Hydrostatic pressure expanding composite technology for bimetal composite pipe

A technology of bimetallic composite pipe and composite process, which is applied in the field of bimetallic composite pipe hydrostatic pressure expansion composite technology, which can solve the problems of increased manufacturing cost, bulging, and the scrapping of the entire pipeline, and achieve pressure balance and uniform expansion pressure , Quality guaranteed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

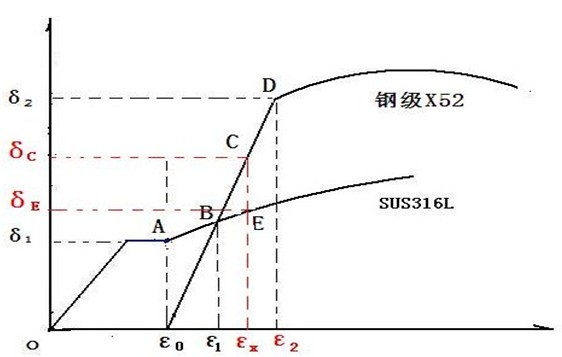

[0034] Theoretical basis of a bimetallic composite pipe hydrostatic pressure expansion composite process of the present invention:

[0035] According to the elastic-plastic theory of metal materials, the hydraulic expansion force and the residual contact stress calculation system between the two-layer pipes obtained after the expansion compound is established, which is used to guide the selection of the hydraulic expansion force and the evaluation of the composite process, such as figure 1 As shown, taking the 316L stainless steel lining corrosion-resistant alloy pipe as an example, the base steel pipe is X52 seamless steel pipe; due to the existence of the assembly gap between the inner and outer pipes, the starting point of the stress-strain curve of the base steel pipe moves to the right to point A, and the corrosion-resistant lining The alloy pipe is first deformed under the action of pressure. When the deformation reaches ε0, the outer wall of the lined corrosion-resistant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com