Preparation method of film bulk acoustic wave resonator with isolation layer and bulk acoustic wave resonator

A bulk acoustic wave resonator, film bulk acoustic wave technology, applied in the direction of electrical components, impedance networks, etc., can solve the problems of film warping, fracture, and affecting the performance of cavity type bulk acoustic wave resonators, etc., to prevent damage to the sacrificial layer Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

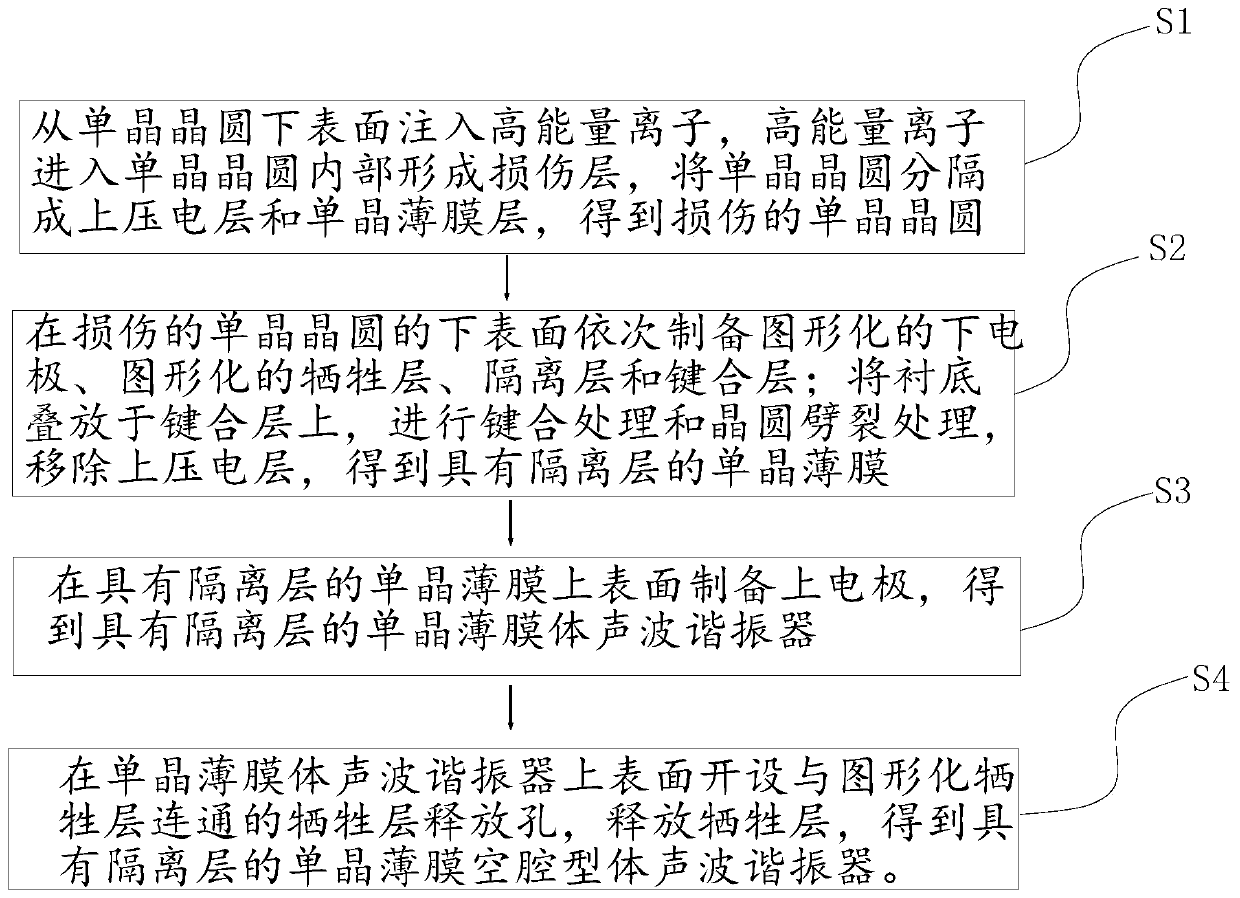

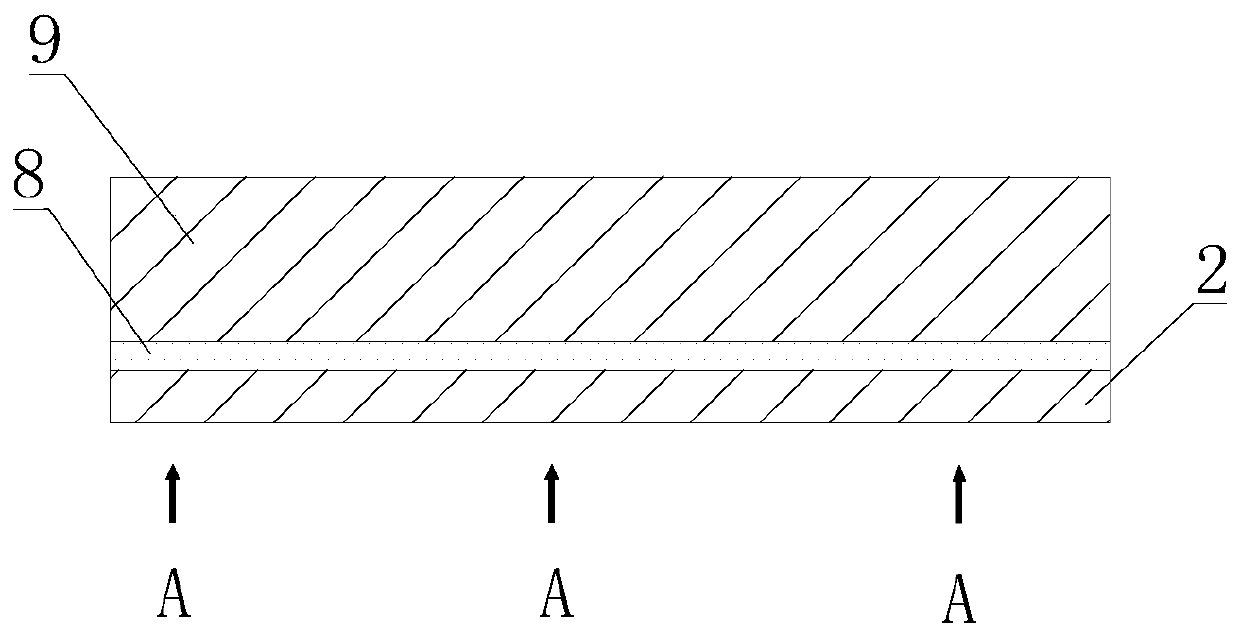

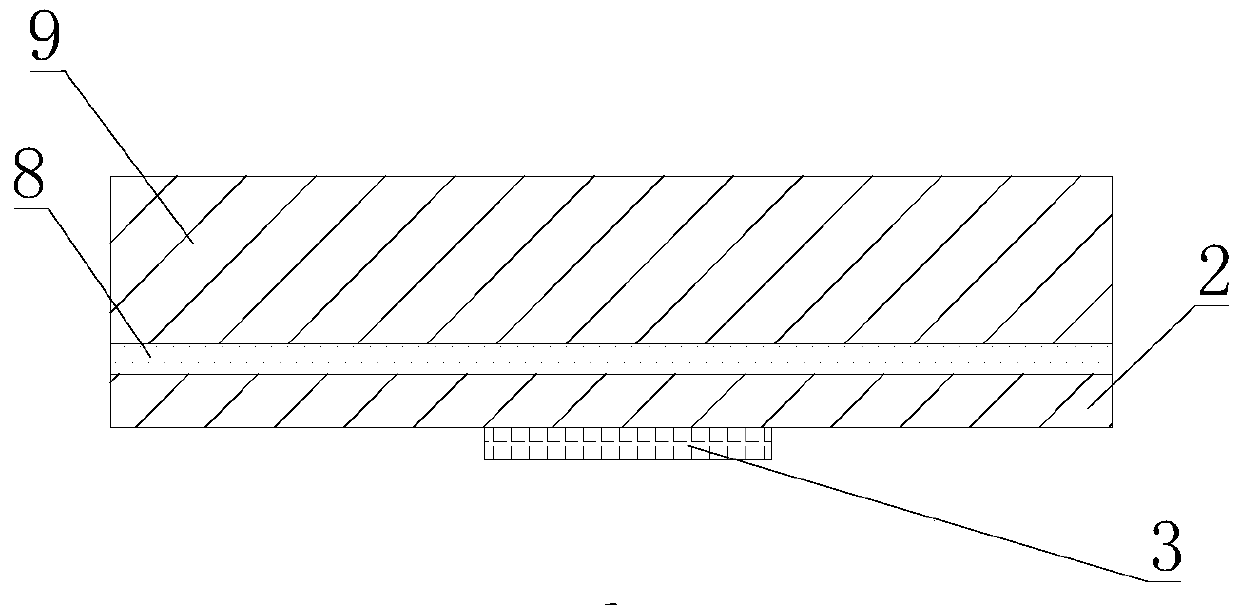

[0050] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 and Figure 10 , a method for preparing a thin film bulk acoustic resonator with an isolation layer provided by the invention, comprising the steps of:

[0051] S1) High-energy ions A are injected from the lower surface of the single-crystal wafer, and the high-energy ions A enter the interior of the single-crystal wafer to form a damaged layer 8, and the single-crystal wafer is separated into an upper piezoelectric layer 9 and a single-crystal thin film layer 2, and the obtained Damaged single crystal wafers;

[0052] S2) Prepare a patterned lower electrode 3, a patterned sacrificial layer 10, an isolation layer 4, and a bonding layer 5 sequentially on the lower surface of the damaged single crystal wafer; stack the substrate 6 on the bonding layer, and perform Bonding treatment and wafer splitting treatment, removing the upper piezoelectric layer 9...

Embodiment 1

[0075] 1) A lithium niobate single crystal wafer is selected, and high-energy helium ions (He 2+ ), so that a damage layer is formed inside the lithium niobate single crystal wafer, and the damage layer separates the lithium niobate single crystal wafer into a lithium niobate upper piezoelectric layer and a lithium niobate single crystal film layer; He 2+ The implantation energy is 200keV, and the implantation depth is 0.6μm;

[0076] 2) The lower electrode is prepared on the lower surface of the lithium niobate single crystal thin film layer. The lower electrode can be prepared in two ways. The first method is to coat the lower surface of the lithium niobate single crystal thin film layer with photoresist (Ruihong AZ6212), forming a photoresist layer, using a patterned mask plate (made of chromium) to expose and develop the photoresist, growing a lower electrode, cleaning with acetone to remove the photoresist, and obtaining a patterned lower electrode; The two methods are t...

Embodiment 2

[0083] 1) A lithium niobate single crystal wafer is selected, and high-energy helium ions (He 2+ ), so that a damage layer is formed inside the lithium niobate single crystal wafer, and the damage layer separates the lithium niobate single crystal wafer into a lithium niobate upper piezoelectric layer and a lithium niobate single crystal film layer; He 2+The implantation energy is 200keV, and the implantation depth is 0.6μm;

[0084] 2) The lower electrode is prepared on the lower surface of the lithium niobate single crystal thin film layer. The lower electrode can be prepared in two ways. The first method is to coat the lower surface of the lithium niobate single crystal thin film layer with photoresist (Ruihong AZ6212), forming a photoresist layer, using a patterned mask plate (made of chromium) to expose and develop the photoresist, growing a lower electrode, cleaning with acetone to remove the photoresist, and obtaining a patterned lower electrode; The two methods are to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com