Patents

Literature

79results about How to "Increase service temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

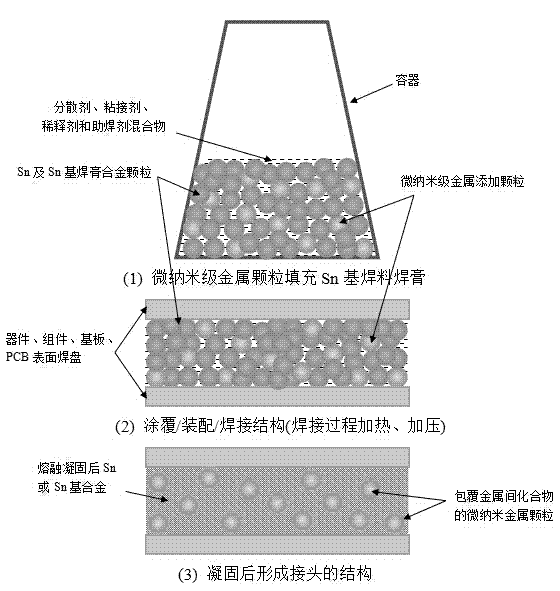

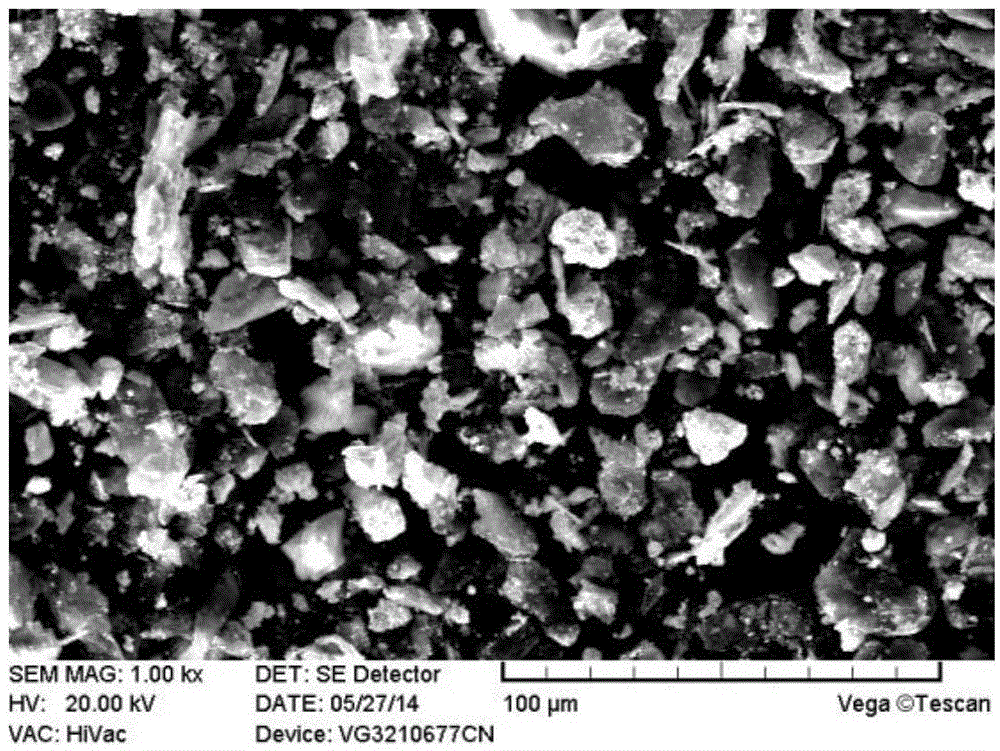

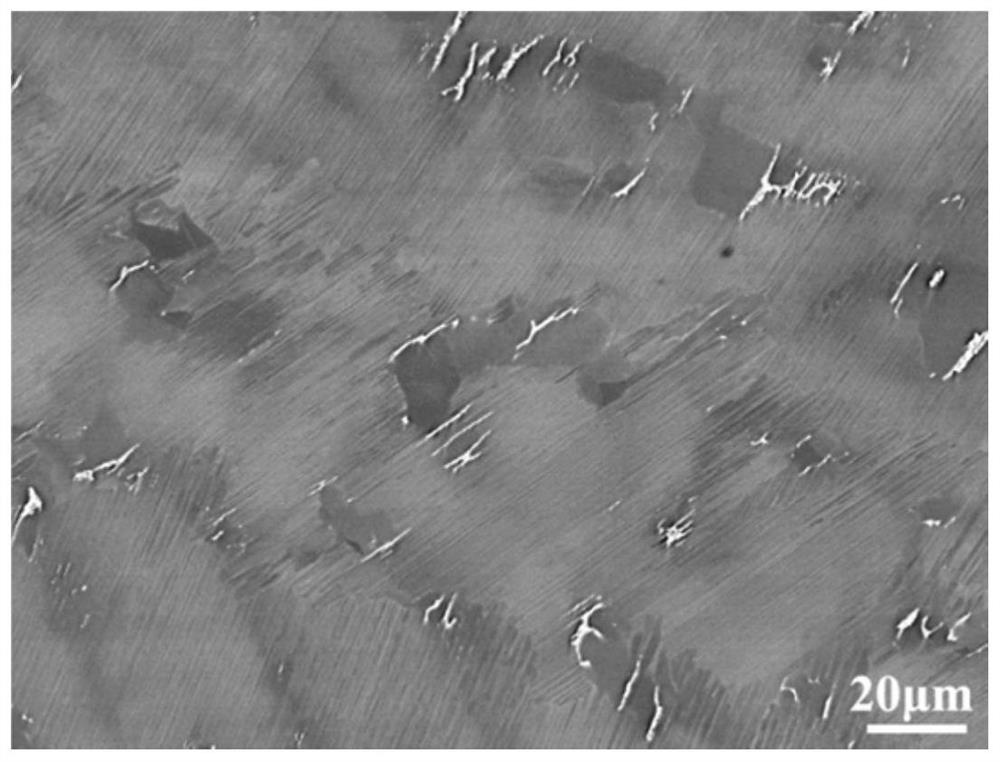

Method for achieving electronic building brick high-temperature packaging by filling Sn-based solder with micro-nano metallic particles

ActiveCN104759725APlay a reinforcing roleImprove cooling effectWelding/cutting media/materialsMetal working apparatusMicro nanoBrick

The invention provides a method for achieving electronic building brick high-temperature packaging by filling Sn-based solder with micro-nano metallic particles. The method comprises the steps that the micro-nano metallic particles are prepared and mixed with a dispersing agent, a caking agent, diluent and scaling powder; a micro-nano metallic particle mixture is evenly mixed with pure Sn or Sn-based soldering paste; the Sn-based soldering paste is filled with the micro-nano metallic particles and placed on a base plate, alignment process of a part to be welded is completed, and pressure is exerted on the Sn-based soldering paste; the Sn-based soldering paste is put back in a reflow oven and experiences a preheating stage, an insulation stage, a reflowing stage and a cooling stage. According to the method for achieving electronic building brick high-temperature packaging by filling the Sn-based solder with the micro-nano metallic particles, the Sn-based solder is filled with the micro-nano metallic particles, connection and assembly of high-power devices or components can be achieved under the process condition of being compatible with traditional reflow soldering, when the devices serve at high temperature, metallic particles are formed inside a connector, excellent conductivity property and heat-conducting property are achieved, and the heat dissipation index and the electrical performance index of the electronic building brick can be significantly improved.

Owner:HARBIN INST OF TECH

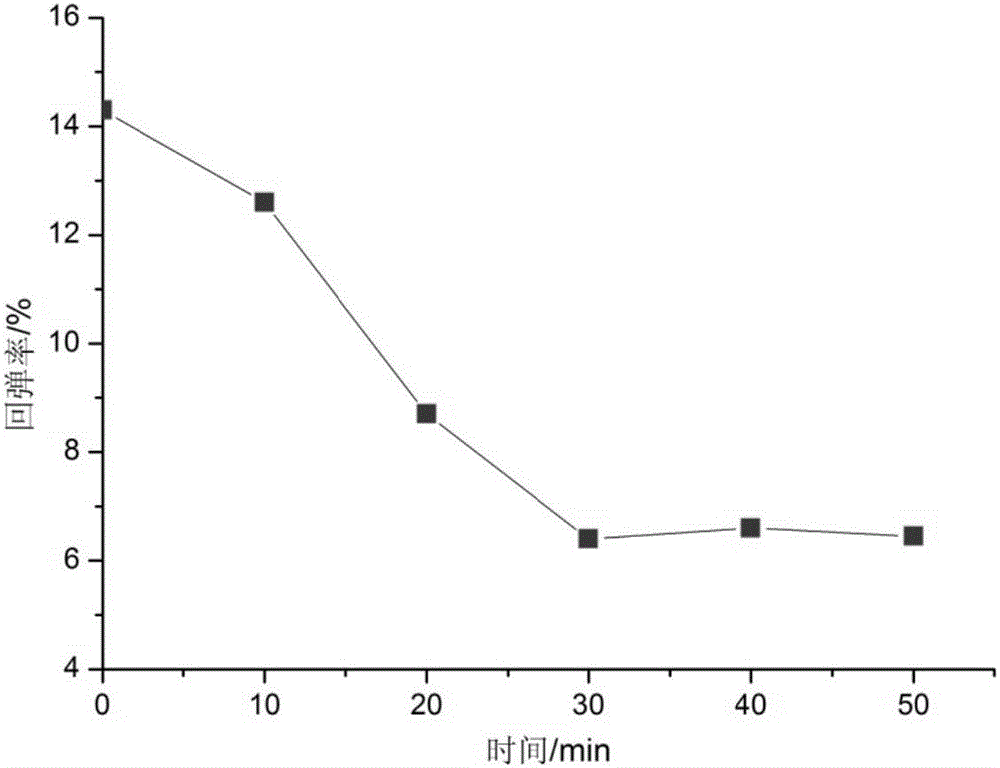

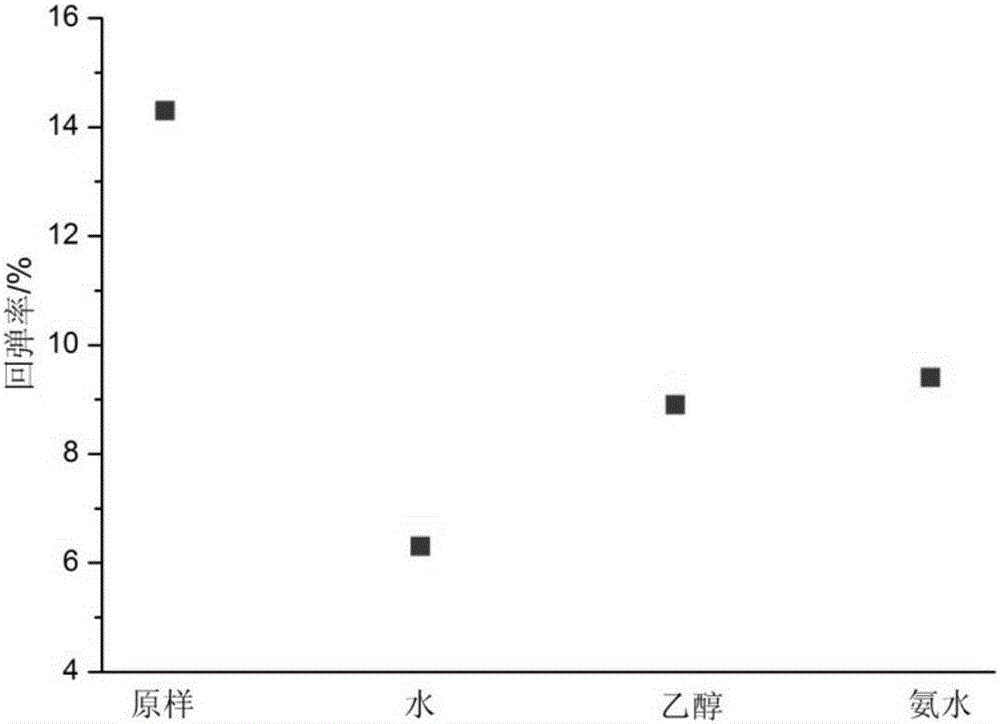

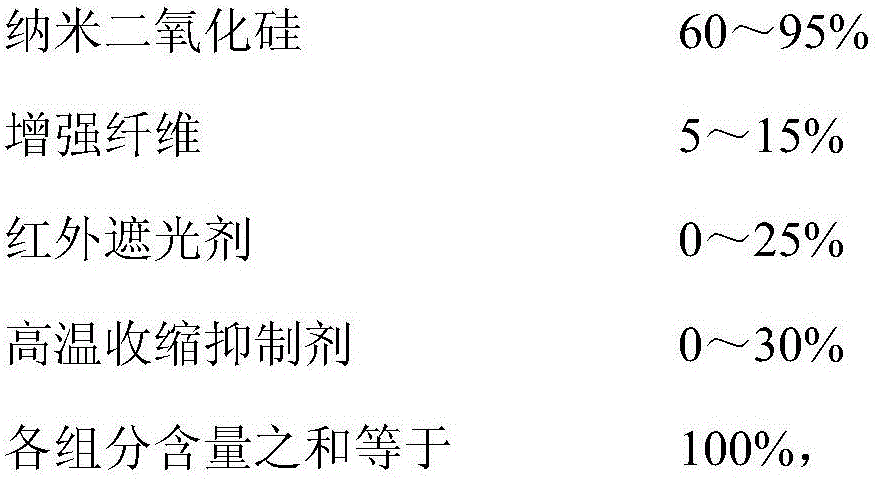

Preparation method of nano-silica powder-based super composite thermal insulation material

The invention provides a preparation method of a nano-silica powder-based super composite thermal insulation material. Nano-silica powder and a functional additive are taken as raw materials, the nano-silica powder accounts for over 60% of total weight of the raw materials and the functional additive at least comprises reinforced fibers; the preparation method comprises the steps of stirring and dispersing the reinforced fibers at a rotating speed of 400-1,000r / min for 0.5-1.5 minutes; mechanically fusing the dispersed reinforced fibers, the nano-silica powder and other functional additives to complete coating modification on the surface of the functional additive by the nano-silica powder; and making the fused materials in full contact with steam at 80-85 DEG C for 28-32 minutes, extruding air and carrying out pressing, molding and drying to obtain the high-performance nano-silica powder-based super composite thermal insulation material. According to the preparation method, the supercritical drying process with strict conditions in an existing preparation technology is abandoned; and the nano-silica powder-based super composite thermal insulation material with excellent performance is prepared through a simple dry process.

Owner:GUANGXI UNIV

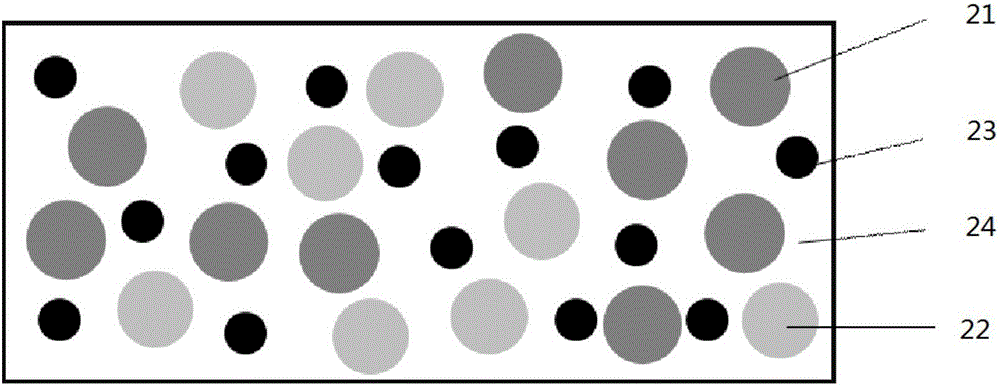

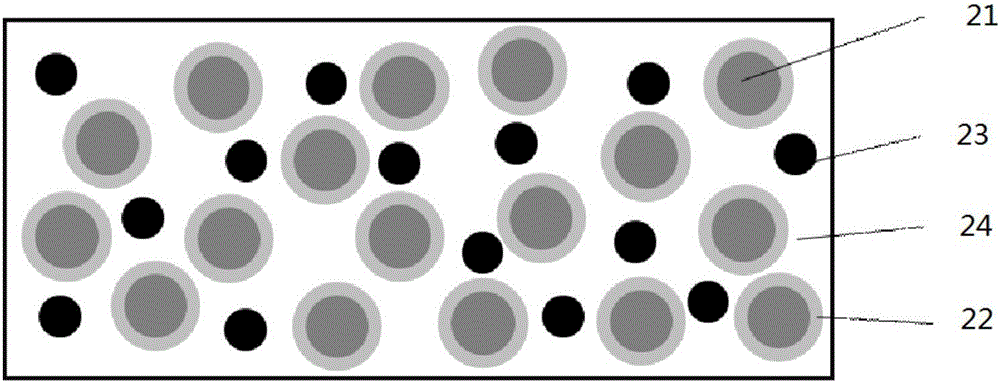

Interconnection brazing material and interconnection forming method thereof

ActiveCN106271177ASolve the problem of long time consumption of phase methodLow Young's modulusWelding/cutting media/materialsMetal working apparatusAmount of substanceThird phase

The invention provides an interconnection brazing material and an interconnection forming method thereof. The heating technological temperature of a product applied by the interconnection brazing material is T, the interconnection brazing material contains a component A with the melting point larger than T, a component B with the melting point smaller than T and a third-phase component C with the melting point larger than T; the third-phase component C accounts 0-30% the total mass of the component A, the component B and the third-phase component C. A compound AxBy is formed through a reaction between the component A and the component B at the heating technological temperature; the ratio of amounts of substances of the component A to the component B is larger than x / y, the third-phase component C does not react with the component A or the component B, the hardness of the third-phase component C is smaller than those of the component A, the component B and the compound AxBy. According to the technical scheme, a high-melting-point welding joint is obtained, and the Young modulus and the thermal expansion coefficient of a joint can be adjusted by adjusting the proportion of the components inside the brazing material.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

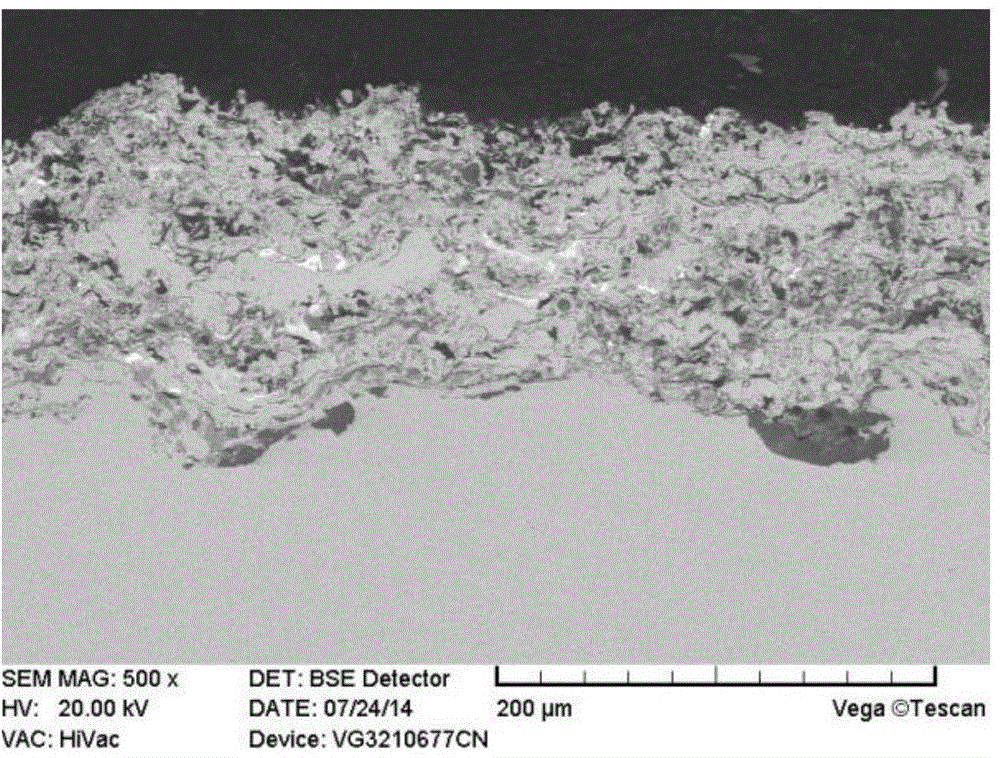

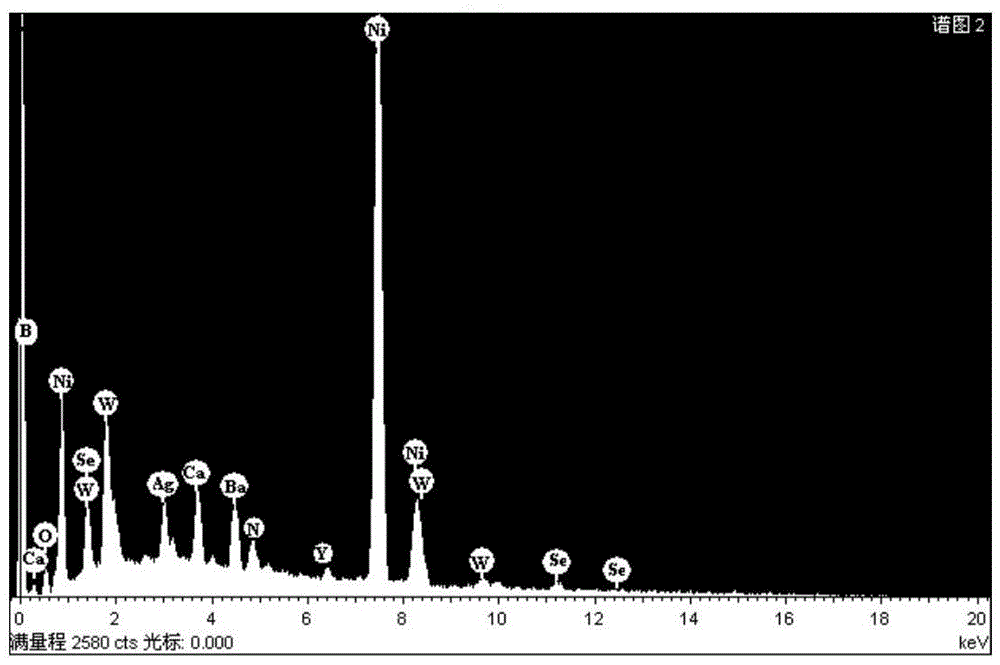

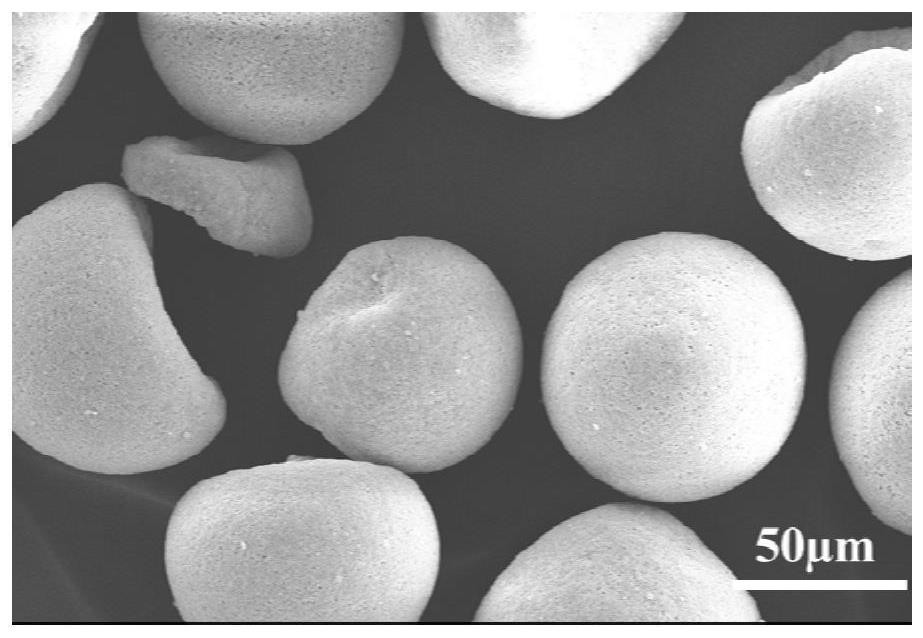

Wide temperature region viscosity corrosion resisting solid self-lubricating coating and preparation method thereof

ActiveCN104928611AIncrease service temperatureAchieve normal workMolten spray coatingPolyvinyl alcoholBoron nitride

The invention discloses a wide temperature region viscosity corrosion resisting solid self-lubricating coating and a preparation method thereof. The coating comprises nano nickel Ni, tungsten selenide WSe2, sliver Ag, yttrium Y, eutectic calcium fluoride fluoride barium CaF2.BaF2 and boron nitride hBN, the raw materials are subjected to mixing with a polyving akohol solution, sintering and breaking and screening, the atmospheric plasma spraying technology is adopted, then the coating is prepared. The solid self-lubricating coating prepared by the method does not contain the chrome Cr element, the working environment of the solid self-lubricating coating is improved, compared with technologies of the same field, the wide temperature region viscosity corrosion resisting solid self-lubricating coating has the advantages that the low friction coefficient is low and stable, the metal melting-drop viscosity corrosion resistance ability is strong, the fluctuation range in the wide temperature region range is smaller, the coating can be used at the temperature ranging from 25 DEG C to 800 DEG C, the service temperature of the coating is improved, and the important engineering application value is achieved.

Owner:PLA SECOND ARTILLERY ENGINEERING UNIVERSITY

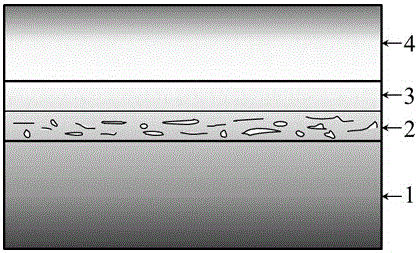

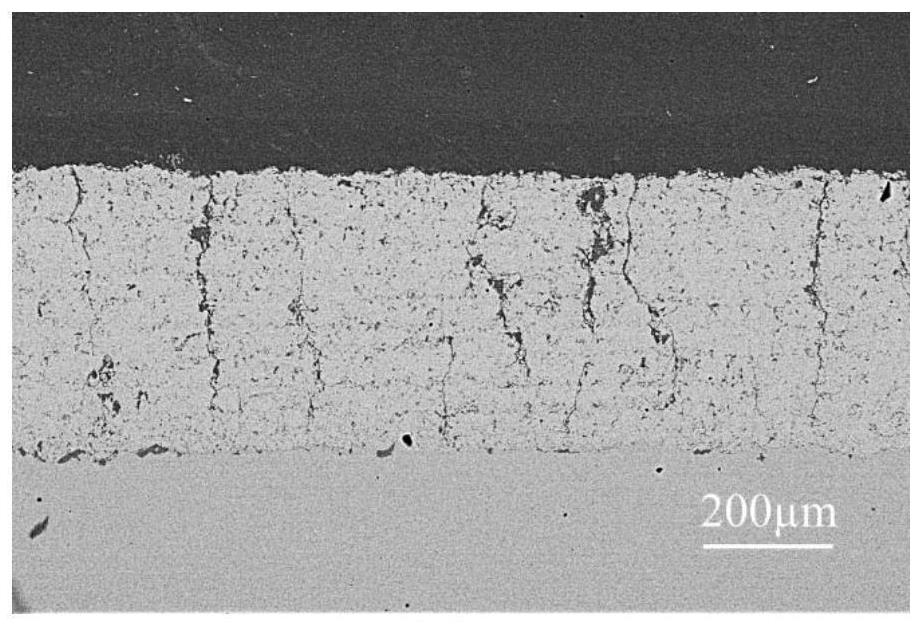

Thermal barrier coating with two bonding layers and preparation method of thermal barrier coating

ActiveCN106119760AReduce vertical stressRelieve high temperature thermal expansionMolten spray coatingPorous layerSand blasting

The invention discloses a thermal barrier coating with two bonding layers. The thermal barrier coating comprises a high-temperature alloy matrix, wherein a first bonding layer, a second bonding layer and a surface ceramic layer are deposited above the matrix in sequence; and the first bonding layer is of a multiporous laminated structure, and the second bonding layer is of a compact structure. A preparation method of the thermal barrier coating comprises the following steps: (1) grinding and performing sand blasting treatment on the surface of the high-temperature alloy matrix; (2) depositing a porous layer, which is the first bonding layer, with the porosity of 10 to 30 percent on the surface of the matrix by adopting gas shield protection plasma spraying; (3) depositing a compact layer, which is the second bonding layer, on the surface of the porous layer by adopting hypersonic flame spraying, low-pressure plasma spraying or cold spraying; and (4) depositing the surface ceramic layer on the surface of the second bonding layer by adopting atmospheric plasma spraying. The thermal barrier coating with the two bonding layers can both ensure that alpha-Al2O3 is continuously generated on the surfaces of the bonding layers and further relieve thermal expansion mismatch between the matrix and the ceramic layer, so that the service life of the thermal barrier coating is prolonged.

Owner:XI'AN PETROLEUM UNIVERSITY

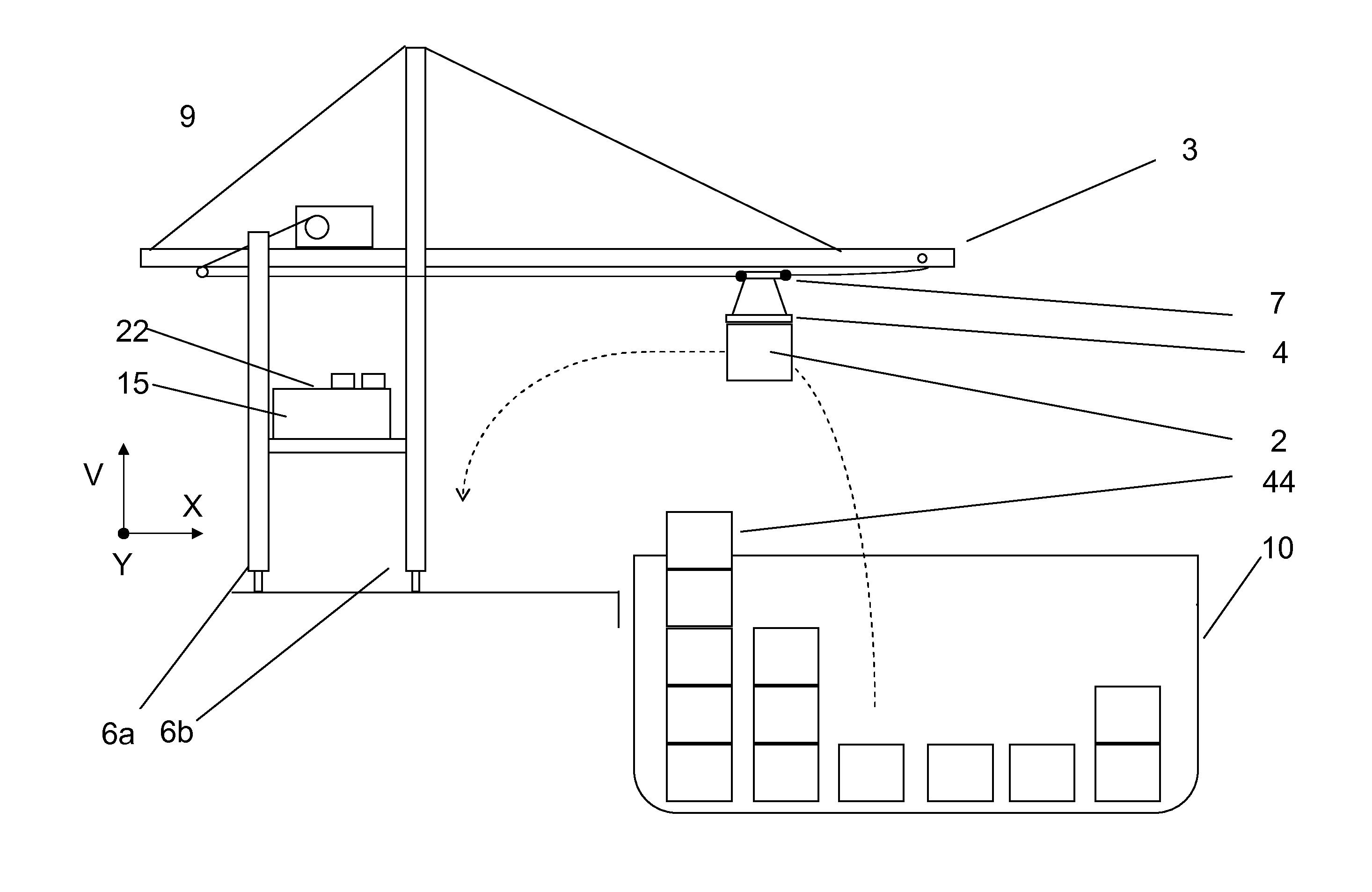

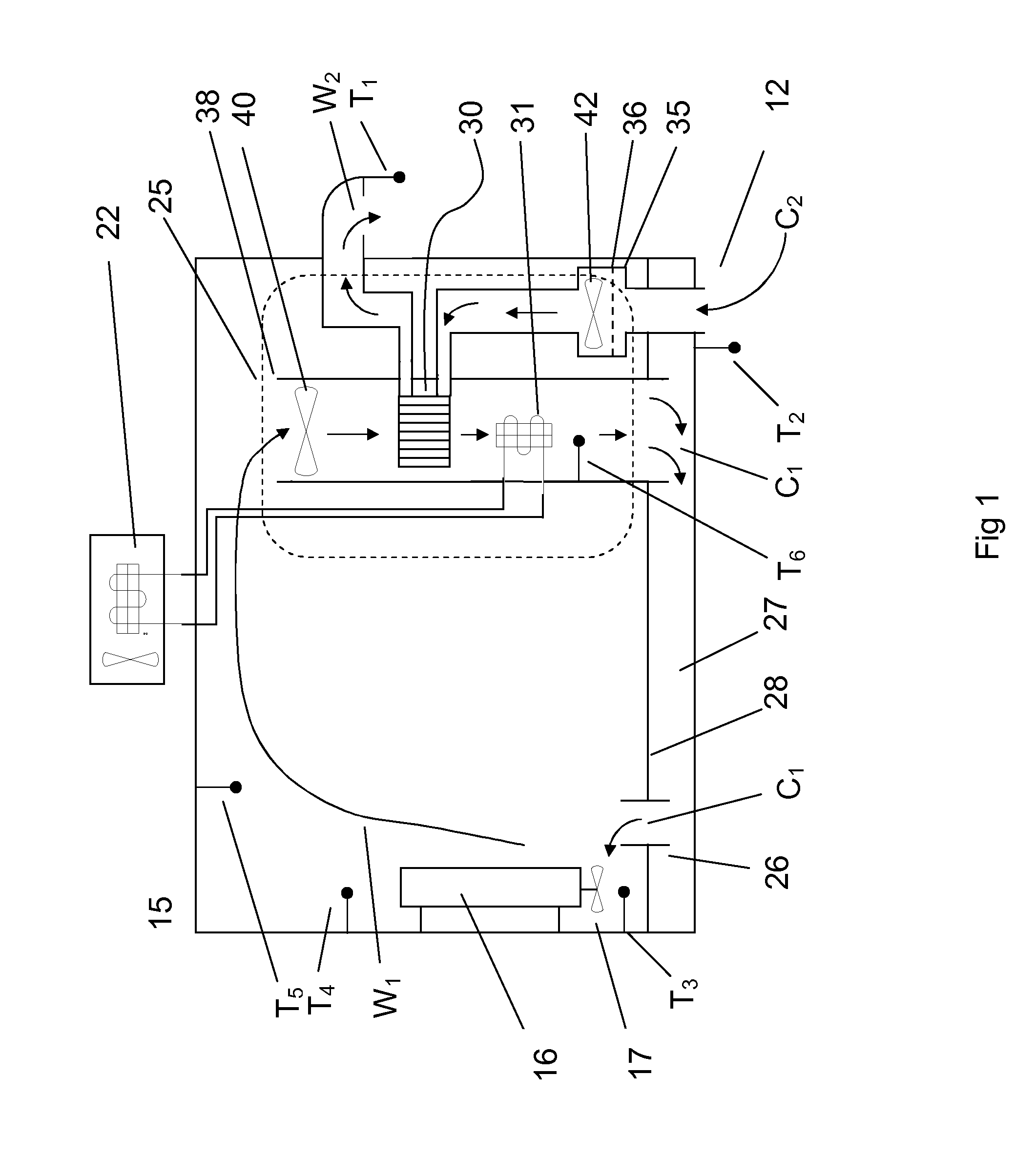

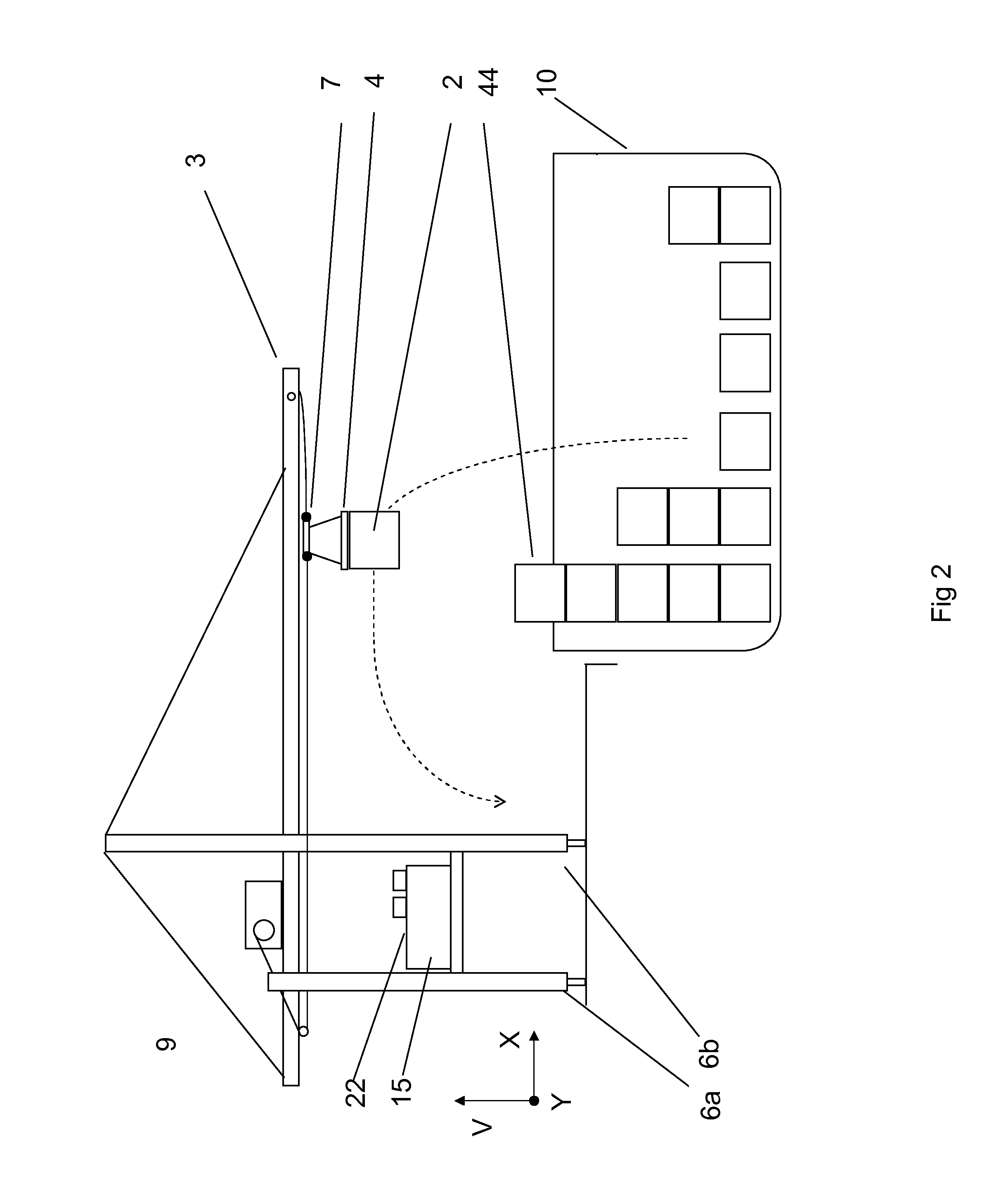

Electrical Room Of An Industrial Equipment Such As A Container Crane, The Electrical Room Comprising A Cooling Device

ActiveUS20150216078A1Easy to useReduce energy consumptionSubstation/switching arrangement cooling/ventilationDistribution substationsContainer craneEngineering

An electrical room housing electrical and electronic apparatus for operating and controlling electrical motors of an industrial equipment is disclosed. The electrical room includes a cooling device with a first heat exchanger which is arranged with a first set of channels through which is conducted a first flow of air drawn from inside the electrical room. Warm air from inside the electrical room is circulated through the first heat exchanger of the cooling device and returned to the electrical room in a closed loop, and the air temperature in the electrical room is controlled dependent on a setpoint of between 24-40° C. A method for controlling the cooling device to cool the electrical room and one or more computer programs arranged for controlling the cooling device are also described.

Owner:ABB (SCHWEIZ) AG

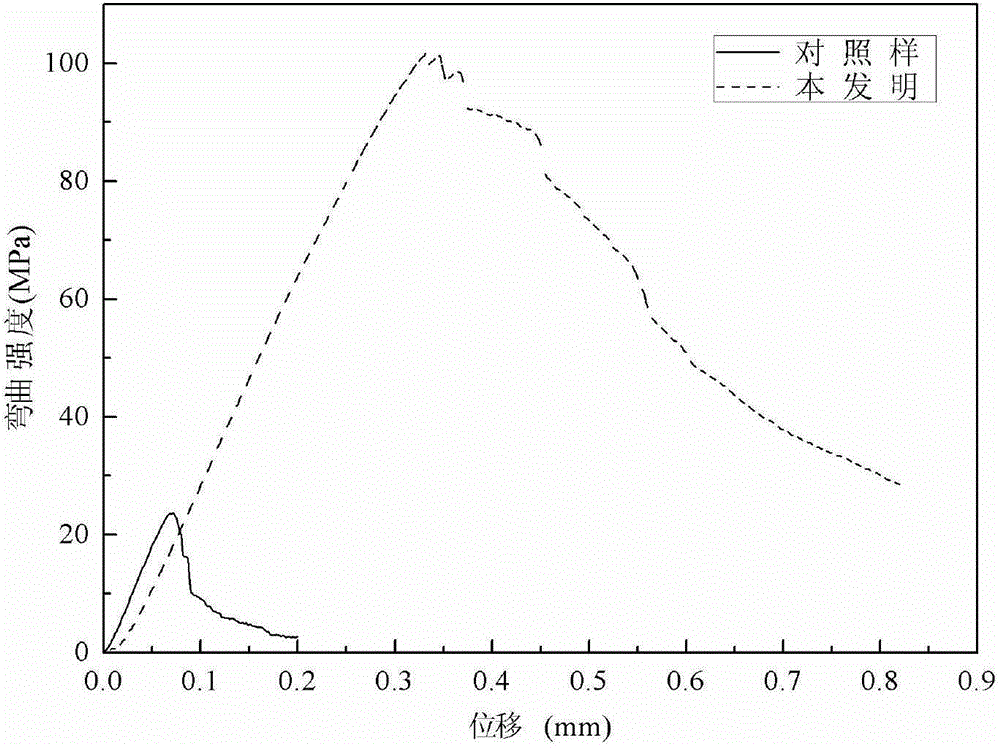

Aluminum silicate fiber reinforced oxide ceramic containing interface phase and preparation method thereof

The invention relates to aluminum silicate fiber reinforced oxide ceramic containing an interface phase. The aluminum silicate fiber reinforced oxide ceramic adopts one or a mixture of more of mullite, aluminum silicate and aluminum oxide as a ceramic substrate and adopts aluminum silicate fiber as a reinforcing phase, and a sacrifice carbon interface phase is formed between the substrate and the reinforced phase. The preparation method of the aluminum silicate fiber reinforced oxide ceramic comprises the following steps: preparing a three-dimensional aluminum silicate fiber fabric, and preparing a pyrolytic carbon coating on the surface of the fiber fabric by utilizing a chemical vapor phase deposition process; taking oxide sol as a precursor, vacuum impregnating the fiber fabric, carrying out the gelatization, then carrying out the high-temperature ceramization, and completing the primary compacting process; repeating compacting for at least 10 times; finally carrying out oxidative cracking on carbon interface phase coating, forming a gap between the aluminum silicate fiber and the substrate, and preparing the product. The product is excellent in mechanical property both at the room temperature and high temperature and has the advantages of short preparation period, low cost, wide applicability and the like.

Owner:NAT UNIV OF DEFENSE TECH

Thermoplastic Polyurethanes Containing A Salt Of Zirconium Phosphate

InactiveUS20080114093A1Improve hydrolysis resistanceIncrease pressureThermoplastic polyurethaneHydrolysis

Thermoplastic polyurethane (TPU) compositions are disclosed comprising TPU polymer, polyisocyanate, and a salt of zirconium phosphate. The compositions have enhanced thermal properties, good processability, and good hydrolysis resistance. Processes are also disclosed to combine the ingredients by melt mixing or to prepare the compositions in-situ as the TPU is being polymerized.

Owner:LUBRIZOL ADVANCED MATERIALS INC

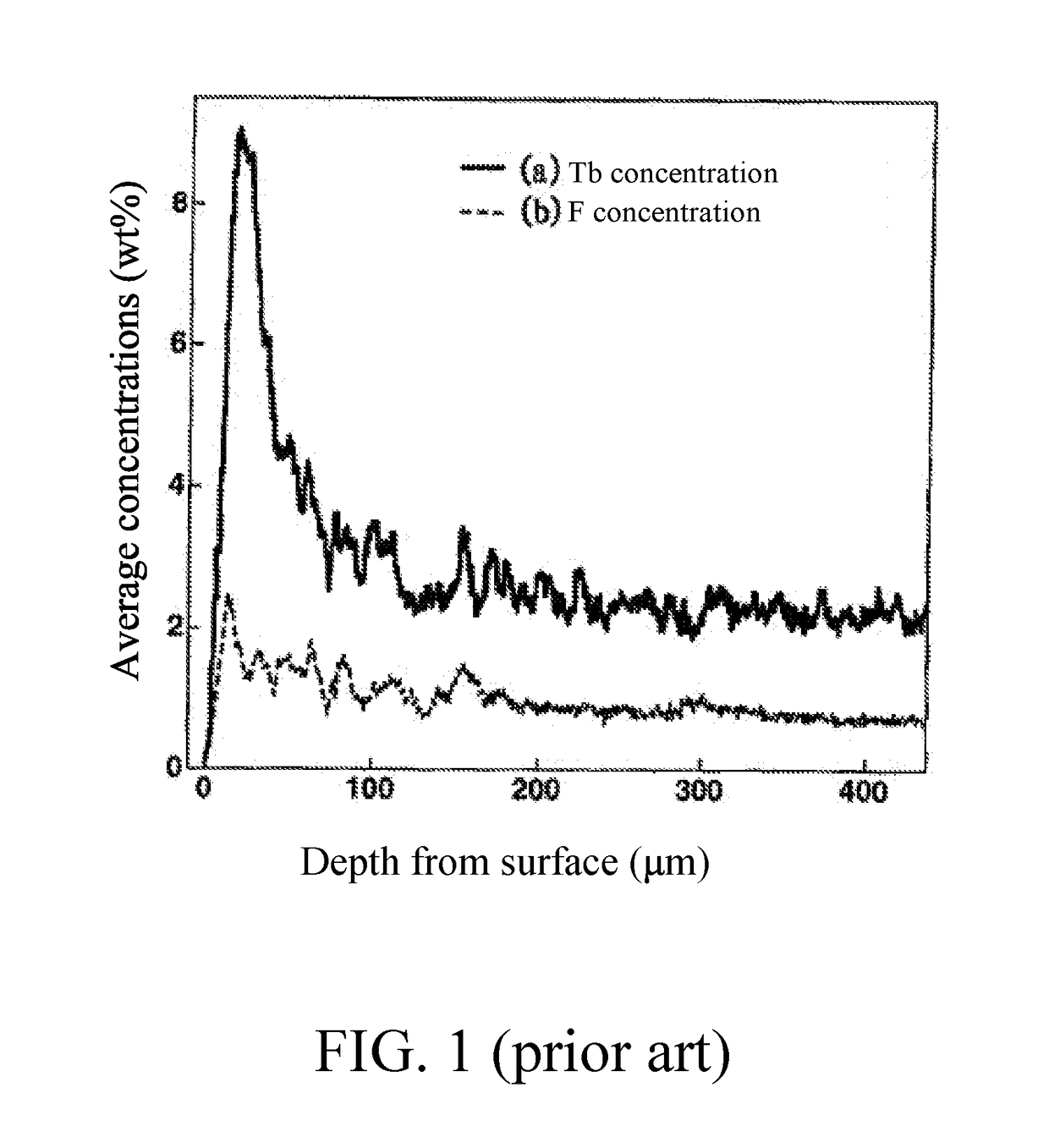

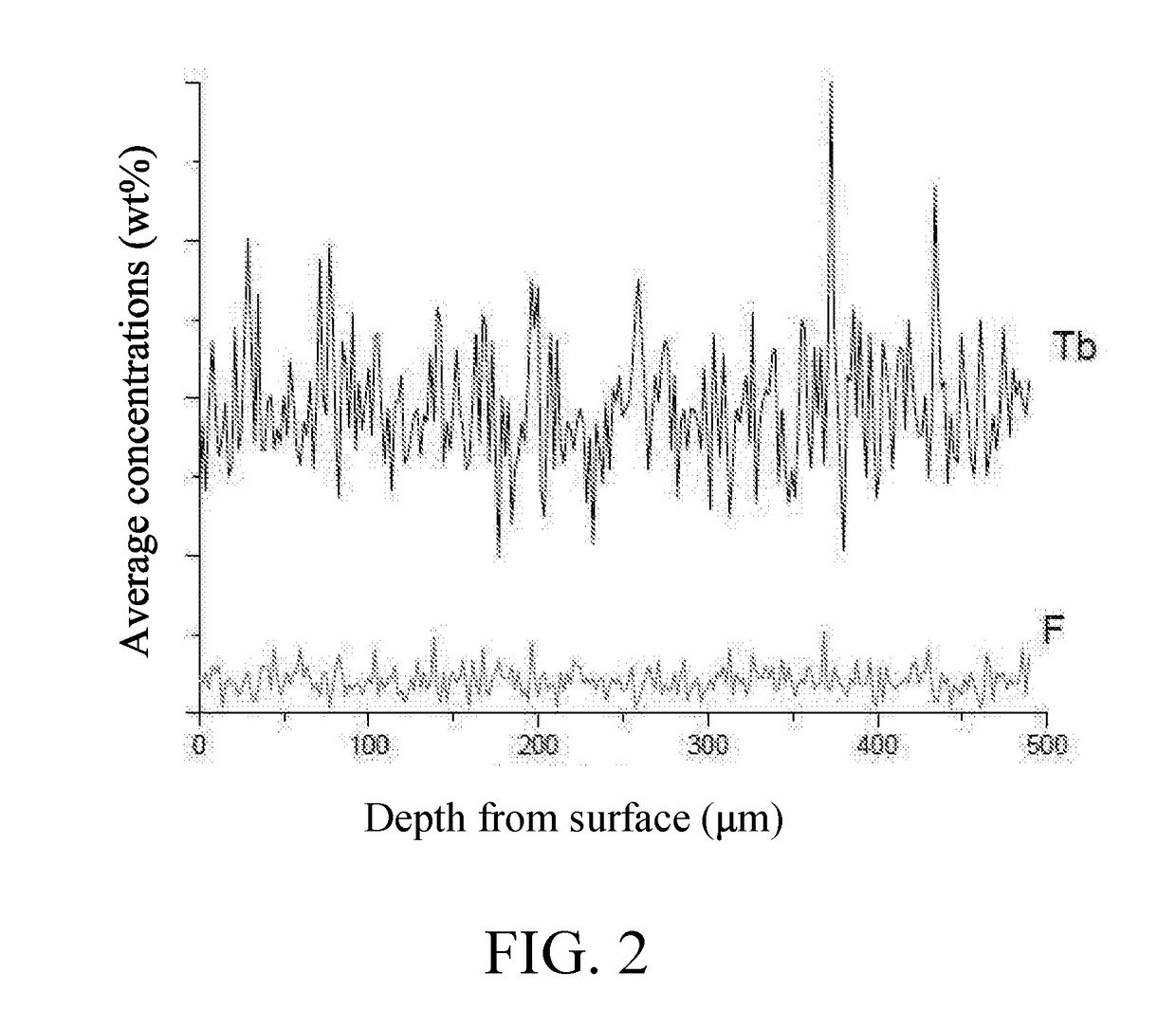

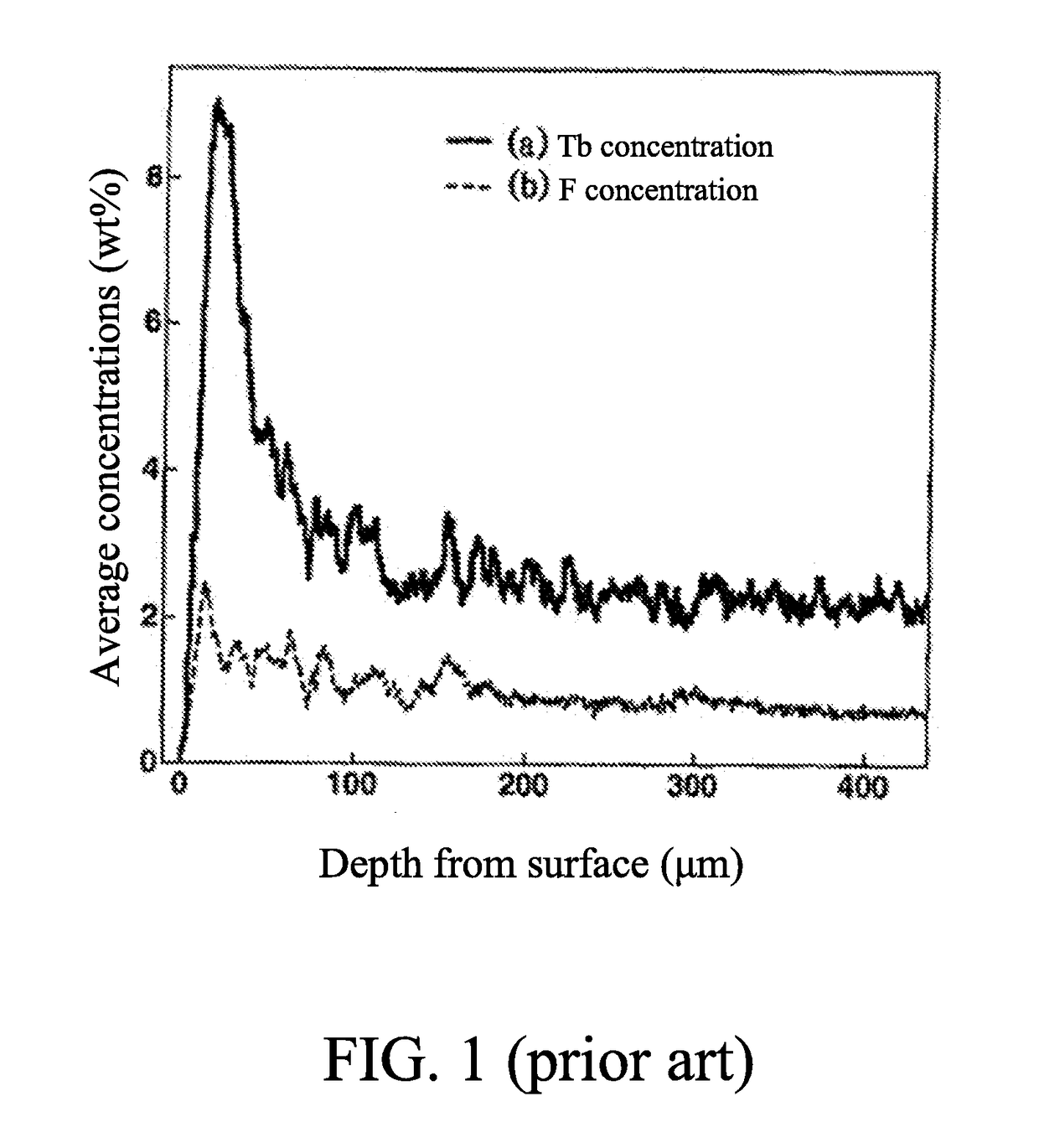

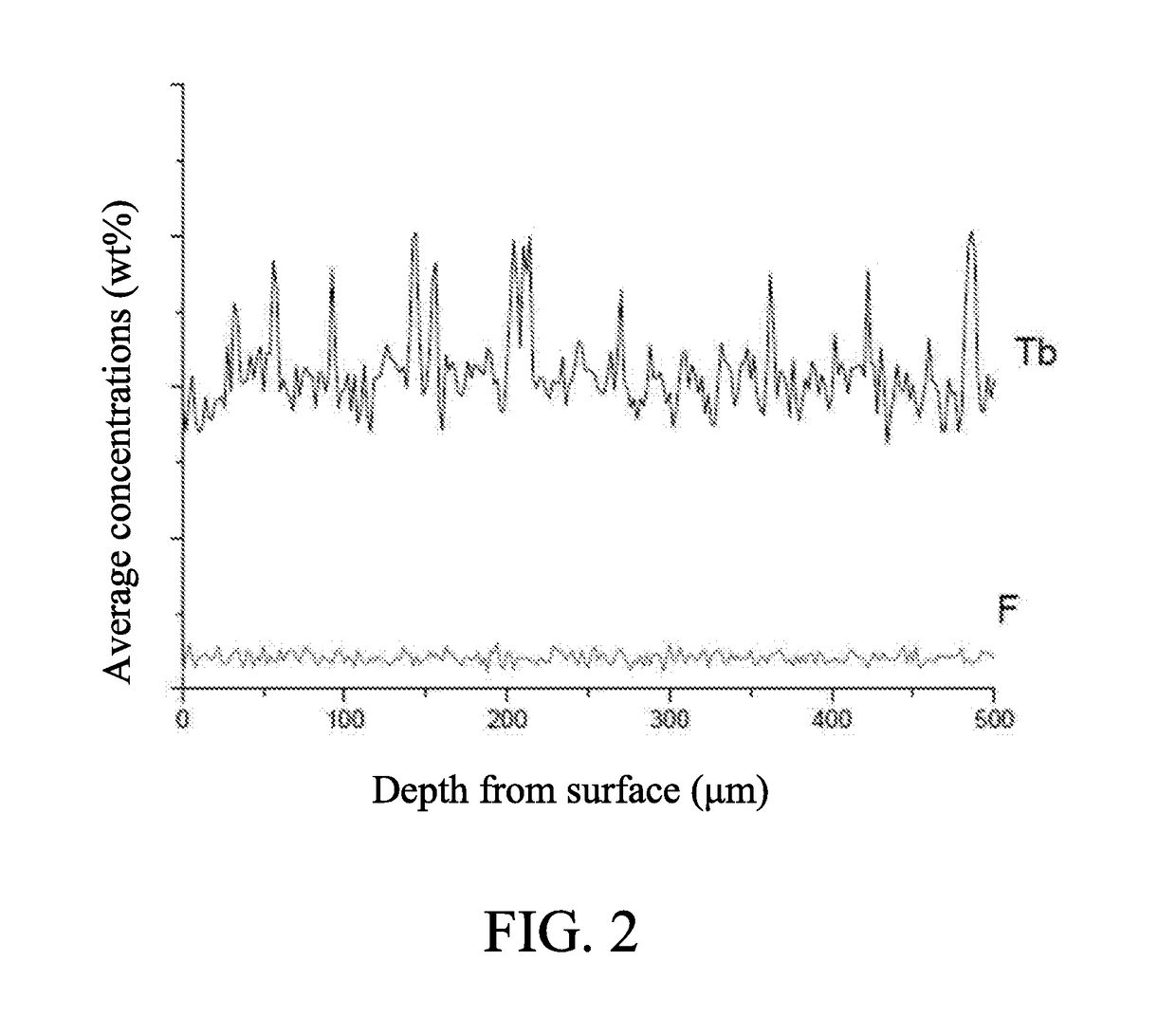

High-performance NdFeB permanent magnet comprising nitride phase and production method thereof

ActiveUS20170098496A1Lower performance requirementsImprove magnetismTransportation and packagingMetal-working apparatusRare-earth elementMetallurgy

A high-performance NdFeB permanent magnet including a nitride phase and a production method thereof are provided. A main phase of the NdFeB permanent magnet has a structure of R2T14B; a grain boundary phase is distributed around the main phase and contains N, F, Zr, Ga and Cu; a composite phase containing R1, Tb and N exists between the main phase and the grain boundary phase and includes a phase having a structure of (R1, Tb)2T14(B, N). R represents at least two rare earth elements, and includes Pr and Nd; T represents Fe, Mn, Al and Co; R1 represents at least one rare earth element, and includes at least one of Dy and Tb; the main phase contains Pr, Nd, Fe, Mn, Al, Co and B; and the grain boundary phase further contains at least one of Nb and Ti. Through placing partially B by N, a magnetic performance is increased.

Owner:SHENYANG GENERAL MAGNETIC

High-performance NdFeB permanent magnet produced with NdFeB scraps and production method thereof

ActiveUS20170117073A1Avoid product qualityReduce contentInductances/transformers/magnets manufactureMagnetic materialsScrapTundish

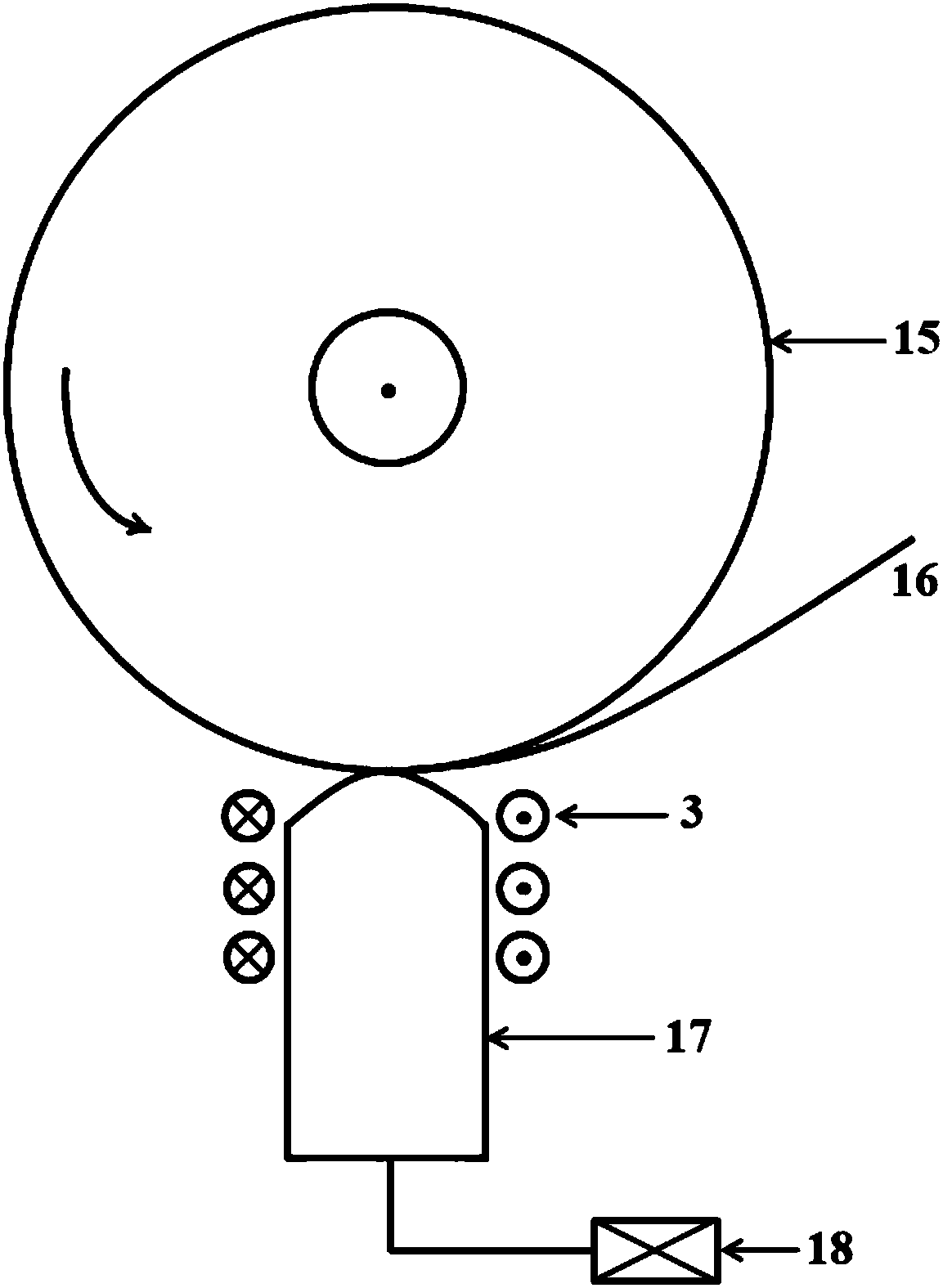

A high-performance NdFeB permanent magnet produced with NdFeB scraps and a production method thereof are provided. The production method includes steps of: under a vacuum condition, sending a portion of raw materials, including pure iron, ferro-iron, the NdFeB scraps and rare earth fluorides, into a crucible, refining, and obtaining a first melting liquid; absorbing slags by a slag cleaning device, and moving the slag cleaning device out; sending a rest of raw materials into the crucible, refining the first melting liquid and the rest of raw materials in the crucible, and obtaining a second melting liquid; pouring the second melting liquid after refining onto a surface of a water-cooled rotation roller through a tundish, and forming alloy flakes; processing the alloy flakes with hydrogen decrepitation, milling the alloy flakes into powders by a jet mill, then magnetic field pressing, presintering and sintering.

Owner:SHENYANG GENERAL MAGNETIC

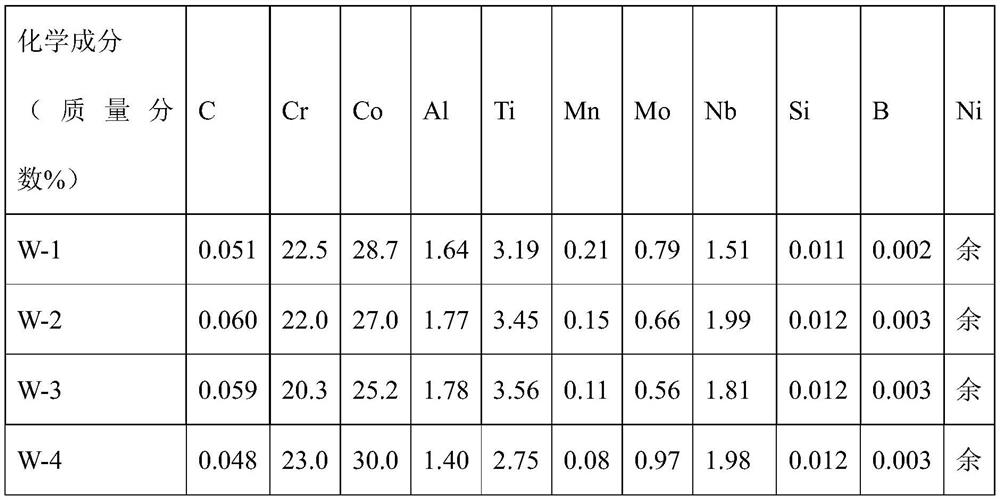

Nickel-cobalt-based high-temperature alloy welding wire

PendingCN112518172AImprove performanceIncrease contentWelding/cutting media/materialsSoldering mediaRare-earth elementSuperalloy

The invention belongs to the field of welding materials, and particularly relates to a precipitation strengthening type nickel-cobalt-based high-temperature alloy welding wire for welding a high-temperature part of an 800-DEG C ultra-supercritical power station. The welding wire is mainly characterized in that Ti / Al is more than or equal to 1.5 and less than or equal to 2, and C / Nb is more than orequal to 0.03. The yield strength of the welding wire at 800 DEG C is not less than 600 MPa. An alloy comprises, by mass percent, 25-30% of Co, 20-23% of Cr, 1.4-1.8% of Al, 2.1-3.6% of Ti, 1.5-2.0%of Nb, 0.5-1.0% of Mo, less than or equal to 0.1% of Si, less than or equal to 0.3% of Mn, less than or equal to 0.01% of Cu, less than or equal to 0.04% of C, less than or equal to 0.003% of B, and the balance of Ni, and no rare earth element is contained. A deposited metal matrix of the welding wire is an austenite (gamma) phase of a disordered face-centered structure, precipitation strengthening phases are a Ni3 (Al, Ti) gamma'phase and a primary carbide NbC, and carbide phases are distributed between crystals. The welding wire fills up the blank in the prior art, has excellent high-temperature performance, can be widely applied to homogeneous and heterogeneous welding of high-temperature alloy parts under the condition of ultra-supercritical water vapor at the temperature of 750-800 DEG C, and can also replace an existing nickel-based / nickel-cobalt-based high-temperature alloy welding wire.

Owner:CHINA HUANENG GRP CO LTD +1

Titanium alloy casting ingot surface glass coating and preparing method thereof

ActiveCN110743765AHigh viscosityHigh softening temperatureLiquid surface applicatorsCoatingsIngotTitanium alloy

The invention discloses a titanium alloy casting ingot surface glass coating. The glass coating is manufactured through the following raw materials including, by mass, 65%-95% of a glass matrix, 5%-35% of a bonding agent and 0%-30% of an additive. The glass matrix is manufactured through the following raw materials including, by mass, 5%-12% of B2O3, 4%-20% of Al2O3, 3%-8% of ZrO2, 3%-9% of NiO and / or Cr2O3, 3%-11% of CaO and / or BaO, 5%-15% of a compound N and the balance SiO2. The invention further discloses a preparing method of the titanium alloy casting ingot surface glass coating, the rawmaterials are evenly mixed and put on the surface of a titanium alloy casting ingot in advance, and the glass coating is formed through heat treatment. The composition of the glass matrix is regulated, and the glass coating can have good high-temperature protection performance; and the technology is simple and suitable for industrial production.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

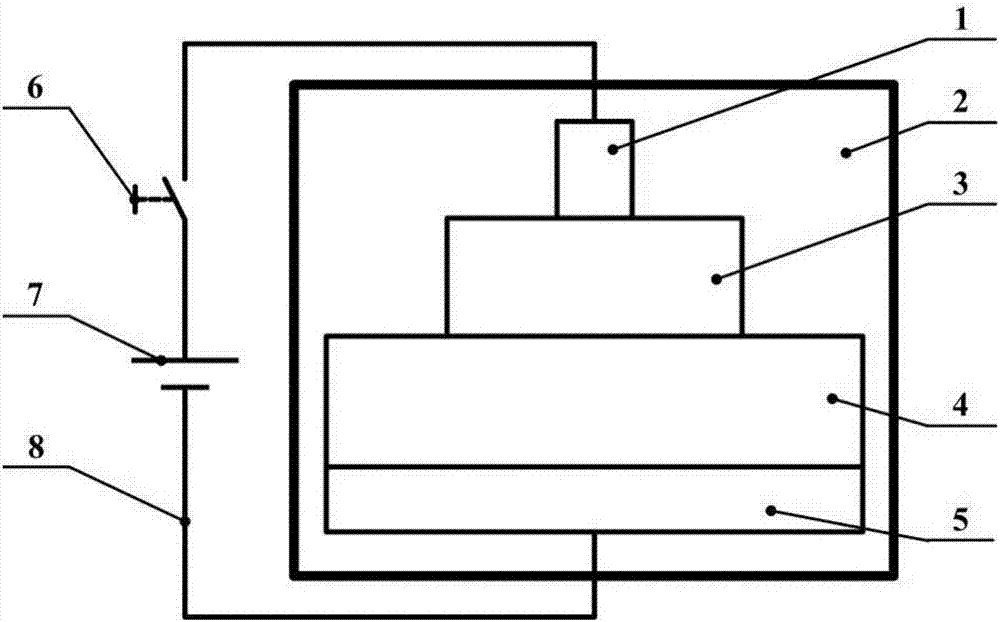

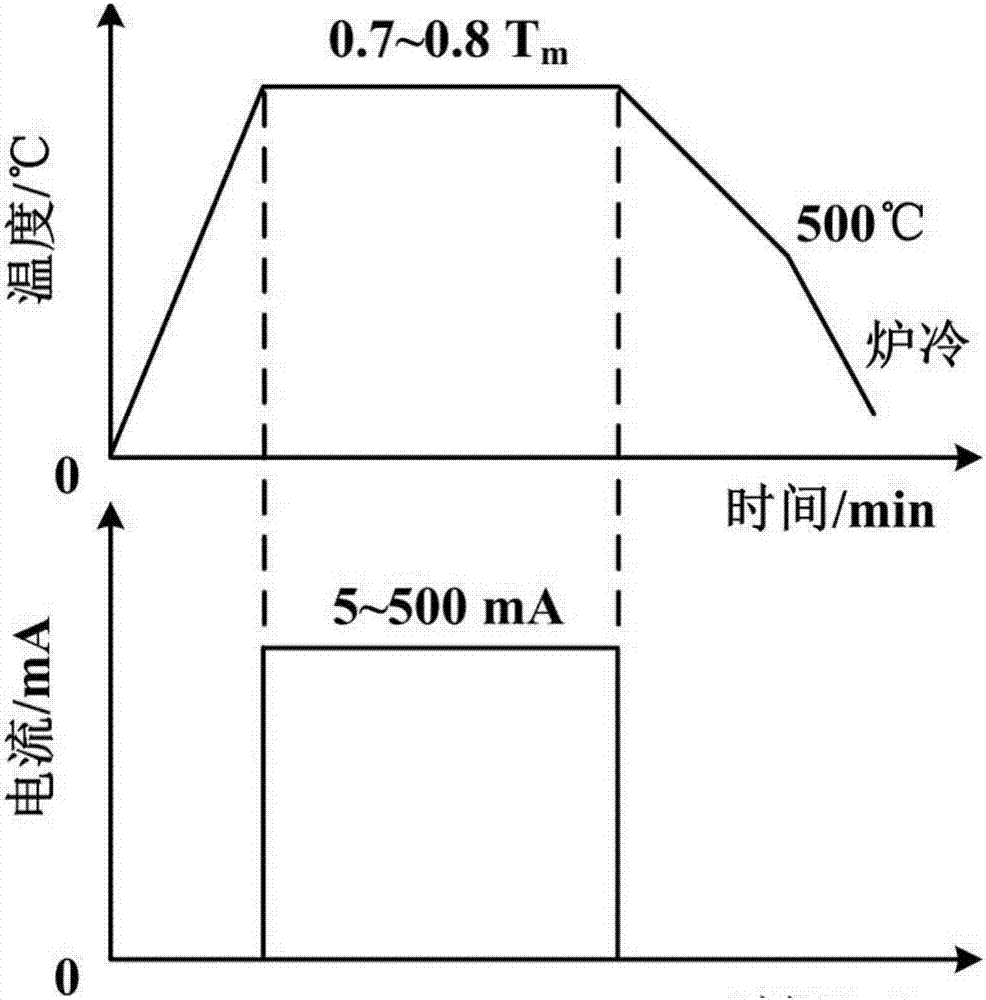

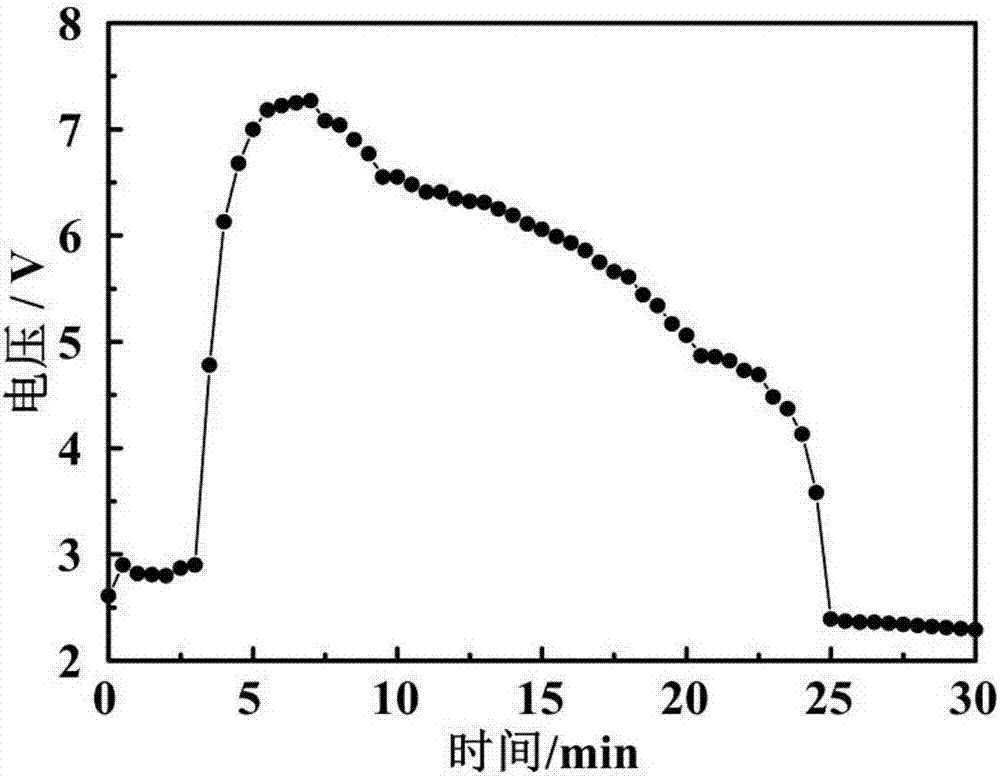

Method for bonding ZrO2 ceramic and metal

The invention relates to a method for bonding a ZrO2 ceramic and a metal. The method comprises the following steps: superposing the ZrO2 ceramic and metal up and down without putting any solder in the middle, putting the ZrO2 ceramic and metal between the top and bottom electrodes in a high temperature vacuum furnace, heating to 0.7-0.8 time of the metal melting point temperature Tm, applying a 5-500mA constant direct current to the metal / ZrO2 ceramic by using the top and bottom electrodes, electrifying and keeping the temperature for 5-60 minutes, and cooling to room temperature, thereby completing the bonding between the ZrO2 ceramic and metal. Compared with the traditional metal-ceramic brazing, the method does not need the solder or need to perform pre-metallization treatment on the ceramic surface, so the technical process is simple and easy to implement. Compared with the traditional diffusion bonding, the method does not need high pressure, and has the advantage of shorter time. Compared with the field-induced diffusion bonding, the method has the advantages of low voltage, low energy consumption and higher operational safety in the bonding process, and thus, has obvious technical advantages.

Owner:JILIN UNIV

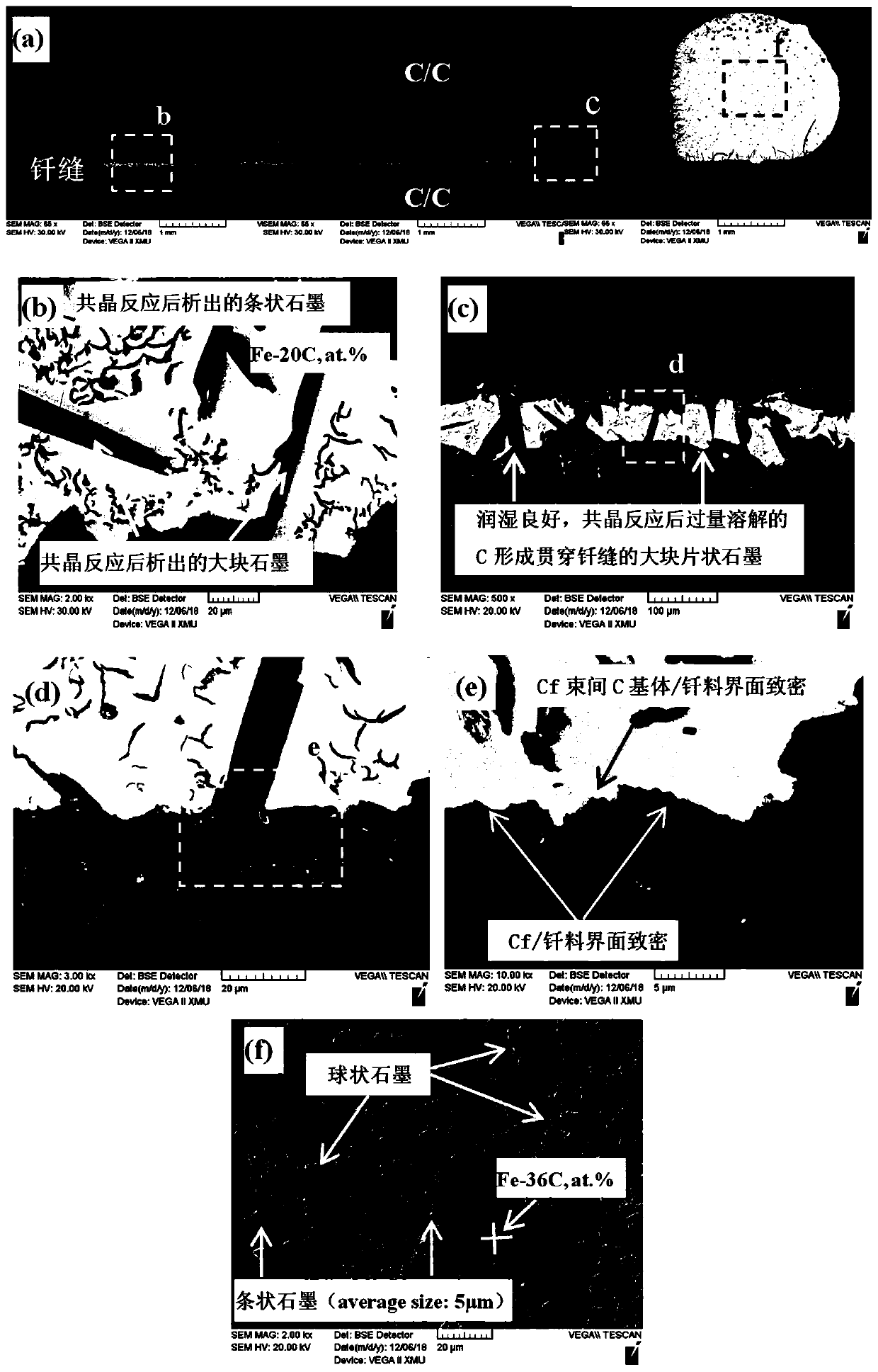

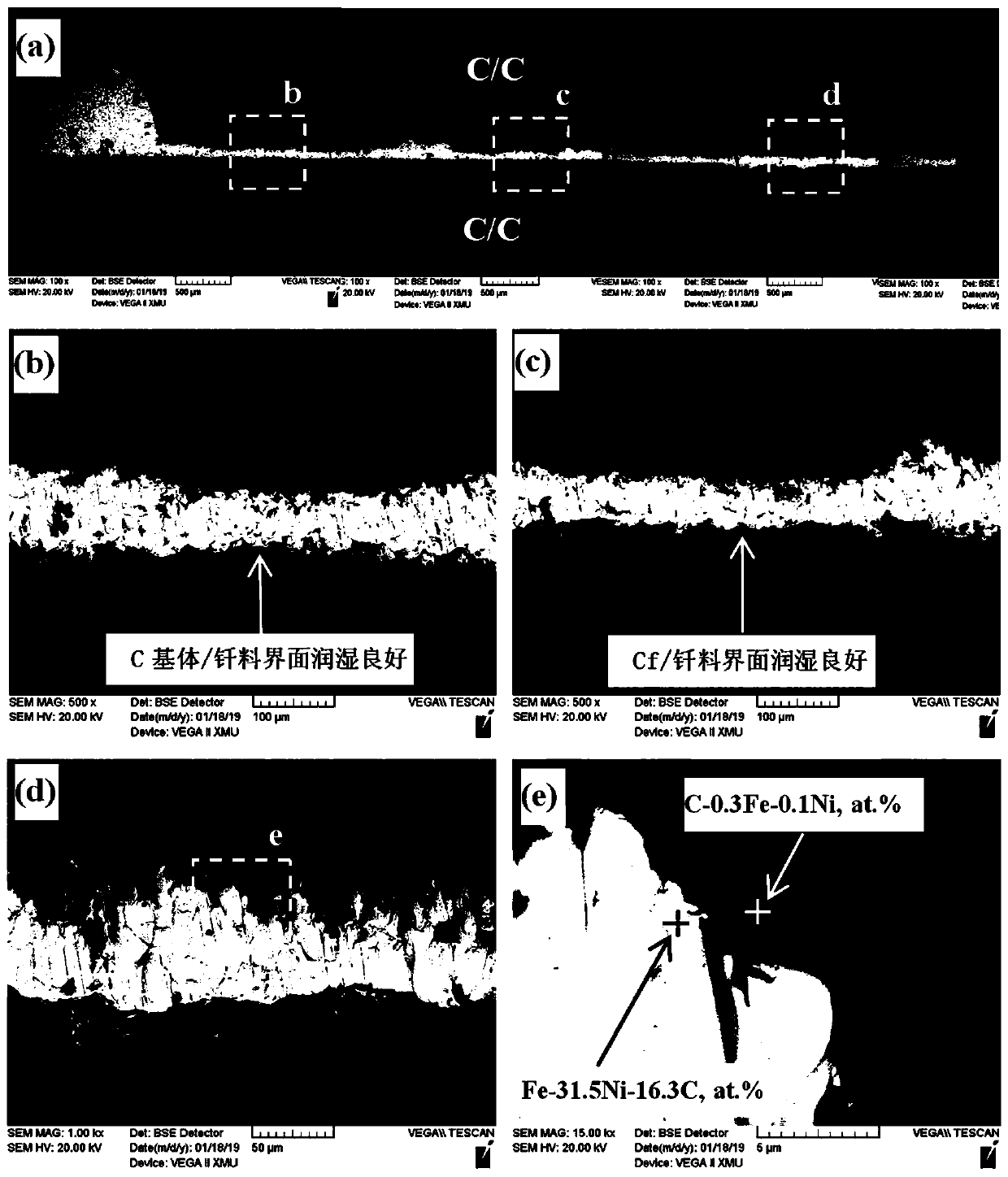

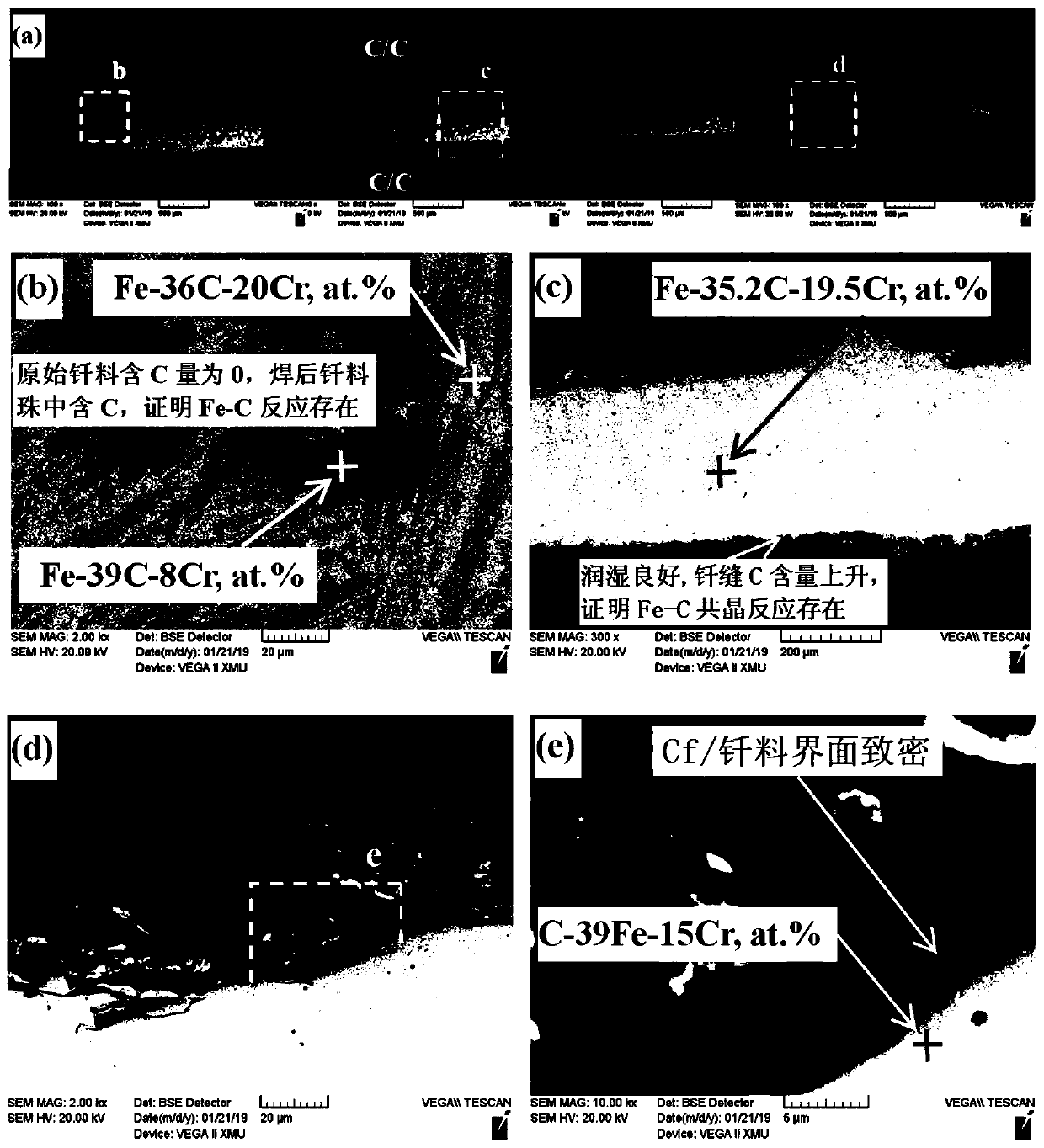

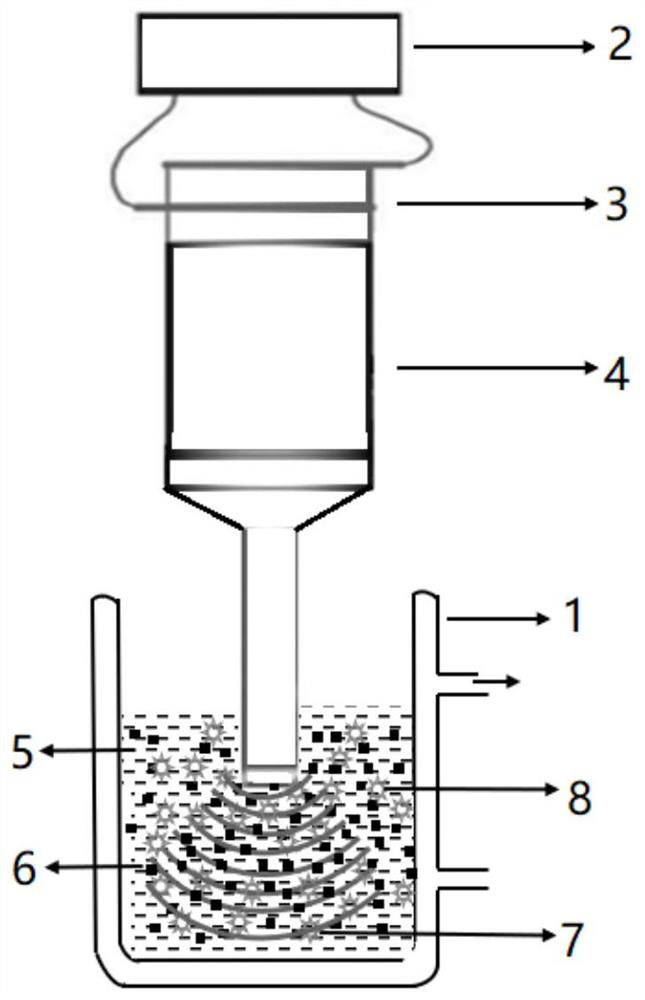

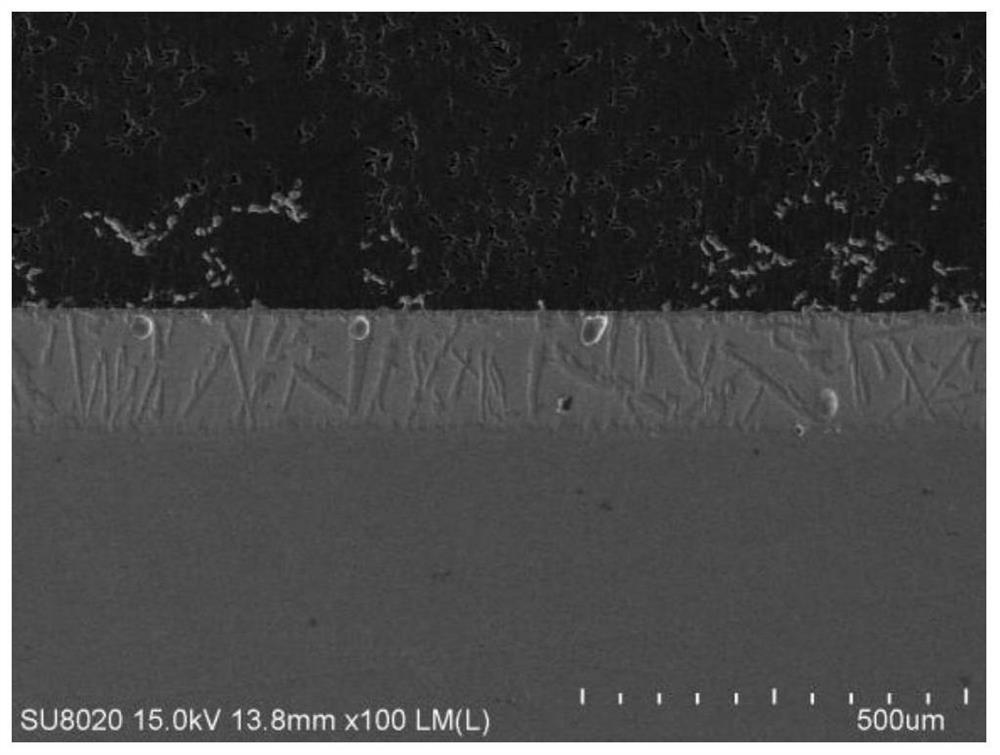

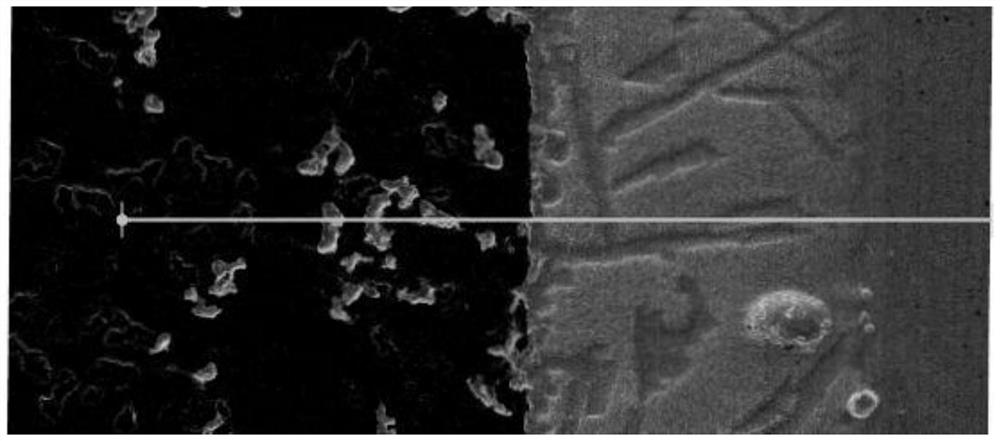

Method for rapidly wetting carbon fibers in ceramic matrix composite material by taking Fe as active element

ActiveCN110524082AWetting is achieved quicklyImprove organizationWelding/cutting media/materialsSoldering mediaCarbon fibersMetallurgy

The invention discloses a method for rapidly wetting carbon fibers in a ceramic matrix composite material by taking Fe as an active element, namely, Fe-based or alloy type brazing filler metal containing enough Fe is taken as high-temperature active brazing filler metal, and rapid and compact wetting of the carbon fibers is realized in a manner that the active element Fe and the carbon fibers aresubjected to eutectic reaction. The method has the advantages that rapid wetting of the carbon fibers and densification of original pores and brazing seams in the composite material base material in the near-seam area are achieved through eutectic reaction, and a continuous interface reaction phase formed by interface reaction is avoided; the dissolved carbon in the brazing seams is fully graphitized, so that the thermal stress can be reduced; the brazing temperature reaches 1154 DEG C or above, and the service temperature of a brazed joint can be increased; long-time heat preservation is notneeded, and the surface of the composite material does not need to be modified before welding; no or a small amount of precious metal is contained. The problems that when traditional Ag-based active brazing filler metal and Ni-based brazing filler metal are used for brazing ceramic-based composite materials, the joint heat-resisting temperature is low, and the heat preservation time is long are solved.

Owner:咸阳瞪羚谷新材料科技有限公司

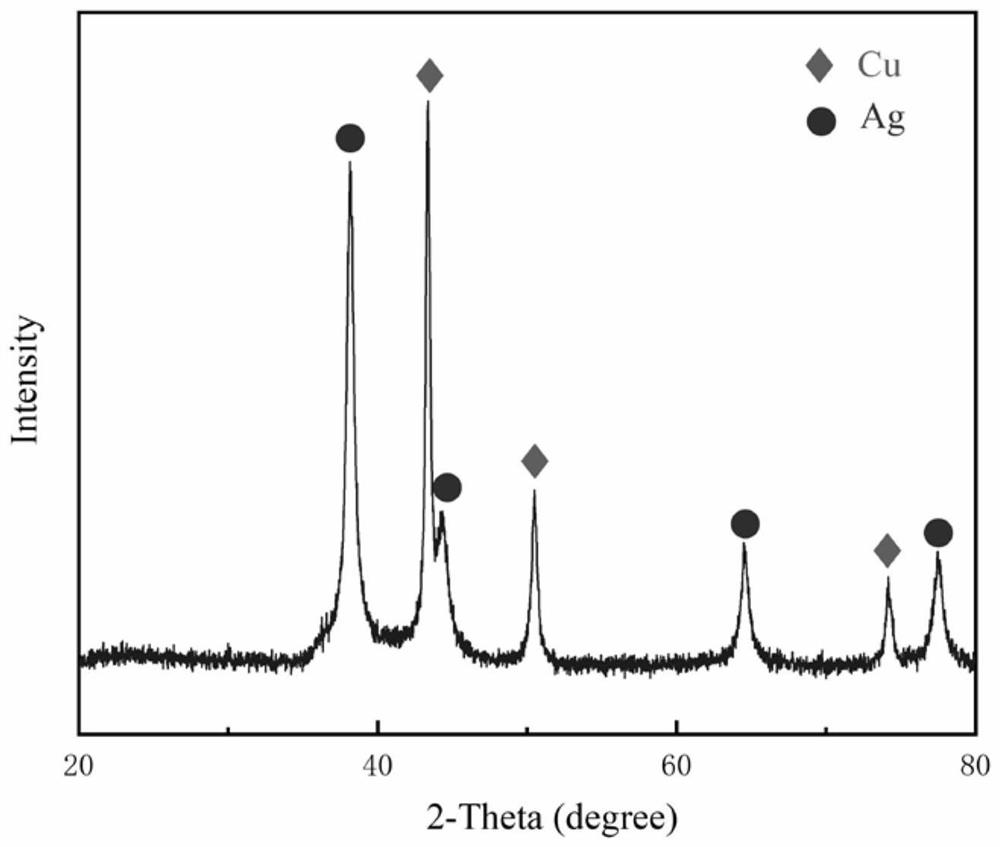

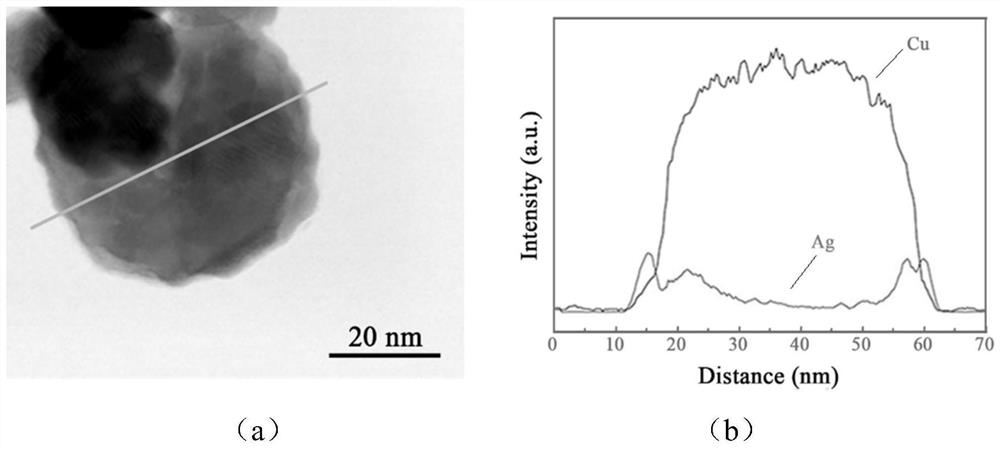

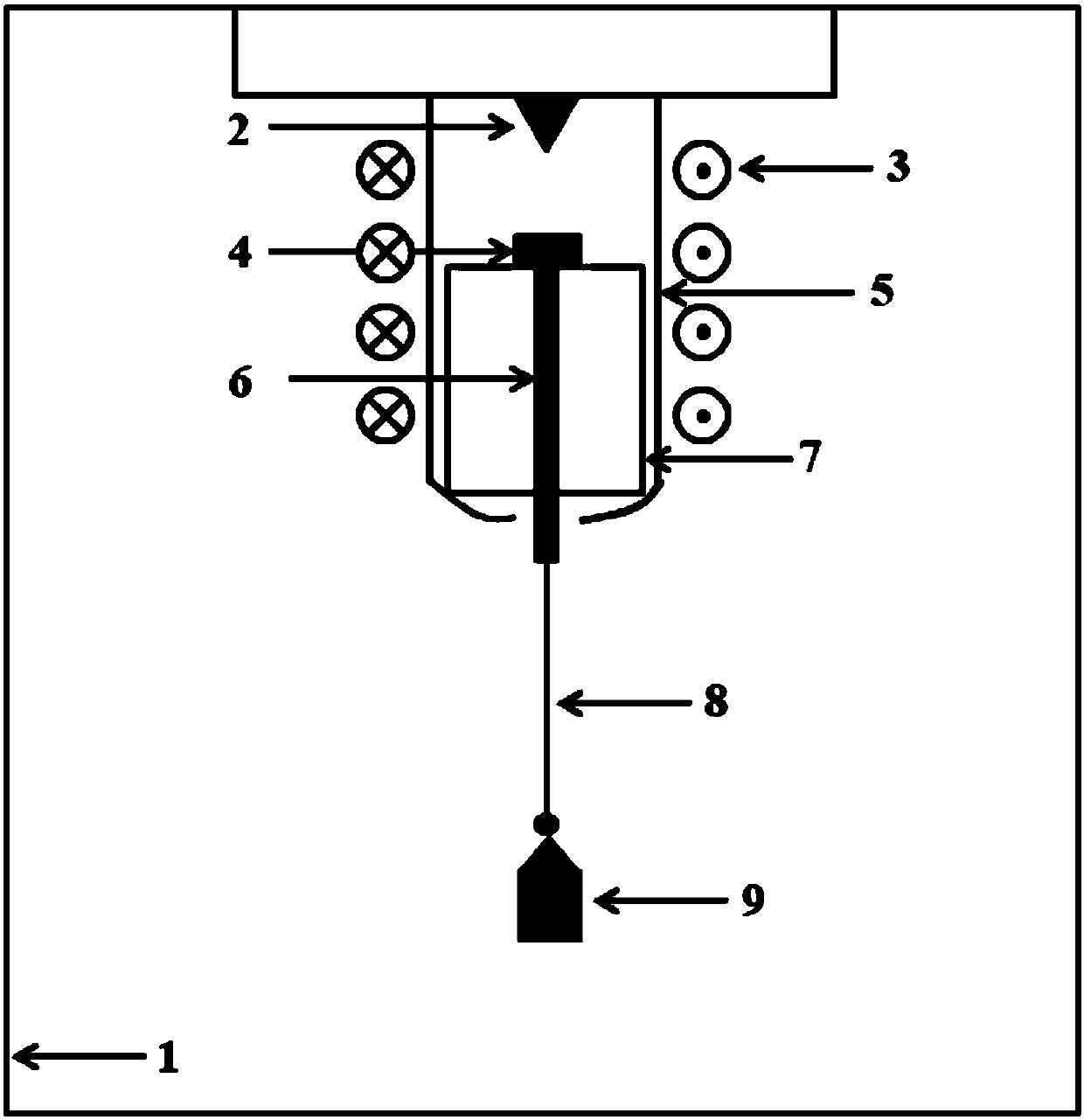

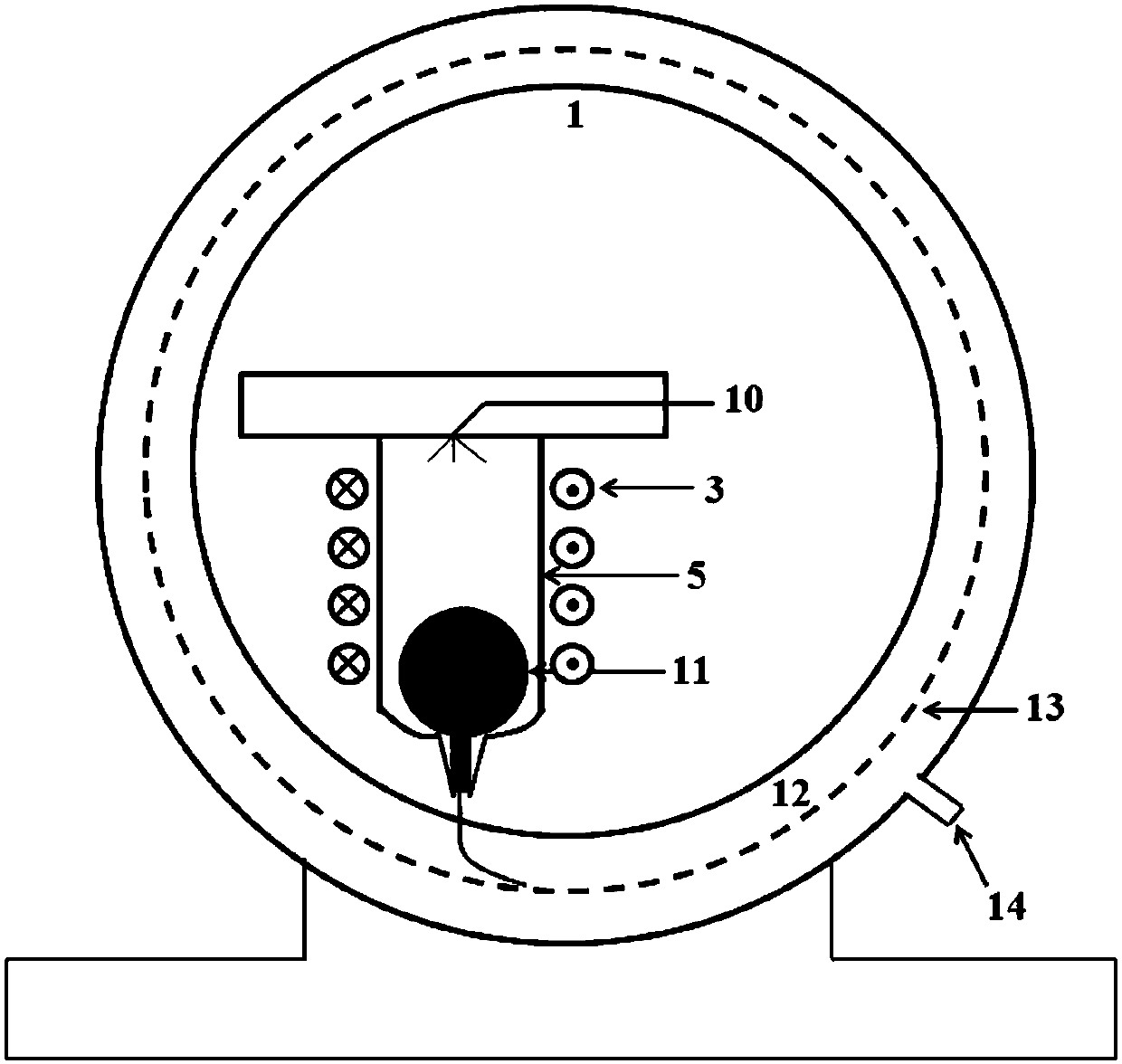

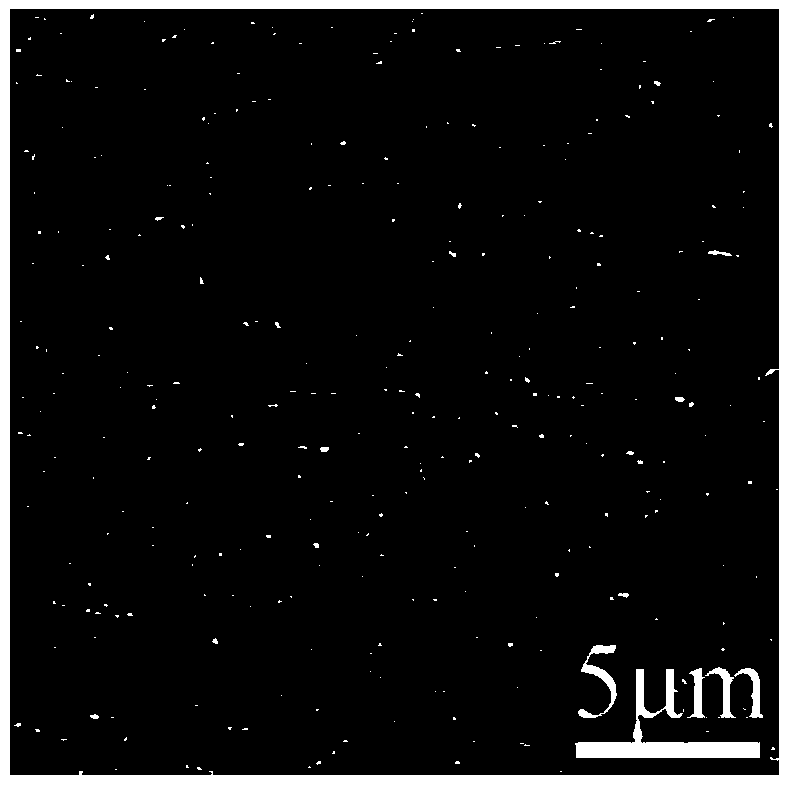

Nano silver copper wrapped welding flux preparing method based on phonochemistry

ActiveCN111618314AImprove reliabilityRaw materials are easy to getTransportation and packagingNanotechnologySodium phosphatesShielding gas

The invention provides a nano silver copper wrapped welding flux preparing method based on phonochemistry. The preparing method comprises the following steps that a copper salt organic solvent solution and a sodium phosphite and protective agent organic solvent solution are mixed, horn type pulse ultrasonic waves straight downwards are applied into the solution, copper nano particle dispersion liquid is obtained through the heating reaction, and Cu nano particles are obtained through cooling, centrifuging and washing; the Cu nano particles and a reducing agent are added in deionized water to be evenly mixed, a silver salt solution is added for the reaction at 30-50 DEG C, silver copper wrapped nano particle dispersion liquid is obtained, the silver copper wrapped nano particle dispersion liquid is centrifuged and washed, and silver copper wrapped nano particles are obtained; and the silver copper wrapped nano particles and a welding paste organic solvent are evenly mixed, and silver copper wrapped nano particle welding paste is obtained. The silver copper wrapped nano particle welding flux prepared through the technical scheme is high in reliability and has the characteristics of low-temperature connection and high-temperature service, protective gas is not needed in the preparing process, the technology is simple, and green and environment protection are achieved.

Owner:HARBIN INSTITUTE OF TECHNOLOGY SHENZHEN (INSTITUTE OF SCIENCE AND TECHNOLOGY INNOVATION HARBIN INSTITUTE OF TECHNOLOGY SHENZHEN)

Iridium amorphous alloy wire and preparation method thereof

The invention provides an iridium amorphous alloy wire. The iridium amorphous alloy wire is alloy wires prepared by iridium amorphous alloy materials and with section diameters from several microns tohundreds microns: Ira-[Tax(Nb)1-x]b-[Niy(Co)z(Fe)r(Cu)m(V)n(W)k]c-Bd, wherein a, b, c and d are all atomic percentages, a is not smaller than 20 and not bigger than 40, B is not smaller than 30 and not bigger than 40, c is not smaller than 20 and not bigger than 35, d is not smaller than 0 and not bigger than 15, a+b+c+d=100; x, y, z, r, m, n and k are atomic percentages, and are not smaller than0 and not bigger than 1, and y+z+r+m+n+k is not bigger than 1; and amorphous phases in the amorphous alloy materials are not lower than 75%. The invention further provides a preparation method of theiridium amorphous alloy materials. Through component adjustment of the iridium amorphous alloy materials, wider supercooling liquid phase areas with excellent iridium amorphous alloy forming capacityare obtained, the sizes of the iridium amorphous alloys are increased, and high-temperature crystallization is prevented, so that micron-scale or nanoscale filiform iridium amorphous alloys never manufactured by the prior art can be prepared.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

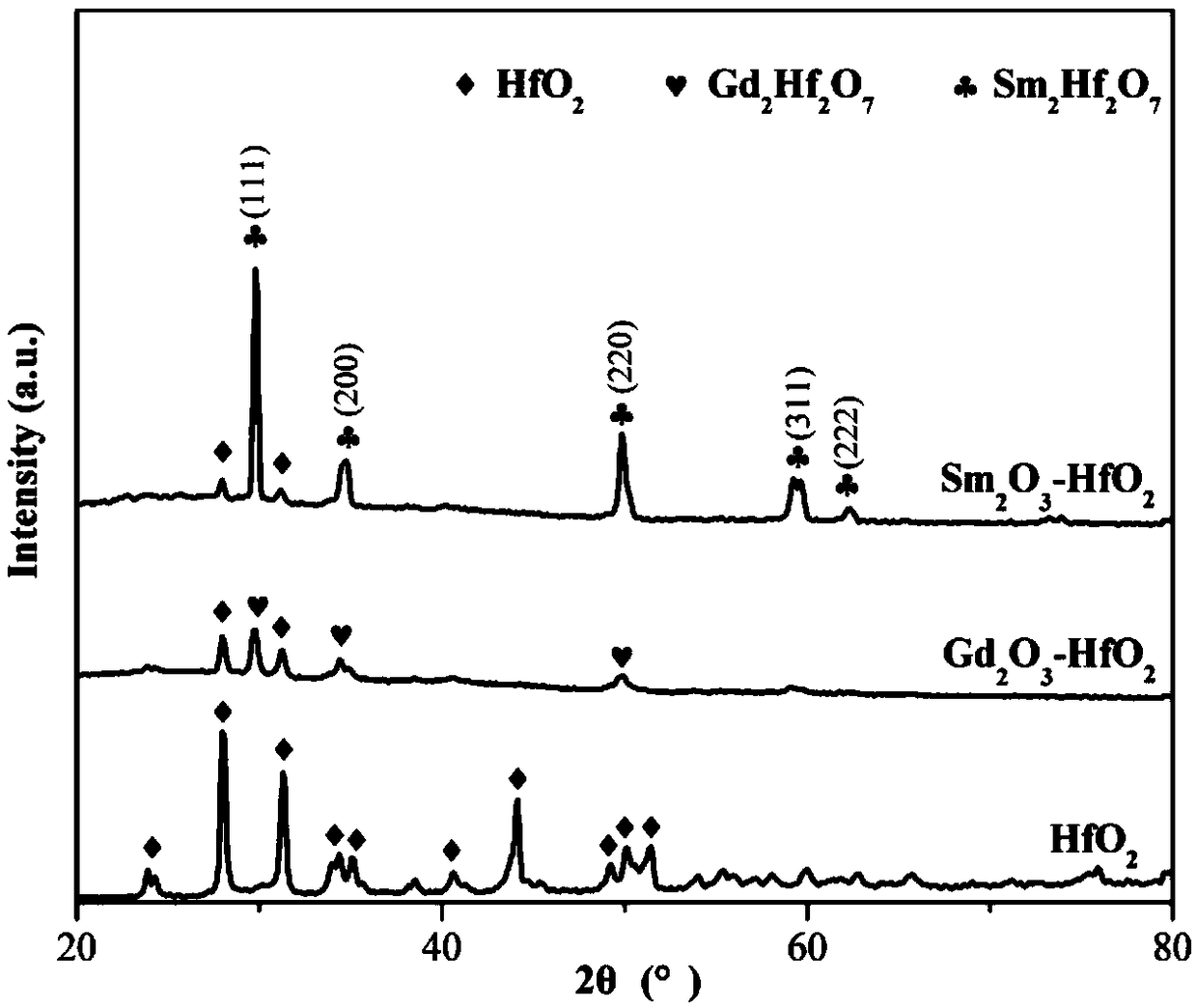

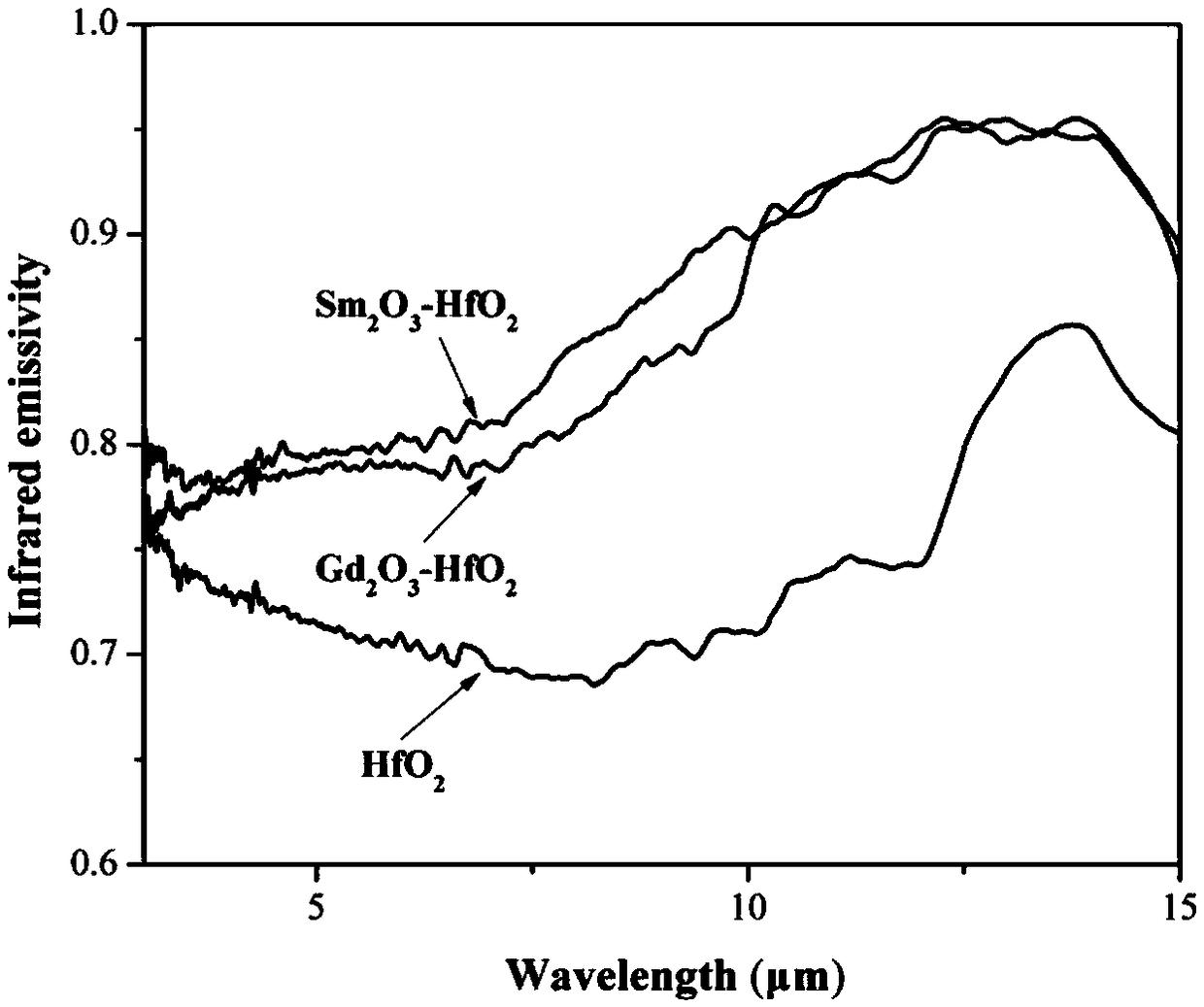

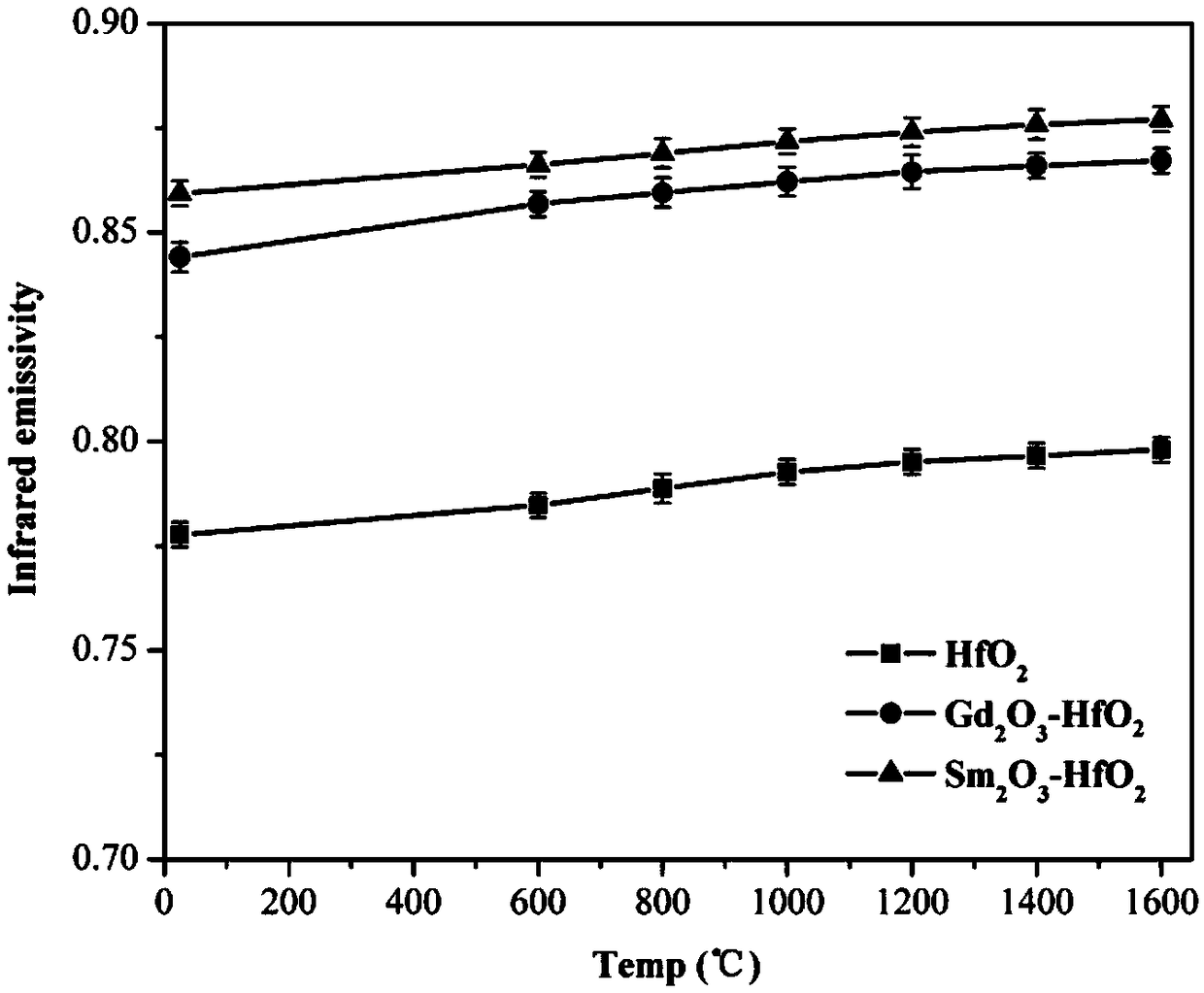

High-temperature and high-emissivity hafnium oxide base infrared radiating coating and preparing method thereof

The invention discloses a high-temperature and high-emissivity hafnium oxide base infrared radiating coating. According to the high-temperature and high-emissivity hafnium oxide base infrared radiating coating, HfO2 powder and rare earth oxide powder serve as main raw materials, water and a binding agent are added in the HfO2 powder and the rare earth oxide powder to prepare uniform slurry, and then the high-temperature and high-emissivity hafnium oxide base infrared radiating coating is formed sequentially through spray granulation, high-temperature roasting and heat spraying. According to the high-temperature and high-emissivity hafnium oxide base infrared radiating coating, compounding of HfO2 powder and Gd2O3 or Sm2O3 and other rare earth oxide is provided for the first time, the heatspraying technology is combined, the full-wave band normal integral emissivity of the obtained high infrared radiating coating at the normal temperature can reach 0.85 or above, the slow ascending tendency is achieved along with increasing of the high temperature, and good high temperature resisting performance and full-wave band infrared radiation performance can be combined; and the related preparing technology is simple, the synthesis time is short, energy consumption is low, and important study and popularization value is achieved.

Owner:WUHAN UNIV OF TECH

Light high-specific-strength high-entropy alloy material and preparation method thereof

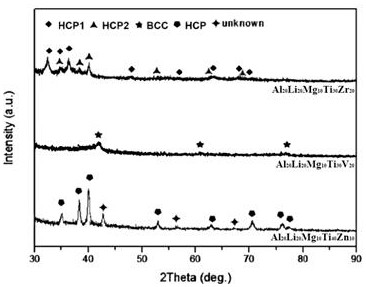

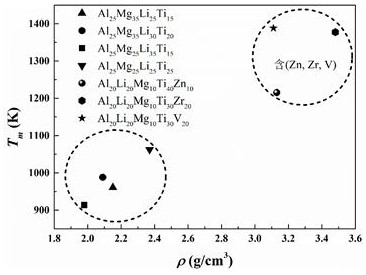

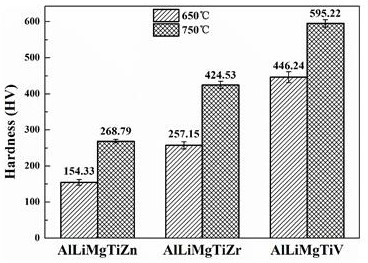

The invention discloses a light high-specific-strength high-entropy alloy material. The high-entropy alloy material is an AlLiMgTiM(M=Zn, V, Zr) high-entropy alloy; and according to the atomic percent, the Al element ranges from 10% to 20%, the Li element ranges from 10% to 20%, the Mg element ranges from 10% to 20%, the Ti element ranges from 30% to 40% and the M element ranges from 10% to 20%. On the basis of the low-density elements Al, Li, Mg and Ti, M(M=Zn, V, Zr) is added to design the high-entropy alloy, so that the obtained alloy has a more excellent structure, the AlLiMgTiZn alloy has a HCP phase structure and an unknown phase structure, the AlLiMgTiZr alloy has a double-phase solid solution structure composed of HCP1 and HCP2, AlLiMgTiV has a single-phase BCC solid solution structure, and by means of the excellent structures, the obtained alloy is low in density, high in specific strength and much higher than the performance of a Ti-6Al-4V alloy in the prior art. The preparation method adopts a mode of combining mechanical alloying and cold pressing sintering, is simple, convenient and feasible, and is suitable for application of industrial production.

Owner:CHONGQING UNIV

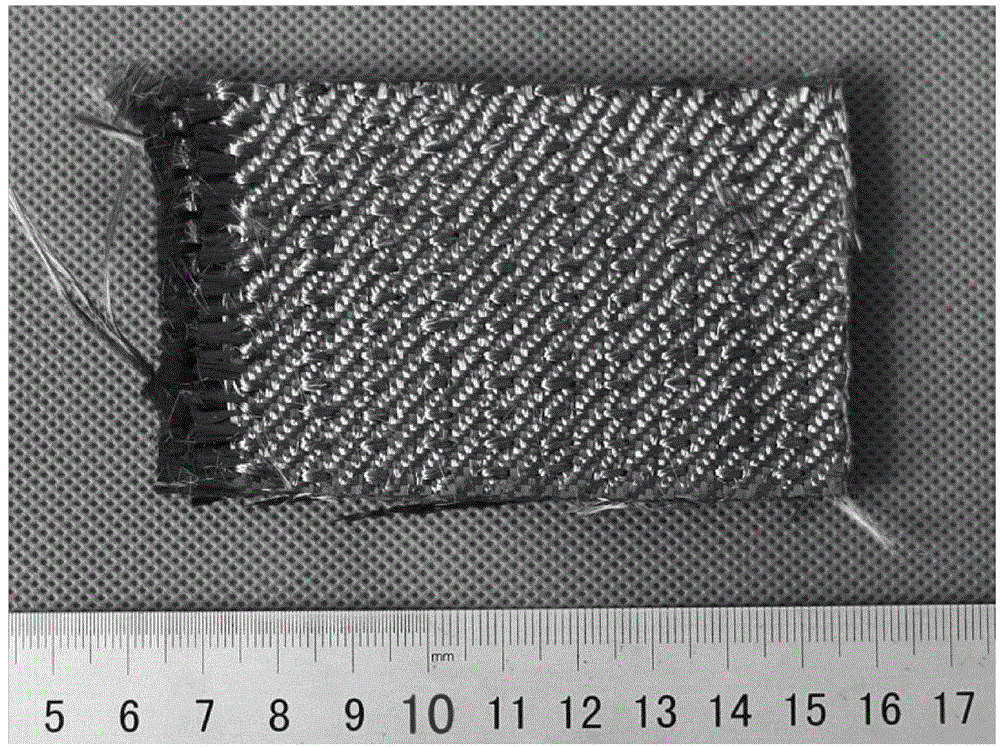

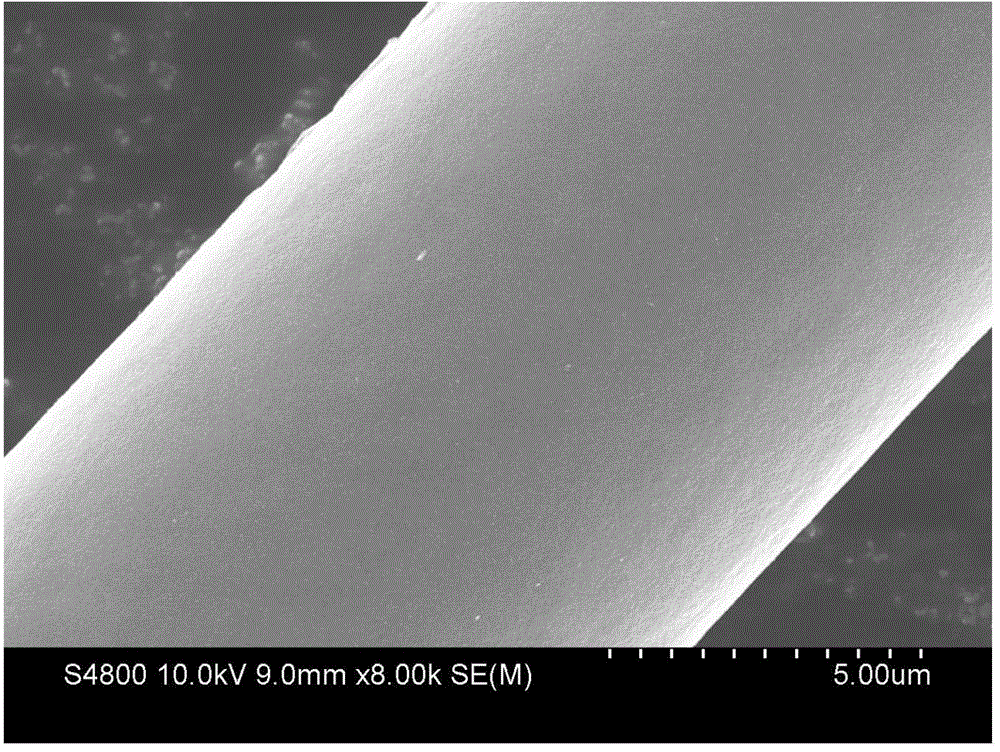

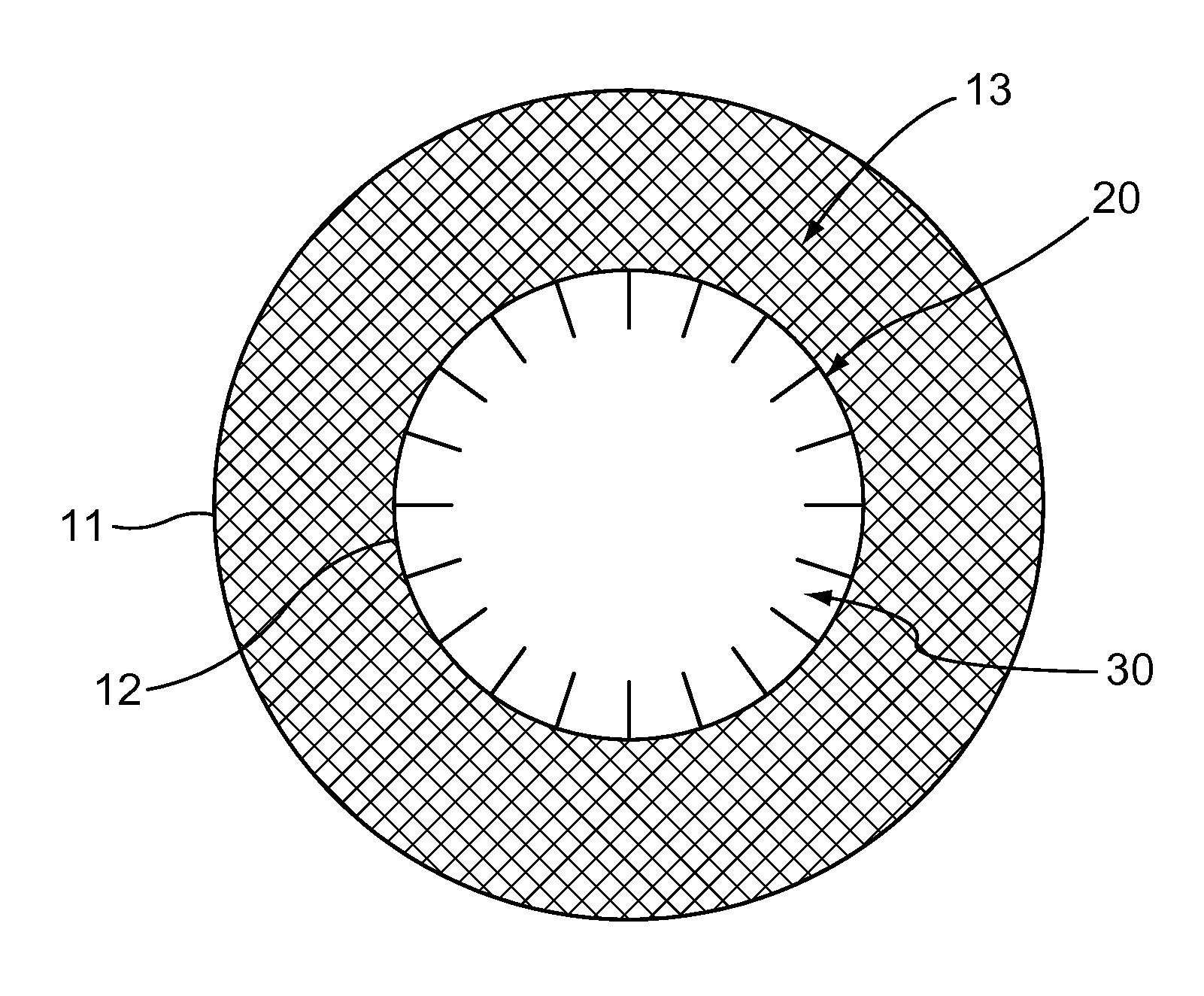

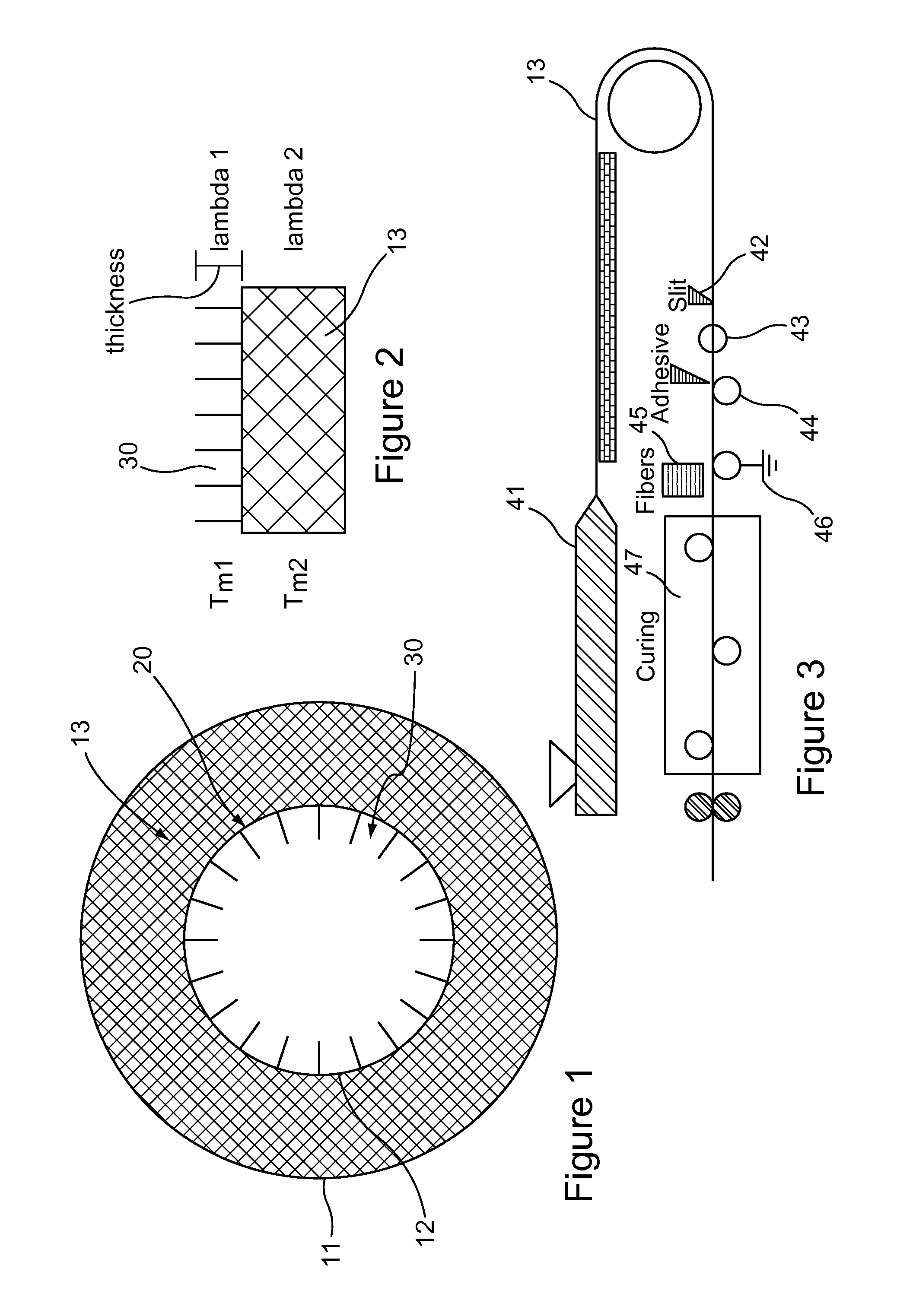

Polymeric foam tube insulations and method for continuously producing such a tube

InactiveUS7854240B2Improve thermal conductivityIncrease thermal resistanceLiquid surface applicatorsThermal insulationPolymer scienceVolumetric Mass Density

The foam tube for pipe insulations has an external surface and an internal surface. The internal surface is provided with an adhesively bonded layer of fibers. The fibers are a material having a melt temperature that is higher than that of the polymeric foam. The fibers are adhesively bonded to the internal surface such as to stand up from the internal surface. The fibers are substantially uniformly distributed over the internal surface providing a surface coverage of 2 to 20 percent. Further, the fibers have a linear density of 0.5 to 25 dtex and a length of 0.2 to 5 mm. With this fiber layer the polymeric foam tube has an improved thermal resistance and thermal conductivity.

Owner:ARMACELL ENTERPRISE GMBH

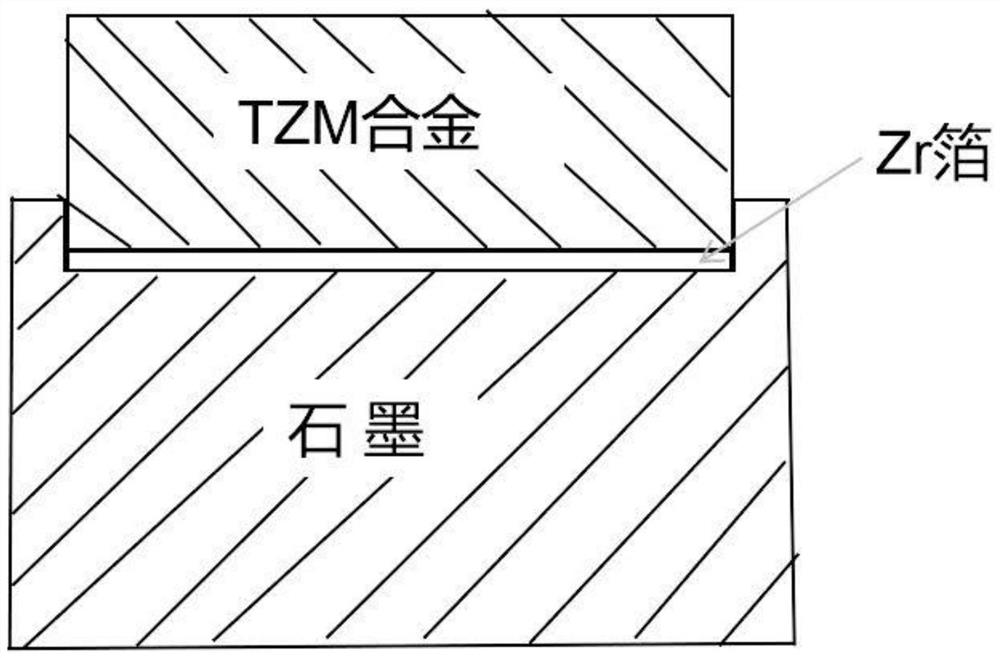

Contact reaction brazing process for connecting TZM alloy and graphite through pure zirconium layer

PendingCN114453693AReduced finish requirementsIncrease mechanical bite forceSoldering apparatusSand blastingGraphite

The invention relates to the technical field of brazing, and discloses a contact reaction brazing process for connecting TZM alloy and graphite through a pure zirconium layer, which comprises the following steps: step 1, taking TZM alloy, graphite and Zr foil to be welded, polishing the surfaces to be welded by using abrasive paper, and ultrasonically cleaning the sample in an organic solution for 30 minutes; and 2, grooving the surface of the graphite in the step 1, and then sequentially putting Zr foil and TZM alloy into the grooves in the surface of the graphite so as to prevent the sample from being misplaced and prevent brazing filler metal from flowing out. And (3) the workpiece assembled in the step (2) is put into a furnace cavity of a vacuum air pressure sintering furnace, the furnace cavity is vacuumized to be lower than 1 * 10 <-3 > Pa, then argon is filled into the furnace cavity to reach the set pressure, and the temperature is increased to 1000 DEG C from 20 DEG C at the speed of 50 DEG C / min. According to the method, the requirement for the smoothness of the welding surface can be lowered by adding the zirconium middle layer, and the welding surface can be subjected to various treatments such as polishing, sand blasting and machining according to the requirements so as to increase the mechanical occlusal force.

Owner:HEFEI UNIV OF TECH

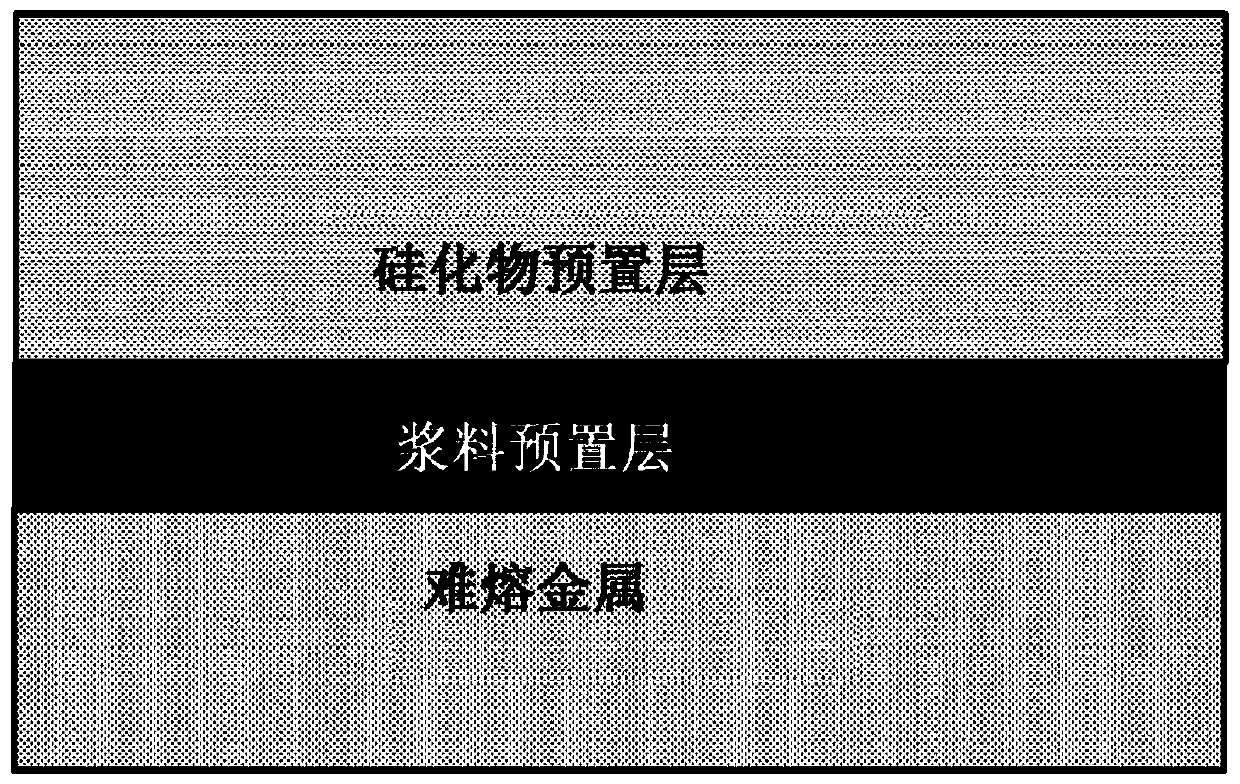

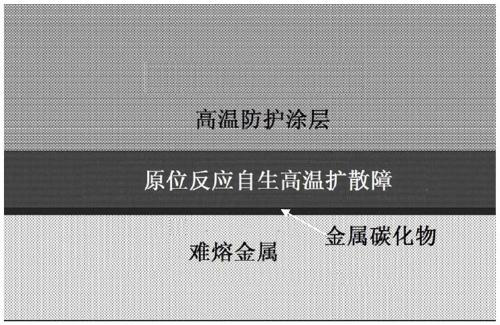

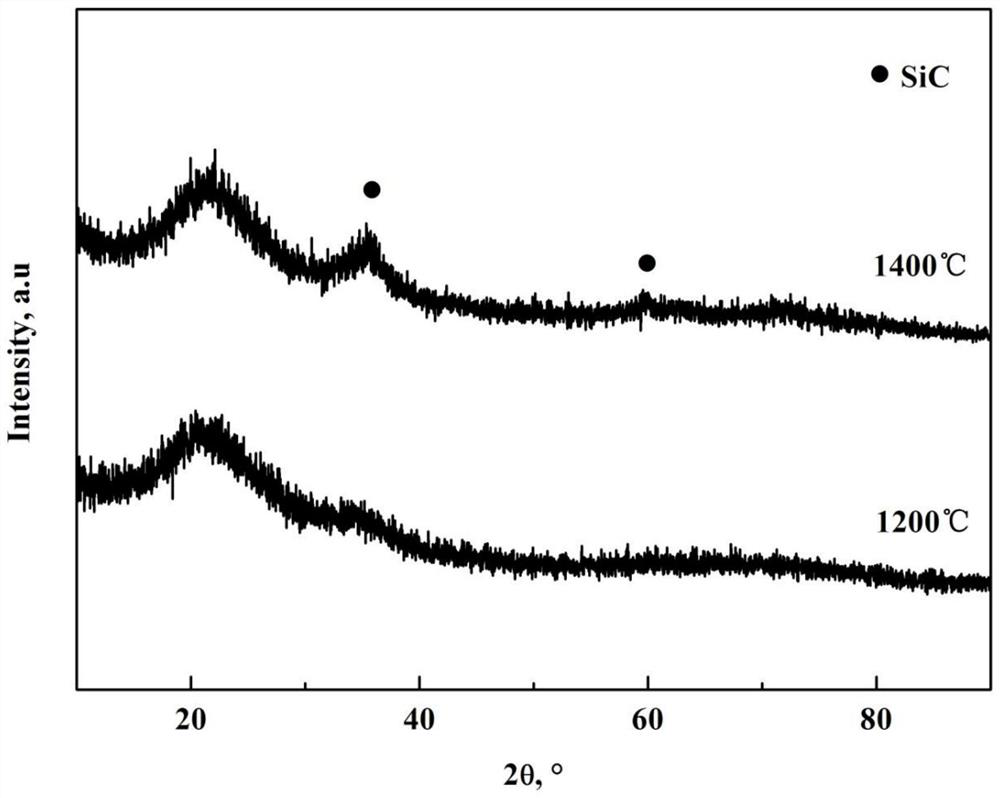

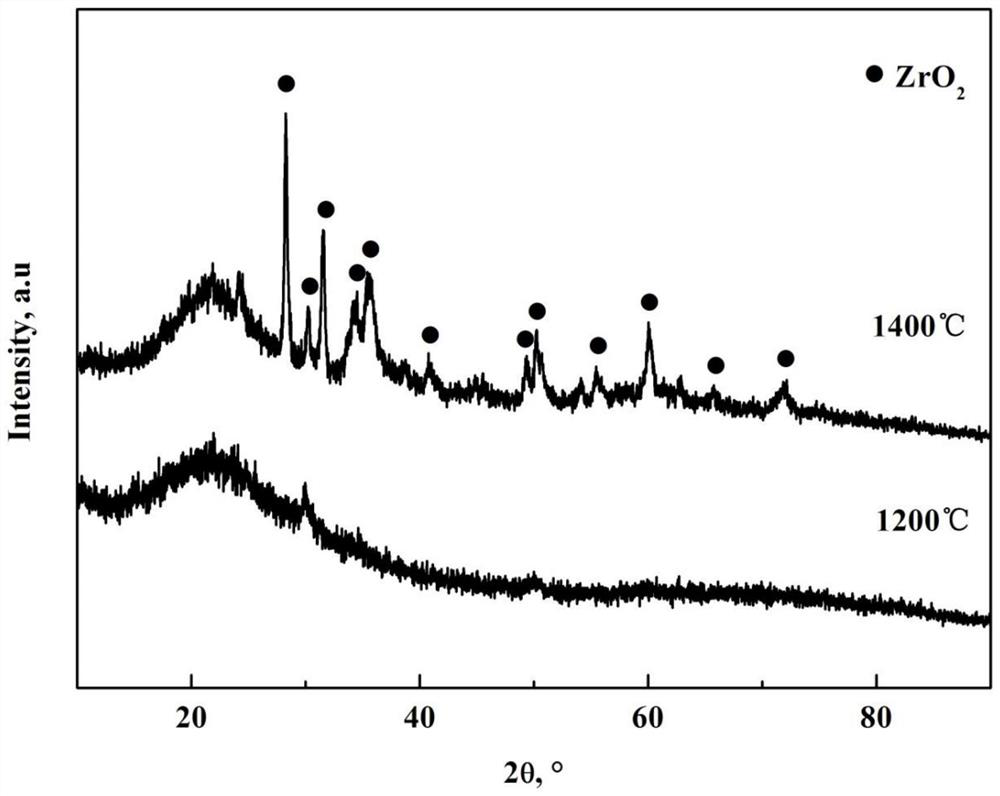

Refractory metal surface in-situ reaction self-generation high-temperature diffusion barrier and preparing method thereof

ActiveCN110373628AGuaranteed high temperature oxidation resistanceImprove high temperature service lifeSolid state diffusion coatingSlurryOxidation resistant

The invention discloses a refractory metal surface in-situ reaction self-generation high-temperature diffusion barrier. The refractory metal surface in-situ reaction self-generation high-temperature diffusion barrier is located between refractory metal and sintered silicide high-temperature protection coating coated on the surface of the refractory metal, and SiC serves as the main phase. The invention further discloses a preparing method of the refractory metal surface in-situ reaction self-generation high-temperature diffusion barrier. According to the method, graphene slurry or graphene oxide slurry and silicide composite suspension slurry are sequentially preset on the pre-treated refractory metal matrix surface, through sintering, the in-situ reaction self-generation high-temperaturediffusion barrier is obtained, the in-situ reaction self-generation high-temperature diffusion barrier reduces the high-temperature mutual diffusion rate between the high-temperature protection coating and the refractory metal matrix, the high-temperature oxidation resistance of the high-temperature protection coating is ensured, the high-temperature service life is prolonged, due to the in-situ reaction self-generation high-temperature diffusion barrier, the interfacial compatibility is improved, and the refractory metal-diffusion barrier-high-temperature protection coating has the good heatcycle resistance and thermal shock resistance.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Tactic styrene type thermoplastic elastomer and preparation method thereof

The invention relates to a tactic styrene type thermoplastic elastomer and a preparation method thereof. The novel tactic styrene type thermoplastic elastomer is prepared by selecting an appropriate rare earth catalyst system, catalyzing styrene and butadiene for coordination copolymerization and considering polymerization activity of two monomers, wherein the content of a cis-1,4 structure of a PB chain segment is greater than 90 percent. The PS chain segment contains rich syndiotactic structures, so that while phase separation of a copolymer is generated, crystallization can be realized, physical crossing points are enhanced and stabilized, a melting point is below 210 DEG C, further the modulus and strength of the segmented copolymer are improved, and meanwhile a material is endowed with excellent workability, heat resistance, abrasive resistance, physical and mechanical properties and the like.

Owner:BEIJING UNIV OF CHEM TECH

A kind of stereoregular styrene thermoplastic elastomer and preparation method thereof

The invention relates to a tactic styrene type thermoplastic elastomer and a preparation method thereof. The novel tactic styrene type thermoplastic elastomer is prepared by selecting an appropriate rare earth catalyst system, catalyzing styrene and butadiene for coordination copolymerization and considering polymerization activity of two monomers, wherein the content of a cis-1,4 structure of a PB chain segment is greater than 90 percent. The PS chain segment contains rich syndiotactic structures, so that while phase separation of a copolymer is generated, crystallization can be realized, physical crossing points are enhanced and stabilized, a melting point is below 210 DEG C, further the modulus and strength of the segmented copolymer are improved, and meanwhile a material is endowed with excellent workability, heat resistance, abrasive resistance, physical and mechanical properties and the like.

Owner:BEIJING UNIV OF CHEM TECH

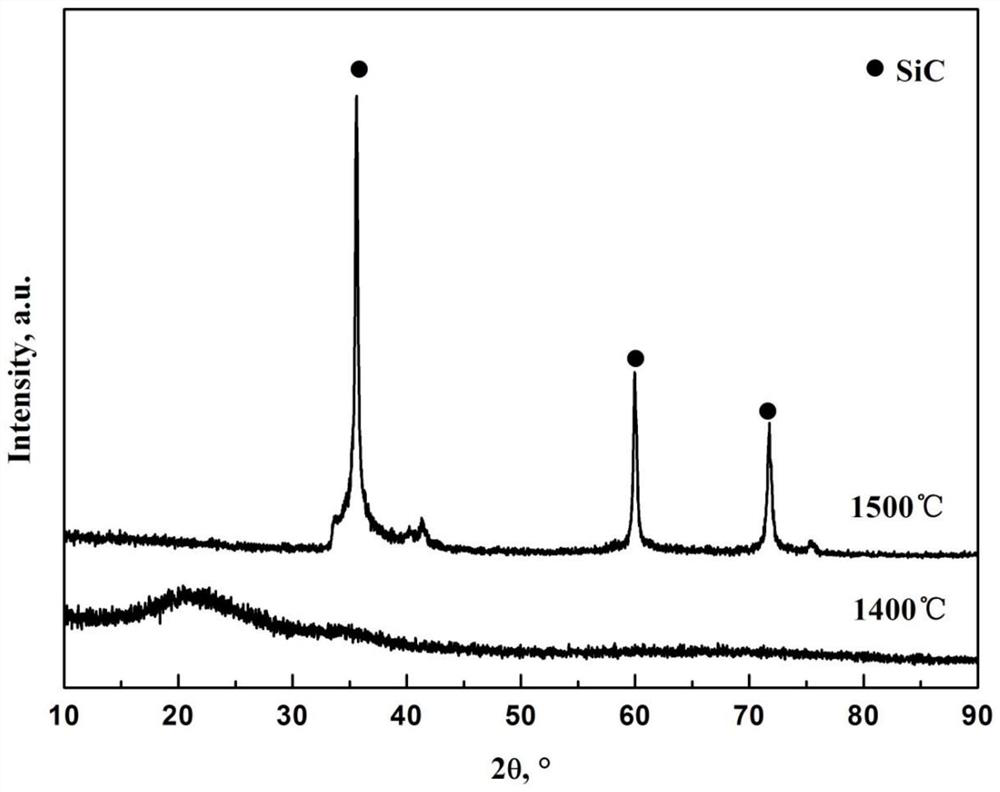

Low-cost SiZrOC ceramic material and preparation method thereof

ActiveCN111704464AImprove high temperature resistanceInhibition of carbothermal reduction reactionsAlcoholZirconium oxychloride

The invention discloses a low-cost SiZrOC ceramic material and a preparation method thereof. Silicon resin with small molecular weight is used as a raw material. The preparation method comprises the following steps: introducing inorganic zircon salt by adopting a sol-gel method to form a Zr-containing PSO precursor; and then carrying out precursor crosslinking and high-temperature cracking to obtain the SiZrOC ceramic. According to the method, the silicon resin adopted in the process is methyl silicon resin and dissolved in ethyl alcohol, the inorganic zircon salt is zirconium oxychloride (ZrOCl<2>.8H<2>O) and dissolved in ethyl alcohol, a small amount of a chelating agent and a steric hindrance agent are added, mixing is carried out to prepare sol, and gel is formed after standing of thesol. The preparation method disclosed by the invention has the advantages of low cost, good high-temperature resistance, simple process, low equipment requirement and the like.

Owner:NAT UNIV OF DEFENSE TECH

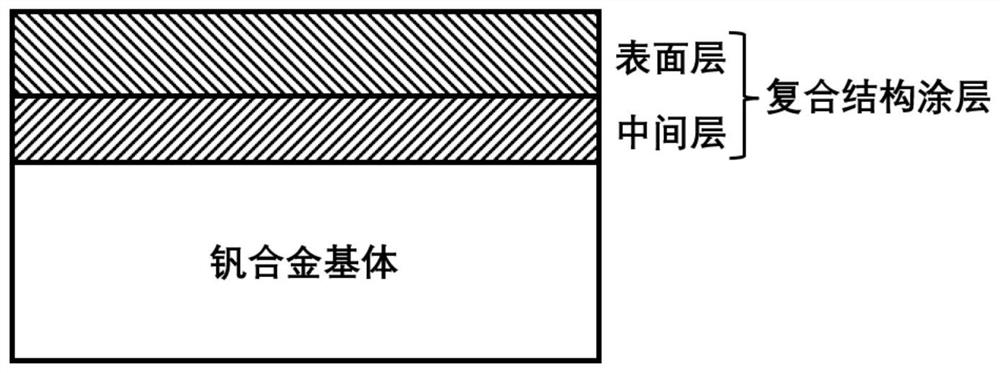

Vanadium alloy

PendingCN113978056AIncrease service temperatureReduce penetrationMetal layered productsNon-electric welding apparatusInter layerAlloy

The invention discloses a vanadium alloy, which is coated with a composite structure coating, wherein the composite structure coating comprises a middle layer and a surface layer which are sequentially attached to the surface of a vanadium alloy matrix. According to the invention, the surface of a vanadium alloy is coated with a composite structure coating, and the composite structure coating is applied to the surface of a vanadium alloy matrix, so that the service temperature of the vanadium alloy can be increased, and the vanadium alloy has the advantages of being low in tritium permeability, excellent in thermal shock resistance and the like, and is applicable to the field of composite materials.

Owner:UNIV OF SCI & TECH BEIJING

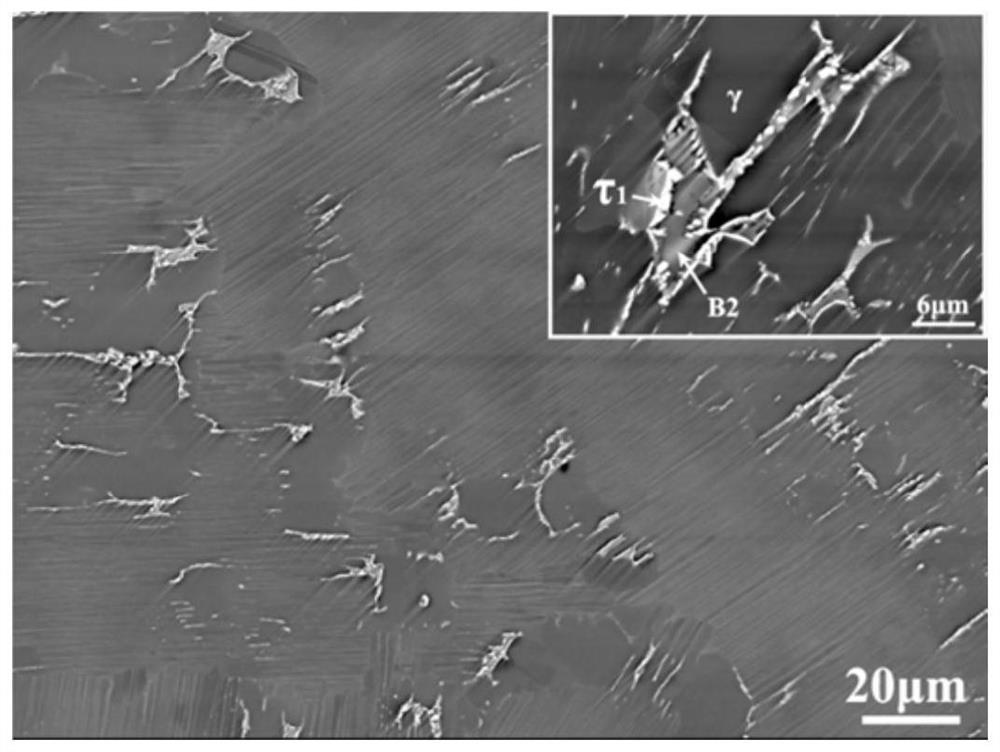

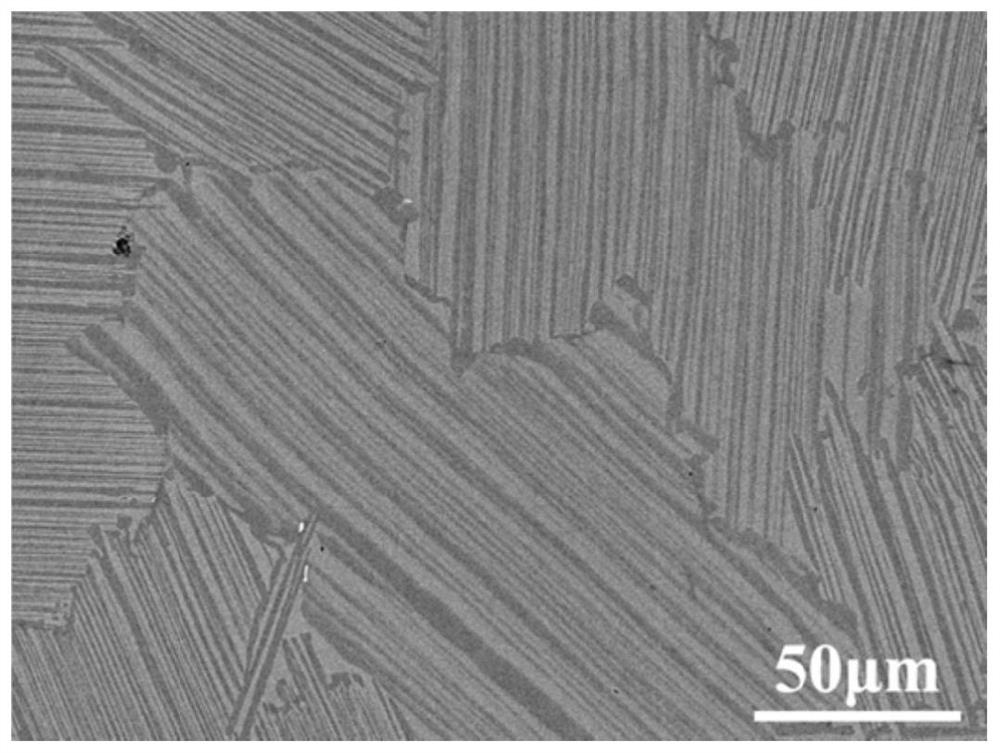

Ruthenium-containing multi-component TiAl alloy suitable for temperature of 800 DEG C

ActiveCN112063885AImprove high temperature performanceIncrease service temperatureSolid solubilityRu element

The invention discloses a ruthenium-containing multi-component TiAl alloy suitable for the temperature of 800 DEG C. The alloy is composed of 47-49 at.% of Al, 4.0 at.% of Nb, 2.0 at.% of Cr, 0.3-1.0at.% of Ru and the balance of Ti, and the alloy is obtained through an ingot casting smelting mode. Different from common alloying elements such as Ta, Nb and Cr, besides solid solution strengthening,the solid solubility of the Ru element is low. Therefore, under the condition that a trace amount of Ru is added, fine tau1-phase particles can be separated out, second-phase strengthening is formed,and then the service temperature is increased to 800 DEG C.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Method for obtaining ferritic heat-resisting steel with the characteristic of austenite structure

ActiveCN103555905AInitial size refinementImprove organizational stabilityRoom temperatureLarge deformation

The invention relates to a method for obtaining ferritic heat-resisting steel with the characteristics of an austenite structure, and belongs to the technical field of heat-resisting steels. A large deformation+heat treatment process is adopted, and the technical parameters controlled in process steps are as follows: heating 9%-12% Cr steel to 1100-1200 DEG C at 20 DEG C / s, and keeping temperature for 30-120 minutes; then cooling to 500-800 DEG C at 10 DEG C / s, keeping the temperature for 3-15 seconds, deforming at the deformation rate of 1s<-1> and the deformation amount of 70%-90%, immediately quenching to room temperature after the deformation is completed; then tempering at 650-800 DEG C for 1-5 hours, and air-cooling to room temperature. The method disclosed by the invention is used for preparing the 9%-12% Cr steel and a large-caliber boiler pipe thereof. According to the invention, the initial size of a precipitated phase is obviously thinner than the initial size of a precipitated phase treated through the traditional heat treatment mechanism, a ferrite structure has characteristics similar to the characteristics of the austenite structure, belongs to an equilibrium state and is small in interface quantity and less in diffusion channel; a base body has good structure stability in a long-time service process.

Owner:CENT IRON & STEEL RES INST

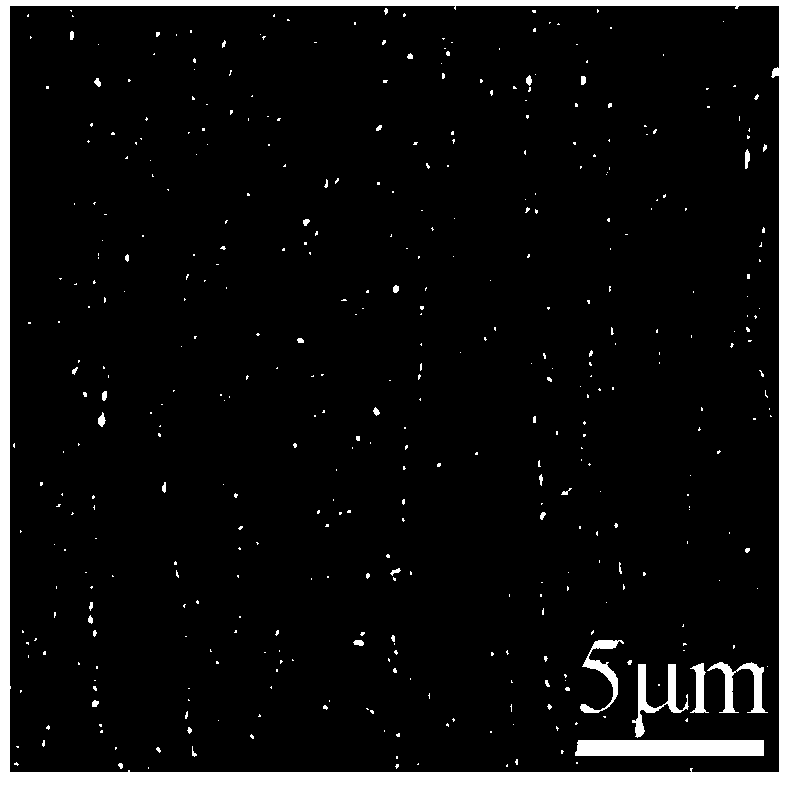

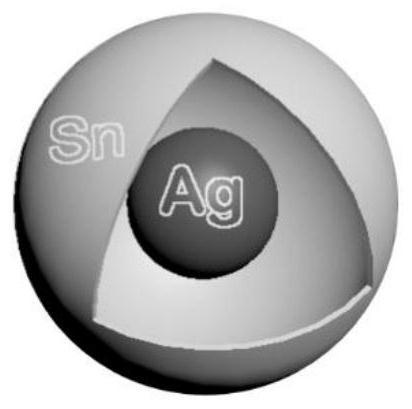

Preparing method of nano metal solder paste for Ag-Sn core-shell structure and application thereof

ActiveCN111230352ANo protectionLower sintering temperatureWelding/cutting media/materialsMetal working apparatusSolder pasteSilver Nano

The invention provides a preparing method of nano metal solder paste for an Ag-Sn core-shell structure and application thereof. Through preprocessing nano Ag, preparing a sodium borohydride reducing solution and wrapping the nano Ag by Sn, the nano metal solder paste for the Ag-Sn core-shell structure is obtained. The sintering temperature of Ag-Sn core-shell layer composite metal is lower than the sintering temperature of the nano Ag, and the service temperature is higher than the service temperature of Sn metal solder paste; the cost price of a sintering paste material is reduced overall; the electromigration phenomenon of Ag is reduced, and the use quality of the solder paste is improved; and the strength of an interconnected material connector can reach 25 MPa or above.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

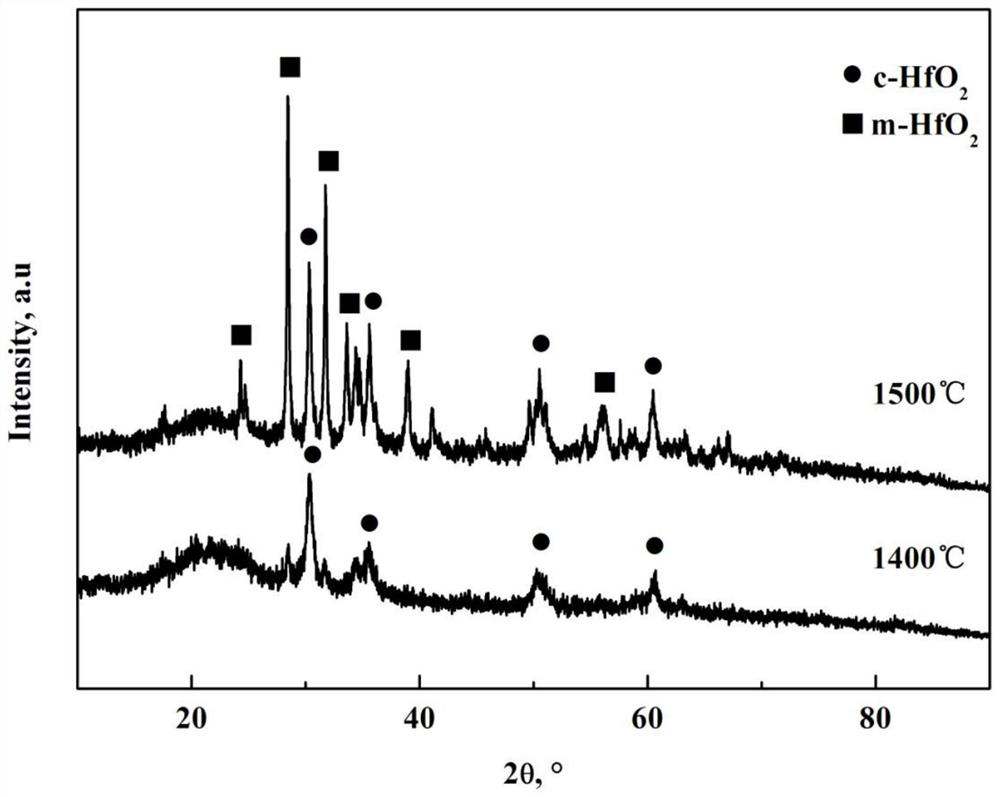

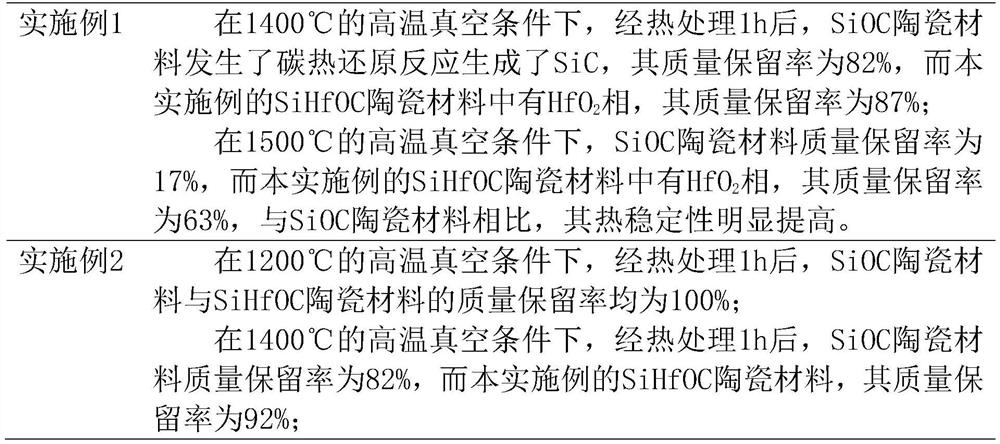

SiHfOC ceramic material and preparation method thereof

PendingCN111747750AImprove high temperature resistanceInhibition of carbothermal reduction reactionsMethyl palmoxirateCeramic

The invention discloses a SiHfOC ceramic material and a preparation method thereof. Silicon resin with small molecular weight is used as a raw material, an inorganic hafnium salt is introduced by a sol-gel method to form an Hf-containing PSO precursor, and the SiHfOC ceramic is obtained by precursor crosslinking and high-temperature cracking. In the process, adopted silicon resin is methyl siliconresin (MK) dissolved in ethanol, the inorganic hafnium salt is hafnium oxychloride (HfOCl2.8H2O) dissolved in ethanol, a chelating agent is added, sol is prepared through mixing, and gel is formed after standing. According to the preparation method of the SiHfOC ceramic, the high-temperature resistance of the SiOC ceramic is improved, and the preparation method has the advantages of low cost, good high-temperature resistance, simple process, low equipment requirement and the like.

Owner:NAT UNIV OF DEFENSE TECH

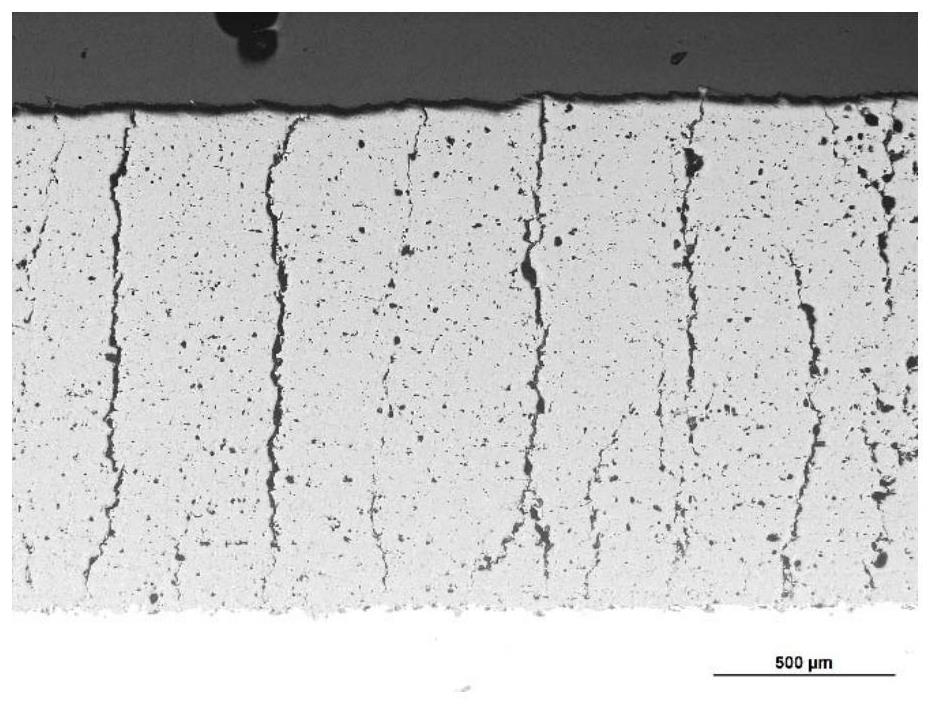

DVC thermal barrier coating and preparation method and application thereof

PendingCN114592164AReduce high temperature fatigue oxidationInterface is well integratedMolten spray coatingEfficient propulsion technologiesChemical compositionWorking temperature

The invention relates to a preparation method of a DVC thermal barrier coating, which comprises the following steps: providing powder, the chemical components of which are YSZ or YSZ + xGd2O3 + yYb2O3 or Gd2Zr2O7 + zYb2O3 or LaMgAl11O19 or La2 (Zr0. 7Ce0. 3) 2O7, x + y is less than or equal to 12wt%, z is less than or equal to 20wt%; the powder forms the DVC thermal barrier coating through high-heat-enthalpy atmosphere plasma spraying. The invention further provides the DVC thermal barrier coating obtained through the preparation method. The invention further provides application of the DVC thermal barrier coating. The DVC thermal barrier coating is used for a high-temperature hot end component of an aero-engine or a gas turbine. The chemical components of the DVC thermal barrier coating are YSZ or YSZ + xGd2O3 + yYb2O3 or Gd2Zr2O7 + zYb2O3 or LaMgAl11O19 or La2 (Zr0. 7Ce0. 3) 2O7, the applicable material range is wide, the strain tolerance can be increased, the working temperature can be increased, the erosion and erosion resistance can be improved, and the thermal shock resistance cycle life can be prolonged.

Owner:EAST CHINA UNIV OF SCI & TECH +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com