High-temperature and high-emissivity hafnium oxide base infrared radiating coating and preparing method thereof

A technology of infrared radiation coating and high emissivity, applied in coating, metal material coating process, fusion spraying, etc., can solve the problems of low emissivity and low service temperature, so as to improve emissivity and enhance emissivity , Enhance the effect of phonon absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

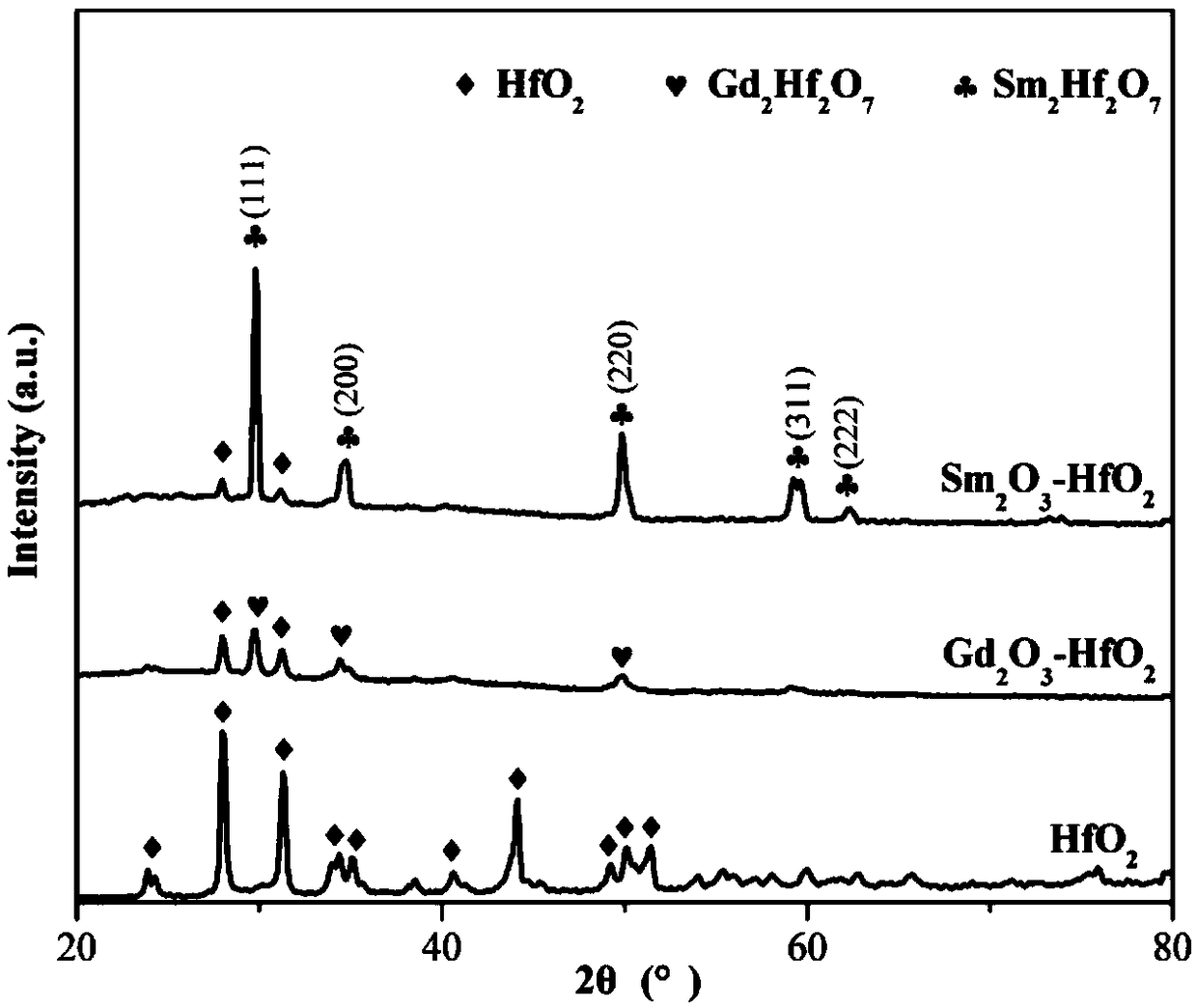

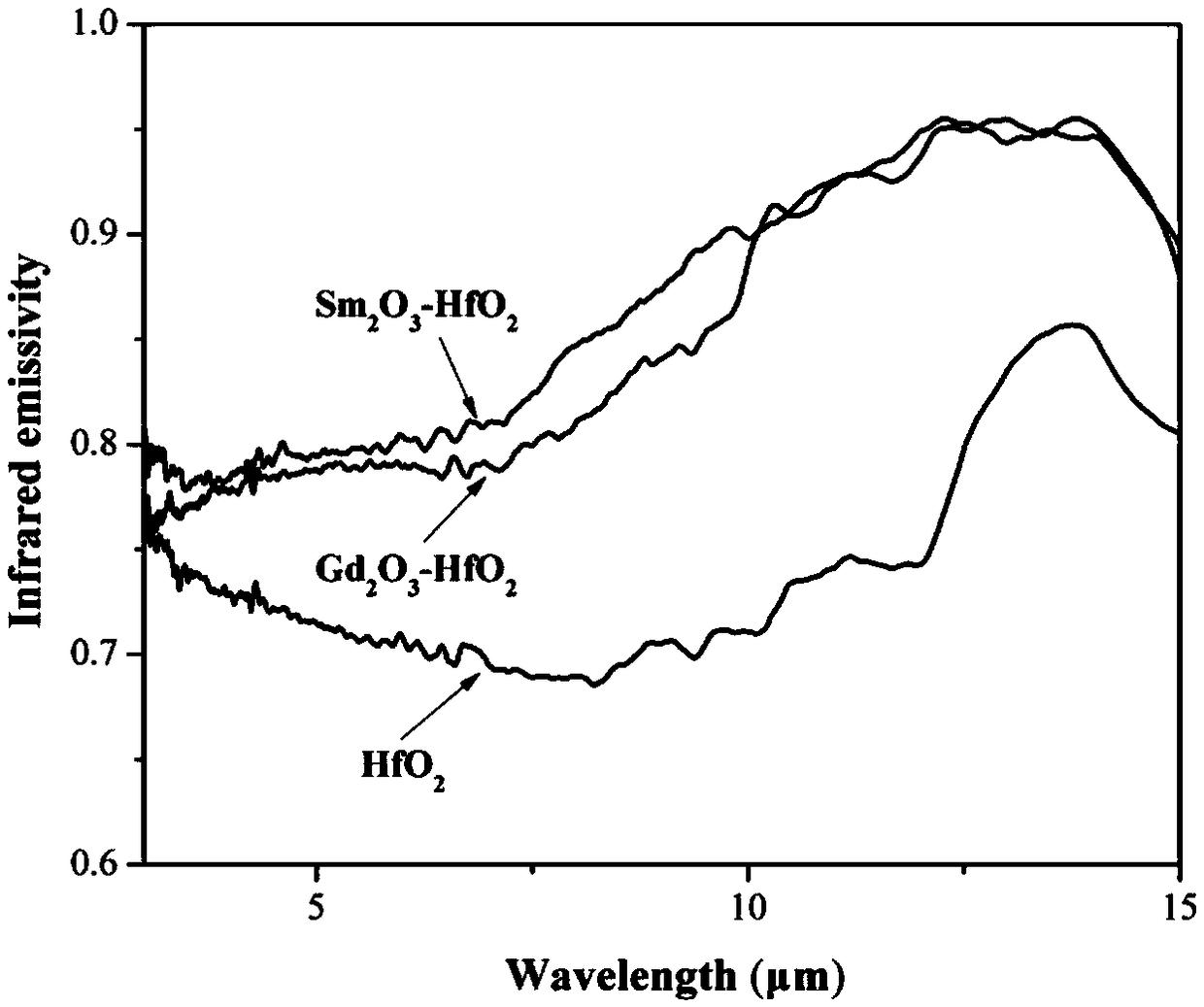

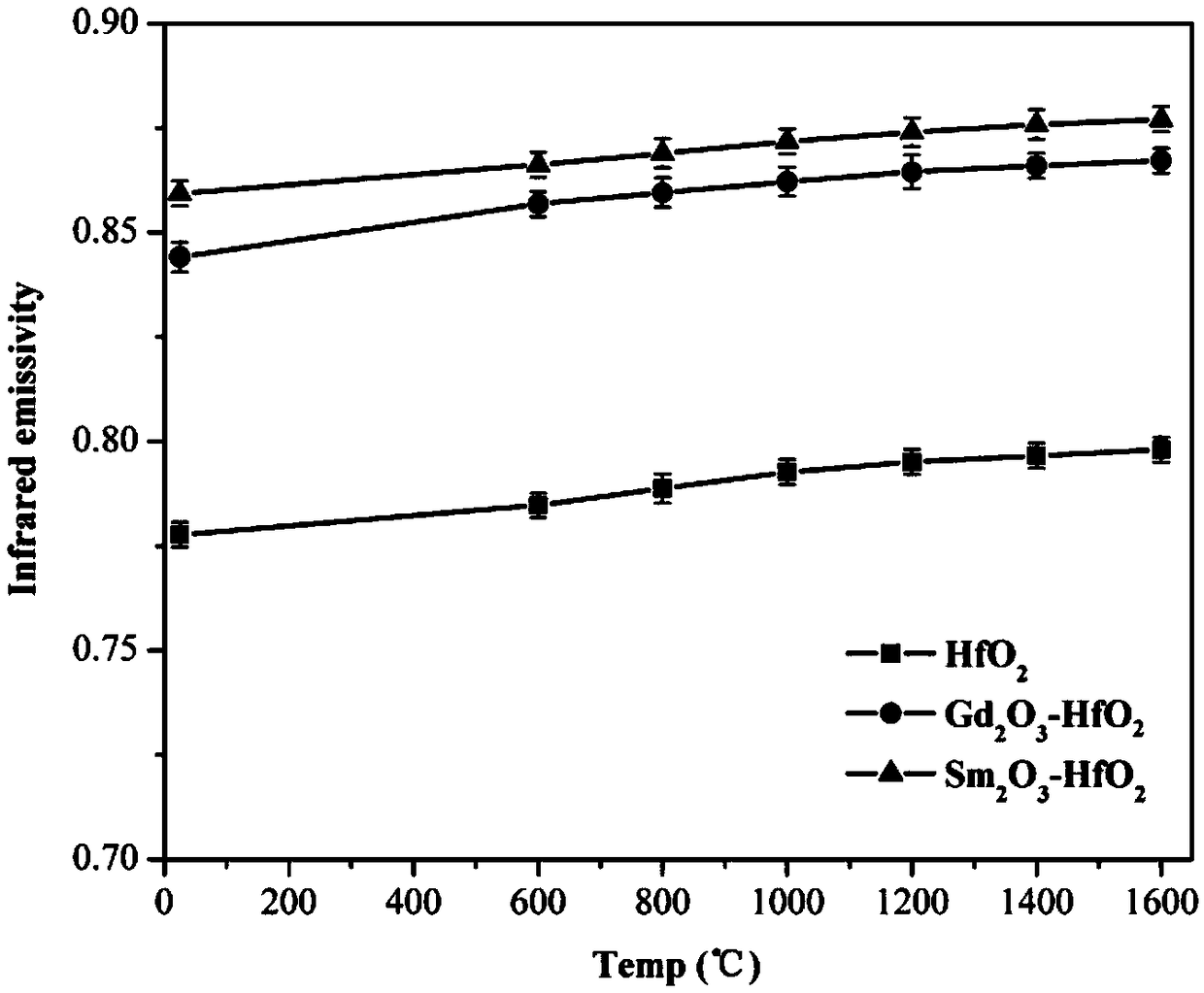

Embodiment 1

[0044] A high-temperature and high-emissivity hafnium oxide-based infrared radiation coating, the specific preparation method and corresponding process parameters are as follows:

[0045] with HfO 2 Powder and Sm 2 o 3 Powder is the raw material (the mass percent of each raw material is HfO 2 Powder 90%, Sm 2 o 3 powder 10%), adding deionized water and binder (polyvinyl alcohol) to it and mixing and grinding to obtain a uniform slurry, wherein the binder accounts for 5% by mass of the raw material, and the volume ratio of water to raw material is 1.5:1; Spherical particle powder is prepared by spray granulation method. During spray granulation, the temperature of the drying tower is 180°C, and the rotation speed of the material pump is 3000r / min; Cool and sieve the composite powder with a particle size of 40-56 μm;

[0046] The composite powder is sprayed on the pretreated tungsten sheet by atmospheric plasma spraying method, wherein: the spraying distance is 130mm, the ...

Embodiment 2

[0052] A high-temperature and high-emissivity hafnium oxide-based infrared radiation coating, the specific preparation method and corresponding process parameters are as follows:

[0053] with HfO 2 Powder and Gd 2 o 3 Powder is the raw material (the mass percent of each raw material is HfO 2 Powder 90%, Gd 2 o 3 powder 10%), adding deionized water and binder (polyvinyl alcohol) to it and mixing and grinding to obtain a uniform slurry, wherein the binder accounts for 5% by mass of the raw material, and the volume ratio of water to raw material is 1.5:1; Spherical particle powder is prepared by spray granulation method. During spray granulation, the temperature of the drying tower is 180°C, and the rotation speed of the material pump is 3000r / min; Cool and sieve the composite powder with a particle size of 40-56 μm;

[0054] The composite powder is sprayed on the pretreated tungsten sheet by atmospheric plasma spraying method, wherein: the spraying distance is 130mm, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com