Barium sulfate and strontium sulfate descaling agent and preparation method thereof

A technology of descaling agent and strontium sulfate, which is applied in the direction of corrosion/scaling inhibition of treatment equipment, petroleum industry, treatment of hydrocarbon oil, etc., can solve problems such as poor effect, achieve the effect of improving descaling performance and increasing the ability of dissolving scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

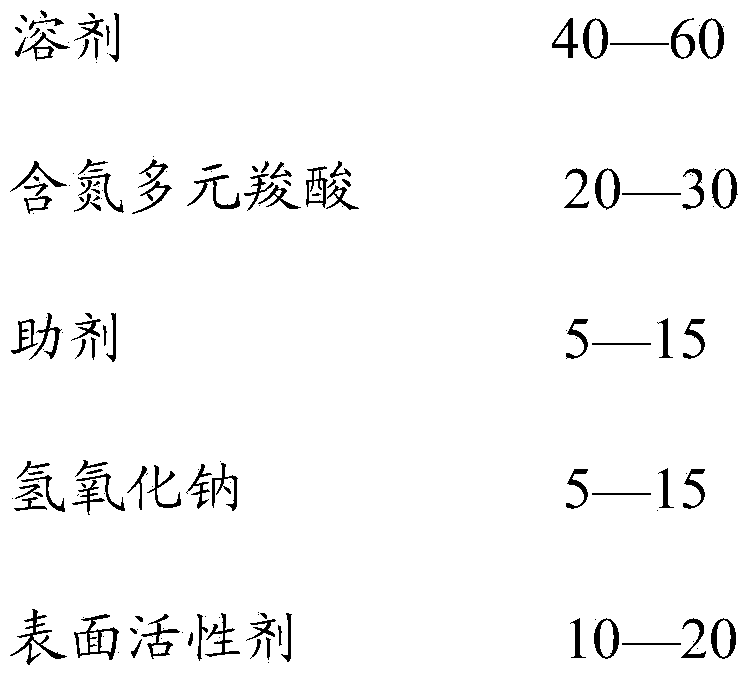

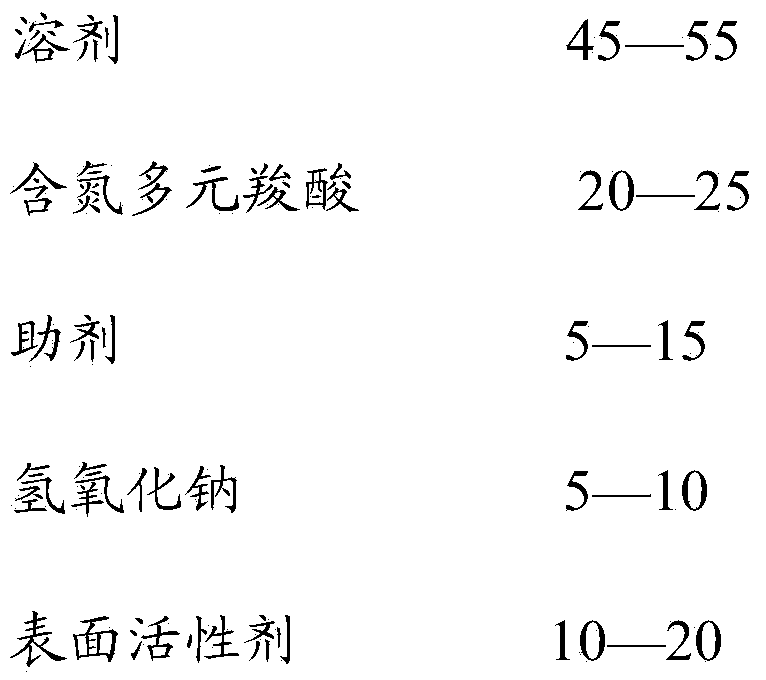

Method used

Image

Examples

Embodiment 1

[0035] The formula of the descaling agent is: the ethylene glycol dimethyl ether of 50% by weight; the nitrogen-containing polycarboxylic acid of 20% by weight; the salicylic acid of 10% by weight; Sodium, 15% by weight OP-10.

[0036] First add ethylene glycol dimethyl ether, nitrogen-containing polycarboxylic acid, and sodium hydroxide into the reaction kettle and stir evenly; then, heat to 40°C and keep the temperature for 1 hour; then, add salicylic acid and OP as a surfactant -10, start stirring at the same time, stop heating after stirring evenly, and after cooling to room temperature, it is the product.

Embodiment 2

[0038] The formula of descaling agent is: the mixture of 55% ethanol and isopropanol by weight, wherein the weight ratio of ethanol and isopropanol is 1:2; 20% nitrogen-containing polycarboxylic acid by weight; Be 8% citric acid; The weight percentage is 5% sodium hydroxide, the weight percentage is the mixture of 12% OP-15 and OP-10, wherein, the weight ratio of OP-15 and OP-10 is 1:1; 0.5% PESA by weight.

[0039] Add the solvent, nitrogen-containing polycarboxylic acid, and sodium hydroxide into the reaction kettle and stir evenly; then, heat to 40°C and keep the temperature for 2 hours; then, add additives and surfactants and start stirring at the same time, and stop heating after stirring evenly , after cooling to room temperature, add synergist, stir evenly and it will be the product.

Embodiment 3

[0041] The formula of descaling agent is: the isobutanol of 45% by weight, the nitrogen-containing polycarboxylic acid of 20% by weight; The oxalic acid of 12% by weight; The sodium hydroxide of 8% by weight, the percent by weight of 15% sodium lauryl sulfonate; 0.4% PESA by weight.

[0042] Add the solvent, nitrogen-containing polycarboxylic acid, and sodium hydroxide into the reaction kettle and stir evenly; then, heat to 45°C and keep the temperature for 1 hour; then, add additives and surfactants and start stirring at the same time, and stop heating after stirring evenly , after cooling to room temperature, add synergist, stir evenly and it will be the product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Proportion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com