Preparation method of nano-silica powder-based super composite thermal insulation material

A technology of nano-silica and thermal insulation materials, applied in the field of thermal insulation materials, can solve problems such as high risk, cumbersome process flow, complex preparation process, etc., and achieve the effects of high mechanical strength, wide application range and low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The preparation method comprises the following steps:

[0036] (1) Reinforcing fiber pre-dispersion. Put the reinforcing fiber into the high-speed disperser for pre-dispersion, the stirring speed is 500-800r / min, and the time is 1min.

[0037] (2) Mixing and modification of raw materials. Add the dispersed reinforcing fibers together with fumed silicon dioxide, silicon carbide, and fumed aluminum oxide into the mechanical fusion equipment at a speed of 1200r / min for 30 minutes. The four component materials are thoroughly mixed. At the same time, the coating modification of the surface of the reinforcing fiber and the infrared sunscreen agent by the nano-powder material is realized.

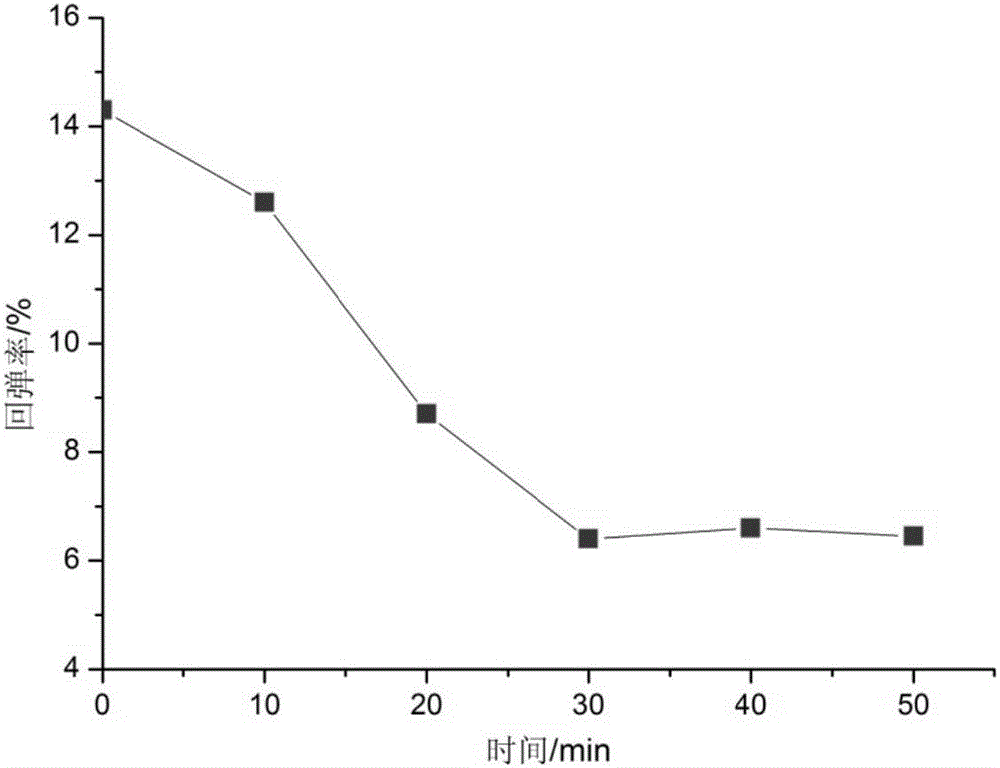

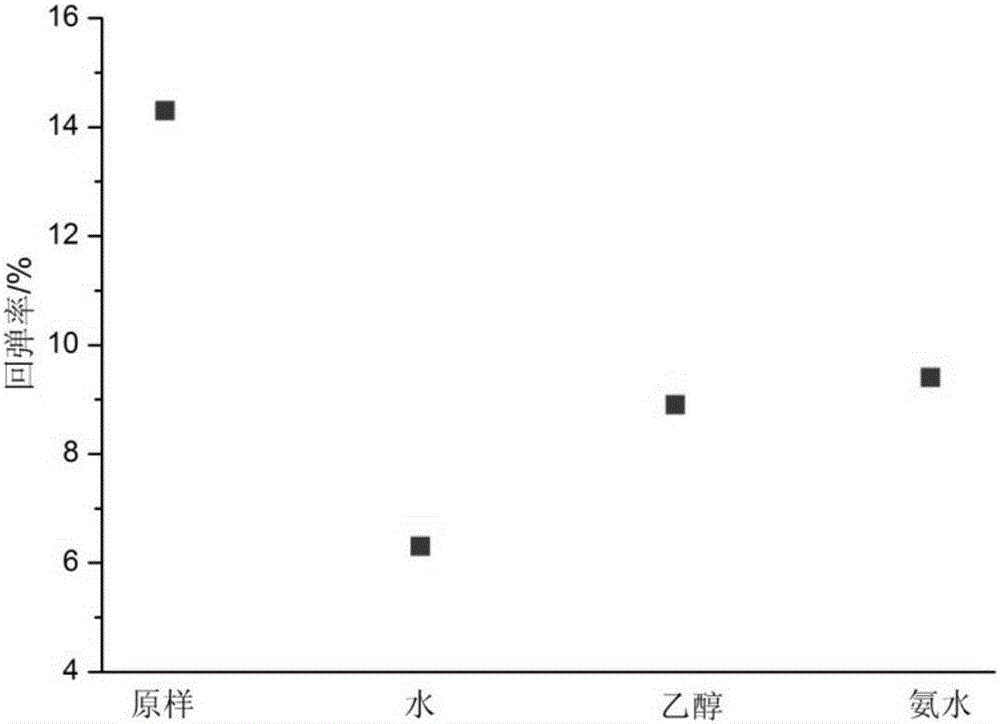

[0038] (3) Anti-rebound pretreatment. Choose steam curing equipment for anti-rebound pretreatment, first add water, ethanol, or ammonia water into the steam curing tank of the steam curing equipment, then put the mixed materials in (2) into the steam curing equipment, and put the materi...

Embodiment 1

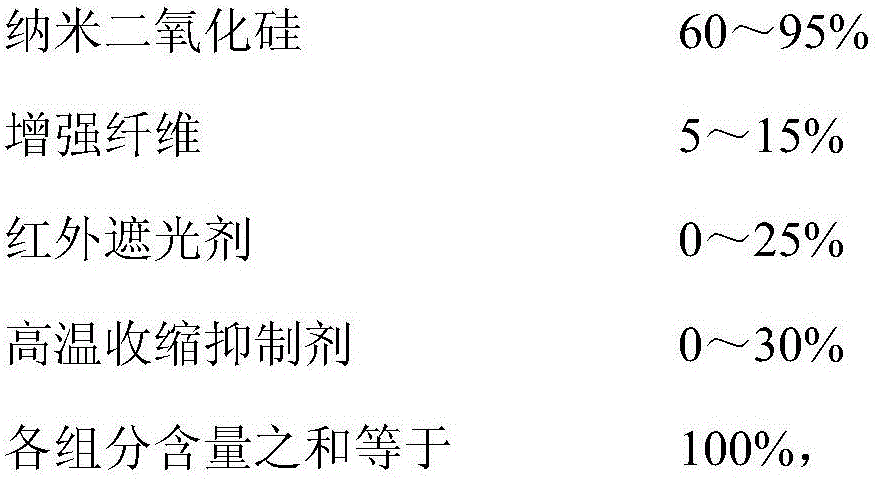

[0044] Get fumed silica 85wt%, length is 15wt% of non-alkali ultrafine glass fiber of 5mm, add non-alkali ultrafine glass fiber in the high-speed disperser and carry out pre-dispersion, stirring speed 800r / min, time is 1min, pre-dispersed Add the dispersed alkali-free ultrafine glass fiber and fumed silica powder into the mechanical fusion equipment, mix at 1200r / min for 30min, and then use steam curing equipment to mix the mixed material with water vapor at 80°C Put the material treated by the steam curing equipment into the mold, press it with a hydraulic press at a pressurization rate of 1N / s and a final pressure of 2MPa, and finally put the formed block material into a drying oven for drying , After heat treatment at 110°C for 6 hours, a high-performance nano-silica powder-based super composite thermal insulation material can be prepared. It is measured that the porosity is as high as 85.84%, the pore diameters are concentrated in the range of 13.5-292.2nm, and most of the...

Embodiment 2

[0046] Get 70wt% of fumed silica, 25wt% of silicon carbide, and 5wt% of alkali-free ultrafine glass fiber with a length of 5mm, add the alkali-free ultrafine glass fiber into a high-speed disperser for pre-dispersion, the stirring speed is 600r / min, and the time Add the pre-dispersed alkali-free ultra-fine glass fiber, fumed silica powder and silicon carbide into the mechanical fusion equipment, mix at 1200r / min for 30min, and then use steam curing equipment to mix evenly The raw material is fully contacted with water vapor at 80°C for 30 minutes, the material treated by the steam curing equipment is put into the mold, and the hydraulic press is pressed at a pressurization rate of 1N / s and a final pressure of 2MPa, and finally the formed block The material is dried in a drying oven and heat-treated at 110°C for 6 hours to obtain a high-performance nano-silica powder-based super composite thermal insulation material. The test results of the mechanical properties of the thermal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| service temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com