Patents

Literature

188 results about "Strontium sulfate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Strontium sulfate (SrSO₄) is the sulfate salt of strontium. It is a white crystalline powder and occurs in nature as the mineral celestine. It is poorly soluble in water to the extent of 1 part in 8,800. It is more soluble in dilute HCl and nitric acid and appreciably soluble in alkali chloride solutions (e.g. sodium chloride).

Additive for increasing the density of a fluid for casing annulus pressure control

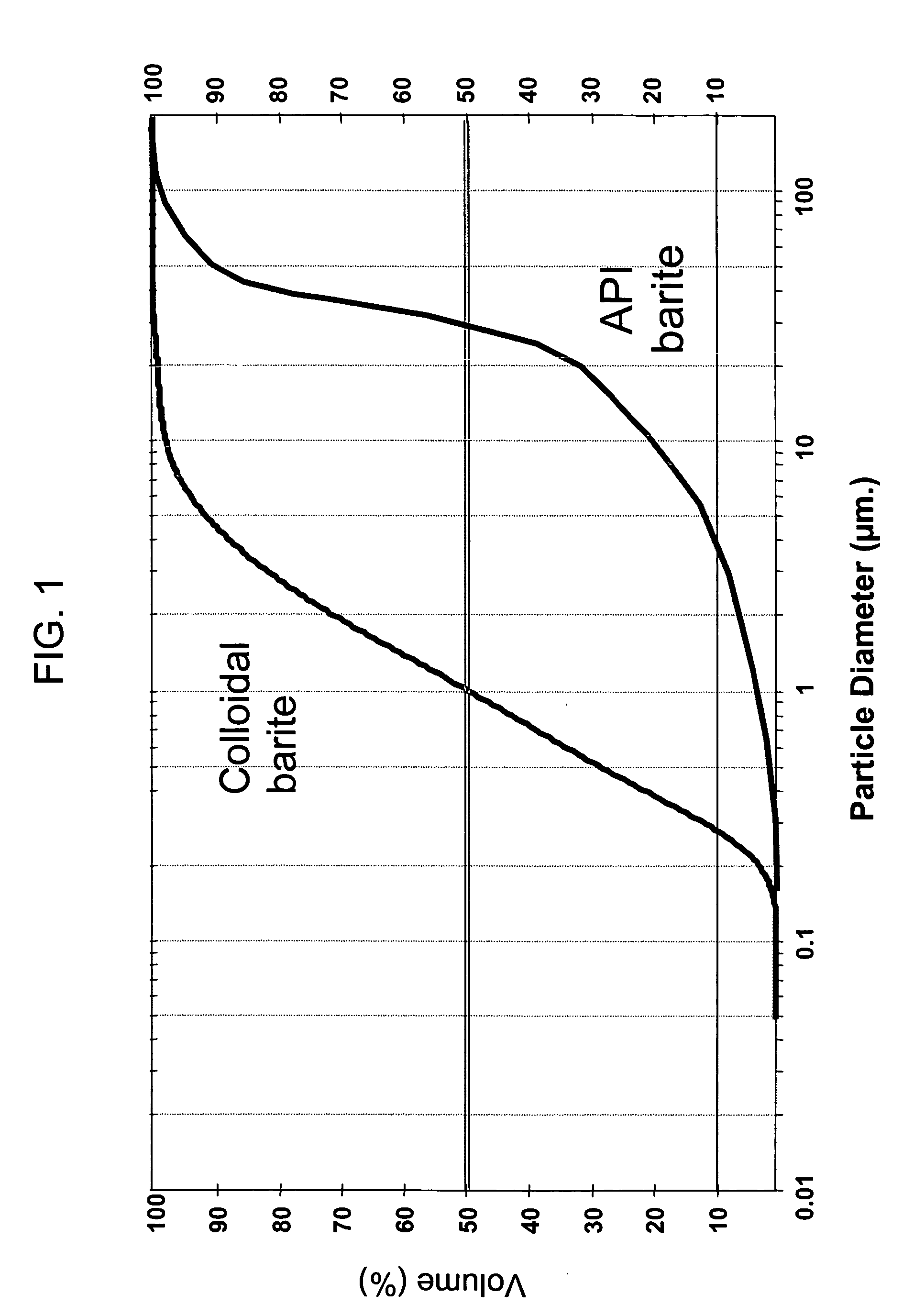

InactiveUS20060188651A1Liquid surface applicatorsOther chemical processesVolumetric Mass DensitySolid particle

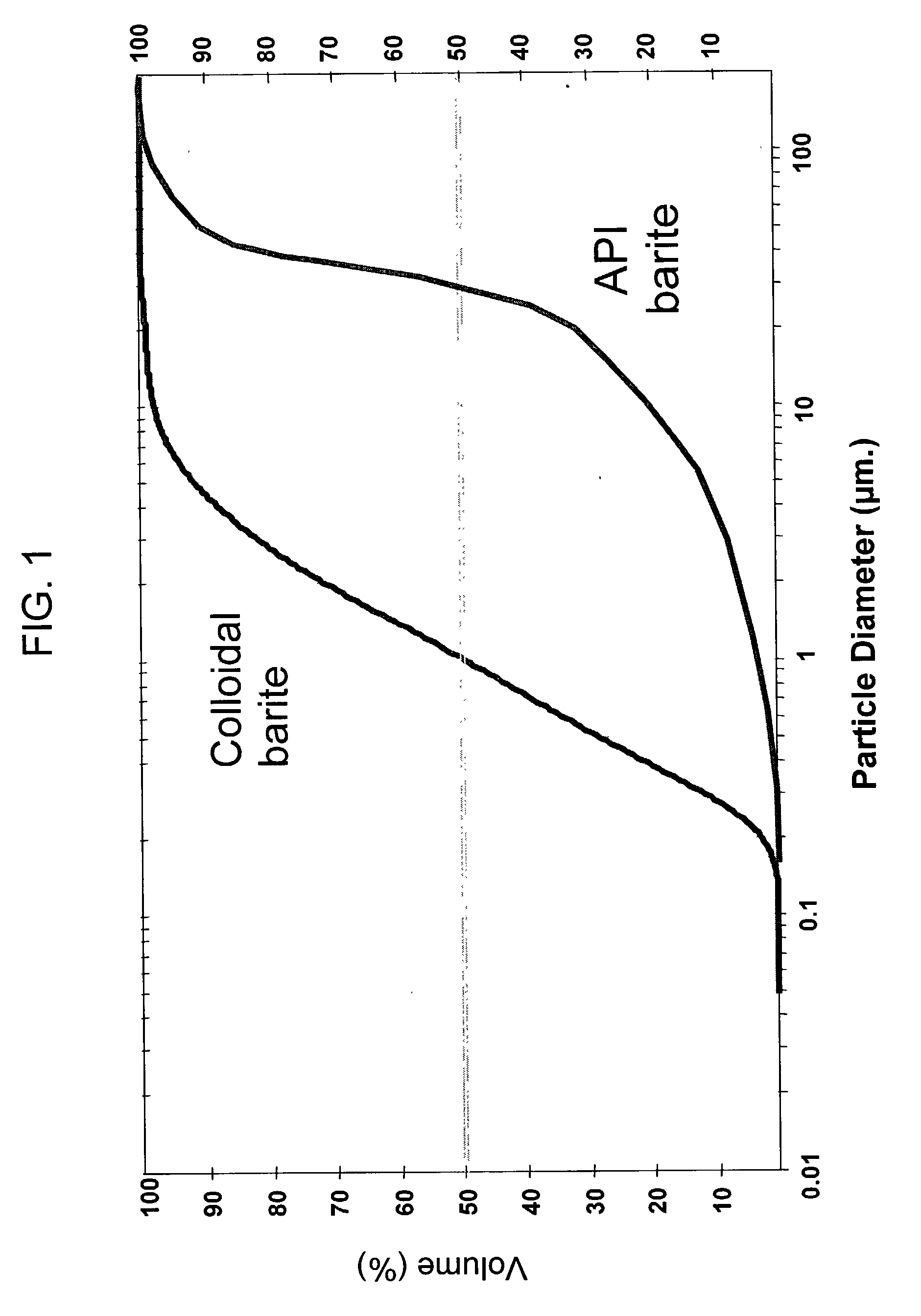

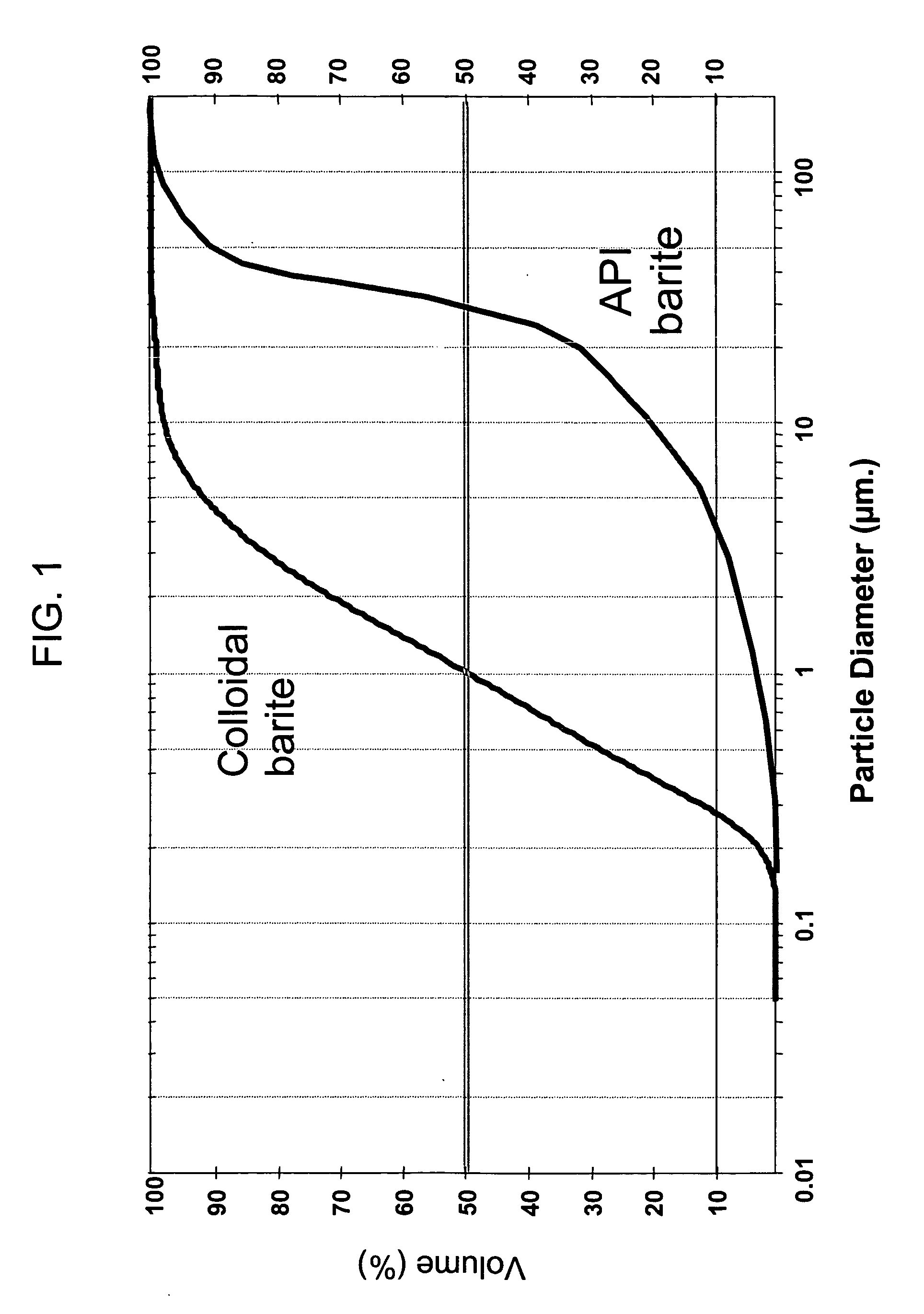

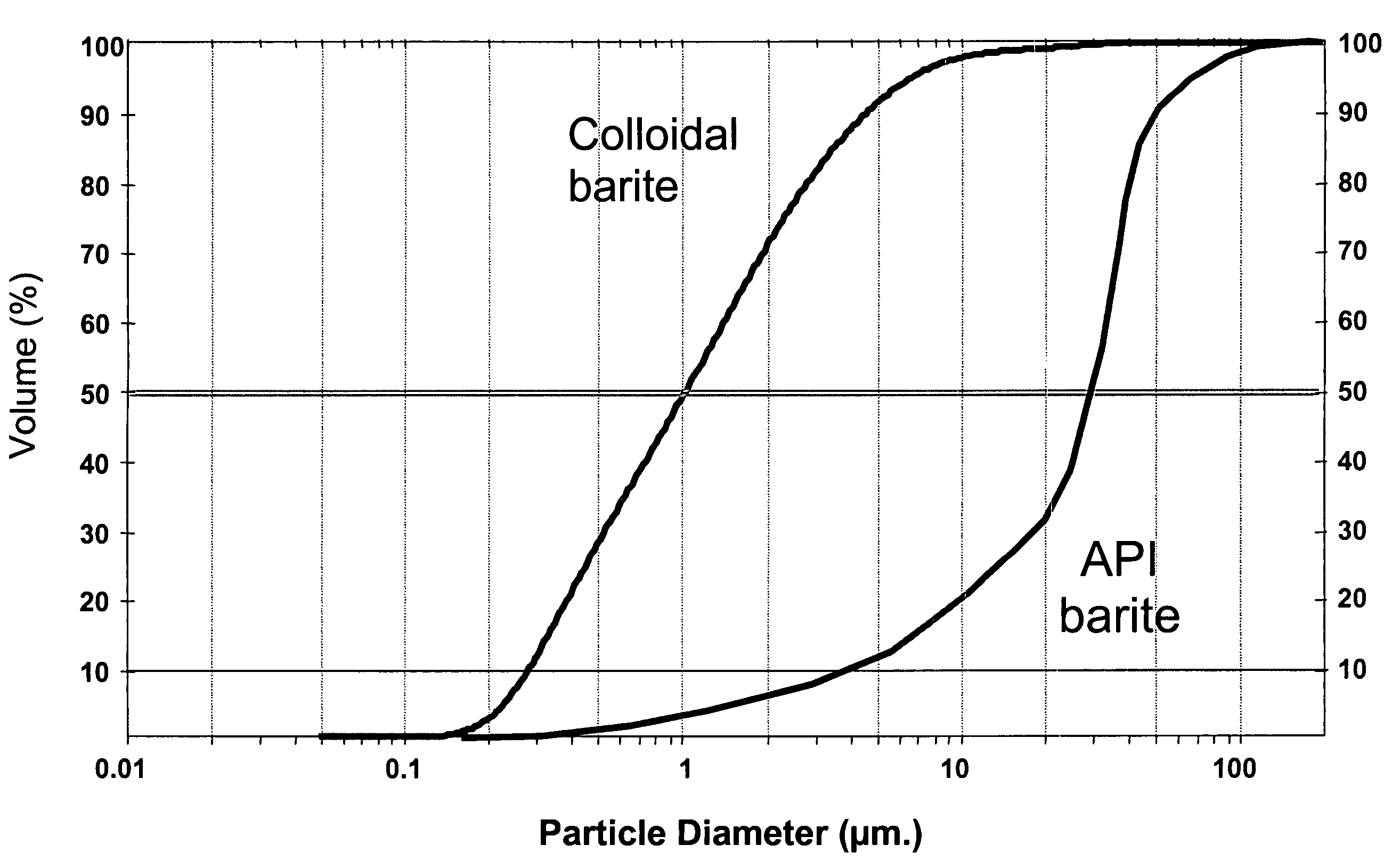

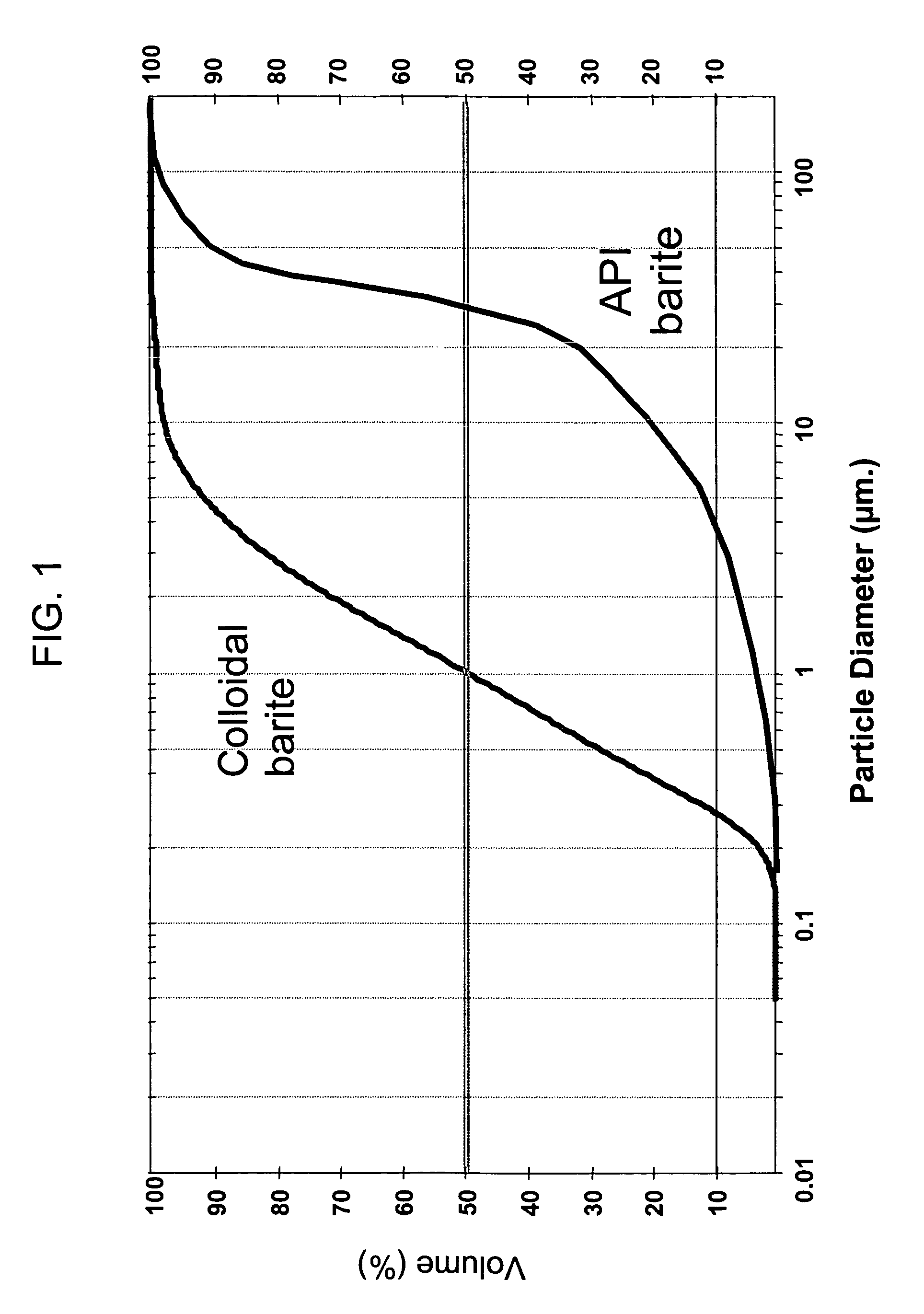

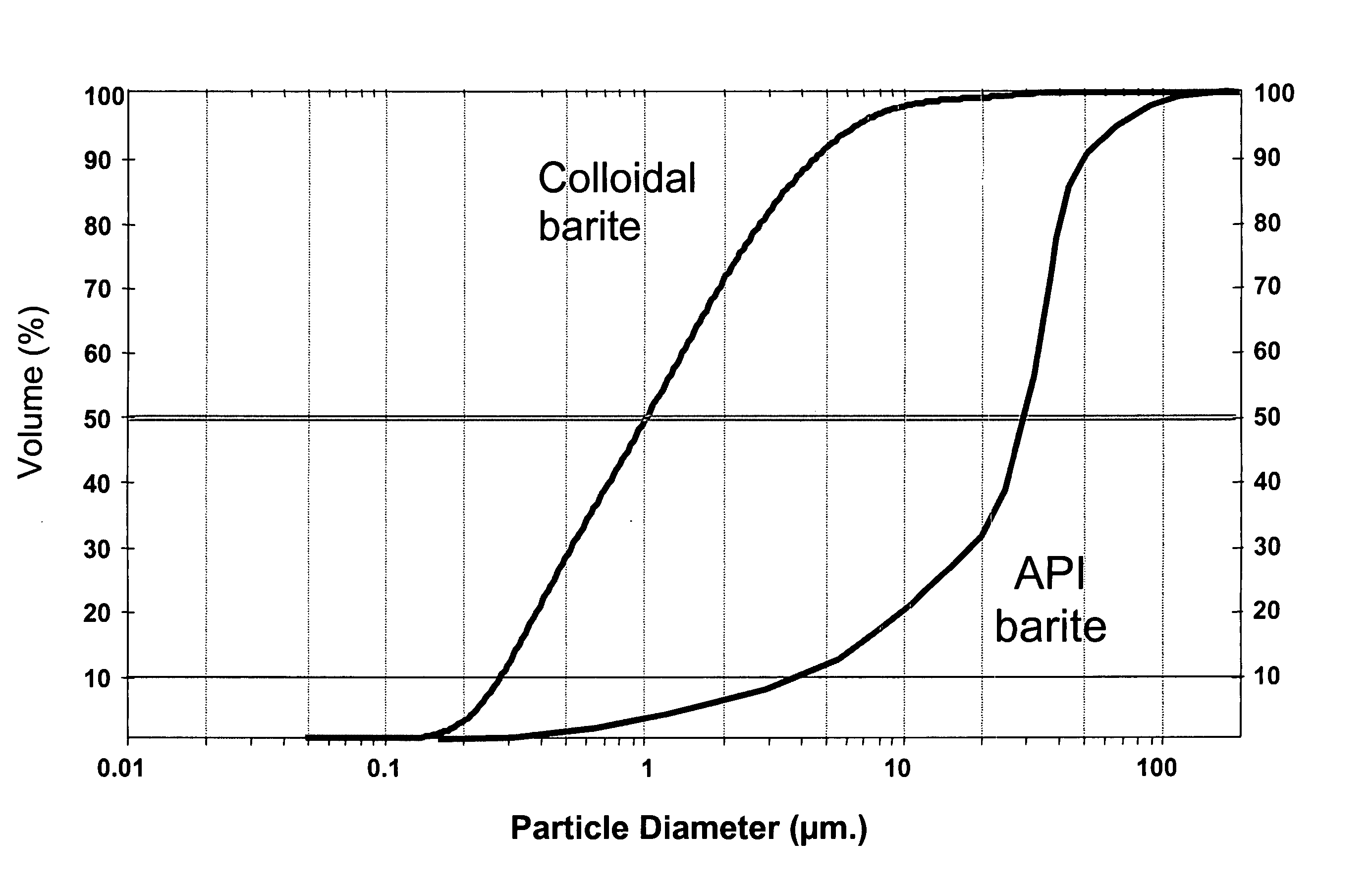

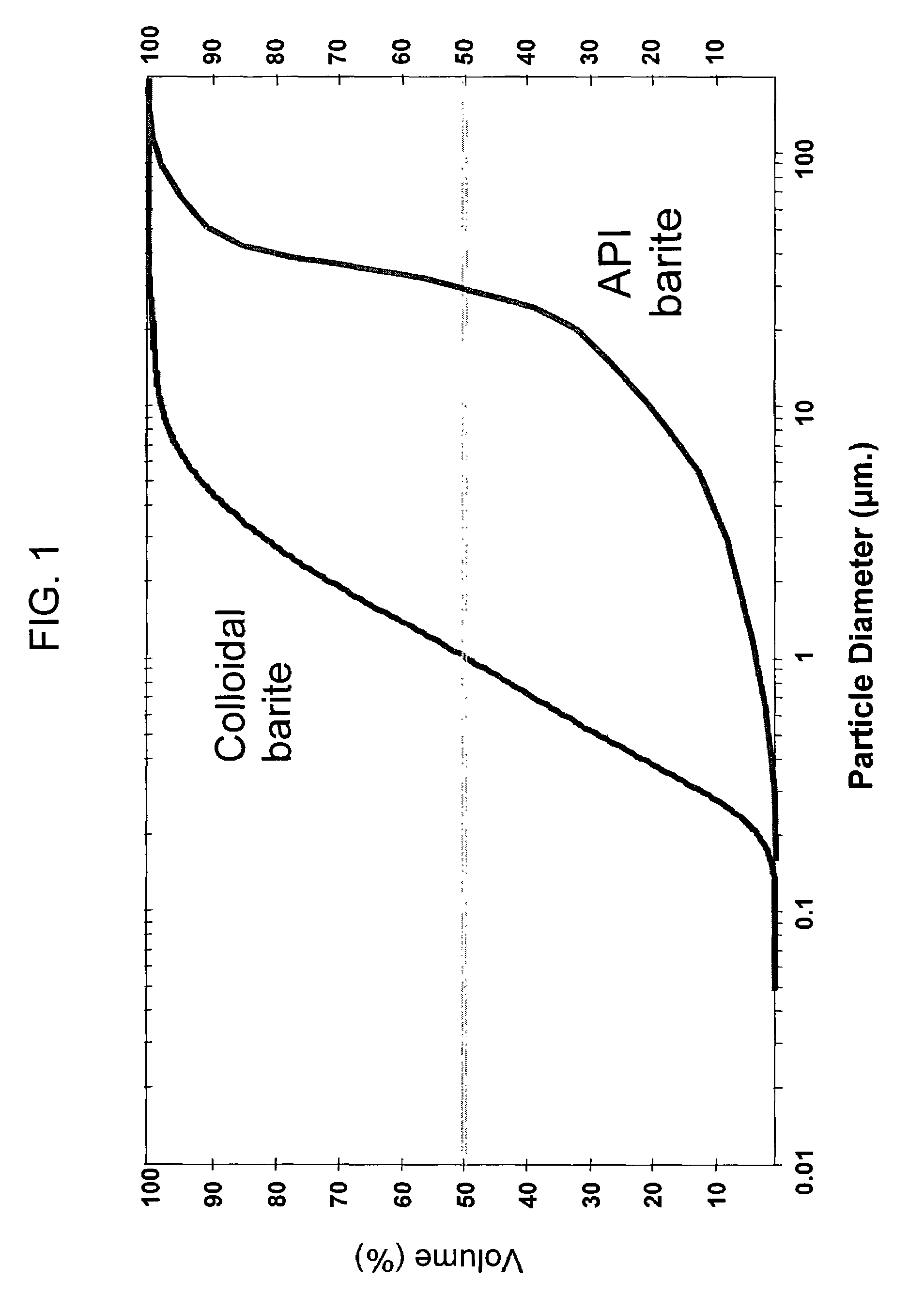

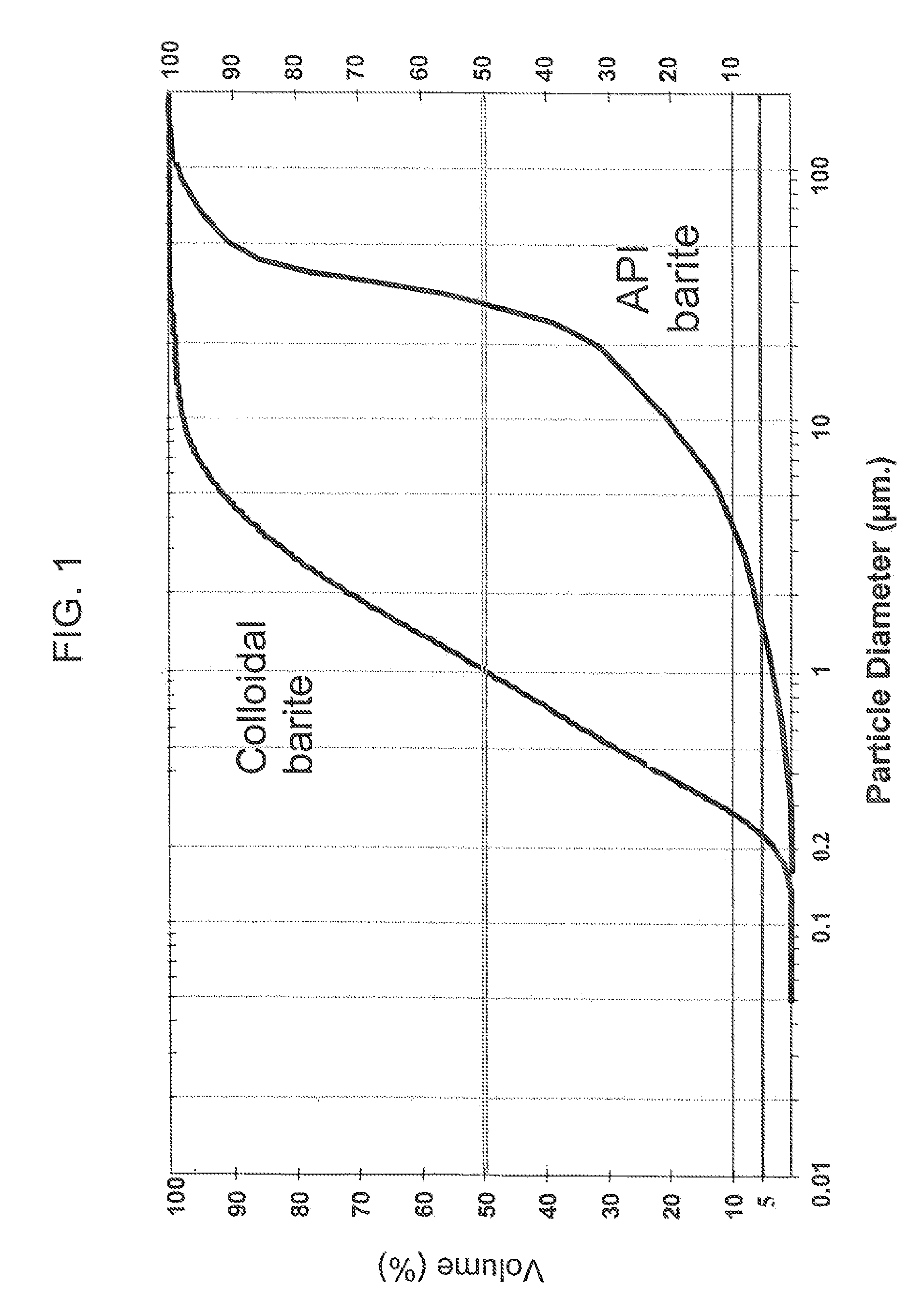

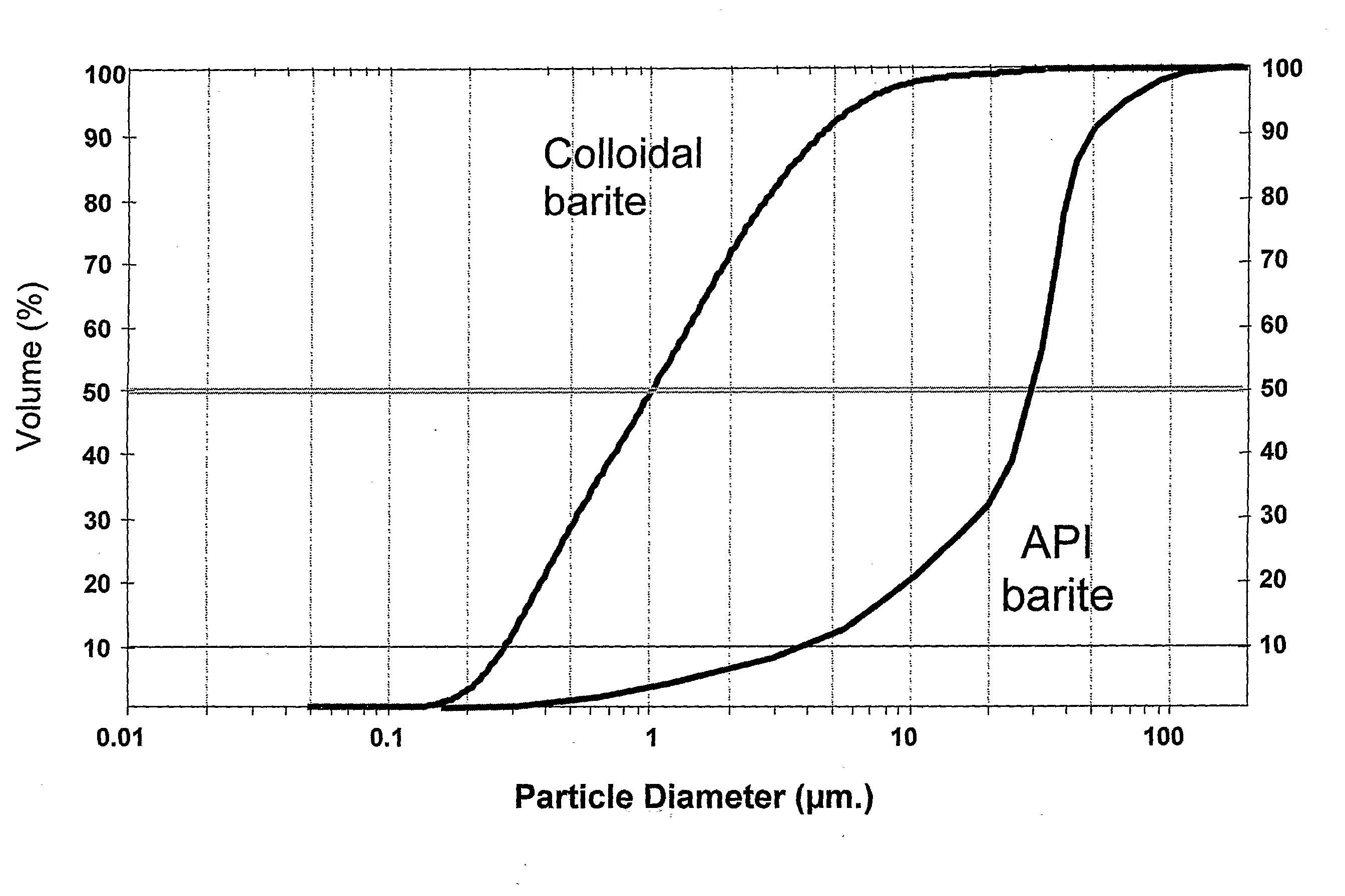

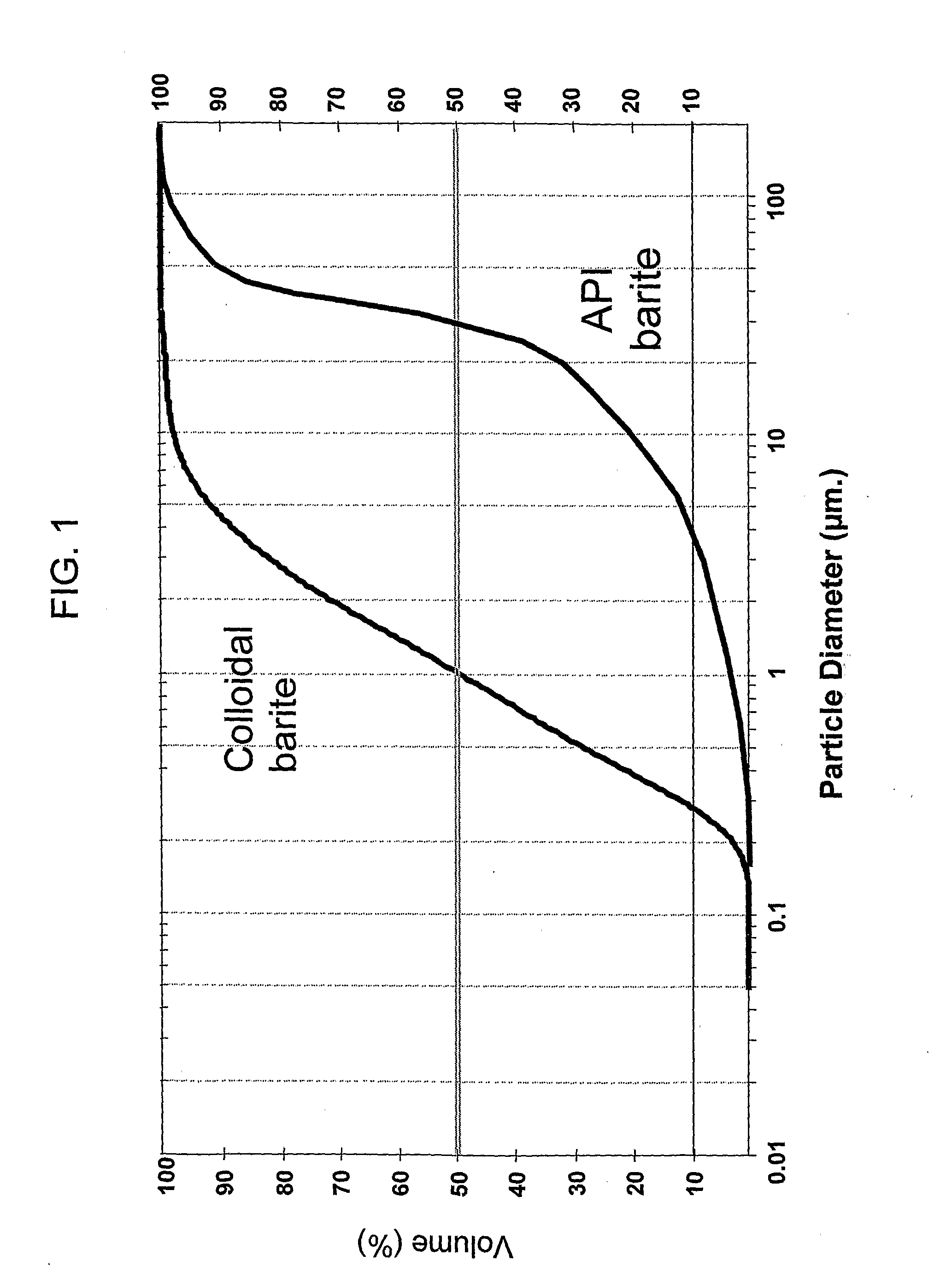

A method of controlling the pressure of a casing annulus in a subterranean well that includes injecting into the casing annulus a composition including a base fluid and a polymer coated colloidal solid material. The polymer coated colloidal solid material includes: a solid particle having an weight average particle diameter (d50) of less than two microns, and a polymeric dispersing agent coated onto the surface of the solid particle during the cominution (i.e. grinding) process utilized to make the colloidal particles. The polymeric dispersing agent may be a water soluble polymer having a molecular weight of at least 2000 Daltons. The solid particulate material may be selected from materials having of specific gravity of at least 2.68 and preferably the solid particulate material may be selected from barium sulfate (barite), calcium carbonate, dolomite, ilmenite, hematite, olivine, siderite, strontium sulfate, combinations and mixtures of these and other similar solids that should be apparent to one of skill in the art.

Owner:MI

Additive for increasing the density of a fluid for casing annulus pressure control

InactiveUS20050101493A1Photosensitive materialsScale removal and water softeningVolumetric Mass DensitySolid particle

A method of controlling the pressure of a casing annulus in a subterranean well that includes injecting into the casing annulus a composition including a base fluid and a polymer coated colloidal solid material. The polymer coated colloidal solid material includes: a solid particle having an weight average particle diameter (d50) of less than two microns, and a polymeric dispersing agent coated onto the surface of the solid particle during the cominution (i.e. grinding) process utilized to make the colloidal particles. The polymeric dispersing agent may be a water soluble polymer having a molecular weight of at least 2000 Daltons. The solid particulate material may be selected from materials having of specific gravity of at least 2.68 and preferably the solid particulate material may be selected from barium sulfate (barite), calcium carbonate, dolomite, ilmenite, hematite, olivine, siderite, strontium sulfate, combinations and mixtures of these and other similar solids that should be apparent to one of skill in the art.

Owner:MI

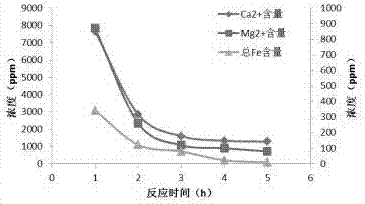

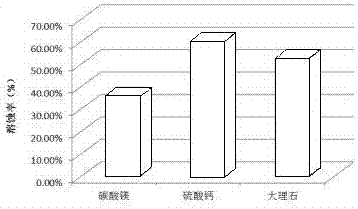

Barium-strontium-calcium descaling and blockage removing agent for near-well area and preparing method of barium-strontium-calcium descaling and blockage removing agent

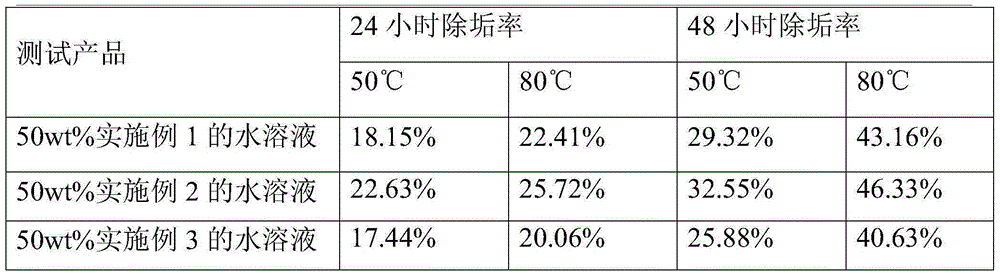

ActiveCN105112036APrevents accumulation of scaleReduce secondary damageDrilling compositionCarboxylic saltChloroacetic acids

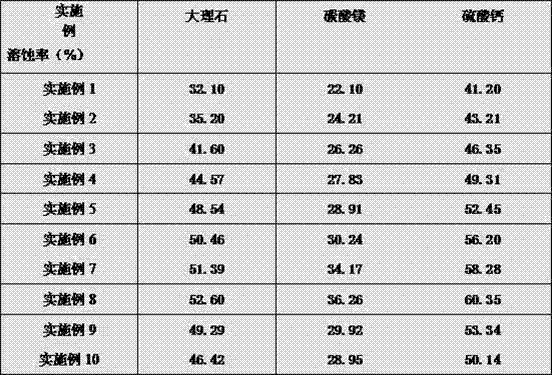

The invention discloses a barium-strontium-calcium descaling and blockage removing agent for a near-well area and a preparing method of the barium-strontium-calcium descaling and blockage removing agent. The barium-strontium-calcium descaling and blockage removing agent comprises a polyamine carboxylate solution, nonionic surfactant accounting for 3%-10% of the total mass of the polyamine carboxylate solution and an emulsion breaker accounting for 2%-8% of the total mass of the polyamine carboxylate solution. The polyamine carboxylate solution is prepared from polyamine midbody and chloroacetic acid salt through a reaction, wherein the polyamine midbody is prepared through organic amine and epoxy chloropropane with the mole ratio of 1.05-1.5:1 through a reaction, and the chloroacetic acid salt is prepared from chloroacetic acid and alkali with the same mole ratio through a reaction. The barium-strontium-calcium descaling and blockage removing agent for the near-well area has a good removing effect on indissolvable salt such as barium sulfate, strontium sulfate and calcium sulfate, and the descaling rate is higher than 40%. Meanwhile, the barium-strontium-calcium descaling and blockage removing agent has the expansion preventing and inhibiting performance, the clay expansion reducing rate is higher than 80%, corrosion to equipment is slight, and water locking can be avoided. Blockage removing can be effectively achieved on a reservoir stratum near a well, the permeability of the reservoir stratum is improved, and thus the recovery ratio of oil and gas resources is increased.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

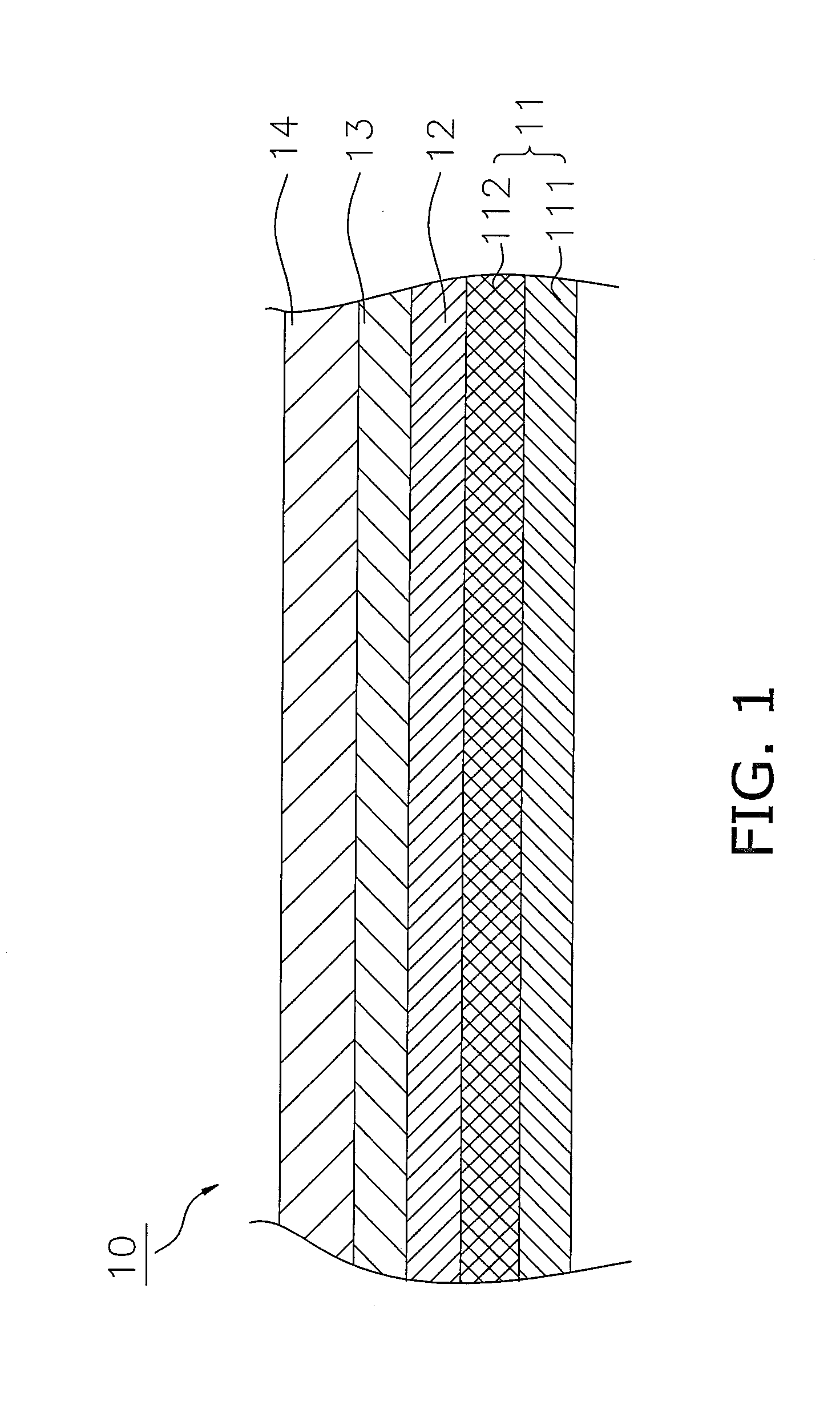

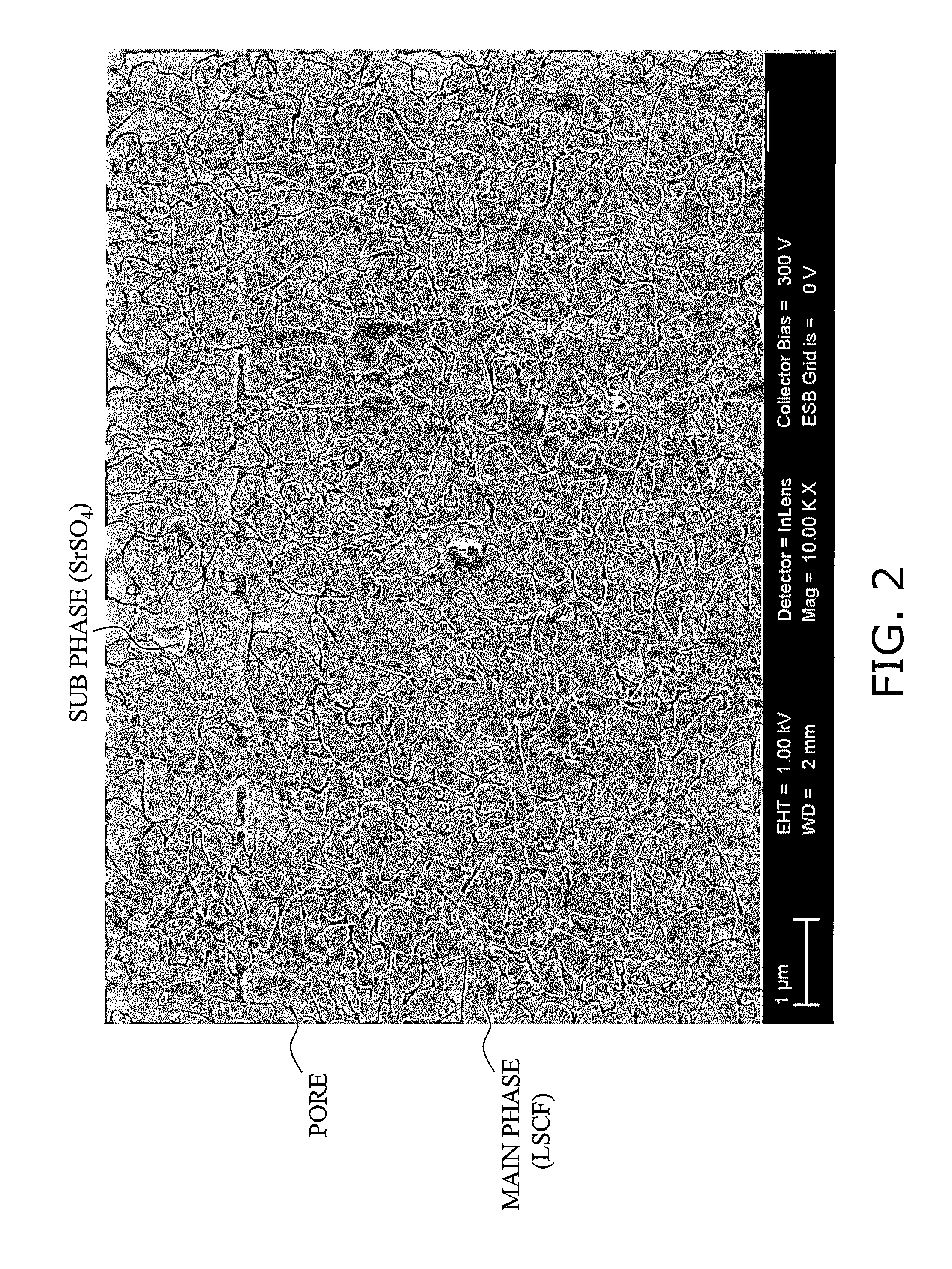

Fuel cell and cathode material

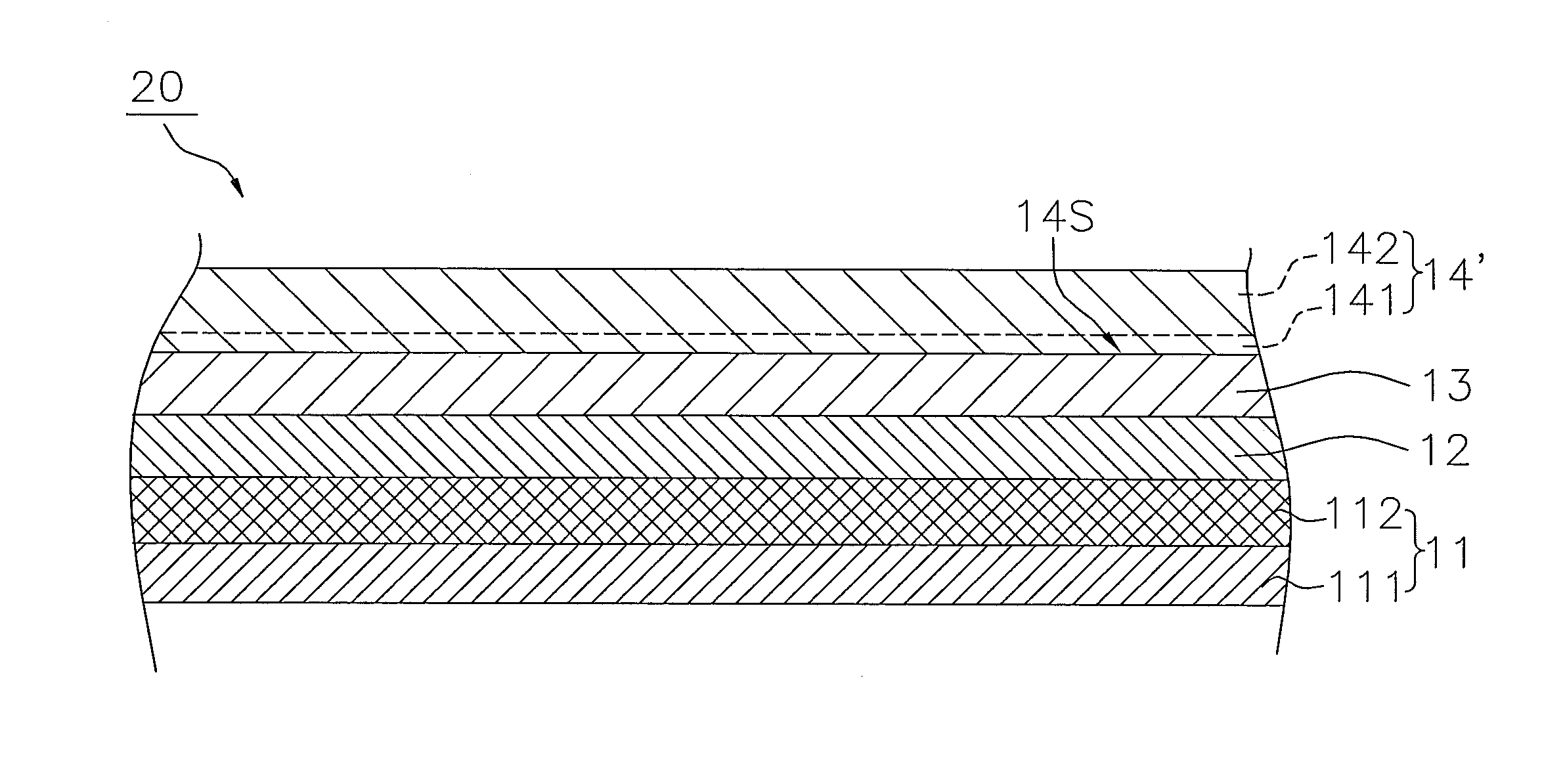

ActiveUS20150024302A1Increase productionCell electrodesCeramic layered productsFuel cellsElectrolyte

A fuel cell includes an anode, a cathode and a solid electrolyte layer that is disposed between the anode and the cathode. The cathode includes a main phase and a sub phase. The main phase is composed mostly of perovskite oxide which is expressed by the general formula ABO3 and includes at least Sr at the A site. The sub phase is composed mostly of strontium sulfate. An occupied area ratio of the sub phase in a cross section of the cathode is no more than 10.2%.

Owner:NGK INSULATORS LTD

Additive for increasing the density of an oil-based fluid and fluid comprising such additive

A wellbore fluid having an oleaginous phase and an additive for increasing the density of the wellbore fluid. The additive comprises solid colloidal particles coated with a dispersant coated onto the colloidal particle during the comminution process of forming the particles. Exemplary starting materials for the colloidal particles include commonly known weighting agents including barite, calcium carbonate, dolomite, ilmenite, hematite or other iron ores, olivine, siderite, and strontium sulfate as well as mixture and combinations of these and other similar weighting materials. The dispersant in one illustrative embodiment, is selected from carboxylic acids of molecular weight of at least 150 Daltons. Alternatively, the dispersant coating may be made of compounds including oleic acid, polybasic fatty acids, alkylbenzene sulfonic acids, alkane sulfonic acids, linear alpha-olefin sulfonic acid or the alkaline earth metal salts of any of the above acids, and phospholipids as well as mixtures and combinations of these compounds. In another illustrative embodiment the dispersant is a polyacrylate ester. The illustrative polymeric dispersant should have an average molecular weight from about 10,000 Daltons to about 200,000 Daltons.

Owner:MI

Chelate blocking remover suitable for complicated scaling reservoir layers, and preparation method of chelate blocking remover

ActiveCN106867490ASatisfy the blocking conditionLow flow resistanceDrilling compositionInjection pressureSulfate

The invention provides a chelate blocking remover suitable for complicated scaling reservoir layers, and a preparation method of the chelate blocking remover. The chelate blocking remover is prepared from the following components by mass percent: 5-20% of a chelating agent, 0.5-1% of a scale inhibitor, 1-5% of an activator, 0.5-2% of a penetrant and the balance of distilled water. The chelate blocking remover can remove most of complex blockages, formed by complex inorganic scale such as carbonate scale and sulphate scale, and organic scale at immediate vicinity of wellbore zones with scaled oil reservoir, can inhibit the growth of the scale, and prolongs the action time. The chelate blocking remover is mainly used for removing complex scale blockages such as calcium carbonate, calcium sulfate, barium strontium sulfate scale and iron sulfide; the scale blockages are removed by means of saturated dispersion, chelating solubilization and crystal nucleus distortion; the chelate blocking remover can be used for dredging seepage channels of shafts and stratum, reducing oil gas water flow resistance, increasing the yield of an oil-gas well and reducing the injection pressure of a water injection well; furthermore, the chelate blocking remover has certain corrosion inhibition property and dissolution property, thus meeting the blockage removing conditions of the complicated scaling reservoir layers.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Additive for increasing the density of a fluid for casing annulus pressure control

InactiveUS7449431B2Photosensitive materialsScale removal and water softeningVolumetric Mass DensitySolid particle

A method of controlling the pressure of a casing annulus in a subterranean well that includes injecting into the casing annulus a composition including a base fluid and a polymer coated colloidal solid material. The polymer coated colloidal solid material includes: a solid particle having an weight average particle diameter (d50) of less than two microns, and a polymeric dispersing agent coated onto the surface of the solid particle during the comminution (i.e. grinding) process utilized to make the colloidal particles. The polymeric dispersing agent may be a water soluble polymer having a molecular weight of at least 2000 Daltons. The solid particulate material may be selected from materials having of specific gravity of at least 2.68 and preferably the solid particulate material may be selected from barium sulfate (barite), calcium carbonate, dolomite, ilmenite, hematite, olivine, siderite, strontium sulfate, combinations and mixtures of these-and other similar solids.

Owner:MI

Additive for increasing the density of a fluid for casing annulus pressure control

A method of controlling the pressure of a casing annulus in a subterranean well that includes injecting into the casing annulus a composition including a base fluid and a polymer coated colloidal solid material. The polymer coated colloidal solid material includes: a solid particle having an weight average particle diameter (d50) of less than two microns, and a polymeric dispersing agent coated onto the surface of the solid particle during the cominution (i.e. grinding) process utilized to make the colloidal particles. The polymeric dispersing agent may be a water soluble polymer having a molecular weight of at least 2000 Daltons. The solid particulate material may be selected from materials having of specific gravity of at least 2.68 and preferably the solid particulate material may be selected from barium sulfate (barite), calcium carbonate, dolomite, ilmenite, hematite, olivine, siderite, strontium sulfate, combinations and mixtures of these and other similar solids that should be apparent to one of skill in the art.

Owner:M1 LIMITED

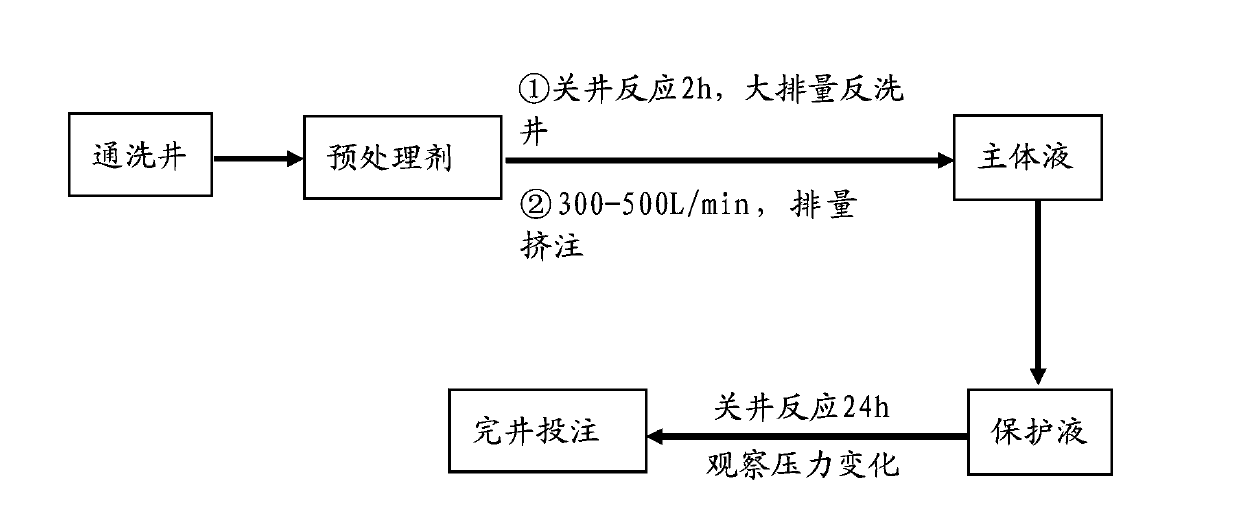

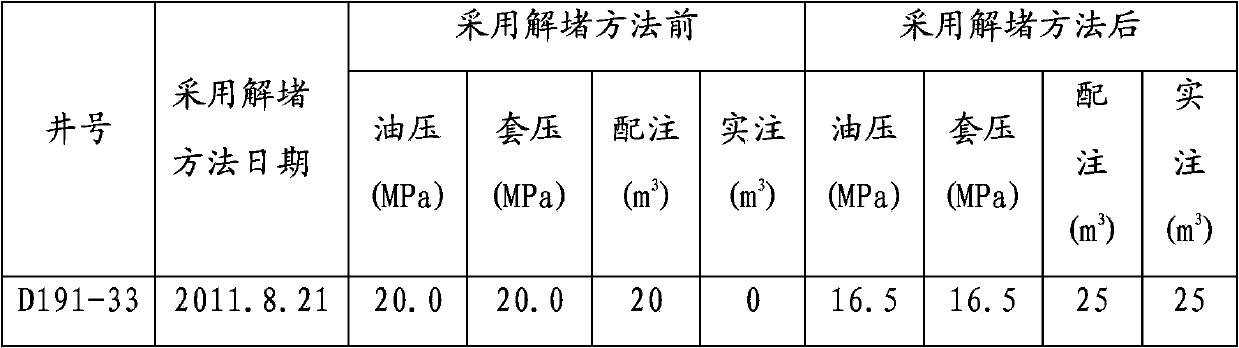

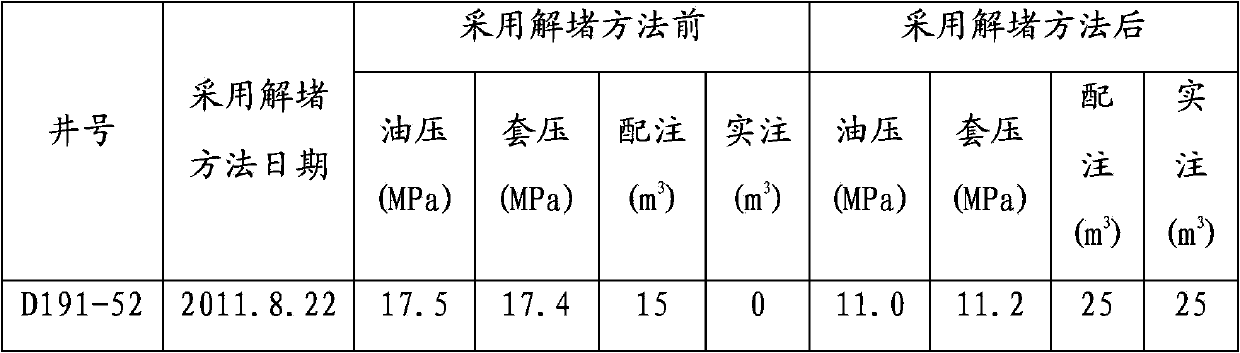

Blocking remover and blocking removal method for corrosion sulfate compound scale

ActiveCN103666425AAvoid cloggingSuppress generationCleaning apparatusDrilling compositionSulfateColloid

The invention discloses a blocking remover and a blocking removal method for corrosion sulfate scale. The blocking remover comprises a pretreating agent, main liquid and protective liquid. The blocking removal method comprises the following steps: firstly, adding the pretreating agent after completely washing a shaft, performing shut-in reaction for 2 hours, then, performing backwashing on the shaft with high flow rate, and further squeezing the main liquid of the blocking remover according to the flow rate of 300-500L / min; next, squeezing the protective liquid after squeezing all the main liquid, performing shut-in reaction for 24 hours, and observing pressure variation; finally, completing and injecting. The blocking remover and the blocking removal method can solve blocking caused by organics, such as colloid and asphaltene, and blocking caused by calcium scale, in the shaft and the near-shaft area, can unblock the shaft and ground channels, simultaneously, clear barium and strontium sulfate / calcium sulfate mixed scale which is difficult to remove by the conventional methods, further restrain generation of scale and clay expansion, and prolong the blocking removal cycle.

Owner:PETROCHINA CO LTD

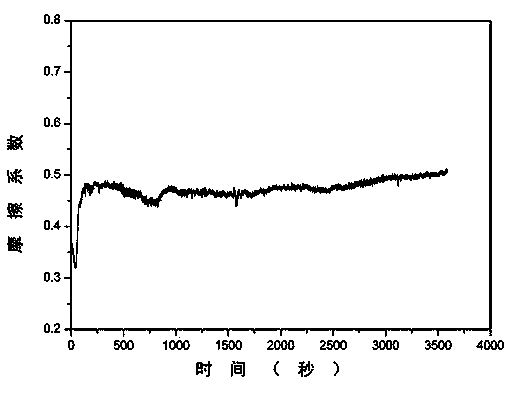

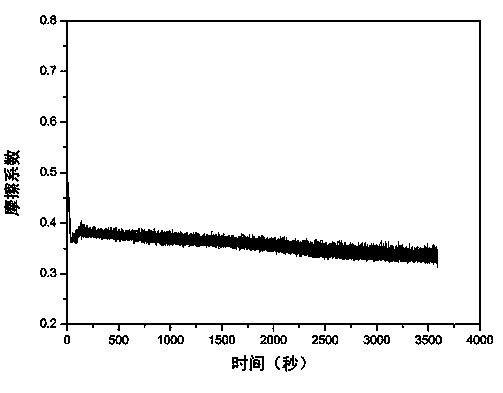

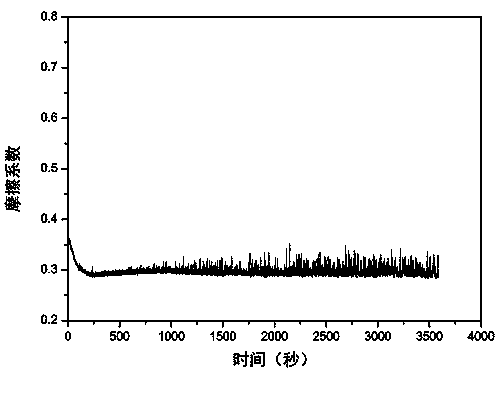

NiCr-Al2O3 self-lubricating composite material and preparation method thereof

InactiveCN103572137ABest friction and wear resistanceGood wide temperature range lubrication performanceRoom temperatureWear resistance

The invention discloses a NiCr-Al2O3 self-lubricating composite material and a preparation method thereof. The material comprises the following components by mass: 35.04-39.36% of nickel, 8.76-9.84% of chromium, 29.2-32.8% of nanometer alumina, 9-11% of strontium sulfate, and 9-16% of silver. The material has the advantages of excellent frictional wear performance and wide-temperature range lubricating property from room temperature to 1000 DEG C, and can be used to solve problems of lubrication and wear resistance between related parts under special environment conditions in industrial fields of aerospace, petroleum, chemical engineering, and the like.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

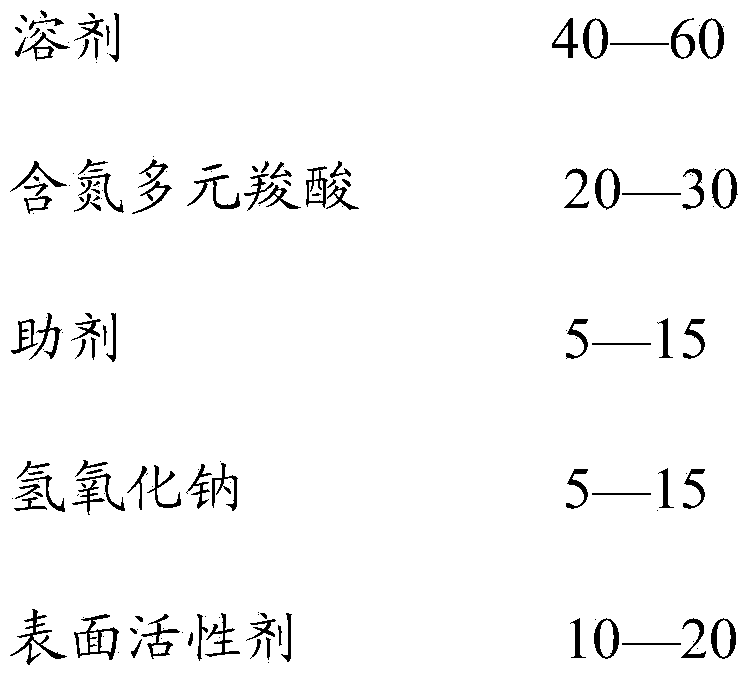

Barium sulfate and strontium sulfate descaling agent and preparation method thereof

InactiveCN103820150AIncrease the ability of dissolving scaleFully contactedTreatment apparatus corrosion/fouling inhibitionNitrogenCarboxylic acid

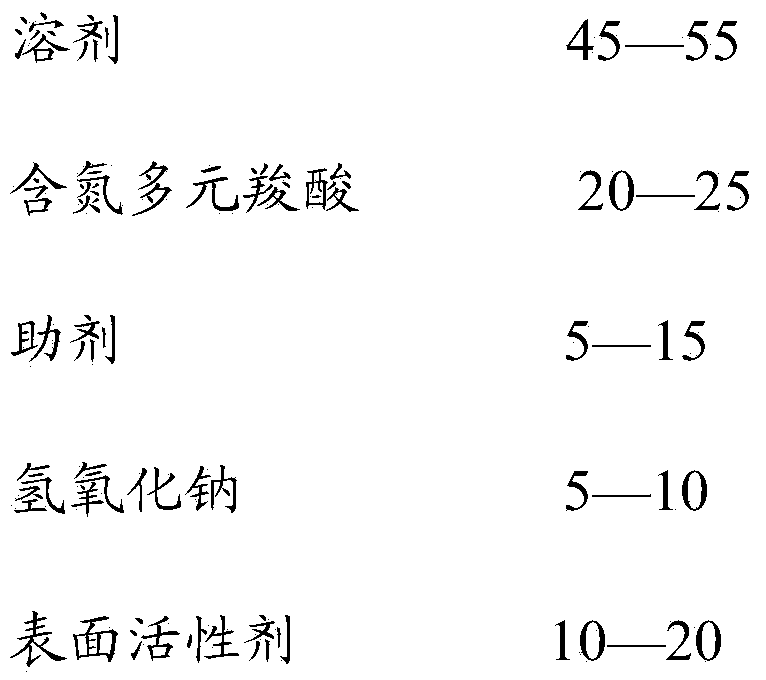

The invention relates to a barium sulfate and strontium sulfate descaling agent and a preparation method thereof. According to the invention, a proper water soluble solvent is added into a formula which takes nitrogenous polybasic carboxylic acid as a main component, so that the components are better matched in function, and the descaling performance of the final product is further improved. In addition, the cost of the solvent is lower than that of other components, so that the cost of the final product is lowered. Raw materials for producing the descaling agent can be purchased from chemical engineering markets at home and abroad, the synthetic process is simple and the product quality is stable. The barium sulfate and strontium sulfate descaling agent for oil prepared by the invention can be suitable for water injection stratums, perforation wells, sleeve orifices, underground pumps, tubing strings, valves, transmission pipelines and the like. The descaling agent is good in compatibility and is an ideal descaling agent for removing barium sulfate and strontium sulfate for an oil field.

Owner:XI'AN PETROLEUM UNIVERSITY

Barium-strontium scale cleaning agent and preparation method thereof

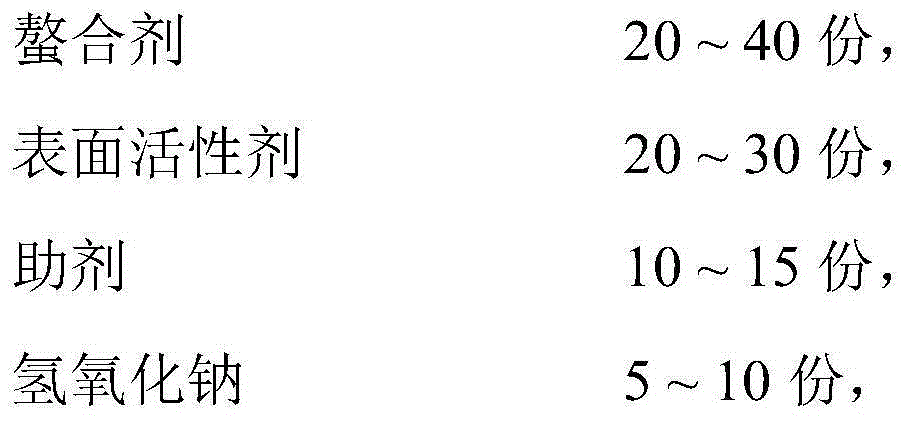

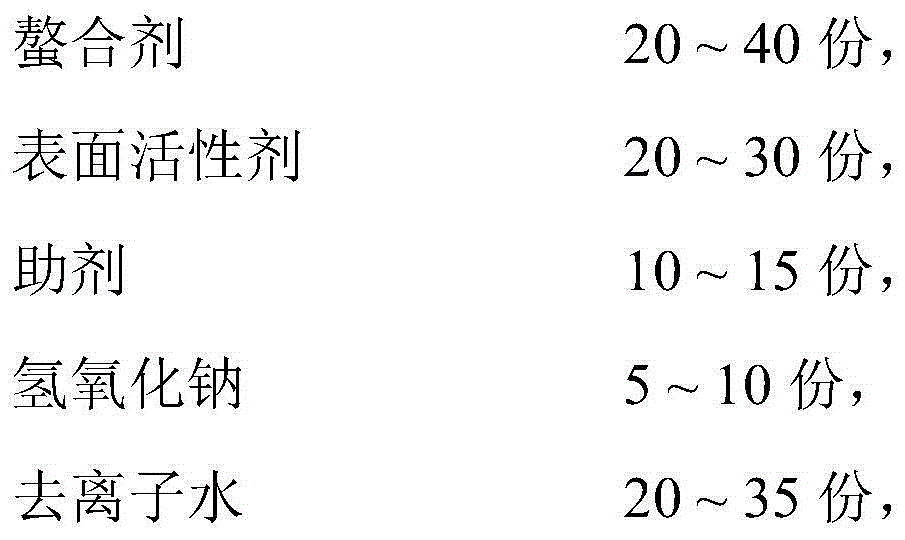

ActiveCN104987858AGood descaling effectNo corrosionDrilling compositionCleansing AgentsSodium hydroxide

The invention discloses a barium-strontium scale cleaning agent and a preparation method thereof. The barium-strontium scale-removing agent is prepared through a reaction of, by weight, 20-40 parts of a chelating agent, 20-30 parts of a surfactant, 10-15 parts of an auxiliary agent, 5-10 parts of sodium hydroxide, and 20-35 parts of deionized water. The preparation method is simple. According to the method, deionized water, the chelating agent and sodium hydroxide are added into a reaction flask and are heated and stirred under a temperature of 40-60 DEG C; the surfactant and the auxiliary agent are sequentially added, and the temperature is maintained; and the obtained product is naturally cooled to room temperature, such that the cleaning agent is obtained. The barium-strontium scale cleaning agent has the advantages of good scale-removing performance, low toxicity, good stability, and no corrosion. With the agent, barium sulfate and strontium sulfate scales can be effectively removed, such that the agent has an important practical significance to oil field productions. The preparation method is simple and feasible, and the raw materials have wide source and low cost. Therefore, the cleaning agent and the method have good market values.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Composition of base fluid and polymeric dispersing agent-absorbed polymer-coated colloidal particles

A method of controlling the pressure of a casing annulus in a subterranean well that includes injecting into the casing annulus a composition including a base fluid and a polymer coated colloidal solid material. The polymer coated colloidal solid material includes: a solid particle having an weight average particle diameter (d50) of less than two microns, and a polymeric dispersing agent coated onto the surface of the solid particle during the cominution (i.e. grinding) process utilized to make the colloidal particles. The polymeric dispersing agent may be a water soluble polymer having a molecular weight of at least 2000 Daltons. The solid particulate material may be selected from materials having of specific gravity of at least 2.68 and preferably the solid particulate material may be selected from barium sulfate (barite), calcium carbonate, dolomite, ilmenite, hematite, olivine, siderite, strontium sulfate, combinations and mixtures of these and other similar solids that should be apparent to one of skill in the art.

Owner:M1 LIMITED

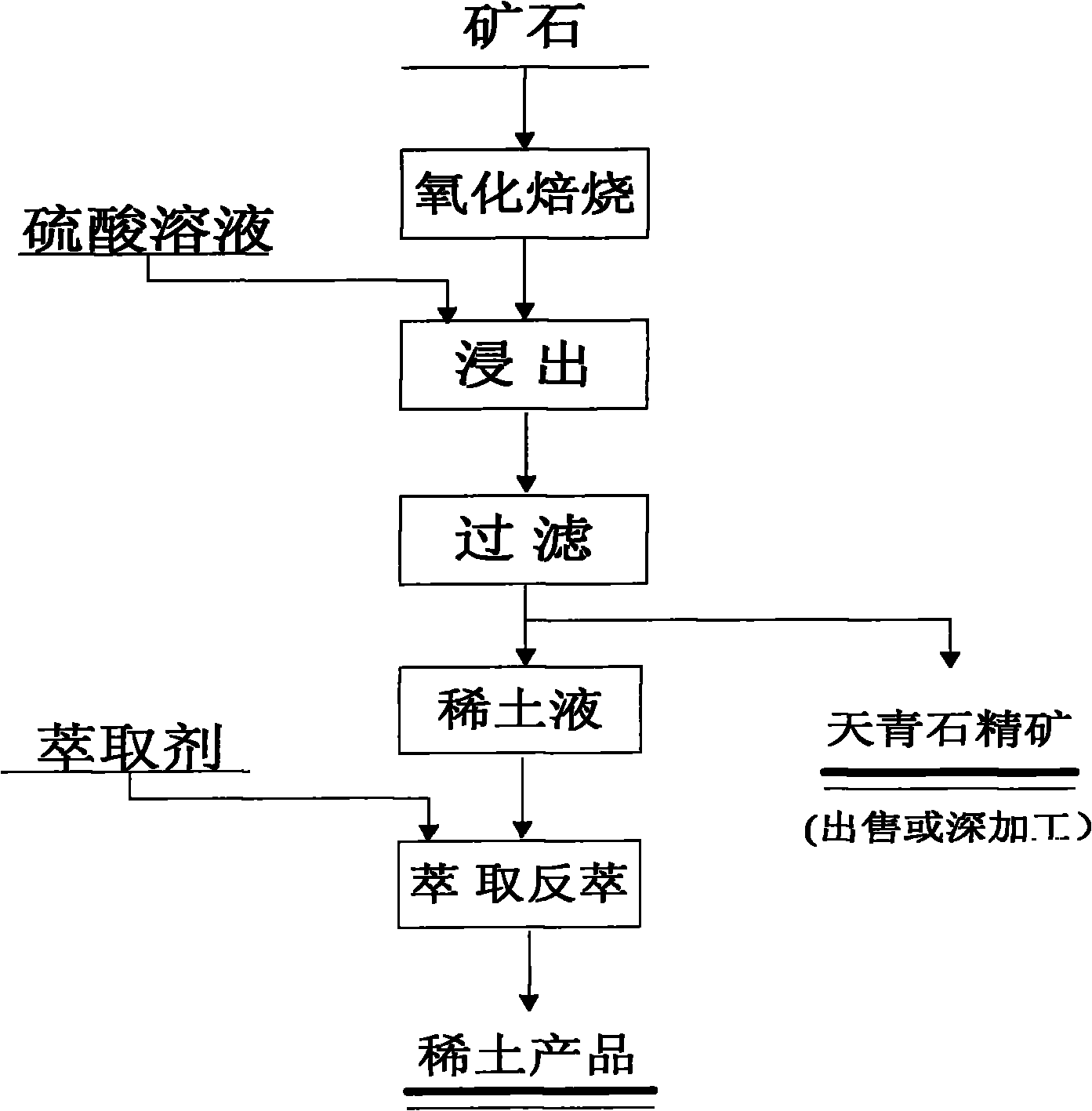

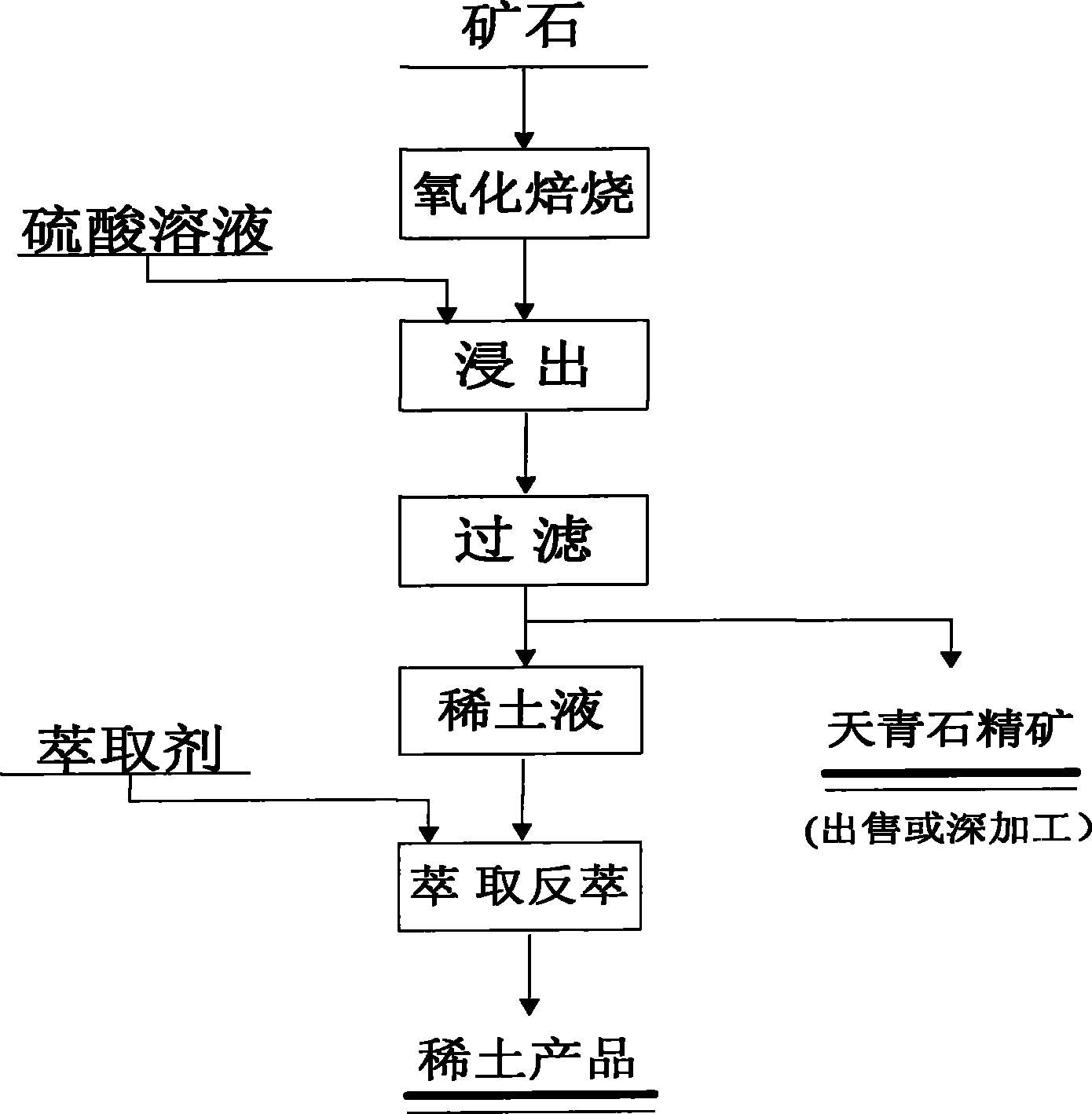

Comprehensive recovery process for rare earth and strontium intergrowth multi-metal ore

ActiveCN102399999AEfficient separationSimple processProcess efficiency improvementAir atmosphereHydrogen-Ion Concentrations

The present invention relates to a comprehensive recovery process for a rare earth and strontium intergrowth multi-metal ore. The mineral mainly comprises rare earth fluoro-carbonate and at least one selected from a sulfate of the strontium, a carbonate of the strontium or a strontium oxide. According to the present invention, at least one method selected from gravity separation, magnetic separation and flotation separation is adopted to carry out concurrent screening for the rare earth and the strontium in the rare earth and strontium intergrowth multi-metal ore to obtain the bulk concentrate containing the rare earth and the strontium; then the bulk concentrate is subjected to oxidizing roasting for 1-8 hours at a temperature of 350-700 DEG C in air atmosphere or oxygen atmosphere; the resulting calcine is subjected to leaching for 1.0-5.0 hours by a sulfuric acid solution with the hydrogen ion concentration of 0.5-12.0 mol / L, wherein the leaching temperature is 20-100 DEG C, the leaching liquid-solid ratio (by weight) is 1-5:1. The comprehensive recovery process of the present invention has the following advantages that: the rare earth is almost entirely leached in the solution; the strontium sulfate (SrSO4) is remained in the residue; the strontium concentrate with the grade of about 70% is obtained, and can be sold directly or deep processed; with the comprehensive recovery process of the present invention, the multi-metal ore containing the rare earth and the strontium can be effectively separated.

Owner:GRIREM ADVANCED MATERIALS CO LTD

Composite antisludging agent of reverse osmosis/nanofiltration system

ActiveCN103007768AImprove work efficiencyExtended cleaning cycleSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisColloidal silicaUltrafiltration

The invention provides a composite antisludging agent of a reverse osmosis / nanofiltration system. The composite antisludging agent comprises the following components in percentage by weight: 2%-10% of cyclodextrin solution, namely a component I, 80%-90% of at least one or a mixture of amino trimethylene phosphonic acid (ATMP), a copolymer of maleic anhydride-acrylic acid (MA-AA), 2-phosphonic acid butane-1, 2,4-tricarboxylic acid (PBTCA), and hydroxyl ethylidene diphosphonic acid (HEDP), namely a component II, and 1%-10% of 2,2-dibromo-2-cyano-acetamid (DBNPA), namely a component III. The composite antisludging agent is prepared by mixing the component II and the component III, and then fusing the obtained mixture with the component I. When being applied to the reverse osmosis / nanofiltration / ultrafiltration system, the composite antisludging agent can be used for effectively relieving the pollution to the reverse osmosis / nanofiltration / ultrafiltration system caused by polcard, calcium sulphate salt, barium sulfate, strontium sulfate, calcium fluoride, colloidal iron and colloidal silica, relieving biological contamination simultaneously, improving the working efficiency of the system, prolonging the cleaning period and the service life of the reverse osmosis / nanofiltration / ultrafiltration system, and reducing the cost of reverse osmosis.

Owner:辽宁莱特莱德环境工程有限公司

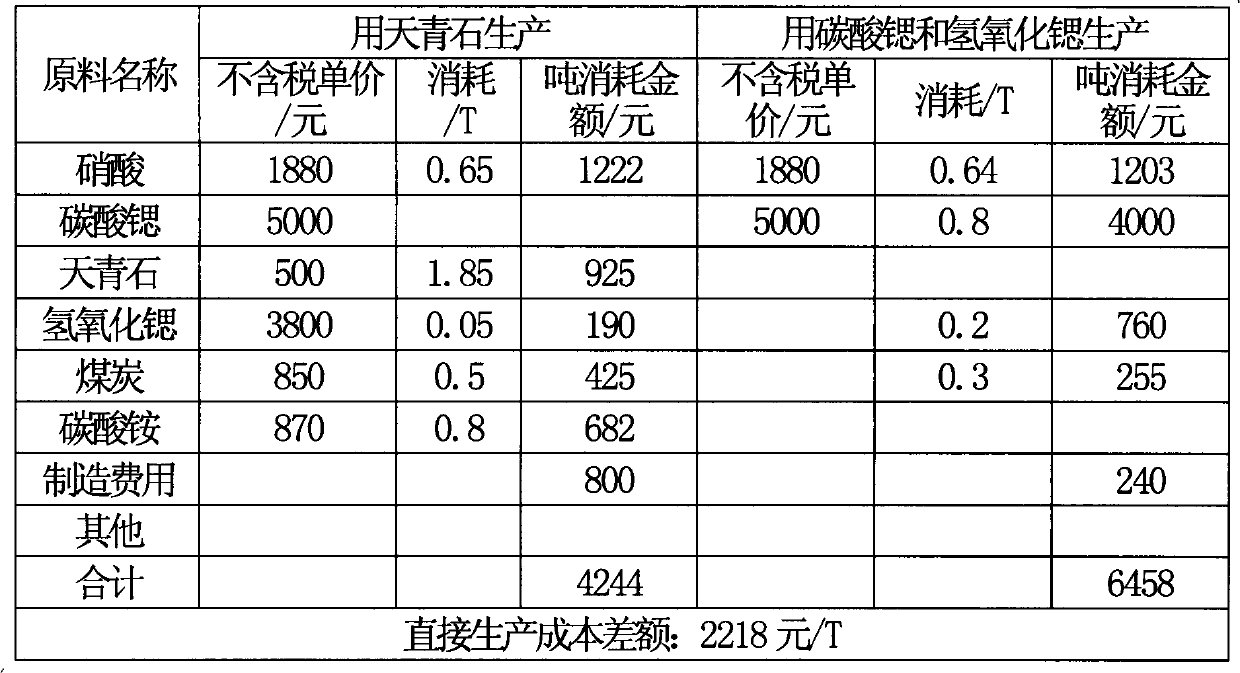

Method for producing less-barium fine strontium salts from celestite

ActiveCN102602974ALow bariumLow costCalcium/strontium/barium carbonatesCalcium/strontium/barium chloridesStrontium carbonateDecomposition

The invention mainly aims to provide a method for producing less-barium fine strontium salts from celestite, and the method is low in cost, which comprises the steps: refining: crushing or grinding the celestite to particles of less than 200 mesh; acid washing: reacting diluted hydrochloric acid with the levigated celestite, and removing a carbonate component in the celestite to obtain high-purity refined celestite; and double decomposition: adding the refined celestite to an ammonium carbonate aqueous solution, uniformly stirring, then reacting in an airtight condition at a reaction pressure of 0.2-0.3MPa and a reaction material temperature of 100-115 DEG C, stopping heating after the reaction is finished, filtering and washing obtained solid to obtain a strontium carbonate crude product, and further refining the strontium carbonate crude product to obtain a product. The method has the advantages that during the double decomposition reaction, when reacting with the celestite, ammonium carbonate only reacts with strontium sulfate in the celestite without reacting with barium sulfate, so that the barium content of the obtained strontium carbonate crude product is very low and lower than 0.05%; and the method is low in production cost and has wide market prospect.

Owner:CHONGQING YUANHE FINE CHEM

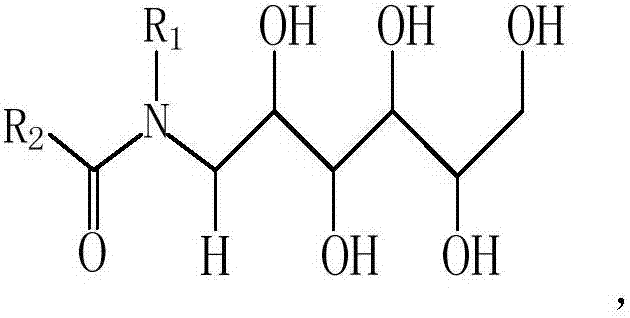

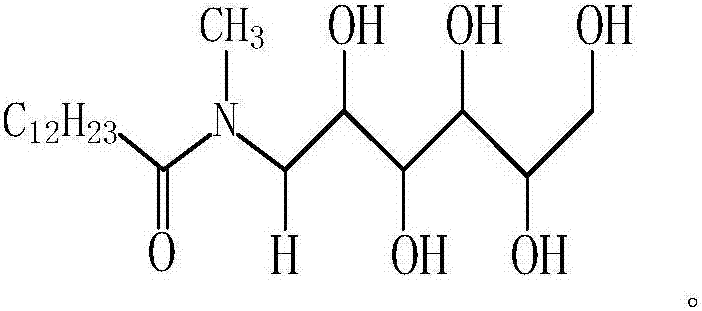

Oil field shaft cleaning and stratum descaling de-blocking agent and preparation and application thereof

ActiveCN106147736AImprove surface activityPromote degradationCleaning apparatusDrilling compositionSodium lactateActive agent

Provided are an oil field shaft cleaning and stratum descaling de-blocking agent and preparation and application thereof. The oil field shaft cleaning and stratum descaling de-blocking agent is prepared by mixing 5-15 parts of EDTA-2Na, 1-8 parts of alpha-d-sodium glucoheptonate, 0.5-5 parts of beta-d-sodium glucoheptonate, 2-8 parts of potassium acetate, 0.5-5 parts of sodium lactate, 2-10 parts of glycol alkyl glucosamide active agent, 0.1-10 parts of enzymes, 1-6 parts of monosaccharide, 0.5-5 parts of ethyl alcohol and 28-87.4 parts of water. The oil field shaft cleaning and stratum descaling de-blocking agent is applied to shaft cleaning and stratum descaling. Active ingredients and a chelating agent are matched, an inorganic dissolution reaction is achieved mainly through a mild chelating mechanism, the product is carried out in a neutral environment from beginning to end, the synergistic effect is good, and barium sulfate, calcium sulfate, strontium sulfate and other impurities which cannot be removed through conventional acid pickling and conventional working liquid can be removed better; meanwhile, viscosity reduction and de-blocking can be achieved, part of viscosity reduction can be removed, the liquidity of crude oil can be improved, and the de-blocking efficiency is high; water sensitivity can be effectively inhibited, water blocking can be eliminated, good improving and stabilizing are achieved for stratum rock cores, oil deposit frameworks are not damaged, and oil deposit is protected well.

Owner:SUNCOO PETROLEUM TECH

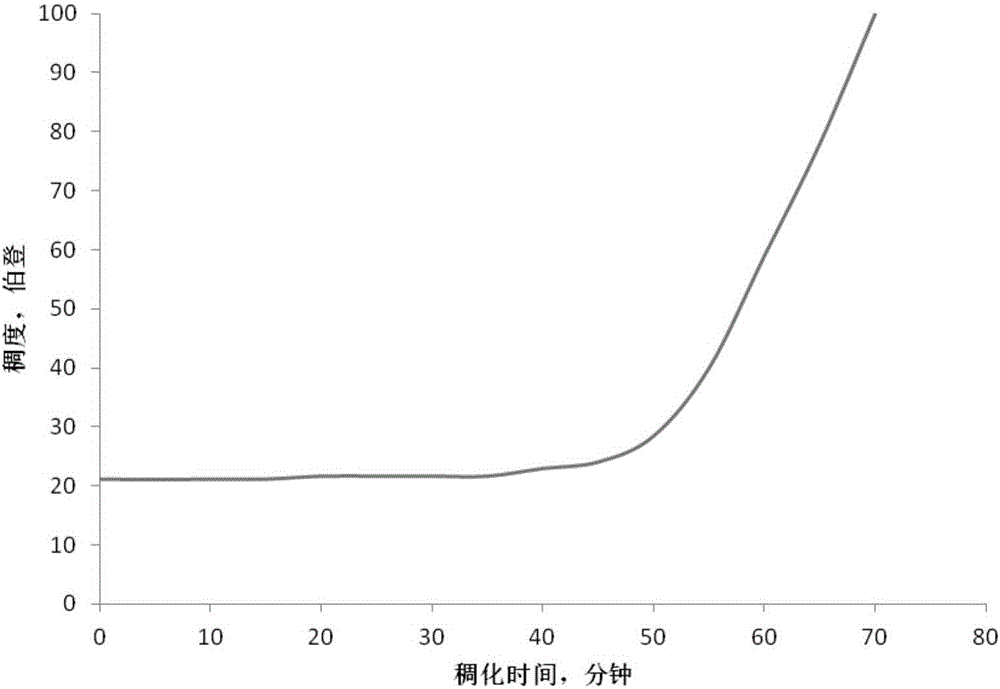

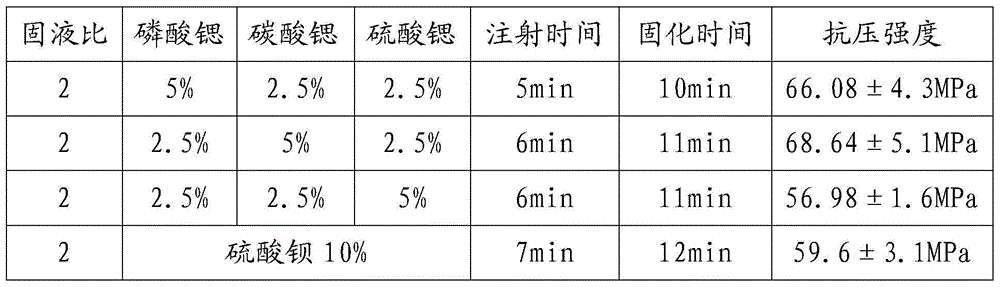

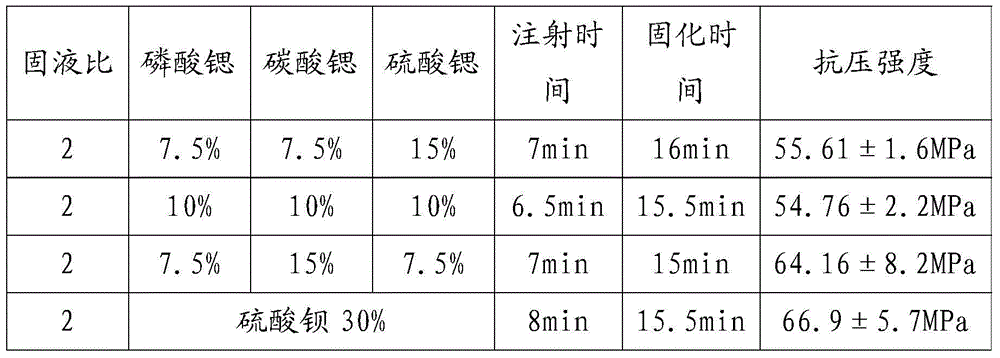

Wide spectrum chlorine-free coagulation accelerating early strength agent for oil field oil well cement

ActiveCN106186777AImprove anti-channeling abilityImprove top strengthDrilling compositionOXALIC ACID DIHYDRATEApatite

The invention relates to a wide spectrum chlorine-free coagulation accelerating early strength agent for oil field oil well cement. The early strength agent comprises the following raw materials in parts by weight: 1 to 1.5 parts of sodium salts, 1 to 1.5 parts of calcium salts, 1 to 1.5 parts of aluminum salts, and 1 to 1.5 parts of other materials, wherein other materials are one or more of hydroxyl apatite, meta-kaolin, magnesium trisilicate, magnesium oxide, strontium sulfate, strontium carbonate, strontium nitrate, lithium carbonate, and oxalic acid. The provided early strength agent is stable, and has an excellent coagulation accelerating performance and early strength property; the early strength is high, the strength development is fast, the thickening transition time and primary-final setting transition time are short; and the early strength agent is suitable for various cement slurry systems such as cement slurry system with a wide temperature range and large temperature difference, AMPS cement slurry system, and the like.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

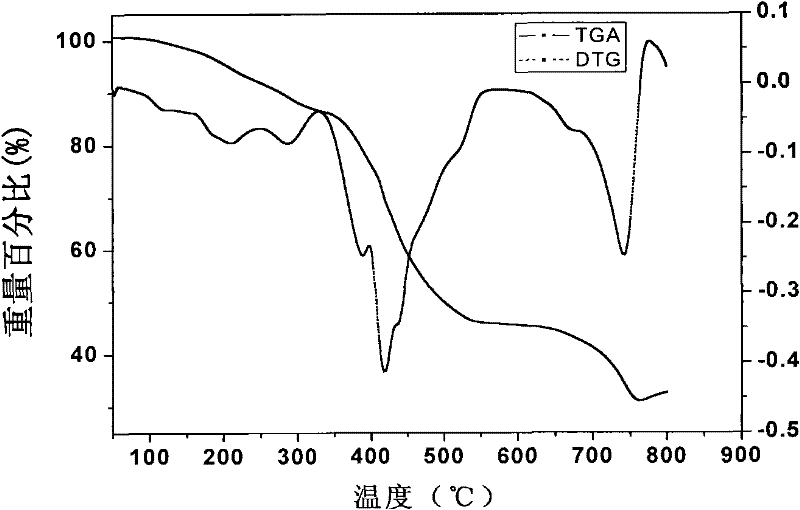

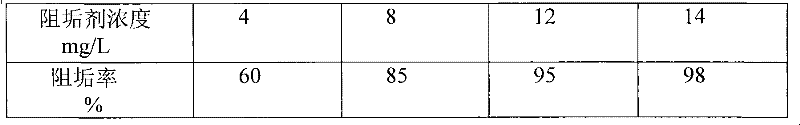

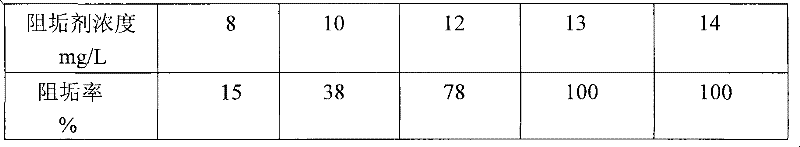

Novel multi-carboxyl and phosphorus-free polycarboxylic acid scale inhibitor and preparation method thereof

InactiveCN102219311AWide applicabilityReduce dosageScale removal and water softeningBarium sulfateSodium salt

Owner:SHANDONG UNIV

Method for preparing strontium carbonate

InactiveCN1394809ATo achieve the purpose of removing bariumSimple processCalcium/strontium/barium carbonatesStrontium carbonateSalt solution

The preparation method of strontium carbonate includes the following steps: pulverizing celestine in which the strontium carbonate content is 30-95%, making it react with soluble carbonate to obtain crude strontium carbonate, adding barium-removing agent to inhibit the conversion of barium sulfate into barium carbonate, then making the crude strontium carbonate react with acidifying reagent to obtain soluble strontium salt solution, removing impurity and making the strontium salt solution react with carbonization reagent to obtain the invented strontium carbonate.

Owner:WUHAN UNIV

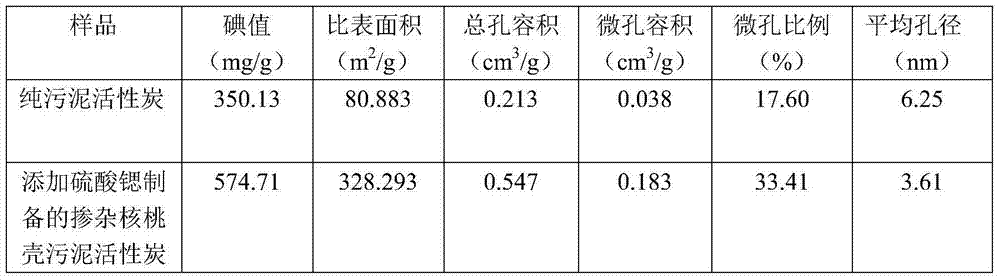

Preparation method of walnut shell-doped sludge activated carbon

The invention relates to a preparation method of walnut shell-doped sludge activated carbon for removing pollutants such as dye, phenols and metal ions in sewage. The technical scheme is that the preparation method comprises the following steps: drying excess sludge until the moisture content is 8-10%; crushing dry sludge and walnut shells respectively until the particle size is 0.3-0.8mm, and uniformly mixing the two at a mass ratio of (70-90):(10-30); adding strontium sulfate powder to obtain a raw material mixture; impregnating with a zinc chloride solution for 24 hours and drying; performing carbonization activation for 45-60 minutes at 400-500 DEG C; washing the product with hydrochloric acid, and washing with deionized water until the pH value is 6-8; and drying the product and grinding to obtain sludge activated carbon. In the method, with the walnut shells as a carburant, strontium sulfate as a catalyst and zinc chloride as an activator, sludge activated carbon is prepared by a one-step carbonization activation method, and harmless treatment of the sludge is realized; and obtained sludge activated carbon has abundant pores, a large specific surface area and a large adsorption value and is applicable to sewage treatment.

Owner:SOUTHWEST PETROLEUM UNIV

Barium strontium calcium scale remover and preparation method thereof

InactiveCN106147735AThe preparation method is simple and feasibleLower synthesis costDrilling compositionSulfatePotassium hydroxide

The invention provides a barium strontium calcium scale remover. The barium strontium calcium scale remover is prepared from, by weight, 20%-35% of a metal chelator, 10%-20% of a solubilizer, 0.5%-5% of a dispersing agent, 5%-15% of potassium hydroxide and 40%-60% of deionized water. Compared with the prior art, the barium strontium calcium scale remover has the good performance, can effectively remove organic composite scale such as barium sulfate, strontium sulfate and calcium sulfate, has the advantages of being high in scale removal efficiency, harmless to the natural environment, safe in use, non-corrosive to equipment and the like and has an important practical significance for increasing the oil and gas recovery rate.

Owner:CNPC BOHAI DRILLING ENG

Additive For Reducing Torque On A Drill String

A method of reducing the torque of a drill string used in drilling a subterranean well that includes injecting into the drilling fluid a composition including a base fluid and a polymer coated colloidal solid material. The polymer coated colloidal solid material includes: a solid particle having an weight average particle diameter (d5o) of less than ten microns, and a polymeric dispersing agent coated onto the surface of the solid particle during the cominution (i.e. grinding) process utilized to make the colloidal particles. The polymeric dispersing agent may be a water soluble polymer having a molecular weight of at least 2000 Daltons. The solid particulate material may be selected from materials having of specific gravity of at least 2.68 and preferably the solid particulate material may be selected from barium sulfate (barite), calcium carbonate, dolomite, ilmenite, hematite, olivine, siderite, strontium sulfate, combinations and mixtures of these and other similar solids that should be apparent to one of skill in the art.

Owner:MI

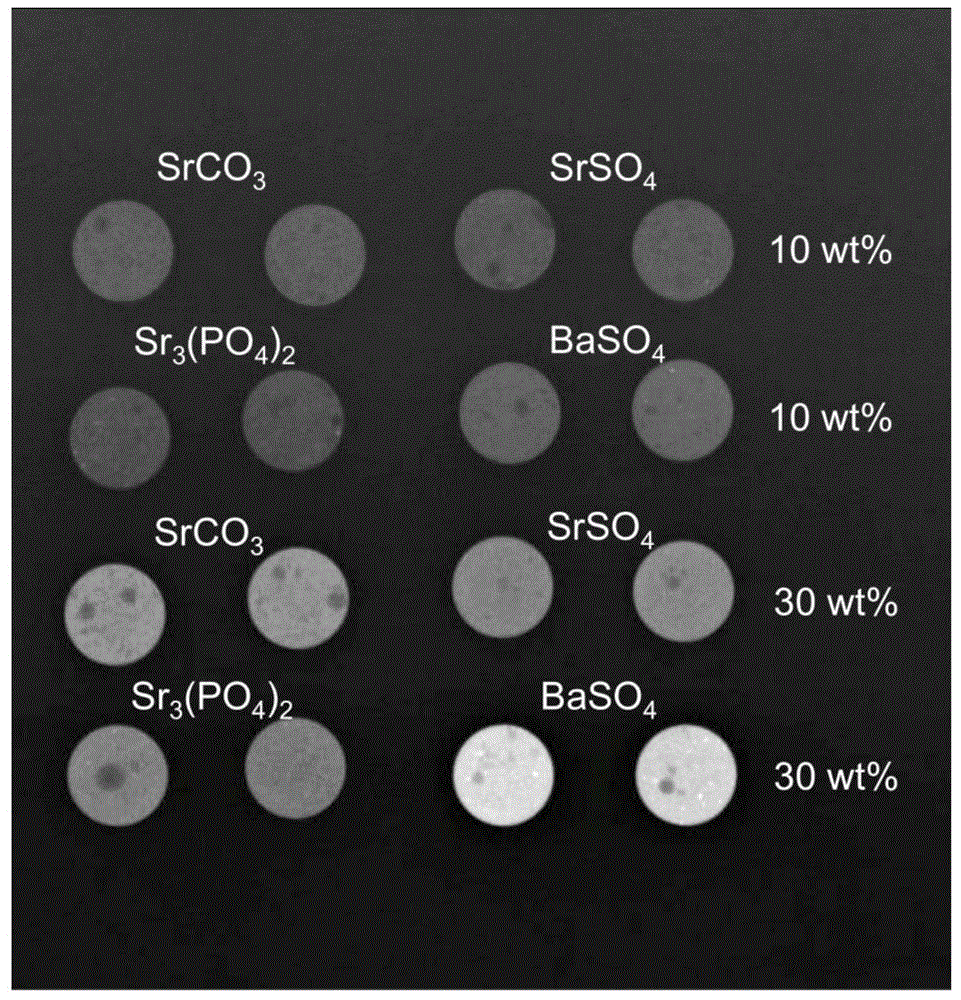

Development bone cement and its preparation method and use

The invention discloses development bone cement and its preparation method and use. The development bone cement comprises powder and a liquid. The powder comprises polymethyl methacrylate (PMMA), a developer and benzoyl peroxide. The liquid comprises a methyl methacrylate (MMA) monomer as a main component. The developer is a strontium salt. The strontium salt is one of strontium phosphate, strontium sulfate and strontium carbonate. A mass ratio of the developer to the bone cement powder is in a range of 10%-30%. The development bone cement can be used for fixing of fracture caused by osteoporosis and bone defect filling.

Owner:山东明德生物医学工程有限公司

Descaling and blockage-removing fluid for clearing blockage in drilling and completion process and preparation method of descaling and blockage-removing fluid

InactiveCN107418541ASolve pollutionImprove permeabilityCleaning apparatusDrilling compositionPhosphatePhosphoric acid

The invention discloses descaling and blockage-removing fluid for clearing blockage in a drilling and completion process and a preparation method of the descaling and blockage-removing fluid. The descaling and blockage-removing fluid comprises the following components in parts by weight: 20-40 parts of a metal chelating agent, 1-5 parts of biological enzymes, 1-2 parts of a high-temperature anti-swelling agent, 2-5 parts of a stabilizer, 1-5 parts of a ligand, 2-5 parts of alkyl glucosamide, 1-5 parts of a phosphate anionic surfactant, 1-5 parts of alkali and 30-60 parts of water. The corresponding preparation method is simple, and the descaling and blockage-removing fluid is applicable to shaft cleaning and blockage removing of immediate vicinity of wellbore in an environment of 80-150 DEG C; the descaling and blockage-removing fluid is capable of clearing scales which cannot be eliminated during acid pickling and in the conventional injected fluid, such as barium sulfate, strontium sulfate, calcium sulfate, the pollution problem on the immediate vicinity of wellbore caused by barite is solved, the permeability is restored and improved, the reservoir skeleton is not damaged, the stability of the reservoir is still maintained after use, and sand production is avoided; in addition, the phenomenon of swelling of the interface and water sensitivity clay can be avoided.

Owner:CNPC BOHAI DRILLING ENG

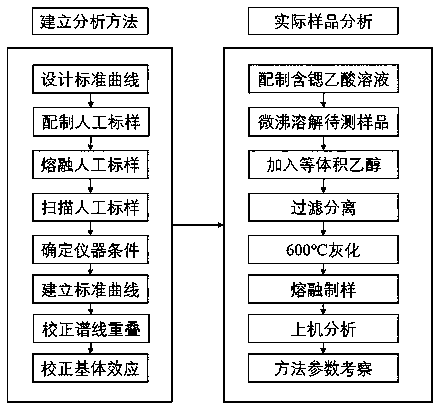

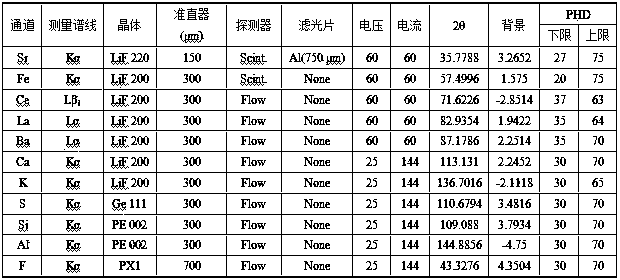

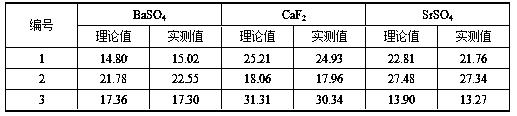

X-ray fluorescence spectrometry method for simultaneously analyzing fluorspar, barite and celestite

InactiveCN108051468AReduce consumptionPromote development and utilizationMaterial analysis using wave/particle radiationLithium metaborateRare earth

The invention discloses an X-ray fluorescence spectrometry method for simultaneously analyzing fluorspar, barite and celestite in ores quantitatively. The X-ray fluorescence spectrometry method comprises the following specific processes: preparing an artificial standard substance by mixing a barite standard substance, a fluorite standard substance, rare earth ore standard substance, strontium sulfate and strontium carbonate, fusing the artificial standard substance by using a mixed fusing agent (the ratio of lithium tetraborate to lithium metaborate is 12:22), scanning obtained standard samples to determine an instrument condition, correcting a matrix effect, and then establishing a standard curve; treating a sample to be tested by using a strontium-containing acetic acid solution, filtering, separating an interferent, ashing a precipitate and filter paper, then adding the mixed fusing agent (the ratio of lithium tetraborate to lithium metaborate is 12:22) for fusing, and analyzing according to the standard curve. An X-ray fluorescence spectrometer is selected as an analytical instrument, pretreatment operation is simplified, and simultaneous quantitative analysis of three components, namely the fluorite, the barite and the celestite, in the ore is achieved; the X-ray fluorescence spectrometry method is suitable for analyzing the single ore or the ore containing the fluorite, the barite and the celestite.

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

Nano corrosion and scale inhibitor and preparation method thereof

InactiveCN108147560AReduce corrosionReduce pollutionScale removal and water softeningEtidronic acidEther

The invention provides a nano corrosion and scale inhibitor and a preparation method thereof. The nano corrosion and scale inhibitor comprises the following raw material components in parts by weight:30 parts of nano calcium carbonate, 5 parts of nano strontium sulfate, 8 parts of a carboxylic copolymer, 8 parts of metallic salt, 5 parts of phosphorus pentoxide, 20 parts of amino ether phosphonicacid, 5 parts of etidronic acid, 3 parts of polymaleic acid, 5 parts of mercaptobenzothiazole, and 2 parts of sodium hypophosphite. The nano corrosion and scale inhibitor has the advantages of beingconvenient to store and transport, low in metal corrosion in boiler, pipeline and pressure vessel washing, high in antisludging capacity, safe to use, and small in environmental pollution.

Owner:沈阳瑞利源环保工程有限公司

Room-temperature self-setting corrosion protective coating and preparation method thereof

InactiveCN104212323AAnti-agingSelf-healingAnti-corrosive paintsPolyurea/polyurethane coatingsZinc phosphateWeather resistance

The invention discloses a room-temperature self-setting corrosion protective coating. The room-temperature self-setting corrosion protective coating is prepared from the following main components in parts by weight: 30-75 parts of polyurethane, 15-18 parts of polytetrafluoroethylene, 12-15 parts of zinc phosphate, 12-16 parts of n-butanol, 5-8 parts of strontium sulfate, 3-8 parts of sodium hexametaphosphate, 5-7 parts of a dispersant, 1-3 parts of a toughening agent, 2-5 parts of a flatting agent and 3-6 parts of a plasticizer. The invention also discloses a room-temperature self-setting corrosion protective coating and a preparation method thereof. The room-temperature self-setting corrosion protective coating can be used under the rigour condition, is long in the corrosion protective life and also has excellent characteristics of weatherability, ageing, radiation, abrasion, impact, high temperature and low temperature resistance and stability in electrical conductivity. With the adoption of the room-temperature self-setting corrosion protective coating, the resistivity can meet the requirement for electrostatic resistance, and long service life of the coating can also be ensured.

Owner:JIANGSU MARINE VICTORY COATING

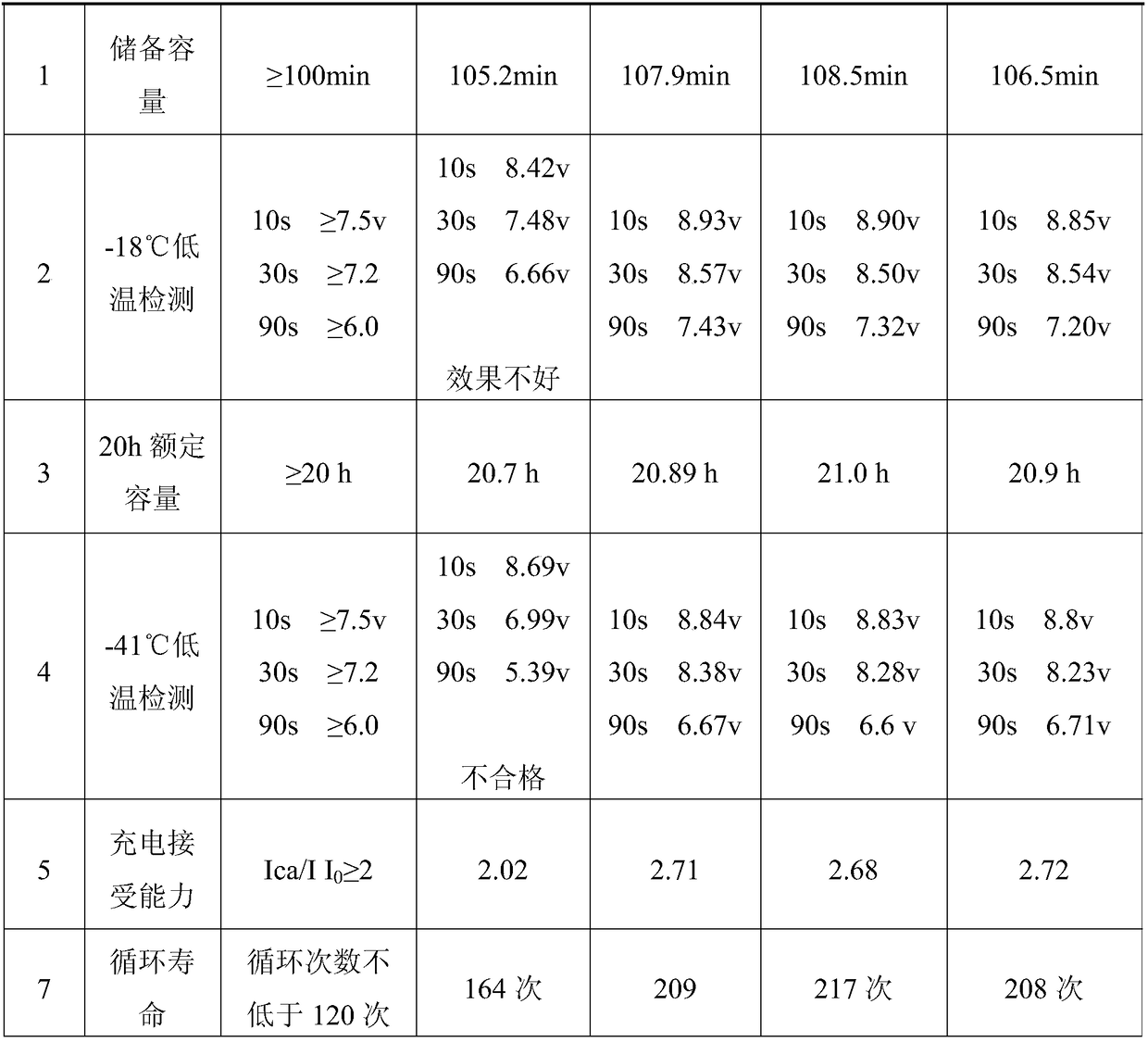

Low-temperature resistant negative lead paste of lead storage battery and preparation method of negative lead paste

ActiveCN108598472AGood dispersionStrong consistencyFinal product manufactureCell electrodesFiberCarboxymethyl cellulose

The invention discloses low-temperature resistant negative lead paste of a lead storage battery and a preparation method of the negative lead paste, and belongs to the technical field of storage battery preparation. The negative lead paste comprises lead powder, a negative additive, water and paste synthesis acid, wherein the negative additive comprises the constituents based on 100 parts by weight of the lead powder: 0.5-1.0 part of strontium sulfate or barium sulfate, 0.1-0.15 part of sodium lignosulphonate, 0.4-0.8 part of humic acid, 0.3-0.6 part of valonea extract, 0.6-1.2 parts of synthesis tanning agent, 0.1-0.2 part of carbon nanotube, 0.05-0.1 part of nanometer Ketjen black, 0.1-0.15 part of conductive carbon fiber and 0.1-0.5 part of carboxymethyl cellulose sodium. During preparation of the negative lead paste, the additive is pre-processed, and the negative lead paste is high in dispersity. The low-temperature discharging capacity of the storage battery produced by employingthe negative lead paste can be improved by 10-25%, and the service lifetime under a low-temperature environmental is prolonged by 20-30%.

Owner:TIANNENG BATTERY GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com