Environment-friendly cooling circulating water system composite corrosion-inhibition antisludging agent and preparation method thereof

An environmentally friendly technology for cooling circulating water, applied in chemical instruments and methods, descaling and water softening, water/sludge/sewage treatment, etc., can solve problems such as application limitations, general corrosion and scale inhibition effects, etc., to achieve Low cost, significant effect, and small amount of addition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

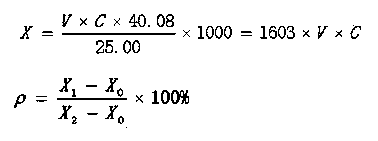

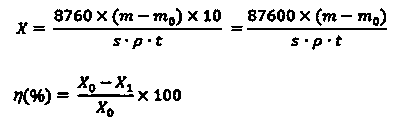

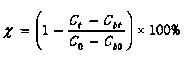

Method used

Image

Examples

Embodiment 1

[0023] It is roughly PEG1000-polyamino acid 3000, where 1000 and 3000 in PEG1000 and polyamino acid 3000 represent molecular weight, and the following examples are the same

[0024] (1) Add 1g of amino functionalized polyethylene glycol (PEG-NH 2 ) (molecular weight 1000) was dissolved in 20 mL of dioxane, added 5 g of aspartic acid-benzyl ester N-carboxylic anhydride, 5 g of glutamic acid-benzyl ester N-carboxylic anhydride, N 2 Polymerize at 60°C for 12 hours under protection, pour the above reaction system into excess absolute ethanol to precipitate the product, that is, polyethylene glycol-polybenzyl aspartate-polybenzyl glutamate terpolymer (hereinafter referred to as Polymer a1).

[0025] (2) Add 2 mol / L sodium hydroxide solution dropwise into the saturated chloroform solution of polymer a1 at room temperature, and heat at 40°C for 2 h until no precipitation occurs, and then remove the solvent under vacuum to obtain The mixture was cooled to 4°C, titrated with 0.1mol / L...

Embodiment 2

[0027] Roughly PEG1000-polyamino acid 5000

[0028] (1) Add 1g of amino functionalized polyethylene glycol (PEG-NH 2 ) (molecular weight 1000) was dissolved in 30 mL of dioxane, added 10 g of aspartic acid-benzyl ester N-carboxylic anhydride, 5 g of glutamic acid-benzyl ester N-carboxylic anhydride, N 2 Polymerize at 60°C for 12 hours under protection, pour the above reaction system into excess absolute ethanol to precipitate the product, that is, polyethylene glycol-polybenzyl aspartate-polybenzyl glutamate terpolymer (hereinafter referred to as Polymer a2).

[0029] (2) Same as Example 1 to obtain polymer b2.

Embodiment 3

[0031] Roughly PEG2000-polyamino acid 5000

[0032] (1) Add 2g of amino functionalized polyethylene glycol (PEG-NH 2 ) (molecular weight 2000) was dissolved in 35 mL of dioxane, added 5 g of aspartic acid-benzyl ester N-carboxylic anhydride, 10 g of glutamic acid-benzyl ester N-carboxylic anhydride, N 2 Polymerize at 60°C for 12 hours under protection, pour the above reaction system into excess absolute ethanol to precipitate the product, that is, polyethylene glycol-polybenzyl aspartate-polybenzyl glutamate terpolymer (hereinafter referred to as Polymer a3).

[0033] (2) Same as Example 1 to obtain polymer b3.

[0034] Preparation example of composite slow-release scale inhibitor of the present invention, wherein the molecular weight of HPMA is 500-1000

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| scale inhibition rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com