Patents

Literature

84results about How to "Small temperature fluctuation range" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Refrigerator and its temperature control method

ActiveCN102589232AImprove practicalityAccurate temperatureLighting and heating apparatusDomestic refrigeratorsTemperature controlFood storage

The invention discloses a refrigerator and its temperature control method. The method comprises the following steps: detecting the current temperature of a variable-temperature chamber; judging whether a difference between a shutdown temperature of the variable-temperature chamber and the current temperature is not lower than a first difference temperature; if yes, detecting an ambient temperature of the refrigerator, and judging whether the ambient temperature is not higher than a preset ambient temperature; and if yes, controlling a temperature compensation heater in a first preset mode to heat the variable-temperature chamber, otherwise controlling the temperature compensation heater to operate in a second preset mode. The refrigerator temperature control method of the inventive embodiment can precisely control the temperature compensation heater to carry out temperature micro-adjustment on the variable-temperature chamber in different modes when the set temperature of the variable-temperature chamber is relatively high (usually used for a refrigerating chamber), to make the temperature of the variable-temperature chamber quickly reach the set temperature, and has advantage of high control accuracy, thus contributing to food storage in the variable-temperature chamber and improving practicability of the refrigerator.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD +1

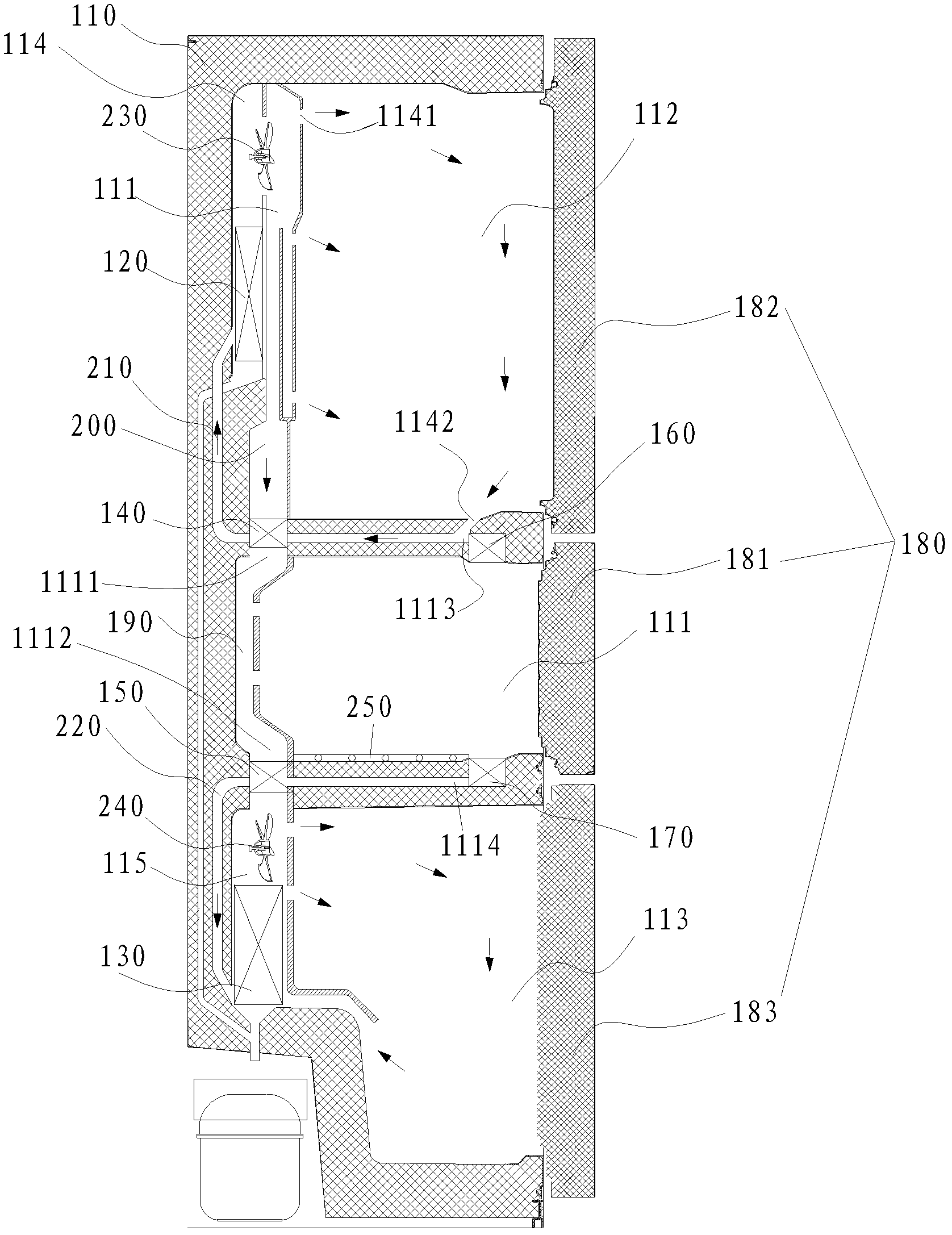

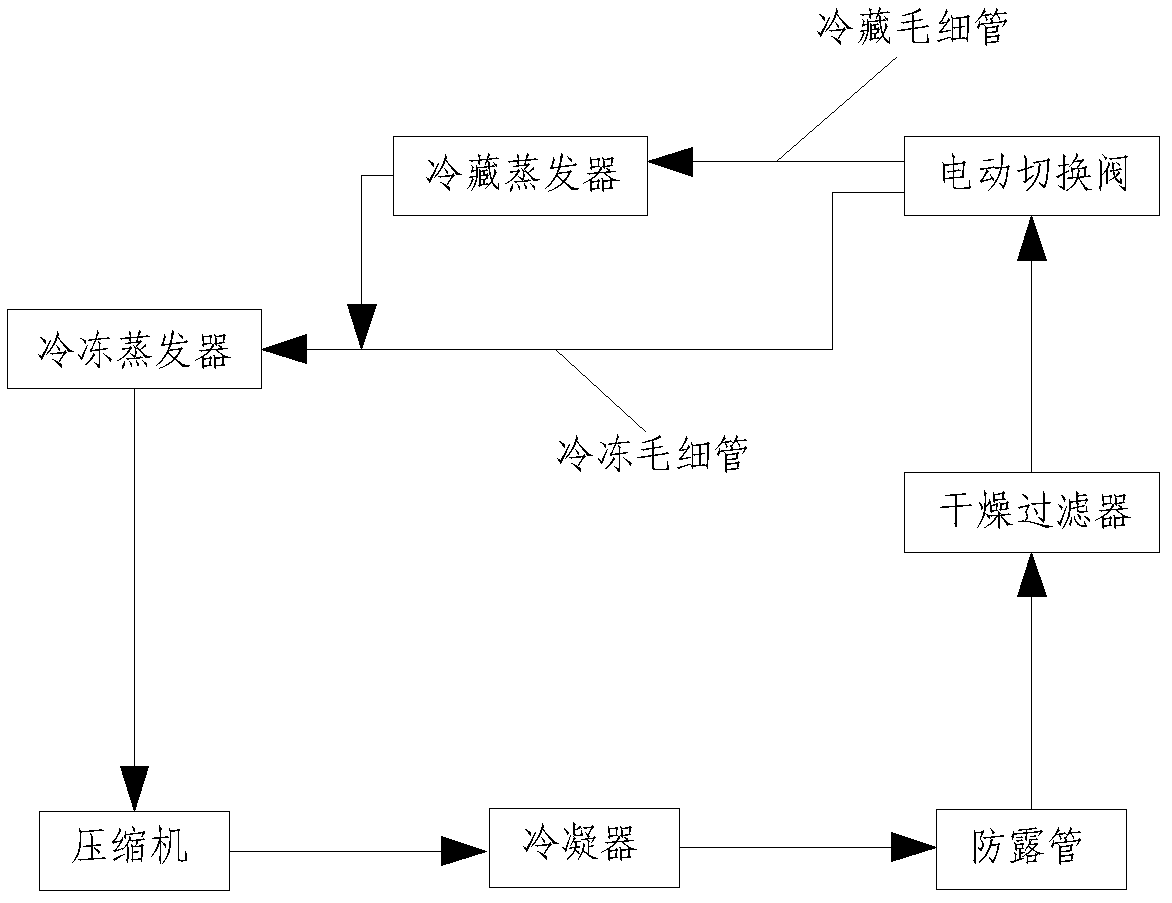

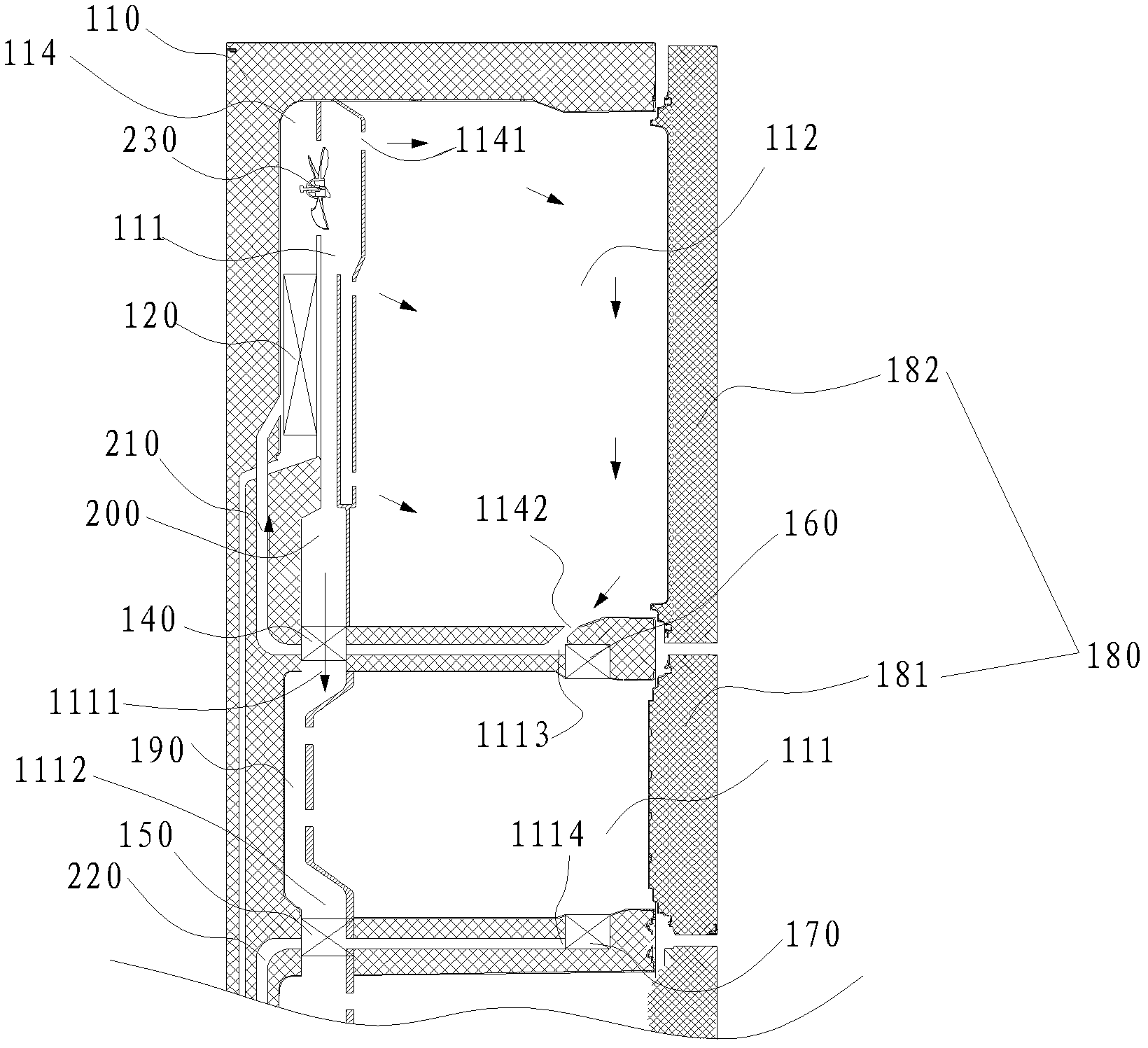

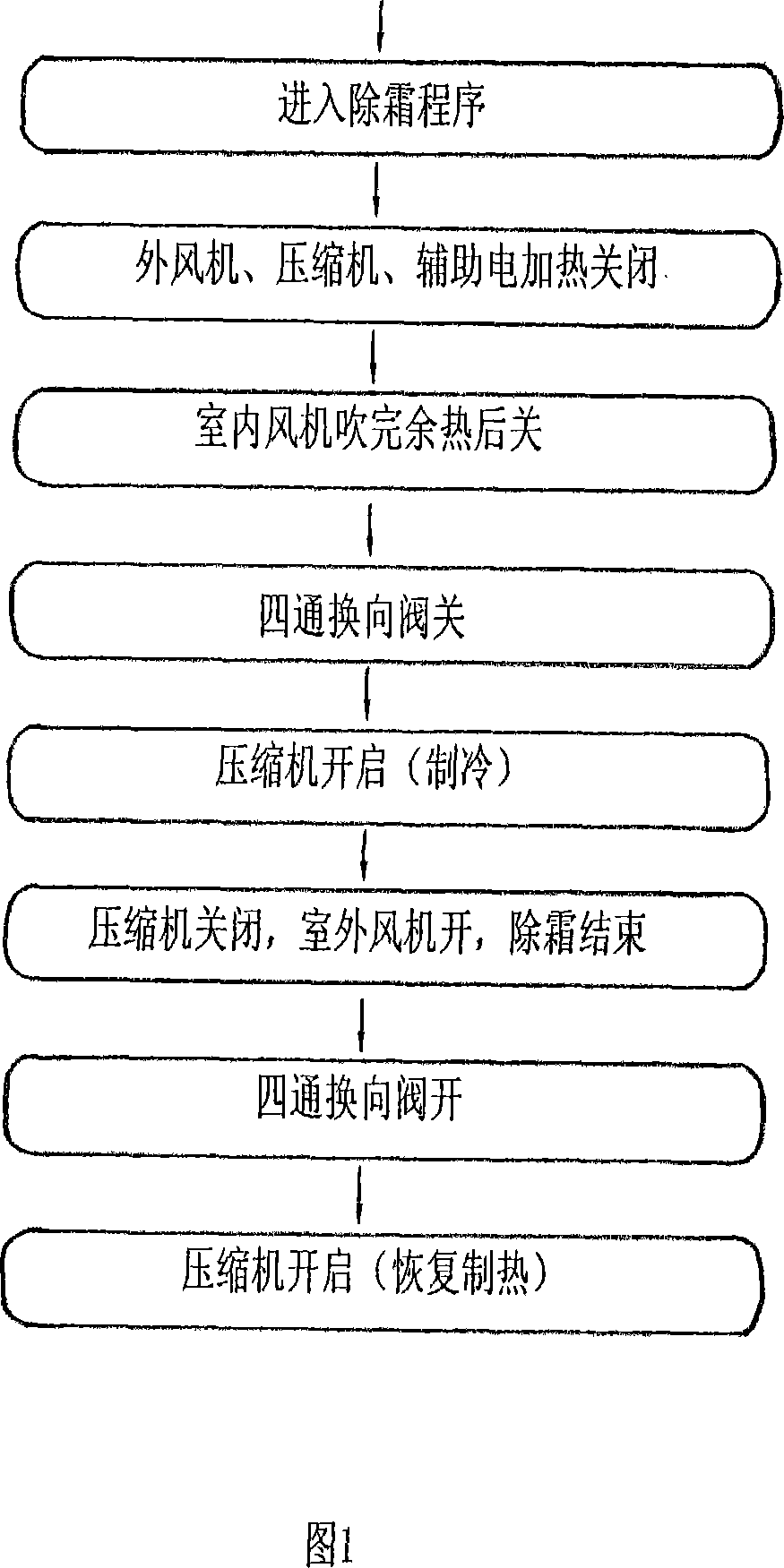

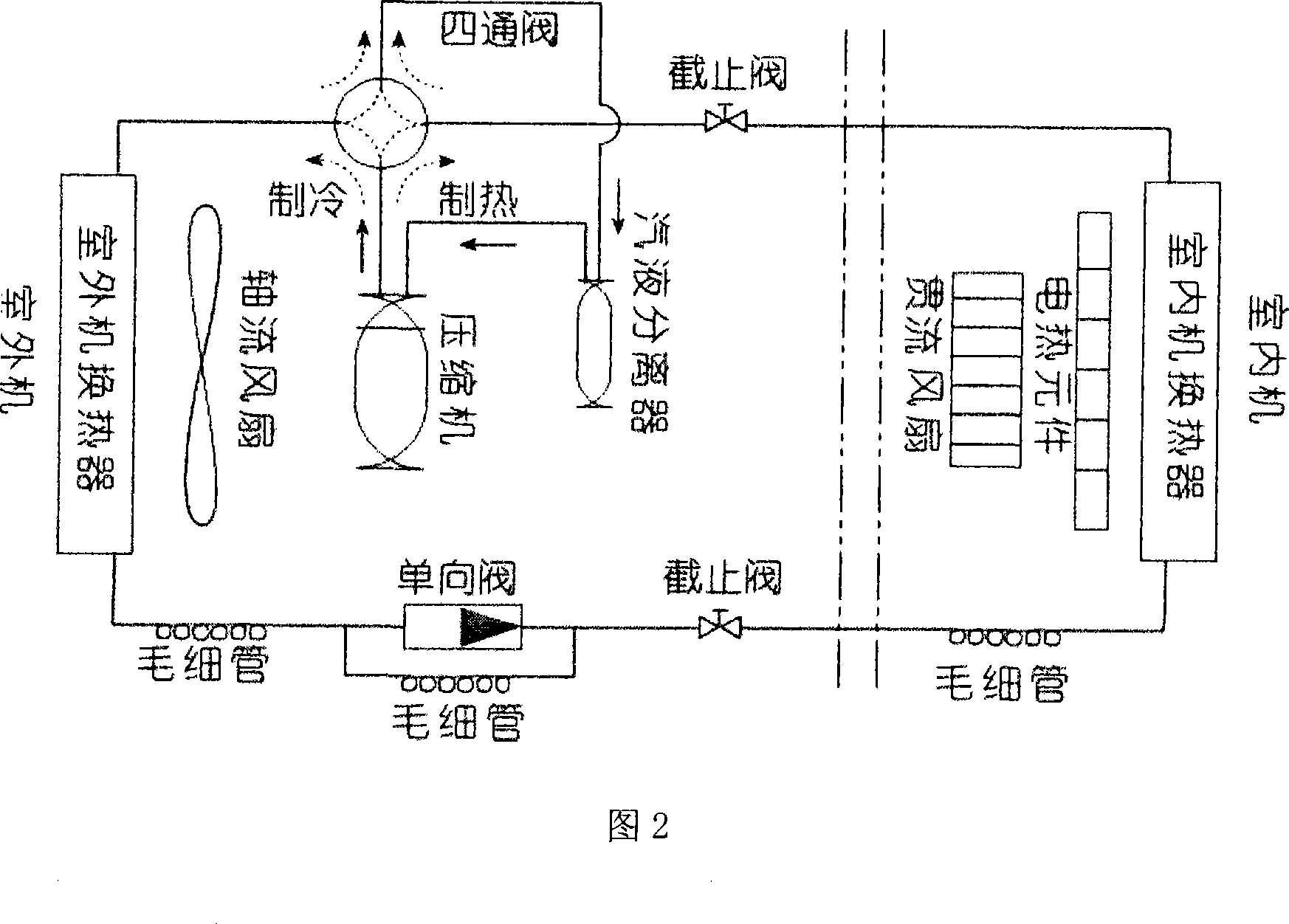

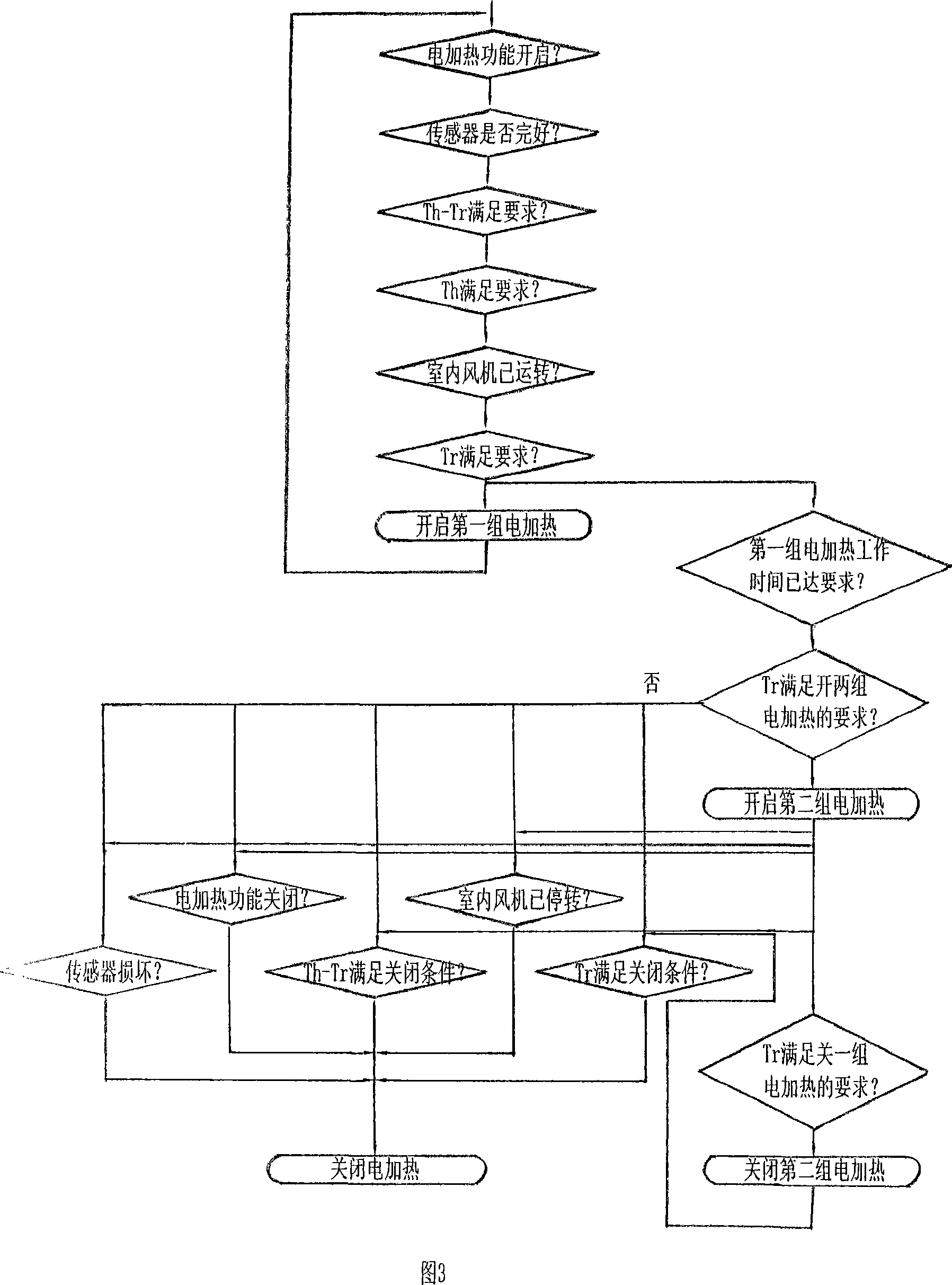

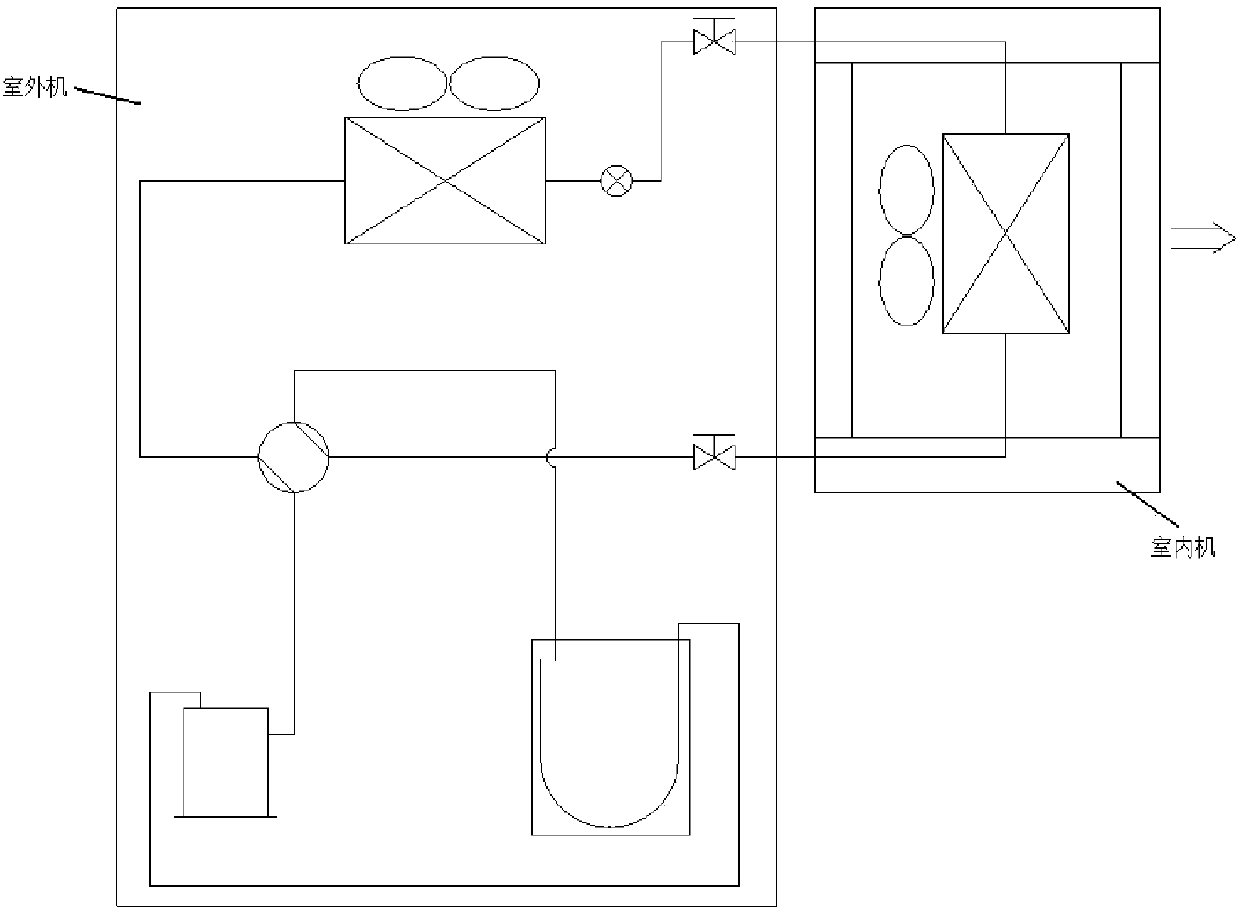

Strong heat air conditioner and defrosting method thereof

ActiveCN101067504ASmall fluctuationRaise the suction temperatureSpace heating and ventilation safety systemsSpace heating and ventilation control systemsLow speedAir conditioning

The heat-flash air conditioning and its method of defrosting and it is in characterized in that: in the indoor machine sets up a big power secondary electric hot device and the big power secondary electric hot device's electric heat power is 0.9 to 1.4 times to the system's standard cooling quantity. When it is defrosting keep the indoor cross flow flan running in low speed and at the same time open the big power secondary electric hot device with the circulate system in the work condition of cooling. The invention can make the heating quantity of system reached two times or more to the cooling quantity so it is satisfied the small cooling quantity and big heating quantity of the setting requirement of system especially it is suited to the southwest area with the lower temperature and the bigger moisture. During the process of defrosting the fluctuation of environment's temperature is small and the time of defrosting is shorter and the defrosting is more clearly and thoroughly.

Owner:CHINA YANGZI GRP CHUZHOU YANGZI AIR CONDITIONERCO

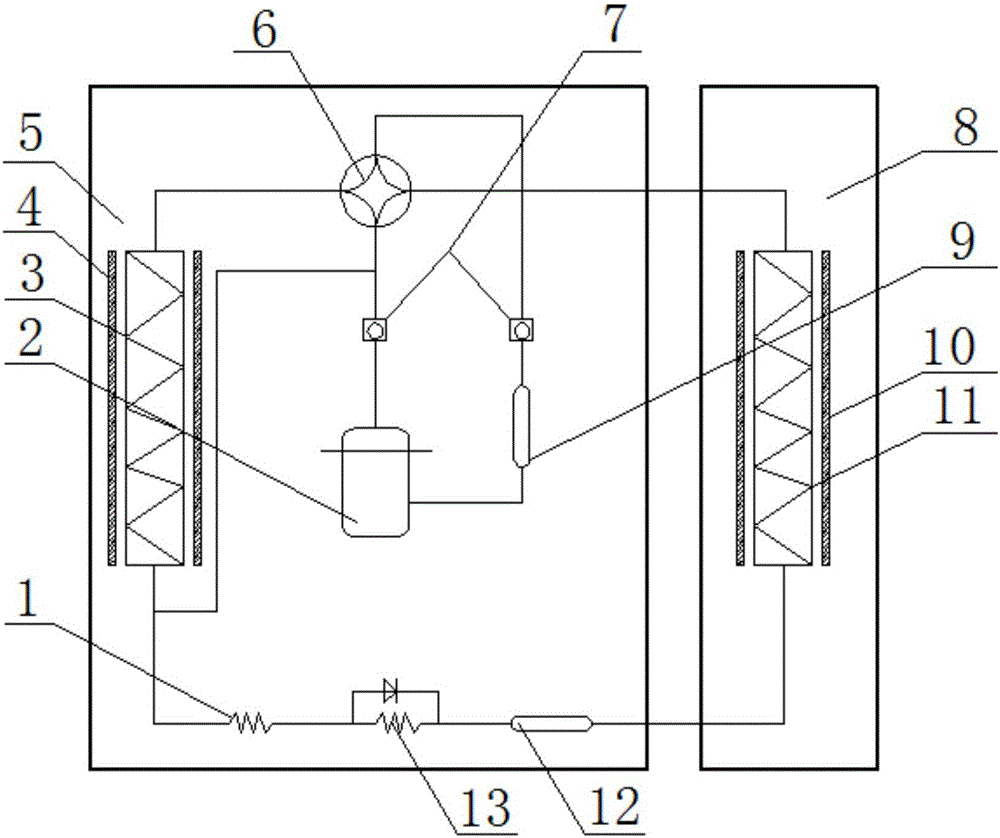

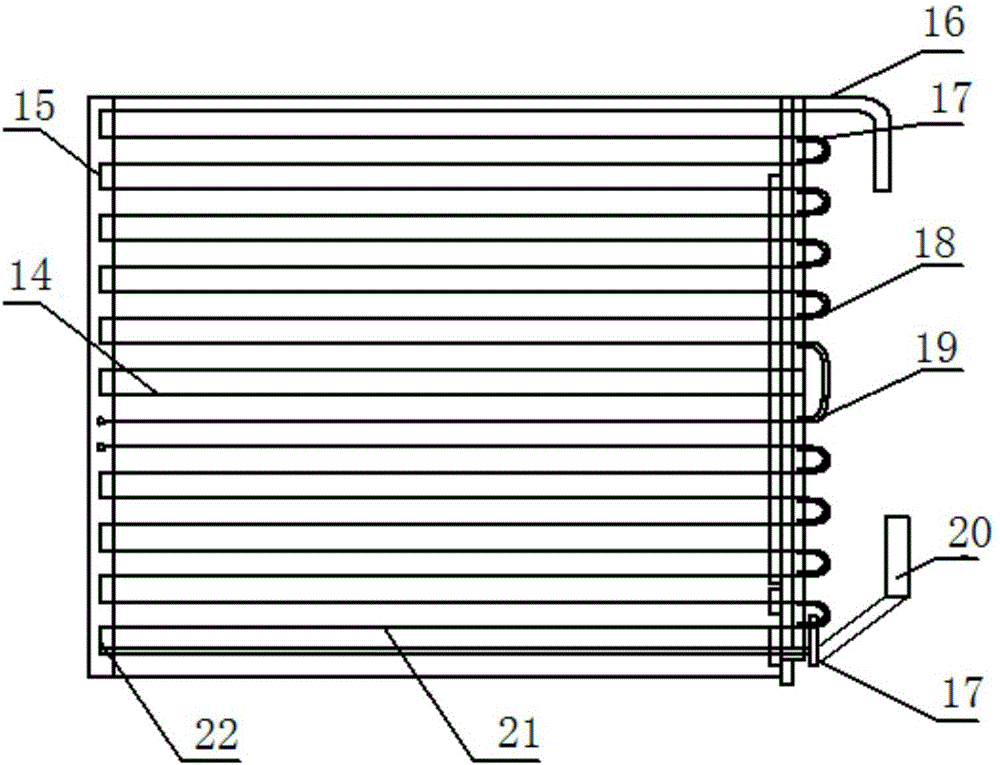

Internal descaling and external defrosting novel air conditioner applying ultrasonic oscillators

InactiveCN105890050AStable operating environmentExtended service lifeMechanical apparatusNoise suppressionVapor–liquid separatorShell and tube heat exchanger

The invention provides an internal descaling and external defrosting novel air conditioner applying ultrasonic oscillators. The internal descaling and external defrosting novel air conditioner comprises an outdoor unit and an indoor unit. The outdoor unit and the indoor unit are connected through a pipeline. The indoor unit comprises the indoor ultrasonic oscillators and an indoor heat exchanger, wherein the indoor ultrasonic oscillators are located around the indoor heat exchanger. The indoor heat exchanger is a shell and tube heat exchanger and comprises fins, U-shaped pipes, an air inlet pipe, process reinforcement tubes, a liquid outlet pipe and bridging elbows. Each U-shaped pipe comprises two free ends extending in the same direction in parallel, and a bent part located between the two free ends, wherein the free ends are inserted in the corresponding fins. Ports of the free ends of every two adjacent U-shaped pipes are connected through the corresponding bridging elbow. The outdoor unit comprises a capillary tube, a compressor, an outdoor heat exchanger, the outdoor ultrasonic oscillators, a four-way valve, air-liquid separators, a filter and a check valve, wherein the outdoor ultrasonic oscillators are located around the outdoor heat exchanger. By means of the internal descaling and external defrosting novel air conditioner, ultrasonic non-stop on-line internal descaling and external defrosting can be achieved, the stable running environment of the air conditioner is ensured, and the service life is prolonged.

Owner:NANJING NORMAL UNIVERSITY

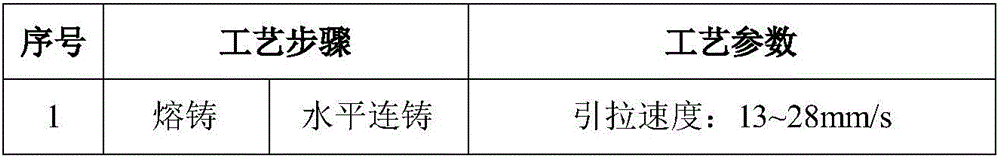

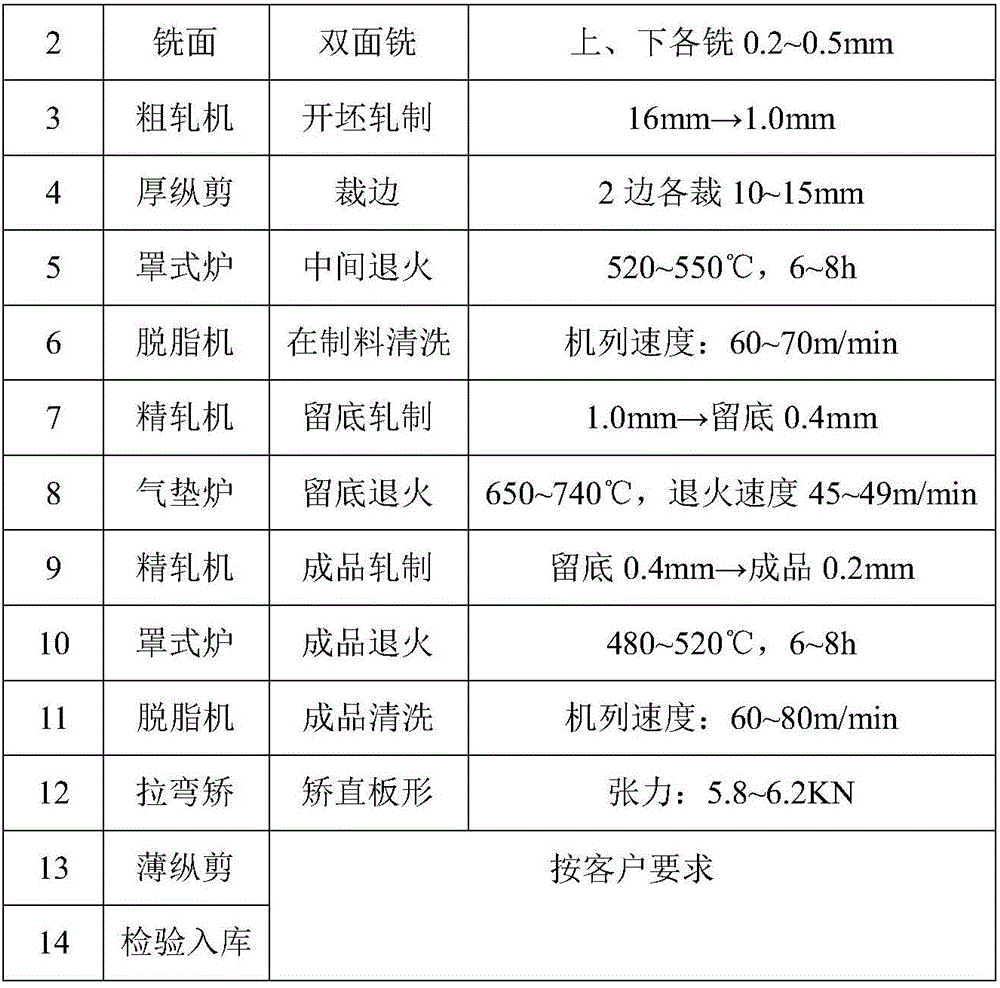

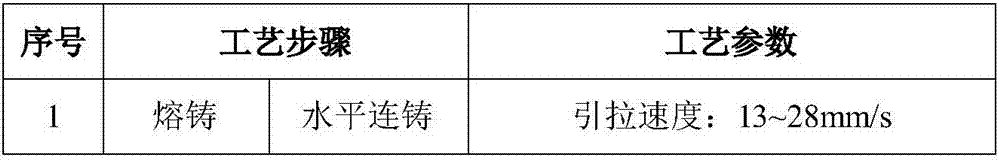

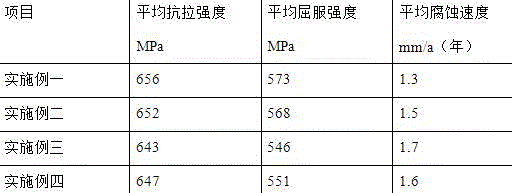

High-performance tin-phosphor bronze strip and production method thereof

The invention discloses a high-performance tin-phosphor bronze strip and a production method thereof. The high-performance tin-phosphor bronze strip comprises, by weight percent, 9% to 11% of Sn, 0.03% to 0.35% of P, not larger than 0.2% of Zn, not larger than 0.1% of Fe, not larger than 0.2% of Pb and the balance copper. Through the strict control over a casting technology, a rolling technology and an annealing technology of a tin-phosphor bronze alloy, a high-performance tin-phosphor bronze strip alloy product with the tin content ranging from 9% to 11% can be produced, and the application requirement of an IT industry and an electrommunication industry for a high-elasticity, high-strength and high-hardness copper alloy can be met.

Owner:安徽鑫科铜业有限公司

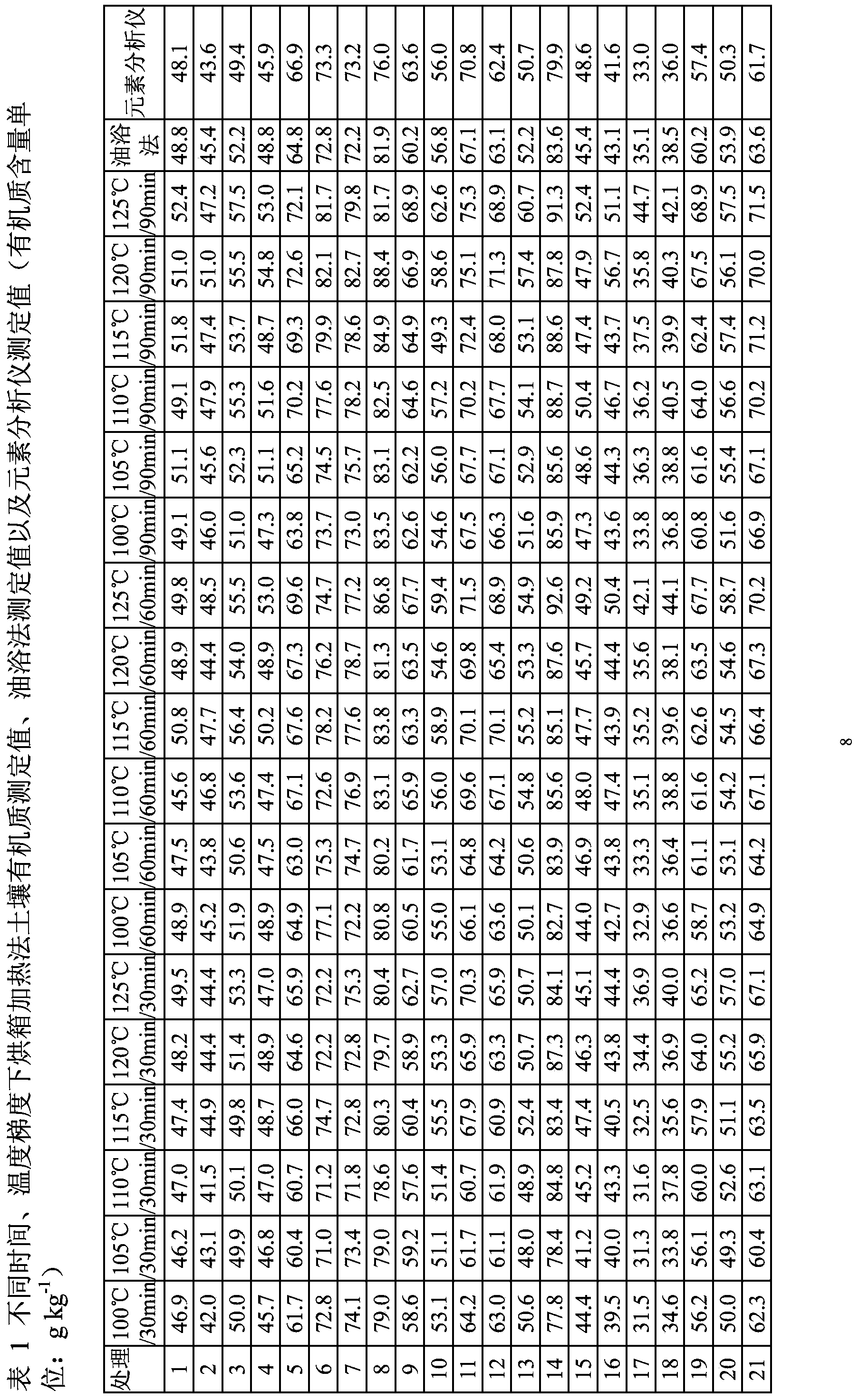

Method for determining organic matters in soil

InactiveCN104280512AHeating evenlySmall temperature fluctuation rangeChemical analysis using titrationSoil organic matterHeating time

Owner:SHENYANG INST OF APPLIED ECOLOGY - CHINESE ACAD OF SCI

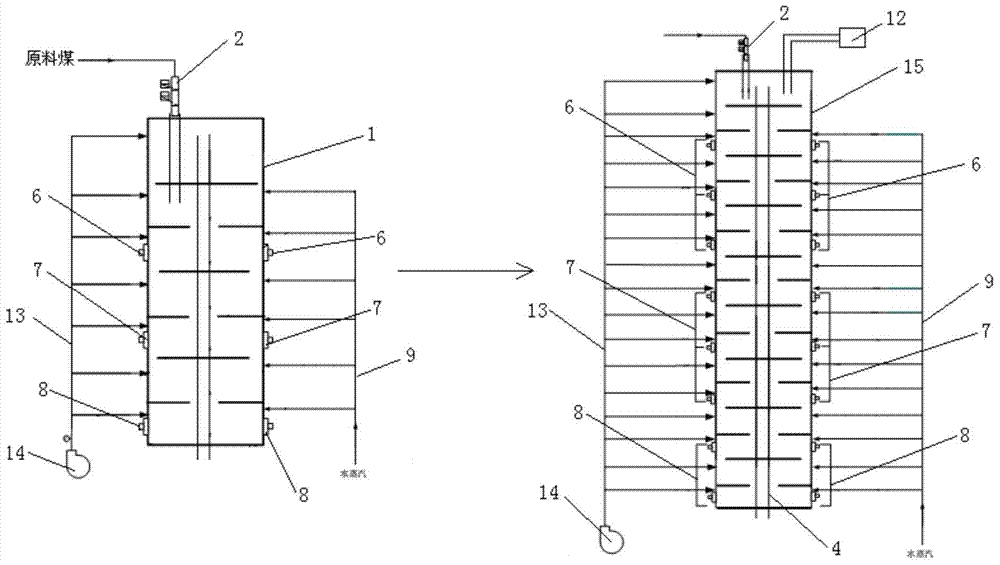

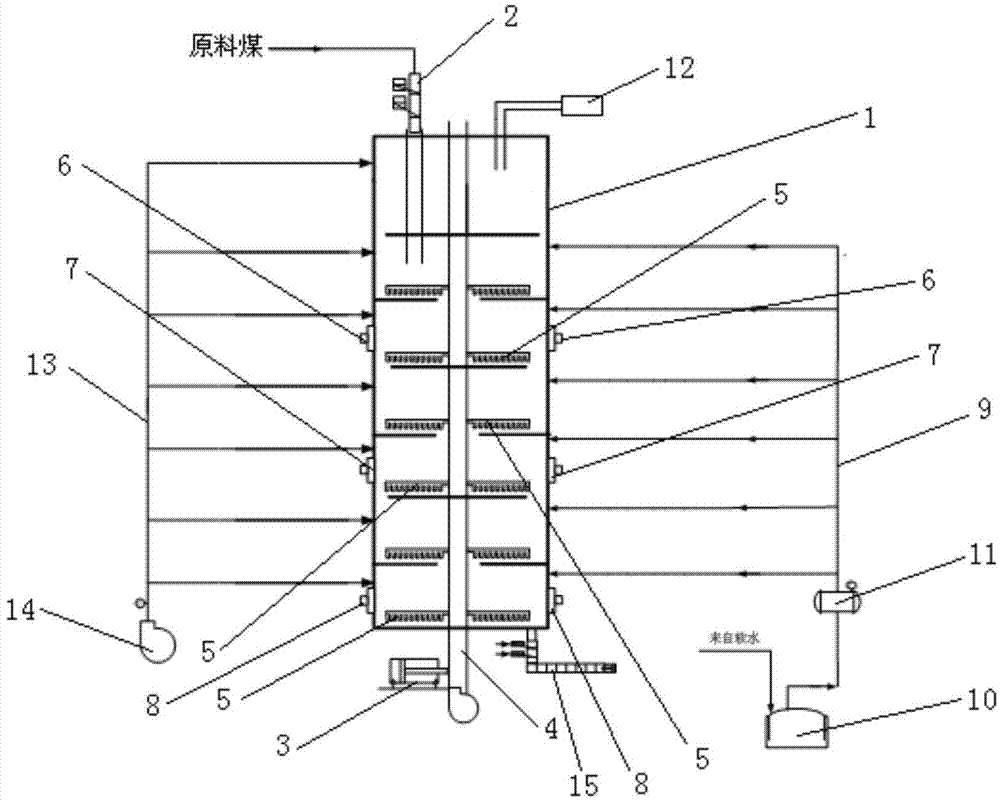

Method for preparing active carbon by using multi-hearth furnace

InactiveCN104773731AReduce consumptionSmall temperature fluctuation rangeCarbon compoundsActivated carbonGas solid

The invention relates to a method for preparing active carbon by using a multi-hearth furnace. The method comprises the following steps: 1) inputting a raw material from the feeding end on the top of the multi-hearth furnace into the multi-hearth furnace; 2) starting a combustor in the bottom of the multi-hearth furnace to heat the raw material, wherein the temperature of the raw material in the furnace layer in the bottom of the multi-hearth furnace is raised to be not less than 600 DEG C in the first place to reach an activating temperature; 3) introducing water vapor into the multi-hearth furnace, wherein the raw material reaching the activating temperature and water vapor which are overturned by virtue of a rabble blade are uniformly contacted to carry out gas-solid heterogeneous activating reaction to generate combustible gases H2 and CO; 4) generating a negative pressure by using an induced draft fan to control the flowing directions of H2 and CO, wherein the H2 and CO move upward from the bottom of the multi-hearth furnace; 5) injecting air into the multi-hearth furnace, wherein exothermic reaction is carried out on H2 and CO and oxygen in air, and released heat is taken as heat required for carrying out gas-solid heterogeneous activating reaction on the raw material and water vapor; and 6) forming active carbon after activating reaction of the raw material, wherein the active carbon is discharged from a discharge opening in the bottom of the multi-hearth furnace. The method provided by the invention can be widely applied to processes for preparing active carbon.

Owner:CCTEG CHINA COAL RES INST

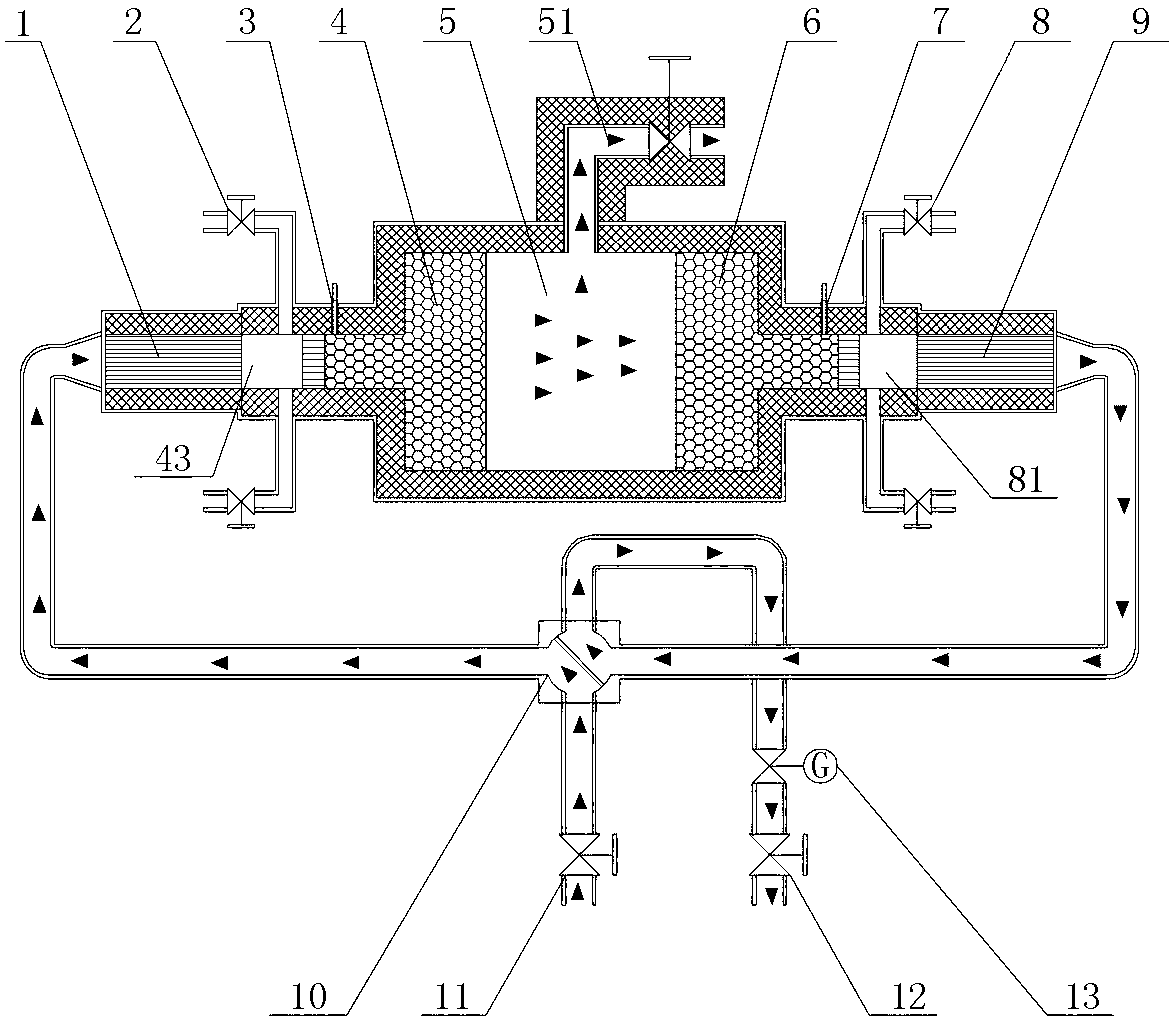

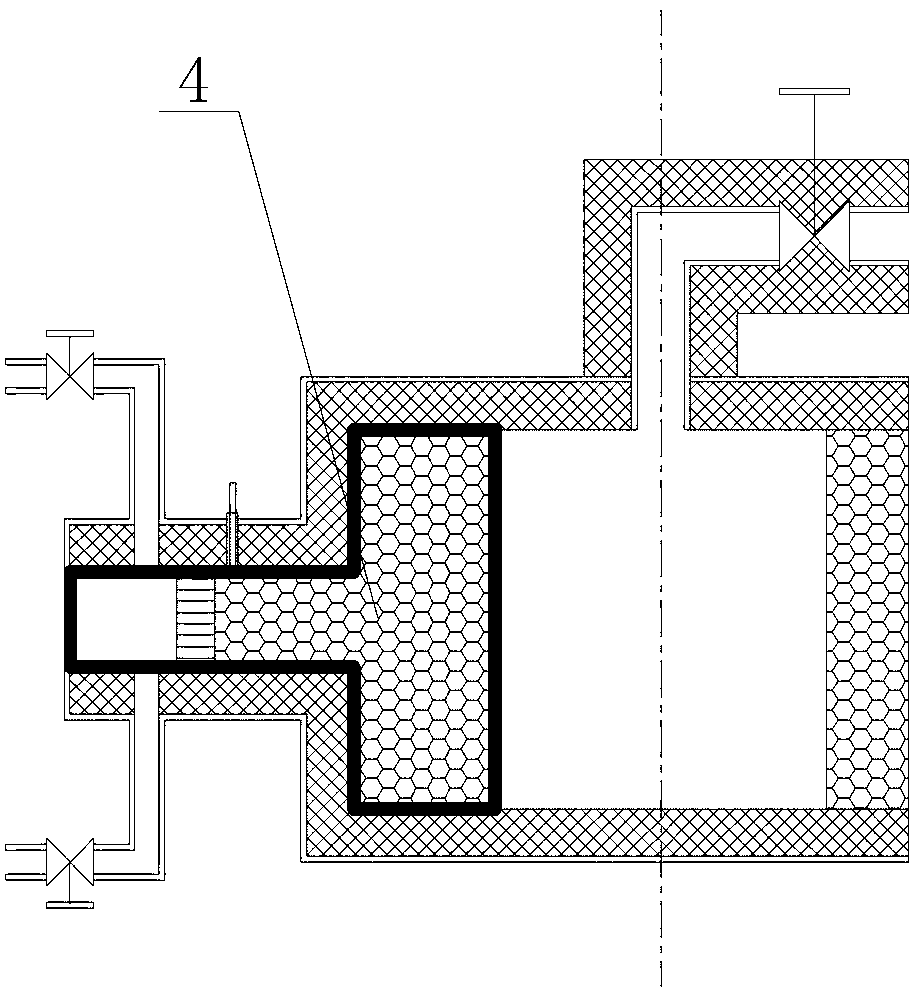

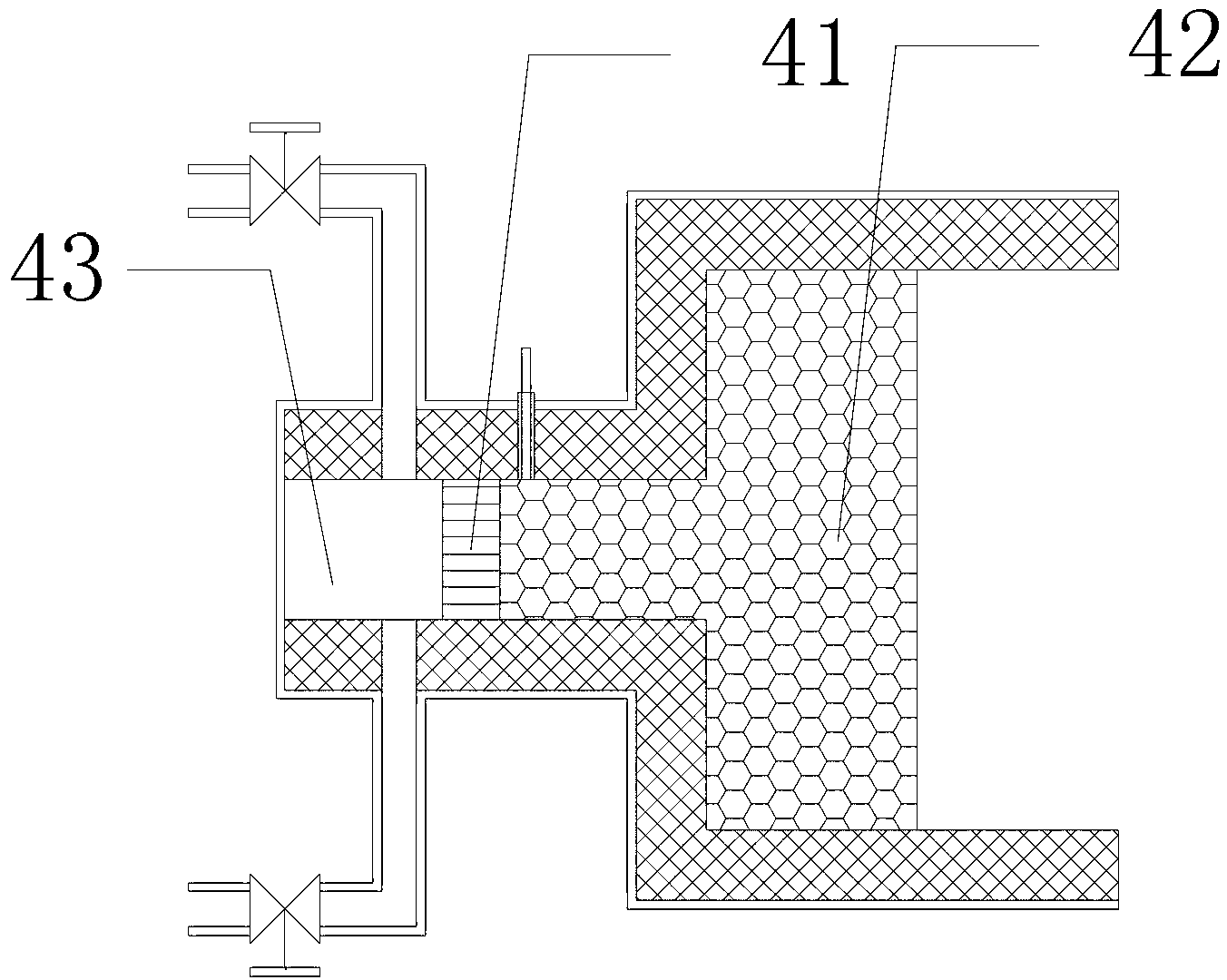

High-temperature gas generating device on basis of porous medium combustion and heat storage

InactiveCN103062770AEmission reductionStable generationIndirect carbon-dioxide mitigationGaseous fuel burnerCombustion chamberCombustor

The invention discloses a high-temperature gas generating device on the basis of porous medium combustion and heat storage. The high-temperature gas generating device comprises a first porous medium heat storage chamber, a first porous medium combustion chamber, a high-temperature flue gas distribution chamber, a second porous medium combustion chamber and a second porous medium heat storage chamber which are sequentially communicated with one another; the first porous medium heat storage chamber is communicated with the second porous medium heat storage chamber by a four-way reversing valve, and other two ports of the four-way reversing valve are respectively connected with an air pipeline and a low-temperature flue gas pipeline; the first porous medium combustion chamber and the second porous medium combustion chamber are respectively connected with a first fuel gas pipeline and a second fuel gas pipeline; and a high-temperature flue gas pipeline is arranged on the high-temperature flue gas distribution chamber. The high-temperature gas generating device is additionally provided with a porous medium combustor on the basis of a heat storage combustor, gas such as gas of coal mines and industrial exit gas with a low heat value can be combusted to generate high-temperature gas, fuel gas can be directly filled into the combustion chambers without being premixed, and accordingly the high-temperature gas generating device is high in safety.

Owner:ZHEJIANG UNIV

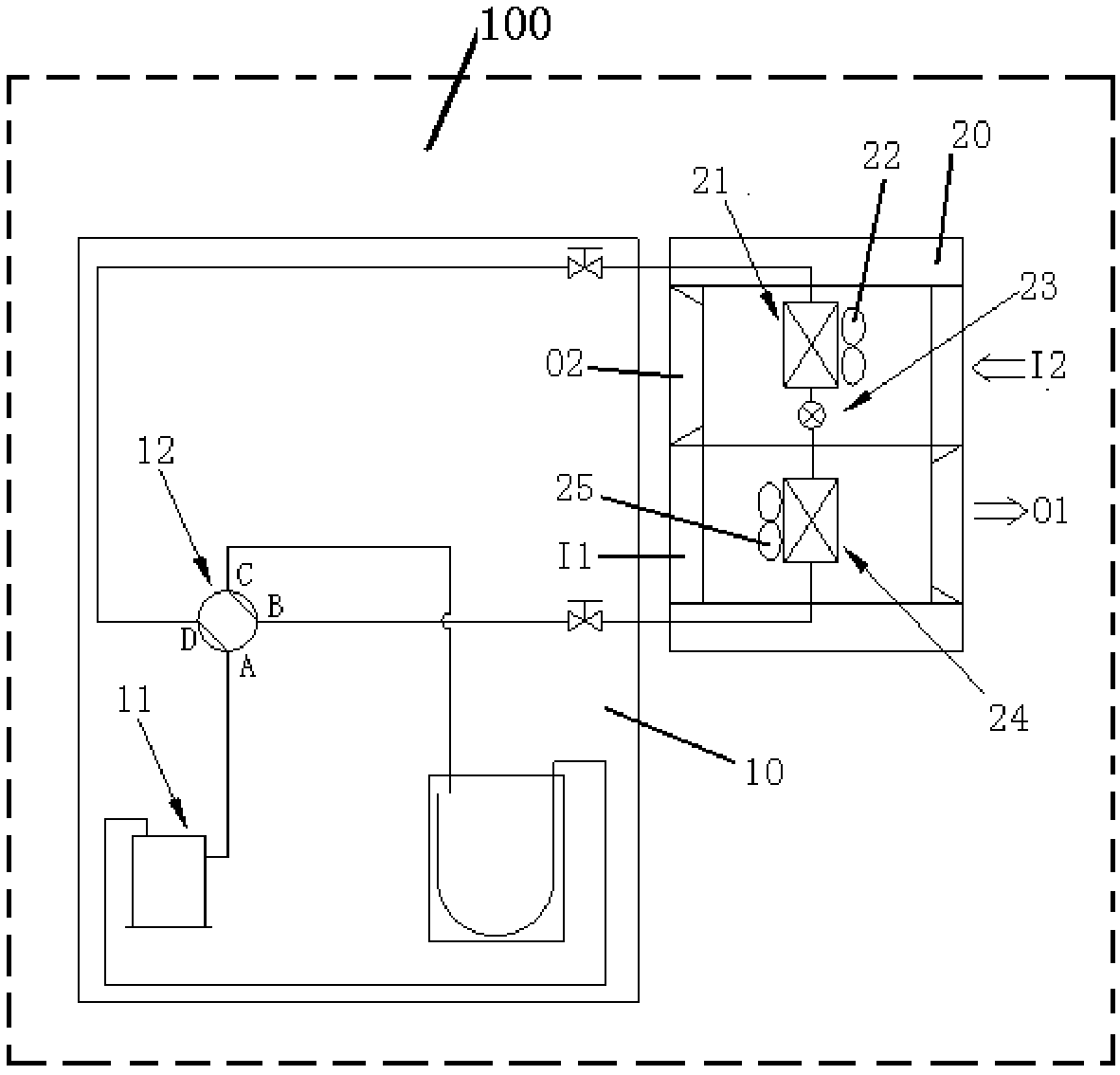

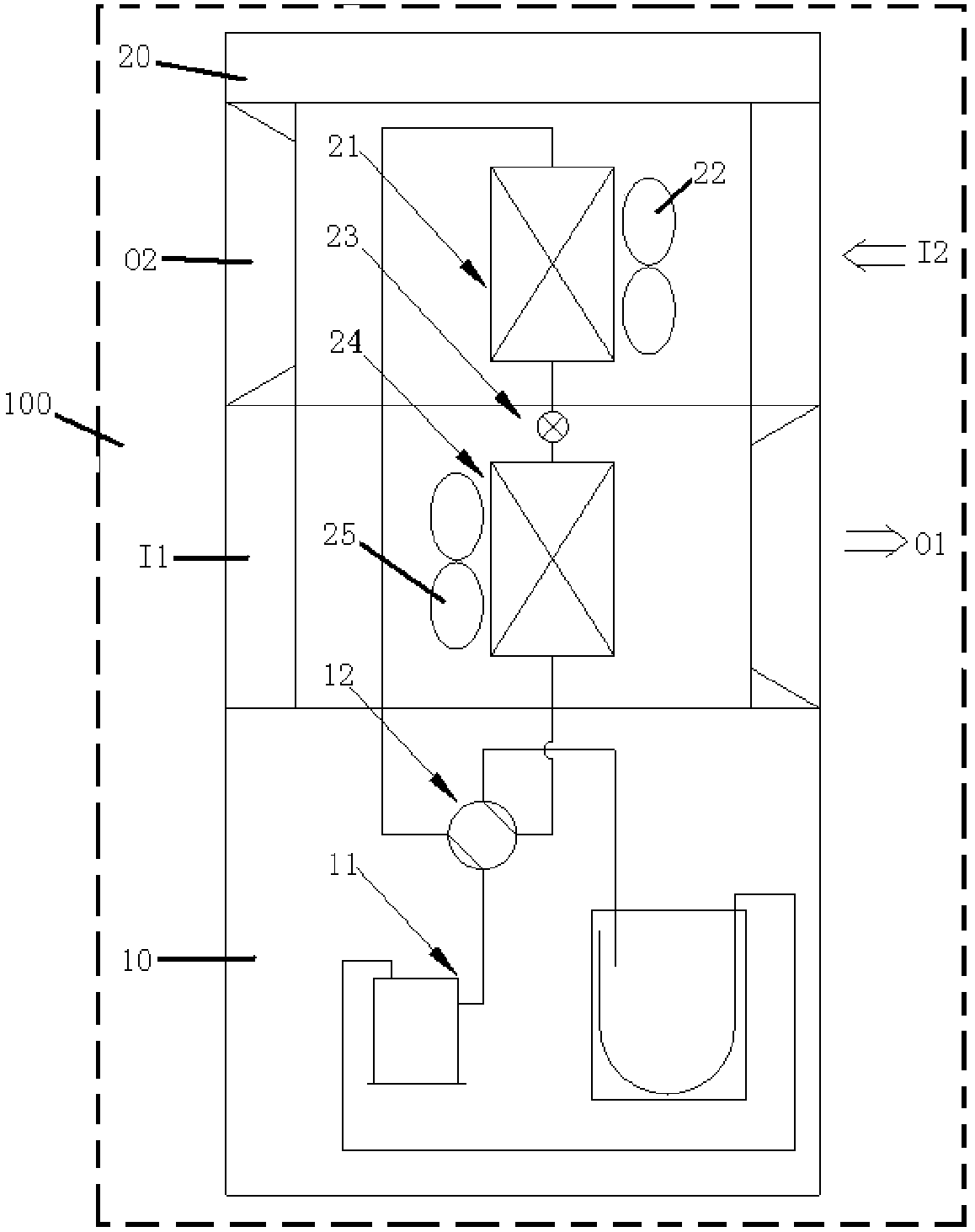

Fresh air system and control method thereof

ActiveCN107559956AHigh power saving efficiencyReduce seasonal energy consumptionMechanical apparatusLighting and heating apparatusFour-way valveEngineering

The invention discloses a fresh air system and a control method thereof. The fresh air system comprises a refrigerant conveying device, an indoor unit and a controller. The refrigerant conveying device comprises a compressor and a four-way valve. The indoor unit comprises a fresh air inlet, a fresh air outlet, an exhaust air inlet, an exhaust air outlet, a first heat exchanger, an exhaust fan, a throttling device, a second heat exchanger and a forced draught fan, wherein one end of the throttling device is connected with one end of the first heat exchanger, and the other end of the throttlingdevice is connected with one end of the second heat exchanger. The controller controls the exhaust fan, the forced draught fan, the compressor and the four-way valve according to a selected operationmode and set target parameters, outdoor fresh air entering the system from the fresh air inlet flows through the second heat exchanger and the forced draught fan to be fed into a room through the fresh air outlet, and indoor air entering the system from the exhaust air inlet flows through the first heat exchanger and the exhaust fan to be exhausted out of the room through the exhaust air outlet. The fresh air efficiency can be improved, energy consumption is reduced, and the using seasons of the system are extended.

Owner:GD MIDEA HEATING & VENTILATING EQUIP CO LTD +1

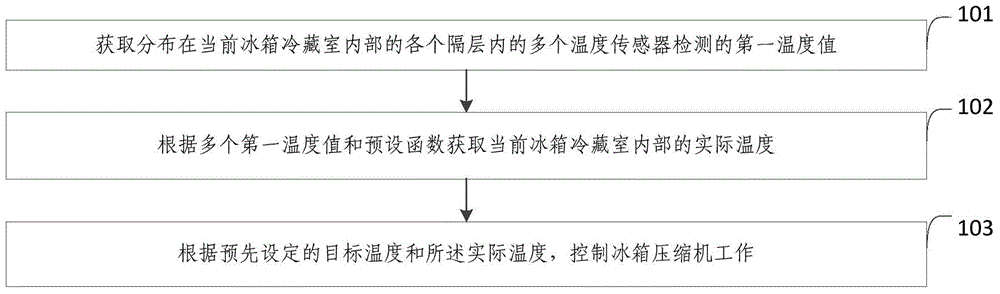

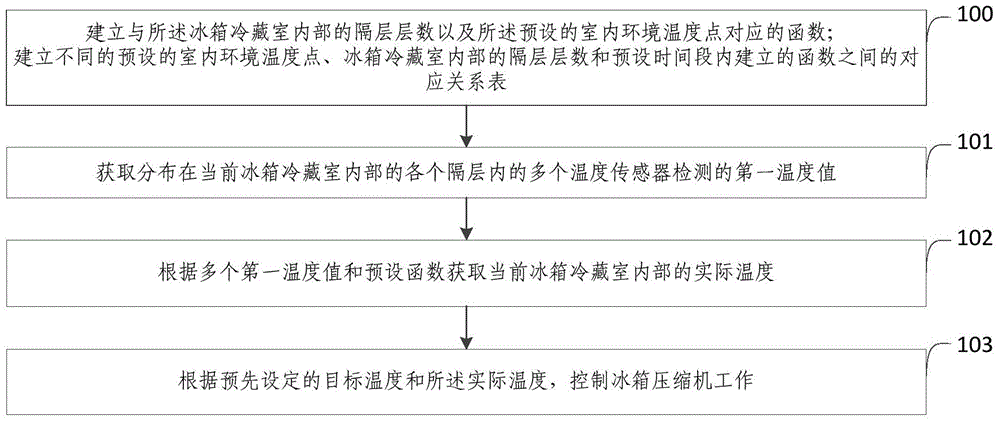

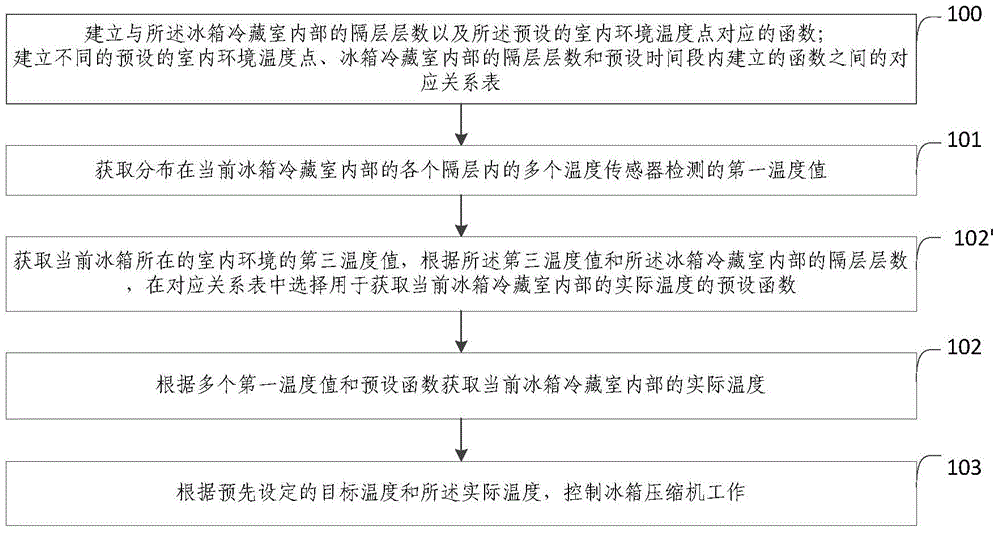

Refrigerator temperature control method, controller and refrigerator

ActiveCN105043004AHigh temperature control accuracySmall temperature fluctuation rangeDomestic cooling apparatusLighting and heating apparatusTemperature controlRefrigerator car

The invention provides a refrigerator temperature control method, a controller and a refrigerator. The refrigerator temperature control method comprises: acquiring current first temperature values detected by a plurality of temperature sensors distributed in a plurality of partition layers in a refrigerating chamber of the refrigerator; acquiring current actual temperatures in the refrigerating chamber of the refrigerator according to the plurality of first temperature values and preset functions; and controlling the work of a compressor of the refrigerator according to preset target temperatures and the actual temperatures, wherein the preset functions are previously determined according to the number of the partition layers in the refrigerating chamber of the refrigerator and a temperature range of an indoor environment in which the refrigerator is positioned. The refrigerator temperature control method provided by the invention can accurately control the temperature in the refrigerator.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD +1

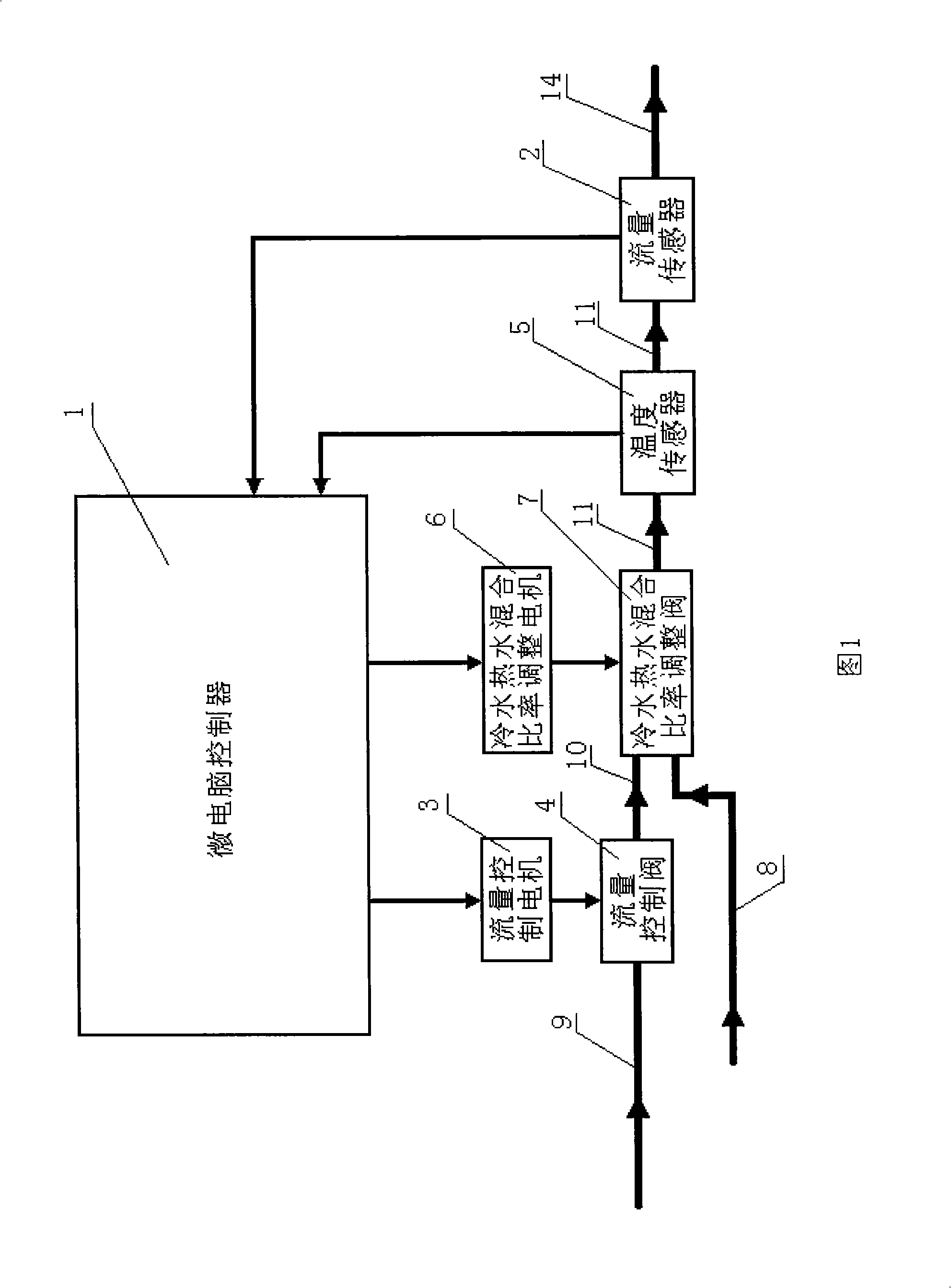

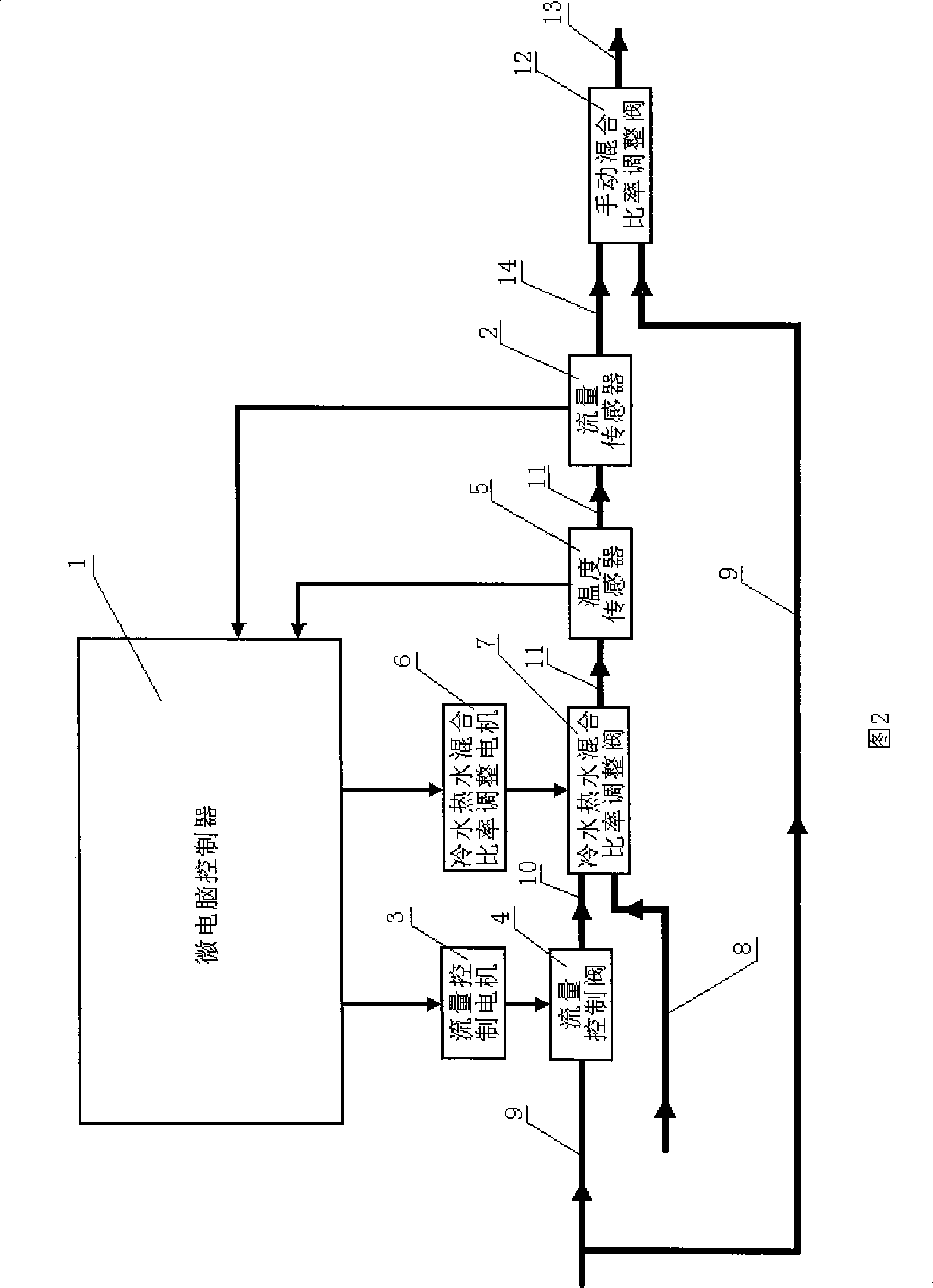

Hot water constant temperature constant-current automatic regulating apparatus

InactiveCN101334189AReduce sensitivitySmall fluctuation rangeLighting and heating apparatusSpace heating and ventilation detailsStreamflowMicrocomputer

The invention relates to an automatic adjusting device of the constant temperature and constant current for hot water, which is suitable for the automatic adjustment of the water temperature and the flow, because the flow can not be controlled by the prior similar products, a certain waste is caused to the resource and the energy. The automatic adjusting device comprises a flow controlling motor, an adjusting motor for the mixing ratio of the cold water and the hot water, a flow sensor, a temperature controlling valve, an adjusting valve for the mixing ratio of the cold water and the hot water and a microcomputer controller. The flow sensor and the temperature sensor are arranged at the mixed water outlet opening part of the cold water and the hot water, according to the electrical signal sent by the flow sensor and the temperature sensor, the microcomputer controller can drive and control the flow controlling motor and the adjusting motor for the mixing ratio of the cold water and the hot water, to drive the valve cores of the flow controlling valve and the adjusting valve for the mixing ratio of the cold water and the hot water, to automatically adjust the flow and the temperature of the hot water, thereby, the purpose of the constant temperature and constant current is achieved, and the consumption of the resource and the energy can be saved.

Owner:韩红桥

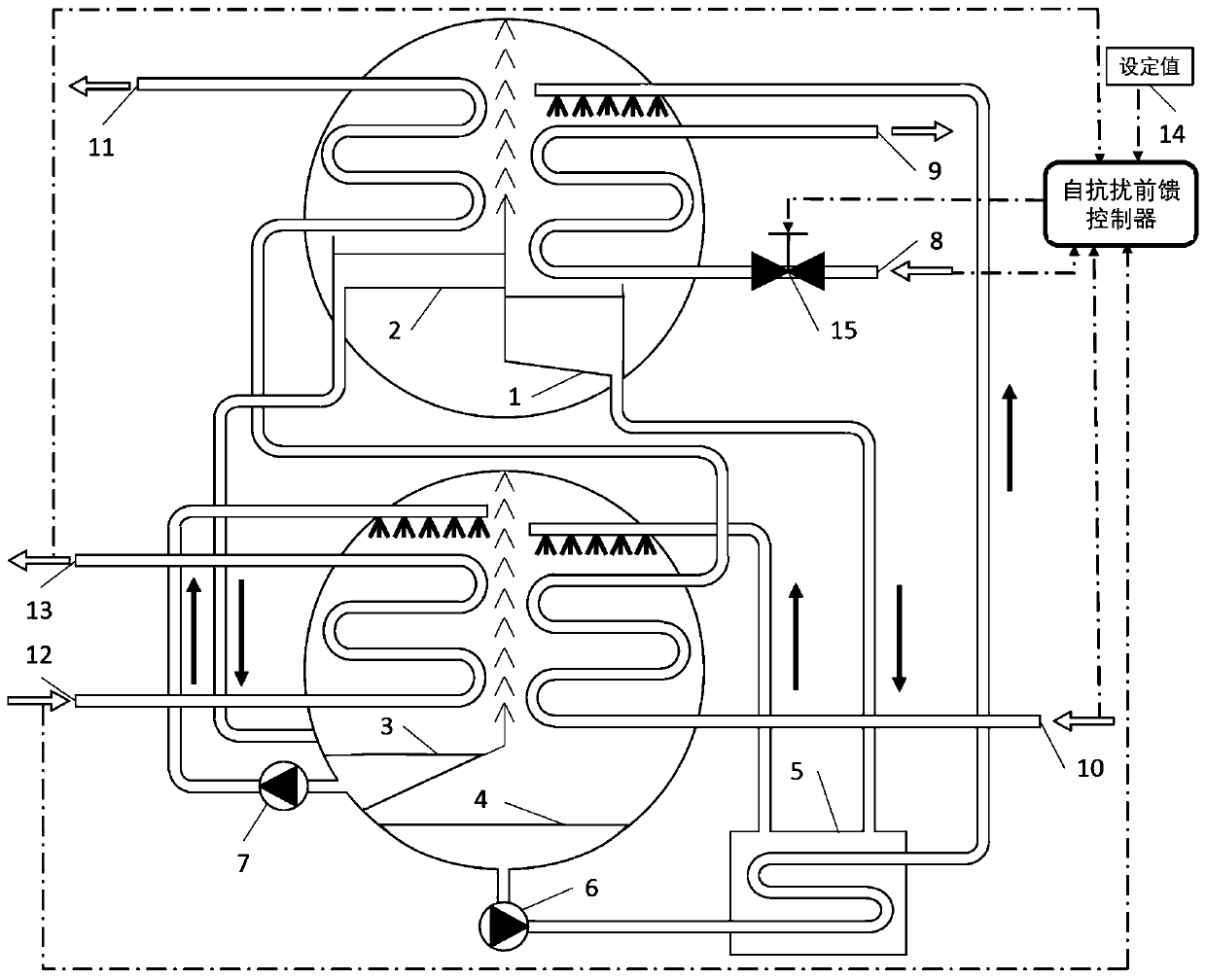

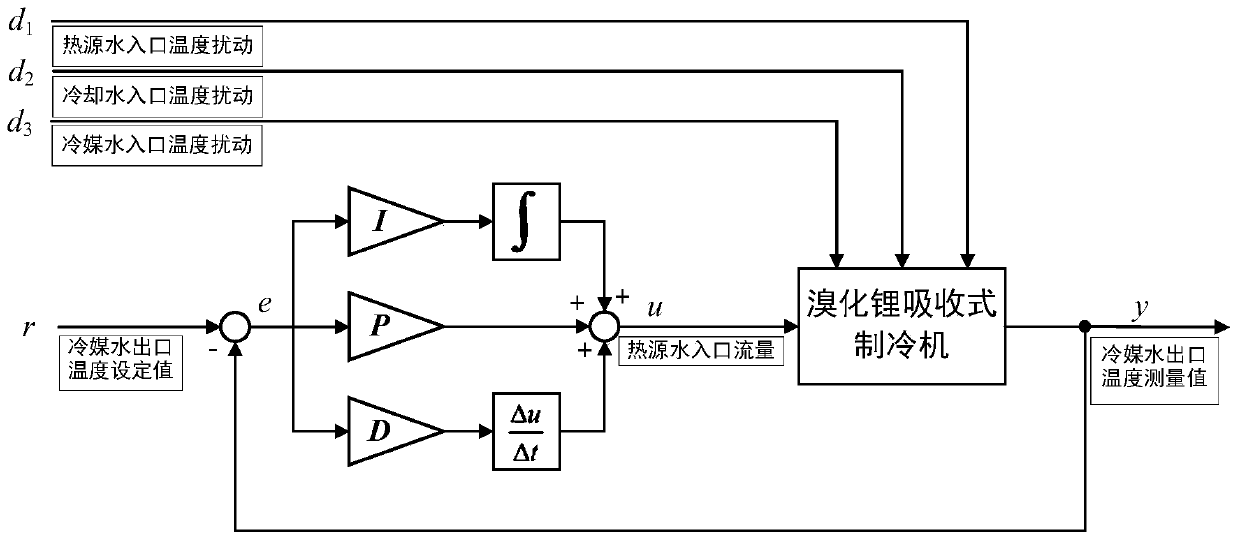

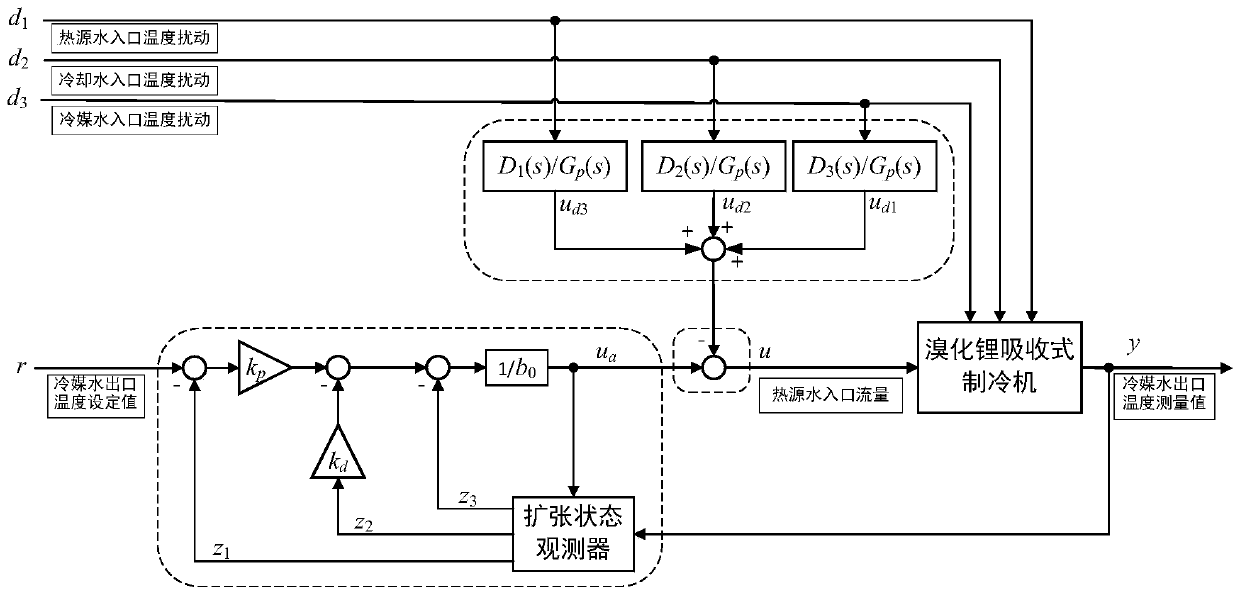

Active disturbance rejection feedforward control method of lithium bromide absorption refrigerator

ActiveCN109858163AReduce complexityReduce workloadRefrigeration safety arrangementSpecial data processing applicationsLithium bromideActive disturbance rejection control

The invention discloses an active disturbance rejection feedforward control method of a lithium bromide absorption refrigerator. According to the method, an object transfer function of the absorptionrefrigerator and a disturbance transfer function from a heat source water inlet temperature, a cooling water inlet temperature and a refrigerant water inlet temperature are obtained through open-loopstep identification; according to the control method, the refrigerant water outlet temperature serves as a controlled variable, the heat source water flow serves as a controlled variable, an auto-disturbance rejection control algorithm is designed, and auto-disturbance rejection control parameters are set through a provided quantitative parameter setting formula; the output of all feed-forward transfer functions is subtracted from the active disturbance rejection control output part, the feed-forward transfer functions are obtained by dividing disturbance transfer functions by object transferfunctions, and the feed-forward transfer functions can be simplified into zero-frequency gain. According to the invention, the implementation complexity of the control method is effectively reduced, and the workload of parameter setting is reduced; meanwhile, various measurable disturbances and unknown disturbances are restrained, the disturbance restraining speed of the refrigerant water outlet temperature is increased, and the fluctuation range of the refrigerant water outlet temperature is reduced.

Owner:TSINGHUA UNIV

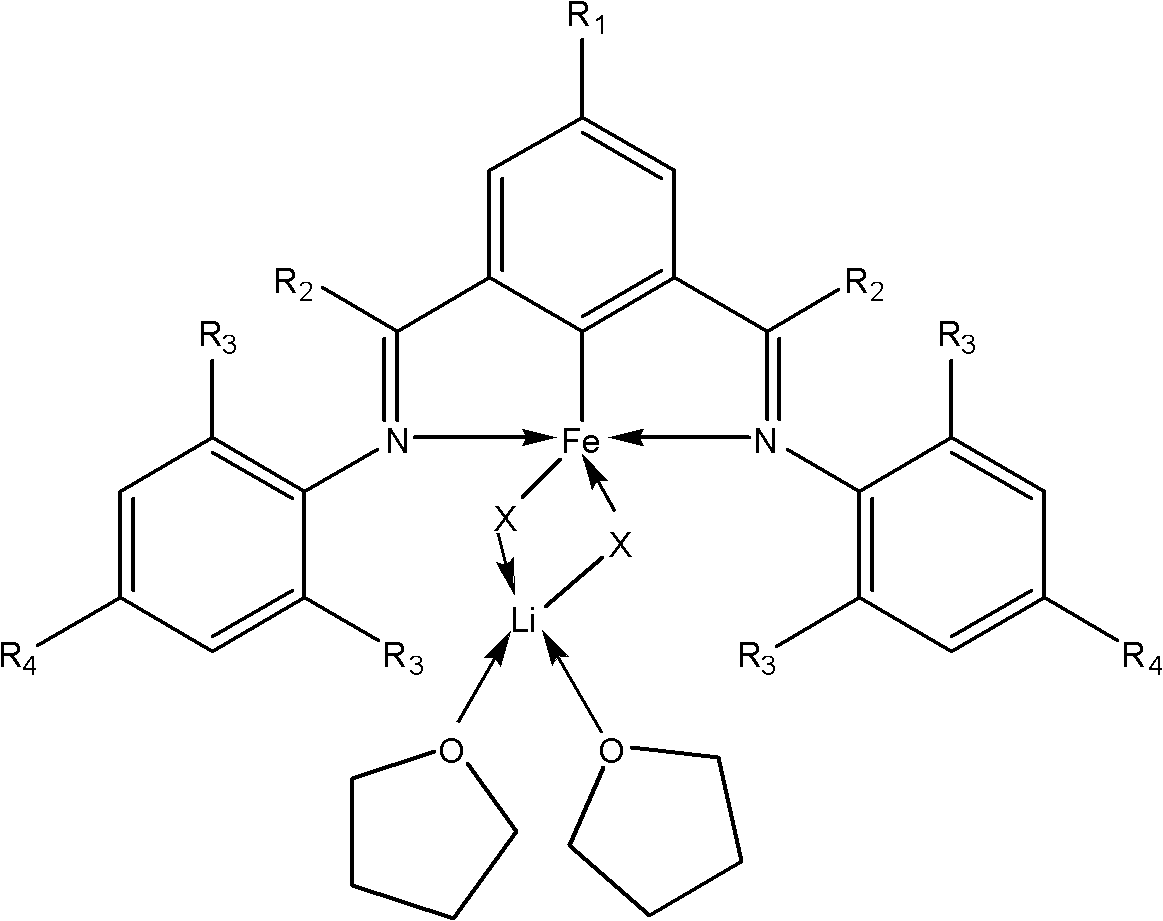

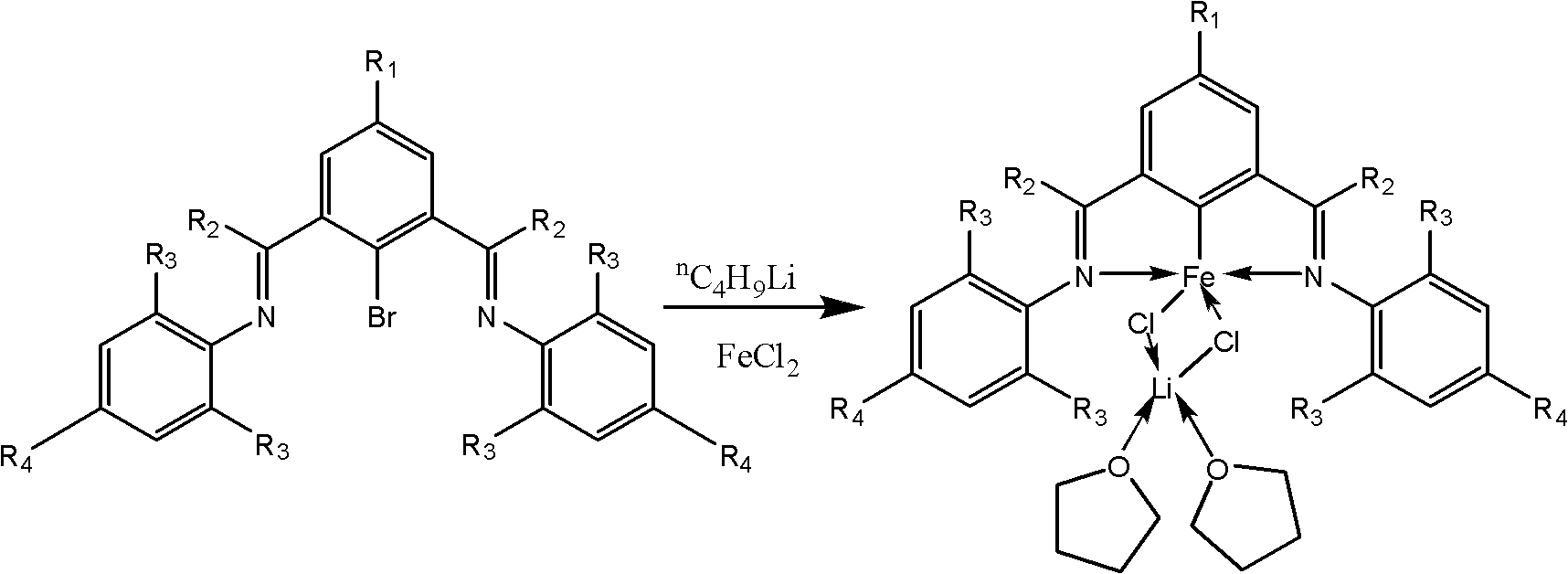

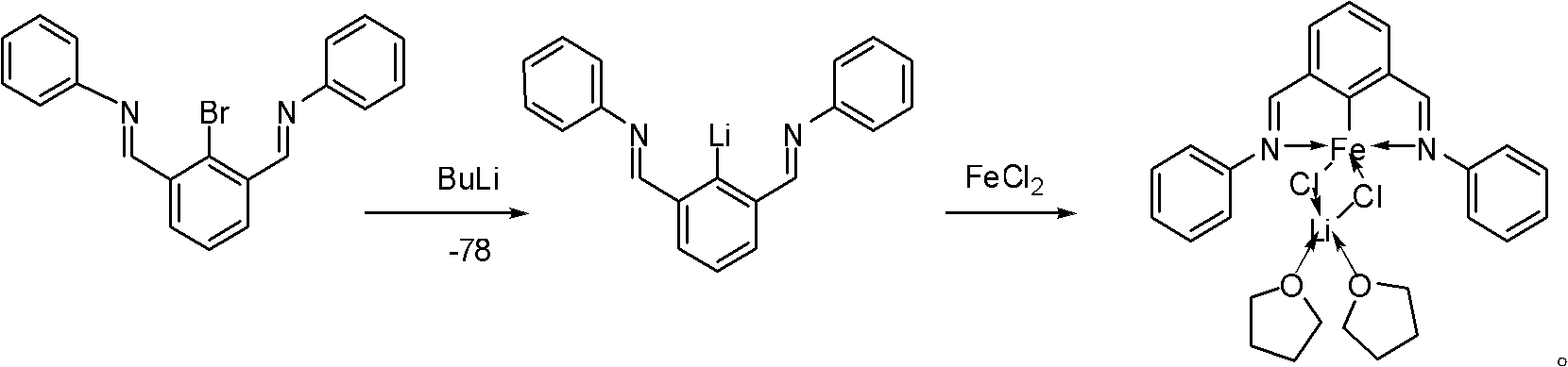

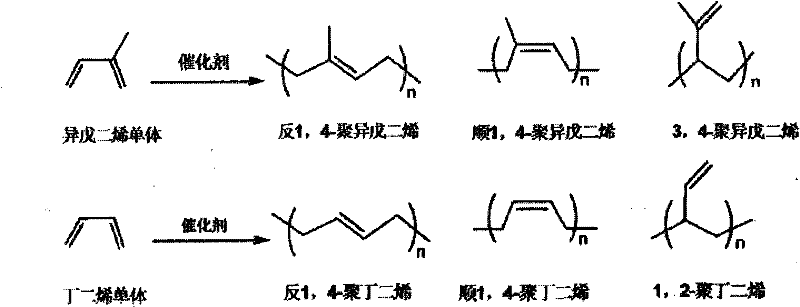

Clamp-type iron complex and preparation method and application thereof

InactiveCN102633840AEasy to manufactureImprove stabilityIron organic compoundsFiltrationRoom temperature

The invention discloses a clamp-type iron complex and a preparation method and application thereof, and belongs to the field of catalysis technologies. The clamp-type iron complex is based on [NCN]-coordination. The preparation method comprises the following steps of: adding a butyl lithium solution into a ligand solution under the condition of the temperature of -78 to -40 DEG C, and reacting to obtain a reaction solution; adding ferrous chloride into the reaction solution, naturally raising the temperature to room temperature, and continuing reaction; and adding hexane to perform filtration and recrystallization. A catalyst consisting of the [NCN]-coordination clamp-type iron complex and alkyl aluminum is used for catalyzing butadiene syn-1,4 to perform selective polymerization. The clamp-type iron complex is convenient to prepare and high in stability; during selective polymerization of the butadiene under the catalyst, the using amount of the catalyst is small, the polymerization reaction speed is high, the conversion efficiency is high, and syn-1,4 selectivity is relatively high, and polymer molecule weight and molecule weight distribution are controllable; the system formed by the catalyst is homogeneous; the clamp-type iron complex is convenient to use; during polymerization, the temperature fluctuation range is small; and the reaction is easy to control.

Owner:JILIN UNIV

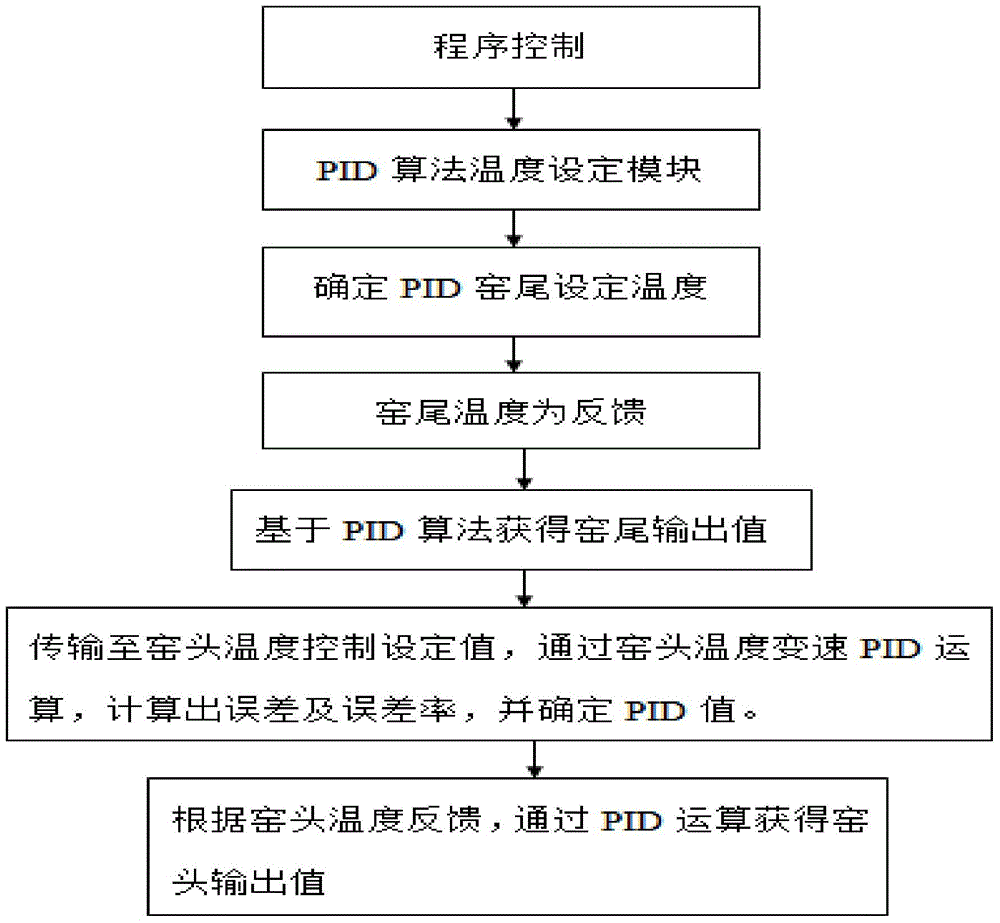

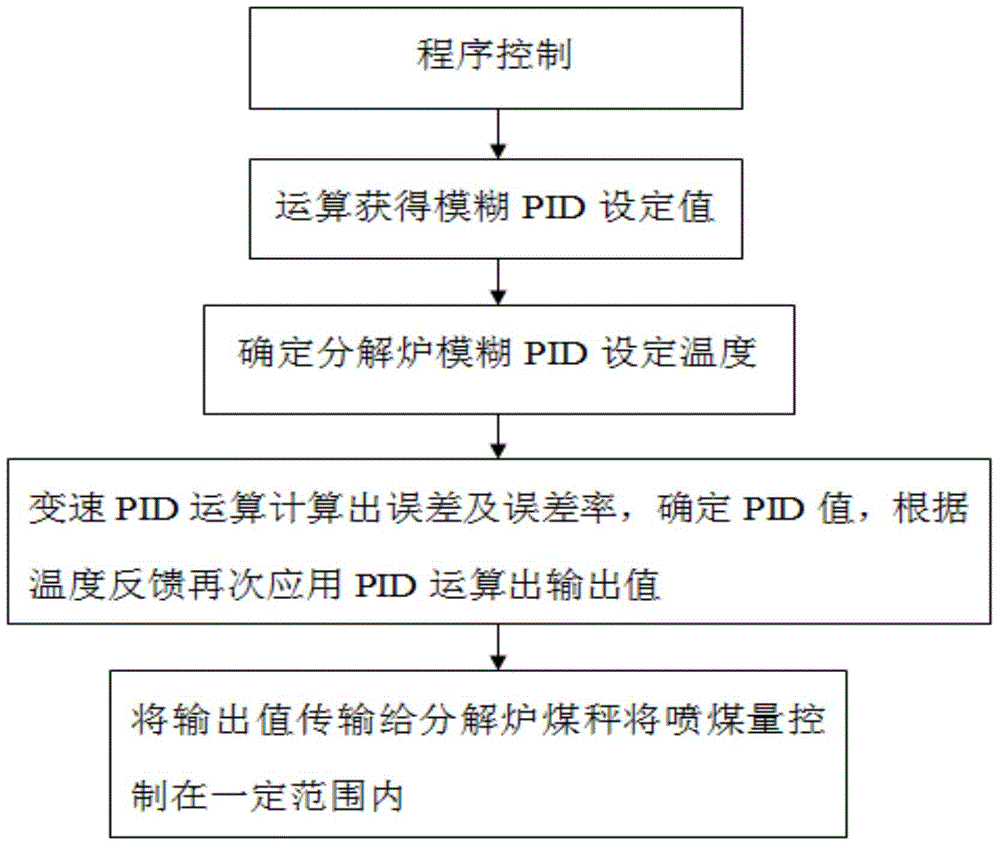

Method for intelligently controlling temperatures of furnaces and kilns

InactiveCN104880093AAutomatic temperature controlHigh temperature control accuracyRotary drum furnacesControl devices for furnacesTemperature controlEngineering

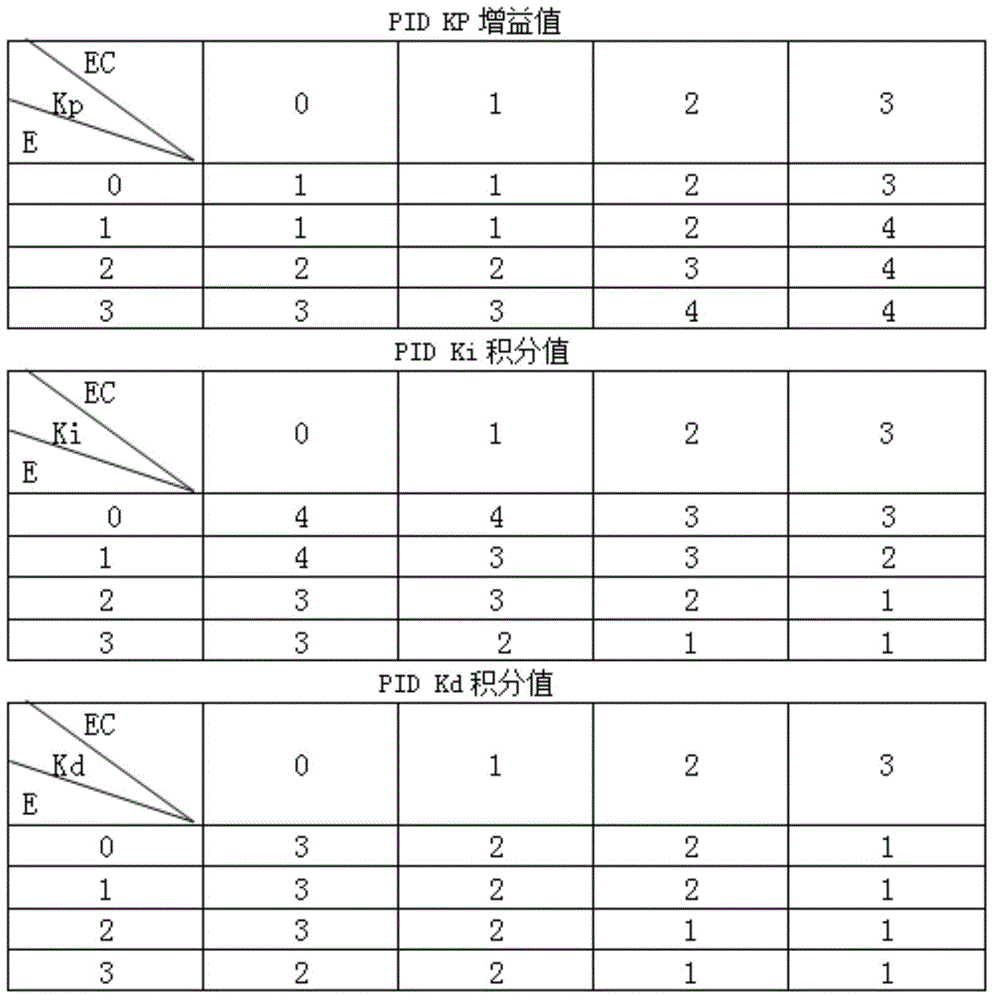

The invention discloses a method for intelligently controlling the temperatures of furnaces and kilns. The method includes acquiring kiln head output values by means of speed change (fuzzy) PID (proportion, integration and differentiation) operation according to feedback temperatures of kiln heads of the rotary kilns; outputting the kiln head output values to coal scales of the kiln heads and controlling coal injection rates of coal of the kiln heads to be within certain ranges; acquiring set values of speed change (fuzzy) PID temperatures, namely, actual set temperatures of the decomposing furnaces, by means of operation by the aid of temperature control subsystems of the decomposing furnaces; computing errors and error change rates by the aid of feedback temperatures of outlets of the decomposing furnaces and the actual set temperatures of the decomposing furnaces, acquiring speed change PID (fuzzy) values by the aid of the computed errors and the computed error change rates, and acquiring output values of the decomposing furnaces by means of speed change (fuzzy) PID operation according to the feedback temperatures of the outlets of the decomposing furnaces; outputting the output values of the decomposing furnaces to coal scales of the decomposing furnaces and controlling coal injection rates of the decomposing furnaces to be within certain ranges.

Owner:李晨光

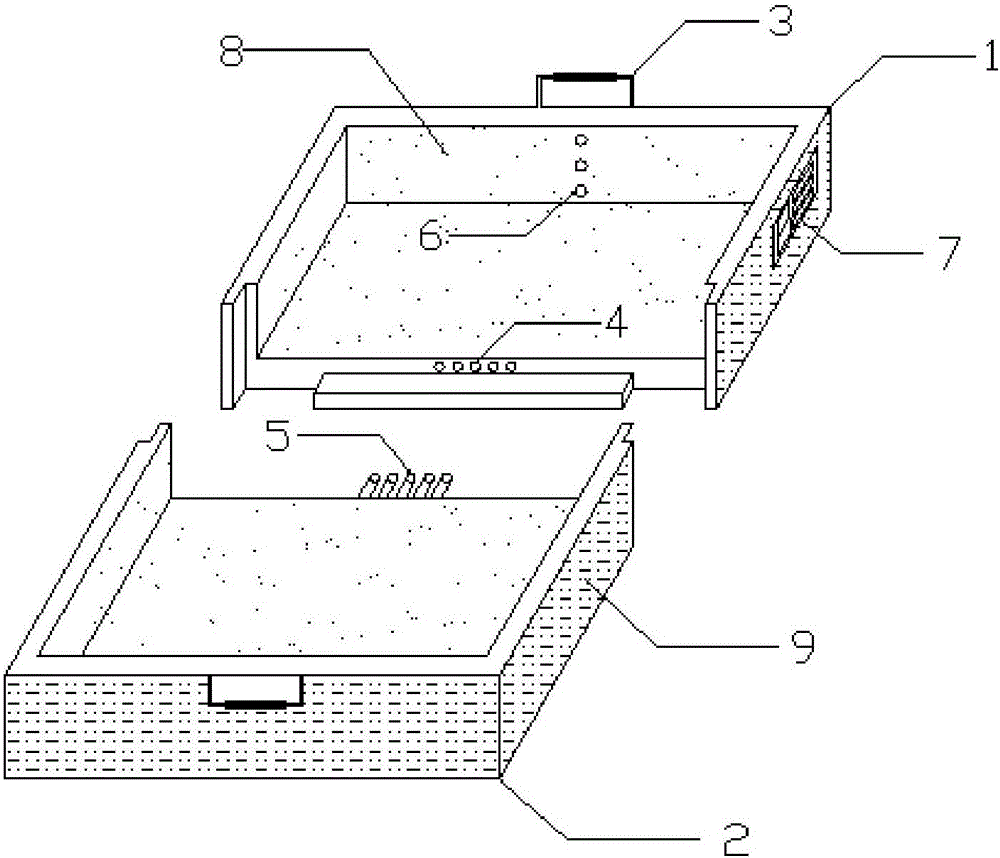

Experimental biological kit for preventing leakage pollution and use method of experimental biological kit

ActiveCN112357314AEasy to storeSmall temperature fluctuation rangeShaking/oscillating/vibrating mixersMixer accessoriesEnvironmental engineeringPolluted environment

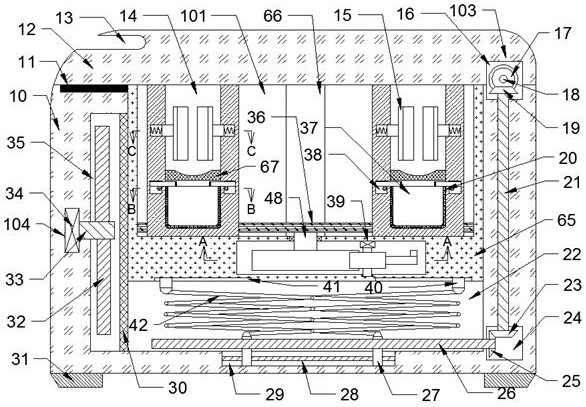

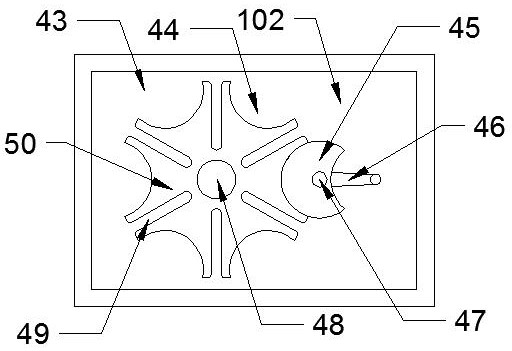

The invention discloses an experimental biological kit for preventing leakage pollution and a use method of the experimental biological kit. The experimental biological kit comprises a kit body, a stretchable cavity with an upward opening is formed in the kit body, sliding blocks are arranged on the front side wall and the rear side wall in the stretchable cavity in a sliding mode, a circular cavity with an upward opening is formed in each sliding block, driven shafts are rotatably installed on the bottom walls of the circular cavities, rotating plates are fixedly arranged on the driven shafts, six bearing elements which can be taken down and are completely the same in shape and structure characteristic are arranged on the rotating plate, the bearing elements comprise placing blocks penetrating through the rotating plates up and down, containing grooves with upward openings are formed in the placing blocks, and spring grooves are symmetrically formed in the left position and the rightposition of the side walls of the containing grooves in a communicating mode. Reagents are independently stored, and when leakage occurs, the reagents are sealed in the kit, so that mutual pollution is avoided, the reagents are stored, the cost is saved, meanwhile, the reagents cannot pollute the environment, and the environment is protected.

Owner:营口博奥医学检验实验室有限公司

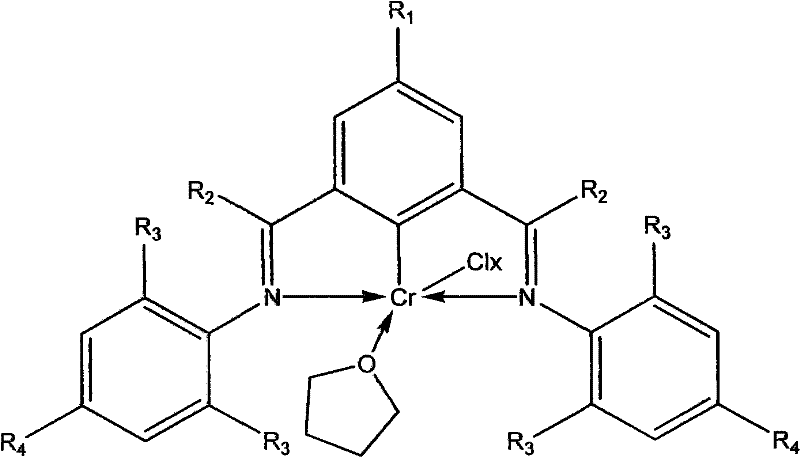

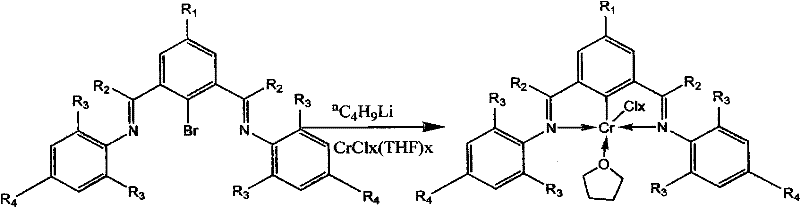

Caliper type chromium complex and preparation method and application thereof

InactiveCN102127116AImprove stabilityGood stability and easy preparationGroup 6/16 element organic compoundsButyl lithiumAdduct

The invention relates to a caliper type chromium complex and a preparation method and application thereof, and belongs to the technical field of catalysts. The caliper type chromium complex is a [NCN]-ligand-based caliper type chromium complex. The preparation method comprises the following steps of: adding hexane solution of butyl lithium into tetrahydrofuran solution of a ligand dropwise for reaction; adding a tetrahydrofuran adduct of chromium trichloride or chromium dichloride; and heating the mixture to room temperature naturally and reacting to obtain the caliper type chromium complex. The ligand can be 2,6-bis(N-2,6- phenyl)imido bromobenzene. The caliper type chromium complex, alkyl aluminum and organic boron salt serving as catalysts are used for catalyzing selective polymerization of isoprene or butadiene. The caliper type chromium complex has high stability and is convenient to prepare; the catalytic system can be used for selectively catalyzing polymerization of the isoprene or the butadiene, and has low using amount of a cocatalyst, high polymerization speed, high conversion rate and high anti-1,4 selectivity; and the caliper type chromium complex can be applied actually by replacing natural trans-1,4 rubber.

Owner:JILIN UNIV

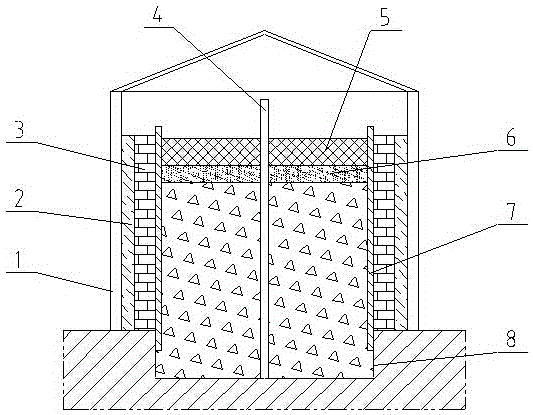

Indoor storage and fresh-keeping method for ginger

InactiveCN105123152AAchieve long-term storageExtended storage timeAgriculture tools and machinesHarvested fruit hanging devicesAgricultural engineeringEconomic benefits

The invention discloses an indoor storage and fresh-keeping method for ginger. The method comprises the following steps: building a storage room provided with a pit, partition wall building blocks, a thermal insulating layer and a plurality of air pipes in a vacant house, then selecting robust ginger blocks which are uniform in size, good in quality and free of diseases, sequentially stacking selected ginger blocks upwards in the storage room in a layering manner, and finally, covering the surfaces of the ginger blocks on the uppermost layer in the storage room with a soil covering layer and an insulating layer, so as to enable the temperature in the ginger block pile to be stabilized to be 13+ / - 1 DEG C. According to the invention, a reasonable and advanced storage technology is adopted, so that ginger is close to the ground and moisturized, the storage cost is effectively reduced, the preservation effect of ginger is good, the storage capacity is high, the ginger rotting rate is 3% or below, moisture and freshness of ginger are effectively maintained, original color, luster and quality of ginger are guaranteed, economic benefits of ginger farmers and commodity values of the ginger are increased and wide-range popularization and application are facilitated.

Owner:LUOPING GINGER TECH PROMOTION STATION

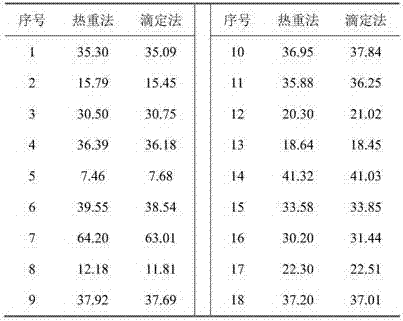

Method for measuring organic matter content of coal gangue

The invention relates to petrology and mineralogy, in particular to a method for measuring organic matter content of coal gangue. The method comprises: grinding air-dried coal gangue, screening, taking a sample, measuring mass loss with a thermogravimetric analyzer, and calculating the organic matter content of the coal gangue. The calculation of organic matters in coal gangue innovatively through mass loss replaces the complex organics-measuring steps of the traditional titration; a temperature rise range of 35-800 DEG C is determined, the temperature of 800 DEG C is held for 10 min, the temperature rise rate is 15 DEG C per min, atmospheric simulation air is N2:O2=79:21, and atmospheric total mass is 100 ml / min; compared with the results of organic matter measurement by the existing common titration method, the method has a standard deviation and a deviation ratio of 0.30 and <4%; correlation of organic matter contents from measurements by the two methods is up to 0.9991. The method for measuring organic matters in coal gangue according to the invention has the advantages of good simplicity, good convenience, and high test result precision.

Owner:ANHUI UNIV OF SCI & TECH

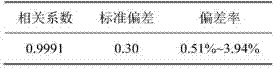

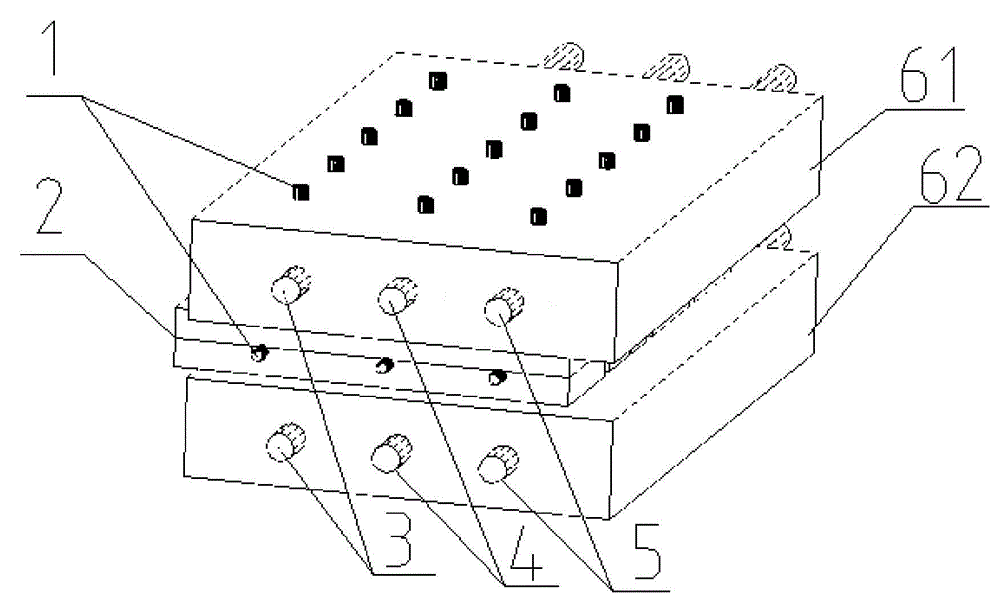

Matrix type heating temperature control platform device for thermocuring mold

The invention discloses a matrix type heating temperature control platform device for a thermocuring mold. The device comprises an upper heating flat plate, a lower heating flat plate, a plurality of groups of heating pipes, a heated mold, a matrix temperature measuring element, a multichannel temperature controller and a multichannel powder module. According to the temperature control platform, the plurality of groups of heating pipes are used for heating the heating flat plates having large areas; the heating flat plates heat the mold in a control range by heat guiding, the matrix distribution type temperature measuring element is adopted for measuring the temperature field of the mold in the mold range, furthermore a special weighting algorithm is adopted for calculating temperature control deviation, and the powder of a heating rod is controlled by the result of the deviation, so that the temperature control accuracy of the mold is within a range of + / -5 DEG C, the temperature difference is less than 5 DEG C in a matrix range, further the production finished products yield is increased, and the production efficiency is improved.

Owner:佛山市顺德区康特博塑料制品有限公司

A high-performance tin phosphor bronze strip and its production method

The invention discloses a high-performance tin-phosphor bronze strip and a production method thereof. The high-performance tin-phosphor bronze strip comprises, by weight percent, 9% to 11% of Sn, 0.03% to 0.35% of P, not larger than 0.2% of Zn, not larger than 0.1% of Fe, not larger than 0.2% of Pb and the balance copper. Through the strict control over a casting technology, a rolling technology and an annealing technology of a tin-phosphor bronze alloy, a high-performance tin-phosphor bronze strip alloy product with the tin content ranging from 9% to 11% can be produced, and the application requirement of an IT industry and an electrommunication industry for a high-elasticity, high-strength and high-hardness copper alloy can be met.

Owner:安徽鑫科铜业有限公司

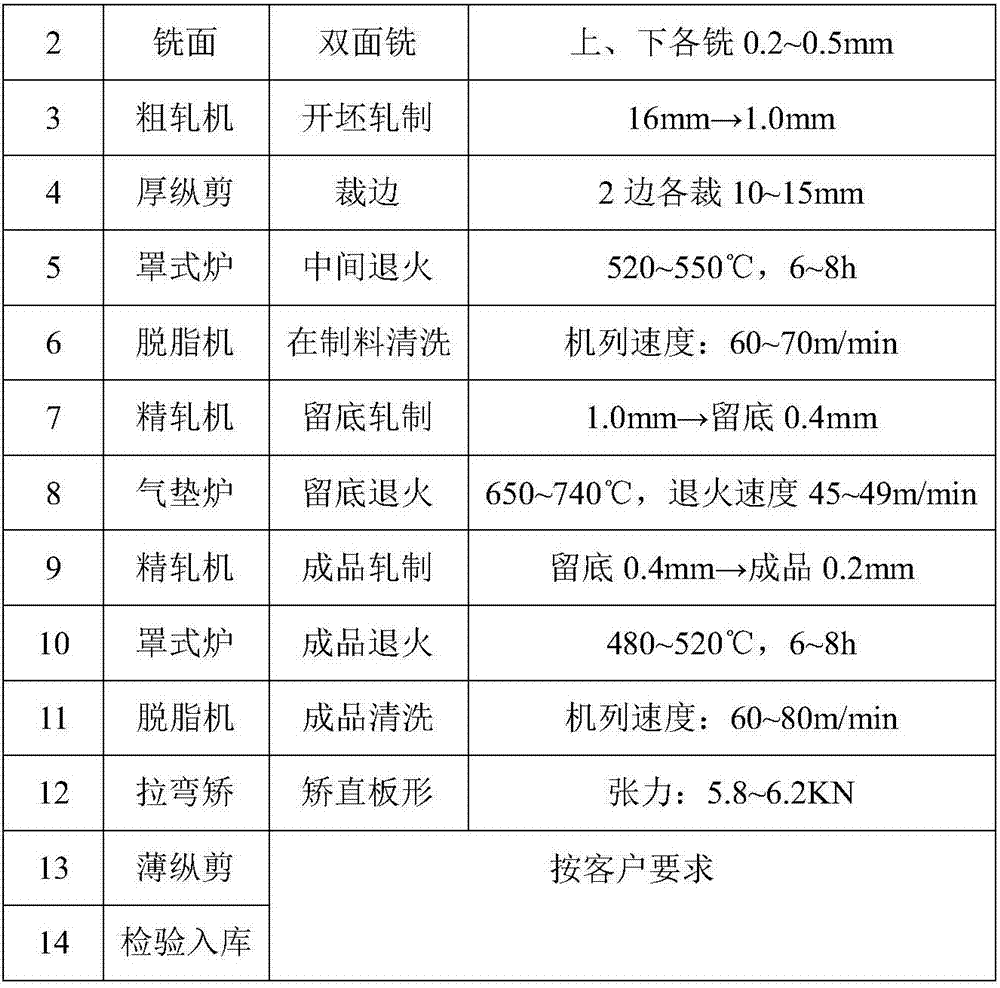

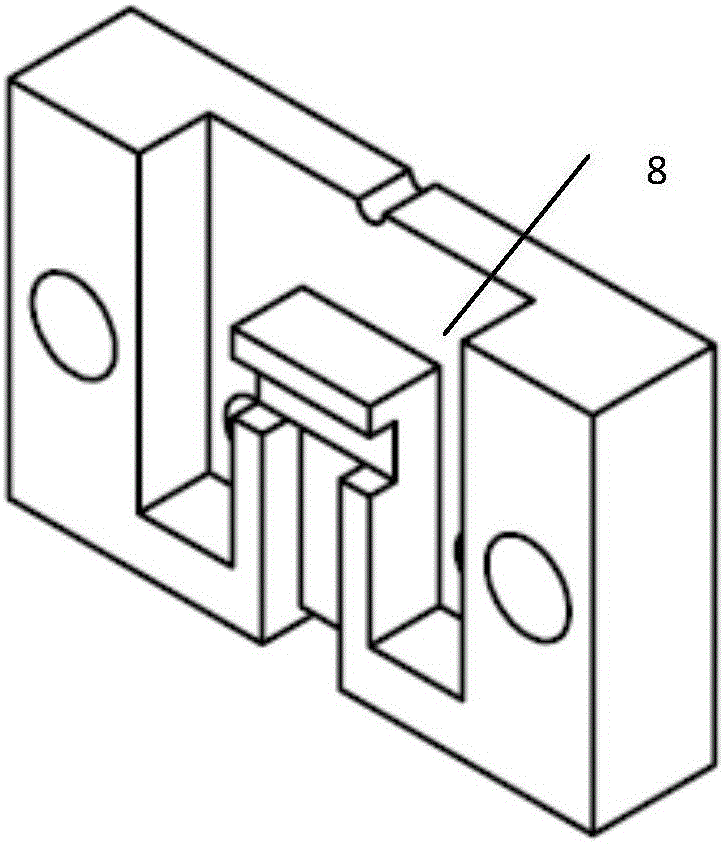

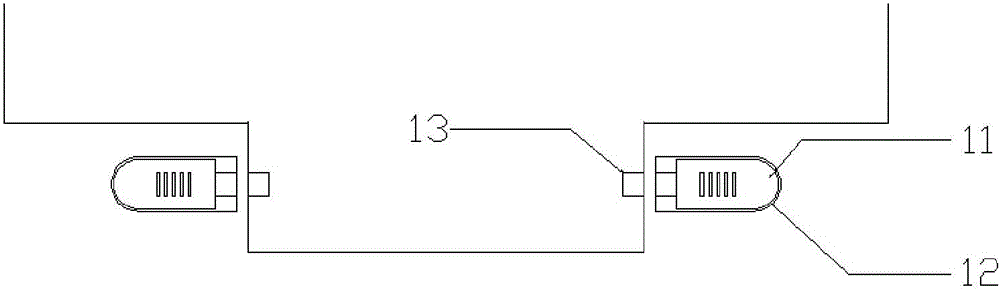

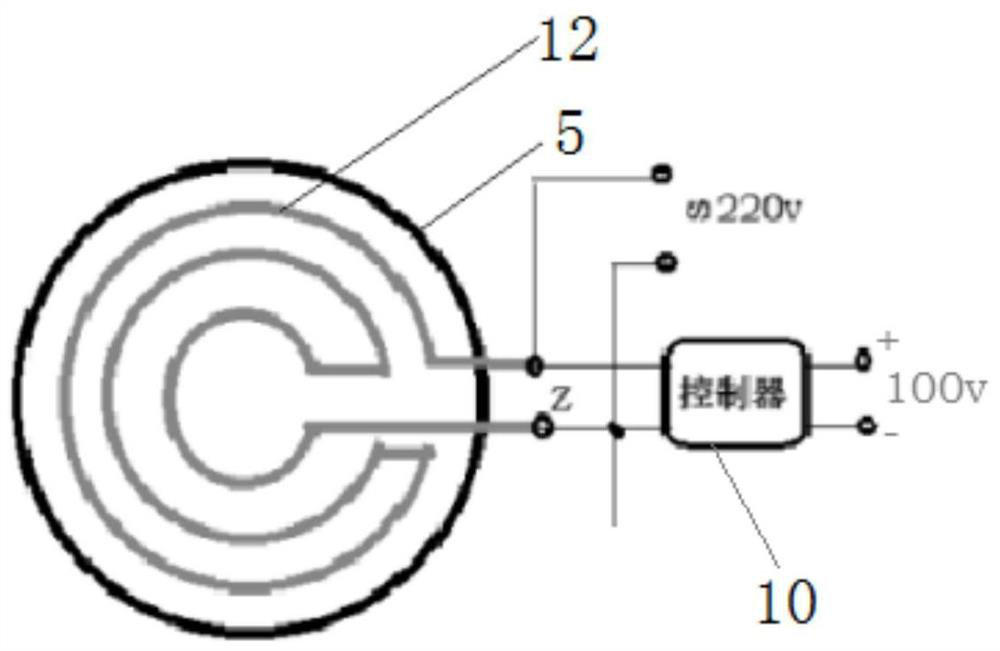

Double-M-shaped electric heating device for multicore fiber fusion

InactiveCN105807370AControl heating powerIdeal temperature fieldCoupling light guidesElectrical resistance and conductanceElectricity

The invention relates to a double M-shaped electric heating device for multi-core optical fiber fusion, which is used in a fusion tapered system to prepare optical passive devices. A double M-shaped electric heating device for multi-core optical fiber melting, the double M-shaped heating device is composed of two identical M-shaped graphite heating elements and a ceramic cover, the first M-shaped graphite heating element and the second M-shaped graphite heating element The concave structure in the middle of the body forms a ring-shaped area as a heating area. The M-shaped heating element should be placed in a ceramic cover, and the internal structure of the ceramic cover is closely matched with the M-shaped graphite heating element. The invention can conveniently control the heating power, as long as one or more of the three parameters of current, voltage or the resistance of the heating body itself can be changed arbitrarily, the heating power can be changed, and an ideal temperature field can be easily obtained.

Owner:HARBIN ENG UNIV

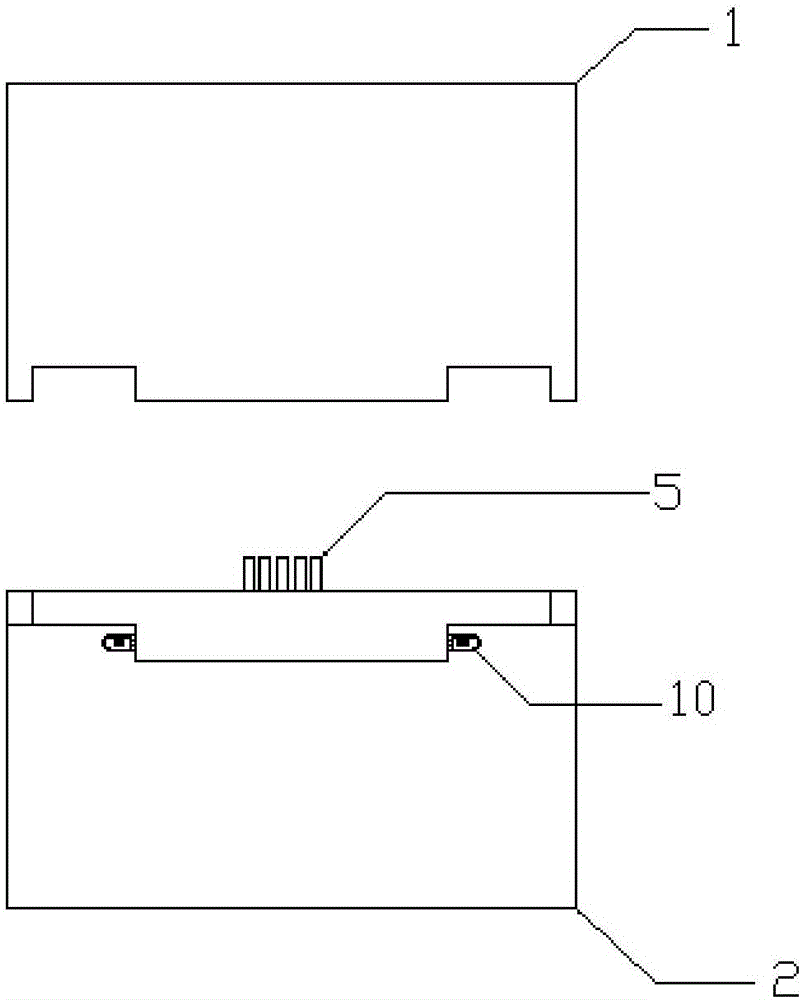

Forming test mold for asphalt mixture rutting test piece

PendingCN106442060AGood insulation effectSmall temperature fluctuation rangeDischarging arrangementPreparing sample for investigationPitch blendeAsphalt

The invention discloses a forming test mold for an asphalt mixture rutting test piece. The forming test mold comprises an upper separating groove and a lower separating groove which are matched, wherein the upper separating groove and the lower separating groove are connected by a sliding locking device to form an opened container; a plurality of temperature sensors are arranged on the inner wall of the upper separating groove; the inner walls of the upper separating groove and the lower separating groove are respectively provided with an anti-sticking coating layer; and the outer walls and the bottom surfaces of the upper separating groove and the lower separating groove are respectively provided with a high-temperature heat-insulating coating layer. The forming test mold disclosed by the invention has the advantages that the demolding procedure after forming completion can be quickly realized; the upper separating groove and the lower separating groove can be separated only by unlocking the sliding locking device at the lower separating groove, so that the defect that the mold is taken out by using a rubber hammer to beat a bottom plate is overcome, the demolding efficiency is obviously improved, the disturbance to the test piece is less, and the influence of operation in the demolding process on all performances of the test piece is reduced.

Owner:CHANGAN UNIV

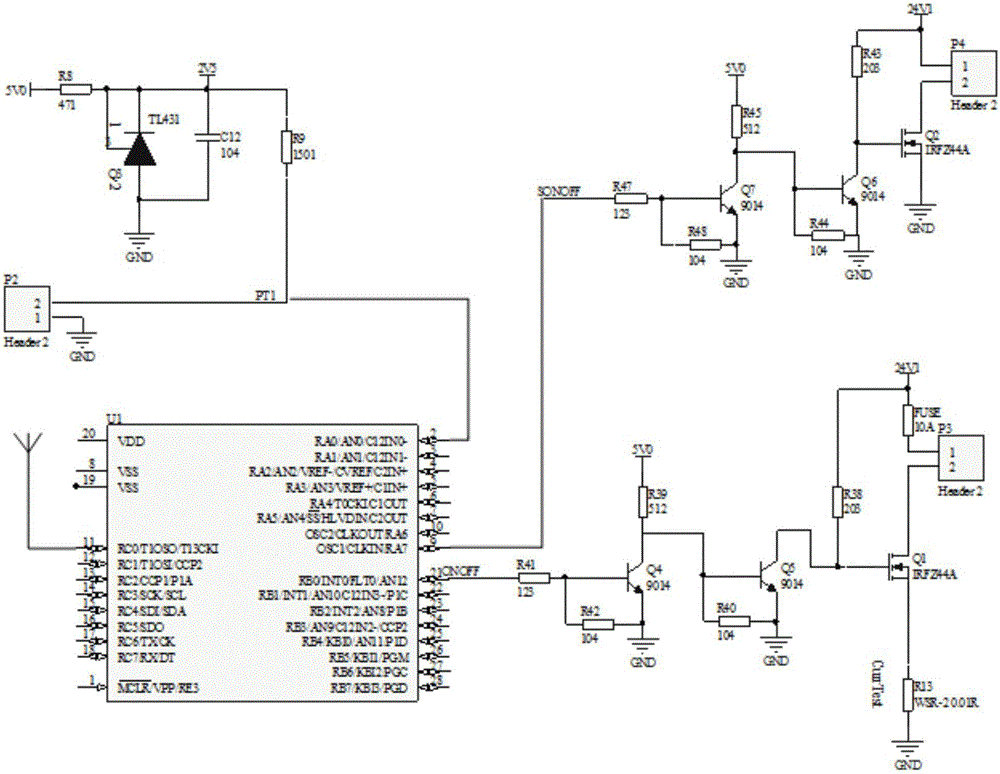

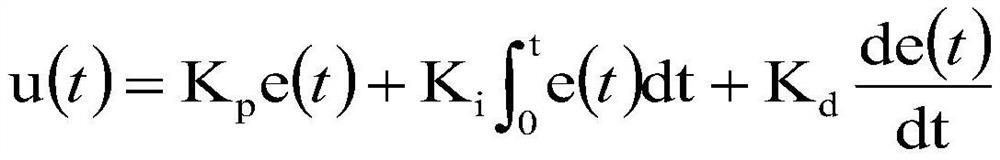

Atomization control device and control method

ActiveCN106040469AEasy to controlSmall temperature fluctuation rangeLiquid spraying apparatusElectricityMicrocontroller

The invention discloses an atomization control device and a control method. The atomization control device comprises a PIC (Peripheral Interface Controller) single chip microcomputer, a temperature sampling circuit, an oil pump driving circuit and an electrical heated tube driving circuit, wherein the temperature sampling circuit, the oil pump driving circuit and the electrical heated tube driving circuit are all connected with the PIC single chip microcomputer; the temperature sampling circuit is further connected with the electrical heated tube driving circuit; the electrical heated tube driving circuit comprises an electrical heated tube with a heating wire arranged therein; the temperature sampling circuit acquires the temperature of the heating wire and feeds the temperature of the heating wire back to the PIC single chip microcomputer; the PIC single chip microcomputer conducts pulse width adjustment via PWM (Pulse-Width Modulation) and outputs power to the electrical heated tube driving circuit through a pin; the heating wire is quickly heated up to a reference temperature; the PIC single chip microcomputer drives an oil pump to work through the oil pump driving circuit; the oil pump pumps a smoke agent through a pipeline and transmits the smoke agent into the electrical heated tube; then the smoke agent is heated and quickly expanded and atomized; smoke is sprayed via the orifice of the electrical heated tube; and the PIC single chip microcomputer adjusts the PWM duty cycle through an internal PID (Proportion Integration Differentiation) regulator to further adjust the output power.

Owner:QINGDAO LINGDING TECH

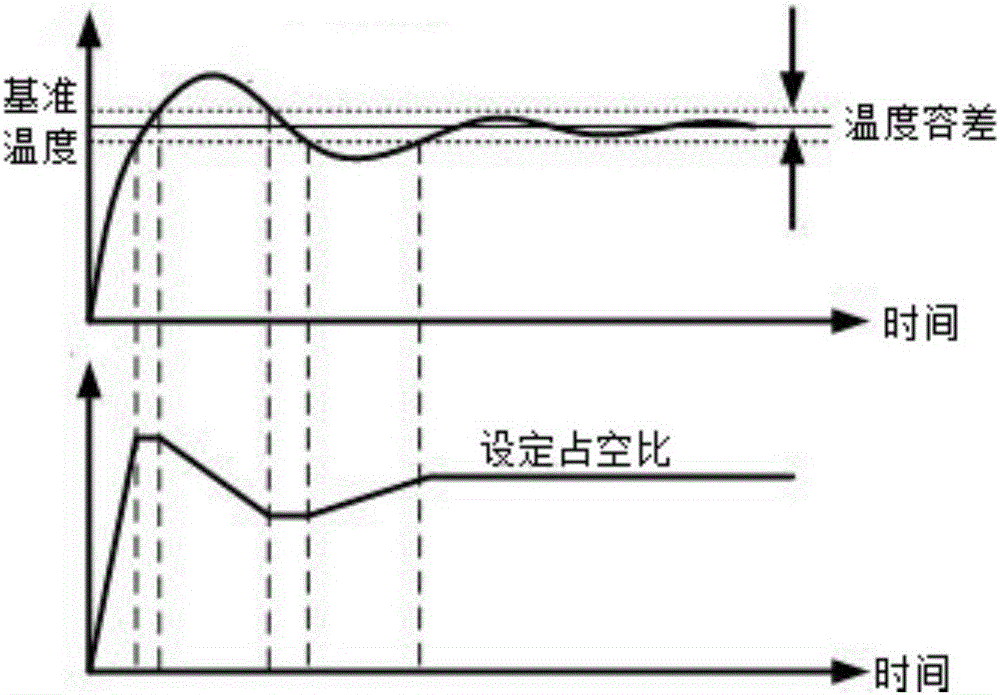

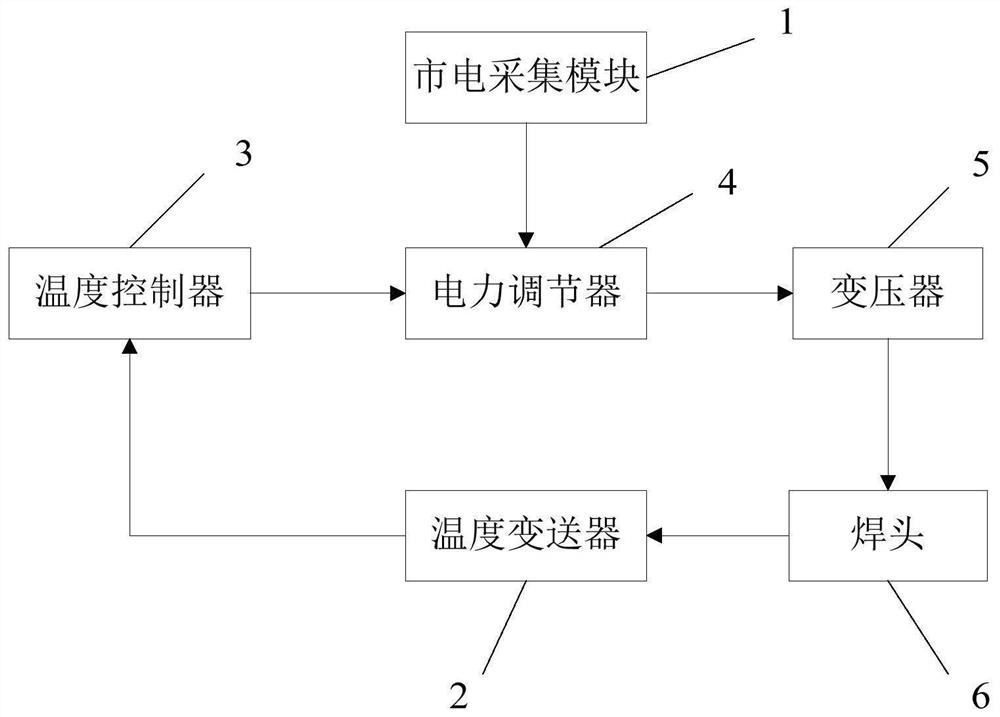

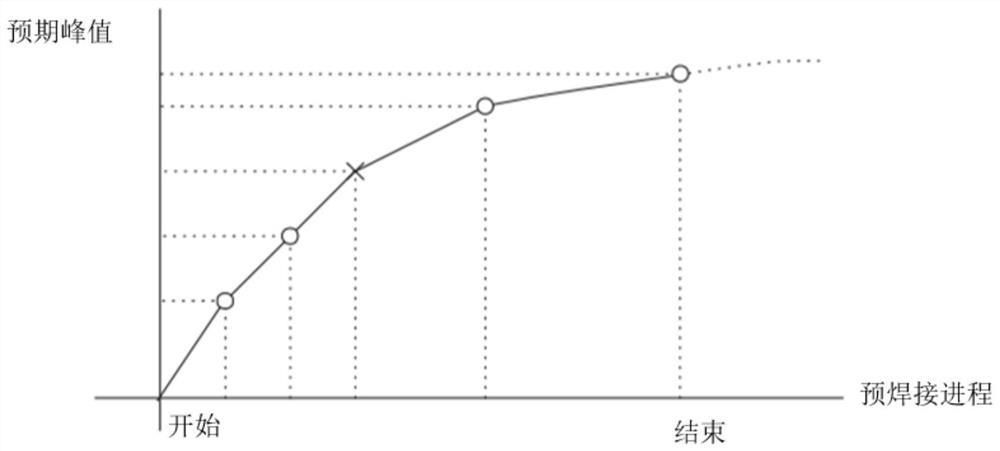

Inductor welding temperature control method and device

ActiveCN112743215AEnsure consistencyEasy to controlHigh frequency current welding apparatusTemperature controlProcess engineering

The invention discloses an inductor welding temperature control method and a device thereof. The method comprises a welding head pre-welding procedure and a welding procedure, in the pre-welding procedure, ideal temperature and actual temperature can be adjusted through a linear adjusting model, so that the temperature of a welding head reaches an expected peak value; Uniform basic heating temperature can be provided for the welding process, and the consistency of the basic heating temperature is guaranteed; the temperature fluctuation range is reduced, and the welding temperature control accuracy is guaranteed; in addition, not only is a temperature control algorithm adopted, but also a power grid fluctuation coefficient is collected; the delay between temperature collection and temperature control is effectively shortened; the control quantity of power output is adjusted in time, and the delay between temperature collection and temperature control is shortened; the temperature control precision is improved, and a welding temperature error is kept within + / -10 DEG C; and an effective molten pool is formed or a plastic state is achieved, and the stability and accuracy of the welding interlayer temperature are guaranteed.

Owner:东莞普莱信智能技术有限公司

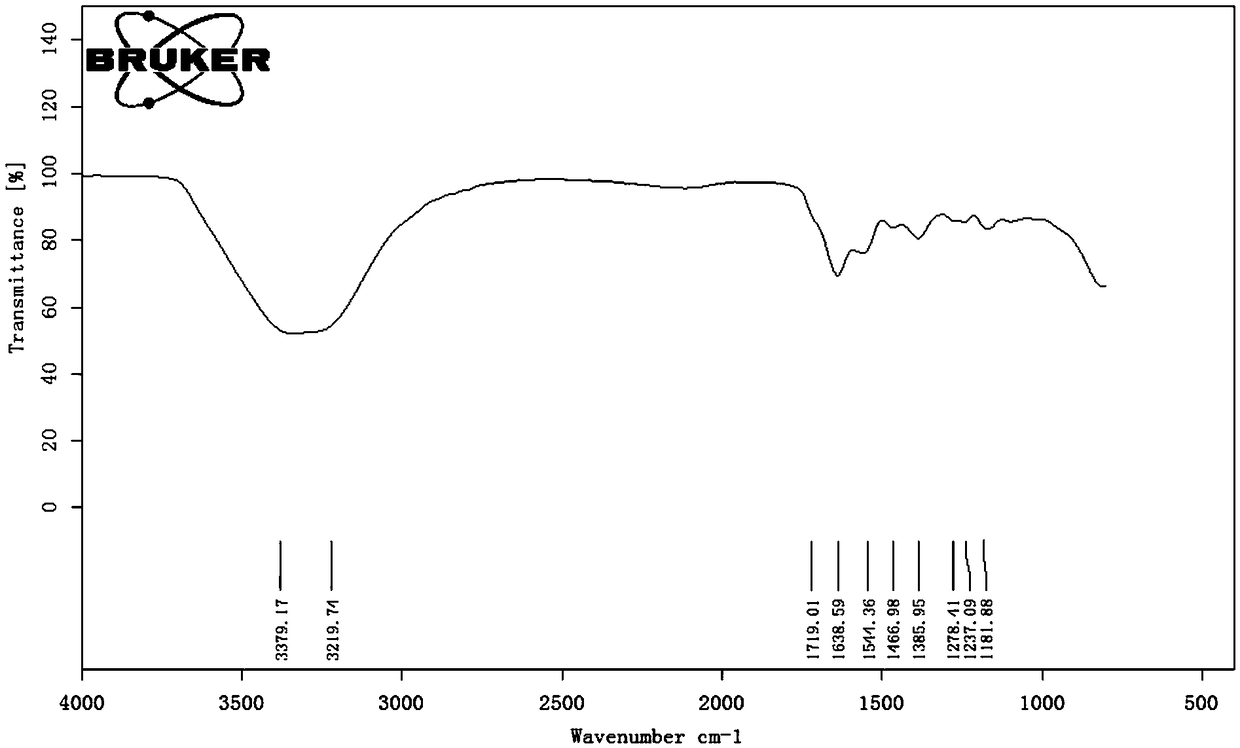

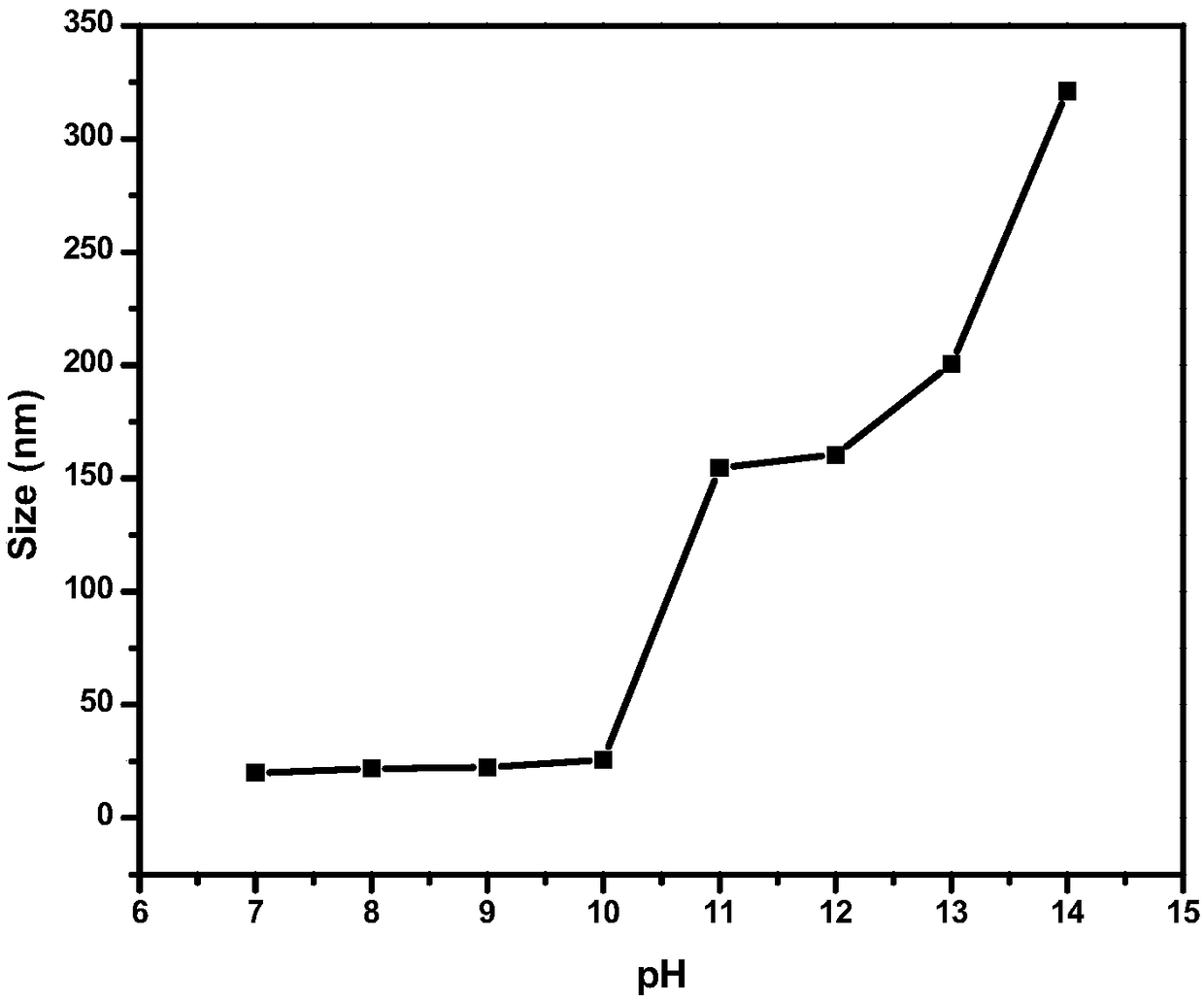

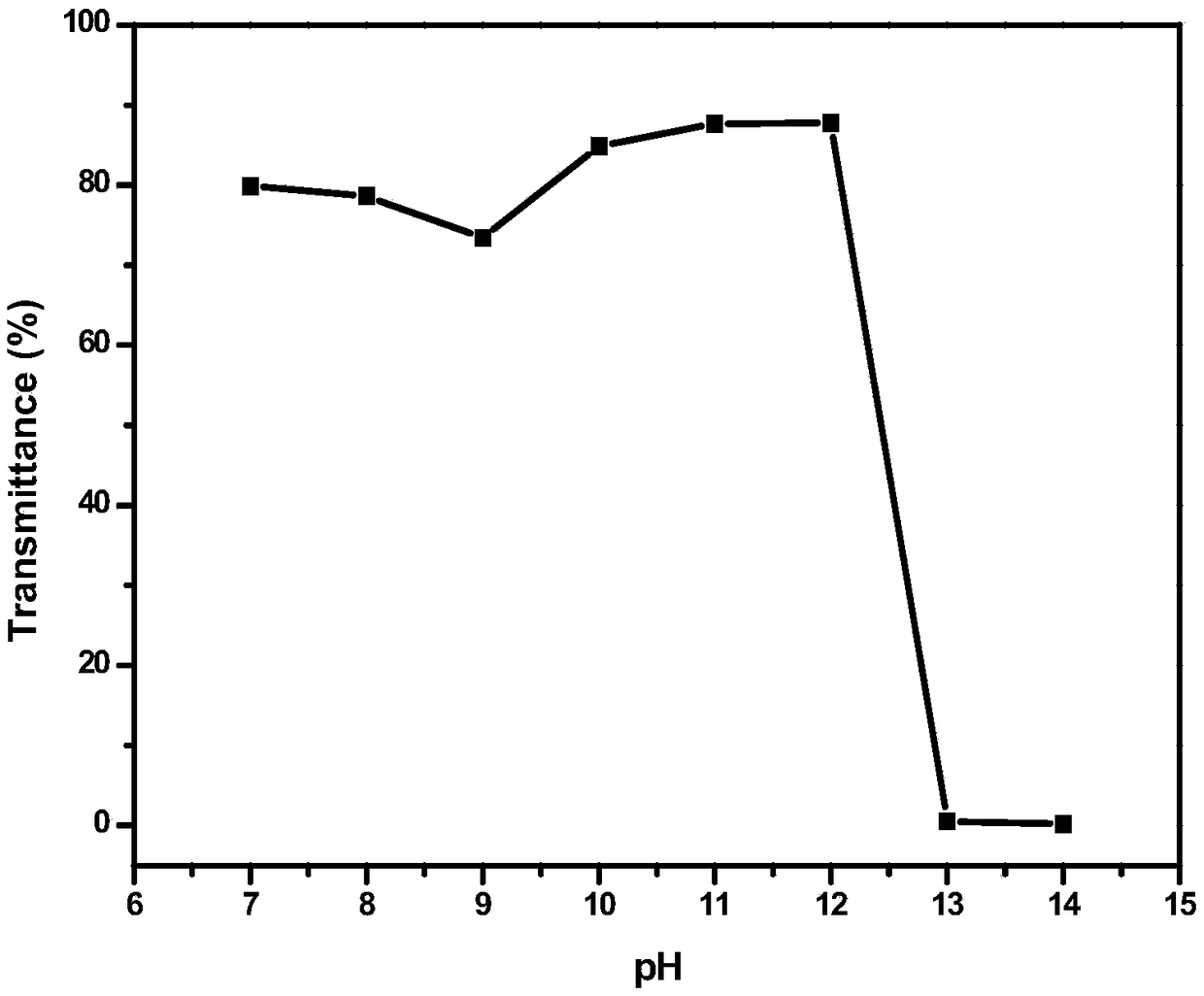

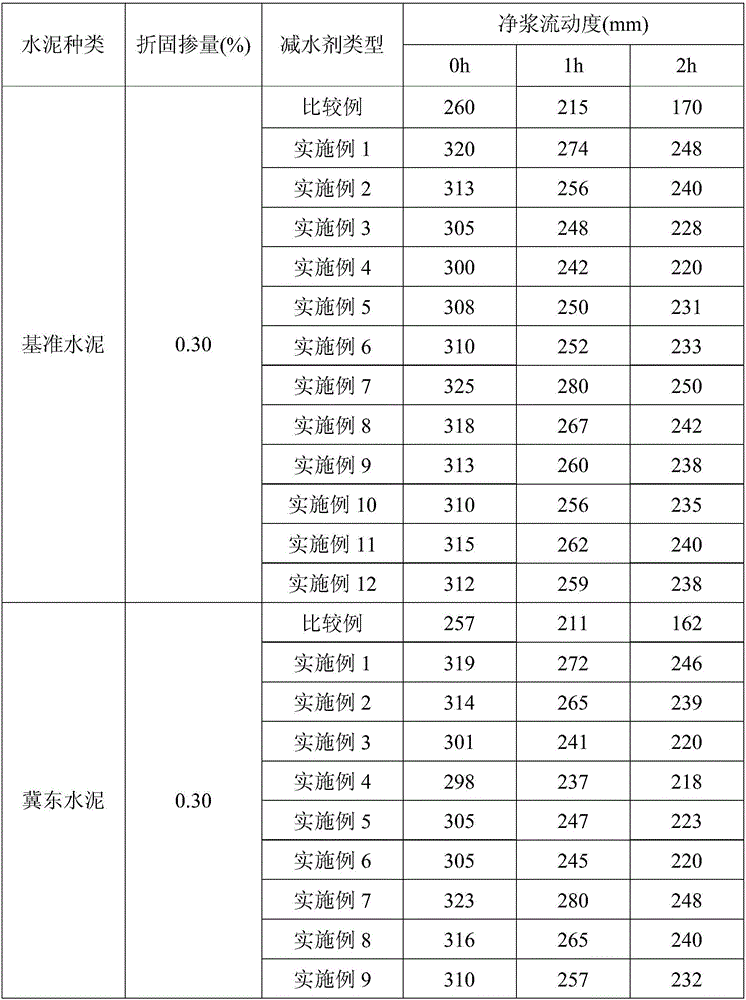

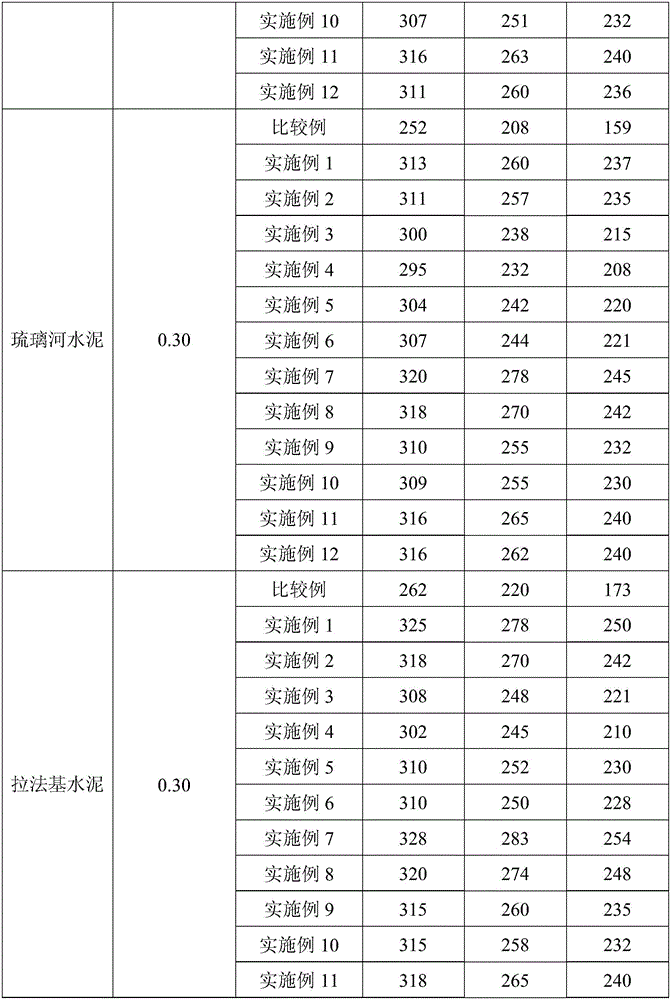

Method for preparing pH-responsive comb-structure polycarboxylic acid through terminal group functionalization

The invention relates to a method for preparing pH-responsive comb-structure polycarboxylic acid through terminal group functionalization. According to the method, with a pH-responsive monomer, unsaturated halogenated hydrocarbon, a small carboxylic acid momonomer and the like as raw materials, a polycarboxylate material is prepared through self-polymerization first, then substitution and then copolymerization; namely, with the pH-responsive monomer as a reactant, a terminal group-functionalized pH-responsive polymer chain is produced through the self-polymerization under the actions of an initiator and a terminal group functionalizing agent, then a substitution reaction is performed on the terminal group-functionalized pH-responsive polymer chain and the unsaturated halogenated hydrocarbon to obtain a pH-responsive macromonomer, and finally a copolymerization reaction is performed on the pH-responsive macromonomer and the small carboxylic acid momonomer under the action of the initiator to obtain a comb-structure polymer which uses polycarboxylic acid as a main chain and has a side chain with a pH-responsive function. By the method, the process is high-efficiency and energy-saving, the conversion rate of a product is high, the functional modification of the polycarboxylic acid is successfully achieved through introduction of the pH-responsive polymer side chain by a terminal group functionalization method, an excellent characteristic of inhibiting shrinkage of cement mortar is shown, and the market competitiveness and the application prospect are very good.

Owner:BEIJING UNIV OF TECH

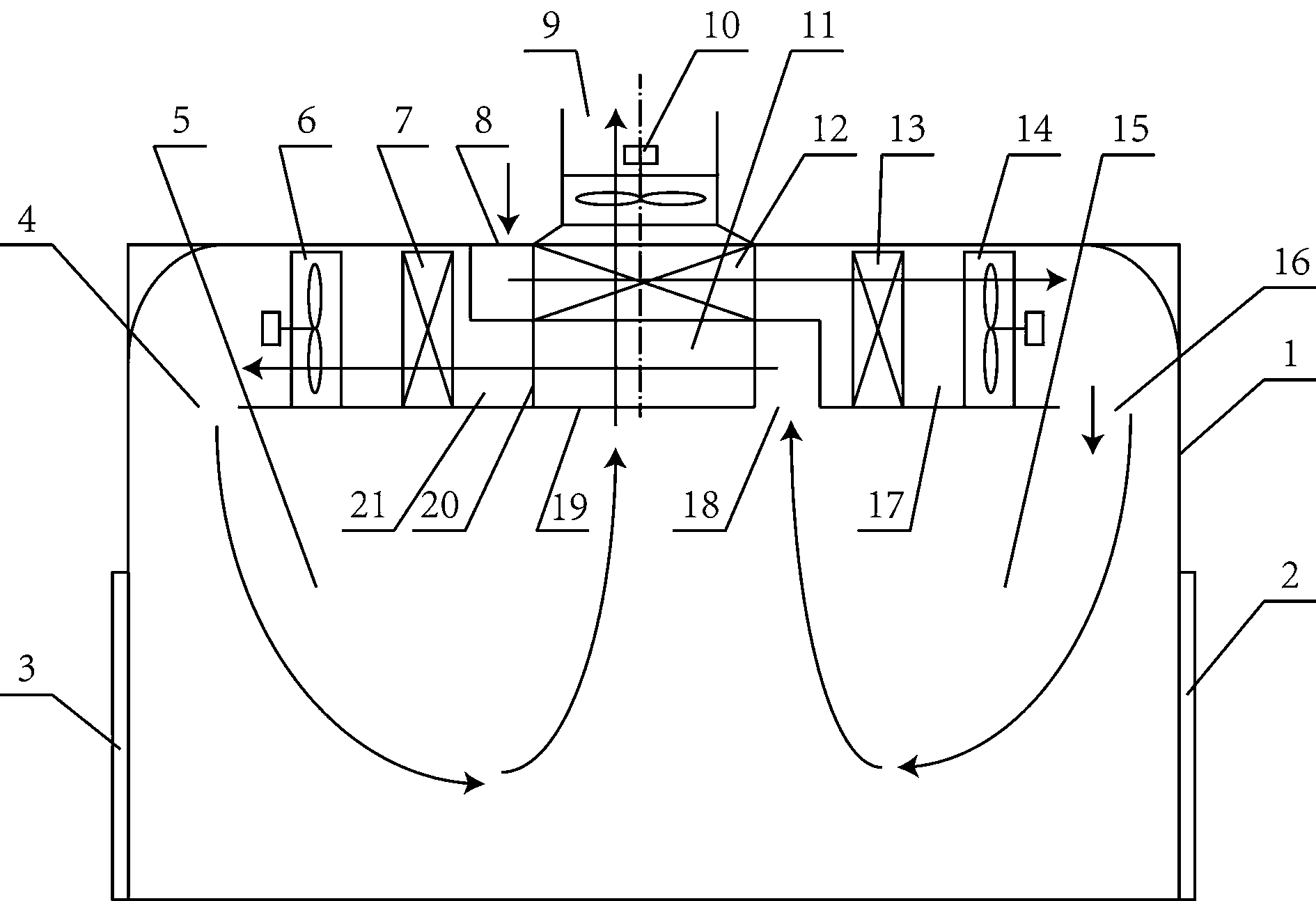

Drying tunnel achieving reheating and pressurizing of circulating air

ActiveCN103542711AUniform air volumeSmall temperature fluctuation rangeDrying gas arrangementsAir volumeEngineering

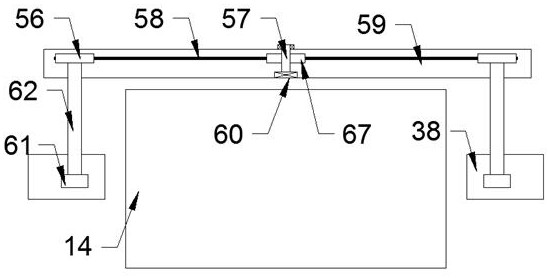

The invention discloses a drying tunnel achieving reheating and pressurizing of circulating air. The air outlet of a fresh air heating channel (17) is a first air inlet (16), the air inlet end of a circulating air heating channel (21) is a return air opening (18) at the upper end of the middle portion of a drying area, the air outlet of the circulating air heating channel (21) is a second air inlet (4), the return air opening (18) is connected with the air inlet end of a second heater (7) through a gap bridge channel (11), and the trends of a moisture removal channel (20) and the gap bridge channel (11) intersects; the first air inlet (16) and the second air inlet (4) are close to the feed end and the discharge end respectively. The design guarantees that air volume inside the drying channel, especially air volume in relatively long drying channel, is uniform, the temperature fluctuation range is smaller, the moisture content of air for extracting moisture is maximized, not only is the drying efficiency improved and product quality guaranteed, but also the effects of energy saving and emission reduction are achieved.

Owner:烟台珈群高效节能设备有限公司

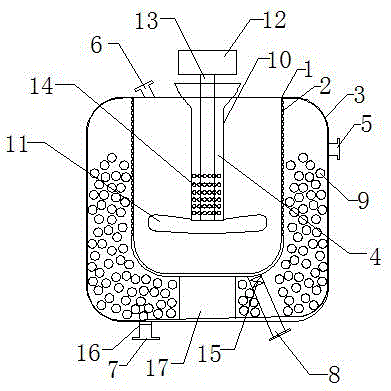

Ammonium chloride neutralization reaction kettle

ActiveCN105457583AAdjustable temperatureSmall temperature fluctuation rangeChemical/physical/physico-chemical stationary reactorsFiberTitanium alloy

The invention discloses an ammonium chloride neutralization reaction kettle which comprises a reaction kettle body, wherein a plurality of U-shaped grooves are uniformly distributed in the outer wall of the reaction kettle body, a layer of shell is arranged at the outer part of the reaction kettle body, a stirring device is arranged inside the reaction kettle body, a cooling liquid inlet is formed in one side at the upper part of the shell, a feed opening is formed in the other side at the upper part of the shell, a cooling liquid outlet is formed in one side at the lower part of the shell, a discharge opening is formed in the other side at the lower part of the shell, a gap is reserved between the reaction kettle body and the shell and fully filled with a fiber ball filler; the reaction kettle is arranged to have a double layer structure, so that the cooling liquid flow rate can be controlled, the temperature of the reaction kettle can be regulated, neutralization reaction of ammonium chloride can be facilitated, and a stirring shaft is arranged to have a hollow structure, therefore the reaction kettle can be cleaned more conveniently and safely, and at the same time, as specifically prepared titanium alloy is taken as the material of the reaction kettle, the reaction kettle has not only a good mechanical property, but also excellent corrosion resistance and heat resistance, the service cycle of the reaction kettle is prolonged, and long-term cost input of manufacturing enterprises can also be reduced.

Owner:内蒙古世杰化工有限公司

Method for preparing concrete water reducing agents from polycarboxylic acid modified acyl halide grafted composite side chains

The invention discloses a method for preparing concrete water reducing agents from polycarboxylic acid modified acyl halide grafted composite side chains, and belongs to the field of water reducing agents. By the aid of the method for polymerizing main chains, modifying acyl halide, polymerizing cationic side chains and then carrying out grafting reaction, polycarboxylic acid modified acyl halide grafted composite side chain type concrete reducing agent materials which are excellent in performance can be prepared. The method includes carrying out free radical polymerization on unsaturated carboxylic acid monomers to obtain the polycarboxylic acid main chains; modifying carboxylic acid groups on the main chains to obtain acyl halide groups; forming oxidation-reduction initiation systems from high-valence ceric salt and alcohol, initiating polymerization of unsaturated cationic quaternary ammonium salt monomers by the aid of the oxidation-reduction initiation systems to obtain the hydroxyl-terminated cationic side chains; carrying out the grafting reaction on the polycarboxylic acid main chains with the acyl halide groups, the hydroxyl-terminated cationic side chains and polyethylene glycol compounds to obtain the concrete water reducing agents. The method has the advantages that owing to modes for modifying the acyl halide by polycarboxylic acid and grafting the cationic side chains and polyethylene glycol side chains, composite side chain structures can be synthesized, reaction procedures are simple and are easy to control, energy can be saved, the method is high in efficiency, and excellent water reduction slump retaining and high-resistant clay composite effects can be realized.

Owner:BEIJING UNIV OF TECH

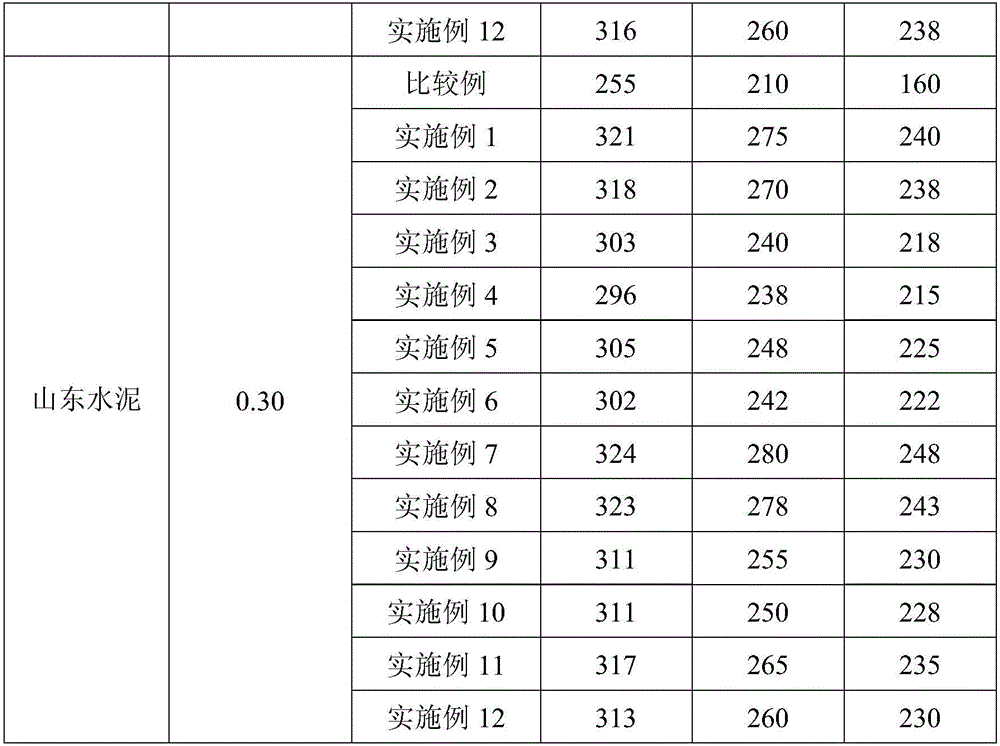

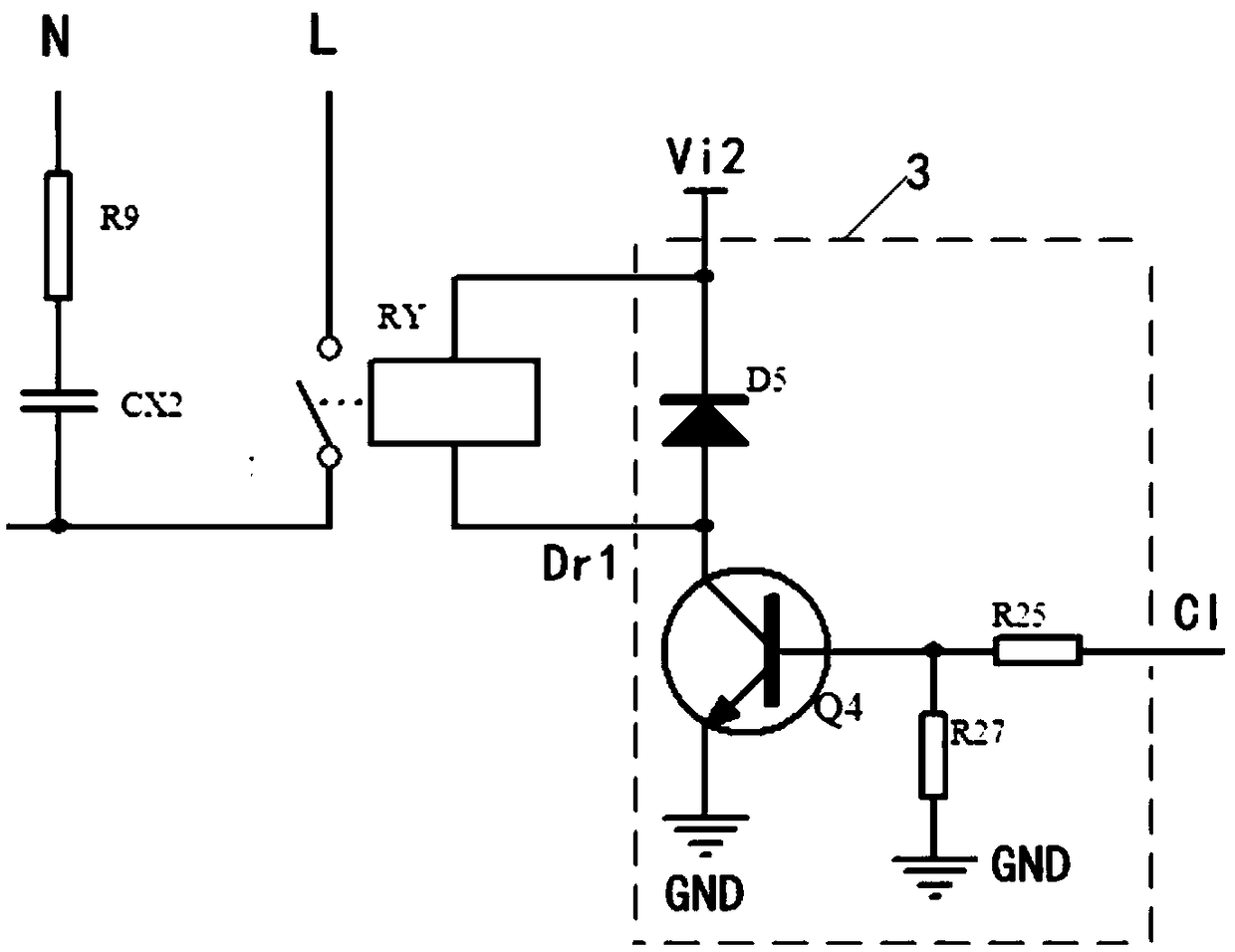

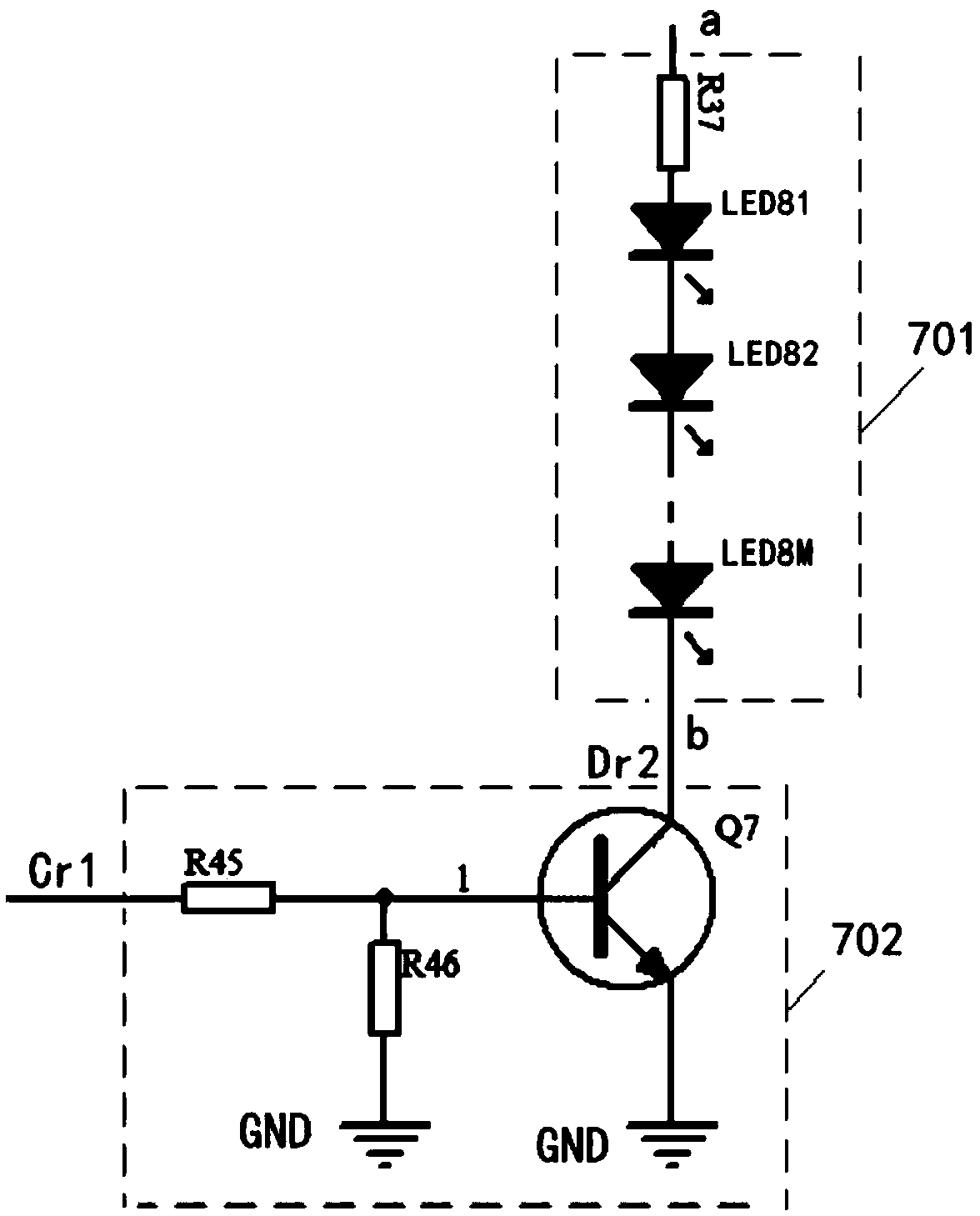

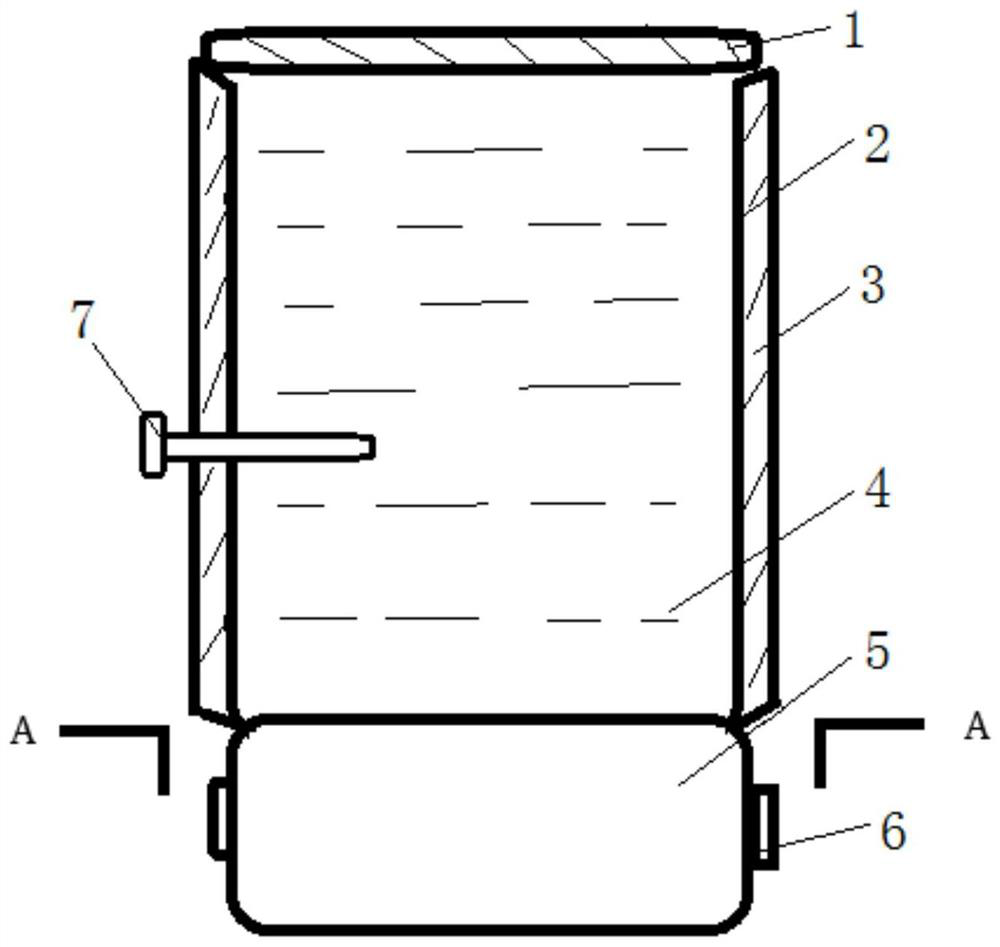

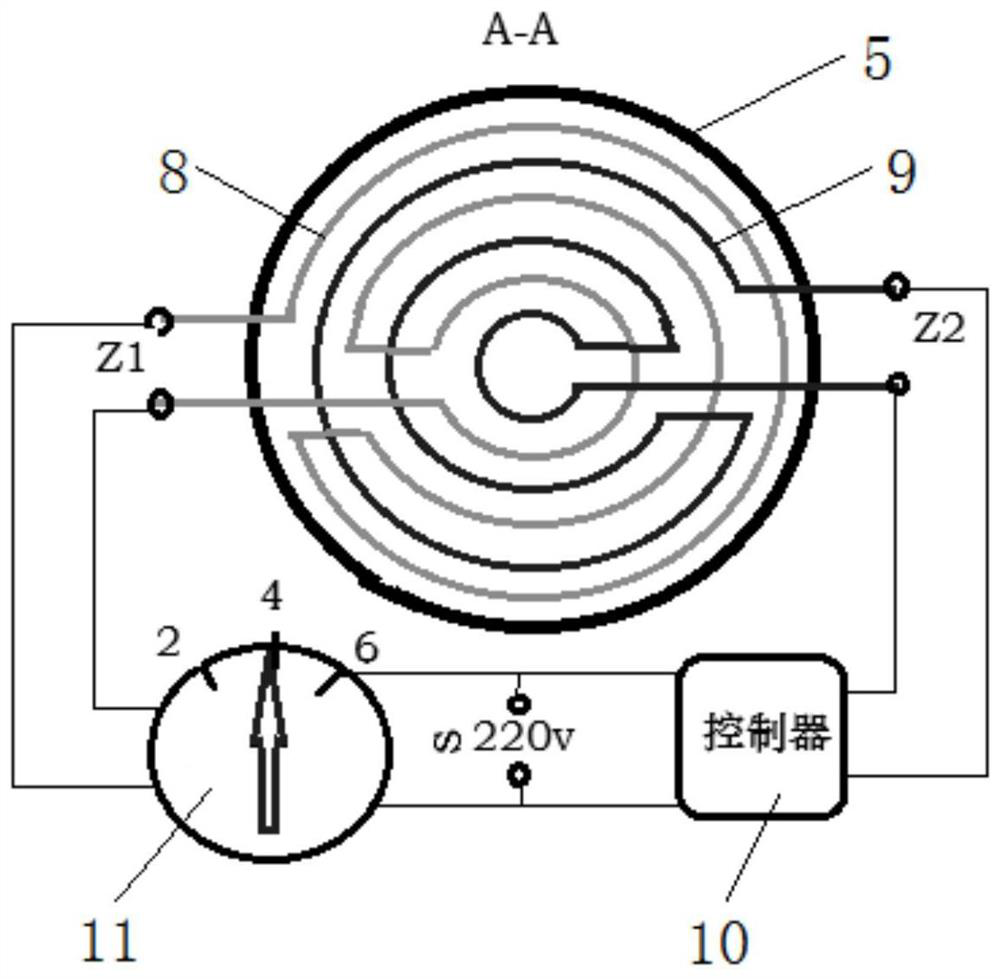

Temperature control circuit, refrigeration device and refrigerator

PendingCN108775766ASmall temperature fluctuation rangeLow costElectrical apparatusElectroluminescent light sourcesTemperature controlControl signal

The invention discloses a temperature control circuit, which comprises a non-isolated power module, a control processing module, a temperature acquisition module, a relay, a relay driving unit and a function key module, wherein the first end of a switch of the relay is used for being connected with an AC live wire; the second end of the switch of the relay is used for being connected with a compressor; the relay driving unit comprises a refrigeration control signal input end, a power supply end and a refrigeration driving end; the power input end of a relay coil is connected with the power supply end; the current output end of the relay coil is connected with the refrigeration driving end; the non-isolated power module includes a first power output end and a second power output end; the first power output end, the temperature acquisition module, the function key module and the refrigeration control signal input end are all connected with the control processing module; and the power supply end is connected with the second power output end. Correspondingly, the invention also discloses a refrigeration device and a refrigerator. The accuracy of temperature control can be improved, thetemperature fluctuation range in the refrigerator is reduced, the structure is simple, and the cost is low.

Owner:GUANGDONG HOMA REFRIGERATOR CO LTD

Device and method for improving temperature control precision

PendingCN113853035AGood heat insulation measuresSmall fluctuation rangeElectric heatingTemperature controlLoop control

The invention discloses a device and method for improving temperature control precision, corresponding closed-loop control is added on the basis of open-loop control to carry out heat dissipation loss heating compensation, dynamic balance of system heat is guaranteed, constant-temperature and constant-speed control is achieved, and the temperature control precision is improved. The device comprises a container for bearing a medium, a heating disc for heating a medium is arranged at the bottom of the container, the container is provided with a temperature sensor for monitoring the temperature of the medium, the temperature sensor is in communication connection with a controller, and the controller comprises an open-loop control unit and a closed-loop control unit; the heating disc comprises an open-loop control load and a closed-loop control load, the open-loop control load is connected with the open-loop control unit, the closed-loop control load is connected with the closed-loop control unit, and the controller is electrically connected with a power supply for supplying power to the device; or the heating disc only comprises one load, the load is respectively connected to the open-loop control unit and the closed-loop control unit, the open-loop control unit is electrically connected with the first power supply, and the closed-loop control unit is electrically connected with the second power supply.

Owner:SHAANXI UNIV OF SCI & TECH

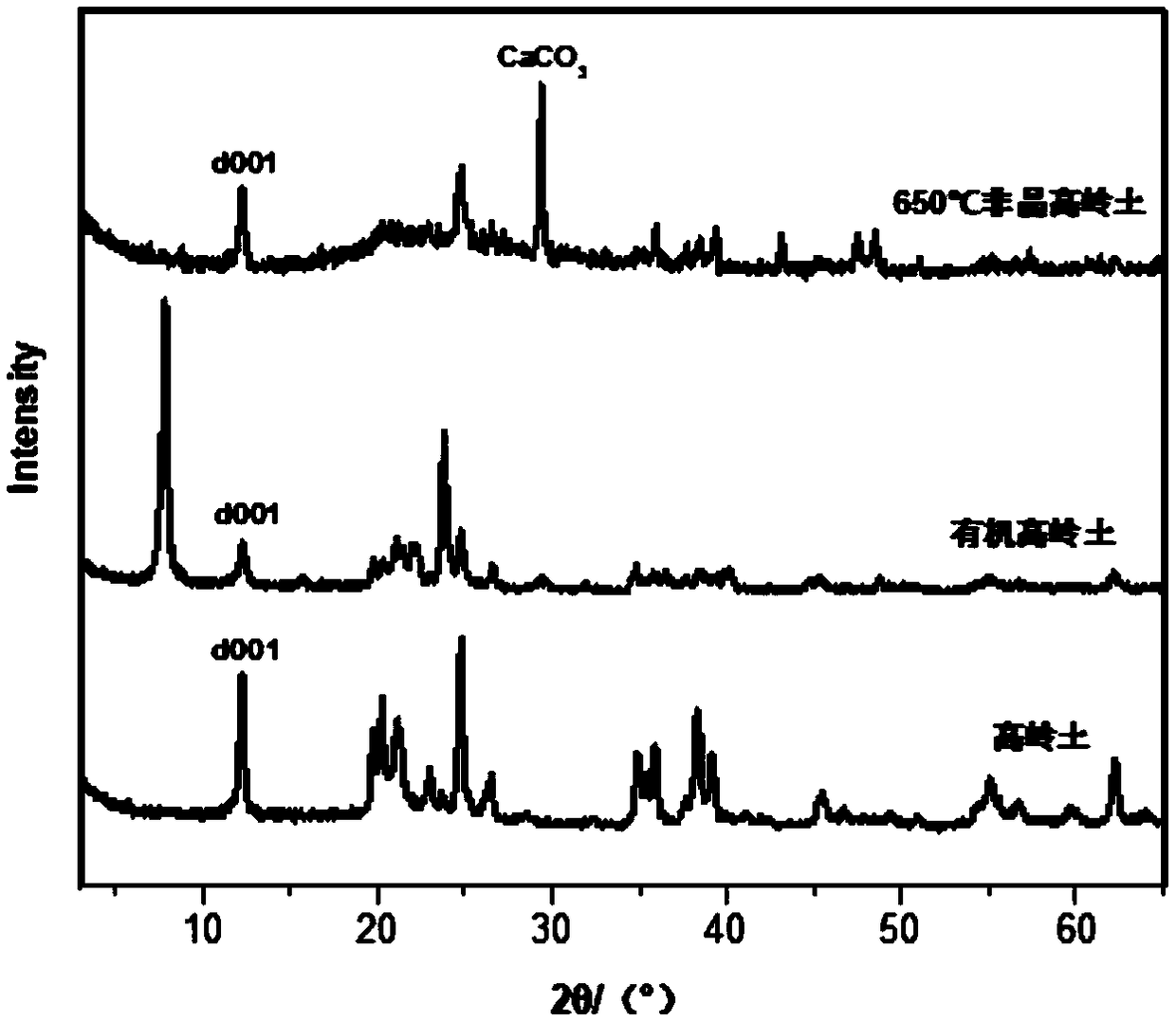

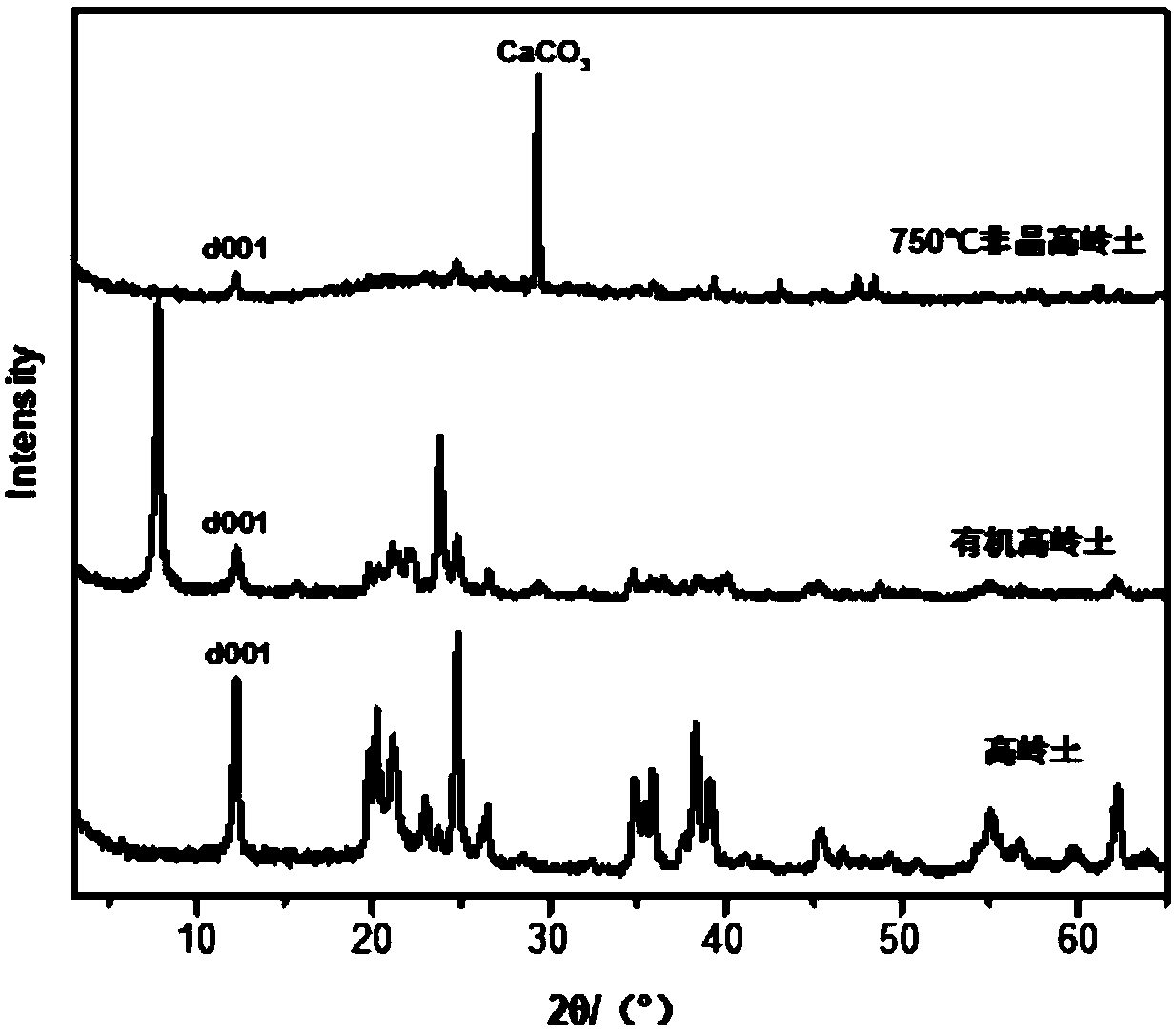

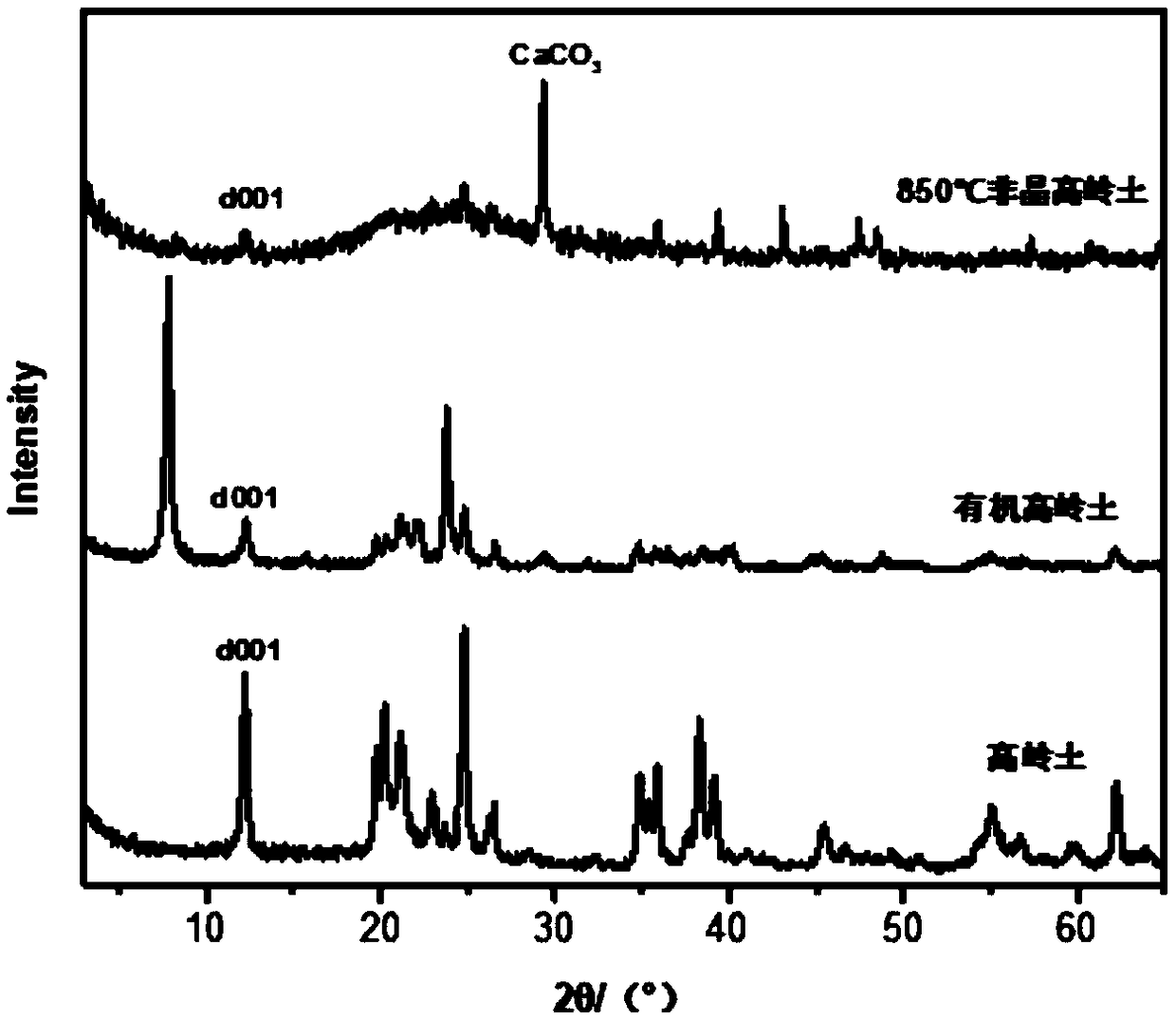

Method for rapidly non-crystallizing flash hot organic kaolin

ActiveCN109485056ASmall temperature fluctuation rangeUniform and stable heatingChemical industrySilicon compoundsRetention timeHeating furnace

The invention discloses a method for rapidly non-crystallizing flash hot organic kaolin. The method comprises the following steps: grading raw kaolin powder, performing intercalation compounding withdimethyl sulfoxide to prepare organic kaolin, grinding and drying, spraying the organic kaolin into a vertical heating furnace, and performing rapid non-crystallizing by a flash heating method at a flash heating temperature of 650-1050 DEG C. The non-crystallizing transformation rate is controlled by regulating the flash heating temperature and the material retention time. According to the methoddisclosed by the invention, the non-crystallizing transformation temperature of the kaolin is effectively reduced, and the transformation rate of the non-crystallized kaolin is stable and controllable. The method is simple in process, energy-saving, high-efficiency and high in treatment quantity, and the product quality is stable and uniform.

Owner:CHINA UNIV OF MINING & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com