Internal descaling and external defrosting novel air conditioner applying ultrasonic oscillators

A technology of ultrasonic waves and oscillators, applied in the field of new air conditioners, can solve problems such as unstable chemical cleaning fluid, corrosion of heat exchangers, and pollution of emissions, and achieve the effects of high descaling efficiency, reduced noise, and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

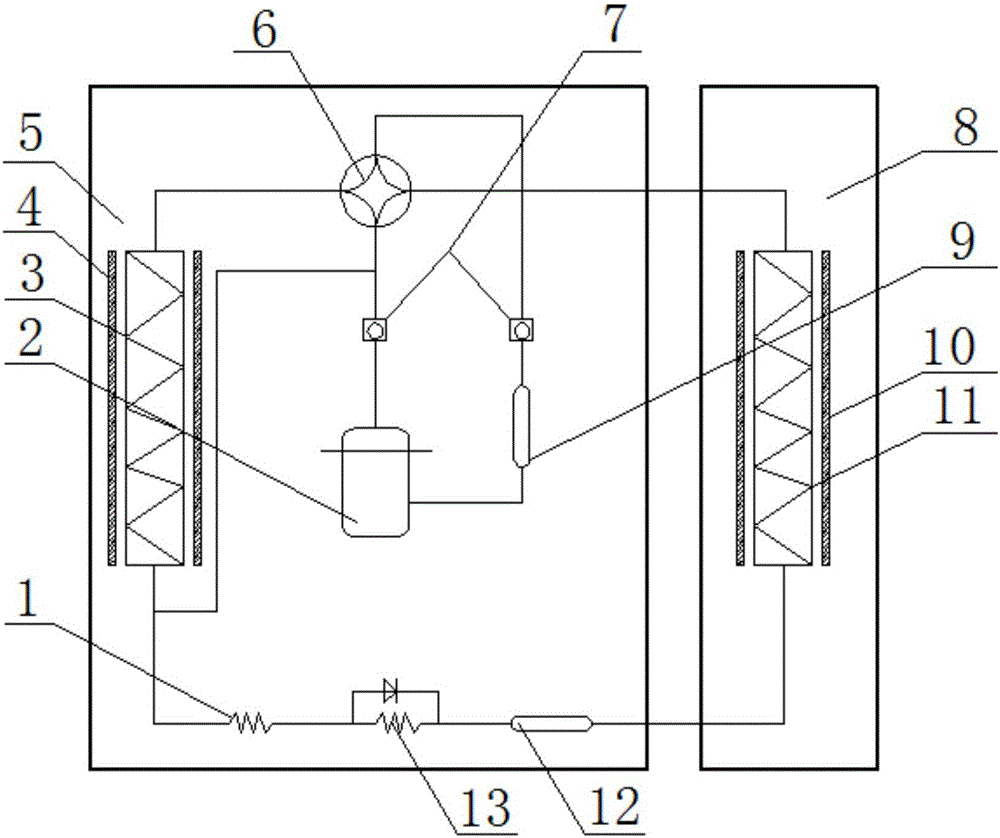

[0025] like figure 1 As shown, the new air conditioner using the ultrasonic oscillator for descaling and defrosting in this embodiment includes an indoor unit 8 and an outdoor unit 5, and the indoor unit 8 and the outdoor unit 5 are connected by pipelines to realize a refrigeration cycle; wherein, the indoor unit 8 It includes an indoor ultrasonic oscillator 10 and an indoor heat exchanger 11. The indoor ultrasonic oscillator 10 is located around the indoor heat exchanger 11. The indoor ultrasonic oscillator 10 is an internal descaling and external defrosting device.

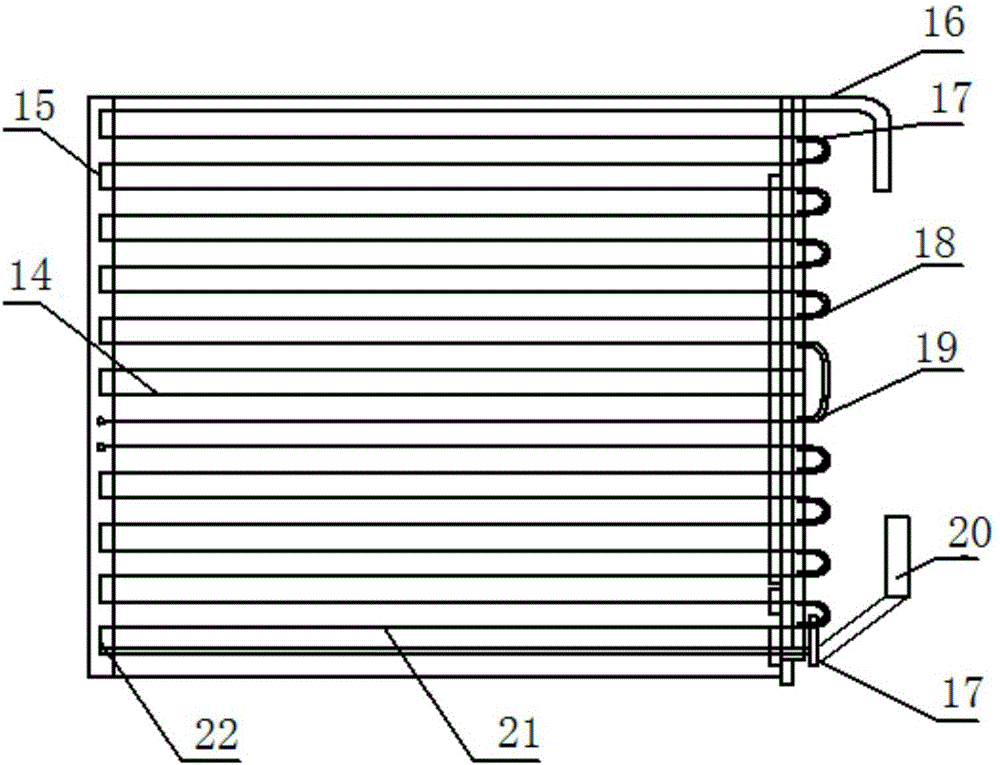

[0026] like figure 2 As shown, the indoor heat exchanger 11 is a shell-and-tube heat exchanger, and the shell-and-tube heat exchanger includes fins 14, U-shaped pipes 15, inlet pipes 16, process strengthening pipes 17, liquid outlet pipes 20 and crossover elbows (big bridging elbow 18 and small bridgi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com