Comprehensive well site measurement and control cabinet

A technology of comprehensive measurement and control and measurement and control cabinets, which is applied in the direction of program control, comprehensive factory control, electrical program control, etc., can solve problems such as large differences in data bandwidth, upper-layer network burden, and impact on communication quality, so as to achieve reasonable internal space layout and improve The effect of improving service life and reliability and communication quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

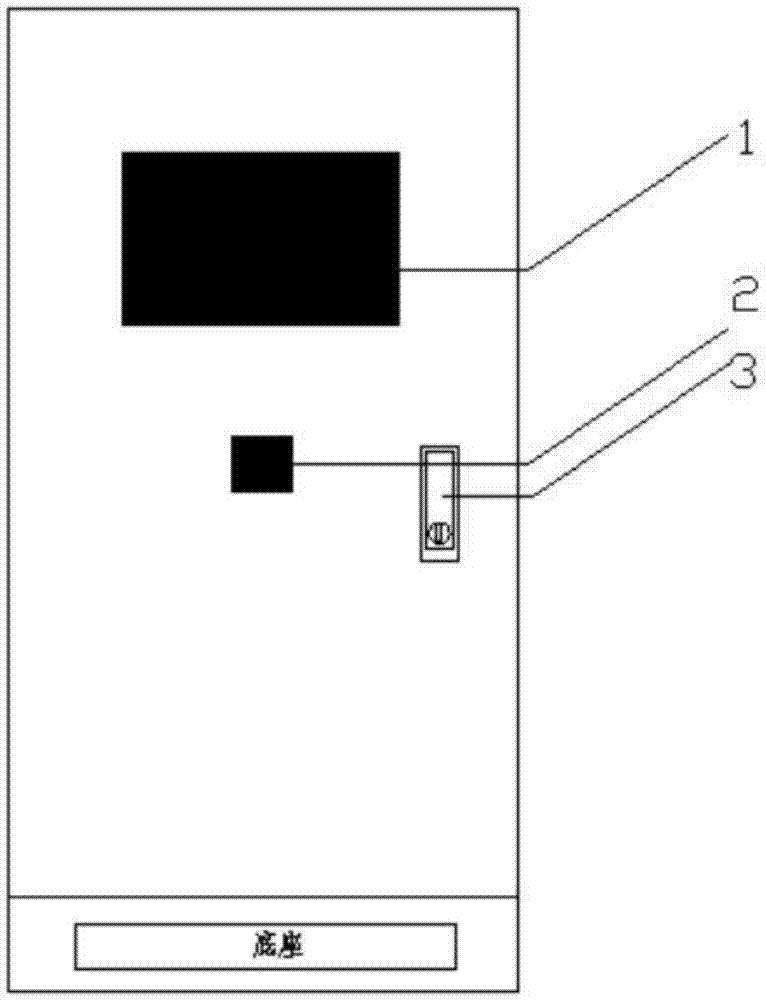

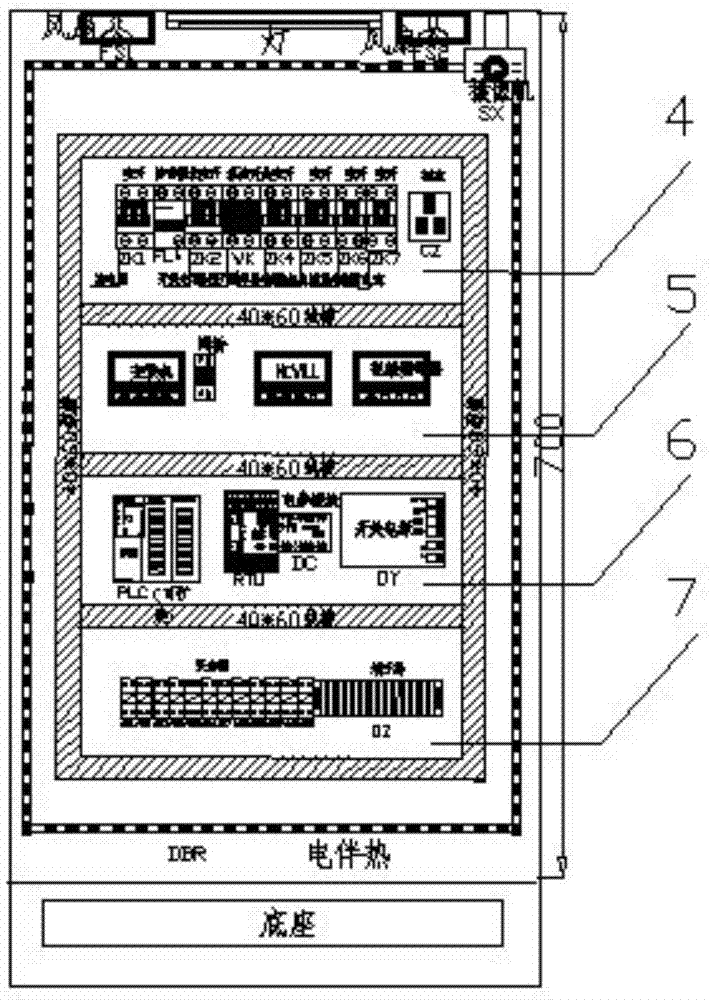

[0020] see figure 1 , a well site comprehensive measurement and control cabinet, the front of the cabinet outer body has a cabinet door, and a 7inch touch screen 1 is arranged on the cabinet door, which can display various parameters of the well site, monitor and capture records, and at the same time monitor the RTU, PLC Parameters can be modified on site (encryption authority is set), and the operation status of each equipment in the cabinet and the ambient temperature in the cabinet can be displayed in real time; the cabinet door is equipped with a local and remote switch 2, which can start and stop the range hood locally or remotely; the cabinet door There is an anti-theft safety lock 3 on the top, using a special key, and the key hole has a lock cover, which can realize a simple anti-theft function; the joint between the cabinet door and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com