A kind of corrosion inhibitor and composite corrosion and scale inhibitor and their application

A technology of corrosion and scale inhibitor and corrosion inhibitor, which can be used in descaling and water softening, chemical instruments and methods, water/sludge/sewage treatment, etc. To achieve the effect of environmental friendliness and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

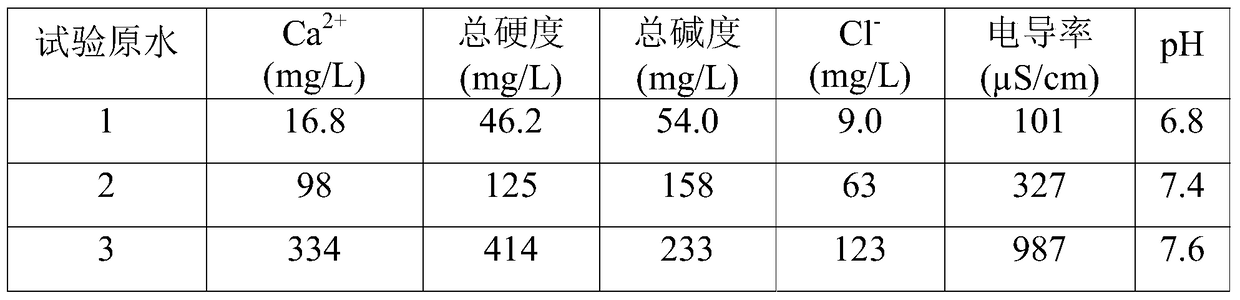

Examples

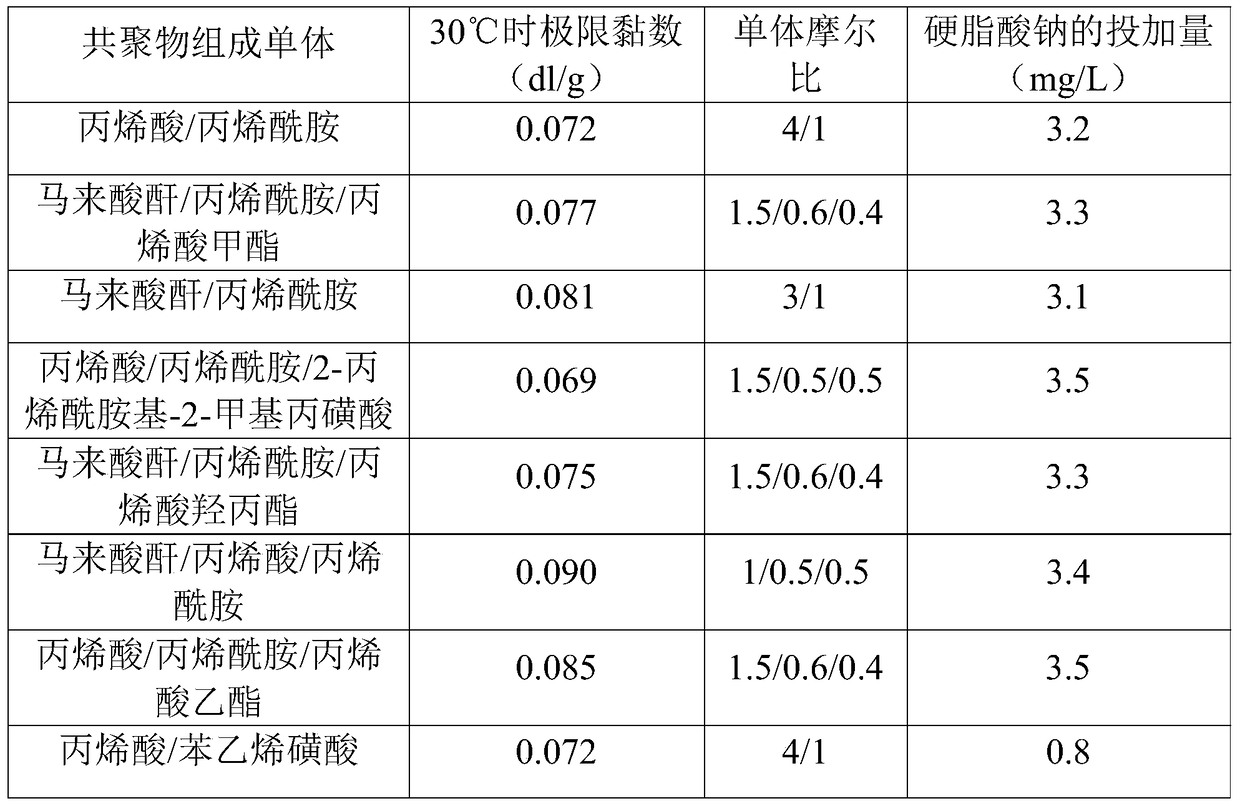

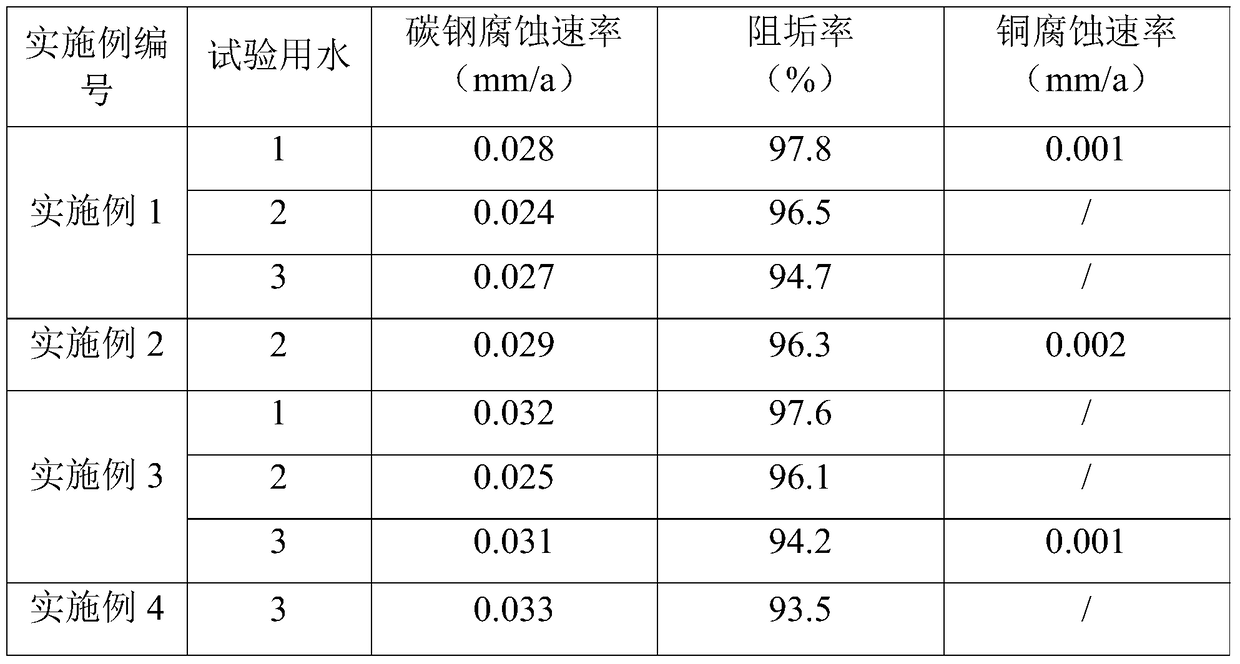

Embodiment 1

[0048] Weigh 2.6g of stearic acid and 66.7g of a copolymer of acrylic acid and acrylamide with an active content of 30% by weight (at 30°C, the limiting viscosity is 0.072dl / g, and the molar ratio of acrylic acid to acrylamide=4 / 1) 10g of hydroxyethylidene diphosphonic acid with an active substance content of 50% by weight and 1.7g of zinc sulfate monohydrate were dissolved in 119.1g of water to prepare a corrosion and scale inhibitor. Add the prepared medicament to the test water 1 so that the concentration of the corrosion and scale inhibitor is 100mg / L test water. And add benzotriazole to the test water 1 so that the effective concentration is 1 mg / L test water.

[0049] Weigh 2.6g of stearic acid and 66.7g of a copolymer of acrylic acid and acrylamide with an active content of 30% by weight (at 30°C, the limiting viscosity is 0.072dl / g, and the molar ratio of acrylic acid to acrylamide=4 / 1) 10 g of hydroxyethylidene diphosphonic acid with an active substance content of 50...

Embodiment 2

[0051] Take by weighing 2.2g sodium stearate, 81.5g active substance content be the copolymer of maleic anhydride, acrylamide and methyl acrylate (at 30 ℃, limit viscosity number is 0.077dl / g, maleic anhydride and propylene The molar ratio of amide to methyl acrylate=1.5 / 0.6 / 0.4), 8.89g of aminotrimethylene phosphonic acid with an active substance content of 50% by weight were dissolved in 107.4g of water to prepare a corrosion and scale inhibitor.

[0052] Add the prepared medicament to the test water 2, so that the concentration of the corrosion and scale inhibitor is 90 mg / L test water. And add mercaptobenzothiazole to the test water 2 so that the effective concentration is 2 mg / L test water.

Embodiment 3

[0054] Take by weighing 2.7g potassium stearate, 54.6g active substance content be the copolymer of maleic anhydride and acrylamide (at 30 ℃, limit viscosity is 0.081dl / g, the mol ratio of maleic anhydride and acrylamide is 30% by weight) =3 / 1), 10.9g active matter content is 2-phosphonic acid group-1,2,4-tricarboxylic acid butane of 50% by weight, 1.1g zinc chloride is dissolved in 130.7g water and is made into corrosion inhibitor and scale inhibitor potion. Add the prepared medicament to the test water 1 so that the concentration of the corrosion and scale inhibitor is 110mg / L test water.

[0055] Take by weighing 2.7g potassium stearate, 54.6g active substance content be the copolymer of maleic anhydride and acrylamide (at 30 ℃, limit viscosity is 0.081dl / g, the mol ratio of maleic anhydride and acrylamide is 30% by weight) =3 / 1), 10.9g of 2-phosphonic acid-1,2,4-tricarboxylic butane with an active substance content of 50% by weight was dissolved in 131.8g of water to prep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com