Patents

Literature

36results about How to "Good corrosion and scale inhibition effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite water treatment agent

InactiveCN103663738AImprove protectionGood corrosion and scale inhibition effectTreatment using complexing/solubilising chemicalsCarboxylic acidCarboxylate

The invention discloses a composite water treatment agent which comprises the following components in parts by mass: 15-45 parts of sodium tungstate, 5-25 parts of polyaspartic acid, 1-5 parts of zinc salt, 2-15 parts of sodium benzoate and 2-25 parts of carboxylate, wherein sodium tungstate is a corrosion inhibitor which is non-toxic, causes no environmental hazard and can generate the synergic corrosion inhibition function with polyaspartic acid. With addition of other assistants, the composite water treatment agent becomes a green composite water treatment agent which has excellent corrosion inhibition and scale inhibition effects, lower in cost, non-phosphorus, easily biodegradable and beneficial to environmental protection. In China, tungsten reserves and yield are abundant, so that the sufficient tungsten compounds can be provided, and the cost of the treatment agent is greatly lowered.

Owner:QINGDAO BAIZHONG CHEM TECH

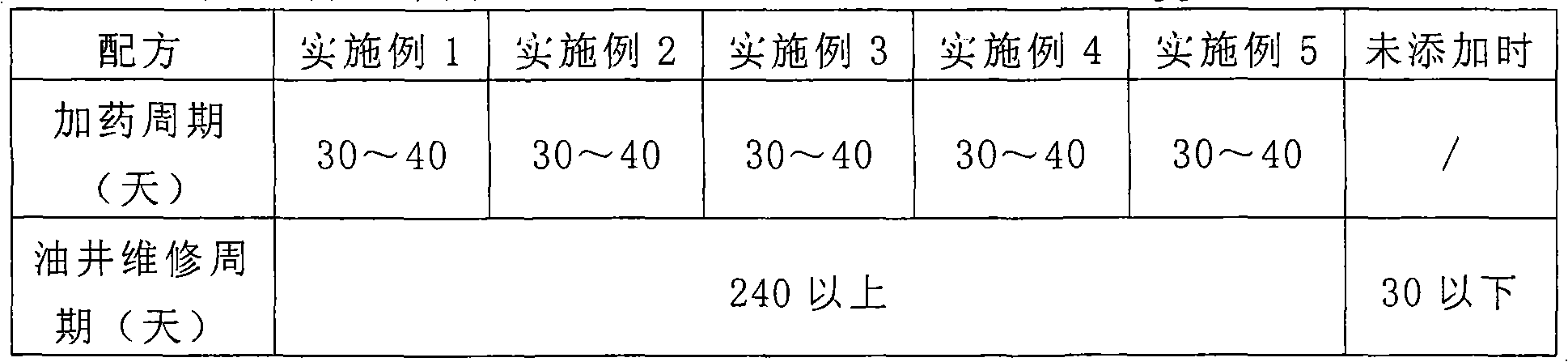

Solid corrosion and scale inhibitor and preparation method thereof

InactiveCN101613599AGood corrosion and scale inhibition effectMeet work performance requirementsDrilling compositionBorehole/well accessoriesPhosphateOil field

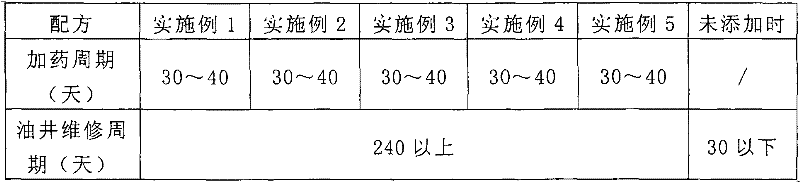

The invention relates to a solid corrosion and scale inhibitor and a preparation method thereof. The scale inhibitor comprises the following components by weight percentage: 5 to 15% of phosphonate, 25 to 40% of phosphate, 20 to 30% of zinc chlorine, 5 to 10% of amine, 5 to 10% of disintegrating agent and 8 to 12 percent of citrate. The solid corrosion and scale inhibitor provided by the invention has excellent corrosion and scale inhibition effect, and drug efficiency is 30-40 days through on-site testing; after operations are carried out according to drug adding cycle, the oil casing, oil pipes, tension rods and other equipment in each oil well can be well protected, thereby meeting requirements on the operating performance of oil rigs during secondary or tertiary oil recovery; meanwhile, the drug adding cycle is prolonged, thus reducing perambulation cycle of the oil wells for maintenance personnel, reducing workload of maintenance personnel, and solving the problem of larger maintenance costs caused by frequent maintenance on oil rigs in current oil field.

Owner:天津开广工业水处理有限公司

Corrosion inhibition anti-sludging agent for boiler heating network

A corrosion and scale inhibitor used for boiler heating network is characterized in that the inhibitor consists of contents with the following percentage: 5-30 percent of organic Phosophono Butane Tricarboxylicacid and salts, 2-10 percent of acrylic copolymer, 20-30 percent of phosphating poly maleic, 3-10 percent of organic oxygen scavenger, 10-30 percent of alkalinity regulator, and the rest is the deionized water. The inhibitor is a corrosion and scale inhibiting complex formula compound which is applied to both first heating network and secondary heating network.

Owner:CHINA NAT OFFSHORE OIL CORP +1

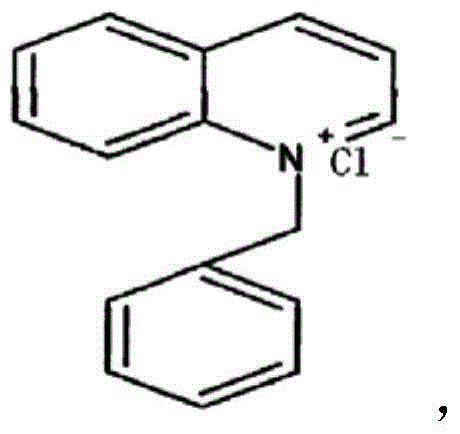

Corrosion and scale inhibitor composition, application thereof, and oil field water injection wellbore corrosion and scale prevention method

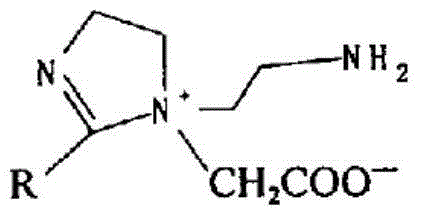

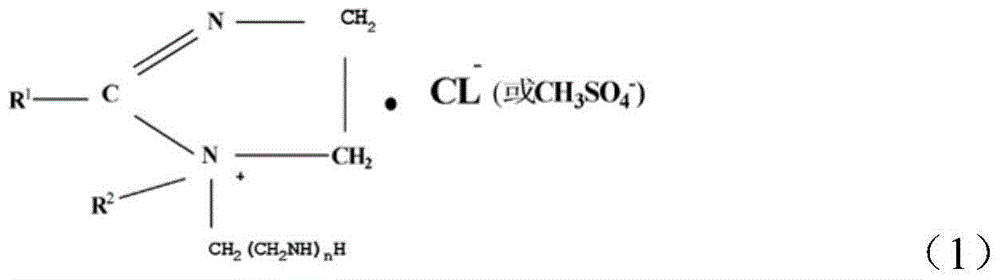

ActiveCN105733541AGood corrosion and scale inhibition effectNo pollution in the processCleaning apparatusDrilling compositionImidazoline derivativesQuinoline

The invention discloses a corrosion and scale inhibitor composition and an application thereof. The composition includes at least one quinoline derivative, at least one imidazoline derivative and at least one acrylic derivative. The quinoline derivative is selected from quinoline containing an ethylene oxide substituent group. The imidazoline derivative is selected from imidazoline quaternary ammonium salt and bisimidazoline. The invention also discloses an oil field water injection wellbore corrosion and scale prevention method which includes a step of feeding the corrosion and scale inhibitor composition into an oil field water injection wellbore. The corrosion and scale inhibitor composition has excellent corrosion and scale inhibition effect on metal members working under a high-temperature and high-pressure environment (such as the oil field water injection wellbore), and in addition, the corrosion and scale inhibitor composition is free of phosphoric compounds and is free of environment pollution, is environment-friendly, is simple in composition and reduces difficulty of on-site operation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Environment-friendly cooling circulating water system composite corrosion-inhibition antisludging agent and preparation method thereof

ActiveCN103613213AGood corrosion and scale inhibition effectAdd lessScale removal and water softeningPolyaspartic acidPolyethylene glycol

The invention belongs to the technical field of water treatment of an industrial circulating water cooling system, and particularly discloses an environment-friendly cooling circulating water system composite corrosion-inhibition antisludging agent and a preparation method thereof. The composite corrosion-inhibition antisludging agent consists of a component A, a component B, a component C and water, wherein the component A is polyethylene glycol-polyaspartic acid-polyglutamic acid ternary copolymer, the component B is hydrolytic polymaleic anhydride, and the component C is benzotriazole. The components A, B and C are dissolved in the water according to the ratio to produce a finished product. The corrosion-inhibition antisludging agent is good in corrosion-inhibiting effect on A3 carbon steel, red copper and stainless steel, the antisludging rate is high, the application requirement of the circulating cooling water can be met, and the biodegradability is good.

Owner:ENERGY RES INST CO LTD HENAN ACADEMY OF SCI

High-efficiency corrosion-mitigation scale-inhibition water saving agent for boiler

InactiveCN101638273AGood corrosion and scale inhibition effectLess corrosiveScale removal and water softeningSodium silicateCorrosion

The invention relates to a high-efficiency corrosion-mitigation scale-inhibition water saving agent used for a boiler, which contains the following components in percentages by weight: 15-20 percent of hydroxyl ethylidene diphosphate, 3-4 percent of sodium hydroxide, 25-35 percent of urotropin, 10-25 percent of benzotriazole and 20-30 percent of sodium silicate. The invention has the advantages ofefficient high-efficiency corrosion-mitigation scale-inhibition effect, water-saving function and minimal corrosion to boiler appliances.

Owner:张振海

Efficient special boiler corrosion and scale inhibitor

The present invention relates to an efficient special boiler corrosion and scale inhibitor. The corrosion and scale inhibitor is characterized in that the corrosion and scale inhibitor comprises, by weight, 5-30% of organic phosphine carboxylic acid and a salt of the organic phosphine carboxylic acid, 2-10% of an acrylic copolymer, 20-30% of polymaleic acid phosphate, 10-30% of an alkalinity adjusting agent, 3-10% of an organic deoxidizing agent, and the balance of deionization water. The efficient special boiler corrosion and scale inhibitor of the present invention is a corrosion and scale inhibition compound formula suitable for the primary heat supply network and the secondary heat supply network, and has effects of strong adaptability, convenient use, no side effect and the like.

Owner:天津通悦科技有限公司

Low-phosphorus high-efficiency corrosion and scale inhibitor and application thereof in scale inhibition of industrial circulating cooling water

ActiveCN105060517AGood scale inhibitionGood corrosion inhibition effectScale removal and water softeningAlkalinityAcid corrosion

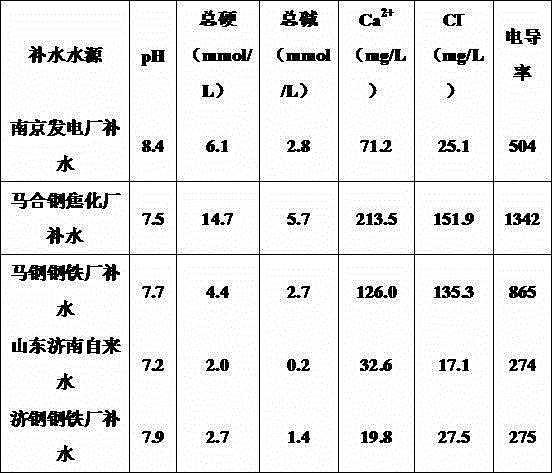

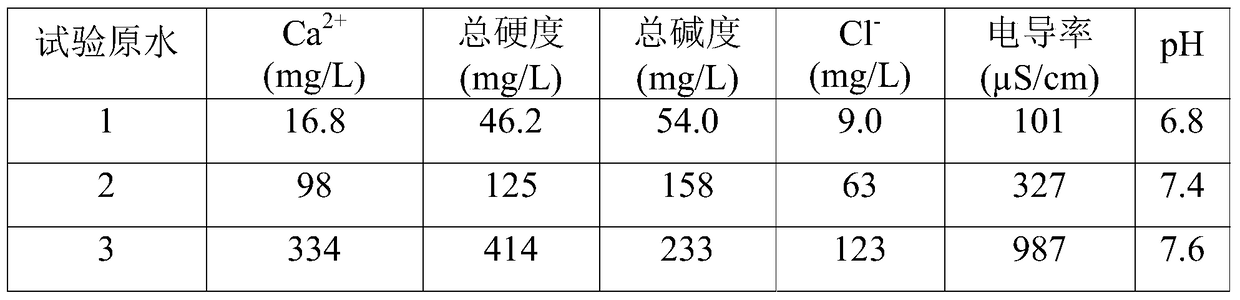

The invention discloses a low-phosphorus high-efficiency corrosion and scale inhibitor and an application thereof in scale inhibition of industrial circulating cooling water. The corrosion and scale inhibitor contains the following effective components in parts by weight: 1-3 parts of an organic phosphonic acid corrosion and scale inhibitor, 3-6 parts of low-phosphorus or phosphorus-free scale inhibitor, 3-8 parts of a sulfonic acid type polymer scale inhibitor, and 1-3 parts of a zinc salt. The corrosion and scale inhibitor has excellent CaCO3 scale resistance, Ca3(PO4)2 scale resistance and corrosion inhibition rate when the industrial circulating water having water quality conditions of Ca<2+> of 120 mg / L, Cl<-> of 60 mg / L and the alkalinity of 110 mg / L is concentrated to 3-6 times, the drug total content is 8-20 ppm, and the phosphorus content is less than 0.5 ppm.

Owner:湖北省兴发磷化工研究院有限公司 +1

Special corrosion and scale inhibitor for water reuse in power plant and preparation method thereof

InactiveCN104843879ANo pollution in the processIncreased slow-release scale inhibition effectScale removal and water softeningEpoxySolubility

The invention relates to a special corrosion and scale inhibitor for water reuse in a power plant and a preparation method thereof. The special corrosion and scale inhibitor comprises the following components by weight percentage content: 25 to 40% of sulfonic methane amino poly epoxy succinic acid, 20 to 30% of N, N-diacetyl adipic dihydrazide, 12 to 30% of maleic acid-acrylic copolymer, 3 to 5% of graphene oxide aqueous dispersion, 3 to 6% of fatty alcohol-polyoxyethylene ether and 15 to 40% of zinc sulfate aqueous solution. The components of the corrosion and scale inhibitor achieve a synergistic effect, and can realize trace removal of pollutants, after the corrosion and scale inhibitor is compounded, the corrosion and scale inhibition properties are greatly improved, the synergistic effect of physical adsorption and chemical adsorption of the pollutants can be effectively realized, and the special corrosion and scale inhibitor can be used in a wider water pH scope and temperature, and has an excellent sterilizing effect. The production process is simple, three-waste emission is avoided, the stability and water solubility are good, and the main components are biodegradable, free of toxic, phosphorus, pollution and corrosivity, less in adding rate, and environment-friendly.

Owner:山东应天环保能源有限公司

Composite corrosion and scale inhibitor and application thereof

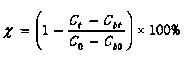

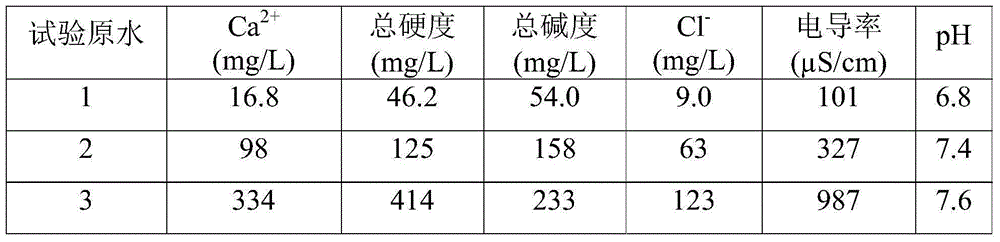

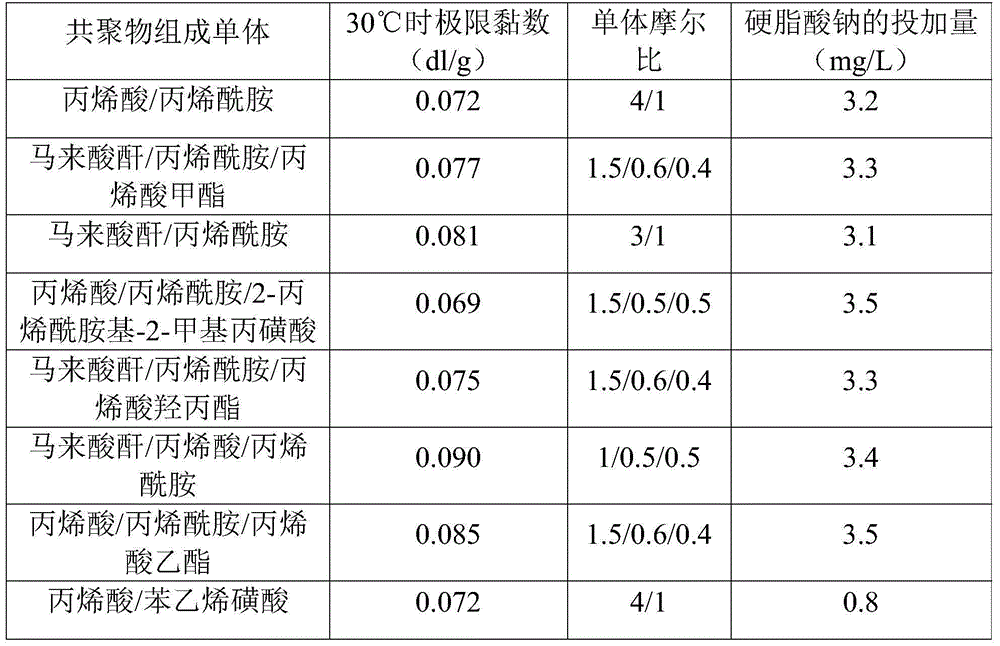

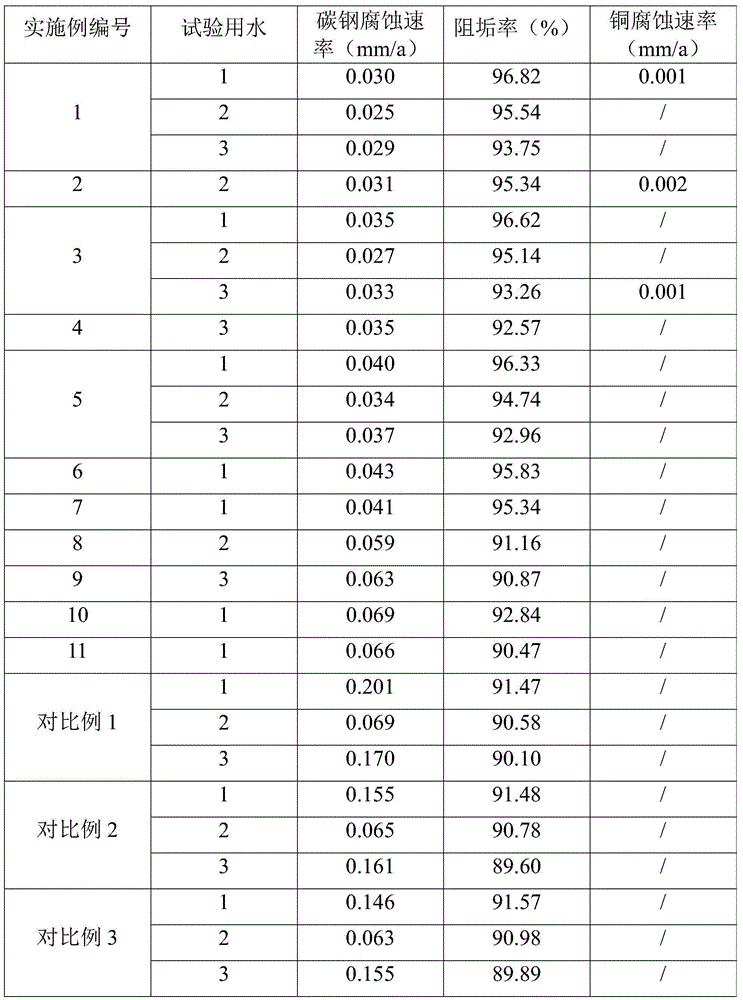

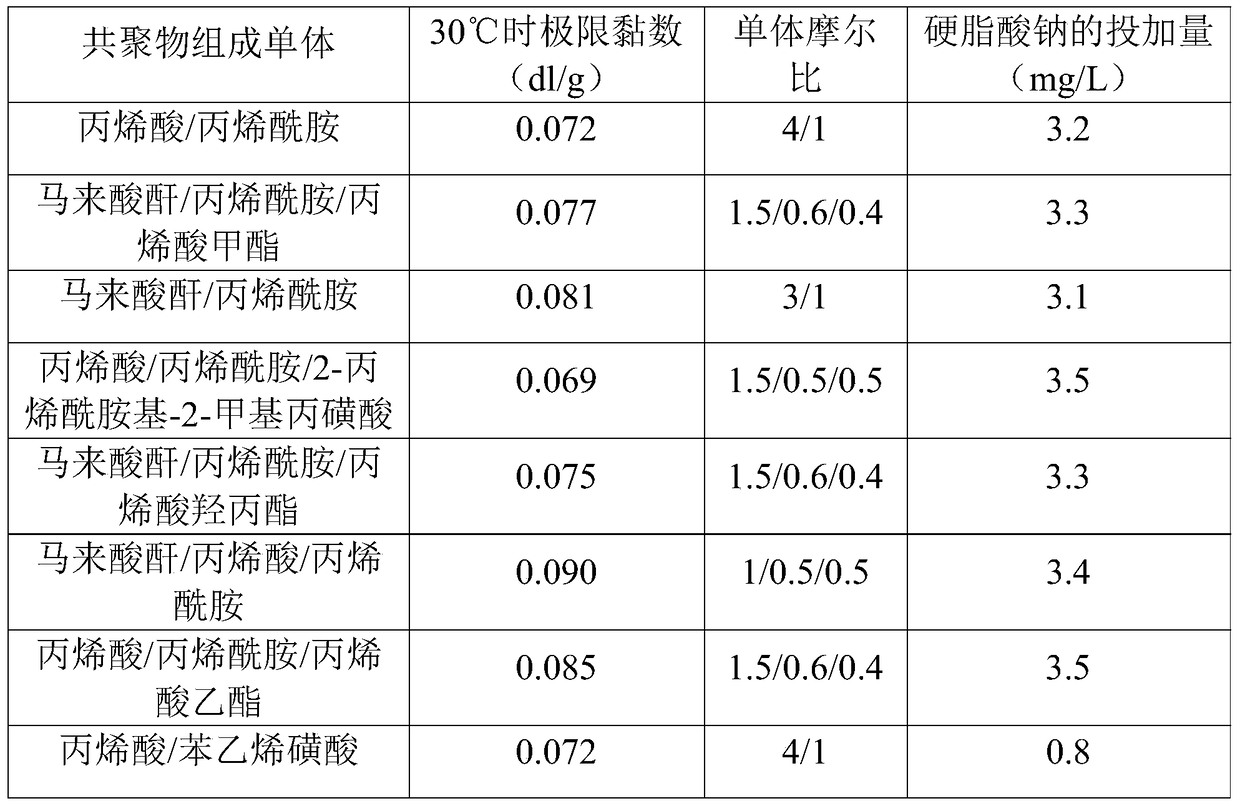

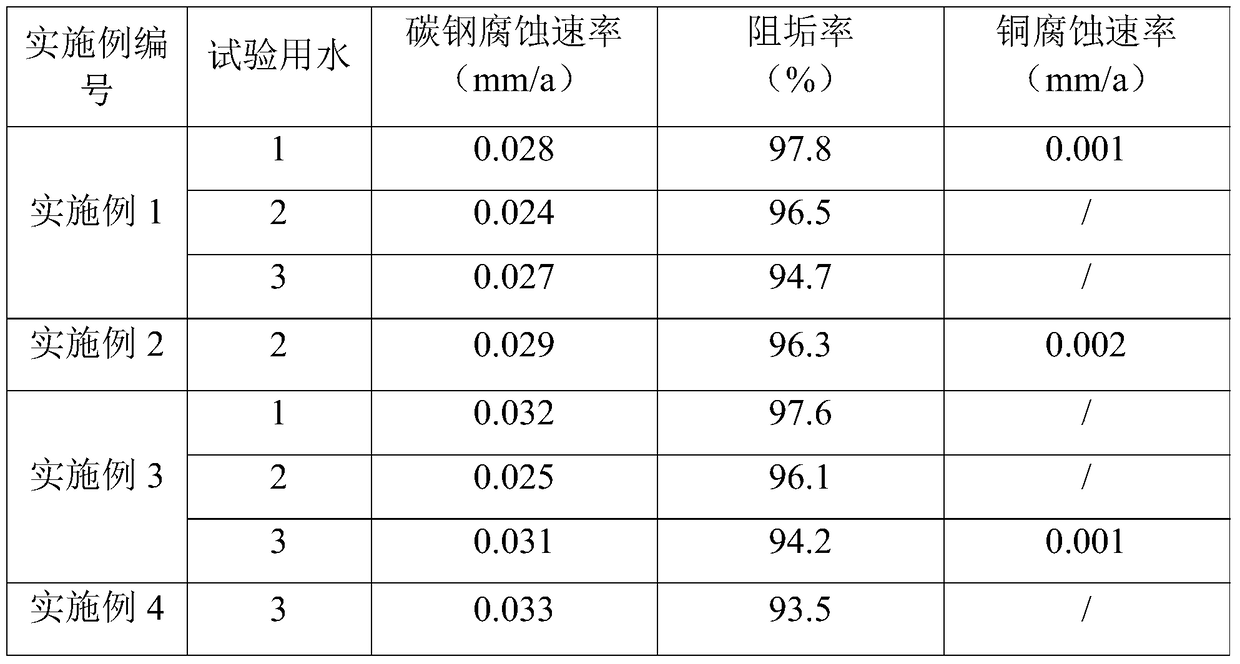

ActiveCN106430645AGood corrosion and scale inhibition effectImprove performanceScale removal and water softeningChemistryStearic acid

The invention relates to the field of chemical cleaning and discloses a composite corrosion and scale inhibitor. The composite corrosion and scale inhibitor comprises stearic corrosion inhibiting agents, dispersing agents and scale inhibiting agents, wherein the stearic corrosion inhibiting agents are selected from stearic acid and / or stearate, the dispersing agents comprise copolymers of constitutional units provided by acrylamide, and the scale inhibiting agents are non-phosphorus homopolymers. The invention further discloses application of the composite corrosion and scale inhibitor in circulating cooling water treatment. The composite corrosion and scale inhibitor has the advantages that excellent corrosion and scale inhibiting effects can be obtained in the absence of phosphorous components, and excellent property and environment-friendliness are realized.

Owner:CHINA PETROLEUM & CHEM CORP +1

Corrosion and scale inhibitor specially used for circulating water system in oxygen production plant and preparation method thereof

InactiveCN104817194AEnhanced slow-release scale inhibition effectGood corrosion and scale inhibition effectScale removal and water softeningSolubilityChemical adsorption

The invention relates to a corrosion and scale inhibitor specially used for a circulating water system in an oxygen production plant and a preparation method thereof, wherein the corrosion and scale inhibitor includes following components, by mass, 25-40% of sulfonic acid methylamino polyepoxysuccinic acid, 20-30% of an acrylic acid / methyl acrylate / acrylamide / AMPS co-polymer, 12-30% of a maleic acid / acrylic acid co-polymer, 3-5% of an aqueous dispersed liquid of graphene oxide, 3-6% of fatty alcohol-polyoxyethylene ether and 15-40% of a water solution of BTA. The components of the corrosion and scale inhibitor achieve a synergistic effect so that trace-amount removal of pollutants is achieved. The corrosion and scale inhibitor is greatly enhanced in performances after compounding, can achieve the synergistic effect of physical and chemical adsorption on pollutants, can be used in wide pH range and temperature range, is simple in preparation method, is free of emission of waste gas, waste water and solid waste and is good in stability and water-solubility. The main components are biodegradable so that the corrosion and scale inhibitor is toxic-free, phosphorus-free, pollution-free and corrosion-free, is less in addition amount and is environment-friendly.

Owner:山东应天环保能源有限公司

Composite water treatment medicament

InactiveCN101462800AReduce pollutionGood corrosion and scale inhibition effectScale removal and water softeningWater cyclingWater quality

The invention discloses a composite water treatment medicine, which comprises the compositions of acrylic acid-2-acrylamido-2-methylpropane sulfonic acid copolymer, phosphono-carboxylic acid, 1-hydroxy ethylidene-1,1-diphosphonic acid, zinc salt and water; and the compositions are mixed according to the proportion to prepare the water treatment medicine. The medicine has excellent effect of scale and corrosion inhibition on treating high-strength and high-hardness water so as to ensure that the corrosion rate and the scale deposit velocity of the treated water are both lower than the control index of recirculated water quality monitoring, and is incomparable with other water treatment medicines in aspects of prolonging service life and repair cycle of equipment, ensuring long-term safe operation of the equipment, saving steel materials and water, reducing environmental pollution and the like. The water treatment medicine is applied to an industrial cooling water circulating system, and has great economic and social benefit and good popularization value.

Owner:王连新

Phosphorus-free corrosion and scale inhibitor as well as preparation method and application thereof

InactiveCN106242090APromote degradationGood corrosion and scale inhibition effectNature of treatment waterTreatment using complexing/solubilising chemicalsWater qualityPollution

The invention discloses a phosphorus-free corrosion and scale inhibitor as well as a preparation method and application thereof. The phosphorus-free corrosion and scale inhibitor is prepared from the following raw materials in parts by weight: 2 to 7 parts of polyvinylpyrrolidone, 1 to 5 parts of neatfoot oil, 23 to 31 parts of attapulgite and 8 to 15 parts of liquiritin. The preparation method comprises the following steps: mixing the attapulgite with a prepared polyvinylpyrrolidone solution and performing heat treatment; then adding a prepared liquiritin solution and performing heat treatment; adding the neatfoot oil, performing heat treatment and then calcining at high temperature to obtain a finished product. The phosphorus-free corrosion and scale inhibitor prepared by the preparation method disclosed by the invention is free of phosphorus, is good in biodegradability and is free of toxin and pollution to the environment; a corrosion and scale inhibition effect of the phosphorus-free corrosion and scale inhibitor is superior to that of a phosphorus-containing water treatment agent. The raw materials are abundant in sources, a preparation process is simple and the cost is low. When the phosphorus-free corrosion and scale inhibitor is applied to an industrial circulating cooling water system, under the condition of water quality in the embodiment, when the dosage of a medicament is 30mg / L, a corrosion rate of carbon steel is smaller than 0.075mm / a stipulated by national standard, and a scale inhibition rate reaches 98 percent or above. The phosphorus-free corrosion and scale inhibitor disclosed by the invention is low in dosage, low in production cost and suitable for industrial production.

Owner:合肥智慧殿机械设计有限公司

Preparation method of sewage corrosion and scale inhibitor

InactiveCN107857375AReduce volumeLow costBiocideScale removal and water softeningReverse osmosisStrontium sulfate

The invention relates to a preparation method of a sewage corrosion and scale inhibitor. The raw materials include: reverse osmosis water, ammonium persulfate, an oxidizing agent, phosphorus trichloride, sodium sulfonate, methylbenzotriazole, expanded graphite, disodium hydroxyethylidene diphosphonate, dimethylamine, acrylic acid, acrylamide, zinc chloride, zinc chloride, sodium lignin sulfonate and isopropyl alcohol. The heavy metal ion elution rate is up to 92-99%, the BOD removal rate is 88-92%, the penicillium fermentation broth and streptomyces griseus fermentation broth have a flocculation rate of 88-90%, the calcium carbonate scale inhibition rate is 98-99%, the corrosion rate of carbon steel is 0.0014-0.002mm / a, the COD removal rate is 84-94%, the SS removal rate is 99.7-99.9%, thecalcium carbonate scale inhibition rate is up to 99-99.6%, the strontium sulfate scale inhibition rate is 99.2-99.6%, the carbon steel slow release rate is 89-97%, and the sustained release rate of galvanized material is 93-97%.

Owner:江苏悠谷未来科技有限公司

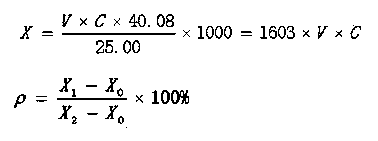

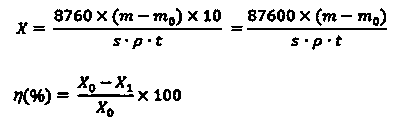

Method for inhibiting ammonia nitrogen corrosion of urban recycled water circular cooling system

ActiveCN102303927AReduce dosageGood effectWater treatment parameter controlSpecific water treatment objectivesWater circulationEnvironmental chemistry

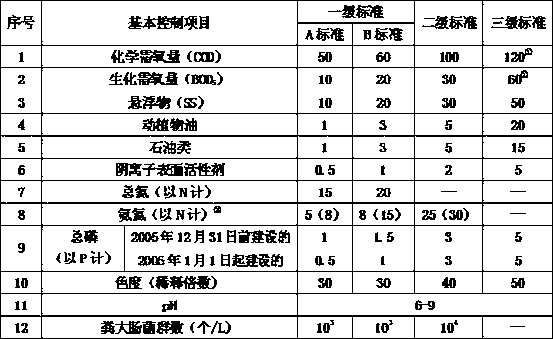

The invention relates to a method for inhibiting ammonia nitrogen corrosion of water circular cooling system in cities, which comprises: adding corrosion and scale inhibiting agent into urban recycled water at a concentration of 8 to 48mg / L; and regulating the pH value of the urban recycled water by using an inorganic alkaline matter according to the ammonia nitrogen content in the urban recycledwater, namely regulating the pH value to 7.5 to 8.0 when the ammonia nitrogen content is less than 60mg / L, regulating the pH value to 8.0 to 8.5 when the ammonia nitrogen content is between 60 and 95mg / L and regulating the pH value to 8.5 to 9.5 when the ammonia nitrogen content is between 95 and 150mg / L. In The invention, by adding the composite corrosion and scale inhibiting agent into urban recycled water and keeping the pH value in a proper range, the corrosion and scale of the high-ammonia-nitrogen-content recycled water circular cooling system are reduced to the maximum degree, which isgood for the long-term stable operation of the system. In the invention, the consumption of the composite corrosion and scale inhibiting agent is small, and in the pH value range of the invention, the corrosion and scale inhibiting effect is excellent.

Owner:STATE GRID HEBEI ENERGY TECH SERVICE CO LTD +1

Method for treating circulating cooling water

ActiveCN109133390AAvoid badSolve corrosiveScale removal and water softeningNon-contaminated water treatmentAlkalinityWater flow

The invention relates to the field of circular cooling water treatment, and discloses a method for treating circulating cooling water. The method comprises the steps that fresh water is adopted as cooling water of an air precooling system, and first agentia is put in the air precooling system; water flowing out of the air precooling system is taken as supplementary water of a circulating cooling water system, and second agentia is put in the supplementary water of the circulating cooling water system; the sum of calcium ion concentration and total alkalinity of the fresh water is less than orequal to 100 mg / L; the first agentia comprises a copolymer of crylic acid and 2-methyl-2'-acrylamide propane sulfonic acid, zinc salt and organic phosphonic acid. According to the method, by changingthe water supplementing point of the fresh water and reasonably adding the scale and corrosion inhibition components, the scaling and corrosion problems of the air precooling system and the circulating cooling water system are solved, the adding amount of the agentia is lower, and the method is especially beneficial for reducing production cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

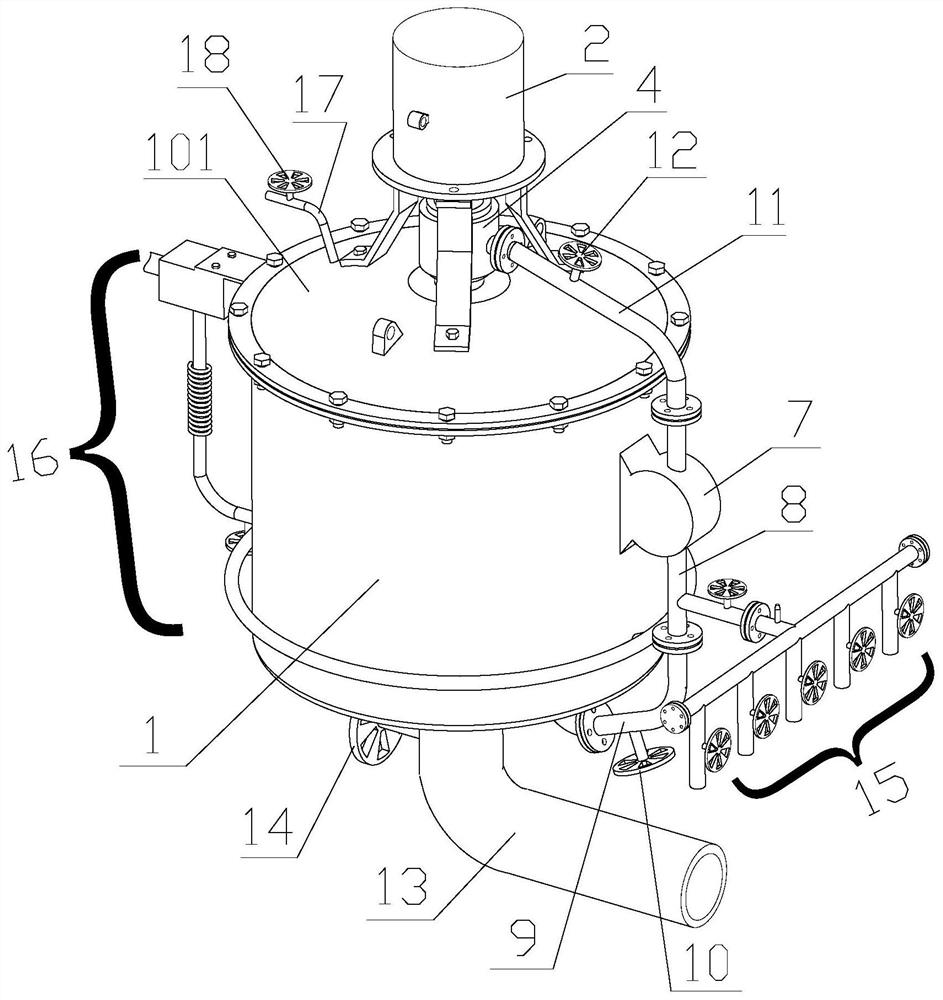

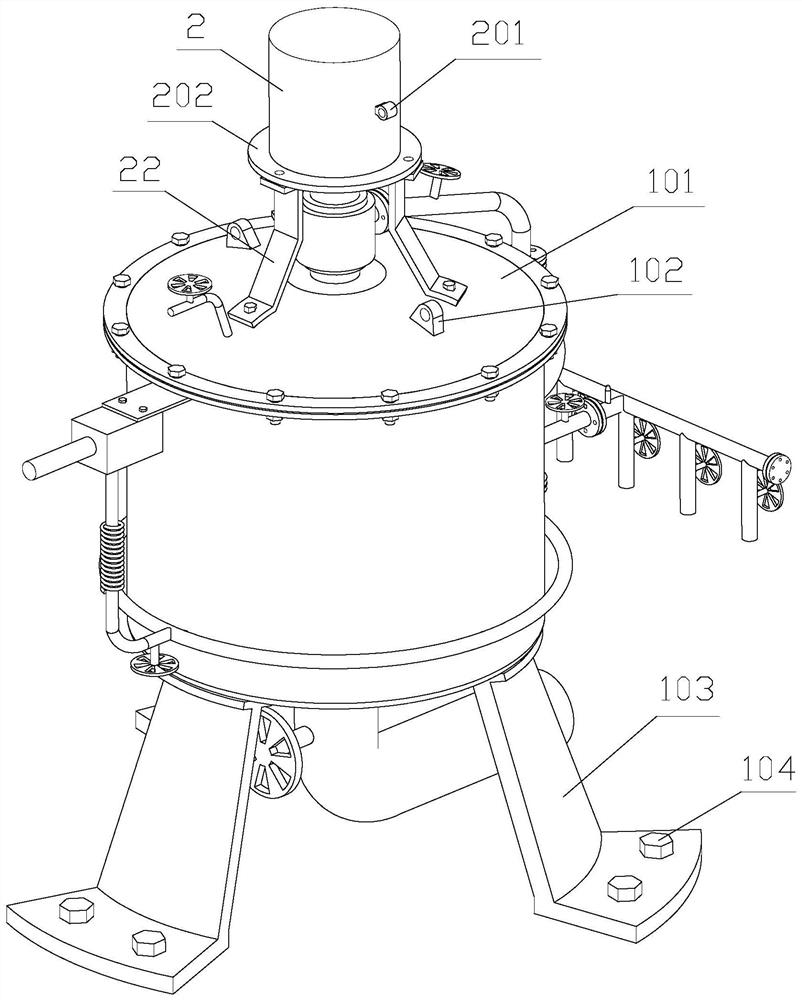

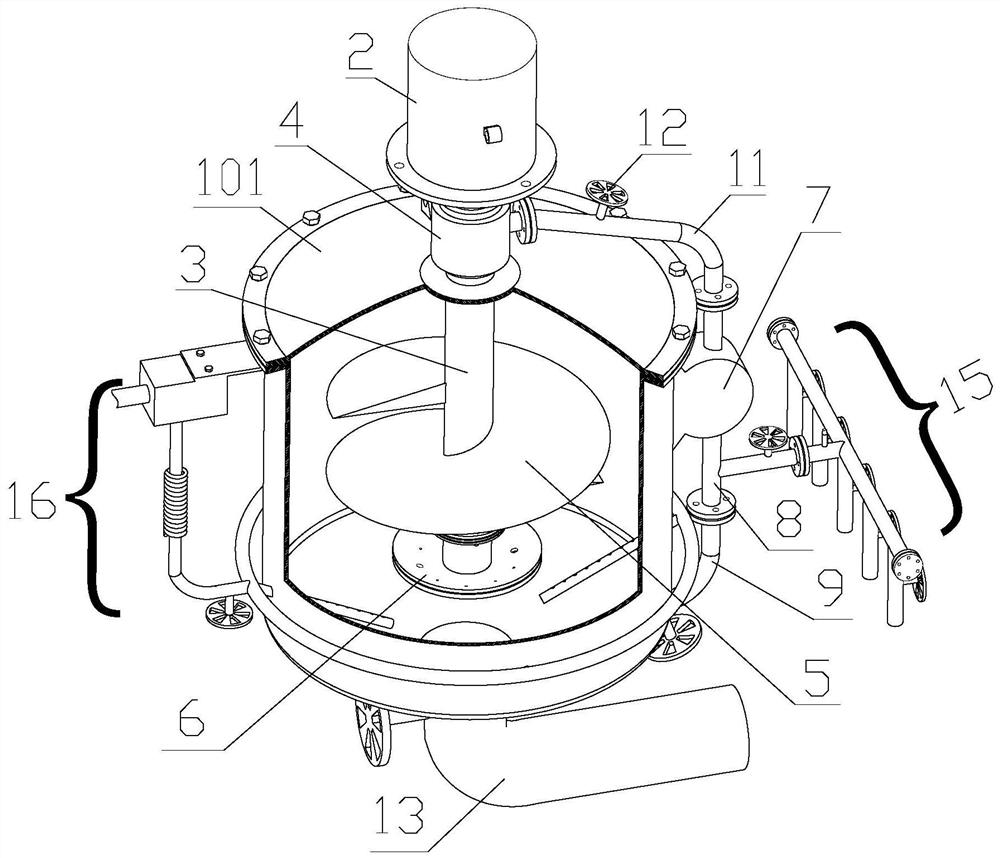

A kind of non-phosphorus corrosion and scale inhibitor and its preparation device and preparation method

ActiveCN111252914BSolve pollutionGood corrosion and scale inhibition effectTransportation and packagingRotary stirring mixersPolyaspartic acidEnvironmental engineering

The invention discloses a phosphorus-free corrosion and scale inhibitor, which is prepared from clear water, zinc salt, polymaleic anhydride, L ascorbic acid and polyaspartic acid, and has good biodegradability and double corrosion and scale inhibition. Functional water treatment agent, this new type of agent is suitable for high-alkali and high-solid water systems, has good compatibility with commonly used bactericidal algicides, strong chemical stability, is not easy to decompose and reduce efficiency, and has no environmental pollution when discharged; and provides this kind of non-toxic The preparation method and equipment of the phosphorus corrosion and scale inhibitor solve the problems of insufficient stirring and long stirring time of the existing stirring mechanism. The invention is applicable to the technical field of water treatment chemicals and preparation equipment thereof.

Owner:海兴县新源化工有限公司

Phosphorus-free corrosion and scale inhibitor for water treatment, and preparation method thereof

InactiveCN105060511AEnvironmental pollutionRich sourcesSpecific water treatment objectivesNature of treatment waterSodium metasilicateMonoglyceride

The invention discloses a phosphorus-free corrosion and scale inhibitor for water treatment, and a preparation method thereof. The phosphorus-free corrosion and scale inhibitor for water treatment comprises, by weight, 30-50 parts of sodium metasilicate, 15-35 parts of ammonium acetate, 45-60 parts of succinylated monoglycerides, 10-20 parts of citric acid and 100-150 parts of water. The method comprises the following steps: dissolving sodium metasilicate in half of water to prepare an aqueous solution of sodium metasilicate; dissolving ammonium acetate in the remaining water to prepare an aqueous solution of ammonium acetate; and heating the aqueous solution of sodium metasilicate to 60-90DEG C, adding citric acid, stirring for 30-50min, heating to 100-120DEG C, adding succinylated monoglyceride, stirring for 5-10min, adding the aqueous solution of ammonium acetate, continuously stirring for 1-1.5h, and cooling to room temperature in order to obtain the phosphorus-free corrosion and scale inhibitor for water treatment. The corrosion and scale inhibitor for water treatment is free from phosphorus, so the corrosion and scale inhibitor is nontoxic to environment and has no pollution to the environment; the corrosion and scale inhibitor has good corrosion and scale inhibition effects; and the corrosion and scale inhibitor also has the advantages of abundant sources of raw materials, simple preparation process, low cost, and suitableness for industrial circulating cooling water systems.

Owner:广州市鑫川工程技术开发公司

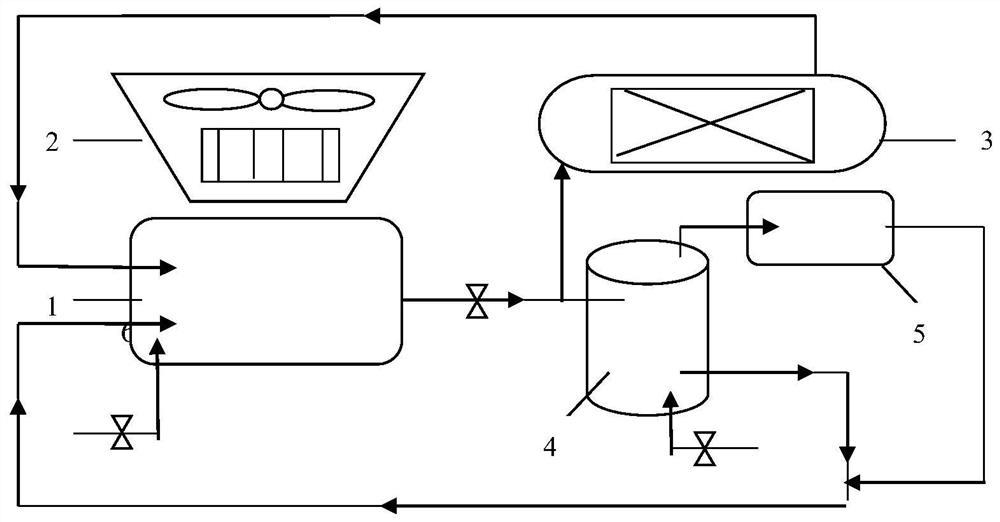

Natural balance ultrahigh concentration multiple and zero emission control method for circulating cooling water system

PendingCN114853240AImprove securityAvoid adding acidWater treatment parameter controlWater treatment compoundsBackwashingHeat exchanger

The invention discloses a natural balance ultrahigh concentration multiple and zero emission control method for a circulating water system. The method comprises the steps that at the initial stage of operation, efficient scale and corrosion inhibition functional chemicals are continuously added into a circulating cooling water pond, the concentration of the efficient scale and corrosion inhibition functional chemicals is maintained to be 100-200 mg / L, after circulation is conducted for 20-30 days, the concentration is controlled to be maintained to be 50-100 mg / L, the chemicals are circulated along with circulating water to reach a heat exchanger, and part of water returns to the circulating cooling water pond after being filtered; when the sum of the calcium hardness and the total alkalinity in the circulating water exceeds 1200 mg / L, high-efficiency micro-foam evaporation pre-precipitation functional chemicals are added into the circulating cooling water tank, the adding concentration is 10-100 mg / L, and micro-foam evaporation pre-precipitation softening treatment is carried out; when the turbidity of the circulating water is greater than or equal to (4-10) NTU or the total iron is greater than or equal to (0.5-1) mg / L, adding an enhanced filtration functional chemical with the adding concentration of 0.5-10 mg / L into a circulating cooling water tank, performing enhanced filtration, directly recycling filtered water to a circulating water system, discharging dirt along with backwashing water, performing water-slag separation on the backwashing water, returning the separated water to the circulating water system, and discharging separated filter residues.

Owner:TIANJIN ZHENGDA SCI &TECH CO LTD +2

A kind of corrosion inhibitor and composite corrosion and scale inhibitor and their application

ActiveCN106430652BGood corrosion and scale inhibition effectImprove performanceScale removal and water softeningChemical industryStearic acid

Owner:CHINA PETROLEUM & CHEM CORP +1

Solid corrosion and scale inhibitor and preparation method thereof

InactiveCN101613599BGood corrosion and scale inhibition effectMeet work performance requirementsDrilling compositionBorehole/well accessoriesCITRATE ESTERPhosphate

Owner:天津开广工业水处理有限公司

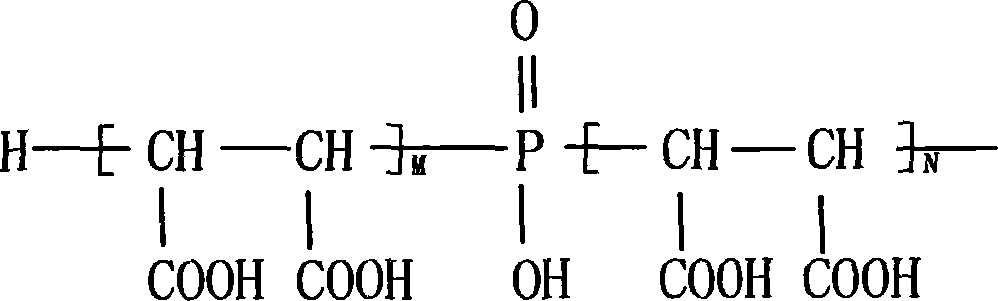

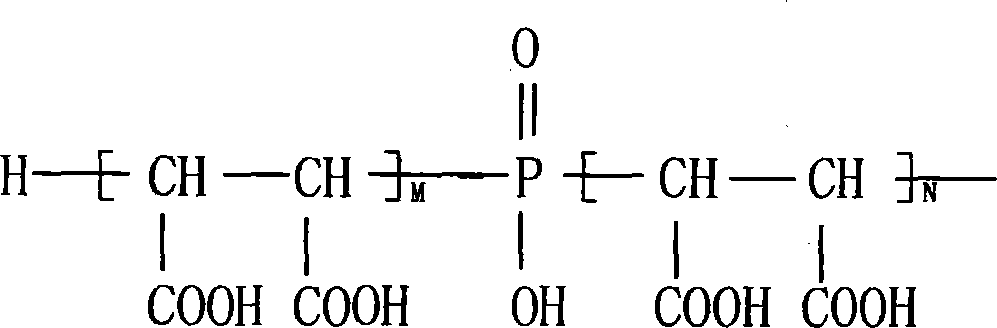

Quinoline deviate and preparation method and application thereof and corrosion and scale inhibitor composition

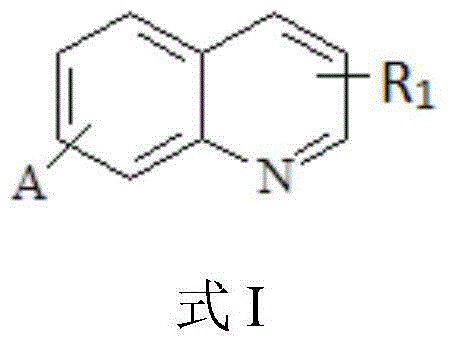

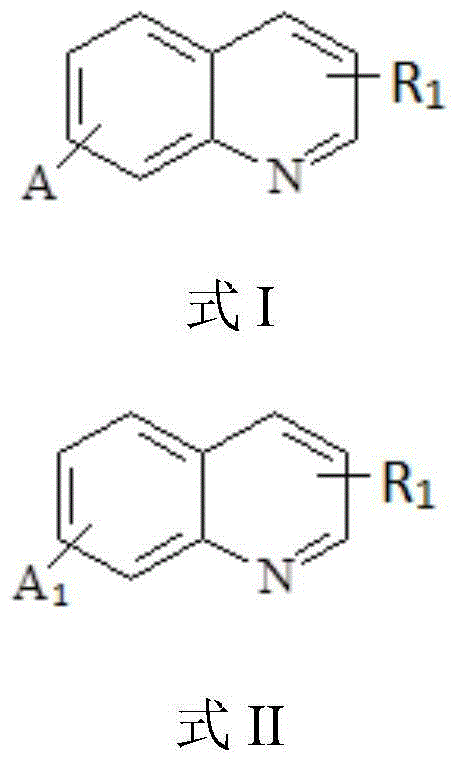

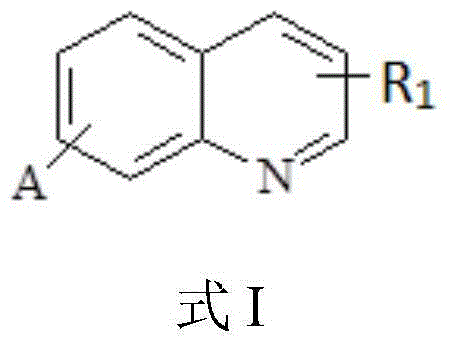

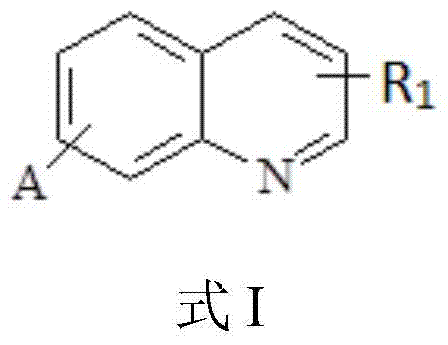

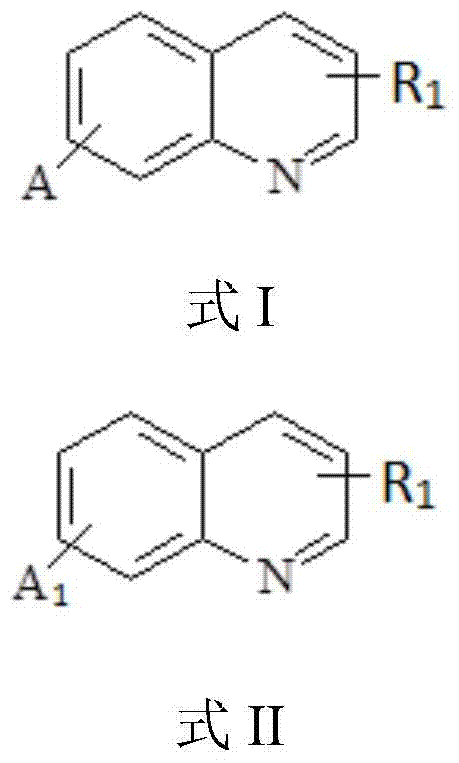

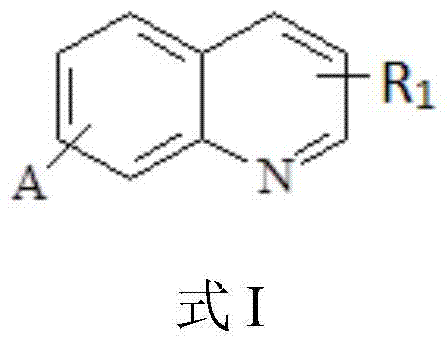

ActiveCN104557694AExcellent corrosion and scale inhibitionGood corrosion and scale inhibition effectOrganic chemistryDrilling compositionHydrogenQuinoline

The invention discloses a quinoline deviate as shown in a formula I in the specification, wherein R1 in the formula I is hydrogen or alkyl; A is -(CH2CH2O)n-CH2CH3, and n is an integer more than 1. The invention further provides a preparation method of the quinoline deviate, application of the quinoline deviate as a corrosion and scale inhibitor, as well as a composition containing the quinoline deviate. The quinoline deviate under a relatively low use amount shows outstanding corrosion and scale inhibition performance for a high-salinity and high-chlorine oilfield reinjection water system, and has an outstanding corrosion and scale inhibition effect on a water injection shaft under high temperature and high pressure conditions.

Owner:CHINA PETROLEUM & CHEM CORP +1

A low-phosphorus high-efficiency corrosion and scale inhibitor and its application in scale inhibition of industrial circulating cooling water

ActiveCN105060517BGood scale inhibitionGood corrosion inhibition effectScale removal and water softeningAlkalinityWater quality

The invention discloses a low-phosphorus high-efficiency corrosion and scale inhibitor and an application thereof in scale inhibition of industrial circulating cooling water. The corrosion and scale inhibitor contains the following effective components in parts by weight: 1-3 parts of an organic phosphonic acid corrosion and scale inhibitor, 3-6 parts of low-phosphorus or phosphorus-free scale inhibitor, 3-8 parts of a sulfonic acid type polymer scale inhibitor, and 1-3 parts of a zinc salt. The corrosion and scale inhibitor has excellent CaCO3 scale resistance, Ca3(PO4)2 scale resistance and corrosion inhibition rate when the industrial circulating water having water quality conditions of Ca<2+> of 120 mg / L, Cl<-> of 60 mg / L and the alkalinity of 110 mg / L is concentrated to 3-6 times, the drug total content is 8-20 ppm, and the phosphorus content is less than 0.5 ppm.

Owner:湖北省兴发磷化工研究院有限公司 +1

A method for treating circulating cooling water

ActiveCN109133390BAvoid badSolve corrosiveScale removal and water softeningNon-contaminated water treatmentMeth-Zinc salts

The invention relates to the field of circulating cooling water treatment, and discloses a method for treating circulating cooling water. The method includes: adopting fresh water as cooling water of the air pre-cooling system, and adding the first agent to the air pre-cooling system; using the outlet water of the air pre-cooling system as replenishing water of the circulating cooling water system, and feeding The second agent is added to the supplementary water of the system; the sum of the calcium ion concentration and the total alkalinity of the fresh water is not more than 100 mg / L; the first agent includes acrylic acid and 2-methyl-2'-acrylamidopropane Copolymers of sulfonic acids, zinc salts and organic phosphonic acids. The invention solves the scaling and corrosion problems of the air precooling system and the circulating cooling water system by changing the replenishment point of fresh water and the reasonable addition of scale and corrosion inhibitors. Save production costs.

Owner:CHINA PETROLEUM & CHEM CORP +1

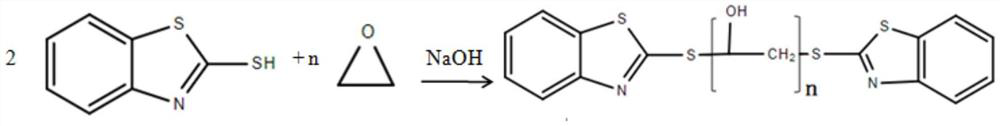

Corrosion inhibitor for cooling water of marine diesel engine and preparation method thereof

ActiveCN112391633BGood water solubilityGood anti-scaling effectOrganic chemistryScale removal and water softeningDiesel engineMaterials science

The invention discloses a corrosion inhibitor for cooling water of a marine diesel engine and a preparation method thereof, which solve the problems in the prior art that the existing corrosion inhibitor has poor water solubility, weak protective effect on the metal inside the condensate pipe, especially Marine diesel engine condensate pipes have poor corrosion inhibition performance, resulting in short service life, and the existing corrosion inhibitors are easy to scale and affect the heat transfer effect of the condensate pipes. The corrosion inhibitor for marine diesel engine cooling water of the present invention is a reaction product mercaptobenzothiazole polymer obtained by ring-opening addition reaction of mercaptobenzothiazole and ethylene oxide; meanwhile, a preparation method thereof is also provided, which can be widely used In the field of cooling water anti-corrosion control technology.

Owner:威海翔泽新材料科技有限公司

Phosphorus-free corrosion inhibitor for low temperature and corrosion inhibition method for circulating cooling water

PendingCN114426336AReduce the temperatureLess componentsSpecific water treatment objectivesScale removal and water softeningGluconatesCopolymer

The invention provides a non-phosphorus corrosion inhibitor and a corrosion inhibition method of circulating cooling water. The non-phosphorus corrosion inhibitor comprises a condensation reaction product of gluconate and aspartic acid, polyepoxysuccinic acid, a sulfonic group-containing copolymer, zinc salt and an optional heterocyclic compound, wherein the mass ratio of the condensation reaction product of gluconate and aspartic acid to polyepoxysuccinic acid is 1: (0.1-1.0). The phosphorus-free corrosion inhibitor disclosed by the invention does not contain phosphorus, meets the environmental protection requirement, and is suitable for corrosion and scale inhibition treatment of closed low-temperature circulating cooling water, especially closed low-temperature circulating cooling water which takes surface water as make-up water and has the temperature of 15-18 DEG C.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing corrosion and scale inhibition adsorbent by taking lignin in papermaking wastewater as raw material

InactiveCN110818104AImprove adsorption capacityGood corrosion and scale inhibition effectSpecific water treatment objectivesScale removal and water softeningIndustrial waste waterSorbent

The invention discloses a method for preparing a corrosion and scale inhibition adsorbent by taking lignin in papermaking wastewater as a raw material, wherein the method comprises the following steps: (1) taking alkaline papermaking black liquor, adding a coagulant aid, adding an acid to adjust the pH value, controlling the temperature at 60-70 DEG C, flocculating and layering the waste liquor, filtering, drying, and grinding to obtain lignin; (2) putting the prepared lignin into a beaker, adding Na2SO3 and formaldehyde, then adding NaOH, putting the beaker into a reactor, carrying out a reaction, and after the reaction is finished, cooling and centrifuging to obtain sodium lignin sulfonate; and (3) taking the prepared sodium lignin sulfonate, sequentially adding H2O, organic phosphorus and zinc chloride into the prepared sodium lignin sulfonate, adding an ethanol solution of benzotriazole, putting the mixed solution into the reactor, carrying out a reaction, and cooling to obtain thecorrosion and scale inhibition adsorbent. The prepared corrosion and scale inhibition adsorbent is applied to industrial wastewater containing a large number of metal ions and corrosive substances, can play a role in corrosion and scale inhibition adsorption, protects pipelines and equipment, and adsorbs various metal ions.

Owner:王其芬

Quinoline derivatives, preparation method and application thereof, and corrosion and scale inhibitor composition

ActiveCN104557694BExcellent corrosion and scale inhibitionGood corrosion and scale inhibition effectOrganic chemistryDrilling compositionPhysical chemistryQuinoline

The invention discloses a quinoline deviate as shown in a formula I in the specification, wherein R1 in the formula I is hydrogen or alkyl; A is -(CH2CH2O)n-CH2CH3, and n is an integer more than 1. The invention further provides a preparation method of the quinoline deviate, application of the quinoline deviate as a corrosion and scale inhibitor, as well as a composition containing the quinoline deviate. The quinoline deviate under a relatively low use amount shows outstanding corrosion and scale inhibition performance for a high-salinity and high-chlorine oilfield reinjection water system, and has an outstanding corrosion and scale inhibition effect on a water injection shaft under high temperature and high pressure conditions.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for inhibiting ammonia nitrogen corrosion of urban recycled water circular cooling system

ActiveCN102303927BReduce dosageGuaranteed uptimeWater treatment parameter controlSpecific water treatment objectivesAmmoniacal nitrogenEnvironmental engineering

Owner:STATE GRID HEBEI ENERGY TECH SERVICE CO LTD +1

Method for preparing phosphorus-free water treatment corrosion inhibitor from gutter oil and the prepared phosphorus-free water treatment corrosion inhibitor

ActiveCN106186374BLow costEasy to operateWater treatment compoundsSpecific water treatment objectivesCyclic etherPolyethylene glycol

The invention discloses a method for preparing a phosphorus-free water treatment corrosion inhibitor from waste oil as a raw material and the phosphorus-free water treatment corrosion inhibitor prepared by the method, and belongs to the waste utilizing processing technology. The waste oil is rich in source, and the method comprises the following steps: firstly, performing reaction on the waste oil and an alcohol amine compound to obtain an intermediate product A; secondly, adding epichlorohydrin to synthesize cyclic ether to obtain an intermediate product B; finally, adding polyethylene glycol and reacting to produce the phosphorus-free water treatment corrosion inhibitor. The phosphorus-free water treatment corrosion inhibitor prepared by the method has the characteristics of high corrosion inhibition rate and small using amount of chemicals. After the phosphorus-free water treatment corrosion inhibitor is compounded with a polycarboxylic scale-inhibiting dispersant for use, the phosphorus-free water treatment corrosion inhibitor can be used as a phosphorus-free scale-inhibiting corrosion inhibitor; after the phosphorus-free water treatment corrosion inhibitor is compounded with alkali, a reducing agent and the like for use, the phosphorus-free water treatment corrosion inhibitor can replace sodium nitrite and be used as a corrosion inhibitor for a closed water system. By the method, the waste oil can be used as the main raw material, so that the waste is turned into a treasure; a new way of disposing and utilizing the waste oil is provided.

Owner:天津沃川水处理工程技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com