Device and method for improving temperature control precision

A technology of precision and temperature information, applied in the field of devices for improving temperature control accuracy, can solve the problems of increased heat dissipation loss, affecting temperature control accuracy, heat dissipation loss, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

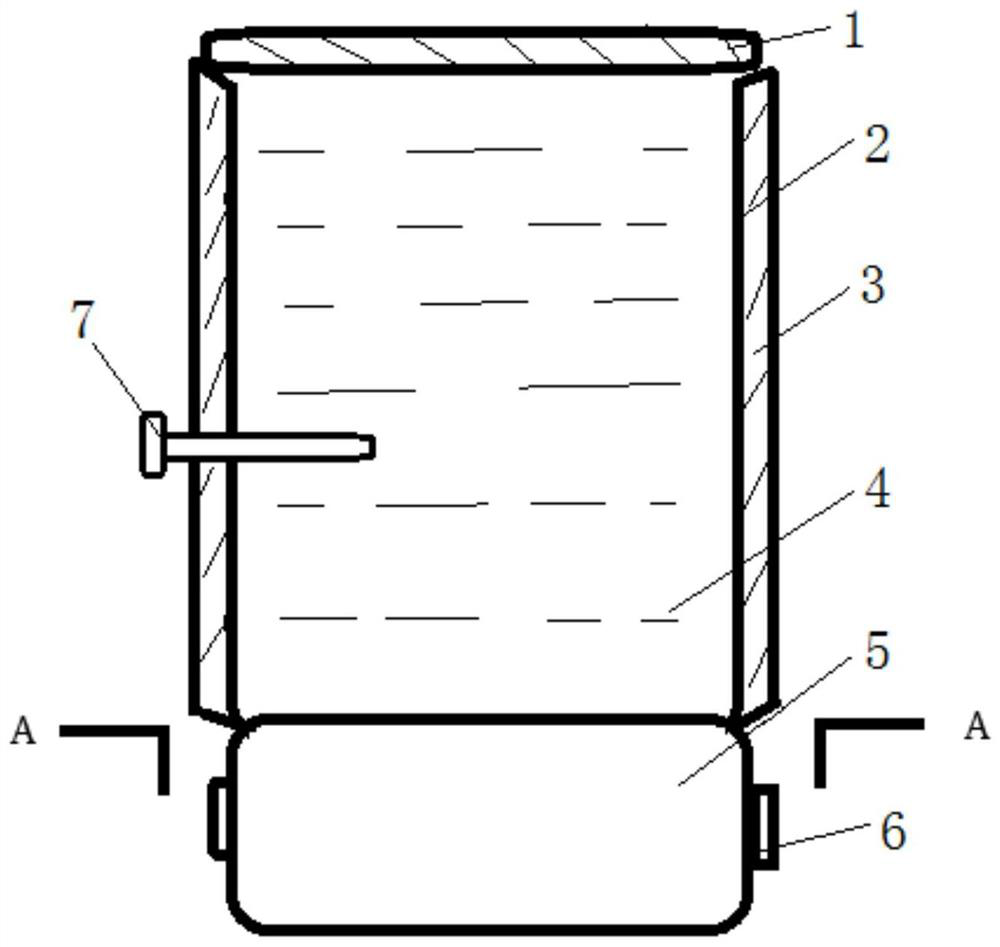

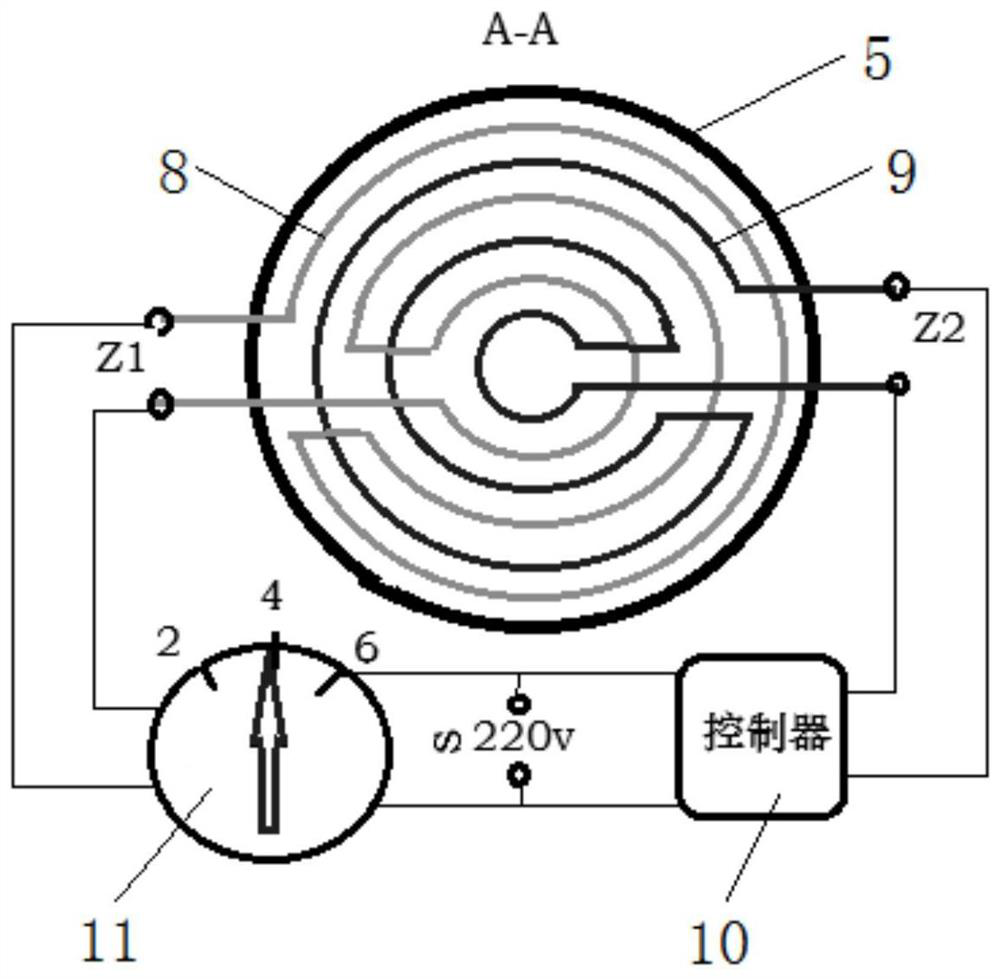

[0029] Embodiment 1 of the present invention provides a device for improving temperature control accuracy, see figure 1 and figure 2 , which includes a container 2 for carrying a medium 4, a heating plate 5 for heating the medium 4 is provided at the bottom of the container 2, the heating plate 5 includes an open-loop control load 8 and a closed-loop control load 9, the controller 10 includes an open-loop control unit and The closed-loop control unit, the open-loop control load 8 is connected to the open-loop control unit of the controller 10 through the stepping knob 11, the closed-loop control load 9 is connected to the closed-loop control unit of the controller 10, and the container 2 is also provided with a device for monitoring the temperature of the medium 4 The temperature sensor 7 is communicatively connected to the controller 10, and the controller 10 is electrically connected to the same power supply for powering the device. Both the open-loop control load 8 and th...

Embodiment 2

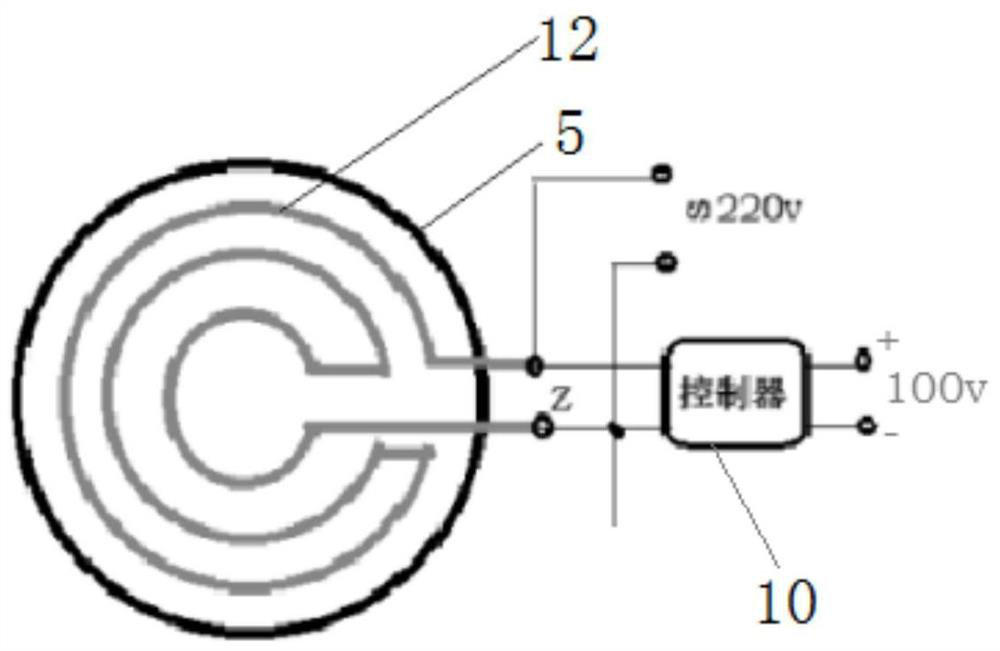

[0040] Embodiment 2 of the present invention provides another device for improving temperature control accuracy, see image 3 , the heating plate 5 only includes a load 12, the controller 10 includes an open-loop control unit and a closed-loop control unit, the load 12 is respectively controlled and connected to the open-loop control unit and the closed-loop control unit, the open-loop control unit is electrically connected to the first power supply, and the closed-loop control The unit is electrically connected to the second power source. The open-loop control unit is connected with a stepping knob 11 , and the stepping knob 11 controls and connects a load 12 . The load 12 may be a load such as a heating wire. The other technical features are the same as those in Embodiment 1, and will not be repeated one by one.

[0041] The temperature control method based on the temperature control device of Embodiment 2 includes: when the temperature rises, the open-loop control unit co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com