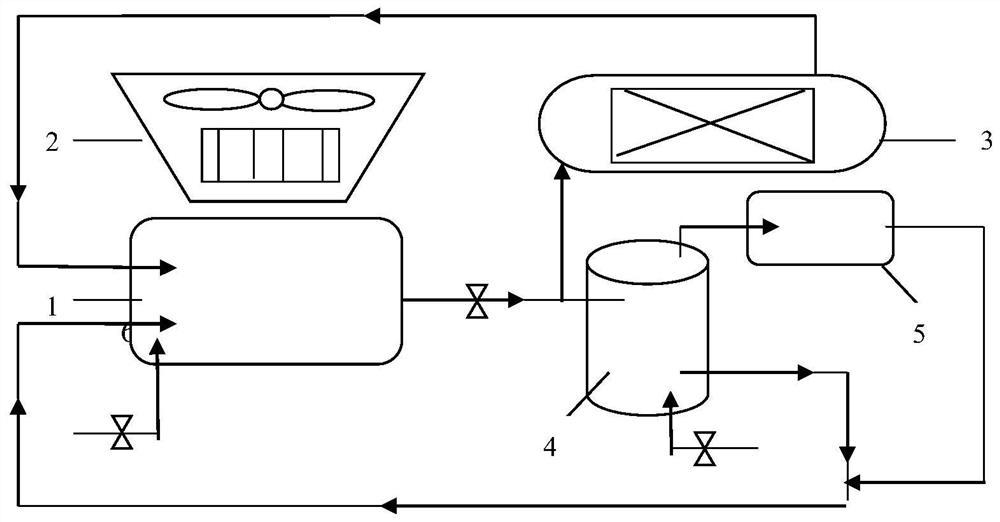

Natural balance ultrahigh concentration multiple and zero emission control method for circulating cooling water system

A technology of circulating cooling water and concentration multiples, which is applied to chemical instruments and methods, water softening, descaling and water softening, etc. It can solve the problems of zero discharge and acid addition, improve safety, reduce environmental hazards, The effect of avoiding secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] In the circulating cooling water system of a steel plant, the natural balance ultra-high concentration ratio and zero-emission control method are applied. In the early stage of normal operation of the system, high-efficiency corrosion-inhibiting and scale-inhibiting functional chemicals are continuously added, with a ratio of 40% polyepoxysuccinic acid. , tracer type scale inhibitor and dispersant 5%, citric acid 10%, zinc sulfate 1%, 4-imidazoline 3%, benzotriazole 0.5%, the rest is water, the dosage is 200mg / L, the system is running After 30 days, the dosage can be reduced to 100mg / L; polyepoxysuccinic acid is a commercially available liquid preparation with a solid content of 40% and a molecular formula of HO (C 4 H 2 O 5 M 2 )nH, the degree of polymerization n is an integer of 6-20.

[0035] When the sum of calcium hardness and total alkalinity in the circulating water reaches 1200mg / L, high-efficiency micro-foam evaporation pre-precipitation functional chemicals...

Embodiment 2

[0041] In a petrochemical plant circulating cooling water system, the natural balance ultra-high concentration ratio and zero-emission control method are applied. The system starts to continuously add high-efficiency corrosion- and scale-inhibiting functional chemicals within 30 days before the initial operation of the system. The ratio is polyepoxy amber Acid 20%, tracer type scale inhibitor and dispersant 2%, tartaric acid 10%, zinc chloride 2%, 4-imidazoline 5%, mercaptobenzotriazole 1%, the rest is water, the dosage is 120mg / L, the dosage will be reduced to 60mg / L after the system runs for 30 days;

[0042] When the sum of calcium hardness and total alkalinity in circulating water reaches 1200mg / L, high-efficiency micro-foam evaporation pre-precipitation functional chemicals are added, and the ratio is 8% acrylic acid-acrylate-propylene sulfonate copolymer; alkane base betaine 10%; the rest is water, the dosage is 100mg / L; acrylic acid-acrylate-propylene sulfonate copolym...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal resistance | aaaaa | aaaaa |

| Thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com