Patents

Literature

367results about How to "Small fluctuation range" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

HRB600E vanadium-containing high-strength hot-rolled earthquake-resistant reinforced bar and production method thereof

The invention discloses an HRB600E vanadium-containing high-strength hot-rolled earthquake-resistant reinforced bar and a production method thereof. The reinforced bar comprises the following chemical components in percentage by weight: 0.23-0.30% of C, 0.5-0.8% of Si, 1.20-1.60% of Mn, 0.15-0.20% of V, no more than 0.035% of P, no more than 0.030% of S, 0.015-0.025% of N and the balance of Fe and inevitable impurities. The production method comprises the following steps: performing converter or electric furnace smelting, performing external refining, performing continuous casting, heating a casting blank, rolling and performing air cooling on a cooling bed. According to the invention, the V and N contents in steel are controlled, thereby promoting formation and precipitation of V (C, N) fine particles; steel making and steel rolling process parameters are strictly controlled, thereby obviously enhancing the strength of the reinforced bar and having certain hydrogen corrosion resistance; indicators of the reinforced bar meets the requirements of an earthquake-resistant reinforced bar; and the reinforced bar has the practical meanings of energy saving, emission reduction, high safety and environment friendliness.

Owner:HEBEI IRON AND STEEL

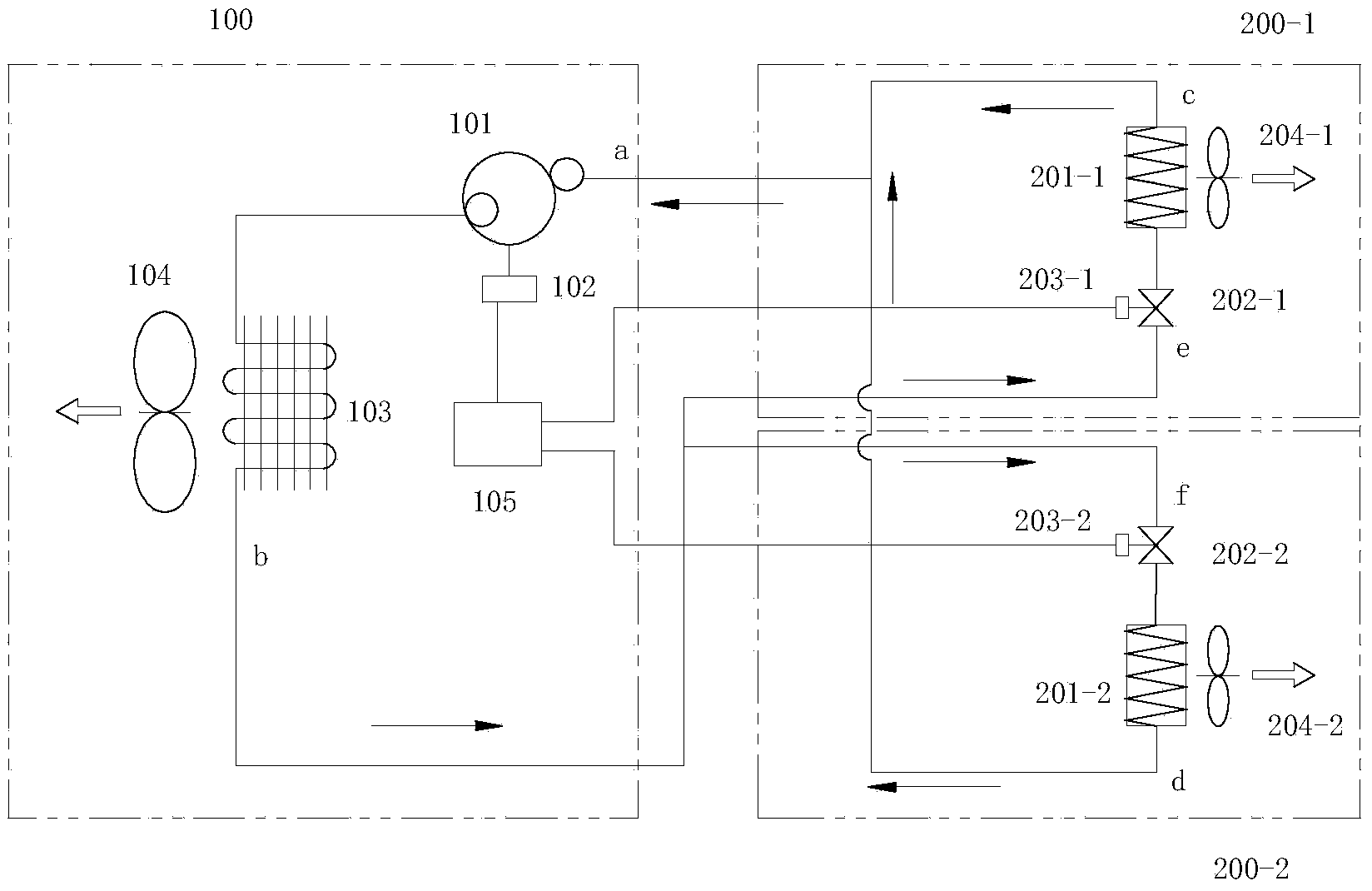

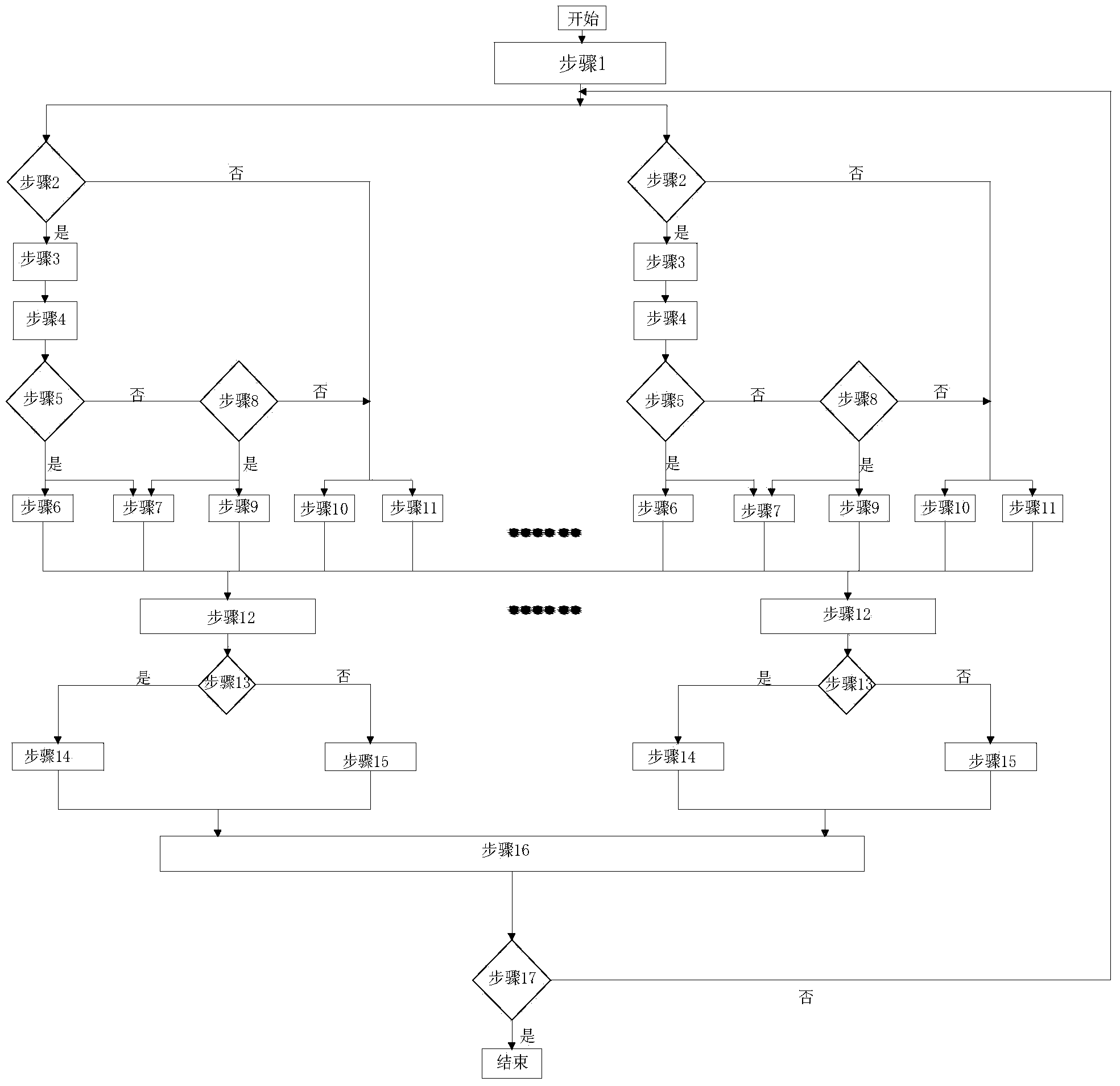

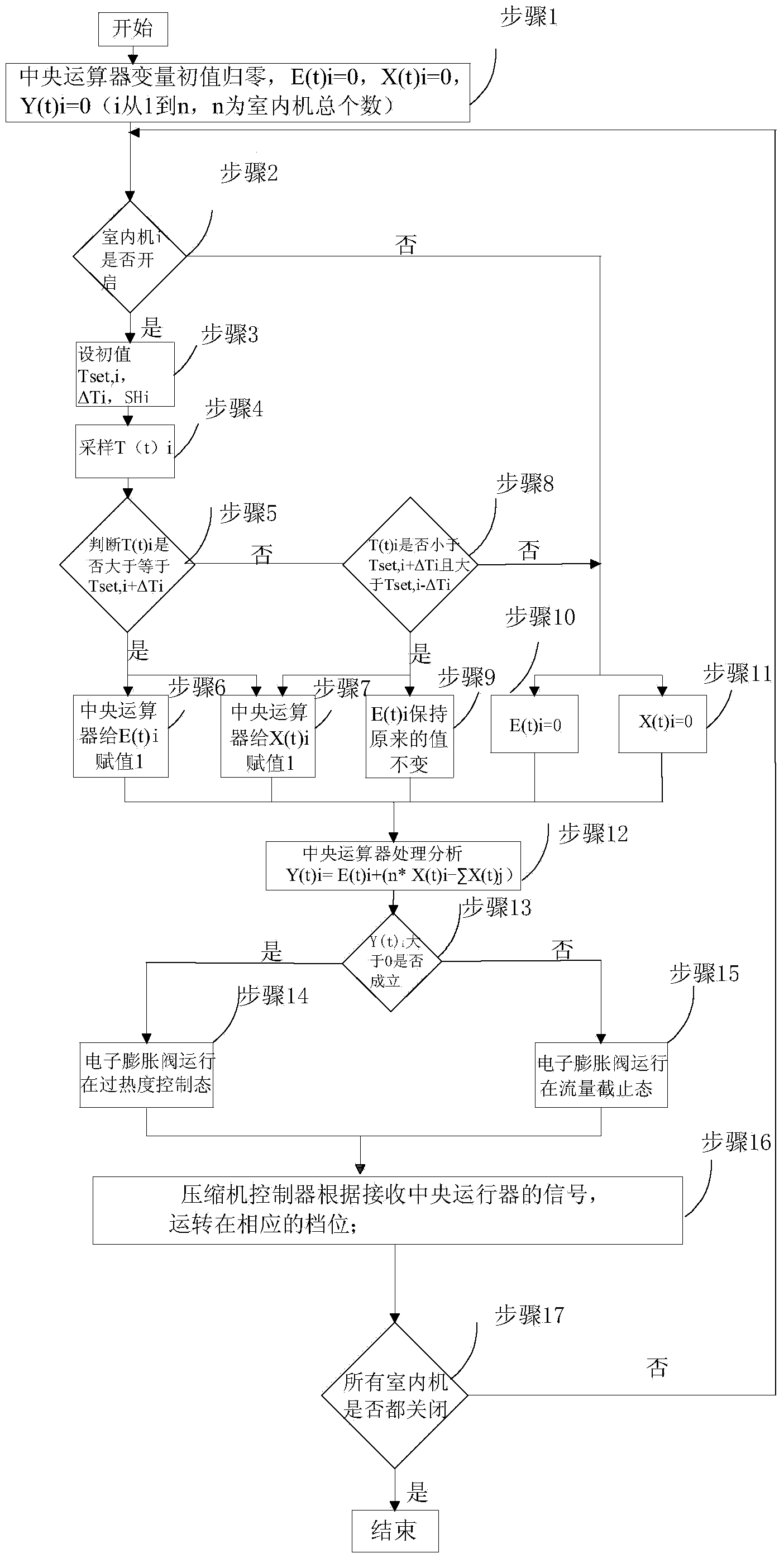

Central arithmetic type multi-split air conditioner system and state switching control method thereof

InactiveCN103644621ASimple structureLow costSpace heating and ventilation safety systemsLighting and heating apparatusEngineeringState switching

The invention discloses a central arithmetic type multi-split air conditioner system and a state switching control method of the central arithmetic type multi-split air conditioner system. The operating states of electronic expansion valves and the operating states of compressors are controlled through a central arithmetic unit, the operating frequency and the corresponding gear of each compressor are determined so that the total refrigerating capacity output by the central arithmetic type multi-split air conditioner system can be controlled easily and efficiently, the refrigerating capacity can be reasonably distributed to rooms, and the refrigerating capacity obtained by each room is matched with the heat load of the room. The central arithmetic unit receives temperature signals of all the rooms, carries out centralized arithmetic processing, sends instructions to the electronic expansion valves and the compressors of indoor units, and has control over execution behaviors of the electronic expansion valves and execution behaviors of the compressors. According to the central arithmetic type multi-split air conditioner system and the state switching control method of the central arithmetic type multi-split air conditioner system, mutual influence among the indoor units is taken into overall consideration, the fluctuation range of the indoor temperature is reduced, the probability that the compressors are in the shutdown state in the operating process of the central arithmetic type multi-split air conditioner system is greatly reduced, loss caused by frequent starting and frequent shutdown of the compressors is reduced, and the fluctuation, caused by starting and shutdown of the compressors, of the indoor temperature can be further reduced.

Owner:ZHEJIANG UNIV

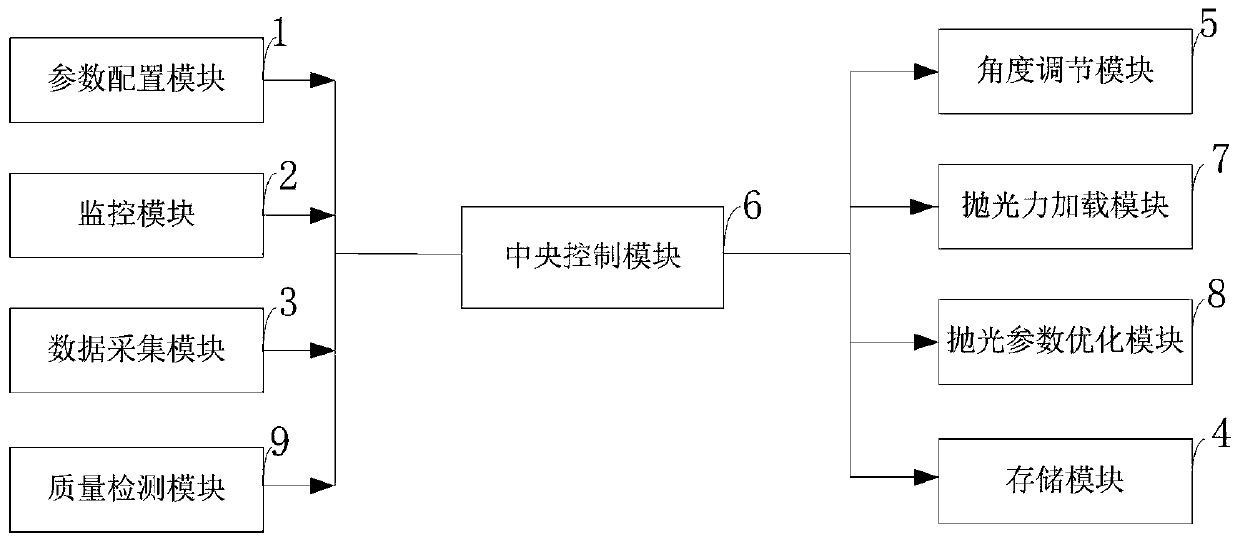

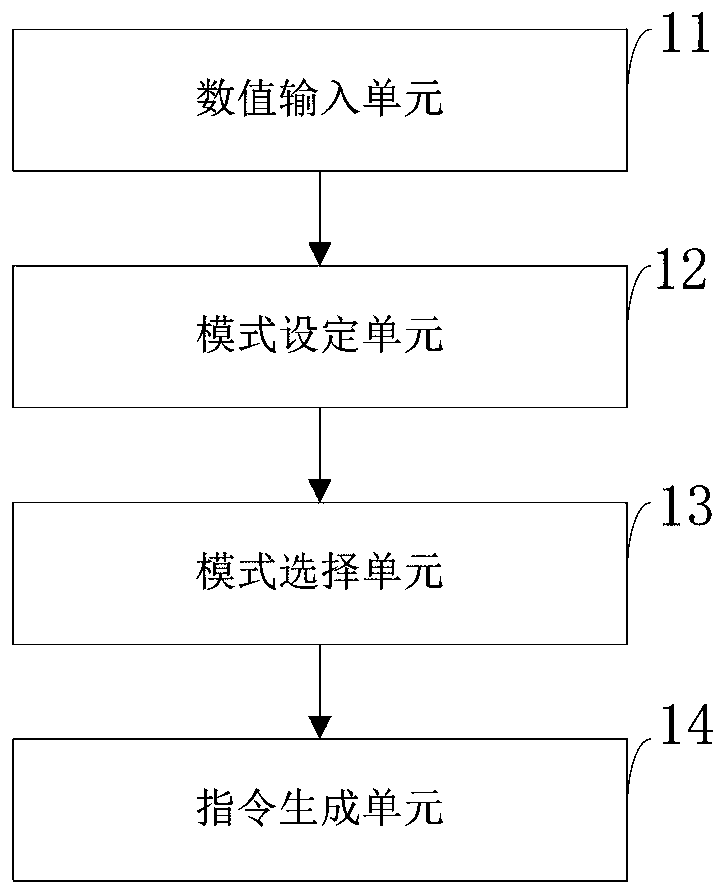

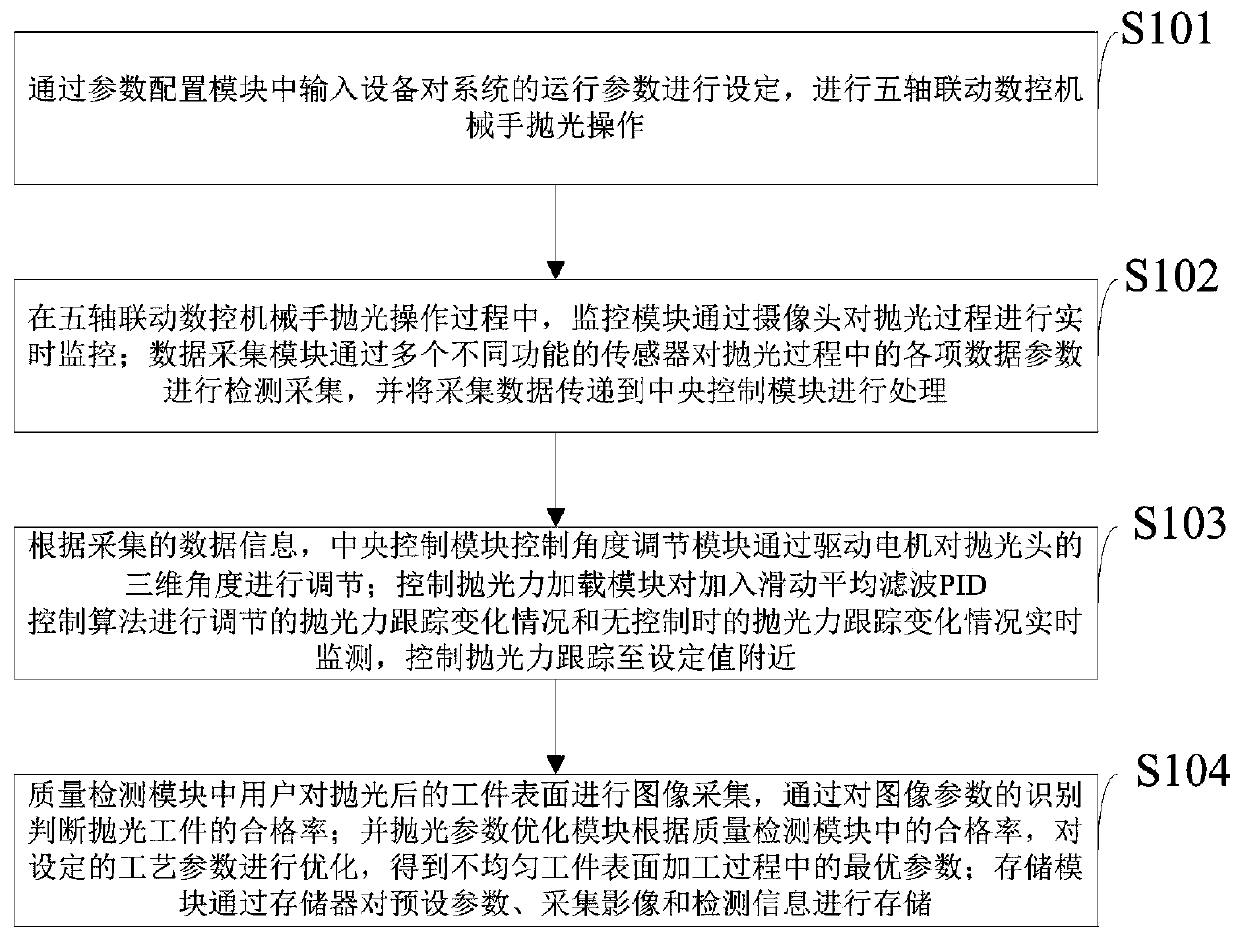

Five-axis linkage numerical control manipulator polishing control system and method

InactiveCN111468989AOptimizing Process ParametersAccurate and fast variable polishing force controlPolishing machinesAutomatic grinding controlNumerical controlControl system

The invention belongs to the technical field of machining, and discloses a five-axis linkage numerical control manipulator polishing control system and method. The five-axis linkage numerical controlmanipulator polishing control system comprises a parameter configuration module, a monitoring module, a data acquisition module, a storage module, an angle adjustment module, a central control module,a polishing force pneumatic loading module, a polishing parameter optimization module and a quality detection module. The parameter configuration module comprises a numerical value input unit, a modesetting unit, a mode selection unit and an instruction generation unit. The monitoring module monitors the polishing process in real time through a camera. The data acquisition module detects and acquires various data and parameters in the polishing process through a plurality of sensors with different functions. According to the five-axis linkage numerical control manipulator polishing control system and method, accurate and rapid tracking variable polishing force control can be achieved in the polishing process, the corresponding polishing force is controlled in real time, and the force control requirement of polishing machining can be effectively met; and on the premise that the polishing quality is guaranteed, the working efficiency is improved.

Owner:YELLOW RIVER CONSERVANCY TECHN INST

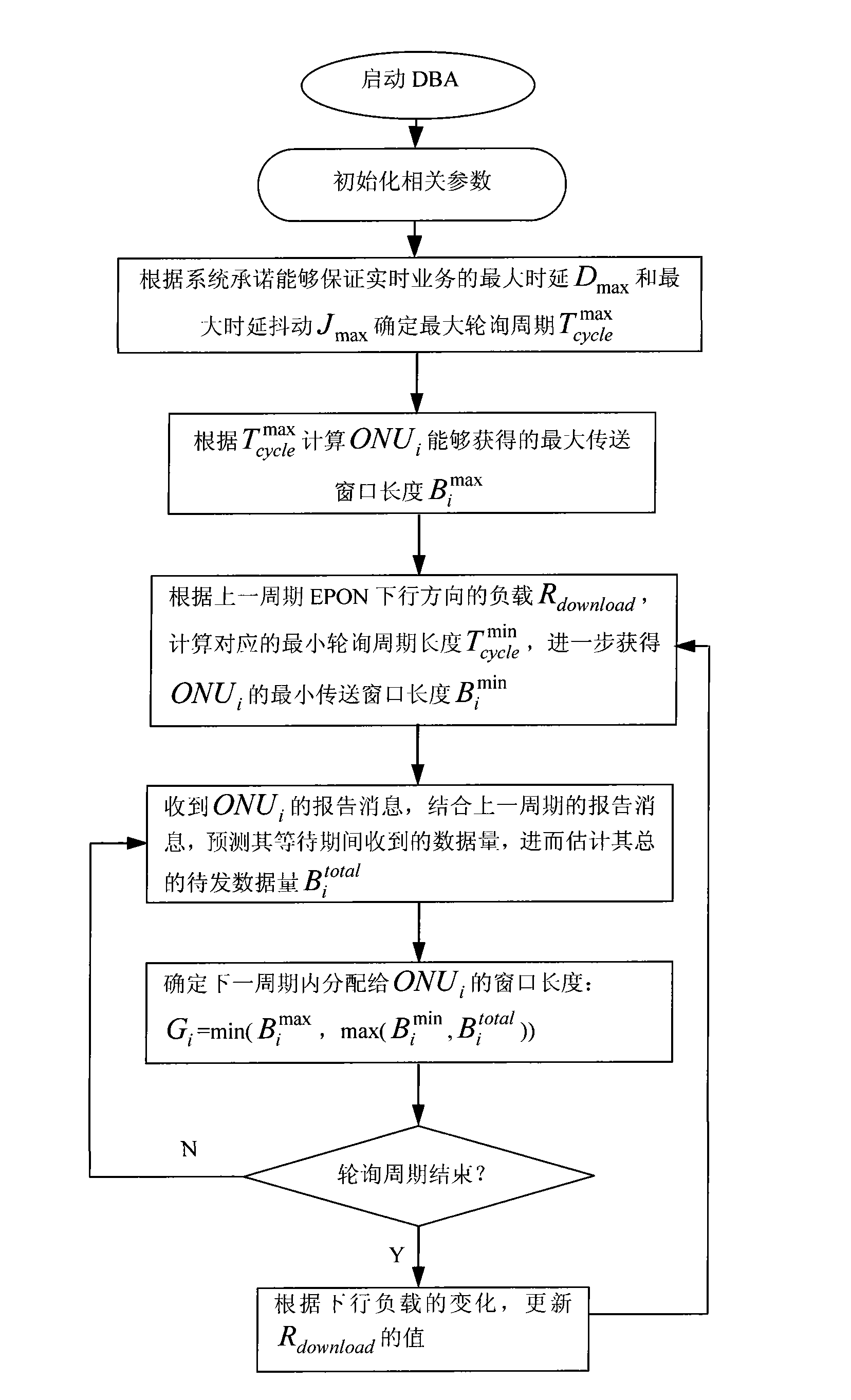

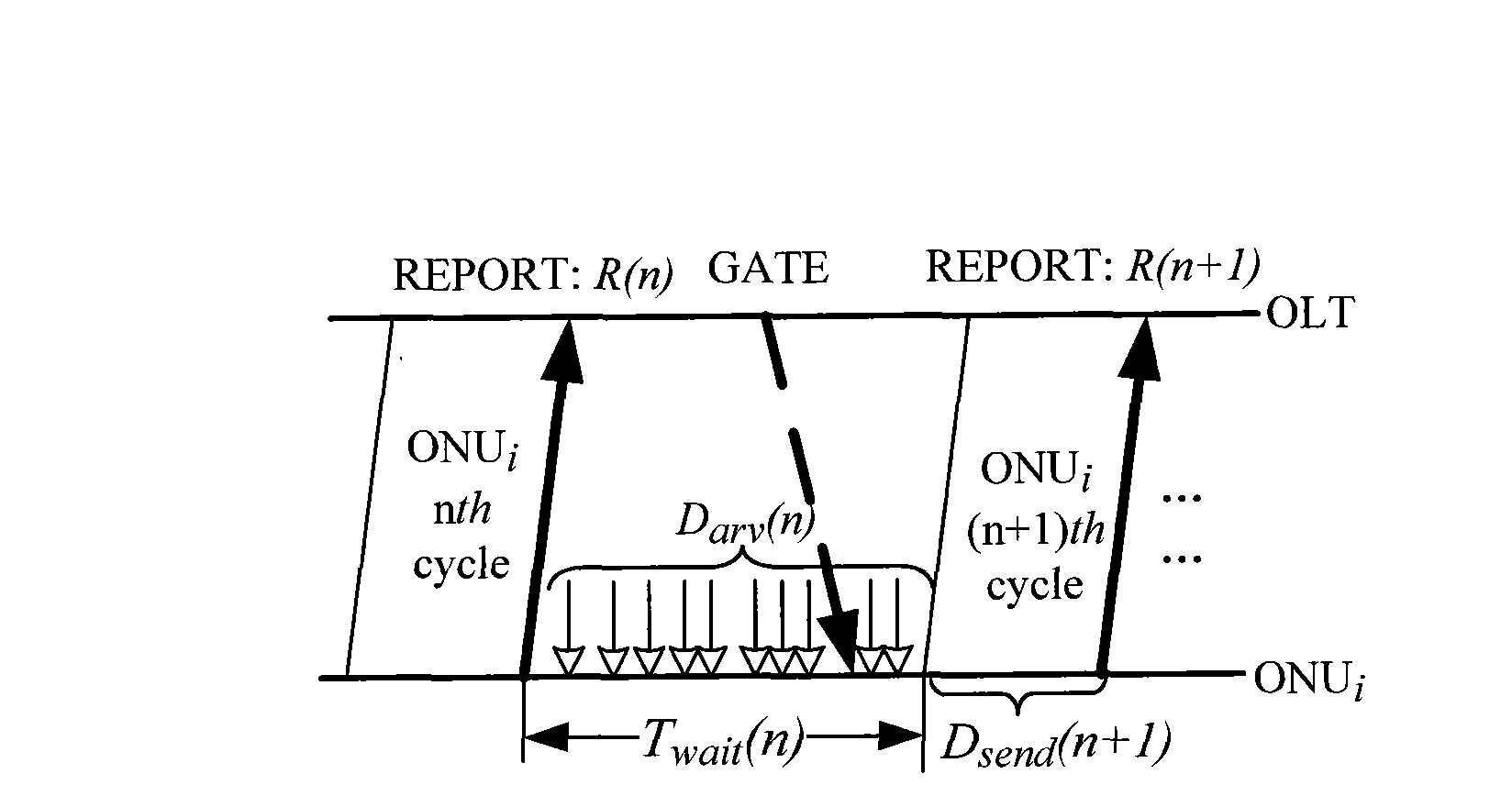

Dynamic bandwidth allocation method for self-adapting service quality assurance in Ethernet passive optical network

InactiveCN101667962AGuaranteed service qualityImprove throughputMultiplex system selection arrangementsData switching networksTraffic forecastTime delays

The invention relates to real-time service transmission quality assurance in the communication of an Ethernet passive optical network, in particular to a dynamic bandwidth allocation method for self-adapting service quality assurance in the Ethernet passive optical network. The method adopts the technical scheme that: on the premise of assuring the service quality promised by a system, such as maximum time delay and time delay dithering of a real-time service, according to uplink capacity and downlink capacity of the system, the polling cycle is automatically regulated to enable the system performances including throughput, time delay and time delay dithering to be optimal. The method comprises the following steps: firstly, determining a maximum polling cycle of the system according to the maximum time delay and the time delay dithering of the real-time service which can be assured by the Ethernet passive optical network (EPON) system; secondly, determining the minimum polling cycle according to the downlink capacity of the system; thirdly, predicting the traffic of an optical network unit (ONU); and fourthly, allocating the bandwidth. The invention is mainly applied to the communication of the Ethernet passive optical network.

Owner:TIANJIN UNIV

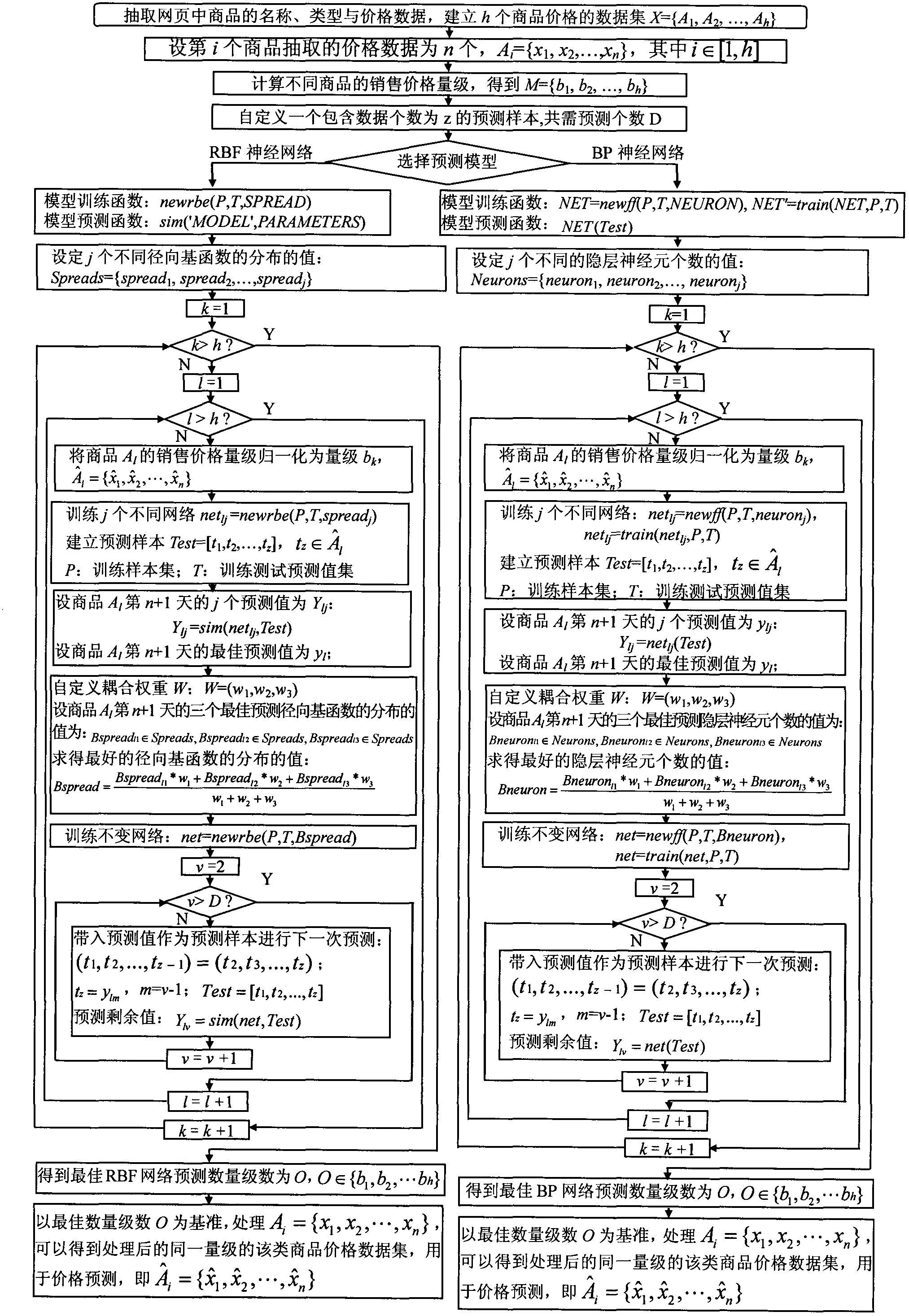

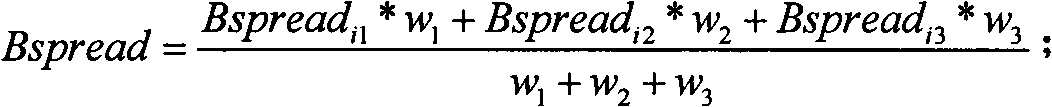

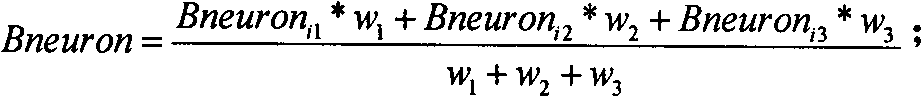

Multi-assortment commodity price expectation data pre-processing method based on neural networks

InactiveCN102982229ASmall fluctuation rangeReduce the differenceSpecial data processing applicationsWeb pageOrder of magnitude

The invention discloses a multi-assortment commodity price expectation data pre-processing method based on neural networks. The best order of magnitude of commodity price data which is obtained from websites is calculated by an improved radical basis function (RBF) neural networks and an improved back propagation (BP) artificial neural networks. The calculated best order of magnitude is used to preprocess normalized order of magnitude of the commodity price. Expectation accuracy of the RBF neural networks and the BP neural networks is improved. Generality of the RBF neural networks and the BP neural networks for expectation of different kinds of commodity prices is improved.

Owner:无锡曼莱软件有限公司

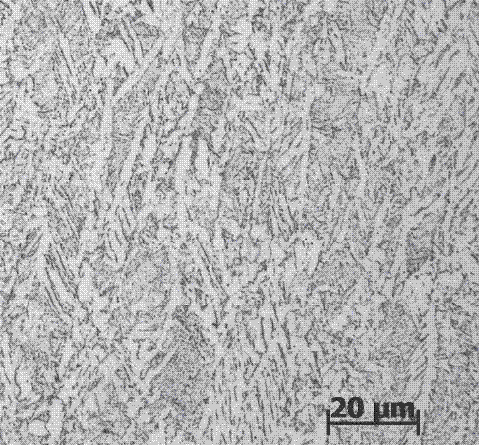

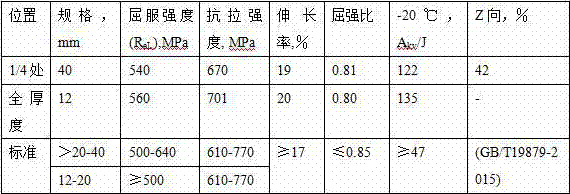

Large-thickness Q500GJCD high-strength steel plate for building structure, and manufacturing method thereof

The invention relates to a large-thickness Q500GJCD high-strength steel plate for a building structure, and a manufacturing method thereof. The chemical components of the steel plate comprise, by mass, 0.12%-0.17% of C, 0.20%-0.50% of Si, 1.10%-1.60% of Mn, no more than 0.015% of P, no more than 0.005% of S, 0.10%-0.30% of Cr, no more than 0.30% of Mo, 0.10%-0.30% of Ni, no more than 0.30% of Cu, 0.02%-0.04% of Al, 0.020%-0.060% of Nb, 0.01%-0.02% of Ti, no more than 0.20% of V+Nb+Ti, no more than 0.006% of N and unavoidable impurity elements, and the carbon equivalent is no more than 0.46%. The technological process comprises the steps of hot metal pretreatment, converter steel making, LF refining, RH furnace refining, blank casting of a continuous casting machine, blank heating, control rolling of a rolling mill, and Acc cooling and finishing. The steel plate for the building structure, provided by the application, has the advantages of uniform performance, excellent comprehensive performance, short production cycle and low production cost.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

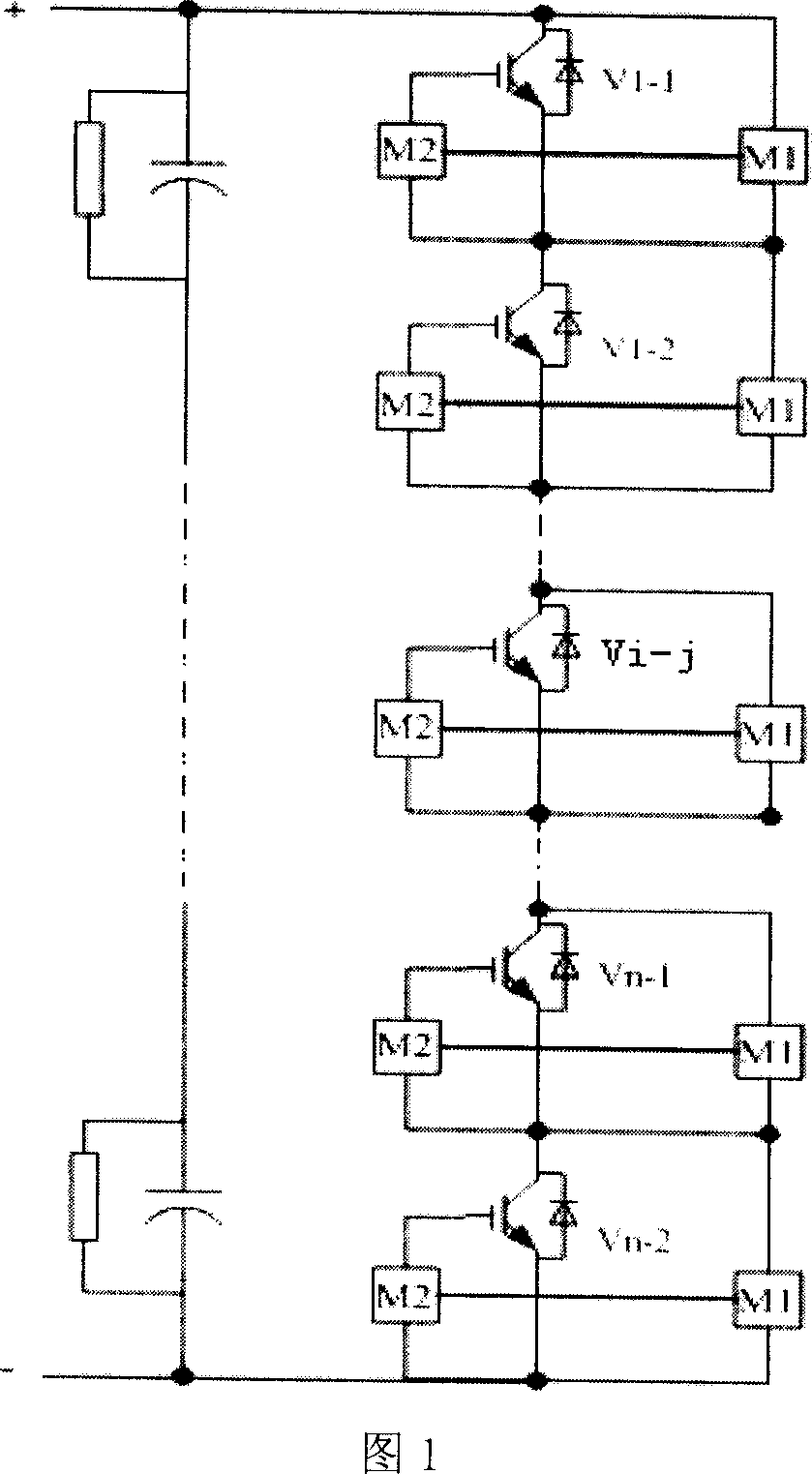

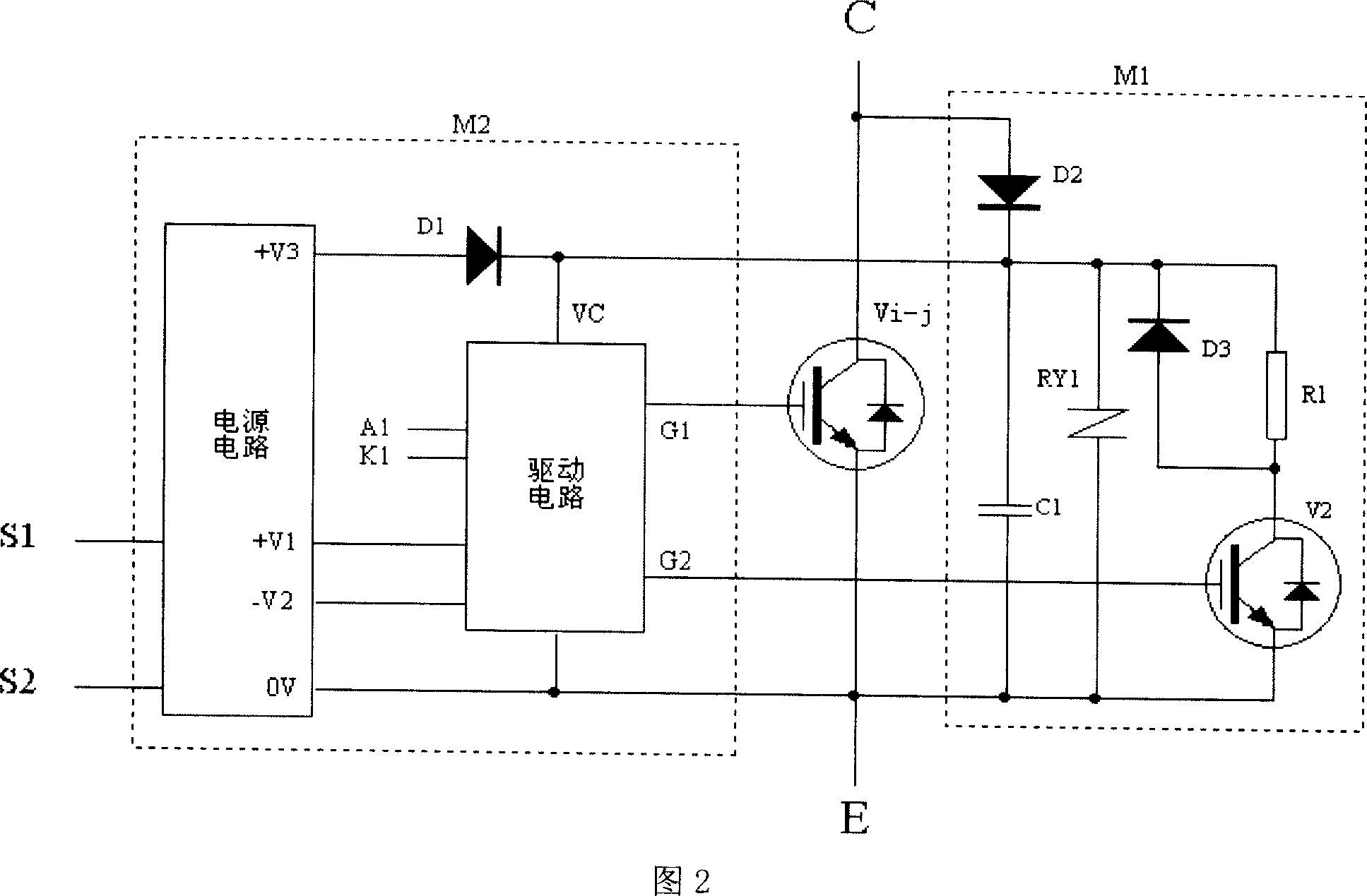

Cascade active voltage-stabilizing controller of power switch

InactiveCN101030701AWide range of choicesStrong pressure equalization control abilityEmergency protective circuit arrangementsControl signalControl theory

The invention is concerned with the active series connection equal-press controlling equipment for the power switch, the characteristic is: sets the active equal-press absorb module for the series power module, the active equal-press absorb module crosses and parallel connects with the C and E end of each main power tube Vi-j; sets the driving controlling module, the outputting controlling signal of the driving controlling module accesses each power module and the active equal-press absorb module. The invention is lower power consumption, simple circuit.

Owner:HEFEI UNIV OF TECH

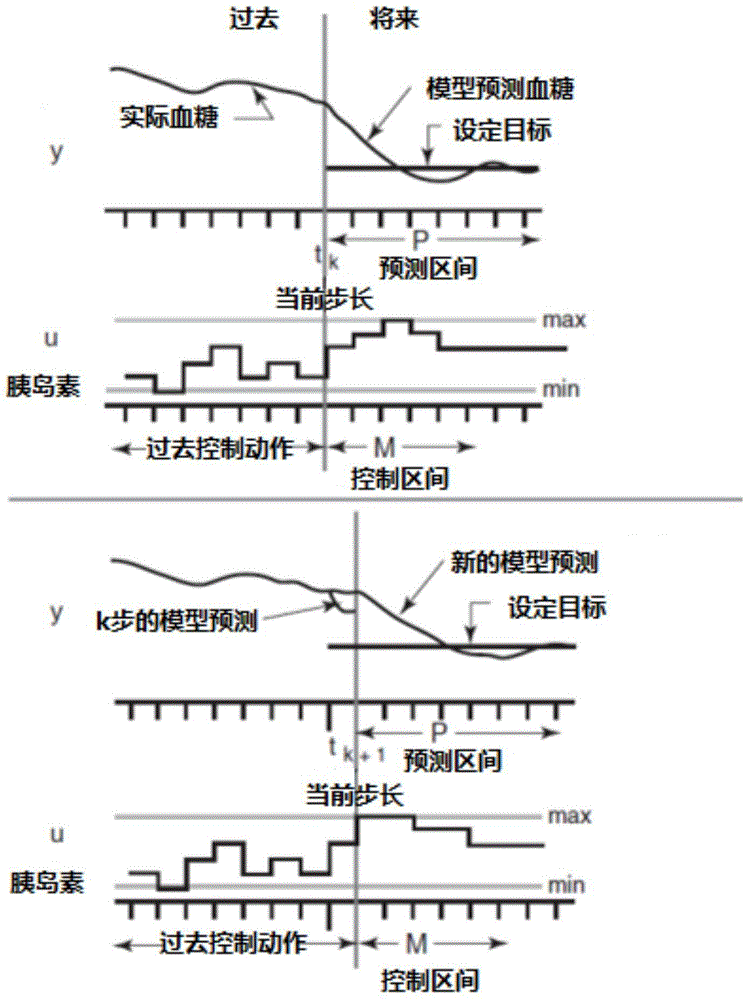

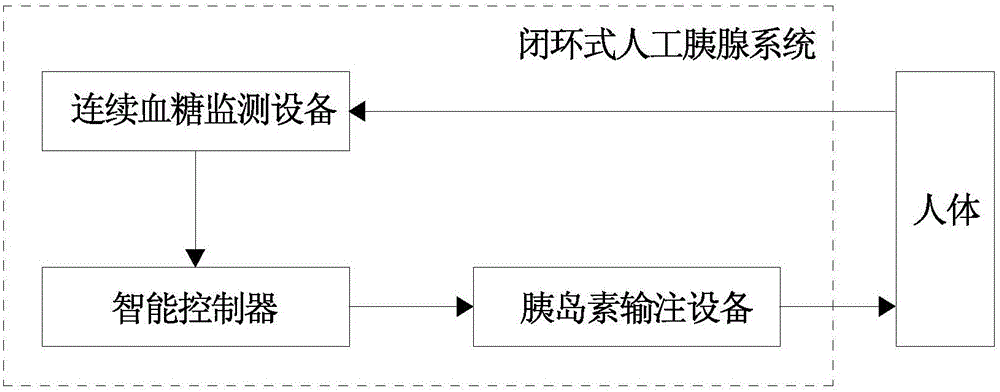

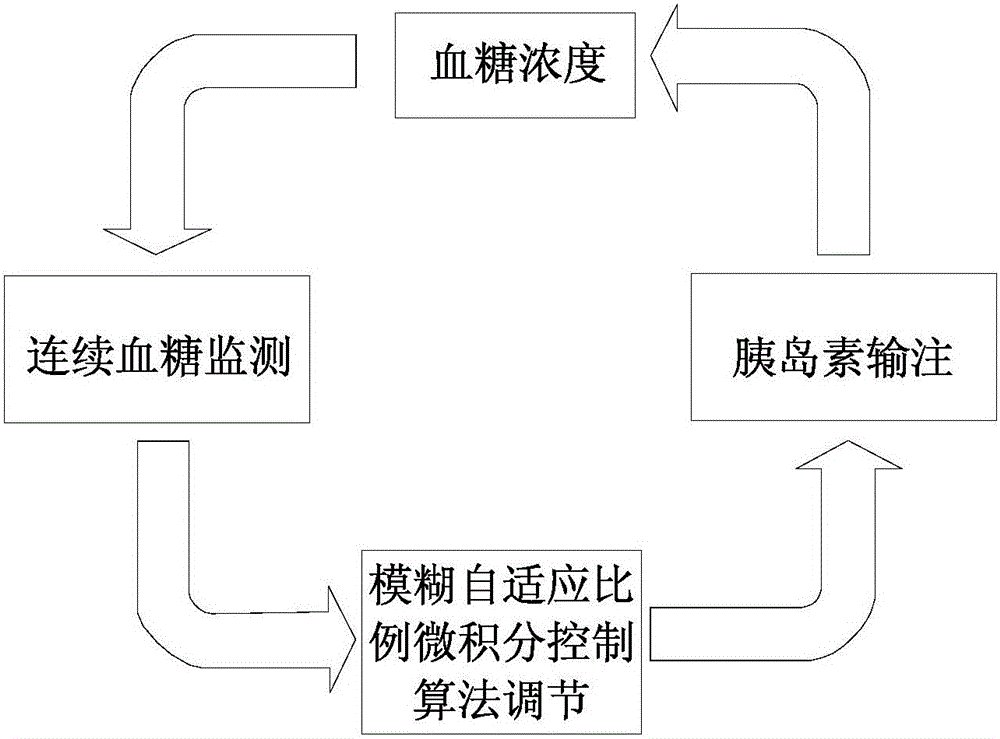

Intelligent control close-loop artificial pancreas system

InactiveCN104958077ASmall fluctuation rangeImprove accuracy and effectivenessPressure infusionBlood characterising devicesHuman bodyInsulin injection

The invention discloses an intelligent control close-loop artificial pancreas system, comprising a continuous glucose monitoring device, an intelligent controller, and an insulin infusion device. The continuous glucose monitoring device is used to continuously monitor blood sugar concentration of a human body according to set interval. The intelligent controller is used to receive human body blood sugar monitoring data of the continuous glucose monitoring device in real time, and according to the real-time human body blood sugar monitoring data, by using a built-in fuzzy self-adaption proportion calculus control algorithm, calculates real-time insulin infusion device dosage. The insulin infusion device is used to receive the real-time insulin infusion device dosage of the intelligent controller, and perform real-time insulin on human bodies according to the real-time insulin infusion device dosage. The system can greatly reduce fluctuation range of human body blood sugar, and control blood glucose level in a set target interval, and improves accuracy and effectiveness of an insulin injection therapy, and makes blood glucose level of diabetics close to or reach standard of normal people, thereby greatly reducing various complications and improving living quality of the patients.

Owner:珠海福尼亚医疗设备有限公司

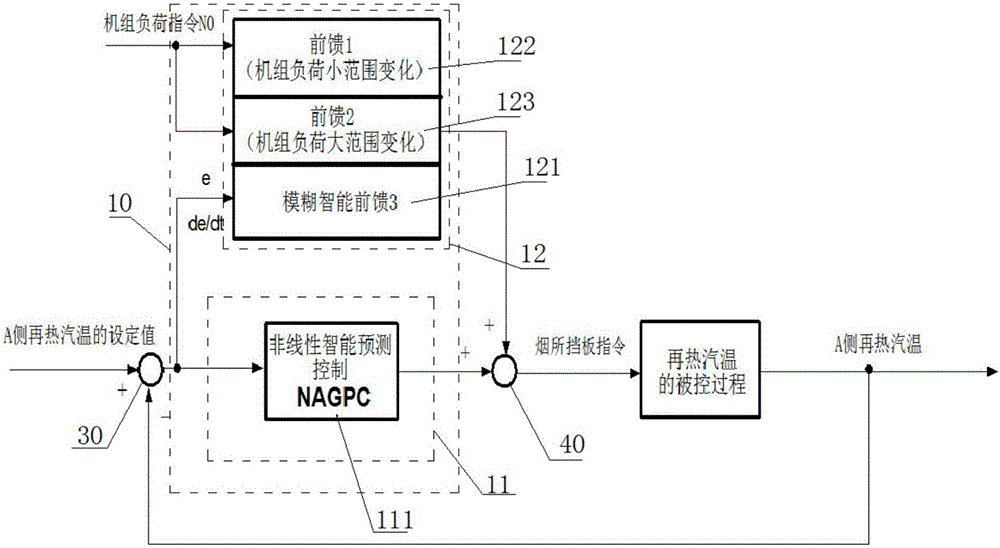

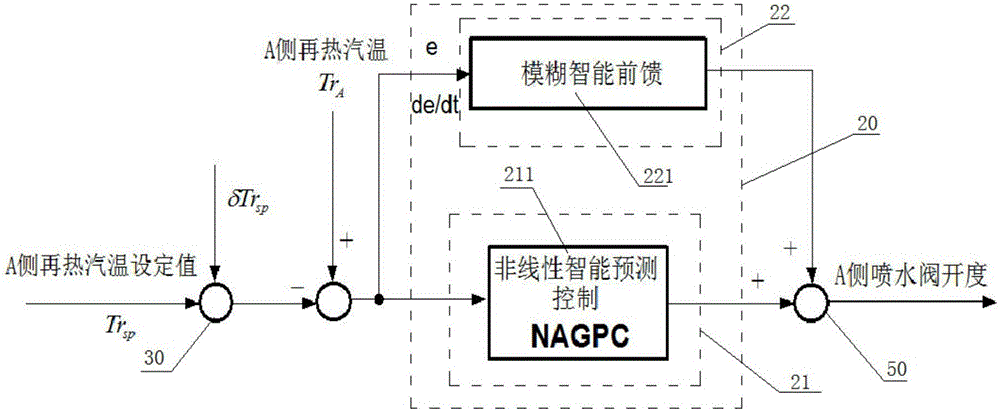

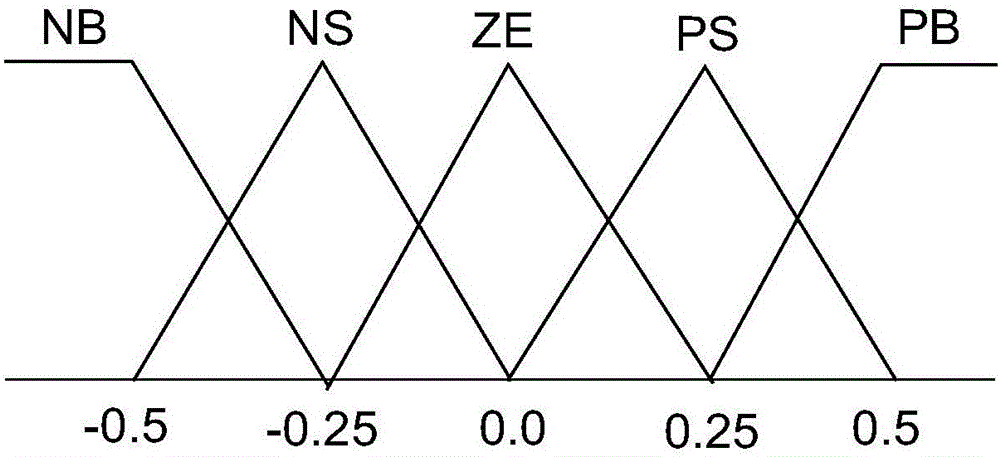

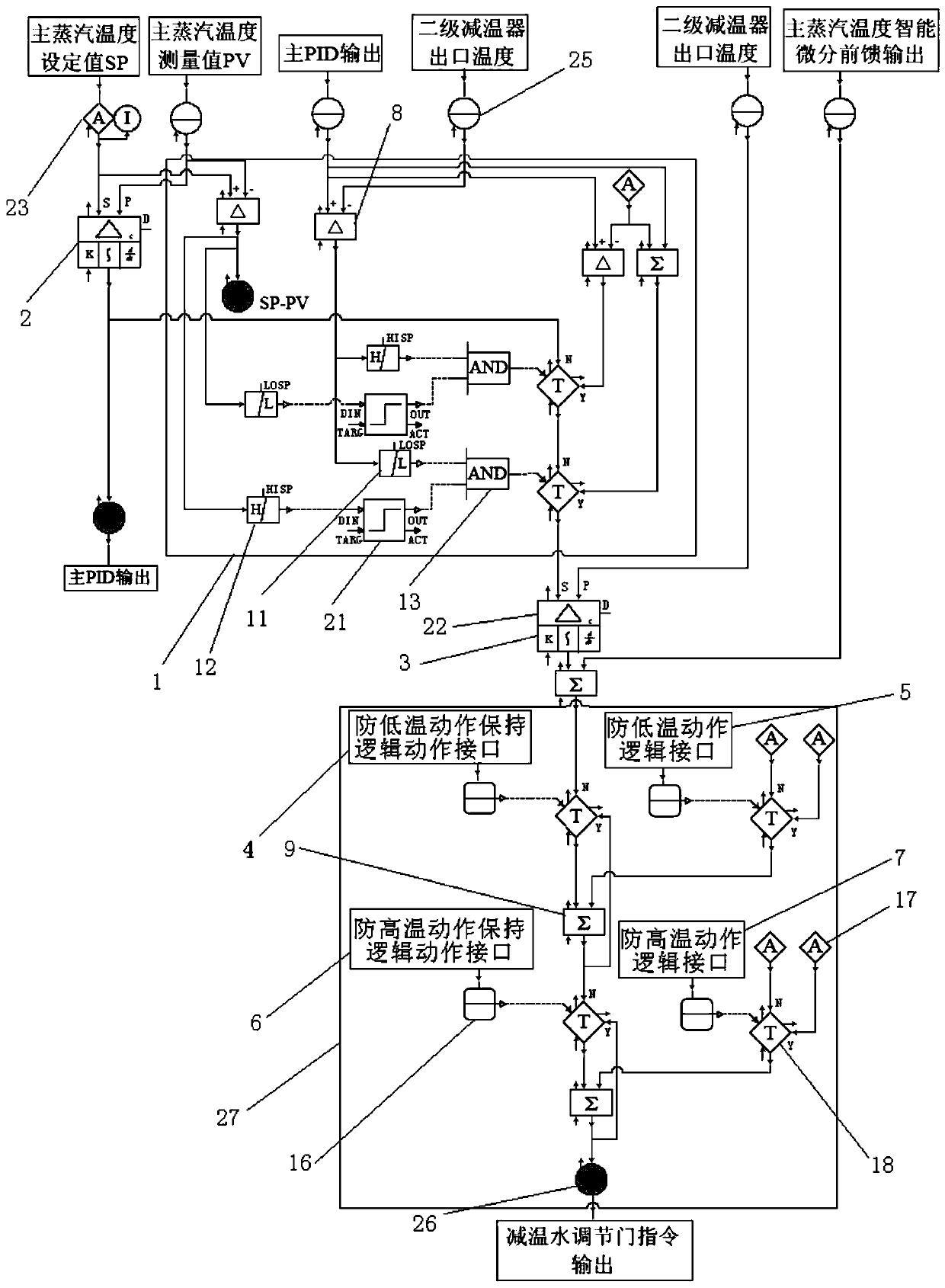

Nonlinear intelligent predictive control technology-based super critical unit reheating steam temperature optimal control system

ActiveCN106019939ASmall fluctuation rangeThe calculation process is clearAdaptive controlFlue gasPredictive controller

The invention discloses a nonlinear intelligent predictive control technology-based super critical unit reheating steam temperature optimal control system. The control system is composed of a flue gas baffle control loop and an accident water-spraying control loop; each of the flue gas baffle control loop and the accident water-spraying control loop includes a feedback loop and a feedforward loop; according to the feedback loop of each of the two control loops, a nonlinear intelligent predictive controller is adopted as a main controller; each of the feedforward loops includes a fuzzy intelligent feedforwarder; and the input variables of the fuzzy intelligent feedforwarder include a deviation variable e and deviation change rate de / dt. According to the control system of the invention, nonlinear intelligent predictive control is adopted, so that a constrained optimization problem can be processed conveniently. The calculation process of the control system is very clear and simple. When the control system is applied to engineering application, programming is very easy to implement, and the control effect of the control system is better than that of traditional PID; and the feedforward variable is additionally adopted, so that fast adjustment of the opening degree of a flue gas baffle can be realized, the overtemperature of the metal wall of a reheater can be prevented, a control effect enabling effective control on reheating steam temperature can be realized, and the economical efficiency and security of the operation of a boiler can be ensured.

Owner:SOUTHEAST UNIV

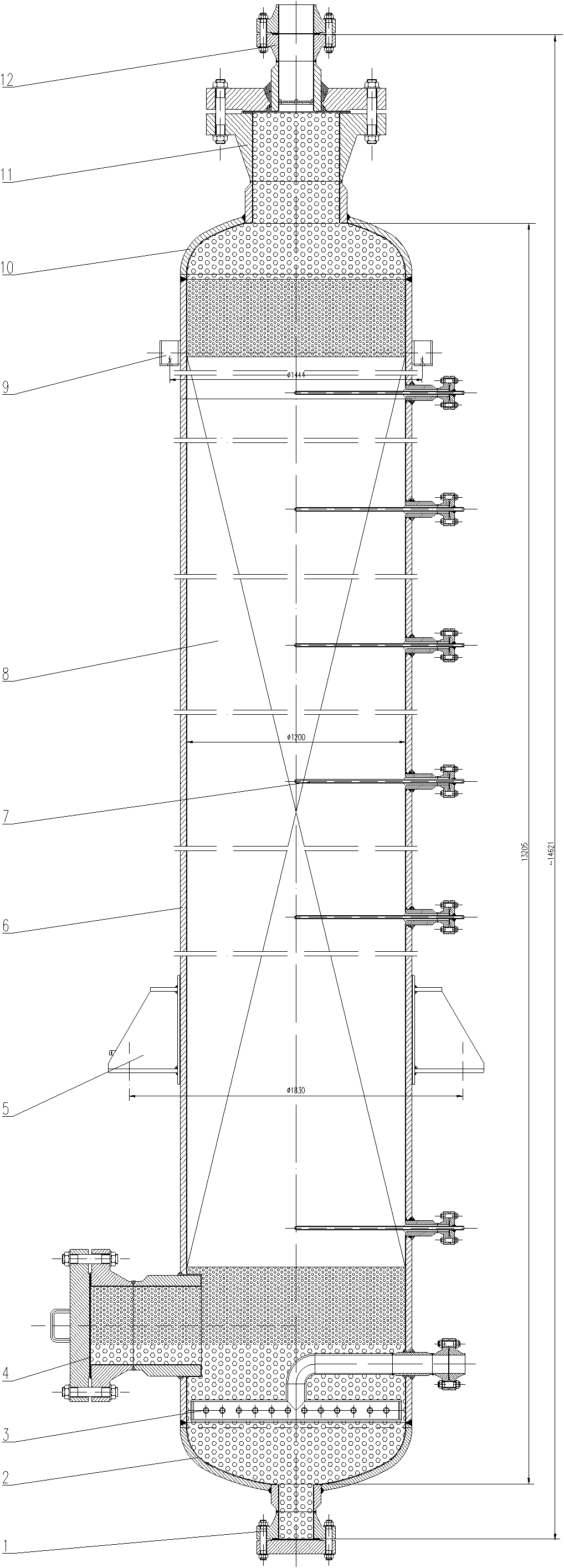

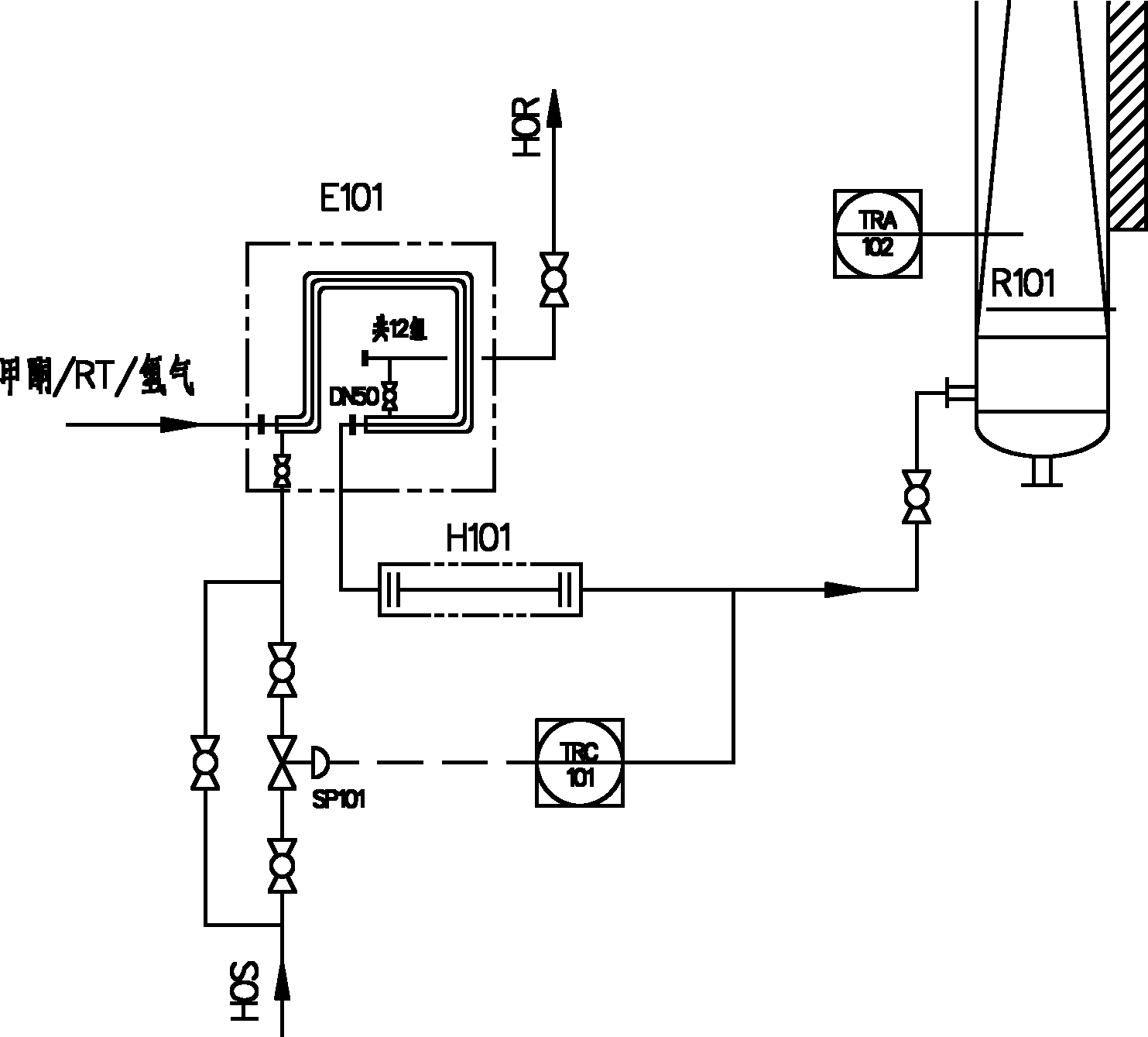

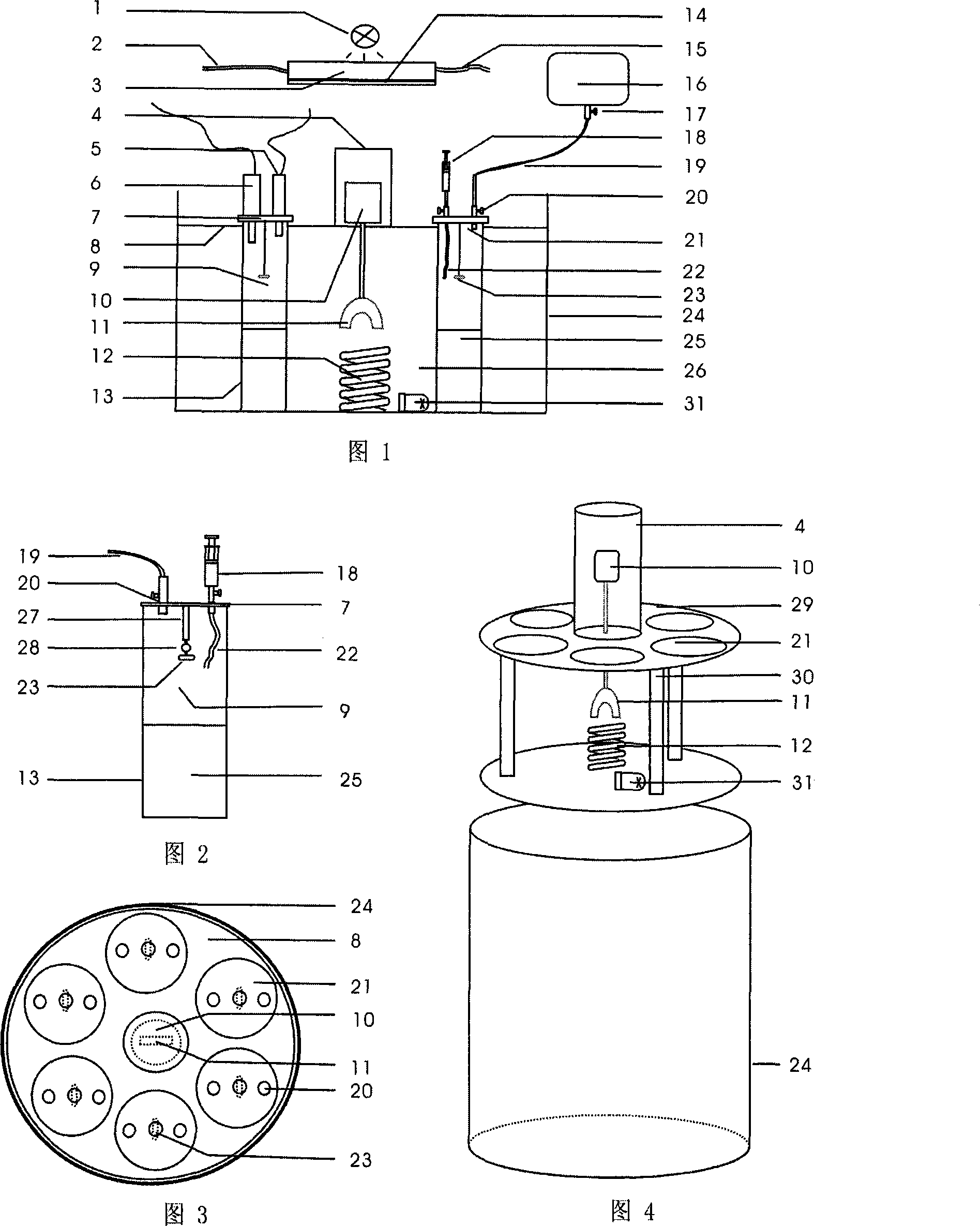

A kind of anti-aging agent 4020 continuous production process

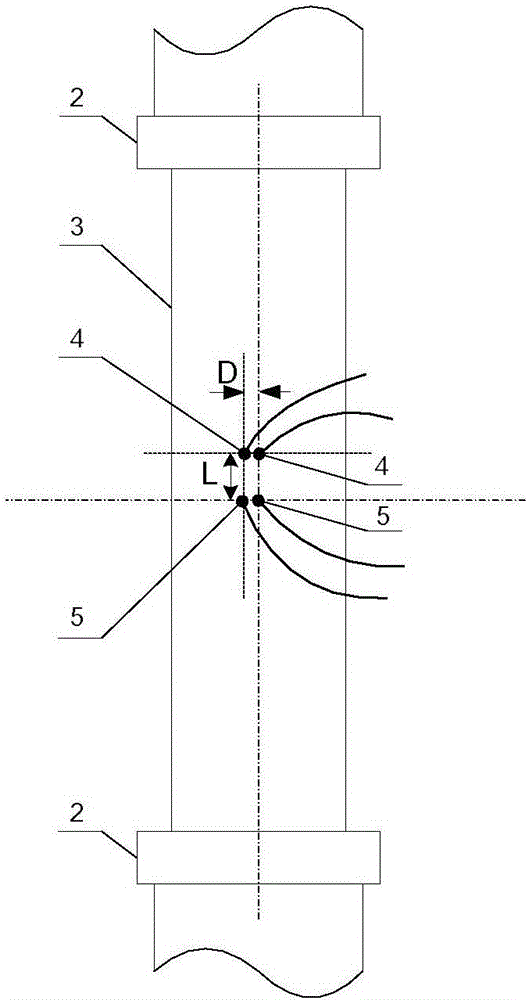

InactiveCN102260176ASmall sizeEven by forceAmino preparation from aminesChemical/physical processesChemistryMethyl isobutyl ketone

The invention discloses a continuous producing process of an anti-aging agent 4020, which has the advantages of stability and reliability in operation and high production efficiency. The process comprises the following steps of: adopting 4-aminodiphenylamine, methyl isobutyl ketone and hydrogen as raw materials; mutually preheating all raw materials by a preheater E101; enabling the preheated rawmaterials to enter a reactor; and carrying out catalytic hydrogenation reaction on the raw materials at a high pressure under the effect of a catalyst so as to obtain the anti-aging agent 4020, wherein the reactor is a gas-liquid-solid three-phase fixed bed hydrogenation reactor; the hydrogenation reaction is continuous operation carried out by using the gas-liquid-solid three-phase fixed bed hydrogenation reactor; the gas-liquid-solid three-phase fixed bed hydrogenation reactor comprises a main body container, a discharging opening, a completely discharging opening, a feed pre-distributor, an upper seal head, a lower seal head, an upper support, a lower support and a temperature measuring opening, wherein the feed pre-distributor is an exhaust pipe type pre-distributor which is mounted at the lower part of the main body container; the upper seal head is an elliptical seal head; and the lower seal head is also an elliptical seal head; and the temperature is 165-230 DEG C, the pressureis 5.5-6.0 MPa, the keto-amine ratio is 2-4:1 and the hydrogen-oil ratio is 2000-5000:1 during reaction.

Owner:NANJING ENVIRO CHEM ENG DESIGN

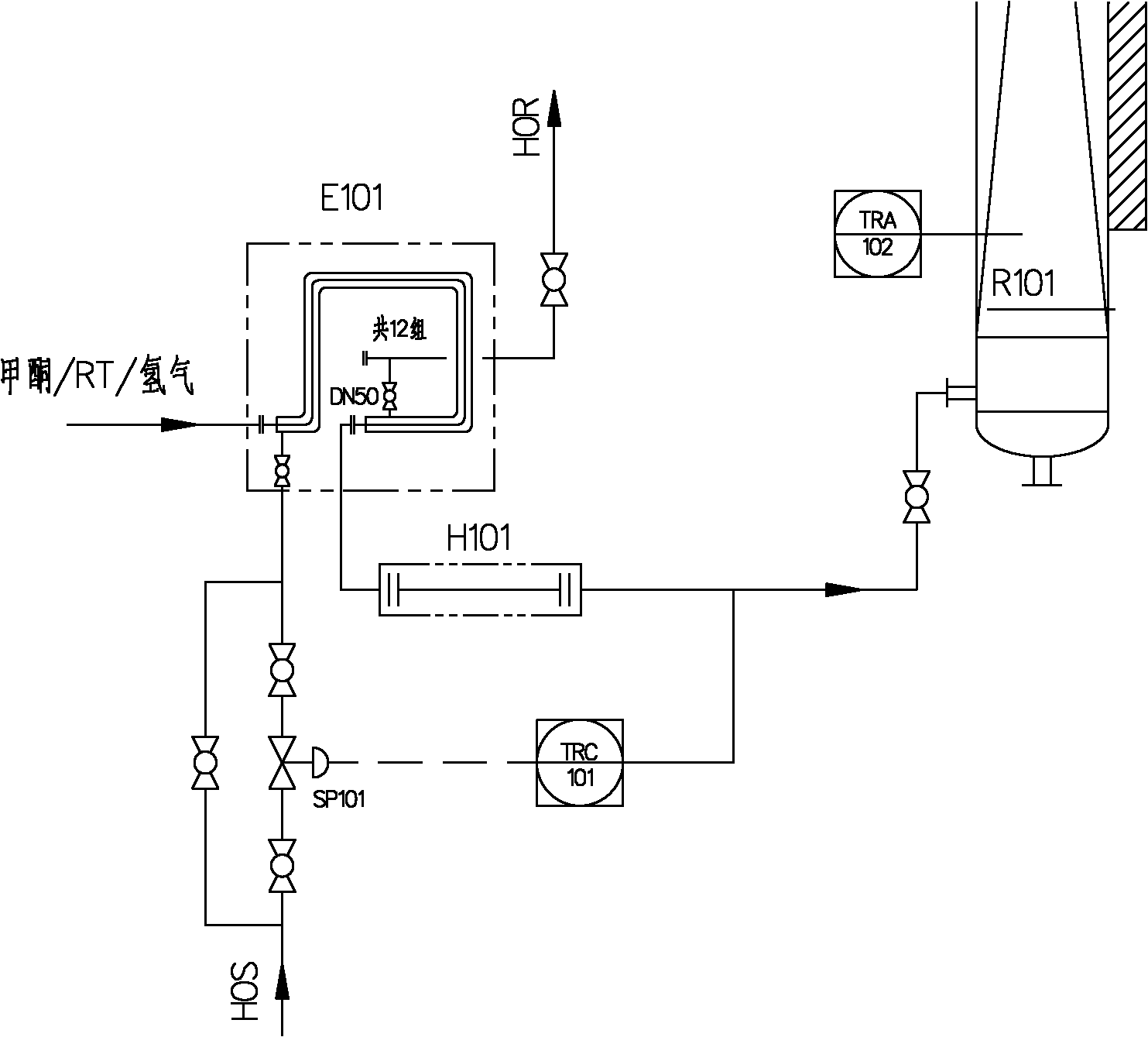

Wort oxygenating equipment system and control method thereof

ActiveCN101412952AReal-time control of oxygenationStable and effective dissolutionBioreactor/fermenter combinationsBiological substance pretreatmentsAir conditioningOxygen

The invention provides a method for controlling a wort oxygenating device system in real time, comprising the following steps of: (1) when the wort oxygenating device system is oxygenated and a wort pipe pressure chagnese, signaling a wort pressure gage to a controller which outputs signals to control opening of a wort pressure valve, thereby adjusting the wort flow; (2) re-feeding information after the wort flow is adjusted to the controller, an air pressure gage on an air pipe changing thereupon, transmitting the information again to the controller, then the controller controlling an air regulating valve and adjusting air filling flow, continuously repeating step (1) and (2), thereby adjusting the wort flow and air flow by the controller according to the wort pressure gage and a wort flowmeter.

Owner:TSINGTAO BREWERY

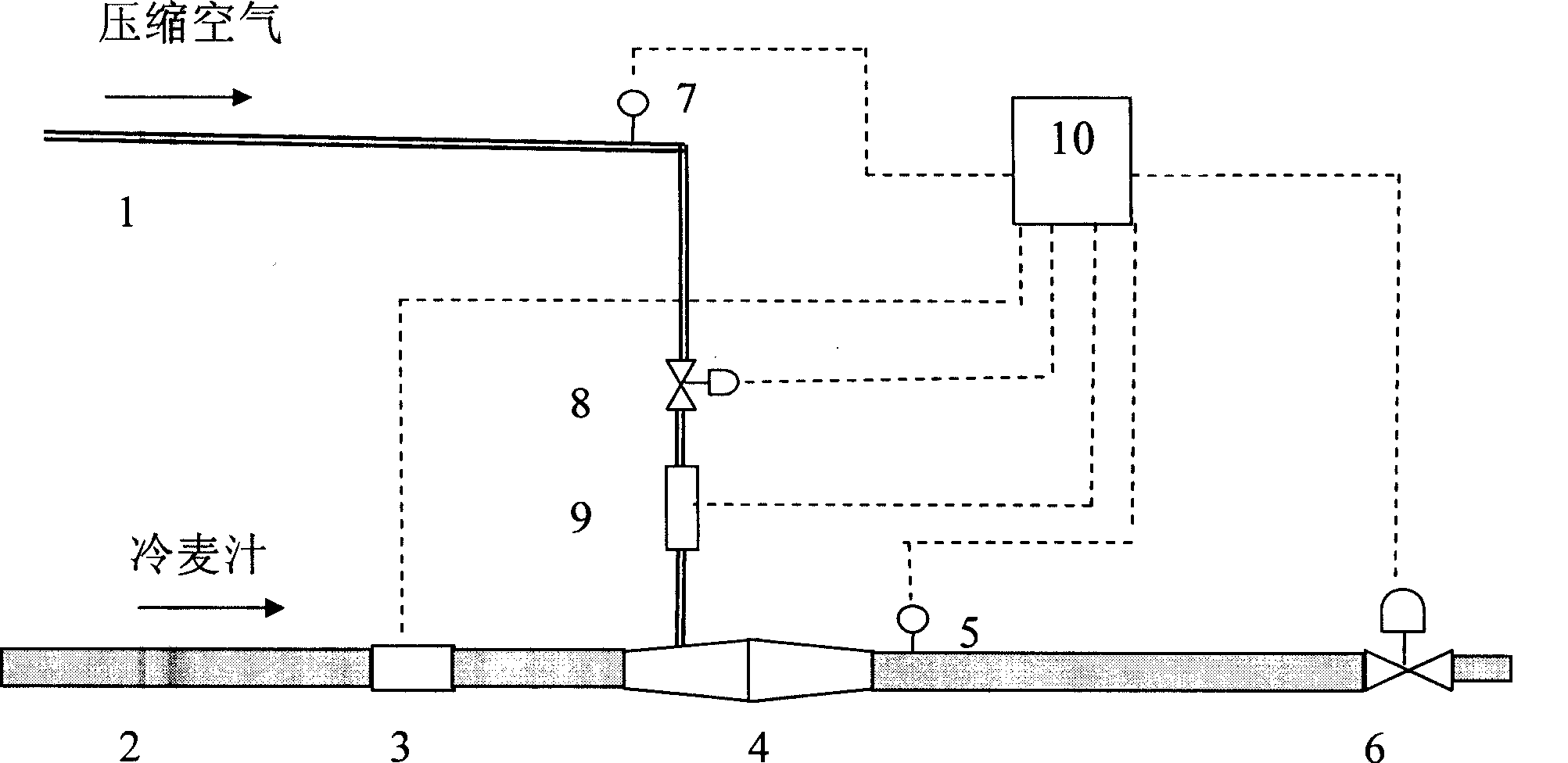

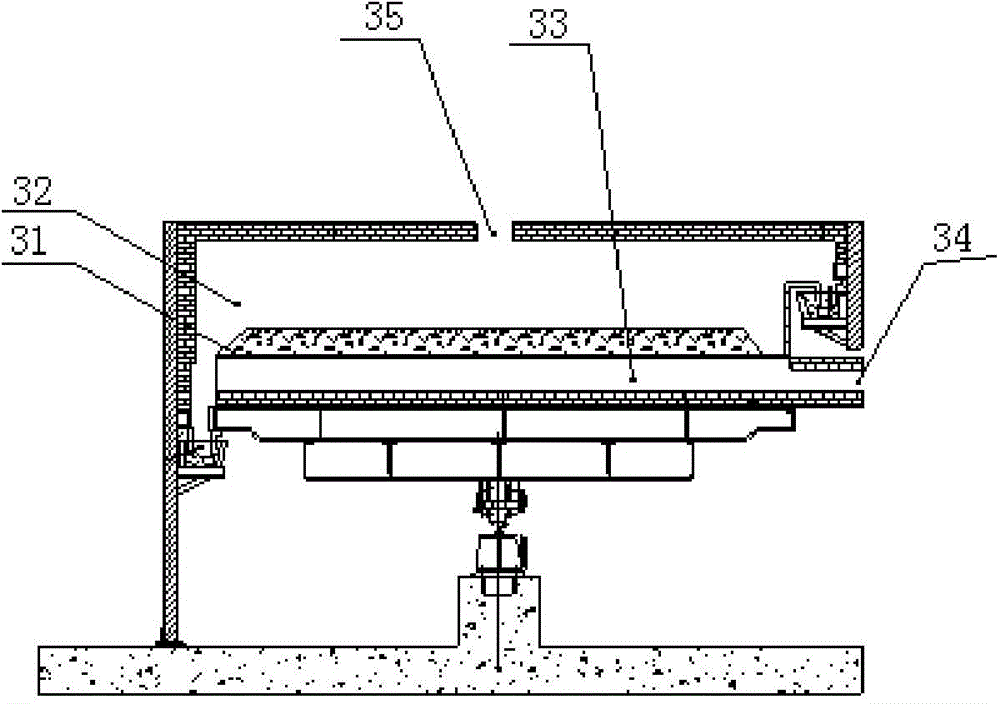

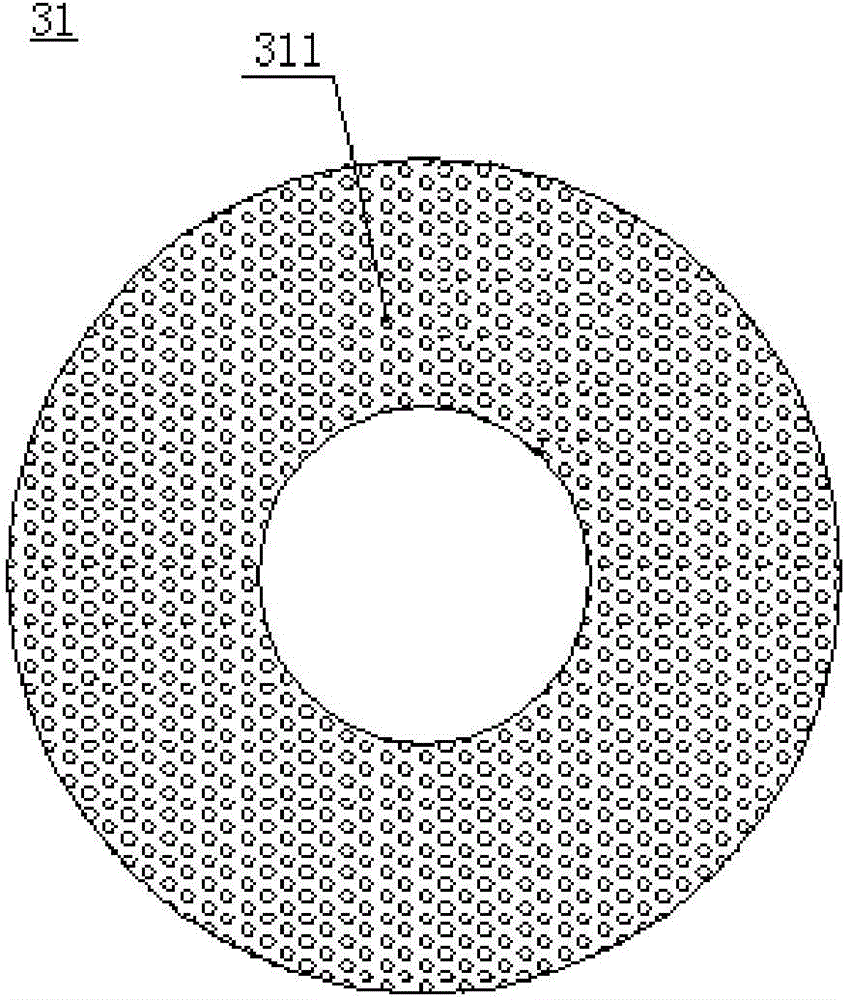

Pyrolysis system and pyrolysis method for organic wastes

InactiveCN104560072AImprove heating uniformityImprove pyrolysis efficiencyDirect heating destructive distillationSpecial form destructive distillationProcess engineeringHeat exchanger

The invention provides a pyrolysis system and pyrolysis method for organic wastes. The pyrolysis system for the organic wastes comprises a crushing device, a drying device, a rotating-bed pyrolysis oven, a pyrolysis solid processing device, a cooling and purifying device, an oil storage tank, and a heat accumulating type rotary heat exchanger, wherein the rotating-bed pyrolysis oven is suitable for performing pyrolysis treatment on pyrolysis raw materials, and a rotatable material distributing tray for containing the pyrolysis raw materials is arranged in the rotating-bed pyrolysis oven, the material distributing tray divides the interior of the rotating-bed pyrolysis oven into a pyrolysis chamber positioned above the material distributing tray and a heat supply chamber positioned below the material distributing tray , wherein a plurality of through holes for enabling the pyrolysis chamber to be communicated with the heat supply chamber are formed in the material distributing tray; the heat accumulating type rotary heat exchanger is connected with the cooling and purifying device and a hot-air inlet of the rotating-bed pyrolysis oven for pyrolyzing heated non-condensable gases. Through the adoption of the pyrolysis system of organic wastes, disclosed by the embodiment of the invention, the organic wastes can be effectively pyrolyzed.

Owner:BEIJING SHENYUAN ENVIRONMENTAL PROTECTION CO LTD

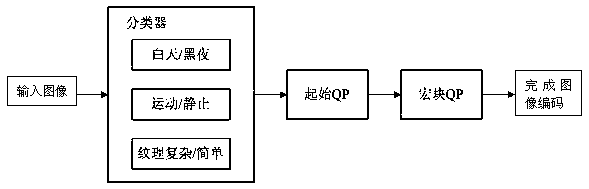

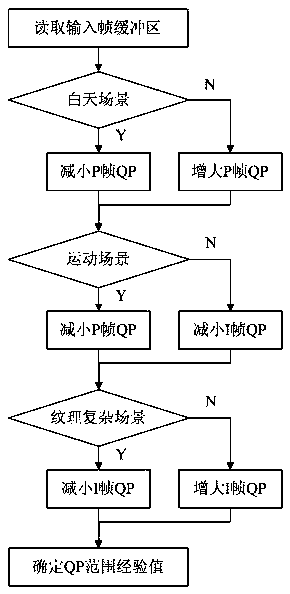

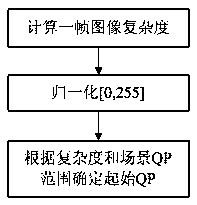

Self-adaptive control method for code stream of surveillance camera

ActiveCN105516720ASmall fluctuation rangeStream quality improvementDigital video signal modificationSelf adaptiveBlock level

The invention discloses a self-adaptive control method for a code stream of a surveillance camera. The self-adaptive control method for the code stream of the surveillance camera comprises the steps of, after frame information of an input image is acquired through a sensor, firstly inputting the image into an image scene classifier for current scene judgment so as to obtain an experience QP value of the current scene; then enabling the image to enter an initial QP obtainer of the image frame and determining the initial QP value of the current frame image based on each frame image after the scene is determined; and finally enabling the image to enter a macro-block level QP obtainer of the image frame to obtain a macro-block level QP value and finish image coding in the end. According to the self-adaptive control method for the code stream of the surveillance camera, the surveillance camera can select the macro-block level QP value exactly based on different scenes, the fluctuation range of the code stream is reduced obviously, the quality of the code stream is improved, the code stream is reduced, the network bandwidth and the storage space are saved, the product quality is improved, and the system storage cost is decreased.

Owner:TIANJIN TIANDY DIGITAL TECH

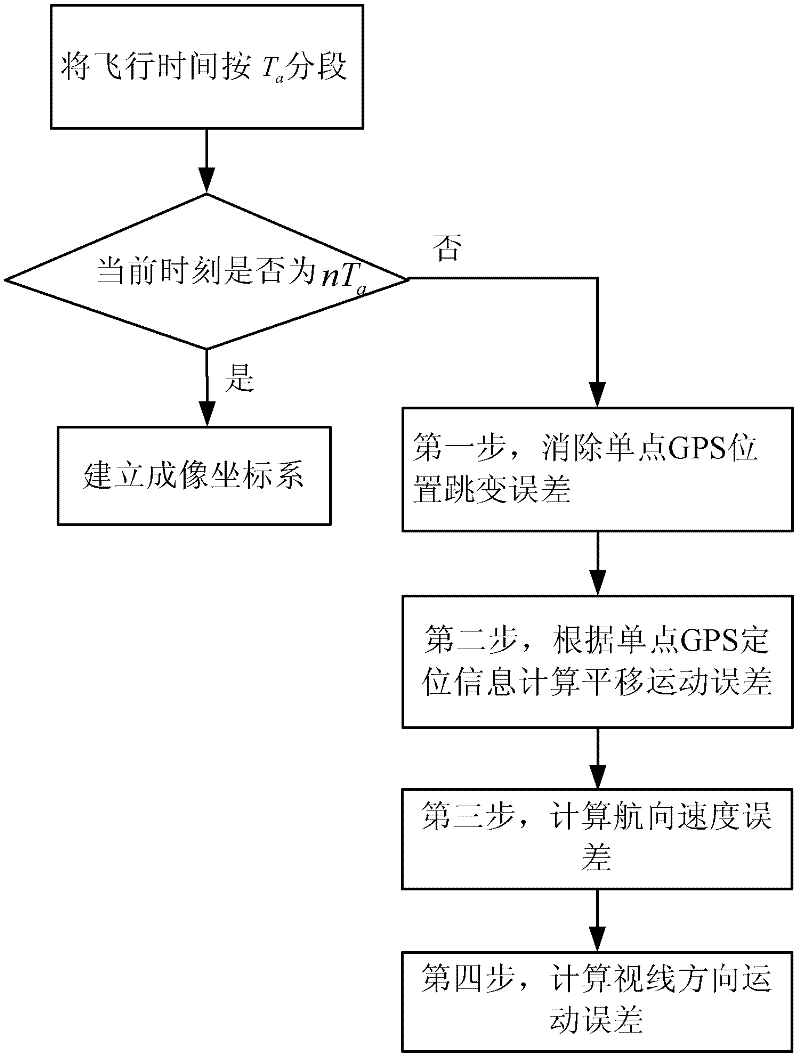

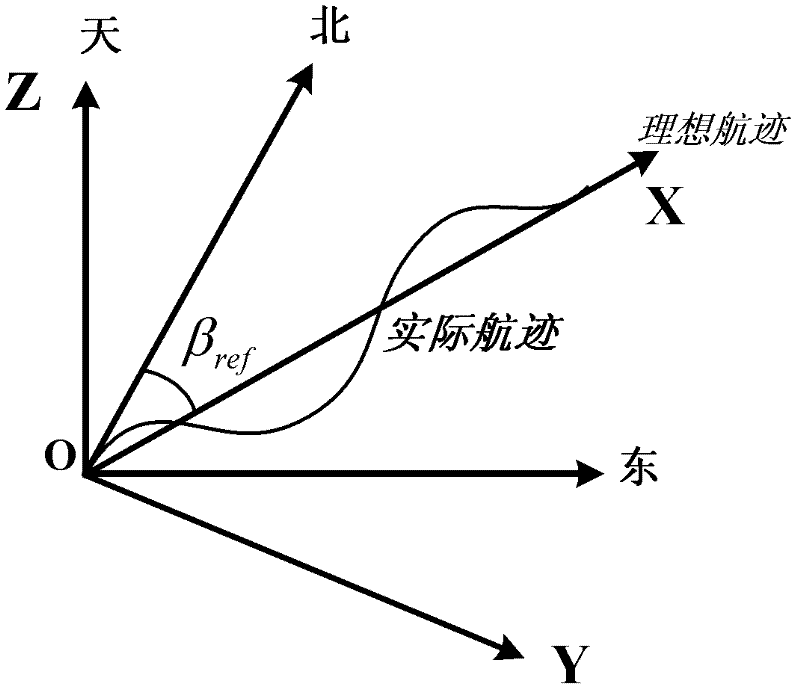

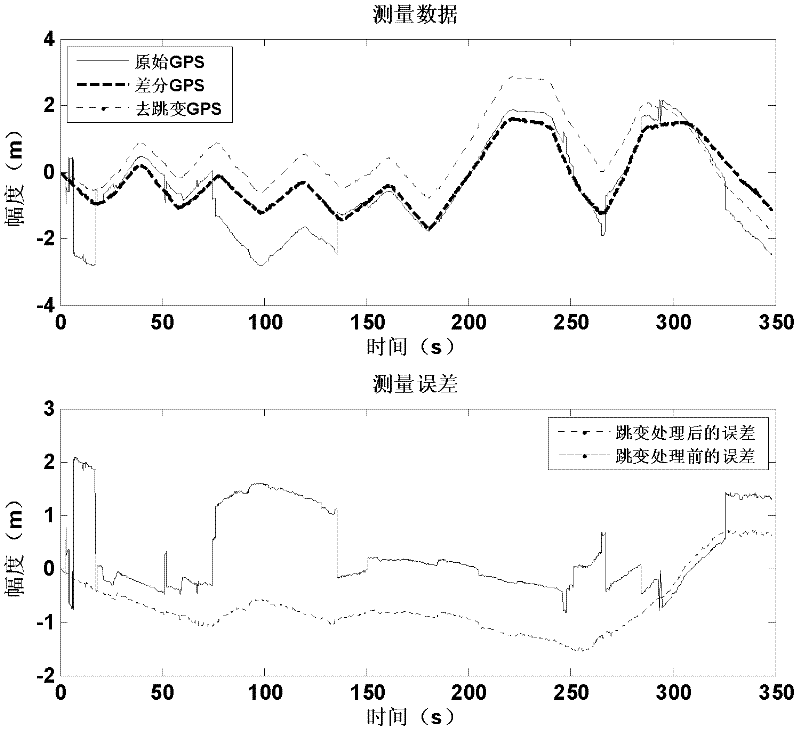

A real-time motion compensation method for ultra-wideband synthetic aperture radar

ActiveCN102288962ASimple compositionLow costRadio wave reradiation/reflectionUltra-widebandInformation processing

The invention provides a real-time motion compensation method for an ultra-wide band synthetic aperture radar (UWB SAR), which is characterized in that motion parameters output by a single-point global positioning system (GPS) are used for carrying out real-time motion compensation of the UWB SAR, the flight time is segmented according to Ta, when the current moment is a starting point of an imaging synthetic aperture, an imaging coordinate system is built, and if not, the next steps are carried out: step 1, eliminating the single-point GPS position jumping errors; step 2, calculating the transverse motion errors according to the single-point GPS positioning information; step 3, calculating the heading speed errors; and step 4, calculating the sight line direction motion errors and compensating the motion errors in the airborne UWB SAR sight line direction. In the method of the invention, the information processing is only carried out on the output data of a navigation system, the motion parameter evaluation does not need to be carried out, the storage space and the calculation quantity are saved, and the large-area imaging compensation precision is high. In addition, the cost is low, and the realization is easy.

Owner:NAT UNIV OF DEFENSE TECH

Gypsum-based self-leveling mortar and preparation method thereof, and gypsum-based self-leveling slurry

ActiveCN109694228AImprove thermal insulationImprove sound insulationPortland cementThermal insulation

The invention relates to a gypsum-based self-leveling mortar and a preparation method thereof. The gypsum-based self-leveling mortar comprises: SiO2 aerogel, Portland cement, desulfurization gypsum, aretarder, a water reducing agent, latex powder, a stabilizer and a filler, wherein the preparation method of the SiO2 aerogel comprises: preparing a silane coupling agent solution from a silane coupling agent and water, adding hydrophobic SiO2 aerogel into the silane coupling agent solution, and stirring until the hydrophobic SiO2 aerogel is completely dissolved in the silane coupling agent solution. The preparation method of the gypsum-based self-leveling mortar comprises: carrying out surface modification on a hydrophobic SiO2 aerogel by using a silane coupling agent; mixing the modified SiO2 aerogel and Portland cement, and carrying out ball milling; and adding other components, and uniformly mixing. The present invention further a gypsum-based self-leveling slurry prepared by using the gypsum-based self-leveling mortar. According to the present invention, the gypsum-based self-leveling mortar and the gypsum-based self-leveling slurry have advantages of good thermal insulation andgood sound insulation property.

Owner:BEIJING NEW BUILDING MATERIALS PLC

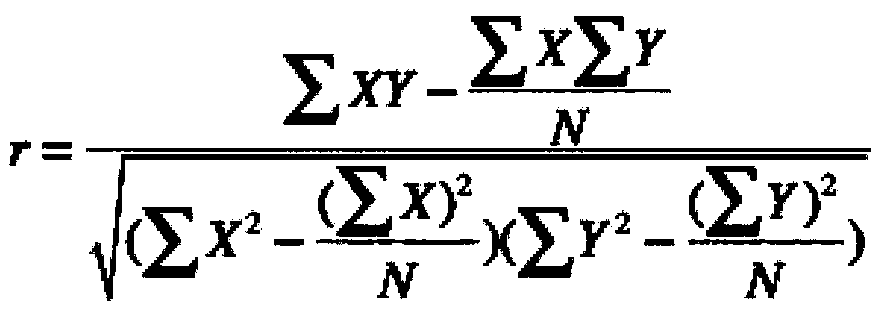

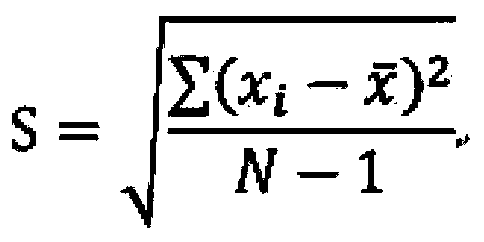

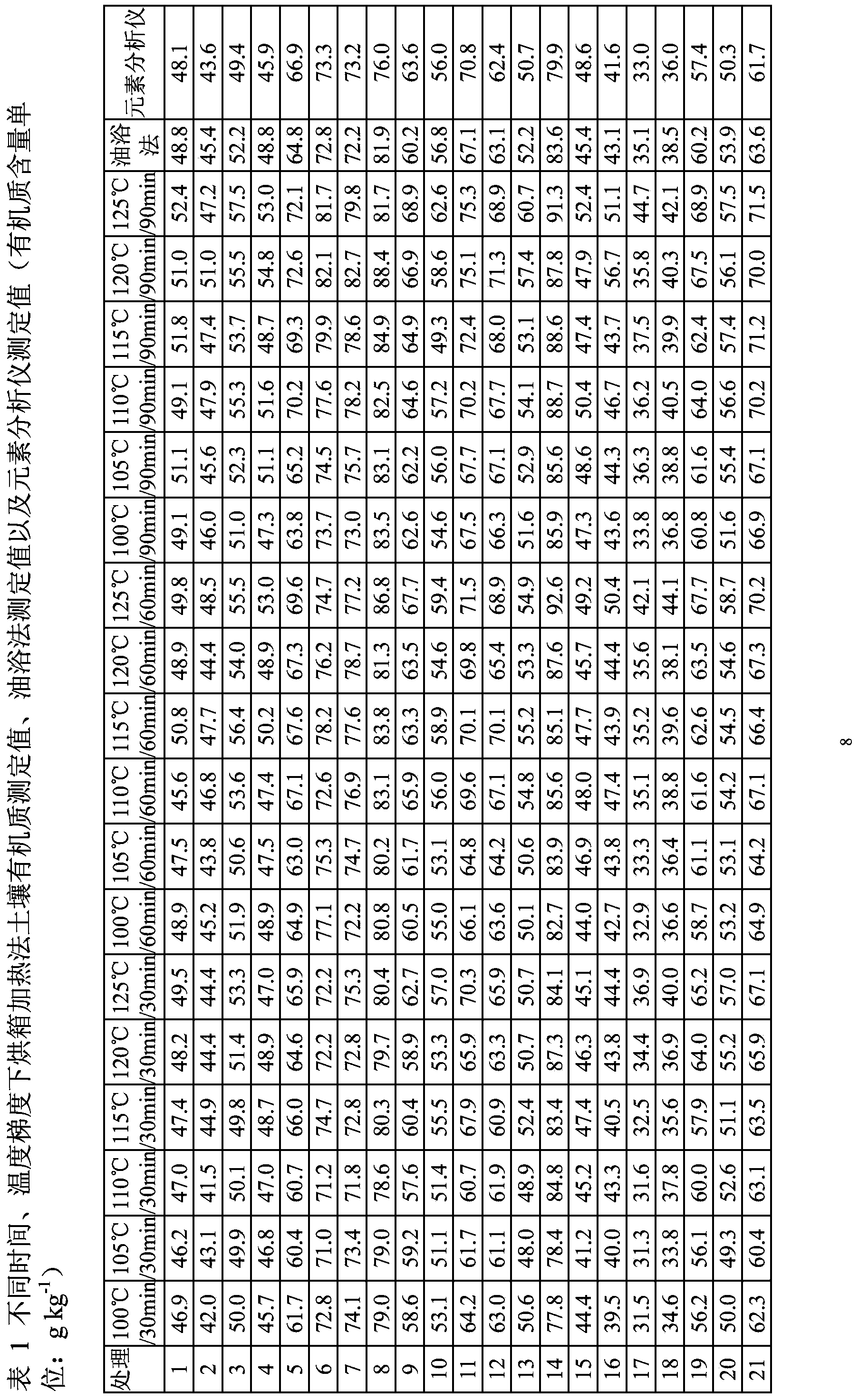

Method for determining organic matters in soil

InactiveCN104280512AHeating evenlySmall temperature fluctuation rangeChemical analysis using titrationSoil organic matterHeating time

Owner:SHENYANG INST OF APPLIED ECOLOGY - CHINESE ACAD OF SCI

Preparation method of rare earth-iron intermediate alloy for low-oxygen rare earth steel

The invention discloses a preparation method of a rare earth-iron intermediate alloy for low-oxygen rare earth steel. The preparation method of the rare earth-iron intermediate alloy for the low-oxygen rare earth steel comprises the steps that a vacuum smelting furnace is adopted, and rare earth metal and pure iron are placed in a crucible of the vacuum furnace at the mass ratio of 1-5:5-9; vacuumizing is conducted on the vacuum furnace until the pressure of the vacuum furnace is below 20 Pa, inert gas is fed for shielding, and the process of high-temperature melting-refining and electromagnetic stirring alloying is executed, wherein the high-temperature melting temperature is 1000-1500 DEG C, the temperature of the refining process is 1400-1500 DEG C, and the time is 5-15 minutes; molten metal is poured into an ingot mold, and then the rare earth-iron intermediate alloy is obtained. By the adoption of the preparation method of the rare earth-iron intermediate alloy for the low-oxygen rare earth steel, the rare earth yield can be significantly improved, the content of the rare earth in the steel can be accurately controlled, the adding cost of the rare earth is reduced, and the plasticity, the low-temperature impact toughness, the thickness-direction property and the corrosion resistance of the steel are improved.

Owner:BAOTOU RES INST OF RARE EARTHS +1

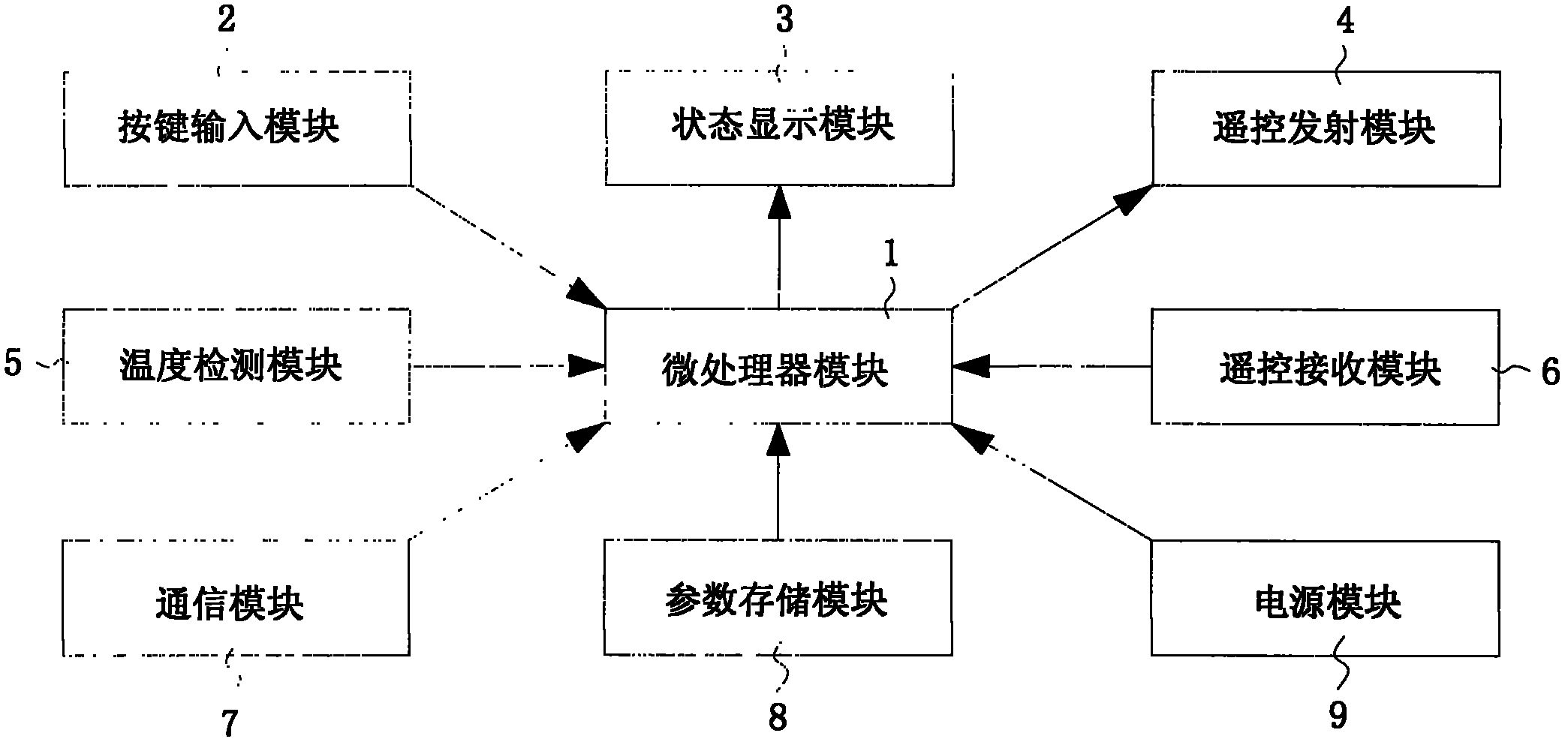

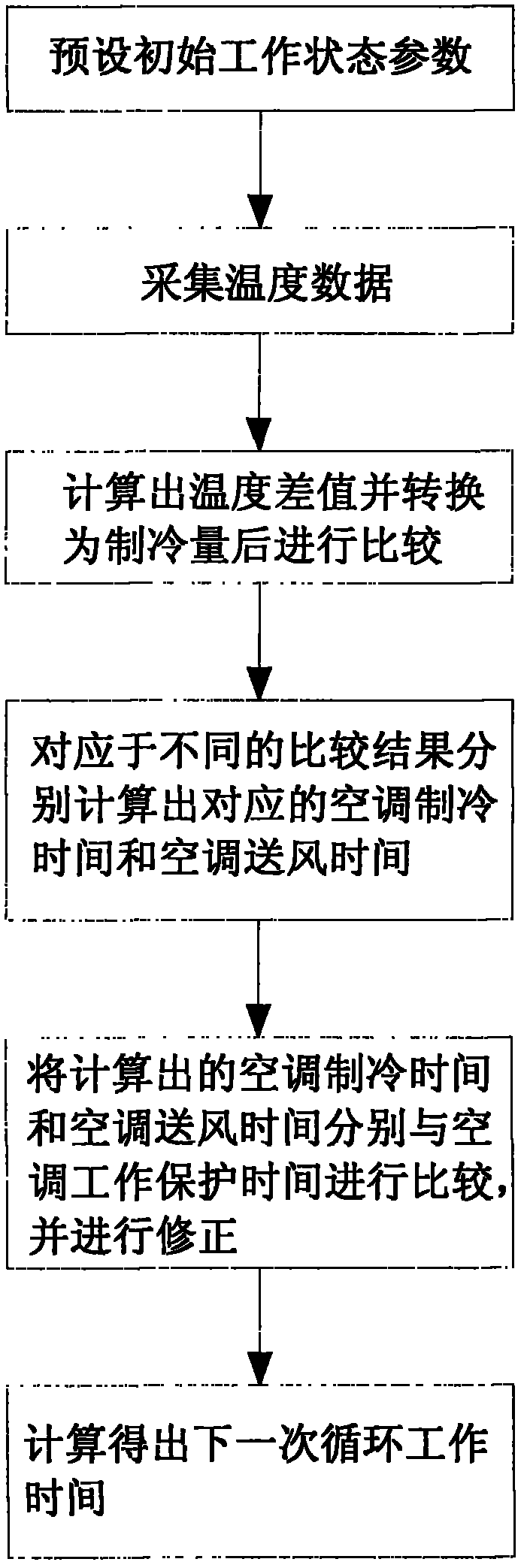

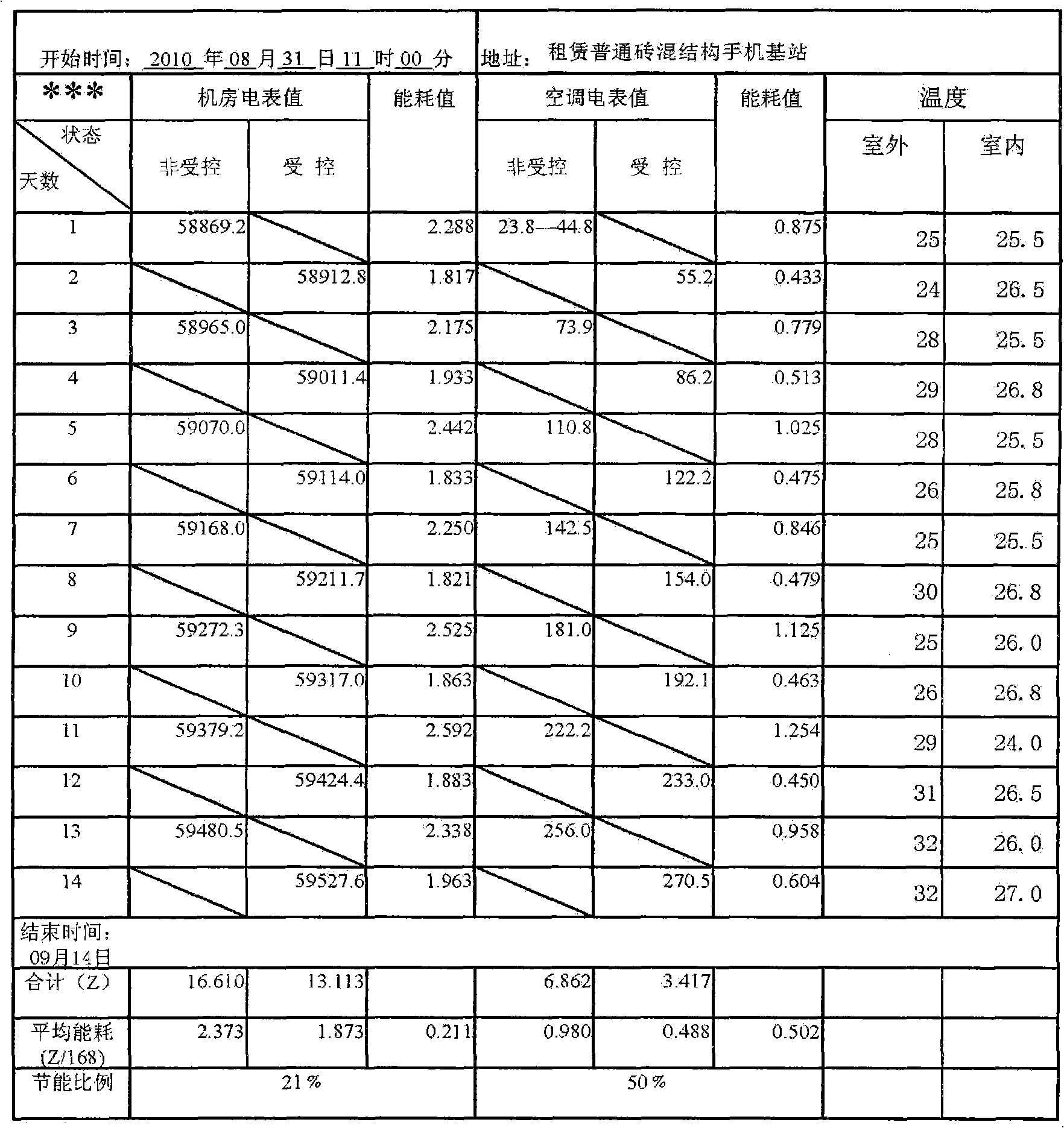

Air-condition constant temperature operation energy-conservation control system

InactiveCN101976050AShorten the timeSmall fluctuation rangeSpace heating and ventilation safety systemsLighting and heating apparatusRemote controlControl system

The invention provides an air-condition constant temperature operation energy-conservation control system which comprises a microprocessor module, wherein a key input module, a status display module, a remote control transmitting module, a remote control receiving module, a communication module, a parameter memory module, a power module and a temperature detection module are connected on the microprocessor module; and the temperature detection module comprises an ambient temperature sensor and an air opening temperature sensor. The system carries out multipoint real-time detection on ambient temperature by means of the sensors; and after carrying out cold and heat computational analysis on the input temperature data, the microprocessor module automatically optimizes the refrigerating and blowing-in time control of an air-condition, thus the working time of an air-condition compressor is reduced as much as possible on the premise of ensuring indoor temperature to reach a set value, thereby achieving the constant temperature purpose and realizing energy conservation.

Owner:田利 +1

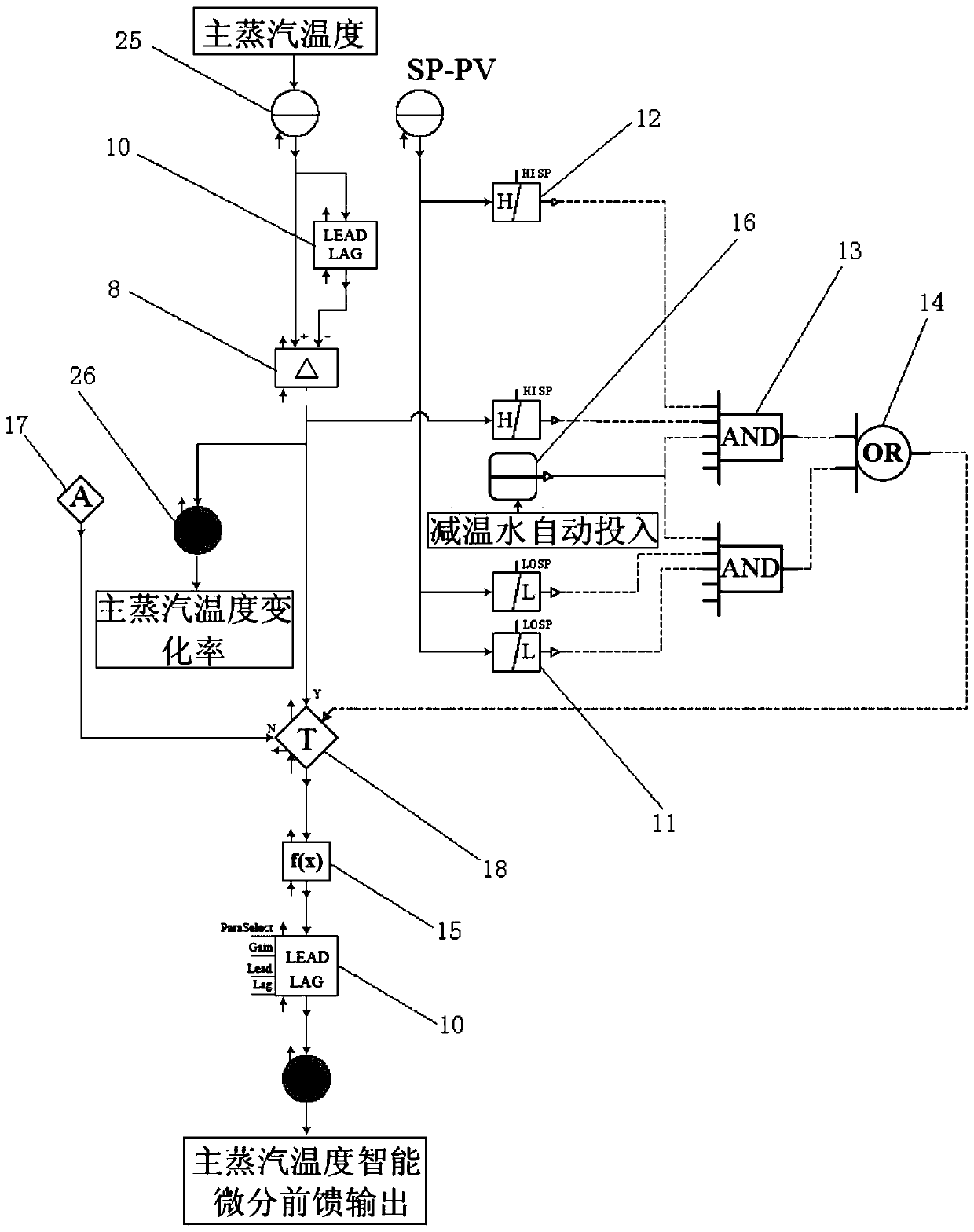

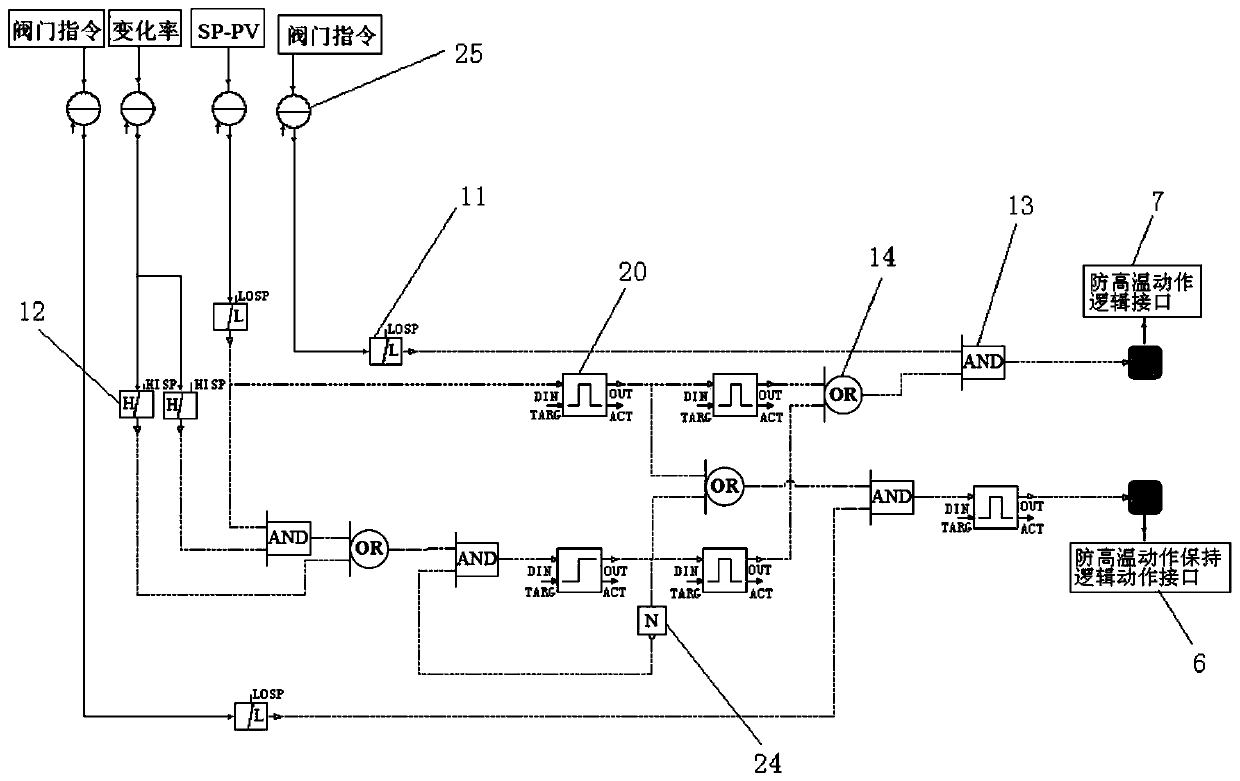

Boiler main steam temperature control method with frequent fluctuation of AGC load instruction of power grid

ActiveCN110360540AImprove adjustment qualityImprove efficiencySuperheating controlBoiler controlLoad instructionPower grid

The invention discloses a boiler main steam temperature control method with frequent fluctuation of an AGC load instruction of a power grid, and belongs to the technical field of boiler main steam temperature control. According to the method, the variation trend of the main steam temperature of a boiler and the difference between the measured value of the main steam temperature of the boiler and the set value of the main steam temperature are comprehensively judged and controlled in advance through a main steam temperature super-differential feedforward control loop; and the desuperheating water jet control logic circuit for preventing the main steam temperature from overshooting is used for working conditions of frequent fluctuation of the AGC load instruction of the power grid, and the main steam temperature is controlled within a set range. According to the method, the main steam temperature regulation quality can be greatly improved, the fluctuation range of the main steam temperature of the boiler is reduced, and the unit efficiency is improved; after using this control scheme, the main steam temperature fluctuation range is reduced by 3-5 DEG C than before; and with the continuous development and maturity of the main steam temperature control technology, the foundation can be laid for improving the safe, stable and efficient economic operation of the unit and achieving the long-term goal of energy-saving optimization.

Owner:JILIN PROVINCE ELECTRIC POWER RES INST OF JILIN ELECTRIC POWER CO LTD +2

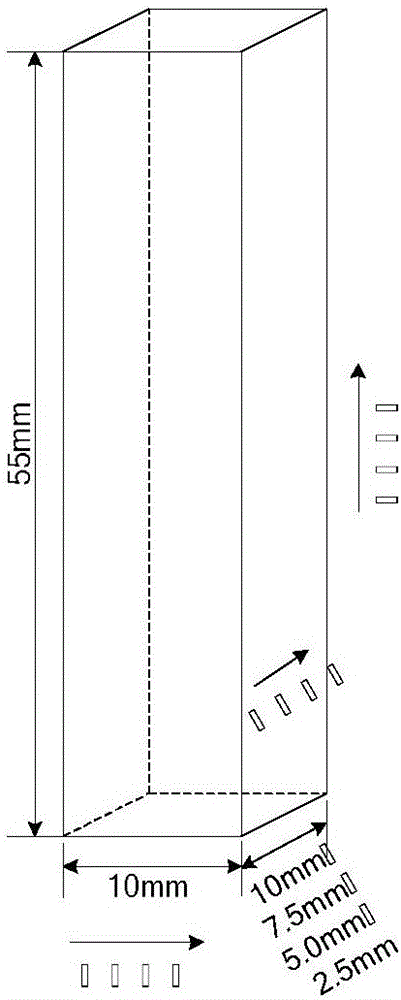

Thermal simulation method of thermal-mechanical treatment of high strength automobile steel impact specimen

ActiveCN106525563AAchieve high precision controlSmall fluctuation rangePreparing sample for investigationRepeatabilityCompression test

The invention provides a thermal simulation method of thermal-mechanical treatment of high strength automobile steel impact specimen, and belongs to the technical field of thermal simulation. The method comprises the steps of (1) based on the size the a standard impact specimen, determining the simulation specimen size, the simulation specimen comprises a simulation rectangle, two ladder platforms and two clamp ends, determining the high temperature thermal-mechanical treatment process parameters applied in the heat simulation process, (2) welding a thermal couple on the surface of the simulation rectangle of the simulation specimen, (3) installing the simulation specimen on a thermal simulator, (4) conducting heat treatment to the simulation specimen, determining the average temperature area of the post-heated simulation specimen, (5) conducting compression test to the simulation specimen, determining the post-compression average temperature area of the simulation specimen, (6) conducting cooling treatment to the simulation specimen, (7) checking the simulation specimen surface, (8) processing the simulation specimen into a standard impact specimen, and verifying if the impact process is effective. The method can enhance the repeatability of the organization and preparation of the impact specimen of high strength automobile steel and the control precision of process parameters.

Owner:NORTHEASTERN UNIV

Manufacturing technique of highlight floor base material

ActiveCN103128826ALess cost increaseHigh surface finish and flatnessWood working apparatusDomestic articlesGrindingHot press

The invention provides manufacturing technique of highlight floor base material. The manufacturing technique of the highlight floor base material comprises steps of wood raw material peeling, chipping, wood chip screening, washing, pre-cooking, cooking, hot grinding, glue mixing, drying, formation and prepressing, slab hot pressing, cooling tempering, sanding saw cutting, grading and packing, wherein in a drying step, moisture content after drying is 9.0-10.5%; in a slab hot pressing step, hot pressing temperature is 170-225 DEG C, five sections of temperature zone are adopted, hot pressing pressure is 0-4MPa, and a hot pressing factor is 7.2-8.0s / mm, maximum pressure is 3-3.7MPa. A small step is arranged at the top end of the highest density in density distribution of a fracture surface and gradually transits to a core layer, and surface highest density is 1100-1150kg / m<3>; in a sanding step, bearing jump of a sander drum is controlled within 2.0mm / s, and in the fine sand, a tape of more than 150 meshes is used to process. The manufacturing technique of the highlight floor base material has high surface smoothness and evenness, surface density and fracture density distribution are matched with pressing and pasting technique, and moisture content is control with quite narrow fluctuation range.

Owner:DARE WOOD BASED PANEL GRP

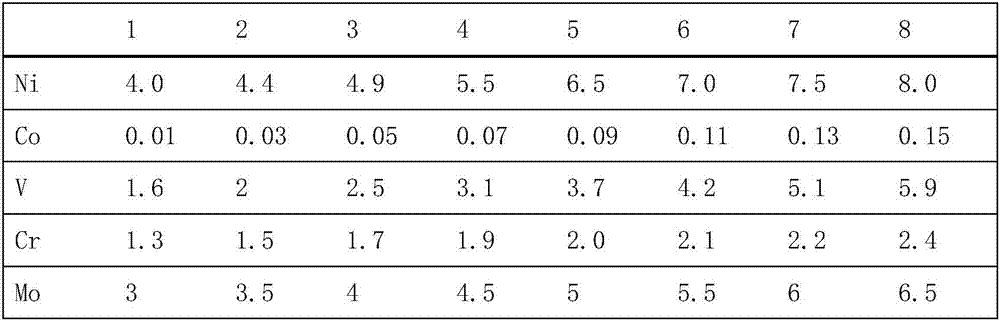

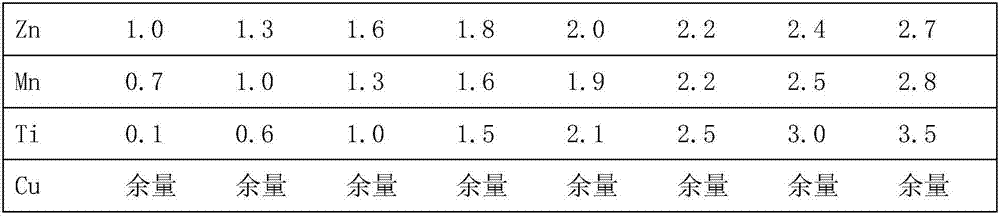

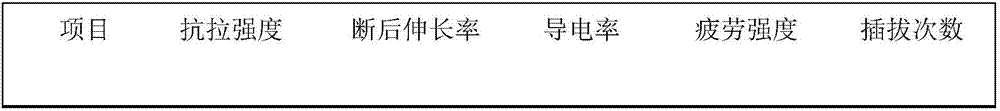

High-strength high-elasticity copper alloy and preparation method thereof

ActiveCN107090553ABeneficial technical effectBeneficial progressNonferrous metalUltimate tensile strength

The invention discloses a high-strength high-elasticity copper alloy and a preparation method thereof, belongs to the field of nonferrous metal manufacturing, and particularly relates to copper-based elastic alloy. The high-strength high-elasticity copper alloy is composed of, by weight, 4.8-7.6% of Ni, 0.05-0.10% of Co, 2.3-5.7% of V, 1.7-2.2% of Cr, 3.5-5.7% of Mo, 1.5-2.3% of Zn, 1.2-2.3% of Mn, 0.7-2.5% of Ti and the balance Cu. The tensile strength of the copper alloy can reach 1300-1600 MPa, the percentage elongation is 11.5% to 16.0%, meanwhile, the copper alloy has quite high fatigue strength being no lower than 460 MPa; and the copper alloy obtained through the method is small in fluctuation range of the tensile strength and percentage elongation, the requirement that the insertion and extraction time is greater than or equal to 40000 when the insertion and extraction force is 1.5 N is met, and the copper alloy can be used for electronic elastic elements.

Owner:宝鸡嘉琦金属有限公司

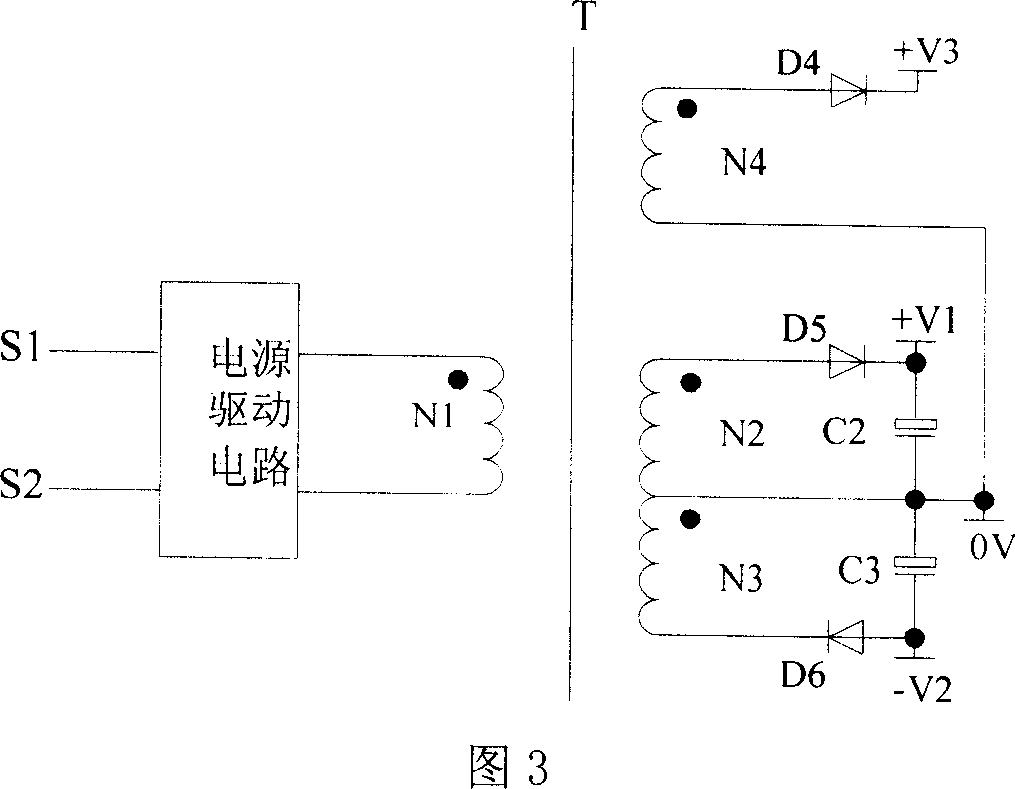

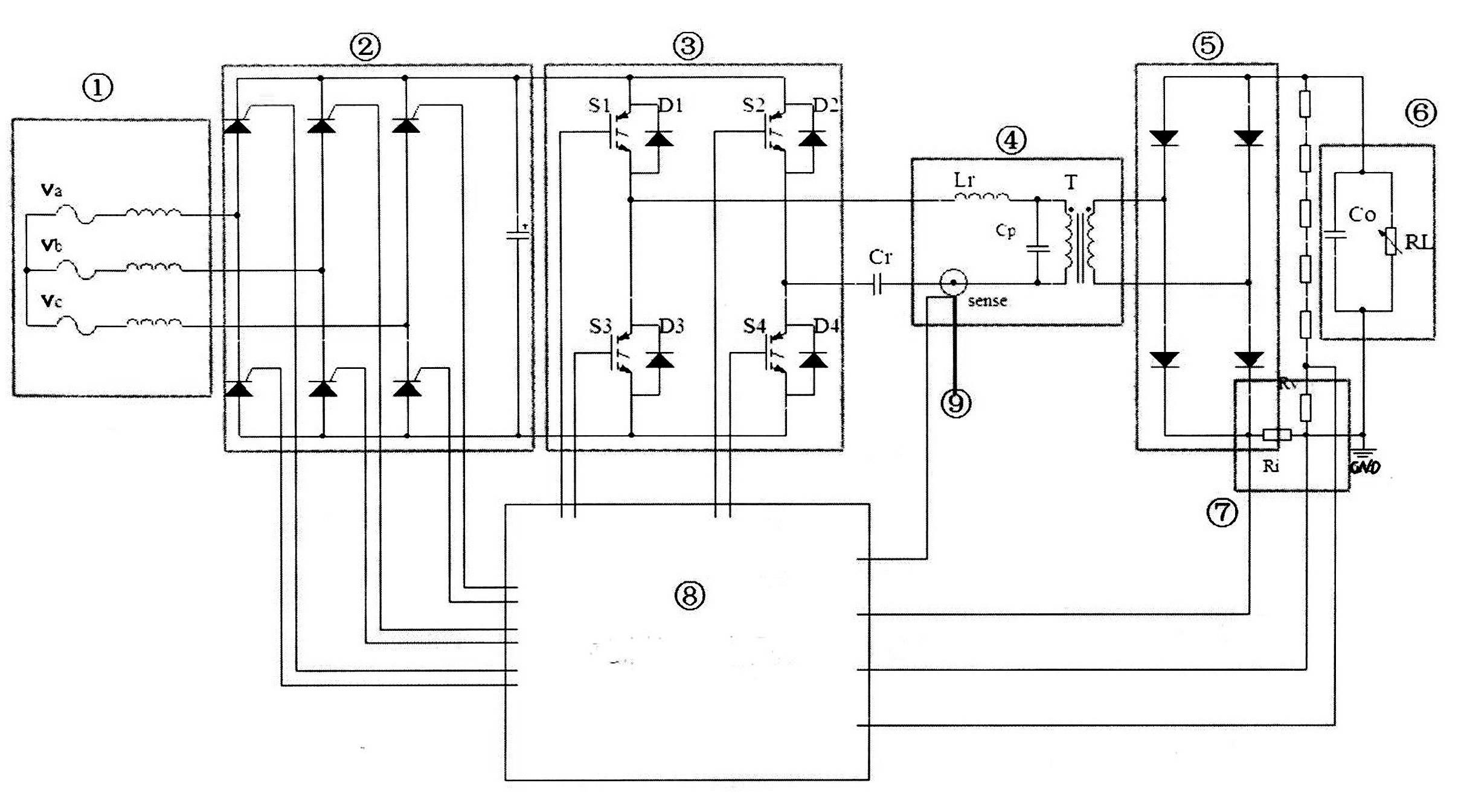

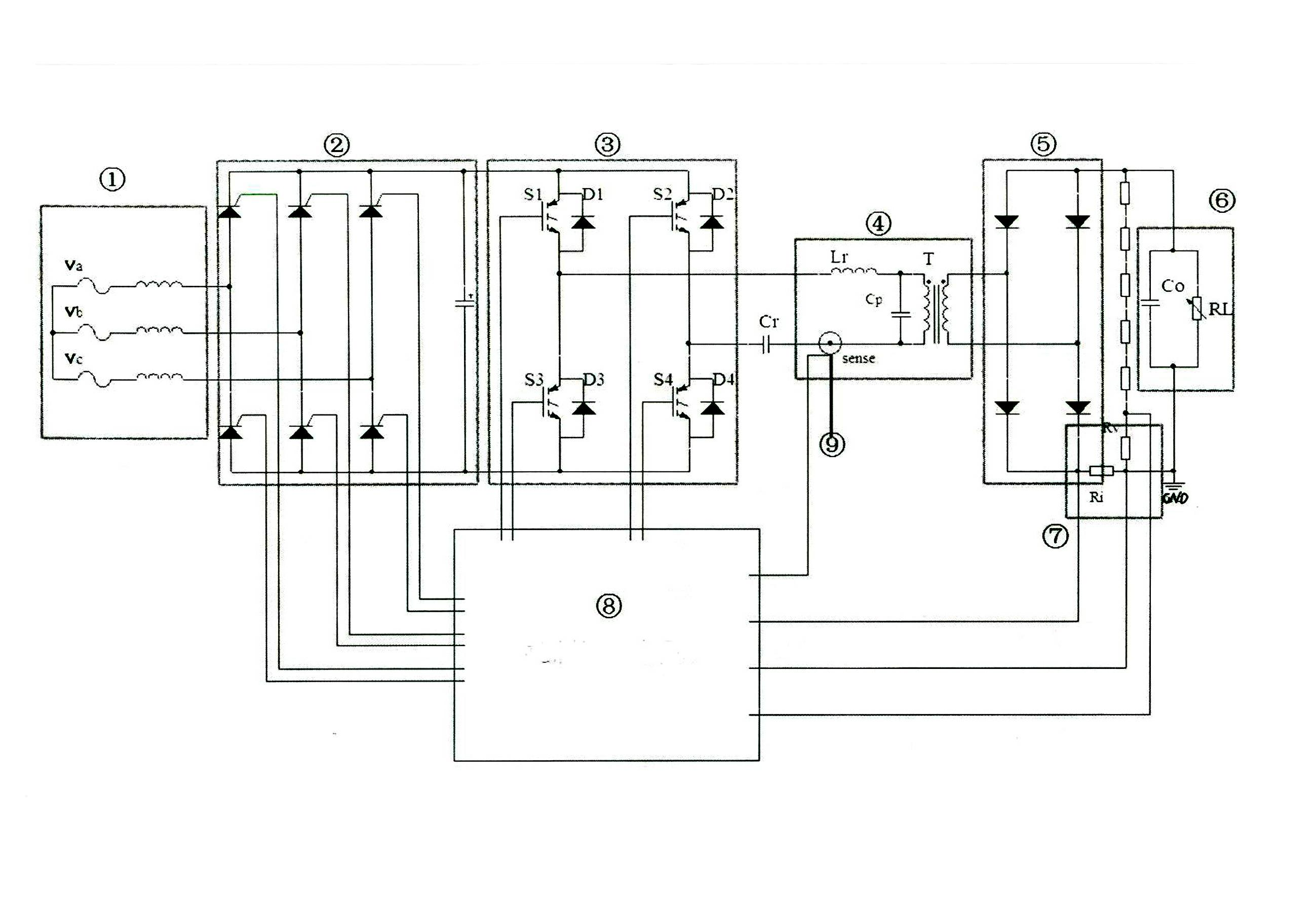

High-frequency high-voltage high-power power supply for electrostatic dust removal

InactiveCN102097956AImprove stabilityImprove control characteristicsAc-dc conversion without reversalDc-dc conversionCapacitanceFull bridge

The invention discloses a high-frequency high-voltage high-power power supply for electrostatic dust removal, which mainly comprises a three-phase power-frequency power supply, a rectification part, an inverter part, a resonant circuit, a high-frequency transformer, a high-voltage rectifier bridge, a load and a control module. The rectification part consists of a thyristor rectification module capable of rectifying the power-frequency electric energy output by the three-phase power supply into direct current, and a filter capacitor; the back of the rectification part is connected with the inverter part consisting of a high-frequency full-bridge Insulated Gate Bipolar Transistor (IGBT) inverter capable of inverting the direct current into high-frequency square wave; the resonant circuit consisting of a series inductor Lr, a series capacitor Cr and a parallel capacitor Cp and supplying power to the post-stage circuit in a resonant manner is connected behind the inverter part. By the invention, the deficiency of the conventional electrostatic dust removing power supply can be compensated, the dust removing effect is improved, and the utilization ratio of electric energy can be increased.

Owner:ZHEJIANG ELECTRIC POWER DESIGN INST +1

Wide temperature region viscosity corrosion resisting solid self-lubricating coating and preparation method thereof

ActiveCN104928611AIncrease service temperatureAchieve normal workMolten spray coatingPolyvinyl alcoholBoron nitride

The invention discloses a wide temperature region viscosity corrosion resisting solid self-lubricating coating and a preparation method thereof. The coating comprises nano nickel Ni, tungsten selenide WSe2, sliver Ag, yttrium Y, eutectic calcium fluoride fluoride barium CaF2.BaF2 and boron nitride hBN, the raw materials are subjected to mixing with a polyving akohol solution, sintering and breaking and screening, the atmospheric plasma spraying technology is adopted, then the coating is prepared. The solid self-lubricating coating prepared by the method does not contain the chrome Cr element, the working environment of the solid self-lubricating coating is improved, compared with technologies of the same field, the wide temperature region viscosity corrosion resisting solid self-lubricating coating has the advantages that the low friction coefficient is low and stable, the metal melting-drop viscosity corrosion resistance ability is strong, the fluctuation range in the wide temperature region range is smaller, the coating can be used at the temperature ranging from 25 DEG C to 800 DEG C, the service temperature of the coating is improved, and the important engineering application value is achieved.

Owner:PLA SECOND ARTILLERY ENGINEERING UNIVERSITY

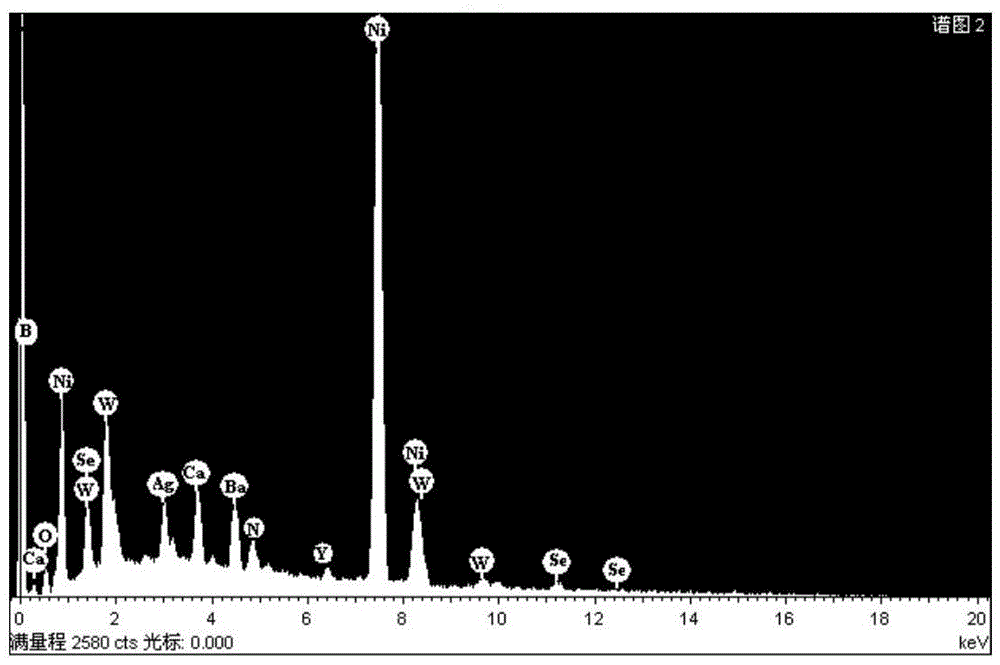

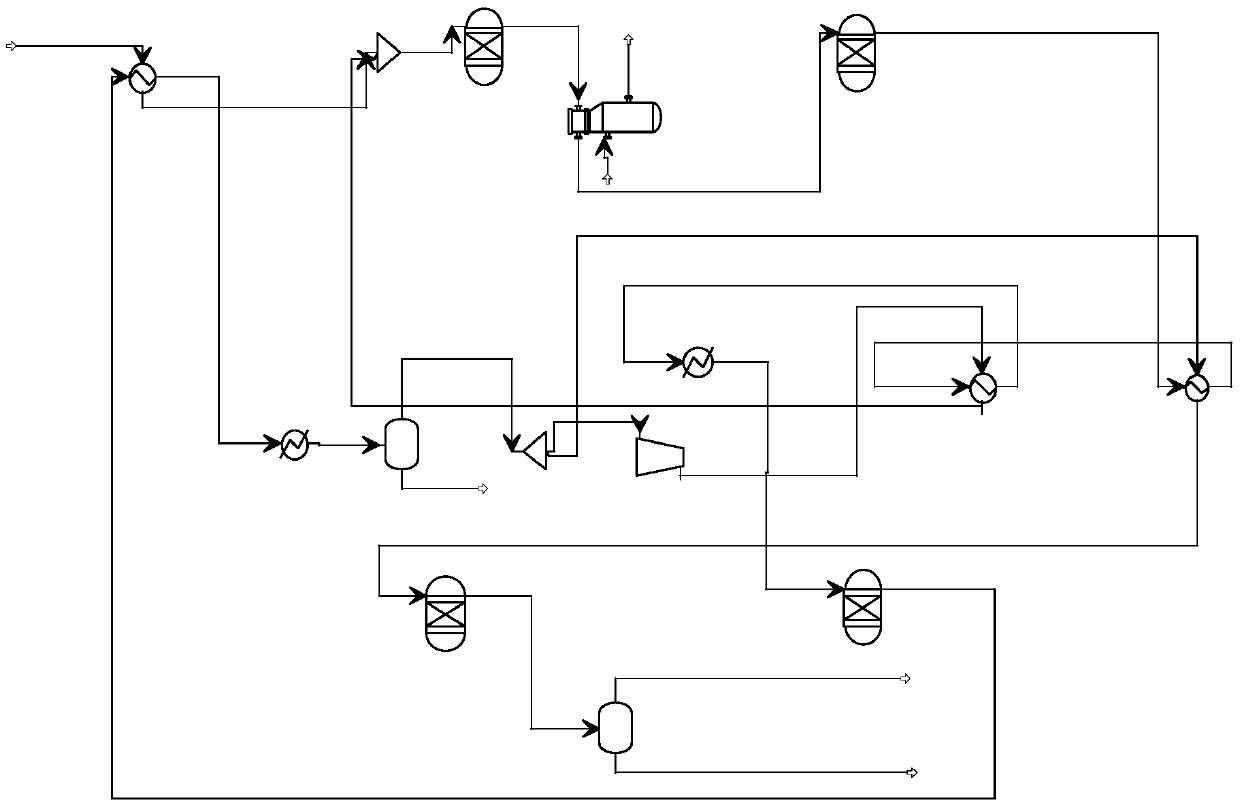

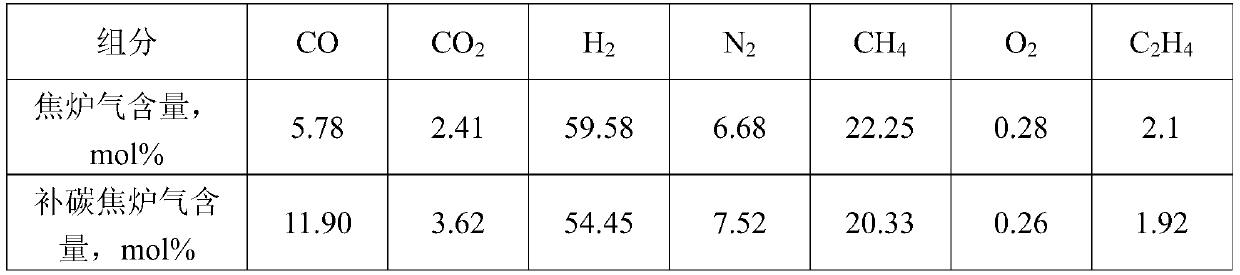

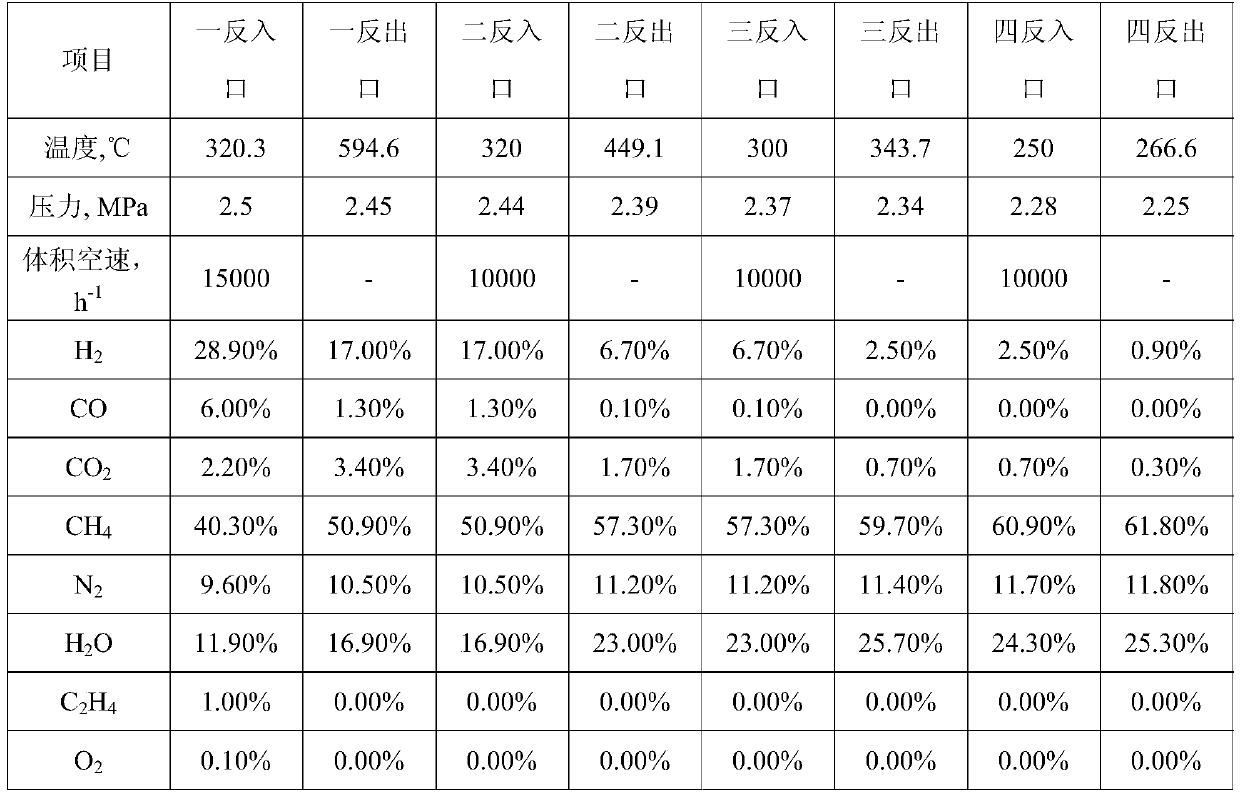

Coke-oven gas methanation catalyst and preparation method and application thereof

InactiveCN105498781ASame growth rateEnhanced decentralizationGaseous fuelsCatalyst activation/preparationMethanationActive component

The invention provides a coke-oven gas methanation catalyst and a preparation method and application of the coke-oven gas methanation catalyst. The coke-oven gas methanation catalyst is prepared from an active component Ni which accounts for 5 percent to 50 percent of the total mass according to the mass of a metal element, an addition agent which accounts for 1 percent to 40 percent of the total mass according to the mass of an oxide, and the balance of a carrier Al2O3. The preparation method of the coke-oven gas methanation catalyst comprises the following steps: (1) preparing a solution I from the Ni, the addition agent and an Al precursor; (2) preparing a precipitant solution, and adding a surfactant to prepare a solution II; (3) mixing the solution I and the solution II in a parallel flow manner, and carrying out ultrasonic precipitation; (4) washing sediment, filtering, drying, granulating and roasting to obtain powder; (5) adding a pore expanding agent, graphite and a binding agent into the powder, molding and then roasting. The preparation method provided by the invention applies a parallel flow precipitation method, which introduces ultrasonic waves and the surfactant. The active component and carrier component of the catalyst have a strong systematic effect, and the catalyst has the advantages of high activity, high-temperature hydrothermal stability and wide active temperature region, so that the catalyst is particularly suitable for a multi-section coke-oven gas methanation process.

Owner:DATANG INT CHEM TECH RESINST

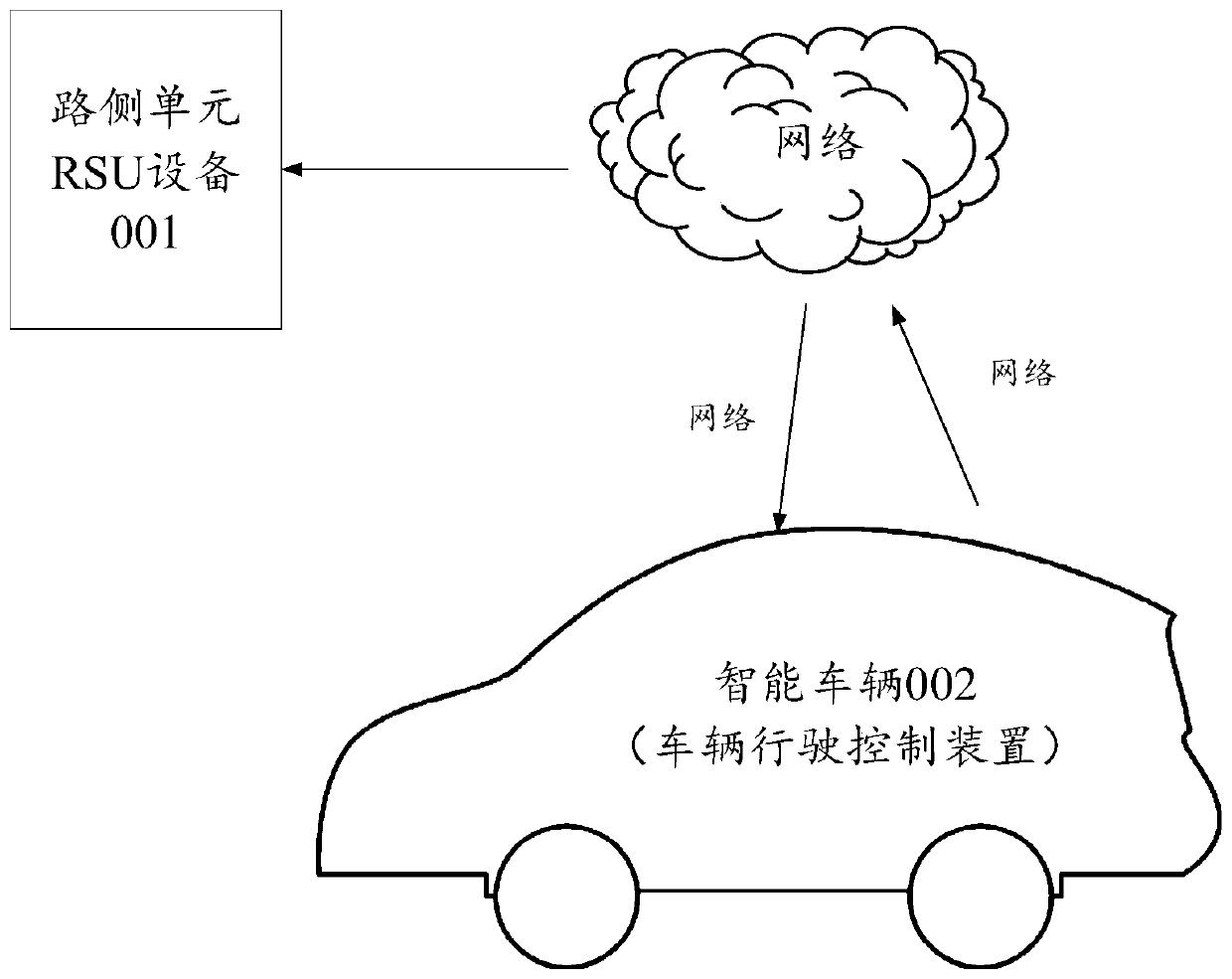

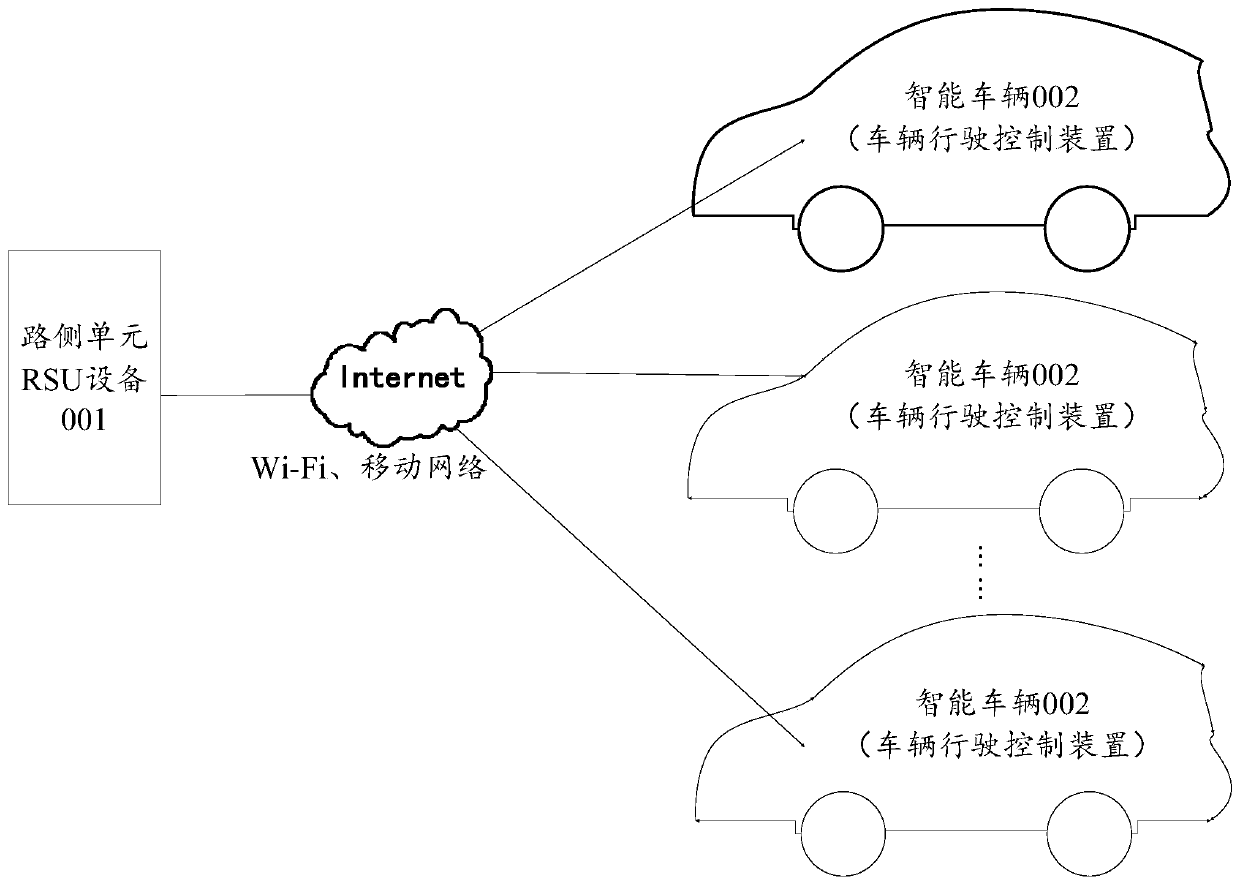

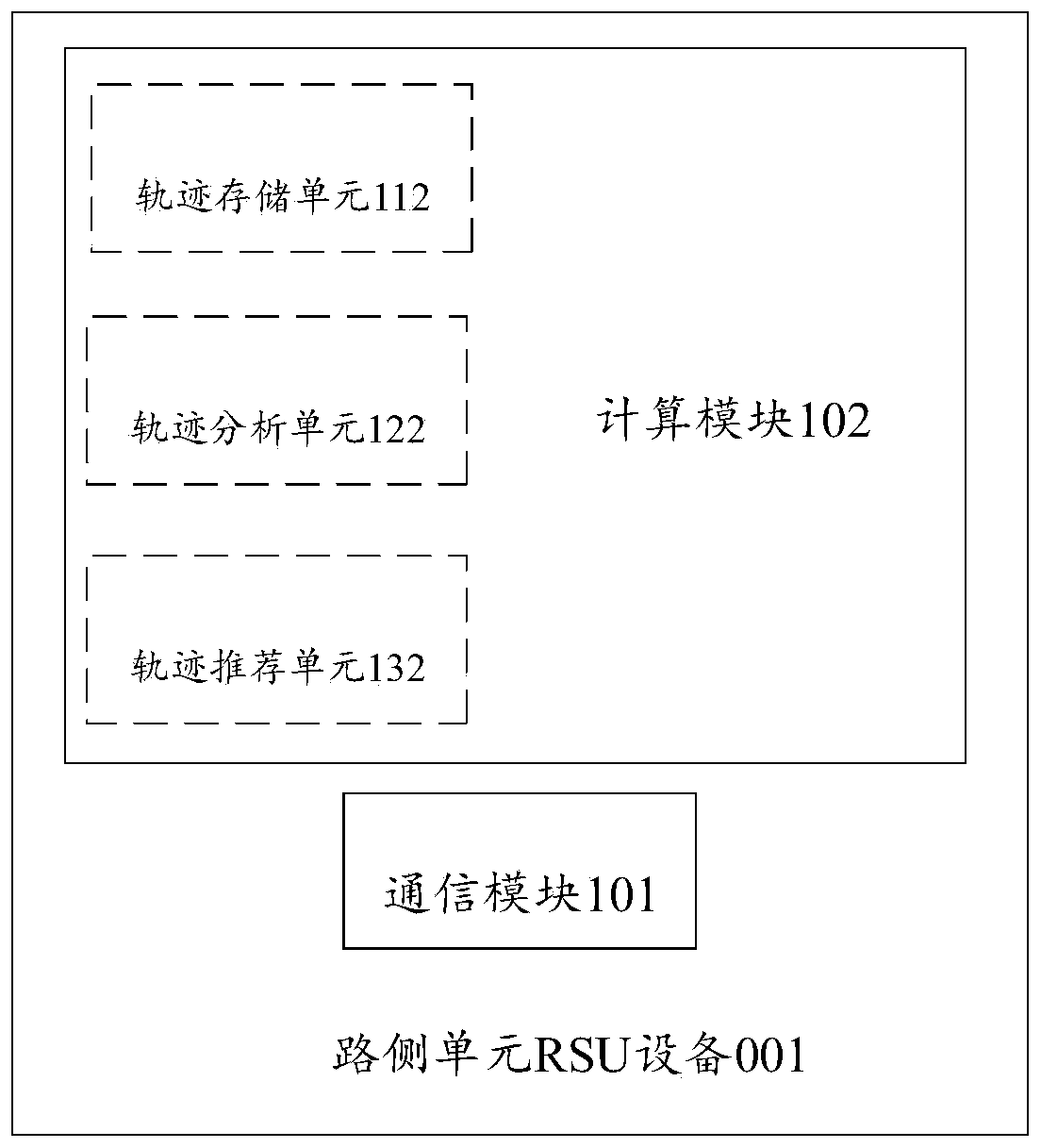

Vehicle driving control method and related equipment

ActiveCN110989569ASafe drivingImprove comfortAutonomous decision making processPosition/course control in two dimensionsVehicle drivingAutopilot

The embodiment of the invention discloses a vehicle driving control method and related equipment. The method can be specifically applied to the fields of intelligent vehicles, automatic driving and the like in the artificial intelligence field. The vehicle driving control method can comprise the steps that the target vehicle receives the first driving information sent by the RSU equipment, and finely adjusts the current speed and the current curvature of the vehicle according to the road information of the target road section and the vehicle speed range and the vehicle curvature range in the first driving information, so that the target vehicle obtains the adjusted target speed and the adjusted target curvature. According to the rough driving information suggestions recommended by the RSU,in combination with the surrounding conditions of the vehicle, the more suitable refined driving information of the vehicle is calculated, so that the situations of emergency acceleration and emergency braking in the driving process of the vehicle can be avoided, and passengers have more comfortable and stable riding experience.

Owner:HUAWEI TECH CO LTD

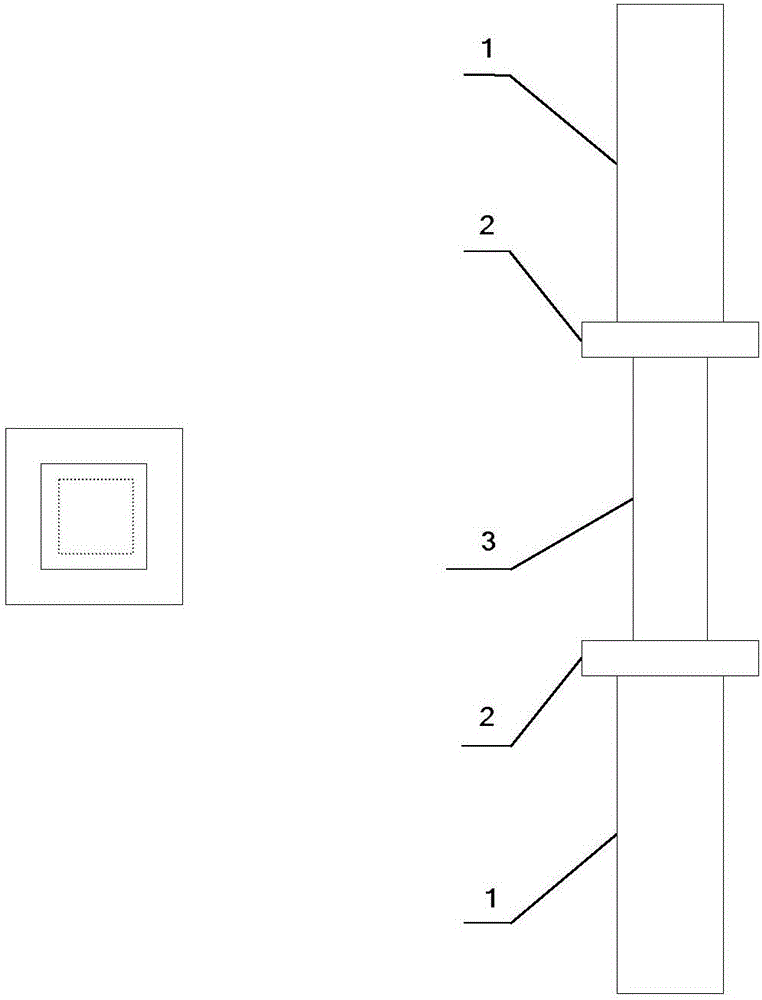

Indoor simulated system applied in lake sediment-water interface process research

InactiveCN101172668ATemperature controlReduce work intensityWater/sewage treatmentBiological water/sewage treatmentWater bathsSea surface temperature

The invention provides an indoor simulation system used for the process study between the sediments and the water surface of a lake. The indoor simulation system mainly comprises a water power disturbance system, an illuminating system, a constant-temperature water bathing system and an automatic sampling system. The invention has the advantages that the lake sediments are collected and directly put into a heat reserving box, the surface water power disturbance, the surface illumination, the surface temperature and the overlying water chemical features can be manually controlled, and long-time operation and multi-sampling are also available, without influencing the sediments and the surface process; the invention can, in fairly large scope, satisfy the requirements of the scheduled experimental conditions, so as to achieve the basic requirements of the researchers on studying the surface chemical or biological process. The system, being reliable and cheap, has advantages of compact structure, stable operation, long-time continuous running and long service life as well as convenient component disassembly-assembly and low cost.

Owner:NANJING INST OF GEOGRAPHY & LIMNOLOGY

Pretreatment method of tobacco stalk raw material

ActiveCN101766329AReduced risk of spoilageReduce browningTobacco treatmentChemical structurePretreatment method

The invention discloses a pretreatment method of tobacco stalk raw material, comprising the following steps: firstly, dissolving 0.1-30 parts of ammonium salt into 10-100 parts of water according to weight parts, mixing and dissolving the ammonium salt to prepare ammonium salt solution for stand-by application; then, smashing quicklime and screening the smashed quicklime through a 40 mesh screen, and then, preparing the quicklime powder whose diameter is smaller than 40 mesh for stand-by application; spraying the ammonium salt solution to the tobacco stalk of 100-1000 parts and mixing them to lead the tobacco stalk to be fully absorbed; lastly, evenly mixing the 0.1-10 parts of quicklime powder and the tobacco stalk which is processed through ammonium salt solution, and stacking and storing the tobacco stalk for 20-40 days. The invention can complete the pretreatment of the tobacco stalk during the storing course of the tobacco stalk, can not affect the re-using of the production process time for the tobacco stalk; meanwhile, the pretreatment of large quantities of raw materials can be simultaneously conducted, therefore, the invention not only can improve the physical and chemical structure of the tobacco stalk, but also can effectively increase the internal quality of the tobacco stalk.

Owner:CHINA TOBACCO YUNNAN REMFG TOBACCO CO LTD

Nutritious health-care food for protecting eyes and producing method therefor

InactiveCN1524448AImprove eye adjustment machineSmall fluctuation rangeSenses disorderPill deliveryVitamin A RetinolTaurine

The invention relates to a nourishing health food for vision protection and method for making same belonging to the field of health products, which comprises retinol, lactoflavin, vitamin E, Zinc, carotene-beta, taurine, sweet orange oil, citric acid, malic acid, Aspartame, glucose, lutein and N- broncholysin. The food can be applied for the improvement and prevention of vision fatigue.

Owner:哈尔滨世一堂视保科技发展有限公司北京一分公司

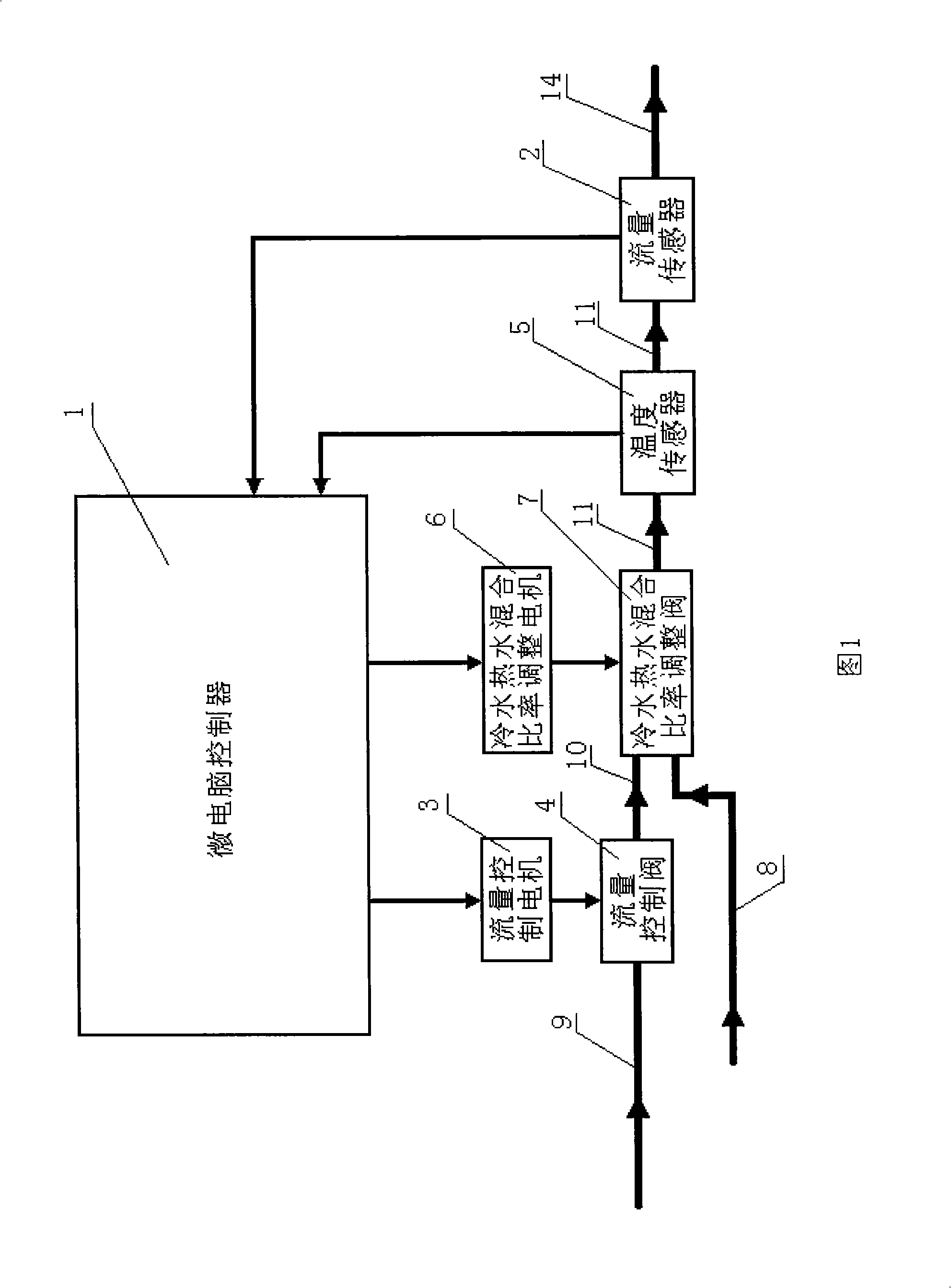

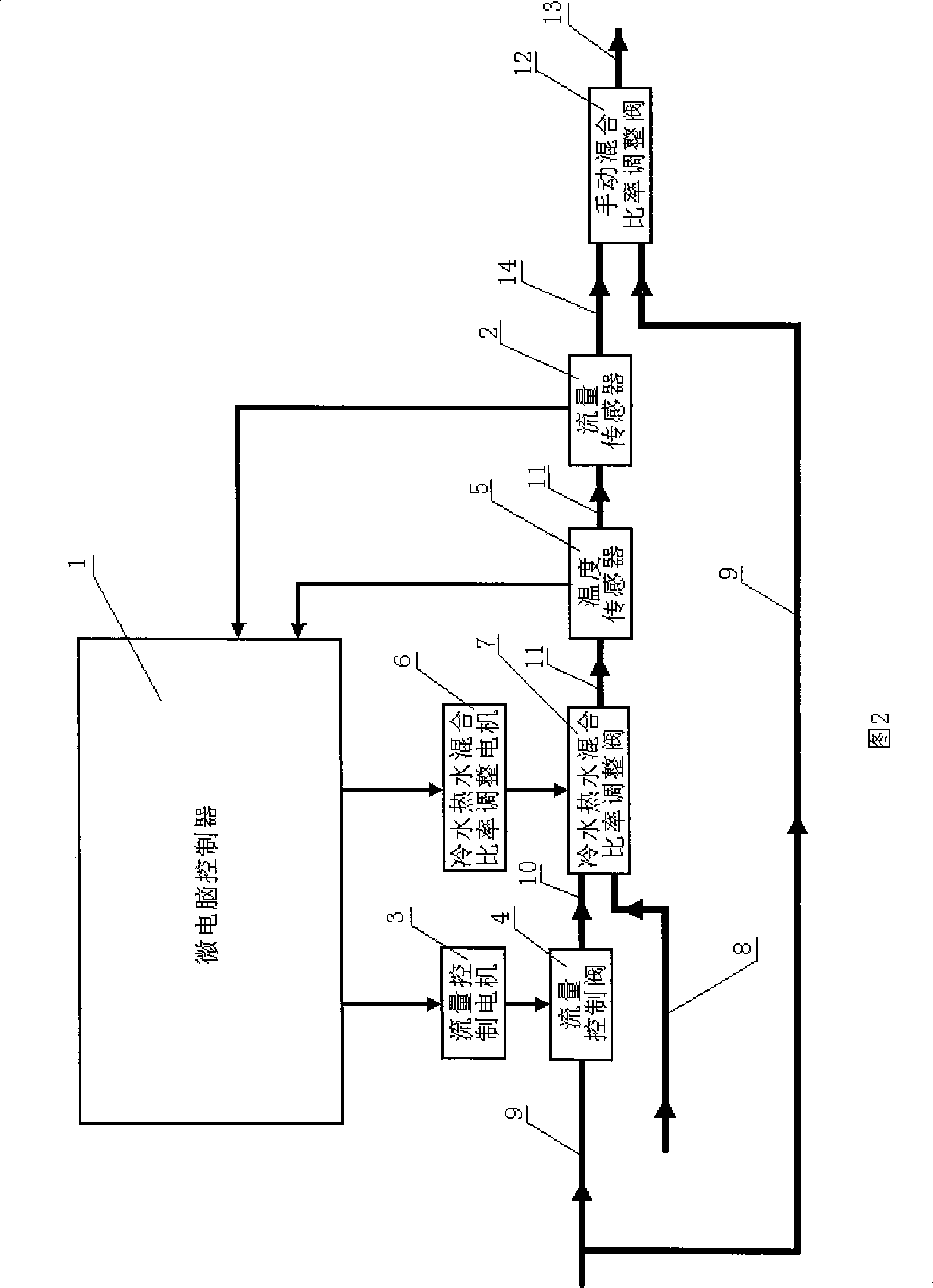

Hot water constant temperature constant-current automatic regulating apparatus

InactiveCN101334189AReduce sensitivitySmall fluctuation rangeLighting and heating apparatusSpace heating and ventilation detailsStreamflowMicrocomputer

The invention relates to an automatic adjusting device of the constant temperature and constant current for hot water, which is suitable for the automatic adjustment of the water temperature and the flow, because the flow can not be controlled by the prior similar products, a certain waste is caused to the resource and the energy. The automatic adjusting device comprises a flow controlling motor, an adjusting motor for the mixing ratio of the cold water and the hot water, a flow sensor, a temperature controlling valve, an adjusting valve for the mixing ratio of the cold water and the hot water and a microcomputer controller. The flow sensor and the temperature sensor are arranged at the mixed water outlet opening part of the cold water and the hot water, according to the electrical signal sent by the flow sensor and the temperature sensor, the microcomputer controller can drive and control the flow controlling motor and the adjusting motor for the mixing ratio of the cold water and the hot water, to drive the valve cores of the flow controlling valve and the adjusting valve for the mixing ratio of the cold water and the hot water, to automatically adjust the flow and the temperature of the hot water, thereby, the purpose of the constant temperature and constant current is achieved, and the consumption of the resource and the energy can be saved.

Owner:韩红桥

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com