Patents

Literature

553results about How to "Good descaling effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

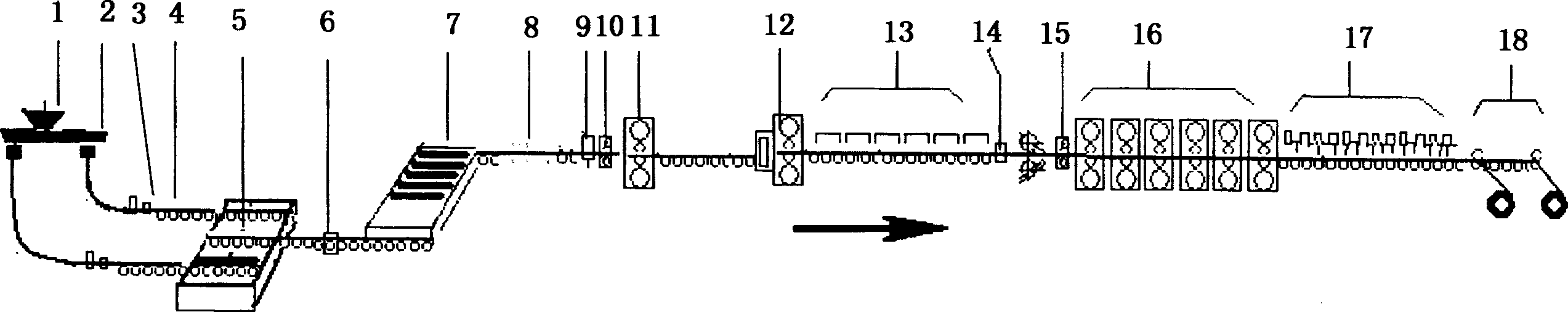

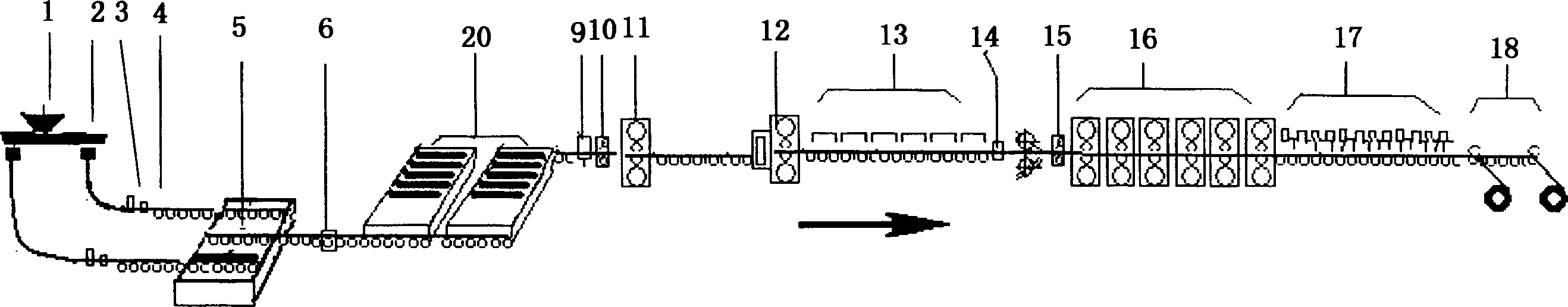

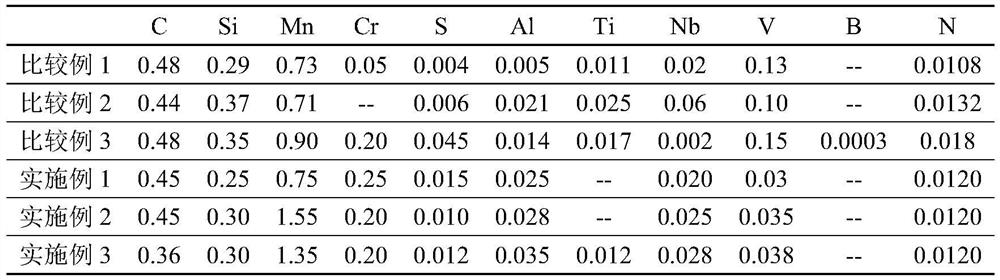

Method for continuous casting, continuoccs rolling intermediate and thin sheet blanket

InactiveCN1483521ASmall temperature differenceImprove surface qualityMetal rolling arrangementsAutomatic controlThin slab

The production method of sheet billet conticasting tandem-rolling coil sheet is characterized by that said invention adopts the following technical measures: using conticasting machine and making pulling rate of casting blank low, and making the blank material have reasonable section; compactly arranging conticasting machine and heating furnace, making the conticasting blank output roller conveyer and inlet roller conveyer of heating furnace have double purpose, making inlet temp. of casting blank be above 900 deg.C; adopting double furnace and hating; and adopting small-cross charging and tapping process; two-high reversing rougher for three passes, four-high reversing rougher for one pass; and adopting thermal coiler box process of workpiece so as to raise coil sheet quality and reduce its production cost.

Owner:ANGANG STEEL CO LTD

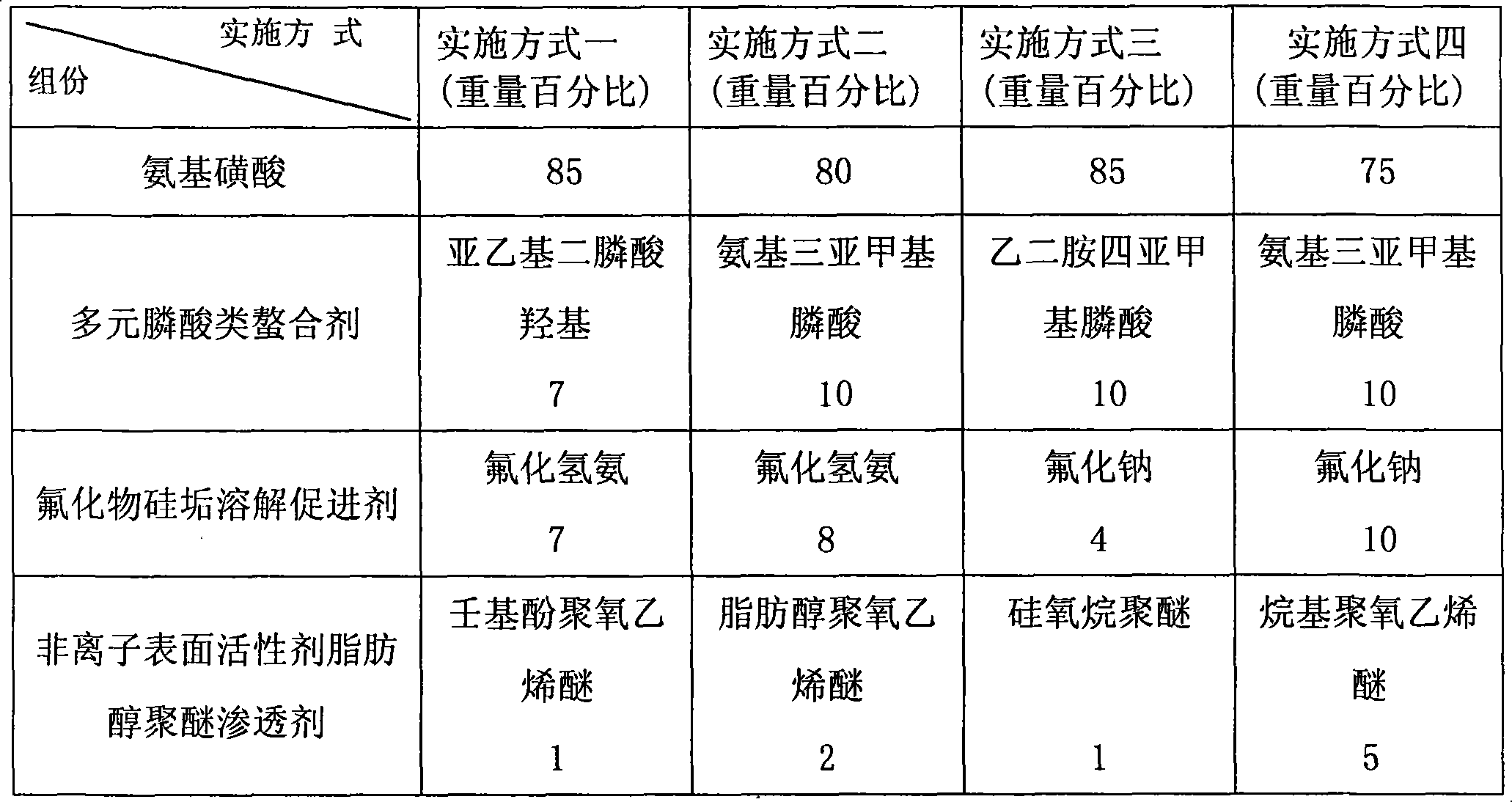

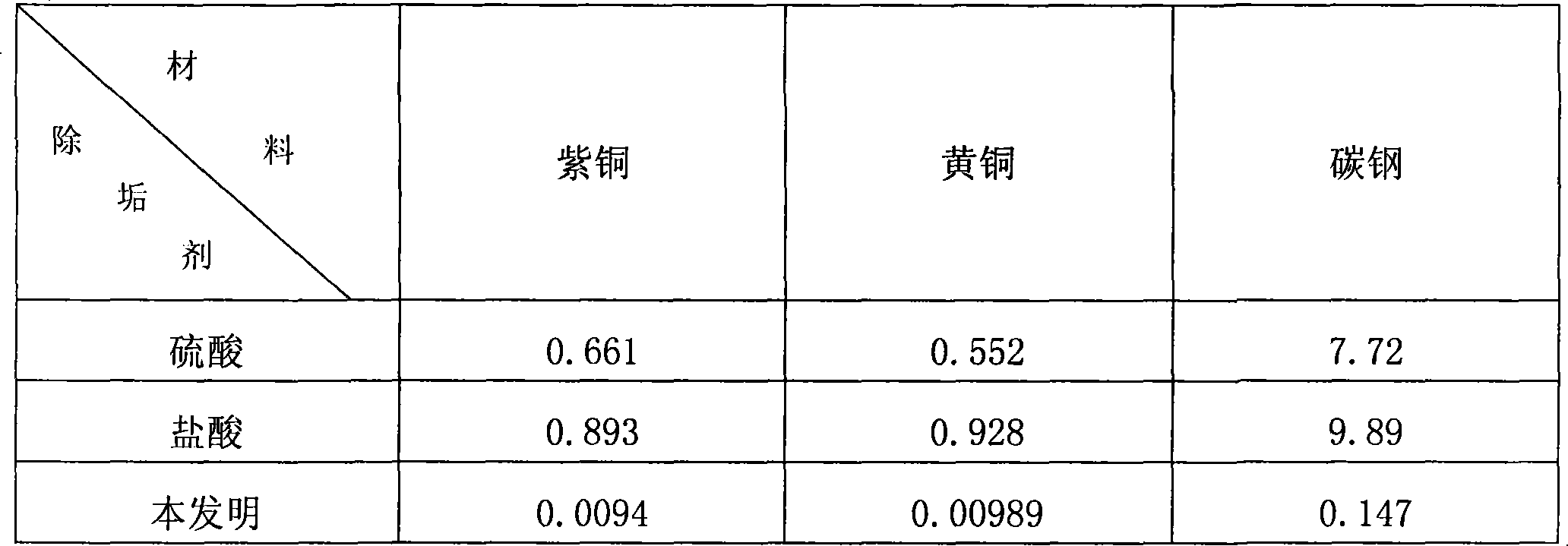

Descaling agent for cleaning central air conditioner main machine

InactiveCN101086065ASolve cleaning problemsStrong acidity of solid organic acidPolyesterHexamethylenetetramine

The invention relates to a scale and rust remover used for cleaning main frame of central air-conditioner. It is characterized in that it comprises solid mixture and liquid inhibitor; said solid mixture comprises amidosulfonic acid, polyphosphinic acid chelating agent, silicofluoride scale and rust dissolution promotor, non-ionic surface activator aliphatic alcohol polyester penetrant, their weight proportions in order are as follows: 75%-85%, 5%-10%, 5%-10%, 1%-5%; said inhibitor is liquid and comprises hexamethylene tetramin, aniline and methyl azimido-benzene according to weight proportion of 2: 2: 1. Said inhibitor is added into acidic washing solution with its weight amount being 0.3% of that of water amount. The product can dissolve carbonate, silicate, sulfate and iron oxide, the descaling speed at room temperature is fast, and is increased within 60 Deg. C, the corrosive rate to metal is pretty low, and there is no acid mist and harmful gas generation during desaling process.

Owner:长沙科惠洁水质处理服务有限公司

Method for producing coiled sheet by continuous casting and tandem rolling of regular slab

InactiveCN1883835AReduce generationUniform temperatureMetal rolling arrangementsProduction lineSteelmaking

The invention relates to a continuous casting and rolling preparation method of general plate blank, which is soaking and heating the normal continuous casting plate blank in stepping soaking pit and inductive heating furnace, and directly rolling by roughing mill group when temperature of continuous casting plate achieves to rolling temperature. The invention is characterized in that arrangement between continuous casting machine and rolling mill is compact, continuous casting plate blank is directly charging, uniformly planning and designing the process equipment such as pretreatment of molten iron, steelmaking, refining, continuous casting, rough rolling, fine rolling to finished strip coiling and so on to constitute a process flow production line for continuous preparing hot-rolled sheet, saving energy, reducing working procedure and area of corresponding apparatus and factory building, and shortening production period. The invention provides a plate preparation method of less investment, good product quality and low production cost for steel corporation with production scale of 3,000,000 ton / year.

Owner:BERIS ENG & RES CORP

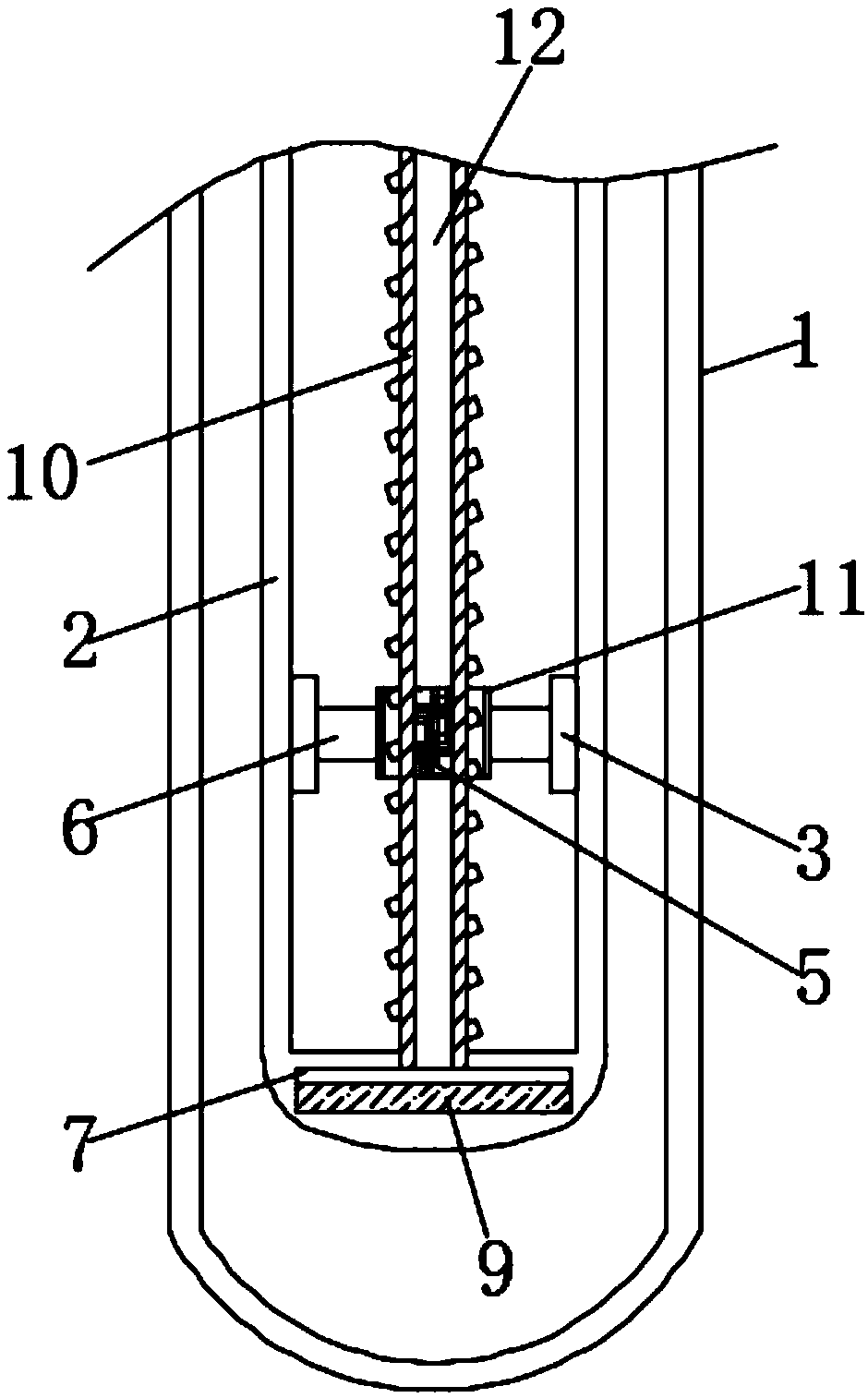

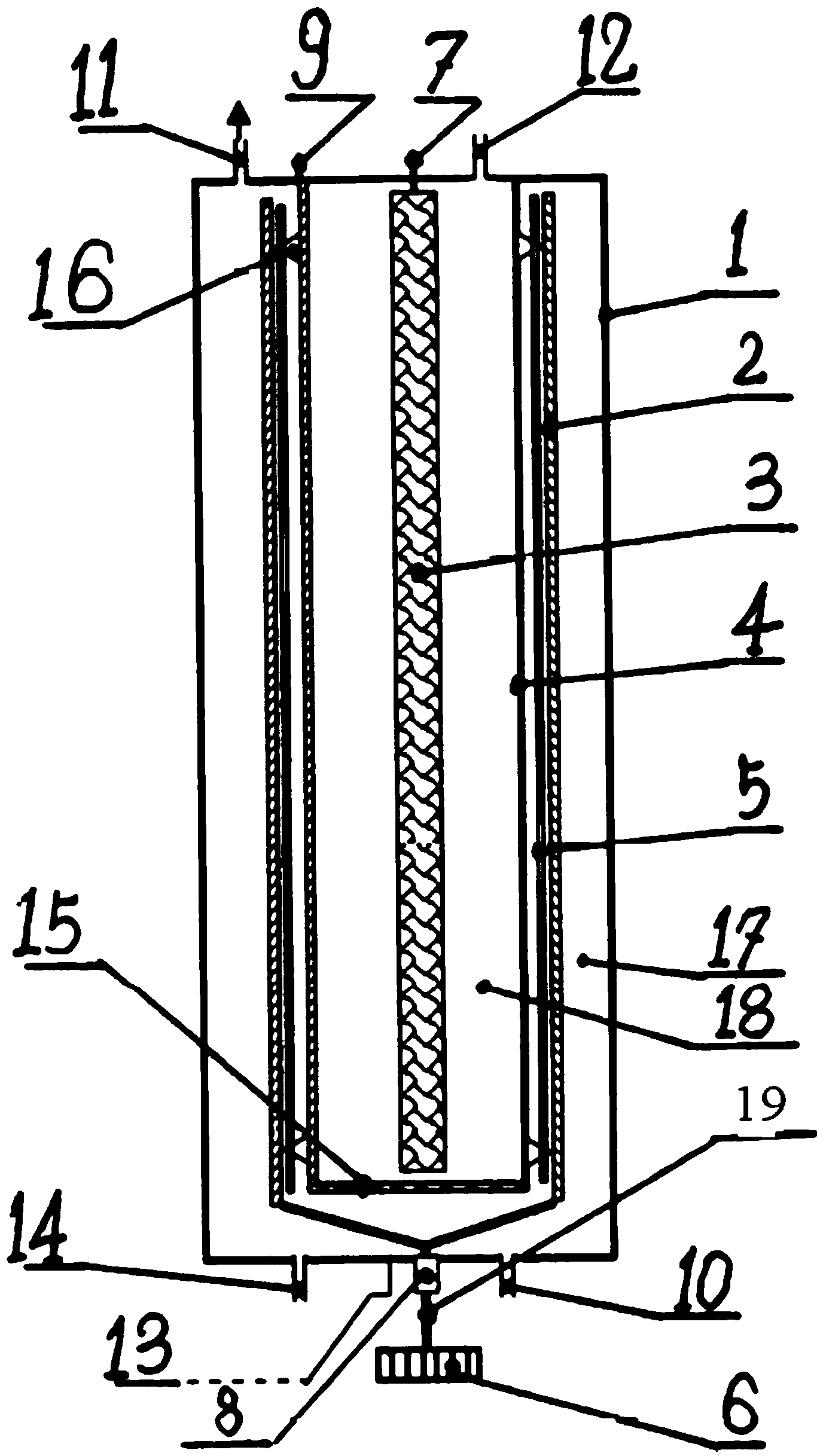

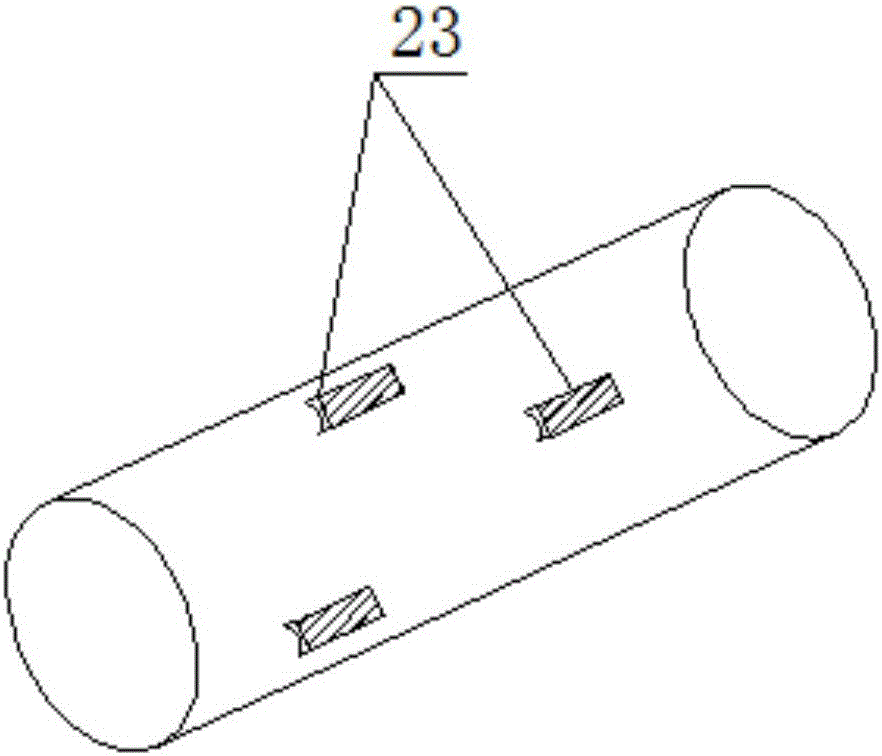

Self-cleaning solar vacuum pipe

ActiveCN109269123AEfficient descalingReduce the level of complexitySolar heating energySolar heat collectors with working fluidsBoiling pointEngineering

The invention discloses a self-cleaning solar vacuum pipe. The solar vacuum pipe is composed of an inner pipe body and an outer pipe body, a liquid storage cavity is formed in the inner bottom of theinner pipe body and contains an evaporating liquid with a low boiling point, and a metal scraping ring which is always in contact with the inner wall of the inner pipe body is slidably connected intothe inner pipe body; a moving device used for pushing the metal scraping ring to move is installed in the inner pipe body and can axially move along the inner pipe body, and the metal scraping ring isfixedly connected to the moving device through a connector. The self-cleaning solar vacuum pipe is novel in concept, incrustation scale on the inner wall of the solar vacuum pipe can be removed, andthe heating efficiency and service life of the solar vacuum pipe are ensured.

Owner:夏进秋

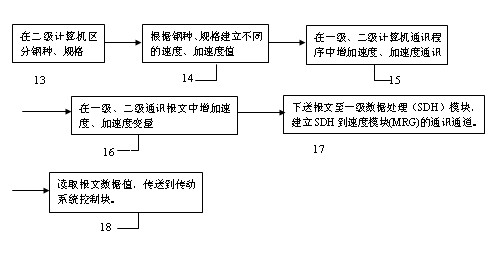

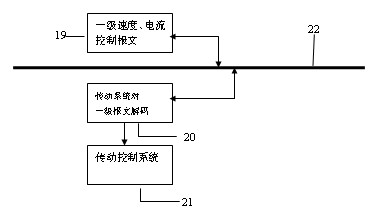

Control method of speed and acceleration of continuous hot rolling roughing rolling unit

ActiveCN102179412AAdd manual intervention functionGood descaling effectRoll speed control deviceAutomatic controlControl system

The invention discloses a control method of the speed and the acceleration of a continuous hot rolling roughing rolling unit, belonging to the technical field of continuous hot rolling. The control method is used for automatically controlling the speed and the acceleration of the continuous hot rolling roughing rolling unit through a computer system, comprising the following steps of: realizing or completing the delivery of a computing method, control values and distinguishing marks of the variable speed and the variable acceleration of the continuous hot rolling roughing rolling unit to a first-level computer through a second-level computer; implementing or carrying out continuous hot rolling automatic control on the continuous hot rolling roughing rolling unit according to the control values and the distinguishing marks of the variable speed and the variable acceleration of the continuous hot rolling roughing rolling unit through the first-level computer, wherein the variable speed is computed according to a formula: (1)V=V0(n)p1(1+p2), and the variable acceleration is computed according to a formula: (2)a=a0(1+p). The method has the advantages of developing a new control methodof the roughing variable speed and variable acceleration in a control system for solving the problems of slipping, unclean surface descaling, and the like of certain steel grade specifications and solving the problems of the slipping and improving the surface descaling effect by realizing the new control method, thereby enhancing the rolling rhythm and the rolling quality and successfully solvingthe problems during production.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

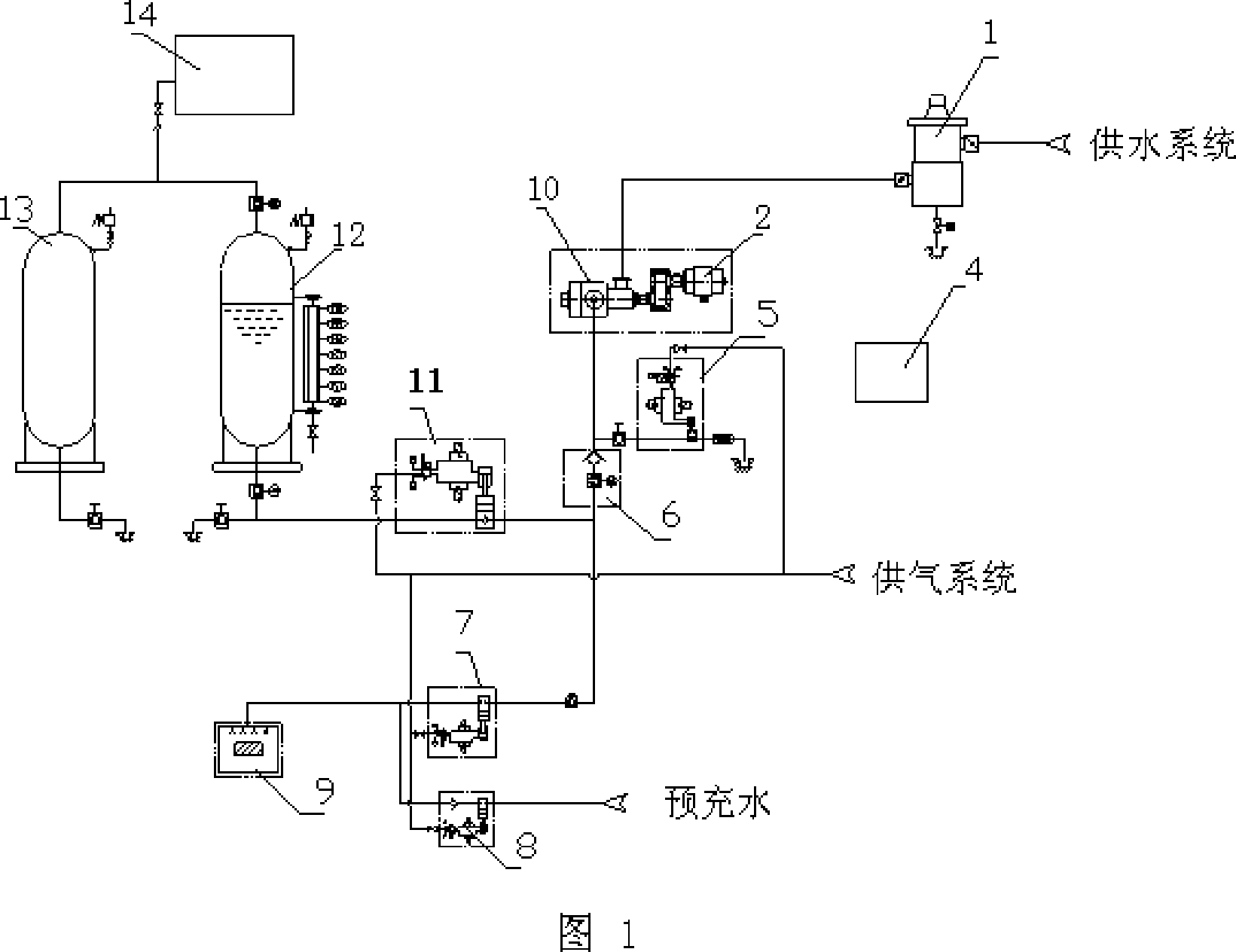

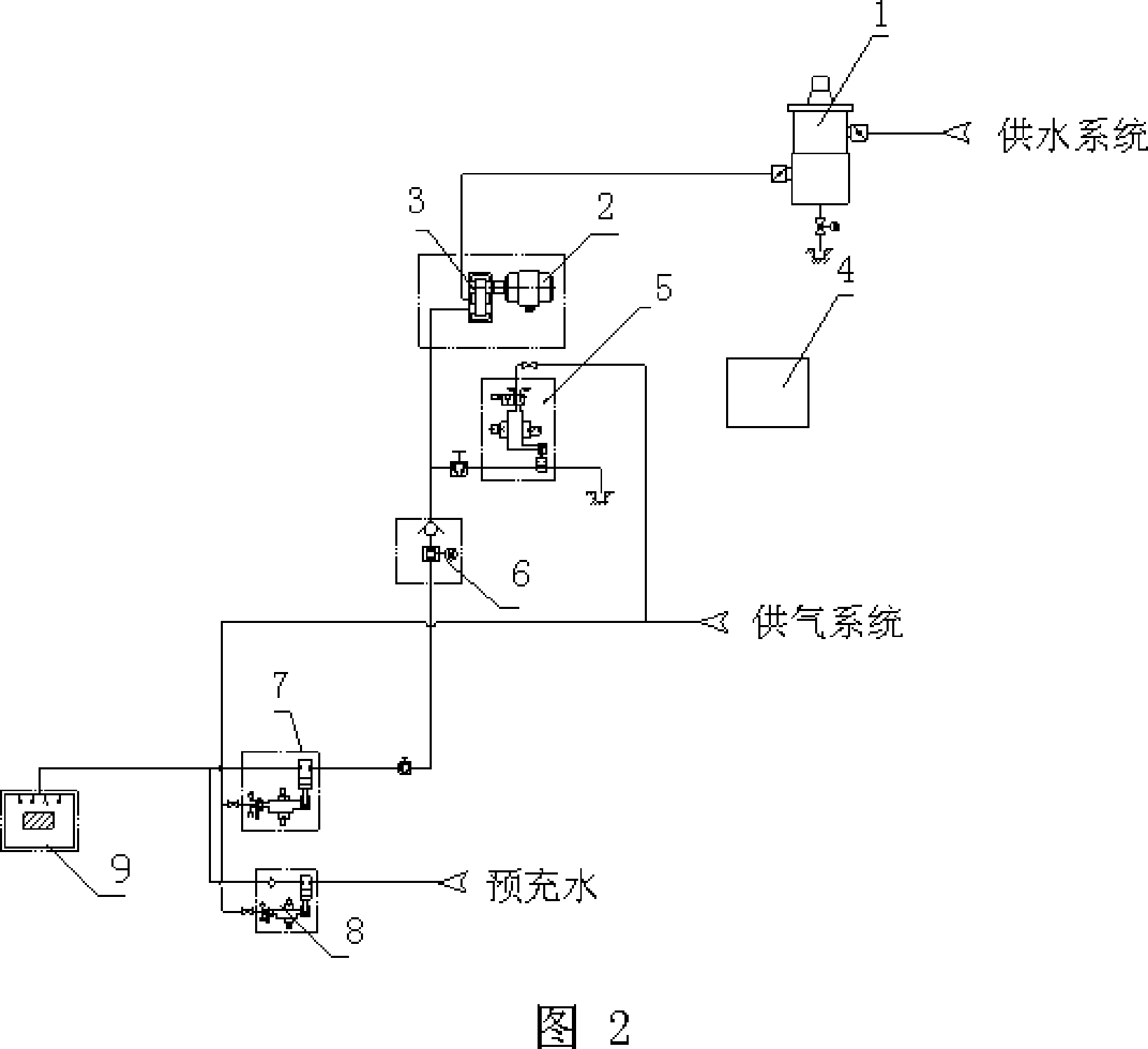

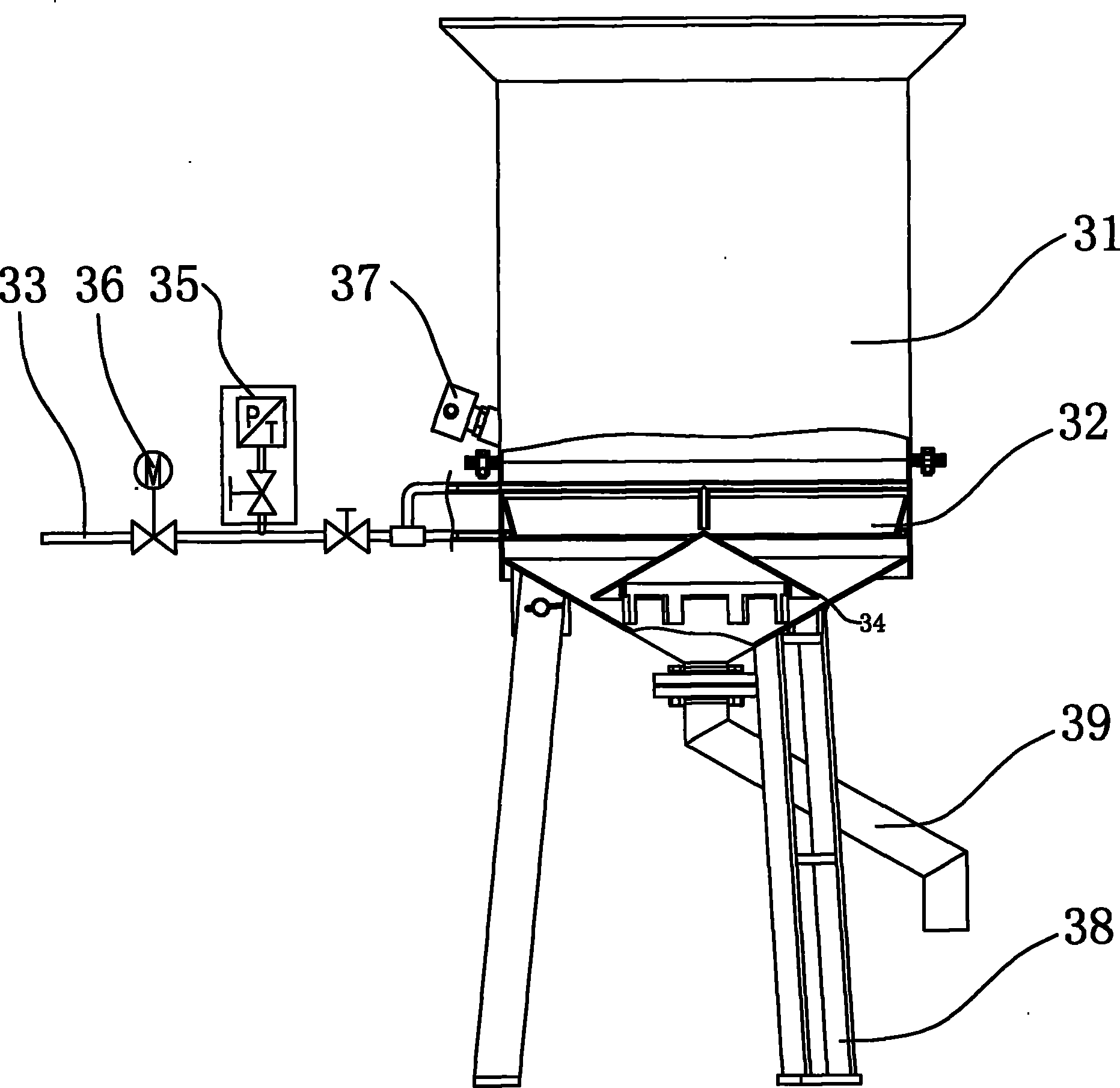

High-pressure water descaling system for hot continuous rolling production line

ActiveCN101147923AEasy temperature controlSmall footprintWork treatment devicesExtrusion cleaning devicesProduction lineElectricity

The present invention relates to a high-pressure water descaling system which can be used in the rolling process in the iron and steel metallurgical field. In particular, it relates to a descaling system which can be used in the process of rolling slab and sheet strip. It is characterized by that said invention is aimed at providing an ultrahigh-pressure small-flow high-pressure water descaling system for sheet bar hot continuous rolling production line. The water-out pressure of its descaling pump group is 25MPa-50MPa, and the water flow rate of its descaling nozzle is 20-40L / min..

Owner:CHINA ERZHONG GRP DEYANG HEAVY IND

Electrochemical water scale removal device

ActiveCN104261573AIncrease supersaturationIncreased chance of crystallizationSpecific water treatment objectivesScale removal and water softeningElectrolysisEngineering

The invention provides an electrochemical water scale removal device, which comprises a water scale crystal nucleus generation unit for electrochemical water treatment, a rotating cathode and an anode, wherein the water scale crystal nucleus generation unit comprises a tank body; a water inlet and a sewage discharge outlet are formed in the bottom of the tank body; a water outlet is formed in the top end of the tank body; the rotating cathode is arranged in the tank body; the anode is arranged in the tank body. According to the device, an aqueous solution is electrolyzed to generate OH- in the vicinity of the rotating cathode, an alkaline solution with a pH value of 14 is obtained in an interface layer in the vicinity of the rotating cathode, water scale crystal nucleuses formed on the surface of the rotating cathode and in the interface layer in an electrochemical process are diffused into the solution by virtue of the rotating cathode, and an ultra-large crystal growth surface and crystal active growth points are provided for scaling ions in the solution by virtue of a great number of crystal nucleuses; the surface areas of a great number of tiny crystal nucleuses are multiple times larger than that of the rotating cathode, so that the crystallization and precipitation probability of the scaling ions is greatly improved, and the scale removal efficiency is also improved.

Owner:银海洁环保科技(北京)有限公司

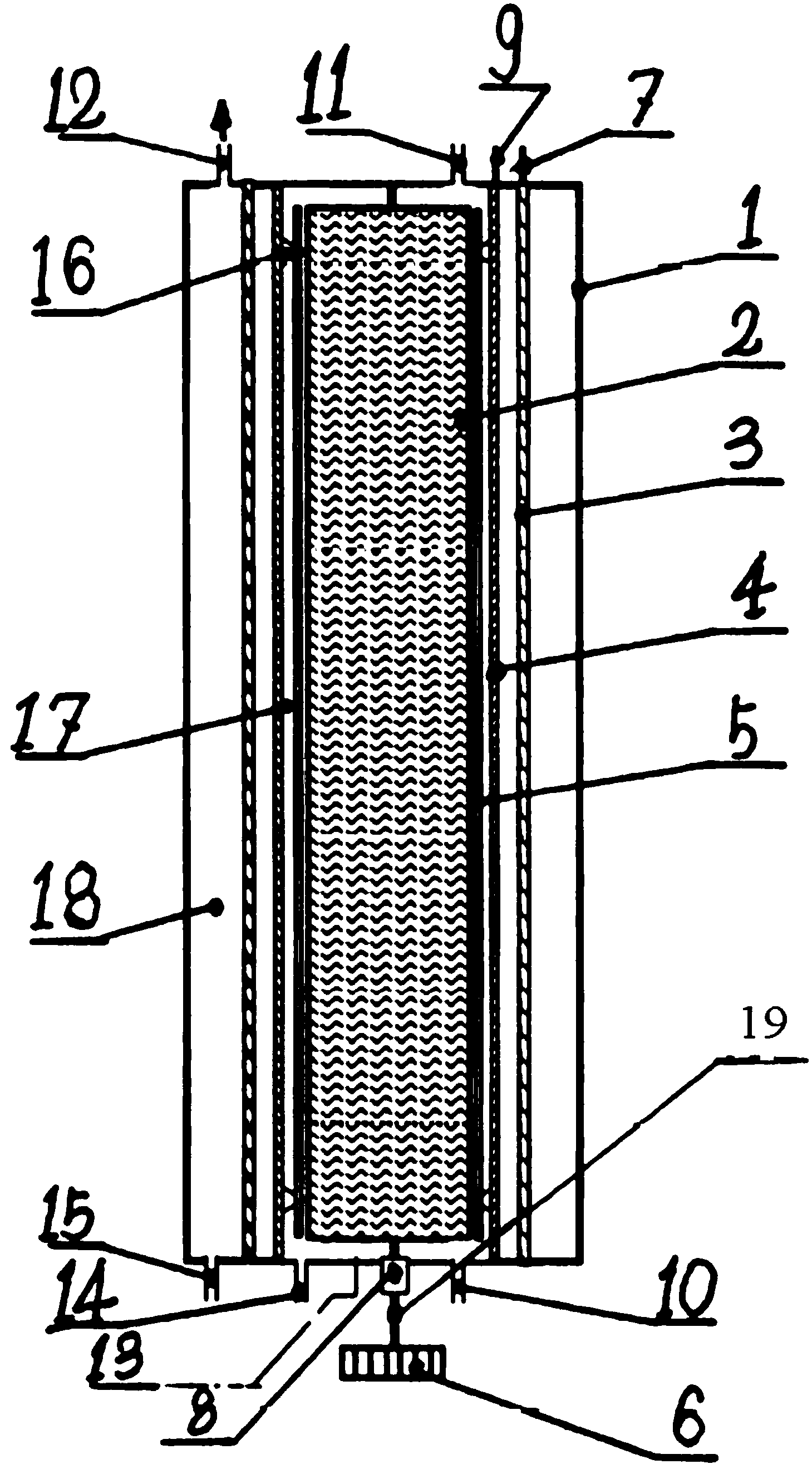

Internal descaling and external defrosting novel air conditioner applying ultrasonic oscillators

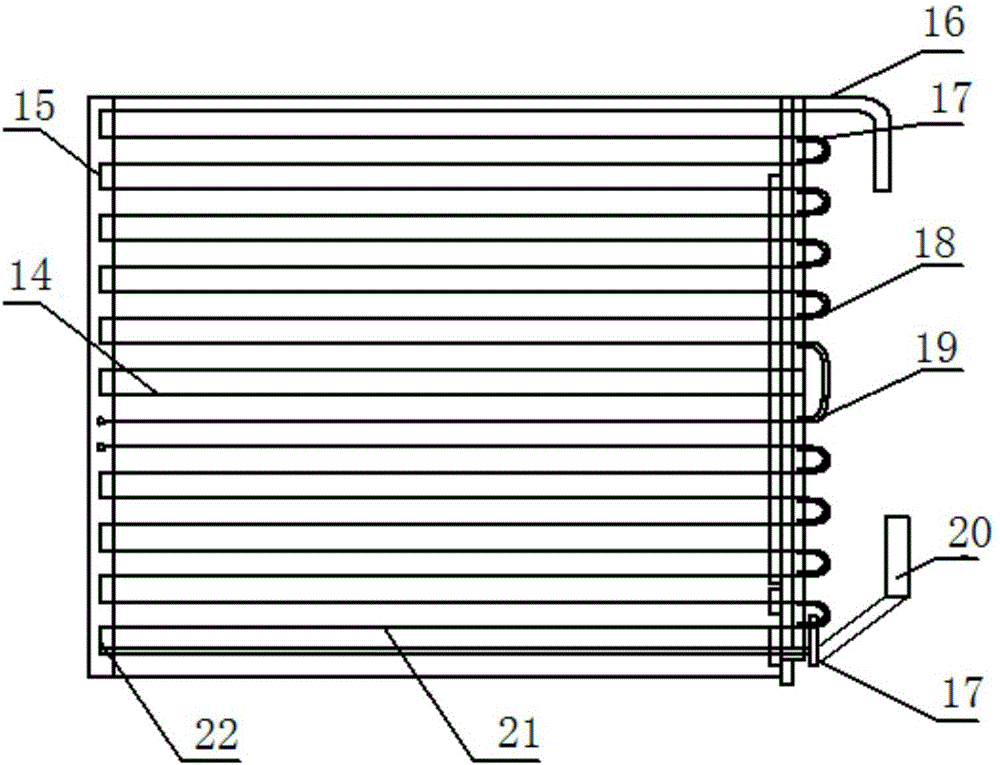

InactiveCN105890050AStable operating environmentExtended service lifeMechanical apparatusNoise suppressionVapor–liquid separatorShell and tube heat exchanger

The invention provides an internal descaling and external defrosting novel air conditioner applying ultrasonic oscillators. The internal descaling and external defrosting novel air conditioner comprises an outdoor unit and an indoor unit. The outdoor unit and the indoor unit are connected through a pipeline. The indoor unit comprises the indoor ultrasonic oscillators and an indoor heat exchanger, wherein the indoor ultrasonic oscillators are located around the indoor heat exchanger. The indoor heat exchanger is a shell and tube heat exchanger and comprises fins, U-shaped pipes, an air inlet pipe, process reinforcement tubes, a liquid outlet pipe and bridging elbows. Each U-shaped pipe comprises two free ends extending in the same direction in parallel, and a bent part located between the two free ends, wherein the free ends are inserted in the corresponding fins. Ports of the free ends of every two adjacent U-shaped pipes are connected through the corresponding bridging elbow. The outdoor unit comprises a capillary tube, a compressor, an outdoor heat exchanger, the outdoor ultrasonic oscillators, a four-way valve, air-liquid separators, a filter and a check valve, wherein the outdoor ultrasonic oscillators are located around the outdoor heat exchanger. By means of the internal descaling and external defrosting novel air conditioner, ultrasonic non-stop on-line internal descaling and external defrosting can be achieved, the stable running environment of the air conditioner is ensured, and the service life is prolonged.

Owner:NANJING NORMAL UNIVERSITY

2250 hot continuous rolling producing method for improving surface quality of steel for automobile outer plate

ActiveCN103752610ADecompressed oxygenImprove product surface qualityWork treatment devicesMetal rolling arrangementsHeating furnaceContinuous rolling

The invention relates to a 2250 hot continuous rolling producing method for improving surface quality of steel for an automobile outer plate. The method includes conducting smelting to obtain molten steel, casting the molten steel into a cast plate blank through a continuous casting machine, arranging the obtained continuous cast plate blank into a heating furnace to be heated, conducting descaling on the plate blank through a primary descaling box after the plate blank is discharged from the furnace, utilizing a width fixing press to adjust the width of the plate blank after the plate blank is descaled, conducting rolling on the plate blank through a coarse rolling machine, conducting descaling on the middle plate blank obtained through the coarse rolling through a secondary descaling box, rolling the plate blank through a finish rolling machine after the plate blank is subjected to secondary descaling, cooling the plate blank through a laminar cooling system after the plate blank is subjected to the coarse rolling and the finish rolling and finally conducting coiling on the plate blank through a coiling machine. By optimizing a heating process, primary sinter generation quantity is reduced, the rolling process is optimized, the descaling effect is improved, secondary and tertiary sinter generation quantity is reduced, and pressure oxygen generation probability is further reduced.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

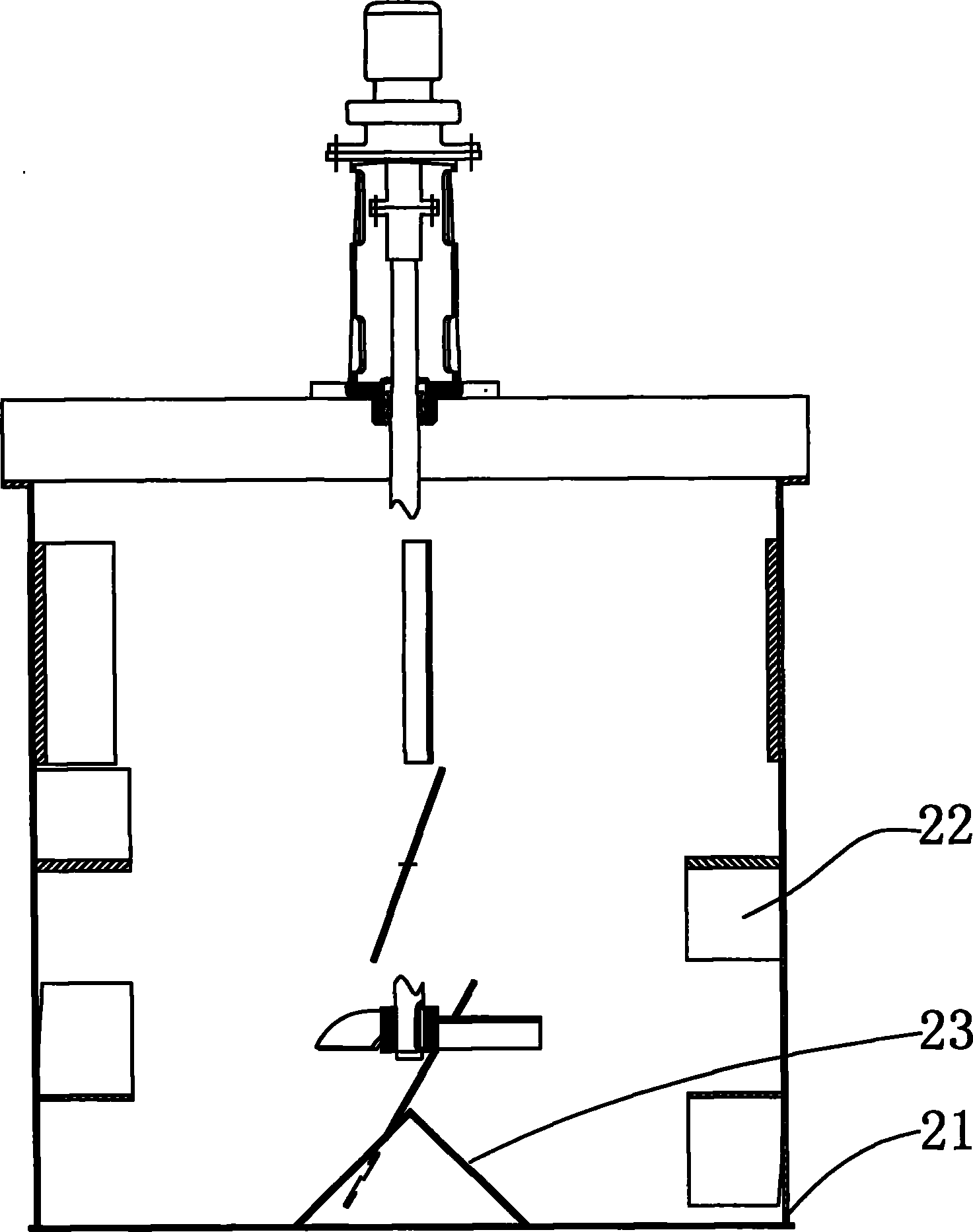

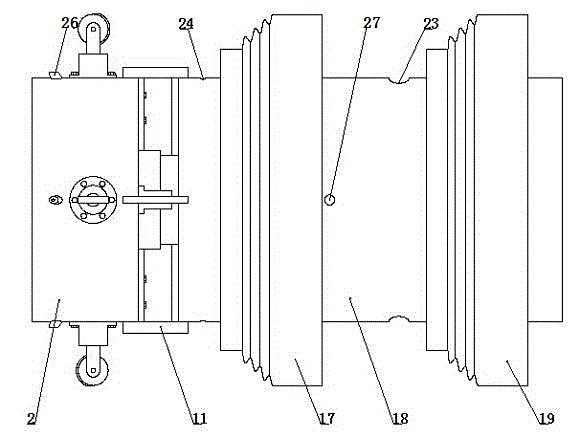

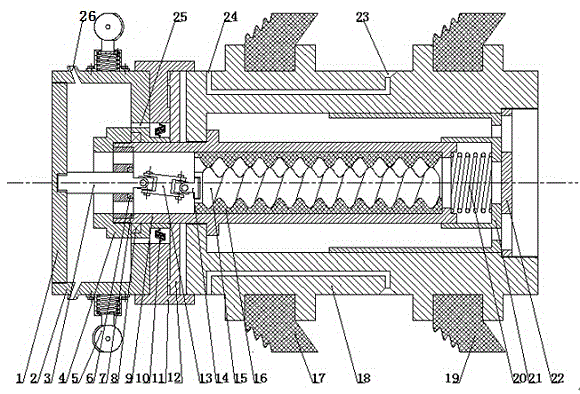

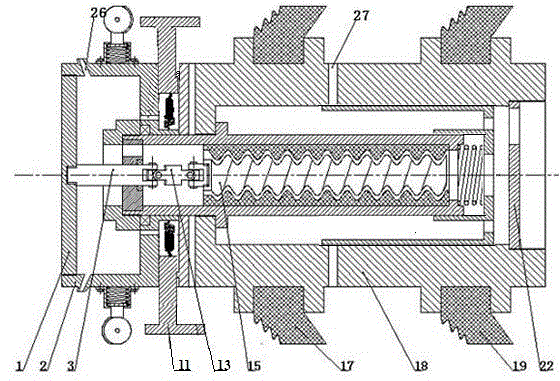

Method and equipment for removing scale on metal wires or metal bars by grinding material water jet

The invention discloses a method for removing scale on metal wires or metal bars by grinding material water jet, which comprises the following steps: 1) preparing a grinding material by mixing sand and water in a preset proportion; 2) pumping the prepared grinding material into a splitter by a mortar pump and then allowing the prepared grinding material to enter a jetting cavity; and simultaneously, pressurizing the water by a high-pressure pump to change the water into high-pressure water and convey the water into the jetting cavity, and impacting the grinding materials by taking the high-pressure water as motive power to remove scale through jetting. Special scale removal equipment provided by the method comprises a mixing tank positioned below a scale removal box, an automatic fluidifying and sanding-up device for sanding up sand to the mixing tank, a jetting device and a water box, and also comprises a sand separator positioned in the scale removal box, a high-pressure pump for generating the high-pressure water and the mortar pump for conveying the grinding materials to the sand separator. The grinding materials are impacted by taking high-pressure water as the motive power to remove the scale on the metal wires or the metal bars, and the method and the equipment have the advantages of improving the working efficiency effectively, relieving the labor strength of workers, along with quick cleaning speed, difficult blocking of sprayers, good scale removal effect, no damage to metal matrixes and no environmental pollution.

Owner:HUNAN NONFERROUS HEAVY MACHINERY

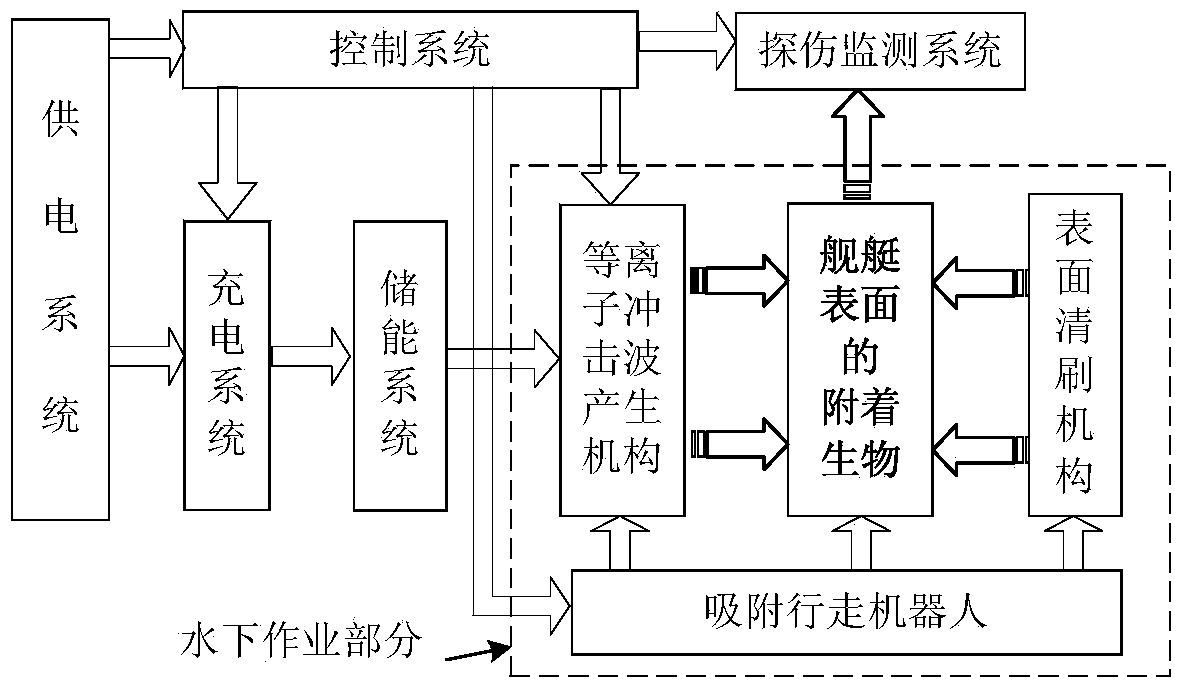

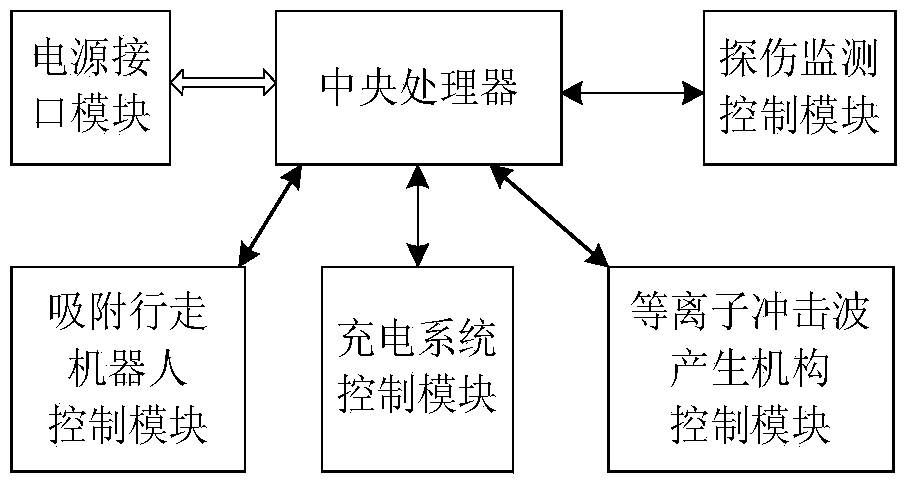

Warship hull descaling and flaw detecting system

InactiveCN103895835ARealize integrated operationVersatileVessel cleaningAnalysing solids using sonic/ultrasonic/infrasonic wavesShock waveNon destructive

The invention provides a warship hull descaling and flow detecting system which comprises a power supply system, a control system, a charging system, an energy storing system, a plasma shock wave generating mechanism, a flaw detection monitoring system, a surface flushing mechanism and an adsorbing and walking robot. When the system runs, probes of the plasma shock wave generating mechanism, the surface flushing mechanism, the adsorbing and walking robot and the flaw detection monitoring system are in underwater operation. Organisms attached to the surface of a warship hull are subjected to primary cleaning by the aid of strong sound shock waves generated from discharging of underwater plasmas, the organisms attached to the surface of the warship hull fall off or are loosened, and then the loosened attachments are cleaned by the aid of the surface flushing mechanism. The descaling effect can be detected through the flaw detecting system after descaling operation, and non-destructive detection can be performed on the surface of the warship hull.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

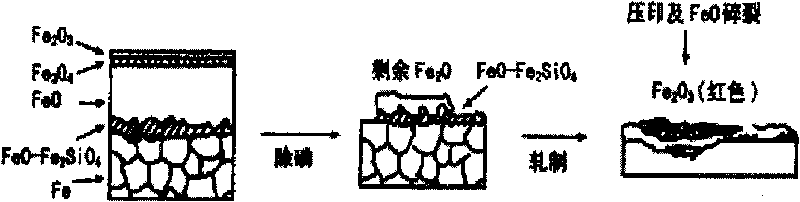

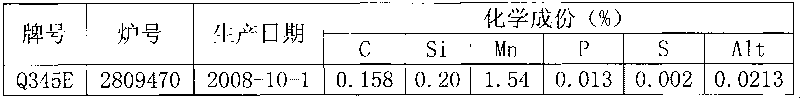

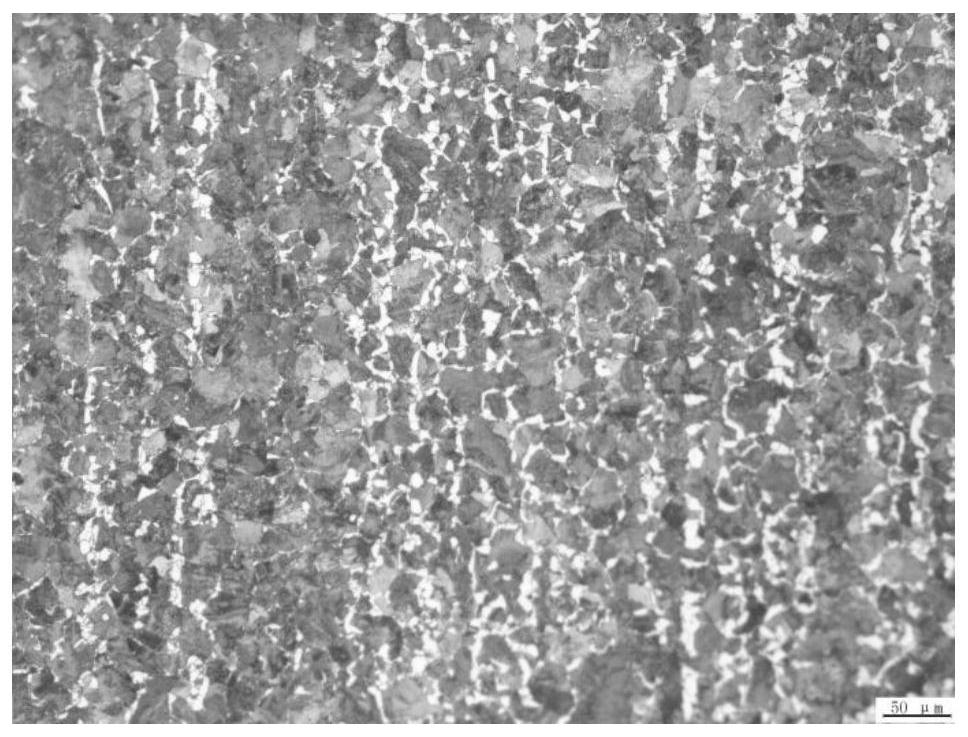

Method for increasing scale removal effect of medium and heavy plate

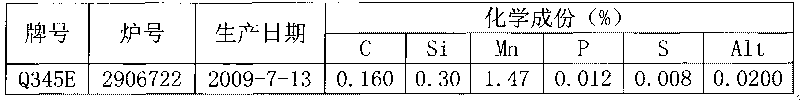

InactiveCN101700533AGood descaling effectEliminate "pockmarks"Work treatment devicesMetal rolling arrangementsFurnace temperatureThick plate

The invention belongs to the technical field of metallurgical technology, in particular to the technology for improving the scale removal effect of a medium and heavy plate. Pocking marks on the surface of the medium and heavy plate are the main defect which affects the surface quality thereof and one of projects to be constantly studied and improved. The invention provides a method for improving the scale removal effect of the medium and heavy plate in order to meet the requirements of high-grade varieties on the surface quality of a steel plate. The method comprises the following steps of: in working procedures of a converter and an LF furnace, the range of Si in molten steel elements is controlled to be 0.15%-035%; in the working procedures of a rolled steel, the furnace temperature in a heating section of the heating furnace is controlled to be 1200-1280 DEG C; and the tapping temperature of a billet steel is 1120-1140 DEG C; wherein the standard thickness of the heavy plate is 10-60mm. The method increases the scale removal effect on iron scale of the billet steel; wherein the scale removal rate of primary iron scale of the billet steel reaches 100%; the scale removal rate of finish rolling secondary iron scale of the billet steel reaches or surpasses 95%, thus putting an end to the generation of the pocking marks of the steel plate and meeting the requirements of the high-grade varieties.

Owner:TIANJIN IRON & STEEL GRP

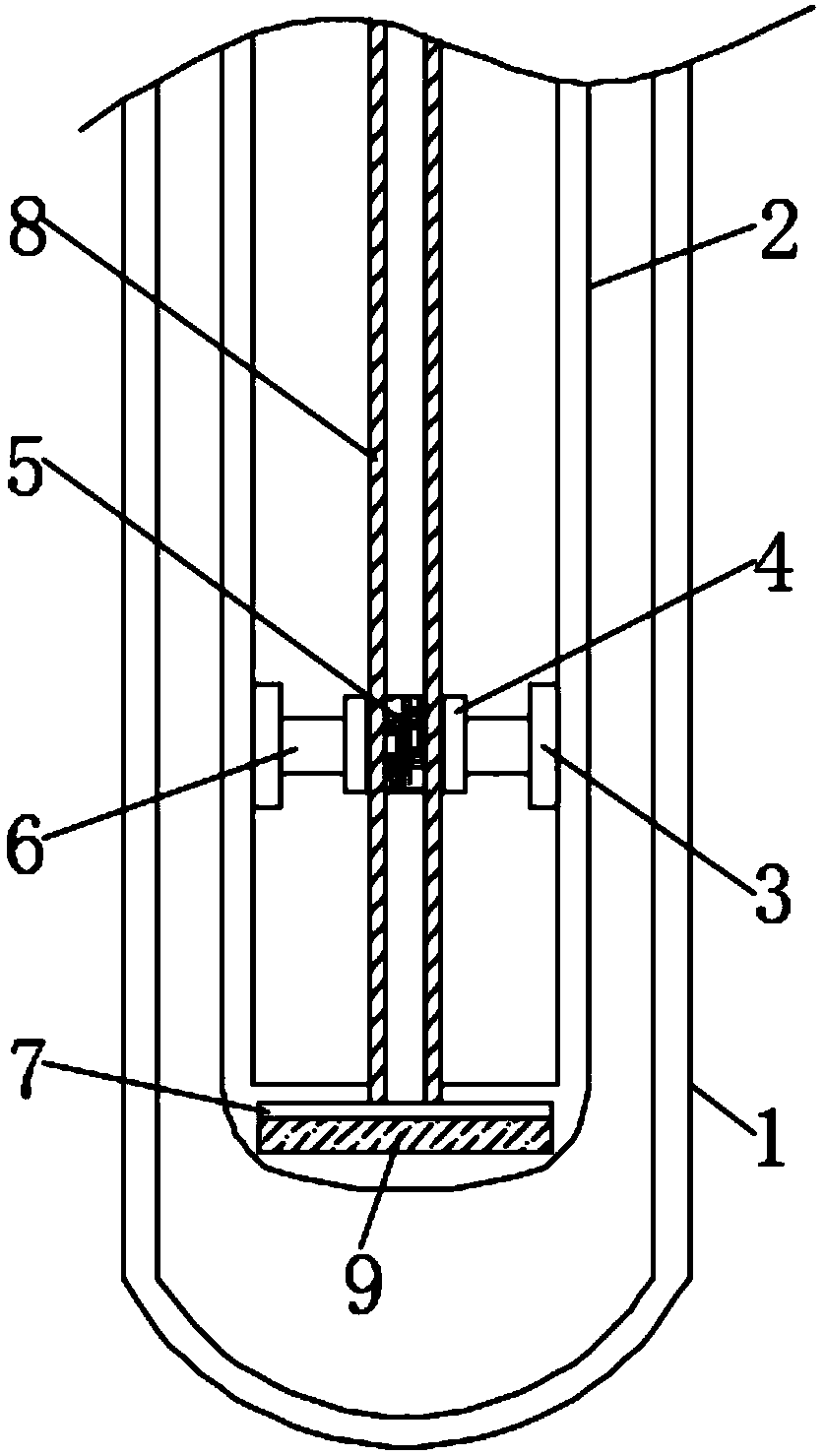

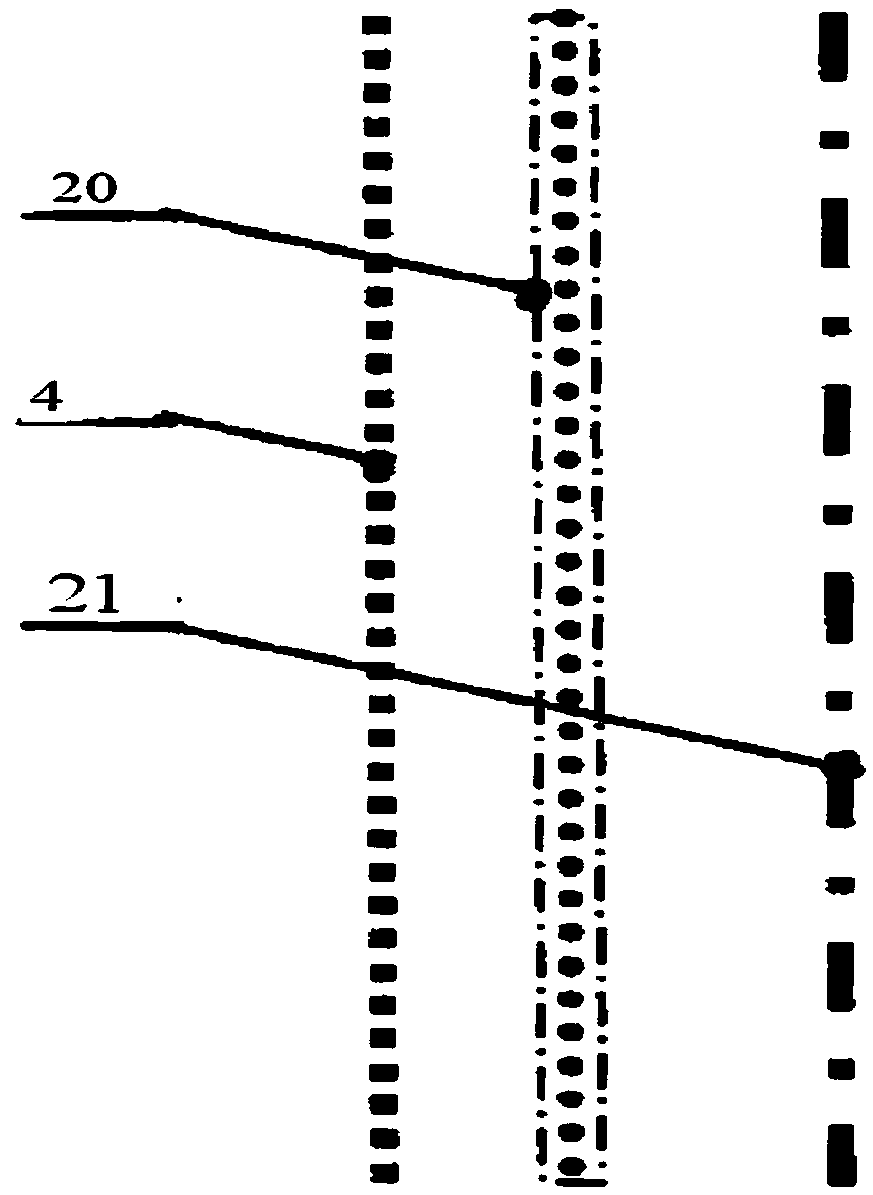

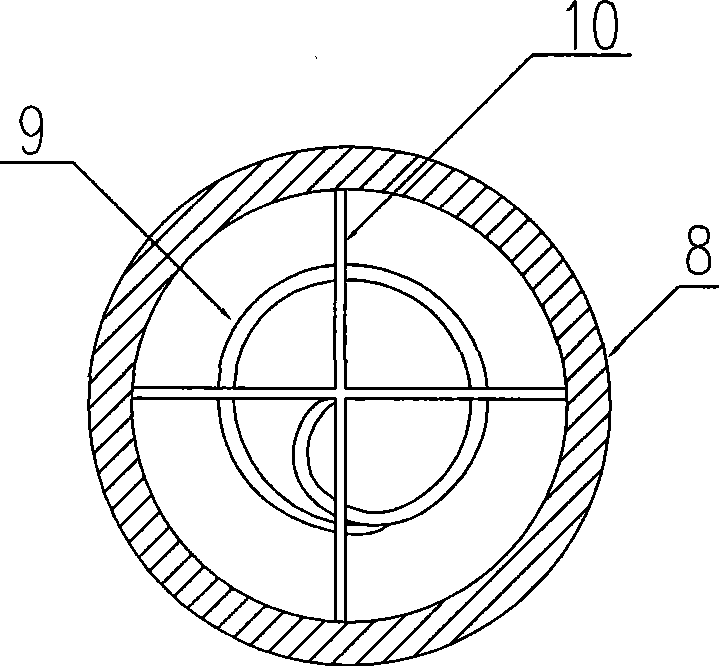

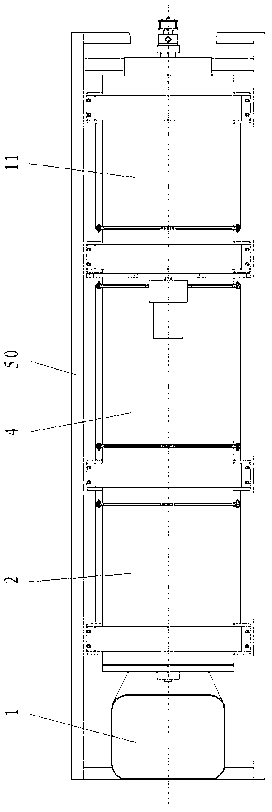

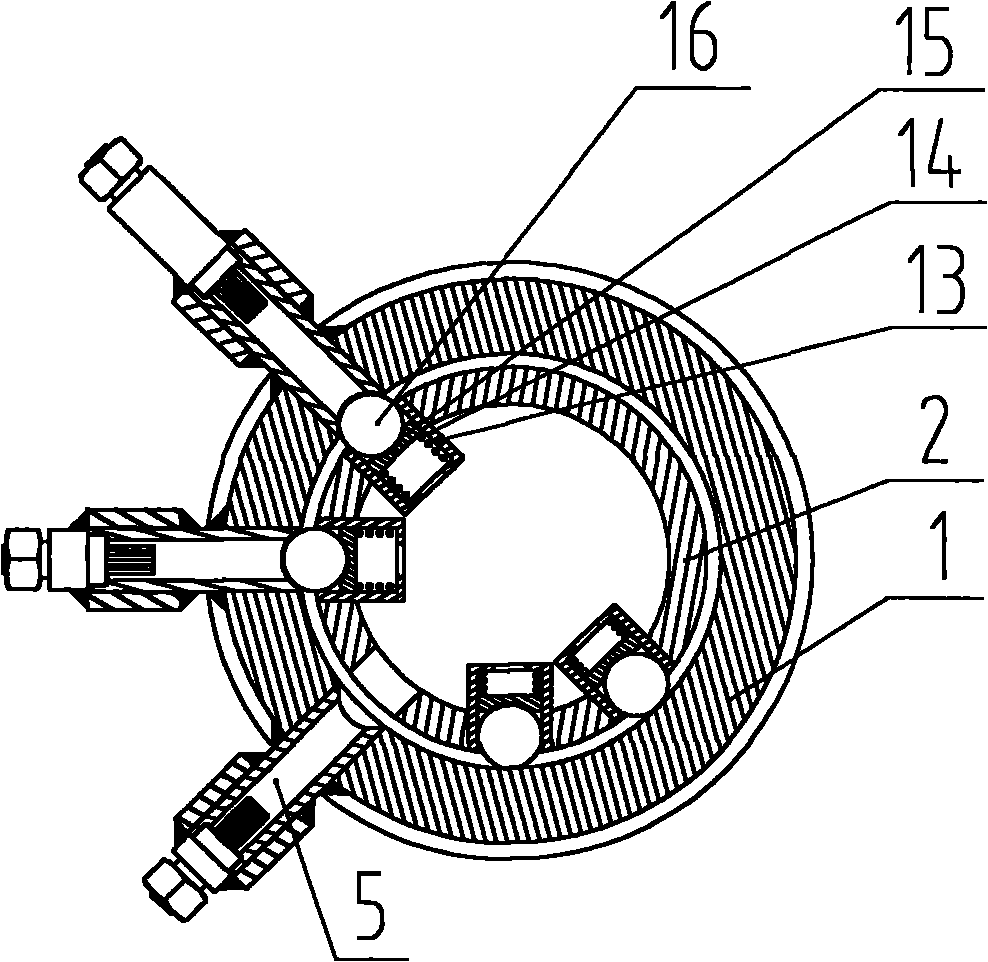

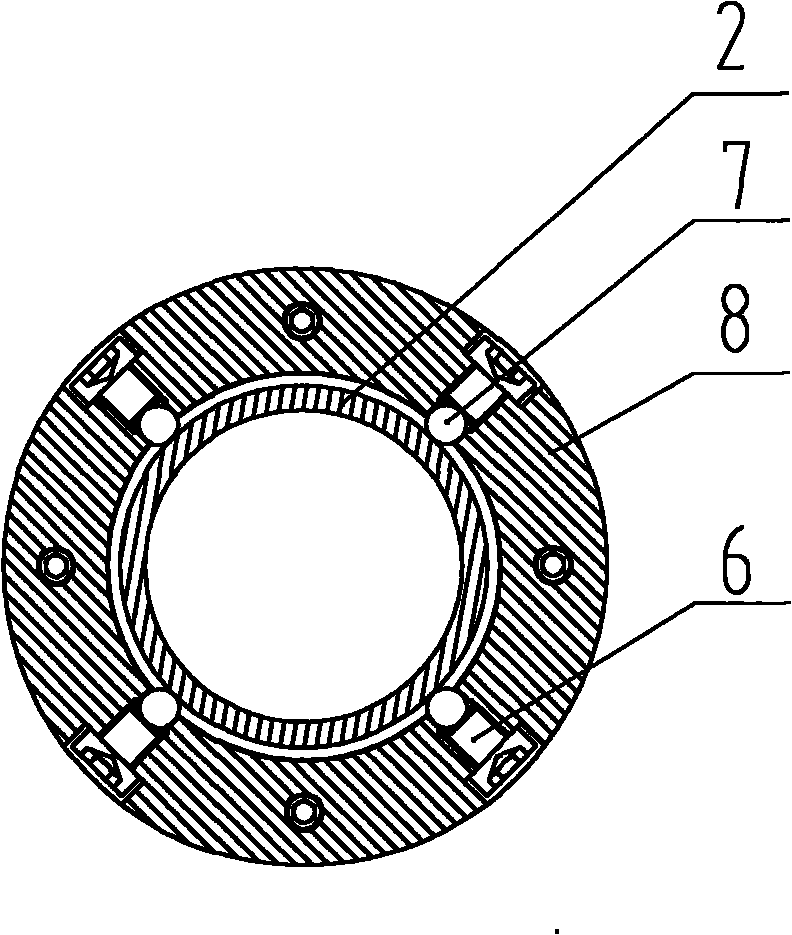

Rotating negative electrode scale scraping and removing device

InactiveCN105329985AImprove scrapingGood descaling effectSpecific water treatment objectivesWater/sewage treatment by electrochemical methodsPower flowPhysics

The invention relates to a rotating negative electrode scale scraping and removing device which comprises negative electrode conductive columns 1, negative electrode plates 2, a rotating shaft 6, positive electrode plates 7 and scrapers 8. The negative electrode conductive columns 1 are closely attached to the negative electrode plates 2. The negative electrode conductive columns 1, the negative electrode plates 2, the scrapers 8 and the positive electrode plates 7 are sequentially connected to the rotating shaft 6 in series. A central limiting and correcting block 3 is arranged between the scrapers 8 and the positive electrode plates 7. The negative electrode plates 2 rotate around the rotating shaft 6. A jackscrew 4 is arranged on one side of each negative electrode conductive column 1. Currents are guided into the negative electrode plates 2 by the negative electrode conductive columns 1. In the rotating process of the negative electrode plates 2, the scrapers 8 are closely attached to and scrap the surfaces of the negative electrode plates 2. The purpose of inputting currents to the rotating negative electrode plates without electric brushes is achieved, electrode intervals are easily decreased to the maximum degree, and the scale scraping and removing effects of the negative electrode plates are improved.

Owner:卫士循环水处理(北京)有限公司

Universal variable-frequency electromagnetic descaler and descaling method thereof

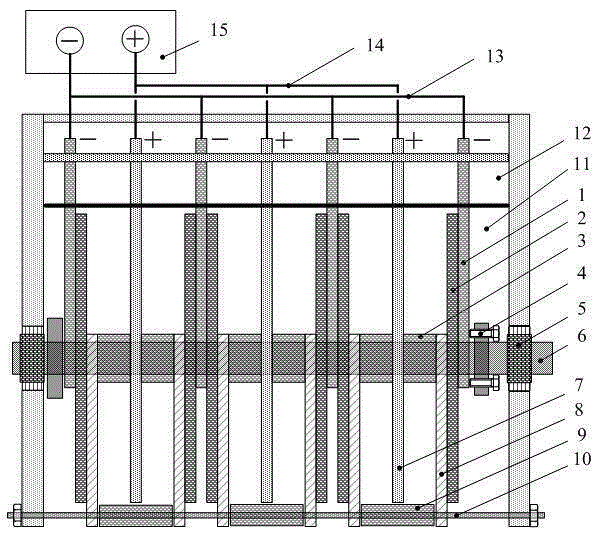

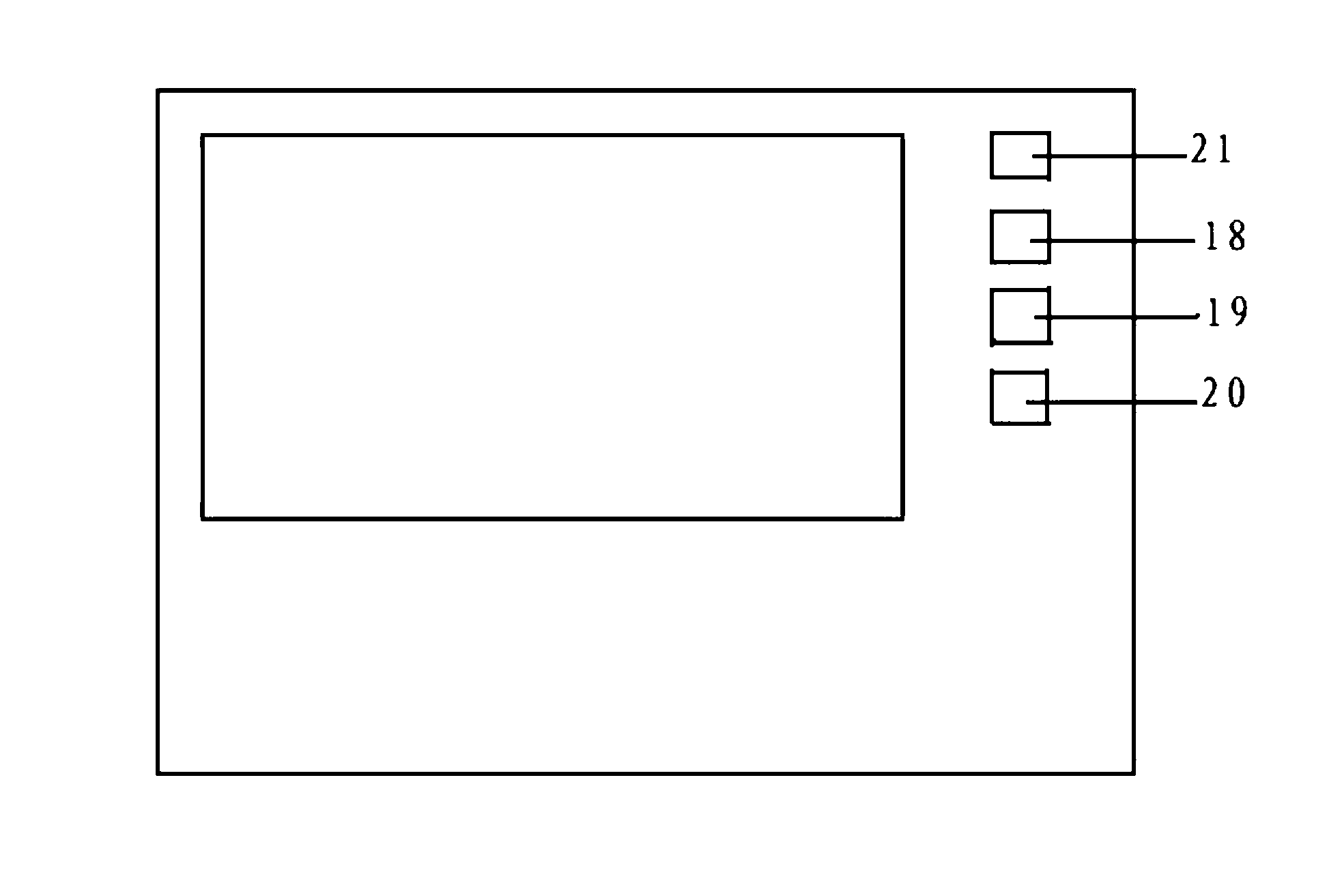

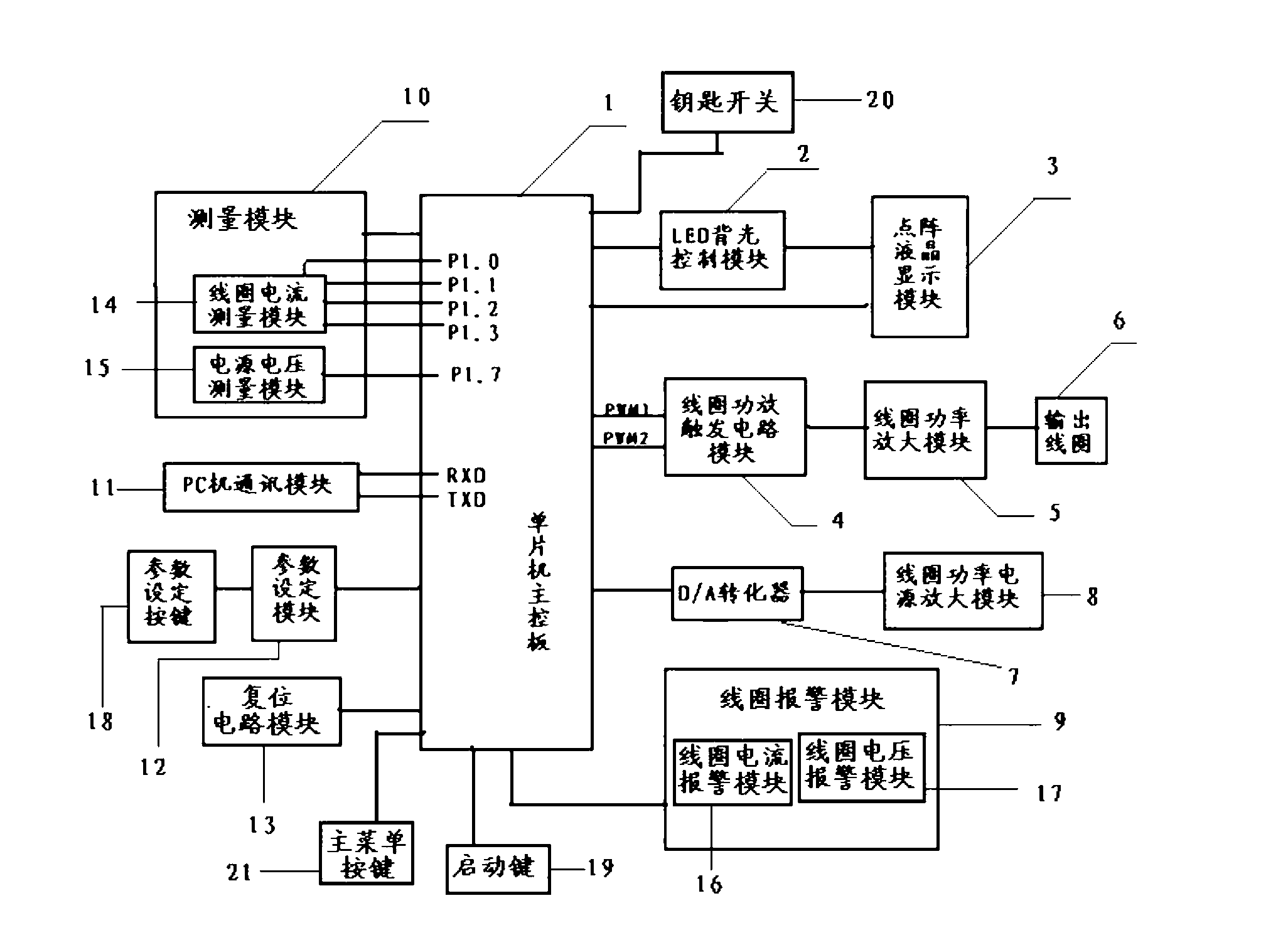

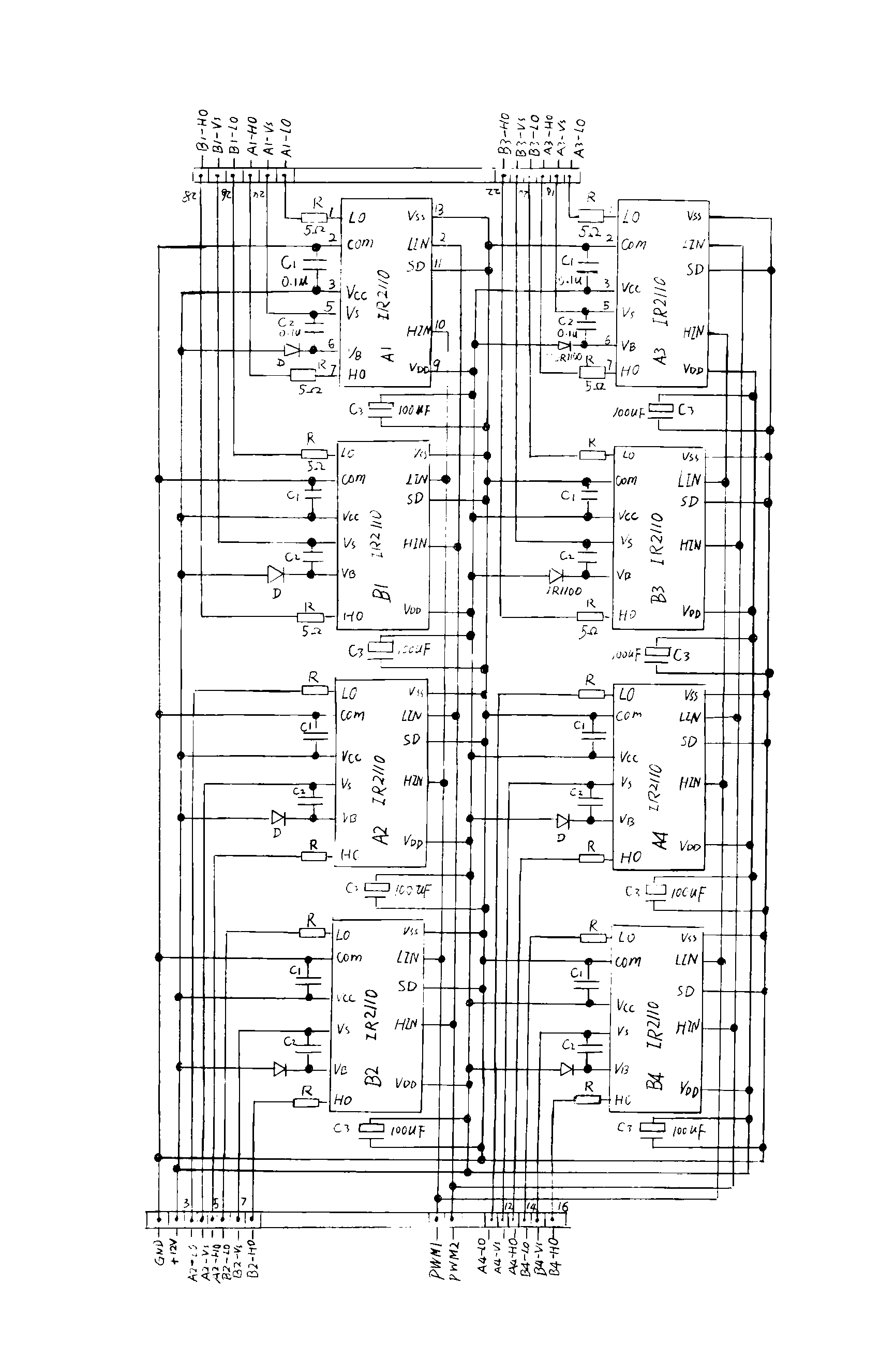

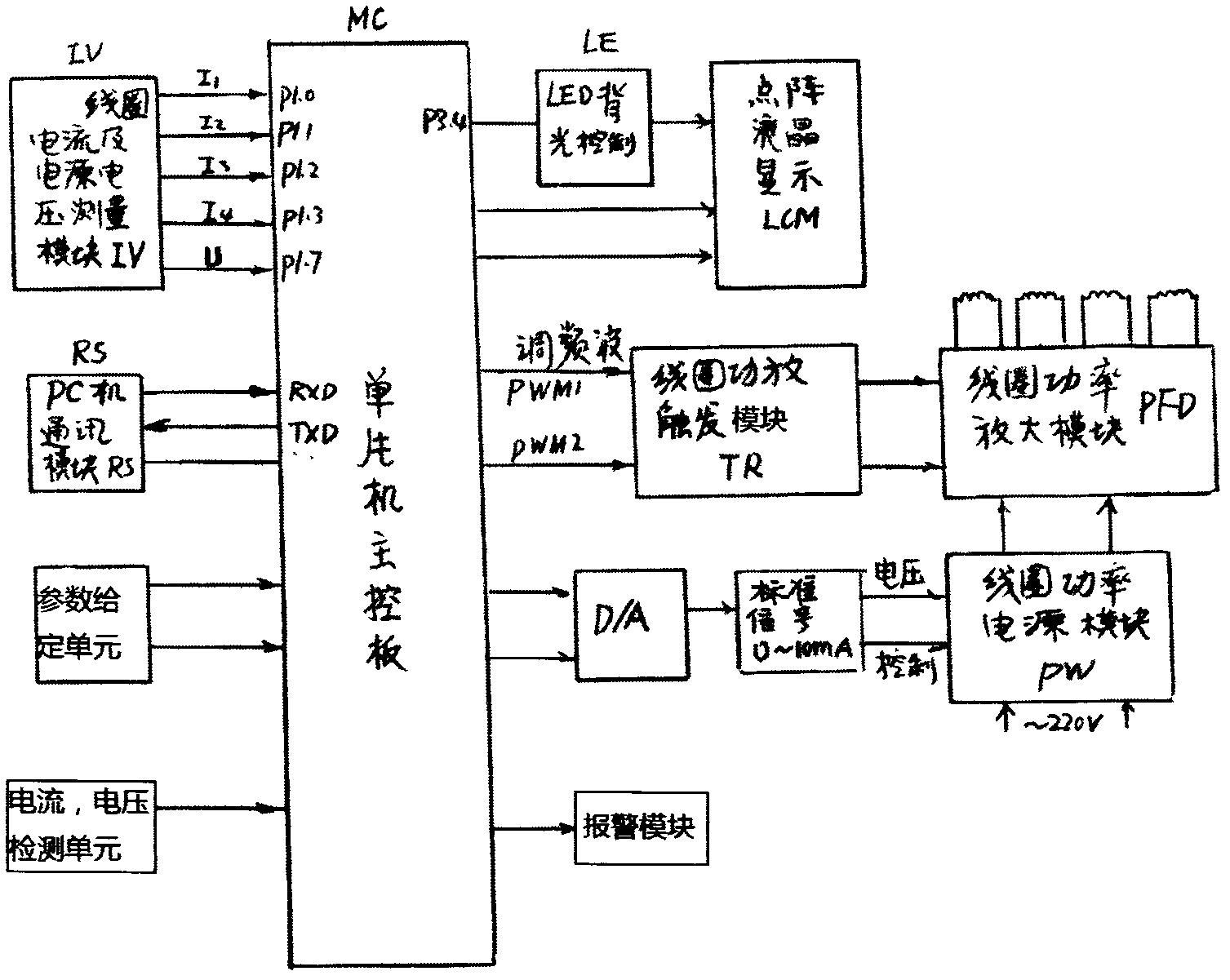

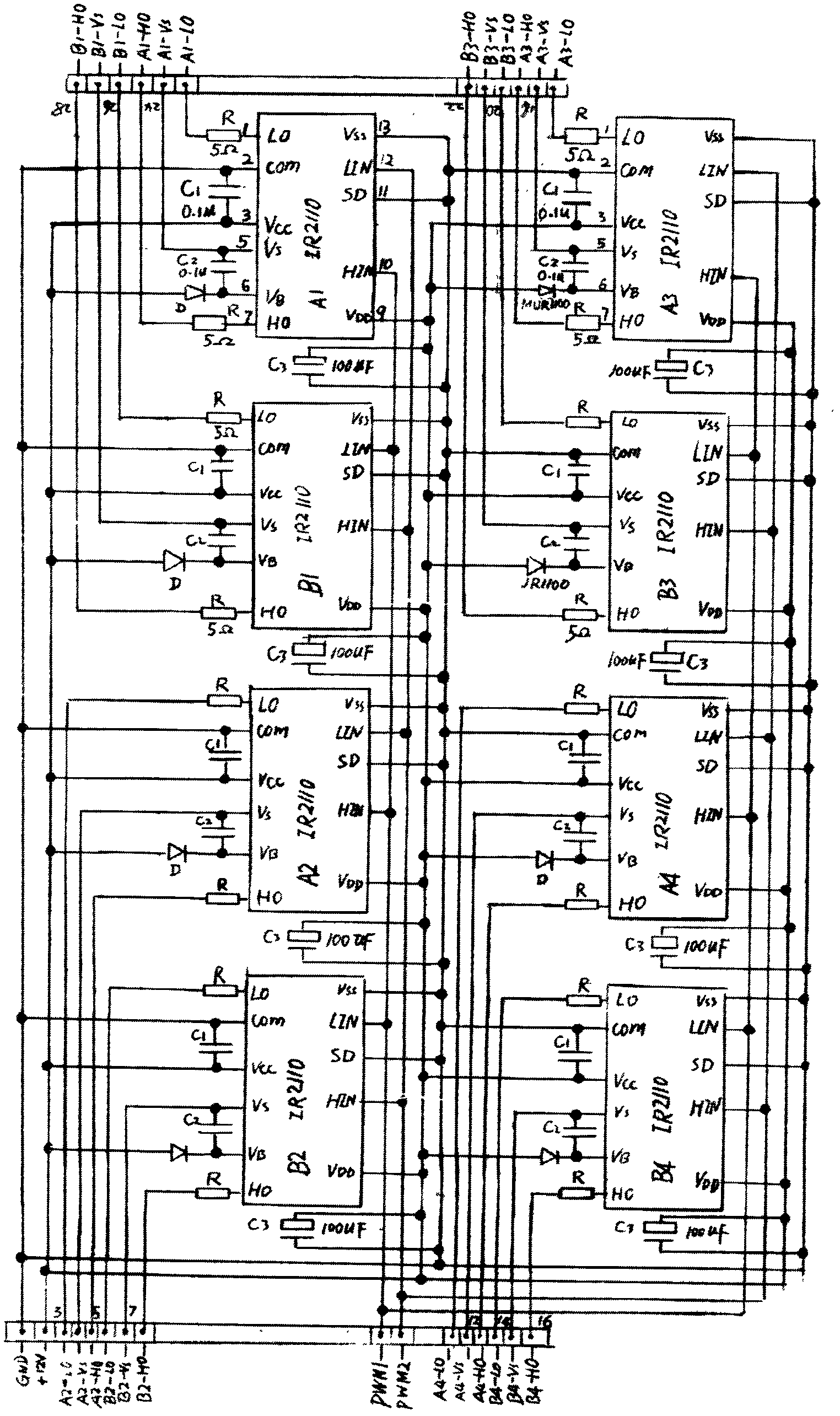

InactiveCN102976501AGood descaling effectImprove versatilityScale removal and water softeningMicrocontrollerMicrocomputer

The invention discloses a universal variable-frequency electromagnetic descaler. The interior of the descaler comprises a one-chip microcomputer main control board which is respectively connected with an LED backlight control module, a lattice liquid crystal display module, a coil power amplifier trigger circuit module, a D / A converter, a coil alarm module, an activate key, a main menu button, a reset circuit module, a parameter setting module, a PC communication module, a measuring module and a key switch through leads, wherein the LED backlight control module is connected with the lattice liquid crystal display module through a lead, the coil power amplifier trigger circuit module is successively connected with a coil power amplification module and an output coil through leads, the D / A converter 7 is connected with a coil power source control module through a lead, and the parameter setting module is connected with a parameter setting button 18 through a lead. The invention further discloses the descaling process of the universal variable-frequency electromagnetic descaler. The universal variable-frequency electromagnetic descaler provided by the invention is convenient to install and use and has good descaling and antiscaling effects.

Owner:XI'AN POLYTECHNIC UNIVERSITY

Scale removal method adapted for circulating and cooling water system

ActiveCN1631814AReduce dosageSuitable for cleaningScale removal and water softeningWater/sewage treatment by oxidationOrganic acidHydrazine compound

The invention relates to a descaling method suitable for cycling water cooling system, which includes: simultaneously or by steps add organic acid or sulphuric acid, corrosion inhibitor, surfactants and hydrazine hydrate of strong reductive agent into the cycling cooling water, then add 4 .The 5 reacts with 4, generating nitrogen, which can combine the chemical washing method and bobble method, increasing the descaling efficiency. Besides, the PH value is controlled by acid between 4-6, by which the quantity of acid can be reduced, so that decrease erosion to the equipment and pipeline of the system.

Owner:BEIJING YANHUA PETRO CHEM

Adjustable-frequency electromagnetic descaling instrument

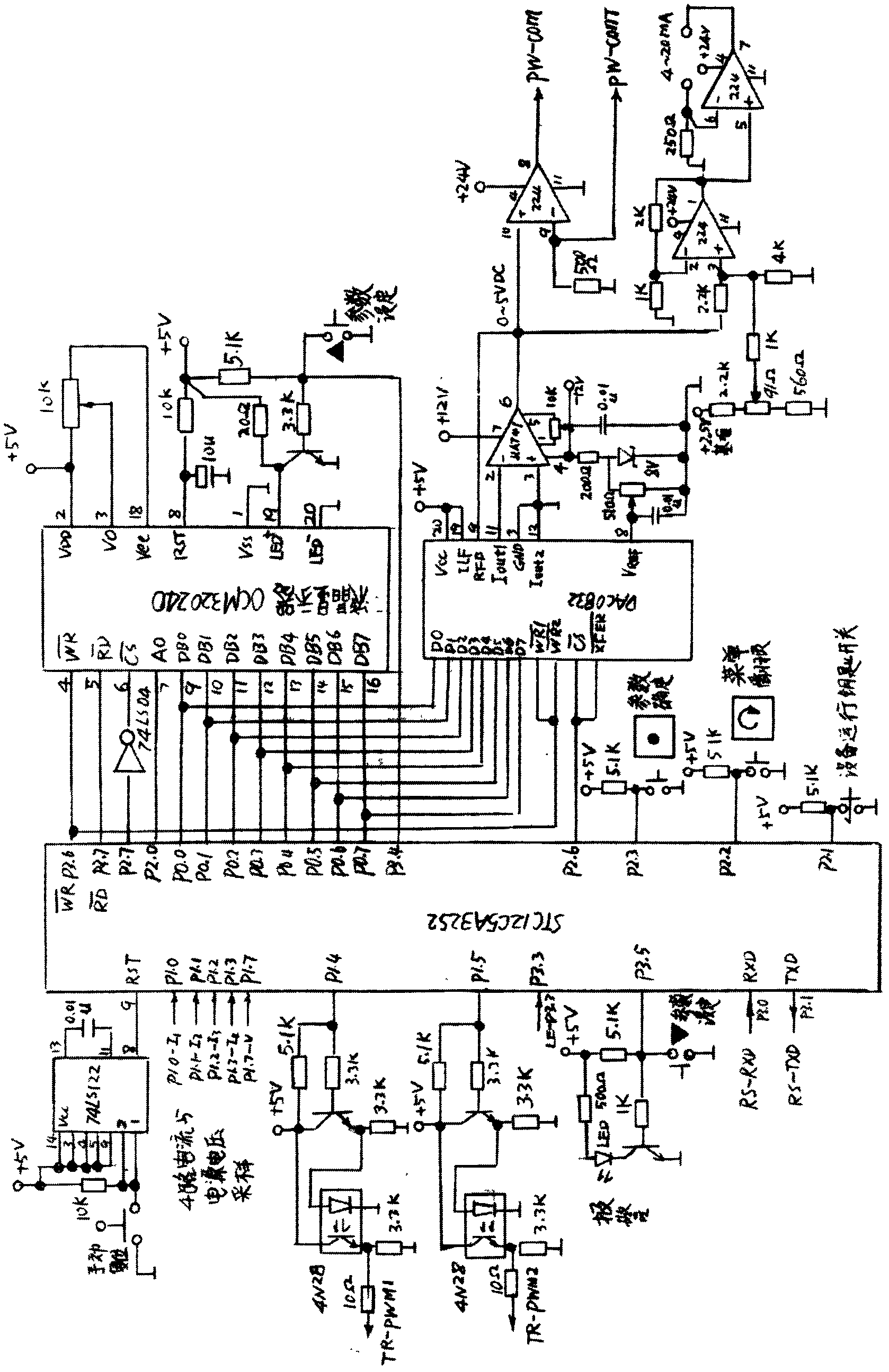

InactiveCN102627358AAvoid disadvantagesGood descaling effectScale removal and water softeningMicrocontrollerElectricity

The invention discloses an adjustable-frequency electromagnetic descaling instrument, which comprises a singlechip main control board, wherein the singlechip main control board is electrically connected with a coil current and power supply voltage measuring module, an LED (Light-Emitting Diode) backlight control module, a PC (Personal Computer) communication module, an alarm module, a parameter giving unit and a current and voltage detection control unit respectively; the LED backlight control module is further connected with a lattice liquid crystal display; the singlechip main control board is connected with a coil power supply control module through a D / A (Digital to Analog) module; a coil power amplification triggering module is connected with a coil power amplifying module; and the coil power amplifying module is connected with the coil power supply control module. The descaling instrument is suitable for descaling and preventing scale under various field running environments and water quality conditions, is arranged in a field wound form, does not damage field pipelines, has the maximum output power of up to 9KW and maximum adaptation pipe diameter of 3 meters, is suitable for the maximum total water hardness of 4,000 mg / L, is suitable for being applied in medium and large-sized industrial enterprises, and is efficient and environmentally-friendly.

Owner:LIGHT INDAL XIAN MECHANIC DESIGN RES INST

Scale scavenger for water cooling heat exchanger system

InactiveCN1565992ASimple production processLow costScale removal and water softeningAdjuvantScavenger

The invention relates to a water treatment composition, in particular a solid descaling agent composition to be charged into water-cooling heat exchanger system, wherein organic acid is utilized as the host agent, ammonium salt is used as the auxiliary agent, surface active agent and metallic inhibitor are used as auxiliary agents, the weight percentage of each raw materials are, host agent 51-65%, the auxiliary agent 16-35%, the adjuvant 8-20%. The process for producing the scale scavenging agent comprises raw material sieving, premixing, machine mixing, measurement, deformer addition, and hermetic package.

Owner:邓武强

Heat transfer medium special for solar heat pump and preparation method thereof

InactiveCN101787263AImprove protectionGood descaling effectHeat-exchange elementsEvaporationPhosphoric acid

The invention discloses a heat transfer medium special for a solar heat pump and a preparation method thereof, which belong to renewable energy source utilization technology. The heat transfer medium is prepared by mixing, heating and stirring ethylene glycol, ionized water, triethanolamine, sodium dihydrogen phosphate, sodium benzoate, phosphoric acid, tolyltriazole styrene, borax, a defoaming agent, an inhibitor and a color concentrate in different weight ratios. The transfer medium has the characteristics of low freezing point, freeze prevention, high low-temperature flowing property, high boiling point, low evaporation loss, high specific heat, high heat conductivity, less foam, high anti-foam performance, and good anti-rust protection and descaling functions for metal pipelines.

Owner:康树人

Novel plugging releasing and pipeline cleaning device

InactiveCN104959355AEasy to adjustImprove controllabilityHollow article cleaningUniversal jointEngineering

The invention relates to a novel plugging releasing and pipeline cleaning device which comprises a body, a first-level cup, a second-level cup, a motor shell, a rotating body and a scraper. The first-level cup and the second-level cup are embedded in grooves in the outer portion of the body, a valve seat is arranged between the body and the motor shell, and a compression spring is arranged between the valve seat and the motor shell. A valve deck is screwed to the rear end of the body, and a screw rod is arranged in stator rubber and connected with an input shaft through threads. One end of an output shaft is arranged in a positioning plate, and the other end of the output shaft is connected with a cover plate through threads. The output shaft and the input shaft are connected through a universal joint, the positioning plate is arranged inside the front end of the motor shell, and the rotating body is arranged outside the front end of the motor shell. A limiting end cover is screwed to the front end of the motor shell, and the scraper is arranged between the rotating body and a baffle and connected with the rotating body through a tension spring. By means of the novel plugging releasing and pipeline cleaning device, multi-level cleaning can be achieved on the wall of an oil conveying pipeline, adjustment is convenient, and controllability is high; pipeline cleaning and plugging releasing are achieved through the mutual act of the scraper and jet fluid, the pipeline cleaning effect is good, and the plugging releasing capability is high.

Owner:SOUTHWEST PETROLEUM UNIV

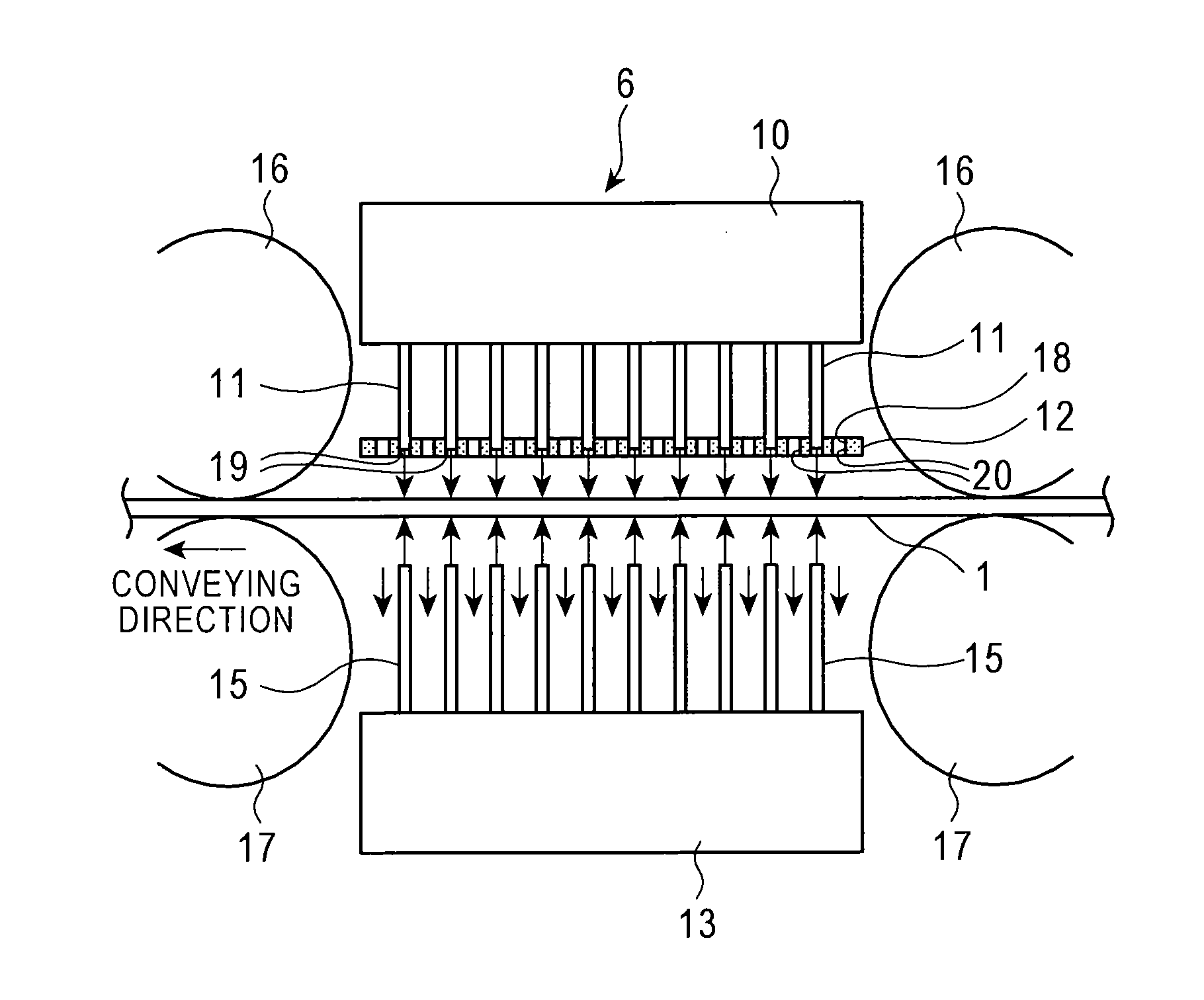

Steel plate manufacturing facility and manufacturing method

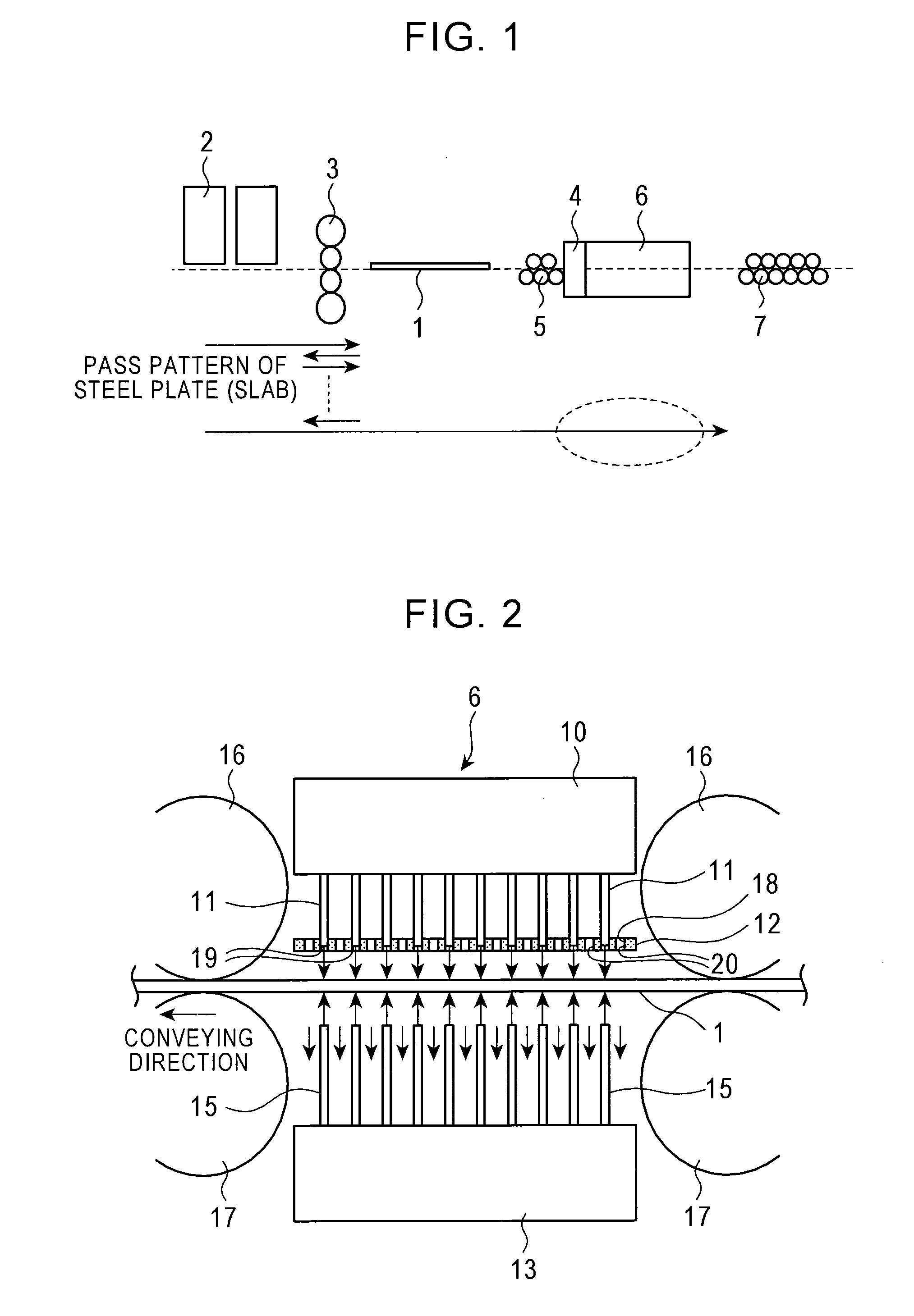

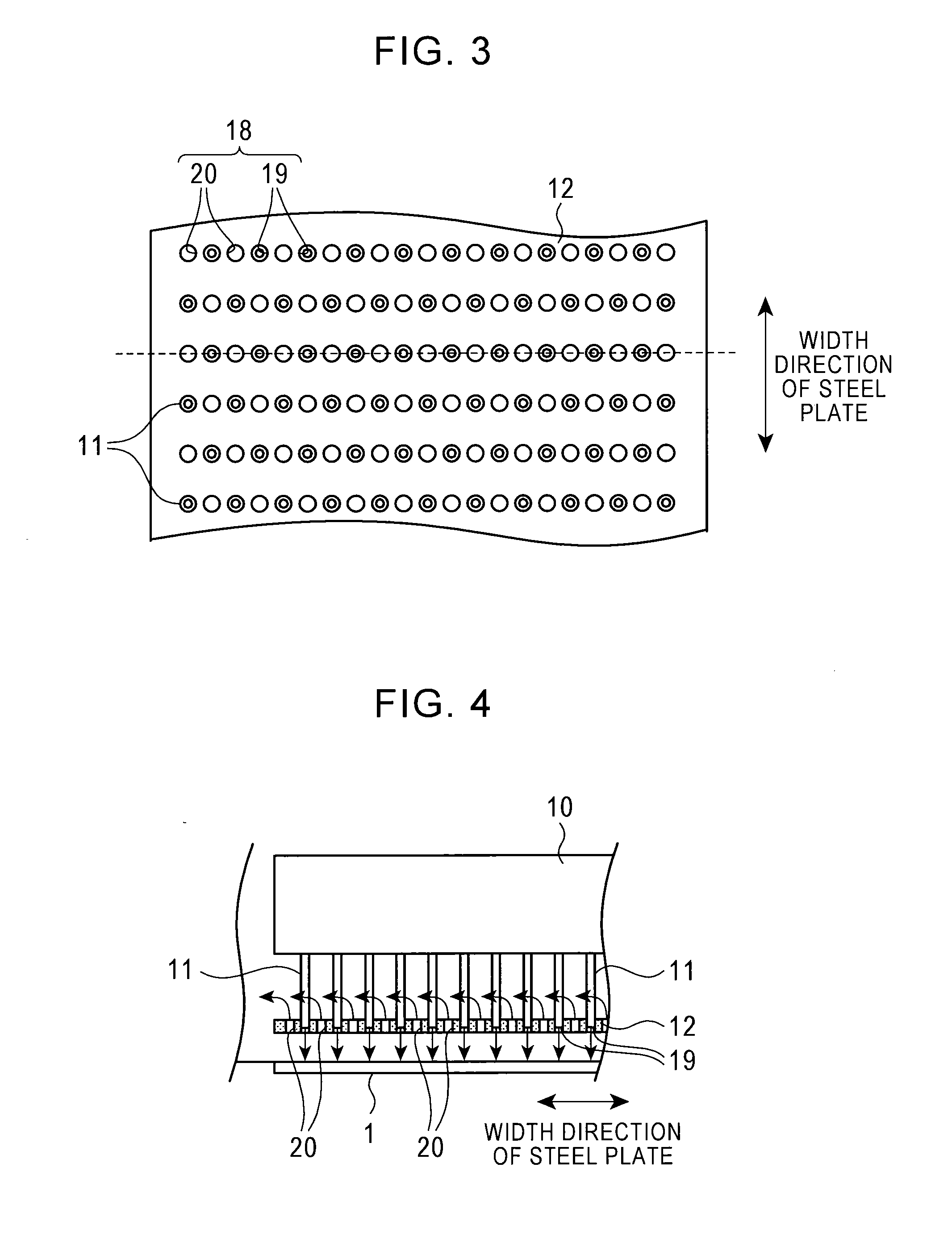

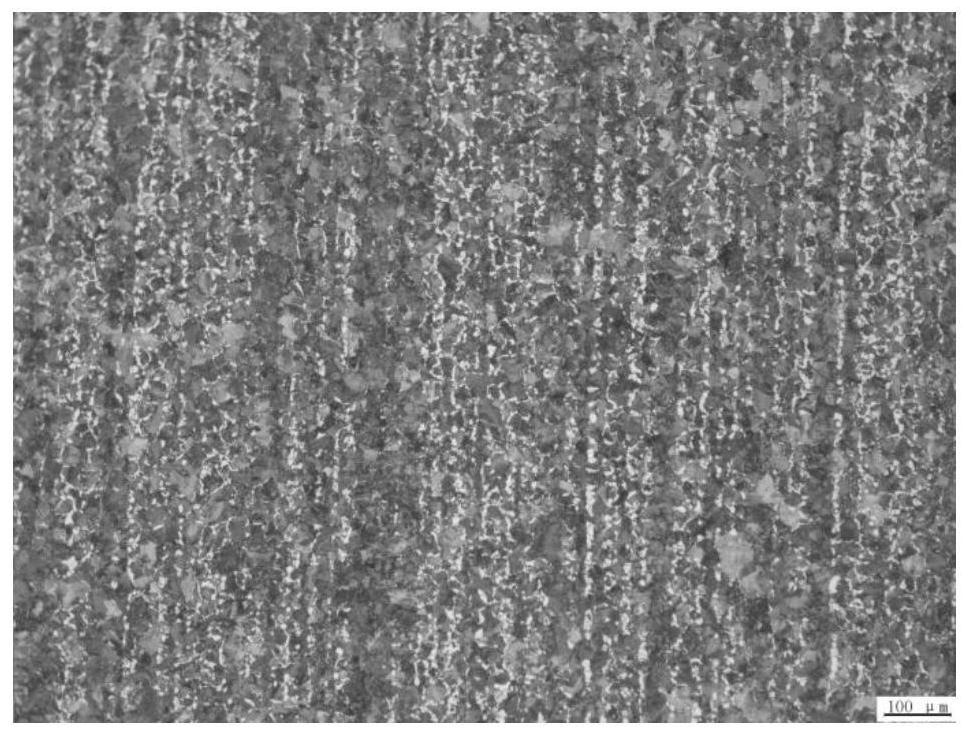

InactiveUS20120017660A1Little surface temperature deviationUniform coolingTensioning/braking arrangementsExtrusion cleaning devicesSteel platesEngineering

A facility is provided for manufacturing a steel plate excellent in steel plate shape and mechanical property while setting low cooling-water spraying performance in a descaling step and achieving uniform cooling in a cooling step. Specifically, a hot rolling mill 3, a first hot leveler 5, a descaler 4, and cooling equipment 6 are arranged in that order from the upstream side in a conveying direction. A pressure P [MPa] at the point of impact of cooling water sprayed from the descaler to each surface of a steel plate 1 is greater than or equal to 1.5 MPa.

Owner:JFE STEEL CORP

High-strength and high-toughness hot-rolled round steel capable of being directly cut and preparation method thereof

ActiveCN111647799ASolid solubility product is smallReduce addFurnace typesHeat treatment furnacesAlloyPearlite

The invention relates to high-strength and high-toughness hot-rolled round steel capable of being directly cut and a preparation method thereof. Elements of the round steel contain Nb, V and other microalloys, so that grain refinement and strength improvement are facilitated. Two-stage rolling of cogging and continuous rolling is adopted, air cooling temperature holding is carried out before two times of rolling, a steel billet is overturned by 180 degrees through a cogging mill during first-time air cooling temperature holding, and after first-time temperature holding, the steel billet is roughly rolled into an intermediate square billet through the cogging mill; second-time air cooling temperature holding is performed before continuous rolling of the intermediate square billet, the temperature of the intermediate billet is held to the initial temperature of continuous rolling of 800-950 DEG C, the intermediate billet is continuously rolled into the round steel by using a continuous rolling machine after the second-time temperature holding, and the final rolling temperature is 780-900 DEG C; and when the temperature of the round steel subjected to hot rolling is held to be lower than Ar3, the round steel is comprehensively cooled through spraying and air cooling, after being cooled to 600 DEG C, the round steel is subjected to stack cooling to obtain a microstructure of lamellar pearlite and a small amount of ferrite.

Owner:JIANGSU VALIN XIGANG SPECIAL STEEL +1

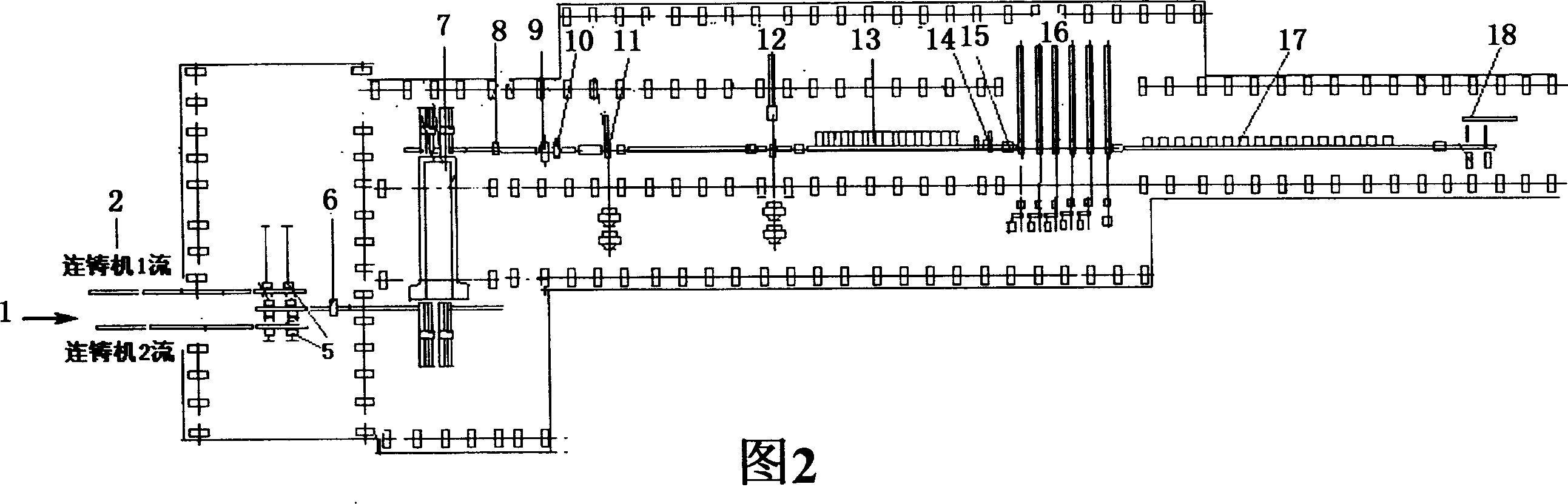

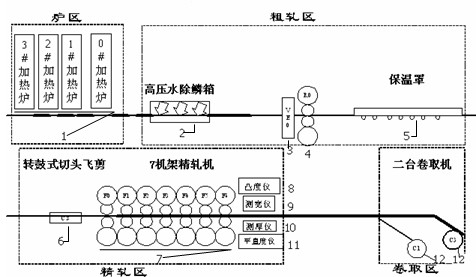

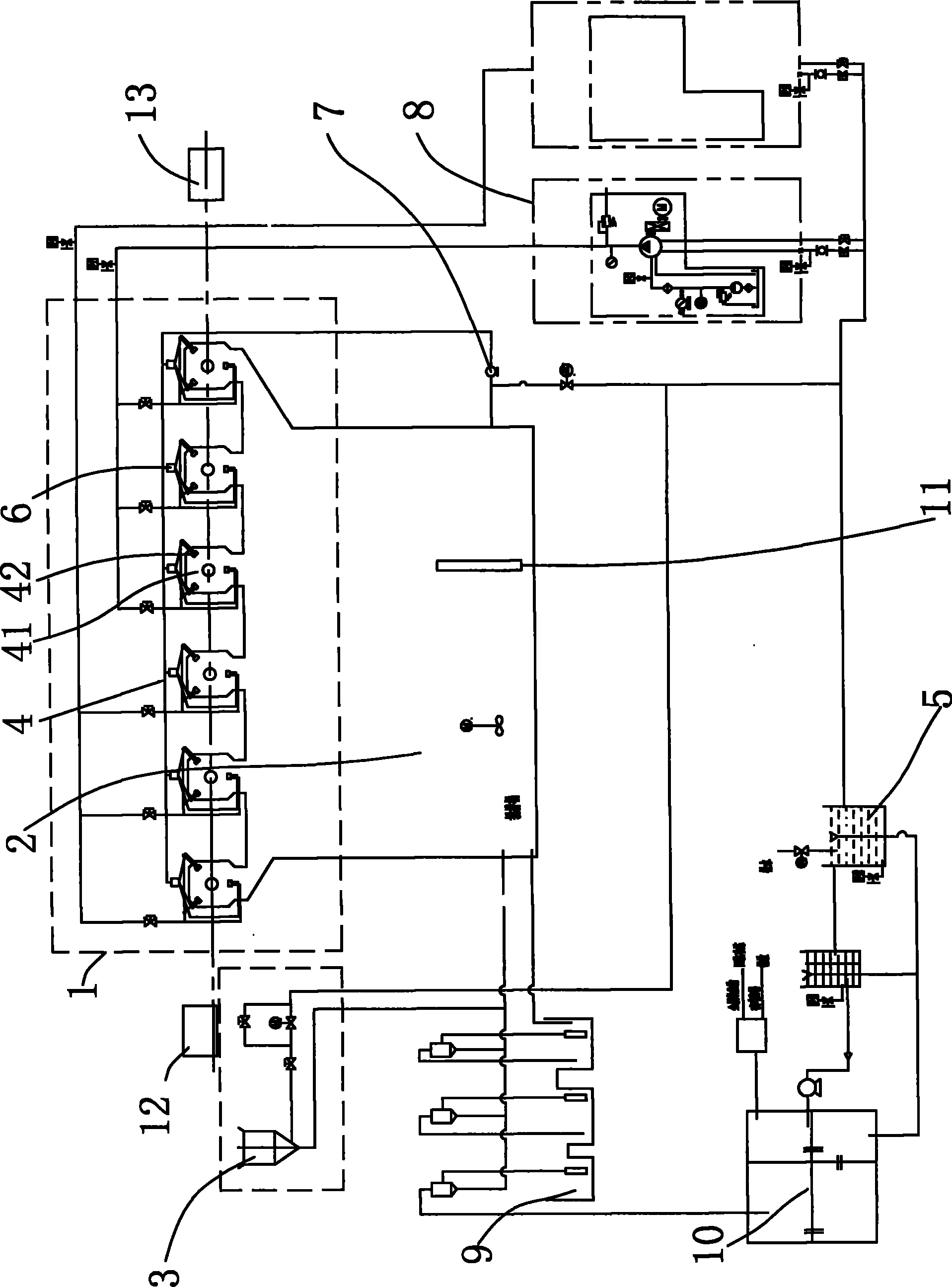

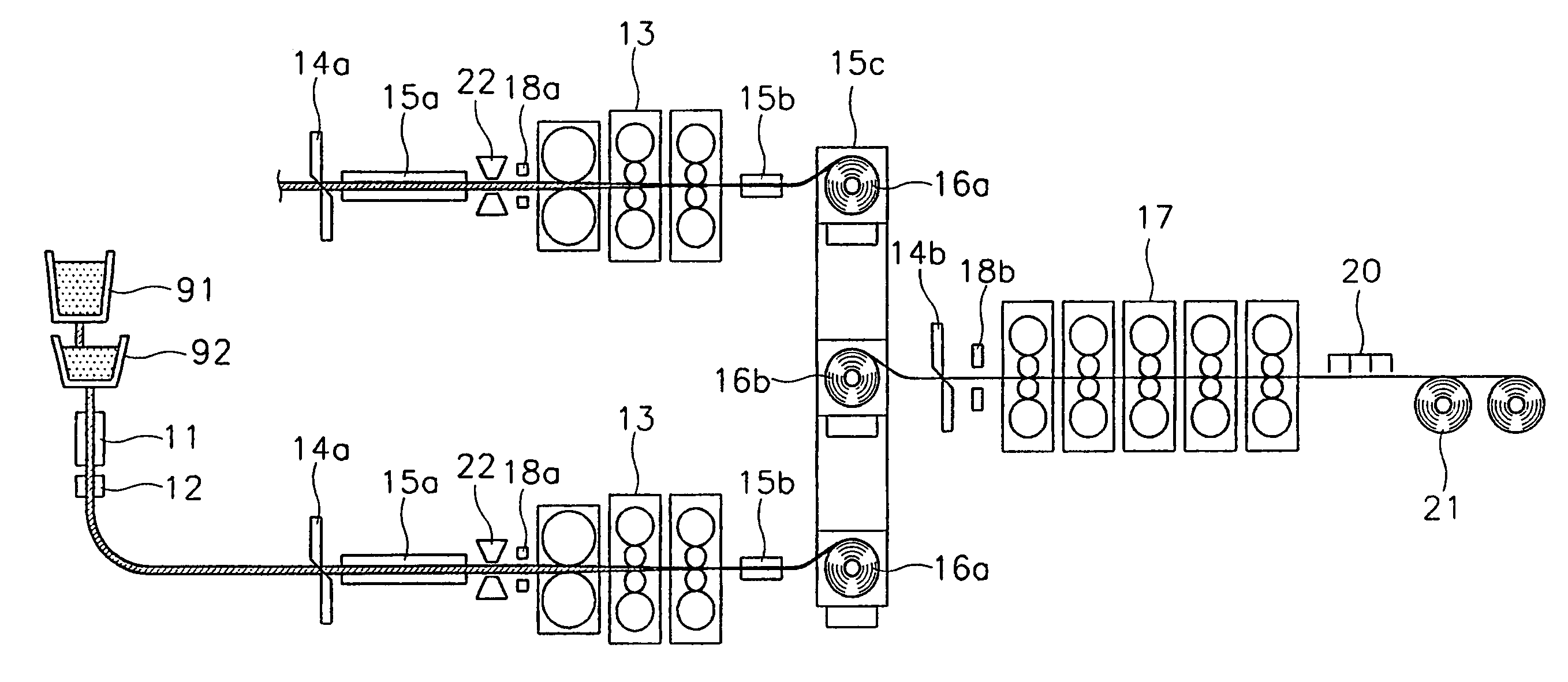

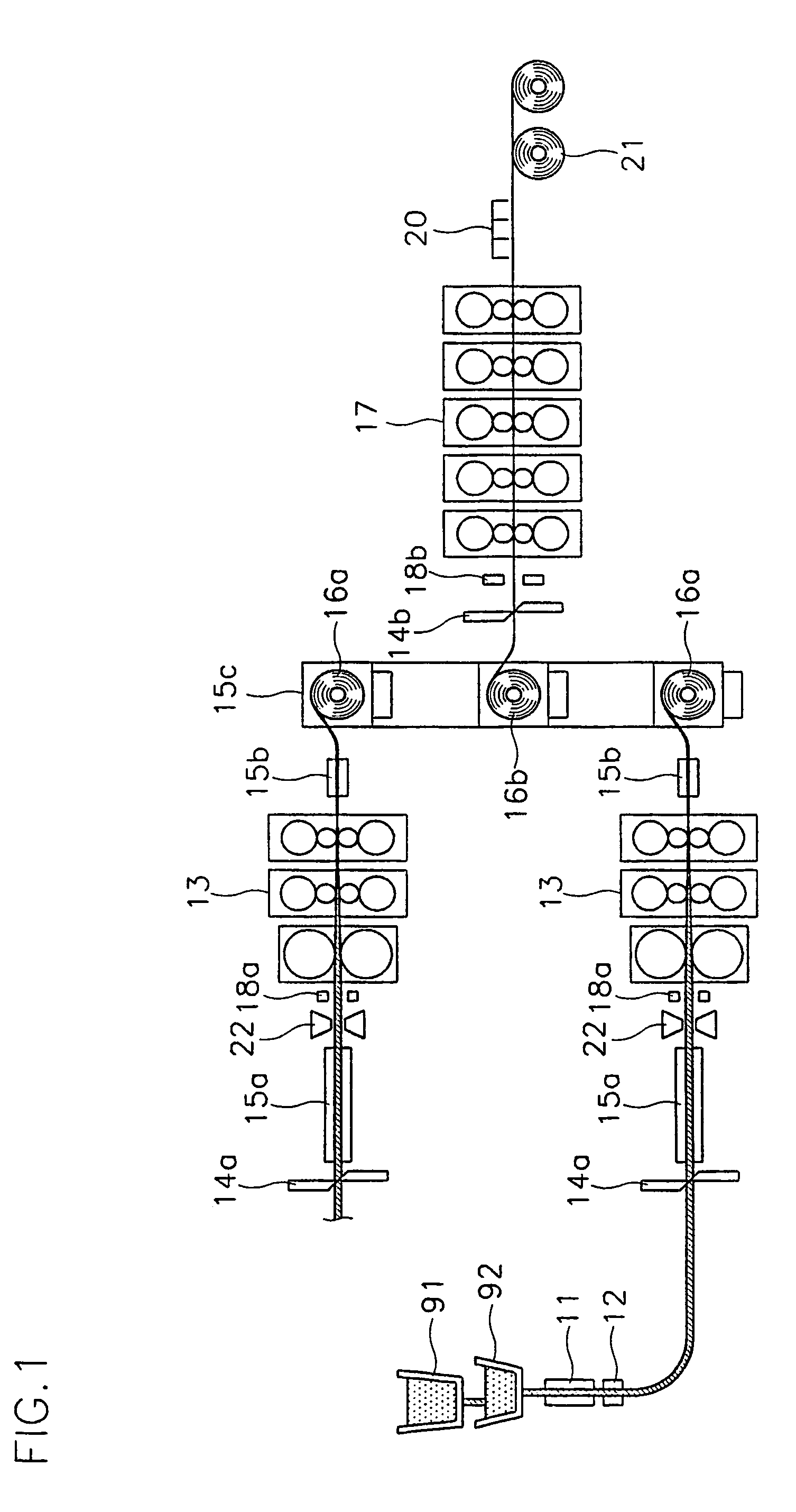

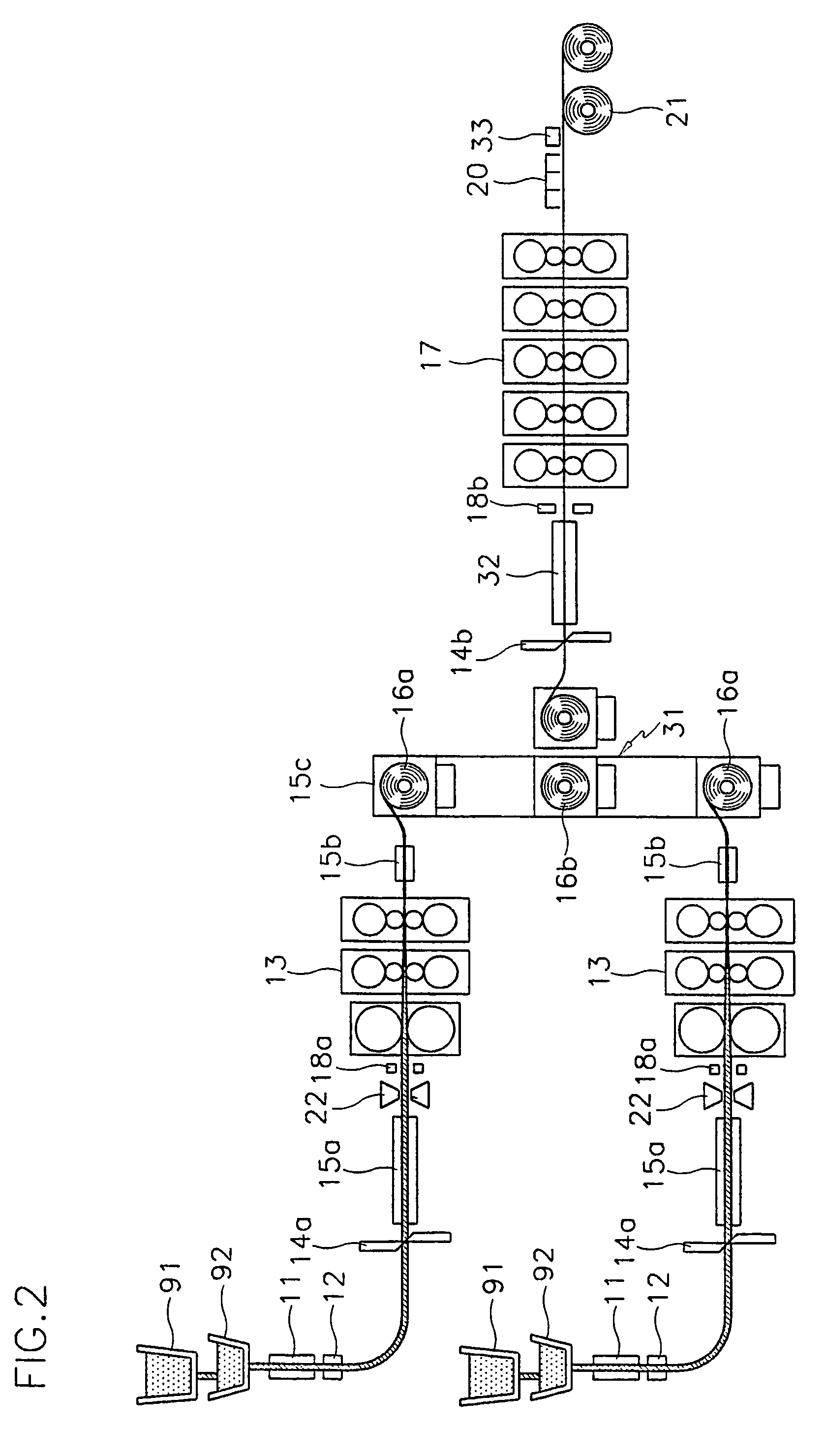

Method of manufacturing hot rolled steel sheet using mini mill process

InactiveUS6978531B1Easy to controlGood descaling effectMetal rolling stand detailsWork heating devicesSheet steelHeating furnace

Disclosed is a method for manufacturing hot rolled steel sheets. The method includes the steps of passing molten steel through a continuous caster (11) having a mold after having been passed through a ladle (91) and a tundish (92) to manufacture a slab; cutting the slab to predetermined lengths using a cutter (14a) to form a plurality of cut slabs; heating the cut slabs to a predetermined temperature in a first heating furnace (15a) descaling the cut slabs heated in the first heating furnace; rolling the slabs in a reduction unit (13) to a predetermined thickness to form a plurality of flat bars; heating the flat bars to a predetermined temperature in a second heating furnace (15b); coiling the flat bars by a coiling station (16a) while the flat bars are maintained in a heated state; uncoiling the flat bars by an uncoiler (16b); and rolling the flat bars to a predetermined thickness in a finishing mill.

Owner:POHANG IRON & STEEL CO LTD

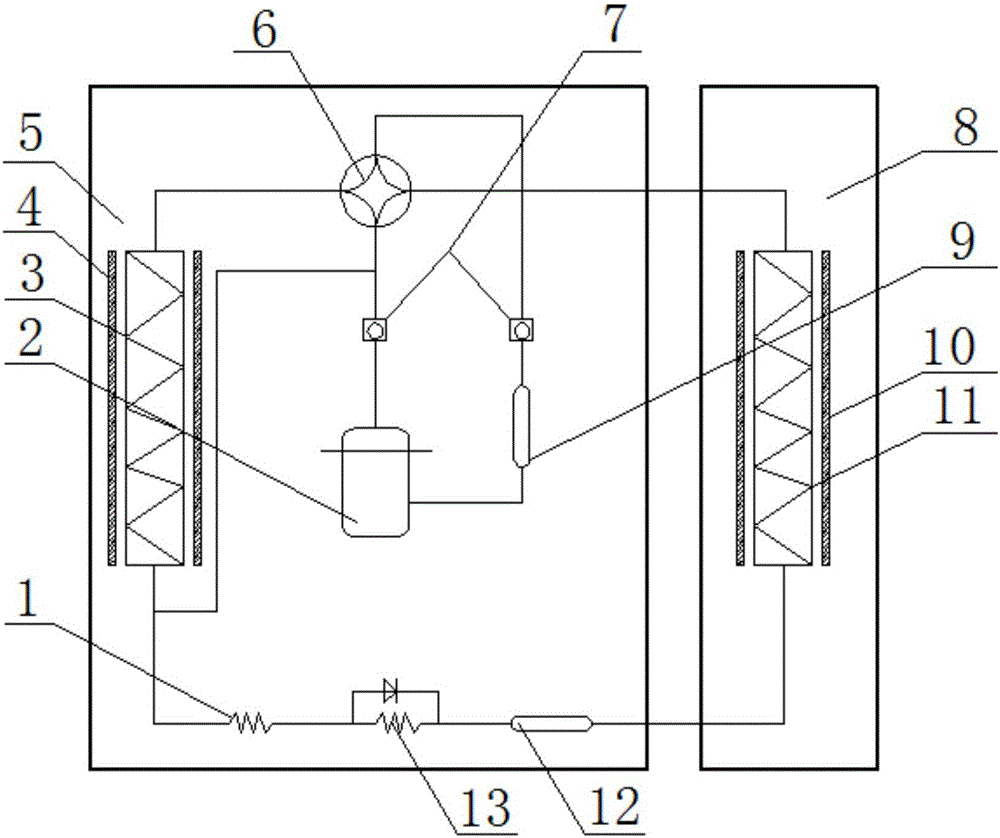

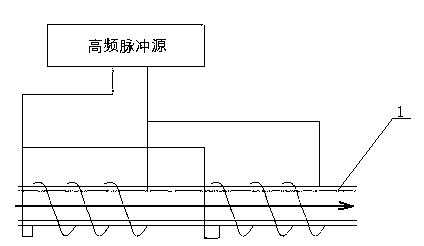

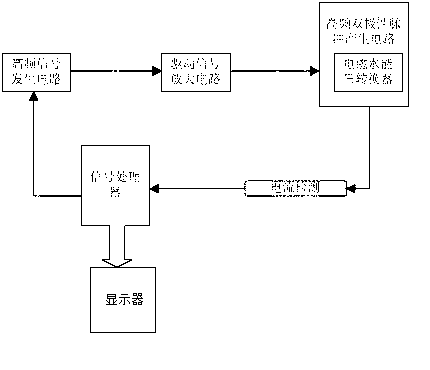

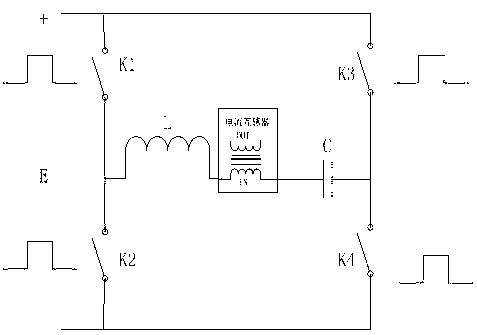

Coil-winding type electronic induction water processing circuit and water processing method thereof

ActiveCN102838214AEasy to installReduce adhesionScale removal and water softeningWater/sewage treatment by magnetic/electric fieldsProcess engineeringAlgae

The invention discloses a coil-winding type electronic induction water processing circuit and a water processing method thereof, belonging to the field of electronic induction water processing. The coil-winding type electronic induction water processing circuit comprises a signal processor, a high-frequency generation circuit, a driving signal amplifying circuit, a high-frequency bipolar pulse generation circuit and a current detection unit which are connected in sequence; and the output end of the current detection unit is connected with the input end of the signal processor. The coil-winding type electronic induction water processing circuit and the water processing method thereof disclosed by the invention can be suitable for different water-quality environments, and have the advantages that the effects of preventing and removing scale, and killing bacteria and algae are achieved and the service life of water supplying equipment is prolonged.

Owner:马鞍山市安工大智能装备技术研究院有限公司

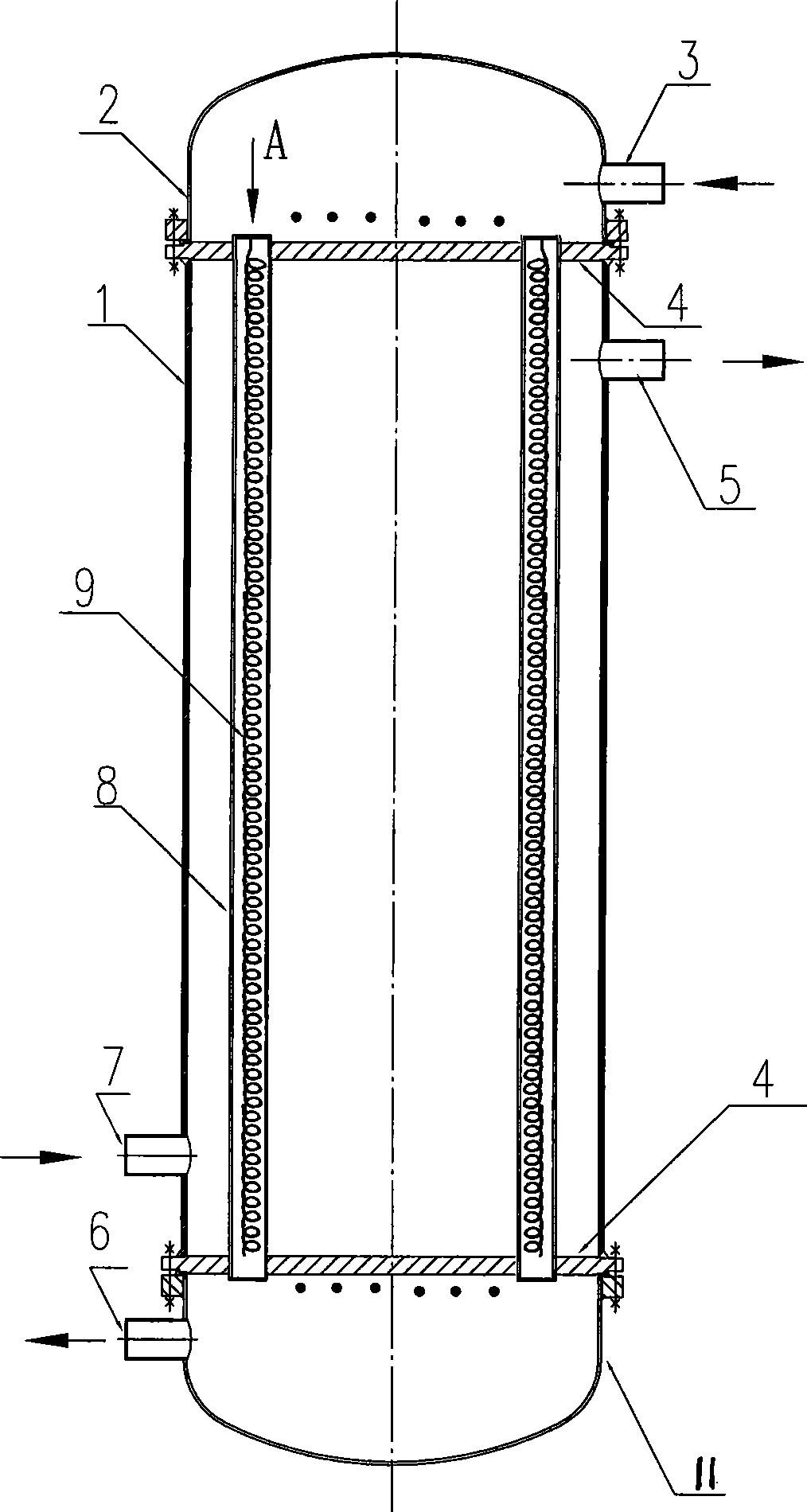

Pipe shell heat exchanger having heat exchange tube embedded with spring

InactiveCN101464101ASimple structureImprove heat transfer performanceStationary tubular conduit assembliesHeat transfer modificationPlate heat exchangerShell and tube heat exchanger

The invention relates to a shell-and-tube heat exchanger, particularly an internal spring type shell-and-tube heat exchanger with a heat exchange pipe. The heat exchanger adopts an insert perturbation enhancing technology to enhance perturbation heat transfer enhancement, and comprises a casing, an upper sealing head, a lower sealing head, a tube plate and a heat exchange pipe, wherein, the two ends of the casing are connected with the upper sealing head and the lower sealing head through the tube plate respectively; and the upper end and the lower end of the heat exchange pipe are fixed on the tube plate respectively. The heat exchanger is characterized in that a spring which is arranged in the center of the heat exchange pipe is arranged in the heat exchange pipe; and one end of the spring is fixed on a spring suspension frame which is arranged on the end surface of the water inlet of the heat exchange pipe, and the other end thereof which is a free end is put near the water outlet of the heat exchange pipe. The heat exchanger has the main advantages as follows: by simply carrying out the structural improvement of a common shell-and-tube heat exchanger, the effects of heat transferring and de-scaling are better enhanced without additional energy supply; the structure is simple; and the installation is convenient.

Owner:HUAZHONG UNIV OF SCI & TECH +1

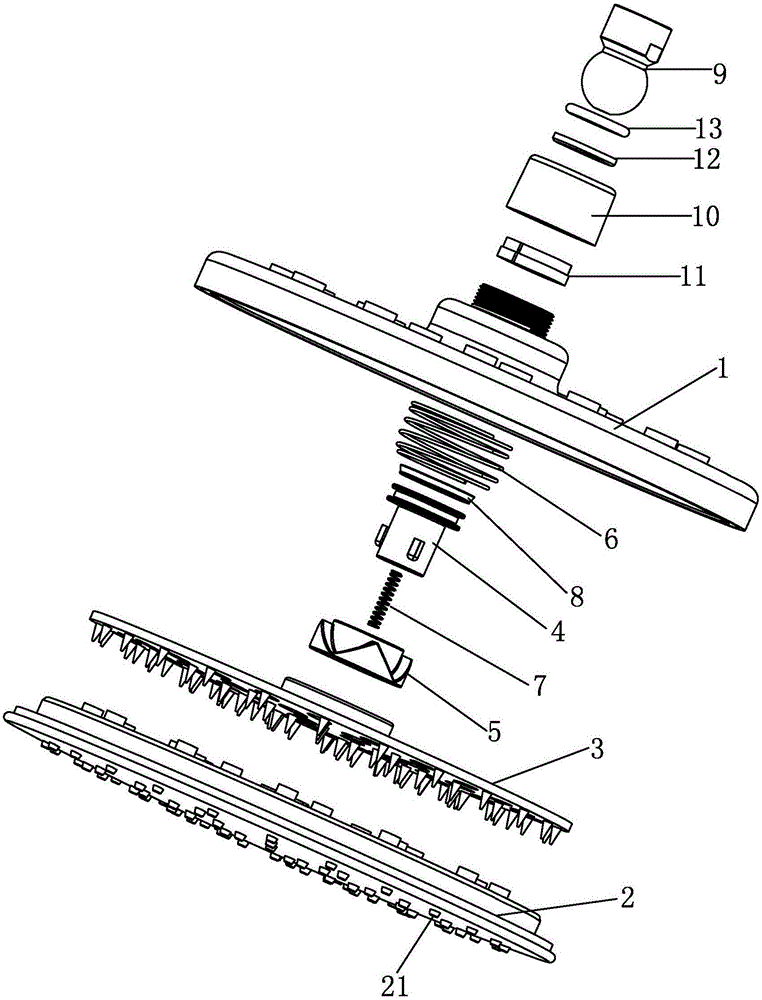

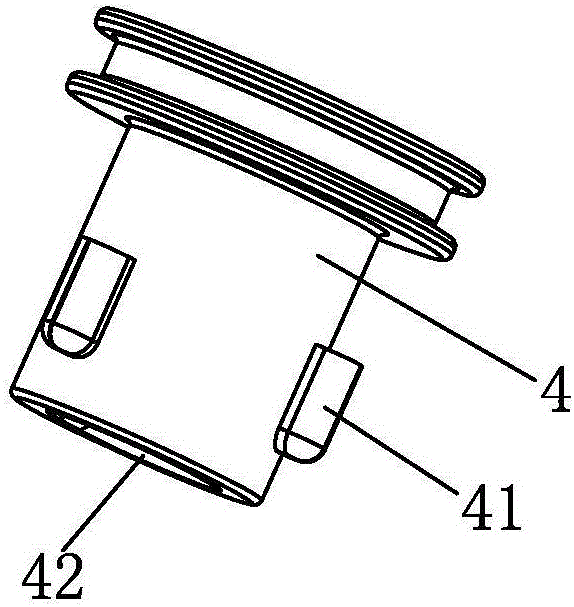

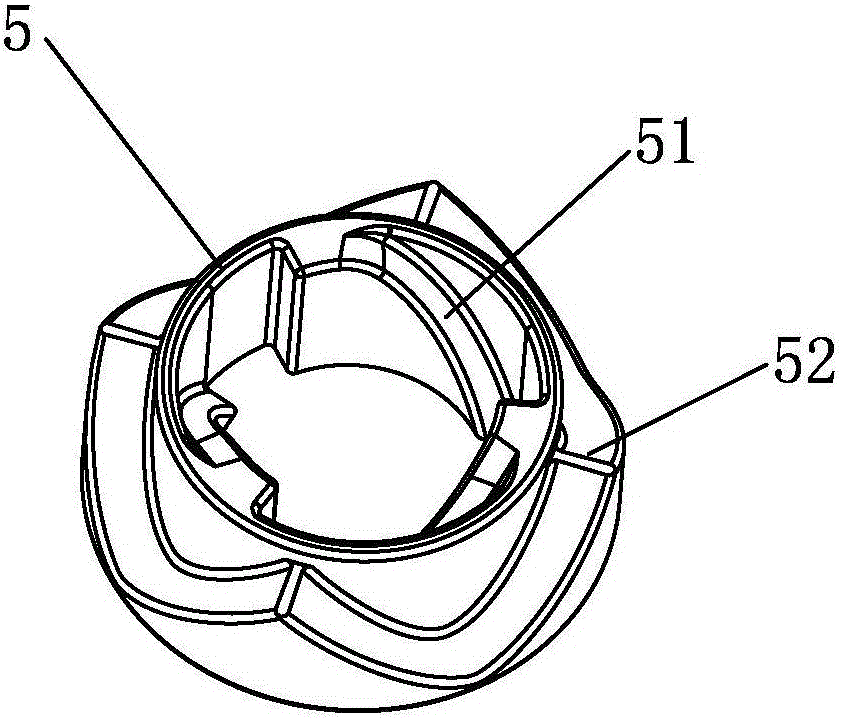

Automatic descaling sprinkler and automatic descaling method for sprinkler

The invention discloses an automatic descaling sprinkler and an automatic descaling method for the sprinkler. The automatic descaling sprinkler comprises a sprinkler body, a water outlet face cover, a descaling plate and an automatic control mechanism. The descaling plate can be vertically and movably arranged between the sprinkler body and the water outlet face cover, and descaling needles in one-to-one correspondence with all or part of water outlet holes in the water outlet face cover are distributed on the bottom face of the descaling plate. The automatic control mechanism comprises a driving part movably arranged between the sprinkler body and the water outlet face cover and impacted by water flow to achieve the movement, a transmission part which is rotatably arranged on the inner side of the water outlet face cover and is matched with the driving part in a linkage manner, and a reset device used for driving any one or more of the descaling plate, the transmission part and the driving part to reset, wherein the driving part moves to drive the transmission part to rotate by a preset angle, the transmission part and the descaling plate are matched with a first transmission structure, the transmission part rotates to drive the descaling plate to move upwards, and therefore the descaling needles of the descaling plate can retreat from the water outlet holes. The automatic descaling sprinkler is small in number of parts, simple in structure, easy to assemble, low in cost and obvious in descaling effect.

Owner:JOMOO KITCHEN & BATHROOM

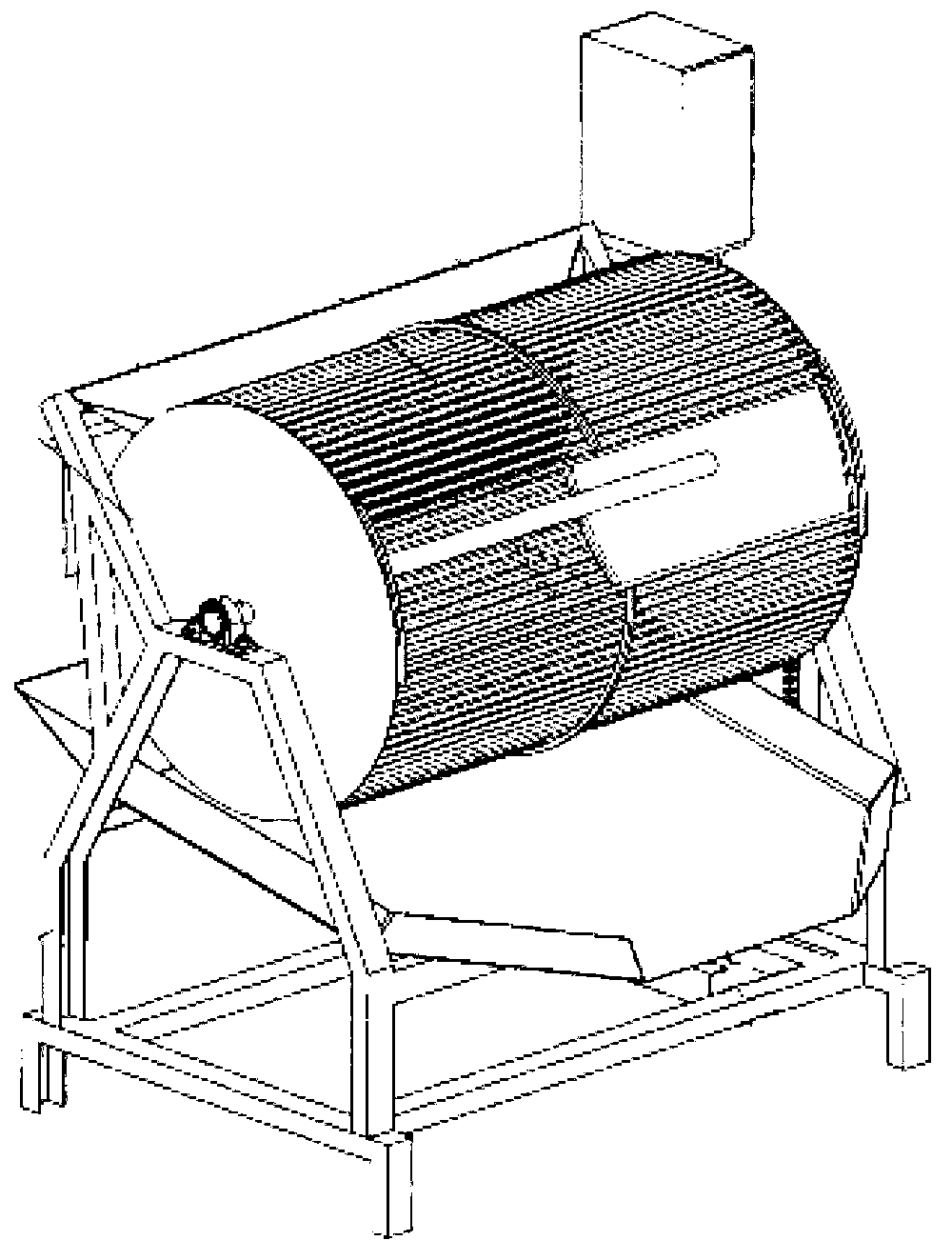

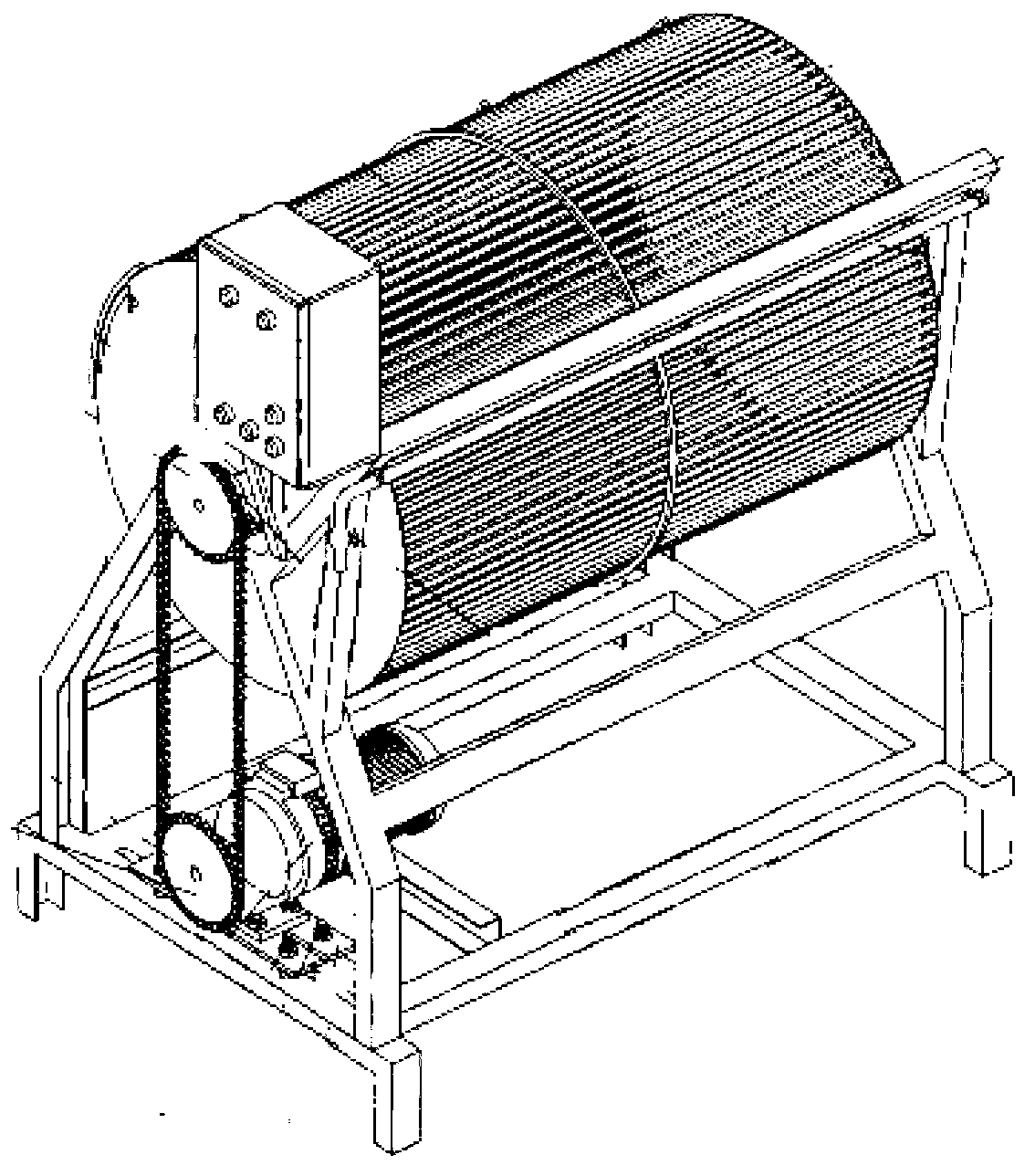

Horizontal multistage roller scaling apparatus for processing large number of freshwater fish, and scaling method thereof

ActiveCN103283806AHigh degree of automationLabor savingFish washing/descalingControl powerScale structure

The invention relates to a horizontal multistage roller scaling apparatus for processing a large number of freshwater fish, and a scaling method thereof. Fish for processing is continuously conveyed to a rotating multistage roller, scales are removed through scaling structure members having diversified shapes on the inner walls of all-stage rollers, a plurality of axial spiral channels are arranged on the inner wall of each of cylindrical connecting pieces and can push the fish to a next-stage scaling roller from a previous-stage scaling roller, a hairbrush roller shafting and the multistage roller are coaxially arranged and are driven by two variable-frequency speed control power devices having different powers at the upper portion of a frame, the rotating speed and the turning direction of the hairbrush roller shafting are mutually associated and coupled, a plurality of hairbrush rollers in the hairbrush roller shafting can realize the scaling assistance and the feeding control of the fish, scales removed from the surface of the fish go through scale through holes on the all-stage scaling rollers and fall in a scale deposition tank for convenient collection, and pressurized water flow in a central tube shaft goes through a plurality of small holes arranged on the wall of the central tube shaft and sprays the processed fish in the multistage roller for flushing.

Owner:FISHERY MACHINERY & INSTR RES INST CHINESE ACADEMY OF FISHERY SCI

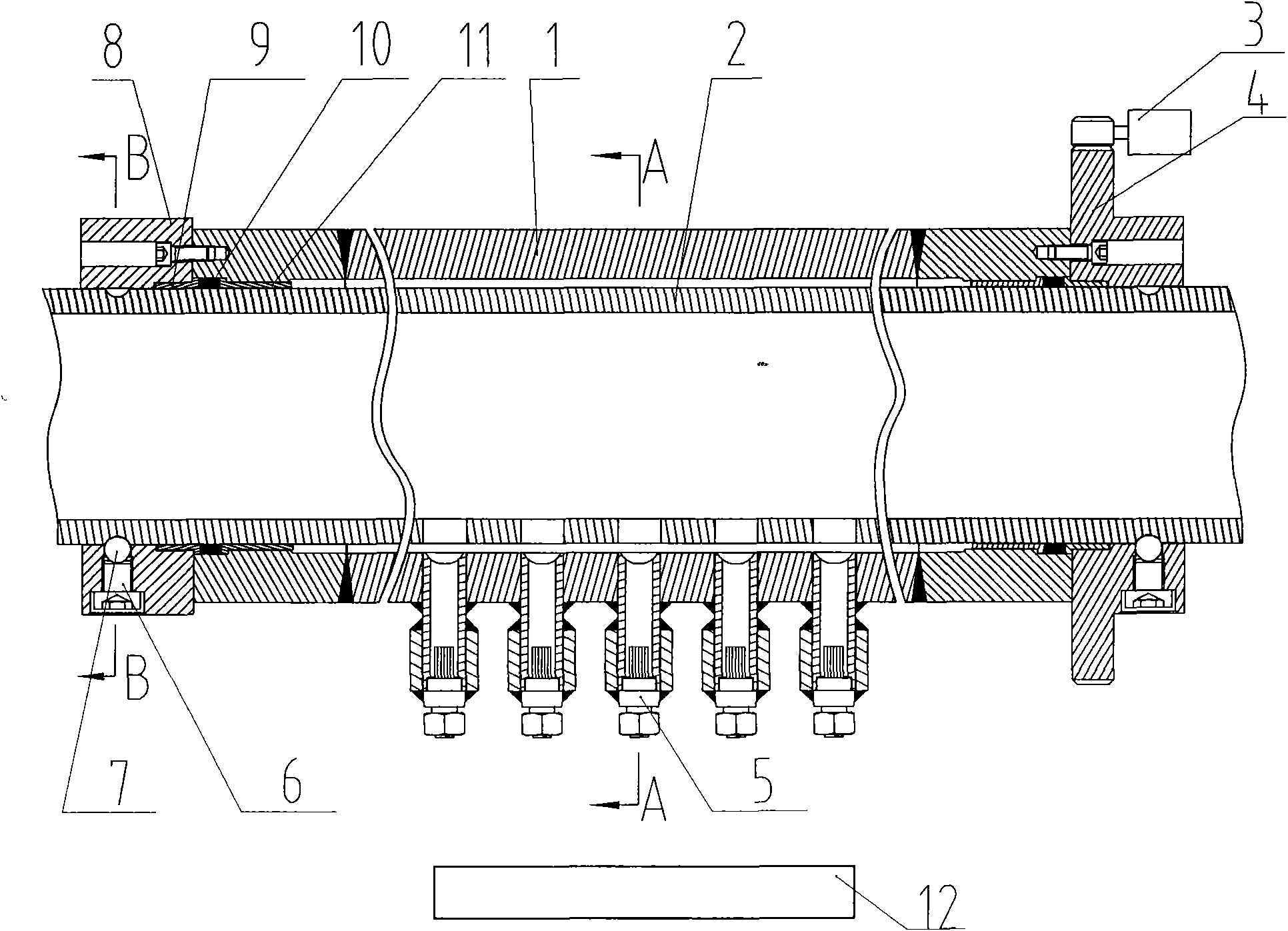

Self-enclosed coaxial equal-angle alternate rotary descaling header device

InactiveCN101954387AHigh control precisionExtended service lifeSpraying apparatusWork treatment devicesOpen waterMotor drive

The invention discloses a self-enclosed coaxial equal-angle alternate rotary descaling header device, which comprises a header provided with nozzles. The descaling header consists of an outer pipe and an inner pipe; the inner pipe is in movable fit arrangement in the outer pipe; nozzle groups in rows are arranged on the outer pipe of the descaling header at equal angles radially; nozzles of each row of nozzle group are uniformly distributed along the axial direction of the outer pipe; the inner wall is provided with a row of normally open water holes corresponding to a row of normal descaling work nozzles of the outer pipe, and is simultaneously provided with nozzle enclosing devices corresponding to other rows of nozzles; one end of the inner pipe is enclosed, while the other end is communicated with high pressure water; two ends between the pipe walls of the inner pipe and the outer pipe are provided with a rotary positioning device and a rotary sealing device; and a motor drives a gear arranged on the outer pipe to rotate the outer pipe. The self-enclosed coaxial equal-angle alternate rotary descaling header device has the advantages of reasonable structure, high control accuracy, high descaling effect, convenient maintenance, long service life, and capacity of automatically switching to corresponding nozzle groups for descaling steel plate and strips with same thickness, different thicknesses and different widths so as to complete descaling work.

Owner:BAOSTEEL GROUP XINJIANG BAYI IRON & STEEL

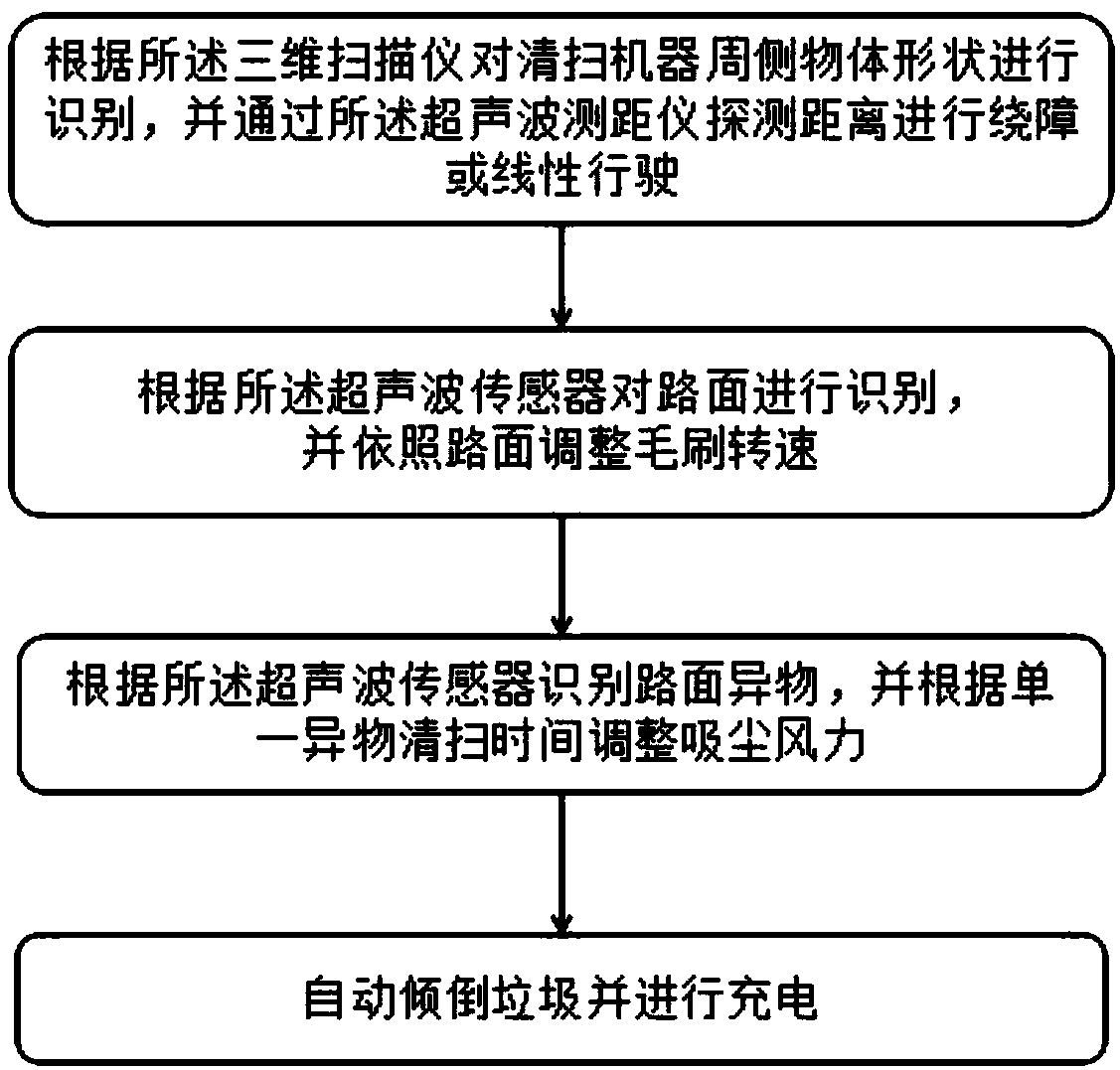

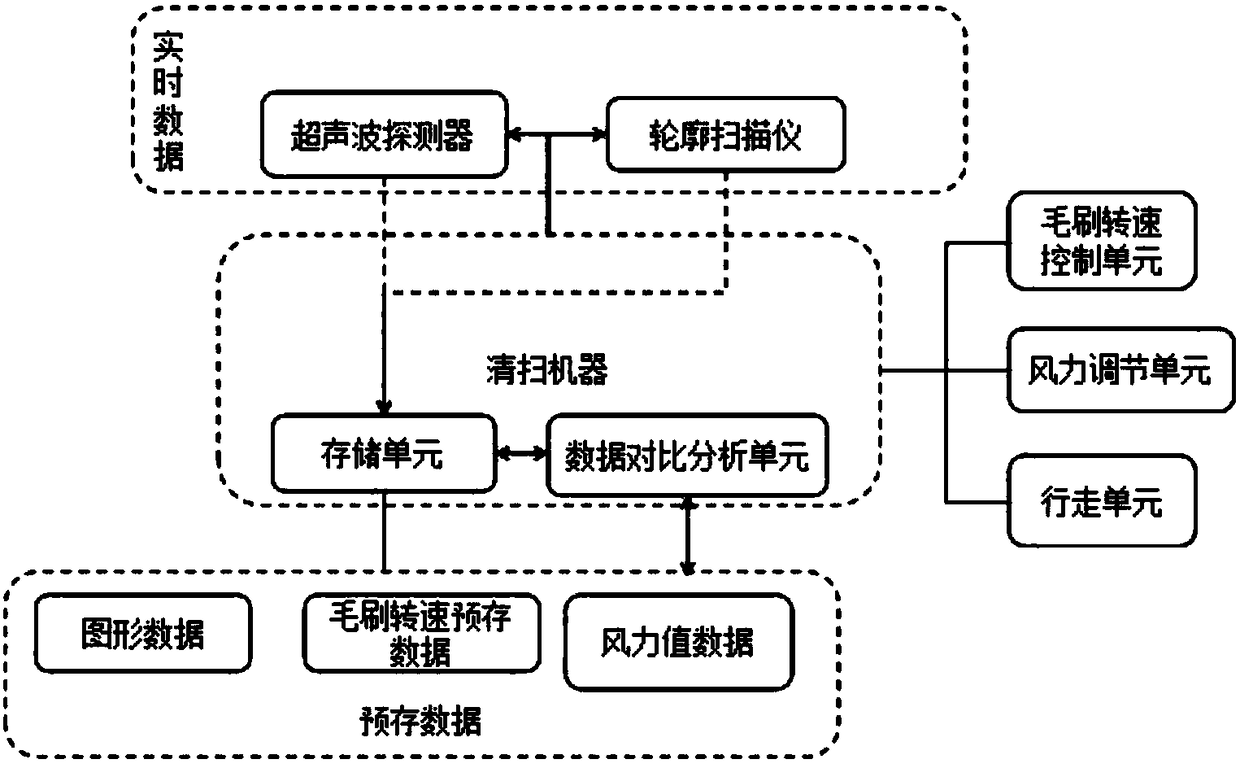

Sweeping and driving method based on shape recognition cleaning machine and control system thereof

InactiveCN108319266AGood descaling effectImprove cleaning efficiencyEnergy saving arrangementsSimultaneous control of multiple variablesForeign matterUltrasonic sensor

The invention discloses a sweeping and driving method based on a shape recognition cleaning machine and a control system thereof, and relates to the technical field of cleaning machines. The method provided by the invention comprises the steps that 1 the shape of an object beside the cleaning machine is recognized according to a three-dimensional scanner, and obstacle avoiding or linear driving iscarried out through an ultrasonic range finder; 2 an ultrasonic sensor recognizes the road surface, and the rotation speed of a brush is adjusted according to the road surface; 3 a foreign object onthe road surface is recognized according to the ultrasonic sensor, and the dust collecting wind power is adjusted according to the cleaning time of the single foreign object; and 4 automatic garbage dumping and charging are carried out. According to the invention, targeted recognizing is carried out on the cleaned road surface and garbage during the cleaning process; the dust collecting wind speedand the rotation speed of the cleaning brush are changed; and the cleaning ability of the cleaning machine is improved.

Owner:ANHUI SANDI ELECTRONICS TECH CO LTD

Barium strontium calcium scale remover and preparation method thereof

InactiveCN106147735AThe preparation method is simple and feasibleLower synthesis costDrilling compositionSulfatePotassium hydroxide

The invention provides a barium strontium calcium scale remover. The barium strontium calcium scale remover is prepared from, by weight, 20%-35% of a metal chelator, 10%-20% of a solubilizer, 0.5%-5% of a dispersing agent, 5%-15% of potassium hydroxide and 40%-60% of deionized water. Compared with the prior art, the barium strontium calcium scale remover has the good performance, can effectively remove organic composite scale such as barium sulfate, strontium sulfate and calcium sulfate, has the advantages of being high in scale removal efficiency, harmless to the natural environment, safe in use, non-corrosive to equipment and the like and has an important practical significance for increasing the oil and gas recovery rate.

Owner:CNPC BOHAI DRILLING ENG

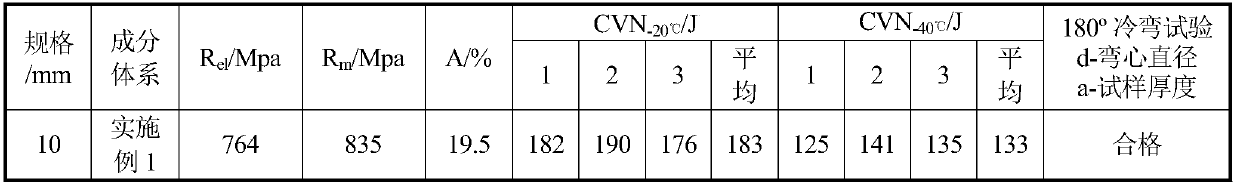

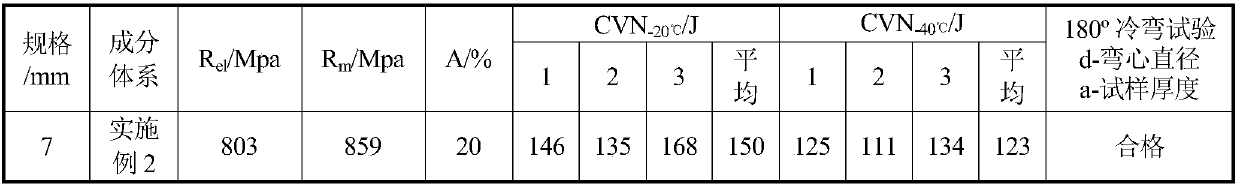

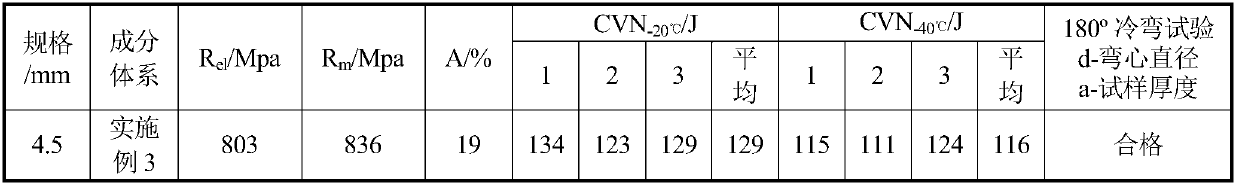

Economical high-toughness 800MPa-level automobile beam steel and production method thereof

The invention provides economical high-toughness 800MPa-level automobile beam steel. The economical high-toughness 800MPa-level automobile beam steel is prepared from the following components in percentage by weight: 0.07-0.11% of C, 1.55-1.80% of Mn, 0.05-0.20% of Si, less than or equal to 0.015% of P, less than or equal to 0.008% of S, 0.020-0.040% of Nb, 0.10-0.20% of Mo, 0.03-0.06% of Al, 0.09-0.13% of Ti, less than or equal to 0.005% of N, and the balance of Fe and inevitable impurities. The invention further provides a production method for the economical high-toughness 800MPa-level automobile beam steel, and the production method comprises the following steps: a top and bottom re-blowing converter process, LF refining, slag continuous casting, 1780mm mill rolling, and front-sectioncooling. The automobile beam steel has high strength, high toughness and low production cost. While used as an automobile structure part, the automobile beam steel can avoid occurrence of a cracking phenomenon in use in processes such as shearing, stamping, bending and welding.

Owner:ANYANG IRON & STEEL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com