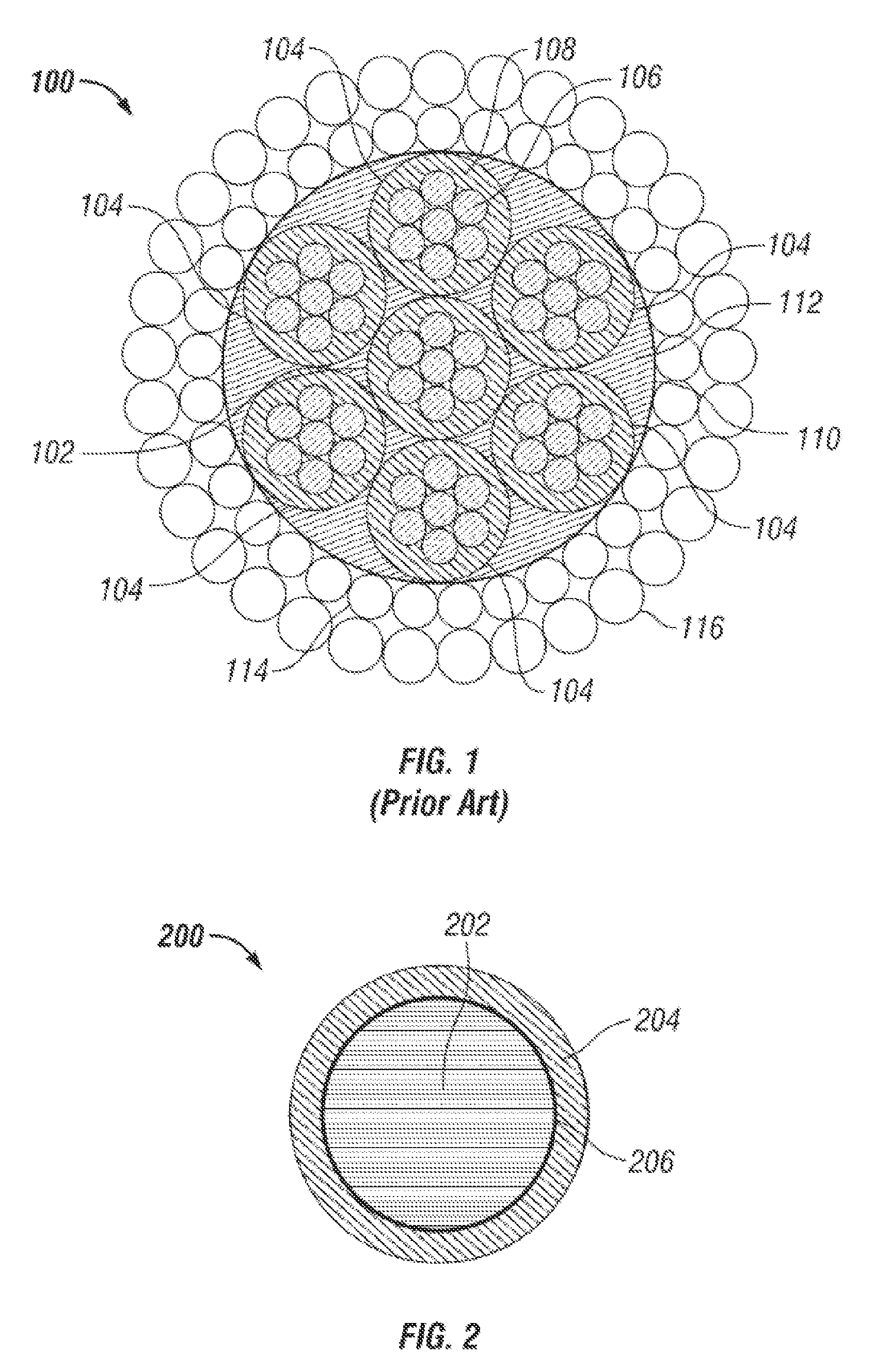

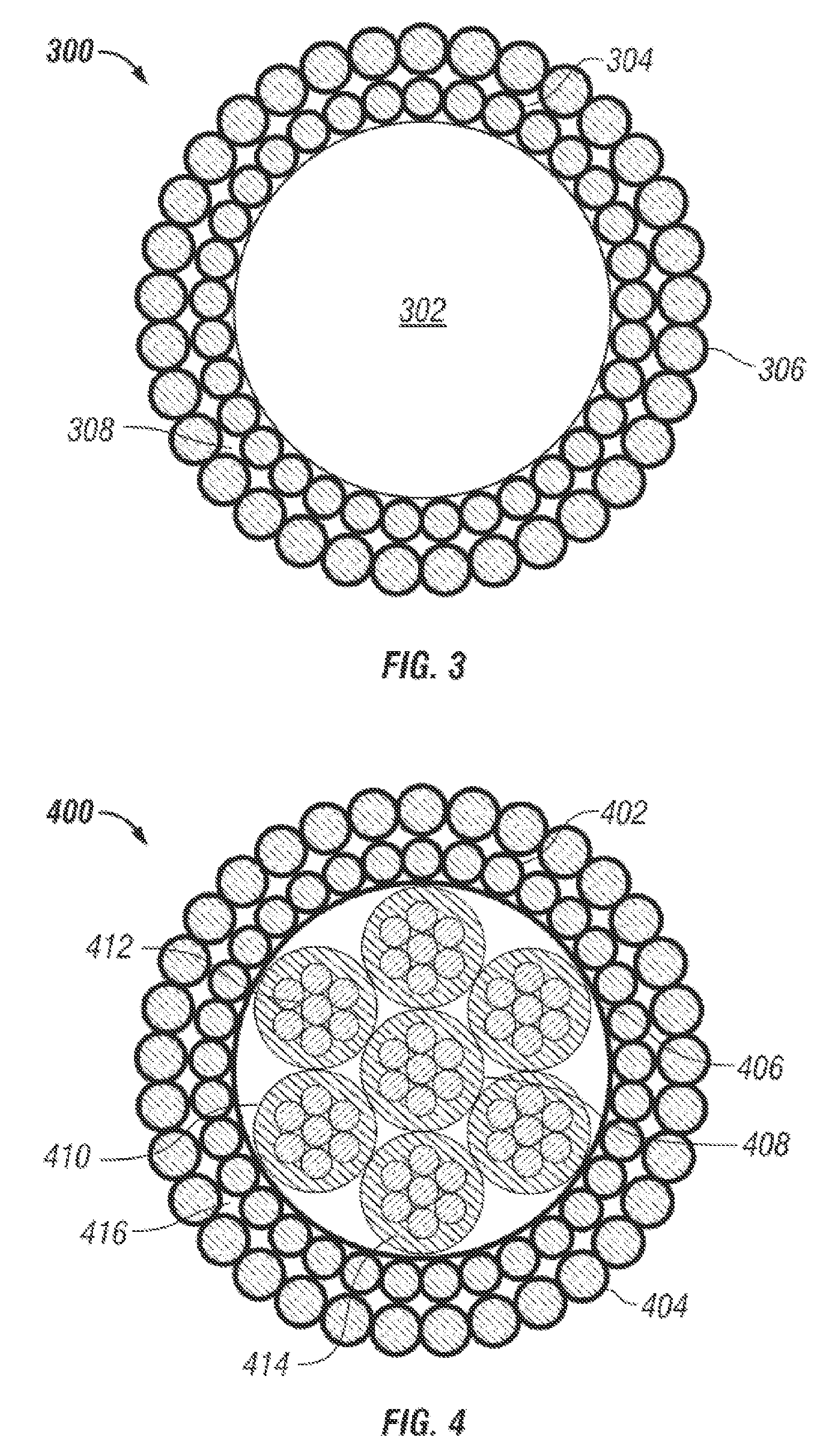

Cables with stranded wire strength members

ActiveUS7326854B2Improve corrosion resistancePrevent and minimize dangerous gas migrationNon-insulated conductorsPower cables with screens/conductive layersCorrosion resistant alloyCoaxial cable

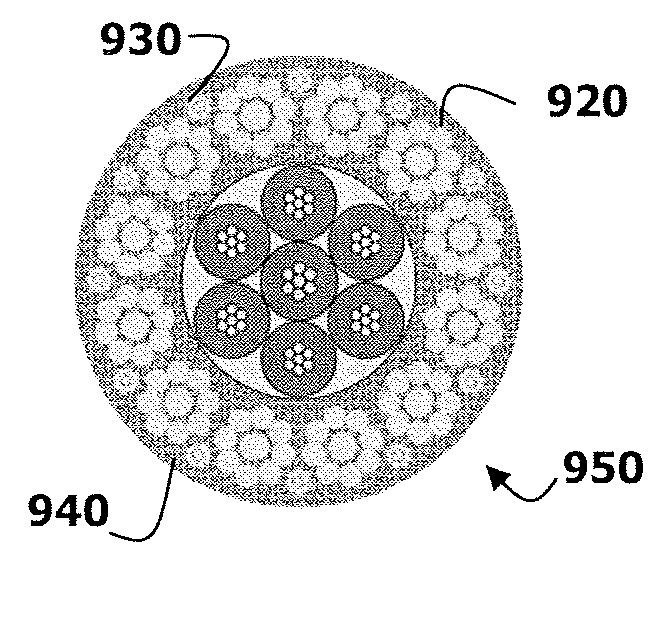

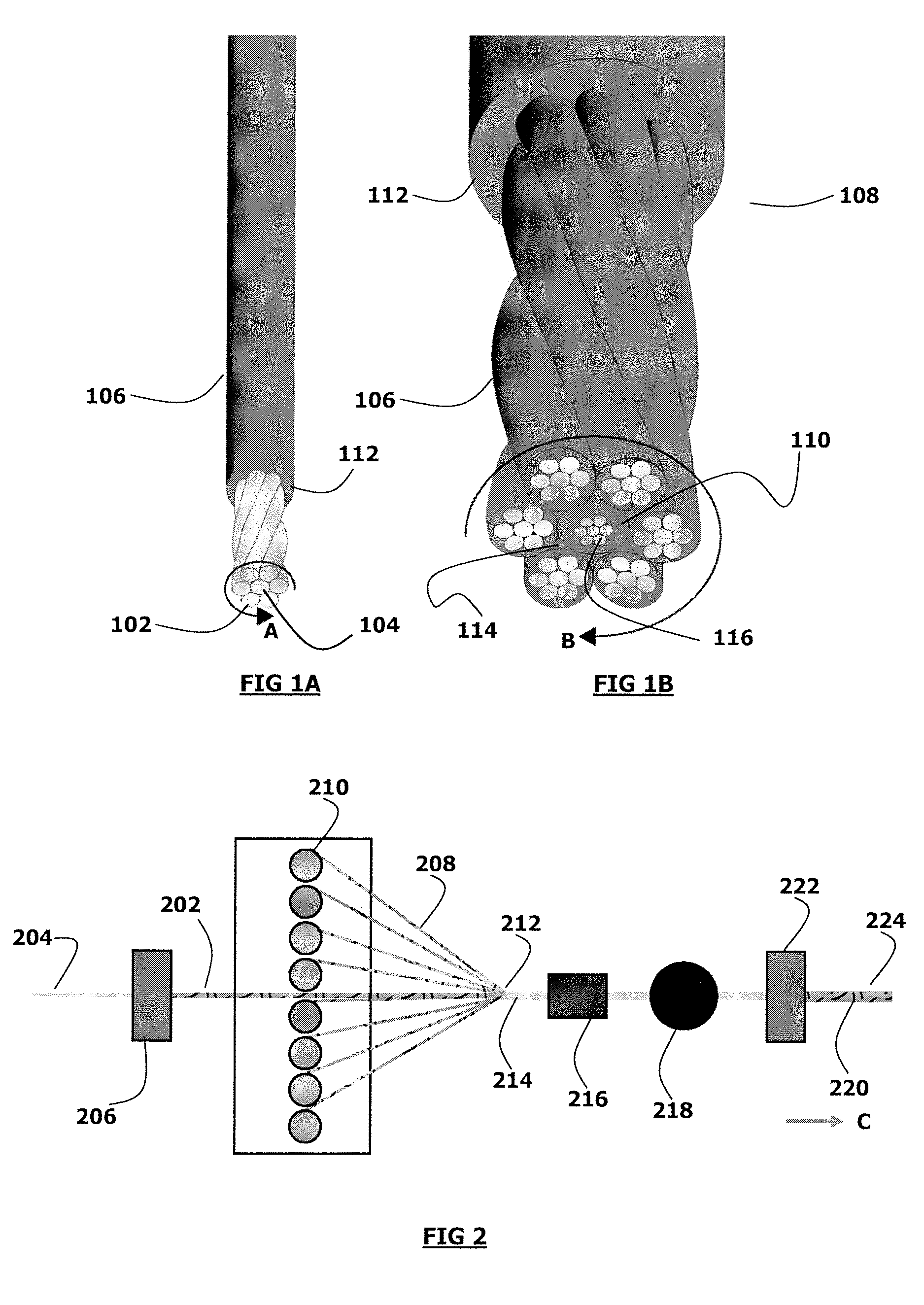

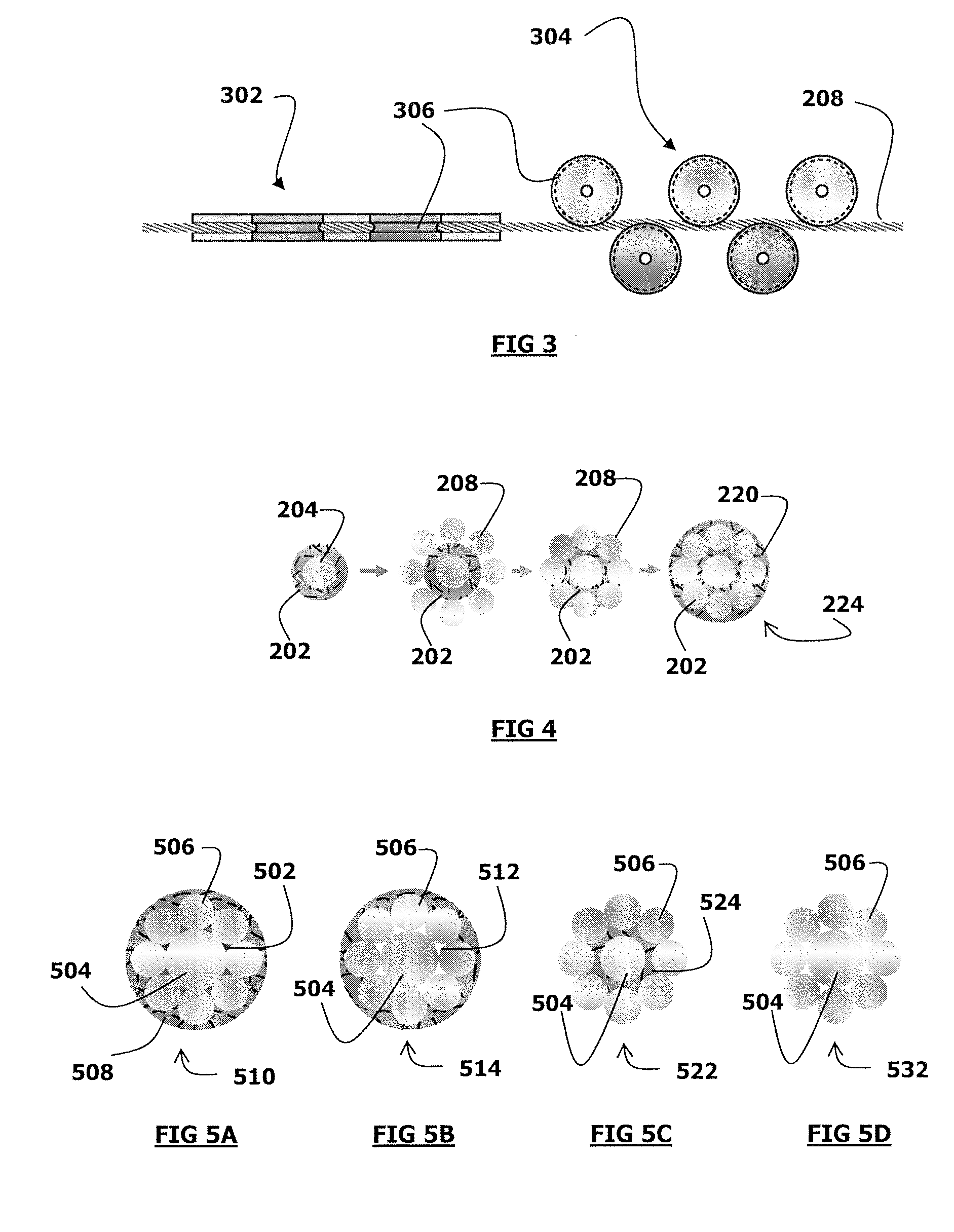

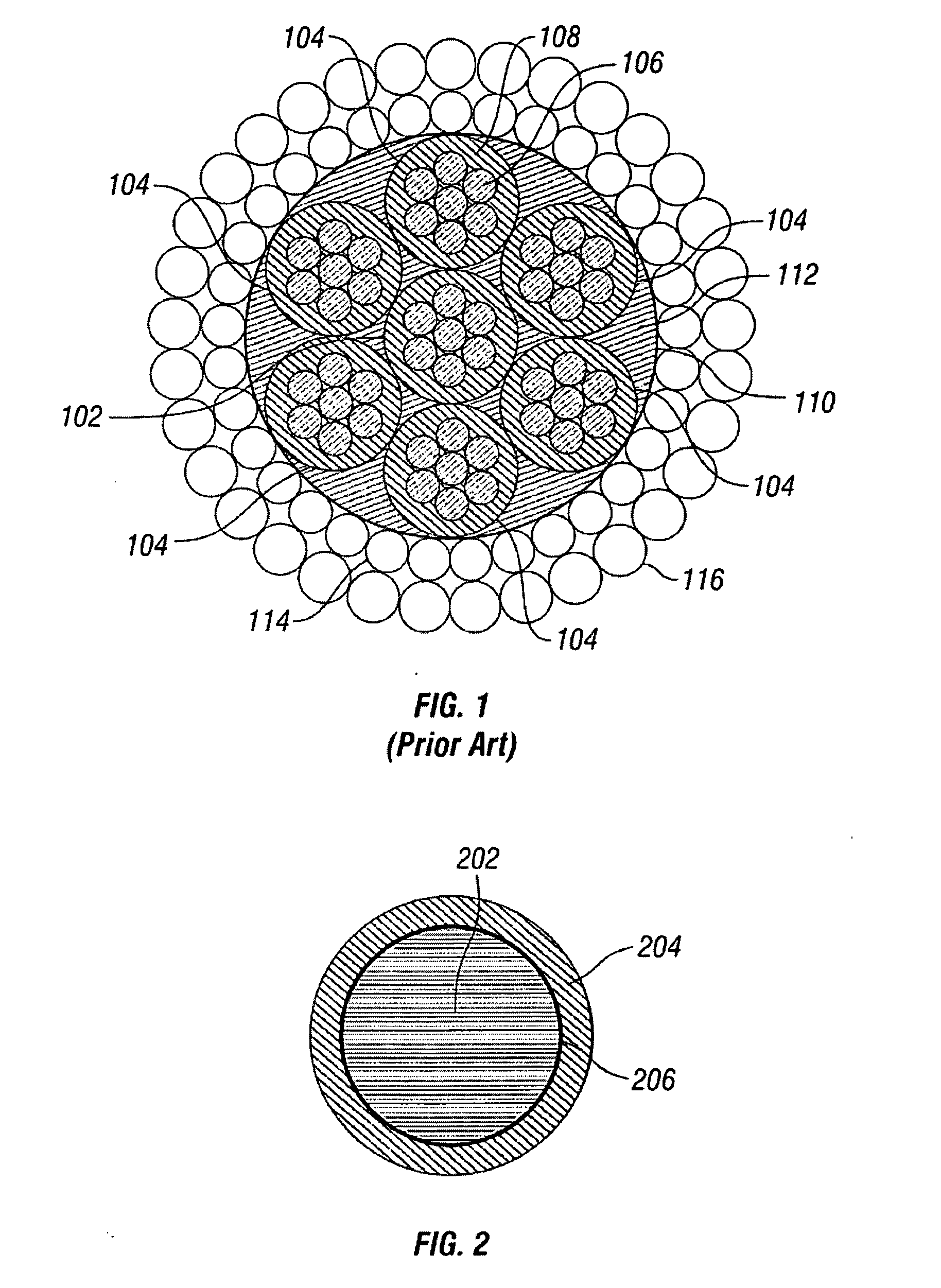

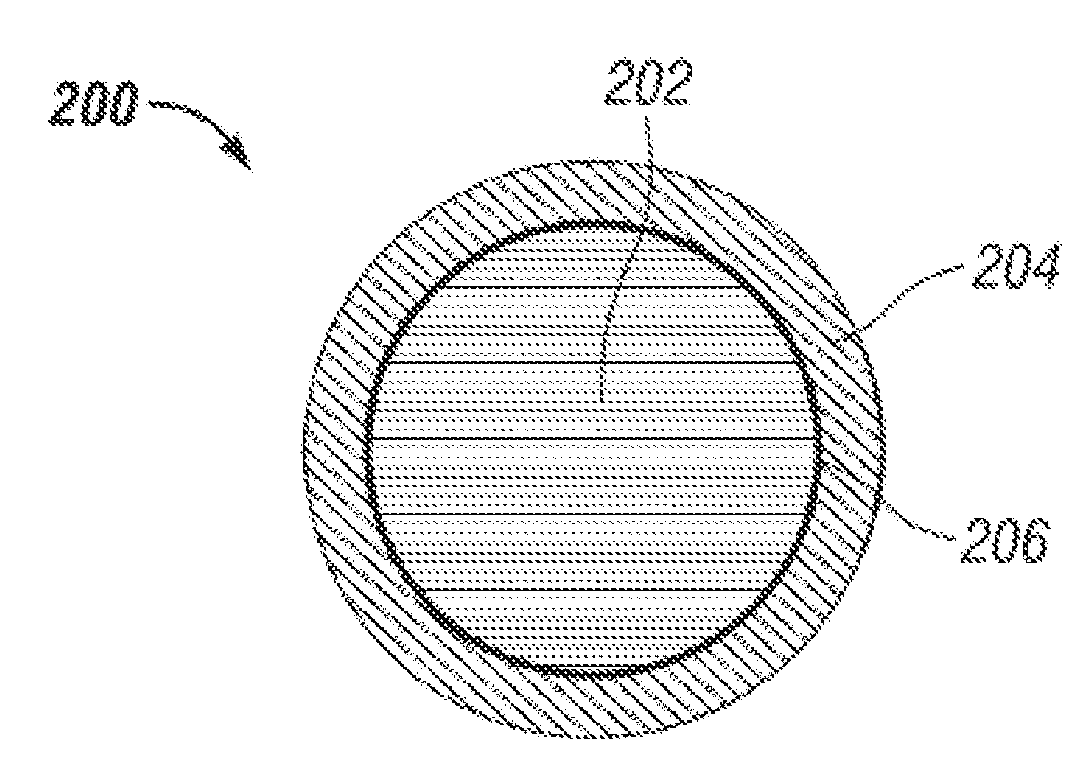

High strength cables formed from strength members. The strength members are formed from bimetallic filament wires which may be encased within a jacket of polymeric material. The bimetallic filament wires wherein the filaments include a high strength core and a corrosion resistant alloy clad forming the outer layer of the filament. The strength members may be used individually, as a central strength member, or even layered around a central axially positioned component or strength member, to form a layer of strength members. Cables of the invention may be of any practical design, including monocables, coaxial cables, quadcables, heptacables, slickline cables, multi-line cables, suspension cables, and the like.

Owner:SCHLUMBERGER TECH CORP

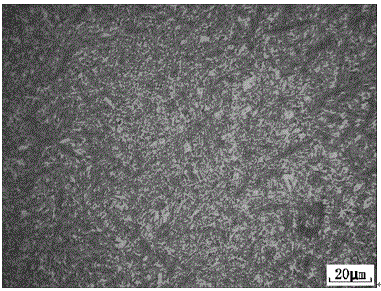

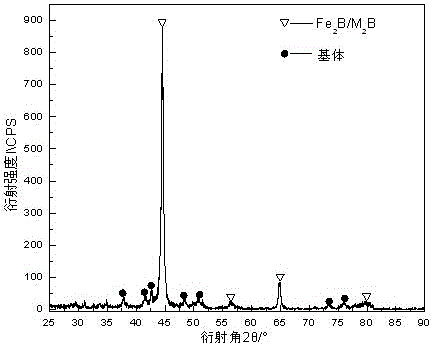

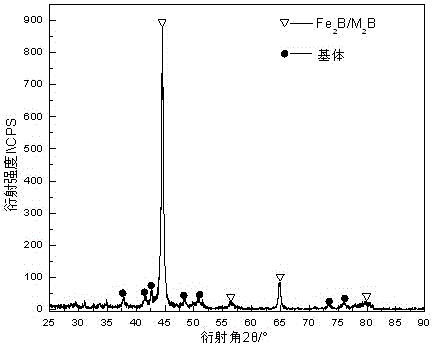

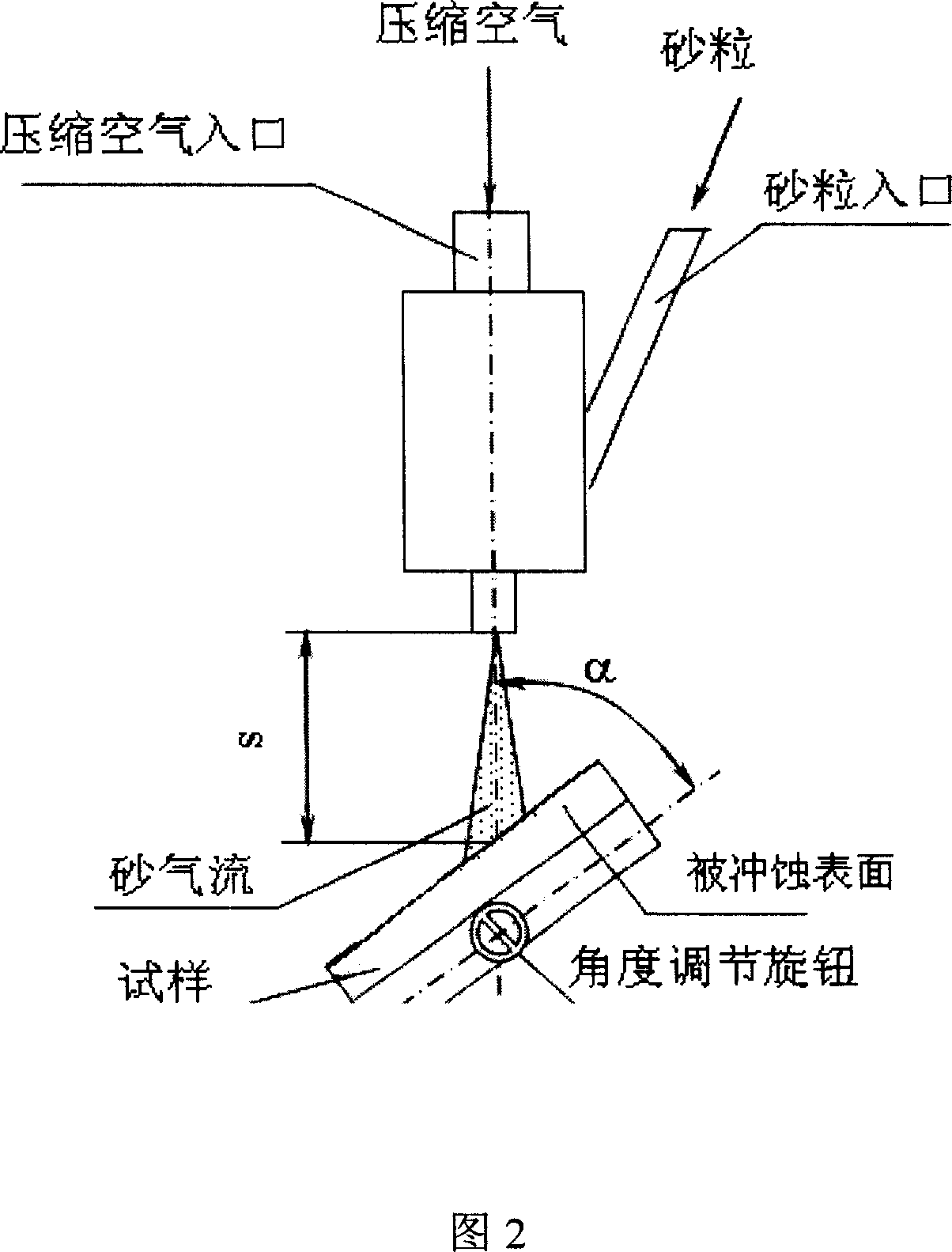

An amorphous/nanocrystalline matrix high-hardness wear-resistant and corrosion-resistant alloy and its preparation method

The invention provides a high-hardness, wear-resistant and corrosion-resistant alloy of an amorphous / nanocrystal matrix and a preparation method of the high-hardness, wear-resistant and corrosion-resistant alloy. The high-hardness, wear-resistant and corrosion-resistant alloy of the amorphous / nanocrystal matrix comprises the following elements in percentages by mass: 9.0-12.0 of Cr, 2.6-2.9 of B, 0.7-0.9 of C, 0.4-0.8 of Nb, 0.4-0.8 of V, less than 0.3 of Mn, less than 0.07 of Si, less than or equal to 0.01 of S and P, and the balance of Fe, wherein the sum of C and B is 3.3-3.6; the content ratio of C / Cr is 0.06-0.08; and the sum of Nb and V is 0.5-1.0. Through multi-component alloying, an eutectic composition is formed, the melting point is low, fluidity is good, requirements of a casting technology are simple, large wear-resistant and corrosion-resistant castings can be cast, and small precision wear-resistant and corrosion-resistant castings can also be produced. The hardness of the alloy is HRC66-70, and impact toughness of the alloy is 4-9 J / cm (2).

Owner:广州市信纳德生物科技有限公司

Cables with stranded wire strength members

ActiveUS20070044991A1Improve corrosion resistancePrevent and minimize dangerous gas migrationNon-insulated conductorsPower cables with screens/conductive layersCorrosion resistant alloyCoaxial cable

High strength cables formed from strength members. The strength members are formed from bimetallic filament wires which may be encased within a jacket of polymeric material. The bimetallic filament wires wherein the filaments include a high strength core and a corrosion resistant alloy clad forming the outer layer of the filament. The strength members may be used individually, as a central strength member, or even layered around a central axially positioned component or strength member, to form a layer of strength members. Cables of the invention may be of any practical design, including monocables, coaxial cables, quadcables, heptacables, slickline cables, multi-line cables, suspension cables, and the like.

Owner:SCHLUMBERGER TECH CORP

Ultra pure electroslag remelting method for high-performance corrosion resistant alloy

ActiveCN102912151AImprove performanceImprove organizationIncreasing energy efficiencyCorrosion resistant alloySolution treatment

The invention relates to an ultra pure electroslag remelting method for a high-performance corrosion resistant alloy, and the method comprises the following steps of: preparing the following ingredient components of a self-fluxing electrode bar in parts by weight: 25-34 parts of Ni, 25-29 parts of Cr, 2.5-4.5 parts of Mo and 30-45 parts of Fe, and carrying out vacuum induction melting, so as to obtain the self-fluxing electrode bar; slowly melting the self-fluxing electrode bar in melted electroslag remelting slag charge comprising the following components in parts by weight: 55-80 parts of CaF2, 5-25 parts of CaO, 5-15 parts of Al2O3 and 5-10 parts of MgO, purifying, and recrystallizing in a crystallizer, so as to obtain an electroslag ingot; and forging the electroslag ingot into a bar material at the temperature of 1130+ / -5 DEG C, and carrying out solution treatment, so that the high-performance corrosion resistant alloy is obtained. By utilizing the ultra pure electroslag remelting method provided by the invention, the content of harmful elements such as sulphur and phosphorus in the alloy can be reduced, the impurity distribution of the alloy is improved, fining of structure can be facilitated, and the hot workability and yield of the alloy can be improved.

Owner:CHONGQING MATERIALS RES INST

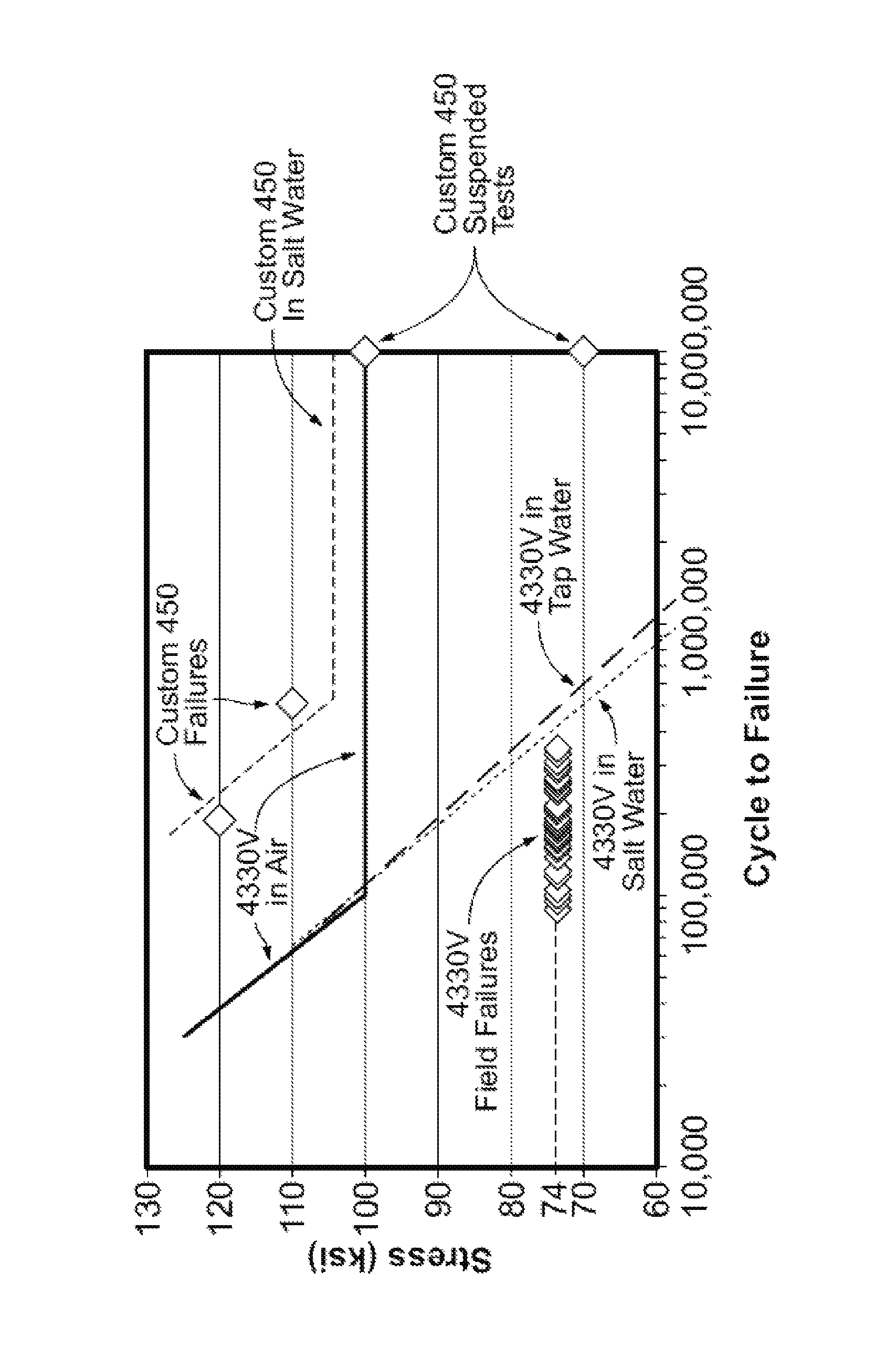

Corrosion resistant fluid end for well service pumps

ActiveUS9435333B2Positive displacement pump componentsFlexible member pumpsCorrosion resistant alloyWorking pressure

Corrosion resistant alloys in fluid ends to prolong the life of a well service pump. Methods of using such corrosion resistant alloys that provide a fluid end that has a corrosion resistant alloy having a fatigue limit greater than or equal to the tensile stress on the fluid end at maximum working pressure in the fluid end for an aqueous-based fluid; installing the fluid end in a well service pump; and pumping the aqueous-based fluid through the fluid end.

Owner:HALLIBURTON ENERGY SERVICES INC

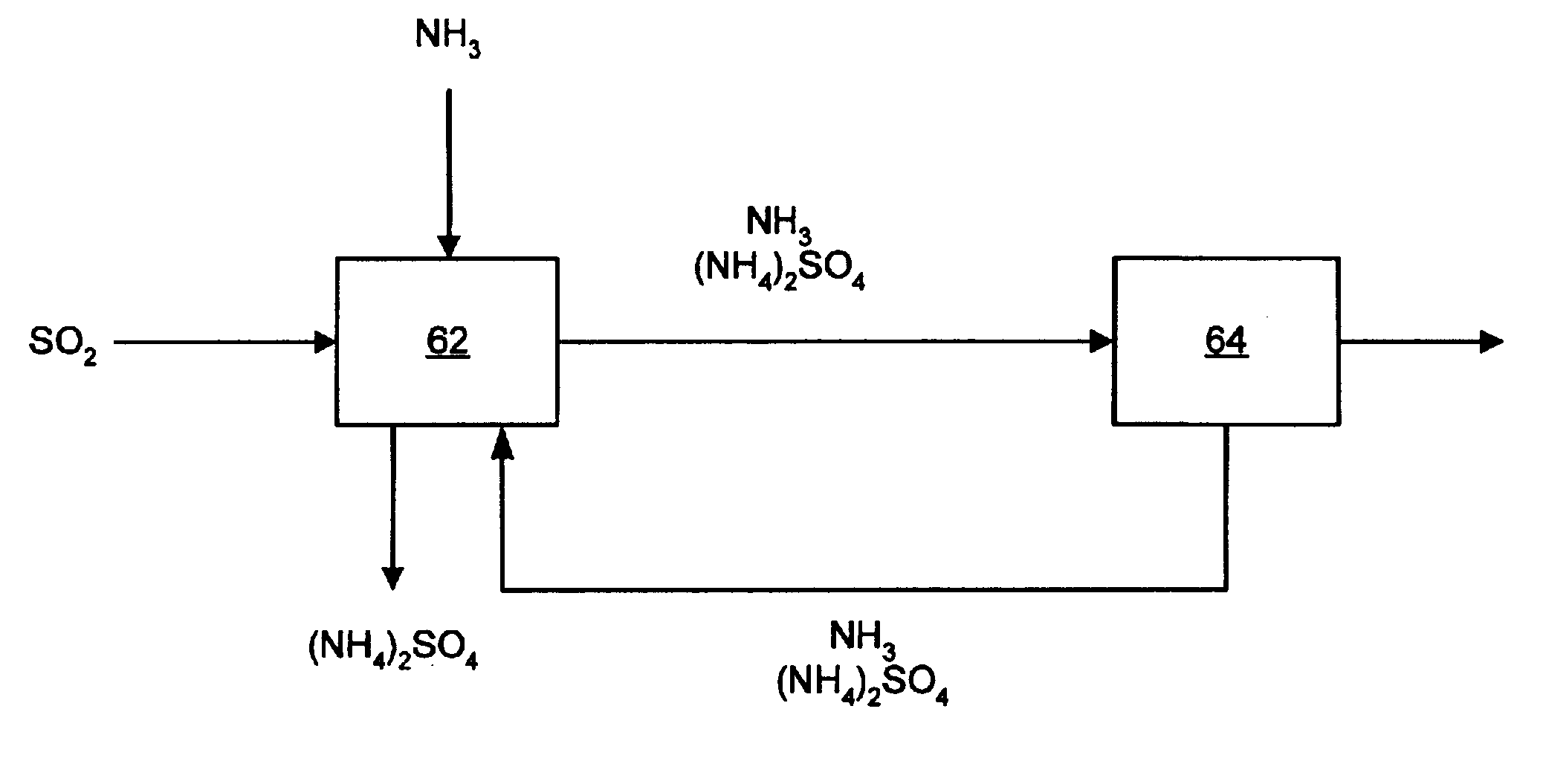

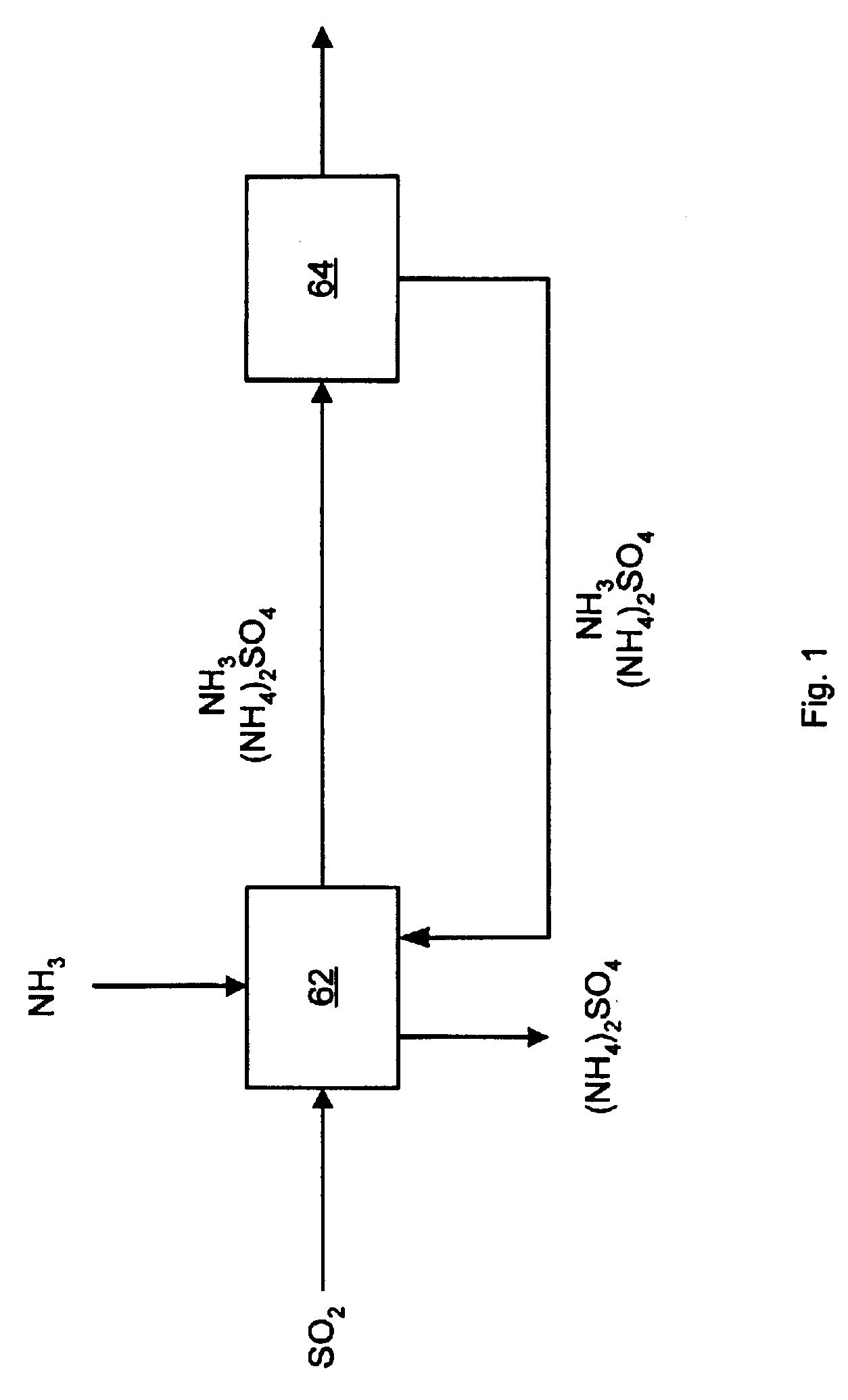

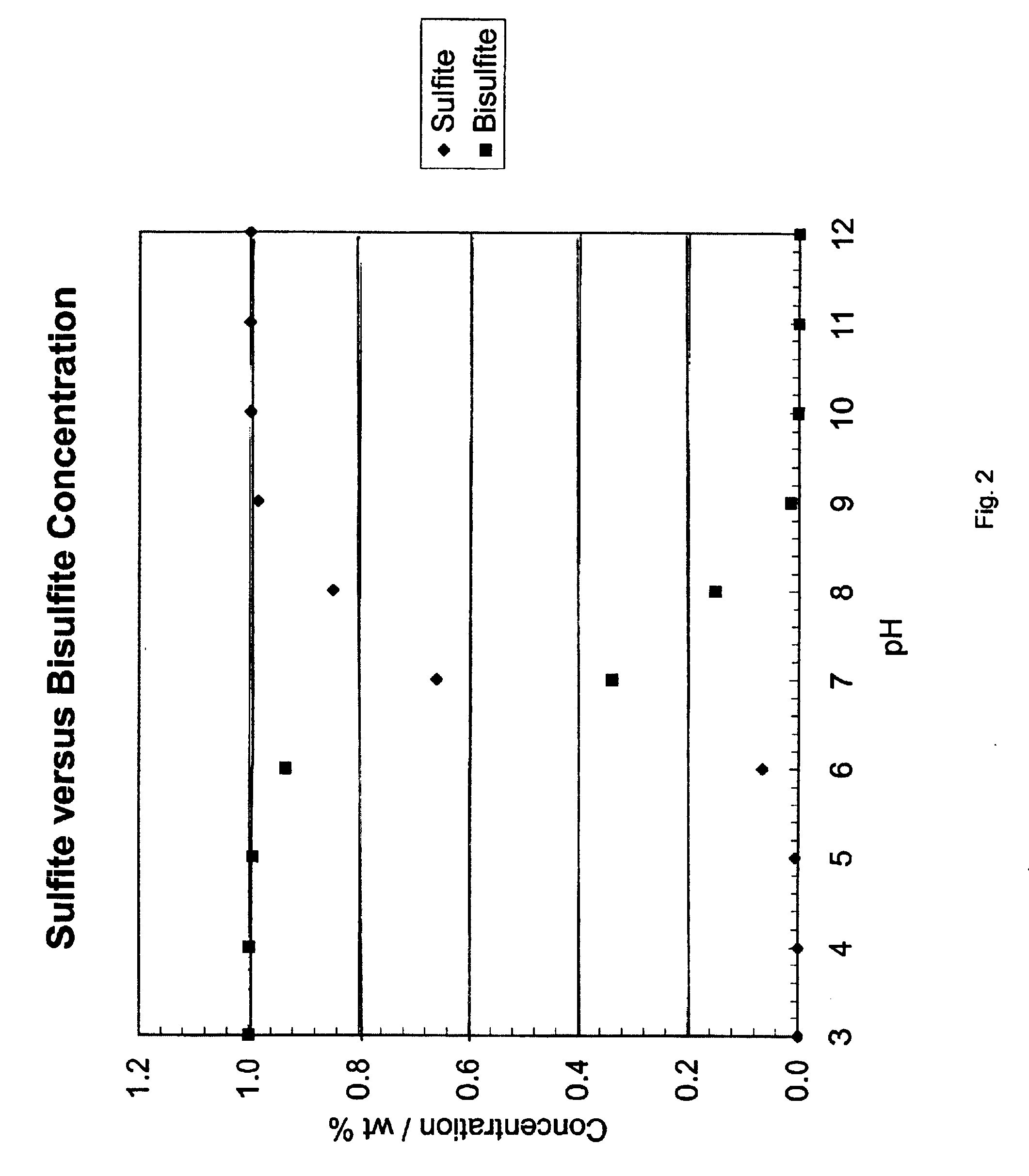

Sulfur dioxide removal using ammonia

InactiveUS6605263B2Small sizeImprove efficiencyCombination devicesAmmonium sulfatesCorrosion resistant alloySulfite

Owner:POWERSPAN CORP

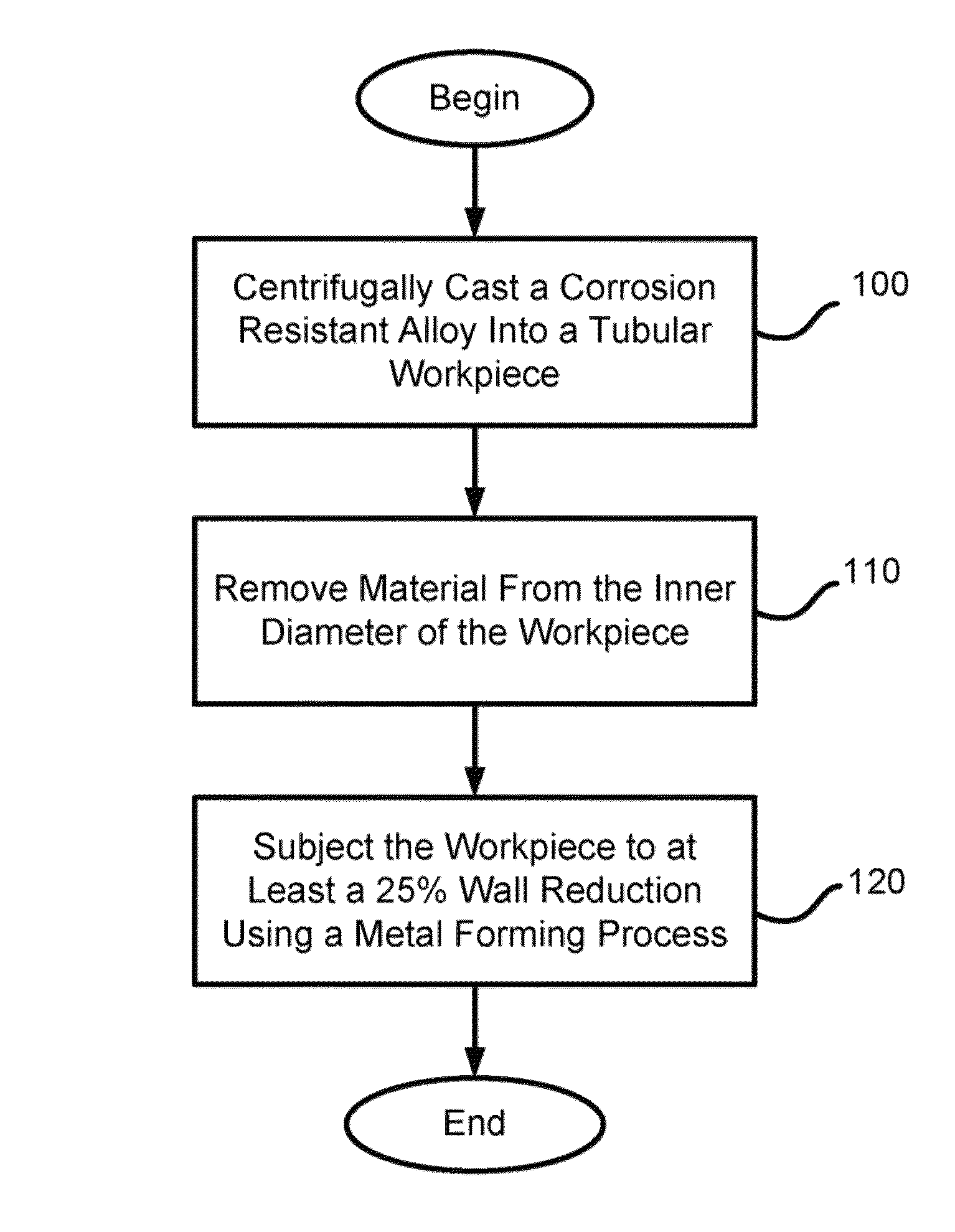

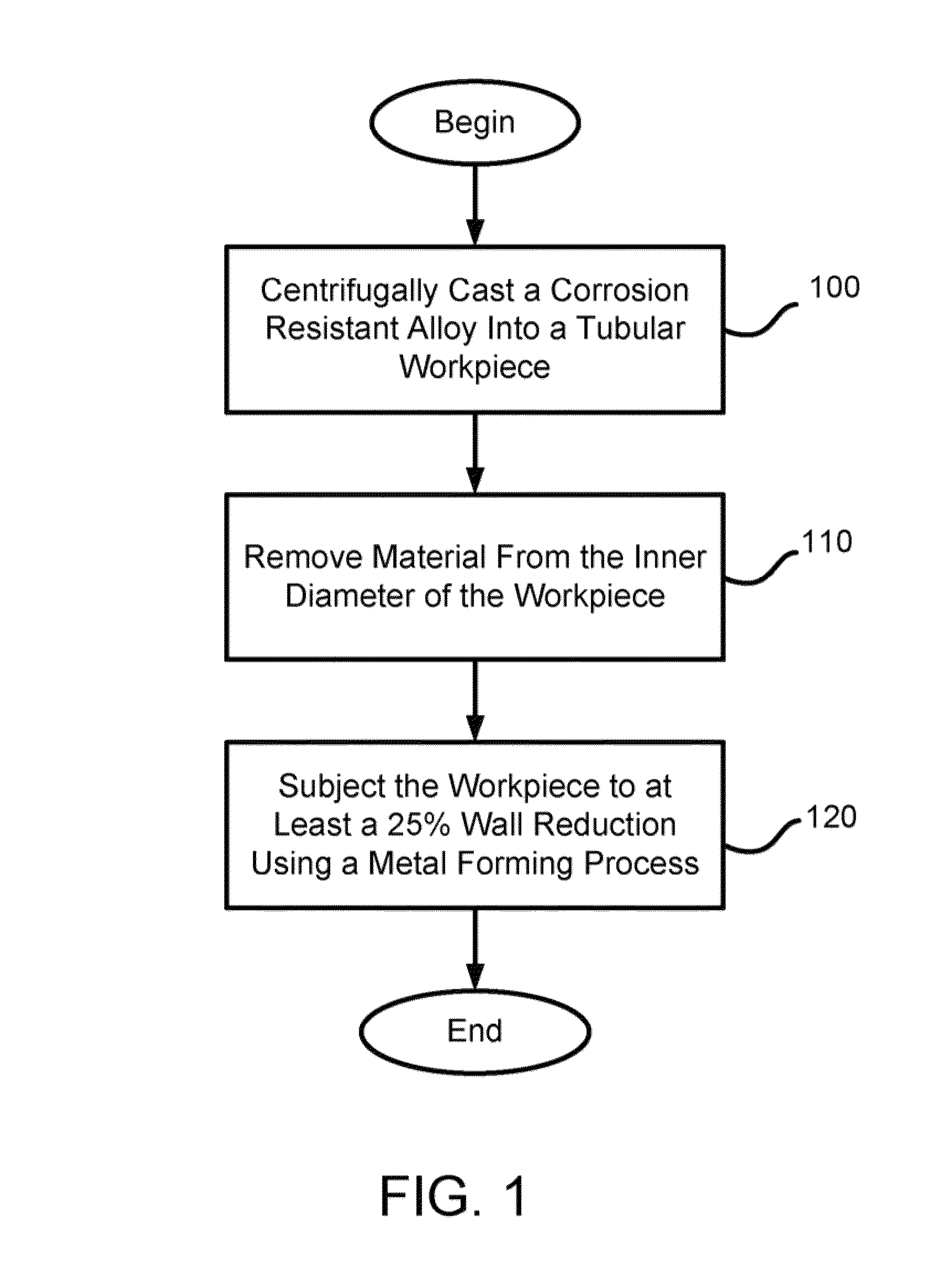

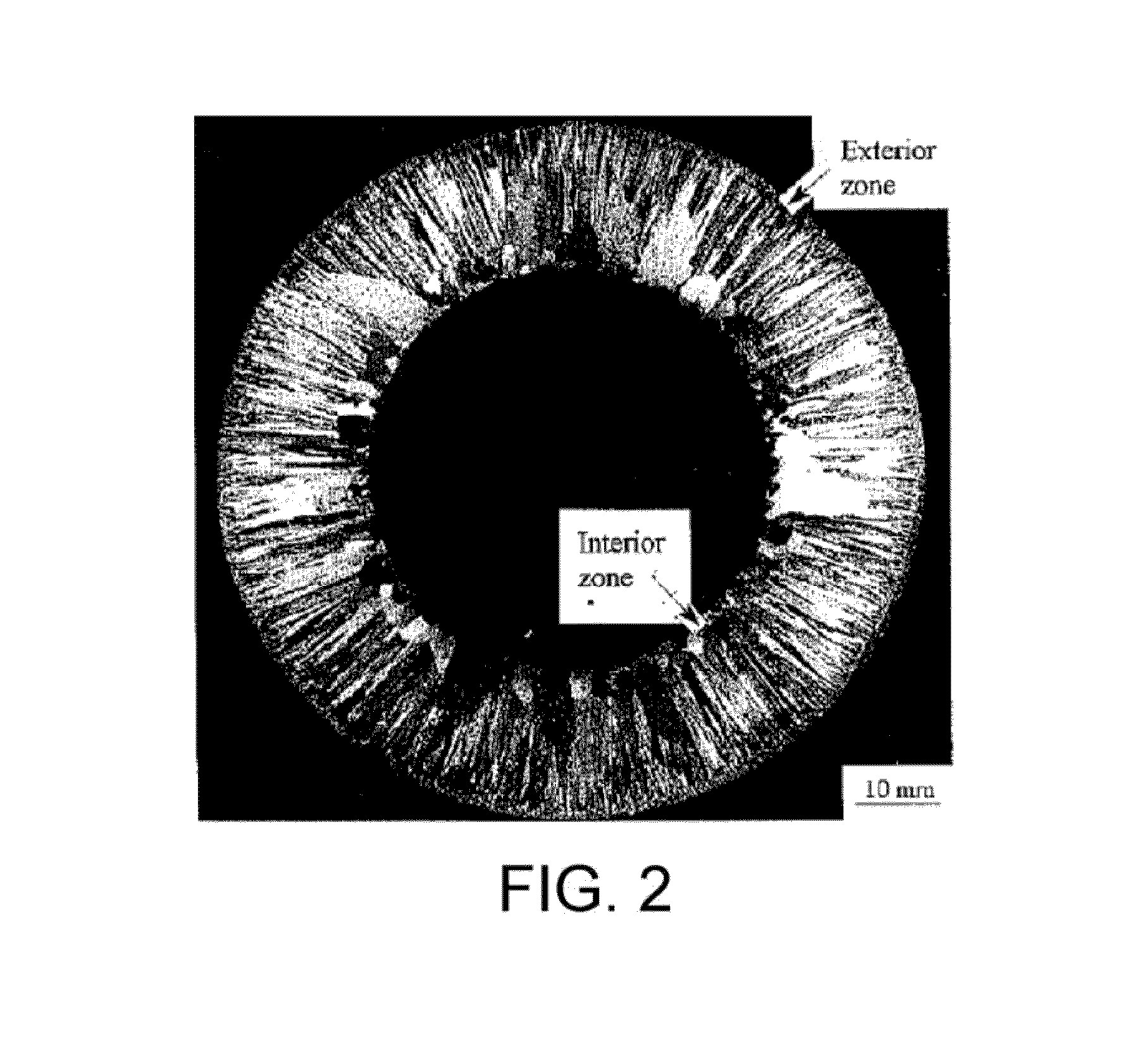

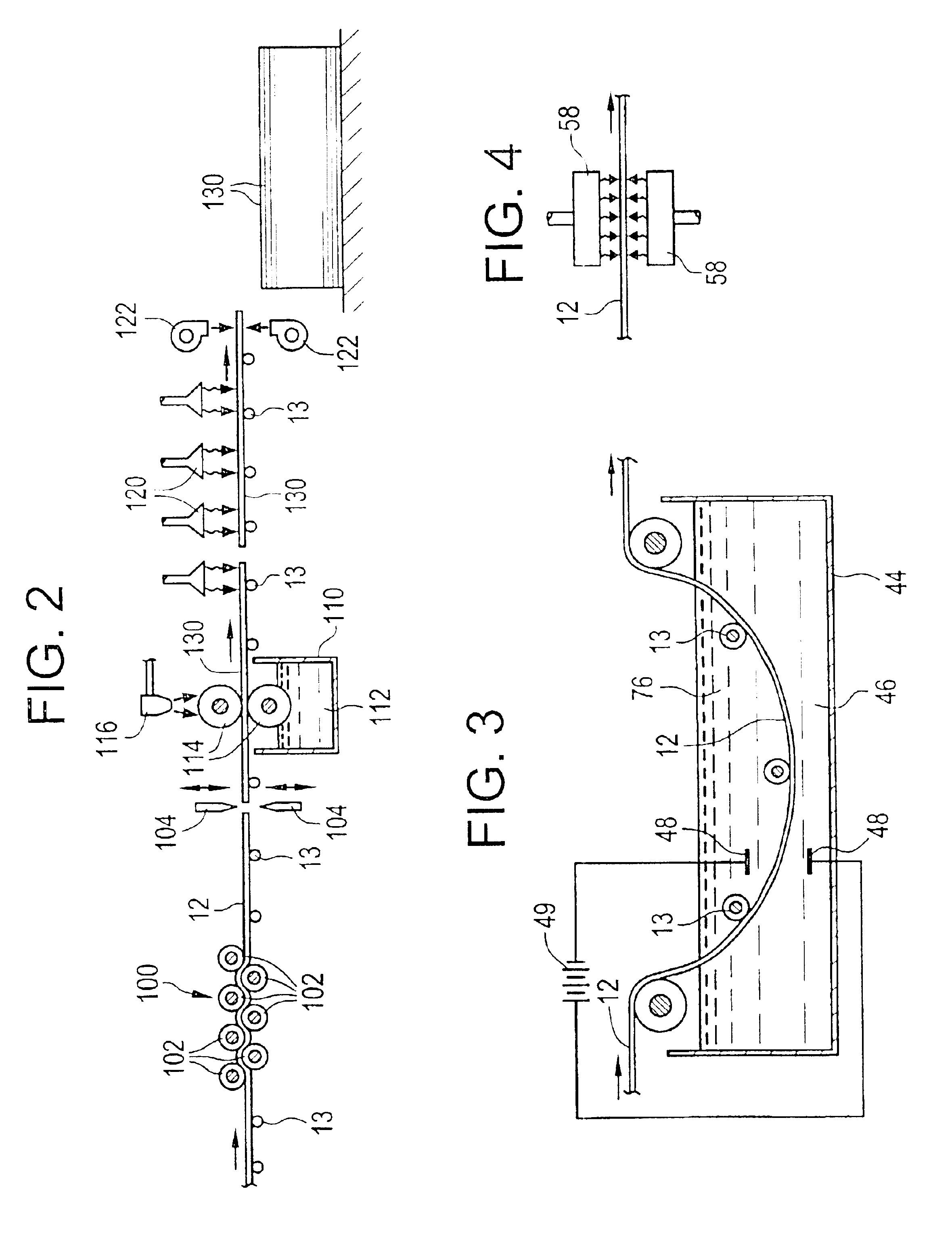

Method of producing cold-worked centrifugal cast tubular products

A method of producing a seamless, tubular product includes centrifugally casting a corrosion resistant alloy into a tubular workpiece having an inner diameter and an outer diameter. The method then removes material from the inner diameter of the workpiece and subjects the workpiece to at least about a 25% wall reduction at a temperature below a recrystallization temperature of the workpiece using a metal forming process. The metal forming process includes radial forging, rolling, pilgering, and / or flowforming.

Owner:ATI FLOWFORM PROD

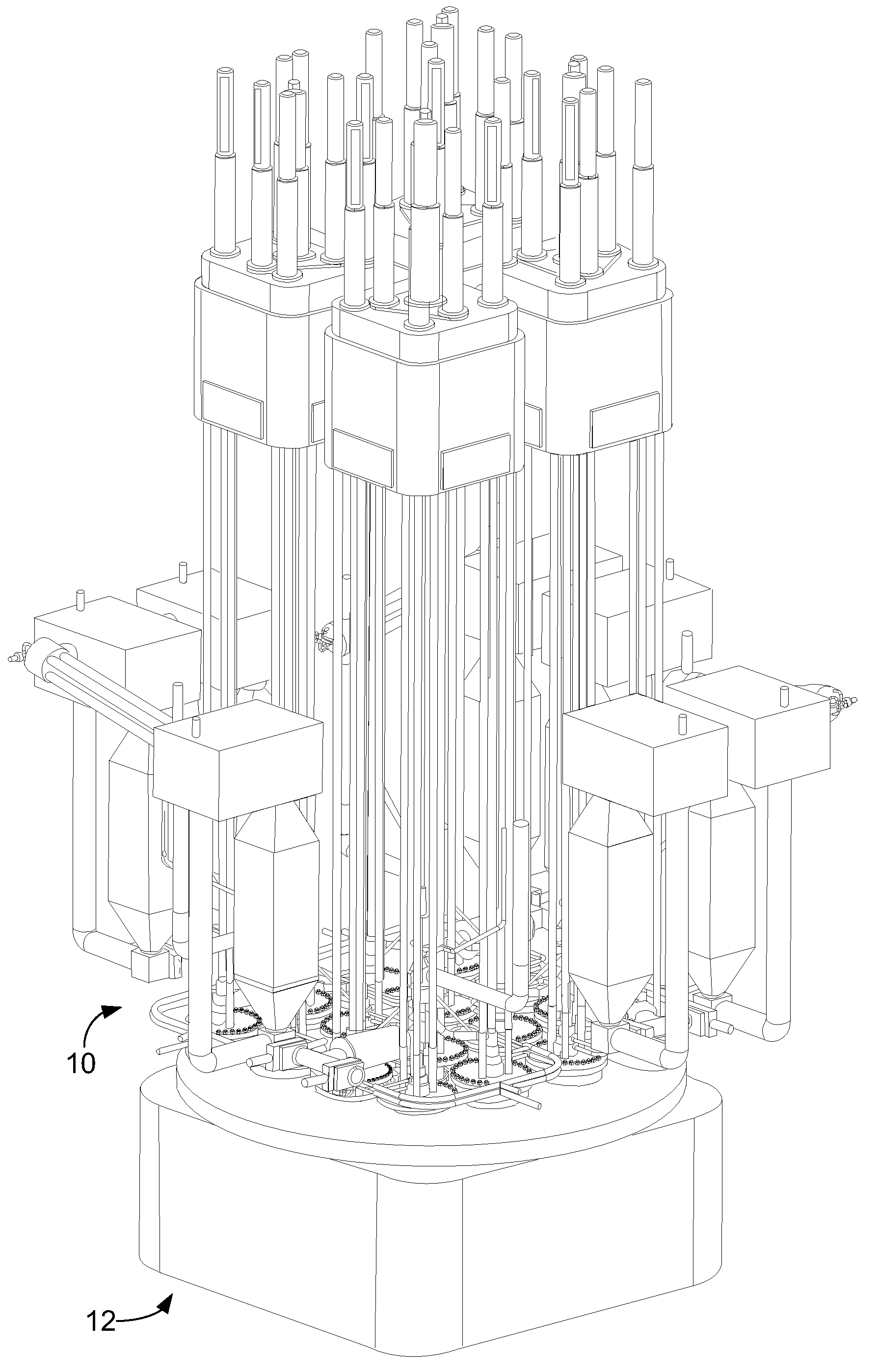

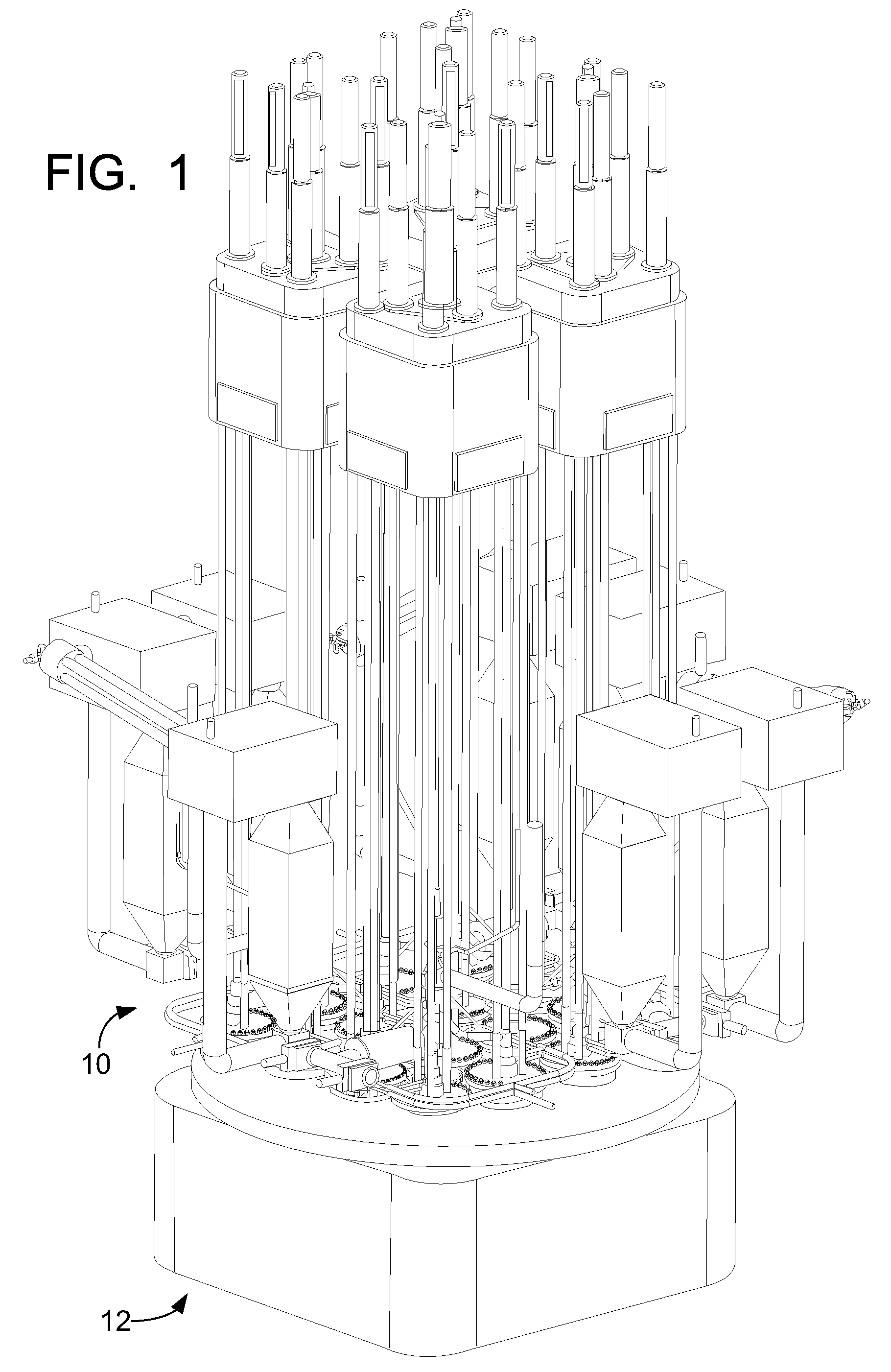

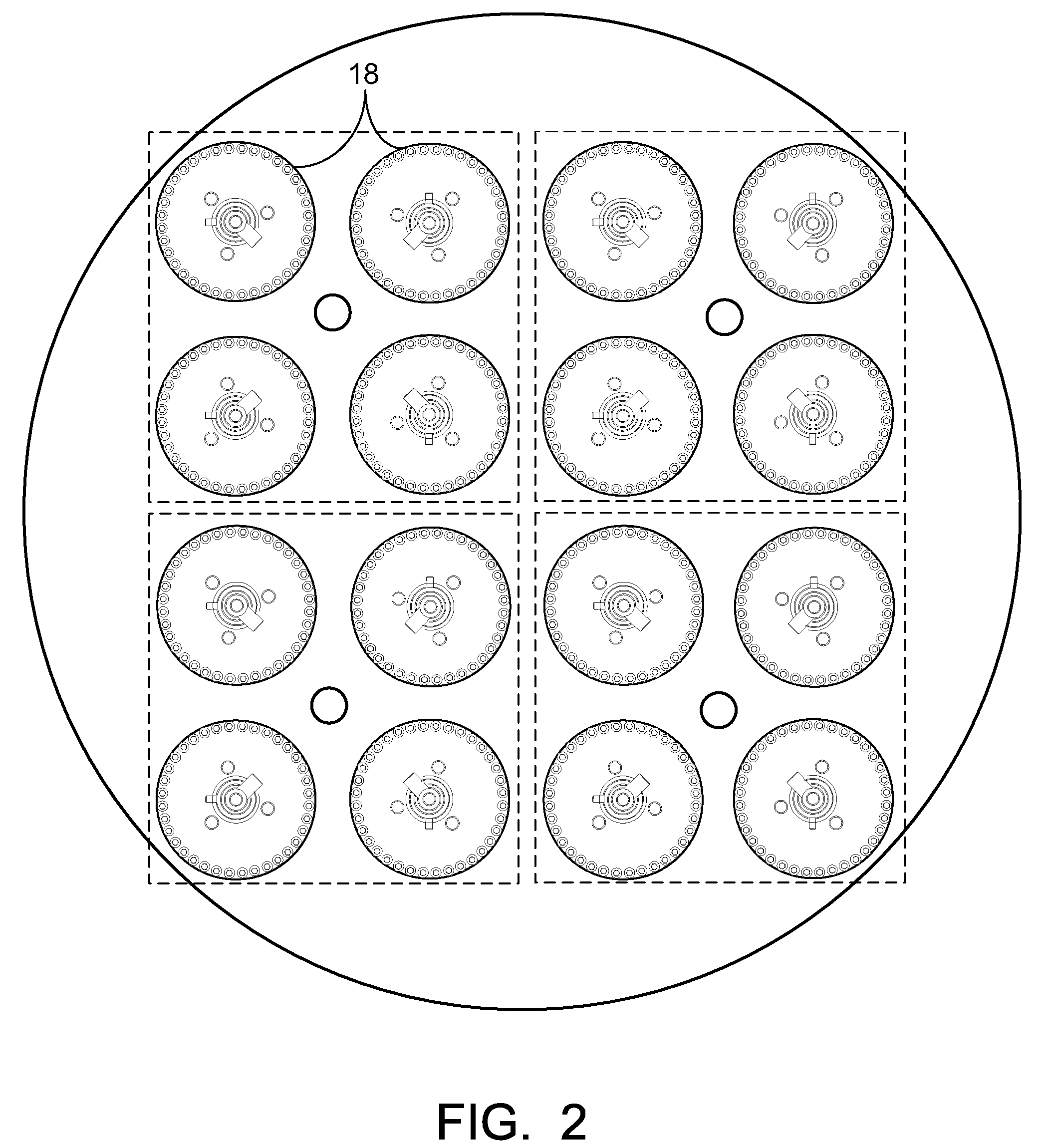

Combinatorial heterogeneous-homogeneous reactor

ActiveUS20090225923A1Reduce power densityIsotope delivery systemsConversion outside reactor/acceleratorsCorrosion resistant alloyNuclear engineering

A combinatorial heterogeneous-homogeneous reactor configuration in which an array or groups of homogeneous fuel assemblies are interlinked together in a heterogeneous lattice. The present invention removes the limitation of a homogeneous reactor by providing a reactor concept that utilizes the inherent advantages of homogeneous fuel elements but in a heterogeneous fuel lattice arrangement that limits the power density of any one homogeneous fuel element and yet forms a reactor arrangement that is capable of producing any product demand of interest. The present invention provides a method for producing medical isotopes by the use of a modular reactor core comprised of homogeneous fuel assemblies arranged in a regular rectangular or triangular pitch lattice. The aqueous fuel solution is contained within individual fuel assemblies that are right circular cylinders clad in corrosion-resistant alloys such as stainless steel, zircalloy, zircalloy alloys, or other metal alloys that are resistant to corrosive fissile environments but preserve neutron economy. The fuel assemblies are supported below by a core plate that is tied directly to the lower reactor support structure. The bottom of each assembly opens into a common plenum area which provides a hydrodynamic communication / coupling path between the individual assemblies in the lattice. The fuel assemblies are supported above by an upper plate that is welded to each assembly tube. The top of each assembly opens to a common upper plenum which provides a means of thermodynamic pressure equalization among the four assemblies in the reactor core lattice.

Owner:BABCOCK & WILCOX TECHNICALSERVICES GRP INC

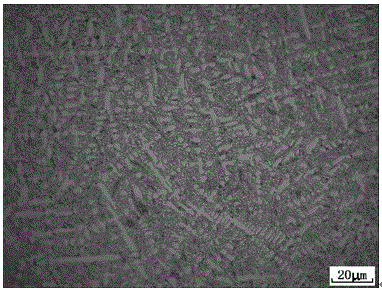

Lightweight armor wires for electrical cables

ActiveUS20070158095A1Simple designHigh strengthNon-insulated conductorsPlastic/resin/waxes insulatorsElectrical conductorTitanium alloy

Disclosed are electric cables with improved armor wires used with wellbore devices to analyze geologic formations adjacent a wellbore. The cables include at least one insulated conductor, and one or more armor wires surrounding the insulated conductor. The armor wires include a low density core surrounded by a corrosion resistant alloy clad, where the alloy clad includes such alloys as beryllium-copper based alloys, nickel-chromium based alloys, superaustenitic stainless steel alloys, nickel-cobalt based alloys, nickel-molybdenum-chromium based alloys, and the like. The low density core may be based upon titanium or titanium alloys. The cables of the invention may be any useful electric cable design, including monocables, quadcables, heptacables, quadcables, slickline cables, multiline cables, coaxial cables, or seismic cables.

Owner:SCHLUMBERGER TECH CORP

High-hardness, wear-resistant and corrosion-resistant alloy of amorphous/nanocrystal matrix and preparation method of high-hardness, wear-resistant and corrosion-resistant alloy

The invention provides a high-hardness, wear-resistant and corrosion-resistant alloy of an amorphous / nanocrystal matrix and a preparation method of the high-hardness, wear-resistant and corrosion-resistant alloy. The high-hardness, wear-resistant and corrosion-resistant alloy of the amorphous / nanocrystal matrix comprises the following elements in percentages by mass: 9.0-12.0 of Cr, 2.6-2.9 of B, 0.7-0.9 of C, 0.4-0.8 of Nb, 0.4-0.8 of V, less than 0.3 of Mn, less than 0.07 of Si, less than or equal to 0.01 of S and P, and the balance of Fe, wherein the sum of C and B is 3.3-3.6; the content ratio of C / Cr is 0.06-0.08; and the sum of Nb and V is 0.5-1.0. Through multi-component alloying, an eutectic composition is formed, the melting point is low, fluidity is good, requirements of a casting technology are simple, large wear-resistant and corrosion-resistant castings can be cast, and small precision wear-resistant and corrosion-resistant castings can also be produced. The hardness of the alloy is HRC66-70, and impact toughness of the alloy is 4-9 J / cm (2).

Owner:广州市信纳德生物科技有限公司

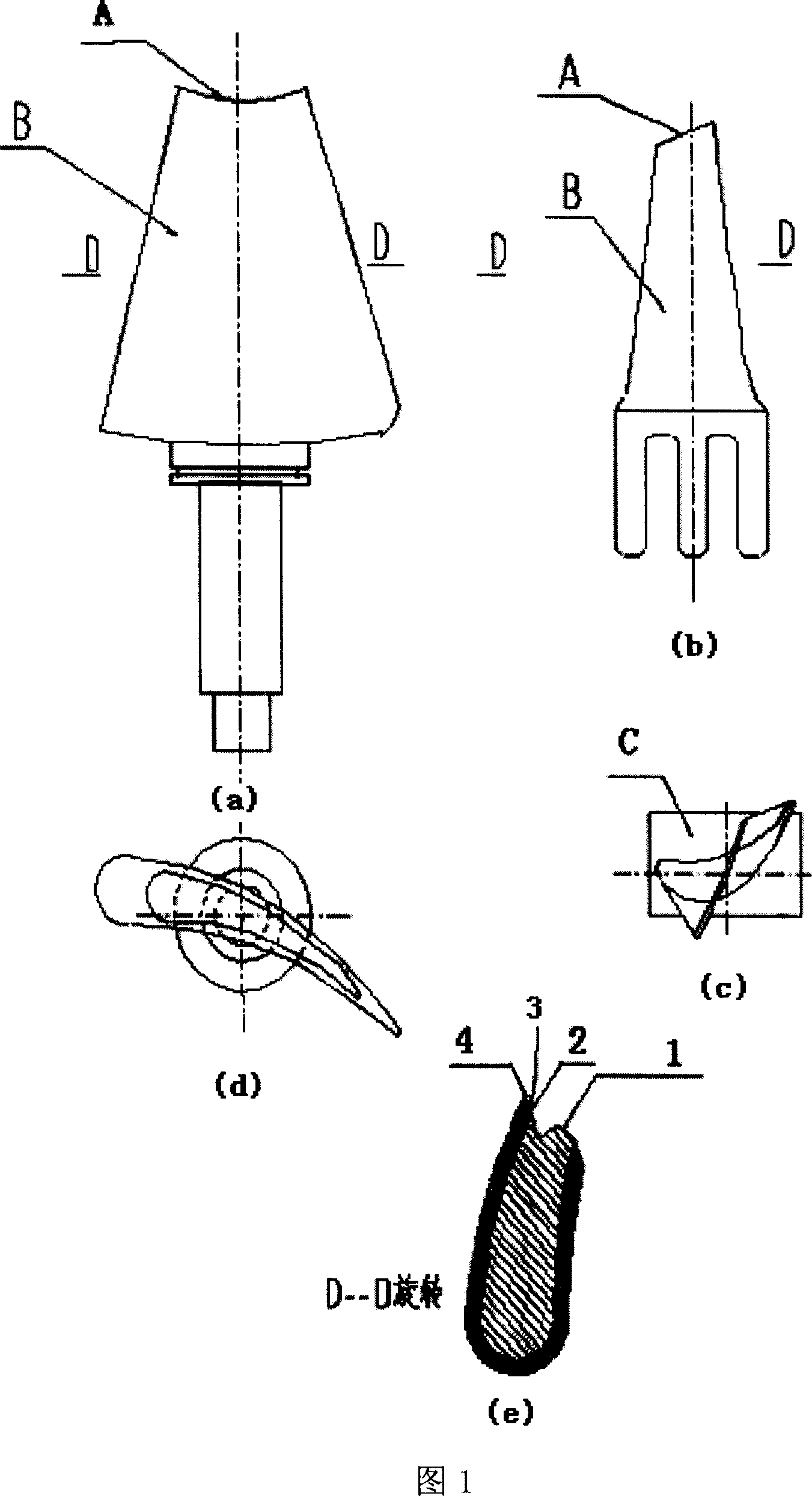

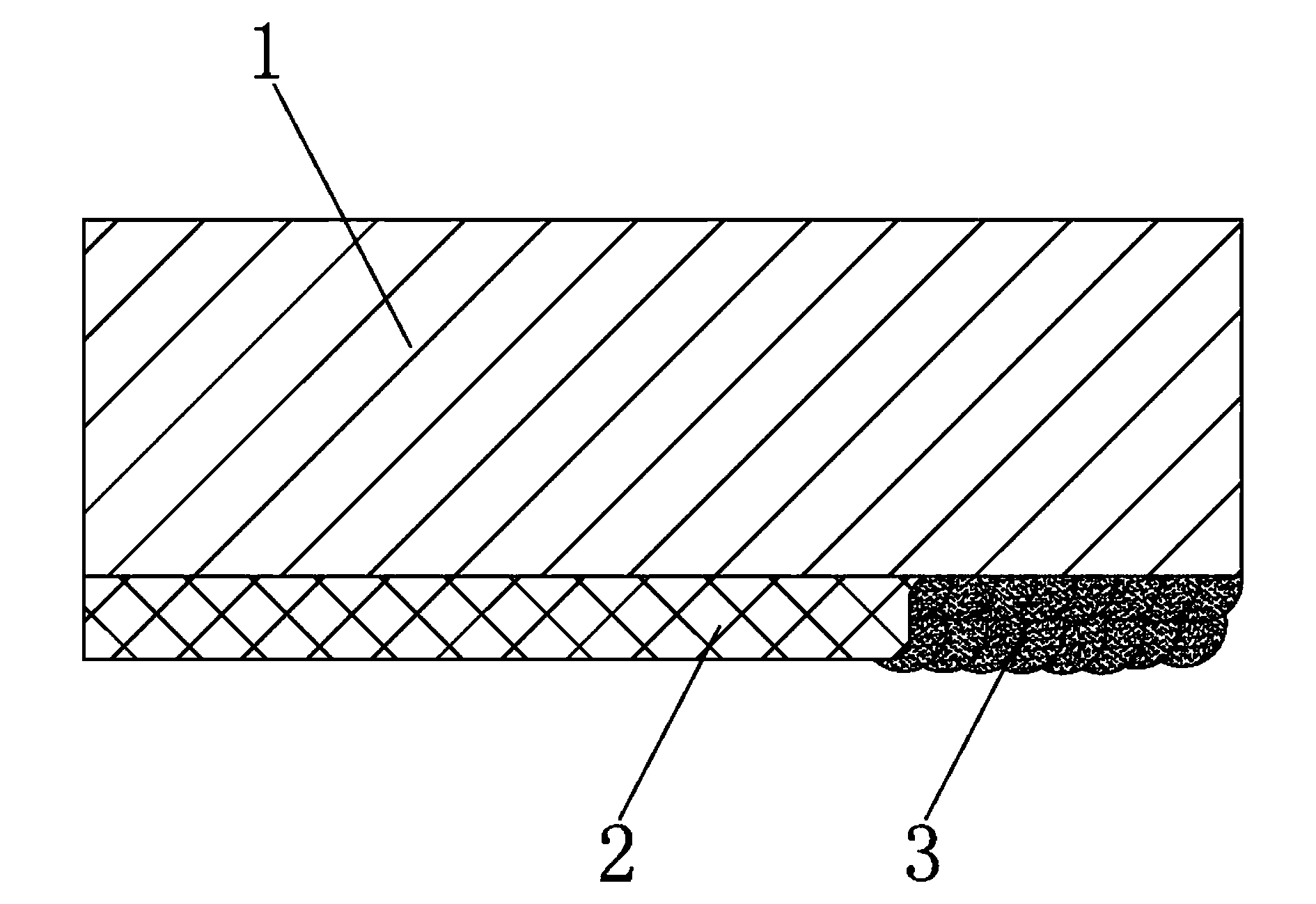

Surface composite coating of turbomachine rotor blade and preparation method thereof

ActiveCN101008324AAlleviate mechanical property mismatchImprove dynamic binding strengthMolten spray coatingBlade accessoriesCorrosion resistant alloyHigh energy

The invention discloses a surface composite coat of the blade on rotor and relative production, wherein, the composite coat is divided into adhesive bottom, middle corrosion-resistance alloy layer and metal ceramic rigid abrasion-resistance layer. The invention utilizes high-energy plasma coater and ultrasonic plasma injector, via ultrasonic plasma coating technique to coat aforementioned three layers on the base of blade; then seal the outer face via macromolecule sealing agent as polyurethane or acrylic acid. The thickness of metal ceramic rigid abrasion-resistance layer is 0.12mm, the thickness of middle corrosion-resistant alloy layer is 0.08mm, and the thickness of bottom adhesive layer is 0.05mm. The invention can improve the corrosion resistance and abrasion resistance of blade.

Owner:XIAN SHAANGU POWER

Composite electromagnetic screen film material and mfg. method thereof

InactiveCN1787114AMeet the needs of normal workLow costMagnetic/electric field screeningScreening apparatusComposite filmElectromagnetic shielding

The invention belongs to the field of magnetic material, relating to an electromagnetic shielding material and the making method thereof. The invention is a composite metallic film formed on a conductive substrate by multiple deposition in the water solution, and the obtained composite metallic film is 1-100 mum thick, and each layer of the composite metallic film is 1.1-99.9 mum thick, and the combination between the layers of the composite film is by chemical bond, and each layer is layered. The substrate can be stainless steel, copper plate, Ti plate, Al plate or one of the corrosion-resistant alloy plates, and also made of conductive glass, conductive plastics, polymer high molecular material, or other material; the composite metallic film comprises two or above different metallic film layers; each metallic film layer can be of copper, iron, iron-nickel alloy, nickel-cobalt alloy, iron-cobalt alloy or iron-cobalt-nickel alloy. The invention can shield the frequencies between 50Hz and 100 Hz and the shielding efficacy reaches above 70dB.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

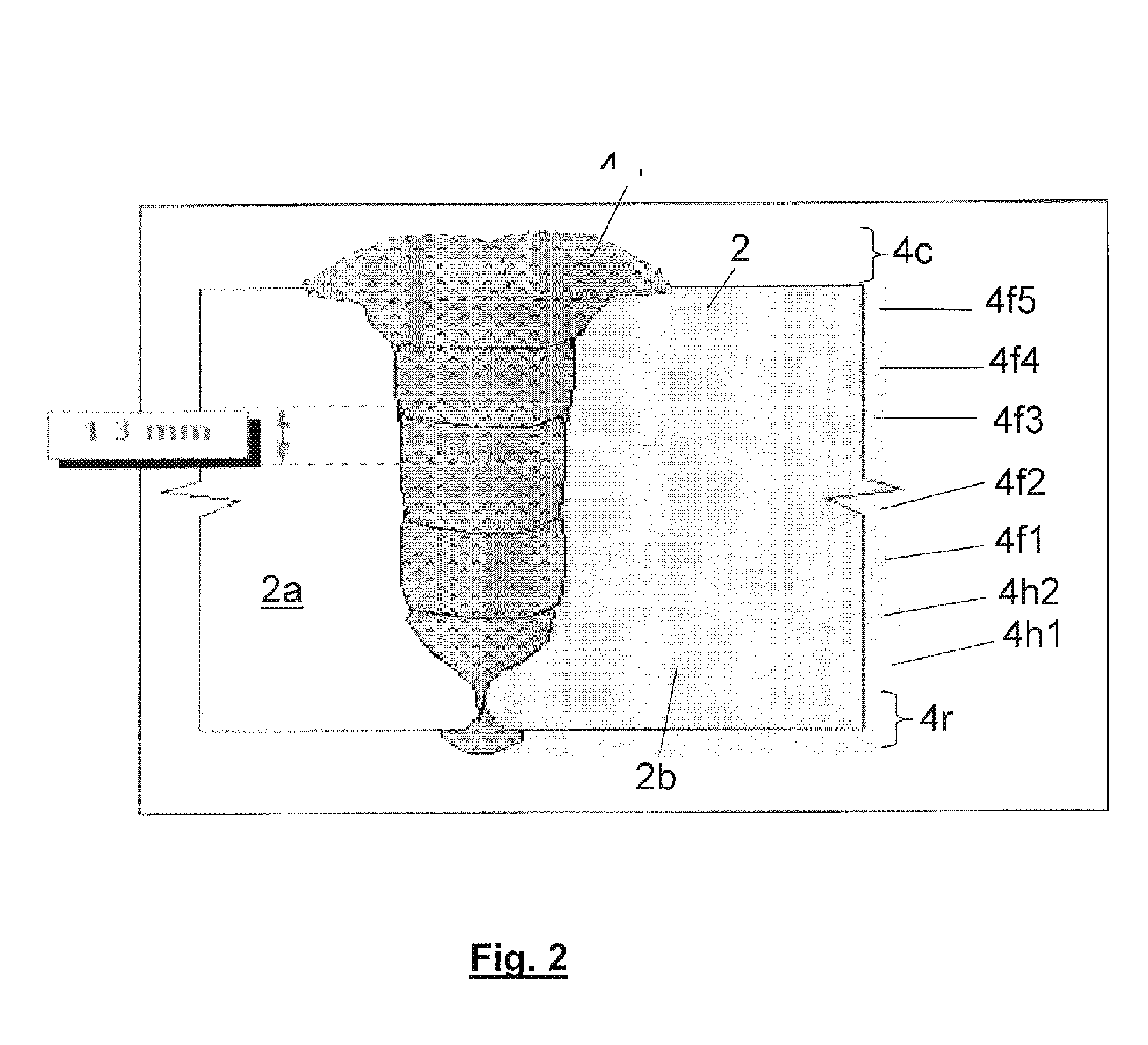

Glass-lined anti-corrosion steel pipe producing and welding processes

InactiveCN103822031AGood chemical stabilitySmooth inner wallLiquid surface applicatorsArc welding apparatusChemical industryGlass corrosion

The invention relates to a glass-lined anti-corrosion steel pipe producing and welding processes. The producing process includes pre-overlaying a nickel-based corrosion resistant alloy layer from 1.5 to 2 mm in inner holes with depth of 30 to 50 mm to the end face of a steel pipe, allowing the nickel-based corrosion resistant alloy layer to fuse on the base material; beveling the overlaid-preprocessed end face of the steel pipe, and smoothly polishing the surface of the nickel-based overlaying layer; performing rust removal and dust treatment on the inner wall of the steel pipe; coating glass powder on the inner wall of the steel pipe in a hot spraying manner to melt and form an inner glass corrosion resistant layer. By coating the inner glass corrosion resistant layer on the inner wall of a metal pipe in a hot melting manner, a glass and metal composite corrosion resistant structure is formed, chemical stability is high, the inner wall is smooth, and fluid resistance is small; the glass-lined anti-corrosion steel pipe has special advantages of corrosion resistance, waxing resistance, wear resistance, resistance reduction and energy efficiency, and can be widely applied in various fields of petroleum, chemical industry, natural gas, tap water, sewage, municipal construction and the like.

Owner:胜利油田金岛工程安装有限责任公司

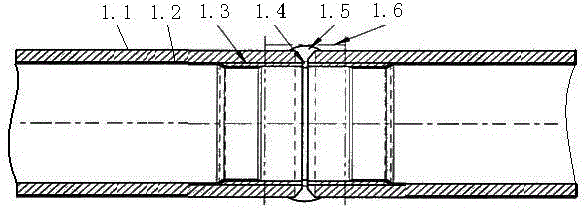

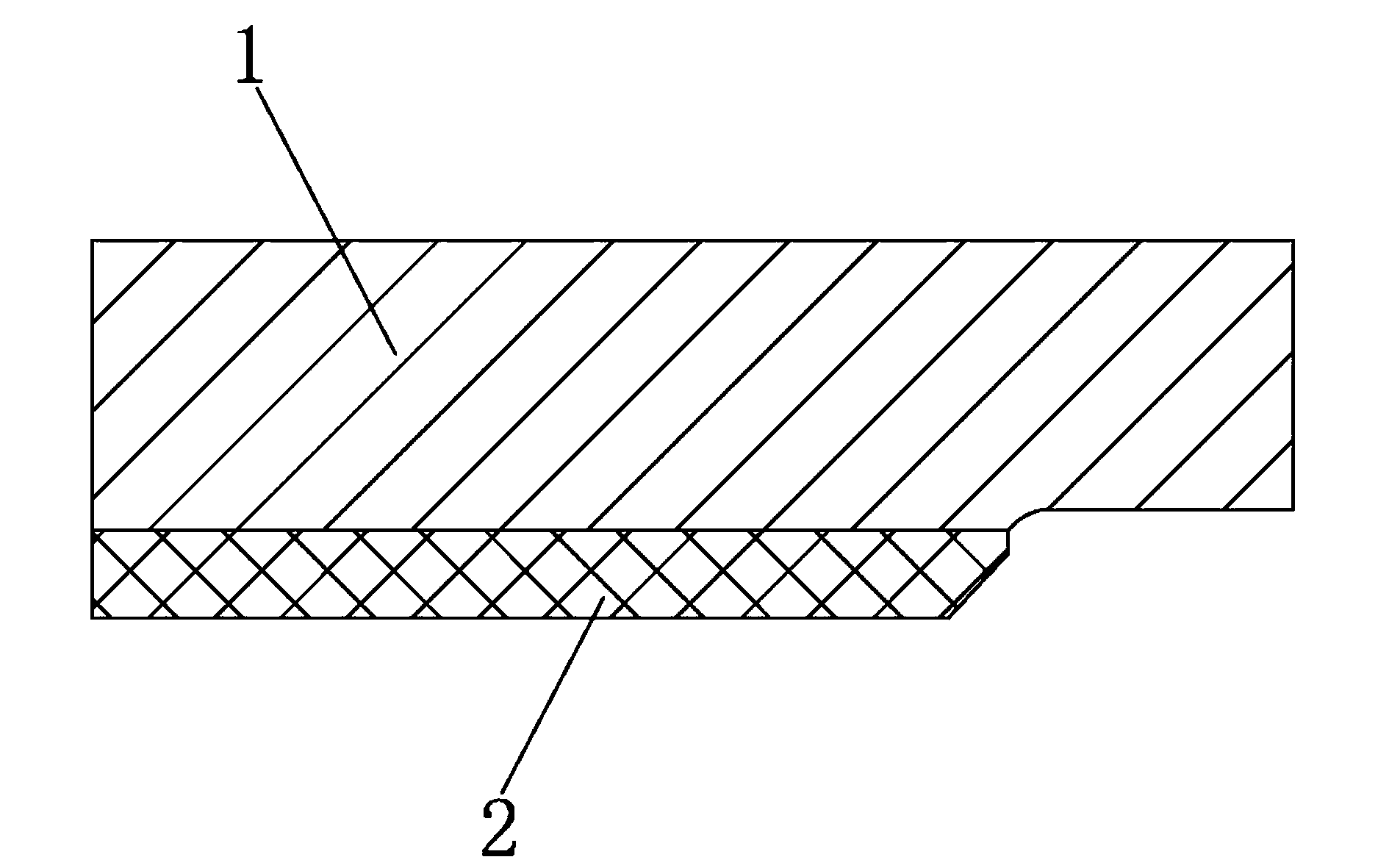

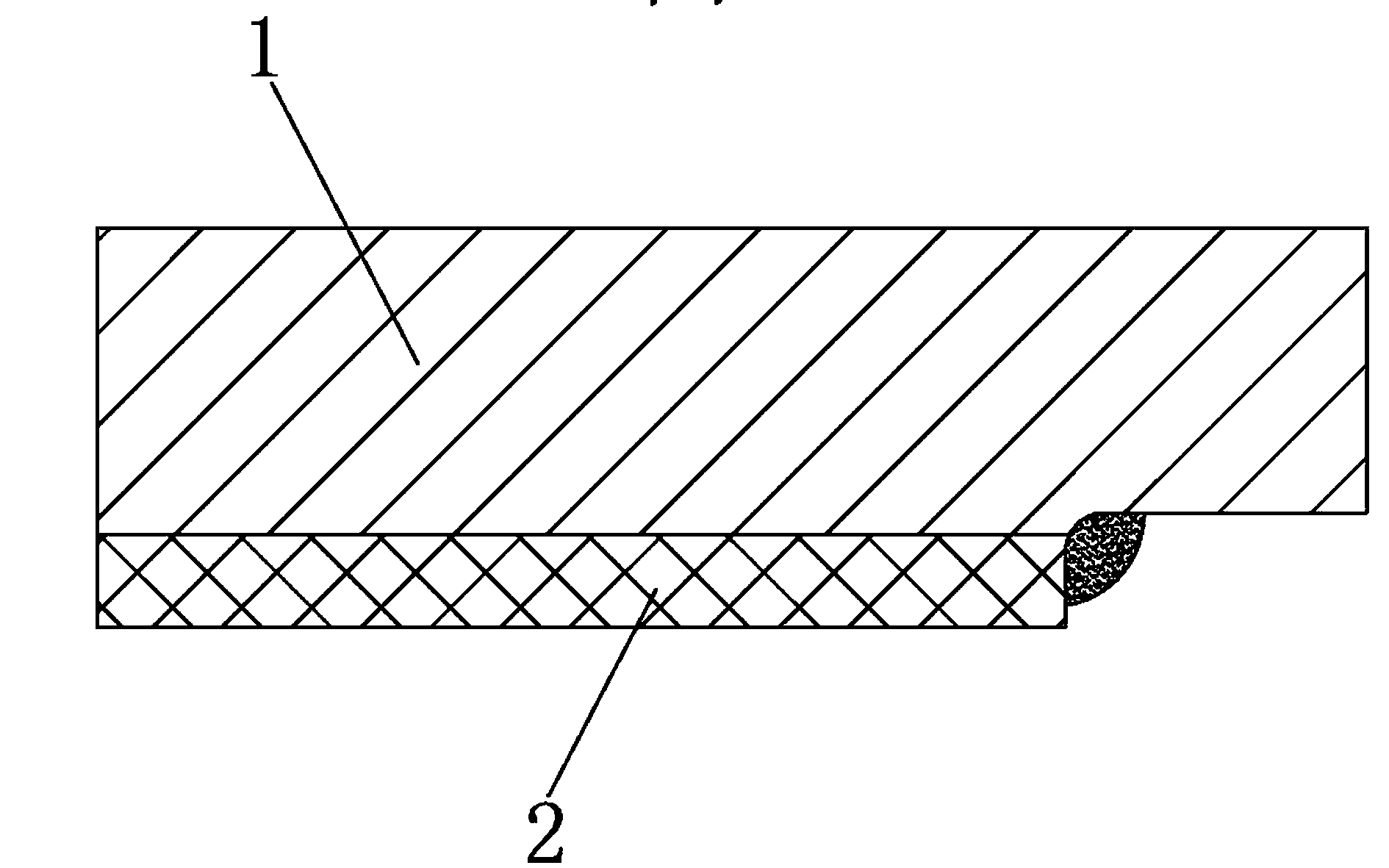

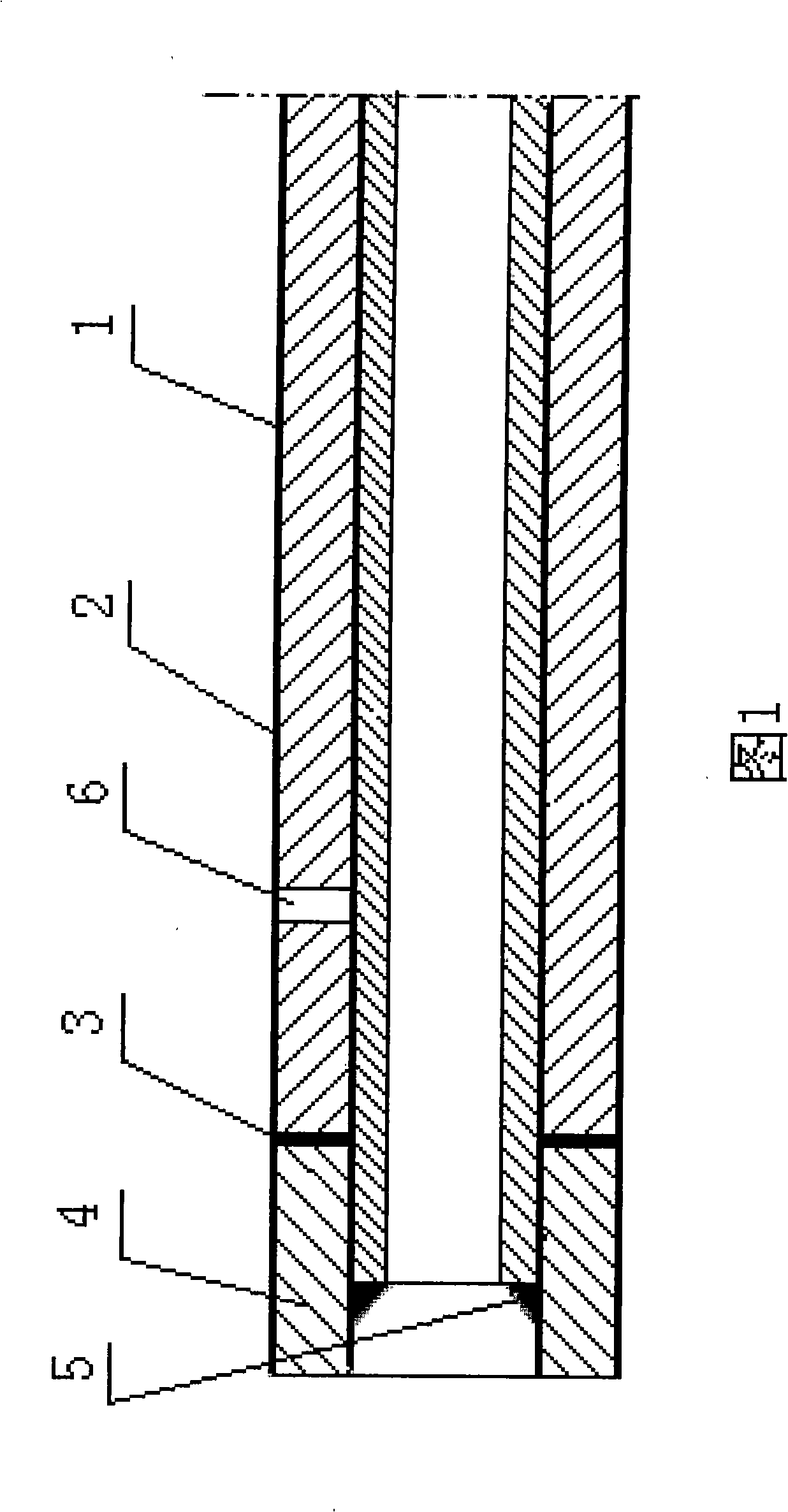

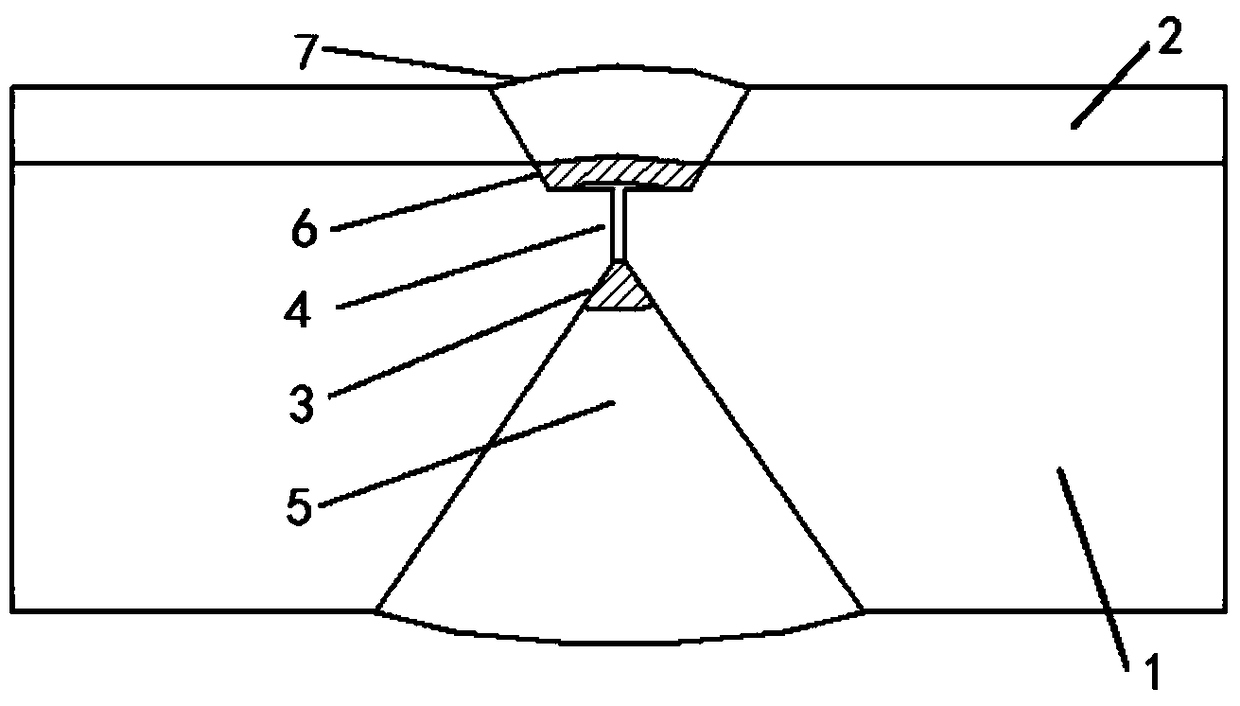

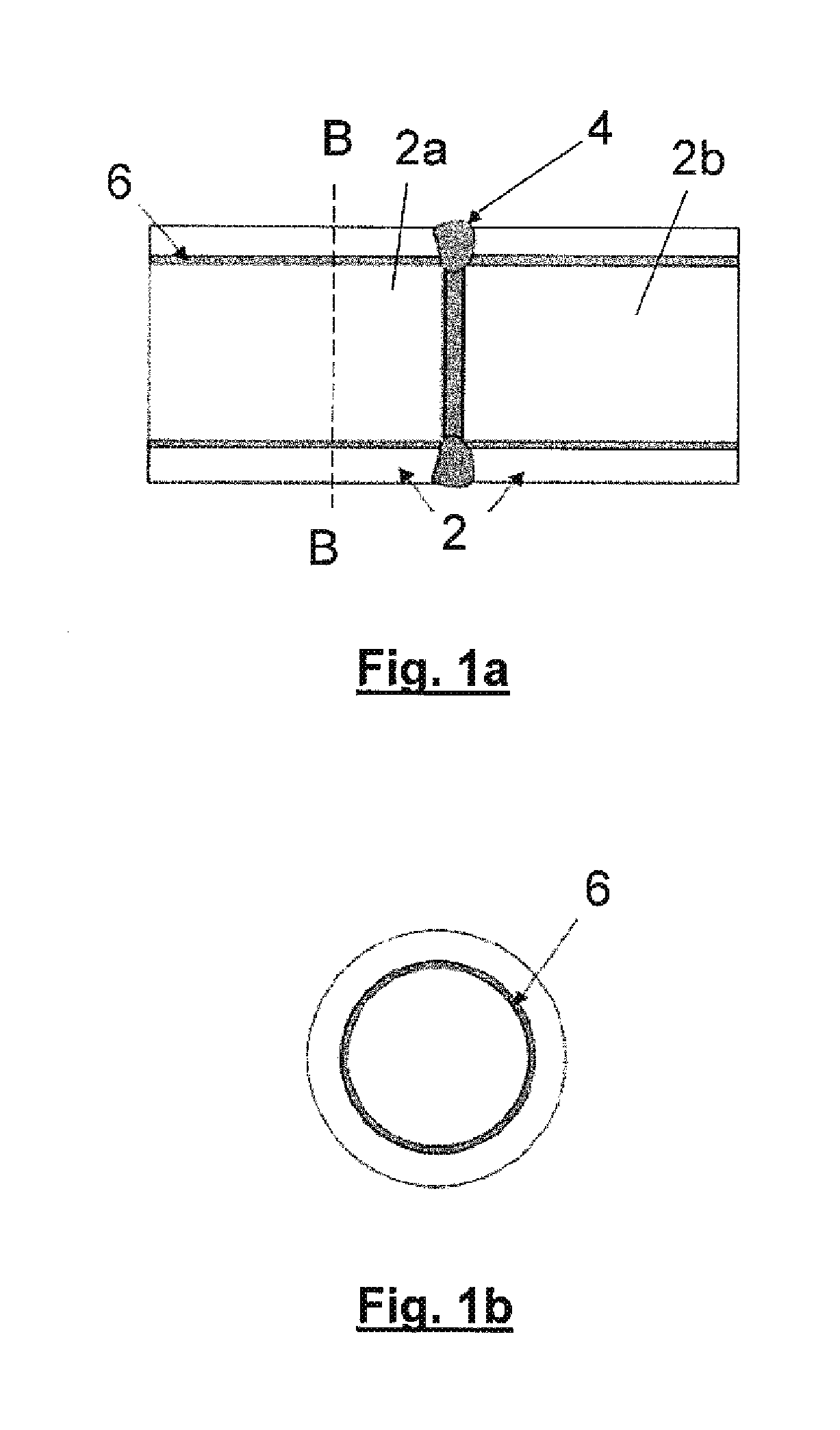

Composite tube and manufacture method thereof

InactiveCN103216682AEliminate relative motionEliminate impact on butt weld qualityRigid pipesCorrosion resistant alloySurface layer

The invention discloses a composite tube and a manufacture method thereof. The composite tube comprises a base tube (1) and a corrosion-resistant alloy liner tube (2) mechanically combined in the base tube, wherein a corrosion-resistant alloy surfacing layer (3) is arranged at the inner circumference of the end part of the base tube, the inner end face of the corrosion-resistant alloy surfacing layer (3) is connected with the end face of the corrosion-resistant alloy liner tube (2), and the axial length of the corrosion-resistant alloy surfacing layer (3) is not less than the distance between the end face of the corrosion-resistant alloy liner tube (2) and the end face of the base tube (1). The manufacture method comprises the following steps of: S1, mechanically combining the corrosion-resistant alloy liner tube (2) in the base tube (1); S2, removing the corrosion-resistant alloy liner tube (2) (with certain length) at the end part of the composite tube; and S3, forming the corrosion-resistant alloy surfacing layer (3) on the inner circumference of the end part of the base tube (1) from inside to outside in a surfacing manner from the end part of the corrosion-resistant alloy liner tube (2). According to the composite tube, the problems of large welding difficulty, low welding qualified rate and low speed of the dual-metal mechanical composite tube are solved.

Owner:CHINA NAT OFFSHORE OIL CORP +1

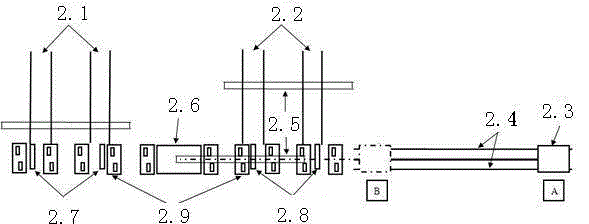

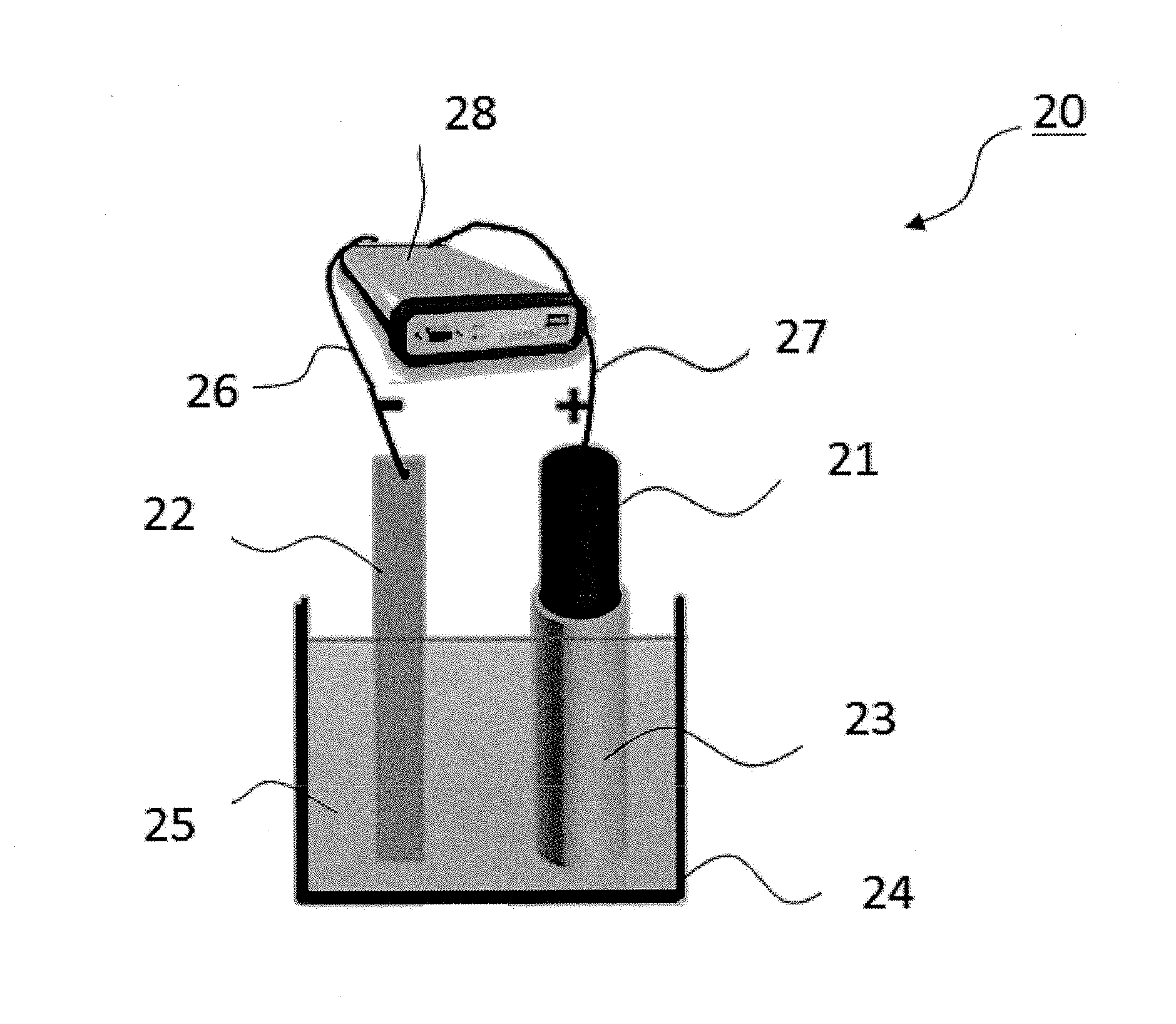

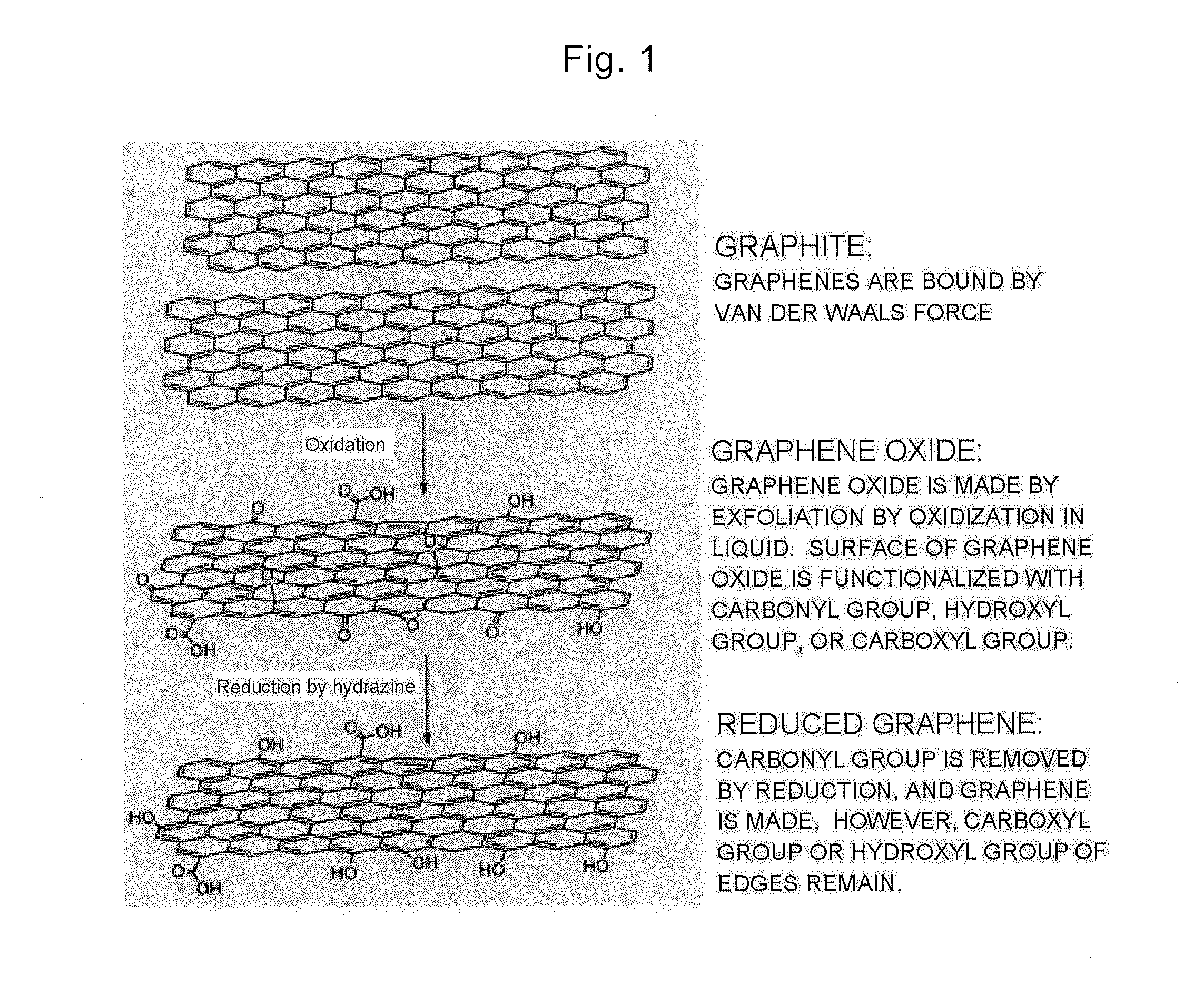

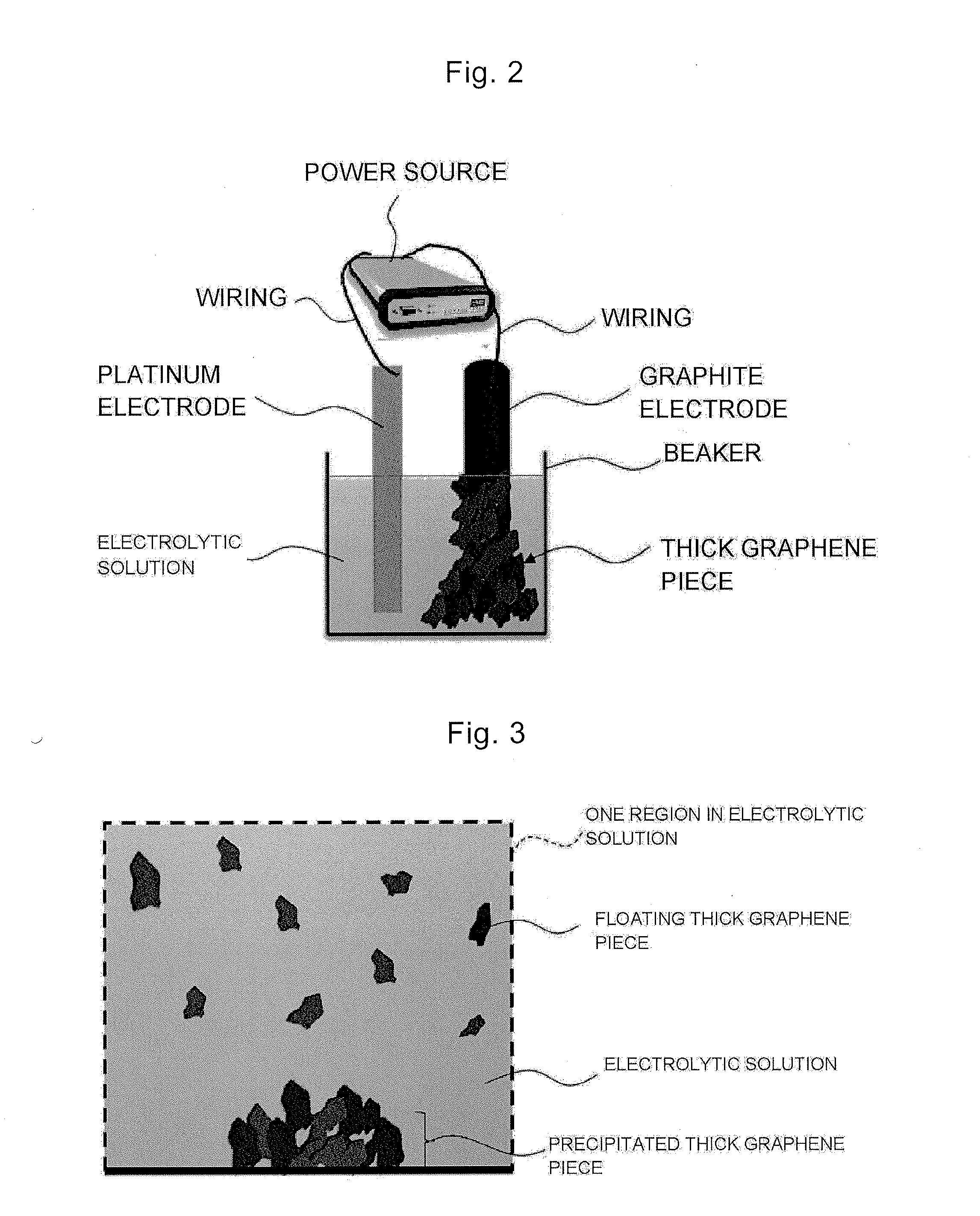

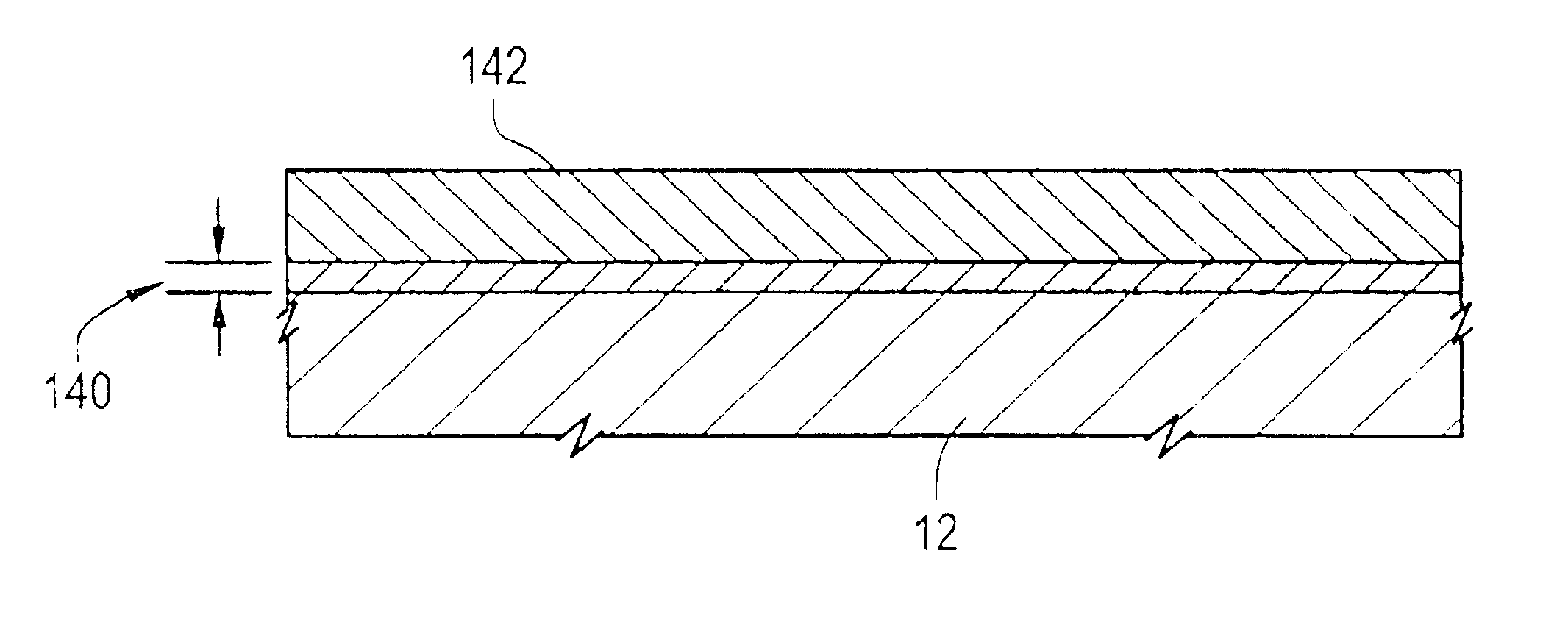

Ultrathin graphene piece, apparatus for preparing ultrathin graphene piece, method for preparing ultrathin graphene piece, capacitor, and method of manufacturing capacitor

InactiveUS20150291431A1Raise the ratioQuality improvementMaterial nanotechnologyPhotography auxillary processesCorrosion resistant alloyGraphite electrode

The problem addressed by the present invention is to provide an apparatus for preparing ultrathin graphene pieces capable of preparing ultrathin graphene pieces in which less than 10 pieces of graphene are overlapped in large quantities, a method for preparing ultrathin graphene pieces capable of preparing the ultrathin graphene pieces with high yield, an ultrathin graphene piece in which less than 10 pieces of graphene are overlapped, a capacitor having high performance by using the ultrathin graphene piece as an electrode, and an efficient method of manufacturing the capacitor. The above-described problem can be solved by using an apparatus 20 for preparing ultrathin graphene pieces, the apparatus comprising: a graphite electrode 21; a counter electrode 22 which is made of graphite, a corrosion resistant alloy, or a precious metal; an electrolytic solution 25 in which one end sides of the two electrodes 21 and 22 are immersed; a container 24 which stores the electrolytic solution 25; and a power source 28 which is connected to the two electrodes 21 and 22 via wirings 26 and 27. The apparatus is also provided with a porous filter 23 so as to cover at least the immersed part of the graphite electrode 21 that is immersed in the electrolytic solution 25.

Owner:NAT INST FOR MATERIALS SCI

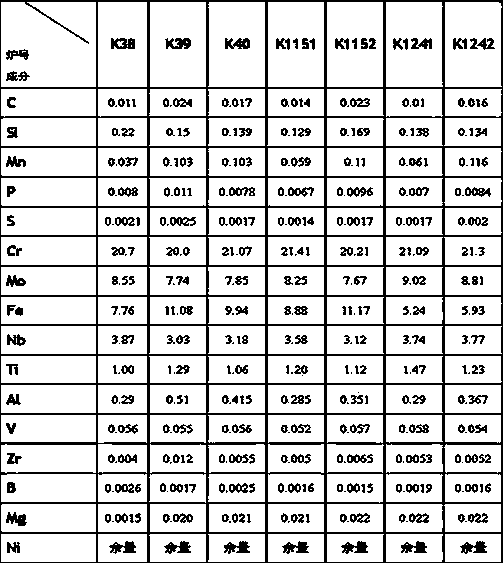

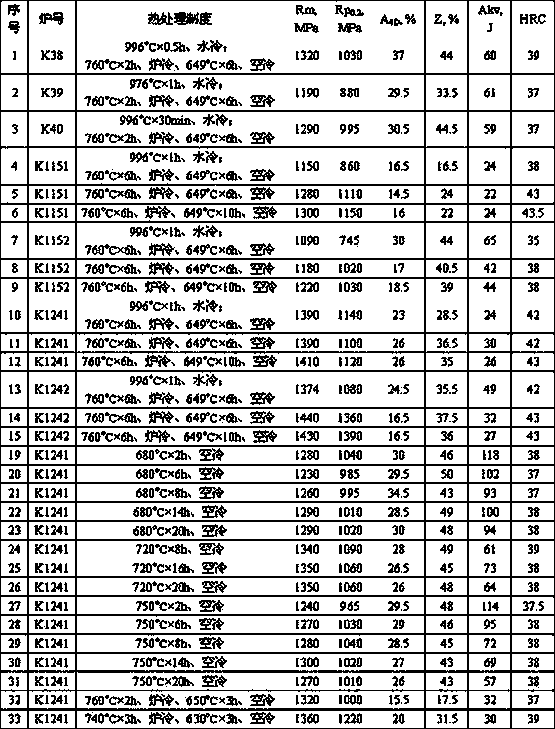

High-obdurability corrosion-resistant age hardening nickel-based alloy and direct ageing heat treatment method

ActiveCN103740983AStrength Optimized BalanceOptimized balance of corrosion resistanceCorrosion resistant alloySulfur

The invention relates to a high-obdurability corrosion-resistant age hardening nickel-based alloy, which is composed of Ni, Cr, Mo, Nb, Ti, Al, V, Zr, B, Mg, (Ti+Al) / Nb, C, Si and Fe. The alloy is obtained by a direct ageing heat treatment method. The alloy provided by the invention has the characteristics of high strength, good ductility and toughness, excellent corrosion resistance and the like just the same as those of the existing nickel-based corrosion-resistant alloy; and compared with the existing nickel-based corrosion-resistant alloy, the alloy provided by the invention is better in thermoplasticity, lower in hot processing difficulty and better in integrated processing properties, and also lower in process cost. The alloy provided by the invention can be used as the material of equipment for high temperature and high pressure high-sulfur oil and gas exploitation.

Owner:CHONGQING MATERIALS RES INST

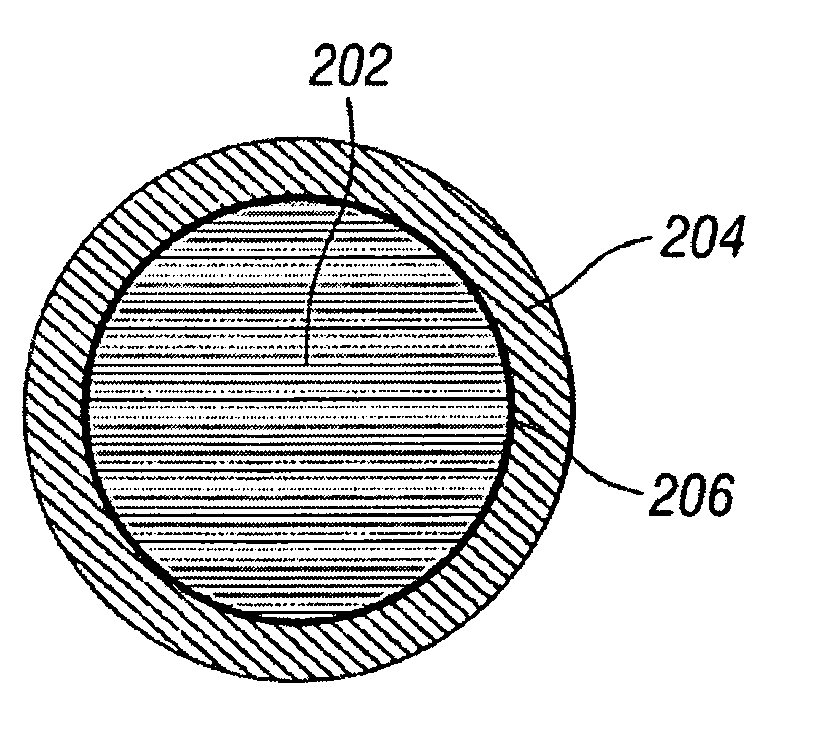

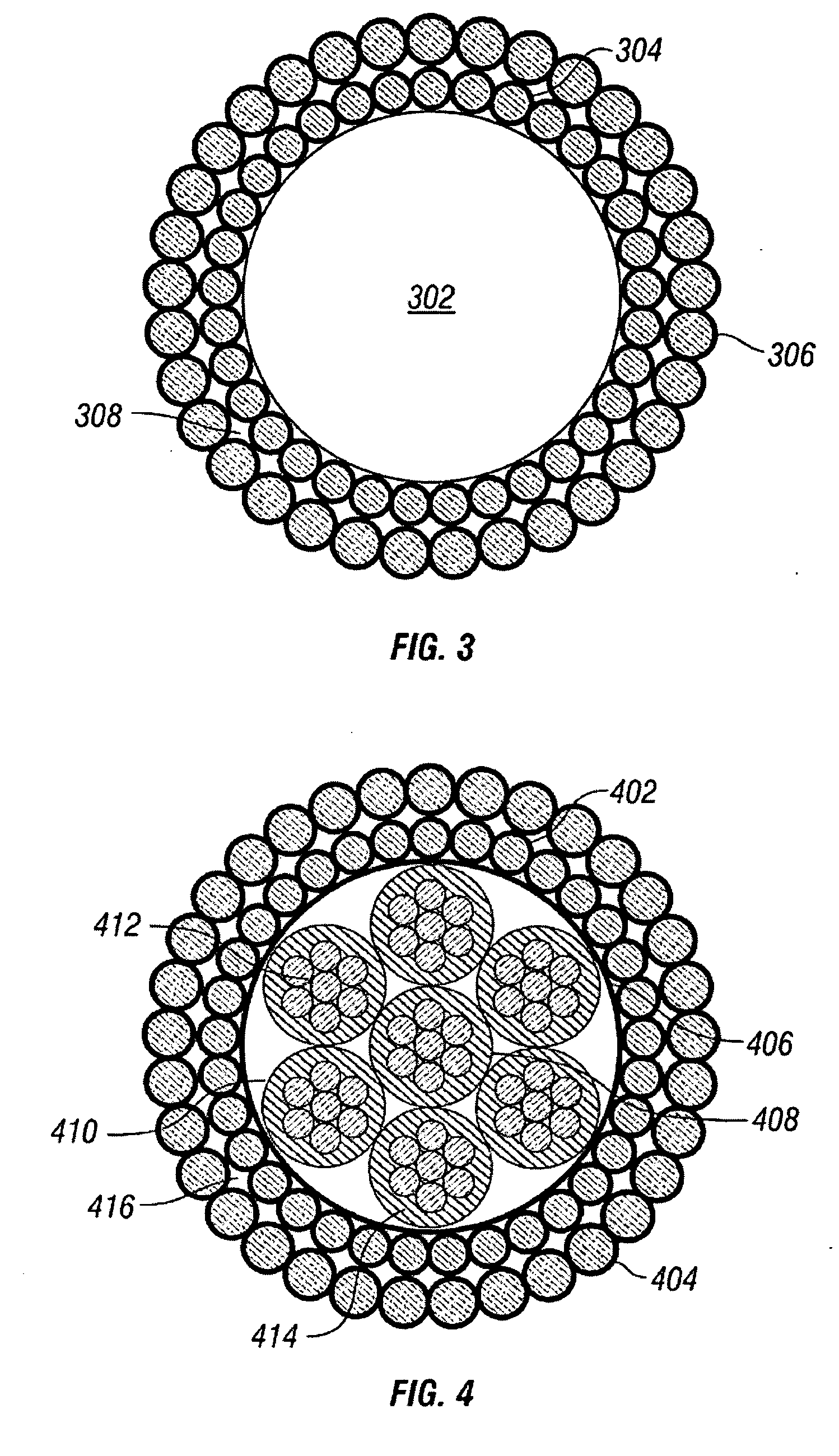

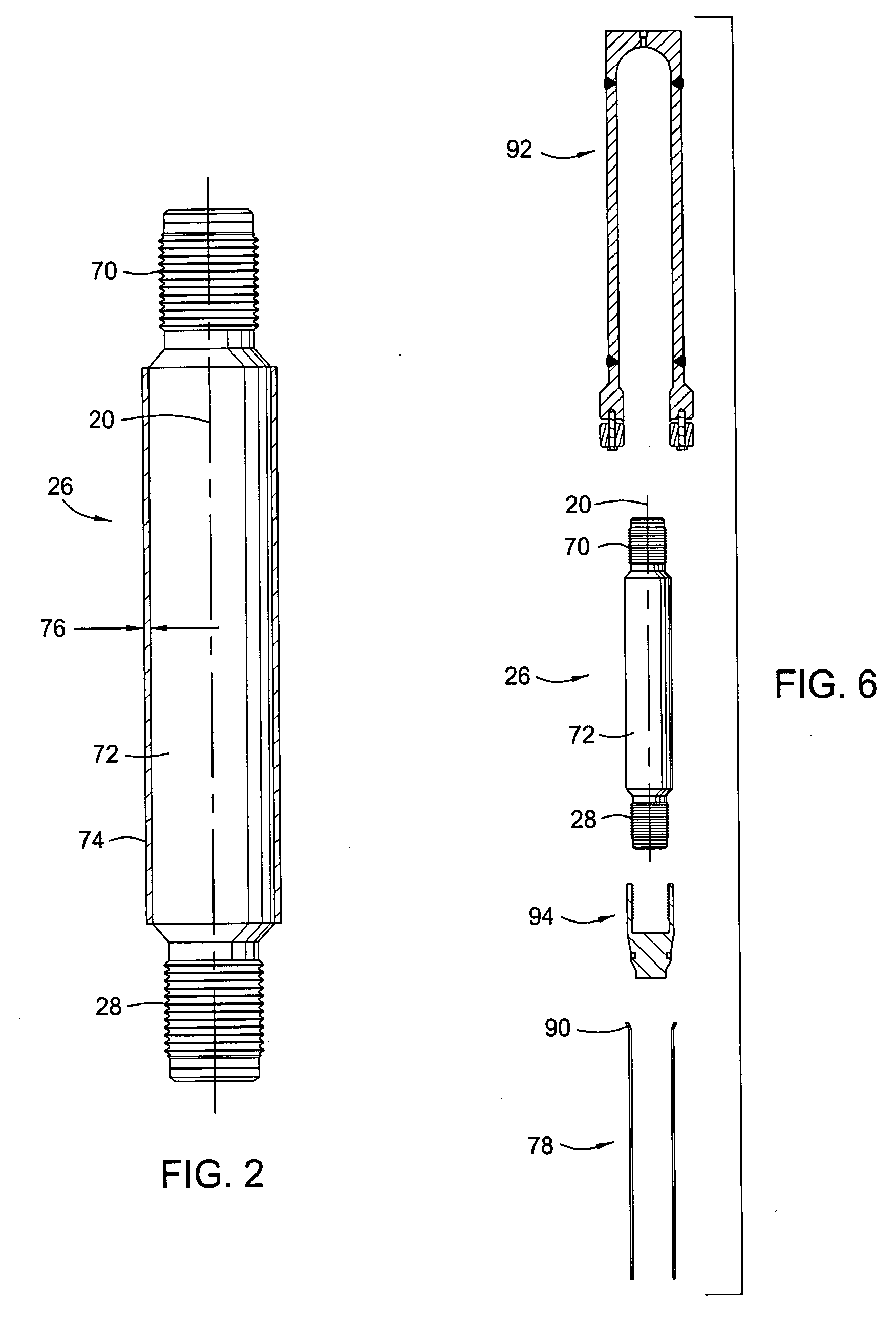

Bimetallic materials for oilfield applications

Corrosion resistant and / or lightweight bimetallic cylinders used in tools and electric cables, including core surrounded by corrosion resistant alloy outer cladding materials, where the alloy clad may include such alloys as beryllium-copper based alloys, nickel-chromium based alloys, superaustenitic stainless steel alloys, nickel-cobalt based alloys, nickel-molybdenum-chromium based alloys, and the like. The core may be a low density core based substantially upon titanium or titanium alloys.

Owner:SCHLUMBERGER TECH CORP

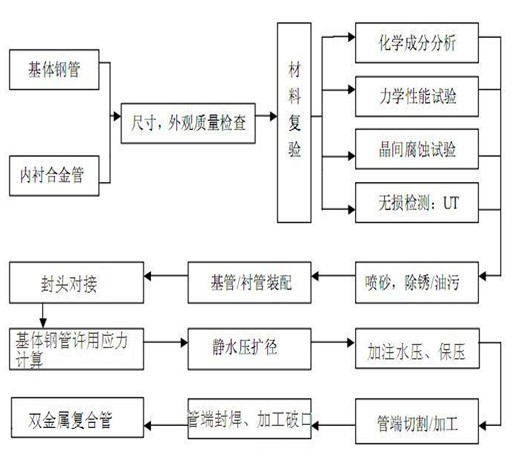

Novel dual metal composite pipes and preparation method

ActiveCN101334119AImprove corrosion resistanceTroubleshoot Connection Sealing IssuesLayered productsRigid pipesCorrosion resistant alloyEngineering

The invention relates to a novel bimetallic composite pipe, which is applied in exploiting oil and natural gas fields. The novel bimetallic composite pipe is characterized in that an inner lining pipe is arranged in an outer wall pipe. Short joints are welded at both ends of the outer wall pipe, welding seams are arranged between the outer wall pipe and the short joints, and both end parts of the inner lining pipe are welded on the inner wall of the short joints. At least 1 through hole with the diameter of 2 to 10 millimeters is drilled on the wall of the outer wall pipe. Electric welding is adopted to completely weld the through hole after the water pressure test, namely, electric welding is used for solidly filling the through hole after the water pressure test. Screw threads are machined at both ends of the novel bimetallic composite pipe or the both ends of the novel bimetallic composite pipe are machined into two welding grooves. The novel bimetallic composite pipe has the advantages that a carbon steel pipe or a low alloy steel pipe is adopted as the substrate material of the outer wall pipe, to exert the superior capability of mechanics of machinery and the low price characteristic of the carbon steel pipe or the low alloy steel pipe; the inner lining adopting layer corrosion resistant alloy is provided with excellent corrosion resistant capability and superior capability of mechanics of machinery. The screw threads coupling connection sealing problem and the bimetallic composite pipe ground welding problem occurring when the prior bimetallic composite pipes are in use are thoroughly solved, the application field of the bimetallic composite pipe is enlarged, and the cost of the oil field exploitation is saved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Ni-based corrosion resistant alloy for high-acidity oil-gas field and manufacturing method of oil casing of Ni-based corrosion resistant alloy for high-acidity oil-gas field

ActiveCN104789816AImprove corrosion resistanceGuaranteed corrosion resistanceOther manufacturing equipments/toolsCorrosion resistant alloySolution treatment

The invention relates to Ni-based corrosion resistant alloy for a high-acidity oil-gas field and a manufacturing method of an oil casing of the Ni-based corrosion resistant alloy for the high-acidity oil-gas field. The Ni-based corrosion resistant alloy comprises the following chemical components by weight percent: smaller than or equal to 0.03% of C, 21.0-24.0% of Cr, 18.0-20.0% of Fe, 7.0-9.0% of Mo, 1.5-2.0% of Cu, smaller than or equal to 3.0% of Co, smaller than or equal to 3.0% of W, smaller than or equal to 0.50% of Nb and Ta, smaller than or equal to 0.50% of Ti, smaller than or equal to 0.5% of Si, smaller than or equal to 0.5% of Mn, smaller than or equal to 0.003% of S, smaller than or equal to 0.005% of P, and smaller than or equal to 0.012% of N, wherein the total amount of (Mo+0.5*W) is 7.0-10.0%, and the numerical value of (Ti / 6+(Nb+Ta) / 8) / (C+N) is greater than or equal to 1 and smaller than or equal to 2. The manufacturing method comprises the following steps: I smelting, to be specific, smelting electroslag refining ingots; II tube blank processing; III tube making including hot-extrusion, reaming and solution treatment, wherein the grain size of a crude tube is 4-7 grade, the hot-extruded crude pipe is cold-rolled into a finished seamless tube, the total cold-rolling pass deformation amount is 30-61%, the cold-rolling speed is 25-35 times / min. The Ni-based corrosion resistant alloy and the oil casing manufactured are excellent in corrosion resistance.

Owner:TAIYUAN IRON & STEEL GROUP

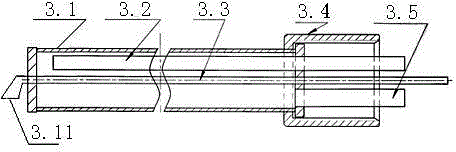

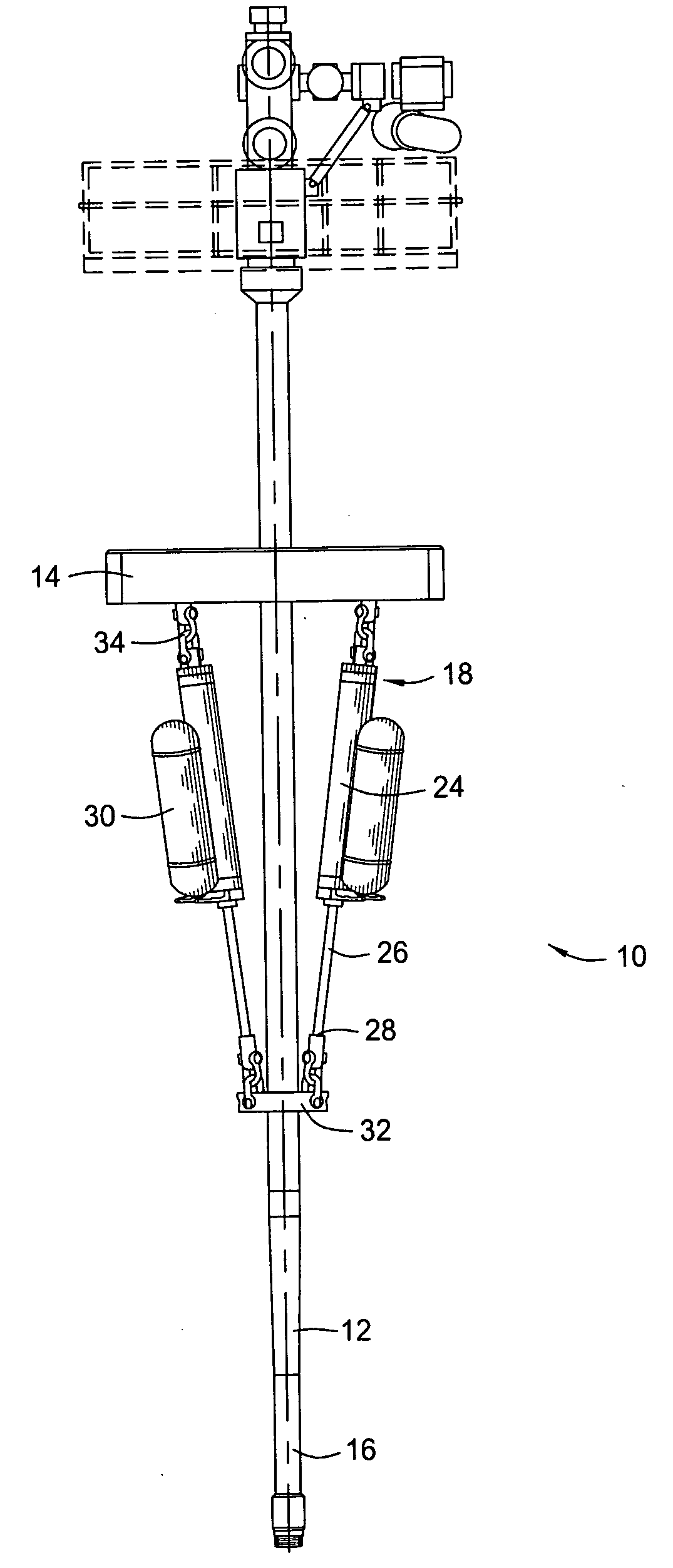

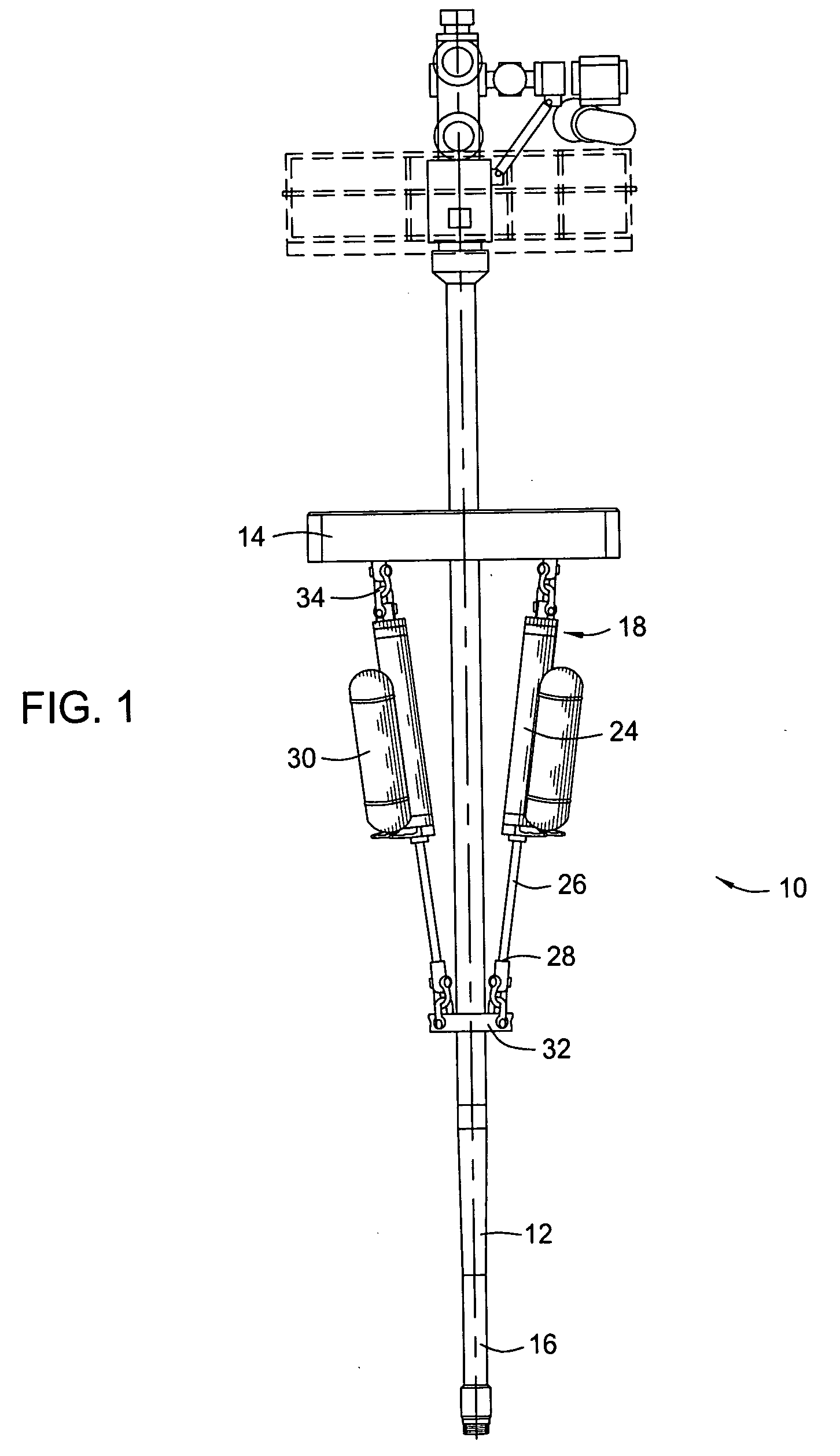

System, method, and apparatus for a corrosion-resistant sleeve for riser tensioner cylinder rod

ActiveUS20070056739A1Reduce manufacturing costShort manufacturing timeMechanical apparatusDrilling rodsCorrosion resistant alloyMechanical engineering

A riser tensioner cylinder rod incorporates a thin, corrosion-resistant alloy tube over a pre-machined steel alloy rod. The tube is swedged at one end and expanded to the inner surface of a split die. A gradual tapered surface on a stretching die provides a smooth transition during a stretching process for the tube. A pressurizing vessel traps an outer lip of the pre-swedged tube. Pressurized fluid in the vessel simultaneously causes the tube to expand and force the rod into the tube inner diameter. At the completion of the process, the pressurizing vessel is removed. The stretched tube is parted off at both ends and the stretching die is removed from the rod to complete the assembly.

Owner:VETCO GRAY

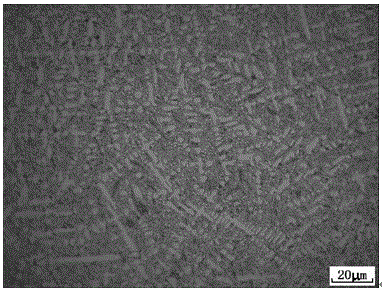

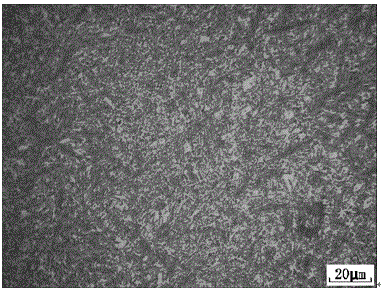

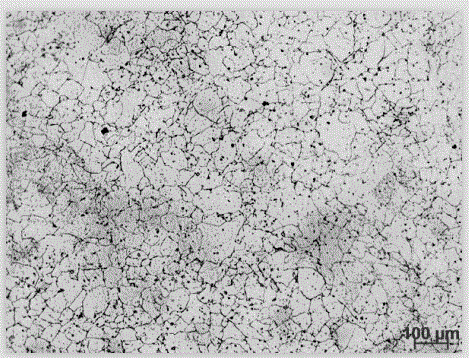

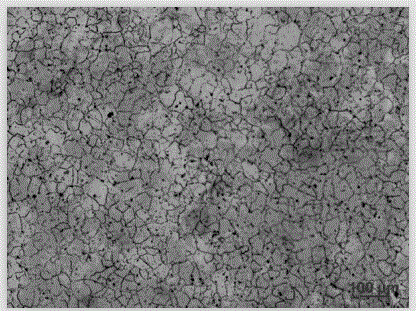

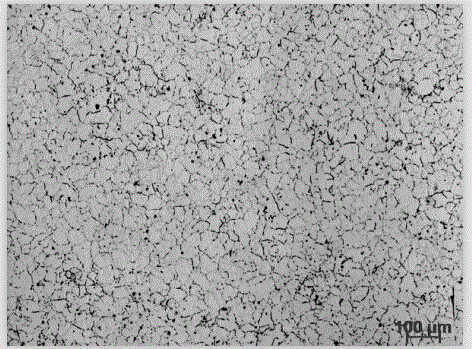

Electrolytic corrosion agent capable of displaying nickel-based corrosion-resistant alloy metallographic structure and corrosion method thereof

InactiveCN104451851AStable in natureSlow down the rate of electrolytic corrosionPreparing sample for investigationCorrosion resistant alloyElectrolysis

The invention discloses an electrolytic corrosion agent capable of displaying a nickel-based corrosion-resistant alloy metallographic structure and a corrosion method thereof and belongs to the technical field of metallographic electrolysis corrosion. The electrolytic corrosion agent comprises 40-60g of oxalic acid, 120-180g of glycerol and 400-500ml of deionized water. The corrosion method comprises the following steps: (1) preparing an electrolytic corrosion agent; (2) grinding a to-be-corroded nickel-based corrosion-resistant alloy by waterproof abrasive paper, then polishing the alloy by using a diamond polishing agent; (3) pouring the electrolytic corrosion agent prepared by the step (1) into an electrolytic corrosion instrument to carry out electrolytic corrosion; and (4) taking a sample out of the corrosion agent, washing the sample by using absolute ethyl alcohol and then airing. The electrolytic corrosion agent is simple in formula, free of toxicity and free of pungent smell; the damage to health of experimenters can be greatly reduced; the electrolytic corrosion agent is hard to volatilize, can be stored for a long time and can be reused, is good in corrosion effect and is capable of clearly displaying the nickel-based corrosion-resistant alloy metallographic structure.

Owner:HEBEI IRON AND STEEL

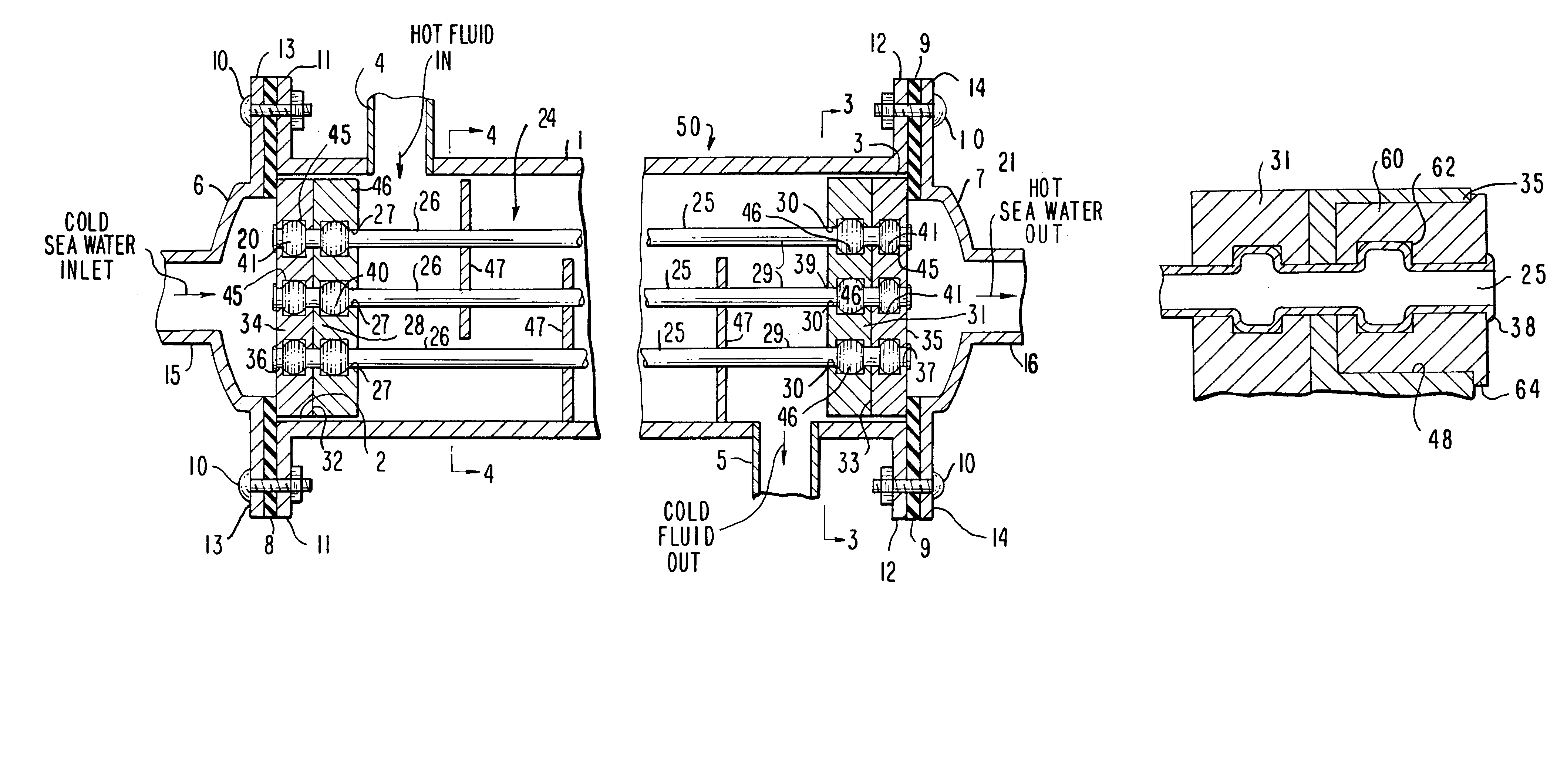

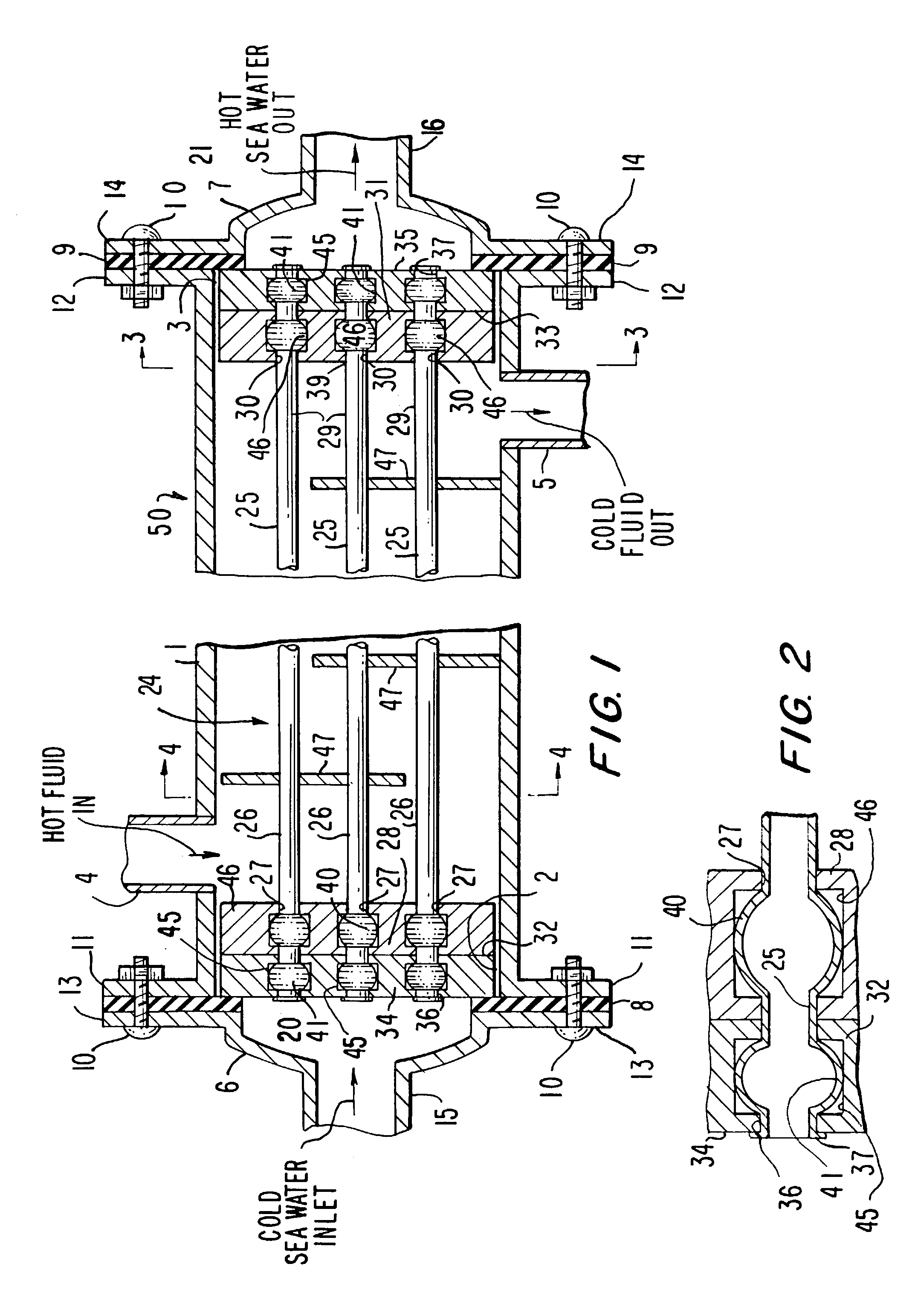

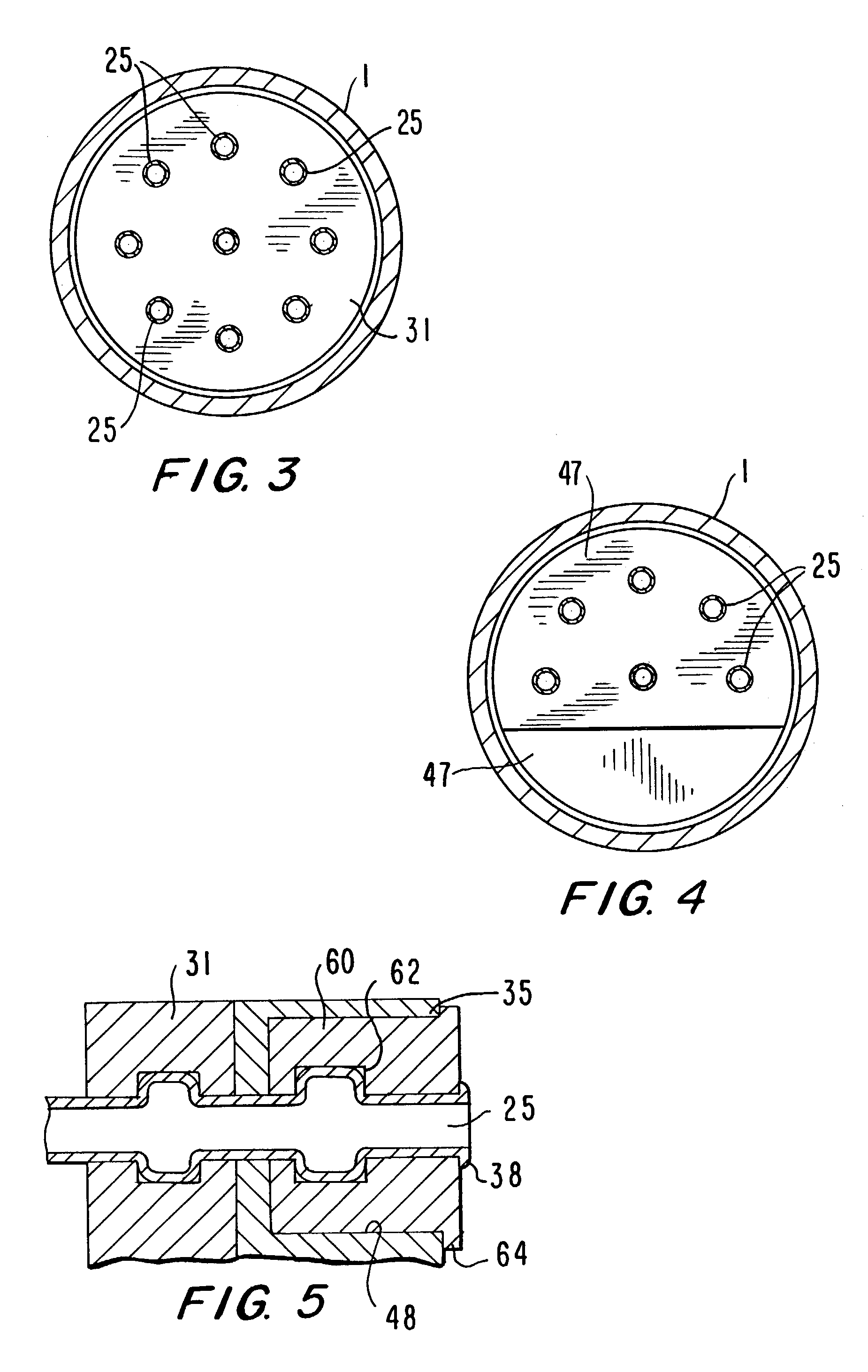

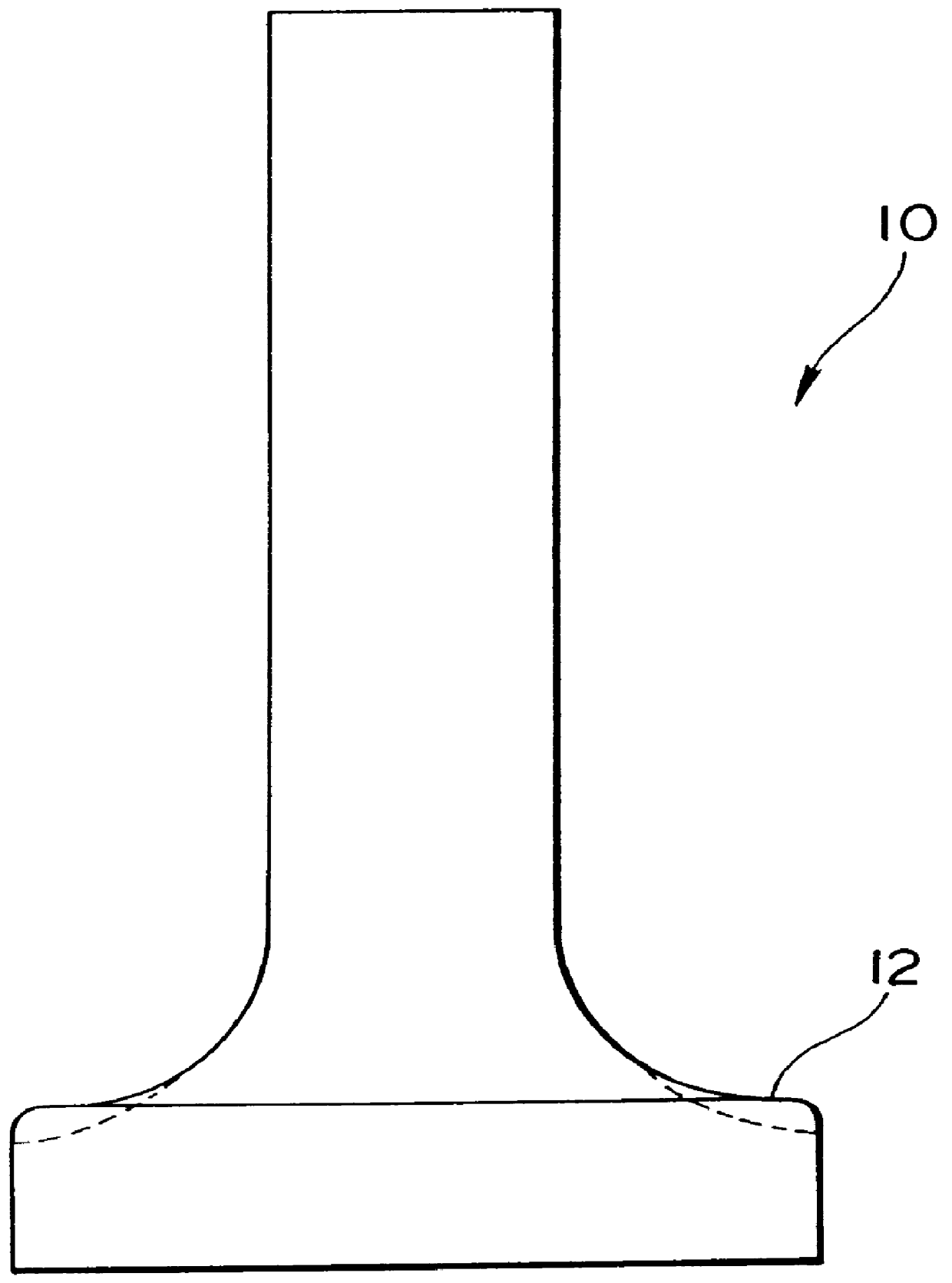

Anti-corrosion protection for heat exchanger tube sheet and method of manufacture

InactiveUS7377039B2Metal-working apparatusCorrosion preventionCorrosion resistant alloyShell and tube heat exchanger

A corrosion-resistant alloy metal tube sheet used to construct a shell and tube heat exchanger (50) for cooling fluids with sea water passing through corrosion-resistant alloy tubes (25) contained in a horizontal carbon steel outer shell (1) that are supported and sealed at each end by passing them through holes (27, 30) in a carbon steel tube sheet (28, 31) and axially aligned holes (36, 37) in alloy tube sheets (34, 35) that cover and protect the adjacent interior carbon steel tube sheets from sea water corrosion. The walls of the holes (27, 30, 36, 37) have at least one annular groove (45, 46) and the ends of each tube are radially expanded to form circumferential ridges (40, 41) on the outside of each tube at a mating location with each of said annular grooves (45, 46) where they are forcibly driven into the grooves to form a circumferential joint having good mechanical strength and water tightness, thereby eliminating the need for welding the external joint between the alloy tube sheets and alloy tubes.

Owner:SAUDI ARABIAN OIL CO

Sea water corrosion resistant hard alloy and preparation method thereof

InactiveCN102400027AMaintain performanceReduce manufacturing costCorrosion resistant alloyManufacturing technology

The invention discloses a sea water corrosion resistant hard alloy and a preparation method thereof, and relates to the technical field of alloy manufacturing. A purpose of the present invention is to solve the technical problems of not high hardness, not high wear resistance, high production cost, low performance-price ratio and the like of the nickel-based sea water corrosion resistant alloy in the prior art. The sea water corrosion resistant hard alloy of the present invention comprises the following components, by weight, 7.3-7.7% of Ni, 0.6-1.0% of Cr3C2, 0.3-0.7% of Mo, and the balance of WC powder.

Owner:四川科力特硬质合金股份有限公司

High corrosion resisting alloy for diesel engine valve and method for producing the valve

InactiveUS6139660AHigh hardnessHigh strengthMachines/enginesLift valveCorrosion resistant alloySolution treatment

A high corrosion resisting alloy for use in inlet and exhaust valves of diesel engines which is low in cost and excellent in corrosion resistance and strength, which consists by weight percentage of C< / =0.1%, Si< / =1.0%, Mn< / =1.0%, 25%<Cr< / =32%, 2.0%<Ti< / =3.0%, 1.0%< / =Al< / =2.0% and the balance being Ni and incidental impurities. The valves for the diesel engines are manufactured through the steps of forging the above-mentioned alloy into near net shapes of the valves, performing aging treatment (after solid solution treatment according to demand), and further enhancing hardness of the valves at their valve faces locally through partial cold forging.

Owner:DAIDO STEEL CO LTD +1

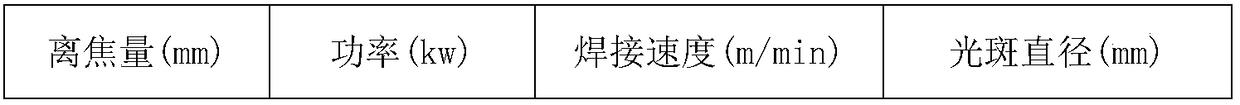

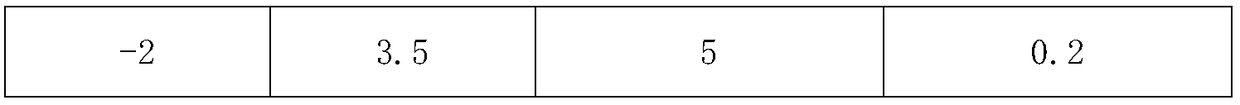

Welding method of stainless steel lining composite board

ActiveCN108705200AWell formedSmall weld widthWelding/soldering/cutting articlesMetal working apparatusCorrosion resistant alloyComposite slab

The invention discloses a welding method of a stainless steel lining composite board. The welding method comprises the steps that double V-shaped grooves are formed; welding is carried out on the bottom of the V-shape groove in one side of a carbon steel layer by adopting MAG welding, and a pre-welding joint is formed; welding is carried out on a groove between the V-shaped groove in one side of acorrosion-resistant alloy layer and the V-shape groove in one side of a carbon steel layer by adopting plasma welding, laser welding or TIG, and a base layer inner weld joint is formed; welding is carried out on exterior of the pre-welding joint on one side of the carbon steel layer by adopting submerged arc welding to form a base layer outer weld joint; welding is carried out on the bottom of the V-shaped groove at one side of the corrosion-resistant alloy layer by adopting the MAG or the TIG, and a transition layer welding joint is formed; and welding is carried out on the exterior of the transition layer welding joint by adopting the MAG or the TIG, and a composite welding joint is formed. According to the welding method, through the matching of the reasonable groove design and the welding process, high-quality and efficient welding of the stainless steel lining composite board is achieved, the performance is excellent, automatic production is easy to realize, and the wide market prospect is achieved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

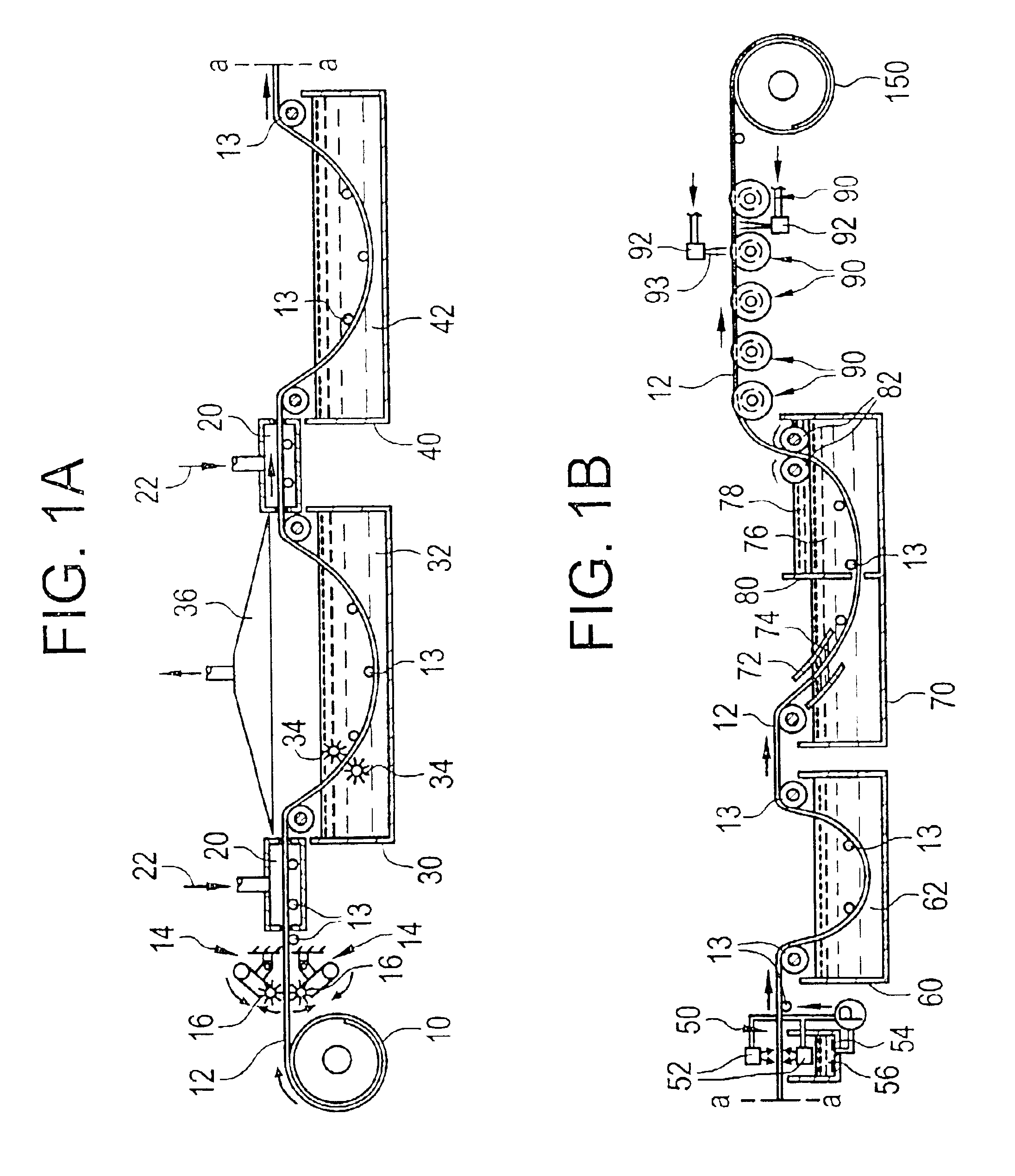

Method of and a welding station for laying a pipeline, with pipe section welded together by internal and external welding

ActiveUS20120298628A1Reduce chanceImprove welding qualityWelding/cutting auxillary devicesArc welding apparatusCorrosion resistant alloyEngineering

A method of laying a pipeline is described in which both internal and external weld passes are performed in order to weld together the pipe sections. The method includes arranging a pipe section adjacent to the end of a pipeline thereby defining a circumferential joint to be welded, performing an external weld pass, with for example GMAW—MIG torches, on the root of the joint to be welded during which weld material is deposited in the root of the joint to be welded, thereby forming a root weld, and then performing an internal weld pass, with for example a GTAW—TIG torch, on the root weld during which the root weld is melted and re-shaped. The method has particular application in relation to pipes clad with corrosion resistant alloy.

Owner:SAIPEM SPA

Corrosion-resistant coated copper and method for making the same

InactiveUS6861159B2Reduction factorMaterial safetyHot-dipping/immersion processesDomestic articlesCorrosion resistant alloyCopper

A corrosion-resistant coated base metal coated with a corrosion resistant alloy. The corrosion resistant alloy includes tin and zinc. The corrosion resistant coated base metal includes a heat created intermetallic layer primarily including copper and zinc.

Owner:REVERE COPPER PROD

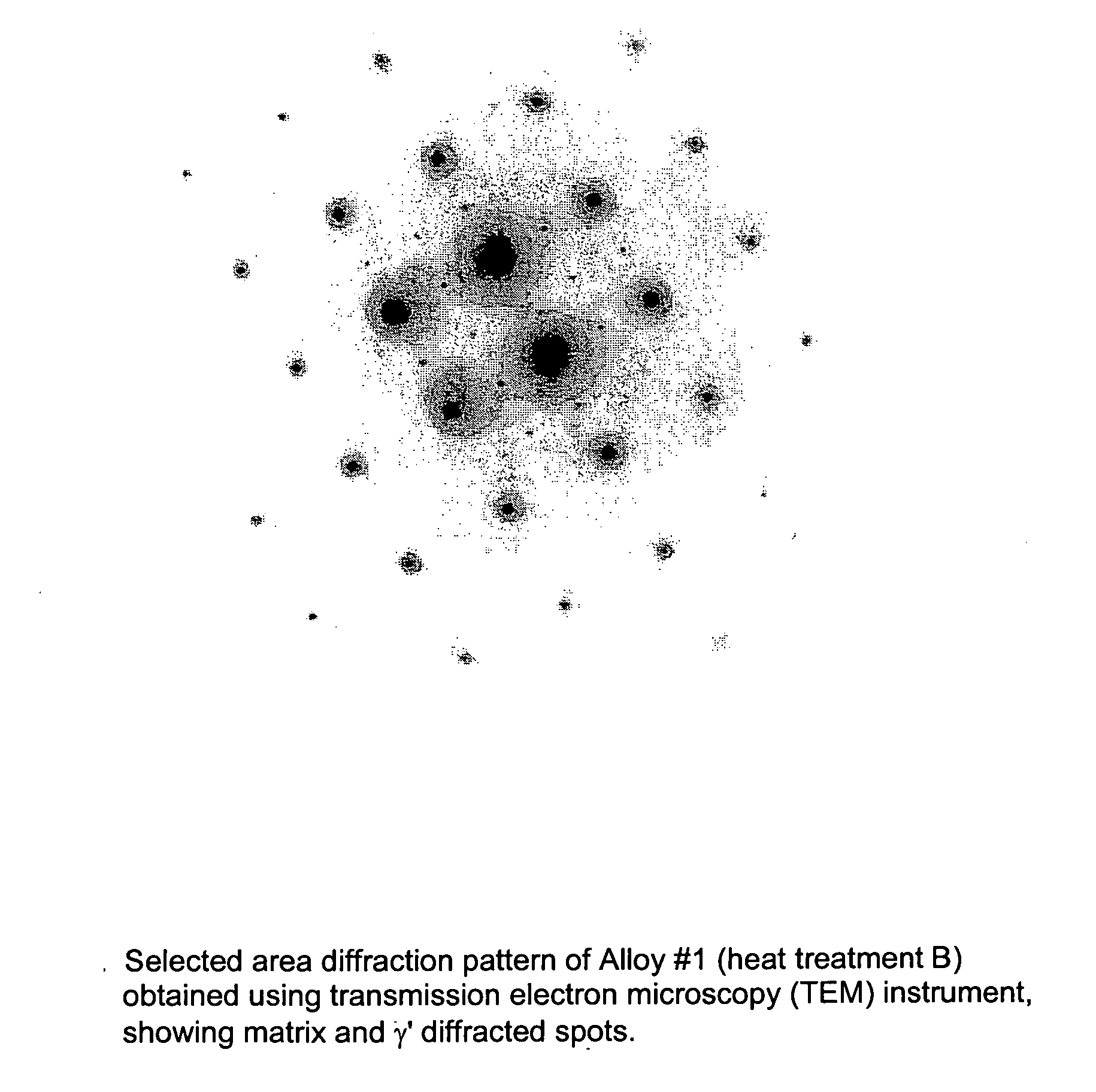

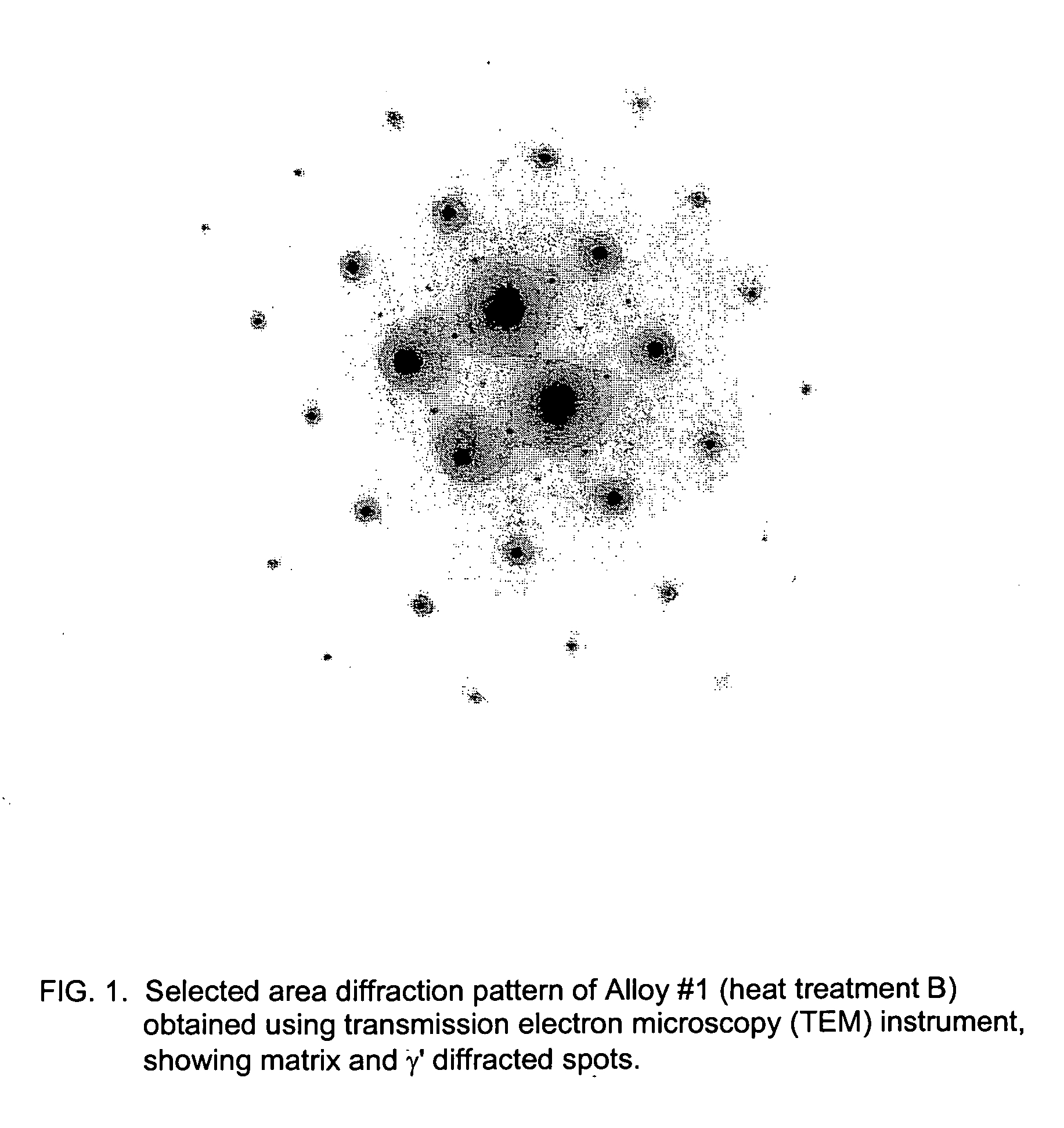

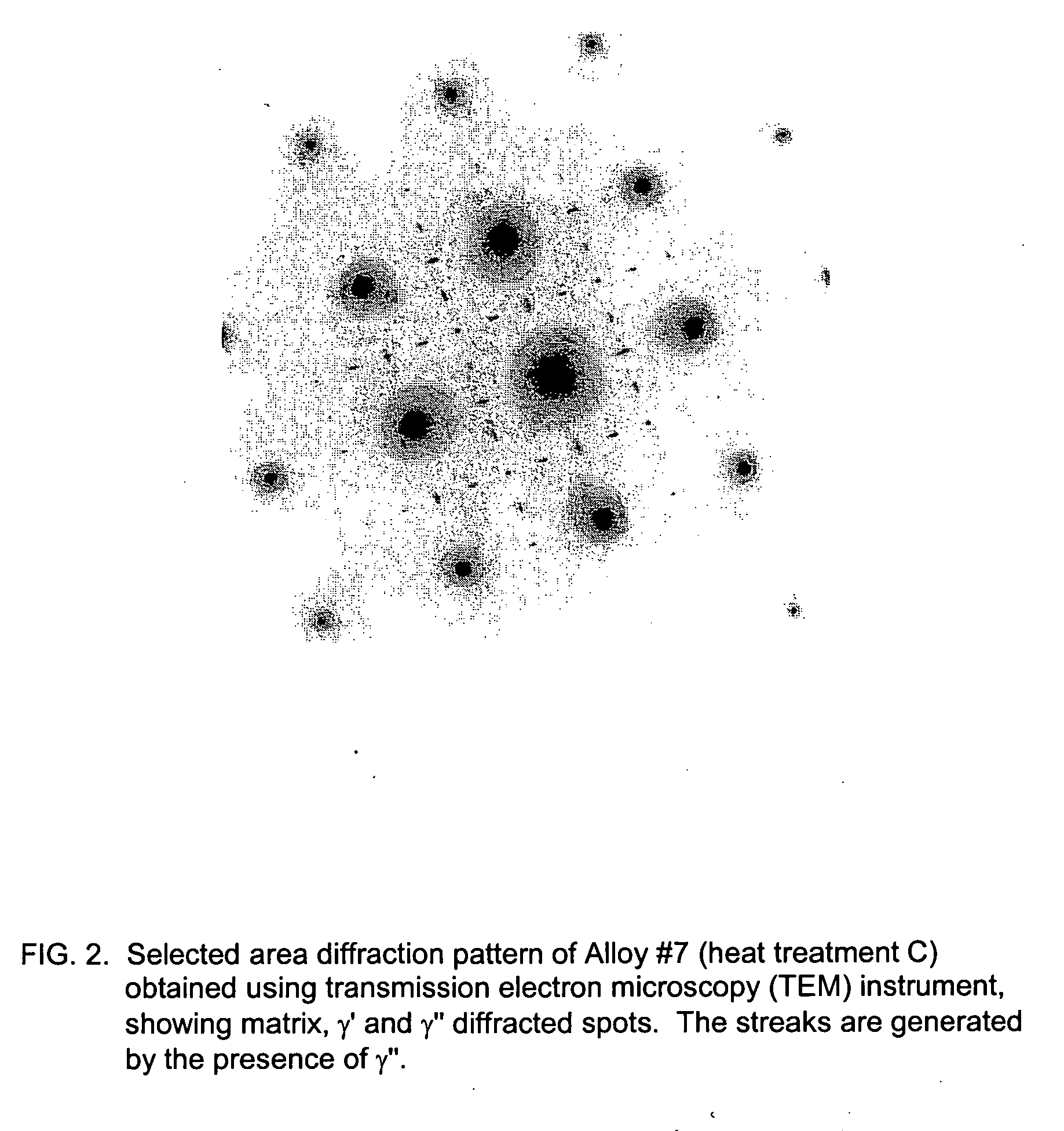

High strength corrosion resistant alloy for oil patch application

ActiveUS20070102075A1Extend aging timeLess strengthCorrosion resistant alloyUltimate tensile strength

A Ni—Fe—Cr alloy having high strength, ductility and corrosion resistance especially for use in deep-drilled, corrosive oil and gas well environments, as well as for marine environments. The alloy comprises in weight %: 35-55% Ni, 12-25% Cr, 0.5-5% Mo, up to 3% Cu, 2.1-4.5% Nb, 0.5-3% Ti, up to 0.7% Al, 0.005-0.04% C, balance Fe plus incidental impurities and deoxidizers. The alloy must also satisfy the ratio of (Nb-7.75 C) / (Al+Ti)=0.5-9 in order to obtain the desired high strength by the formation of γ′ and γ″ phases. The alloy has a minimum of 1% by weight γ″ phase dispersed in its matrix for strength purposes and a total weight percent of γ′+γ″ phases being between 10 and 30.

Owner:HUNTINGTON ALLOYS CORP (US)

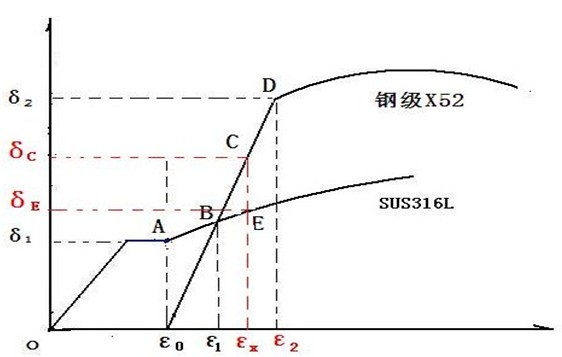

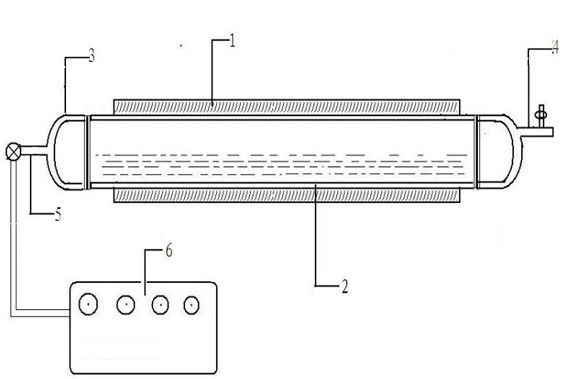

Hydrostatic pressure expanding composite technology for bimetal composite pipe

The invention discloses a hydrostatic pressure expanding composite technology for a bimetal composite pipe. On the theoretical basis of the metal material elastoplastic theory, a residual contact stress calculation system between two layers of pipelines is finally obtained after hydraulic expanding force and expanding compounding technology are built for guiding to select the hydraulic expanding force and evaluate the compounding technology. The invention aims to provide the hydrostatic pressure expanding composite technology for the bimetal composite pipe, which is used for the production technology of the bimetal composite pipe with big caliber, long pipeline and the thick corrosion resistant alloy layer of which the maximum thickness can be 8.00mm.

Owner:JIANGSU XINPENG COMPOSITE MATERIALS

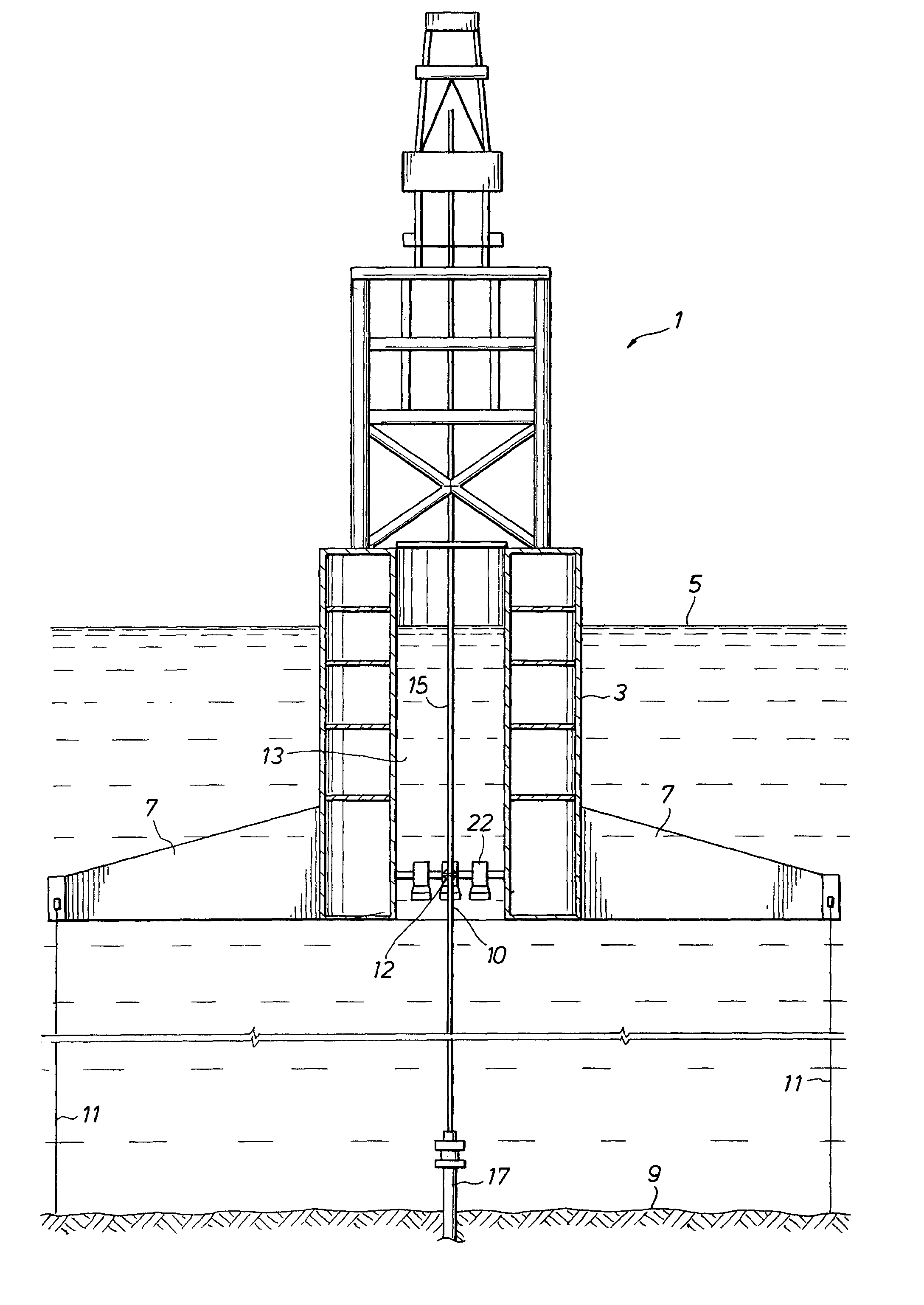

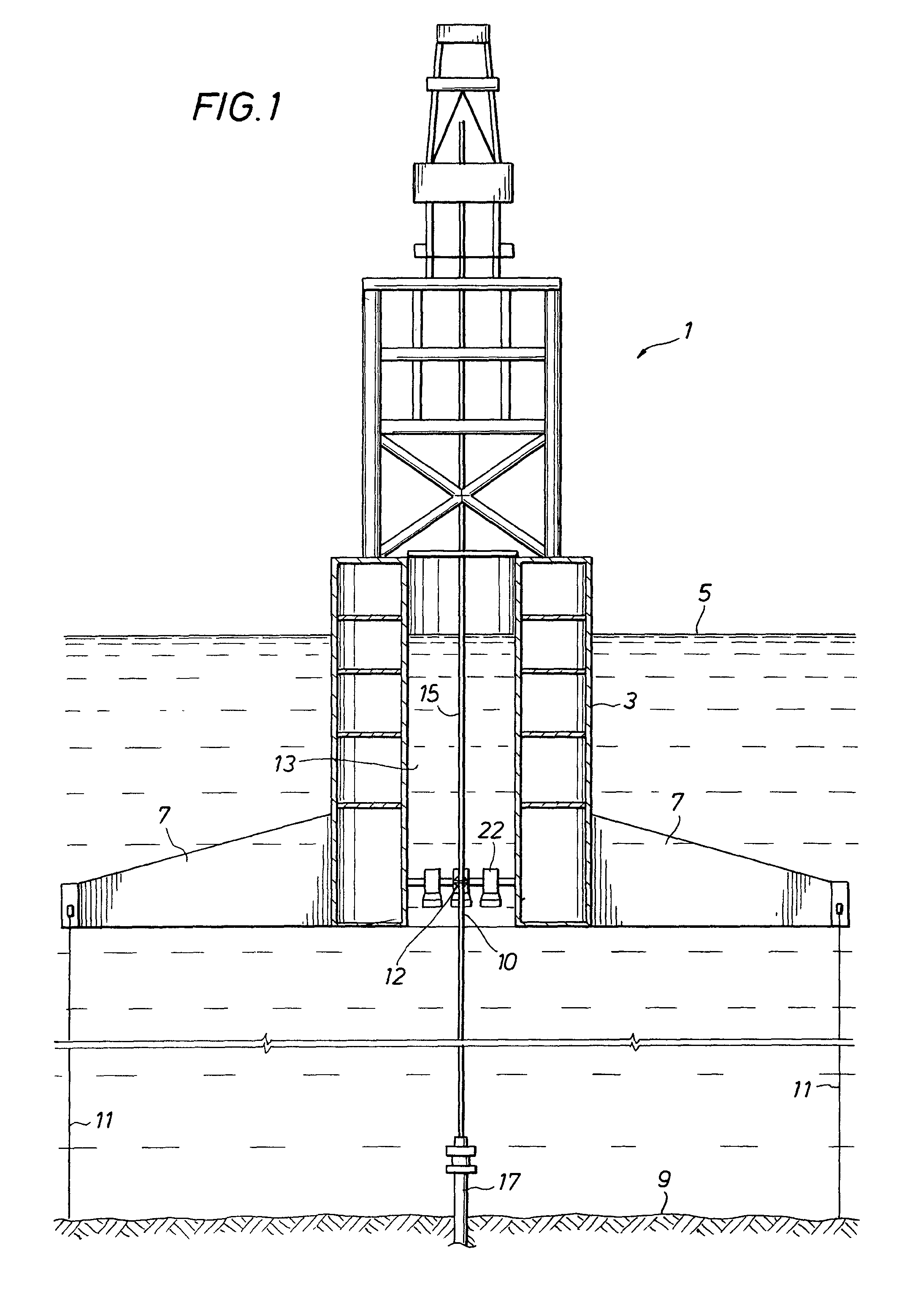

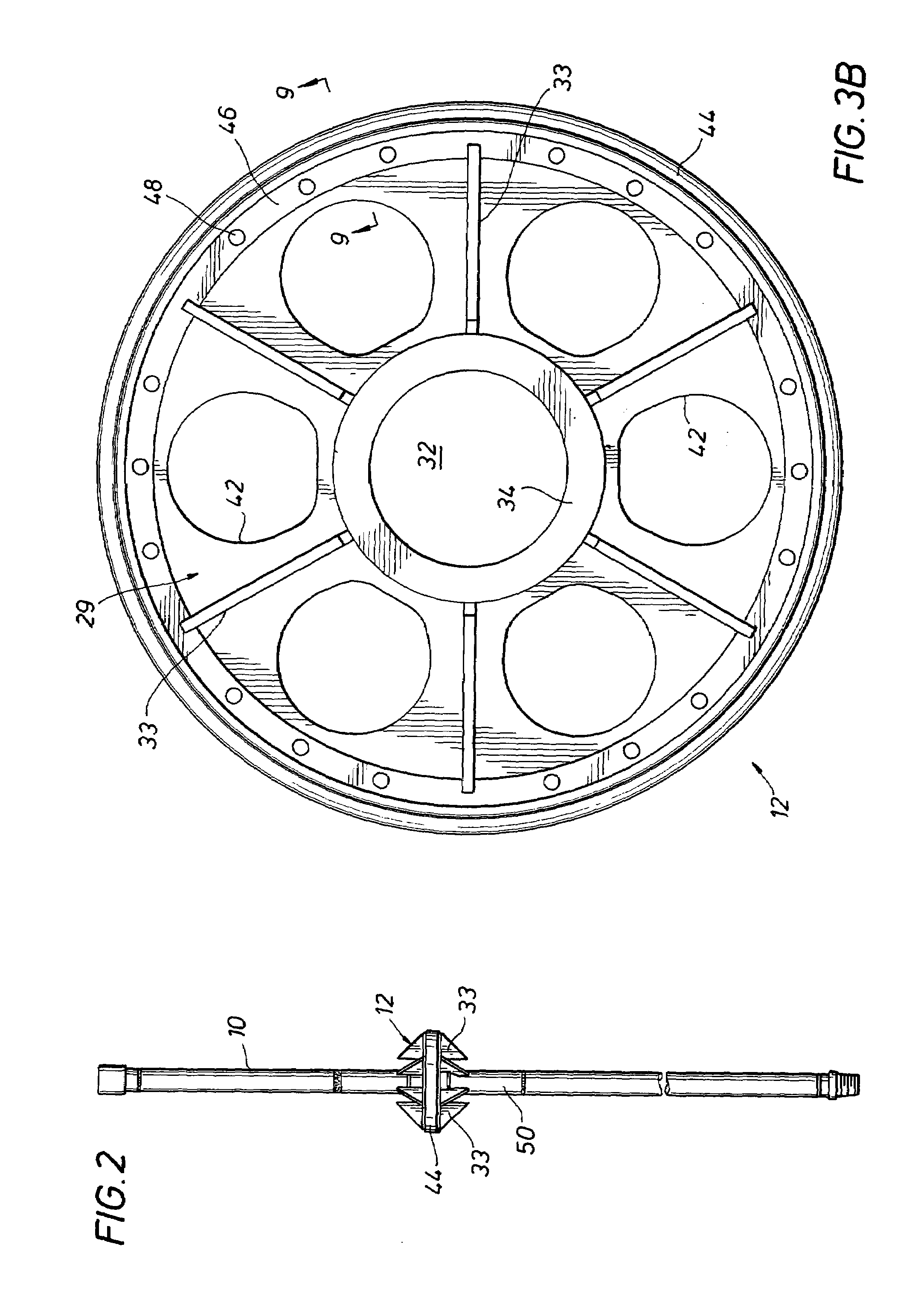

Keel joint centralizer

A riser centralizer for transferring lateral loads from the riser to a platform hull includes a keel centralizer mounted on a keel joint. The keel centralizer is received within a keel guide sleeve secured in a support mounted at the lower end of the platform hull. The keel centralizer includes a nonmetallic composite bearing ring having a radiused peripheral profile for minimizing contact stresses between the keel centralizer and the keel guide sleeve in extremes of riser and platform motion. The internal surface of the keel guide sleeve is clad with a corrosion resistant alloy and coated with a wear resistant ceramic rich coating.

Owner:SEAHORSE EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com